AUTOMATING BEHIND THE SCENES: Robotic Process Automation offering back-end support. 14

AUTOMATING BEHIND THE SCENES: Robotic Process Automation offering back-end support. 14

Industry association discusses how it supports the industrial automation sector. p. 16

Your resource for Canada’s industrial automation news

Meet the inaugural winners. Pictured here: Rick Black, president of Black Controls Company p.9

CASE STUDY: A machine-builder standardizes EtherCAT and PC-based automation. p. 19

Circuit protection including MCCBs, circuit breakers, and transfer switches (Circuit breakers starting at $15.00)

Wiring solutions including cut-to-length cable, hookup wire, wire duct, conduit, terminal blocks, and cable entry systems (Wire duct starting at $7.50)

Drives, soft starters, and motor control devices (Micro AC drives starting at $128.00)

Enclosure lighting and thermal management (Thermoelecric coolers starting at $718.00)

Industrial power supplies, transformers, and converters (DC power supplies starting at $20.00)

PLCs, field I/O systems, motion controllers, servo and stepper systems (PLCs starting at $85.00)

Industrial Ethernet switches, gateways, and VPN routers (Ethernet switches starting at $83.00)

Safety products including safety controllers, safety relay modules, intrinsically safe isolators, etc. (Safety relays starting at $103.00)

Modular and pre-fabricated enclosures (Modular enclosure kits starting at $875.00)

Plus motors, HMIs, pneumatics, a huge assortment of sensors and pilot devices, and so much more. All at great

The latest industry news, deal makers, and movers and shakers

7 Industry watch

Leading for success: Empowering the right people to build your business

20 Learning 4.0

Industrial 3D printers: Supporting SMEs and inspiring the future workforce

22 The big picture Investing in innovation during economic downturns

Presenting the future leaders of the industry who are inspiring innovation and driving growth today.

By Sukanya Ray Ghosh

Robotic Process Automation is eliminating repetitive tasks in back-end processes that support the shop floor.

By Jacob Stoller

Industry association Automate Canada discusses how it is helping build a stronger industrial automation sector in the country.

By Automate

Canada

A machine-builder achieves rapid time to market for custom assembly machines by standardizing on EtherCAT and PC-based automation.

By James Figy

Industry4.0 is no longer a novel concept in the manufacturing industry. It has been here for a while now. Automation technologies are evolving regularly, transforming the manner in which manufacturing facilities operate day in and day out.

In recent years, many manufacturers have taken the plunge and started their digital transformation journeys on some level. However, making a decision and embarking on the journey can be a daunting task. As industry experts have said time and again, even within the pages of this magazine, manufacturers have to first understand their own business and plan what needs to be changed before automating and transforming their facilities.

Something to keep in mind is that there is no need to take these crucial decisions alone. Education and information on how to begin are always available if you look for it. For example, Manufacturing AUTOMATION often hosts webinars where experts discuss implementing automation in complex manufacturing environments. Attendees can directly interact with the speakers at such webinars. If timing is a constraint, most webinar recordings are available for viewing on-demand if you register for them.

Industry events are always a good place to meet vendors and systems integrators who can not only offer information but also plan and facilitate the journey to automating both the shop floor and back-end systems. The networking opportunities at live trade shows are immense. With restrictions easing and being lifted everywhere this year, most major industry events are back.

Taking time out of very busy schedules is not always easy. Keeping this in mind, Manufacturing AUTOMATION is hosting its virtual event, Future of Automation, again this year. Thought leaders with expertise in different areas of automation and digital transformation will join us to share the latest developments in technology, solutions to challenges that manufacturers commonly face and what to look forward to in terms of technological advancements.

The future of automation is constantly evolving. It was once a matter of great concern that

automation will take away jobs from people. However, it is now evident that automation is changing the type of jobs that the industry needs. The need for reskilling and upskilling the labour force is a major conversation topic today. This is where the concept of Industry 5.0 comes in, where human beings will work side-by-side with intelligent machines and robots.

Challenges abound in the manufacturing industry today. Supply chain disruptions, increasing costs, inflation and shortage of skilled labour are some of the common things on everyone’s plate. Investing in automation, technology and innovation may seem risky at this point. However, as Stephanie Holko from NGen says in her back-page column in this issue, investing in innovation during economic downturns can often pay off. The Future of Automation event intends to bring in experts that highlight practical solutions that manufacturers can implement in their near future.

As I mentioned earlier, manufacturers need not embark on their automation and digital transformation journeys alone. Industry associations can offer a lot of support when the need arises. In this issue, Automate Canada president Jeanine Lassline-Berglund talks about the different steps the association is taking to build a stronger industrial automation segment in Canada.

It often helps to take a look at how industry peers have approached the implementation of automation and advanced manufacturing technologies. Case studies can offer insight into how new technologies are integrated with legacy systems to achieve the desired results. You will often find such case studies within the pages of this magazine or on our website automationmag.com. Have you recently automated your facility? What was your journey like? What kind of support did you receive when taking this major step? Share your story with industry peers through this magazine.

Manufacturing AUTOMATION will soon be launching our Automation Awards. Check out our website, e-newsletters and social media feeds for announcements and updates. | MA

@AutomationMag srayghosh@annexbusinessmedia.com /company/automation-mag

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquires or changes, please contact:

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Svetlana Avrutin savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

COO Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Paul Hogendoorn, Matthew Mongeon, Jacob Stoller, Jeanine Lassline-Berglund, James Figy, Maxime Lacouture and Stephanie Holko

Manufacturing AUTOMATION is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing AUTOMATION are © 2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Association Partner

Weidmuller and Shelley Automation sign distribution partnership

Weidmuller has added Shelley Automation as a distribution partner for the Ontario region in Canada. This move is aligned with the company’s growth strategy spearheaded by managing director Michael Daly. Daly took over the leadership position in December 2021.

“With Shelley Automation’s integration, Weidmuller’s distribution network looks more robust than ever. In addition, Shelley has a good team of professionals who know their trade, and we are confident of this alliance,” said Daly.

As per this new partnership, Shelley Automation will market and distribute Weidmuller’s complete product portfolio in the Ontario region. This includes I/O systems, industrial ethernet, relay modules and power management, among other things.

“This is an exciting time for Shelley. We believe there is good synergy between Weidmuller products and our expertise in automation. We can confidently go to market with Weidmuller products because they are an established brand and have quality products that address many industry problems,” said Selman Qadri, director of sales and marketing at Shelley Automation.

Omron Automation adds RAMP to its Certified Systems Integrator program

Omron Automation Americas added Waterloo-based RAMP as a new partner in its Certified Systems Integrator program. RAMP designs and builds custom automation and robotic systems.

Peter Brouwer, vice-president of sales for Omron Automation Americas noted that RAMP helps customers leverage IIOT to transform their factory and integrate robotics safely and effectively.

Brouwer added that the company’s product and process knowledge of tooling and automation, as well as its extensive experience in machinery and systems design, provides a turn-key solution that satisfies customers’ quality and performance requirements.

“We are proud to join the Omron SI partner program,” said, Mike Balzan, director at RAMP. “Together with Omron, we’ll

continue to help our customers meet their challenges with innovative and reliable automation solutions.”

Matrox announced that Zebra Technologies is set to acquire the Matrox Imaging division. The

companies have entered into a definitive share purchase agreement to that effect.

The Matrox Imaging division headquarters will remain in Montreal even after the acquisition is complete.

