Colin Breukelman reflected on his decision, saying,

‘The

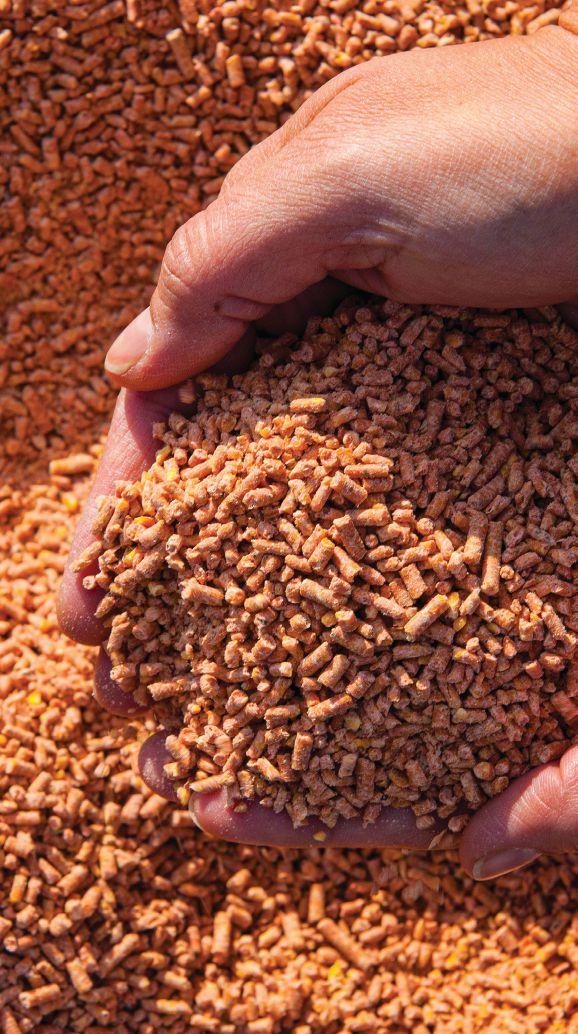

Ingredient selection for broiler feed

Good-quality feed begins with good-quality ingredients.

Injection of optimism

France becomes the first Western nation to vaccinate against avian influenza.

2024 Poultry Sector Outlook

Strong demand supports profitability, analysis finds.

by Brett Ruffell

When it comes to the biggest poultry story of 2023, history has, sadly, repeated itself.

For our year in review podcast series, I interviewed leaders from all four sectors. Most agreed that the biggest issue over the past 12 months was, once again, avian influenza. Up until this fall, the situation looked to be improving. Quebec suffered an unprecedented winter outbreak, but overall things looked brighter on the avian influenza front.

But then fall came and Western Canada, particularly B.C., got hit hard. As of mid-December, the province had more than 50 premises infected since the fall outbreak started.

“It’s tough on the farmer, emotionally, mentally, physically and just draining financially,” says Phil Boyd, executive director of Turkey Farmers of Canada, adding that one positive is the number of turkeys euthanized because of the disease was significantly lower in 2023.

It’s, likewise, been difficult for the hatching egg sector. “We’re still struggling with how it’s getting into our producers’ barns,” says Brian Bilkes, chair of Canadian Hatching Egg Producers. On that note, he says he hopes to eventually learn more from work the Canadian Food Inspection Agency is conducting.

Avian influenza outbreaks have had a downstream ripple

effect on the poultry supply chain. The disease has also caused uncertainty around trade for the chicken sector, which had anticipated Chile would begin taking advantage of the increased access it was granted to Canada’s market under the CPTPP agreement.

But then the South American country got hit with an avian influenza outbreak of its own, delaying its expansion into our chicken market. “That was a bit of a challenge for the board of directors when it came to setting allocations,” says Tim Klompmaker, chair of Chicken Farmers of Canada.

“It’s tough on the farmer, emotionally, mentally, physically and just draining financially.”

One positive development around trade in 2023 that has the potential to provide the poultry industry with more stability is the advancement of Bill C-282.

The legislation prevents Canadian negotiators from surrendering more access to supply managed markets in international trade discussions.

It was passed by the House of Commons in June and advanced to the senate. It now needs to go to a senate committee for further discussion, after which it would be reintroduced. If passed it can receive royal assent and become

the law of the land.

Drew Black, CEO of Egg Farmers of Canada, says when talking to policymakers in person, most pledge their support for supply management. But then when negotiators are back at the bargaining table, they end up giving away more access to supply managed markets.

“So, this is a way to really enshrine that commitment into a piece of legislation,” Black says.

And new research shows this impassioned effort to safeguard supply managed sectors is in line with the views of Canadians.

A recent survey conducted by Abacus Data delved into Canadians’ perspectives on the food system and the value they place on supply management. According to the findings, nine in 10 Canadians say it’s important to them that the dairy, eggs, chicken and turkey they buy come from Canada.

The Abacus survey highlights that 94 per cent of Canadians consider it a ‘good thing’ when they hear that local dairy, poultry and egg products are produced with high standards of food safety and animal care under supply management.

Furthermore, 92 per cent of Canadians express confidence in the food safety and animal welfare of dairy, chicken, turkey, and eggs produced at home because of supply management.

The survey was conducted online with a sample size of 2,000 adult Canadians from November 9 to 12, 2023.

To hear my full discussions with these poultry leaders, please visit canadianpoultrymag. com/podcasts.

Happy New Year!

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada – 1

$105.57 CDN GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

From the first day your chicks and poults are placed, water is one of the first things they look for, and for decades farmers and poultry have relied on our drinkers for a consistent flow of fresh water.

Our drinkers provide poultry the single most important ingredient for the BEST POSSIBLE START, AND HEALTHIEST LIFE DURING LAY PERIOD AND GROW-OUT.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc. Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

More than 50 poultry farms in British Columbia have been infected with avian flu since October, but animal health officials say that rate is slowing as the fall migration of wild birds ends. The Canadian Food Inspection Agency said in mid-December 47 commercial farms and five small flocks have been infected with the highly pathogenic H5N1 virus this fall. B.C.’s Agriculture Ministry said in a news release that it is working with the agency and B.C.’s poultry producers to ensure enhanced biosecurity measures are in place to limit the spread of disease.

Only time will tell if a case of avian influenza detected in Manitoba was an isolated incident or if it’s the “tip of the iceberg,” Manitoba Chicken Producers says. On November 8, a case of highly pathogenic avian influenza was confirmed by the Canadian Food Inspection Agency on a commercial poultry operation in the Rural Municipality of Rhineland, located 241 kilometres southeast of Brandon. This marked the first domestic case Manitoba in about a year.

