OPERATIONS: Manitobabased vehicle guard manufacturer scales up its facility. p.20

OPERATIONS: Manitobabased vehicle guard manufacturer scales up its facility. p.20

3D printing begins to move past consumer hype into industrial design and onto the production floor. p.22

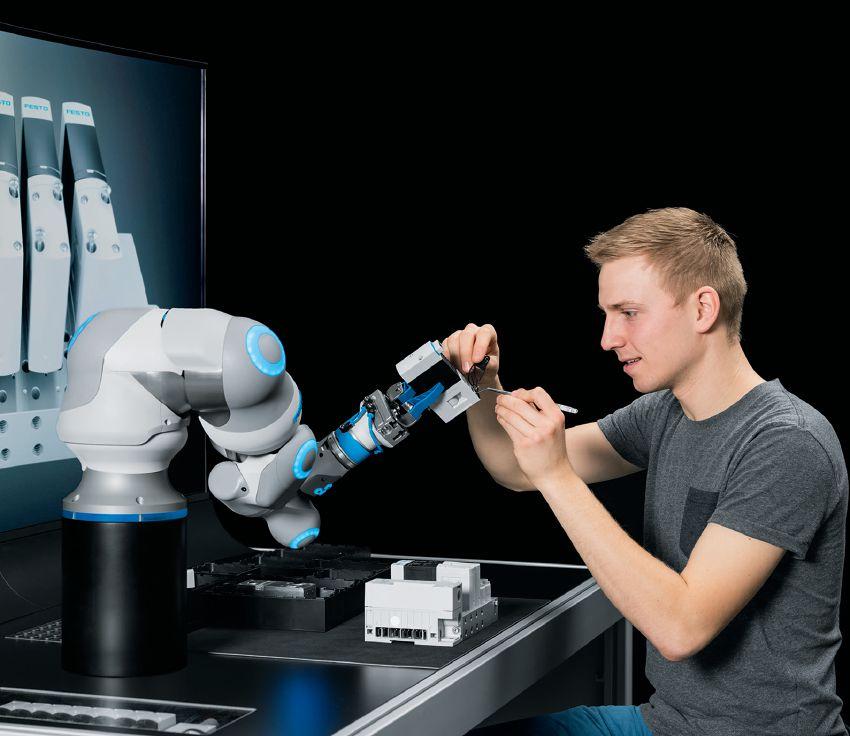

ROBOTIC CONCEPT: A new seven-axis pneumatic cobot mimics the movement of the human arm. p.19

The CLICK PLC family offers extreme value for simple systems where time and resources are limited. The compact size, affordability and easy programming make CLICK great for small applications and beginner projects.

• NEW! Ethernet Analog PLC Units with 8 discrete I/O points, Ethernet and serial communication, and up to 6 analog I/O channels built in. Starting at $179.00

• Easy expansion with snap-on I/O modules for up to an additional 128 discrete or 48 analog I/O points

• Communicate with, and power a low-cost C-more Micro HMI from the RS232 serial port for even more savings

• All CLICK PLCs use our FREE programming software with a simple but practical instruction set

C-more around your plant for less C-more Micro HMIs provide graphical system status and operator interaction for a fraction of what you’d pay elsewhere. Paired with the CLICK PLC, C-more Micro panels provide practical and complete control for any small system.

• Numerous sizes up to 10-inch with touch and non-touch screen versions available

• FREE easy-to-use programming software with simulator

the Digital Twin to artificial intelligence to Big Data, the top trends and technologies automation experts predict will impact the factory floor

@Edge_Group

An excellent guide to energy manufacturing. https://buff. ly/2ChDGuo via @AutomationMag #energy

@DLLgroup

#Servitization is not a buzzword – it’s a promise, via @ AutomationMag: bit.ly/2AnLu09.

Learn about the “as a service” movement in #manufacturing and how #financing plays a major role.

@TimG_ SmartGrid

Ian Almond of Siemens’ Peterborough plant talks about our $10M investment & what’s next w/ @AutomationMag: bit.ly/2zJIYQm

@CiscoCanada

Is your factory future-proof? Our @JenniferKR answers the question in @AutomationMag. http:// cs.co/6013D8bEX

BY ALYSSA DALTON

Dozens of analyses have been released over the past decade estimating a large segment of the labour market will be displaced due to increased automation in the workplace. The McKinsey Global Institute recently predicted up to 800 million workers worldwide — or onefifth of the global workforce — will lose their jobs by 2030 and be replaced by robotic automation.

“All workers will need to adapt, as their occupations evolve alongside increasingly capable machines,” states the report. In the manufacturing sector, the report notes machine operating and production line jobs as two areas more susceptible to automation.

For millions around the world, the fear of intelligent robots taking away their jobs remains top of mind.

But the future manufacturing landscape is not one without humans. While there’s no denying the impending affect of industrial automation on the labour force, the Fourth Industrial Revolution has also prompted a movement to ensure new value-added, highly skilled human jobs are created.

“Overall we found that nearly 42 per cent of the Canadian labour force is at a high risk of being affected by automation within the next 10 to 20 years,” writes Creig Lamb, senior policy advisor for the Brookfield Institute for Innovation + Entrepreneurship, in a 2016 report. “In all likelihood, in some cases technology will replace entire jobs. But for others, technology will complement labour, improve productivity and help to create more, specialized jobs.”

The McKinsey report describes how training can be improved: “To achieve

good outcomes, policy makers and business leaders will need to embrace automation’s benefits and, at the same time, address the worker transitions brought about by these technologies.

“Mid-career job training will be essential, as will enhancing labour market dynamism and enabling worker redeployment. These changes will challenge current educational and workforce training models, as well as business approaches to skill-building. Another priority is rethinking and strengthening transition and income support for workers caught in the crosscurrents of automation.”

In November 2017, Autodesk announced it is teaming up with LinkedIn Learning to provide free access to 42 courses for the manufacturing and design industries, among others. The unlocked courses are available in five languages.

Meanwhile, Rockwell Automation and workforce solutions company ManpowerGroup recently committed to upskilling 1,000 American veterans every year to help strengthen the talent pool for in-demand advanced manufacturing roles.

We must ensure today’s workers have the training and skills needed to transition to the jobs of tomorrow.

As Jonas Prising, chairman and CEO of ManpowerGroup, puts it: “We are seeing the emergence of a Skills Revolution today — where helping people upskill and adapt to this fast-changing world of work will be the defining challenge of our time.” | MA

CONNECT @AutomationMag adalton@annexweb.com AutomationMag.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, President and General Manager, Excellence in Manufacturing Consortium, and Chairman and CEO, Canadian Manufacturing Network

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, founder and owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexweb.com

PUBLISHER

Klaus B. Pirker kpirker@annexweb.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Elena Novinskiy enovinskiy@annexbusinessmedia.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com

COO

Ted Markle tmarkle@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Kimberly Connors, Treena Hein, Paul Hogendoorn, Dick Hyatt, Matthew Littlefield, Danny C. Marmora, Dan Miklovic, Craig Resnick, Jennifer Rideout, Jon Robinson

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel 416-510-5187 Fax 416-510-5167

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-5170

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year Students — $20 per year

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

McCain Foods has officially opened its new 35,000-square-foot potato specialty production line, expanding the company’s flagship potato processing facility in Florenceville-Bristol, N.B.

According to McCain Foods, the $65-million commitment represents the largest capacity expansion investment in Canada in nearly a decade.

“Florenceville continues to be the french fry capital of the world. The official opening of the new production line reflects McCain’s ongoing commitment to invest in the needs of our consumers and customers today, and also the company’s focus towards future product development and innovation,” said Jeff DeLapp, president, North America, McCain Foods Limited. “During our 60th year of business, investment in the Florenceville-Bristol facility is a testament to the importance the community holds as the birthplace of McCain Foods.”

The investment will also help create more than 40 new jobs.

Established in 1957, McCain Foods operates eight production facilities across Canada, approximately 2,600 employees and in addition to its french fries and potato specialties, makes frozen desserts, snacks, appetizers and Chinese entrées.

Schneider Electric commits to renewable electricity by 2030

Schneider Electric has committed to sourcing 100 per cent renewable electricity and is throwing light on the doubling of its energy productivity.

The energy management and automation giant has decided to join two global collaborative initiatives, led by The Climate Group, bringing together businesses committed to accelerating climate action:

• RE100: to use 100 per cent renewable electricity by 2030

Interfaces:

with an intermediary objective of 80 per cent by 2020; and

• EP100: to double energy productivity by 2030, against a 2005 baseline, setting an ambitious target to doubling the economic output from every unit of energy consumed.

In order to deliver on its new promises and its sustained energy efficiency efforts, Schneider Electric will leverage its own technical solutions: EcoStruxure Power and EcoStruxure Grid. Using these solutions, the group has already reduced its energy consumption by 10 per cent every three years for the past decade. These commitments will cover more than 1,000 electricity consuming sites around the globe, including 200 factories. The company said it plans to leverage various renewable energy sources, such as solar, wind, geothermal and biomass.

