DIGITAL THREAD

Xpansion I/O has never been so practical

Built to be versatile in the field, the Protos X Field I/O system has a slim design with numerous I/O point configurations. The small footprint lets you install Protos X I/O assemblies exactly where you need them, even in tight locations. No need for excess field wiring, no need for unused I/O points and with the already low price, you’ll save money again and again with Protos X.

• Rackless design for easy installation in areas with limited space

• Bus Couplers available in Modbus RTU/ASCII, Modbus TCP and EtherNet/IP protocols to integrate with a wide variety of controllers and SCADA/HMI packages

• Discrete terminals available in AC and DC with a variety of point

•

•

•

• A variety of power supply and power distribution options give you added versatility

Distributing I/O for your process saves space, wiring and money!

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it

than ever to order

U.S.! Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low flat rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

(PX-EIP1: 1-port EtherNet/IP Coupler)

Motion monitoring on an external unit allows combines safety functions with machine efficiency By

Marcel Wöhner and Jörg Forcht

Draw

By Jason Kasper

A

Shane Novacek

a digital thread

Michele Markey

NOTABLE TWEETS

@Rajant Corporation

In the market for a future-ready #network with #autonomous adaptability, mission-critical reliability, and complete mobility?

Rajant’s Shawn Lemley shares his insight in @ AutomationMag

Check it out:

bit.ly/2QIQgck

#wirelessmesh

#industrialIoT

@ROK Guardmaster

A majority of industrial companies are using #safety to not only mitigate risks but also to improve productivity and profitability, according to a survey by LNS Research.

bit.ly/2RKv7zN

@euautomation

As sensors continue to advance, the gap between old and new technology becomes more apparent. This is made worse by the fact that many of the experts in legacy equipment maintenance are retiring.

euau.to/2DKlUo8

BY KRISTINA URQUHART

Industrial networks: The IIoT’s workhorses

Because it’s relatively intangible, the concept of the Industrial Internet of Things (IIoT) can be a difficult thing to wrap your head around. But it’s essentially a catch-all term for the network of physical devices embedded with sensors, actuators and other connectivity enablers that collect data to send to the cloud, where it can be accessed by end users in your plant.

The IIoT relies on many components to operate, but perhaps the most fundamental are the industrial networks that power it all – the underlying architecture of technologies (such as fieldbus or the industrial Ethernet) that allow all of these devices to talk to one another.

According to the Industrial Internet Consortium (IIC), a global body that advocates for the adoption of the IIoT, every organization requires a different industrial network depending on its needs – and that involves a lot of decision-making. These range from basic decisions (i.e. whether to use a wireless or wired system), to the complex (i.e. which safety protocols to follow).

Navigating these variables can be challenging for manufacturers, and so the IIC recently released a white paper to familiarize the industry with use-case scenarios. The paper, titled “Industrial Networking Enabling IIoT Communciation,” is a precursor to the IIC’s forthcoming Industrial Internet Connectivity Framework, which will detail best practices for IIoT communication and evaluate the merits of currently available technologies.

According to the paper’s authors, despite frequent product turnover, the future of networking will need more design considerations to accommodate

things like security, reliability and technology lifecycle management.

“In contrast, operational technology (OT) systems comprise systems with longer life cycles, on average 19 years,” the report says. “This difference in development speed leads to slow adoption of new network technologies into existing OT deployments. Manufacturing subsystems should therefore be decoupled from the network devices while keeping a consistent interface between them.”

It’s an interesting idea, but one that will likely take a long time to become reality. A plant that has made significant investments in the integrated technology solutions offered up to this point will be hard-pressed to justify the cost of modifications needed to separate their manufacturing systems from their industrial network architecture.

Yet the convergence of information technology (IT) and OT may make it a more urgent priority. 5G connectivity – the latest evolution of wireless technology – is being rolled out over the next few years to replace 4G/ LTE networks. 5G will enable faster connections and lower latency rates to allow for operational information to be delivered in real-time.

The industrial networks that govern the IIoT boast other benefits, too. Advanced network architectures are what enable things like the digital thread, which has become an important view into a product’s lifecycle. We highlight how the digital thread can help manufacturers earn new revenue on p. 18.

Ultimately, that’s what this entire IIoT concept is about – maximizing profitability and productivity. And who doesn’t want that? | MA

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com

VICE-PRESIDENT & EXECUTIVE

PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext. 3537

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Eric Ehlers, Jörg Forcht, Paul Hogendoorn, Jason Kasper, Michele Markey, Shane Novacek, Gurvie Waraich, Marcel Wöhner

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year

Students — $20 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

AUTOMOTIVE

Honda of Canada Mfg. donates $50K to Ontario pathway

Honda of Canada Mfg. (HCM) has made a $50,000 donation through the Honda Canada Foundation to the Nottawasaga Valley Conservation Authority (NVCA) to build a new, accessible pathway in Riverdale Park in Alliston, Ontario.

The pathway will commemorate two significant production milestones for the company. Working in collaboration with the NVCA, the Town of New Tecumseth, the Rotary Club of Alliston and the Alliston BIA, construction of the new trail will commence in the spring of 2019.

“Riverdale Park plays an important recreational role in New Tecumseth,” says Doug Hevenor, chief administrative officer of the NVCA, which is a public agency dedicated to preserving the environment across Simcoe, Dufferin and Grey, Ontario. “As the landowner, the NVCA is privileged to partner with HCM on this important trail project that will enhance access throughout this wonderful greenspace.”

In September, HCM hosted several events to celebrate 20 years of production at its Plant 2 frame plant and 10 years of production at its Engine Plant. Opened in 1998, HCM’s Plant 2 provided Honda the opportunity to add nameplates to its product offering including its first entries into the minivan (Odyssey), SUV (MDX, Pilot) and light truck (Ridgeline) segments.

In 2008, the addition of an engine plant boosted productivity and flexibility. As the first Japanese automaker to build a manufacturing plant in Canada, these investments in additional plants have allowed HCM to grow over its 32-year manufacturing history in Canada.

From eight cars a day in 1986, HCM now has 4,200 associates and produces 1,690 vehicles and 1,000 engines daily. To date,

more than eight million vehicles have been built at HCM.

“We are incredibly proud of how HCM has evolved over the years to meet the needs of both our associates and our customers,” says Bill Easdale, senior vice-president of Honda of Canada Mfg. and vice-chair of the Honda Canada Foundation.

“Our contribution today is our way of thanking our community

for their ongoing support and partnership. We are excited to be a part of a project that will provide

everyone in the community with more access to enjoy the amazing parkland along the Boyne River.”

Honda of Canada Mfg. (HCM) donated $50,000 to the Nottawasaga Valley Conservation Authority (NCVA) to build an accessible pathway.

AUTOMATION UPFRONT

TRADE

Manufacturers relieved in wake of NAFTA

Reaction from Canadian business groups to the terms of a renegotiated trade pact between Canada, the U.S. and Mexico range from relief to dismay as the details of the proposed new pact begin to sink in.

The deal, which will be called the United States Mexico Canada Agreement (USMCA), was reached late on Sept. 30 amid 11th-hour negotiations ahead of the U.S.-imposed Oct. 1 deadline.

The steel and aluminum industry has expressed concern that the trade deal doesn’t include an end to tariffs, dairy producers claim it will completely undercut their industry, while manufacturers – especially the automotive industry – have welcomed an end to the threat of tariffs and

the many months of uncertainty.

“Disappointed because they didn’t agree on a solution on the 232 sanctions regarding aluminum and steel,” says Jean Simard, CEO of the Aluminium Association of Canada.

“We find it very unfortunate, and to us it’s certainly very important in the coming days and weeks leading to the final signing of the agreement that they are able to resolve the situation.”

United Steelworkers Canadian director Ken Neumann says Canada “sold out” steel and aluminum workers by not getting the 25 per cent steel tariffs and 10 per cent aluminum tariffs lifted.

“It appears Canadian steel and aluminum workers are among those being sacrificed in the concessions made by the Liberal government in this deal,” he says in a statement.