The RCMP is scrutinizing a break and enter at a poultry wholesale facility in Steam Mill, N.S., which left thousands of chickens dead. At midday on November 22nd, 2023, RCMP received word of a break and enter and mischief in Steam Mill, N.S. Police later determined that thousands of chickens had died because of the incident, resulting in an estimated loss of $160,000. An RCMP spokesperson could not answer questions about how the break and enter led to the deaths of the chickens because the situation is still under investigation.

CFO’s Murray Opsteen with Lisa Thompson, Ontario’s agriculture minister.

The Ontario government has recognized Chicken Farmers of Canada (CFO)’s food donation program with an award.

8M

is how many chicken meals producers have contributed since 2015 under the CFO Cares: Farmers to Food Banks program.

The CFO Cares: Farmers to Food Banks program has been bestowed the 2023 Excellence in Agriculture’s Supply Chain Excellence Award for its efforts to provide stability to Ontario’s agri-food supply chain and support Ontario’s food banks.

Through the initiative, CFO works to ensure that farmers are empowered to donate chicken from their individual farm businesses on an annual basis.

“The Ontario agriculture and food sector continues to demonstrate a spirit of resilience and innovation, and CFO and Ontario’s chicken farmers have worked diligently to address supply chain challenges and ensure Ontario families and food banks have reliable access to safe, healthy,

locally grown chicken,” says CFO chair Murray Opsteen.

CFO Cares: Farmers to Food Banks Program enables a steady supply of chicken to Ontario food banks and families.

Over 500,000 Ontarians rely on food banks annually, and that number is increasing.

Each year, CFO farmers aim to provide one million meals – a goal they have reached annually despite challenges. Since 2015, donations have contributed to over eight million chicken meals.

“The CFO Cares: Farmers to Food Banks program is only made possible by support from Ontario’s chicken farmers who individually donate 700 kg of chicken each year to food banks across Ontario, providing a steady supply of safe, high quality, locally grown chicken,” says Andrea Veldhuizen, CFO board director for CFO Cares & District 4.

Think Turkey announced the first-ever recipients of the 2023 Wishbone Awards this week. Launched in response to rising food insecurity in Canada, the awards program recognizes and supports people who help put holiday meals on the table for those in need.

Nominations were open nationally from November 2 to 15, 2023, inviting Canadians to share the story of someone from their community who helps fight food insecurity. Eight recipients have been selected and will be recognized with a Wishbone Award and a $2,500 grant to help fund their 2023 holiday community efforts.

“From hand-delivering hundreds of turkeys to dedicating their holidays to hosting a community dinner, these eight selfless heroes go above and beyond each year to spread holiday cheer in their communities,” said Darren Ference, Chair, Turkey Farmers of Canada.

“We were incredibly moved by the Wishbone Award recipients’ stories and are honoured to contribute to their holiday initiatives at a time when Canadians need it most.”

Among the first honourees are Mike and Deanna Diab, founders of Talking Over Turkey, which has donated thousands of turkey dinners within the Windsor-Essex community, and Raymond Carignan, president of the Fondation d’Entraide de Brossard, Quebec, who works during the holidays and year-round to provide meals to students and community members.

“We hope the stories of these outstanding individuals inspire even more Canadians to pull together to make people’s holiday wishes come true,” says Mark Hubert, president and CEO of Canadian Poultry and Egg Processors.

The Wishbone Awards are part of The Wishbone Project, a charitable initiative launched in 2020 by Canada’s turkey farmers and processors to give back to communities across Canada through foods and funds. Since its launch, The Wishbone Project has raised over $240,000, empowering local non-profits, charities, and community heroes to combat food insecurity.

In addition to the $20,000 in Wishbone grants awarded to recipients, Think Turkey will be donating $10,000 to Food Banks Canada.

JANUARY

JANUARY 3, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

JAN. 8, 2024

Canadian Poultry Disease Webinar Series canadianpoultrymag.com

JAN. 10, 2024

PIC’S Poultry Producer Update, Brodhagen, Ont. poultryindustrycouncil.ca

JAN. 15, 2024

Canadian Poultry Disease Webinar Series canadianpoultrymag.com

JAN. 22, 2024

PIC’S Science in the Virtual Pub, Guelph, Ont. poultryindustrycouncil.ca

JAN. 22, 2024

Canadian Poultry Disease Webinar Series canadianpoultrymag.com

JAN. 29, 2024

Canadian Poultry Disease Webinar Series canadianpoultrymag.com

JAN. 30-FEB. 1, 2024 IPPE, Atlanta, Ga. ippexpo.com

FEBRUARY

FEB. 7, 2024

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

FEB. 7-8, 2024

National Poultry Show, London, ON. poultryindustrycouncil.ca

FEB. 13, 2024

Canada’s Agriculture Day, Ottawa, Ont. agriculturemorethanever.ca

FEB. 28, 2024

PIC’S Poultry Producer Update, Lincoln, Ont. poultryindustrycouncil.ca

By Maggie Van Camp

Agreat deal of confusion surrounds the words “transition”, “succession” and “estate” planning. It’s not surprising, as they’ve been used interchangeably and our knowledge about them has evolved quickly over the last few decades. Also, historically death tended to care of transferring farms to the next generation.

Today, the average age of Canada’s farmers is 56 and, as a result, multiple generations are farming together. Also, farm asset values are at historic highs and farms are more complex than ever before. It’s has become more complicated to transfer a farm from one generation to the next.

So, let’s start by understanding the difference between estate, succession, and transition plans so you can think more clearly about what you need for your family and how to use it on your farm.

Estate planning involves figuring out the distribution of your assets and wealth when you die. Basically, an estate plan legally defines who gets your stuff and your money at death, usually in wills and trusts.

It’s important for everyone, starting at 18 years old, to have a will. It is a simply way for you to give your family the peace of knowing your wishes during a time when emotions and vulnerability can make decisions difficult. An estate plan is part of a transition or succession plan.

Succession planning is how to transfer a business and responsibilities from an exiting generation to the next generation. Not only does this

include the transfer of assets but, involves training the next generation farmers so they can move with competency and confidence from labour to management to ownership.

It involves learning how to make decisions together collaboratively, including the awkward people-decision like defining roles, responsibilities, career paths and compensation.

Succession tends to have connections to inheritance because the word succession is based on the old-world term of “succeeding” the throne. Such as, after the queen dies, she will succeed all the reigning power of their kingdom to the prince.

That’s why about 10 or 15 years ago the agriculture industry in Canada agreed to use the term “transition planning” instead of succession planning. Planning for transition has a broader meaning than succession as it used for nonfamily, tends to be more strategic, and is on-going, in other words, not

“There’s power in the process of doing a transition and succession plan.”

a one-time event.