The plan to drive the transition to 100 per cent renewable electricity, with an interim goal of achieving 80 per cent renewable electricity use by 2020 to 100 per cent in 2030, includes a range of initiatives such as solar rooftops, on-site renewable energy projects, offsite long-term procurement through Power Purchase Agreements, and Energy Attribute Certificates (EACs).

Survey shows low adoption of industrial cybersecurity measures

A recent study shows industrial companies are not moving quickly to adopt cybersecurity measures to protect their data and operations, even as attacks have increased around the globe. The survey, Putting Industrial Cyber Security at the Top of the

CEO Agenda, was conducted by LNS Research and sponsored by Honeywell. It polled decision makers about their approach to the Industrial Internet of Things (IIoT) and their use of industrial cybersecurity technologies and practices. Some finding highlights:

• More than 50 per cent of respondents reported working in a facility that has already had a cybersecurity breach.

• Forty-five per cent of the responding companies still do not have an accountable enterprise leader for cybersecurity.

• Only 37 per cent are monitoring for suspicious behaviour.

• Although many companies are conducting regular risk assessments, 20 per cent are not doing them at all.

“Decision makers are more aware of threats and some progress has been made to address them, but this report reinforces that cybersecurity fundamentals haven’t been adopted by a significant portion of the industrial community,” said Jeff Zindel, vice president and general manager, Honeywell Industrial Cyber Security. “In order to take advantage of the tremendous benefits of industrial digital transformation and IIoT, companies must improve their cybersecurity defences and adapt to the heightened threat landscape now.”

The study suggests three immediate actions for industrial organizations to capture the value of the new technologies:

1. Making industrial cybersecurity part of digital transformation strategies;

2. Driving best practice adoption across people, processes and technology, from access controls to risk monitoring, and tap external cyber expertise to fill gaps; and

3. Focusing on empowering leaders and building an organizational structure that breaks down the silos between IT and OT.

Canada’s Mechatronics duo takes bronze at WorldSkills Abu Dhabi

Skills/Compétences Canada, a national not-for-profit organization that promotes careers in skilled trades and technology, has announced that WorldSkills Team Canada has been presented with one medal and 13 Medallions of Excellence at WorldSkills Abu Dhabi 2017.

Canada’s Best of Nation Award was presented to Avery Bird of Toronto, Ont., and Theodor Willert of Etobicoke, Ont., for their performance in Mechatronics.

Held every two years, the competition is described as the world’s largest vocational, education and skills excellence event. WorldSkills Abu Dhabi 2017 took place October 15 to 18 at the Abu Dhabi National Exhibition Centre and recorded more than 100,000 visitors.

Officials say the 2017 event was the largest in the 67-year history of WorldSkills with approximately 1,300 competitors from 59 member countries and regions from around the globe.

“We are very proud of the 31 members of WorldSkills Team Canada 2017 for their outstanding performance at the 44th WorldSkills Competition,” said Shaun Thorson, CEO of Skills/ Compétences Canada. “The determination, hard work and skills that these talented young individuals have demonstrated is truly remarkable. We look forward to seeing them prosper in their careers as they join Canada’s skilled trade and technology workforce.”

WorldSkills Team Canada 2017 is made up of 31 young skills champions, including 22 men and nine women, ranging in age from 16 to 24, from across the country.

The group participated in 28 out of 51 skill areas relating to the following six sectors: construction and building technology, creative arts and fashion, information and

technology, manufacturing and engineering technology, social and personal services and transportation and logistics.

The 2019 WorldSkills Competition will be held August 29 to September 3 in Russia.

Stanley Black & Decker to open Advanced Manufacturing Center of Excellence

Stanley Black & Decker aims to accelerate its global Industry 4.0 smart factory initiative with its new Advanced Manufacturing Center of Excellence in Hartford, Conn.

Named Manufactory 4.0, after the original Stanley Bolt Manufactory founded in 1843, the 23,000-square-foot centre will employ approximately 50 Industry 4.0 professionals. The company is also launching an additive manufacturing accelerator with Techstars that will be housed at the new facility.

“Our Manufactory 4.0 will serve as the epicentre for the latest technologies and processes with respect to Industry 4.0,” said Don Allan, CFO for Stanley Black & Decker.

The company has three locations designated as Lighthouse Factories, that have partially implemented Industry 4.0 across their facilities from

manufacturing execution systems (MES), to 3D printing, virtual reality and artificial intelligence.

Omron Automation Americas has announced the grand opening of its expanded and relocated Montreal, Que., offices, occupying new offices in a business complex in Dorval.

“Our new offices enhance customer interaction with our latest technologies as they seek solutions to their manufacturing challenges,” said Omron Canada general manager Peter Brouwer. “Now that we operate as a Pan-American business, we are able to provide uniform service and support for our French-speaking customers’ needs.”

The company says the expanded test lab will allow customers to engage in hands-on, proof-ofconcept testing of automation solutions, and will be fully outfitted with robots, motion control, machine safety, HMI, vision, sensors and control components that can be tested together, simulating integrated

interactions. Other recent investments designed to invigorate Omron’s operations include the acquisition of Adept Technology, Delta Tau Data Systems, and Microscan Systems.

“The acquisition of Adept Technology is intended to integrate Omron’s strength of ‘Input, Logic, Output and Safety’ and Adept’s competence in ‘R’ (Robotics) to generate unique automation solutions for global manufacturers,” said Yutaka Miyanaga, Omron senior managing executive officer & IAB company president. “By adding Adept intelligent industrial robots to our automation portfolio, we are able to offer differentiated solutions that provide our customers with a competitive advantage.”

Through the acquisition of Delta Tau Data Systems, Omron aims to reinforce its technology development and engineering capabilities in the field of motion control designed to drive manufacturing equipment. Merging products and technologies of both companies will also enable the delivery of optimized motion control solutions globally through combined distribution networks.

The Microscan Systems acquisition allows Omron to develop new code reading devices and solutions that combine software

The open remote I/O system o ers maximum flexibility for the adaptation of existing system environments with head modules for PROFINET/PROFIsafe, Ethernet/IP and CIP Safety. A simple substitution of the head module allows the communication within di erent networks. Wide ranges of safe and standard I/O modules are available.

technology from Microscan with Omron’s control components and equipment lines.

Arcam AB, supplier of additive manufacturing (AM) solutions and part of GE Additive, has signed a lease agreement with Castellum for its Electron Beam Melting (EBM) business to move into a refurbished 11,800-square-metre facility in Härryda, Sweden.

Arcam Group provides EBM systems through Arcam EBM in Sweden and powder metals through AP&C in Canada.

According to Arcam EBM, the new Härryda facility, which is almost three times the size of the current site, will offer the ability to expand and set the stage for the accelerated growth of the AM industry. The space will allow for increased machine production capacity and a more collaborative setup within the company; uniting logistics, research and development, services and operations.

In December, Linamar announced it had entered into a definitive agreement to acquire Winnipeg, Manitoba-based MacDon Group of Companies for roughly $1.2 billion.

Established more than 65 years ago, family-owned MacDon designs and manufactures specialized agriculture harvesting equipment, such as drapers and self-propelled windrowers, for customers in more than 40 countries worldwide.

“The acquisition of MacDon provides a truly once-in-alifetime opportunity to move our agriculture business into a market-leading position while

providing meaningful diversification to the end markets we serve,” said Linda Hasenfratz, Linamar CEO. “MacDon is a strong, well-managed company and an innovative market leader in both customer penetration and technology evolution; it will be the centrepiece of our agriculture business, which includes our existing European corn header business, highly complementary to MacDon products. We get diversification, innovation, growth and a solid deal, we couldn’t be happier.”

Linamar’s previous acquisitions in the industry include Skyjack, Montupet and Seissenschmidt — resulting in broader product lines, additional capabilities in new markets, and expanded geographic presence.

The Manitoba government is partnering with Opaskwayak Cree Nation (OCN) and Manitoba Aerospace for a new manufacturing company in the Paskwayak region that will supply products for the aerospace industry.

“Manitoba is one of the largest aerospace hubs in Canada, and this partnership will ensure the products and expertise needed for further growth and innovation are available,” said Ian Wishart, education and training minister. “We are pleased to work together to create high-paying, highly skilled jobs and allow our province to maintain its global competitiveness in the aerospace industry.”

The minister noted the goal is for a new facility, which aims to be up and running within two years, to supply products that are currently unavailable from local suppliers. Training partnerships will be established and several Manitoba-based aerospace companies have offered to work with employees in a mentorship role to assist them in moving into their new jobs with confidence, he said.

“We are excited to partner with

OCN on this initiative which will determine the feasibility of establishing a manufacturing facility in northern Manitoba,” said Wendell Wiebe, CEO of Manitoba Aerospace. “We are grateful to the Manitoba government for supplying the funds that will be used to collect the data so that all partners can make an informed decision.”