The dairy industry was also heavily critical of the deal, which

NEW Network-Capable Absolute Encoder from EPC

will grant expanded market access to the domestic dairy market and eliminate competitive dairy classes.

Bruno Letendre, head of the association that represents Quebec’s milk producers, says the concessions in the agreement are the equivalent of 13 days fewer production for his members.

“We’ve been sacrificed,” he says. “There’s no doubt about that. Supply management has been sacrificed.”

The measures will have a “dramatic impact” on dairy farmers and cause the industry to shrink, says Pierre Lampron, president of Dairy Farmers Canada, in a statement. “This has happened, despite assurances that our government would not sign a bad deal for Canadians.”

The general sentiment among manufacturers is one of relief, says Dennis Darby, president and CEO of Canadian Manufacturers & Exporters.

“It removes that uncertainty that was hanging over the sector, in terms of our access to this North American market, in terms of the rules related to our integrated North American supply chain.”

He says he hopes the aluminum and steel tariffs can be resolved shortly, but that the manufacturing industry didn’t lose on what’s in the new deal.

“At a minimum we haven’t lost any ground. Versus a very unpredictable and protectionist U.S. administration, I think

Canada did as well as it could.”

The deal preserved dispute-resolution provisions in Chapter 19, which allow for independent panels to resolve disputes between companies and governments, and in Chapter 20, the government-to-government dispute-settlement mechanism.

A side letter published along with the main text of the agreement exempts a percentage of eligible auto exports from the tariffs. A similar agreement between Mexico and the U.S. preserves duty-free access to the U.S. market for vehicles that comply with the agreement’s rules of origin.–The Canadian Press

EXPANSION

Graybar to open new Ontario branch

Graybar Canada has announced it is opening a new branch in Vaughan, Ontario this fall.

Located near Highway 427 and 407, the new 90,000-square-foot facility will be a consolidation of the existing Markham and Mississauga branches. As Graybar Canada’s biggest branch to date, the Vaughan location will be an electrical, communications and data, automation, and wire warehouse hub for the Greater Toronto Area (GTA).

To service current and local customers in Mississauga, Graybar Canada will be opening a counter pick-up location nearby at 160 Brunel Road.

Graybar Canada’s biggest branch to date will open in Vaughan, Ontario this fall. The 90,000-square-foot facility will service the Toronto region.

PHOTO: GRAYBAR CANADA

“With more and more customers taking advantage of our full lines of business, it makes sense for us to position ourselves in a central location,” says Brian Thomas, executive vice-president and general manager of Graybar Canada.

The Vaughan branch will be sized for growth and feature a wire-paralleling machine. “With a significantly larger warehouse, we’ll be able to stock more inventory and provide more efficient wire cutting services,” says Thomas. The new facility will also include energy-saving LED lighting and controls plus a larger training room to accommodate staff and customers on site.

Zund America to build North American office

Zund America is building a new North American headquarters in Wisconsin. The company is

the U.S. sister of Zünd Systemtechnik, the Swiss manufacturer of digital cutting systems.

The new space in Oak Creek, Wisconsin, will include offices as well as areas for product display, customer and employee training, and warehousing for product.

From these offices, Zund America will support customers all over the U.S. and Canada, in graphics, packaging, leather, textiles/composites, manufacturing

and other industries. The project will be completed in September 2019.

LABOUR RELATIONS

WSIB cuts employer premium rates for 2019

The Ontario Workplace Safety and Insurance Board (WSIB) and the provincial government have announced that the WSIB

has paid off its unfunded liability, which will lead to a 29.8 per cent cut in employer premium rates by January 1, 2019.

The unfunded liability, which stood at $14.2 billion in 2011, is the difference between future obligations to pay injured workers and the money available to pay them. WSIB was a unique case, as private insurance companies are not permitted to have a “cushion” if they go bankrupt.

The government and the WSIB say that eliminating the unfunded liability not only helps employers put money back into the economy, but also ensures an accountable workplace safety and insurance system.

Critics say that the move hurts workers, who they say may receive less benefits as a result of the loss of the pool. The WSIB maintains that the government determines the benefits to workers, not the board itself.

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs. Contact us

Zund America has announced a new North American headquarters in Wisconsin, which will serve U.S. and Canadian customers.

CARLO

AUTOMATION UPFRONT

The unfunded liability was due to be paid off by 2027, and the WSIB says it was able achieve its goal 10 years ahead of schedule through collection of premiums and a reduction in number of overall claims.

The 2019 average premium rate for Ontario will decrease from $2.35 to $1.65.

ROBOTICS

Rethink Robotics shutters

Rethink Robotics, the Boston-based maker of collaborative robots, has closed its doors.

According to media reports, the company was low on cash flow and a planned acquisition fell through.

Rethink Robotics, founded in 2008, was one of the early trailblazers of the cobot, with its double-arm Baxter model appearing on the robotics market in 2011. In 2015, the company released the single-arm Sawyer, a smaller, more controlled version of Baxter. Sales of the cobots did not perform as expected.

Ninety-one employees were laid off as part of the closure.

OTTO Motors debuts first self-driving forklift

Matt Rendall, CEO of OTTO Motors (see p. 13), says that the release of OTTO OMEGA, the

company’s new self-driving lift truck, at IMTS 2018 was the realization of a longtime goal.

“The autonomous forklift has been on our roadmap almost since day one,” Rendall says. “We just weren’t ready as a company to tackle that challenge in the first couple of chapters of our go-to-market.”

OTTO Motors, a division of the Canadian-based Clearpath Robotics, says that OMEGA is world’s first self-driving lift truck.

Designed to increase efficiency and improve plant safety, OMEGA is unlike other lift trucks in that it is able to react to changes on the factory floor in real-time, use laser-based perception to navigate around obstructions and learn new behaviours as it moves along using its advanced artificial intelligence system.

OMEGA constantly collects data from its surroundings while communicating with a centralized control system. The vehicle receives orders, reports on its status and notifies human operators of issues.

The vehicle specializes in two jobs: autonomous floor-to-floor deliveries and a semi-autonomous mode, where workers can work with OMEGA by taking over complex loading or unloading tasks, such as pallet deliveries. The lift truck can pick up and drop off skids fully autonomously, receive items to be put away, deliver parts to

production lines, cross dock, transport trash – everything from storage to shipping.

Operators can make changes anytime with the OTTO Fleet Manager software, which connects OTTO vehicles to the user’s production process for higher levels of efficiency and control. For example, a user can download the software to an iPad and see their floor plan, the jobs OTTO is doing, battery life and future tasks. They can use the software to make changes to job types, schedules and where the vehicles can move.

OTTO OMEGA will roll out to select partners over the next year to measure success before it heads to market.

EDUCATION

Sandvik Coromant gives scholarships to Alberta students

Sandvik Coromant has awarded nine students in their fourth year of the Machinist Apprenticeship Program at the North Alberta Institute of Technology (NAIT) with its annual scholarships.

The awards dinner took place in Edmonton on September 25. Seven of the recipients were given the Sandvik Coromant Award, based on top academic achievement in the fourth year of the program. In addition, the Sandvik Coromant Leadership Award was granted to two

individuals who demonstrated initiative, creativity, leadership with their fellow students and enthusiasm in conjunction with academic achievement.

Malcolm Haines, dean of the School of Skilled Trades at NAIT, says, “We are very grateful to Sandvik Coromant for all they have done to support our program and our students [...] they are helping to ensure that our programs can stay on the cutting edge of what the machining industry requires now and will require in the future. Our students have greatly benefitted by having both the financial support provided by the awards [and] the opportunity to use the state of the art tooling that Sandvik Coromant is renowned for.”

NAIT is a polytechnic school that specializes in science, technology, business and trades.

Tom Henry, partner marketing Americas manager at Sandvik Coromant, adds, “Support for education and sharing knowledge to gain the skillsets required by our industry is a priority at Sandvik Coromant. The NAIT education partnership provides students with the opportunity to develop their skills leading to pathways to real world career advancement and we are proud to support that.”

