TOP TRENDS IN 2021

COVID-19 changed

p.12

COVID-19 changed

p.12

Order your cut-to-length and bulk cable, or bulk wire today and save with AutomationDirect’s affordable pricing - No gimmicks. No hidden charges.

Instrumentation Cable (Shielded) - Cut to Length

Starting at $0.20 (per foot with low 20-foot minimum)

We just added 20AWG twisted pairs and 20AWG and 18AWG twisted triad instrumentation cable to our already extensive selection of cables. These cables are primarily used for industrial instrumentation, control, alarm, and energy management circuits.

• 20AWG, 18AWG and 16AWG with 1, 2, 4, or 8-twisted pairs with overall shield or individually shielded with an overall shield

• 20AWG and 18AWG with 1, 2, 4, or 8-twisted triads with overall shield or individually shielded 2, 4, or 8-twisted triads with overall shield

• Individually shielded pair models also available with crosstalk protection

• A 22AWG orange PVC insulated communications conductor (talk wire) is included on 16 AWG & 18 AWG multi-pair cables

Don’t be fooled by suppliers that add cutting charges, hidden fees, and inflated shipping costs that end up tripling the cost at checkout.

At AutomationDirect, we’ve got you covered with these advantages:

• UL certified re-spooling facility - ensures that our cut-to-length cables maintain the UL certifications

• Low price per foot - Starting at 19¢ (Q7120-1)

• Low minimum cut lengths

• Fast shipping (typically 2-day delivery), free on orders over $49*

• Easy online, phone or email* ordering

• 30-day money-back guarantee* (yes, even custom cut cable)

Types of cable available:

• Flexible Portable Cord

• RS-485 & RS-422/RS-232 Cable

• Flexible Control Cable

• Power Machine Tray Cable

• Variable Frequency Drive (VFD)

• Variable Frequency Drive (VFD) / Servo Cable with Signal Pair

• DLO, RHH, RHW-2 Heavy-Duty Flexible Power Cable

• Instrumentation Cable

• Continuous Flexing Tray Rated Control

• Continuous Flexing Control

• Continuous Flexing Motor Supply

• Continuous Flexing Industrial Ethernet Cable

• Continuous Flexing Profinet

• Continuous Flexing Profibus-DP

• Sensor/Actuator

• Control and Signal

• Multi-pair Thermocouple Extension Cable

• Quabbin DataMax Extreme Industrial Ethernet Cable

We also have a large selection of quality THHN and TFFN electrical wire that meets all NFPA and NEC requirements, at unbeatable prices.

TFFN Fixture Wire

Starting at $35.00 (500 ft.)

•Sizes up to 18AWG and various color options

•500 or 2,500 ft. reels

MTW Machine Tool Wire

Starting at $18.00 (500 ft.)

•Sizes up to 22AWG and various color options

•500 or 2,500 ft. reels

THHN General Purpose Building Wire

Starting at $51.00 (500 ft.)

•Sizes up to 14AWG and various color options

•500 or 2,500 ft. reels

Bulk or Cut-to-Length shipped fast!

Research, price, buy at: www.automationdirect.com/multi-conductor-cable www.automationdirect.com/wire

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Industrial

The

As I write this, we’re deep into the second wave of the coronavirus – cases are rising again across many parts of Canada. While B.C. and Alberta are stabilizing, Quebec is under an 8 p.m. curfew, Manitoba has seen a spike in numbers over the past month and, here in Ontario, it’s day two of stay-at-home orders from the provincial government, with increased testing for manufacturing workers and a major safety campaign and inspection “blitz” underway. After nearly a year of upheaval and re-charting the course, it’s like we’re right back in April 2020. You know the saying: the more things change, the more they stay the same.

Except things are very much not the same. We’ve come so far from a year ago, arguably advancing knowledge, technology and human resilience more rapidly in the span of the last 310 days than any other year in recent memory. In some ways, 2021 is the dawn of the new decade we were all excited about at the beginning of 2020. Vaccines are rolling out nationwide, and, while it sounds like it’ll be another year before things are back to “normal,” it does seem that we may be in the back half of this crisis.

In November, Dennis Darby, president of Canadian Manufacturers & Exporters, called on lawmakers to evaluate the way we do business north of the border. “To support manufacturing here in Canada, the government will have to offer a competitive business environment that includes important investment tax measures and find ways to ensure Canadian companies have access to the U.S. market in the same way that U.S. companies access ours,” he said in a statement.

MA is proud to support Canadian manufacturers and the automation companies in their supply chain, which is why I’m pleased to welcome Automate Canada as our new association partner. Automate Canada, founded as the industrial automation arm of the Canadian Association of Mold Makers (CAMM), has provided valuable resources to its members to help them navigate the pandemic. Along with CAMM, Automate Canada also recently established an action plan for SMEs to increase Canadian-made production (see p. 18).

Manufacturers are embracing automation and digitalization at a pace unlike ever before. In a post-COVID world, it’s the only way to compete.

Joe Biden is the new president of the United States and, at the time of this writing, he has tabled a US$1.9-trillion COVID-19 relief plan aimed at stimulating America out of the case-spread spiral. Canada needs this to happen, and quickly – until cases are more under control on both sides of the border, only “essential” access continues, stifling the freedom of movement that makes our countries such robust trading partners.

How that partnership will evolve in the Biden era remains to be seen. He’s already announced he plans to kill the Keystone XL pipeline, and that government contracts won’t be awarded to companies that don’t produce their products in the U.S. American protectionism has the potential to hurt the Canadian market, but it may also be a springboard for innovation, as I wrote in an editorial on our website after Biden’s election.

@AutomationMag

The association is expanding its network nationwide, so I encourage you to visit automatecanada.ca and see what they can offer your business. Making new connections is just one good way to fortify your supply chain for crisis – manufacturing veteran Dan Lionello discusses this in more detail on p. 8.

It would not be the first issue of the year without our annual trends article, which you’ll find on p. 12. Trends are always interesting to look back on – and our pre-COVID roundup in 2020 was filled with promise about the new decade ahead.

While most of those predictions were sidelined by the manufacturing sector’s herculean effort to simultaneously produce PPE and dig out of a historic economic slump, they all came true in one way or another. Manufacturers are embracing automation and digitalization at a pace unlike ever before. In a post-COVID world, it’s the only way to compete. | MA

@mfgautomationmag /company/automation-mag kurquhart@annexbusinessmedia.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Reader Service

Print and digital subscription inquiries or changes, please contact:

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

ACCOUNT COORDINATOR

dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221 COO

CONTRIBUTING WRITERS

Alena Barreca, Jim Beretta, Paul Hogendoorn, Don Matthew, François Gaudreau, Craig Resnick, Jacob Stoller, Bob Voss

Manufacturing AUTOMATION is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191 Printed in Canada ISSN 1480-2996 Publication Mail Agreement #40065710

SUBSCRIPTION RATES Canada — $43 per year

United States — $75.50 (US) per year Foreign — $86 (US) per year Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing AUTOMATION are © 2021 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Ontario invests $332K to manufacture inclusive PPE

A Mississauga–based digital printing company will manufacture inclusive PPE for the Deaf and hard-of-hearing community with a $332,000 investment from the government of Ontario.

McRae Imaging is making three-layer face masks that feature a lens for lip reading, which is impossible to do with traditional surgical-style or N95 masks.

The My Access Mask was designed by the Como Foundation, a not-for-profit enterprise also based in Mississauga.

Through a partnership with the Como Foundation, McRae Imaging plans to produce 1.4 million My Access Masks, which will feature the Ontario Made logo as part of the Canadian Manufacturers and Exporters program to highlight made-in-Ontario products.

Online marketplace for made-in-Canada PPE gets an upgrade

RRP Canada has relaunched its website that connects Canadian manufacturers and suppliers of protective personal equipment (PPE).

The Rapid Response Platform site has evolved into the Trusted PPE Marketplace as part of a project supported by Next Generation Manufacturing Canada (NGen), the country’s advanced manufacturing supercluster.

The site features products manufactured in Canada, underscoring role that Canadian manufacturers have played in responding to the pandemic. With the new upgrade, users can now view a product’s manufacturing origins, including the province it was manufactured in, and access a match-making tool to power-rank top suppliers for direct-buying.