Additionally, transition plans tend to be more focussed on how to transfer control of labour, management, and ownership, when the exiting generation is still alive and active in the business.

The idea of using this term instead of succession was to alleviate the fear and procrastination often associated with traditional succession. However, despite these good intentions, a decade late succession planning is still the most used term used within the farming community.

When I searched the internet for “farm succession” over 20,500,000 results popped up whereas a search for “farm transition” resulted in only about 110,000.

To add to the confusion, some people also call succession and transition planning “business continuity” planning.

Honestly, I use transition and succession planning interchangeably. If it helps you to take actions toward setting up our next generation of farmers for success, I really don’t care what you call it. However, I think it does help to understand that an estate plan is not a succession or transition plan.

There’s power in the process of doing a transition and succession plans, as your family learns how to communicate and navigate the most complicated and satisfying change in their entire lives.

In January, Maggie Van Camp will be launching FarmComms – a multidisciplinary foundational approach to succession with on demand video training and one-on-one coaching so your farm and family can learn how to better communicate.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic IBD and AL-2.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative or visit PoulvacProcerta.com.

By Lilian Schaer

In many ways, 2023 will be remembered as the year of the usual suspects where poultry health is concerned. That’s according to two veterinarians who spoke at the annual Poultry Service Industry Workshop this past fall: Dr. Gigi Lin, an independent B.C. practitioner at the time, and Dr. Jessalyn Walkey of Production Poultry Veterinary Services in Ontario.

“There hasn’t been much emerging disease across all commodities, and also a relatively stable year for natural disasters like heat and flooding,” says Lin, who provided a Western Canadian perspective. “Things have been quite stable – when a veterinarian says it’s been a boring year, that’s a really good thing!”

According to Lin, the year did start with higher than usual early mortality in chicks and poults, but that was likely because of chick quality issues and a shortage of supply due to avian influenza. It was an issue that was essentially resolved by the third quarter of the year.

“The biggest issues year over year continue to be bacterial. The major diseases may shuffle through the top positions, but bacterial challenges continue to be the dominant source of the top one or two health issues,” adds Walkey, who addressed trends in Ontario, Quebec, and Atlantic Canada. “That’s the context I’m seeing from the provinces I was representing.”

Leading the way for turkeys as a top issue were bacterial infections like E. coli , E. cecorum, C. perfringens and others in both eastern and western Canada, resulting in septicemia and other health challenges.

Another common thread in turkeys were birds presenting with neurological symptoms, leaving them weak and with necks twisted backwards and unable to coordinate movements. This was reported in all four western provinces, as well as Ontario and Quebec.

Tissue samples showed inflammation in the brain, but subsequent testing was negative for avian encephalomyelitis (AE), as well as Newcastle, avian influenza, and viral diseases with neurological symptoms.

Some cases resulted in very high mortality rates of five to 30 per cent. A few birds were found to subsequently develop lameness with lesions in the heart and tendons consistent with reovirus.

“The only positive test was for reovirus in some cases, which we saw in Western

and Eastern Canada and from some U.S. practitioners as well,” notes Lin, who adds neurological reovirus had previously only been reported in broilers in recent years. “There are many dif-

ferent diagnoses for poults with neurological symptoms. So, it’s important that growers work with their vets to submit birds to labs for accurate diagnosis.”

Inclusion body hepatitis (IBH) continues to be one of the most common broiler diseases veterinarians see in broiler chickens across Canada. Infectious bronchitis and bacterial challenges caused by E. coli, E. cecorum, Salmonella and others also persistently cause problems for producers.

“IBH was a major challenge for Ontario this year, reaching anywhere from moderate to severe mortality,” Walkey notes. “In Quebec, the number of clinical cases has decreased but we are seeing the IBH cases in older birds in the 28-to-35-day range.”

According to Lin, B.C. has started seeing a rise in infectious bronchitis cases over the last two or three years during seasonal temperatures changes in fall and winter. It can result in a sudden, acute increase in mortality during the last few weeks of production or extremely high condemn rates of up to 20 percent due to airsacculitis.

“Infectious bronchitis is highly contagious, and we see new

Now more than ever, with diseases like Avian Influenza challenging your birds at every turn, your ability to prevent disease has never been more critical and Neogen® can help!

Neogen provides a full range of disinfectants to help in your prevention efforts. From quaternary ammonium/glutaraldehyde combinations like our industry standard Synergize® to oxidizers like Neogen Viroxide Super™. From phenols like BioSentry ® BioPhene™ to quaternary ammoniums like BioSentry ® 904 to disinfectant wipes like COMPANION™, Neogen has a chemistry to fit your specific needs.

Call your local animal health provider or visit neogen.com today to find out which HPAI solution is right for you.

© Neogen Corporation, 2023. Neogen and Synergize are registered trademarks and BioPhene, COMPANION, and Viroxide Super are trademarks of Neogen Corporation. BioSentry is a registered trademark of BioSentry, Inc. All rights reserved. All other trademarks are property of their respective companies.

variants often,” Lin says, adding the virus can cause respiratory, renal, or reproductive issues. “Vaccination is one (control) strategy; also, work on ventilation and tighten up biosecurity to minimize the impact.”

Disease trends for broiler breeders have remained relatively status quo this past year. Infectious bronchitis has contributed to sudden mortality spikes, decreased production and cystic oviducts in Ontario. What’s more, Atlantic Canada reported challenges with IBH in the winter and spring months.

In B.C, Alberta, and Manitoba, Staphylococcus arthritis has become a common infection in broiler breeders, resulting in joint, tendon, bone, and foot pad infections. It’s a painful condition that causes welfare issues and can lead to increased mortality and culling.

Alberta reported cases of focal duodenal necrosis, which were also seen in Ontario. Additionally, B.C., Alberta and Manitoba all had problems with egg drop. Meanwhile, Atlantic Canada, Ontario and Quebec dealt with issues related to infectious bronchitis. Layer flocks in Quebec were also challenged with avian encephalitis, resulting in a 15 per cent drop in egg production.

“There can be many things that cause a drop in egg production; the bottom line is to make an accurate diagnosis, so you know what you have and how to treat it,” Lin says. “Keep good records, and keep your vaccine program current. It is hard to do a good disease investigation if you have incomplete data or records.”

Additional challenges in Eastern Canadian layer flocks included a rise in fatty liver syndrome, ammonia blindness in eight-week-old layer pullets and cage

layer fatigue reported in Atlantic Canada.

