Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

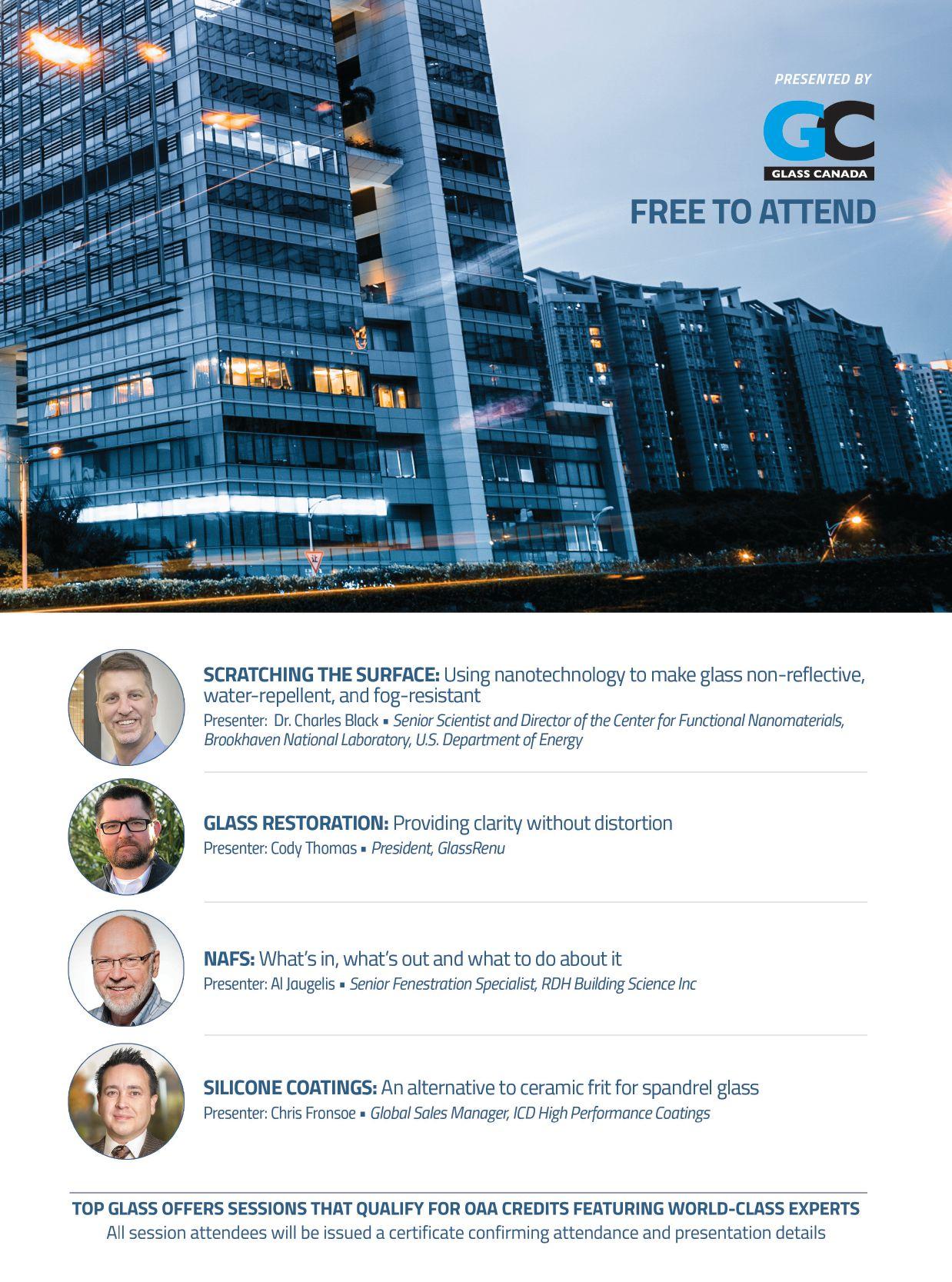

Top Glass 2018 is your chance to spend a day working on the business rather than in the business. Find the information and connections you need to meet the challenges of our ever-shifting architectural glass business.

Get updates when new content is posted to glasscanadamag.com. See commentary and updates from industry events. Join the conversation @GlassCanadaMag.

A look at the cutting edge exclusive education on offer April 17.

Once again Top Glass is proud to host the OGMA’s Awards for Excellence.

Our preview of the innovative technology on display on the show floor this year.

The plan, the process and the follow-up are all critical to quality, especially when procuring products overseas.

Unintended consequences

Minimum wage increases could reverse the good course we were on.

I heard an interesting statistic the other day on Fareed Zakaria’s excellent international affairs show on CNN. Between 2013 and 2016, income for the lowest 20 per cent of Canada’s wage earners increased 20 per cent. In the U.S., incomes for their lowest 20 per cent fell 16 per cent over the same period. I can’t lie, I felt a little surge of pride at having such a flattering statistic for our society read out on a national broadcast in the country that considers itself the greatest in the world.

NEXT ISSUE

• Top glazing projects

• Flat glass showcase

This improvement to the fortunes of our poor was achieved without any significant increases to welfare benefits. Yes, some social services that benefit lower-income families (affordable day care, for instance) have been introduced or expanded in various parts of the country, but the statistic addresses income, not wealth, and therefore isn’t affected by those programs. Essentially, Canadians in the lower income strata are finding more work, getting paid better or the lower-earning ones are somehow vanishing off the record and skewing the statistics. Our labour participation rate is not that different from the U.S.’s, so it’s not the latter. Somehow, we are doing better at providing lower income jobs, helping people to get those jobs and/or maintaining and raising wages in those jobs. There could be a lot of reasons for that and, since I’m not an economist, I won’t hazard a guess at what they are. It’s worth noting that the period covered by the statistic is after the Great Recession, so if anything the American numbers should have been improving.

The point I’m making here is that these increases also occurred before the minimum wage hikes that have been proposed or implemented in various provinces.

Those hikes have been sold by their proponents as measures to help the poor. There’s no question that the statistic I’m admiring above will be improved even more in the short term once they take effect. My concern is whether they will undermine the factors that were causing us to do so well in the first place.

Companies in the glass industry don’t hire many workers at minimum wage, but increases at the bottom end have a way of putting upward pressure on wages all the way up the chain. Our businesses have been growing – most contractors and fabricators I speak to are busier than they want to be. That means more jobs. Unless, of course, a sharp hike in the minimum wage causes you to look for other ways to support your growth. Maybe investing in some new software could allow you to streamline operations and do more with the same or fewer workers. Maybe you could focus your efforts online and let sales staff go. Maybe you simply defer growth and keep the business the same size.

However you decide to react, I don’t think I’ll be able to take the same pleasure from statistics like Zakaria’s the next time they come up. And if you are looking for productivity-enhancing solutions, may I suggest a visit to Top Glass on April 17. You can find all the details inside. •

April 2018

Volume 30 • Number 2

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexweb.com

COO | Ted MARKLE tmarkle@annexweb.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

INDUSTRY NEWS

Jim Shepherd, 1952-2017

With heavy hearts the family of Jim Shepherd has announced the sudden passing of their beloved husband, father and grandad on Friday Dec. 8, 2017, at the young age of 65. He is survived by his wife and best friend Marilyn, his devoted son Steven (Julie), his cherished daughter Lynne (Stu) and his grandchildren Cavan, Sam, Tatum, Allie and Jack. Jim and Marilyn married in his birthplace of Dundee, Scotland, where he enjoyed playing soccer and working. He then answered the call of many and moved to Canada to pursue his career as a semi-pro soccer player and forge a new life for his family. Shepherd was an industry veteran and role model for many individuals in the glass and aluminum industry across multiple decades, continents and countries. He was an inspiring leader who brought a balance of humour and honour in every situation he crossed. Shepherd began his glass and aluminum career over 35 years ago in the manufacturing side of the business and worked his way through many leadership positions as supervisor, plant manager, vice-president of operations and finally as executive vice-president. He worked for industry giants such as Antamex, Alumicor

and Oldcastle BuildingEnvelope. During his career Shepherd carved a niche as a unitized manufacturing expert and completed many mobility assignments, such setting up manufacturing plants in Calgary, England and Houston. He played an instrumental role in many notable and landmark curtainwall projects across North America and Europe, specifically but not limited to: Canary Wharf (England), ExxonMobil Headquarters (Houston), The Bow (Calgary), GTAA Pearson Terminal 1 (Toronto), AGO (Toronto) and many, many more. He will be dearly missed by his family, friends and colleagues.