Wishart confirmed the Manitoba government is investing $85,000 through the departments of Education and Training and Indigenous and Northern Relations, and OCN is contributing $25,000. With this funding, Manitoba Aerospace will hire an external partner to develop a proposal and business plan.

Reko International Group has hired Mark Read as director of the automation division, succeeding Rick Stone, who is retiring after almost 29 years of service. Read has 31 years of experience in the automation industry including senior positions at ATS Automation in the automotive, life science and energy sectors.

Wago has named John Bukowski its new distribution channel manager of North America. He brings a wealth of experience to the company having worked in technical sales for more than 30 years in companies such as Eaton, Pepperl+Fuchs and Schneider Electric. Shaun Nagi has been appointed regional sales manager for the province of British Columbia. Bringing technical knowledge and a sales background to the company, Nagi has previously worked at Wesco Distribution, Associated Labels, and PSI Fluid Power.

The executive board of the International Federation of Robotics (IFR) has elected Junji Tsuda of Yaskawa Electric Corp. as its new president. Tsuda succeeds Joe Gemma of KUKA who is leaving the rotating post after his two-year term. Meanwhile, ABB’s Steven Wyatt has been appointed the new vice president. Tsuda serves as the representative director chairman of the board of Japanese robot manufacturer Yaskawa Electric Corp. Since the 1990s, he has headed various business units and has been active in the parent company since 2003. Wyatt is the global head of marketing and sales for ABB’s Robotics Business Unit. He joined the company in 2010.

Raven Telemetry an artificial intelligence company for manufacturing, is welcoming Rob Lander to the team as chief strategy officer, board member, and investor. Lander rounds out Raven’s line-up of manufacturing industry veterans, adding more than three decades of experience in data-driven manufacturing. Most recently, he was the president and CEO of Stackpole, a global Tier 1 automotive parts manufacturer.

Susan Uthayakumar has been named Schneider Electric Canada president, reporting to Annette Clayton, CEO and president, North America, and chief supply chain officer. A 13-year veteran of Schneider Electric, Uthayakumar was most recently vice-president, national sales, Canada, responsible for developing and executing the sales strategy for the company’s electrical distribution and industrial automation products and solutions. She succeeds Juan Macias, who will be leading Schneider Electric’s Prosumer in the New World of Energy initiative across the company. | MA

Let the new Fluke 729 Automatic Pressure Calibrator change the way you calibrate.

Download your free pressure calibration application note at fluke.com/729calibrator

• Fast, easy setup with automatic pressure regulation

• Automatic, no-hassle calibration and documentation

• Built-in HART communication

• No hand pumps or manual adjustments required

BY DANNY C. MARMORA

Danny C. Marmora, B.Eng., P.Eng., CET, (danny@marmoraconsulting. com) is the principal at Marmora Consulting based in Stoney Creek, Ont. His firm specializes in Pre-Start Health & Safety Reviews, fire code consulting and forensic engineering.

One question I get asked almost daily comes from industrial clientele asking me about the emergency stop (e-stop) function on their machines. Specifically, they ask very fundamental questions about what the e-stop is used for, when it is to be used, its use for personnel/operator safety at the machine, and whether the e-stop is part of the machine’s overall safety system and if it needs to be wired via safety relays and redundant circuitry.

To answer these questions and dispel a number of myths and misconceptions about e-stops, we need to establish the framework that allows e-stop devices to exist via the applicable standards.

The definition of an e-stop In Canada, two predominant general machinery safety standards, CSA Z4322016 – Safeguarding of Machinery and NFPA 79-2015 – Electrical Standard

for Industrial Machinery (current editions noted herein), define the requirements of the e-stop function. Specifically, CSA Z432-16 Clause 3 –defines the e-stop as: “A function that is intended to avert harm or to reduce existing hazards to workers, machinery or work in progress.”

Reading a little deeper into CSA Z432-16, C7.15.1.1 states the e-stop shall: “be fully in accordance with NFPA 79, ISO 13850, and IEC 602041, override all other machine controls, cause all moving parts to stop, and remove drive power from the machine actuators. Final removal of energy to the machine actuators shall be ensured and shall be by means of electromechanical components.”

Similarly NFPA 79-15 Clause 3.3.35 –defines not the e-stop device itself but the condition of Emergency Switching Off as: “an emergency operation intended to switch off the supply of electrical energy to all or part of an installation.”

Further, NFPA 79 C9.2.5.4 states

The primary difference between an e-stop and cycle stop is how each device attains the no motion condition.

an e-stop, which enables the Emergency Switching Off, shall: “override all other functions and operations in all modes. Power to the machine actuators, which causes a hazardous condition(s), shall be removed as quickly as possible without creating other hazards (e.g., by the provision of mechanical means of stopping requiring no external power, by reverse current braking for a Category 1 stop. The reset of the command shall not restart the machinery but only permit restarting.”

While the two definitions do allow e-stops for injury avoidance, it is only under the condition whereby the machine is malfunctioning. Hence the use of the e-stop in lieu of a traditional safeguarding method such as fixed guarding, interlocked gate or other protective device — i.e. light curtain, area scanner, etc. — is prohibited.

Myth #2: The e-stop is a safeguarding device E-stops and similar systems are commonly referred to as complementary protective measures (CSA Z432-16 C6.3). These types of devices/systems are in addition to the prescribed/defined/required safeguarding systems/methods. As a complementary protective measure, the e-stop affords the operator an independent means outside the regular control and provided safeguarding devices to shut down the machine. Given this specific use, e-stops are not safeguarding devices.

Myth #3: The e-stop can be used as/in lieu of a cycle stop

From a performance perspective only, the outcome of activating an e-stop and cycle stop would appear to be the same — the machine comes to a stop. It’s important to note that an e-stop and a cycle stop attain that end result differently, due to an e-stop’s unique role within a machine’s control architecture as further defined by the standards.

By definition, an e-stop removes power/energy from the prime movers of a machine, bringing said machine to a standstill as quickly as possible, regardless of where the machine cycle is and/or what mode of operation it is in (automatic versus manual versus jog). Furthermore, the machine cannot by definition resume power to operate until the e-stop (fault) has been manually reset. To that point, the machine remains paralyzed.

Further by definition, e-stop systems are to provide a minimum PLc or SIL1 performance level. This is a minimum requirement and a detailed risk assessment could result in more robust e-stop circuitry being provided. This requirement loosely translates to a Category 0 or 1 type “stop” as defined by NFPA 79.

Conversely, the cycle stop function allows for the controlled stop of the machine during or at the end of the respective cycle (variance based on control design for cycle stop). Furthermore, the cycle stop functionality allows for

power to be left available after use. NFPA 79 defines this as a Category 2 stopping system.

The primary difference between an e-stop and cycle stop is how each device attains the no motion condition. E-stops remove power and prohibit the resumption of machine power until the e-stop push button is physically reset (this is a discernible action required by

someone), and then there is the ability to resume control power. Meanwhile, cycle stops do not require a discernible reset or power resumption. By definition, post cycle stop, power is still available to resume the cycle or a new one at the operator’s discretion.

In summary, e-stops are present on almost all machinery, and

while ubiquitous by design, their use is restricted until needed. CSA Z432-16 suggests the application of e-stops unless a risk assessment can show the e-stop would not contribute to the overall risk reduction of the machine. There are many myths around e-stops, however, relying on the applicable referenced herein will help support future educated and complaint decisions. | MA

HPN Harmonic Planetary® value series provides a low cost solution without the need to compromise on quality or performance. This new value series of planetary gears carry the reputation for quality and reliability for which Harmonic Drive® products are known throughout the world.

• Helical Gearing

• Available in 5 frame sizes

• Peak Torque: 9Nm to 752Nm

• Ratios: 3:1 to 31:1, new two-stage ratios available soon

• Quick Connect® mounting system

• High Efficiency

• Backlash: <5 arc-min (single stage), <7 arc-min (two stage)

• Fast Delivery

• Shaft output available with key and centertapped hole or with center-tapped hole

BY PAUL HOGENDOORN

Paul Hogendoorn is the co-founder of FreePoint Technologies, “Measure. Analyze. Share.” (Don’t forget to share!). He can be reached at paulh@getfreepoint.com or www.getfreepoint.com.

By now you will have heard about the next big thing that is projected to affect manufacturing — the Industrial Internet of Things or the IIoT. New technology geeks seem to like to create acronyms and terms that mean something to them but leave the rest of us in a fog. Think B2B, Y2K, B2C, M2M, IoT and now IIoT. The list goes on and on.