RRP Canada has also introduced enhanced quality control to screen products that protect against COVID-19, including hand sanitizer, surgical masks, N95s, surface

sanitizer, face shields, gloves and gowns. A running ticker on the homepage shows how many units of each are currently available in the marketplace.

The site’s administrators ensure all suppliers and products are vetted through regulatory approval pathways reviewed by Health Canada, and users can access provincial safety guidelines directly on the site.

The new site at rrpcanada .org also features a 100 per cent accessibility score for users with disabilities, and is available in both official languages.

The University of Waterloo and the National Research Council of Canada (NRC) are partnering to help Canadian companies use metal 3D printing technologies.

The collaboration between the NRC and the Multi-Scale Additive Manufacturing (MSAM) Lab at Waterloo will run for at least seven years.

“We want to create in southwestern Ontario a unique

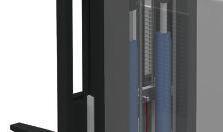

Eliminate and shrink control cabinets while expanding dynamic motion control: The AMP8000 Distributed Servo Drive System from Beckhoff integrates a servo drive directly into a servomotor. A unique benefit of the AMP8000 series is that servomotor power ratings* and installation sizes remain virtually unchanged. Proven One-Cable Automation in the EtherCAT P standard delivers real time communication and industrial power on one cable, and an innovative IP65-rated supply module powers multiple motors in the field. As such, the AMP8000 minimizes space requirements, installation effort, material costs and motion system footprint in a big way. sizes remain almost identical to standard AM8000 servomotors from Beckhoff no changes in existing machine designs required same high power ratings as before despite drive integration* TwinSAFE drive safety technology built into every servomotor

*Compared with a combination of servo drive and servomotor

ecosystem to support metal additive manufacturing (AM) in terms of research and development and to translate competencies to industry partners,” says Mihaela Vlasea, the associate director of MSAM.

The partnership combines MSAM’s expertise in metal AM process optimization with the NRC’s experience in materials science and metal powders development to enable research from powder to part.

Teams at Waterloo and the NRC have worked closely for the past three years in the areas of metal AM and process optimization, materials and product characterization, standardized testing and validation.

The collaboration will build on that relationship at a new NRC facility in Mississauga, Ont. that was officially inaugurated on Nov. 16.

The site will launch powder synthesis, recycling and

characterization capabilities in Ontario to customize AM and reduce material costs for industry applications.

A major thrust of the project will be the development of new AM powders – the raw materials at the heart of the technology –using metal alloys that currently aren’t available or are prohibitively expensive.

Researchers will also study re-using and recycling leftover powders, and the use of cheaper, less-refined powders that may still be capable of producing high-quality parts.

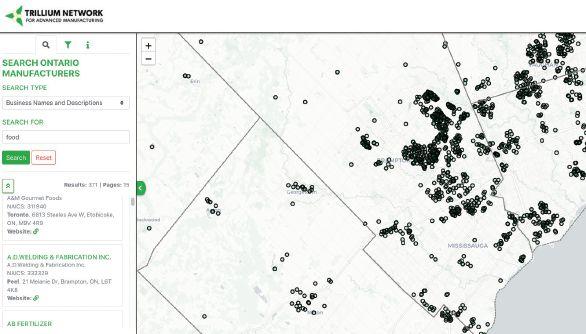

Trillium Network creates online map of available assets

Information about manufacturing capabilities of more than 6,000 producers in Ontario

is now available via an onine map platform developed by the Trillium Network for Advanced Manufacturing.

TrilliumGIS is an open-access platform available to the general public and catalogues manufacturers from large motor vehicle and aircraft assemblers to craft breweries and wineries.

more Ontario manufacturing establishments will be added during the next few months.

All of the data in TrilliumGIS are compiled from publicly available sources of information. Access it at trilliumgis.ca/map.

The Association for Advancing Automation (A3) will absorb its robotics, advanced vision and motion control sub-associations this spring.

The platform can be used by manufacturers as they seek to identify potential customers, suppliers and partners, as well as economic development officials at all levels of government, educational institutions looking for co-operative education and work-integrated learning partners, and site selectors looking for promising locations for new manufacturing investments.

The Robotic Industries Association (RIA), Advancing Vision + Imaging Association (AIA) and the Motion Control & Motor Association (MCMA) will all become A3, the company says.

Users are able to identify manufacturers by industry and customize searches according to production networks, supply chains, type of business, Statistics Canada industry codes or location.

Data about several thousand

The association will continue to offer events, market intelligence, standards and safety work, education initiatives, certifications and networking opportunities.

There are about 1,200 member companies in the A3 network.

Excellence in Manufacturing Consortium (EMC) has launched a new reskilling certification training and onboarding program.

The Manufacturing Essentials Certification (MEC) – Reskilling/ Upskilling and Onboarding Initiative is designed to address recruitment and retention challenges in Ontario’s manufacturing sector.

The MEC reskilling/upskilling stream includes tracks for both production workers and supervisors, with additional sessions covering topics such as leadership, continuous improvement and health and safety.

These streams focus on the development of skills of incumbent workers, providing participants with the skills they need to be successful within the workplace.

In addition to the training and workplace performance projects provided by this initiative, EMC will also deliver an MEC onboarding resources stream, which is focused on encouraging the development and delivery of employability and essentials skills with under-represented, unemployed and underemployed individuals interested in manufacturing.

The first cohort in the program started in fall 2020 in London and Chatham, Ont. Seventyfour participants started the MEC training, representing 19

different manufacturing organizations.

EMC is facilitating the initiative with funding support for manufacturers from the Ontario government and the Skills Advance Ontario Program, and with additional support by industry and community partners such as Fanshawe and Algonquin Colleges. This program is open to all Ontario manufacturers, with cohorts planned in all regions. For more information, contact Project Coordinator Lisa Steudle at lsteudle@emccanada.org.

Magna International’s new CEO and director has officially stepped into his role.

Seetarama (Swamy) Kotagiri has been with Magna for more than 21 years and served in various product groups and corporate roles, spanning functions including engineering, operations and R&D. He contributed to the company’s recent growth and evolution through his leadership and aligned the organization’s strategy around the trends shaping future mobility. Kotagiri was recently featured in Business Insider’s 100 People Transforming Business, an annual list highlighting those across industries who are changing the way the world does business.

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now

LIONELLO, CEO

Manufacturing AUTOMATION:

You were running your own manufacturing company when you started thinking about a cloud-based platform for global supply chain networking. What was your challenge?

Dan Lionello: The recognition of the problem really became obvious about 13 years ago. We had pivoted to move all of our manufacturing offshore. We had to develop systems that would be very clear about information transfer and timeliness. And then, secondly, focus on those vendors that had the capabilities – to not just purportedly to make the product, but to also have the integrity and the quality systems that we could have faith [in] without us having to see it all day, every day.

We were shipping directly to customers from factories that were global, without actually having to do inspections. The reason we were able to do that was because of all of these other things that we did from a vendor qualification standpoint, and then from an information management standpoint once we had the partners up and running.

We [started] looking at where the world was going to go with manufacturing. We saw it being more global, and we saw a lot more requirement for information. I recognized that there was going to be a good need for something that would manage this information globally.

MA: What led you to develop Omnae five years ago?

DL: Scarily enough, email, Excel spreadsheets, PDFs, WhatsApp, WeChat, phone, fax – all of those methods are the way that manufacturing is managed globally, even today. An order is typically entered into a

computer a half-dozen different times between the purchasing side, the vendor side, the quality side and engineering.

So as a result, you’ve got this hairball of information and communications that’s happening in all kinds of different ways between different people in different companies. And if there is ever a challenge, even the challenge of managing quality, it means you’ve got to pull all that information together in another place, coordinate it and sort it in order to report it.

We built a system designed to manage the relationships, quality, communications and agreements – including sustainable and ethical manufacturing – between outsourced manufacturing partners going from product lifecycle management and the design side, through to order management and quality

management. Then it’s able to, in real time, aggregate it and give you the analytics that you need to be able to know how vendors are performing for you.

MA: How does automation like this help in situations of supply chain crisis?