E. cecorum and necrotic enteritis are two bacterial conditions that aren’t new to the poultry industry. What is new, however, is that they’re becoming more common and more challenging to deal with, something Walkey believes could be exacerbated by the demands modern production is placing on the birds.

“As we try to meet the asks of our (production) system, like new genetics or reduced antibiotics, the energy it takes a bird to reach its full performance potential isn’t guaranteed,” she explains.

“To be able to perform in the presence of challenge or disease demand is not new, but the ask of the bird is getting taller. As tools are shifting and diseases are becoming more prevalent, we have to be realistic about what the birds are up against and how those diseases can and are impacting them.”

Highly pathogenic avian influenza (HPAI) continues to be a challenge for poultry producers across Canada, albeit at different times and to varying degrees. For Lin, a positive outcome has been more and better communications between veterinarians, and many new opportunities to educate growers, allied industries, veterinarians, and academics in the fundamentals of prevention and control.

It’s a perspective shared by Walkey, who believes that although the industry can’t control the wind, producers can stay informed to influence other variables that can help keep flocks healthy.

“I’m very pleased with how information is being distributed for producer awareness. People are always hungry for more info and want to stay connected. This is something that knows no bounds, so we have to work together,” she says.

“There is a big focus on biosecurity and my job is to be able to help spread the information and make sure that we can help if there are practices that need to be tweaked.”

E. cecorum is now affecting younger birds and causing more severe symptoms.

By Lilian Schaer

The Canadian poultry industry is no stranger to Enterococcus cecorum (E. cecorum). Pathogenic strains of the bacteria have been identified in chickens in various countries, including Canada since 2002, mainly resulting in lameness and bone lesions.

More recent poultry outbreaks, however, have shown up as septicaemic at a much earlier age and are proving much harder to address.

Presenters during a recent Broiler School webinar series hosted by Canadian Poultry all identified E. cecorum as an emerging threat to chickens. And at the 2023 Poultry Industry Services Workshop, Ontario veterinarian Dr. Jess Walkey spoke about the changing nature of the bacteria and the

problems it’s causing for poultry producers.

“From my Ontario perspective, I would say that although it isn’t new, Enterococcus is becoming a tricky one to solve. It’s a bacterial condition that seems to create many challenges and its prevalence in Ontario is on an upward trend,” Walkey says.

This is backed up by the regular health summaries released by the Ontario Animal Health Network (OAHN) every three months: for the past year or so, both E. cecorum and E. coli have been the top two bacteria isolated from poultry.

Bone lesions and lameness

E. cecorum had long been considered as what is called commensal bacteria in avian species – present but not causing negative health impacts. However, that changed over 20

years ago, when pathogenic strains of the bacteria were first identified in chickens.

Outbreaks happened first in the UK and the Netherlands, followed by other countries like Canada, the United States and South Africa. These pathogenic strains changed the impact of E. cecorum on the health of broilers and broiler breeders, causing primarily bone lesions and lameness.

“We started seeing a problem like kinky back in older broilers that eventually paralyzes the bird,” explains veterinarian Dr. Benoit Lanthier, Technical Services Representative at Cobb-Vantress, adding this would result in dehydration, starvation and in welfare-related culling or birds deemed unfit to ship.

“Lameness was the biggest symptom of

E. cecorum: birds limping or sitting on their hocks with legs stretched out,” adds Dr. Emily Martin from the Animal Health Laboratory at the University of Guelph. “There are multiple places the bacteria locate, but one area in the spinal column that it locates in is a moveable vertebra in the back, where it causes an abscess, putting pressure on the spinal cord and causing lameness.”

At some point over the last several years, the situation began to change, however. According to Martin, poultry pathologists and bacteriologists were starting to see different presentations, including septicemia conditions in two- to three-week-old birds.

“As our technology improves, we have better abilities to detect different types of bacteria and how they evolve. Bacteria are like any other living thing, they have their family trees, and we look at their genetic structure,” she says. “What was probably happening in earlier lameness cases is that the birds were septicaemic, but it wasn’t a huge problem in flocks causing sick birds and mortality.”

Experts believe the E. cecorum strains have evolved again, with different strains now causing the bacterial septicemia with symptoms similar to those from an E. coli infection.

Birds as young as 10 days of age are now being affected, with symptoms including pericarditis (an inflammation of the lining of the heart), a yellowish membrane over the surface of the liver and abscesses in long bones like the tibia. Birds that survive the initial infection will most likely develop lameness problems as they get older.

Producers will most likely first see sick birds with uniformity issues, reduced daily gain, increased mortality and culls, and potentially an increase in condemnations at the plant.

“Any birds with any type of bacterial infection, like E. cecorum or E. coli or a mix, will be inactive, fluffed up and depressed with their eyes closed so you know they’re sick,” Martin says. “We have to send tissue to have them culture it (for diagnosis), but

we often see E. cecorum in combination with E. coli.”

According to both Martin and Lanthier, once E. cecorum infection is present onfarm, it tends to reoccur and can be difficult

to eradicate. It’s an organism that is more likely to survive longer in the litter, for example, as well as in cold and dry environments than other pathogens.

“It’s pretty much everywhere in Canada and the U.S. and everybody will struggle with it at some point,” Lanthier notes.

The Chore-Time Direct-Drive Fan allows for maximum precision control of your house ventilation while saving you money.

Fully compatible with your CHORE-TRONICS® 3 Controller, EnduraMax™ Fans use your existing sensors with its variable speed motor to ensure stable temperatures for better bird performance.

The 57-inch (145-cm) diameter makes it easy to upgrade from your belt-driven fans.

•

•

“Although it isn’t new, Enterococcus is becoming a tricky one to solve.”

“Once one flock is hit, then it’s every flock.”

Maintaining a healthy barn environment is important, with a strong focus on cleaning and disinfection between flocks, particularly of waterlines, and keeping some downtime after birds go out.

Biosecurity is also key to keep other immunosuppressive viruses at bay. Watch birds closely once they’re placed and consult with your flock veterinarian on how to treat sick birds and reduce their symptoms.

Experts suspect that this latest evolution of E. cecorum bacteria could be linked to hatcheries halting the preventative use of antibiotics to keep newly hatched chicks healthy. This has caused a need for greater attention to detail and environmental control during and right after hatch.

Lanthier has seen some of his customers experience success in hatching chicks in HatchCare incubators. The HatchCare system gives chicks the best and most uniform temperature conditions and light, feed, and water as soon as they hatch, as well as a quieter, calmer environment with more space to move around. It also allows for excellent biosecurity and hygiene control.

“When hatching with HatchCare, we don’t see the problem in the flock or only see it very mild,” Lanthier says. “The management piece is important, having those good conditions early on with access to feed and water right away. If it’s done well, the chicks hatch and do well right away.”