“The combination of Matrox Imaging’s technical expertise with the global footprint of Zebra Technologies will present an opportunity for Matrox Imaging

to accelerate its long-term strategic plan,” said Matrox president and co-founder Lorne Trottier.

Zebra Technologies specializes in automatic identification and data capture (AIDC). It is an enterprise solutions company that provides technology used to sense, analyze and act in real-time.

“Matrox Imaging brings deep expertise that will strengthen our recently established machine vision business unit and help Zebra further differentiate our growing portfolio of machine vision solutions,” said Anders Gustafsson, CEO of Zebra Technologies.

Endress+Hauser Canada unveils new Customer Experience Centre in Burlington

Endress+Hauser Canada officially christened its new Customer Experience Centre in Burlington, Ont. on May 10.

On hand for the ceremonies were CEO Matthias Altendorf and Klaus Endress, president of the supervisory board, who both took pride in “staying the course” in creating the new centre, which is completely self-sufficient in providing its own power and having a zero-carbon footprint.

The two-storey, 47,000 sq. ft. $28-million centre – located at 1244 International Blvd. – features some of the latest instrumentation technology that Endress+Hauser Canada has to offer, and houses the company’s Burlington-based sales, service and administration staff.

Customers can get a hands-on feel of the latest process automation offerings from the company before deciding on the most suitable products and solutions to match their needs, states E+H.

The facility has a Process Training Unit (PTU), as well as a full-service calibration laboratory that can handle the entire spectrum of flow, temperature, pressure, and liquid analysis instrumentation. The PTU concept is a full-sized pilot plant with a wide range of

the company’s instrumentation installed and fully functional.

The new centre will serve the company’s customer base from Manitoba to Atlantic Canada.

GM Canada is investing $2 billion with support from federal and Ontario governments

GM Canada announced an investment of $2 billion in its Ingersoll and Oshawa Assembly plants in Ontario. The company will begin production at Canada’s first full-scale electric-vehicle manufacturing plant in Ingersoll, Ont., later this year. It is also adding light-duty pickup production and a third shift at the Oshawa Assembly facility.

With support from the federal and Ontario governments, GM Canada’s investment is being used to fund the transformation of its manufacturing operations.

The Ontario government is offering a $259 million grant while the Government of Canada is making a matching contribution of up to $259 million toward the project.

The company will retool CAMI Assembly in Ingersoll this spring and summer and begin production of BrightDrop’s electric delivery vans in December 2022.

GM Canada’s Oshawa Assembly plant will be adding light-duty pickup production and a third shift of production in

the coming months. Oshawa will be the only GM plant producing both heavy-duty and light-duty pickups.

Adding the third shift will help create more than 2,600 new jobs in the Oshawa plant since it reopened. Fifty percent of new production hires at the Oshawa plant are women, reflecting GM’s focus on diversity in the workplace.

Honda of Canada Mfg. (HCM), a division of Honda Canada, recently announced that it is

investing $1.38 billion over six years to upgrade its manufacturing plants in Alliston, Ont.

The funds will be used to add and implement new and innovative technologies, processes, supply chain and vehicle research and development programs in the plants. This is aligned with Honda’s goal to reach zero emissions by 2040.

With the investment, HCM is set to become the North American lead plant for Honda’s 2023 CR-V Hybrid crossover. This will bring Honda’s total Canadian facilities investments to more than $6.5 billion since the opening of its first manufacturing facility in Canada in 1986.

The governments of Canada and Ontario are each supporting HCM’s investment with an equal and conditional contribution of $131.6 million.

In a statement released by the company, Honda explains that retooling both production lines at HCM will help secure thousands of jobs in Alliston and throughout Honda’s extensive Canadian supplier network.

The company is also investing in enhanced job training initiatives and expanded inclusive hiring practices, as well as research and development programs that further reduce the environmental impacts of vehicle production. | MA

General Motors Canada has appointed Marissa West as its president and managing director. West brings with her extensive leadership experience to her new role. For the past three years, she led the design, engineering and development of several key programs within the GM truck family. Prior to that, she was director of global noise and vibration and vehicle dynamics centre after holding various leadership roles throughout the global product development organization.

WAGO recently named Tyrone Visser as its North American business development manager for IIoT and Linux. In his new role, Visser will lead WAGO’s efforts in demonstrating how the company’s PFCs and edge devices can offer more than what is possible traditionally with a PLC. Visser served as a regional sales manager in Canada for the Alberta, Saskatchewan and Manitoba territories at WAGO for six years before this promotion. | MA

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn. paul@gmail.com or linkedin.com/in/paulhogendoorn.

I’m continuing the top 10 tips gleaned from successful companies and leaders that I’ve worked with over my 40year career. Although the two tips shared in this column are very similar and intricately related, they are also critically distinct.

TIP #7: “If you want something important done, ask a busy person.”

A colleague on a church board once said to me many years ago, when the two of us were assigned a task, “If you want to get something important done, ask a busy person.”

Here’s why that’s a great tip for a manufacturing setting. Truly busy people in manufacturing have a knack for getting things done. They are not looking to put new things on their list but instead are trying to find the quickest way to get an item off their list. Yes, there are people in manufacturing that know how to make themselves busy or keep themselves busy, but successful company leaders innately know the difference between routinely busy people and truly busy people that get things done. How do I know this is true? Easy. A task that is critical and needs to get done seldom gets assigned to a person with a track record of managing never-ending projects that seem to go on. They get assigned to people trusted to deliver an outcome. Without even deliberately knowing they delegate tasks in this way, they do. Truly busy people know how to delegate, when to stay out of the way and when to roll up their sleeves and just do it themselves. Their focus is on getting the important tasks done and making themselves less busy. Routinely busy people are looking to remain busy, and often without knowing they are doing it, they keep tasks open and keep themselves positioned as a critical

Successful manufacturers build on the people that take them forward. As they empower, enable and grow the people, they build their businesses. The company’s culture encourages its people to imagine, plan and persist on finding ways to move forward.

communications conduit. They resist closing the task out to get assigned another task, or worse (in their minds), have no important task assigned to them. Truly busy people don’t have this aversion, because as soon as they have any bandwidth at all, other important tasks are assigned (or reassigned) to them. What I’ve observed over the last four decades is that most progressive company and department leaders already instinctively know this. They just aren’t aware of it. The key is to not burn out your truly busy people. Instead, let them graduate up the ranks as they succeed, confident that there is another high-achieving candidate ready to follow their lead and fill their shoes.

TIP #8: “Leaders find a way.”

The second tip comes from someone I was also on a board with. We faced many challenging situations together. His closing mantra was “leaders find a way”. And indeed, they do. The leader is not the person with the position or title, or the education, or the letters behind their name. The leader is simply the person that finds a way when others don’t or can’t. In all of our workplaces, there are many people that can point out the reasons why something can’t get done. In fact, we often admire, empower, and even promote individuals that

have great abilities to foresee or articulate problems that others can’t see. But how does that get a company ahead?

At best, it keeps the company from going backwards – It doesn’t pull the company forward. Many managers are to some degree inclined to keep companies from going backwards, but leaders are more often inclined to find a way forward. There are leaders in every organization, in roles up and down the org chart. In the most successful organizations I have come across, the people that find a way (leaders) are supported, encouraged and appreciated. In less successful organizations, the

folks that have a knack for finding a way become discouraged and move on. A leader’s true role is to develop new leaders. A successful company’s culture fosters and encourages people to imagine, plan and persist on finding ways to move forward.