DL: It will allow you to have a higher level of confidence in the suppliers that you’re moving to, because you can see how they’re performing for other people historically. That’s one piece that you don’t see, typically, until you start to work for someone and you create your own quality data for how they’re performing. Quality is an island for everybody, because they all see what they experience, but they don’t see what others have experienced as well. For example, as a brand owner or as a customer, I can see what’s happening with my vendor,

but I can’t see what’s happening below them with any critical other processes or other parts.

The [platform] does two things: it creates transparency. It will also allow you to find a new vendor – if the vendor you’ve got is either in a geographic location that’s in trouble, or if you’re just solely wanting to second- or third-source, you can then find companies in other regions. It becomes a single source of truth for the specifications, what it is you’re supposed to build. So from a vendor standpoint, it makes the probability that they’re going to build the right thing much higher, because all the information is in one place. If there is a problem, it’s typically very easy to see where that problem came from.

MA: We talk a lot about single source of truth, Industry 4.0, etc., but what we hear, especially from SMEs, is that they’re still in Industry 3.0. What’s your take on that?

DL: These companies that are still in 3.0, the biggest challenge is the mind shift to do things in a new way – because people have been doing things for three decades [in another] way. They don’t even recognize the amount of time and energy that they’re spending chasing information until suddenly they’re not doing it.

Humans are averse to change generally. They get upset until the change is ingrained and then all of a sudden, they can’t even remember what it was like beforehand. From our standpoint, when we’re working with clients, the biggest thing is actually the change management in the habits that people have. The biggest thing is getting into the new habit of using the system versus going back to email and spreadsheets.

The bigger companies [are] the ones that typically have the budgets for the enterprise systems. But their challenge is that they don’t have visibility below, and into, the deep parts of the supply chain. Our target market is the two-thirds of the manufacturers on the planet that have no ERP systems at all, and are doing everything longhand. Our longer-term plan is to have the brands and the OEMs recognize the visibility that having these things mapped will give them, and the value that’s going to create for them.

MA: What is that value?

DL: It either allows you to scale, or it allows you to use your people in areas where they can add more value, which is what I think is the most important thing – for people to be able to reach their potential in life. The purpose is to create efficiency, but a second reason is risk mitigation. And the third is scalability. So, even if it doesn’t change your numbers of people, it means that you can grow without adding new people. And it also means that your information is going to be much better.

MA: You mentioned the ethical supply chain — what is that? How can unethical behaviour be mitigated by automation technology?

DL: The biggest challenge with ethics, and this is from a sustainability standpoint and from a human standpoint, is that to date, all of the companies have to audit themselves and report what they’re doing themselves, and it’s a massive amount of overhead. Plus, there’s a probability that people [don’t] necessarily tell the truth about what’s going on. What we’ll be able to do in the future is use the same processes that we use for reporting and managing quality to report and manage ethical manufacturing.

I envision a system that will be like ISO coming at some point in the next few years, but it’ll

be more to do with ethical and sustainable manufacturing, and there will be a governing body. We built this network where we have connected all of the different manufacturers…[and] the same system that we’re using to manage quality can be used to both manage and report ethical manufacturing.

Quite simply, if a factory gets caught, then everyone on the

system will know immediately. And that’s where the resilience and the ability to move factories and all of these other things becomes important, because it will then allow them to find other companies that haven’t gotten into this kind of challenge and very quickly move there. The companies that are acting ethically and sustainably will grow and get better, and

the ones that choose to be not transparent and to hide things and get caught – they’ll either choose to change, or the world will choose for them to not be around anymore.

Brands and OEMs only have seven per cent of their supply chain visible. That 93 per cent invisibility is allowing a lot of people to hide a lot of things. | MA This interview has been edited for length and clarity.

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at paul.hogendoorn@getfreepoint.com.

The manufacturing industry in North America has proven to be very robust, resilient and durable during the crisis. Even before the pandemic, there was a concerted effort by industry to secure their supply lines by reshoring to North America, and the motivation to do this has only intensified.

Through the aggregated productivity data that my company gathers for many companies across all the major industry sectors (automotive, heavy equipment, food and bev, wood products, steel and metal processors), I see that overall “value-adding activity” has, by and large, returned to preCOVID-19 levels.

Because the services my company provides are essential to these operations, I have had opportunities to visit some of these plants and gain key insights that offer an interesting narrative to support that data. Though not scientific or empirical, I’d like to offer three reasons for the resilience of our manufacturing sector – and why some have come through it stronger.

1. Demand for products. The demand for the products remains strong. North American manufacturers are primarily focused on “higher-value” products (as low-value products have mostly moved to low-cost regions of the world in previous decades). The products produced include cars, other transportation vehicles and components, appliances, building materials, food and beverages, medical devices and many more high-value items.

These companies sustain many decent, middle-class jobs, and the people they employ continue to have a secure, sustainable source of discretionary income. That discretionary income (from the still-healthy middle class at large) is no longer being spent on vacations, entertainment and services, but on homes, home improvements, cars, etc. – in other words, on high-value “durables.”

2. Employees are their customers. We, as consumers, buy what we make. Manufacturing produces more than simply the products that consumers purchase; it produces the jobs that

help create and sustain the economic wealth that supports a marketplace of consumers able (and willing) to purchase their product. (Case in point: car producers in North America are not laying off people, because people are continuing to buy their cars).

The rewards of their efforts are not just their paycheck, but the satisfaction of building, making, finishing, achieving something, every day. When there is no crisis or pandemic, they deliver. When there is a crisis, they rise to the occasion, adapt, invent and deliver even more.

When there is no crisis or pandemic, they deliver. When there is a crisis, they rise to the occasion, adapt, invent and deliver even more.

The goal of a sustainable manufacturing industry must include the people that build, and buy, the products produced. After visiting a range of factories the last few months, I remained convinced that the leaders and owners of these companies are committed to their people, community and our society. About 20 years ago, when I was the chair of the London Region Manufacturing Council, I recall hearing Ray Tanguay, then-president of Toyota North America, respond to a question about whether or not the value of the Canadian dollar would prevent them from opening their new Woodstock facility. His answer was simple: “We will build our cars (and trucks) where our customers are buying them.” Our factories create both the product and the market for the product, just as they did in Henry Ford’s day.

3. Great people. Certainly, we’ve heard about how special our front-line workers are (and they truly are), but our manufacturing people are pretty special, too. They are inventive, creative, dedicated, dependable and loyal. In short, they are hardworking folks that deliver tangible, tactile results that meet the objectives set every week, day and shift. Everyone involved depends on others to do their jobs too, every hour, every shift. No excuses.

On one recent plant visit, one worker shared with me that the world outside of the factory was pretty topsy-turvy. Life at home was different, he said; education was now at home, entertainment was curtailed, and social activity limited to “virtual” connection (which is not really social at all). But, at work in the factory, life was pretty close to feeling normal. PPE was already a part of most jobs and interaction with others was already structured and limited to breaks. By their nature, most of his coworkers appreciate having their personal space, he suggested, and didn’t mind having it delineated a bit more. Changes in the workplace are there for sure, but comparatively, the workday has been a welcome period of near-normalcy for many.

And lastly, I have to mention technology, and focus. Technology allows a lot of the administration and management to be done remotely, and most folks on the floor – those that add value to the product produced every shift and day – don’t mind that at all either. The companies that have come through this stronger have done so by sharpening their focus on their value-adding activities, getting more done in less time, and by unleashing the adaptive, dedicated and innovative potential of their people. | MA

BY ALENA BARRECA

is a marketing coordinator at Mentor

a business support organization specializing in Canadian government funding. To find out your business’s eligibility for grants and tax credits, visit mentorworks.ca.

Corporate leaders and human resource departments in the manufacturing industry across Canada face numerous time-sensitive and critical matters on a weekly basis.

One of the greatest challenges for many manufacturing businesses continues to be the need for qualified and educated team members working in the shops. Although leaders know the importance of hiring skilled personnel, the task of training new and existing staff can often take a backseat to seemingly more urgent matters.

Knowing the skills gap exists in many industries, the Government of Canada has implemented a training grant called the Canada Job Grant (CJG) that can provide manufacturing businesses with government grants and incentives for hiring and training new employees, such as apprentices and interns, and upskilling their current staff.