It can be hard to control all the variables in more traditional systems, especially keeping chicks from getting overheated, which has been linked to higher levels of E. cecorum, and preventing them from being exposed to bacteria.

Research is ongoing to get a better understanding of both how the organism behaves and what can be done to effectively prevent or minimize its risk.

By William Alexander

When experiencing cold weather, keeping your barn well insulated without drafts, while producing proper air flow are the first steps to maintaining bird comfort. Secondly, monitoring the ammonia levels and identifying the root cause of increased amounts of ammonia are critical to the health and wellness of the flock.

Controlling the environment in the barn will keep your birds comfortable – no matter the external weather conditions. During the winter months, minimum ventilation is recommended to direct and circulate exterior air into the barn.

Sidewall exhaust fans create a consistent vacuum inside the poultry house to pull in outside air. The incoming cold air should be kept in contact with the ceiling for as long as possible to be blended in with the warm in-house air above the flock. No cool air should come directly in contact with the birds, to avoid chilling and stressing the birds.

The biggest potential risk with negative-pressure minimum ventilation is that when there are any unplanned openings, the house will draw air through every available opening in the building. Unsealed curtains, unused and dirty fans, and improperly sealed end doors are all areas that commonly contribute to heat loss and should be inspected regularly.

By properly managing moisture, air flow,

and temperatures turkey flocks can keep growing and thriving even during extreme temperatures outside the poultry house. Controlling air flow inside the house is critical. Poor direction of airflow can lead to wet litter, chilled birds, and increased strain on heaters that lead to heightened carbon dioxide and ammonia levels.

When directing air in the barn the goal is to: promote uniform temperatures throughout the house during cold weather; mix warm air in the barn with incoming cold air to reduce humidity; and reduce fuel use and improve litter quality.

High ammonia levels can have a negative effect on bird health. With extended exposure to ammonia, the immune system becomes suppressed, and birds are more vulnerable to several health risks. It is important to regularly monitor ammonia since humans can become accustomed to levels of ammonia and not realize the levels are increasing. Ammonia is an irritant when it is inhaled. It can injure/burn the respiratory tract and alter oxygen uptake making it hard to breathe. In cooler weather, ammonia levels increase in the barns due to de -

creased ventilation rates. Birds can detect ammonia at levels as low as five ppm, and levels of 10 ppm or more start to compromise health and welfare.

Levels over 25 ppm can cause long-term damage to human and bird respiratory systems and poultry food pads. Industry standards recommend maintaining levels below 25 ppm however, we recommend it is best practice to target the 10 ppm or under range. Ammonia levels should be monitored

and footpad burns and breast blisters. Some common practices to maintain dry litter, in addition to using proper ventilation, include top dressing pens with new shavings as needed; moving drinkers daily to prevent the formation of donuts around the drinkers; and tilling litter regularly (weekly up to approximately three weeks before slaughter for female flocks and weekly up to approximately 13 weeks of age for male flocks).

For additional details and information regarding the survey mentioned, please refer to the official website at https://abacusdata.ca/canadians-see-importance-of-buying-canadian-dairy-eggs-chicken-and-turkey/

Ingredients play important roles in pellet quality and broiler performance..

Broiler feed accounts for approximately 70 per cent of broiler production, and ingredients are the major contributor. Ingredients play important roles in pellet quality and broiler performance. In general, ingredient selection often uses commercial parameters including price and supply. However, quality parameters are also important. This article aims to provide the general aspects of ingredient selection for commercial broiler feed.

Nutrient values are important for nutritionists in terms of ingredient selection. Typically, the focus is on incoming ingredients composition in terms of factors including moisture, crude protein, fat, fiber, and ash. However, we cannot consider only amounts when selecting ingredients.

Instead, nutrient bioavailability including metabolizable energy, digestible amino acids, fatty acids, available phosphorus, and other nutrient values should be considered. Many references can be used as the guide-

line values (Institut National de la Recherche Agronomique [INRA], Brazilian Tables for Poultry and Swine).

The nutrient matrix is very important for feed formulation. The precision and accuracy of the analyzes will consequently affect the structure, cost, and chemical composition of the feed.

The nutrient matrix of each ingredient can be influenced by season, source, and storage

time. For example, the starch content in cassava is lost during storage. The longer the storage time, the more cassava starch and energy will be lost. Therefore, nutrient matrices of each ingredient must be frequently evaluated and separated by sources.

Antinutritional factors are compounds that can interrupt nutrient absorption and metabolism and negatively impact health. Antinutritional factors can be found in a

variety of ingredients (Table 1). Their adverse impact can be alleviated by physical, chemical, and/or biological processes. The limited inclusion of ingredients is another option to reduce the risk of antinutritional factors.

Supply and demand influence feed costs. The sufficient supply of ingredients must be considered prior to evaluating the cost and nutritional value. Generally, the ingredient

supply and price vary depending on the season.

In some cases, it is necessary to find a lower-priced alternative to replace a higher-priced ingredient without adverse effects on broiler performance. For example, soybean meal may be partially replaced with other alternative protein sources such as canola and rapeseed.

Enzyme application is widely used in the broiler feed production. It can alleviate the effects of antinutritional factors and reduce

feed costs by releasing nutrients from the feed matrices. Enzyme applications have many benefits for broilers.

However, some enzymes may not tolerate heat treatment during the production process. Although post-pellet liquid application systems can be used to circumvent heat sensitivity, the enzyme recovery and uniformity in the final feed must be monitored regularly.

Relative value (RV) is the one tool that can determine the nutrient value of ingredients by comparing standard nutrients such as crude protein, digestible amino acids, metabolizable energy, or available phosphorus among ingredient sources. This value does not consider the inclusion level. It can be calculated and expressed in a costper-nutrient unit (Table 2).

Feed safety is an important criterion for

We handle everything from planning and building complete systems to providing maintenance and repairs for operations of all sizes. Whether it’s in poultry, dairy, hog, grain handling, or feed milling, we’ve got you covered.

Reach out to our experts to discuss your farm’s operational needs today.

Ingredients

Corn, sorghum Mycotoxin Sand, plastic, wood Pesticides

Animal products Salmonella Sand Melamine

Plant protein Mycotoxin Plastic, wood Pesticides, melamine

Cassava Mycotoxin Sand, wood Hydrogen cyanide (HCN)

Phosphate sources, limestone -Heavy metals, dioxins

Oils - - Pesticides, dioxins

ingredient selection. Feed ingredients must be from safe sources. To reduce the risk of broiler feed contamination, feed safety assessments with testing and auditing are prudent.