This is a key differentiator that I’ve observed that sets successful thriving manufacturers apart. They build on the people that take them forward. As they empower, enable and grow those people, they build their businesses. Who are those people in your organization – the ones that find a way and get things done? Are you building on them? | MA

BY SUKANYA RAY GHOSH

The future of the manufacturing automation industry looks bright. Armed with a strong work ethic, initiative, curiosity and a commitment to innovation, the winners of our inaugural Top 10 Under 40 program are setting the bar for young professionals across the industry.

Whether they work in leadership, operations, maintenance, sales, support or research, these industry professionals are highly regarded by their colleagues, clients and peers.

Congratulations to all the winners!

RICK BLACK President, Black Controls Company

Inc. Barrie, Ont.

In 2019, at the age of 33, Rick Black invested everything. He left a full-time, secure job because he identified a need in the industrial controls industry and wanted to service it. His whole home was consumed with the Black Controls Company. He hired one full-time employee to support him and established a mutually beneficial relationship with a large business in Ontario. Black Controls quickly grew. In June 2021, Black Controls moved into the current 13,000 square feet building and currently employs 20 people.

During Rick’s 14 years of work experience, he mastered his craft before honing his natural ability

to mentor, lead and teach. He has managed and trained more than 35 programmers and has led teams of designers, electricians and administrative staff.

For Rick, Black Controls Company is a huge achievement. This successful business was established through an accumulation of small achievements over the past three years. At the inception of his business, he oversaw everything. As Rick secured more work, he expanded the number of employees and officially established his core team. With foresight and organization Rick was able to curate a work schedule that ensured this business not only survived but thrived during the COVID pandemic.

As a resident of Barrie, Rick strives to contribute to positive, sustainable, and ethical change in his community. He has established local partnerships between Black Controls and Georgian College, the City of Barrie and the small business center in addition to the Barrie Chamber of Commerce.

President and general manager, Raven.ai Ottawa, Ont.

With over 13 years of experience in management, operations and continuous improvement, Maxime Blouin’s colleagues

describe him as a passionate, vibrant and resourceful leader in the manufacturing world. From working on the shop floor to pitching technology in the boardroom, Maxime shapes his career around making a positive impact throughout factories and the frontline’s work life.

In his current role, Maxime is committed to growing Raven.ai, an automated contextualization and OEE technology. Through his leadership, he has driven successful market penetration, increased deployment of scalable smart solutions worldwide and managed a growing team of motivated employees to achieve bottom-line results.

His accomplishments are many, according to his co-worker Marisha Sesto.

He established and executed business growth strategies and

boosted revenue by three times for two years in a row. He has closed expansion deals with 80 percent of the customers.

Maxime grew the company from 15 to 63 employees within two years, averaging seven percent month-over-month growth and net churn of 0.4 percent. He is dedicated to building a diverse and equitable company with 46 percent of the team being women.

“As someone who started working for Raven.ai in 2022 with no manufacturing experience, the strong understanding and empathy for the manufacturing world that Max has, on top of the passion and determination to better the work lives of the frontline, has truly made me believe in what we do and gets me excited to work every day,” says Marisha.

Simmie Thiara is the third generation of her family working on fuelling the growth of AceTronic. AceTronic, a family business, was established by her grandfather. Simmie’s mother, Kim Thiara, became the second generation to continue his passion and grow the company further to become a three pronged business, offering customers service, distribution and manufacturing capabilities.

To come in as a third generation member and create a legacy is not an easy task.

“Being a woman in the manufacturing is not easy, but anything can be possible if we find that spark within. Simmie has discovered her spark and has shown that she is up to it,” says Kim.

Plastics, a major part of AceTronic’s business, has much negativity surrounding it. Simmie was instrumental in creating the SWAP program, so that AceTronic could play a small part in fostering a circular economy.

Under Simmie’s guidance and leadership, AceTronic has partnered with Greentech and is ensuring that industrial waste (electronic components) are disposed off ethically.

Simmie has sat on the association for WBE (Women’s Business Association) and has been involved with CAMSC (Canadian Aboriginal and Minority Suppliers Council). These associations are focused on showcasing women and minority owned businesses and furthering their opportunities across the globe. She has also spoken on panels on behalf of Build A Dream, an organization that is intent on providing insight and direction to young females to consider careers in the trades and typical non-female roles.

SIMON DREXLER General manager for the products division, ATS Automation

Simon Drexler is the general manager for the products division at ATS Automation in Cambridge Ontario, where he drives growth by leveraging his over 12 years of experience in the industry. With a passion for technology, he constantly strives to drive innovation in the world of industrial automation.

Simon has earned himself a spot on Plant Magazine’s “Top 40 Engineering Leaders Under 40,” and was named Supply & Demand Chain Executive Magazine’s “Pro to Know.”

Along with leading the SuperTrak team, Simon currently sits on the board of advisors for Canadian Manufacturers and Exporters. He also sits on the National Board of Directors for CME. Simon has appeared on multiple editions of The Robot Industry Podcast and on educational webinars with the Robot Industry Association.

“The future of the manufacturing and automation world is exciting because there are a number of global trends that are driving new types of demand. Everyday, we see novel applications and opportunities for technology, which bring firsttime users into our segment. Personally, I would like to contribute to the accessibility of automation technology for these new entrants with the goal of helping companies scale their manufacturing,” says Simon.

“My contribution through both my professional and community efforts is to enable the manufacturing industry to better understand where and when to apply automation with the goal of helping them to successfully scale their operation. By making solutions more accessible, we will drive growth in the industry as a whole.”