The CJG reduces the burden on cashflow while saving essential time and helps new and existing team members learn skills specific to the job while building upon the skills they already possess.

Ultimately, CJG training grants can help Canadian manufacturers improve the quality and quantity of work that their new and existing staff are able to perform by offsetting costs of up to $15,000 per trainee or current employee (in Ontario, as amounts vary by province).

1. What is the Canada Job Grant (CJG)?

The Canada Job Grant (CJG) is a federal funding program that helps employers reduce the costs associated with thirdparty employee training programs. The government grants offered for training do vary from province to province. The Canada-Ontario Job Grant (COJG), for example, offsets up to 50-83 per cent of businesses’ training costs to a maximum $10,000 to $15,000 per trainee.

For leaders and hiring departments in the manufacturing industry, CJG grants can vastly improve and save time on the onboarding and training aspects of a new hire by accessing third-party training programs that

teach job specific skills to qualified candidates that may need a refresher, or training to understand the processes of machinery or processes they’ve never worked with before.

less than 100 employees, an increased amount of up to 83 per cent of eligible training expenses are available to a maximum of $10,000 per trainee.

For small business employers hiring and training unemployed individuals, up to 100 per cent of eligible training costs are available to a maximum of $15,000 per trainee.

3. Who can apply for COJG grants?

To receive COJG grant funding, employers must maintain operations in Ontario, provide cash contributions to pay non-grant-covered training costs, abide by the Occupational Health and Safety Act and the Employment Standards Act, and have sufficient Workplace Safety and Insurance Board (WSIB) or private workplace safety insurance.

The Canada Job Grant (CJG) is a federal funding program that helps employers reduce the costs associated with third-party employee training programs.

Upskilling for existing staff is also a bonus, as many manufacturers may be introducing new systems over time and need to train their entire team at once. Without putting extra pressure asking a supervisor or shop foreman to train the team, a third-party training program can save critical time while teaching crucial skills.

In most provinces, manufacturers can receive up to 50 to 83 per cent of eligible manufacturing training costs to implement training programs that lead to employees’ improved skillsets.

This next section will further explore the Canada Job Grant as it pertains to its Ontario variant, the Canada-Ontario Job Grant (COJG). While the program is not unlike other provinces’, each variation supports unique eligibility criteria. Be sure to consult your province’s unique criteria prior to application.

2. How much funding is available?

For the Ontario variant of the Canada Job Grant, the amount of grant funding a manufacturing business can receive depends on the size of their business.

For a large business employer with over 100 employees, up to 50 per cent of eligible training expenses are available to a maximum of $10,000 per trainee.

For small business employers with

4. What types of training programs are eligible?

The Canada-Ontario Job Grant also maintains specific criteria to evaluate the eligibility of training programs. To access COJG grants, training must take place in Ontario, be led by a qualified third-party training provider, deliver training that directly relates to a business’ needs, and not exceed one year in duration.

A few examples of third-party training programs that may apply specifically to manufacturers may include new product installation and demonstration by the provider, skills training by an expert professional, health and safety protocol training, leadership management and/or customer service training, and other essential or developmental training programs offered to improve the ongoing processes of any type of manufacturing business in Ontario.

5. How to apply for CJG employee training grants

To receive CJG grant funding for an upcoming manufacturing training project, employers must submit a comprehensive application package consisting of a company overview, detailed training plans, and multiple vendor quotes. Typically, applications are reviewed within 2-4 weeks. | MA

Industrial automation experts share their predictions on what manufacturing technologies may impact your plant this year

COMPILED BY KRISTINA URQUHART

We all know COVID-19 changed the game. If your company was affected by production shutdowns, workforce reductions, cash flow challenges, increased safety measures, supply chain bottlenecking and any other problems that presented themselves during the pandemic, you already know how critical the next year will be for your company. Here are the top things to think about for your plant this year, submitted by our trusted experts. To look back on to pre-pandemic predictions, check out our digital archive at automationmag.com/digital.

Craig Resnick is vicepresident at ARC Advisory Group. He supports both automation supplier and financial clients. He has more than 30 years of hands-on experience in marketing, business development and strategic planning. Resnick graduated from Northeastern University with an MBA and BS in Electrical Engineering.

1. Technology convergence becomes technology fusion The convergence of information technology and operations technology (IT/OT convergence) is progressing rapidly as manufacturers realize it is key for successful digital transformation. Connectivity and/or convergence between OT and IT is essential for businesses to compete with the increasing demand for tighter integration and more information that leverages Industrial IoT, Industry 4.0, 5G, cloud, edge, additive manufacturing, advanced analytics, digital twin, AR/VR, AI, ML and other emerging technologies.

IT/OT convergence includes cybersecurity, which helps fill existing security gaps and ensures consistent security levels across the entire organization. Increasingly, convergence also includes the integration of power and automation, which involves converging information about electrical assets (such as in motor control centres) and the production process to help improve sustainability across the entire lifecycle of a manufacturing plant.

Convergence between power and automation also provides an integrated, digitalized

approach that increases interoperability and flexibility, reduces capex and opex expenditures, increases production efficiencies, decreases unscheduled downtime and improves overall profitability.

Rather than a trend, ARC believes that this convergence between IT and OT, IT cybersecurity and OT cybersecurity, and power and automation will become permanent, representing a true technology fusion. In 2021, look for the introduction of new solutions where these technologies will move beyond convergence and be fused into a single offering.

One of the objectives of a company’s digital transformation journey is to ensure resilient operations, improving a manufacturer’s capabilities against heightened business risks. These include increasing cybersecurity threats, new regulatory compliance mandates, and more strenuous plant and personnel safety requirements. Even before COVID-19, manufacturers faced numerous challenges such as market and commodity uncertainty, rapid fluctuations in demand, supply chain disruptions, and the need to become more agile, efficient and sustainable.

However, the current pandemic magnified those challenges, leading manufacturers to focus on operational resilience as a key corporate objective. Operational resilience means that companies are breaking physical and organizational boundaries to engage a real-time workforce, connecting teams and enhancing collaboration. It means supply

chains are being managed in real-time to maintain their integrity, agility and flexibility to respond to market demand and material availability shifts.

Operational resilience means that new methodologies are being deployed for companies to protect against unscheduled downtime and asset failures, ensure product fulfillment, protect personnel and enhance security architectures. In 2021, manufacturers will look to increase their operational resilience to reduce their supply chain vulnerability, lower safety risks, improve remote operational performance and optimize production throughout the plant lifecycle.

The COVID-19 pandemic has forced companies to shift to running their operations remotely, with many employees working from locations outside of the plant, such as their homes.

This requires a connected workforce with the right cyber-secure tools to provide real-time visibility and control and meet the challenges of fully remote access of operations.

Remote operations require appropriate enabling technology for a connected and remote workforce, facilitate collaboration and reduce paperwork, provide secured access to information from anyone, anywhere, and support interactions with remote experts.

This improves the efficiency of performing tasks and offers a safer working environment for employees. It also helps companies capture and manage knowledge, and incorporate and deploy new workflow processes.

Remote operation greatly benefits from

technologies such as augmented reality (AR), where the remote user can see any asset in the plant with information digitally overlaid. AR devices sense what the remote worker is looking at and displays the data needed for the operation at hand using tablets, smartphones, smart glasses or wearable computers. In 2021 (and beyond), manufacturers will continue practicing remote operations to a significant extent even after the effects of the COVID-19 pandemic have passed.

4. Automated operations become autonomous operations

Accelerated by the COVID-19 pandemic, industry urgently requires new modes of operation.

Thanks to advances in digitalization and new open process automation standards, IT/ OT convergence and digital transformation, manufacturers have an opportunity to move from “automated” to “autonomous” operations where appropriate. Not only do these advances present the opportunity to improve overall business value, they present an opportunity to further advance safe and flawless operations. The goal of moving from automation to autonomous operation is to improve the reliability and predictability of the operating plant.

Today, human operators decide what to do when something unpredictable happens. Tomorrow, the autonomous systems may be making those decisions, with the humans serving as observers and overseers. One concern often expressed is the aging workforce and how to pass on the knowledge gained over years of making decisions. This is often

based on intuition and experience. While these human characteristics can be hard to replicate in systems, when trained with appropriate historical data and combined with adequate real-time data, artificial intelligence (AI)–based applications can enhance the human’s understanding of what is normal and abnormal in plant operations.