The hazards in feed ingredients are somewhat dependent upon the ingredient sources and processing types. Ingredient hazards can be classified into 3 main groups: chemical, biological, and physical.

The major chemical hazards include pesticides, heavy metals, dioxins, melamine, and antibiotic residues. Pesticides are primarily monitored in grain products whereas heavy metals are issues

associated with mineral sources.

Microbes present biological hazards that can cause broiler health issues and include bacteria, primarily Salmonella, as well as fungi that can produce mycotoxins. The last group, physical hazards, are contaminants such as plastic, glass, or metal. Physical hazards can be detected within process interventions (magnets) and laboratory analyses (Table 3).

Quality assurance (QA) methods and standards must be used for ingredient selection to minimize hazards. The QA process starts from ingredient purchasing by setting standards and conducting ingredient quality checks at reception in feed mills.

The inspection of ingredients must be in place to ensure all newly arrived ingredients are safe to use in broiler feed production. The sampling and analysis must be rigid and precise.

Sampling should be suitable for the volume and nature of ingredients, and methodology should be appropriate for the ingredients. Additionally, a monitoring program must be efficiently scheduled and suitable.

Feed safety must comply with the regulatory agencies. Therefore, the national and international regulations must be considered as criteria for ingredient selection, particularly export and import requirements.

Regulatory criteria include prohibited ingredients, safety levels of ingredients, and contaminants that relate to food safety. Different countries have different restriction levels and regulations. For example, animal protein in broiler feed is prohibited for use in flocks reared for meat that is exported to the European Union.

Ingredients also impact the feed mill performance and pellet quality. The varying content and type of starch in ingredients require different levels of conditioning to achieve gelatinization. Moreover, different inclusions of starch-rich ingredients require specific dyes to extrude an optimal pellet while maintaining optimum production capacity.

Other factors that can affect pellet quality and feed processing are fat and fiber content in ingredients. Fat is a necessary nutrient but also acts as a moisture barrier. Consequently, steam cannot be transferred to make the optimal gelatin. Fiber can reduce the capacity of the feed mill process and can cause equipment wear due to the abrasive properties.

Ingredient selection is an important process for broiler feed production. Considerations should include the cost, quality, and safety of the ingredients. A solid QA program is key to a consistent supply of quality ingredients. Given the importance of feed for high-production performance, clearly well-performing flocks require high-quality feed ingredients.

Dr. Suttisak Boonyoung is a regional nutritionist for Cobb and serves the Asia-Pacific region. He has 13 years of experience in the agriculture and poultry industry. He holds a bachelor’s degree in animal science and a Ph.D. in animal nutrition.

Brought to you by DOES THE FUTURE OF AGRICULTURE SEEM GREY TO YOU?

Agriculture in the Classroom is cultivating curiosity by providing hands- on, immersive learning experiences to educate and engage students. The next generation of farmers, policy-makers, and innovators is in the classroom today. Together, we can inspire young people to drive our industry forward.

Change the future at aitc- canada.ca

France becomes the first Western nation to vaccinate against avian influenza despite threat of trade restrictions.

By Melanie Epp

Apersistence of a particularly virulent strain of H5N1 highly pathogenic avian influenza (HPAI) has been circling the globe since 2021, debilitating poultry production systems around the world. In France, most of the outbreaks have occurred in poultry-dense regions.

During the 2021–2022 outbreaks, nearly 20 million birds were lost, and economic losses reached more than $700 million. Once the cost of culling infected flocks and enhancing biosecurity is factored in, the total price tag is closer to $1.5 billion.

In October 2023, France began vaccinating ducks – the most susceptible poultry – against avian influenza. It is the first Western nation to adopt such a program, despite the threat of trade restrictions.

Vaccination program kicks off France’s decision to vaccinate did not come easy. The country brought the sub -

ject forward at a European Commission meeting in 2022.

After much discussion, the Commission published a set of rules around vaccination in February 2023. EU member states were given authorization to begin vaccinating against the virus. The decision to do so was left up to the individual member states. The process, the Commission said, would be strictly monitored.

France’s poultry sector, under the guidance of the ministry of agriculture, made the decision to go forward with a vaccination campaign early this spring. Initially, it is focused on France’s most vulnerable poultry market: ducks.

Ducks were chosen because they are more susceptible to avian influenza than other poultry species, and their level of excretion is much higher.

According to Yann Nedelec, director of ANVOL, the interprofessional poultry association, duck producers welcomed the decision. ANVOL represents producers of

ducks for consumption, approximately 30 to 35 million ducks or 50 per cent of the duck industry in France. The remaining 50 per cent are produced for the foie gras sector. Duck production accounts for just eight per cent of total poultry production in France.

Currently, vaccination is mandatory for ducks on farms with more than 250 birds whose products are meant to be sold as either foie gras or as meat. In total, some 64 million ducks on over 2,700 farms will need to be vaccinated. The campaign will cost nearly $150 million, of which 85 per cent is to be footed by the French government.

Immediately following France’s decision to begin vaccinating ducks, both Canada and the U.S. announced trade restrictions. Of the two countries, the U.S. took the much stricter stance. Immediately following the announcement, the U.S. Department of Agriculture suspended all poultry

High laying performance under optimal animal welfare conditions.

imports from France and the EU. Currently, it does not allow the importation of poultry from countries affected with HPAI, nor from flocks that have been vaccinated against HPAI.

Since EU member states and other European countries have open access to the European common market for trade in poultry commodities, the USDA extended the restrictions to include member states that fall within the European Poultry Trade Region (EPTR). Their reasoning is that authorities cannot be certain from where poultry products originate, which means there’s increased risk of introducing HPAI infections to the U.S.

The Canadian government also suspended poultry imports from France, but did not extend that suspension to the rest of the EPTR. In a recent interview, the Canadian Food Inspection Agency (CFIA) said it has engaged with authorities in France and is conducting an assessment to evaluate the potential risks of the vaccination campaign.

Since the risk assessment is still underway, CFIA decided to implement the temporary measure, effective as of October 1. The measure suspends the importation of all live poultry, hatching eggs, and raw fresh and frozen poultry products originating from France.

“This is necessary, as the CFIA must evaluate any risks posed by these imports on Canadian public health, animal health, the poultry industry, as well as any secondary trade implications for poultry and poultry products exported from Canada,” the agency said in an email.

In the meantime, the assembled task force – a team of experts that includes veterinarians and academia, as well as industry and government representatives – will discuss issues relating vaccination. The task force will serve as a forum for discussion, information-sharing and consensus building on an approach to

• Nests at the front for excellent egg quality thanks to the short egg travel distance

• 24 birds per compartment

• Increased height reduces coccidiosis

• Backwall between the compartments for easy access to the birds

• Choice between perforated, solid or wire partitions

“Healthy hens, perfect eggs!”