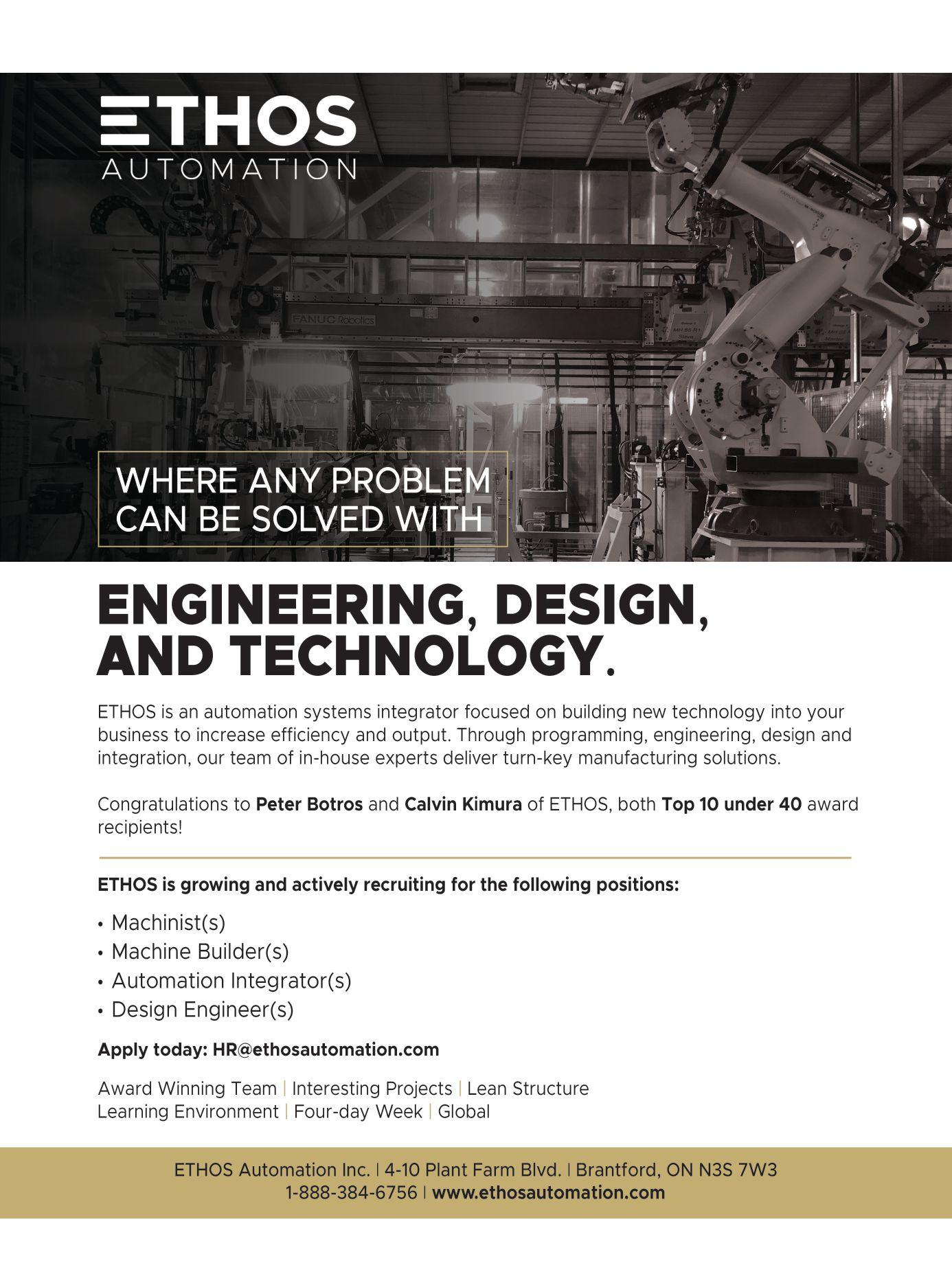

PETER BOTROS Co-founder, Ethos Automation. Brantford, Ont.

Peter Botros is the co-founder and in charge of engineering operations at Ethos Automation. Ethos Automation was created as a company with an ethical approach to building complex automation systems for its customers. Before establishing his nearly four-year-old company, Peter gained experience in the manufacturing industry working in different capacities over the course of his career. He was a mechanical designer at Gosco Engineering, manufacturing engineering coordinator at Magna International and manufacturing specialist at The Elite Engineering Group.

Peter is also a part-time professor of Mechanical Engineering at Sheridan College where he gives back to the automation community by sharing his real world experience in industrial automation and robot-based applications with his students.

“Growing this business from a small start-up to what it is now, means that I’ve been involved in every aspect of our projects. This has given me unique experiences and a skill set that allows me to continue to be active in all areas of our operations. One of my biggest motivators is my ability to visualize a fully automated system before pen is on paper. This visualization does not only allow me to bid on projects a lot more accurately, but it allows me to take on challenges that do not seem to have a clear solution,” shares Peter.

CALVIN KIMURA Automation specialist and co-founder, Ethos Automation Brantford,

Ont.

Calvin Kimura’s passion for automation and robotics brought him into this industry. He completed an electromechanical engineering technology program in Humber College, learning all about automation and robotics.

Calvin began his career as an automation technician with a leading Tier 1 automotive supplier. Here, he grew and honed his automation skills and knowledge with real-world experience. After leaving this role he took

his knowledge to the systems integration industry, working on large projects.

Always looking to innovate, his next move was starting his own machine-building company where he spent time taking it forward. Eventually, he helped cofound Ethos Automation. Calvin’s extensive automation experience perfectly complements his colleague and co-founder Peter Botros’ engineering background.

“Calvin had the courage to start an automation integration company in a complex time and with hearty competition. He wanted to start a company that builds automation where he could be proud to service and support,” says his friend Jim Beretta.

“In both my business and my personal life, I am constantly noticing inefficiencies and contemplating on how I can improve them. I enjoy the challenge of coming up with comprehensive automation solutions that exceed our customers’ expectations. Working in mostly a project-based capacity means I get to experience the satisfaction of seeing our projects come to life from a screen to moving parts on the factory floor. This is a great motivator for me personally, as I enjoy the thrill of innovative solutions for modern problems,” shares Calvin.

Adam Keller has been a part of Konnexio for around three years now. In the relatively short time with the company, he has worked in and has had a great impact on various automation and robotics projects. His passion for automation comes from being able to impact a variety of industries.

Adam started as a mechanical designer for automation systems. When Konnexio pivoted during the COVID-19 pandemic, he was instrumental in developing robotics for greenhouses.

Starting from mechanical design he also assisted heavily in the controls development and has

now taken on the complete project engineering for the entire robotics platform. He has guided a team to deliver the company’s first greenhouse robot in only nine months to a customer for initial testing.

Adam is now leading a team to implement additional features and capabilities so that the robot is able to deliver further value to the company’s customers.

“I plan to be a road map to automation for many companies that may not have even considered automation before meeting with me. I strive to solve problems for any manufacturer and industry, but that starts at home. I would like automation to allow Canada to overcome labour concerns and keep Canadian production a viable option,” says Adam.

TIM WEBER

Machine tool builder Level 1, Systematix Inc. Waterloo, Ont.

A part of the company for six years, Tim Weber joined Systematix’s fabrication team in 2016. With his drive to learn and grow, he became a general machinist apprentice in the following year. After receiving his general machinist license, Tim went on to complete the MTBI apprenticeship at Conestoga College. He received his MTBI license in 2021.

Now a Level 1 machine tool builder and integrator, Tim is an asset to any build team that he works with, says the Systematix team. In 2021, Tim volunteered with the local school that he graduated from, teaching a class in machining. To ensure that Tim was able to inspire the next generation of machinists and builders Systematix gave Tim half a day off every Monday for teaching.

“I am most passionate about building high quality machines that are robust and visually attractive. I am proud of the machines that I build; proud that they solve our customers challenges,” shares Tim. He adds, “I want to continue to learn from others how best to approach building machines. Eventually, I want to be a leader of the build team. I have always enjoyed showing new machine builders to Systematix and apprentices how to build machines. I had the opportunity last Fall to teach a machining class at my old high school and really enjoyed introducing concepts to the students. I think my biggest impact to growing the automation industry is by mentoring new builders.”

Intermediate controls integrator Systematix Inc. Waterloo, Ont.

Ryan Terpstra graduated from the University of Waterloo with a Bachelor of Applied Science – Honours in Machatronics Engineering. He joined his current company Systematix in 2017 after graduating after spending some time co-running a start-up.

Ryan began as a junior controls integrator and immersed himself in learning from Systematix’s experienced controls team. He is now an intermediate controls integrator, providing the same guidance to new graduates and junior controls integrators that join the team.

Ryan enjoys being involved in the building of a machine from

start to finish. He primarily programs PLCs and robots but is very interested in complex data tracking and sequencing.

His great attitude makes it easy for build team members and customers to work with him. His ability to solve problems and come up with innovative solutions, make him a key member of the controls team at Systematix, according to his colleagues Octavio Gonzalez and Erin Montag.

Ryan says, “I enjoy working on the floor where the action is; and seeing it all come together is exciting. Watching my offline logic come to life and developing unique solutions to unexpected issues is something I can immerse myself in and before I know it the day is gone.”

He adds, “In the future I would

like to be in a position where I can make decisions that have a broader and more significant impact, perhaps outside of the scope of controls. New technology allows for innovative new solutions to existing problems and therefore can help the industry expand into markets it previously could not.”