In 2021, manufacturers will continue to make inroads toward moving operations from automated to autonomous.

Edge computing platforms and applications continue to grow rapidly, but these often require support from corporate IT personnel with specialized skills to install, program, operate and support them.

This has led to the development of edge automation platforms designed to provide the full capabilities and benefits of computing at the edge, such as gathering, analyzing, processing and storing data locally in real-time at or close to the point that the data is gathered.

The key difference is that personnel without specific IT skills will be able support these new edge automation platforms. Edge automation platforms are critically important because edge computing platforms used in industrial processing and manufacturing applications are typically under the jurisdiction of the OT group, the same people who install, program, operate and service automation equipment, such as PLCs, PACs, DCS, sensors and other instrumentation. This creates tremendous savings in time and personnel costs.

Furthermore, the edge automation platform is designed to run continuously without the need for specialized onsite or remote IT support. Look for new edge automation platforms to be introduced in 2021.

Jim Beretta, president of Customer Attraction Industrial Marketing based in London, Ont., works with advanced manufacturing, robotics and automation companies. He is also the host of The Robot Industry Podcast in partnership with the Robotic Industries Association/A3.

1. The innovation decade

Expect to see more money being poured into industrial automation, robotics, software and accessories with the expectation that innovation will come out the other side. Robot companies are releasing new models of robots, and end-of-arm accessories are becoming innovative, especially in supply chain: point, click and ship.

Young engineers from the University of Waterloo and similar institutions are creating innovative technologies that solve unique, niche problems and they are doing it at the speed of Amazon. Universities, government and even cities are prepared to create environments where these start-up companies can thrive. Individual companies such as Linamar and Mazak locally are investing in innovation spaces, labs and even entire buildings, understanding that innovation comes at a cost and focused innovation efforts pay off for stakeholders, shareholders and customers.

The robot and automation industry is fairly conservative when it comes to innovation. Baby steps are more common than large leaps. This is understandable as engineers, factories and buyers of automation are loath to take risks that may end careers or, worse, get a poorly working machine named after you. Take collaborative robots, for example. One of the largest cobot manufacturers in the world just announced that they have sold their 50,000th robot. From nothing to 50,000 units is quite an accomplishment, but it is tiny compared to the total install base of three million robots. The thing that we often miss in talking about cobots by themselves is the value of collaboration.

2. The collaboration of safety

One of the interesting trends for 2021 is a new focus on industrial safety. Everything has to have safety baked-in whether it is wireless, wired, safe PLCs or autonomous technology. Where we really see safety shine though is

in the design and implementation of collaborative tech: robotics, autonomous material handling bots, such as a new breed of forklifts and autonomous mobile robots (AMRs). Now automation is just working better with people.

Elon Musk redesigned one of his Tesla factories when he came to the realization that over-automation – too many robots – just doesn’t work. People are good at thinking, problem solving and anticipation. I predict that going forward, we will see a renewed interest to make anything that moves in a factory (think smart conveyors) have safety, plug and play, and collaboration with humans as part of their industrial design. We are now witnessing companies producing bolton technologies to make all robot applications collaborative, aware and smart.

3. The appification of automation

Industrial automation is hard. Robot programming is extremely difficult. There are fewer and fewer engineers, and fewer robot programmers in factories. We are seeing many different languages and cultures on our factory floors. Connecting and monitoring automation over your cell phone is expected, not just a nice-to-have.

One robot company changed the industry rules when it created its “app store” and later “application kits,” just like Apple’s App Store. You can now buy a cobot with an approved and proven end-of-arm tool and software algorithms pre-built –and get it installed and up and working in just hours, allowing you to make money or save money, depending how you look at it. This company offers an easy programming interface and online community of support, just a click away.

The algorithm “set” here is key. Imagine you want to sand wooden furniture using a cobot. Just buy the application kit; it has the sanding patterns included. You just saved weeks in programming and debug. This is our new normal, at the speed of Amazon and as easy to use as your smartphone.

4. The KISS principle

There are a growing number of companies that want to make factories run better and “keep it simple.” These are well-funded companies, often start-ups, that are accustomed to breaking a lot of rules. They envision simpler operator interfaces, better reporting, increased uptime, mistake proofing, easier decision-making and even programming all robots in a facility with a common language, which is a huge cost and barrier in industrial automation.

Software toolkits are getting better and companies that can offer big data solutions to reduce or eliminate unplanned downtime and control spares will just win more work.

We are seeing companies disrupting the supply chain by supplying DIY knock-down machine bases or complete conveyor systems. Or even robots delivered in a few days’ or weeks’ time instead of 14 weeks, because they have a better configurator. Other companies get creative by offering services on a monthly basis: robotsas-a-service. For 2021, think automation-as-aservice or machine-vision- or AI-as-a-service.

5. Improving training and knowledge bases

I am suggesting that in 2021, employers will invest in training and knowledge. Our skilled labour shortage is well upon us. For manufacturers, investing in automation is an easy way to attract and retain talent. After all, who wants to load and unload a machine tool all day long, when one can literally learn to program a robot instead? Manufacturing has changed, with high-mix, low-volume manufacturing being very common, especially here in Canada. Poka-yoke systems complete with smart screens and dynamic rich content are now affordable and increase manufacturing quality overnight, reducing returns and errors. Bite-sized, daily employee education delivered on cell phones using gamification increases product quality, product safety and engagement, affecting the entire workforce.

There are still challenges ahead. Manufacturers will need to spend more on software going forward. Whether it is artificial intelligence, Internet of Things, Industry 4.0 integration or protecting networks against outside threats, amping up capex and IT budgets with increased monthly investments will be a reality for the next few years, maybe forever. Investing in STEM, in students and in apprentice or mentorship programs is probably more important now than it has ever been. Fighting for talent is costly, so growing your own talent is much better.

Don Matthew, CPA, CA, is the national sector leader for KPMG in Canada’s industrial manufacturing group. He is a member of the board of directors and chair of the finance, audit and risk management committee of Canadian Manufacturers & Exporters. François Gaudreau is a partner in KPMG’s advisory practice, leading the Canadian Intelligent Business Process Automation practice.

1. Shifting to functional-based business process automation

While not a new trend, business process automation continues to evolve. The COVID-19

pandemic ramped up the automation of monotonous manual processes and tasks.

For too long, organizations focused on creating digital versions of legacy analog systems in their middle and back offices, instead of reimagining how digital technologies can improve the entire enterprise value chain from decision-making to the way people work and connect with customers or suppliers. The pandemic has made companies realize that they could embrace digitization technologies.

Recent Forrester research commissioned by KPMG International finds that two in five Canadian companies will start automating all or part of their operations moving forward. Also, they will continue to automate all or part of their inventory management and distribution process (48 per cent), followed by IT processes and procurement (32 per cent) and supply chain (27 per cent).

The focus is shifting from task-based automation to functional-based business process automation across multiple tasks and areas.

The shift to Industry 4.0 solutions – which includes connectivity, advanced analytics, intelligent business process automation and advanced manufacturing technologies –started before and gained momentum during the COVID-19 pandemic and will accelerate rapidly post-pandemic, as companies look to build resilience and radically improve operations, production efficiency, speed to market, customer service and end-to-end supply chain transparency.

Intelligent business process automation – that is, the integration of robotic process automation (RPA), low-code/no-code tools, intelligent document processing, integration platforms (iPaaS), machine learning, natural language processing and decision management systems – has the power to increase speed, scale, quality and precision of business process execution exponentially while also complementing and augmenting human skills. Companies that can power up scalable and agile intelligent business process automation efforts become long-term winners.

But piecemeal efforts that focus mainly on cutting the cost of legacy processes and reducing headcount – with, for example, siloed efforts to automate payroll, invoice processing and customer service enquiries – will not move the needle in a post-pandemic world.

Over three-quarters (76 per cent) of Canadian CEOs surveyed in KPMG International’s special COVID-19 Global CEO Outlook report acknowledged that investing in technologies, such as AI and automation, is critical to achieve long-term sustainable

growth. Over four in five are now prioritizing their technology spend.