Sandvik Coromant is part of the global Sandvik Corporation and develops manufacturing tools and machining solutions for the metalworking industry.

Ontario’s OTTO Motors recently debuted the OTTO OMEGA, which the company says is the world’s first self-driving lift truck.

Nine machinist apprenticeship students at the North Alberta Institute of Technology (NAIT) recently won scholarships from Sandvik Coromant.

Rethink Robotics, creator of the Sawyer robot (pictured), abruptly closed its doors in October, citing poor sales.

DEAL MAKERS

Endress+Hauser and Lumen partner on process automation

Endress+Hauser, a specialist in process measurement and instrumentation, has partnered with Quebec-based electrical distributor Lumen.

“The evolution to Industry 4.0 and Industrial Internet of Things offers limitless opportunity for Canadian companies,” says Anthony Varga, general manager at Endress+Hauser. “Thanks to the strength of our partnership with Rockwell Automation and Lumen’s expertise, we’ll be able to go to greater lengths to help modernize the Canadian manufacturing sector.”

As part of the partnership, Lumen can provide its process automation customers with opportunities through the

integration of Endress+Hauser’s measurement technology with the Rockwell Automation platform. The companies say that the pre-tested and validated designs between Rockwell Automation and Endress+Hauser offerings help reduce the costs associated with bringing new measuring points or a new production line into the manufacturing facility.

Customers of Lumen will also have the opportunity to work with a single-source provider, enabling them to acquire the PlantPAx system, a modern distributed control system with field instrumentation and measurement solutions.

MOVERS AND SHAKERS

Jody Fildey is the newly appointed vice-president of sales at Gray Tools Canada and will head its new automotive and heavy truck aftermarket division. Fildey brings 30 years of

MEET THE NEW POWER COUPLE

experience serving the industry. According to Gary Nuttall, president of Gray Tools, “Our expansion into the automotive and heavy truck aftermarket is a strategic fit, and part of our medium-term business plan. The addition of Jody to our executive team allows us to greatly advance our pursuit of this strategy.”

Bombardier has appointed Sam Abdelmalek as its new chief transformation and supply chain officer. Abdelmalek will report to Alain Bellemare, the president and chief executive officer of Bombardier. In this position, Abdelmalek will assume responsibility for the continued transformation of the company’s operations and lead the company’s supply chain activities to reduce costs and improve efficiency and quality to support Bombardier’s growth objectives. “We are

very excited to welcome Sam to the Bombardier leadership team,” says Bellemare. “He is a strong and dynamic leader, with a proven track record of creating value through effective supply chain management and process improvement.” Abdelmalek brings almost 30 years of aerospace and industrial experience to Bombardier.

Applied Motion Products has appointed Josh Burns as its northwest regional sales manager for the western U.S. and British Columbia. Before joining Applied Motion Products, Burns spent four years as a sales engineer with Eaton. Burns holds a degree in supply chain management and marketing from the University of Illinois. | MA

• Power Supplies – scalable size, power and technology for all budgets

• WAGO-I/O-SYSTEM – bus couplers support 16+ networks and 500+ I/O modules

• Power supplies with TopBoost / PowerBoost enhance your automation application

• UPS, ECB, redundancy and buffer modules round out your power quality needs

Explore the benefits of the power couple at www.wago.ca/powercouple

BY TOM KNAUER

Implementing device-level safety communications

Manufacturing is rapidly changing, driven by trends such as low volume/high mix, shorter lifecycles, changing labour dynamics and other global factors. One way industry is responding to these trends is by changing the way humans and machines safely work together, enabled by updated standards and new technologies including safety communications.

In the past, safety systems used hard-wired connections, often resulting in long cable runs, large wire bundles, difficult troubleshooting and inflexible designs. The more recent shift to safety networks addresses these issues and allows fast, secure and reliable communications between the various components in a safety control system. Another benefit of these communications systems is that they are key elements in implementing the Industrial Internet of Things (IIoT) and Industry 4.0 solutions.

Within a typical factory, there are three or more communications levels, including an enterprise level (Ethernet), a control level (Ethernet-based industrial protocol) and a device/ sensor level (various technologies). The popularity of control- and device-level industrial communications for standard control systems has led to strong demand for similar safety communications solutions.

Safety architectures based on the most popular control-level protocols are now common and often reside on the same physical media, thereby simplifying wiring and control schemes.

Devicelevel safety protocols are fairly new and realize many of the same benefits as the Ethernetbased safety protocols, while addressing some of the drawbacks.

The table below includes a list of the most common safety control-level protocols with their Ethernet-based industrial “parent” protocols and the governing organizations.

These Ethernet-based safety protocols are high speed, can carry fairly large amounts of information and are excellent for exchanging data between higher-level devices such as safety PLCs, drives, CNCs, HMIs, motion controllers, remote safety I/O and advanced safety devices. Ethernet is familiar to most customers, and these protocols are open and supported by many vendors and device suppliers –customers can create systems using products from multiple suppliers. One drawback, however, is that devices compatible with one protocol are not compatible with other protocols, requiring vendors to offer multiple

communication connection options for their devices. Other drawbacks include the high cost to connect, the need to use one IP address per connected device and the strong influence by a single supplier over some protocols.

Device-level safety protocols (see table, opposite) are fairly new and less common, and realize many of the same benefits as the Ethernet-based safety protocols while addressing some of the drawbacks. As with Ethernet protocols, a wide variety of safety devices can be connected (often from a range of suppliers), wiring and troubleshooting are simplified, and more data can be gathered than with hard wiring. The disadvantages are that they are usually slower, carry much less data and cover shorter distances than Ethernet protocols. On the other hand, device connections are physically smaller,

Tom Knauer is the Safety Business Champion for Balluff, Inc., a sensor manufacturer and supplier of automation system solutions. balluff.com

much less expensive and do not use up IP addresses, allowing the integration into small, low-cost devices including E-stops, safety switches, inductive safety sensors and simple safety light curtains.

The awareness of, and the need for, device-level safety communications will increase with the desire to more tightly integrate safety and standard sensors into control systems. This will be driven by the need to:

• Reduce and simplify wiring

• Add flexibility to scale up, down or change solutions

• Improve troubleshooting

• Mix “best-in-class” components from a variety of suppliers to optimize solutions

• Gather and distribute IIoT data to higher-level systems

Many users are realizing that neither an Ethernet-based safety protocol nor a device-level safety protocol can meet all their needs, especially if they are trying to implement a cost-effective, comprehensive safety solution that can also support the IIoT. This is where a safety communications master (or bridge) comes in to assist – it can connect a device-level safety protocol to a control-level safety protocol, allowing lowcost sensor connection and data gathering at the device level, and transmission of this data to the higher-level communications and control system.

Combining device-level and control-level protocols helps users optimize their safety communications solutions, balancing cost, data and speed requirements, and allows IIoT data to be gathered and distributed upwards to control and MES systems. | MA

GOING DIGITAL

BY ERIC EHLERS

Moving collaboration technology to the plant floor

The modernization of the factory is changing the way manufacturers are conducting their operations by connecting the entire business. The factory floor, formerly isolated, is now connected and producing vast amounts of data whose analysis is used to improve business operations, reduce downtime through predictive maintenance programs and integrate complex supply chains. The siloes that existed between operations technology (OT) and information technology (IT) are now converging around new solutions with focused projects around the Internet of Things (IoT) and improving end-to-end security are just a few examples. An underlining foundation to this evolution of manufacturing is more focused collaboration across teams with integration of all this new data that is being produced.

The reality of the manufacturing industry today is that many teams are dispersed across the globe, whether engineering, operations, supply chain or sales teams. They all need to communicate securely on a regular basis. Collaboration technology has been in place for years, either within the enterprise or the carpeted space. However, when it comes to collaborating directly on the factory floor, it has been a challenge. In many cases, factories are harsh environments – they are noisy, and there is a lot of interference from machines that can make communications difficult. This challenge has resulted in the continued use of older technology such as two-way radios. Technology has shifted now, and modern collaboration technology is very secure and viable on the plant floor for a host of applications. Industrial Ethernet and wireless advancements support higher data rates and throughput, and help create coverage across a connected factory. This advancement enables workers to take advantage of mobility with the ability to access voice, video and data on their handheld devices.