Putnam, Ont.

As an undergraduate mechatronics student at the University of Western Ontario in 2014, Stefan Glibetic became aware of the lack of manual labour in the global mushroom industry. He was captivated with the idea of combining the principles of automation with machine vision, artificial intelligence, and novel embedded systems, to create a

new set of autonomous robots that are capable of effectively operating in these environments. He joined forces with a local mushroom farmer, wrote his Masters thesis on the topic, and moved the development of the technology to Mycionics, as a coowner, CTO and lead engineer.

“Ever since I was a young, I was completely preoccupied with trying to figure out the inner workings of various machines that were all around me. I would grab some tools from my father’s tool box and take them apart in order to get a better understanding of its underlying mechanisms. Although that usually didn’t end up so well for the machine, or myself for that matter, I did gain a little glimpse into the world of automation each time. It was just mind-boggling that one could take various smaller components, each with a simpler purpose of its own, and assemble them together to end up with a system that can perform a complex action as a whole. As I grew older, this passion directly led me to the field of engineering that taught me the principles of automation, which then led me to industry which taught me how to apply this knowledge and actually create the automated systems that once mesmerized me as a child,” shares Glibetic. | MA

Whatever rolls your way, our uniforms and services experts have you covered, so you can work harder, smarter, and safer.

Explore our offerings like Red Kap ZeroSkratch,™ OilBlok Technology, and classic ripstop fabric.

Scan the code to get started on your custom uniform program.

Shop floor automation helps manufacturers eliminate repetitive physical tasks, freeing humans to focus on value-added work. Robotic Process Automation extends this approach to the back-end processes that support the shop floor.

BY JACOB STOLLER

One of the most important applications of industry 4.0 technology is the early detection of deviations that could lead to inefficiencies, product defects, equipment failure, safety hazards or other problems. The value of these warnings, however, depends on the processes that ensure that appropriate interventions take place.

The challenge for many manufacturers is that many of their data-handling processes are manual, creating a weak link in the chain between important signals and timely response. The gap is driving the adoption of what has been dubbed Robotic Process Automation (RPA), which is essentially the deployment of sequences of computer code, called

bots, that execute repetitive tasks in robot-like fashion.

“It [RPA] provides value in automating processes based on structured data, many of which previously required manual intervention,” says Dinesh Nirmal, general manager at IBM Automation. “For manufacturers, RPA bots can be used as input to manufacturing analytics tools to analyze the overall progress, identify gaps and find improvement opportunities. More specifically, using RPA can help businesses improve go-to-market time by eliminating routine tasks that would have required human labour.”

“The essence of manufacturing is mostly repeatability,” says Gavin Davidson, industry product manager at Oracle NetSuite. “You design a product and end up with a list of materials (BOM)

These repetitive interventions –alerting a supplier, issuing a work order, removing a safety threat, correcting a quality problem –often extend far beyond the shop floor. Davison explains that beyond the manufacturing process, there are many opportunities for RPA to automate other business processes such as engineering changes, approvals, vendor onboarding and performance monitoring, planning, inventory management, invoicing and collections.

The most common ways manufacturers are using RPA, according to Nirmal, is to automate some of the repetitive supply chain and inventory processes. He notes that global supply chains can be complex given that manufacturers may work with suppliers in multiple countries.

Recent technology developments have enabled RPA to take off. “There’s a lot more data out there, and there’s a lot more digitization,” says Ibrahim. “Every organization’s assets from machinery, cameras, thermometers and more are connected to the internet, giving us more signals than we’ve ever had.”

that are required along with a process to make it. At its core, RPA can assist manufacturers in repeating actual processes, or by ensuring that deviations are properly routed or handled.”

Repetitive mind-numbing work that’s prime territory for automation can often be found behind the scenes of existing shop-floor automation.

“Whenever there are robots on the shop floor, there’s going to be a host of processes that surround that, maybe from a maintenance perspective, a quality control perspective or a safety perspective,” says Sherief Ibrahim, GM, business applications, Microsoft Canada. “It’s one thing to say we’ve got a machine that can automate a task. But how well are we automating the human intervention or human processes surrounding that task?”

Another important improvement is better interoperability between diverse apps. For example, a maintenance workflow might touch on production scheduling, equipment support, and procurement. “That workflow can be automated because we’re now able to connect all the apps and machines that are involved,” says Ibrahim. Power Automate, a Microsoft tool used to design and implement RPA workflows, can work with 580 different connectors, he notes.

Software for designing and implementing RPA automation is also becoming more user-friendly. According to a recent case study referenced by Ibrahim, an operations analyst at Rockwell Automation used Power Automate to automate a workflow involving 150 file locations. This triggered a number of employee-initiated automation projects.

“People don’t think of RPA as something that a business user can handle,” says Ibrahim. “They think it’s complex and can only be handled by experts. You do need to have the app developers engaged to help govern how RPA is managed. However, we have more and more case studies where a person who’s not a developer at all was able to take the platform and automate a process.”

The incremental nature of RPA also allows for solutions that pinpoint specific problems. “The start of automation really comes from capturing and understanding data that is relevant to a process,” says Davidson. “You can then begin by focusing on that data and designing repeatable processes to review, analyze and act on the data in order to generate a positive outcome.”

RPA solutions, however, should not be seen as a substitute for comprehensive solutions that unify workflows across diverse departments and business units. “RPA or robotic “process” automation is a misnomer,” says Nirmal. “It should have been called robotic “task” automation. RPA can be useful to automate a task and includes a workflow automation, but it is not intended to be used to orchestrate work across multiple people or multiple systems.”

Security and governance can also be of concern when incremental solutions begin to show up on the network. “I don’t want someone to automate a process where something sensitive ends up posted on Twitter,” says Ibrahim. “So we need to have guard rails to prevent sensitive information from flowing into the wrong places. An organization’s IT or developer team has built-in governance tools that will make sure Robotic Process Automations stay compliant and follow a company’s policies.

It’s also important to keep in mind that automation has its limits. “As automation adoption increases, more human tasks are automated in today’s digital world,” says Nirmal, “but there is still a large portion of our

daily work that requires manual labour, even if these tasks are repetitive. This is because some tasks still require human cognition and intuition to receive optimal results. RPA bots are programs and can make use of AI to help them to make sense of the world, but they cannot think by themselves beyond simple and well-defined tasks.”

The key is that RPA can’t solve every problem, nor is there a magic starting point.

“The best opportunities for using RPA will vary depending on the existing technology in the workplace and the desire to invest in or implement them,” says Davidson. “Investing in new machinery and robotics might offer a quick way to automate

One connection level covers all interfaces: directly on the servo drive without requiring upstream I/O

The AMI812x integrated servo drive: integrated servo drive for compact drive technology (up to 48 V DC) combines highly compact servomotor, output stage and fieldbus connection for all motion requirements in the power range up to 400 watts for single axes or with daisy-chain solutions on the machine supports machine concepts without control cabinets IP65 protection degree possible with sealing ring option Safe torque off (STO) safety over FSoE (Safety over EtherCAT) reduces installation and integrates seamlessly into safety solutions

Beckhoff offers a complete, compact control solution including a range of compact motion technologies for servo, stepper, DC motors and more

manufacturing processes, and utilizing your business systems automation capabilities would be another quick win. Usually, the best place to start is with a simple repeatable process of any kind that can be easily measured and monitored to ensure success.” | MA

Scan to experience the benefits of compact integrated servo drives

By Jeanine Lassline-Berglund, president, Automate Canada

Automate Canada is a national association representing companies involved in the industrial automation industry as well as service and supplier companies which provide specialized technologies to our industry. Automate Canada was formed as a committee in 2018 and by 2021 was Federally Incorporated.