3. Ramping up cloud networks

According to KPMG International’s Enterprise reboot research, 61 per cent of Canadian companies expect cloud to be their predominant app, data and computing infrastructure within the next five years. With remote work having become the norm and a hybrid model likely to be adopted post-pandemic, cloud computing provides more flexibility to deal with future uncertainties. It has become a business imperative. We anticipate companies will build out cloud-enabled capabilities, including AI, software and data analytics. Increasingly, companies are using machine learning to make robots teach themselves how to perform tasks better and that knowledge can eventually be shared via the cloud, allowing robots to learn from one another to improve speed and efficiency and reduce waste.

4. Building cyber resiliency

Cybersecurity has never been more critical. With the growing use of networked sensors and intelligent devices, cyber resiliency is a concept whose time has come.

It includes information security, IT infrastructure, business policies, processes and governance practices and business continuity. There’s a growing realization among companies that they’re sitting on a treasure trove of information that if better organized and made more efficiently accessible can create value.

However, cybercriminals are also looking for ways to access that same information. The pandemic fast-tracked the need to digitally transform security and widen the security perimeter to encompass remote workers. The shift to the automation of security functions from identity authentication to threat detection and response has accelerated.

Companies are looking to automate first and second lines of defence via the cloud to better respond to enterprise-wide threats, while simultaneously confirming that security controls are operating as expected.

5. Increasing process analytics

Process and task mining helps organizations discover and visualize all business processes across the enterprise, and analyze operative process data created by IT systems, providing greater business process transparency and optimization.

Leveraging purpose-built analytics tools, users can analyze vast amounts of data in real-time, contributing to an end-to-end operational intelligence platform. One of the biggest challenges of business process analysis is understanding how the process is currently performed.

Process experts often design processes expecting that their execution will be faithful to the design. However, designs tend to be incomplete and not executable in practice, and people tend to overlook or bypass designed processes and work in silos.

These challenges are more prevalent than ever due to digital transformation programs, adoption of global business services, and the introduction of bots and other AI into the business processes. Process and task mining offer a set of novel tools and techniques for the factual analysis of business processes. Based on system logs and/or screen recordings, they automatically map and visualize how processes have been executed in reality, and help companies to remove all assumptions and guesswork from processes. | MA

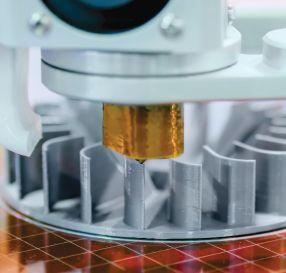

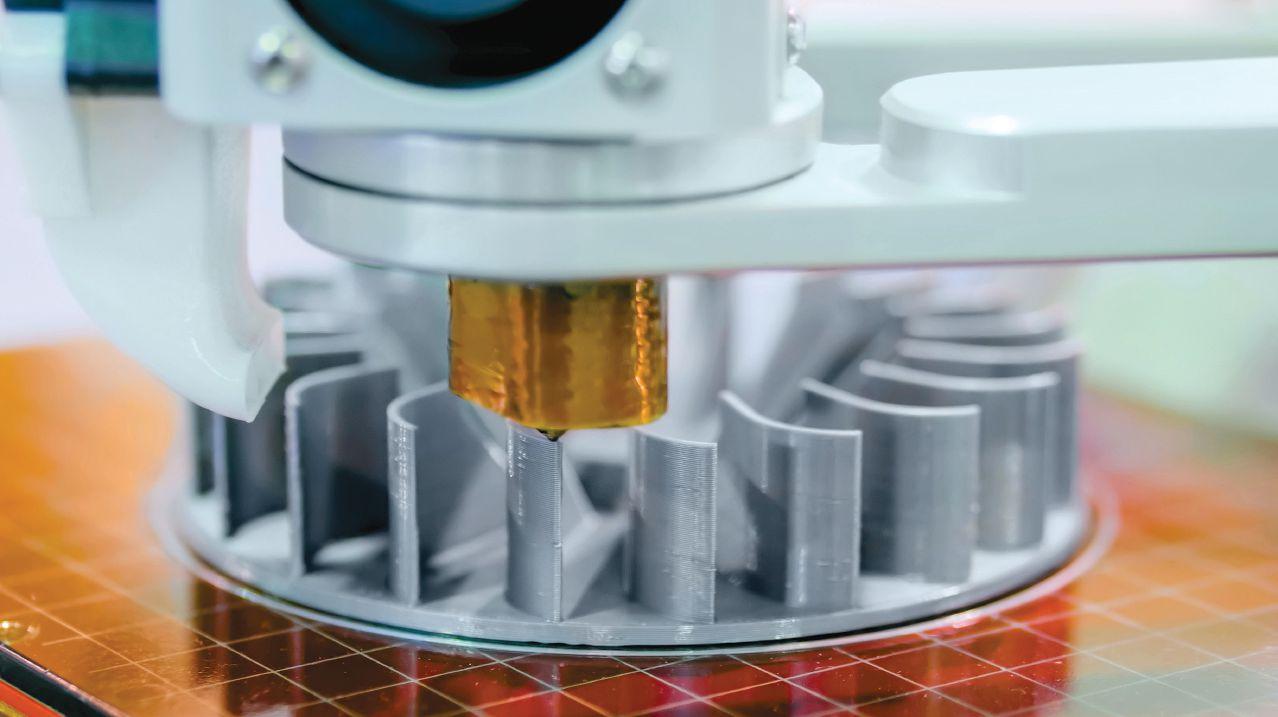

The rapid

evolution of

3D

printing

technology for both plastics and metals is creating new opportunities, however finding solid business cases remains a challenge

BY JACOB STOLLER

Thanks to the wide proliferation of consumer-grade 3D printers, the apparent ease of printing a finished product directly from a digital model with no moulds or tooling, has caused many to underestimate the challenges of applying the technology in production environments. This is particularly problematic in AM (additive metal) manufacturing, where the barrier to entry is much higher than it is for plastics.

“Additive is a unique process, and I think it’s probably one of the most over-hyped technologies in the world,” says Peter Adams, president and CEO at additive manufacturer Burloak Technologies, “and I truly believe that this is creating a major misunderstanding of the technology. And that is causing a lot of people to invest money that they never would have to put at risk if they asked the right questions.”

Understanding capabilities

The most common misconception is that 3D printing is a viable cost-cutting replacement

for machining and other traditional methods.

“If you say, ‘let’s go and print this and see if we can get it cheaper than we can with a CNC machine,’ then you’re on the wrong path,” says Adams, noting that his company frequently advises prospective clients to continue making parts the same way they’ve been making them.

“3D printing is slow,” says Gilles Desharnais, CEO of Montreal-based additive manufacturer Axis Prototypes. “You’re building 20-micron layers or 40-micron layers at a time. Your machine might cost a quarter of a million dollars, and the material cost is ten times higher than feedstock you normally use for machining. So when somebody comes up to you and says, ‘I machined this today, and I want to 3D print it,’ the probability that the business case will fly is maybe 0.1 per cent.”

That said, 3D printing is a game-changing tool, and additive manufacturers like Burloak and Axis are making important inroads in the marketplace. The key is identifying areas where the advantages of additive over other methods create opportunities to produce a unique

product or part that solves a particular problem.

“You really have to look for opportunities where you’re taking advantage of the design liberties that 3D printing gives you,” says Desharnais, “and this is where design for additive manufacturing (DfAM) comes in. So a lot of people have to look at ‘what does the capability of additive give me?’ And that applies to plastics as well as metal.”

An important example is parts consolidation, where additive’s unique ability to fabricate complex shapes and geometries allows manufacturers to create assemblies with fewer components. Another is the ability to produce more efficient designs that improve performance or reduce weight.

“I think aerospace and space in particular are obvious sweet spots,” says Adams. “You’ve got a high-complexity, highly engineered product, and you’ve got opportunities for mass reduction. Parts consolidation takes away risk and solves problems.”

A classic example is a fuel nozzle assembly developed by GE Aviation, which is now widely installed on its LEAP aircraft engine. This reduced the parts count from 20 to one, and it is lighter and five times more durable. Fewer parts and higher durability reduce maintenance costs and improve safety, and lighter weight improves the efficiency of the aircraft. These advantages justify the much higher costs of additive fabrication.