Overcome challenges with collaboration technology

Some of the areas where manufacturers can take advantage of collaboration technology:

1. Improving their new product introduction (NPI) process. With the use of team rooms and video conferencing, multiple teams can work through ideation concepts, design and development. Email or phone is often an inefficient mode of working through complex details. Having the ability to share and annotate technical

documents in real time means that the latest versions are always available and shared in a central, secure location.

2. Leveraging collaboration technology for remote maintenance. Collaboration technology helps teams respond faster to downtime or to any issues on the plant floor. Video conferencing allows remote experts to view and resolve efforts at the source without having to be directly onsite. Messaging apps provide for a connected workforce, so workers can communicate across the plant in real time.

3. Archiving and documentation. The ability to access key documents and diagrams in a central location can assist with troubleshooting and help improve processes, and also promote workplace safety.

4. Integration of collaboration technology with IoT. IoT technology enables more communication and insight into the machine performance on the factory floor. This advancement means machines can share real-time updates on performance, and broadcast alerts on machine health issues. Integration of those communications with collaboration technology opens up an array of transformative possibilities. Open-application programming interface (API) allows multiple technologies to connect and communicate with one another. As an example, an alert triggers critical personnel to interact in a designated incident “response room.” Those users then communicate via calls, video conferencing and chat as a means of mitigating the issue.

Bring collaboration technology to the factory floor

To successfully deploy collaboration technology, consider the following:

1. Change management: Consider how collaboration technology will impact existing processes. Before any changes occur, make sure to document all existing processes and then outline where any changes via collaboration technology might take place. Training will be essential to ensure users don’t default to the old way of doing things.

2. Security: It’s critical to ensure collaboration tools don’t compromise an organization’s security. Collaboration technology involves multiple users and devices engaging from numerous sites, often remotely. Remote access security measures are critical. Additionally, collaboration enables the exchange of knowledge sharing that could contain sensitive information or intellectual property (IP). Collaboration platforms should support end-to-end encryption to keep content safe.

3. Infrastructure: As noted earlier, there have been tremendous leaps in networking technology on the factory floor. Companies should ensure their infrastructure is robust and up to date so they can enjoy the full benefits of collaboration technology. The benefits of collaboration technology are no longer limited to carpeted space. Collaboration technology is mature and ready to support manufacturing efforts. The time is now for manufacturers to embrace collaboration technology and streamline their operations. | MA

Eric Ehlers is the marketing manager in the SME, manufacturing and energy verticals at Cisco. He is filling in for regular columnist Jennifer Rideout while she is on leave.

INDUSTRY WATCH

BY PAUL HOGENDOORN

Smart, hungry and humble

It is easy for me to identify the “true all-stars” on the teams I worked with over the years. They were the performers that not only got things done, but that products, divisions, and even companies were built upon. Some were diamonds in the rough, discovered along the way. Some were fresh graduates with that certain “spark.” Some were well educated, and some had great previous experience. It is easy to identify who those exceptional individuals were because the results spoke for themselves.

However, it wasn’t always as easy for me to identify exactly what it was that made them special, until I heard Patrick Lencioni speak at a conference I attended. His assertion was that the ideal team player was “smart, hungry and humble.”

Smart. It’s easy to understand that intelligence would be a critical characteristic. All of the all-stars on my list are very smart people. Some are highly educated and “academic,” but others had an extra degree of common sense. Others just had a type of internal compass that led them intuitively through what seemed to others to be random processes – to conclusions that others might not have ever gotten to.

Hungry. This took me a little longer to digest. A few of the people I’ve worked with came to Canada as refugees, brought over by parents hungry for a better future for them. They were eager to dedicate themselves to the task of achieving a better life. Others were hungry in other ways. They were persistent in their efforts and simply driven to achieve the goal. Whether it was a new product, a groundbreaking technology, or a new way to get the message out, the completion of the goal was all that mattered. Tenacity. Persistence. Relentlessness.

Humble. This one took me even longer to sort through, but then I realized it might actually be the most definitive trait of the three. Smart people often have trouble listening to the insights and input from others, unless those insights come from people they believe to be as smart, or smarter than themselves. And driven, persistent people often don’t have the

Paul Hogendoorn is president and co-founder of FreePoint Technologies. He can be reached at paul.hogendoorn@getfreepoint. com or getfreepoint.com. “Measure. Analyze. Share. Don’t forget to share!”

patience to slow down and consider other voices; their determination often includes an element of stubbornness. Both conditions are sort of natural and can be expected – smart and driven people usually rise to the top of the class and move up in the ranks of the company because of their smarts and dedication.

Humble people are more likely to actively and genuinely listen to all input from everyone, and to consider those insights as just as important, if not more so, than their own.

So, here’s where humble separates the good and very good from the exceptional: humble people are more likely to actively and genuinely listen to all input from everyone, and to consider those insights as just as important, if not more so, than their own. Humble people are also more likely to praise and “honour up,” acknowledging the achievements of people one or two rungs above them. Pride often gets in the way, but not for humble people. Humble people count on other insights and opinions to fill holes in their own blind spots. Without humility, it’s often hard to even accept that you have those blind spots.

A friend of mine recently retired as president of a major international technology company. He started when the company had only 30 people. He was an engineer but started his career there in marketing, eventually heading that department and becoming vice-president. After many years in that role, he was passed over for the top role, despite having served very effectively as second in command and helping build the company to a very successful state. He continued to serve the new leader, just as humbly, smartly and dedicatedly as

he had the previous leader, but the company’s growth stalled. After a few years, the new president was removed and he was asked to take the leadership role, which he did. The company’s growth returned. When he eventually retired, there was nothing that had to be said about his importance or the contribution he made to the company, because the results spoke for themselves. The company was strong, vibrant and succeeding. I have known him for over 30 years now and can look back on all the conversations I had with him, recalling that he was more interested in hearing my opinion and thoughts than expressing his own, and the times he would genuinely acknowledge and honour not just his subordinates, but also his peers and the people above him. It sounds simple and perhaps easy, but it’s not. It’s actually a rare trait among people that are very smart and very driven.

Congratulations to M on your retirement. You have set a fine example for others to follow. A big thanks to S, F, M and K. Having you on my teams was an honour – you have the talent and the drive, but it was your humility that allowed us to do the spectacular things we did. And a big vote of encouragement to C, J and B – your future looks bright if you continue to follow your strong internal compass. And, lastly to R, the smartest, most unwavering and humblest person I know – without you on the team, nothing of true importance would have ever gotten done. | MA

PREVENTING HAZARDS

Motion monitoring on an external unit combines safety functions with machine efficiency

BY MARCEL WÖHNER AND JÖRG FORCHT

Motion monitoring enables efficient machine operation – but standards also demand maximum safety. With an external monitoring unit, safety functions can be implemented as standard on frequency converters and servo amplifiers of various performance classes and from various manufacturers; in most cases this can be achieved very economically.

The objective of safety technology was and always will be to prevent potentially hazardous movements. Nothing, then, is more obvious than to have a close connection between safety technology and motion generation. For technical and economic reasons, the drive electronics – servo amplifiers and frequency converters – have remained as non-safety-related components in very many applications. In such applications, the required safety

is guaranteed through additional safe components, which bring the drive to a de-energized, safe condition in the event of a fault, or safely monitor the movement of the connected motor.

Motion monitoring has two main tasks: it must detect any violation of the limit values and then trigger an appropriate safe reaction. It must also detect any potential errors in the encoder system and likewise trigger an appropriate error reaction.