The pace of robotics adoption among key Canadian manufacturers is speeding up. Canada offers robotics companies one of the best test and development regulatory environments in the world. Automate Canada’s mandate is to promote and develop the global exposure of the Canadian industrial automation industry.

Automation has seen an uptick in productivity despite the negative effects of the COVID-19 pandemic. In 2020, it

was reported that more than “two-fifths of large companies surveyed by the WEF plan to reduce their workforces due to the integration of technology.” While this is a drastic shift, the WEF also reported that the robot revolution will create 97 million more jobs worldwide. Automation in Canada in particular is showing no signs of slowing down. New advances in technology means economic growth, improved efficiency and brand-new occupations.

As an industry association, Automate Canada, is taking the lead on representing this important sector as well as supporting the organizations who operate within. In the long term, our goal is to combat the hollowing out of the advanced manufacturing sector, a risk faced by small- and

medium-sized manufacturing facilities.

The board and the staff have been busy with the standard obligatory responsibilities of becoming a notfor-profit association. In addition, the staff have been putting action behind the strategic pillars that were developed in 2020: skill and talent development; branding and collaboration and (helping companies with) technology adoption and building a culture of innovation.

Our mandate is to be the voice of our industry, whether it’s advocating for their needs with all levels of government, or working with community, academic and service partners who can support our member companies, regardless of their location. Supporting Canadian

You don’t need to look very far to see the many job openings in the Canadian manufacturing industry. Every employer we talk to needs skilled and talented workers. Right now, it is a major conversation topic and at the top of every employer’s list of challenges. So why are people not applying for jobs? Why are young people not overwhelming this industry with their recently earned skills from technical and STEM programs at colleges and universities? While Automate Canada doesn’t know the answer to this, we are deeply engaged at understanding it. More importantly, we are motivated to change it. The work we do can be summarized into three phases.

We are working to impact academia to improve the awareness and importance of STEM and technical skills, while continuing to showcase career paths, growth and upward mobility opportunities that are available in this sector. Canada has well-established robotics-centred universities and technical training opportunities with over 20 Canadian universities and technical colleges offering programs in robotics, mechatronics, computer control methods, hydraulics and pneumatics. But these programs and the potential opportunities need to be showcased or discussed at an early stage.

This phase focuses on the impact we can have today in working with service providers and community and government partners to funnel available talent to available work. By re-skilling, upskilling and working with immigration and

SMEs in their path to prosperity by assisting them in the industrial automation industry to grow their businesses locally and globally is also a part of our mandate.

We want to encourage the development and adoption of technology in the manufacturing sector as a whole as well as in the industrial automation industry, by becoming the association of “go-to” experts for automation of processes, regardless of sector or size.

Are you in the automation sector or supply chain? Why not join us? Gain the values of being a part of an association that is supporting member operations while moving the interests of our industry forward. This won’t be the last time you hear from us. We intend to continue sharing information about what we are up to in all strategic areas.

settlement partners, we can hope to fast track skill development for the immediate future. Many SME’s need support with re-skilling and upskilling right inside their buildings. We constantly work on partnerships for professional and skills development. We also focus on programs that can help our member companies take advantage of employing the under-represented. Initiatives in diversity, inclusion and gender parity continue to keep us running and finding tools that can help manufacturers transition their cultures and workplaces.

This phase is really about sustainability for the future. Workforce data is being collected and available since 1996 from the Workforce Development Board of Ontario. Statistics Canada collects information. Industry experts collect data and information. We have been collecting labour market data and looking at industry trends for the future for a long time and from many perspectives. How does this information find its way to educators and academic institutions? Many members feel that available skill and talent is at an all-time low and for some has already surpassed “critical.” Automate Canada is working at local, regional, provincial and federal levels to change this. We want to make a long-term impact, for advanced manufacturing in Canada and on behalf of the members we serve.

We have actions and activities big and small. Want to join our efforts? Connect with us today.

Automate Canada is a vibrant community of like-minded industry companies and professionals, working together to ensure Canada’s automation industry continues to thrive. Why not join us?

Automate Canada leads and advocates for the Canadian automation industry, assisting and promoting our members. Our mission is to engage in activities that support business success and continued innovation and development within our member companies.

Our mandate is to promote and grow the global exposure of Canada’s industrial automation industry, through advocacy to all levels of government. We support the next generation of skilled personnel via youth focused initiatives, and we assist SME’s growth locally and globally.

As a member of Automate Canada, you are part of an organization dedicated to the best interests of our industry and members. Whether it be advocating to government, or supporting and encouraging your industry connections, Automate Canada is here for your business. For more information, contact us today!

BY JAMES FIGY

When building series machines in high volume, timeframes are straightforward. But one-off, custom applications can prove tricky, with many unknowns during design, development and commissioning. To help meet incredibly tight time to market, Sodecia’s Global Tech and Automation Center (GTAC) applies principles from series production to its custom machinery for the notoriously demanding automotive industry. For years, the London, Ontario-based machine builder has invested time and resources in creating standardized control architectures and modular, reusable code.

“Based on our control code, we turn around projects that would typically take eight months to a year in just three to four months,” says Chris Drees, controls engineer at Sodecia GTAC. “This also means any of our engineers can easily troubleshoot code for standard or custom machines.”

The machine builder’s skill and agility quickly garnered global attention. In 2012,

Sodecia acquired an automation group as part of a larger company buyout. This automation group formed the base for what is now Sodecia GTAC, an automation division under the Sodecia umbrella. Sodecia adopted many of the automation group’s time-saving innovations into its own global standards, across the company’s nearly 40 manufacturing facilities around the world. These developments, which GTAC has continued to advance, have enhanced and accelerated design, programming and commissioning for Sodecia’s automated assembly and welding solutions for the automotive market. However, the benefits were critical when the Canadian engineers received an order from a global automotive manufacturer for a new version of a Seat Belt Height Adjuster (SBHA#3) in 2021.

Beyond faster throughput, the SBHA#3 machine presented some unique technical demands, according to Jessy Underhill, PLC and robot technician at Sodecia GTAC. “Compared to welding machines with large robots, the Seat Belt Height Adjuster features

faster-paced assembly processes in a smaller footprint,” Underhill says. “But we adapted our standard code structure – for things like dial table logic with the servo-based motion control and data transfer – to provide that functionality.”

SBHA#3 features five sections. Two substations assemble the button for activating the seat belt adjustment – essentially a small actuator with a spring. Next, the assembly is inserted into the component that slides up and down a steel rail, which has a small steel plate with a nut. The fourth section installs that assembly into the rail, which will ultimately be mounted to the vehicle chassis. The last section is quality assurance, so it performs height and load measurements on the components to ensure the button will actuate correctly. To accomplish this, the system features two servo drives powering four servomotors, two machine vision cameras, five VFDs, six KUKA robots, 13 solenoid valve banks and more than 100 I/O terminals. Therefore, real-time control and communication was key.

The automotive manufacturer needed SBHA#3 to increase the throughput of the current system, which presented new challenges even though the GTAC engineers had already optimized the existing machine in the past. The original assembly line, designed by an overseas OEM, had multiple separate cells and external conveyance equipment to transport workpieces between them. When Sodecia first redesigned this for the automotive manufacturer, the GTAC engineers cut the machine footprint nearly in half to a roughly 20-by-20-foot enclosure.