The manufacturing industry has traditionally been a slow adopter of new technologies compared to other parts of society. There are always exceptions — most companies have a few new machines — but by and large, if a machine is working reasonably well, it is left in place to do its job for a long, long time. I often ask plant managers how many times they have replaced their photocopying machine; every five to eight years seems to be a reasonable answer, but their manufacturing equipment stays in use a lot longer. Similarly, look at the computers being used in the engineering, administration and executive offices, and compare them to the computers on the floor. Indeed the majority of PCs I see in use on the plant floor are operating Windows 7.

I don’t necessarily see this as a problem — not in most cases anyway. The reason that equipment is still in place on the factory floor is because it works. It continues to do its job effectively and everyone knows how to use it. The cost of replacing it is often very high, and the benefit is usually not big enough to warrant the expense and time to replace it. On top of that is the relentless production demand — there’s just no time to replace something that is working, often while taking a chance on something new. The result is that many plants run a lot of older, proven equipment, augmented by new technology equipment that gets installed when they start a new product or operation. This is true for all major segments in the manufacturing industry, but some more so than others.

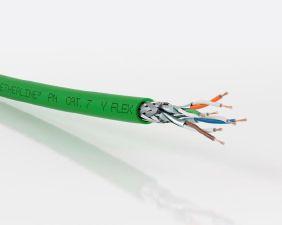

The IIoT however, is the manufacturing industry’s opportunity to catch up, especially lagging industry

The rapid emergence of this new technology is this industry’s chance to build data bridges — not data fences and silos.

segments. At its core, the IIoT is intended to connect things to the Internet, and to do it in a cost effective manner. It’s intended to be integrated into common household devices and as such, it should be easily adaptable for a wide variety of possible uses, and it should be available in commodity prices. It’s when solution providers start adding other new acronyms and terms, such as Industry 4.0, smart manufacturing and Big Data, that the price starts to rise quickly. The IIoT in and of itself is aimed at connecting devices, ubiquitously and cost-effectively, to the Internet, and there’s no reason that an older piece of equipment can’t be easily and cost-effectively connected.

In my opinion, there is no manufacturing sector that has more to gain from this new technology than Tier 1 and Tier 2 suppliers in the automotive industry. Most plants I’m in produce products at parts per second speeds and pennies per part prices. The tolerance for defects is effectively zero, and the requirement for accountability and traceability is ever increasing. Tier 1 suppliers have to keep track of the raw material and components that went into each part, the equipment it was run on, the tooling that was used, and even when that tooling was last

serviced or refurbished. In-process and end-of-process test results often have to be associated not just with the batch, but with the specific product produced. IIoT technologies do not solve all these problems by themselves, but what they can should do is provide solution providers with simple, ubiquitous, cost-effective ways to connect all the devices.

The rapid emergence of this new technology is this industry’s chance to build data bridges — not data fences and silos. In previous IT evolutions, equipment and solution providers have scurried to align themselves with a half dozen or dozen other providers and claim an implied superior compatibility. Although it is often promoted as being to the customer’s benefit, this kind of data fence is primarily to the compatibility group’s benefit. If the IIoT movement is allowed to sweep across the manufacturing floor the way that Internet technologies have swept through our banking, entertainment and communications industries, the change to our industries will be dramatic — and that’s not something we should fear. The IIoT is not just the next new thing coming to manufacturing, it will be many companies’ opportunity to catch up. | MA

BY JENNIFER RIDEOUT

Delivering better, more personalized experiences — that’s what customers, all customers, expect. Whether products leave your factory ready for consumers or ready for the next step in production, your customers expect a high level of service. And that includes an experience that leaves them thinking favourably about your brand so they come back again and again.

It is here — the customer experience — where your supply chain plays an integral, and perhaps surprising, role. Your experiences as a customer are based on a combination of interactions with a company, for example, how long it took to order and receive a purchase, as well as experiences based on direct interactions. As customer expectations increase, a premium is placed on product customization, next-day delivery and quality. The ability for manufacturers to execute on these expectations relies on the integrity and accuracy of their data. In fact, the goal must now be to delight customers as they order, customize, receive and use your products — from beginning to end of your supply chain.

To quote KPMG’s 2017 Global Consumer Executive Top of Mind Survey: “Companies are making customer service and brand loyalty a priority but many of them aren’t recognizing the part that supply chains can play in that.”

Leveraging data to improve performance across the supply chain is not a new concept for professionals in the field. According to the SCM World Future of Supply Chain Survey 2016, 81 per cent of professionals listed Big Data analytics as disruptive and important to their company. What is less clear for factory professionals is how they can get there.

Harnessing the power of supply chain data begins with collecting data from every step of the manufacturing process. The manufacturing industry produces more data than any other in the U.S., so from planning to distribution, manufacturers have the ability to collect data through sensors, RFID tracking and software programs, and use that data to their advantage. To do this, manufacturers need to consolidate data from multiple software systems, suppliers and factories to get a full view of their supply chain. This data must then be analyzed so that meaningful actions can be taken to improve planning, production efficiency, and the customer experience.

Before deploying a new technology, assess your current supply chain data. What does it tell you? What does it not tell you? What could you do better, faster and more accurately if you had additional insights? Consider also what data you are collecting from equipment on your factory floor, and whether you are consolidating and analyzing it to improve production efficiency. These answers will help identify a specific application within your supply chain for better data visibility and analysis, allowing you to gather insights to solve that challenge in a smarter, more efficient way.

For example, an assessment of data collected in your factory may reveal a gap in your visibility from when products leave the line until they arrive at their destination. While this may not seem like an immediate concern, having visibility into your products during this stage could ensure proper product handling, assist with fleet optimization, and enhance forecast and demand planning.

Once an optimization project is identified, manufacturers must deploy the right solutions to get the data they require. If your challenge is to better manage inventory and demand purchasing, this might require an investment in additional Enterprise Resource Planning (ERP) software capabilities and wireless asset tracking to keep abreast of warehouse stock.

If your challenge is your factory’s efficiency score, the right technology could include edge computing and collaboration endpoints to speed up machine troubleshooting and decrease unplanned downtime.

As new solutions are deployed and your supply chain visibility increases, it’s important to evaluate and review the success of each project. What new opportunities and challenges did it create? What feedback are you receiving from employees, suppliers and customers? Did the project achieve its objectives and goals? Or, to reference my example above, did adding visibility into your product warehousing and shipping status identify opportunities for faster, more accurate deliveries?

Remember that while it’s important for manufacturers to increase visibility into their supply chain, it should not come at the expense of other elements of your business; before moving onto a new project, always review the impact and outcomes delivered.

The manufacturing industry is in the middle of a transformation. As customers expect increased personalization, product quality and next-day delivery, the traditional supply chain is no longer enough. To deliver a better customer experience and increase profits, manufacturers need to improve visibility across their supply chain — from planning to purchasing, fabrication to delivery. Where will you start? | MA

shares his thoughts on some of the opportunities and challenges

today’s manufacturing industry.

MA: Can you tell me a bit about Tech-Con Automation?

NL: We are a custom equipment machine builder and through an acquisition approximately two and a half years ago, became the Canadian operations of Shape Technologies Group. We build custom automation equipment, which include robotic material handling solutions, systems integration and conveyors for multiple industries such as automotive, food and beverage, aerospace, and consumer goods. We have 70-plus employees in our [Burlington, Ont.] 58,000-square-foot facility. We’ve taken the last two and a half years to invest not only in technology internally – like new engineering and project management tools – but also in some machinery for the shop.

MA: What are your thoughts on today’s manufacturing industry?

NL: I’m a big advocate of the industry. I’m a CPA by trade but I’ve always enjoyed manufacturing and automation. I’m thrilled to see a lot more companies are considering implementing some form of automation into their plants and not just because [employers] want to reduce headcounts but [because they] want to make it a much safer environment for their people.

I get a real kick when customers want to improve efficiency and reduce downtime and costs [because] that’s what we like to do. We like to get our thinking caps on and really look for ways to help customers achieve those goals.

I will say this, there is a huge shortage of skilled labour and I think we’re all starting to suffer from that. I think the baby boomers are slowly starting to retire and they’re the ones [who] have a lot of intellectual capital property in their brains,

and there is that gap because we just haven’t been promoting these jobs strongly enough.

[Even though] we’re starting to see a lot of kids go to colleges and universities for courses like mechatronics, robotics and automation, we’re still seeing a void right now. Everybody’s fighting for the exact same skill set but it’s refreshing to see that colleges and universities are promoting this skill set. I strongly advocate for the need of automation and with [this] need comes an opportunity for more highly skilled jobs.

MA: Along with implementing these programs and promoting

this skill set, what else can we do to help lessen the skills gap?

NL: [We can] give them a chance. For example, we’ve brought in some co-ops here from both high schools and colleges and we are hiring recent graduates to [work] here — we’re really giving them an opportunity to learn the trade. It’s much more than just learning the trade with those technical skills, you have to learn the trade with the soft skills. We have a young individual here and we have assigned him to shadow a much more seasoned individual. He’s been shadowing him for the last six months and he’ll continue to [do so] for the

next six months until he’s ready to be on his own and I think that’s what we have to do as employers. [We have to] prepare these recent graduates to be highly effective employees, and we have to give them an opportunity. We can’t just expect for them to walk in here and know what they’re doing. We can’t expect to throw them into the line of fire — we have to hold their hand and give them a great platform to be trained on.