Retrofitting safety

Even with external, safe motion monitoring systems, it is possible to implement many of the safety functions that are defined in IEC 61800-5-2 by reusing the existing actuator and sensor technology, even on older drive systems. This is significant, particularly where a retrofit is involved, because it means the cost of exchanging the drive, motor and sensor technology can be saved. Existing drive functions can also continue

to be used. What’s more, it is no longer necessary to undergo the sometimes-complex process of converting the existing drive program to a new system, along with the additional training required to program the safety section.

The task of the external devices is to detect motion. The safety characteristic data of the employed sensors, e.g. rotary encoders or proximity switches, is significant in determining the safety level that can be achieved. Different solutions to suit the various requirements are available to monitor movements with external monitoring devices. At the highest level, it is important to distinguish between so-called standard encoders and “safe” encoders.

Pre-assembled adapter cables simplify connection of the external monitoring devices. These are inserted between the drive and feedback encoder and record the motion monitoring signals. Appropriate adapters are available for all common drive manufacturers and drive models.

Another advantage of using external motion monitoring modules is the fact that the safety system is independent from the employed drive system. So all the safety functions, special motion

generation functions and motion control functions can be implemented within the usual system.

Compatibility with encoders

An important requirement for solutions with external safety is the ability to evaluate all standard sensor systems (rotary encoders in various designs, incremental encoders (TTL, HTL), Sin/Cos encoders) up to Performance Level (PL) d of ISO 13849-1 and two proximity switches up to PL e. This is made possible via feasibility checks within the external safety component that monitors the sensor signals. As a result, it is possible to achieve diagnostic coverage of up to 90 per cent on the encoder system. Through appropriate warning messages, a potential encoder failure can be detected early. It is also possible to use internal encoder diagnostics and to react to a potential fault signal from the rotary encoder with a protection violation. If a higher PL is required, this can be achieved by using an appropriately certified, safe rotary encoder. The important factor here is the correct interaction between encoder and safety relay. The documentation belonging to the respective encoder describes

Safe speed monitors and a configurable control system can be integrated into existing speed monitoring structures (pictured), or used to create new structures with flexibility of design options.

the requirements of the monitoring device, which must be met in order to use the device and to claim the certified safety-related characteristic data.

If a certified, safe sensor cannot be used, it is still possible to achieve a higher PL with little effort. An additional proximity switch is fitted so that it scans the hazardous movement on a toothed wheel or shaft coupling, for example. The monitoring device can now continuously compare the established speed values from both encoder systems (standard rotary encoder and proximity switch). If the values are no longer feasible, the monitored axis is brought to a stop. As a result, motion monitoring up to PL e is possible with two standard components. Monitoring for broken shear pins or gear monitoring can also be implemented in the same way.

Safe motion monitoring solutions with external monitoring devices can be used in conjunction with standard, certified Sin/ Cos encoders designed for up to PL e. As a result, safe motion monitoring can be implemented up to the maximum PL with only one encoder. If there are only a few safety functions to be linked to motion monitoring, individual relays provide an appropriate solution.

Reacting to errors

The more complex the task, the more beneficial existing add-on functions of the external monitoring devices are likely to be. In the event of an error, e.g. if a speed-monitoring function reacts, a drive should always be shut down as quickly as possible. Long transmission times to centralized safety systems and their program cycle times can often present a problem. With local stop outputs, which can drive the safety

functions SS1 (Safe Stop 1) and STO (Safe Torque Off) directly, motion-monitoring modules can trigger a stop of the corresponding axis just a few milliseconds after the monitoring function has reacted. Thanks to integrated delay stages, it is even possible to implement the SS1 function, after an emergency stop signal has first been transmitted to the drive and after the drive’s STO

function is activated when the set delay time has elapsed. This way, an axis can still be brought to a controlled standstill in the event of an error, before the controller inhibit makes braking impossible. If you need to shut down not just one but multiple drives simultaneously, a cascading function

can allow you to do it simply, within a few milliseconds; this is independent of fieldbus times or task cycles on the controller.

In their independence of the rest of the system, external motion monitoring systems allocate for future developments, both on the drive and the encoder side.

Marcel Wöhner is a product manager and Jörg Forcht is a product developer at Pilz GmbH & Co. KG. pilz.com

DESIGNING A DIGITAL THREAD

Draw on the power of the Internet of Things to ensure traceability throughout a product’s lifecycle

BY JASON KASPER

Lo w margins, intense competition, and risk aversion in the digital era have become a formula for disruption in industrial manufacturing. So, how are you ensuring that your organization is on the right path not only to survive, but also to gain the digital edge over competitors?

A priority for any organization’s digital transformation should be implementation of the digital thread. Why? Because in order to meet your customers’ demand for the latest technology and stay ahead of your competitors, you must continuously be innovating. And you can’t do it with legacy business processes, outdated engineering and manufacturing systems, or siloed information. You need to unlock that knowledge, harness existing systems and connect people across the enterprise.

What is the digital thread?

The digital thread makes connections to critical information, enabling you to follow a product’s digital history

and all related digital assets – from concept and planning, through design, manufacturing, quality assurance, field maintenance, and disposal. The implementation of the digital thread increases productivity, improves responses to customers, provides market-expansion opportunities, and creates sustainable feedback loops for innovation. The digital thread connects product information generated by a multitude of functions and phases, including product requirements, simulation models, electronics and embedded software, manufacturing process plans, service records and the Industrial Internet of Things (IIoT).

Removing information silos – connecting critical information and then understanding when it changes, how it changed and what it means – enables a collaborative environment throughout the design-to-manufacturing process. Everyone has a view into information and therefore users can see the changes in real-time, enabling conversations to occur that otherwise would happen after the fact or maybe not at all.

Legacy IT systems are incapable of

managing today’s – and tomorrow’s –product complexity. These proprietary closed systems were designed for specific engineering and manufacturing disciplines. The inability to integrate across disciplines disrupts on-time delivery of new products, because these complex products now contain not just the mechanical and electrical disciplines, but software as well.

The impact of change, coupled with increasing product complexity across the lifecycle, is a fundamental reason for pursuing the digital thread. It increases visibility into what is happening between disciplines, enabling collaboration and reducing quality defects that could impact your bottom line and affect customer perceptions.

Adapt to new business needs

Increased product complexity has exposed the shortcomings of legacy engineering, manufacturing systems and business processes with information locked in silos, making collaboration between teams and disciplines difficult if not impossible. Simultaneously, IT architectures and systems lack the power and sophistication to effectively coordinate engineering product development and manufacture across disciplines – mechanical, electrical, and software – across the entire product lifecycle.

The best way to resolve this problem is by connecting those disparate

systems to gain access to all of the information locked away in legacy systems. With complete traceability across the product lifecycle, various teams can work concurrently with the latest product information.

The foundation for growth in an era of complex connected products requires a modern, platform-based approach that enables organizations to quickly change course as business needs change. It is this connection of processes and systems that is at the heart of the digital thread.

Close the loop for quality

A s competition increases for the best new products with the latest technological improvements and materials, there is added pressure to shorten development cycles. Yet, many businesses still use standalone systems and spreadsheets to manage quality, which leads to disconnected information and process gaps. This can then lead to higher rates of product recalls, which can result in fines, compliance issues, and, ultimately, a damaged brand.

B y contrast, the digital thread allows cross-disciplinary teams and the extended supply chain to create closed-loop capabilities that identify and manage risk, improve quality, meet customer requirements, and attain environmental, safety, medical, and other forms of compliance.

As an example, a large jet-engine manufacturer built a digital thread to synchronize its bill of materials across multiple legacy manufacturing systems and locations. This resulted in the creation of a traceable digital thread between engineering and manufacturing, improving visibility to changes between disciplines as well as a 62 per cent reduction in changes to analyze, an 82 per cent reduction in data entry by eliminating spreadsheets and siloed data, and an 80 per cent reduction in tools used, simplifying user training and IT maintenance.

Enable product innovation

In previous years, determining and matching a product’s functions and capabilities with what a customer required was an art form. Today however, we need new connections to information to build a little science into the process and increase our effectiveness and

Look for an open architecture, including open standards, APIs and connectors to ensure that the platform integrates with other enterprise applications and legacy PDM/PLM systems.