“The two previous iterations produced a part every 5.4 seconds, but this one needed to reduce that to 5.1 seconds,” Drees explains. “We also wanted to boost uptime, OEE and other capabilities, while expanding functionality by leveraging some recent updates to our standard code.”

As always, the project required a tight production schedule. It’s a competitive advantage that was born out of necessity, according to Brent Lekx-Toniolo, one of the founders of the original automation group who now works as an R&D contractor for Sodecia. “We designed the concept of building a framework around 2000 because customers ordered machines with very quick time-to-market requirements,” Lekx-Toniolo says. In 2007, GTAC discovered Beckhoff Automation, which offered the industrial control and networking technology to make the framework a reality. “After so much trial and error with other control platforms, Beckhoff truly was the solution we had been

waiting for,” he adds. “Ever since then, we’ve been a Beckhoff house.”

Automation solutions securely strapped in SBHA#3 relied on PC-based automation to meet the new challenges. This approach uses a flexible, universal engineering and runtime platform, TwinCAT 3 automation software, to control all machine processes from PLC and robotic kinematics to functional safety and IoT. A model of openness, other software can run alongside TwinCAT on the PC-based machine controller. The TwinCAT engineering environment is fully integrated into Microsoft Visual Studio and supports programming in the object-oriented extensions of IEC 61131-3, predefined and custom function blocks and computer science languages. This allows the GTAC engineers to program in the languages they are most comfortable with or that best suits the application at hand.

The TwinCAT runtime is on GTAC’s standard control hardware, a CP2215 Panel PC from Beckhoff. This device serves as both machine controller and user interface (UI). The 15-inch touchscreen features a rugged aluminum housing and five-finger multitouch functionality. This allows GTAC to design intuitive UI screens for operation, diagnostics and troubleshooting. “We have failed our customer if they have to get online with the PLC code for troubleshooting,” Lekx-Toniolo explains. “In our mind, we need to build a UI that is so robust that they can handle all troubleshooting from the UI and only need to go deeper if they want to make modifications or add on functionality.”

The EtherCAT industrial Ethernet system also played an important role. EtherCAT provides real-time communication and free selection of network topology. The motion bus enabled fast cycle times for the Beckhoff AX5000 series servo drives, third-party VFDs and KUKA robots. “KUKA has adopted EtherCAT, so beyond simplified communication, we can even leverage safety over EtherCAT (FSoE) for safer systems,” Drees says. This TUV-certified safety protocol eliminates the need to hardwire safety controllers to every e-stop, light curtain or other safety device. Using a “black channel” approach, FSoE sends safety data over the same Ethernet cables used for standard I/O. The AX5000 drives also feature a TwinSAFE card to enable FSoE right in the drive.

2020-Nema-Electric-Motors-MANUFACTURING-AUTOMATON-third-page.pdf 1 11/6/2020 9:52:35 AM

The GTAC engineers see robust diagnostics as another major benefit of EtherCAT. These diagnostics, combined with the intuitive UI, allow the Sodecia machines to display a cable break, faulty connection or other rare fault graphically for quick correction.

With interfaces to over 30 prominent fieldbuses and communication protocols, EtherCAT simplified integration of the two machine vision cameras, which connect via EtherNet/IP, with the simple addition of an EK9500 Bus Coupler. This, along with a variety of EtherCAT I/O terminals in DINrail-mountable IP20 or machine-mountable IP67 form factors, delivered the right solution for each unique requirement. “The broad Beckhoff I/O portfolio gives us the most modular, customizable system based on the requirements for our machine fixturing and components,” Drees adds.

The GTAC engineers achieved great results with SBHA#3. Sodecia made key updates to its code base with TwinCAT automation software. SBHA#3 met the 5.1-seconds-per-part throughput rate, with the EtherCAT-enabled machine controller running at 125 µs scan rate. The project met a tight timeline – starting in September 2021, with commissioning in March 2022.

Sodecia worked closely with the local team from Beckhoff Canada during the project. Going forward, the automation experts at GTAC hope to leverage more Beckhoff technologies. The team plans to standardize on TwinCAT HMI software, a flexible, responsive HTML5-based solution for modern UI. Building on this firm foundation in rapid machine design and delivery, Sodecia continues to innovate at full speed. | MA

than 15 years of experience in the manufacturing sector and is a national sales manager at Javelin –A TriMech Company. Javelin provides a full range of 3D technology solutions, including software, hardware, training, and services. maxime.lacouture@trimech.com

All across Canada, on-campus applied research and innovation centres are supporting inventive start-ups, small to medium-sized businesses and faculty and students by providing access to leading technology and expertise.

The centres are a vital part of an ecosystem that inspires Canadian innovation, smarter product design and quick commercialization of creative ideas. In addition, skill development for post-secondary instructors and students helps tackle a shortage of technically skilled talent. Student projects and job placements equip graduates to confidently use the technology they will encounter in manufacturing workplaces.

These are some of the reasons why Javelin – A TriMech Company has a long history of supporting educational institutions and their technology centres. A prime example is Javelin’s work with the Barrett Centre for Technology Innovation (Barrett CTI) at Humber College in Toronto. The Barrett CTI is home to Humber’s Advanced Manufacturing Skills Consortium, a group of nine industry partners. Javelin sells and supports a full range of 3D printing technology and is the lead partner for additive manufacturing.

Advanced 3D printing equipment at the Barrett CTI includes two Stratasys Fortus 450mc printers and an exciting new addition – the large-format Stratasys F900.

Delivered this spring, the F900 is an additive manufacturing system and one of the most powerful FDM printers available. It opens up opportunities for larger single builds, eliminating the need to spend time printing separate parts and assembling them.

No longer limited by project size, the Barrett CTI team can now attract a wider variety of business clients, even in demanding sectors such as automotive, aerospace and national defence. The Stratasys F900 build envelope measures 36 x 24 x 36 inches and has 18 cubic feet of build volume.

The large-format Stratasys

Advanced 3D printing equipment at the Barrett CTI includes two Stratasys Fortus 450mc printers and an exciting new addition – the large-format Stratasys F900.

It offers 16 different high-performance materials to serve any manufacturing application – the engineering grade thermoplastics make strong, reliable, and repeatable functional prototypes, jigs and fixtures, factory tooling and production parts.

Interestingly, several IoT projects are in the pipeline at the Barrett CTI, waiting for access to the F900. When thinking about IoT product development, large-format 3D printing may not immediately come to mind as a pressing need, yet additive manufacturing is essential in designing, testing and producing large, aesthetically pleasing housing for sensitive electronics.

In this time of digital transformation, desire for connectivity and smart devices, it was the promise of contributing to IoT projects that made the Barrett CTI’s bid for a government grant successful, leading to the purchase of the F900.

In many communities, the local on-campus applied research and innovation centre leads the way, providing access to technology not (yet) available on site at local manufacturers. Before investing in their own hardware or software, industry clients can learn about the technology, test their application and see the results they can achieve.

Javelin’s advanced manufacturing professional services team works in a similar way. We combine technical advice with on-demand services, including 3D printing, post processing,

reverse engineering and 3D scanning. Sometimes, clients want to prove out the additive manufacturing process for their unique application before they purchase a printer. In other cases, we handle overflow work for manufacturers who need more part production than they can manage using their own 3D printer(s).