AAMA appoints new executive VP

Janice Yglesias has been promoted to be the American Architectural Manufacturers Association’s (AAMA) executive vice president, as approved by the association’s board of directors. Yglesias previously served as association services director before taking on this new position. “During her 18 years with AAMA, Janice strived to learn and understand all AAMA operations, programs and services. That knowledge has been transferred into countless improvements in AAMA procedures and productivity, making this a very well-deserved promotion,” said AAMA president and CEO Rich Walker.

Yglesias’s new role will involve creating, communicating and implementing the orga-

nization’s vision, mission, values, beliefs and strategic goals, as directed by the president and CEO, and the board of directors, as well as assisting in planning, organizing and directing staff, programs and activities of the association. She also will oversee, guide, direct and evaluate the work of other executive leaders including directors and managers of the association and will determine ways to reduce costs, increase revenues and improve overall company performance for association products and services. In addition, Yglesias will establish effective internal and external relationships, and work on other specific assignments.

Walker went on to say that Yglesias is “a tireless worker who always finds time to consult with members and staff, extending her outstanding ethical standards, personal integrity, strong leadership and teamworking skills.”

Yglesias celebrated 19 years at AAMA on Feb. 16.

April 12

Spring Seminar Richmond Hill, Ont. ogma.ca

April 17

April 23 - 28

May 10

May 31

Spring Golf Milton, Ont. ogma.ca

June 11 - 14

June 21 - 23

N.Y. conferenceonarchitecture. com

CGA Newsletter

CANADIAN GLASS ASSOCIATION

Efforts are ongoing as the CGA board works on a new mission and focus for the association. We are determined to deliver value for our members and do what we can as a national association to help the architectural glass industry across the country.

The consistent challenge in every region is access to the skilled labour we need as an industry. This is not a local or even provincial phenomenon, but something that concerns fabricators and contractors in every part of Canada. Yet the response has been regional, with different approaches tried in different areas with little communication of success or failure and little sharing of knowledge when we find something that works. As a national organization, the CGA is in a unique position to knit together the various threads and create a cross-Canada strategy. This could include:

• Promotion of the glazing trades at the high school level

• Creation and promotion of college-level trade courses that meet requirements in any region

• Lobbying governments to invest in apprenticeship programs and promotion

• Hosting career fairs

• Populating a national online job board

• Promoting Red Seal certification among glaziers

As a first step, the CGA will be contacting our regional partners to collect information on what works, what doesn’t and what is needed in your area. We

need your help! To offer your input, or volunteer your time, please email CGA president David Langton at dlangton@ compglass.com.

PROVINCIAL GLAZIERS ASSOCIATION OF ALBERTA

Our last meeting was held Jan. 17. Minutes and reports from that meeting are on the PGAA’s website.

As we prepare for our March Annual General meeting, to be held March 21 in Red Deer, Alta., the call for nominees has gone out. This will be a busy year as we continue the development of our Master Glazier Program, where our third and fourth courses – Structural Glazing and Specialty Glass – will be released and should bring us to a bit of a tipping point in terms of having a more comprehensive offering.

The market in Alberta seems a bit softer with more public sector projects and a lot of pre-construction work ahead of what should be a busier, more robust 2019 market.

FENESTRATION

ASSOCIATION

OF B.C.

The

FenBC Technical Conference and AGM took place at Northview Golf Course in Surrey, B.C. The agenda included Cori Maedel, our keynote speaker from the Jouta Performance Group, who offered some insight to the attendees on the challenges of communicating with different

generations. Dan Braun and Jason Loutet from Intertek presented on how to manage risk through effective mock-up testing.

Amber Gundersen of Chameleon TopCoatings and Marco Patermann from Benecke Hornschuch Surface Group answered the question, “What is laminate?”Al Jaugelis of RDH Building Science discussed important changes affecting commercial fenestration in the 2015 National Building Code that will not appear in the next B.C. building code. Our day rounded off with the FenBC Annual General Meeting and a round table discussion.

Save the date for the FenBC Annual Golf Tournament, May 17 at Northview Golf Course. Registration and sponsorships are posted on our website: fen-bc.org.

FenBC is working with Morrison Hershfield to update our Glazing Systems Specifications Manual to meet the current NBC.

ONTARIO GLASS AND METAL ASSOCIATION

Thanks for the memories

After a lifetime of serving on the boards of the OGMA and prior to that the Metro Toronto Glass Association –and putting in a few terms as president – Ennio Rea decided it was finally time for a break and to move on to make room for some new blood. Ennio was the face of the association for a long time and his years of dedication and countless contributions are greatly appreciated by everyone in the industry. Ennio has no plans

of retiring from his day job any time soon so you’ll still see all you can stand of him.

The board would also like to thank Doug Morris for his service to the OGMA, particularly in recruiting new members and driving our charitable contributions. Doug is also moving on.

OGMA welcomes new directors

We’re happy to announce the additions of Jeff Makimoto from TAGG Industries and Darryl Morton from Ontario Glass Werx to the OGMA board.

Jim Shepherd

It is with sadness that we relay the news of Jim’s passing in December, just a week ahead of his planned retirement. Jim was a long-time contributor in our industry, participated in many OGMA events, and worked his final years at Oldcastle Building Envelope in Concord. Please see his full obituary notice in this issue and on the OGMA website.

Spring Seminar

The topic of fire-rated glass will be presented by Fred Fulton of F1 Glazing Solutions and the topic of workplace violence and harassment investigations will be presented by Jennifer Threndyle from WSPS. The seminar will take place on Thursday, April 12 at the Richmond Hill Country Club.

Top Glass

Do yourself a favour and come spend a few hours seeing everybody that’s anybody at Top Glass on Tuesday, April 17. Make sure to stop by OGMA’s table to say hello. If we have it in the budget, we’ll give you a candy.

Managing

Top Glass at a glance

Date: April 17

Time: 10:00 am - 6:00 pm

Location: International Centre, Mississauga, Ont.

Parking: Free on site

Admission: Free

Who should attend: Glazing contractors, glass fabricators, architects, building engineers, architectural glass specifiers

Managing change

New technology, new science and new ideas set the tone for Top Glass 2018.

by PATRICK FLANNERY

If everything always stayed the same there would be no need to come out to trade shows. Instead, we are inundated with change. Tightening energy efficiency standards are entering the market unevenly across the country, challenging contractors and fabricators to maintain esthetics and margins as designs adjust. The trend toward larger, unbroken glass panels marches on, forcing new approaches to every aspect of fabrication and installation. Commercial products and designs are getting more popular in luxury custom homes while vinyl and hybrid vinyl products are knocking on the door of multi-unit high-rise projects. Environmental concerns about bird safety, internal daylighting and reflectivity are driving innovation in window/ wall ratios, glass marking, spandrel design and colour. Advances in automated motion control continue to make manufacturing faster and more efficient, with the possibility of automation in information processing and even decision-making on the horizon. A strong market is exposing structural deficiencies in Canada’s skilled trades development market, challenging the industry to find new ways to attract and train workers, or do with fewer of them.

A quick look at our exhibitor showcase on page19 shows how Top Glass suppliers are offering to help you meet some of these challenges. Window systems with hybrid designs and improved thermal breaks can help you meet those energy efficiency targets. Innovative glass and IG options can help address some of the special requirements of today’s facade designs. How about a better saw, or a sealant system designed to handle larger glass sizes?

As always, the Top Glass education program presents some of the latest thinking to prepare you for the future. The North American Fenestration Standard has upped the demands for air/water tightness in facade design and is now part of the National Building Code. Al Jaugelis of RDH Building Science explains how architects can design around this standard. Chris Fronsoe of ICD Coatings talks about those needs for innovative solutions to glass opacifying and what can be done beyond traditional ceramic frit. Cody Thomas of Glass Renu knows a thing or two about how to fix scratched glass to help you rescue those big panels rather than throw them out at a cost of thousands. And for a look into the far future, we have Chuck Black of Brookhaven National Laboratories presenting new etching techniques that might revolutionize what is possible with glass. •

Schedule of events

10:00 Registration desk and exhibit hall open

11:00 Scratching the surface: Using nanotechnology to make glass non-reflective, water-repellent, and fog-resistant

presenter: Chuck Black, Brookhaven National Laboratory

12:00 Lunch break

1:00 Glass restoration: Providing clarity without distortion

presenter: Cody Thomas, GlassRenu

2:00 NAFS: What’s in, what’s out and what to do about it

presenter: Al Jaugelis, RDH Building Science

3:00 OGMA Awards of Excellence

4:30 Silicone coatings: An alternative to ceramic frit for spandrel glass

presenter: Chris Fronsoe, ICD Coatings

All presentations take place in the lecture theatre located on the show floor. Sessions are eligible for OAA Structured Learning Hours – certificates of attendance issued on request.

11:00

TOPIC / Scratching the surface: Using nanotechnology to change glass

PRESENTER / Charles Black, Brookhaven National Laboratories

Small changes, big results

Nanoscale etching alters the behaviour of glass surfaces

Dr. Charles (Chuck) Black of Brookhaven National Laboratory in the United States will present his team’s research using nanomaterials to render glass and some plastics virtually invisible by eliminating nearly all surface reflections. The nanotechnology-based approach uses self-assembly of block copolymers to design surface textures that endow materials with improved properties, such as full-colour antireflection across the visible and near-infrared wavelengths. Similarly designed surface nanotextures further impart water and fog-repellency to the glass, making it able to resist water droplet impacts even in excess of 10 metres per second. In this presentation, Dr. Black will discuss the physics behind light reflection and water repellency, as well as the process his team uses to create these surface textures. Attendees will get a look at technology that may change the future approach to glass treatment with implications for common problems with glare, coating durability, solar heat reflection, building energy efficiency and esthetics.

About the speaker

Dr. Black is a senior scientist and director of the Center for Functional Nanomaterials (CFN), a national scientific user facility operated at Brookhaven National Laboratory for the U.S. Department of Energy. Each year, the CFN supports the science of more than 550 researchers from universities, industry and national laboratories worldwide. The CFN mission is advancing nanoscience to impact society by being an essential resource for the worldwide scientific community and by carrying out transformative basic nanomaterials research. Dr. Black earned a Ph.D. degree in Physics from Harvard University in 1996, and B.S. degrees in Physics and Mathematics from Vanderbilt University in 1991. Dr. Black is a member of the board of directors of the Materials Research Society, a fellow of the American Physical Society, and a senior member of the IEEE. •

This is not a test: Your design vision was made to impress—just like jumbo coated glass. Guardian Glass® has a long history of creating jumbo coated glass around the world, and we’re bringing our newest jumbo coater to North America soon. Let us help you bring your vision to life.

TOPGLASSSEMINARS

TOPIC / Glass restoration:

Providing clarity without distortion

The science of restoration

With new methods, scratched glass can be fixed

PRESENTER / Cody Thomas, GlassRenu

Scratched glass is a major issue, especially on high value, heavy fabricated or hard-to-acquire materials. Jobsite damage from other trades can also be a major issue for the glazier. The thought of being able to salvage the glass is one that has been worked on for several years but understanding has been limited. Major advancements have been made in this field to repair glass and return it to a form that does not leave any optical evidence of rework. In this presentation, Cody Thomas, president of GlassRenu, a California glass restoration company, will go over the challenges and historical approaches to glass damage restoration and take a look at some new methods and technology impacting the industry.

About the speaker

Cody Thomas has been involved in the glass industry for over a decade as president of GlassRenu, a California-based manufacturing firm focused on developing and delivering comprehensive glass surface restoration tools. With a background in the sciences, Thomas has brought his experience in solving technically difficult problems to the glazing and glass fabrication industries. Following a decade of developmental work in building and distributing his tools to window cleaners and other contract maintenance companies on several continents, Thomas set his sights on the issues plaguing glass manufacturing companies — notably the elimination of scratches and damage involved in the glass production and fabrication process. His goal is to drastically increase the quality output of manufacturers by reducing the amount of re-work typically encountered in most glass plants. Drawing from his experience and technical expertise in dealing with scratch damage on glass, Thomas and GlassRenu are quickly proving to be instrumental in solving quality issues that otherwise have been left untouched in glass fabrication. Prior to Founding GlassRenu in 2006, he spent five years in purchasing and production with Symtx, a defense subcontractor based in Austin, Texas. Symtx serves a wide range of clients, including government agencies like the U.S. Navy and Air Force, as well as private sector firms such as Boeing and Lockheed. Thomas received his MBA from the Peter F. Drucker School of Management with dual concentrations in Marketing and Business Strategy, as well as a Bachelor of Arts in Biology, with a concentration in Genetics from Pitzer College, both in southern California. Thomas currently lives in the San Francisco Bay Area with his wife and three daughters. In his spare time he can be found coaching his local high school men’s lacrosse team. •

See the beauty — not the glass — only with Starphire® glass

Don’t accept imitations. Only Starphire Ultra-Clear® Glass by Vitro Architectural Glass (formerly PPG Glass) allows views so brilliant, you’ll forget the glass is even there. For interiors, exteriors as well as heavy and safety glass applications in thicknesses up to ¾ inch, no low-iron glass consistently maintains its transparency, color fidelity, vivid beauty and distinctive blue edge like Starphire® glass.

Request samples at www.starphireglass.com

Starphire Ultra-Clear® Glass Conventional Clear Glass

TOPGLASSSEMINARS

Knowing NAFS

How to work with the North American standard for air/water ingress

With the title “North American Fenestration Standard,” it is tempting to think that NAFS applies equally to all fenestration products. This is not the case: while NAFS applies to a great many fenestration products, it excludes many products used in larger buildings from its scope. Fortunately, the code recognizes this and provides complementary compliance paths for products within and outside the scope of the standard.

This presentation will examine NAFS and the Canadian Supplement to NAFS from the perspective of the National and Ontario Building Codes. It will explain why Performance Class is so central to NAFS, yet peripheral to the code. And why in Canada we dismantle the Performance Grade – the “American ABC rating” – to specify air-water-structural properties independently of one another.

This session will also address the matter of products outside the scope of NAFS and how the methods provided in CSA A440S1, the Canadian Supplement to NAFS, can be used to determine suitable design pressure and water-penetration resistance test pressure values for products within as well as outside the scope of the standard.

TOPIC / NAFS: What’s in, what’s out and what to do about it

PRESENTER / Al Jaugelis,

RDH Building Science

As a bonus this presentation is supplemented with a free e-book for participants titled “An Architect’s Guide to NAFS: Using with the North American Fenestration Standard in Canada.”

About the speaker

Al Jaugelis is a senior fenestration specialist with RDH Building Science and contributes to research, new construction and renewal projects as well as assisting fenestration manufacturers with product performance and regulatory compliance issues.

Al brings to this role practical experience in the fenestration manufacturing industry and a clear understanding of Canadian code requirements applicable to fenestration. He is an effective communicator and is in demand as a speaker on topics related to fenestration performance and Canadian building codes.

Al is a member of the CSA A440 Committee on Performance Standards for Windows, the Fenestration Canada and FenBC Technical Committees, the NRCan Energy Efficient Fenestration Steering Committee, and is also a technical consultant member of the American Architectural Manufacturers Association (AAMA)

He is recognized as an authority on the North American Fenestration Standard (NAFS) and writes about it in the NAFS in Canada blog. •

VISIONARY DESIGN

Decades after Dow Corning helped pioneer the foursided silicone structural glazing technology that opened architects’ eyes to a new era of design, studies confirm our structural silicone sealants have an expected service life of at least 50 years.

Emphasizing silicone’s high performance, these sealants –and our full line of proven high-performance building products – are now available as DOWSIL™ brand, with the same trusted silicone chemistries, features and product benefits you’ve come to expect from Dow Corning® brand products.

Imagine a future that’s possible with long-service-life sealants. Visit our new website.

www.consumer.dow.com/construction

New name. Same trusted products.

TOPGLASSSEMINARS

4:30

TOPIC / Silicone coatings

Silicone secrets

When and where to apply silicone opacifiers to spandrel glass

PRESENTER / Chris Fronsoe, ICD High Performance Coatings

RDH Building Science

trosifol@kuraray.com

In this AIA-accredited presentation, Chris Fronsoe of ICD High Performance Coatings will discuss the use of silicone opacifiers in spandrel applications, educating attendees about the technological concept, application process and implications for surface performance, durability and esthetics. The presentation will address strengths in a variety of applications including monolithic, insulating glass and IG with low-E. Attendees will also learn about relevant techniques for fabricating and assessing spandrel glass performance and look at comparisons with other opacifier technologies.

About the speaker

Chris Fronsoe is the Global Sales Manager of ICD High Performance Coatings and has held that role since early 2016. Fronsoe joined ICD in February of 2015 in a sales and marketing position. Fronsoe sits on several task groups within the Glass Association of North America (GANA) and is very active in the industry at large. Fronsoe has a BA in Business Management and Organizational leadership from George Fox University. Chris also holds many certifications in wine and spirits and is a nationally recognized sommelier.•

Perfect for different glass thicknesses, without changing gaskets, our multi-directional adjustment allows pivot point, flush, and zero position adjustment—even after installation.

The clean precision of MUNDUS patch fittings offers smooth transitions between glass panels for greater transparency. MUNDUS fittings support glass thicknesses up to 7/8", tempered laminates, and glass doors weighing up to 440 pounds. So simple to install, the fittings can be mounted and fixed in place as delivered to provide a secure hold. Post installation, multidirectional adjustability ensures a perfect fit. It’s easy to see why MUNDUS is the clear choice for creating contemporary glass environments. Are we clear?