Eggcellence. Made in Germany. Visit us at the National Poultry Show 2024 Booth 721E

www.hellmannpoultry.com

HPAI vaccination in Canada.

A CFIA spokesperson said the group is exploring the use of vaccines based on scientific research, international trade and disease control considerations. Topics of discussion include: the availability of effective vaccines; ability to distinguish vaccinated and unvaccinated birds; implementation considerations; approaches to surveillance; and trade implications, among others.

Shayan Sharif, a University of Guelph professor whose research is focused on the chicken immune system and avian influenza, is one of the members of the task force. There are several layers of complexity around vaccination that first need to be thoroughly explored before a decision can be made, said Sharif.

“Are we vaccinating to protect poultry from disease?” he said. “Or are we vaccinating to reduce the amount of transmission of the virus? And would there be any trade consequences, and would we be able to mitigate the risk of trade consequences?”

For now, the answers to these questions are unknown. One thing is clear, though: a post-vaccination strategy will be necessary. “There’s going to have to be a major surveillance activity post vaccination to ensure, if you vaccinate, that these vaccinated birds are not going to become silent carriers of the virus,” Sharif says.

The EU has very strict rules around the monitoring of vaccinated flocks. This is to ensure that, as Sharif points out, the virus doesn’t silently circulate. “It is quite complicated,” ANVOL’s Nedelec says. “They are very heavy measures to put in place.”

Not only are the regulations complicated, but the rigorous surveillance programs that track the vaccine’s effectiveness are costly. Thomas Delquigny, veterinarian and avian technical manager at Boehringer-Ingelheim, says just 25 per cent of the total cost to vaccinate is represented by the vaccination itself. The rest of the costs go towards surveillance, certification, sampling and analysis.

The French government chose to au -

thorize just one vaccine. It was developed by Boehringer-Ingelheim. Delquigny says it was selected because the company showed it was the most effective option for protecting flocks from infection and reducing expression of the virus in the environment.

The sub-unit vaccine contains one part of the H5 virus. It is administered via injection. Two injections are required to complete the cycle, the first at 10 days and the second at 28 days.

According to a recent Reuters article, only 70 per cent of ducks in France have received their first injection; 40 per cent are fully vaccinated. France reported its first outbreak of avian influenza on a turkey farm in Brittany in late November. The poultry sector will be watching closely to see if the vaccination program will prove effective.

But even if the program proves successful, producers will still need to remain vigilant when it comes to biosecurity. “It’s going to be a tool in the toolbox,” says Sharif, referring to the vaccine. “It can’t be used for every farm, and it shouldn’t be used for every farm.

“Producers have done a really good job protecting their flocks,” he adds. “My kudos to them.”

After the Poultry Industry Services Workshop this past fall, cases of avian influenza were on the rise again in Western Canada. Here’s where things stood as of November 2, 2023, according to data from the Canadian Food Inspection Agency (CFIA) website.

December 20, 2021

Is when CFIA confirmed the presence of HPAI, subtype H5N1, in a small flock in Newfoundland, marking the start of the ongoing situation.

7.9 million

is how many poultry birds have been impacted by avian influenza in Canada this year.

British Columbia has the highest number of birds impacted, followed by Alberta and Quebec.

800 is the number of people that have contracted H5N1 since 1997, making it extremely rare in humans.

2,500

is the number of wild birds that have tested positive or are suspected to be positive for avian influenza since late-2021, according to the Canadian Wildlife Health Cooperative.

By Martha Roberts

Prices in 2024 are expected to be higher year-over-year (YoY) for each poultry subsector (broilers, turkeys, and layers) in the East and the West (see table 1 online). This is supported by continued strength of demand from households and foodservice sectors.

Despite some headwinds from production slowdowns, high feed costs and a recent change in tariff rate quotas for poultry, broiler operation profitability will be positive throughout the outlook period.

While feed costs have fallen from their highs in 2022, Western canola, representing meal and wheat rations, will be pressured by 2023’s drought-limited production. Eastern soybeans may stay elevated with Brazil’s weather challenging production amid strong global demand.

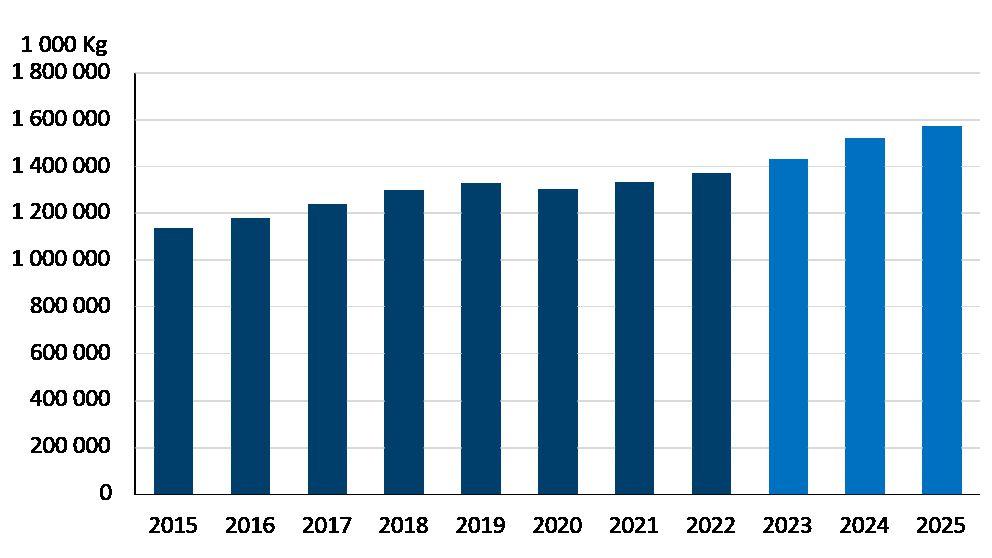

Canadian broiler production is forecast up year-over-year in 2023, 2024 and 2025 (see Figure 1), but there are cautions about whether such growth is attainable.

In 2022 and 2023, there have been shortfalls in production relative to allocations (i.e., planned production) deficits caused by a shortage in bird availability since early 2022.

Canada and the U.S., which supplies approximately 20 per cent of Canada’s supply of day-old chicks and hatching eggs, experienced widespread losses in their breeding and hatching flocks in 2022 due to avian influenza.

Figure 1 represents the chicken meat production best-case scenario based on population growth and current consumption trends. But the shortages that have limited production in 2022 are expected to continue to hamper production in 2023 and 2024.