MA: What other challenges do you think are prominent in the manufacturing world?

NL: I would say technology. I think everything is becoming so much more sophisticated out there and you really need to understand how it all works. We have a lot of our suppliers in here for lunch-and-learns and product training because we need to ensure we are up to date on all new products — not just on what they are but what they can do.

I can only speak to what I see but I think there is a lot of traction being made and developed in terms of [Industry 4.0] technology. Shape Technologies, with [help from] the private equity firm that funds [us], has taken on an initiative to develop the Industry 4.0 and Internet of Things for its customers, starting with those in the waterjet space, by [helping them] receive and understand the equipment data so they can track downtime, the causes of downtime, and when maintenance is required. They make long-term investments [in their equipment] and they [see the value] in this data.

The days of trying to lower costs by minimizing headcount are long gone. We certainly have to get more creative with technology and how we do things in order to remain competitive. | MA

Automation experts predict the top trends and technologies coming to your plant floor

COMPILED BY ALYSSA DALTON

What do you see when you look into the manufacturing crystal ball? It’s a Manufacturing AUTOMATION tradition to highlight the top five trends and technologies to keep an eye on at the start of a New Year. Read on for expert predictions about the impact of Big Data analytics, the Digital Twin, artificial intelligence and more

Craig Resnick is the vice president of ARC Advisory Group. He covers automation supplier and financial clients, with more than 30 years of experience in marketing, business development, and strategic planning. He graduated Northeastern University with an MBA and BS in Electrical Engineering.

1. Better systems and connectivity at the edge, improving real-time decision making

As more data-intensive compute workloads are pushed to the edge, real-time remote management and a simplified edge infrastructure are crucial for success. Operational issues, such as managing asset performance to improve production while reducing unplanned downtime, will drive end-users to deploy edge computing. The companies who are quick to take advantage of self-managed, edge computing infrastructures will be able to unlock the data that has long been stranded inside machines and processes. They will also be able to quickly identify production inefficiencies, compare product quality against manufacturing conditions and pinpoint potential safety, production

and environmental issues. Remotely managing this edge infrastructure will immediately connect operators with off-site experts to more quickly resolve, or better yet avoid, downtime events. This will free operations personnel and IT staff to perform their respective roles versus distracting them from their fields of expertise.

2. Further advances in industrial cybersecurity management solutions

Additional advances in industrial cybersecurity management solutions for maintaining a facility’s security posture will be deployed to address the unique features of industrial automation equipment. These solutions will further address the special requirements of industrial plants — in particular, the stringent constraints on system updates and network communications. They will incorporate commercial-type IT cybersecurity management solutions but in a manner that limits any negative impacts on control system operation. More importantly, these new industrial cybersecurity management solutions will extend this functionality to include unique, non-PC-based industrial assets and control system protocols. These solutions will also

recognize and manage industry-specific cybersecurity regulations, such as NERC CIP and leverage new integrated strategies that combine IT, OT and Industrial Internet of Things (IIoT) security efforts, maximizing the use of all corporate cybersecurity resources.

The open process automation vision will gain additional traction, adding new end-user and supplier members. Initiated by ExxonMobil and The Open Group, the vision of this initiative is specifying the process automation system of the future that minimizes vendor-specific technologies and increases return on system investment while maintaining stringent levels of safety and security. This would be achieved by specifying highly distributed, modular, extensible systems based on standards-based architecture for interoperable components with intrinsic cybersecurity. The objective of this vision is to eventually replace large CapEx automation retrofit programs with smaller OpEx programs that require less analysis, engineering and planning. Updates to these new open systems will be managed as a maintenance activity. As well, these new systems will consist of smaller, more modular and more easily distributed components, helping to better empower technical personnel while reducing the level of training required and facilitating additional benefits through collaboration.

4. The merging of virtual and physical worlds will create new business models

An integral part of the digital transformation are the technologies that accelerate the merging of the virtual and physical worlds, enabling the creation of new business models. Manufacturers are introducing new business models where they sell digital services along with products. An example of these services is the selling of the Digital Twin, which is a virtual replication of an as-designed, as-built and as-maintained physical product, augmented by providing real-time condition monitoring and predictive analytics. Customers use the equipment and products along with maintenance and operational optimization services based on predictive and prescriptive analytics. Augmented reality (AR) technologies are used to connect virtual design to physical equipment for operator training and visualization, as well as for machine maintenance. Thanks to the IIoT, the Cloud, Big Data and operational analytics, machine pattern recognition can be achieved by data mining

and statistics, enabling artificial intelligence (AI) technologies that teach machines to make operational changes without the need for programming.

“Thanks to the IIoT, the Cloud, Big Data and operational analytics, machine pattern recognition can be achieved by data mining and statistics, enabling artificial intelligence technologies that teach machines to make operational changes without the need for programming.”

5. Distributed analytics extending data processing and computing at data source

IIoT-enabled distributed analytics will further extend data processing and computing close to or at the data source, typically though intelligent, two-way communication devices, such as sensors, controllers and gateways. In many instances, the data for distributed analytics comes from IIoT devices located at the edge of the operational network. These devices can be located near or embedded in a wide variety of edge machines and equipment, such as robots, fleet vehicles and distributed microgrids. The analytics can be embedded within distributed devices or created in a Cloud environment and then sent to the edge for execution. From an operational perspective, security, privacy, data-related cost and regulatory constraints are often the reasons cited for keeping the analytics local. In terms of benefits, distributed analytics can help support revenue generation from new methods of serving existing customers and ways of reaching new ones; asset optimization through improved, proactive, and highly-automated management of infrastructure and resources; higher satisfaction and retention by engaging customers with highvalue products and services where and when they need them; and improved operational flexibility and responsiveness through better and faster data-driven decisions.

Kimberly Connors is EY Americas Technology Solutions leader, and Canadian Advisory Technology leader. With more than 25 years of experience, she has consulted with major corporate and mid-market clients across North America, leveraging technology to drive business value and insight, and optimize IT operations.

Today, leading companies are already using an augmented reality Digital Twin to bridge the virtual and physical worlds of manufacturing machines and systems. By adding continuous monitoring — enabled by the IoT and AI algorithms — operators will be able to predict, identify and address potential problems on plant floors before they happen. Taking it a step further, this technology can allow voice-controlled access to experts who will be able to see a live stream of what the operator is seeing, providing even greater productivity.

Many manufacturers have introduced new technologies to drive improvements in areas such as production and supply chain efficiency, and asset management, but the increasing connectivity of previously isolated manufacturing systems — together with a reliance on remote supporting services for operational maintenance — has introduced new vulnerabilities for cyber attacks. Manufacturers need to become increasingly focused on closing these vulnerabilities.

The IIoT was initially about generating increased productivity, operating and energy efficiency, and accuracy. Now it’s about generating information, driving improved customer outcomes, enhancing responsiveness to customers and ecosystem partners, producing higher levels of product performance, and finding new revenue streams. As things become increasingly intelligent and connected, there’s a competitive necessity for manufacturers to “listen” to the IIoT and use the generated data to create actionable insight. The IIoT allows for the synchronization of information, enabling different parties in different locations to have access to the same information at the same time. Although the process of becoming a manufacturer driven by Big Data analysis is far from simple, the potential benefits are vast.

“If 3D printing delivers on even a fraction of its disruptive potential, it will still mean the upturning of a whole range of business and industrial landscapes.”

Any physical product runs the risk of being disrupted by 3D printing. At its simplest, 3D printing is analogous to a teleporter — able to transmit the designs of any product instantly to any printer in the world. If 3D printing delivers on even a fraction of its disruptive potential, it will still mean the upturning of a whole range of business and industrial landscapes. Companies need to start thinking now about how to get ahead in order to capitalize on its disruptive potential.

The ability to deliver real-time information to customers is one of today’s biggest success factors, yet it is also one of the most significant challenges for manufacturers. Customers are looking for timely and accurate information, wherever and whenever they want it. Blockchain can permit end-to-end, IoT-enabled chain-of-things across scanners, transponders and other devices. Further, dashboards can provide access across all stakeholder groups — internal, corporate customers as well as consumers — creating a tangible real-time solution to solve the visibility problem.

Matthew Littlefield co-founded LNS Research in 2011 and is now president and principal analyst. In this role he oversees LNS’s coverage of the industrial value chain. Dan Miklovic joined LNS Research in May 2014 and is a research fellow with his primary focus being research and development in the Asset Performance Management (APM) and Operational Architecture practices.