Visit www.dormakaba.ca/Mundus-CG

Celebrate great glazing

The smiles say it all. Here, OGMA directors Steve Gusterson and Angelo Cairo

Each year Top Glass is proud to host the Ontario Glass and Metal Association’s Awards for Excellence. The Awards for Excellence are annual awards that recognize excellence in the design and execution of a building that incorporates the use of architectural glass and metal. There are two awards, one for Excellence in Architectural Glass and Metal Design and one for Excellence in Architectural Glass and Metal Execution.

About the OGMA

The Ontario Glass and Metal Association represents the interests of Ontario businesses involved in architectural glass construction and supply. Founded in 1990, the association’s mandate is:

• To promote and assist to develop an image of a responsible and valuable Canadian industry.

• To provide educational, social and collaborative events relative to the glass and metal industry.

• To promote the interests and conserve the rights of those engaged in the manufacture, sale and installation of flat glass, architectural metal and related products.

• To promote co-operation between its members and other groups within related industries.

• To gather information related to the industry and to communicate such information to members of the Association and other interested parties.

present the award for design to Gary Watson of Diamond Schmitt Architects at Top Glass 2017.

BOOTHPREVIEW

SNEAK PEEK

Here’s a look at the groundbreaking technology on display at Top Glass 2018

PROVEN THERMAL PERFORMANCE

Booth: 39 alumicor.com

Alumicor will show off its new Integra 6000 integral rain screen window system. The Integra 6000 is a single-platform window system engineered to deliver unlimited configurations of fixed, open-in and/or open-out operable combinations within one system, along with superior thermal performance. Canadian winters demand windows with superior thermal performance and condensation resistance and both are delivered by the innovative Integra 6000 window system. There’s even an option for additional insulating foam in the frame, sash and around the glazing unit for accredited-laboratory tested 10-per-cent-improved thermal system performance, as well as improved condensation resistance and acoustic performance. Ideal for the institutional, commercial and residential markets, the integral design allows for many configurations without the need for additional sub-frames. Available in 60-, 100- and 150-millimetre frame depths and horizontal and vertical intermediates, the varied options allow for limitless creation of unique architectural details. Accommodating a one-inch double-glazed sealed unit, the Integra 6000 is available in fixed, awning, hopper, casement and combination units, as well as large size capacity, appealing to all project requirements. The Integra 6000 is completely fabricated by Alumicor. In Alumicor’s controlled environment, quality can be easily monitored and achieved, reducing field issues, all with Alumicor’s product

guarantees. As a rain screen system utilizing Alumicor’s ITGRseal, the cost of caulking and backer rod installation can be reduced as well as making glass replacement easier, while improving air and water performance. The Integra 6000 has been accredited-laboratory tested and rated to NAFS AW-PG85 for open – in-and-open – out and fixed windows.

FIELD-FRIENDLY INSTALLATION

Booth: 54

commdooraluminum.com

The Commdoor 8200 HP curtainwall system has been designed to meet new thermal performance requirements, such as SB 10. The initial series 8000 curtainwall utilized standard curtainwall design based on a thermal break between the back section neck and the pressure plate. The newest version, the 8200 HP series, now offers a dual polyamide thermal break which is capable of achieving the desired thermal performance. The system face width is 2 ½ inches with five back section depths available from four to 10 inches. Traditional caps and pressure plates are available along with structurally glazed versions offered in stock lengths up to 24 feet,two inches. Available in both traditional stick and split vertical mullion versions, the 8200 HP system provides greater flexibility to suit varying job site applications. It is designed for low- to mid-rise building designs and is desirable for its ease of shop fabrication and field-friendly installation. The 8200 HP series is designed to accept a variety of infills: glass and glazing up to 1 3/4 inches triple glazed along with Series 225 operable vents, 2000 series SSG vents or commercial doors including Series 4487 high-performance terrace doors. Most system profiles are in stock in either clear or bronze anodized finishes, with custom colours also available.

MATERIAL SYNERGY

Booth: 49

rpmroll.com

RPM Climatech Spacer is a technology that had been designed by RPM and is manufactured right here in Canada. RPM believed there was a better solution for saving energy and cost, so the engineers went to work and designed a better way to insulate glass. The demanded for thermally broken technology increased in 2017 so that RPM Climatech Spacer became Canada’s most recommended spacer for commercial use. Combining the strength of steel, the corrosion resistance of chrome and the thermal performance of plastic, this premium product has set the industry standard for energy efficiency and structural conformance. And because it is direct from the manufacturer it is customizable to your dimensional needs, colour preference and desired lengths. RPM Rollformed Metal Products cares about your product reputation and about conserving energy and is committed to making it better.

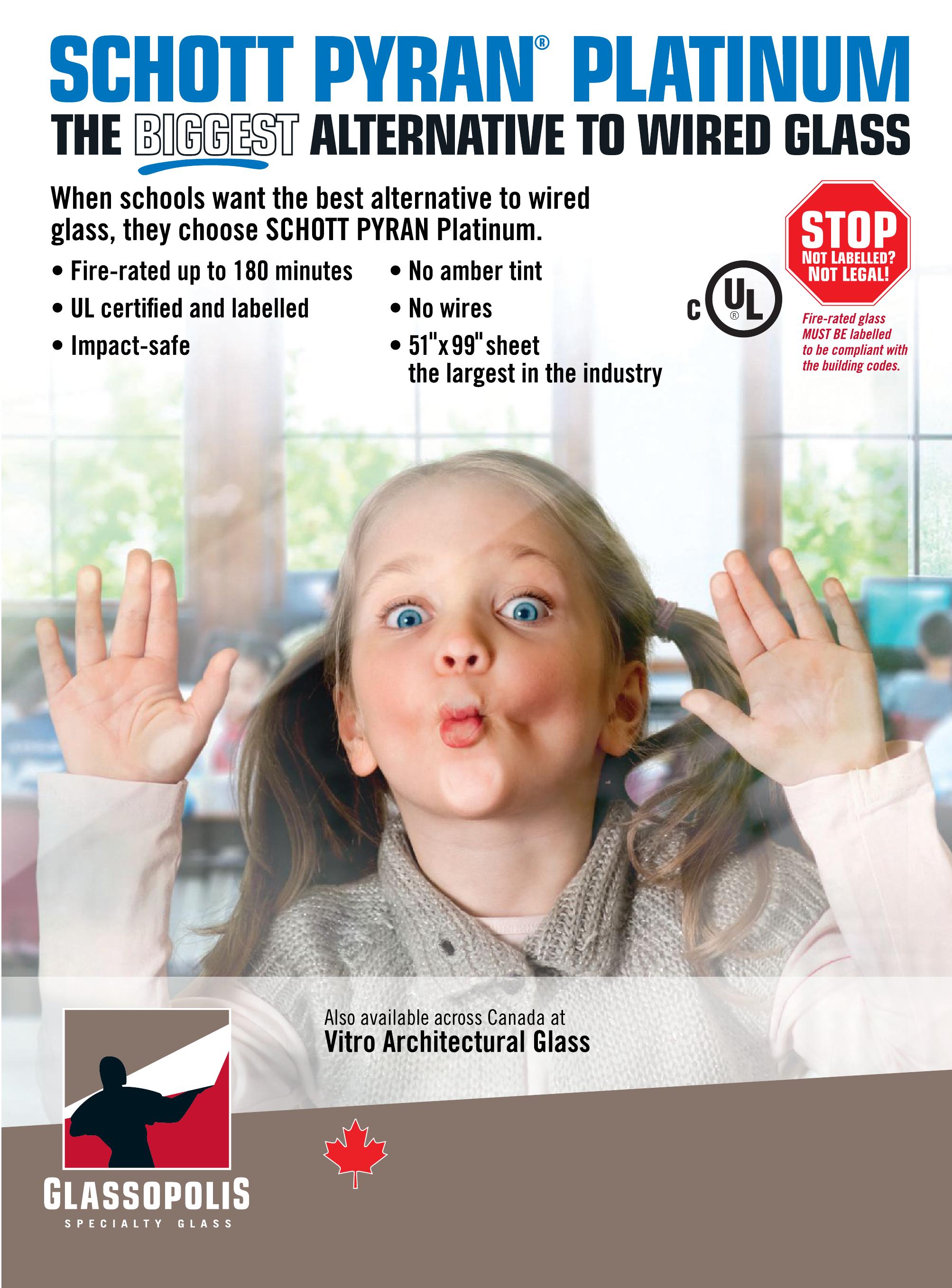

FLOAT GLASS-CERAMIC

Booth: 44

glassopolis.com

Bigger is clearly better. Glassopolis announces that the most innovative fire-rated glass-ceramic in the industry is now also the largest. At 51-by-99 inches, the new Schott Pyran Platinum sheet size lets you realize projects that were previously impossible. For years architects have appreciated the smooth surface, neutral colour and proven technical performance of Pyran

BOOTHPREVIEW

Platinum – the world’s first and only floated glass-ceramic. Pyran Platinum is produced using Schott´s unique Microfloat process. The hot molten glass ribbon is floated on an inert bed of liquid tin and is allowed to cool slowly without any mechanical contact that could blemish the smooth surface. The result is Pyran Platinum’s smooth, distortion-free mirror finish. Pyran Platinum is also clear and colourless, without the distracting amber tint associated with competitive fire-rated glass-ceramics. The neutral color allows Pyran Platinum to blend in with the surrounding architecture of the building. With the new Schott Pyran Platinum, bigger is clearly better. Glassopolis has the new Pyran Platinum in stock right here in Canada for immediate delivery.

KNOWS THE INDUSTRY

Booth: 30 lothars.ca

Lothar’s Industrial Sales is a knowledgeable machinery supplier to the Canadian PVC window

and curtainwall industries, proud to supply manufacturers and contractors with quality products for over 30 years. Lothars carries custom-made multi-spindle drill heads and parts; high-speed steel and carbide router bits; quality Teflon products for vinyl welding equipment; custom-made fabrication equipment; bending forms for PVC; punch dies; saw and welding fixtures; and corner cleaning and end mill cutters.

SOLUTIONS FOR GLASS RAILINGS

Booth: 25

can.sika.com

Sika Canada offers two innovative products with the mechanical strength necessary to outperform existing structural glazing and insulating glass silicone adhesives: Sikasil SG-550, rated at a superior 0.20 Newtons per square millimetre, and IG secondary-edge sealant, Sikasil IG-25 HM Plus, evaluated at 0.19 Newtons per square millimetre. This kind of innovation allows for slimmer frames, cost savings and lighter designs. Furthermore, Sika offers a solution for embedding glass guardrails – the SikaGlaze GG-735. Glass rails need to be affixed to the floor with the lowest stress possible on the glass panes, but mechanical fasteners transfer high punctual stress to the glass resulting in thicker glass panels being used. SikaGlaze GG-735 allows for a more uniform distribution of the stress allowing for less punctual stress, and is impervious to moisture, making it ideal for outdoor applications.

Semi-Transparent Mirror Glass

It is the perfect solution for a sleek, modern look. When the TV or digital display is off, it appears to be a normal mirror. Once it is on, a clear image of the screen comes through providing optimal versatility.

BOOTHPREVIEW

PURPOSE-DESIGNED FOR CURTAINWALL

Booth: 38

int-machinery.com

The ACK 550 from INT Machinery is an upcut miter saw specifically designed to perform straight and miter cutting with large aluminum profiles such as curtainwall or industrial extrusions. The ACK 550 features a 550-millimetre saw blade and a 5.4 horsepower, 230-volt, three-phase, 60-Hertz, 2,400 RPM motor. The pivoting range from minus 75 degrees left to plus 75 degrees right is infinitely adjustable, but the saw is also provided with pre-set location points at 75, 60, 45, 30, 22.5, 15, and zero degrees in both directions for accurate and quick adjustment of most common mitre angles. The up-raising of the saw feed is hydro-pneumatic to guarantee a constant raise feed. A two-year factory warranty covers the whole Yilmaz product line.

HIGH PERFORMANCE IG

Booth: 6

litezone.ca

LiteZone is a new kind of insulating glass unit that can achieve insulating values up to R19.6 at the centre of glass and as high as R17.0 for an overall window. Winner of the 2016 prestigious Green Building Product of the Year from the Canada Green Building Council, LiteZone embraces the need for thicker insulating glass to achieve these remarkable insulating values. LiteZone can be thicker because it has a proprietary system to allow the air pressure between the inside and outside of the glass unit to equalize with changing temperatures, while keeping water vapour from entering the unit. Its insulating and other performance values are customized to specific project

requirements by varying the number of suspended films, the space between the layers and the number of low-E coats used in the configuration. LiteZone is air-filled so that there is no concern over performance loss due to inert gas escaping over its life. LiteZone has an extremely strong and flexible edge seal that is impermeable to water vapour. Edge seal stress due to changing temperatures is minimal because all the materials used have comparable coefficients of thermal expansion and because the unit is pressure-equalized. The expected life of LiteZone is more than 60 years. Because it only uses two glass lites, LiteZone weighs less than triple-pane glass units. With its weight, performance and other important advantages, LiteZone provides design flexibility to use large windows and generous glass areas.

BONDED PIB

Booth: 32

viracon.com GlassCan will exhibit Viracon’s new proprietary warm-edge spacer technology for insulating glass units called Viracon Thermal Spacer (VTS). VTS replaces a traditional spacer, desiccant and primary sealant with a better-performing, single component spacer available in glass sizes up to 130 by 236 inches. VTS’s exclusive formulation consists of a black thermoplastic with integrated desiccant and polyisobutylene (PIB) that is chemically bonded to the glass and the secondary silicone sealant. This exclusive technology has been engineered to outperform other spacers and edge seal systems. Thermal performance is 14.4 per cent better than aluminum spacers and condensation resistance is notably higher. VTS is the newest addition to Viracon’s spacer offering which includes aluminum, stainless steel, and ExtremEdge. VTS’s exclusive technology delivers excellent thermal performance. It is available in a range of thicknesses; it improves edge of glass aesthetics; and units produced with VTS include an argon fill.

RESTORATION SOLUTION

Booth: 34

tremcosealants.com

Spectrem Restoration Overlay (SRO) extrusions are custom-designed, patented solutions for restoring leaking skylights, sloped glazing, pressure bar and zipper/ lockstrip systems. Adhered to substrates using Spectrem 1 silicone sealant, SRO’s patented design allows it to encapsulate

leaking purlins while completely enclosing the silicone sealant bead. Leak points are drastically reduced when all joineries, other penetrations and screw heads are completely covered. With sealant minimally visible on the interior and exterior, SRO creates straight sight lines on the interior and exterior. SRO’s colour-fast formula resists the effects of UV exposure. The result is a clean, esthetically pleasing appearance plus an extra layer of protection that shields the sealant bead from exposure to the elements and eliminates air and moisture penetration. Compared to traditional dry glazing repair methods involving total removal and replacement of the system components, SRO offers a cost-effective alternative requiring less sealant and reducing down time and labour costs. The product is easy to install and clean up and offers a 20-year warranty. Custom colour matching also is available.

RAISES THE STANDARD

Booth: 5

erdmanautomation.com

The Erdman high-speed Dura line produces IG vertically in a fashion that nearly doubles the speed of traditional vertical lines. The Dura line is a pioneering solution for vertical automation for the single seal IG market. Never before has Dura been produced vertically. Vertical production eliminates the need to tip a unit up to four times in the production sequence. This saves time, eliminates injury potential, qualifies more operators for service and minimizes breakage. The Erdman high-speed Dura line produces IG at a rate nearly twice as fast as a traditional IG line. Total labour for the Dura high-speed line is three to four operators making at least 1,200 units per shift. Speed is joined with other innovations and benefits such as reduced

MOVE & MOUNT

BOOTHPREVIEW

floor space, reduced labour and higher-quality product. The Dura high-speed line has inspired IG manufactures to expect more out of their IG production equipment. This has raised the standard expected output in the IG industry.

We have listened to glaziers and the glass industry and developed our

A strong lift able to transport and mount windows hairstraw precise in wild angles.

lift is like the rest of the family - when it gets tough, it shines!

INSULATING ALUMINUM

Booth: 59 everlast.biz

The Everlast Altitude Plus Window Series sets a higher standard for aluminum windows. This window features extruded aluminum profiles interior and exterior connected to a thermal insulation system called the “performance core,” representing the core of the window. The performance core is a new proprietary engineered material designed for specific tasks offering improved dimensional stability and higher deflection temperatures. The resulting increased strength gives manufacturers access to the perfect combination for their market. The Altitude Plus Window Series provides window manufacturers with a competitive edge. It also features mitered corners assembled with gaskets and corner keys all crimped together. This window series has achieved Energy Star certification both in Canada and the US. Low profiles make it an ideal window for today’s modern homes. Altitude Plus also meets the CW classification, making it suitable for mid-rise buildings with institutional applications. It provides the possibility of multiple assembly and opening configurations. It’s available in casement, awning or fixed window configurations. Combination windows are achieved using modular construction. The frame depth is 114 millimetres. The standard sash depth is designed for 31-millimetre glazed units. The frames and sashes can hold a triple glazed unit as well.

A BETTER VENT

Booth: 22

eltonmanufacturing.com

Elton Manufacturing will display the 2248 three-quarter vented door lite, part of its well-established collection of high-quality venting units and residential entry door

products. The addition of the 2248 three-quarter vented door lite gives customers and trade partners access to a full line of venting units in a wide array of standard sizes and glass options. Key features of the 2248 vented unit include a constant force balance sash for ease of operation and a large open area for ventilation. This well-designed vented insert comes with a contemporary injectionmoulded frame that will not fade in the sun and includes a high-heat foam caulking rated to 240 Fahrenheit for a secure fit and finish. Celebrating over 34 years of business, Elton Manufacturing continues to grow through its commitment to deliver innovative quality products with superior service. Top Glass visitors can get coomplete information about Elton’s entire line of quality residential entry door products, including a wide selection of both traditional and contemporary injection-moulded, PVC and aluminum door lite frames. Recent additions to the Elton product line include a full line of laminated wood profiles in two distinct finishes. With all production completed in Elton’s own facilities, quality control is maintained and customer service maximized.

HARVESTS LIGHT

Booth: 63 velux.ca

The Velux Dynamic Dome is an innovative commercial skylight designed to harvest low-angle light for up to two additional hours, keeping flourescent lights off longer. In addition to delivering bright, diffused light at midday it also creates a more consistent light level through the day. The revolutionary dome balances the structural demands of industry professionals with an architecturally progressive design. The smooth outer dome provides up to 20 per cent more light than a prismatic outer dome. The white prismatic inner dome achieves 100 per cent diffusion/haze. The sidewall of the dome is engineered to match the sun angles of the morning and afternoon hours to improve light transmittance.

by MARGARET WEBB

Report from the Winter Conference

Here are some highlights from the technical meetings at our very productive and enjoyable Winter Conference in Tucson, Ariz.

The new quality manual TM‐4500, Quality Management System for the Fabrication of Insulating Glass Units to the ISO 9001:2008 Standard and the Tier 2 document TM-4510, Quality Procedures for the Fabrication of Insulating Glass Units to the ISO 9001:2008 Standard are now both available from the IGMA Publication Store.

TM-4515, Quality Work Instruction for the Fabrication of Insulating Glass Units to the ISO 9001 Standard has been balloted to the Certification Committee. Once that work has been completed, the task group will focus on the forms. Once all four tiers have been developed, users will be able to purchase the complete quality management system or each of the separate manuals. When finished, these documents will constitute a ready-made, ISO-compliant quality program specifically for the glass fabrication industry.

TB‐2700‐18, Sealant Adhesion to Spacer Test Method has been published and is also available from the IGMA Publication Store.

The ISO standard for vacuum insulating glass will be published shortly. Now that there is a standard for the product, the task group will be developing certification guidelines for testing VIG under the glazing guidelines working group’s glazing guidelines for VIG.

The Emerging Technologies and Innovation Committee formally voted to participate in the revision of the Window Product Category Rules with the American Architectural Manufacturers

All presentations from this conference and from past conferences are available at igmaonline.org.

Association and the Window and Door Manufacturers Association. The current proposal, which requires review from the joint industry Memorandum of Understanding Committee, is to develop separate PCRs for residential and commercial fenestration products. The residential PCR would include a use phase while the commercial one would be a B-to-C PCR.

The IG cavity compensation task group has developed a technical manual providing generic design alternatives for cavity compensation for insulating glass units and ways to determine conditions that impact the pressure in the IGU cavity. Items included in the document are capillary and breather tubes, one-way valves, desiccant adsorption/desorption, pre‐inflating/pre‐deflating the unit, temperature manipulation during fabrication and the use of bladders. The draft document, identified as TM‐3200‐XX is already in its seventh draft. The document will be formatted the same as the Guidelines for Use of Capillary Tubes and will address pros and cons; special manufacturing and handling requirements; and other information specific to each methodology.

Working jointly with the AAMA Glass Materials Council, the visual quality task group has developed a consumer guide to understanding glass standards, which will be posted as a webpage rather than a technical publication.

CSA is seeking participation from the industry to develop a standard for bird-friendly glass. If you are interested in participating in this standard development, please contact the IGMA office.

An update was provided on the Canadian government’s industry stakeholders meetings on the new proposed energy requirements to achieve Net Zero for all buildings by 2030.

The IG Fabricator Workshop held Nov. 7 through 9 at the Intertek test facilities in Plano, Texas, was sold out and, due to group size limitations, several interested individuals were turned away. Originally it was reported that a workshop would be held in conjunction with the IGMA 2018 Summer Conference (July 31 through Aug. 2 in Vancouver), however the committee has decided that due to the interest in the workshop the location for the next couple of years will be set to the Intertek facilities. Dates need to be confirmed but will be during the first two weeks of November 2018.•

IGMA

BRINGING OFFICE INNOVATIONS TO LIFE.

Cutting-edge façades deliver real business value. From increasing natural lighting to optimizing temperature, our façade solutions create spaces that contribute to increased productivity and a positive culture that defines the modern workplace. Office buildings that promote employee well-being deliver performance from the outside in. High-performance office façades for high performers.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s Building Sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at david.heska@wsp.com

Getting your fill

As our industry kicks in to gear for another construction season, it’s a good time to look at a few best practices and common failures. First, let’s start with some background before discussing a recent project example.

The use of low-E coatings and inert gas-fills (such as argon or krypton) is widespread among insulating glass unit (IGU) manufacturers seeking improved thermal performance. Research has shown that in double-glazed units low-E coatings can increase the R-value by 50 to 70 per cent and argon fill can increase the R-value by an additional 25 per cent. But here’s an important question: how do we know if this invisible gas has actually been installed in the IGUs?

How do we know when an invisible gas has actually been installed in the IGU?

On one of my recent projects we checked this and what we found out was not good (for either the contractor or the IGU manufacturer). I’m not here to point fingers and I don’t presume that everyone is guilty because of a couple of bad apples, but I do think that this is something that should be discussed. We all know that the industry-accepted standard argon gas fill level is a minimum of 90 per cent out of the factory. As part of a recent project our team visited the manufacturing plant and completed testing with a spark emission analyzer. The spark emission analyzer is a handheld portable device that is battery operated. A high-voltage spark is launched into the IGU cavity, causing a light to emit, which is then analyzed and a fast reading of the gas concentration is presented within a couple seconds. We were happy to find that most of the IGUs exceeded the 90 per cent fill requirement. However, for one manufacturing run the argon content was between 69 to 74 per cent for small IGUs (approximately one foot by three feet) and between 81 to 86 per cent for large IGUs (approximately four by three feet). The contractor refused to accept these IGUs from the manufacturer and modifications were made to correct this deficiency going forward.

THE ENGINEER

Of course, insulating glass manufacturers have been aware of these issues for some time and the Insulating Glass Manufacturers Association has been working to correct them. There is even a standing task group within the association – the gas measurement validation group – that sets the standard for verifying gas fill levels. It turns out to be a very complex and scientific problem to solve. Right now it looks like they have argon pretty much licked and the effort is moving on to figure out how to properly calibrate the spark-emission tests to look at other exotic gas fills.

Another deficiency that we look for when reviewing IGUs are discontinuous primary seals. The polyisobutylene (PIB) primary seal prevents moisture from entering the air/gas space in an IGU. But sometimes there are small gaps in the primary seal (typically at corners) and these gaps allow the inert gas fill out and moisture in. The overall life expectancy of an IGU is greatly reduced if there is a discontinuous primary seal. As a regular part of a typical quality assurance process, manufacturers should be reviewing samples of their product to ensure that the gas fill requirements are met and that primary seals are continuous. Proper workmanship is critical when manufacturing IGUs and the glass needs to be clean and dry for sealants to adhere. It is also important that corner keys are crimped without any gaps and that the plugs/ports are tight.

So whatever your role on projects this summer, whether its leading the manufacturing process, a contractor installing windows, or as an engineer specifying and reviewing work on site, let’s all keep these two items in mind. Let’s do our part to discard the IGUs with discontinuous primary seals and inadequate gas fill and let’s keep our heads held high knowing we’re in this together. •

THE THREE QS

by GEORGE TOROK and YVON CHIASSON

Meeting the budget for construction of a building can be a challenge, especially when a proposed design may be aspirational rather than strictly practical. Public and private sector owners, construction managers, general contractors, sub-contractors, fenestration system and component suppliers have, for many years, looked for cost savings through continental and increasingly, global procurement (i.e. outside North America and overseas). Sourcing product from afar has its opportunities and rewards, and associated risks. A QA, QC and QF process is vital to achieving expected quality construction.

What is QA? QC? And especially QF? The meaning of the first two acronyms should not be unfamiliar – Quality Assurance and Quality Control. Quality Assurance is the plan to achieve the desired quality. Quality Control is how that will be done – the nuts and bolts, test methods, frequency

Attention

to each aspect of quality is important,

especially

when buying offshore.

of test methods, pass/fail criteria, responses to failure to correct what’s been made incorrectly and then preventing recurrence of the same mistake, and documenting all of it. QF means Quality Fade, or the drift in quality that may occur during manufacture or installation of a building component or assembly. Quality Fade may occur because of ‘loopholes’ in building code requirements, referenced standards, familiarity

with industry practices (North American practices different than overseas practices), and/or lack of accountability/ transparency from remote manufacturers (input from third part review of QA/QC not considered, and not followed/ implemented in a regimented fashion). A QA plan and QC procedures must recognize the potential for QF and include ways and means to prevent it, to remediate incorrectly made

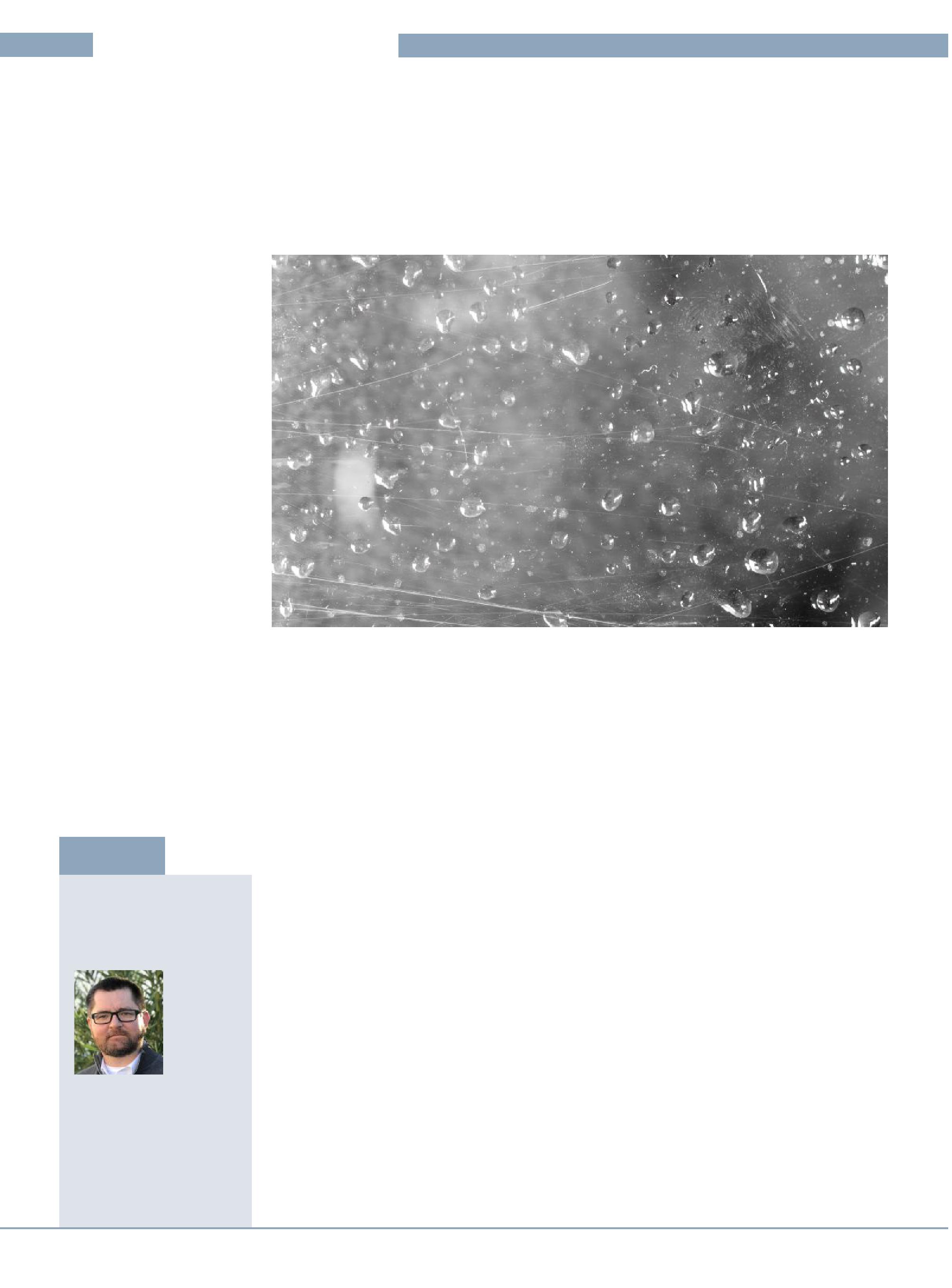

ABOVE: Distortion of reflected images is visible in this heat-treated glass. Improved tempering technology is making roller wave distortion less of a concern for sophisticated manufacturers.

Photo credit: Torok/Chiasson

FEATURESTORY

ABOVE: Hand lay-up of laminated glass. Offshore production may cost less, which may be an indicator of poor quality.

RIGHT: Output end of an articulated quench for a top-of-the-line tempering system by Land Glass. As in western countries, low price may be achieved by labour cost savings through automation, while at the same time improving quality.

product, and to rectify the required steps in the QA/QC to prevent recurrence, and mitigate future risks.

There are surprising omissions within and between building codes, referenced standards (ASTM, ANSI, CSA, CGSB, etc.), and industry practices (IGMA, GANA, SGCC, AAMA,

etc.) that may result in less than desirable quality outcomes. Have you ever heard a supplier state that a building code does not include, or it is not typical industry practice to meet, a certain requirement of the project specifications so that requirement will not be met? It wasn’t included in the price because it is not normal to do so? With remote, off-shore procurement, there may also be conflicts between codes, standards and industry practices of the country of origin and those of the destination country that are not recognized by either party . The design and construction team should be aware of potential omissions in codes, standards and industry practices and address them as early as possible to avoid surprises too late in the construction process to make changes. The project schedule is king and often cannot be swayed to correct unexpected quality issues.

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass

Phone: 416-285-1890

• SentryGlas Lamination 91 Crockford Blvd.

Toll Free: 1-855-757-8367

Fax: 416-285-9468

Email: cs@tritempglass.com

When should QA/QC/QF begin? Ideally, in the construction document preparation phase, definitely before selecting the remote suppliers. What issues are important to the owner, the designers, the constructor? In speculative construction, the end user does not have a seat at the table so those present must not forget those who are missing. Reach out to trusted manufacturers and constructors from past work in which good quality success was achieved, even though for them, early in the design development or construction documentation phases, there are no guarantees they would secure a portion of the work to compensate for time spent. Engage the services of a façade consultant with experience in remote procurement for their perspective on recommended QA/QC/QF traps and solutions.

Consider remote procurement of insulating glass units to be included in, say, a curtain wall for a commercial or residential tower. Performance parameters can be established with the assistance of a building performance analytics consultant to meet locally applicable energy code requirements (OBC SB-10 in Ontario, NECB in other provinces, etc.) including solar heat gain coefficient, winter U-factor and perhaps

Photo credit: Torok/Chiasson

condensation resistance. Products considered during design must meet the required performance characteristics but be careful, performance must be calculated to North American and sometimes, Canadian norms. European U-value is not the same as a North American U-factor. USA Condensation Resistance Factor (CRF) is not the same as a Canadian Temperature Index value. Other aspects of glass and façade appearance and performance to be considered include colour, exterior reflectance, visible light transmission/daylighting contribution. It is not uncommon for combinations of thermal performance and aesthetic requirements to give rise to thermal stress and consequently, a need for glass to be heat treated. Heat treatment may also be necessary to address wind loads and safety for building occupants and passers-by at grade. Unintended consequences of heat treatment are distortion of reflected images (roller wave distortion, photo 1) and colour shifting of transmitted light (anisotropy, sometimes also referred to as quench marks or strain pattern, photo 2). Neither is limited by Canadian building codes and referenced standards for heat treated glass (ASTM C1048, referenced through CGSB-12.1). The good news is manufacturers of tempering equipment are constantly striving to reduce roller wave distortion so fabricators with late model equipment should be able to limit

FEATURESTORY

distortion of reflected images. The not so good news is anisotropy is generally regarded by the glazing industry as a fact of life and ignored, although a few manufacturers of tempering furnaces have identified anisotropy as a growing concern and are developing furnaces and quench equipment to control the underlying causes.

How can these issues be addressed by a QA, QC and QF process? QA should identify the quality goals to achieve, the codes, standards and practice documents to be followed, and supplemental guidance/requirements to fill in omissions within and between them. Some quality aspects may be difficult to achieve, such as heat treated glass that is free of roller waves or anisotropy, so it may be necessary to consider alternatives such as using heat strengthened glass instead of tempered glass in the outboard pane of insulating glass units whenever possible (roller wave distortion is typically less in heat strengthened glass). The QC program needs to be designed to empower workers on the assembly line to set aside fabricated components that are demonstrably ‘out of spec’ without being disciplined.

QC should set out reasonable and achievable goals to achieve or limits to undesirable outcomes, and recording results. For example, specifying maximum allowable wave peakto-valley dimensions for roller wave distortion of heat treated glass. Other aspects of heat treated glass manufacture could also be defined and limited, such as maximum allowable edge lift and overall bow values and surface compressive stress. Anisotropy would be harder to define and limit since it is not

Anisotropy (quench marks) observed in a factory-glazed, unitized curtain wall panel being readied for installation. This visual condition – not considered a defect in the glazing industry – becomes noticeable under strongly polarized light such as the blue sky reflected in the glass and light reflected of nearby, non-metallic surfaces, including the water.

addressed by codes, standards or practice documents. It may be possible to establish a qualitative metric, for example preparation of full sized mock-ups to define an acceptable range of colour variation which then serve as a guide for assessing subsequent production. Recently, on-line scanners have been developed to assess anisotropy during manufacture so once an maximum acceptable limit is defined, heat strengthened glass exiting from the quench can be checked, accepted or rejected. Feedback from such systems into numeric control for the furnace allows adjustments to be made to subsequent production to be within accepted limits.

This brings us to QF, the ‘boots on the ground’ process to make sure QC is being properly executed and enforced to achieve QA goals. An implicit assumption in codes, standards and practice documents is self-regulation by manufacturers. North American Industry associations such as IGCC, IGMA and SGCC provide, for members, auditing processes to help manufacturers consistent fabricate products well, consistent with compliance tested samples, but those services are not project specific. Like any human endeavor, there are top-ofthe-line manufacturers and those less so; price is often a good indicator of quality locally but when procuring globally from countries with different standards and cost of living, more or less access to natural resources, etc., it may be difficult to assess if a submitted price is fair for the effort anticipated. Will the quality of the manufactured product be as good as from a local supplier (Photo 3)? Or better (Photo 4)? A QA/QC document may seem right but if not actually put into practice,

Photo credit: Torok/Chiasson

the QA plan and QC ways and means are meaningless. Whether local or remote/global supply, we recommend adding a project-specific QF process. This involves critical review of each manufacturer’s QA plan and QC ways and means to ensure it clearly sets out the goals to achieve and appropriate and necessary test methods, outcome limits and sampling frequency, revision of the QA and QC document until it is suitable, preparation of mock-ups when needed to establish acceptable limits, followed by visits to manufacturing facilities to verify QA and QC are being followed, and following through with corrective action if QF is detected. It is better to nip a problem in the bud than to deal with it later, causing delays in construction or unacceptable quality in the finished product.

At the recent FenCon18 conference in Winnipeg, Ian Marshall of Canadian Manufacturers and Exporters held workshops on applying Continuous Improvement (CI) and Lean manufacturing concepts in a fenestration fabrication environment. A lot of the discussion was about improving manufacturing efficiency, but the Lean process also integrates quality to a high degree and makes better quality possible by making time and resources available to dedicate to it. And, of course, the whole idea of Continuous Improvement is to get continuously better at everything you do, all the time.

QA is improved through CI processes because the fundamental concept of CI is to make a plan and upgrade it. Rather than leave things to chance or just let processes evolve as they may, CI demands you evaluate everything you do very carefully and ask whether it could be done better. It’s inevitable that this approach will improve quality, and you’ll probably look askance at any supplier that isn’t doing this.

CI and Lean have even more application on the QC side, since fixing processes down to the smallest detail is what these programs are all about. In Marshall’s workshop, which involved window manufacturers building airplanes with Lego, it was easy to see how a poorly thought-out process, especially under time pressure, led to quality issues. And conversely how a good process, with QC integrated at every step, could lead to predictable quality.

For brevity, we’ve discussed only a few aspects of glass fabrication. There are other performance and quality concerns to consider in the manufacture and assembly of fenestration systems and other factory assembly enclosure systems, including a myriad of on-site assembly procedures not covered in this article. Building enclosure systems are increasing in complexity and as performance requirements become more stringent, the tolerance for failure becomes lower. But it has to be on the QF end that CI really shines. Quality fade comes from a lack of process, or a process that is abandoned under time and resource pressure. CI and Lean programs are specifically designed to address and mitigate these issues. Looking for suppliers and partners that embrace these concepts could be one way to escape the QF problems that can plague offshore outsourcing. •

RESOURCEDIRECTORY

by FRANK FULTON

Moribund Canadian Glass Association

The glass and contract glazing industry in Canada is a sizeable entity employing thousands and one would expect it to have a voice that represents our collective interests on a national basis. In the United States, the National Glass Association recently merged with the Glass Association of North America to create a formidable national presence. I hate to tell you that Canada’s national voice is today on life support.

The Canadian Glass Association is a wonderful concept. Founded by David Husson over 10 years ago, its purpose was to “represent and support the interests of the glass and related industries at the national level in matters of building codes, standards, legislation, and other industry related matters,” as well as to develop and promote glazing specifications and apprenticeship and other educational programs. The CGA is essentially an umbrella association made up of regional associations from B.C., Alberta, Saskatchewan, Ontario and the Atlantic provinces. The provincial associations would continue to look after their local interests as usual and hold regular meetings together to address matters of national interest. Funding for the association was provided by a levy applied to the dues collected by the provincial associations and from putting on the Glass Connections seminars across the country.

The beginnings of the CGA were encouraging. In 2009, the Glazing Systems Specifications Manual for Ontario was completed and distributed widely by the OGMA and AGMCA in Ontario. A few years later a national version was produced, then squabbles about the ownership of the manuals arose and what began as a cooperative effort between the provincial associations devolved into a situation of mistrust.

Canada’s national voice is today on life support.

YOU BET YOUR GLASS

Jim Brady with Cal-Tech Glass Services in Calgary served as president of the CGA from 2013 until earlier last year. He dedicated a mountain of time and energy into trying to keep the association channeling in the right direction but found the challenges to be a continuous uphill battle. “The intentions of the association are good and justifiable but getting the regions working together is often ‘tasking,’” he reports. The biggest problems we face are a lack of funding and people willing to volunteer their time to do the work and tackle the issues.”

In recent years, it has been a challenge just raising enough money to cover basic administrative costs. Creating and updating technical manuals, drafting and negotiating changes to codes, lobbying legislatures and developing training programs takes a lot of money.

Angelo Cairo, OGMA president and CGA treasurer, states, “The CGA is basically stepping back for the coming year to re-focus on a national approach and develop a viable mandate. Over the years we lost our direction and offered services that overlapped with the provincial associations, mostly due to having to raise funds to survive. On the other hand, some of those services are definitely needed in regions where there is not a strong local representation.”

If the CGA is to survive, Brady sees the need of hiring an administrative manager capable of tackling the association’s fundraising needs, doing the work and the organizing and freeing up the directors to focus on setting the direction towards code advocacy and education. He would still like to see the Glass Connections format continue as a networking forum.

Cairo thinks CGA’s focus should shift to apprenticeship training and perhaps getting glazing listed as a national compulsory certified program. However, Brady points out that this would be a daunting task given that the apprenticeship programs are run by the provinces and the hurdles in achieving compulsory certification are formidable and differ from province to province.

Notes Brady, “How does it make sense that a hair stylist must be certified but there is nothing stopping some fly-by-night operator from sending a guy up to the 30th floor of a building on a swing stage to cut out a four-sided structurally glazed unit with a new lite and a tube of Mono.” Without a viable association representing our interests, pushing for changes that make sense, our industry will be much worse off. I hope the CGA will be able to regroup. •

Explore the artistic possibilities of digital printing with a variety of opacities, multiple colors and custom designs – all created by digitally mixing six basic ceramic inks – black, white, green, blue, red and yellow – to create a durable, UV resistant, long lasting design. Start today with your own custom graphic or choose from one of Vitrum’s exclusive ready-to-print designs. For additional information visit vitrum.ca or call 1.888.391.1166.

THERMAL DOORS, REDEFINED

MINIMAL SIGHTLINES, MAXIMUM PERFORMANCE

For the first time, all-glass aesthetics and full-frame thermal performance in one entrance system. Entice® meets stringent energy codes and looks great doing it. ULTRA-NARROW

• Ultra-Narrow 1-1/8" Vertical Stiles

• Thermally Broken with U-Factors as Low as 0.33

• NFRC Rated and Satisfies ASHRAE 90.1-2016 Air Infiltration Criteria

— Maria A. Gomez, Principal, GFF Architects