Additive is also being used to help improve the efficiency of machining operations by creating better tooling. Drill bits with cooling channels, for example, allow operators to reduce the cooling time in drilling operations.

The apparent ease of printing a finished product directly from a digital model with no moulds or tooling has caused many to underestimate the challenges and the costs.

Many of the best-known additive solutions involve medical implants and prosthetics, which must not only match the contours of an individual human body, but may be required to have complex surface textures. A unique example is an improved spinal implant using lattice construction, which allows tissue to grow into it.

“Printing is probably the only way to create a true 3D lattice,” says Mark Kirby, industry training manager at the Multi-Scale Additive Manufacturing Lab at University of Waterloo, “and the spinal cage that has a true 3D lattice throughout it is now considered the gold standard for spinal cages.”

As the technology improves, Kirby predicts we may soon see a day when individual hospitals can produce implants such as hip replacements on demand using 3D printing. “If I print on demand, I don’t have to have 100,000 hip replacements in a warehouse, and I don’t have to ship them around the world,” he says.

High-volume capability is also beginning to enter the picture. Last summer, Winnipeg-based manufacturer Precision ADM used 3D printing to mass-produce three million plastic nasopharyngeal swab sticks for COVID-19 testing, the largest production run for 3D printing in history. The key business advantage was time – gaining approval requires many iterations with regulators such as Health Canada, a stage that would have taken many months if injection mould tooling had to be created each time.

While saving lives was the overriding requirement, Kirby points out, the project also shows that 3D printing can be economical at high volumes. “On a unit cost, the injection-moulded parts would be cheaper,” says Kirby, “but if you look at the lifecycle cost with the tooling in there and factoring in the delay time, 3D printing makes economic sense.”

The number of opportunities to apply 3D printing is growing exponentially as the technology improves. As Desharnais points out, there were only six materials for printing plastics in 2009, and today, there are hundreds if not thousands. We’re seeing additives like carbon fibre, fibreglass, wood fibre and graphene (used to make conductive plastics).

The low cost of plastic printers is also creating opportunities. Sienci Labs, a Waterloo-based startup that manufactures CNC equipment for woodworking, found that plastic parts could be economically fabricated by a farm of $300 consumer-grade printers. Sienci is also implementing low-cost equipment for automatically unloading the printers, reducing the labour component.

“If you’re a start-up like us, it’s much cheaper to build a 3D printer farm than to pay for all the moulds and then do all the engineering,” says Andy Lee, Sienci’s CEO, “because we have no idea how many parts we’re going to need, or if there are going to be any changes made in between. We’re also in kind of a sweet spot because we order all the filament material in

Use the configurable control system PNOZmulti 2 to implement multiple safety functions on your machinery.

Don’t miss our “ready-to-use kit”, which includes:

✓ Base Unit mB0

✓ Set Screw terminals

✓ Chipcard 32kb ✓ USB Cable ✓ Basic License for PNOZmulti Configurator Contact us for more information: +1 905 821-7459 - info@pilz.ca BONUS: FREE Assembly and configuration training!

bulk.” Once volumes increase and the product reaches maturity, he says, the company will likely switch over to injection moulding.

The plethora of options makes it almost certain that the technology will alter the competitive landscape in many, if not all, areas of manufacturing. To capitalize on opportunities, manufacturers will not only have to experiment with the technology, but look carefully at their designs and processes to see where traditional methods might be holding them back.

“People forget that additive is a tool,” says Frank DeFalco, director of member relations for the supercluster Next Generation Manufacturing Canada, “so it’s going to fit into a solution. Very, very rarely will it be a standalone solution. So, it’s all about a journey of understanding the redesigning of a solution.”

Part of this is understanding how additive machines behave, which is often different from what appears onscreen. “The best way to learn the language is to buy, maybe, a $2,000 printer and start to experiment,” says Kirby. “That way, you’ll be part of the business conversation.”

There is no textbook for applying 3D printing, and the key is starting the learning process. “I think if you have no 3D printing capability at all,” says Kirby, “you’re going to limit the kind of conversations and the kind of business interactions that you’re likely to have going forward.” | MA

The Canadian Association of Moldmakers (CAMM) and Automate Canada have developed a strategy aimed at increasing conversation on “Made in Canada” manufacturing processes for SMEs.

The report, compiled from the results of industry focus groups, provides a list of recommendations and observations from the SME segment of Canada’s advanced manufacturing sector, which the associations say have so far been largely excluded from policymaking conversations.

“This is a broader examination of the state of advanced manufacturing in Canada with a focus on small- and medium-sized manufacturing facilities, which are the heart of many towns and mid-sized communities across Canada,” says Jonathon Azzopardi, CAMM chair, about the Advanced Manufacturing is “Made in Canada”: An SME Perspective report. “The impact of COVID-19 has only further amplified the need for action now.”

The document highlights that past studies in the industrial automation and moldmaking sectors focus heavily on the capabilities of larger firms while SMEs have been overlooked. The associations cite a 2017 McKinsey report that says a lack of support has led U.S.-based small and mid-size firms to not be able to keep up with the gains of large companies, rendering them unable to invest in new equipment and technologies.

“MGI concluded that this was a concerning trend that impacts large firms because they face more risk without a healthy ecosystem of domestic suppliers to provide

more agility and opportunities for collaboration,” says the CAMM and Automate Canada report. “This prescient conclusion is being played out in Canada.”

The associations identify objectives for industry and suggest how other institutions and government can support a strong, sustainable domestic manufacturing sector in Canada under the following three topic umbrellas.

Skills and talent development

The associations stress the need for a skilled talent pipeline, which can be achieved by more apprentices, improved access for underrepresented or disadvantaged workers, and streamlining the process for temporary foreign workers.

Among the action items:

• Encourage students, parents, teachers and counsellors to visit facilities for tours.

• Rally companies to participate in Manufacturing Day, held annually on the first Friday in October.

• Push to integrate First Robotics into school curriculums and support First Robotics teams.

• Re-assess how labour costs are measured, encouraging a more holistic approach that considers logistics, risk, demand, proximity to other suppliers, etc.

• Increase diversity and inclusion through strategic plans, participation in Girls Day, and working with organizations like Build a Dream.

• Improve access to NGen’s AmpUp (Accelerating Manufacturing Performance Upskilling Program).

SMEs need support with the transition to Industry 4.0 and implementing digital transformation plans, says the report. Incentives to “buy Canadian” or develop new products and patents will help to close the productivity gap between Canada and the U.S.

Among the action items:

• Increase use of robotics and cobots.

• Ensure that existing programs and services are well used and well known.

• Push for government to back a technology adoption centre that works to lower the perceived risk of tech adoption.

• Suggest companies implement innovation catalyst programs and mentorship programs, and/or appoint a chief innovation officer.

• Support “Buy Canadian” at all government levels and encourage large firms to reconsider their purchasing structure to include local suppliers through incentives.

• Continue local investment through support of community initiatives and venture funds.

The report says that promoting Canada’s advanced manufacturing sector as a source of quality products and innovation is key to strengthening the industry.

Among the action items:

• Develop a coordinated marketing strategy for CAMM, Automate Canada and members to push the “Made in Canada” message.

• Use messaging and social media to appeal to the new generation of workers.

• Connect companies through strategic alliances.

• Ensure regions across Canada have a seat at the table – not just companies in the GTA, Kitchener-Waterloo and Ottawa regions – by nominating members for inclusion at policymaking discussions.

“The time is now to not only talk about our value but to show our strength in a collaborative approach,” says Shelley Fellows, Automate Canada board chair.

The moldmaking and industrial automation sectors employ 58,000 skilled workers and contribute $7.2 billion to Canada’s GDP. The strategy was developed with assistance from the Windsor Essex Economic Development Corporation, Institute of Border Logistics and Security, Trillium Network for Advanced Manufacturing, and CAMM and Automate Canada member companies. | MA

BY KRISTINA URQUHART

Pl ant technicians and engineers may deeply understand their machines, but they can’t monitor their performance 24/7. That’s why we’ve had sensor technology in place for decades, says Sebastian Christian, director of AI engineering for ADI Otosense, a platform that analyzes sensing data.

