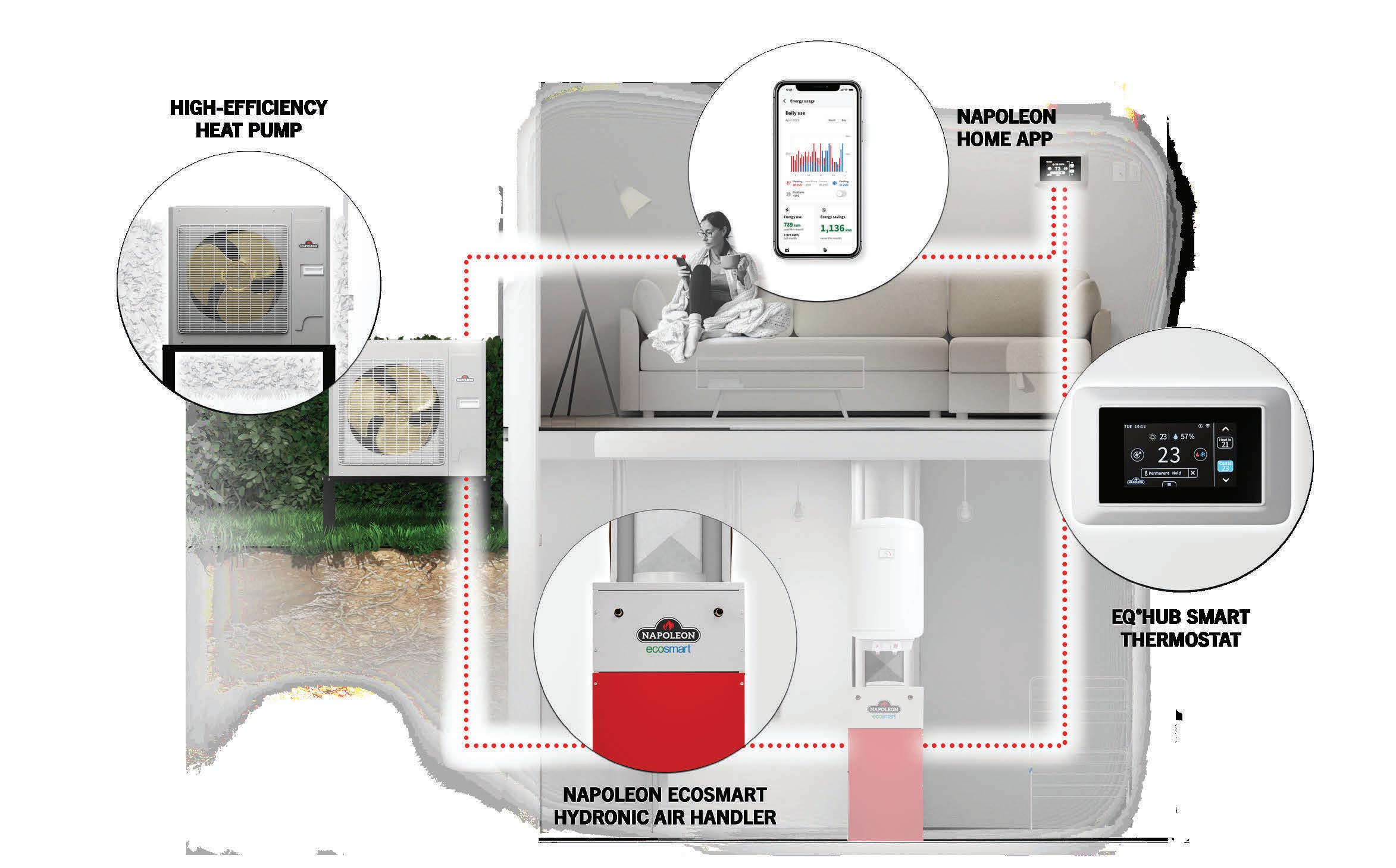

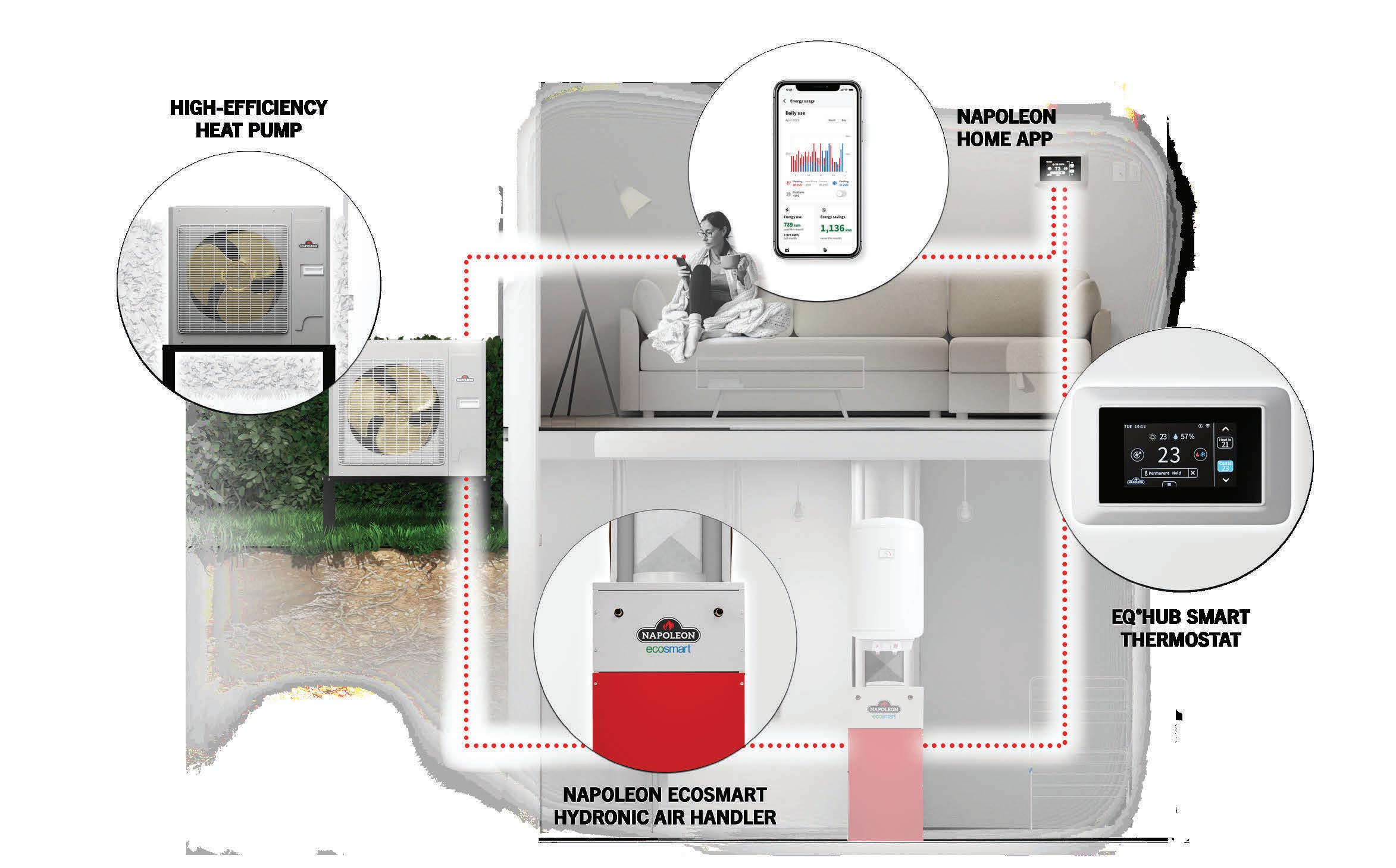

NAPOLEON ® ECOSMART HYDRONIC AIR HANDLER

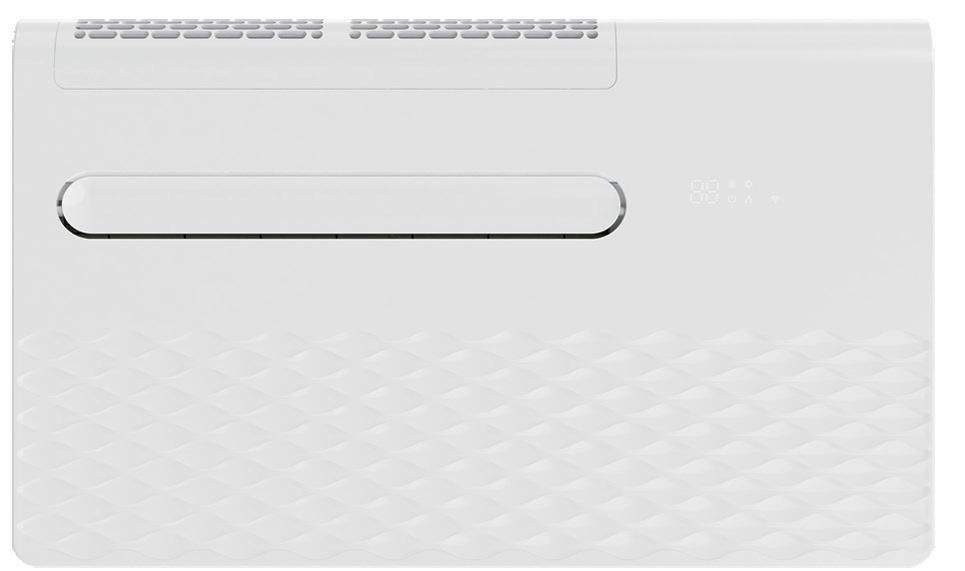

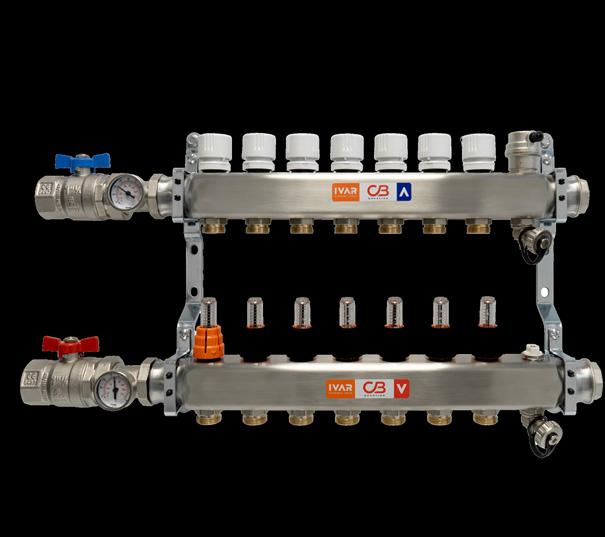

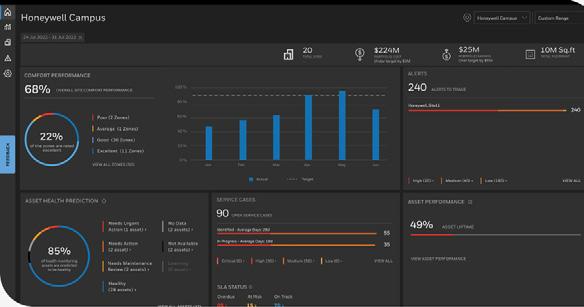

Napoleon Ecosmart hydronic air handlers use hot water from a boiler, tankless water heater, or heat pump to deliver consistent, energy saving heat.

By transferring heat through water instead of air alone, they offer a quieter, cleaner, and more efficient alternative to traditional forced air systems.

Designed for multi-position installations, each unit fits into tight spaces while delivering the performance to heat full sized homes with ease.

NAPOLEON ® EQ ® FUSION HYBRID SOLUTION

The Napoleon EQ®Fusion Hybrid Solution combines a high efficiency heat pump with a hydronic air handler, all intelligently managed by the EQ®Hub Smart Thermostat for unmatched comfort and energy efficiency.

• Smart electric/gas switching

• Simultaneous operation for max savings

• Backup heat & compressor protection

• Auto fuel selection by utility rates

• Zone control: up to 5 zones, 10 sensors/zone

• Humidifier & dehumidifier integration

• Compact, flexible installation

• Rebate & grant eligible

14 COVER STORY

HVAC

TROUBLESHOOTING WITH INTENTION

Exploring the philosophy of residential HVAC diagnostics and reinforcing the importance of continuous learning. By Ian McTeer

20

HYDRONICS

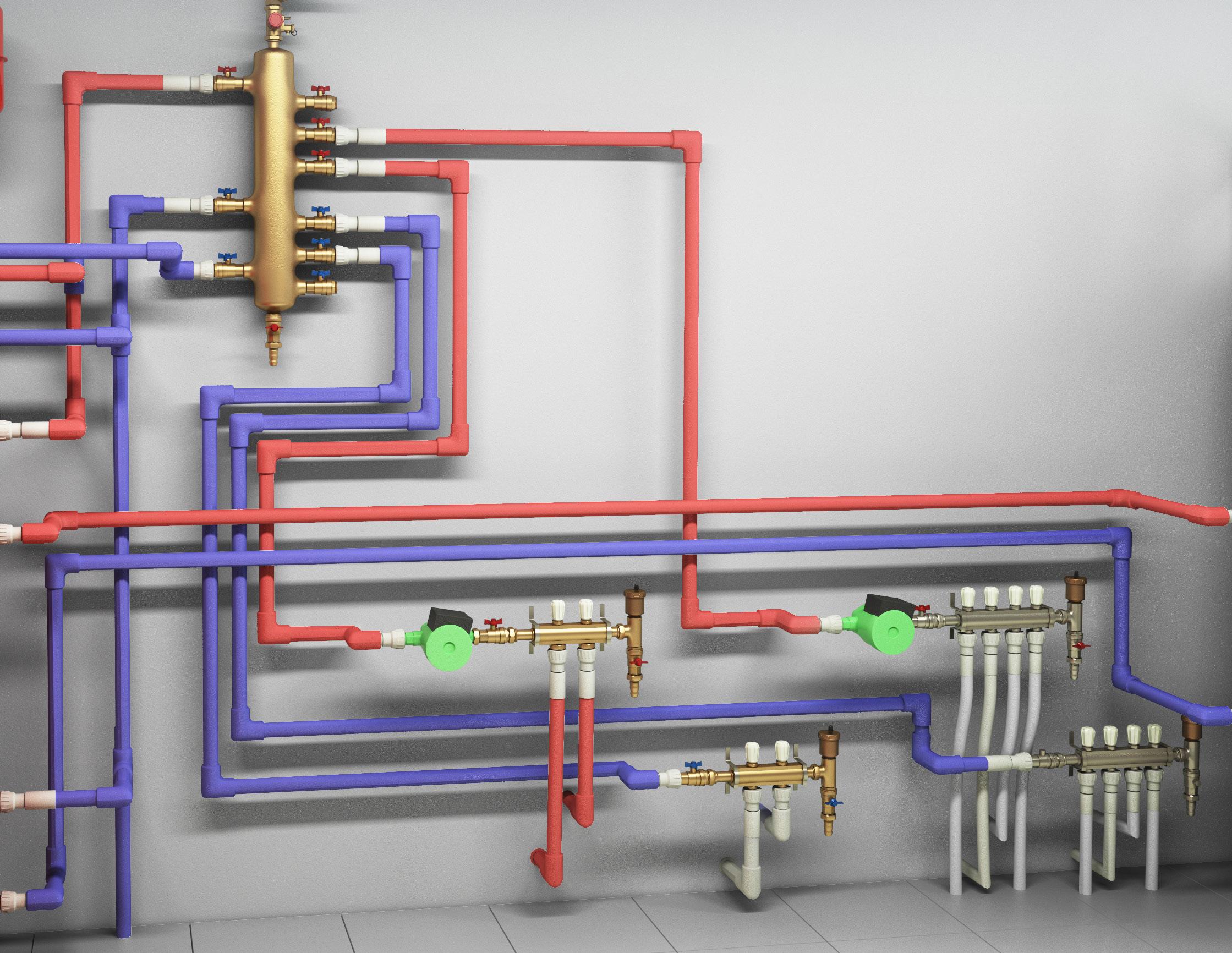

MULTIPLE APPROACHES

Creating hydraulic separation within closed-loop hydronic systems can be accomplished in many different ways. By

John Siegenthaler

26

30MM

HYDRAULIC SEPARATION

Together with John Siegenthaler we point out how to achieve hydraulic separation in hydronics systems. By Doug Picklyk

30

INTEGRATED DESIGN

EFFICIENCY IN EVERY DROP – PART 3

The efficiency and effectiveness of hydronics and heat pumps in modern buildings is reliant on smart system design and unified controls.

By Zachary Londo, Jean-Claude Rémy & Chris DesRoches

• Up to 98% Thermal E ciency

• 301,000 – 1,000,000 Btu Models

• 10:1 Turndown Ratio

• Intuitive 7" Touchscreen Display

• Stainless Steel Water Tube Heat Exchanger (ASME H stamp)

• 2 Wall-Hung, 3 Floor-Standing Models

• Factory Certified Common Vent

• A companion to the RCB Series, Rinnai’s new Commercial Water Heater Series is compact, rolls in easily, and sets up fast

• Perfect for high-Btu applications where space is tight

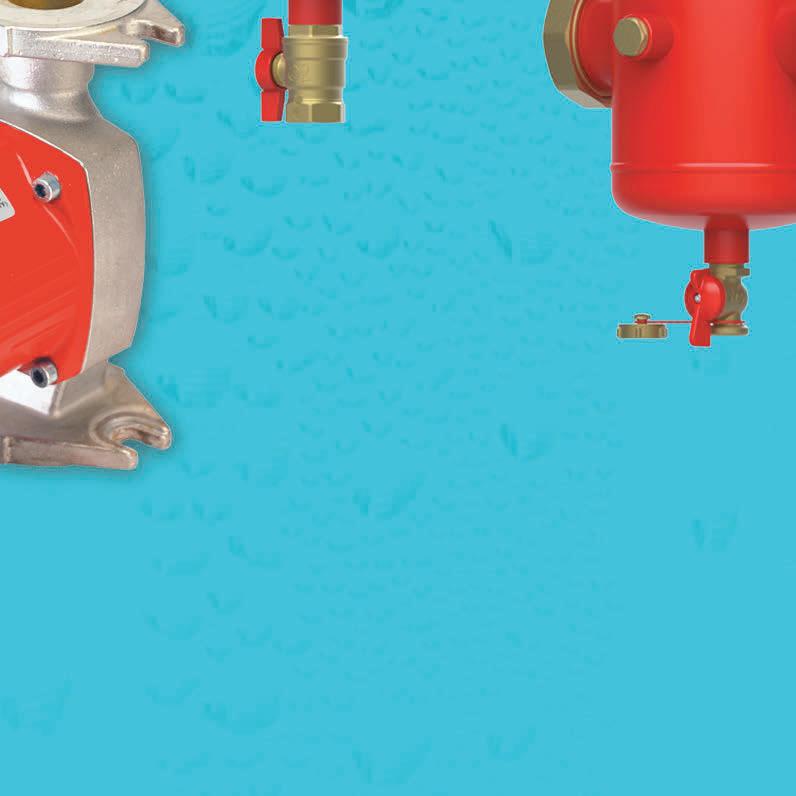

40 PLUMBING

BACKFLOW PREVENTION

Recognizing efforts to raise the level of awareness of cross connections and the tools that keep our drinking water safe.

By Doug Picklyk

VIVA LAS VEGAS

AHR Expo hits the strip in February 2026 as HVAC/R professionals flock to Las Vegas for the industry’s largest North American trade show and conference.

PLUS: 2026 AHR INNOVATION AWARD WINNERS

By HPAC Staff

A WINTER PLAYBOOK FOR FINANCIAL CONTROL

Why a weekly cash flow forecast beats checking your bank balance, providing improved operations and peace of mind.

By Matthew Birch

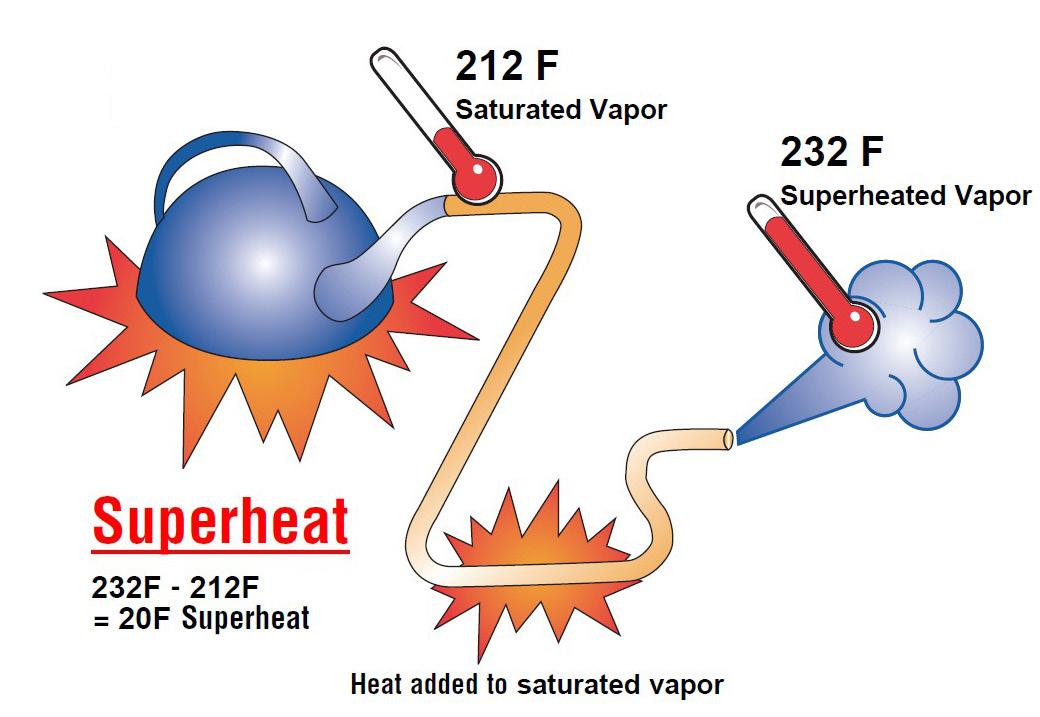

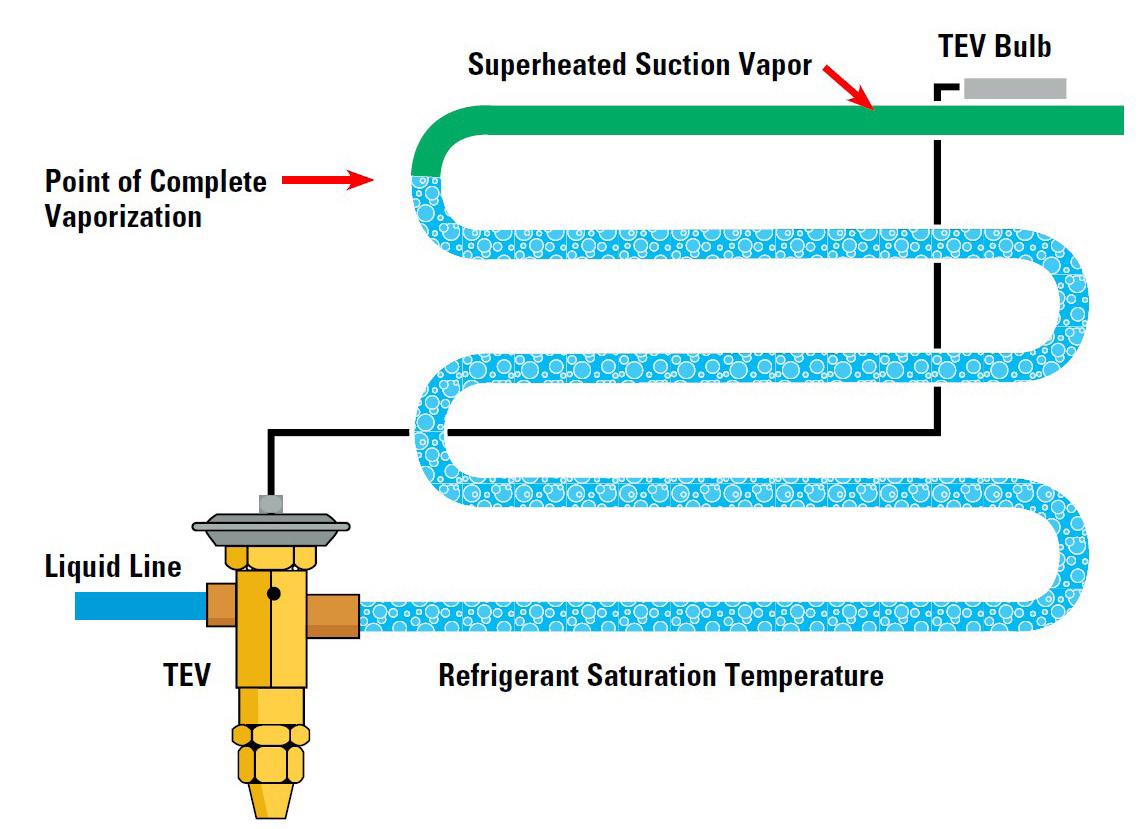

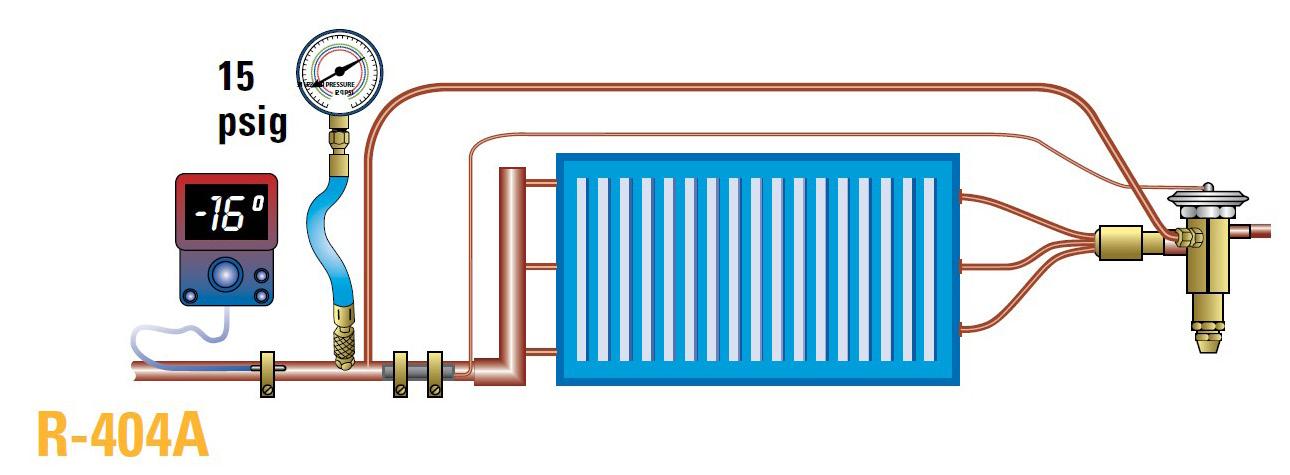

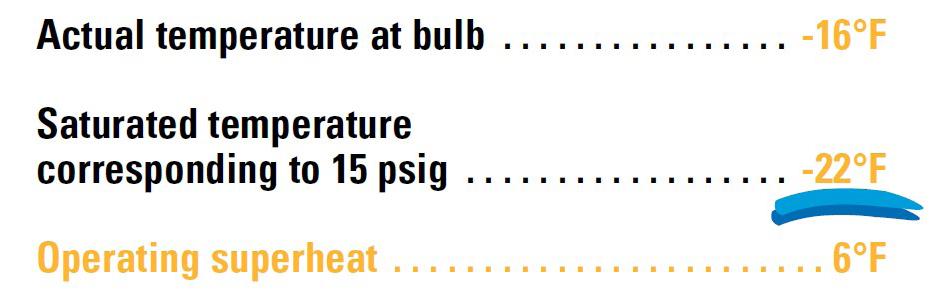

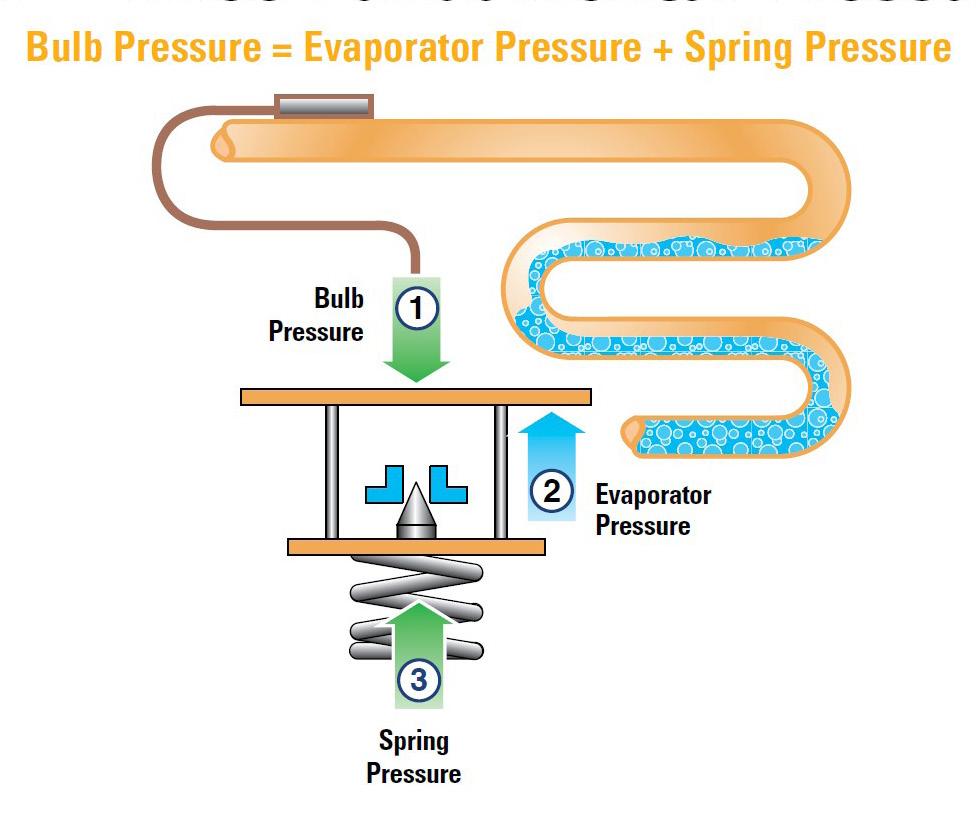

THERMOSTATIC EXPANSION VALVES

EXPLAINED

Critical to the refrigeration system, understanding TEV fundamentals goes a long way to identifying potential system problems.

By Dave Demma

DILLON, AND I’M GLAD I DID. Industry trade shows and events are great places to see new technology, but even more important is the opportunity to reconnect with friends in the industry and meet new people. It’s a gathering where everyone has a common interest in the welfare of the trades

As Liam explained to me, and can be read on his website, he began in this industry as a warehouse helper and went on to earn his Red Seal as a refrigeration mechanic. But ups and downs in his work life, combined with mental health and substance abuse battles, left him lost. It took a while, but he found his way back and now he works in a leadership role. His new purpose is to give a helping hand to others in the construction trades who are struggling because he’s personally been there.

In the plumbing and HVAC world, December usually marks the start of two things: the rush of emergency calls as temperatures drop, and the rare moment when we all stop to catch our breath and reflect on the year behind us. The holiday season is meant to be a time of celebration, gratitude and connection, but for many people it can also be a difficult period of the year.

The skilled trades attract hardworking, resilient men and women who pride themselves on problem solving and showing up no matter the weather or workload. But beneath that toughness, many technicians, installers, apprentices and even owners are quietly carrying burdens.

Mental health challenges don’t take the holidays off. Stress, loneliness, financial pressure, grief, depression and anxiety can intensify this time of year. The long hours, physical strain and unpredictable nature of the work add to it. And like every profession, the trades aren’t immune to substance-use struggles. Drug and alcohol dependency affects more people than most realize.

The holiday season is a reminder that behind every uniform is a human with a life beyond the job. As coworkers, leaders and members of the trade community there are always ways to help. Support doesn’t mean having the answers. It can be as simple as checking in with a colleague who seems off their game. Something as small as, “You doing alright?”—can make a difference.

Contractors and business owners can take this further by fostering a culture where mental health is not ignored or stigmatized. Mental health is health, and there are many trusted places where people can turn.

For many, simply knowing their employer or coworker cares enough to guide them toward help can be life changing. It's why Liam launched nostracura.ca. Having gone through challenges himself, when he says, “I know what you’re talking about.” He means it.

As we wrap up another busy year, let’s take a moment to extend that same care inward—to our own teams and to ourselves. Compassion is not just good leadership; it’s the foundation of a strong, healthy, trade workforce.

From everyone at HPAC magazine, we wish you a joyful, peaceful and restorative holiday season. Take care, stay safe, and may the coming year bring health, happiness and continued success to you and your teams.

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

DIGITAL Macenzie Rebelo (416) 510-6851

EDITOR mrebelo@hpacmag.com

GROUP Danielle Labrie (226) 931-0375

PUBLISHER dlabrie@annexbusinessmedia.com

ASSOCIATE David Skene (416) 510-6884

PUBLISHER dskene@hpacmag.com

NATIONAL Amanda McCracken (647) 628-3610

ACCOUNTS amccracken@hpacmag.com

ACCOUNT Kim Rossiter (416) 510-6794

COORDINATOR krossiter@hpacmag.com

AUDIENCE DEVELOPMENT Urszula Grzyb (416) 510-5180

MANAGER ugrzyb@annexbusinessmedia.com

MEDIA Emily Sun

DESIGNER esun@annexbusinessmedia.com

PUBLISHER Peter Leonard (416) 510-6847 pleonard@hpacmag.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 6 times per year by Annex Business Media. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners. ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2025 by Annex Business Media may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.88 (plus tax) CDN; United States: $114.24 CDN; Elsewhere: $125.46 CDN; Single copy Canada: $8.00 CDN. Heating Plumbing Air Conditioning (establish 1925) is published 6 times per year by Annex Business Media. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-510-5113, Fax: 416-510-6875; E-mail: apotal@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 Annex Privacy Officer

Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

Representatives from the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI), the Canadian Institute of Plumbing and Heating (CIPH) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) convened on Parliament Hill, Tuesday, October 7th, to hold a press conference and present a unified statement to the Federal Government.

Under the banner, “We make life better for Canadians,” the contingent of association leaders shared a proposed roadmap for positioning the Canadian HVAC/R and plumbing industries for success across six priority areas:

Energy Savings & Retrofits: Since buildings in Canada are responsible for 18% of national greenhouse gas (GHG) emissions, the HVAC/R and plumbing industries are positioned to lead retrofit solutions that help Canada achieve its net-zero goals. As such, the associations recommend that representatives from the HVAC/R and plumbing industries play key advisory roles offering guidance when the government is developing new regulations and/or incentive programs that encourage building owners and homeowners to invest in new HVAC/R solutions.

Workforce Development: A BuildForce Canada report highlights the need for Canada’s HVAC/R workforce to quadruple by 2030 to meet net-zero goals. “The industry lacks the skilled workforce capacity to deliver on Canada’s objectives,” voiced Joe Muchynski, national Chair of the HRAI and vice president with Arvin Air Systems. “We recommend that the Federal Government commit to establishing a $100 million decade-long HVAC/R workforce re-training fund to subsidize tuition and up-skilling for HVAC/R and plumbing professionals and support the establishment of national trade certifica-

tion for HVAC/R and plumbing technicians, with the aim of certifying 5,000 workers by 2030.”

Indoor Environmental Quality : “We recommend that the Federal Government convene with the HVAC/R and plumbing industries and technical organizations and relevant scientific and health experts to advise on the adoption of appropriate standards and building codes, the establishment of professional certifications and training requirements for indoor air quality assessments and solutions, and support a communications programs to educate Canadians about the health benefits of investing in improved indoor environmental quality,” said Dennis Boyce, past-President of ASHRAE, adding, “HRAI specifically recommends that the Canadian government commit $5 million towards this communications campaign.”

International Trade: “Canada’s HVAC/R and plumbing supply chains are at risk of serious harm from any further escalation from cross-border trade disputes with the United States,” noted Brent Cornelissen, Chair of CIPH and CEO of +osb. In addition, Martin Luymes, vice-president of

government and stakeholder relations with HRAI, noted: “While we understand the government may need to consider [further] retaliatory measures, the HVAC/R industry’s products and services are too essential to be caught in the crossfire of trade disputes.”

Enhanced Regulatory Coordination: “Additional regulatory harmonization between the Federal Government and the provinces is needed to streamline the adoption of new technologies, encourage sustainable construction and improve Canada’s ability to meet its climate and housing goals,” added Cornelissen. “We recommend, accelerate federal/provincial collaboration to harmonize and accelerate building, plumbing and energy codes, promote interprovincial agreements and reduce trade and regulatory barriers in the construction industry.”

Investment in Infrastructure: The group recommends: the government expand tax credits and scientific research and experimental development (SR&ED) tax incentives to encourage made-in-Canada sustainable technologies. hrai.ca ciph.com

The Ontario Building and Construction Tradeswomen (OBCT), a committee of the Provincial Building and Construction Trades Council of Ontario, has released the results of a 2025 Advancing Recruitment and Retention of Women in the Building Trades survey, revealing both progress and challenges facing women working in Ontario’s construction sector.

The report identifies that while most women are committed to long-term careers in the industry, systemic barriers continue to affect recruitment and retention.

Currently, women represent just 5% of on-site trades and occupations in Ontario’s construction sector, with only 14,200 women working directly on the tools.

The survey gathered insights from 342 women across Ontario and five key takeaways included: women are committed to staying

in the trade; women often discover trades later in life (so earlier outreach is being encouraged); worksite culture remains a challenge (52% reported experiencing harassment); structural barriers limit participation (65% cited need for better-fitting PPE); more women in leadership is key to retention (67% said women in leadership is the top priority for long-term retention).

The report calls for coordinated action among labour, employers, and government to strengthen recruitment and retention through 16 recommendations, including: targeted outreach to schools; zero-tolerance enforcement for harassment; mandate/legislate anti-discrimination and anti-harassment training in all apprenticeship, union, and employer programs; improvements to personal protective equipment, washrooms, and childcare solutions; mentorship programs to support women’s advancement; accountability through transparent reporting on women’s participation and progress.

“We can’t afford to lose skilled tradeswomen to preventable barriers,” said Kate Walsh, program manager of the OBCT. “When women succeed in the trades, the entire industry benefits, from improved safety and innovation to stronger recruitment and retention overall.” obctradeswomen.com

TECA and BCIT have partnered to launch a new microcredential program designed to meet the growing demand for skilled residential heat pump professionals.

Industry-recognized certification through TECA

Hands-on learning in BCIT’s post-secondary environment

Accessible tuition – affordable rates with additional grant opportunities for eligible participants

Upskilling support – provincial funding streams available to help workers advance their careers

This program combines TECA’s industry expertise with BCIT’s proven training approach, giving professionals the skills and certification needed to succeed in Canada's growing clean energy sector.

Returning to Vancouver after four years, the 2025 edition of CIPHEX West added a new partner and new attractions, while the trade show and conference also revisited some similar features of past events and seemed to maintain a distinctive easy-going West Coast energy, laid back.

The name of the two-day event (held November 5th & 6th) was expanded to CIPHEX West and Electrical Learning Expo since the Canadian Institute of Plumbing and Heating (CIPH)—producers of CIHPEX West—joined forces with the British Columbia Electrical Association (BCEA) and the Alberta Electrical Alliance (AEA) to add an electrical contractor element to the show. But by far the plumbing and heating exhibits dominated the show floor area.

Once again held at the PNE Pacific Coliseum (the original home of the Vancouver Canucks), this year featured more exhibits on the upper concourse along with some new features including an Educational Build Event with some recognizable social media influencers— including EH Team members—putting together a boiler panel and also assembling an HVAC furnace.

The upper concourse level also included a New Product Stage, where Colin Sadler, president of John Sadler Plumbing and Heating of Vancouver, hosted a series of equipment company representatives, and together they talked through some new product features.

The main show floor, down one level with booths located both within and outside the confines of the hockey rink configuration, was lined with exhibitors, and the main Learning Theatre with educational sessions on the hour was located just off the main show floor.

The session topics ranged from pump sizing and code-compliant firestopping, to the fundamentals of grease separation and the return of a familiar panel discussion on the future of hydronics.

For many visitors and exhibitors this

type of gathering is an opportunity to reconnect with friends and colleagues while also gaining insights on new products and applications. The informal networking and gleaning information about current industry market dynamics from different perspectives, both within the local region and from different parts of the country, also makes the experience valuable for those who make the time to attend.

The next edition of CIPHEX West will be taking place in Calgary, November 3 & 4, 2027. ciphexwest.ca

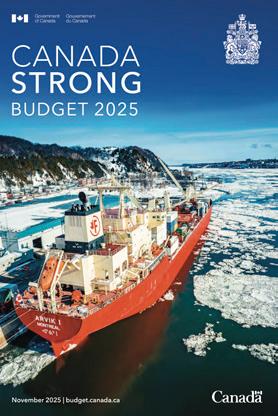

Prime Minister Mark Carney tabled the 2025 federal budget, titled Canada Strong: Budget 2025, prioritizing capital projects and spending in an aim to build resiliency and infrastructure across the country.

The budget projects a $78.3 billion total deficit for the fiscal year. Capital spending, including the construction of infrastructure and homes, accounts for 58% of 2026’s projected deficit. This includes $213.8 million to the Major Projects Office over the next five years for the execution of projects to strengthen Canada’s autonomy, resilience and security.

The Mechanical Contractors Association of Canada (MCAC) commends the budget and its priority to strengthen the nation’s construction industries,but cautioned

these goals can only be supported through collaboration and policies supporting mechanical contractors and related trades across Canada.

“Mechanical contractors across the country are integral to building and maintaining the infrastructure and built environment that is required to ‘Build Canada Strong,’” said MCAC CEO Tania Johnston. “We look forward to helping the government to align on policies to directly address workforce development and retention, productivity-improving investments, and the sustainability of mechanical and major trade contractors across the country.”

The Canadian Construction Association (CCA) was also complementary, but noted the federal government must remain mindful accommodating both union and non-union workers among the large volume of projects budgeted for across the country.

“Union training programs play an im -

portant role in building Canada’s workforce, but we must ensure equitable access to training and credential recognition for all workers, including the 70% of Canada’s construction workforce that is non-unionized,” said CCA CEO, Rodrigue Gilbert. “If we want to build more homes and infrastructure faster, we need investments that don’t leave the majority of workers behind.”

A note from the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) highlights how the budget lacks a climate emphasis but it does support some industry goals including the focus on re-training, In a post-budget news announcement, HRAI remarks that while the budget does not include much in terms of new support for tariff-hit sectors it does reference previously announced funds, including $3.7 billion over three years to support workers, enabling them to “re-skill and retool”. mcac.ca cca-acc.com hrai.ca

Exploring the philosophy of residential HVAC diagnostics and reinforcing the importance of continuous learning.

BY IAN MCTEER

Almost everyone finds themselves regularly troubleshooting something or other: whether it’s a car that won’t start, a phone that won’t charge or a computer that refuses to cooperate. Most of us will at least attempt to resolve the issue, regardless of our expertise. After all, isn’t that what YouTube and social media tutorials are for?

Sometimes the instruction manual helps—if you can find it, and if it actually addresses your problem.

Recently, my sophisticated all-in-one washer-dryer tripped the 15-amp breaker in my panel. The machine boasts a diagnostic feature that sends data to a smartphone app whenever there’s a problem. Much to my surprise, after running the “smart diagnosis,” the app reported: “no problem detected.”

In my universe, a tripped breaker is definitely a problem. Yet, after resetting the breaker and checking for obvious faults, the machine worked normally.

I’ve since installed an ammeter in the dedicated 115 VAC circuit to gather more data before calling in an expert. It seems, at least for now, machine learning and “smart” diagnostics aren’t quite on the same page as the rest of us.

Once the fall heating season arrives, “no heat” service calls become a daily reality for HVAC technicians. With a backlog of appointments and a mitt full of urgent calls, it’s easy for even experi -

Continued on p16

With its dual-hole design for air intake and air exhaust, this Monobloc Heat Pump is a great solution that is easy to install and ideal for the user’s comfort in situations where placing a condensing unit outside the building is not possible or desirable.

enced techs to miss the real problem— sometimes fixing an obvious issue while overlooking a deeper fault.

The truth is, many HVAC systems suffer from misapplication or improper installation, leading to premature failures that aren’t always addressed during a rushed service visit. Often, the proper fix is expensive, and technicians may hesitate to alarm the customer, opting instead for a quick solution to restore heat.

While some problems stem from a lack of regular maintenance, which can lead to tense discussions about service costs and responsibility. These challenges underscore the importance of troubleshooting with intention: taking the time to diagnose thoroughly, communicate honestly, and consider both immediate needs and long-term solutions.

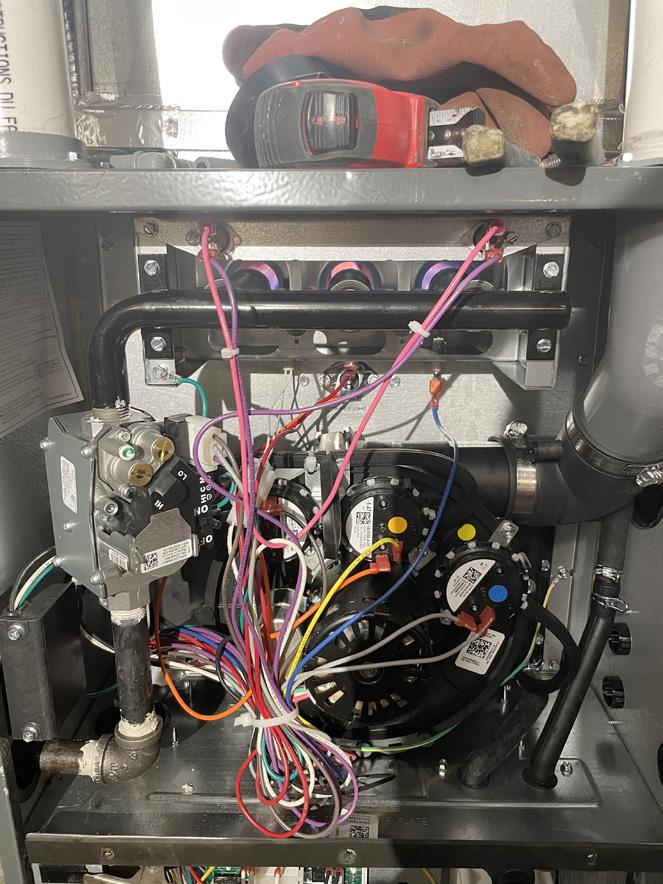

In my former role as a field service representative, I regularly provided product knowledge and servicing seminars for experienced technicians and installers. Every seminar began with an equipment installation overview, because so many service calls stem from installation faults—such as improper ducting, vent pipe sizing and slope, incorrect vent termination, control wiring issues, control board settings, gas pressure settings, and more.

The challenge is especially acute for technicians who service all makes and models. One minute they’re working on a gas fireplace; the next, a modulating boiler. With little time to consult a hundred-page installation manual, it’s understandable that a technician might jump to a quick conclusion, one that may or may not resolve the real issue. Not that I had a flawless troubleshooting career. I made my share of mistakes over the years, but sometimes I managed a triumph!

Early one heating season, I was dis-

patched to service a Lennox G14 Pulse furnace, a unit known for its unconventional combustion cycle, and one I had no formal training on. When I arrived for the call, I learned that several technicians had already tried to fix the problem, replacing parts like the gas valve, control board, flame rod, flapper material, and even the fan relay, all without success. It struck me that this furnace probably didn’t need yet another new part. So, I ran it through a cycle. It started, pulsed a few times, then shut down, sounding much like a car engine sputtering out of gas.

Using a manometer, I measured 7-in. of static pressure in the service gas line, but the working pressure dropped to zero as soon as the unit demanded fuel.

The homeowner assured me the unit had worked properly for years; no alterations had been made to the gas piping. So, I checked outside at the gas meter and discovered the pressure regulator vent was blocked by a large, abandoned wasp nest. Once I cleared the nest, the furnace resumed proper operation.

This experience taught me that effective troubleshooting starts with resisting the urge to jump to conclusions

based on assumptions. Sometimes, the real issue is hiding in plain sight.

Thus, the best diagnostics begin with observation, especially with the knowledge that something might be amiss since day one.

Before tools come out of the bag, take some time to look around. If the snow is up to your knees, check the vent termination and gas regulator for blockages caused by snow or freezing rain.

Indoors, use a bright flashlight and have a mirror handy. Look for water pooling, and listen for noises. Talk to the owner, ask about any odd system behaviour, and when did it start?

Look for smart thermostats that have performance logs; I used to carry a small notebook to log observations and serial numbers, a smartphone can do all that now. This isn’t wasted time; it’s detective work in which technicians ask “Why?” at every step looking for answers that make sense.

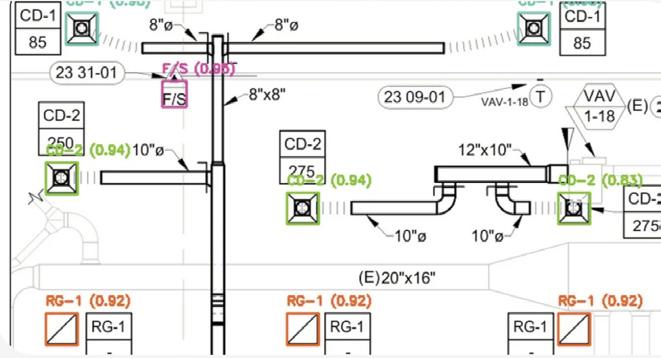

Technicians too often must deal with equipment malfunctions that were inevitable since startup. In residential highefficiency gas furnaces, increased heating efficiency depends less on condensing heat exchangers and precision burners and more on dramatically increased airflow.

Modern furnaces running at a 60F temperature rise require much more air movement than their older counterparts rated for a 100F rise. Limit control failures are frequently caused by insufficient airflow—even when the air filter, evaporator coil and secondary heat exchanger components are clean.

For instance, many homes originally had an 80% AFUE furnace rated for a 100F rise, requiring about 592 cfm and typically paired with an 8- x 18-inch trunk duct. When these old blisters are replaced with, for example a 60K Btu/h 95% AFUE condensing furnace, this new

unit will likely demand approximately 27% more airflow, despite a 33% smaller gas input.

Swapping out the limit control may restore heat temporarily, but the underlying airflow problem remains, risking premature heat exchanger failure.

Perhaps the best solution derived from intentional troubleshooting in this situation is to have an expert conduct a proper load calculation meant to ensure the furnace and ductwork are correctly sized to support long-term reliability.

Effective HVAC troubleshooting starts with understanding the system’s purpose and design. Service managers should consider why a particular furnace, boiler or rooftop unit was specified for a troublesome job, and what performance it was meant to deliver.

This means reviewing the original load calculations, equipment specifications and control strategies. When problems arise, it’s not enough to identify

what isn’t working, because the technician must ask why the unit is behaving this way. Are the controls operating as intended? Is the equipment matched to the building’s needs?

By investigating both the symptoms and the underlying design, technicians can provide solutions that address root causes, not just temporary fixes. Figuring things out as you go is no longer an effective strategy.

Imagine an automobile mechanic who insists on replacing your expensive engine management computer simply because the engine won’t start; even though it turns over. Most of us would expect the mechanic to first check the basics, like whether there’s enough fresh fuel in the tank.

Yet, in HVAC troubleshooting, it’s surprisingly common for technicians to jump to replacing parts when faced with

start-up issues, flame failures or poor performance.

Is a new part always the answer? Not necessarily.

For example, electronic circuit boards are “fueled” by a steady voltage supply, so verifying voltage at the board should be an early diagnostic step before considering replacement.

All gas-fired appliances depend on a properly sized and unobstructed fuel supply line to operate under all conditions. Canada’s B149.1 code book, specifically Annex A, provides capacity tables (such as Table A.2) which detail the maximum natural gas flow for schedule 40 steel pipe including fittings at pressures from 7-in. w.c. to 14-in. w.c., assuming a 1-in. w.c. pressure drop. When diagnosing issues like delayed ignition or persistent flame failures, it’s essential to check for fuel input problems.

on p18

While technicians often verify the manifold pressure (typically 3.5-in. w.c.), two upstream tests are equally critical: static pressure and working pressure in the gas line.

The static pressure, measured with the appliance off, should be around 7-in. w.c. Once the unit is running, the pressure should not drop by more than 1-in. w.c. A significant drop points to an undersized or restricted gas line, or, as I discovered with the Pulse furnace, a problem with the utility gas supply regulator.

One of the most valuable resources a service technician can have is accurate, comprehensive start-up and commissioning data. For residential work, it should become a best practice leading to standard procedure.

In my view, having the ability to compare current readings to original values will help to reveal deviations from optimal performance. Complex problems should be more easily diagnosed reducing guesswork and unnecessary parts replacements.

Start-up data provides a baseline snapshot of how the system performed when it was new and properly configured. What data should be recorded?

Typical start-up/commissioning data includes, but is not limited to:

• Equipment model and serial numbers.

• Instal date and installer contact info.

• Initial operating pressures (gas, refrigerant, static, working, manifold) .

• Gas meter timing.

• Voltage readings at key components.

• Airflow measurements (CFM, temperature rise/drop) .

• Control settings (thermostat, board configuration) .

• Combustion analysis results (for gas or oil-fired appliances) .

• Ductwork sizing and air filter type.

• Venting system details.

Code soure guide for gas-fired appliances.

“Before tools come out of the bag, take some time to look around.”

• Any deviations from manufacturer specs or site-specific notes.

Technicians, contractors and homeowners all benefit from this approach: it saves time, reduces costs and ensures that systems deliver reliable comfort for years to come. In short, intentional troubleshooting begins with intentional documentation.

There is a lot of sophisticated equipment in the field intended to better utilize resources such as natural gas and electricity. Ironically, fewer skilled technicians and installers are available to shepherd all these products, especially when things go wrong.

Manufacturer installer guides and service literature exist, but too often the documents are not immediately available on the jobsite and are not designed for quick reference under pressure.

Some equipment has a QR code providing video support that can be helpful if the technician has the time and a decent wireless signal. And third parties like Xoi Technologies enable remote diagnosis with real-time video support, workflow automation and access to manuals along with training content.

LiveSwitch, a recent entrant into the HVAC world having expanded its expertise from other home services, can help with diagnosis using live video combined with visual images provided by a technician’s smart phone aimed at the problem area.

I follow the HVAC Know it All website, Bryan Orr’s HVAC School, and ESCO Institute to name several of my sources, because writing about today’s HVAC is almost as daunting as the actual handson experience.

In the end, I believe all companies must provide frequent, targeted inhouse training so technicians will have the knowledge needed to troubleshoot complex systems. The most successful service companies invest in regular morning seminars or weekly sessions where technicians can review recent service calls, discuss new technologies, and share best practices.

Ongoing education not only improves first-time fix rates and reduces call backs, but training sessions also help build a culture of great teamwork. When technicians (and installers) feel more supported and prepared, they are better equipped to install, commission and solve problems with intention. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician. For comment, he can be reached at imcteer@outlook.com.

VERSATILE, SUPEREFFICIENT & ULTRA-QUIET

Keeping your home comfortable has never been more convenient—or customizable. Designed to match your unique heating and cooling needs, Rheem® Floating Air™ Ductless Mini-split Systems are available in single and multi-zone options. Plus, every unit offers high energy efficiencies and quiet operation, delivering year-round peace of mind.

Creating hydraulic separation within closed-loop hydronic systems can be accomplished in many different ways.

BY JOHN SIEGENTHALER

any technologies have their “glory days,” those times when technical improvements happen quickly, performance gains are impressive, and interest is strong. In my opinion, the 1940s through the 1990s were the glory days of aviation. Huge progress was made, starting with the propeller-driven fighters that helped win World War II, and extending through research jets that could fly five times the speed of sound just three decades later. A lot of kids, including me, wanted to be a pilot and strap themselves into one of those incredible machines.

Although less glamorous than aviation, North American hydronic technology also had its glory days. In my experience, this period began in the mid 1980s when PEX tubing made its way here from Europe. Prior to PEX, residential hydronic heating was mostly two or three of zones of fin-tube baseboard supplied from a cast iron boiler.

These systems worked, but they weren’t very “sexy.” In those days there weren’t many homeowners who wanted to give their guests tours of their boiler rooms.

The availability of PEX tubing led to a revival of interest in radiant panel heating. Although there were plenty of early mistakes (like stapling PEX to the side of floor joists and expecting it to heat the space above), progress was made.

+

+ Up to 10:1 turndown ratio (residential boilers)

+

+

Boasting efficiency greater than 95%+

Direct venting up to 150 ft

Built-in cascade control up to 16 boilers

Display can be set up to 18 languages

Limited warranty 10 years on heat exchanger

Warranty 5 years residential & 3 years commercial on parts

Soon designers were looking for ways to expand systems beyond just radiant panel heating. They wanted to incorporate multiple boilers, higher temperature emitters along with low temperature radiant panels, and domestic water heating into the same system. Houses were growing in size and adding “thermal amenities” such as snow melting and pool heating. The multiload systems designed for these projects usually included several circulators, often of different size and performance, and in many cases two or more of those circulators operated simultaneously.

This all led to an increase in problems that could be summarized as the big circulators “bullying” the small circulators. There were large shifts in flow rates

depending on which circulators were operating at any time. I even witnessed one system where interference from a large circulator completely stopped flow in a circuit powered by a smaller circulator, even with the latter running on its highest speed setting.

While trying to solve these problems the North American market eventually rediscovered a technique that had its roots back in the 1960s: primary/secondary piping.

Coupling one circuit to another circuit using a pair of closely spaced tees all but eliminated any interference between the circulators in the two circuits.

Designers, including myself, began

Very minor change in circuit 1 flow rate when circulator 2 is running

cranking out schematics where multiple secondary circuits, each serving a different load, were coupled to a primary loop using pairs of closely spaced tees.

For the most part these designs worked, and the primary/secondarytechnique grew in popularity.

Still, I’m convinced that a significant percentage of designers or installers don’t fully understand why closely spaced tees do what they do. They just install the tees as shown on plans and wait for the “magic” to happen.

Primary/secondary piping is one of several ways to achieve hydraulic separation. It’s one way to couple two or more overlapping hydronic circuits, each with its own circulator, so that the circulators don’t interfere with each other.

If you understand the underlying principle of hydraulic separation, you’ll understand why a pair of closely spaced tees is one way to achieve it.

Consider the hypothetical piping system shown in Figure 1 (previous page). This system consists of two parallel circuits, each with its own circulator. Assume that the circuits can have dif-

ferent pipe sizes, pipe lengths, fittings, etc. And notice that the two circulators are also different in size.

The two circuits “overlap” at the “bulge” to the left of the circulators. We can call this bulge the common piping because it is shared by each circuit.

Because it has a wide cross section, and its length is relatively short in comparison to the lengths of each circuit, the head loss across the common piping will be very small.

Start by assuming that circulator one is running, and circulator two is off.

Figure 2 shows the pump curve of circulator one (orange), along with the head loss curve for circuit one (green).

That head loss curve includes the head loss of the piping in circuit one, and the very small head loss across the common piping.

The operating point, the location where the pump curve crosses the head loss curve, corresponds to a flow rate of 10 gallons per minute (gpm).

Next, assume that circulator two in Figure 1 is turned on, and circulator one remains on. The total flow of both circuits now passes through the common piping. This will cause a slightly higher head loss across the common piping, which will slightly increase the total head loss of circuit one.

The change is represented by the

blue curve shown in Figure 3. For comparison, the original (green) head loss curve for circuit one is also shown.

Notice that the operating point moved very slightly to the left, from the (green) dot to the (blue) dot. This slight change causes the flow rate in circuit one to drop from 10 gpm to 9.9 gpm.

That change, for all practical purposes, is of no consequence. Thus we can consider the two circulators in this system to be hydraulically separated from each other. This desirable effect is a result of the two circuits “sharing” common piping that has very small head loss.

Another way to think about two circuits that are hydraulically separated is to image each circuit as being physically separate from the other (see Figure 4).

The flow rates that would be established by each circulator in its associated sub-circuit (such as 10 gpm in circuit one, and 12 gpm in circuit two) would be approximately the same regardless of the two circuits “overlapping” as shown on the left, or completely isolated from each other, as shown on the right.

So here’s the take away: Anything that couples together two or more hydronic circuits, each with its own circulator, and where the head loss of the coupling method is very small, results in hydraulic separation of the circulators.

There are several hardware configurations that meet this criteria:

1. A pair of closely spaced tees (classic primary/secondary piping).

2. A buffer tank piped as either a twopipe, three-pipe, or four-pipe configuration.

3. A typical cast iron boiler combined with short/fat headers.

4. Or, a hydraulic separator (low loss header) combined with short/fat headers.

These hardware configurations are all illustrated in Figure 5. All of these arrangements bring together two or more circuits, each with their own circulator, in a way that creates very little head loss where the two circuits overlap.

For the closely spaced tees, this overlap is a tube stub just long enough to join the tees side by side.

For systems with buffer tanks piped as shown in Figure 5, the buffer tank is the low head loss common piping. The large cross sectional area of the tank produces very low flow velocities inside the tank, and thus very low head loss.

The cast iron boiler consists of several sections that each have large cross sectional areas and thus create very low flow velocity and head loss. Still, it’s important to use what I call “short/fat headers” to preserve the hydraulic separation effect of the cast iron sections up to the point where the circulators connect to the system.

Then there’s a hydraulic separator. The cross-sectional area of the vertical portion of the separator is about nine times larger than the cross section of the piping connected to it. This reduces flow velocity to about 1/9th that in the piping, which again results in very low head loss.

The nice thing about a hydraulic separator is that it also can provide efficient air and dirt separation for the system. To “preserve” the hydraulic separation it’s also important to use short/fat headers on both sides of the separator. Another benefit of headers and a hydraulic separator, relative to a classic series loop in primary/secondary pip ing, is that each parallel load circuit re ceives the same supply water temp.

Combinations of the details shown in Figure 5 can also be used in the same system. One example of such a combi nation is shown in Figure 6.

In this system the fixed speed circula tor (P1) providing flow through the wood gasification boiler is coupled to a vari able speed shuttle circulator (P2) using a pair of closely spaced tees. This de coupling allows (P2) to adjust speed as necessary to maintain the boiler inlet temperature high enough to prevent sustained flue gas condensation.

The variable speed injection circulator (P3) is hydraulically separated from the oil-fired boiler circulator (P4) and the distribution circulator (P5) by two more sets of closely spaced tees.

This system has five circulators and four points of hydraulic separation.

Although the overall schematic may look complicated, think of it as broken up into five subsystems (Figure 7).

The flow rate established in each of these subsystems is essentially unaffected by flow rates in the other four subsystems. That may be hard to believe when looking at the overall system, but it’s true.

There’s no “magic” involved with hydraulic separation. Anything that couples two or more circuits together so that the piping they share has very low flow resistance, and thus very low head loss, can provide it.

In this context it’s a really a simple concept, but also one that’s extremely useful in hydronic system design.

By the way … I don’t think the “glory days” of modern hydronics technology have ended. The opportunities at hand for creative system designers continue to expand.

Water is still the best stuff on earth for moving thermal energy around. Just make sure your designs respect the concept of hydraulic separation to “keep the peace” between potentially competing circulators. <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating & Cooling (4th edition) as well as Heating with Renewable Energy (for more information visit hydronicpros.com).

The thermal storage tank provides hy draulic separation between variable speed circulators (P2) and (P3). Note that the piping circuits containing these two circulators tee together very close to the tank. This minimizes head loss in the short headers that connect the tees to the tank.

Together with John Siegenthaler we point out how to achieve hydraulic separation in hydronics systems. BY

DOUG PICKLYK

On October 30th HPAC Magazine once again hosted a free live webinar, part of the ongoing 30 Mechanical Minutes series of free webinars, and this one featured hydronics industry expert John Siegenthaler joining us for a conversation on the topic of hydraulic separation. The sponsor for this edition of 30 Mechanical Minutes was Residio, a manufacturer with a broad portfolio of products, covering HVAC, thermostats, security systems, and of course plumbing and specifically hydronics products including hydraulic separators.

To illustrate the basic concept of hydraulic separation, Siegenthaler shared an illustration of two kids in conflict, one larger than the other. “The big guy represents a bully on a playground and think of that guy as the big circulator in a system, and then think of the small guy as a small circulator,” explained Siegenthaler.

“Unfortunately, if two or more circulators “see” each other from a pressure dynamics standpoint—if they can communicate their pressure differentials in the same system—they will interfere with each other, and typically the larger circulators can cause the smaller circulators to operate at lower flow rates than they normally would if they were running by themselves.”

It’s the attempt to avoid this struggle over control of the flow that requires the pumps (circulators) to be separated on a closed-loop hydronics system, thus the need for hydraulic separation, he explains.

“The general idea is, whenever you have a hydronic system

with two or more circulators that are capable of running at the same time (and today that is the vast majority of systems), we need to make sure that they are hydraulically separated from each other,” he says plainly.

What’s important for hydronics contractors, system designers and installers is the ability to look at systems, whether schematics or installed systems in the field, and identify where there is common piping leading to two circuits or more and ensure there is no interaction between the circulators. To ensure there is no interaction will depend upon the head loss (or the pressure drop) through the common piping. “The lower the head loss is, or the lower the pressure drop through the common piping, the less the circulators will be able to interact with each other,” he says.

Siegenthaler insists that hydraulic separation is not a concept that you either have it or you don’t have it, because in theory you can never have perfect hydraulic separation, but if you make the pressure drop quite low in the common piping it will be adequate.

One change in modern hydronics has been the introduction of modulating variable speed electronically commutated motor (ECM) circulators, as opposed to the common fixed-speed circulators.

For example, you might have a system that has a variable

Continued on p28

speed circulator on the same header as a fixed speed circulator, and the variable speed circulator can be set to respond to the pressure differential it feels. A lack of hydraulic separation could cause conditions that would fake out what that variable speed circulators is trying to do on its own circuit.

So Siegenthaler always recommends hydraulic separators in systems with variable-speed circulators.

Designing common piping with very low head loss and pressure drop characteristics can be accomplished in many ways.

“If we look historically at the North American hydronics market, rolling the clock back at least 20 maybe even 25 years ago, many systems were being designed with what’s called primary/secondary piping where we use closely

Ensure your HVAC/R appliances, equipment and components are certified to meet the latest regulatory requirements utilizing low global warming refrigerants. Intertek’s experts will help you gain compliance and certification for flammable refrigerants with speed to market.

+1 800 WORLDLAB (967 5352) icenter@intertek.com Intertek.com/HVACR FOR MORE INFORMATION

spaced tees to separate the hydraulics of one circuit from the hydraulics of another circuit,” he says.

The closely spaced tees are where the two circuits overlap, so that is the point of common piping, and because the tees are right next to each other the pressure drop through those connections is almost zero.

“Because the pressure drop is so low between the tees the flow rates in those two circuits that overlap at those tees is essentially independent of which circulator is going to operate,” explains Siegenthaler.

In answer to, “How close should closely spaced tees be positioned?” He was very clear: “As close as you can get them.”

“Primary/secondary piping was first developed around commercial chilled water systems, and these systems typi -

cally use larger pipes, 3-in., 4-in., even larger in some cases. So putting two 4-in. tees next to each other you might have close to a foot between the centre of one tee and the centre of the other. But there’s no reason to have them a foot apart if it’s smaller piping.”

He notes that there are companies that make fittings that essentially give you the equivalent of two closely spaced tees in a single fitting. And he’s noted some installers have also used a tool called a Tee Drill where they can drill two holes in a pipe and spin out the collars necessary for the two connections.

Siegenthaler also showed other methods of creating hydraulic separation including hydraulic separators and buffer tanks. He explains that in a hydraulic separator the flow velocity slows down to about one-ninth of the entering flow rate, and thus because it slows down you have very little pressure drop between the top and bottom of that separator.

The nature of these devices also allows the ability to collect and vent air bubbles at the top as well as collect dirt sediment at the bottom. And newer versions are also designed with magnets to remove iron oxide, or magnetite, out of the system.

He also showed three variations of buffer tank piping (4-pipe, 3-pipe, and a 2-pipe) with the tank providing the separation.

He then also pointed to the cast iron boiler as a component that has a very low pressure drop as flow goes through it. “We had hydraulic separation in hydronic systems decades ago when we were largely using only cast iron boilers; we just didn’t realize it. And if we follow the history of hydronics, when boilers with much higher pressure drop characteristics started to come into the market (some of the initial condensing capable boilers), suddenly there were problems with flow that were never present with cast iron boilers.

When it comes to sizing headers Siegenthaler has long referred to “short fat headers,” and what he’s suggesting is to keep headers as short as possible and be generous in how you size the pipe. “I would say your header should be, at a minimum, one pipe size larger than your branches, and even more generous would be two pipe sizes larger.”

Why? Because the idea is to keep the pressure drop in the headers as low as possible and create the best hydraulic separation.

“Hydraulic separation a very powerful concept, and it’s a broad concept as well,” says Siegenthaler. “It’s not limited to just primary/secondary piping with closely spaced tees, and it’s not limited to just systems with a hydraulic separator in them. It can be achieved with buffer tanks, it can also be achieved with low head loss boilers, like a cast iron

What’s the maximum velocity for common headers?

“If you have a header with several circulators that are being supplied by the header, take the total flow when all those circulators are operating (assuming all those circulators can operate simultaneously), and size the header pipe so that under that total flow rate condition the flow velocity doesn’t exceed two feet per second.

What is the most cost-effective way to achieve hydraulic separation?

If you’re using a cast iron boiler just keep your headers short and fat, and you’re done. A hydraulic separator would displace the need for an additional air separator and dirt separator. People figure they can install an air separator, dirt separator and a pair of tees cheaper. Well, the hardware might be less expensive, but not by much, and you have to consider the labour and space in the mechanical room.

Where to put the expansion tank when using a hydraulic separator?

The place not to put it is at the bottom of the separator, it’s going to collect dirt onto the diaphragm in the expansion tank. Put it on either side at the bottom of the hydraulic separator.

boiler. There are many solutions.”

A recording of this session (and past episodes of 30 Mechanical Minutes) is

FREE WEBINAR I JAN 13 @ 2PM ET

VISIT HPACMAG.COM AND SCROLL DOWN TO 30 MECHANICAL MINUTES.

There you can select from a number of recent hydronics focused episodes featuring John Siegenthaler.

• Hydraulic Separation

• Hydronics and Thermal Storage

available at hpacmag.com under the webinars tab, and on our YouTube channel youtube.com/@hpacmag. <>

Sponsored by Virtual Content for Real Time Professionals MISSED PREVIOUS EPISODES?

• Glycol and Hydronics

• Electric Boilers

• Air-To-Water Heat Pumps

The efficiency and effectiveness of hydronics and heat pumps in modern buildings is reliant on smart system design and unified controls.

BY ZACHARY LONDO, JEAN-CLAUDE RÉMY & CHRIS DESROCHES

The Laws of Physics do not change. Heat will always move from hot to cold, and this remains true for hydronic systems used within commercial buildings. Present and future challenges require better management and control of heat flow in buildings beyond trying to slow down the transfer from inside to outside through better insulation. Improving internal heat flow entails better piping arrangements with multiple heating/ cooling sources, diversified terminal units and, of course, improvements to

how everything is controlled like a perfect symphony.

In the design process, especially with mechanical design, controls are often an afterthought added into the project specifications at the eleventh hour. Instead, controls should be viewed as a critical aspect of holistic design, which is why they are one of the fundamental pillars we’ve identified in this series of articles which identify the promise of heat pumps and hydronics as keys to efficient building designs.

Controls act as a conductor, ensuring all systems work together instead of fighting against each other. Without properly tuned controls, you are left with setpoint hunting, short-cycling, under or overheating or even premature failure of equipment and unnecessarily high operating costs. This is why it’s important to keep controls in mind early and often in the process of thermodynamic design. Ask yourself, “What am I trying to achieve, and how do I do it?”

Large commercial or institutional buildings often have diverse loads with different terminal units at different supply water temperatures which directly influences piping strategies and controls. In Canada, most heating systems using heat pumps require some kind of supplemental heat for the coldest period of winter. The first step to adding an auxiliary heat source is understanding how it should be piped, and when it should run.

Passing the supply water from a heat pump and then through a “booster” to achieve higher fluid temperature (piping units in series) is usually not a good idea. Just like in an orchestra, each part of the system must be able to work independently to achieve proper results and maximize efficiency.

While both primary and auxiliary heat sources will add energy into the supply loop, their design flow and delta T requirements will vary. An in-series piping

Continued on p32

Continued from p30

strategy disrupts the system’s harmony which is why they need to be piped in parallel, where each source can “inject” the energy it produces into a common, primary loop, or something equivalent like a storage tank.

One of the simplest solutions for the coldest days when the heat pump cannot keep up with the load, and temperature in the system begins to drift, is to shut off the heat pump and turn on an auxiliary boiler. This solution provides resilience and redundancy to the design, and it also allows the less efficient boiler to turn on only when needed, eliminating system downtime. How can the piping strategy accommodate that?

While all projects are different and piping strategies will vary, each with their unique control requirements, the most common design in Canada involves the use of a heat exchanger to decouple the glycol-water mix, required for its antifreeze properties by the outdoor air-towater heat pumps, from the 100% water used within the rest of the building (see Figure 1, next page).

This design requires an additional pump, but it reduces the total volume of glycol needed and its negative performance impacts. Using glycol for the entire heating distribution would require increasing the flowrate compared to 100% water, and it can add up to 30% more head depending on the concentration (requiring more energy). Of course, there is also the added cost of the glycol and feed tank if used for the whole system. This can more than offset the price of the heat exchanger and an additional pump. There are additional control advantages that will be apparent when this article discusses delta T’s.

With the heat exchanger in place, the boiler is postitioned on the secondary side of the system, heating water in -

stead of glycol. The boiler has its own elevated setpoint to manage, and the heat pump may or may not act as the first stage of heating to the system. The key to having this setup controlled effectively is to ensure the return temperature comes back low so the heat pump will keep working.

If the return temperature on the secondary side comes above the setpoint of the heat pump, the unit will shut off its compressor resulting in non-optimal usage of the boiler and potential shortcycling of the heat pump.

A simpler way to integrate auxiliary heat is by substitution: If the outdoor temperature drops below a predetermined point the heat pump shuts off and the boiler becomes the primary source. Again, each building is unique and thus the design should be tailored to suit, since the equipment used is much more complex, rather than trying a one-size-fits-all approach.

When multiple heat pumps are used, flow must be managed in the system. Most heat pump units now have integrated pumps that serve the unit needs based on load and delta T. Controlling this is simple since the unit has its own internal sensors. It confirms flow with a

flow switch and only starts the compressor when it has detected a flowrate.

At the heat pumps, heating and cooling often requires a different flowrate which is frequently overlooked. One option is to use a variable frequency drive (VFD) to get two flowrates, a heating flow and a cooling flow, in which case the terminal units and distribution is sized for fixed delta T’s for both heating and cooling.

The other option is to size the system and terminal devices for the higher of the flows (usually cooling) which will result in a smaller delta T in heating. Either method is a tradeoff between performance and control simplicity.

To design a variable flow system using a large, centralized, pump would require several control valves in the system. This adds complexity and could lead to “ghost flows,” providing heating or cooling when it’s not desired. The pump will have to modulate between the smallest and largest design flows between heating and cooling modes, which may not be the best option.

Using multiple pumps in parallel offers some redundancy in case of pump failure (you don’t lose the whole system) and allows for more precise control of

terminal units. In the piping design, using closely spaced tees, low loss headers and storage tanks permit independent operation and easier balancing in such situations. There is a need for isolation valves when the pressure differential developed by the pumps is higher than ~13psi (30 ft. of head). Going beyond this may induce “ghost flow.”

Because of such widely varying conditions, in the plant room and zones, primary-secondary (P-S) piping is preferred over a single primary loop system. P-S allows more flexibility and simpler con -

trol of the terminal units in the buildings at many different sets of conditions that can vary drastically.

The primary (plant) side maintains the outlet water temperature setpoint, in effect isolating it from the dynamics of the loads in the building. With this strategy, the secondary side of the system can be operated and controlled much more effectively.

When a heat exchanger is used, it permits different delta T’s between the mechanical room and the terminal units. Typically, at very cold design conditions of -15C to -20C, the heat pump will be limited to producing about a

10F-degree delta T, yet several terminal units will work at different flow rates and delta T’s.

We can now size fan coils, air handling unit (AHU) coils or radiant systems on higher temperature differentials, typically 20F-degree delta-T, cutting the flow rate in half, reducing the size of pipes, valves, pumps (thus also reducing cost) while delivering comfort to the occupants and providing control flexibility by having two independent control systems working together.

From the last issue, the benefits of a decoupled ventilation system used to leverage hydronics and use lower heating temperatures and higher cooling temperatures was explained.

There are several controls considerations to keep in mind to ensure that the ventilation strategy is controlled effectively.

Demand control ventilation (controlling zone ventilation based on space CO2 levels) means only ventilating spaces when needed. This can offer significant improvements over variable air volume (VAV) systems to reduce energy consumption. In fact, without using demand control ventilation, energy usage of the system could increase the need for additional heating or cooling in zones because the ventilation air still needs to be treated. What better way to save energy than to reduce the ventilation and the associated energy required to condition the fresh air and maintain the zone setpoints.

Zone ventilation also requires relative humidity (RH) control. If either humidity or CO2 is out of range of the desired setpoint, the room air should be flushed with fresh, pre-treated air from the central dedicated outdoor air system (DOAS) unit to get the setpoint back into the desired control range.

Centrally, at the DOAS unit the ma -

chine controls the leaving air temperature setpoint as well as a humidity setpoint. Enthalpy wheels may be used to provide a “first stage” of dehumidification (or humidification in winter) and sensible temperature.

After air-side recovery, the remaining post heating/cooling treatment of the air can be controlled using water from the central plant to achieve a neutral air temperature that is in the 40-60% RH range. From there, the zone equipment handles the rest of the sensible load to satisfy the temperature setpoint (see Figure 2).

As discussed in previous articles, when DOAS is used to decouple the latent load from the zones, by supplying fresh pre-treated air to the zones directly with smaller ducts, this also facilitates the use of low temperature heating and high temperature cooling for the remaining sensible loads at improved efficiencies.

In heating mode, lower heating temperatures can be used with radiant systems that modulate to maintain the room temperature setpoint by regulating the water flow to the slab or to other heat emitters in the space.

In summer, when the building requires cooling, the water temperature to the local zones must be carefully managed when using radiant cooling. The first and most important rule for radiant cooling is to keep the humidity level below 50% for optimal operation.

Monitoring the fluid temperature relative to the zone dew point is essential, and the water temperature supply to the zone should be kept above the dew point to avoid condensation. Mixing valves are usually used to mix return water into the supply to the zone to ensure the surface temperatures in contact with the water are above the dewpoint. When DOAS systems are sized properly, and when humidity and

fresh air supply to the space are properly controlled, the additional sensible load can be managed using higher cooling temperatures.

Dehumidification still must occur somewhere in the system, typically this is achieved by using a chilled water temperature from the central plant at the traditional 42F to 44F. This is a temperature that is cold enough to dehumidify the

“An integrated design process considering piping in conjunction with controls is imperative.”

fresh air by overcooling the air to about 50F to 55F to dehumidify the outside air. Since 55F air is too cold to send to the zones, it must be reheated to about 65F to 70F before supplying the fresh air to the spaces. When heat recovery chillers, or four-pipe heat recovery heat pumps are used, this is a great way to get the reheating energy for “free” at the central plant by recovering the heat to the hot water loop, instead of rejecting it outside like what is done with a conventional chiller.

If additional sensible cooling is required in the spaces, it is usually supplied from a second chilled-water loop, kept above the dew point by mixing return water with the supply water to each tertiary loop to ensure a temperature that is above the dew point. From there the warmer chilled water loop provides sensible cooling in the zones.

There are other methods and strategies, however these options all involve decoupling the latent and sensible loads somehow to achieve energy efficiency

and comfort. Humidity and fresh air must be properly controlled where cooling is required, and the different parts of the system must work together in unison.

While integrating the individual pillars (building envelope, indoor air quality, heating/cooling, controls) required for a high efficiency building might seem more complex to design, it is merely an adaptation of integrating heat pumps and their specific needs into the design.

In order to optimize the efficiencies of the components, we cannot avoid the fundamentals of heat transfer, fluid flow, humidity management and the required controls if we seek to fit the pieces properly together.

One must also consider that piping a heat pump to a system is not the same as a boiler. Designs from a decade ago might have been simple and routine, sizing components with rule-of-thumb calculations, but in today’s world an integrated design process considering piping in conjunction with controls is imperative to achieve the stringent performance targets of a low-carbon, highly efficient system without compromising comfort.

The next and final article in this series will look at integrating all of these principles into retrofitting existing systems, a requirement that is estimated to makeup a significant portion of the HVAC market in the coming decades. <>

This four-part series is a collaboration among: Zachary Londo, PE, is a senior design engineer with GF Building Flow Solutions (Uponor); Jean-Claude Rémy is a business development manager with GF Building Flow Solutions (Uponor); and Chris DesRoches, P.Eng., is the business development manager, heating and cooling, with Swegon North America.

Over $12,000 worth of hydronic equipment will be won including:

Thank you CB Supplies and Grundfos Canada for rewarding Canadian excellence in hydronic installations!

Send us pics of your installation. Include a brief description of the particular challenges that you faced with this installation and how you overcame the obstacles. Submissions are limited to one per contractor, per category. Deadline to enter is July 31, 2026. All submissions will be featured on screen at Modern Hydronics - Summit 2026.

There are three categories:

• Commercial installations

• Residential new build

• Residential retrofit

The three winners will also be announced by John Siegenthaler at the Summit. In addition to having your winning entry shared across our social media channels you’ll also be interviewed by HPAC’s editor and featured on the cover of the October edition of HPAC!

NTI Boilers/Ariston Canada, headquartered in Saint John, New Brunswick, has struck up a partnership with the local major junior hockey team, the Saint John Sea Dogs. As part of the relationship, NTI has a rinkboard ad along with the NTI logo displayed with some other signage in the arena.

In early November NTI Boilers legally changed its name to Ariston Canada to reflect its parent company, the Ariston Group. Strictly legal in nature, the NTI brand will continue to be used in the marketing and sales of its products. ntiboilers.com

>> Carrier Enterprise Canada announced a new distribution agreement with Kerr Controls, whereby Kerr will be the exclusive Atlantic distributor for both residential and commercial Carrier branded products. kerrcontrols.ca

>> Barclay Sales now represents the made-in-Canada Vulcano high velocity and low velocity hydronic air handlers. vulcanoair.com barclaysales.com

>> Rinnai opened a warehouse in Canada, stocking and shipping from a Canada Cartage Logistics Solutions’ distribution centre in Markham, Ont., offering direct access to major Highways 404 and 407. www.rinnai.us

>> Carrier Enterprise Canada has moved its headquarters, including a distribution centre and wholesale parts

NEXT Suppy Scores Again … at this year’s Road Hockey to Conquer Cancer tournament, held at the end of September as a fundraiser for The Princess Margaret Cancer Foundation, NEXT staff together with customers, vendors, friends and family led the event in both the number of teams (30) and people participating (over 400) as well as fundraising dollars (over $600,000) to win the Corporate Cup. Michael Storfer, CEO of NEXT, was the Honourary Chair of the event. Overall, the tournament raised $3.2 million this year (a new record).

Daikin Applied Americas has acquired Chilldyne, specialists in liquid cooling systems for high-performance data centres. Earlier this year (August) Daikin Applied acquired DDC Solutions, a San Diego-based developer of high-density cooling cabinets and management software for data centres.

Chilldyne’s liquid cooling distribution unit (CDU) technology uses a negative pressure system that delivers chip-level cooling. The system removes heat directly from processors through cold plates. daikinapplied.com chilldyne.com

store, to a new 116,000 sq. ft. facility in Brampton, Ont. The new site with 24 bay doors and a drive-in door is more accessible than its previous Mississauga location. carrierenterprise.ca

>> Bradford White Canada will soon be stocking Bock oil-fired water heaters (32- and 50-gallon). This follows the parent company’s acquisition of Wisconsin-based Bock Water Heaters in April of this year. bradfordwhite.com

>> Mits Airconditioning is now the master distributor for Exinda Eco-Energy Solutions products across North America, including Exinda’s residential and commercial air-to-water heat pumps across Canada (excluding Quebec and the Maritimes) and the U.S. mitsair.com exindagroup.com

VAST Industrial Corp., a privately held Canadian holding company which owns Unilux HVAC Industries, has acquired The Whalen Company, the Maryland-based manufacturer of heat pumps and fan coil products for the high-rise HVAC market in North America, the same space as Unilux HVAC.

Alex Heisz, director of Vast, will become president of Whalen. “The acquisition of The Whalen Company is an exciting opportunity to bring together two of the premier brands in North American high-rise HVAC,” said Heisz in a media release.

Founded in 1962, The Whalen Company were pioneers of the vertical stack concept, and Whalen products are operating throughout North America with an install base of over 750,000 units. vastindustrialcorp.com

David Minnis has joined Navien as the national HVAC sales manager. With over 25 years of industry experience, most spent in the wholesale space, Minnis brings management, sales and previous contractor experience to the role. Based in Ontario, he is responsible for growing the new HVAC business across Canada.

Uponor has announced the retirement of Dan Kirkpatrick. Serving customers across Canada for 37 years, Kirkpatrick began as a design technician with Canapex, followed by Wirsbo then Uponor— now GF. He has held various roles since, his primary title being technical field representative.

Stone Mountain Technologies, manufacturers of the Anesi gas absorption heat pumps, has appointed Brad Monaghan as their North American sales director. With over 25 years of HVAC and water heating experience, Monaghan has been with the company since 2022.

Fujitsu General America has appointed Bojana Prorok as director of sales – Canada. Based out of Toronto, Prorok brings over 15 years of experience in residential, commercial, design/build, and plan/ spec HVAC. In her new role she is now responsible for Fujitsu’s residential and commercial HVAC products across Canada.

Fowler Sales Agency, a manufacturer’s representative agency in Ontario, has welcomed back Leah Chamberlain as Eastern Ontario territory manager. Chamberlain, a seasoned HVAC and mechanical industry professional with over 25 years of experience in sales, supporting contractors and manufacturers, is based in the Ottawa area.

MIFAB welcomed Penelope Hilgartner as regional trench drain business development manager covering the Canadian regions along with northeast and southeast U.S. Hilgartner brings over four years of experience, and was previously with Zurn.

Boiler and water heater manufacturer Triangle Tube announced on November 3rd that it has ceased operations.

The West Deptford, NJ-based company announced on its website that as a part of this closure, all orders for equipment and accessories will not be processed, with spare parts to be available for purchase through stocking distributors as availability allows.

Additionally, all purchases will no longer be under warranty as of November 3.

The news follows a product recall in February of this year for Triangle Tube’s Prestige Solo, Prestige Excellence and Aerco Esteem condensing gas boilers, in cooperation with the U.S. Consumer Product Safety Commission (CPSC) and Health Canada. Despite the company’s closure, the product recall remains in effect.

Noble hosted its 2025 Fall Tradeshow on Oct. 2nd at the Universal Event Space in Vaughan, Ont., just north of Toronto. There was plenty of food and drink, over 85 brands on display and prizes to be won.

A.O. Smith signed a definitive agreement to acquire LVC Holdco (Leonard Valve) with the transaction set to close in the

Wolseley Canada held a series of Fall Expo events this year including Oktoberfest in Toronto on Oct. 23rd (photo above), Montreal Oyster Night (Nov. 12) and the Calgary Expo (Nov. 18).

Founded in 1911, Leonard Valve is a leader in digital and thermostatic mixing valve technologies for commercial and institutional applications, while its HeatTimer brand provides boiler controls that optimize hydronic heating. Together, their solutions ensure control of water temperature in both commercial and institutional settings including hospitals, schools, universities and industrial facilities.

“This acquisition represents a compelling strategic fit and a meaningful expansion of A.O. Smith’s presence in the water management market,” said Steve Shafer, A.O. Smith CEO. aosmith.com leonardvalve.com

Copeland is set to grow its Vilter industrial heating portfolio with its acquisition of German-based heat pump manufacturer SPH - Sustainable Process Heat.

SPH manufactures high temp. heat pumps of up to 180C for industrial steam applications. In addition to the expansion of Copeland’s Vilter range, the transaction also increases Copeland’s range of supported refrigerants across its industrial customers and thus expanding its portfolio of sustainable heating solutions in this sector of the industry. copeland.com spheat.de

MARCH 25–27, 2026

Metro Toronto Convention Centre

South Building

Get hands-on with the latest equipment, tools & tech

Connect with 500+ suppliers & manufacturers

Stay sharp with live demos, code updates & training

Unlock timesaving & profit-boosting solutions

Recognizing efforts to raise the level of awareness of cross connections and the tools that keep our drinking water safe.