Digital thread

The digital thread is a framework that gives a manufacturer an integrated view of a product’s entire lifecycle, from concept to completion.

responsiveness to customer demands. One primary means of achieving that is by connecting operations and maintenance information from assets in the field back into the four walls of manufacturing. This starts by connecting to information in the field, where the product operates. Next, couple that information with the evolution of the product configuration as it operates in different environments. Finally, apply powerful analytics to understand failure rates of components, maintenance historie s and environmental operating conditions. Armed with this level of information, you’re in a better position to foster more collaborative discussions with customers about their needs that can shape the next generation of design, manufacturing and quality improvements.

Harness new revenue opportunities

The ability to create and deliver new services and models presents great opportunity. This is particularly true as product complexity increases. Customers seeking the latest technology in order to gain a competitive advantage more quickly may soon realize they lack the proper resources to maintain your new solution. Instead, they might look to progressive manufacturers that can package the right product with enhanced field-service capabilities, such as real-time monitoring, predictive maintenance techniques, and rapid responses. In many cases, this product-asa-service approach is easier and more reliable than traditional ownership and do-it-yourself maintenance.

Build your digital thread

A platform approach should use a model-based technology and a service-oriented architecture that allows companies to develop and modify applications, processes and workflows far more easily than traditional PLM systems that take a hard-coded approach and struggle to adapt.

L ook for an open architecture, including open standards, APIs and connectors to ensure that the platform integrates with other enterprise applications and legacy PDM/PLM systems. Industrial manufacturers must rethink their business processes and connect siloed systems with the digital thread. The result will be sustainable connections of critical data that will enable new business models and handle increasing product complexity. Follow these seven steps to begin:

1. Understand commitments made by the business for new product direction; outline the gaps in achieving direction.

2. Align the organization to your strategy based on resource competencies – people, process and technology.

3. Face facts about legacy IT situations; be realistic about the approach and timeline to get tangible results.

4. Embrace the opportunity for business process change – this will power the digital thread.

5. Power the product lifecycle by using a platform that is open, flexible, scalable and upgradeable.

6. Ensure that employees buy in to supporting all of the new business goals and objectives. Management needs to communicate openly by clearly defining and reinforcing the purpose of the new direction. This helps employees to accept where the organization wants to head in the future.

7. Finally, be realistic about the time needed to implement change. Not following through, or measuring and reinforcing organizational alignment will lead employees to stray and go back to what they think are tried-and-true approaches to align to business goals. | MA

Jason Kasper is the product marketing manager for Aras, a developer and publisher of product lifecycle management software. aras.com

STANDARDIZING MACHINE DESIGN

An Ontario-based manufacturing technology provider uses PC-based control to improve automation efficiencies

BY SHANE NOVACEK

Old adages advise against reinventing the wheel, but what is a manufacturer to do when customers all want different wheels? Answering this question for global manufacturers every day is RAMP, Inc., an automation technology services provider located in Waterloo, Ontario. RAMP develops custom solutions that balance highly tailored manufacturing functionality with standardized connectivity, operation

and maintainability. RAMP has tackled many large-scale automation projects across North America and Europe in numerous industries. The company has deep application experience in many markets, with particular strength in energy recovery and automotive projects, and also has major clients in healthcare and consumer products manufacturing, electronics assembly, food production, and scientific research at various universities and institutes.

With increasing domestic

manufacturing activity in industrialized countries, manufacturers need more efficient production methods to improve global competitiveness. “For example, there is a strong push in domestic automotive manufacturing to increase the adoption of techniques such as lightweighting to make vehicles more fuel efficient and handle better when driving,” says Michael Balzan, director of RAMP. “The burgeoning electric vehicle market is also driving manufacturing investments and will continue to rapidly expand in the near future.

We see major developments in machine autonomy, with IoT becoming more pervasive across industries.” These transformative changes push manufacturers to adopt next-generation manufacturing technologies, and the engineering team at RAMP can handle all the design aspects, including mechanical components, automation and controls.

RAMP projects can involve the manufacturing of new products without predefined processes, and they can also modernize and replace legacy systems. To cover the entire application spectrum, RAMP follows a structured project management development (PMD) model that stresses agile engineering. This supports concurrent project development and engineering to optimize all processes. “RAMP provides customers a significant value-add through proper and thorough engineering analyses of the end users’ products and processes,” says Jeff Kerr, manager of mechanical design at RAMP. “We start this at the outset of system implementation – even before we think about the control platform. We cross-functionally examine

all requirements and break them down into individual conceptual designs. This way, we ensure that all mechanical and control components are fully compatible, resulting in the best possible solutions for customers.”

Agile engineering

RAMP exudes creative engineering ideas through the company’s breadth of knowledge in diverse industries, and the company identifies potential risks upfront. From the first customer visit, the RAMP team manages risk with proof-of-concept consultation backed by practice-proven design techniques. “A strength at RAMP is our ability to rapidly customize solutions according to each customer’s unique needs,” explains Stephen Gugeler, manager of control systems at RAMP. “We can accommodate multiple part types and rapid changeover requirements while providing standard interfaces and production methodologies. Regardless of the particular machine type or range of products they’re manufacturing, custom solutions from RAMP are designed to be inherently familiar.”

W ith standardized machine

With standardized machine design, RAMP customers that have multiple divisions or facilities can move cross-functional teams between facilities and still learn new processes quickly.

design, RAMP customers that have multiple divisions or facilities can move cross-functional teams between facilities and still learn new processes quickly. This understanding spreads across engineering, technician and maintenance teams so all personnel can operate new machines and navigate changing manufacturing processes more easily.

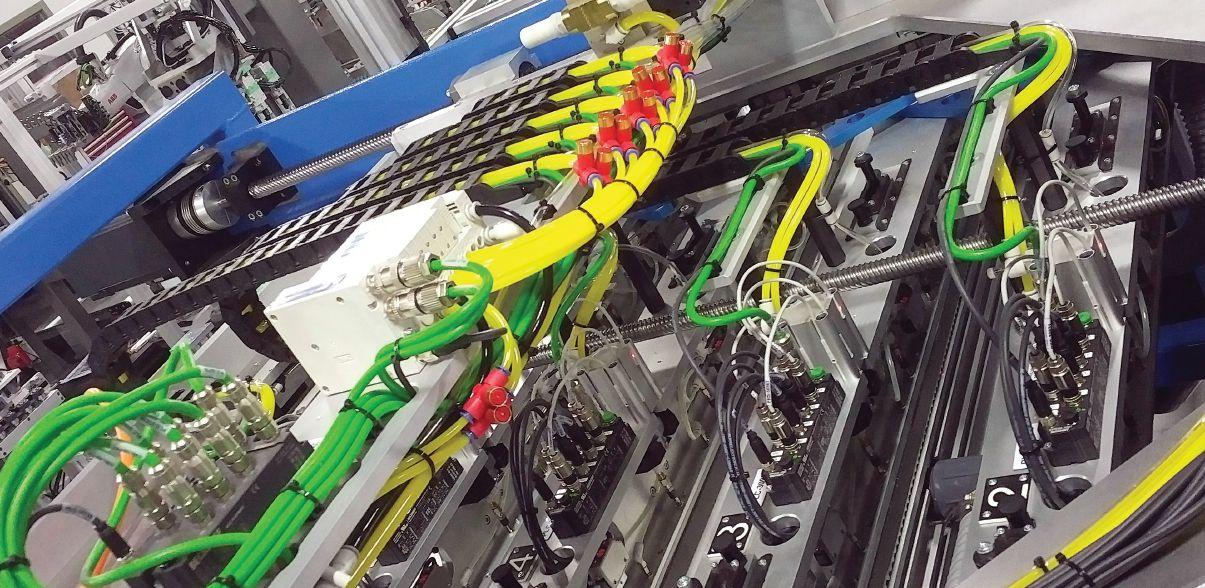

A recent RAMP client to integrate custom-built machinery is CORE Energy Recovery Solutions based in Vancouver, British Columbia. A RAMP-built machine installed in 2018 at CORE manufactures energy recovery ventilators (ERVs) that increase air exchanger energy efficiency in residential and commercial buildings. The ERVs are used in the CORE Mustang crossflow exchanger line.