In the world of IIoT and digital transformation for industry, the past year has been one to remember. Many will look back as this being the year where we passed peak hype and moved from talking about the realm of the possible to practical. Despite some high-profile setbacks for vendors in the space — there is still more positive momentum than negative — LNS Research believes there will be many vendor and end-user winners as we move into a post-peak hype era.

From Matthew Littlefield:

1. Large industrials reinvent operational excellence with Big Data analytics

The industrial space has always been characterized as insular, organic and conservative in how we approach the adoption of technology and process improvement techniques. Lean manufacturing was developed out of the Toyota Production System. Six Sigma was developed out of Motorola and GE.

However, as these methodologies spread, they became hardened — and in some circles even turned to dogma — meaning as technology advanced, the process itself couldn’t change without severe repercussion and criticism.

We predict 2018 will be the year this dogmatic approach breaks down, and a new breed of large industrial companies will emerge and publicly prove through improved best-in-class results that a new approach to Lean and Six Sigma is needed to fully capture the potential benefits of Big Data analytics in manufacturing.

2. IIoT platform adoption gains critical mass by industry

Last year we predicted that 2017 would be the year where the industry saw IIoT platform providers move from pilot to enterprise rollouts with more than one vendor going on the record with customers making enterprise commitments.

In 2018, we believe it will be the year that some of the platform players gain critical mass — i.e. gain multiple major customers on the same multi-tenant platform with shared services and apps running across. There will however be some caveats. Each end-user will have multiple platforms for multiple use cases and inter-Cloud connectivity will become both a requirement and reality. We also believe that IIoT platforms (not including Cloud platforms like Microsoft Azure and Amazon AWS) will have to differentiate on subject matter expertise and relevance.

3. Edge and Cloud both have record years

Microsoft Azure and Amazon AWS have emerged as two Cloud leaders for the industrial space and are delivering record results for shareholders. At the same time, edge is sexy again, and there have been a slew of nextgen startups focused on the industrial edge and delivering new analytics as close to the data source as possible.

We believe 2018 will be the year the

industry realizes that a hybrid analytics approach really means that both edge and Cloud are growing markets and there is more than enough business for both types of vendors to have record years.

From Dan Miklovic:

4. APM becomes all about business

Ever since the advent of APM, the focus has been on improving reliability, decreasing downtime and reducing unplanned maintenance. Most of this has been predicated on the premise if “it’s” broken “it” can’t be contributing to the business.

We predict 2018 as being the year we see a shift in focus toward actually optimizing the profitability from equipment. Machine learning and better Big Data analytics will enable business to decide the best operating profile for the plant based on the order backlog, reliability issues and the Digital Twin model of the plant.

“The industrial space has always been characterized as insular, organic and conservative in how we approach the adoption of technology and process improvement techniques.”

5. Digital Twins in 2018 simulate possible futures

To date, much of the hype around Digital Twins in asset-intensive industries has been about maintenance-focused applications such as superimposition of operating conditions on virtual x-rays of the equipment to aid technicians in diagnosis or using the twin to model expected service life.

In 2018, we expect the Digital Twin focus to shift to include not just the physical aspects of the twin but the process aspects as well. This will drive new interest in process design and engineering applications, so changes in operating performance required to facilitate reliability can be assessed for production impacts, as noted above. | MA