Christian was on hand at the recent CES trade show, hosted online by the Consumer Technology Association, from Jan. 11 to 15, to discuss intelligent sensing and how it can be used to further a machine’s capabilities – and augment human workers.

Smart sensors are not your average switching-signal sensors: they’re IoT components that can generate and process data in real-time, 24/7. They measure temperature, proximity, pressure, weight, flow, etc., and turn the data they collect into a stream of information that can be read by an edge device that’s local to the machine.

The sensors are equipped with microprocessors, connectivity and often other diagnostics tools that, via near-field communication, Bluetooth, Wi-Fi or other transmission networks, feed the data back to operators at the plant level, or up to the cloud for further computation and analysis. (There are some direct sensor-to-cloud solutions emerging on the market, but it’s more uncommon due to the storage required).

Processing sensor data at the edge is ideal because it offers scalability, Christian said. “As long as you only send insights, then you become way more scalable,” he said. “A thousand edge devices are not 1,000 times the bandwidth, like with cloud computing.”

Using smart sensors and edge gateways in tandem also offer safety and security. “The more you keep data locally, the less risk you’re taking of it being tampered with, modified, corrupted – or worse, hacked or breached.”

Ultimately, using smart sensors over time leads to additional benefits, like increasing operational efficiency across production processes, inventory and product lifecycle management, and reducing maintenance costs.

The safety laser scanner

PSENscan from Pilz can be mounted on an automated guided vehicle (AGV) to ensure safety in production or logistics. The safety laser scanner uses simultaneous localization and mapping to plot the environment, then sends the signal to the AGV so it avoids obstacles.

PSENscan meets the

industrial requirements of the ROS Industrial Consortium, and the ROS packages can be installed directly from the Open Source Framework, which simplifies integration.

ABB has developed a new line of its smart sensors to monitor motors in hazardous areas, like in chemical processing. The wireless smart sensor monitors key parameters to provide detailed analytics into the performance and health of assets to help maintenance teams predict failure. The sensor is sealed, with an IP66/67 rating and extra-long battery life, and can be mounted directly to the equipment. The sensor communicates with smartphones, tablets, PCs and plant gateways using low-energy Bluetooth or WirelessHART over distances of up to a few hundred metres. These sensors are sensitive to small changes in the condition of the equipment and provide advanced warning of bearing damage.

Ideal for general factory automation, packaging and food and beverage applications, Balluff’s new set of multi-function photoelectric sensors use IO-Link for connectivity and transmission of diagnostics. Three optical operations are available – a diffuse sensor (featuring a onemetre detection range), a retroflective sensor (eight metres) and a through-beam emitter and receiver (up to 20 metres). Each is rated IP67 and IP69K and is also Ecolab approved for its metal housing, sealing and plastic lens.

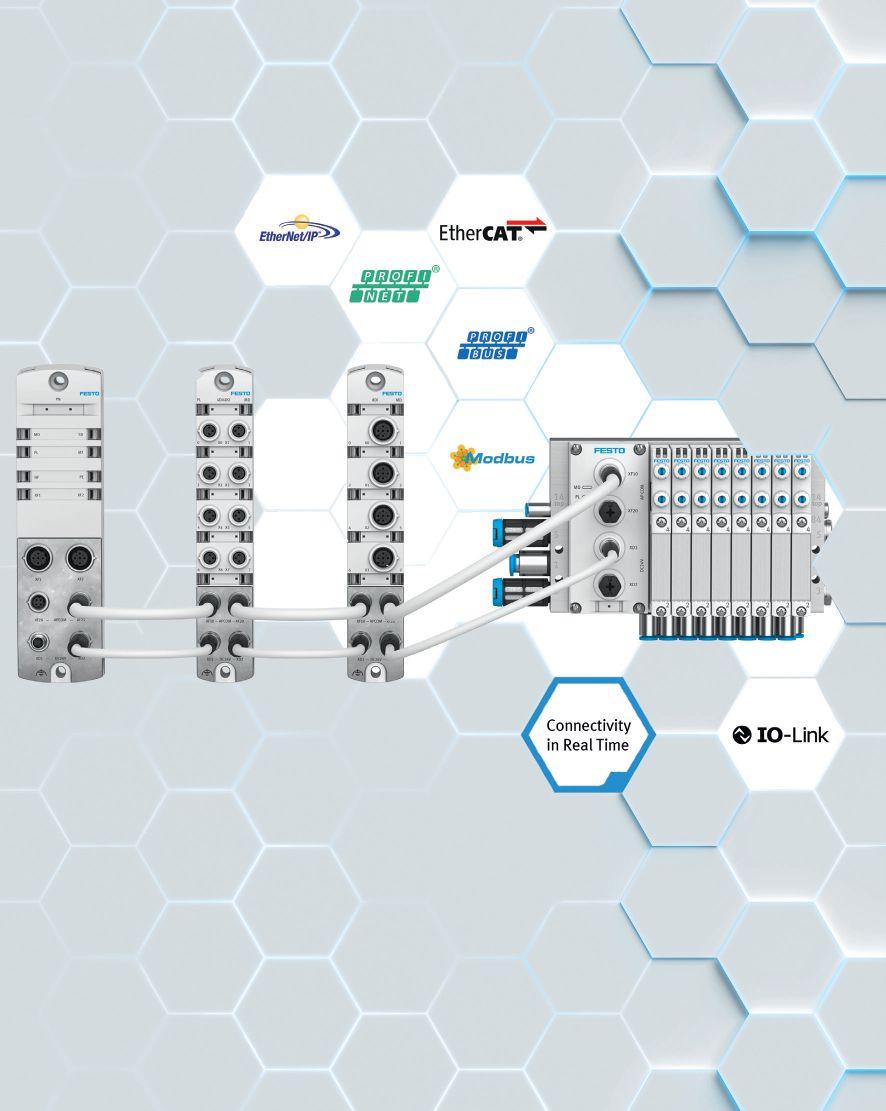

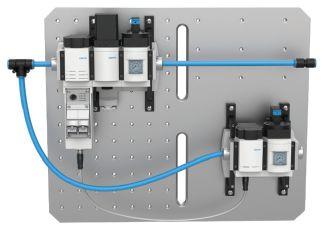

Festo’s intelligent pneumatic energy savings platform now includes two modules, MSE6-C2M and MSE6D2M, that combine sensors with proportional pressure regulator, on/off valve and fieldbus communication. The C2M combination monitors the flow rate and, when production is not taking place, it automatically shuts off after a defined idle time. The module simultaneously prevents the system pressure from falling below a defined standby pressure level, which saves energy. The D2M intelligent module monitors the compressed air supply and automatically shuts off the compressed air during breaks in production. Unlike the C2M, the D2M completely depressurizes the system. The D2M also provides leakage detection and process data acquisition for condition monitoring.The C2M can be fully integrated into the machine network via PROFINET and also through the Festo CPX platform, which is compatible, as is the E2M, with major fieldbus protocols, including Ethernet/IP and EtherCAT. This allows operators to access data on flow rate, air consumption and pressure.

Red Lion has introduced NT4008, a new eight-port Gigabit–managed industrial Ethernet switch series. The NT4008 series switches are certified to meet PROFINET PNIO v2.34 Conformance Class-B standards to ensure integration into PROFINET networks using standard PLC configuration and management tools. Red Lion’s NT4008 are UL Class 1, Division 2 and ATEX listed for use in hazardous and ordinary locations. The IP-30 metal DINRail enclosures, redundant 12–58 VDC power inputs, -40 to 75°C operating temperature ranges and up to 50G shock resistance can handle extreme industrial conditions. Copper and fibre options are available in both Fast Ethernet and Gigabit configurations, as well as advanced security and traffic control. redlion.net

Linear motor series with

Beckhoff has added the AL8000 series, a new generation of modular linear motors developed in cooperation with Fertig Motors, a Beckhoff subsidiary. The new AL8000 product family is based on a modular system design consisting of linear motors and magnetic plates. Users can choose between three widths: 50 mm (AL8x2x), 80 mm (AL8x4x) and 130 mm (AL8x6x). Each width category offers different linear motor types in terms of overall length, type of winding and cooling type. The standard product portfolio contains a total of 28 different linear motor types to suit