For Humber College faculty members and students, the expanded capabilities of the F900 will be built into future curriculum. Students are already wide-eyed at the size of the two in-house Fortus 450mc printers. Many students arrive on campus having seen only desktop printers for hobbyists. After creating complex designs and problem-solving with high-performance industrial machines, they are ready to impress (even teach!) their future colleagues.

We leverage our experience across industries to share what we learn from our commercial clients with our education sector clients. As a committed partner to educational institutions and their technology centres, we prepare students for advanced manufacturing careers. Employers appreciate not only the graduates’ solid understanding of hardware and software, but also how they maximize the use of these tools to solve complex problems.

As additive manufacturing technology continues to advance, high-impact solutions are delivering incredible results. It’s an exciting time to be at the centre of the transformation. | MA

AutomationDirect’s new ReeR MOSAIC safety controller components offer expanded capability. The Reer MOSAIC (Modular Safety Integrated Controller) is modular, expandable and configurable for managing all safety functions of a single machine or an entire plant. The new MOSAIC-MV series speed monitoring expansion modules allow speed monitoring of rotating machinery via proximity sensors or TTL, HTL, and SIN/COS encoder inputs. The new M1S enhanced controller master module includes more built-in safety I/O and supports newer safety modules. These new ReeR MOSAIC safety controller components start at $299 and have a two-year warranty. automationdirect.com

Reliable and flexible switches

Antaira Technologies’ expanded industrial networking infrastructure portfolio includes the new LMX-3228G-10G-SFP Series of managed Ethernet switches. Each of the five switch models that make up the series are embedded with twenty-four 100/1000 SFP slots, four 1G/10G SFP+ slots and four 10/100/1000 RJ45 ports. The switches are equipped with

remote port configuration setting and statistics monitoring for added visibility, plus support port mirroring for online diagnostics. antaira.com

Amphenol RF’s two new cable connectors expand its HD-BNC product series.

The new HD-BNC connector options utilize the familiar bayonet mating interface and provide performance up to 6 GHz. The bodies are machined from nickel-plated brass with PTFE used for the insulator components. The interface contacts are made from goldplated phosphor bronze and beryllium copper to ensure electrical performance. The straight plug and bulkhead mount jack join a broad portfolio of HDBNC products which include IP67 and 12G SDI connectors, adapters and cable assemblies. This interface is a compact version of the popular BNC connector. amphenolrf.com

OTTO Motors’s smartest autonomous forklift, the OTTO Lifter, is in the market. OTTO Lifter, a material handling robot, has the ability to pick up and drop off pallets autonomously. With advanced safety sensors and autonomous driving capabilities, OTTO Lifter works alongside people, other vehicles and existing infrastructure providing businesses a safe material

handling solution for as low as $9 per hour. The autonomous forklift is compatible with the entire OTTO Motors fleet of AMRs through OTTO Motors’ Fleet Manager. Its autonomy software makes intelligent, real-time decisions. With dynamic path planning, lane tending, intelligent pallet detection and stretch wrap piercing, it navigates traffic and obstacles to predictably and precisely deliver materials. ottomotors.com

Kollmorgen’s new TBM2G series of frameless servo complement

its existing TBM and KBM series of frameless motors. The TBM2G series offers high-performance torque in an extremely compact electromagnetics package. These next-generation motors enable robots with lower joint weight, higher load-carrying capacity, improved energy efficiency, lower thermal rise and faster, smoother movements. TBM2G motors remove the sizing limitation that engineers often face when using off-the-shelf strain wave gearing, also known in the robotics market as harmonic gearing. The new TBM2G series motors are sized for a perfect fit with readily available strain wave systems, eliminating. The TBM2G series is available in seven frame sizes with three stack lengths each – a total of 21 standard motors that can be integrated directly into robotic joints and similar embedded equipment. kollmorgen.com

BY STEPHANIE HOLKO

of project

at Next Generation Manufacturing Canada

She loves connecting emerging technologies with existing manufacturing problems and believes the future of manufacturing is in the adoption of new ways of working.

As manufacturers are aware, the cost of doing business is increasing. Volatile market conditions have created a squeeze on companies that are stuck between the rock of increasing raw materials prices and the hard place of customers who are not ready to shoulder new costs. Along with the cost squeeze is the issue of excess production capacity. Canadian manufacturers have headroom to produce more and while there has been recovery over the last two years, production levels are still at a similar level to five years ago.

Cost-cutting is a natural response to decreasing margins in this context, but it does not need to be the only response. Flipping the concept of excess capacity on its head, we can see it as an opportunity for investment and growth. There is room to play within that excess capacity. The magic here is in the time horizon. Short-term cost cuts can help a company through the downturn, but long-term investment to stepwise improve the company’s cost structure will pay off in the long run.

Focusing only on cost-cutting can undermine the longevity of a business. It commodifies products and becomes a race to compete on price which feeds into a cycle of cost-cutting that becomes hard to win. More interestingly, we’ve seen Canadian companies with strategic priorities working to differentiate their products and services using technology. This could be a better customer experience, customized products, value-added services and platforms, or even a new revenue stream or business model. Solving customer problems as part of your strategy can open new avenues to invest for long-term growth and create more margin for your company. An example of this is the women’s fashion company, Carmina De Young (London, Ont.), which began recycling hospital PPE early in the pandemic and now offers contract manufacturing services for other clothing companies.

Cost-cutting is a natural response to decreasing margins in this context, but it does not need to be the only response.

It can seem counterintuitive to talk about investing in a downturn. However, savvy investors know that investing when things are down can reap rewards if you’re patient. It takes discipline and a little courage to double down when times are tough and money is tight. Consider that a similar approach can be beneficial for companies regarding innovation and investment in technology. Canadian manufacturers are investing less in equipment purchases today than they were two years ago, and it is worth revisiting this trend.

On one hand, a downturn means fewer sales and less cash flow. This can make technology investments less attractive to companies that are looking to keep the lights on and the factory running. However, if you have a long-term strategy that requires the integration of new technology, a downturn can be the right time to make those investments. There may be more idle time on the production line to complete technology upgrades. There may be more time available for technical and maintenance staff to devote to training to support those upgrades. The excess in manufacturing capacity is an opportunity.

Investments in innovation and new technology should be aligned with your business strategy. Otherwise, a company runs the risk of spreading its resources

too thin without a clear benefit to business goals. Manufacturing strategy has shown up in industry trends and if there are technologies that can fasttrack or enable strategy, that is a place to risk investment with little regret. An example of a trend and complementary strategies is the recent investment in electrification for automotive and aerospace by several levels of government in Canada. The trend in electrification investment is coordinated throughout the value chain – from critical minerals to OEMs to recycling. Government, industry, and academia have rallied to the electrification of mobility and there are exciting projects underway across the country that will enhance Canada’s position and leadership in this sector. If you are a manufacturer – in any sector – there are avenues to get support for technology investments. Governments in Canada want to support manufacturing businesses in their technology adoption journey, including employee upskilling, project support for adoption as well as technology development. Manufacturers can also partner with companies to bring their technology to life as well as improve the bottom line. Collaboration is a successful strategy for nimble businesses to unlock new value for their companies and customers. You don’t have to go it alone! | MA

Have company news, case studies, events or story ideas to share? Send to srayghosh@annexbusinessmedia.com and you could be featured in Manufacturing AUTOMATION!

You’re gonna want SOME CUT OFF DISCS, grinding wheels & EYE PROTECTION

Email:

Phone: