Labor-Saving

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available

Looking for the right shim?

Grove Shims has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

union

FEATURES

17 Hiring help

Governments are motivated to help companies hire and train workers. AKR Consulting expert Bonny Koabel has helped a lot of glass companies access these funds, and shares some of her inside knowledge.

23 Laminate showcase

As glass gets larger and architects get more creative, new technology in interlayer and laminating is helping us to meet the challenge.

DEPARTMENTS

7 Canadian Glass Association

20 Insulating Glass Manufacturers Alliance

COLUMNISTS

22 The Engineer By David Heska

26 You Bet Your Glass By Frank Fulton

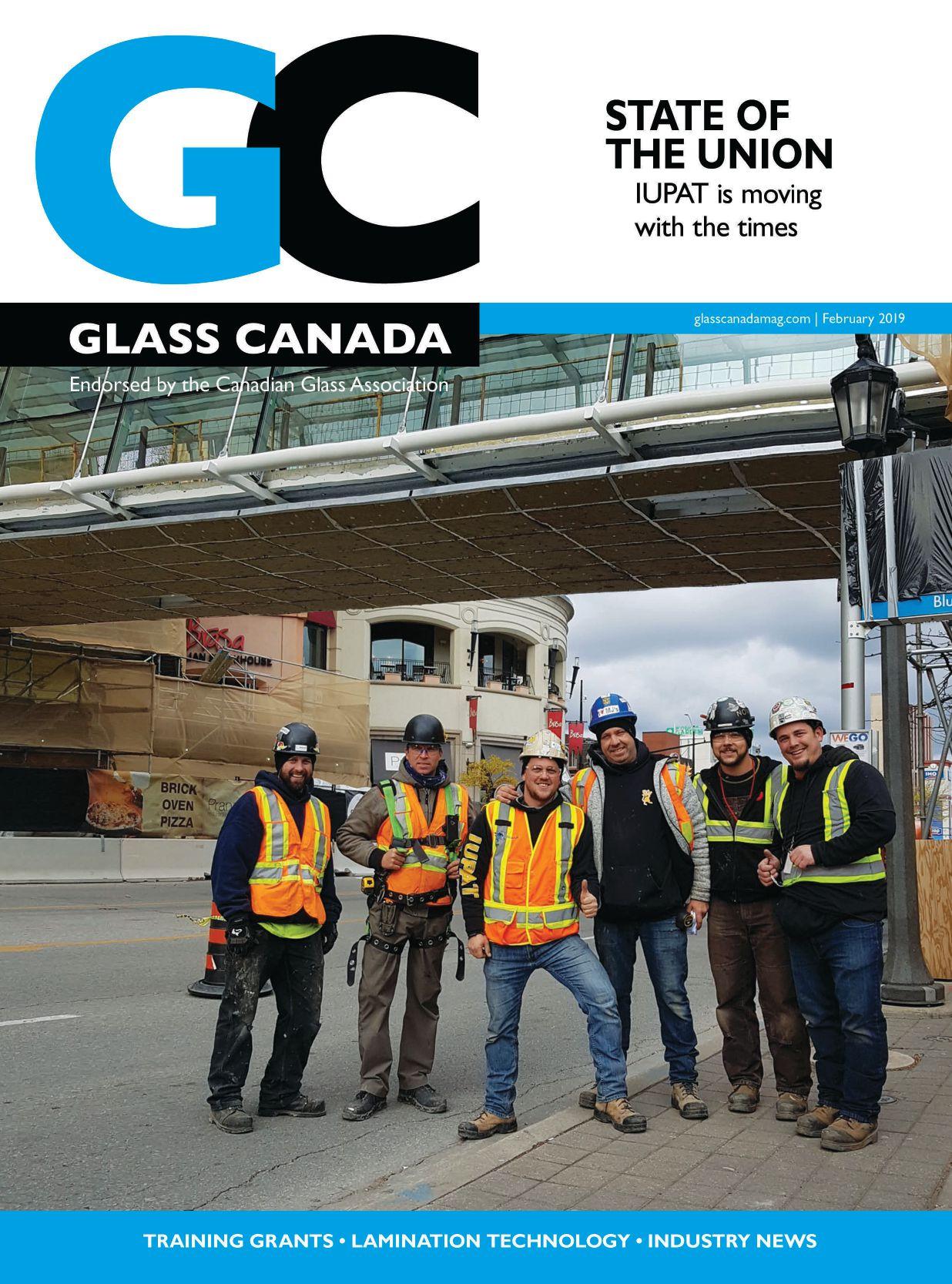

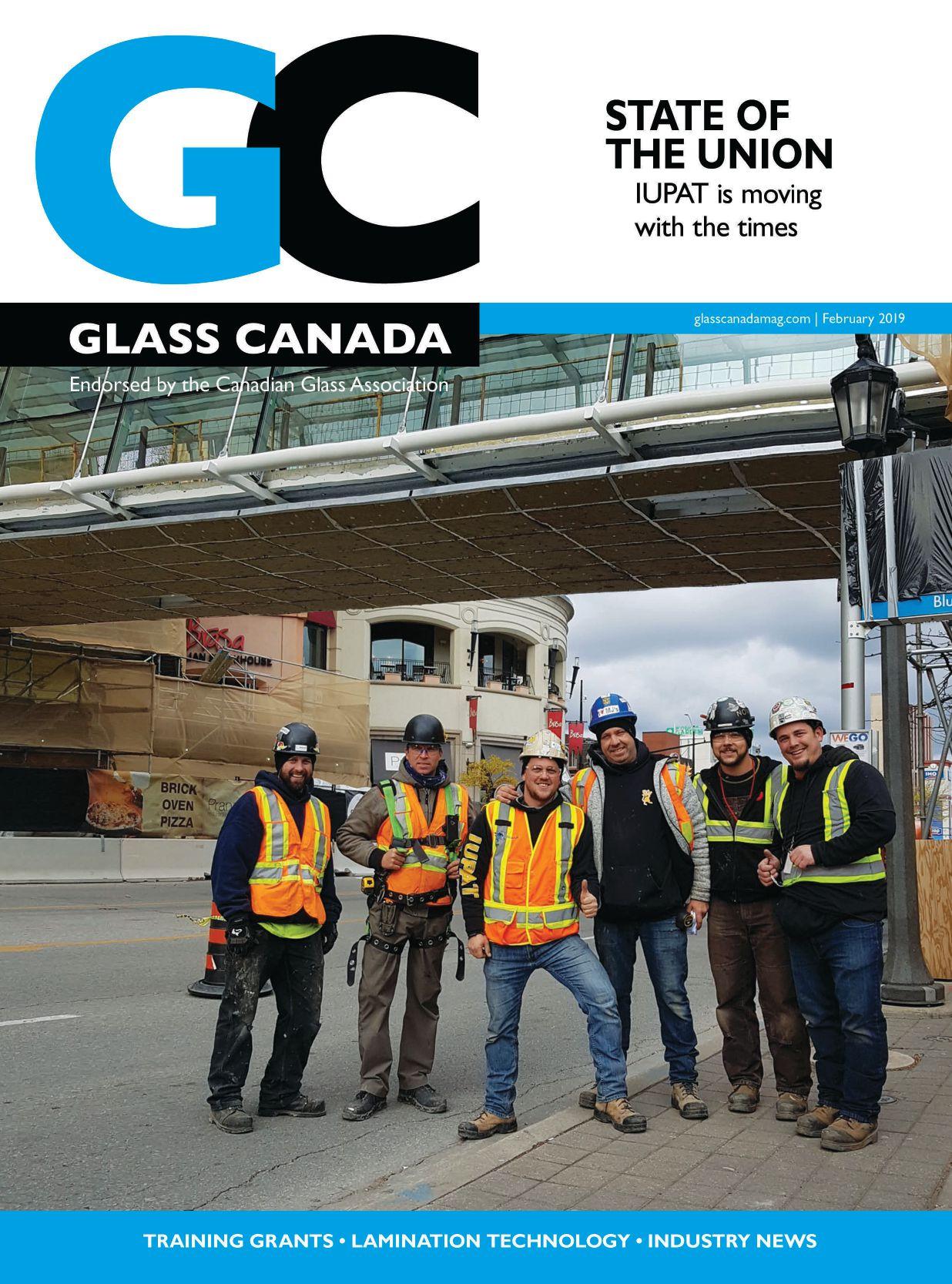

Our look at the union that serves the men and women of glazing in Canada. On the cover from left: Darryl Paige, Ian Humphries, James Ely, Chris Pocknell, Tom McNair and Kevin Peace installing the new IBG bridge in Niagara Falls, Ont. Above, a better view of the bridge.

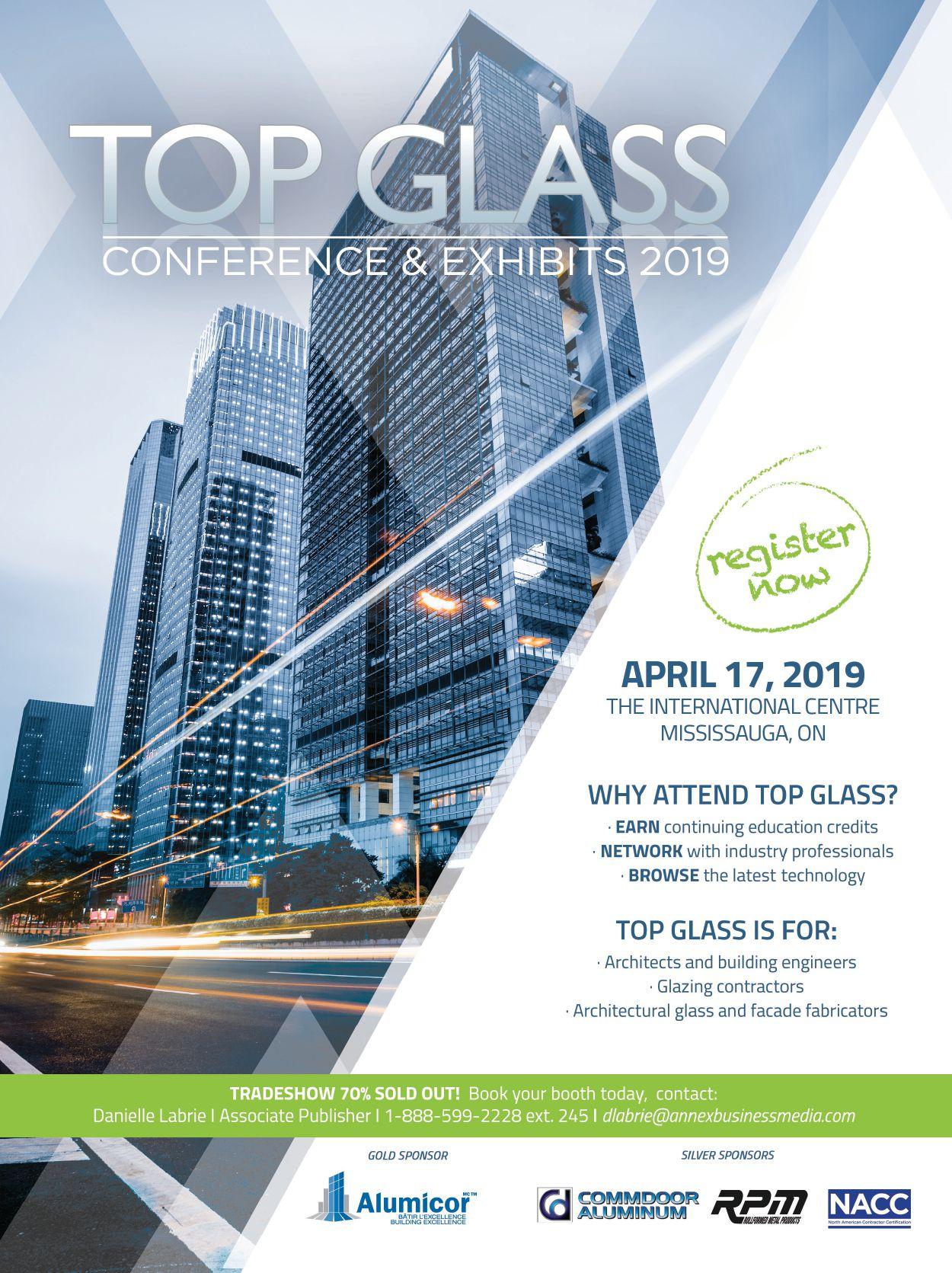

What’s up with Top Glass?

It’s that time of year when Glass Canada staff start to get daily calls and emails asking about Canada’s favourite commercial glazing event. We love the contact, but if you want to look it up online, just head over to topglasscanada.com.

Not just a great putter

Thanks to Frank Fulton for all he does for this magazine and this industry.

Congratulations to Frank Fulton who is celebrating his 10th year writing the You Bet Your Glass column on our back page. He’s been in this magazine longer than I have! Frank is a precious resource to this publication because he combines a deep knowledge of this industry – gleaned from a lifetime working in it as a contractor and supplier – with a really high level of writing ability. That’s incredibly rare. I barely need to touch his copy.

But all the writing ability in the world is no use if you have nothing to say. Frank does not suffer from this disability. I never tell him what to write about or even need to consult with him to help develop topics. I just receive a spirited, well-informed, well-written column in my inbox every two months, usually before deadline. It’s an editor’s dream. Frank is deeply interested in all aspects of architectural glass – technical and business-related – and his constant reading and discussions with industry folks combine with his curious, analytical mind to generate stories and opinions that entertain, stimulate and inform. Far from simply belching the contents of his mind onto the page, he actually interviews sources and conducts background research to support his columns! I don’t know what I did to get so lucky.

NEXT ISSUE

• Top Glass

• BEC report

As if all that weren’t enough, Frank also has the courage and determination to take a position and say what he feels needs to be said, even if it’s unpopular or runs against the accepted line of thinking. In our April 2018 issue, he drew attention to the uncomfortable fact that the Canadian Glass Association has lost its way and faces existential peril if it can’t find new enthusiasm and a new mission. Not something that anyone wanted to hear, but something we all needed to hear. His last column addressing Xinyi Glass’ ouster from the Guelph-Eramosa region was a blistering takedown of the shortsightedness and hypocrisy of small-minded municipal politicians – all the more effective for its firm grounding in the facts. His pressure on the forces guiding Ontario’s Prompt Payment reforms has been unrelenting, reflecting his determination to make sure those reforms actually address the needs of small glass businesses. Frank is one of those rare people who strongly believes in an integrated industry community and is willing to put in the time and energy to see it built. He’s the beating heart of the Ontario Glass and Metal Association, dedicating more than his share of the time to organize every golf tournament, social event and education seminar. He’s also the deserving recipient of its Lifetime Achievement Award. Ever wonder where the OGMA update comes from in our Canadian Glass Association newsletter each issue? Hint: I don’t write it.

Because of Frank’s efforts, any of us can look back on what he’s written and done and get a sense of what makes this business special. If this magazine is worth reading and serves any purpose in this industry, a very large part of it is due to Frank Fulton’s contributions.

No, Frank, I don’t have any more budget to pay columnists. •

GLASS CANADA

February 2019

Volume 31 • Number 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Curtis MARTIN

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189 Fax: 416-510-6875 (main) 416-510-5133 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $65.50 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

New management at Dip-Tech

Ferro and its Dip-Tech business have announced the appointments of Erik de Jongh and Jens Risse to jointly serve as Ferro Dip-Tech’s managing directors. Risse and de Jongh will replace Dip-Tech’s managing director, Alon Lumbroso, who has left to pursue other career opportunities. Lumbroso, who joined Dip-Tech as CEO in 2015, contributed to the company’s growth and development, as well as its sale to Ferro in August 2017 including subsequent activities to integrate the business within the overall Ferro organization. Under his leadership, the company has recently launched its innovative Ultra-Fix technology for the home appliances market, extending Dip-Tech’s segmented solutions to a new market on top of architecture and automotive.

Risse has been with Ferro since 2001. He is currently European business manager for industrial specialties and has also served as Dip-Tech integration manager since the acquisition. He will assume his new Dip-Tech leadership role while continuing as European business manager. His new responsibilities will centre on further growing the digital business: driving development projects, integrating teams of field

professionals to supply colours close to the customers and expanding the abilities of traditional analog decoration with digital decoration printers and inks for a onestop-shop solution.

Erik de Jongh has been responsible for Dip-Tech’s worldwide sales for over 10 years. He has served as Dip-Tech vicepresident of sales and continued to lead the sales team after the integration into the Ferro Performance Colors and Glass organization. With many years of experience in the field, de Jongh is well-known among Dip-Tech customers and within the Ferro organization. He will take a lead position in terms of global digital printing sales and marketing, as well as additional responsibilities in terms of operations, R&D, supply chain, human resources and finance, with local groups reporting to him.

Dip-Tech, a Ferro company, is headquartered in Kfar Saba, Israel, with North American headquarters in Smithfield, R.I. It is a leading supplier of digital glass printers and digital ceramic inks. In addition to printing hardware, the company offers advanced software and colour-sensing technology to glass fabricators worldwide.

COMING EVENTS

February 21

Fenestration West Surrey, B.C. fen-bc.org

February 27

CSC Building Expo Toronto, Ont. toronto.csc-dcc.ca

February 28

FenBC Technical Conference Surrey, B.C. fen-bc.org

March 18 - 21

Fensterbau Frontale Nuremburg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

May 16

FenBC Golf Tournament Surrey, B.C. fen-bc.org

May 30

OGMA Spring Golf Milton, Ont. ogma.ca

June 6 - 8

AIA Conference Las Vegas, Nev. conferencearchitecture.com

June 16 - 28

Glass Performance Days Tampere, Finland gpd.fi

Oct. 23

FenBC Industry Conference Surrey, B.C. fen-bc.org

CGA Newsletter

Canadian Glass Association

National activities of the Canadian Glass Association are on hiatus pending discussions of a new direction for the association. To help chart a course forward, please contact David Langton at dlangton@compglass.com.

Fenestration Association of B.C.

The FenBC Technical Conference 2019 is ready to go! The FenBC Technical Committee has put together another great program for the fenestration industry. Following our promise at our FenBC October conference we will have the return of the keynote breakfast panel, The Code Talkers. Our keynote lunch will be with Graham Finch of RDH Building Science: How the New BC Energy Step Code will Impact Window Selection and Detailing. The program will also include:

• So You Think You Know How to Install a Window and Door?

• BC’s Energy Step Code: A $2.9 billion market in Metro Vancouver

• Vacuum Insulating Glass

• The Use of Safety, NonSafety and Fire Rated Glass

The event happens Thursday, Feb. 28 from 7:30 a.m. to 4:00 p.m at Northview Golf Course in Surrey, B.C. Register online through fen-bc.org.

SAVE THE DATES:

• Golf tournament: May 16

• FenBC Industry Conference: Oct. 23

Architectural Glass and Metal Contractors Association

The AGMCA recently held its annual general meeting and is subsequently pleased to announce its board of directors for 2019.

• Tony Menecola, Applewood Glass and Mirror – president

• John Bastedo, National Contract Glazing – vicepresident

• Al Jones, Parkway Glass and Mirror – treasurer

• Kline Holland, AGMCA – director of labour relations

• Bill Byers, Transit Glass and Aluminum – director

• Joe Buck, AGMCA –director

• Richard House, Glass Houses Management –director

• Barrie Eon, AGMCA –director

• Angelo Cairo, Stouffville Glass – director

• Noel Marsella, AGMCA –executive director

• Tracey Oliveira, AGMCA – membership services coordinator

As a new member benefit for 2019, Tracey Oliveira is pleased to be able to offer Commissioner of Oaths services to our membership at no cost (by appointment only).

Our association looks forward to a prosperous 2019. As this is a contract year, much of our focus will be on our upcoming negotiations with the International Union of Painters and Allied Trades. We can be contacted at info@ agmca.ca.

Ontario Glass And Metal Association

OAKVILLE GLASS AND MIRROR CLOSED:

After more than 50 years in business, Dieter and Ingrid Ringler decided it was time to retire and closed the doors at Oakville Glass and Mirror for the last time on January 10. Oakville Glass was a longtime dedicated member of the OGMA and both Dieter and his son Steven served as directors and held terms as president. We wish the Ringler’s a long and healthy retirement. Steven is going to stay on the OGMA board for 2019.

SPRING SEMINAR: We plan on having one and we’ll be sending you the details once we figure them out.

SPRING GOLF: It may seem a ways off, but what better way to spend a cold miserable day than to dream about getting back out on the links.

Mark Thursday, May 30, in your calendar now and plan on being out at Pipers Heath Golf Club in time for lunch that day.

BILL 142 – THE CONSTRUCTION LIEN AMENDMENT ACT, 2017: One component of the Act came into effect on July 1, 2018, introducing new performance and labour-and-material payment bond wordings for all publicly funded work in the province. It is mandated that all public projects in excess of $500,000 are to be bonded (50 per cent performance bonds and 50 per cent labour-and-material payment bonds) and new bond wordings will be provided in support of public contracts. A member bulletin on the topic will be released soon.

Provincial Glaziers Association of Alberta

Skills Canada was another great success for the PGAA in 2018. With 10,871 attendees and 50 Try-A-Trade booths, we saw a ton of young people exposed to the glazing trade and to the life of trades overall. Our winner this year of the TV giveaway was a young girl named Lindsey from Mary Butterworth School in Edmonton. Congratulations, Lindsey! Maybe we will see you again as a glazier. The next Skills Canada competition in Alberta takes place May 8 and 9 in Edmonton. We encourage everyone to come out and see the future.

The Alberta Construction Association (ACA), of which we are an associate member, is seeking assistance from the PGAA and others to help identify areas where they will be able to advocate for change in post-election Alberta. The ACA’s question to us is, would we be willing to distribute a simple questionnaire to our employees to have them discuss and rank candidates on various issues and then provide feedback to the ACA to help direct their post-election advocacy. Please respond to this request with your opinion. Email me at president@pgaa. ca or at gary.p@albertaglass. com. Thanks very much for your feedback.

SAVE THE DATES:

• GAMA Dinner Meeting: Feb. 14

• PGAA Annual General Meeting and Executive Meeting: March 20

Oakville Glass and Mirror closes

Oakville Glass and Mirror has closed its doors. After more than 50 years in business, Dieter and Ingrid Ringler have decided it is now time to retire. As such, Oakville Glass and Mirror wound down business effective January 10, auctioning the company assets on Jan. 19.

“It truly has been a wonderful 51 years and we would like to thank all our customers, suppliers, trades and contractors who have helped make this experience so enjoyable and successful,” says Dieter, as he reflects on his many years in business.

Ringler purchased Oakville Glass and Mirror in 1967 and over the years the business grew continuously. In 1974 the company expanded adding a second location in Oakville and increasing its commercial fabrication space. The company expanded again 1980, merging both locations into its current location and over the years added additional fabrication space. Five decades is enough to challenge any business, but according to Dieter the key to the company’s success was always a focus on exceeding customer expectations along with developing a firm understanding of new products and technologies. Dieter is a past president of the Ontario Glass and Metal Association, as well as a founding member and former president of the Canadian Glass Association. He was honoured by the OGMA in

Pits

The Ringlers immigrated from Germany to Montreal in 1965 and opened Furi Aluminum in partnership with Frank Furtner. Walter Peterson of Repla Windows sponsored his move to Canada.

“This has always felt very much like a family. Together we have shared many happy times, seen friends and families grow, and helped many colleagues get their start in this industry.”

B.C. released changes to its building code and Energy Step Code in December. Full details of the changes are outlined in a technical bulletin available online at gov.bc.ca/ buildingcodes. Some highlights:

Prelco expands Xinyi still looking at southwestern Ontario Changes to B.C. step code

relco currently has three main fabrication locations for the commercial market (one in St-Jacques, N.B., and two in the province of Quebec: one in Riviere-du-Loup and another one in Montreal). This fall, it began expanding the facility in Montreal in order to get closer to its main markets and thus serve customers better and faster. Prelco is building a brand-new 47,000-squarefoot section and installing a state-of-the-art tempering furnace and increasing insulating glass capacity. These new pieces of equipment will be in operation in May. The company is also building a new plant for Veralex, its leisure boat windshields division. The building will be built in Princeville, Que. Lastly, Prelco is expanding its building located in Rouses Point, N.Y., where it serves the transportation market.

“Overall, we anticipate a contribution to the creation of several jobs between now and the end of 2019,” said Nathalie Thibault, architectural sales director.

• Peak Thermal Load has been removed as a compliance option in the BC Energy Step Code. Builders may now only use Thermal Energy Demand Intensity to demonstrate envelope performance requirements are met.

• Builders may now demonstrate compliance with the BC Energy Step Code’s airtightness requirements using the EnerGuide Rating System (ERS).

• The BC Energy Step Code for Part 3 buildings may now be used beyond Climate Zone 4.

• The Step Code was changed to address the specific conditions in hotels and Part 3 office buildings.

• Design air leakage rates were reduced to facilitate compliance with the Step Code in all climates, especially in cold climates.

Chinese glass manufacturer Xinyi is looking at four Ontario communities – London, Stratford,Welland and Amherstburg – as potential locations for a new $450 million float glass plant, according to multiple reports. Xinyi is searching for a new location after its application for bylaw amendments was turned down by Guelph-Eramosa township over concerns about water use.The plant is expected to employ about 400 workers if built.

2012 with

Lifetime Achievement Award.

BC drives permit surge in late 2018 Feds to allow full

The value of non-residential building permits rose 11.6 per cent to $3.3 billion in November, according to Statistics Canada. Construction intentions rose in five provinces, with British Columbia accounting for most of the gain. In the commercial component, the value of building permits was up 16.8 per cent to $2.1 billion, the highest level since May 2007. The increase was led by higher construction intentions for office buildings in the census metropolitan areas of Vancouver and Quebec. Following three consecutive monthly declines, the value of industrial building permits rose 21.9 per cent to $527 million in November. The increase was mainly attributable to permits for new agricultural buildings. In the institutional component, the value of permits was down 7.2 per cent to $682 million in November, with Quebec and Newfoundland and Labrador reporting the largest decreases. The decline in the institutional component was largely attributable to fewer high-value permits issued for nursing homes compared with the previous month. The value of building permits increased in six provinces in November, led by British Columbia and Quebec. Meanwhile, the value of permits rose in 14 of the 36 metropolitan areas,

led by Montreal,Vancouver and Calgary. In B.C., the value of permits rose 14.3 per cent to $1.7 billion. The commercial component posted the highest value on record, driven by a $240 million permit for an office building in Vancouver. The value of building permits in Quebec was up 13.9 per cent to $1.8 billion in November, following a decrease of 14.9 per cent the previous month. The increase was largely the result of the issuance of high-value permits for large apartment buildings in Montreal and a record high for commercial permits across Quebec. In Alberta, the value of building permits increased 10.4 per cent to $1.1 billion. The gain was largely driven by Calgary (up $131 million), where every component, except for industrial buildings, reported an increase. In contrast, the value of building permits in Ontario was down 10.3 per cent to $3 billion, following an increase of nine per cent in October. The value of permits in Toronto dropped 17.4 per cent to $1.5 billion in November. The decrease in multi-family dwellings (down $225 million) was the main contributor to the decline. Despite the decrease in November, the year-todate value in Toronto for multi-family permits ($6.8 billion) has surpassed the total value for 2017 by 20.2 per cent.

write-off of machinery costs

In its fall economic statement, the federal government has announced its intention to allow businesses to write off the entire cost of machinery used for manufacturing and processing the same year it is put into use. This is is up from the 25-per cent write-off allowed in the first year presently. In the announcement, the Ministry of Finance points directly to a drive to improve the competitiveness of Canadian manufacturers in light of American tax and tariff moves. The U.S. slashed the corporate tax rate to 26 per cent from 39 per cent in its last budget, compared to rates of about 26 per cent in combined federal and provincial taxes in Canada. The announcement from the federal government says these changes will give Canadian businesses the lowest effective tax rate on new investment in the G7. Specifics of the machinery eligible for the new rules are not given, but the measures are broad and would likely apply to architectural glass fabrication equipment.

AGMT nears release of glazier certification

The Architectural Glass and Metal Technician Certification Program (AGMT) has continued beta testing its knowledgebased and performance-based portions of its certification exam. Team members spent the week in San Leandro, Calif., administering, grading and analyzing the latest versions of the exams. San Leandro is the most recent testing location for this process. A total of 12 candidates were tested, each participating in both portions. The participants ranged in age and experience, some in the very first years of their glazing careers and others with more than thirty-five years in the industry.

Ben Saylor, a glazing instructor in San Leandro, observed the beta test. “I believe this test will give an accurate assessment of the required skill necessary to safely and efficiently complete glazing projects and tasks. For the future endeavors of this field it is essential that we combat the inconsistency in the installation of glazing systems,” says Saylor.

The test site and candidates provided constructive insight for the AGMT team, helping them understand both what is working and what could be improved. The purpose of beta testing is to evaluate the status of the test and prepare it for official certification use. The results so far are promising. Individual exam results met anticipated time and performance

targets serving as validation that the exam is operating as designed. Additionally, candidate feedback was positive and encouraging, with many candidates saying that the exam is both fair and an accurate depiction real-world glazing tasks. To complete the final phase of development, AGMT is planning to beta test in other locations across North America before officially rolling the program out to the glazier population.

STATE OF THE UNION COVERSTORY

IUPAT wants to

by RICH PORAYKO

be the source of a new generation

Last October, the PC government of Ontario announced it will wind down the Ontario College of Trades, set all journeyperson-to-apprentice ratios to oneto-one and put a moratorium on adding new compulsory trade classifications or reclassifying existing classifications. It has also promised an unspecified “replacement model for the regulation of the skilled trades and apprenticeship system” by early 2019. It’s just one example in a rapidly changing landscape riddled with tariffs, labour shortages, collective bargaining agreement negotiations and a federal election this October. How is the International Union of Painters and Allied Trades evolving to stay competitive in today’s divisive business climate?

“Chartered on December 8, 1954, IUPAT has been representing Canadian glaziers for 65 years,” says Jason McColl, a business representative for IUPAT Local 1795 in Ontario. According to McColl, IUPAT has just under 10,000 members across the country. There are different district councils and IUPAT collective bargaining agreements that represent the glaziers depending on the region you’re working in.

“We are on job sites every day asking if there are any problems or concerns,” says McColl. “We enforce our collective bargaining agreement to ensure our members are getting fair wages, health and welfare and pension contributions.” McColl says IUPAT involves members by conducting monthly meetings and participates in annual events such as the Community Day of Action, giving back through providing a communities with a free day of painting, glazing and drywall finishing.

“We’re definitely growing by membership and market share,” says McColl. “But the reality in all trades in construction is that we’re losing 80,000 tradespeople in the next five to seven years. We are coming to a bit of a difficult situation where we’re amping up our organizing and our recruiting campaigns.”

Immigrant, indigenous and female workers are IUPAT’s three big targets. “We use programs such as Hammerheads, which introduces youth to various construction trades, Helmets to Hardhats, which provides career transitions to members of the Canadian Forces, or Sticks to Hardhats, which helps retrain former NHL players.”

IUPAT’s Red Seal apprenticeship programs are 8,000 hours. Typically, that’s four years

generation of glaziers.

at 2,000 hours per year and includes three levels of trade school: beginner, intermediate and advanced. “We offer a curriculum equal to the college level at our Ontario Industrial Finishing Skills Centre, which is being renamed the Finishing Trades Institute,” says McColl. “The government provides a $1,000 grant for your first term of school, another $1,000 for your intermediate, and then once you’ve completed the advanced module and successfully challenged the Certificate of Qualification examination you get a $2,000 grant. The $167 fee to write to the C-of-Q exam is reimbursed as well.”

According to McColl, IUPAT members contribute one dollar from every hour worked to the Apprenticeship Education Fund. So when apprentices go to school not only are they getting their Employment Insurance but they are also getting a cheque when they first arrive to help alleviate some of the bills and stresses of not working for eight weeks.

Pension is another big benefit of IUPAT. “It sells itself and separates the non-union from the union,” says McColl. “Any new apprentice coming in has to work 4,000 hours before they’re vested into that program. Our pension contributions are $6 per hour, which is $4 to your Canadian Pension and $2 to your American pension. When an IUPAT glazier retires, odds are that they most likely own real estate as well as collect CPP, a Canadian and an American pension. You’re not going to drive Lamborghinis or Ferraris, but you’re setting yourself up to maintain a happy, middle class lifestyle when you retire.”

McColl says the biggest selling point for using a union glazing contractor is their safety record. According to Ontario Construction Secretariat reports, union glaziers are 28 per cent safer than

Except in Quebec, using a certified journeyperson glazier is not mandatory on Canadian jobsites. IUPAT is making efforts to show contractors it can be a helpful partner in resolving their labour issues.

non-union. “We want our members home at the end of the day, where the non-union company just cares about the bottom line.”

“We have contract negotiations coming up in May 2019,” says McColl. “We have already started negotiating and definitely have a good open relationship with all of our contractors as well as with the association.”

“If you came into our plant, you would see how quality starts right from the get-go. Right before you enter,” says Peter Neudorf Jr., director of field operations for union contractor, FergusonNeudorf Glass. “People are pre-trained and certified on machinery. They are responsible for their department, so they sign off on every single frame that’s built and comes out. There are no scratches, gouges or defects and it comes out as a perfect window; shrink wrapped into a frame and signed off to send to the project.”

Neudorf has worked in the glass industry for over 40 years and has volunteered on numerous committees for the betterment of the glazing industry including Red Seal Canada and National Occupational Analysis (Glazing Industry). In addition, he has served as chair of the Provincial Advisory Committee for Glazing Contractors. Neudorf currently sits on the board of directors for the Architectural Glass and Metal Contractors Association of Ontario as well as being the chair of the AGMCA for the Finishing Contractors Association. Most recently, Peter has become a founding member and board member of the North American Contractor Certification Program. He has also recently joined the International Glazier Certification Board of the Green Advantage Certification Organization.

“The union has the Finishing Trades Institute training centre where our men become full-fledged journeymen.” Neudorf says

training doesn’t end there. “There are all these certifications that the men have to have and need to be renewed every one to three years. The union handles the training and pays for it.”

“Our training centre will train nonunion, but a lot of non-union contractors don’t have certifications or training, says Neudorf. “They don’t pay the wages that we pay. And obviously if you have all the things in place, it costs money, so your price has to go up. It is one of the reasons non-union can outbid union.”

Neudorf says it is always an issue. “Union is going to be higher. Unfortunately the cheaper price gets the job. But the consultants and architects out there are getting tired of non-certified people and crappy workmanship. Consultants and architects send us letters saying thank you for certifying workers and contractors.”

“We need to always be learning,” says Neudorf. “We need to be bettering ourselves. The architectural and engineering worlds are changing and the things that they’re drawing up are incredible. But you have to have workers trained in order to do these things. Everybody has to be on the same page and this is where myself and

several other contractors feel this is spectacular. Let’s get the training done. Let’s take ourselves seriously. Let’s corner the market on good workmanship and quality.”

You get what you pay for. “You want to pay a cheaper price?” asks Neudorf. “You want to pay for unqualified workmanship? You get shit. You get leaks and glass falling out of the building. We pride ourselves in installing it safely and correctly and not having to come back and forever be patching holes.”

Baby boomers are retiring and the glass industry needs up-and-coming people to take over. “IUPAT advertises and has programs to get people interested in the glazing trade,” says Neudorf. “The training centre sends students over and I give them a tour of our facility. They love it and I enjoy doing it because these are the kids that are coming up and we’re looking for kids that are interested. It’s going to happen. It has to happen, because there’s going to be so much work out there.”

Ferguson-Neudorf Glass is also certified by the North American Contractor Certification (NACC). “I plan to send a lot of my people to have that extra certification so that when it comes down the pipe, we’re

the qualified choice,” says Neudorf. “Being NACC certified, our plant is very much in tune with qualifications of everybody being responsible for putting out a good product. Our quality control is by far above the norm.”

“The Architectural Glass and Metal Contractors Association was established in 1979 to provide a strong and unified voice for unionized glazing contractors primarily working in Ontario’s ICI sector,” says AGMCA executive director, Noel Marsella. “We are designated by the Ministry of Labour as the official employer bargaining agency. Our volunteer board of directors works hard for the betterment of our entire industry and we continue to bring any and all of our members’ concerns to the forefront.”

AGMCA has a long-standing interest in trades training. “Our association was the main catalyst behind Ontario’s Glazing and Metal Mechanic Apprenticeship program,” says Marsella. “To this day, AGMCA believes that apprenticeship training is vital to the health of our industry. Our members have invested heavily in our worldclass training facility and the programs it delivers. Our members demand a strong, well-trained, centralized workforce that can meet our needs.”

“It is the union’s mandate to provide us with this manpower,” says Marsella. “We have what we consider to be a strong working relationship with the IUPAT, as led by Bruno Mandic. We strive to work together to maintain and indeed increase our market share. Under Bruno’s leadership, the union seems to understand that what is good for our employers is ultimately good for the union and the members.”

“We need a reliable partner who is willing to listen to the concerns of our members, not brush them off, and Bruno seems genuinely interested in solutions, not roadblocks,” says Marsella. Having spent 35 years as a glazing contractor, Marsella says he prefers a no-nonsense approach, in order to remain relevant. “We need to interact with the union in an open and constructive manner, without fear of repercussion, and we look forward to further strengthening our relationship with the IUPAT under Bruno’s leadership.”

“Unions had their place 60 to 100 years ago to keep dishonest and abusive employers in line,” says Jim Brady, general manager of an Alberta-based non-union glazing contractor. “IUPAT has little to no relevance in Alberta. As far as I know, there are four companies that are certified in Alberta.”

The comments of Brady, who is a

former certified journeyman glazier and past-president of the Canadian Glass Association, the Provincial Glaziers Association of Alberta and the Glass and Architectural Metals Association of Calgary, are his own and not those of his current or past employers. Brady tells Glass Canada that for a long time the union paid wages that were lower than what the free market was paying and that his employees have never tried to organize. “Generally, we offer better compensation and benefits than what the union does.”

Another view

In Alberta, according to Brady, the union’s share will likely stay the same. “With that said, the NDP government has made many changes to employment standards which effectively are placing rules on owners which are very much in line with a union environment.”

In Alberta, union-trained workers used the same education program as non-union. It was delivered through the Southern Alberta Institute of Technology, which is a neutral party. However, the Master Glaziers program at SAIT was recently put on hiatus due to lack of enrolment. It’s unclear where Alberta’s glaziers are going to get training and certification going forward.

“The skills of union versus non-union are basically the same, however the attitude may be vastly different,” states Brady. “Good employees don’t want a sub-par coworker to have the same benefits and wages as themselves so they are not in favour of a union. Good employees that are being underpaid can always apply for a position at another company that appreciates, compensates and treats them fairly. The free market takes care of good employees and causes employers to compensate good employees fairly.”

IUPAT advertises its commitment to training and safety as reasons to use its workers. It hopes to convince contractors they will get better work from a unionized crew.

What about bad or sub-par employees? “This is who the union caters to and protects,” says Brady. “The union makes it impossible to get rid of bad employees. Why would a good employee want to continue to perform well when a bad or sub-par co-worker gets compensated the same and gets considered first for promotions purely based on tenure? In my opinion, unions create animosity in the workforce.”

Brady says he once had an employee that worked for him for over seven years and did great work. Unfortunately, his attitude was declining and he became a “cancer” in his work environment. “For over two years, I tried to get him to change his attitude,” says Brady. “It would work for a couple of months but then it would get worse than it was before. I finally made the decision that he was no longer a benefit to our company so I had to let him go. If we were unionized, that would never have been allowed to happen. As an owner or manager, I don’t need some union boss telling me who I can and cannot employ. I am quite capable of making those decisions.”

“My own philosophy is that without your people, you are nothing,” says Brady. “So treat your people well and they will work hard for you. If they take advantage of you, you can let them go. The trouble with unions and the NDP government is that they think that all employees are model employees and as such should all be treated the same. That’s a fairy tale. Not all employees are created equal. The free market rewards good employees and weeds out the bad ones or pays them lower wages.”

Neudorf, who runs a unionized shop, says he might have agreed with many of these sentiments 20 or 30 years ago, but feels unions have changed in the last 15 years. “The unions work with us,” he says. “If I have a problem with an employee I can talk to a representative, show them the bad work and we’ll come up with a solution.” Neudorf doesn’t want to go into the specific tactics, but explains that a consistently poor employee won’t be on his jobsites long and the union won’t stand in his way. “We had another situation where we had a lot of Flip the first single-quote mark the other way around the shop,” he remembers, referring to workers who had fulfilled almost all the requirements for their tickets but not done the paperwork to complete their certification. “The reps came out to one of our jobsites after hours, got all the guys together in a trailer and explained to each of them what they needed to do to get passed. I think about 15 or 20 guys had their tickets a couple months later.” Neudorf also says the union has never raised any barrier to rewarding good performance with travel and training opportunities, awards and even raises. “If a senior guy asks why he isn’t getting something, I can say, ‘You can get it. Just show me you’ve earned it.’” According to Neudorf, the union has never raised any objection to this approach. He says his union local invites employers to see the union as a resource to help them with human resources issues. In his case at least, pursuing a good relationship with the union has paid off.

We’ve heard for years that unions are eager to acknowledge the realities of business and work as partners with employers to benefit both sides. Sometimes, it’s felt like lip service. But perhaps a new day is dawning where worker representatives and glass company owners can find common ground to address some of the persistent labour issues dogging our sector. •

HIRING HELP

by BONNY KOABEL

When most people hear that the government is giving money away their reaction is that it must not be true. Why would the government want to give businesses money and receive nothing in exchange? The reality is governments do receive something in exchange for the money they give away: increased revenues in tax dollars. For every dollar the government gives out in funding it receives approximately $3 back in tax revenue. It is a win-win situation for businesses and government. Businesses receive funds they need to run, grow and expand and the government receives increased tax revenue from increases in company payrolls, HST, corporate taxes and employer health taxes.

Glass grab

There are a number of funding programs open to the glass Industry. We will focus

Governments plan to give away $2 billion in employment funding in 2019

on employee-related funding programs. These include:

• Apprentice salary refunds – Up to $12,000 per apprentice, per year, retroactive for four years

• Hiring grants – Up to $10,000 per new hire

• Training grants – Up to $10,000 per employee

A company may use all of these funding programs as long as they meet the funding criteria. There is no upper limit to how much a company may receive and these funding programs may be used on a yearly basis.

Apprentice salary refunds

Apprentice salary refunds have been available since 2005 and are incentives given to businesses to hire and train apprentices, as many experienced tradespeople are now retiring. Since it takes years of training for an apprentice to become a master in their trade, most companies are reluctant to hire apprentices and invest valuable time in training them. By making apprenticeship salary refunds available to employers, the government is setting the stage to encourage more employers to take on the task of training apprentices.

ABOVE: Good help is hard to find, but it’s even harder to develop internally. Believe it or not, there is help from the government you can access to defray the costs of hiring and training new talent.

Employee incentives for training apprentices are generous. Ontario offers the largest amount of funding, which is up to $10,000 per apprentice per year, retroactive for four years. This applies to the first three years of the employee’s apprenticeship, whether or not the apprentice is still with the company. It does not matter how short a period of time the apprentice was with the company; it could be one week or the last four years.

Apprentice salary refunds apply to both union and non-unionized companies. If your company is not unionized, you need to make sure that the apprentices you have on staff are registered apprentices in a qualifying trade in the province that your company operates in. In most provinces, the trade will be glaziers. If you have had apprentices on staff that are not registered with the province, unfortunately you will miss out on funding. If you are hiring an employee who is already a registered apprentice, you need to call your apprentice training representative with the government and make sure the new employee receives a transfer of apprenticeship to your company. If this does not happen, your company will miss out on funding. Two

of the biggest reasons why companies do not receive apprentice salary refunds are because they have not registered their apprentices with the government or they did not receive transfers of apprenticeships for new employees who were already registered apprentices with other companies.

One of the statements we often hear from unionized companies is, “The apprentices we have do not qualify for funding because they are from the union. We bring them in for jobs as required and send them back to the union. And since under the apprentice agreement the employee is registered to the union, the union is entitled to receive the funding, not our company.” This statement could not be further from the truth. While an apprentice may be registered with a union, the union does not pay a salary to the apprentice. Companies that bring in union employees pay their wages and, because the apprentice salary refund is a refund on the wages paid to the apprentice, the company that pays the unionized apprentice and has them on their payroll (even if only for a week) is entitled to the apprentice salary refund, not the union.

If your company has both unionized

and non-union apprentices and you have only claimed apprentice salary refunds for your non-union apprentices, you can still file for apprentice salary refunds for the unionized apprentices as long as you are still within the four-year time limit.

The apprenticeship salary refund program applies to foreign-owned companies and even divisions of companies that have had apprentices and are now closed. As long as the company is not dissolved, the company is able to apply retroactively for the last four years of funding.

Lastly, if your company has applied for apprentice salary refunds in the past and was denied due to incomplete or inaccurate information, you may be eligible to get that funding as long as the application is re-filed within the four-year period when you had the apprentices on staff.

Hiring grants

Hiring grants are a re-direction of Employment Insurance premiums. The government would prefer to compensate a business to train a new employee rather than to have the person sit at home and collect EI. Hiring grants have been available for decades, regardless of what party is in power, and will almost certainly continue to be available going forward.

Hiring grants are available for any new hire that is not an apprentice. This applies to all potential new hires including preapprentices, administrative staff, sales staff, estimators, engineering staff and general labourers. To qualify for funding, the new employee must be currently unemployed. Also, the new employee cannot be leaving a job to take a position with your company. Funding is available to recent graduates, new immigrants and self-employed people taking on a paid position with a company. The new employee’s position must be paid hourly or on salary. Pure commission jobs will not qualify for funding. Also, the job must be a full-time position with a minimum of 25 hours per week. Temporary and part-time positions do not qualify for funding. The goal of the hiring grant program is to create long-term employment. Businesses may apply for hiring grant funding as often as required. As long as the new employee qualifies for funding the company will receive the hiring grant.

If you are planning a new project with glass – we have the right solutions. We are the leading global specialist in structural and functional interlayers for safety and security applications, sound insulation and UV control. For further information about our SentryGlas® ionoplast and Trosifol® PVB interlayers, please visit us at www.trosifol.com . trosifol@kuraray.com

Hiring grant funding works very differently than apprenticeship salary refunds. In order to qualify for funding, a company needs to apply for funding before the new employee’s start date. It will take up to seven business days to get a hiring grant

in place. After the application is submitted to the government, the new employee will need to attend a brief meeting where the hiring grant amount for the employer will be determined.

Hiring grants vary depending on the province and are up to 50 per cent of an employee’s wage to a maximum of $10,000 for a period of six months. Once an employee qualifies for funding, the company will receive funding for the period of time the new employee worked even if the employee is fired or quits. The government understands the employment relationship does not always work out and it was the company’s intention to hire the employee on a full-time basis.

Training grants

Training grants are available to existing employees to increase their skill set. Training must be through a Canadian third party including colleges, universities and specialized training providers. This includes sales training, quality system training (for instance, ISO) and ERP system training. The Canada Job Grant program was introduced in 2014 with funding committed to 2020. Routine training such as WHMIS, health and safety, forklift re-certification and fall arrest training do not qualify for funding.

Funding is up to $10,000 per employee. If your company has under 100 employees, you will receive a reimbursement of 80 per cent of the training costs. If your company has over 100, the reimbursement rate will be 50 per cent.

Training grant funding works similar to hiring grant funding. In order to qualify for funding, a company needs to apply for funding at least one month before the employees receive the training. The application is completed and submitted online. It will take up to seven business days to hear back from a government representative who will review your application and let you know if the application is approved. Once the application is approved, the employees are now able to take the training. Once the training is completed and the invoice for training has been paid, the company will need to apply to the government for reimbursement. The government will send out the refund cheque four to six weeks after receiving the invoice.

About the author

Bonny Koabel CPA, CGA is the President of AKR Consulting Canada located in Mississauga, Ont. Bonny can be reached at bonny@akrconsulting.com or 905-678-6368. •

by MARGARET WEBB

The edge of science

One of IGMA’s main strategic activities is supporting leading-edge research supporting the insulating glass industry. Past R&D activities include the 25-year field correlation study, a validation of the spark-emission spectrography device which is now the basis of measuring gas content for certification programs, and the gas permeability project.

In the past two years, IGMA funded the ASTM thermal stress modeling project. Developing the models has been completed and a new standard to model and predict thermal stress in insulating glass units is under development. In addition to the ASTM standard, a software program is being developed to conduct the modeling. Use of this software will be complimentary to the IGMA membership.

IGMA’s R&D fund is funded entirely by the IGMA membership through a modest annual fee as part of the membership fee. It is accounted for separately and as of January 2019 the fund is approximately $100,000 U.S.

The main research project under development in 2018 was the ASTM field correlation study pilot program which will allow the organization to determine if test methods will in fact deliver data that will accurately represent field conditions and provide correlation to the ASTM E 2190 standard including gas content. The request for proposal was issued in September 2018 and we received four bids. The rapid response team is reviewing the bids to ensure that all parameters were addressed in each bid and provide for an “apples to apples” comparison. The full task group and the Emerging Technology and Innovation Committee will be reviewing the bids to determine

We look for opportunities to proactively support quality manufacturing though our research and development activities.

IGMA

the successful bidder and forward a recommendation to the IGMA board of directors. It is anticipated that the study could start by the end of the first quarter of 2019.

Other R&D activities undertaken in 2018 were support for the development of a Rapid Assessment Chamber (RAC) and a new test fixture for measuring the edge pressure of insulating glass units. Both of those activities will continue through 2019 and we hope to have a prototype of the edge-pressure device at the 2019 Winter Conference.The RAC, a joint IGMA-IGCC project, has evolved from activities undertaken by the Advanced Fenestration Testing Group where three new test methodologies were researched to determine the best approach to providing a more rapid test than the CAN/CGSB or ASTM test methods. A prototype has been manufactured and is housed at the AMS offices in New York state. This is a long-term project but promises to provide accurate, quick results and it could provide interim testing so that the formal certification test period could be extended.

The joint IGMA-AAMA edge pressure task group has researched a number of methods to determine how to measure the edge pressure of an insulating glass unit in the frame. Anecdotal reports had suggested that too much edge pressure is being applied to the IG units causing premature failure. An initial design was reviewed and sent out for bid. However, the task group is now looking at a device developed by one of our member companies many years ago to determine if this perhaps will provide the solution to how to measure the edge pressure. A demonstration of this device is planned for either the 2019 Winter or Summer Conference depending on access to an existing device.

A new task group has been established to validate the Sparklike laser device. It is anticipated that a similar validation methodology as was conducted for the Sparklike Gasglass device will be followed. The task group has met once but many online meetings will be scheduled in 2019.

As part of IGMA’s commitment to our members and the industry at large, we look for opportunities to proactively support quality manufacturing though our research and development activities. It is a strong component of IGMA’s return on investment for our members. •

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David.Heska@wsp.com

Sounds good

Walking around the trade show floor at The Buildings Show in Toronto and the WinDoor show in Quebec City before Christmas gave me the opportunity to discuss trends in our industry with clients, contractors and manufacturers. Surprisingly, what’s old is now new again. Even with a lot of talk focused on more efficient windows with lower U-values, I still had multiple conversations related to sound transmission. Sound transmission issues are not new. In the mid-1980s, the National Research Council published many articles on this topic and here we are 30 years later still discussing it.

A wall or window is typically rated in either sound transmission class (STC), apparent sound transmission class (ASTC), or by the outdoor-indoor transmission class (OITC). The higher the number the better. Even though OITC is a better indicator of noise reduction at lower frequencies (such as highways, train tracks or airports), the STC rating is much more commonly used. Recommended STC ratings for meeting rooms and offices are 45 to 50, however a common STC rating for a standard double-glazed window is only between 28 and 32.

This has given rise to the increased use of laminated glass for increased sound comfort. Bonding two pieces of glass together with a thin plastic interlayer has proven to increase the STC rating of glass by around four. Two laminates can increase the original STC rating by around eight. Even still, until the STC rating is above 40, building occupants will often complain about exterior noise.

By adding insulation into the framing components both the thermal and sound performance are improved.

THE ENGINEER

According to the NRC’s published data, in order to exceed STC 40 you need one of the following configuration options:

• Double glazing with glass four millimeters thick and an interpane spacing of 100 millimeters

• Double glazing with glass six millimeters thick and an interpane spacing of 90 millimeters

• Triple glazing with glass three millimeters thick and interpane spaces of six and 100 millimeters

They also clearly state that “The STC data listed in the table are for typical windows, but details of glass mounting, window seals, etc., may result in slightly different performance for some manufacturer’s products.” We have seen instances where missing heel beads, window seals and pinholes have resulted in noise complaints due to greater sound transmission through these voids. Since glass is only one part of the window or curtainwall system, consideration also needs to be given to the sound transmission occurring through the frame. By adding insulation into the framing components both the thermal and sound performance are improved.

So why were a couple people talking about this with me on the trade show floors? It was because both the contractor and supplier wanted to go above and beyond on specific projects they were working on. Our building codes are not pushing us to improve STC ratings and rarely will clients pay the premium cost to increase to triple-glazed or laminated windows when double-glazed will do. But as the push continues for lower U-value window systems, one of the side benefits will be improved STC ratings. And that sounds good to me.•

LAMINATIONTECH

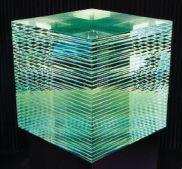

Load-bearing

finnglass.com

Finnglass has developed a 50-centrimetrethick laminate to open possibilities for architecture and design. This newcomer in the glass industry was developed as a response to a challenge to enable more ambitious use of glass in architecture. The end result is a horizontally stacked multilayer laminate that lets light, shadows and moving shapes be seen through translucently, while being suitable to be used as a load-bearing structure. What started as a need from architects and designers has led to the development of a 50-centrimetre-thick laminate composed of 31 layers of tempered, ultra-clear Pilkington Optiwhite glass, with each layer 15 millimetres thick. Once the layers are assembled together, the strength of the resulting laminate can challenge concrete. Thick laminate gives architects and designers new possibilities to realise their artistic visions without compromising the beauty and simplicity of glass with supporting concrete or steel structures. It all began when architects found it hard to find solutions that allowed for more ambitious use of glass in load-bearing structures and state-ofthe-art facades. When such constructs seemed hard to build with existing products and methods, European firms challenged the glass industry to develop a solution to meet demand.

“We took on the task, seeing increasing potential for the use of structural glass in the construction business,” says Timo Saukko, CEO of Finnglass. “We leveraged our expertise in glass processing and heat transfer models to solve problems, such as how to transfer heat into the massive laminate structure during the manufacturing process. It took a combination of technical problem-solving and handson experience to put the solution into practice. Our showcase piece of thick laminate is just an example of what we can achieve in this field.”

In the future, Finnglass will be optimizing its manufacturing processes and pursuing opportunities to demonstrate the value of thick laminate in constructing architectural masterpieces along with further growing their decades-long experience in applying electrically heated glass in diverse demanding architectural projects.

Resistance to heat and aging

salemdist.com

Salem Flat Glass and Mirror, in partnership with Folienwerk Wolfen, brings a premier EVA film to North America: EVGuard. Ethylene-vinyl acetate, or EVA, is a copolymer best known for its outstanding resistance to heat and aging. EVGuard is a special EVA film for laminated glass and laminated safety glass that is tailored especially to the high demands of architecture and interior design. The Folienwerk Wolfen company is a pioneer in the processing of EVA films. EVGuard was developed, and is manufactured, in Germany with European raw materials. Laminated glass manufactured with this premium laminating film has been tested extensively in Europe and the U.S. as well as in regions with extreme climatic conditions. Thanks to its safety properties, high-performance EVGuard EVA film is especially suited for laminated safety glass and sound insulation glass. Its high elasticity and adhesion also make this innovative product perfect for use in burglary protection and safety barriers. EVGuard is the result of years of research and development and exhibits its superior properties as it forms a full crosslinked composite layer for long-lasting fade resistance, stronger resilience over time and no delamination. It is certified for impact, weathering and sound reduction and meets all U.S. standards.

Decorative options

agcglass.com

Colour and privacy are strongpoints of the laminated safety glass Stratobel Colour from AGC. From transparent via

translucent to opaque, this glass offers coloured light transmission as desired through the use of multiple films. In architectural projects this provides the possibility to design artistically using transparency both in the interior and externally, and to combine colour with aesthetics and security. The colour tones – Stone Grey, Mineral Grey and Terra Brown - add harmonically to the decorative glass range. The interplay of these colour tones has been brought to life in the form of rotatable glass fins. Decorative glass types Lacobel T and Matelac T are also available and offer many opportunities for combinations. The products are perfectly colour-matched across the Stratobel Colour range. Individual colour tones for decorative and laminated safety glass can be created via the online service My Colour for an order volume of 200 square metres and above.

Low yellowness

trosifol.com

Kuraray’s Trosifol business is a leading global specialist in the development, manufacture and supply of PVB and ionoplast interlayers for laminated safety glass in architectural applications. With the acquisition of the DuPont Glass Laminating Solutions business in 2014, Trosifol PVB and SentryGlas ionoplast provide the broadest range of interlayer solutions in the market. The Trosifol portfolio’s innovative glass-laminating solutions include structural and functional interlayers for safety, security and hurricane resistance, sound insulation and UV protection. In glass railing and canopy applications, SentryGlas ionoplast interlayer has proven to be the premier product with its post-glass breakage performance and edge stability in exterior projects. For decorative applications, Trosifol offers coloured interlayers for interior design projects and shower enclosure applications. Trosifol UltraClear and SentryGlas exhibit the lowest yellowness index in the industry for low-iron glass applications.

Enhanced strength

everlam.com

While the growing trend for very large glass panels makes beautiful buildings, it also creates technical challenges, key among which is ensuring the strength of the glass panels. Everlam Super Tough enables architects and designers to unleash their creativity. Everlam Super Tough is Everlam’s extra-resistant PVB solution, which provides extra strength and safety in applications where safety can’t be traded, such as glass balconies, balustrades, curtainwall, floors and stairs. It offers outstanding structural stability by making the glass stronger, so that thinner glass can be used to minimise the weight and cost of the entire glass structure. Should a glass panel break, Everlam Super Tough will maintain broken glass fragments firmly in place for a longer time than standard PVB. The product is manufactured according to the Everlam standards of absolute quality and performance consistency and can be processed on a standard lamination line, which represents a clear benefit for laminators. Other Everlam PVB solutions include Clear, White, Color and Quiet.

Greater uniformity

glaston.net

The ProL-zone full convection laminating furnace upgrade from Glaston is designed to be a quick and cost-efficient modification for your existing laminating line. The upgrade replaces a damaged or outdated heating chamber. Glaston has made ProL-zone as easy as possible to operate. The process is practically recipe-free. Fabricators only need to put in one parameter and the rest will take care of itself. No more trial and error with juggling a number of variables. The very concept of ProL-zone is based on reaching a production capacity balance with low-E and clear glass. ProLzone uses full convection technology, which does not differentiate between glass types or product modes. The convection system provides extremely even heat uniformity, giving users consistently superb glass quality and an up to a 100 per cent capacity increase compared with traditional infrared heating. ProL-zone’s full convection technology gives the operator the best possible control over the chamber temperature. This eliminates heat loss, which means considerable savings in energy costs.

Automate the process

intermac.com

Genius LM is a range of cutting tables from Intermac for laminated glass aimed at companies that wish to automate their laminated glass cutting processes, and which require superior ease of use and an intuitive approach to machining for all glass thicknesses.The Genius LM family is designed to facilitate the handling of glass sheets and of the machine crosspiece, significantly improving productivity. A short-wave lamp warms the plastic film without overheating the glass. At the same time, the upper cutting bridge ensures that a portion of the sheet is held in place by pressing down on it and a suction cup bar, which is pressed against the underside of the glass, enables the separation of the finished volume.The grinder coating removal device can remove low-E film with a 20-millimetre diameter cup grinder. It delivers constant removal quality, thanks to automatic grinding wheel wear compensation.When integrated with smart software, Intermac solutions serve to minimise operator intervention, ensuring a clearer overview of the entire process, as well as greater levels of safety.The operator interface is simple and intuitive and enables cutting programs generated by many of the optimisers present on the market to be imported, courtesy of the integrated Optimiser Transferring Data universal interface that automatically defines cutting parameters and generates the program for the cutting table.

Aligned with trends

hhhtempering.com

Glass laminating machines from HHH Tempering Resources helps diversify glass fabrication offerings and keeps fabricators aligned with current glass industry trends. HHH technology can process glass down to 71 by 94 inches in thicknesses from three to 19 millimetres. Speeds from 0.5 to five metresper-minute are possible, generating production capacities from 1.5 to two hours per cycle. HHH laminating machines are built with strong, stable materials and all electrical work is UL-approved.The independent control cabinet and touchscreen display each working stage.

Complete control

billco-mfg.com

Billco’s Lami-Pro is a customizable laminating assembly line built for producing high quality laminated glass. The line is designed to clean glass, assemble, laminate, heat and pre-press the unit prior to autoclaving. Available conveyor widths are 60, 84, 96 or 108 inches. Glass thickness range is 2.2 to 19 millimetres with processing speeds from five to 26 feet per minute. Maximum laminate thickness is three inches. The modular design allows for custom line configurations and drop-in replacement options. Precision recipe line control simplifies operations and maintains complete control of all aspects of the line. Infrared heating technology and convection offers precise temperature control for a consistent, high quality laminate. Lami-Pro is designed for minimal energy consumption, lowering production costs. Turnkey solutions are available with all supporting equipment such as PVB cutters, clean rooms and autoclaves.

RESOURCEDIRECTORY

by FRANK FULTON

Frank Fulton is a former principal of Fulton Windows and former president of the OGMA.

Ten years later

This column just so happens to mark the 10th anniversary of yours truly penning You Bet Your Glass for Glass Canada. One of my favourite columns over the years was also one of my first, entitled “Glass For Dummies” in the April 2009 edition of Glass Canada. It was full of interesting information about the history of glass. I bet you’ve either forgotten everything by now, or never read it in the first place. So, it is with pleasure that I bring you some excerpts from this timeless piece.

Glass is roughly composed of 70 per cent silica sand, 13 per cent lime, and 12 per cent soda. When heated to about 1,500 C, this mixture turns into a thick molten mass like molasses on a cold day. Some definitions refer to glass as an “amorphous solid.”

Like many great inventions, glass was first produced by accident in about 5,000 B.C. when a crew of Phoenician sailors transporting blocks of soda landed ashore on a beach near Belus in Asia Minor. When it came time to eat, they couldn’t find any rocks to put their cooking pots on so they improvised and used blocks of soda to support the pots over the fire. Once the fire got blazing, the sand and soda created a pool of molten glass.

Around 1,500 B.C., Egyptians discovered how to produce goblets and small bottles by repeatedly dipping a silica paste core on the end of a metal rod into molten glass, then later removing the core. At some point around 250 B.C., Babylonians began using hollow metal rods for this procedure and stumbled upon glass blowing. As a result, producing bowls, bottles, and cups became relatively much easier and less expensive, and the Romans’ demand for glass products as status symbols skyrocketed. Demand throughout the Roman Empire in many ways lead to the birth and growth of the glass industry. There is even evidence that crude cast glass was tried in some impor-

This column so happens to mark the 10th anniversary of yours truly.

tant Roman buildings and villas, but mostly the rich used thin, translucent sheets of alabaster to enclose wall openings. Unfortunately, with the demise of the Roman Empire, the fledgling glass industry stagnated for almost a thousand years and almost disappeared.

The 11th century saw the birth of the flat glass industry. German glass craftsmen are reported to have developed a technique, further developed by Venetians in the 13th century, where molten glass was blown into an elongated balloon shape, cut and flattened. This produced what was known as broad sheet glass. For the next 600 years, most flat glass was produced from flattening out blown glass in one manner or another. Crown glass and cylinder glass were advancements, but still required laborious hand-grinding and polishing to produce.The industrial revolution brought about steam-powered machines to improve on these functions. As the production of glass lites became possible, some of the rich began to replace the shutters on the “wind-eyes” in their homes with windows made of glass.

In 1688, a technique for the production of cast polished plate glass was developed.This made large vision areas possible rather than holding a bunch of small pieces of glass together with lead. By the mid-1800s the use of glass to enclose wall openings became commonplace. PPG started production in the U.S.A. in 1883.

Machine drawn cylinder sheet glass – the first drawn glass as opposed to blown or cast – was produced in the U.S. in 1903. The commercial production of vertically drawn flat sheet glass began in 1914. For the first time it was possible to create a continuous ribbon of reasonably good quality glass economically.

The most significant strides in the manufacture of glass were made by Alastair Pilkington in the 1950s when he conceived the idea of forming a horizontal ribbon of glass by floating the melted raw materials at high temperature over a bath of molten tin to create the high-quality float glass we are accustomed to today.

With this modicum of glass knowledge you should now be capable of impressing your friends and maybe even the occasional architect.•

PRINTED DESIGNS

IN SIZES UP TO 110" X 200"

SERIES HP3253 CURTAIN WALL

SERIES 2202 CURTAIN WALL CURTAIN WALL SYSTEMS THAT DELIVER

For information on additional CRL-U.S. Aluminum Curtain Wall Systems, visit usalum.com

HP3253

Series HP3253 High Performance Curtain Wall System represents the latest advancement in thermal performance. With three thermal break points and 2" (50.8 mm) triple pane insulating glass, it’s engineered to act as an efficient thermal barrier in the most

– U-factors as low as 0.17

– Injection molded water deflectors

– Vertically butt-glazed option

Series 2202 Curtain Wall is thermally improved to meet and exceed thermal performance requirements. The system features a skip and debridge thermal break that complements a continuous thermal spacer to effectively mitigate heat transfer.

– Slim 2" (50.8 mm) face trim for improved sightlines

– 1" (25.4 mm) insulating glass

– Shear block assembly with no exposed fasteners