30%

The RAMP machine takes base materials, including a patented polymer membrane and aluminum foil, through the machine process that laminates layers of membrane and corrugated aluminum in various heights and pitches unique to each customer recipe. The second half of the machine takes the laminated materials through a high-precision vacuum conveyor designed and built by RAMP. This custom sheet layer then has separating

materials placed on it using a unique pick-and-place process with common pick positions but recipe-driven place positions varying from 250 mm to one metre. Finally, the layers are stacked across multiple dimensions and heights to create the last recipe-driven dimension and then exited off a conveyor to the operator.

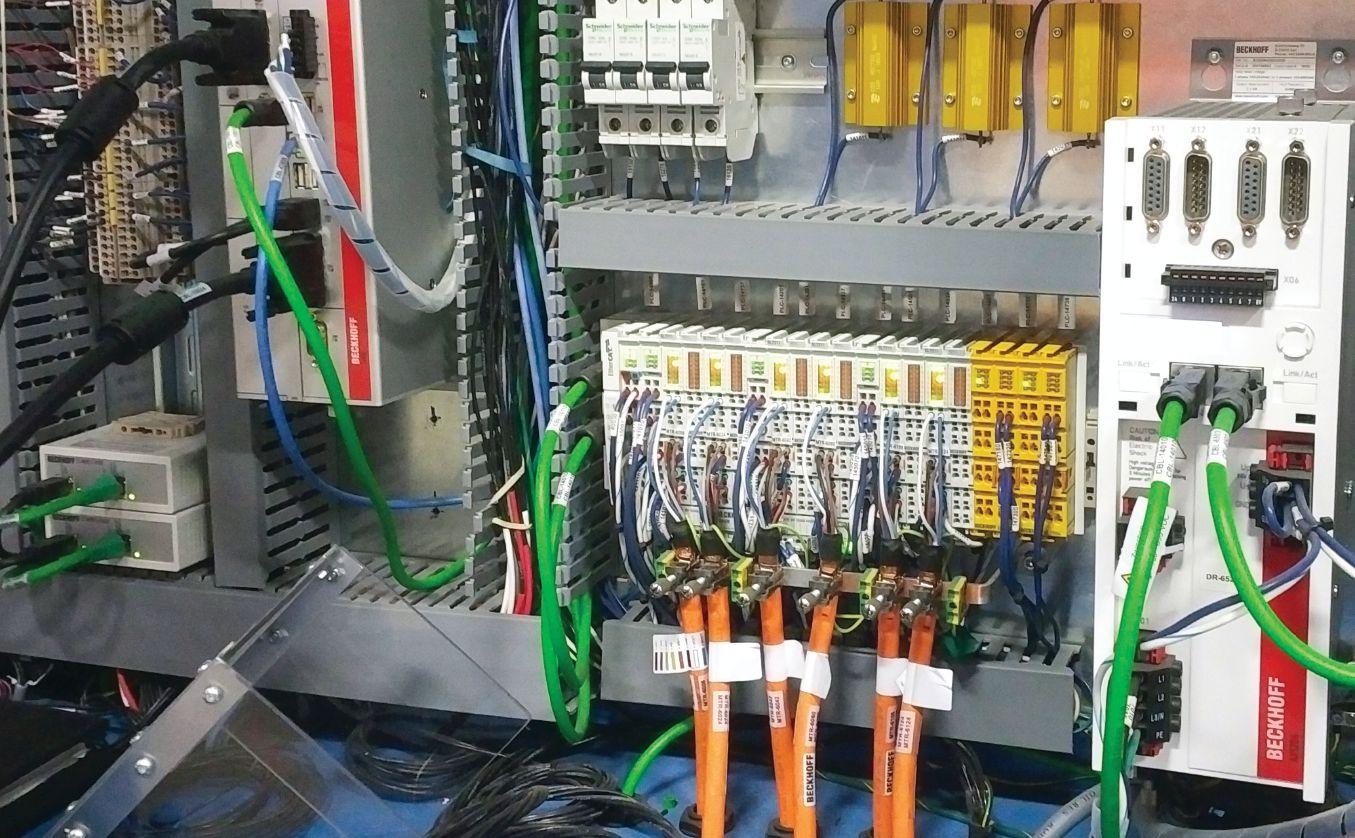

PC control software

RAMP has used PC- and EtherCAT-based control technology from Beckhoff Automation for over four years and has since increased its usage across the organization. “The Beckhoff control platform is the standard on three of our primary systems, including this web handling system for CORE, as well as our moulding machinery and measurement equipment used in automotive applications,” Gugeler says. TwinCAT 3 software from Beckhoff allows RAMP to handle PLC and motion control, plus I/O mapping and configuration in a single software solution. The RAMP team creates code using various IEC 61131-6 languages, ensuring that the company’s standards-based approach extends to software engineering. TwinCAT also helps RAMP leverage open, vendor-neutral technologies like the OPC

Using PC-based control, RAMP was able to reduce both PLC cycle times and overall automation system costs by 30 per cent.

Members of the RAMP engineering team, from left: Martin Pinnau, mechanical technician; Stephen Gugeler, manager of control systems; Jeff Kerr, manager of mechanical design; and Stephen Slothouber, controls program lead.

RAMP used a C6930 IPC (left) and AX5000 series EtherCAT servo drives (right) for high-end motion control.

In order to minimize wiring distances over to field devices, RAMP uses a machine-mounted EtherCAT Box I/O in IP 67 protection throughout the system.

UA standard for secure connectivity to higher level databases such as Amazon Web Services (AWS) and SAP.

RAMP uses a variety of TwinCAT tools for high-speed data analysis and advanced code development. “TwinCAT 3 excels in all areas of PLC and motion control programming, but goes far beyond this,” Gugeler says. “For example, ScopeView makes troubleshooting and modification efforts faster and more efficient. And since the platform directly integrates with Microsoft Visual Studio, RAMP can take advantage of standard computer science tools and methods, such as C# for UI development. This means we can fully leverage emerging engineering talent from local universities and colleges. These new engineers entering the workforce are very familiar with IDEs like Visual Studio, but may not have interacted with a traditional PLC before.”

Industrial PCs

Based on the application requirements and specifications from CORE Energy Recovery Solutions, RAMP required a high-powered industrial PC (IPC) to handle all automation software and Windows applications, as well as the company’s recipe and data acquisition solutions. “We needed an IPC that

could run our applications at a one millisecond update rate to provide maximum control over the process. That led us to the high-power, cabinet-mounted C6930 IPC from Beckhoff,” says Steve Slothouber, project control lead at RAMP. The C6930 that RAMP selected features a fourth-generation Intel Core i5 processor (two cores, 2.7 GHz).

RAMP connects the C6930 IPCs to CP2916 multi-touch control panels to display dashboards that run on an HMI server for local and web-based access. The dashboards are filled with overall equipment efficiency (OEE) information and important data from existing validation systems. RAMP uses two CP2916 panels with 15.6-inch displays for HMI hardware, allowing for easy operation and process control. To cover I/O requirements, RAMP standardized on an EtherCAT system that offers analog and digital devices rated in IP 20 and IP 67 for all data acquisition and machine safety requirements. The IP 20 EtherCAT terminals result in a smaller enclosure footprint and permit a free mix of safe and nonsafe I/O in the same segment. Highdensity (HD) EtherCAT terminals, which offer as many as 16 I/O channels in a 12-mm wide terminal housing,

CORE

RAMP built custom machinery this year for CORE Energy Recovery Solutions in Vancouver, backed by PC-based control from Beckhoff Automation.

promote space savings. These also greatly reduce wiring effort through DIN rail installation and cage clamp wiring connections.