At the other end of the spectrum, the USDA’s Foreign Agricultural Service (FAS) has forecasted Canadian chicken production to grow three per cent YoY in 2023 and 2.5 per cent YoY in 2024.

Through October 2023, chicken production in weight was running 1.2 per cent higher relative to a year ago, a gain made possible by slaughtering heavier birds.

B.C. chicken meat production has been hit especially hard in a year that some are calling the worst on record. An AI outbreak (2022 to 2023) has brought the province’s infected premises to 142 (of 387 for Canada), and B.C. accounts for 52 per cent of all Canadian impacted birds as of November 19 (9.3 million birds, or less than one per cent of total Canadian bird slaughter in 2022 and 2023).

The total number of eggs laid in B.C. was down 14.3 per cent YoY (January to August), and the total number of eggs laid in B.C. hatcheries (i.e., for layer and broiler production) was down even more.

The good news for the sector is that Canadians’ appetite for chicken picked up in 2023 Q3 after showing declining interest earlier in the year (see figure 2 online).

While beef demand continues to outweigh beef consumption and beef has been Canadians’ most preferred meat since 2020 Q1, FCC Economics’ meat demand index shows chicken meat demand (i.e., consumer preferences for chicken not explained by purely economic factors) was the highest of the three traditionally big sellers (beef, pork, and chicken) in Q3. Chicken was also the meat consumed most by Canadians in that period.

Beef consumption has seen the largest decline of the three meats since 2021 Q2, with beef prices, as measured by the Con-

sumer Price Index, rising a further eight per cent in 2023 (January to September) from already elevated levels.

In comparison, chicken prices (whole chicken, breasts, thighs, and drumsticks) rose 3.2 per cent in 2023 to September. However, pork may pose a challenge as Canada’s pork supply is also elevated, which should, in turn, keep prices more competitive.

To meet strong demand in a year of reduced production, Canadian retailers can access current production, storage stocks and imports.

With production up only minimally in 2023, frozen chicken stocks were still enough to satisfy demand in 2022 and early 2023.

U.S. imports are seven per cent higher YoY (September 2022 to August 2023) and may grow further in 2024 with an increase in Canada’s total tariff rate quotas to 119,000 MT, a 7.4 per cent YoY increase.

Poultry producers will start to fill allocated production levels once the damaging avian influenza outbreaks are under control – a daunting task given the disease’s recently evolved ability to infect and kill wild bird and mammal populations.

Demand is still strong from in-home dining and foodservice sectors and is currently being met with the ample frozen stocks on hand.

But with prices for competitive meats still relatively much higher than those for chicken meat, we can expect Canadian poultry demand and consumption to remain high, pressuring those stocks.

Population growth overall and growth stemming from immigration will also help to boost consumption levels.

Imports from the U.S. are set to increase and ease some of the pressure in 2024, but it may be a while before Canadian producers can meet domestic demand with our production.

The GrowerSELECT Water Line Regulator is a new regulator from Hog Slat for existing water line systems that the company says is a cost-effective option. Its key features include a large flushing valve, an extended adjustment knob, and optional 18 or 24-inch standpipes. A wide selection of adapters allows the regulator to fit almost any drinker system.

After over two years of field testing, Ziggity has recently introduced its Nuvo product line, featuring regulators and riser assemblies made from enhanced chemical resistant (ECR) materials. The company launched this line in response to the poultry industry’s increasing need for watering systems that are resistant to aggressive disinfectants, water treatment chemicals and pharmaceutical products

administered through the watering system. The Nuvo Riser Assemblies, available in rigid fold-down and flexible versions, are intended to simplify the managing and monitoring of your system pressure settings. The company says Nuvo components can be easily incorporated into existing systems. In addition, Ziggity has upgraded its Max3 TL drinkers for pullets and broilers with ECR materials.

The Sonata water meter, from the water measuring technology company Arad, is an ultrasonic water meter. Typically, a water meter will have a turbine in it that is spun as water flows through it and usually will require 0.25 GPM to be able to register flow. The Sonata, which is sold in Canada by County Line, has no moving parts that would be susceptible to water quality issues and can register flow as low as 0.05 GPM. County Line notes that, for smaller flocks or small birds, the low flow is critical.

The new Universal Pressure Regulator from Plasson is a corrosion-resistant option for producers. Most pressure reducers on the market are brass or composed of components susceptible to rusting and water quality issues. However, this new regulator, which is distributed in Canada by County Line, has a sturdy polypropylene and fiberglass body, non-metal valve components and stainless-steel spring design for long-term performance. It’s also compact and includes an adjustable pressure range.

Available stateside for a few years, the Agrow-Clean Whole Farm Treatment system from Proxy-Clean Products is now available in Canada. The system’s first generation had a generic diaphragm pump. In contrast, the newly available second generation uses a peristaltic pump from Stenner, which has been designed to treat up to 315,000 gallons of water at 50 ppm hydrogen peroxide while birds are in the barn. It eliminates the need for making stock solutions that are injected with the medicator because this Stenner pump can handle the water treatment of an entire farm. It is placed in a central location, the well house, which allows it to treat not only the entire farm, but also all those forgotten underground lines. It can inject an oxidizer such as hydrogen peroxide or an acid to lower pH.

Location

Didsbury, Alta.

End-to-end chicken operation

The business

Kamlah Farms is an end-to-end chicken operation based in Didsbury, Alta. Owned and operated by Grejanka and Jeff Kamlah, with a team of support staff, the business includes hatcheries, hatching egg barns and broiler barns.

The Kamlahs had 10 hatching egg barns that were a 45-minute drive away from their home farm. This created challenges around everything from feed deliveries to moving equipment to teamwork to their availability. What’s more, some of the barns dated back to the sixties. “Insulation in the old barns was sawdust shavings in the rafters,” Jeff notes. For these reasons, in 2020 they sold the old real estate where the hatching egg barns were located while retaining their quota. They then replaced those barns with four new ones on their home farm.

Working with Eagle Builders and Penner Farm Services, the Kamlahs built four stateof-the-art facilities. They say the biggest difference-maker has been the new Prinzen Egg Packer. In the old barns, staff collected eggs by hand. Now, the process is automated. What used to take them six hours a day now takes just 2.5 hours. “It doesn’t matter if it’s a high school student doing eggs or our most experienced employee, the quality of the work is the same because we’re letting the machine do it,” Jeff says, adding that the system has enabled them to cut three staff positions.

A unique coccidiosis vaccine that balances the safety and efficacy needed for poultry that are raised without antibiotics, or in management programs to reduce resistance against anticoccidials.