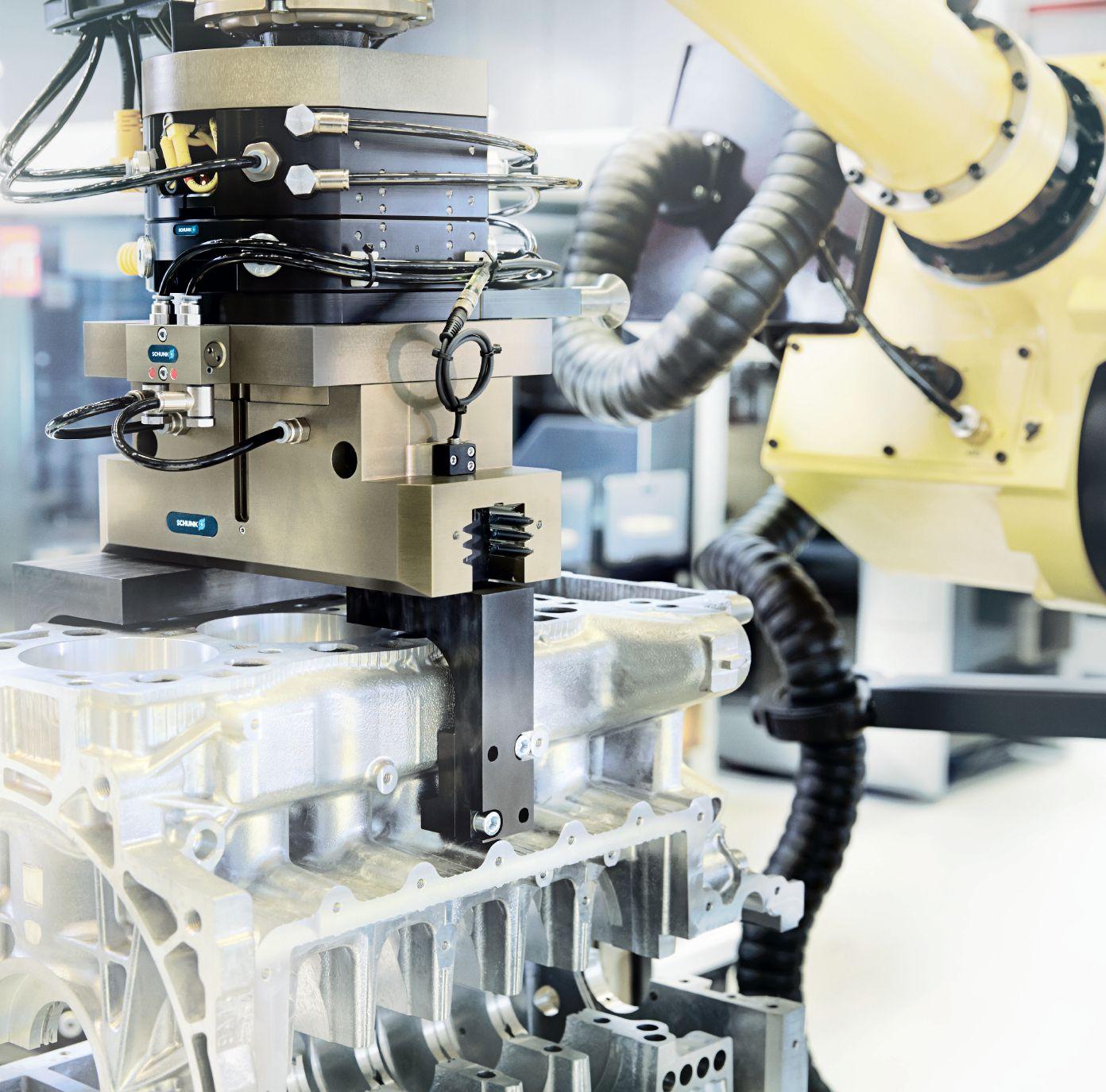

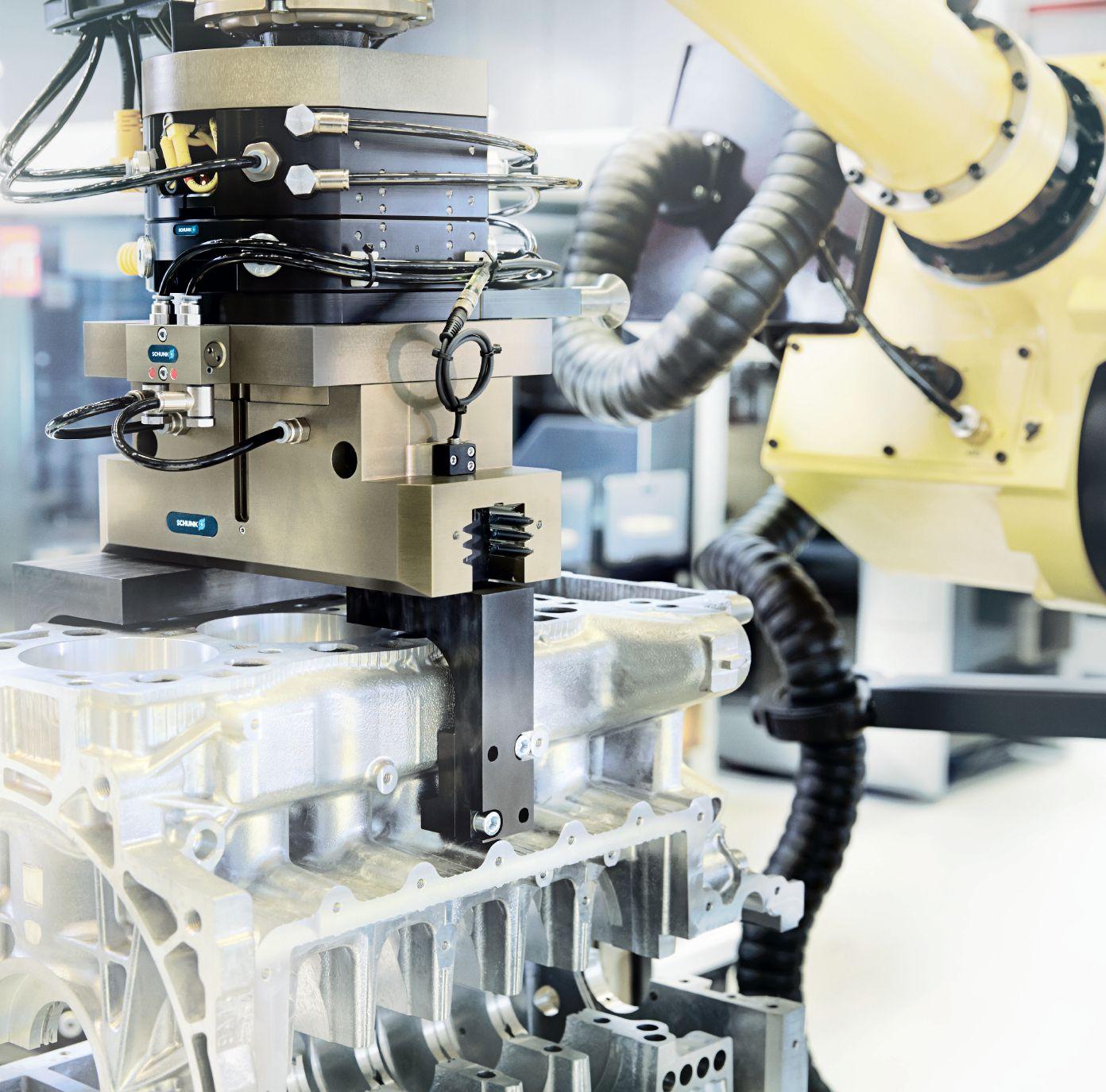

A pneumatic collaborative robot inspired by the movement of the human arm BY

ALYSSA DALTON

Described as the first pneumatic seven-axis robot, the Festo BionicCobot promises to deliver unparalleled movement, flexibility and safety for human-robot collaboration. Making its first appearance at Hannover Messe 2017, the robotic concept was developed by the company’s Bionic Learning Network, which studies natural concepts and principles in an effort to improve automation technology.

“In research, there are some pneumatic robots available but they offer very limited degrees of freedom and are not as complex as the BionicCobot,” says Dr. Elias Knubben, head of Corporate Bionic Projects at Festo.

“Its flexibility allows it to work directly and safety together with humans. We use direct drives — pneumatic drives — and this allows

us to adjust the stiffness of the force and the speed of each movement quite precisely, which is what makes it safe.”

The BionicCobot is modelled after the movement of the human arm from the shoulder, down through the upper arm, elbow, radius and ulna to its gripping hand. The developers have implemented the principle of agonist (player) and antagonist (opponent) on the BionicCobot in all seven joints, explains the company, adding that each joint makes use of the “natural operating mechanism of the biceps and triceps — the efficient interplay of flexor and extensor muscles needed to execute very delicate movements.”

Three axes are located in the shoulder area, along with one each in the elbow and

lower arm and two in the wrist—all of which include a rotary vane with two air chambers forming a pair of drives that can be adjusted like a mechanical spring by filling them with compressed air.

“If an actuator is filled with compressed air, the motion generated can be exactly set in terms of speed, force and rigidity. In the event of a collision, the system eases off, thus posing no risk to the worker,” according to the company.

Dr. Knubben says the BionicCobot received a lot of positive feedback and attention from Hannover Messe attendees, including numerous requests to pilot the unique system in various manufacturing sites and applications. Dr. Knubben says the data and insight gained from pilot testing will help the development team decide if modifications to the seven-axis robotic concept are needed.

“In this [era] of human-machine collaboration, you [need to] have a lightweight robot that is able to interact in a safe way with humans,” he says, adding that the BionicCobot’s movements can be finely regulated to suit the particular task it is performing. “I think there are a lot of robots already being used in the industry but there will [continue] to be many more tasks that can still be partly or fully automated. Today there are many tasks that are done either completely manually or completely through fully automated tools

or factory lines, but in order to efficiently [produce] small batch sizes, users should [consider] fully automating their [processes] with flexible robots or [implementing robots that can] assist humans.

“[Thanks] to digitalization, manufacturers are able to produce customized pieces efficiently — it’s not all about mass production anymore. This kind of production has changed and therefore robots [are] needed.” | MA

BY TREENA HEIN

Companies ramp up automation for a wide variety of reasons, but the how and the why are different in each situation. For HERD, headquartered in Winnipeg, Man., investing in new equipment to automate some of its processes allows it to produce large amounts of a new product line. More automation was added in order to make HERD’s manufacturing more consistent and flexible, easier on its workers and, of course, faster. The manufacturer will soon be shipping the newest versions of its hotly demanded transport truck protection products — AeroPLUS truck guards and stainless steel grill guards — at a pace it has never achieved before.

Before we get into how the new product and its raw materials have been integrated with new equipment to make company’s ramped-up automation successful, let’s delve briefly into its history. Back in 2003, founder Mark Daudet could see there was a demand for protection that would custom-fit North American truck models, and he decided to look into manufacturing his own products. He connected with a company in Australia to learn the ropes. Truck guards are often referred to as ‘roo bars’ in Australia, and while they are very popular for protecting transports in collisions with kangaroos, they are essential on the ‘road train’ trucks that drive across the outback — trucks that pull three, four, five or even six 48-foot trailers behind them.

Daudet and his startup team studied

1.3M

hard, tried different designs and manufacturing methods, and eventually marketed several lines of HERD’s stylish transport truck guards for various major brands. The truck guards replaced the factory bumper while still protecting the grill. According to Daudet, the products don’t just prevent damage from collisions with animals such as deer or moose, they protect trucks from the many incidental bumps and scrapes that happen all the time on the road. The company now has about 100 employees and sells its products across Canada and the United States.

Working with extruded aluminum is how all products are made.

“Manufacturing with extruded aluminum is a very labour-intensive process,” explains Dave Gata, director of operations. “There are three components in fully integrated guards: the bumper section, the uprights and the tubes. The bumper and uprights go through a similar process. The uprights start off as C-channel pieces, cut to size and shape, followed by welding, sanding and polishing. The bumper sections are manually formed from extrusions, with holes put in and angled cuts made to allow for airflow and installation of signal lights. Then, it’s onto MIG welding, which again

involves lots of angle measuring, as well as the addition of hinges so that the whole guard can be lowered to access the engine for maintenance.”

The third component – the tubes –come to the company as extruded pieces, which are then cut and bent to size for the best fit and finish for each truck.

All three components are now ready for assembly. Parts are tacked and then MIG welded, polished and buffed. The company uses a proprietary set of aluminum finishing steps to achieve a spectacular mirror finish, involving various tools, polishes and techniques. Lastly, hinges are tested and various pieces of hardware and components are added in preparation for shipment and truck mounting.

“A lot of people are blown away by what we accomplish with aluminum using grinders, skill saws and routers,” Gata says. “Our people are highly skilled and are basically doing woodworking but with aluminum.”

About two years ago, the leadership team began designing a different truck protection product — one that addressed growing customer demand for easier installation/operation and better aerodynamics.

“Prior to the arrival of the tube bender, we had to cut and weld two stainless tubes together that were bent by a vendor, which really added to our process time. Before,

we were pushing 20 to 30 hours to get one grill guard done and now we’ve halved that. It’s astounding.”

“The new AeroPLUS was engineered to be lighter and stronger than all previous HERD truck guards, providing superior protection for a truck’s vital systems,” explains Leroy Peters, director of marketing. “It’s the best product we’ve ever made and is a reflection of the advancements in vehicle design.”

The purchase of a CNC press brake was the only way to make on-site manufacturing of the AeroPLUS feasible. “From the moment we began planning this new product, we knew outsourcing the cutting and bending of flat pieces would cost too much money,” says Gata.

with holes already laser cut, and then we preform the product using our new CNC brake press and CNC tube bender,” Gata says. “Prior to the arrival of the tube bender, we had to cut and weld two stainless tubes together that were bent by a vendor, which really added to our process time. Before, we were pushing 20 to 30 hours to get one grill guard done and now we’ve halved that. It’s astounding.”

Implementing the bender has also slashed prototyping time. “We used to rely on our vendor but now our designer knows just what our bender is capable of, and that means so much speed is added to everything in the process,” says Gata. “We can produce a prototype in one day as opposed to waiting for the vendor to fit us in, which could mean two to four weeks. So while it’s hard to gauge ROI on this machine, with just being able to massively decrease prototype time, it’s an invaluable purchase. We just need to have the design program finished and we’re good to go. The whole process is determined by us and how fast we can get things done. The design process before was like molasses and now, it’s like lightening.”

The brake press was installed in October, and with training time, it only had about 50 hours on it in early November. “We are so good at what we do with aluminum, and so

“But it’s not just about cost. Using laser-cut flat aluminum sheets and having our own equipment gives us endless possibilities for shaping and bending and forming products to specific brands of truck. With flats, we have a complete blank page and complete flexibility.”

The new grill guard product line is made using tubular stainless steel and offers multipoint brackets that use both the tow receivers and the truck’s frame for mounting, along with box uprights and right-sized tubes for strength.

“The stainless steel comes in as flat sheets

Higher production levels mean more labour will be needed in other departments, such as grinding and polishing.

skilled with all the tools we have been using for so long, that some employees don’t think the press will speed up the entire process much,” Gata explains. “But it’s sure to, and

• HERD started on the garage floor of founder — now president and CEO — Marc Daudet.

• The company used to rent a manufacturing facility on month-to-month terms and moved several times. It has built several additions onto its present facility and added buildings to the site as well.

• HERD received the 2013 Emerging Manufacturer Award from Canadian Manufacturers & Exporters. Daudet stated that “the biggest challenge of this enterprise, particularly with its growth, has been the constant change. Nothing stays the same for very long…there is no comfort, status quo is just never to be found. It makes it very exciting and fun…I get my greatest pride, truly, from our workforce. We have, hands down, the hardest-working group of individuals you’ll find anywhere.”

• To make life easier and prevent injuries for long-haul drivers — especially older or smaller drivers — and also help the industry recruit more drivers (including women), HERD created Lift Assist several years ago. This patent-pending spring system helps to lift the Original Series products up so that drivers can easily access their engines to check the oil and more. The system reduces lift weight by up to 75 per cent, for some HERD styles down to as little as 13 pounds. | MA

it’s really about the precision and consistency it will provide.”

Gata adds that higher production levels will mean more labour will be needed in other departments, such as grinding and polishing. “I’d really like a second brake press,” he says. “In the future, we want to do more bending in-house, and work on how we can move production eventually away from aluminum extrusion to aluminum flats instead.”

HERD only did a limited rollout of the AeroPLUS and Grill Guards in 2017, and was focused in the fall on making a suite of SKUs for various fleet brand models to get ready for a full product line launch in early 2018. With its new automated processes fully in place and new labourers hired, this Canadian company is well-positioned to meet the expected onslaught of orders. | MA

BY JON ROBINSON

ING in late-2017 reported the current trajectory of 3D printing could result in one-quarter of world trade being wiped out by 2060. This was its Scenario I, in which 3D printing continues to evolve at an annual growth rate of 19 per cent, with the possibility of locally 3D printed goods cutting trade by 40 per cent. Scenario II considers an accelerated 3D printing growth rate of 33 per cent, which would wipe out twofifths of world trade by 2040. ING’s analysis also predicts, that at current growth rates, half of all manufactured goods will be printed in 40 years. These long-term predications cannot consider all future supply-and-demand variables, of course, but today

57%

Based on an early 2017 survey by Sculpteo, with respondents from consumer goods (17%), industrial goods (17%), high tech (13%), services (9%) and healthcare sectors (7%), 57% of all 3D printing work done is in the first phases of new product development, which speaks to reducing time-to-market for new products.

3D printing constitutes less than 1 per cent of global manufacturing revenue. Wohlers Associates, a consultancy specializing in 3D printing research, estimates 3D printing will eventually capture 5 per cent of global manufacturing capacity, which would make it a $640 billion industry (all figures in U.S. dollars). A 2016 report called 3D Printing: The Next Revolution in Industrial Manufacturing, published by logistics giant United Parcel Service (UPS), estimates today’s 3D printing market to be worth anywhere from $7 billion to $9 billion. Consultancy firm McKinsey & Company estimates the 3D printing market could reach anywhere from $180 to $450 billion by 2025.

The range of these growth predictions largely comes from the inability to fully understand how massive companies — with the ability to shift markets — might alter manufacturing models to leverage 3D printing. It is unlikely 3D printing can predominately replace — or even penetrate — mass production processes in several sectors, but it does hold the potential to touch most any category of discrete manufacturing. IT research firm Gartner estimates 10 per cent of all discrete manufacturers will be using 3D printers by 2019 to make parts.

Watching

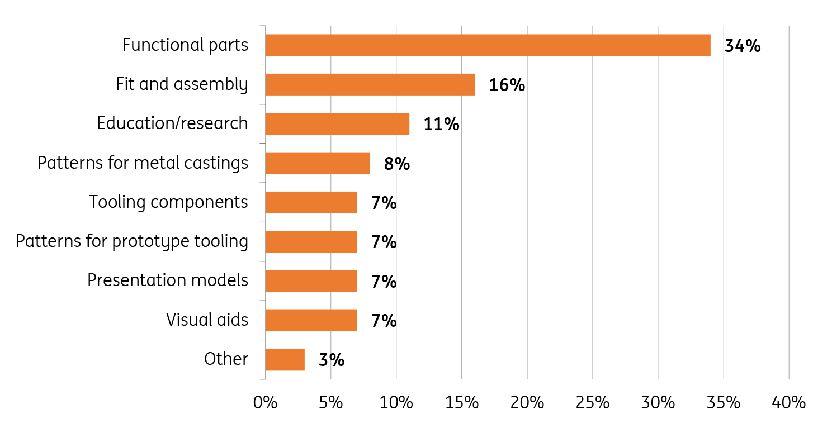

3D printing is best suited for making complex, small-batch products, as illustrated by its heavy usage for prototypes and parts. The 2016 UPS report describes parts production as its fastest-growing application, specifically functional parts at 29 per cent and prototypes at 18 per cent. In November 2016, UPS invested in a company called Fast Radius to launch a new global logistics model for parts production via 3D printing. Fast

This is illustrated in Gartner’s annual hype cycle of emergtechnologies which shows the accelerating maturity enterprise 3D printing (see figure 2). Over the past five years, enterprise 3D printing has successfully moved from being a nascent technology to reaching the cusp the plateau of productivity, signaling that mainstream adoption is starting to take off. In contrast, consumer 3D printing is still at the peak of inflated expectations and will require more time before it reaches mass adoption.

This uptick in 3D printing investments and adoption can be attributed to the increasing number of companies beginning to realize, on the one hand, the possibility for new 3D printing business models and services and, on the other hand, the major economic advantages of 3D printing compared to conventional manufacturing techniques. With traditional manufacturing, materials are usually sourced and shipped from several locations to centralized factories that develop and assemble the final product.

Ricoh’s 3D printed jigs and fixtures boost assembly line productivity, as the company assembles electronic components using a 3D printed fixture produced in anti-static ABS plastic.

under a service-bureau model as technologies mature in both function and cost. 2017 research by Gartner shows interest in establishing in-house 3D printing capabilities is “rapidly gaining traction.” Gartner predicts 40 per cent of manufacturing enterprises will establish what it calls 3D printing Centers of Excellence (COE) by 2021, pointing to existing industrial-scale efforts by Boeing, Johnson & Johnson, Rolls-Royce and Siemens. In September 2016, Fortune.com reported 3D-print startup Carbon received $81 million from a group of investors, including GE Ventures, BMW Group, Nikon and JSR, as an extension of a $100-million funding round in August 2015 led by GV (formerly Google Ventures).

Does 3D printing make sense?

The economics of 3D printing

Radius’ primary production facility is now located in what it describes as the world’s largest packaging facility, UPS WorldPort (Louisville, Ky.), which also serves as the company’s global air hub. Fast Radius

explains this “strategic end-of-runway location” provides up to six hours of additional production time versus using a near-site location, typically controlled by a third-party. 3D printing will likely experience growth

The finished goods then pass through several steps in the supply chain, usually being stored in warehouses before delivery to stores or directly to the end-customer once an order has been placed.

In December 2017, Yahoo Finance reported Carbon closed on $143 million of a new funding round. “Once completed, this round will bring the Silicon Valley-based company’s total raise to a whopping $422 million and reportedly boosts its valuation to a mighty $1.7 billion,” wrote Beth McKenna. “To provide some context, the two largest publicly traded pure-play 3D printing companies, Stratasys and 3D Systems, have market caps of $1.14 billion and $1.13 billion, respectively.”

Prospects for 3D printing growth are buoyed by venture-capital investments

Responses from 61 producers of 3D printers asked what their global customers use the printers for, including 11 per cent of 3D printers sold to train engineers or for research purposes. Source: Wohlers Associates report 2017, 3D Printing and Additive Manufacturing State of the Industry

with established companies like UPS, which holds the world’s largest network of distribution centres. Billed as The Global Platform for Part Production , Fast Radius supports its 3D printing capabilities with third-party providers of techniques like CNC machining and injection molding.