“The EtherCAT I/O system provided the high-speed networking and fast scan times we needed while ensuring flexible network topologies,” says Matt Buchwald, electrical design lead for RAMP. “The CORE application requires high-end control technology that can react to production changes and adjust output controls in under 10 milliseconds.” The application also had to integrate with various third-party field devices on different networks, and each protocol had to be managed in the central controller. In this case, the EtherCAT I/O system directly connects to EtherNet/IP hardware required on the machine. This included devices installed on web handling equipment, vision system hardware, automatic power tensioning controls and dispensing units.

In order to minimize wiring distances to field devices, RAMP uses machine-mounted EtherCAT Box I/O in IP 67 protection throughout the system. “This allows us to place our field inputs and outputs closer to the application and reduce overall cable length and cable track requirements,” says Buchwald. “Integrating all safety systems on the same EtherCAT network via TwinSAFE I/O further reduces overall cabling and electrical assembly

“Even before we think about the control platform, we cross-functionally examine all requirements and break them down into individual conceptual designs. This way, we ensure that all mechanical and control components are fully compatible.”

time. The safe inputs and outputs efficiently connect with safety doors, light curtains, area scanners and e-stops. TwinSAFE also handles Safe Torque Off (STO) functionality on some hard-wired motion control equipment.”

For drive technology that would reduce cabinet space, RAMP applied 24-mm wide EL7211 servomotor terminals for some of the machine’s motion control requirements. “We can use one low-cost 48-volt power supply for the EL7211 drives, significantly reducing space and cost requirements for servo drives,” says Gugeler. Beckhoff stepper technology also factors into the application, with AS1020 stepper motors used for low-cost control of motion, velocity and position. These are driven by EP7041 stepper motor modules rated at 50 V DC, 5 A, with

built-in incremental encoder for resonance-critical applications.

For higher power and load requirements, the RAMP machines also incorporate AX5000 series digital compact servo drives for high-end position control, electronic gearing, velocity control and super-imposed position control. The drives connect to AM8000 series servomotors, which cut up to 50 per cent of motor cabling and connectors, to handle conveyance, pick and place, web lamination, tension control and height adjustments for the production line.

Lowering costs

As the machine control system for CORE Energy Recovery Solutions evolved over a year of development, RAMP repeatedly added new field devices for data acquisition. “We were initially

The drives used in RAMP’s soluctions connect to Beckhoff Automation’s AM8000 series servomotors to handle conveyance, pick and place, web lamination, tension control and height adjustments for the production line.

concerned about over-taxing the IPC from a data-processing perspective, but the system capably handled continual increases in data, even while handling all automation and control functionality,” says Balzan. “The stakes were high in this tight deadline project, because if the CPU and RAM couldn’t keep up, it would have required a major redesign.”

Since RAMP first transitioned to PC-based control and EtherCAT technology, the company has had ample time to compare metrics with older generation PLC- and PAC-based systems. “We

clearly increased control quality, improved system reliability, increased productivity and boosted OEE for all RAMP solutions with PC-based control,” says Gugeler. “Specifically, we improved PLC cycle times by 30 per cent and reduced control system costs by approximately 30 per cent.” With the results apparent in the company’s engineering approach to networking technology, RAMP continues to use PC-based control to create fully customized machines with the efficiency found in standard, series production machines. | MA

Safety Laser Scanner PSENscan. Experienced system planners and design engineers know the score: the monitoring of danger zones is just as indispensable for automation as protection is on the mountain. Risks must be detected immediately and processed reliably. Based on many years of experience in the field of optoelectronic sensors, Pilz is now taking the next step. With a new product group: flexible, configurable safety laser scanner for productive area monitoring. Play it safe: sensor technology, control technology, drive technology and visualisation. A one-stop shop. The complete solution from Pilz.

Pilz Automation Safety Canada L.P., Internet: www.pilz.ca

Shane Novacek is the marketing communications manager for North America at Beckhoff Automation. beckhoff.ca

LEADERSHIP SUCCESSION STRATEGIES

Prepare your plant’s pipeline of talent by offering development opportunities

BY MICHELE MARKEY

Baby boomers have left a footprint on every industry since they joined the workforce five decades ago. In leadership roles, they have set the organization’s vision, established the company’s culture and built the business’s reputation. Each day, more than 10,000 baby boomers turn 65 years old, and this trend will continue until 2029, according to Pew Research. As boomers reach retirement age, younger leaders who step into their positions will be challenged to maintain the quality of the brand, products or services.

Retirement isn’t the only reason why companies lose leaders. Although many CEOs plan to leave, there are those who exit the company due to an emergency or illness, a merger or acquisition, board dismissal or resignation.

Between 10 to 15 per cent of corporations across all industries appoint a new CEO each year. In

the industrial manufacturing environment in the United States and Canada, that number is even higher at 15.5 per cent, according to PWC’s Strategy& group and its Strategy+Business magazine. In the 2016 version of its annual study on CEOs, governance and success, Strategy+Business reported that 2.1 per cent of CEOs in the United States and Canada were forced out of their positions (one per cent of CEOs in industrial manufacturing), and 3.4 per cent left due to a merger/ acquisition (3.1 per cent of CEOs in industrial manufacturing).

With a strong succession plan and a talent pipeline in place, the organization can avoid gaps in leadership, reduce costs associated with finding a replacement and nullify any lost confidence in the company by employees, shareholders and the market.

What is succession planning?

Succession planning focuses on identifying the knowledge, skills

and abilities that will be needed to perform certain functions. The plan prepares individuals to perform these functions in the future. Considerations must be made for:

• Identifying skills gaps and training needs

• Retaining institutional knowledge

• Boosting morale and retention by investing in employees

• Replacing unique or highly specialized competencies

Any organization can plan for leadership succession based on company vision and goals. The goals of the business will drive the skills and attitudes that are critical for those in key positions.

While many organizations believe they have a succession plan in place, it is often confused with replacement planning. This typically identifies one or two current company leaders who are available to replace someone on short notice or during an emergency. The replacement is often a temporary measure. It doesn’t account for a long-term, continual solution like succession planning.

By establishing a robust leadership succession plan, businesses can bolster their employees’ abilities to move into these roles.

Companies that develop their upand-coming leaders benefit from:

• Improved retention of talented employees.

•Reduced costs in external searches and faster decisions made to fill key positions.

• Engaged employees who are encouraged by their career progress and new skills.

• A positive corporate culture that encourages outside talent to seek employment with your company.

Start with a plan

Build a business case by determining the needs of the company and how to address these needs with talent. Key company leaders may have their own ideas for succession plans. Start with them sending their plans informally, either through email or in conversation.

If they are having trouble articulating their plans, ask questions that help generate ideas.

• What is your talent strategy, and how does it support the business?

• What would you do if the CEO quit next week?

• What are the roles that need to be actively managed, and what are your plans for them?

• Who among your current employees do you identify as having potential for growth?

• What are the top three things you need to manage risk, as it relates to personnel?

Talented people are a major component of a company’s future

success. Start by identifying top talent at different levels: company contributors, middle management and leaders. Each position at these levels can be viewed as potential leaders, whether it is moving contributors to management, middle management to executive positions, or VPs and executives to the C-suite.

Assess these people for key competencies, like team building and communication. How do they inspire and persuade employees? How do they communicate to generate buy-in? Can they build a support team with complementary skills, yet different perspectives, to generate healthy discussions and avoid groupthink?

Develop top talent

Once talent has been identified, drive their growth with experiences and training. Create new positions, roles and assignments that expose them to high potentials; assign a second-in-command role that allows upcoming leaders to take over key responsibilities; and have them fill in for a senior leader for short periods.

Staff projects with development in mind (what can be learned from projects, and who would perform best?). Performance reviews, mentoring programs, experience paths, rewards and incentive programs can track progress.

Relevant and engaging learning and development is driving today

workforce, and a formal training program also should be included to develop your future leaders. Popular delivery methods are: