Now proudly unified under the AGTIV® co-brand to showcase their distinctive qualities, our proprietary technologies, BACILLUS and MYCORRHIZAE, remain unchanged.

October 2024 Vol.44, Issue 8

Adoption of autonomous agriculture in the greenhouse setting is poised to excelerate in the years to come. Are we ready for it?

4

News 6

the zone 8 A guideline for growing happy and productive roots.

Blooms 2024 34 Growers in Alberta and Saskatchewan put new varieties to the test.

Exploring innovation and the adoption gap.

Getting to the root of the matter. Photo by Melhem Sawaya. Read more on Page 8.

BY J LYNN FRASER

Research from Assiniboine College into optimizing production through winter.

BY

DR. SAJJAD RAO AND JANE DE PAUW

VS. T. PARVISPINUS?

An update on the battle against this challenging enemy.

As the greenhouse industry prepares to converge in Niagara Falls this month, and perhaps in the spirit of Thanksgiving, I find myself reflecting on the energy, optimism and man power that goes into organizing an experience like the Canadian Greenhouse Conference.

For 12 months of the year, there is a small, dedicated group of individuals whose job it is to ensure that this event remains accessible, engaging, entertaining and, above all, relevant. There is a rather large group of volunteers from amongst the industry who meet regularly to help support and facilitate these efforts. Then there are the speakers who put a tremendous amount of thought and preparation into their sessions, not to mention the hundreds of exhibitors and generous sponsors whose investment in the CGC makes it all possible.

As someone who has had the opportunity to work in the background, I can report that

issue of Greenhouse Canada wouldn’t have been possible without the hard work of our industry contributors, sharing their expertise and valuable insights on root zone management, alternative energy research, the latest on Thrips parvispinus, autonomous ag, and flower trials.

Consultant Mel Sawaya offers a basic guideline for optimizing one’s approach to managing the rootzone on Page 8. He gets back to basics and encourages growers to not be afraid to reach out for help when they’ve hit a snag.

OMAFA’s Sarah Jandricic and Plant Products’ Judy Colley offer an in-depth update on T. parvispinus and the possibility of using biocontrols in to control it on Page 28. Another research update from Dr. Sajjad Rao and Jane De Pauw from Assiniboine College explores the use of passive solar energy to optimize greenhouse production through the winter months, particularly in more northern climates on Page 22.

‘It is truly humbling to witness their dedication and passion.’

organizers of this event are very much driven by a desire to make life easier for growers and it is truly humbling to witness their dedication and passion.

I want to offer my congratulations and deepest gratitude to Carol Pupo and Julia VanStaalduinen, the CGC board of directors, trade show committee, sponsors and exhibitors for once again bringing this industry together in the spirit of community.

With the spirit of togetherness and innovation top of mind, this month’s

We also get another update from our friends out West who recently hosted New Blooms 2024 in Alberta and Saskatchewan. High Q Greenhouses’ Michiel Verheul reports on the success of this year’s trials and offers his take on best picks for next year on Page 34.

Also, don’t miss our columnist Gary Jones’ piece on what he’s looking forward to at this year’s CGC on Page 38.

Until next time, come visit Greenhouse Canada at booth #2000 at the CGC and enjoy the show!

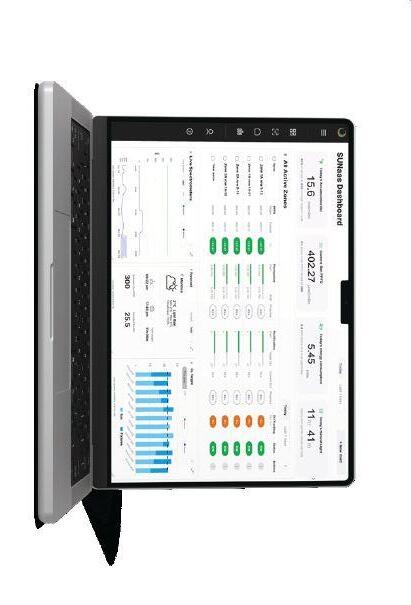

Agronomic and technical support are on call, and SUNaaS monitors fixtures 24/7.

Our SUNaaS platform delivers custom spectrums and advanced data to optimize growth. Automatic dimming delivers the right amount of light all the time to lower energy costs.

commitment commitment. Our dynamic solution enables unlimited zoning to grow an infinite variety of crops.

Your journey in advanced greenhouse cultivation starts here. Count on the expertise of our team of agronomists and horticultural specialists to reap all the benefits of your dynamic LED grow lighting experience.

Bioworks appoints Dr. Carlos Bográn as their new technical service director. Bringing over 30 years of IPM experience to BioWorks, Dr. Bográn will be responsible for leading a team of technical managers and specialists to develop and support integrated pest management (IPM) programs for growers and channel partners in the United States, Mexico, Canada, and Central America.

Most recently, he held the position of Senior Technical Manager at OHP/American Vanguard, where he led IPM product development and technical support of specialty crop growers throughout North America. Prior to OHP, he was associate professor & extension specialist at Texas A&M Arglife Extension,

where he also earned his Ph.D. in entomology from. During his tenure, Dr. Bográn developed numerous applied research and education programs that focus on integrated management of arthropod pests and plant diseases. He’s also implemented educational initiatives in Entomology and Plant Pathology that supported English and Spanish-speaking professionals.

“Dr. Bográn’s extensive understanding of the bioproducts market is the perfect match for our growers, his experience and overall character will also have an immediate impact on our entire technical services team,” said Troy Bettner Vice President of Sales and Technical Services. (Source: BioWorks)

U.S.-based marketing firm, Garden Media Group, released its twenty-fourth annual Garden Trends Report, symbolically named ‘Nature’s Renaissance.’

The 2025 Report explores eight upcoming trends that will likely have an impact on consumer gardening behaviours in the coming year.

The unifying theme of the coming year’s trends, Nature’s Renaissance, highlights the movement to reintegrate natural elements into our lives, landscapes, and cities— bringing ‘green’ back into the picture. This renaissance isn’t just about returning to the roots; it’s about planting new ones for the future.

Up to $22.6 million in funds are being allocated to the Agri-Tech Innovation initiative to further develop energy efficiency and expand production capacity in the agriculture and food sector.

The governments of Canada and Ontario recently announced the expenditure through the Sustainable Canadian Agricultural Partnership (Sustainable CAP) to help 319 farming and agri-food businesses expand production capacity or enhance efficiency.

The initiative is expected to generate up to $61 million in production improvements in the industry, through the combination of government and costshared resources by the agriculture and food sector.

(Source: Government of Ontario)

The 2025 Garden Trends Report delves into various topics, including the decline of major social platforms and the increasing consumer preference for in-person community interactions. It also discusses the surge in artificial intelligence and shifts towards antireality, allowing brands to stay ahead of these

changes and better engage their customers. This year’s colour of the year is also unveiled in the report (it’s teal), which also offers some insights on how growers and retailers alike can lean into these trends. The report is available to download for free on Garden Media’s website. (Source: Garden Media Group)

Source: Statistics Canada, Energy Statistics, June 2024

0.8% the amount by which Canada’s electricity generation was down in June.

3.3% the number to which the delivery of natural gas to Canadian consumers climbed in June.

the amount by which the production of marketable natural gas rose in June 5.6%

BY MELHEM SAWAYA

When I walk in a greenhouse and start checking the plants with the grower, we will always take the time to tip the plant out of the pot to look at the roots. This is done whether the plant foliage or flowers look great or not. The story of the plant condition is mostly evident in how the roots look and the factors that led to this condition are many but not complicated:

• Species and Cultivar

• Soil properties

• Growing media handling

• Watering practices

• Environmental conditions

• Diseases and insects

ABOVE

Knowing how species, in general, are supposed to look will help tremendously when you are trying to diagnose the health of a plant, especially the roots. Certain cultivars have green leaves and other cultivars of the same species have yellow variegations and just being aware of this fact it will save you time when you are trying to find out why these leaves have yellow spots or stripes.

Some cultivars of the same species have vastly different root structures: they could be thick, thin, fibrous, or plump. It’s important to know how to water the different root structures. For example, fibrous roots need light, frequent watering. Plump roots need heavy watering and then left to dry

Before adding material to soil mixes that look more economical, one should take into consideration how it is going to affect the media performance and its impact on the roots and the plant in general.

Fertilizer for plug mixes and seed germination: one pound each of each calcium nitrate and potassium nitrate would be an enhancement of the media. Do not go above one.

before watering again. Failing to do this might be a cause for root diseases.

1. Stability of organic material

When the volume of the soil in pots is low, (ie: when smaller pots are used in production) and the plants are getting bigger, it is very important to ensure the organic material in the soil is stable and NOT easily degradable to support root development and plant growth.

2. Carbon and nitrogen ratios

Fifty per cent of the organic material in soil is carbon which is utilized by microorganisms. Nitrogen in the decomposing soil must be available to the microorganisms in the ratio of 1 N:30 C for decomposition to take place. If at any time the

ratio of 1N to more than 30C then Nitrogen in the media or added to the media will be used by the microorganisms rather than being available to the plants. That is why we need the material in the soil to be slow in decomposing. Before we jump to using material in soil

mixes that looks more economical, we should look at all the factors in how it is going to affect the media performance and its impact on the roots and the plant in general.

3. Bulk density

The soil media be able to support

the plant material without having to be very bulky.

4. Moisture retention and aeration

It’s important to know how to water the different root structures. Fibrous roots need light, frequent watering. Plump roots need heavy watering and then left to dry.

charges some positive and some negative. Positive charged fertilizers are Ammonium Nitrogen, potassium, Calcium, Magnesium, Iron, Manganese, zinc, and copper. Good growing media attracts and holds these nutrients, so they are not leached fast, and they are available to the plant roots and rest of the plant. Cation exchange capacity (CEC) is a measure of the magnitude of electrical capacity of electrical charge and is expressed as milliequivalents per 100g (me/100g) of dry root media component. A level between 10 and 30 me/100g is considered desirable for root health. More is even better but hardly achieved. If it is less, then the media is not suitable because you must fertilize much more to achieve the same result.

6. PH

The story of the plant condition is mostly evident in how the roots look.

An ideal media consistency, after being watered, is 10 to 20 per cent of the root media should be occupied by air and 35 to 50 per cent by water. It’s important to understand that deeper pots tend to have less water-holding capacity, despite having the same capillary forces in the root media. Well formulated media have high air- and waterretention capabilities.

5. Cation exchange capacity

Root media components: organic matter, vermiculite, clay-like (turface) have negative electric charges. These charges will attract and hold positive electric charges (cations). Most fertilizers have electrical

The PH level controls the availability of nutrients to the plant. Many crops do well in a slightly acid PH range of 6.0 to 6.5 and others like lower PH range of 4.5 to 5.5. Different components have different PH:

• Peat moss: 3 to 4

• Perlite, sand: 7.0 neutral

• Vermiculite: 8.0 plus

• Field soil: 3.5 to 8.5. It is advisable to measure the field media before incorporating it in the planting media.

• Limestone is to be added to the soilless media for PH adjustment.

7. Fertilizer content

For plug mixes and seed germination, one pound each of each calcium nitrate and potassium nitrate would be an enhancement of the media. Do not go above one. For finished media, phosphorous is to be

added but not calcium and potassium nitrate since that could be toxic if the planting media is stored for a long time. Incorporation of micronutrients is beneficial in seed/plug media or regular growing media.

Watering practices

With the shortage of labour and/or the cost of watering, growers are looking to automate the watering process. Many systems are in use in greenhouses and each system brings certain advantages

and disadvantages.

In all systems, the goal is to provide water to the roots without affecting the soil porosity where the air particles need to exist. Failing to do so increases the risk for potential diseases.

We try to add oxygen to the water through many methods or chemicals through the stock tanks, so it is especially important to have a media that will be able to use this enhancement and mitigate the effect of practices such as:

• Over watering

• Using media that holds excessive

water for an extended period.

• Hold the water longer than necessary in flood tables or floors.

• Filling growing containers with very dry soil

• Not to compact the soil by stacking the containers

• Heavy hand watering rather than frequent light repeated waterings.

• Predrilling holes for transplanting large liners into pots with augering the media out beforehand rather than force the large plant liners.

Other practices to support root health are:

• In vegetative propagation, set your target on having a high humidity environment and just moist media.

• Avoid any chemical treatment that requires drenching the media unless absolutely needed, this includes any bio control applications. Do all the treatments if needed on the liners before planting.

• Watch the media EC and PH to be at needed but not exceeded levels (check very frequently). Many times, we drench with a fungicide because the roots do not look great and we see improvements, where sometimes is all what we are doing is reducing the high EC levels giving the plant roots a chance to recover.

• Always find the cause of the problem to prevent the issue the next time and avoid using treatments after the fact as procedure.

And finally, if media porosity and air content is so important for the media and our irrigation water an oxygen meter is as important as our EC meter to have on hand.

The best management for soil pests and diseases is concentrating on our inputs ahead of time by paying attention to all the details we already discussed.

A piece of advice that has always worked for me, and I see many successful people practice, is the LALA model for learning, which stands for LOOK, ASK, LISTEN, ACT and yes there is always a better way to do things.

Melhem Sawaya is a greenhouse consultant and is the owner/operator of Sawaya Gardens in Waterford, Ont. He can be reached at mel@focusgreenhousemanagement.com.

The brightest energy saving climate screen.

Luxous screens offer outstanding light transmission, exceptional quality, and significant energy savings, making them perfect for both day and night greenhouse use. These screens reduce plant damage by better absorbing nighttime condensation, maximize production, and maintain light transmission even when not in use, thanks to their compact design. FR-rated and eligible for rebates across Canada, Luxous screens provide a reliable, efficient solution for greenhouse growers, ensuring optimal growing conditions and energy efficiency throughout the year.

ludvigsvensson.com

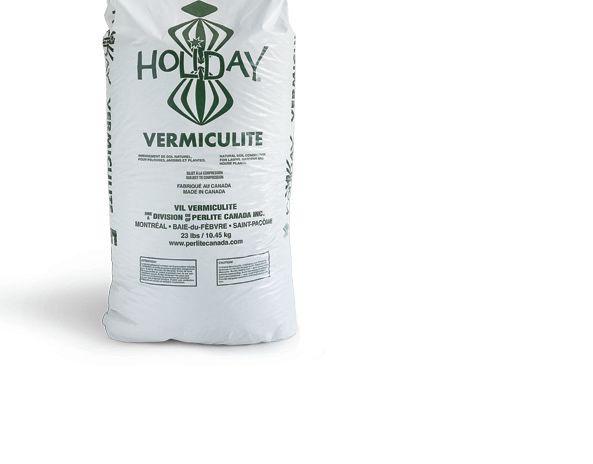

BY J. LYNN FRASER

Artificial intelligence applications have the potential to make agriculture ‘hyper-optimized.’

Farming, open air or in greenhouses, is a stressful profession. Stressors include human error, which can cost money and jeopardize crops; unpredictability due to climate change and increasingly extreme weather; market uncertainty; debt; and a lack of time to accomplish tasks. Loss of skilled labour is another stressor. According to a 2022 report from the World Economic Forum, in Canada, the loss of skilled agricultural labour could increase to 114,000 by 2025.

To this list of concerns, Brian Lynch, PhD, Director, Horticultural Technology Solutions, Vineland Research and Innovation Centre, adds profitability. While other businesses in the greenhouse value chain, such as retailers, have leeway to accommodate increasing costs, Dr. Lynch notes that growers face smaller margins. Many of the issues growers face are connected to a lack of control that contribute to both mental anxiety and physical fatigue. Suicide is a risk for farmers due to the stressors they face (Alam, 2023).

Promoters of Autonomous Agriculture (AA) state that artificial intelligence (AI) applications will facilitate “inferences, predictions and decisions” and will allow agriculture to become “hyper-optimized,” according to Jacqueline Keena, managing director of Manitoba-based Innovation Farms that specialize in digital

George Sant & Son Greenhouses

Kleinburg, Ontario

George Sant & Sons is Canada’s premier pre-finished supplier and a Ball Horticulture rooting station, supplying top quality rooted material throughout North America. For their 2019 growing season, they installed a small two-bay trial of Philips LED toplighting linear. Due to the trial’s success, the Sant team expanded their Philips toplighting installation in 2021, and 2022, and again in 2023. The Sant team discovered the many benefits of propagating young plants under Philips LEDs including more compact plants, stronger rooting, and improved plug quality.

#growwiththepros www.philips.com/horti

Can we trust robots to take our place in the greenhouse? Experts say trust is one of the major roadblocks to growers embracing high-tech innovations.

agriculture (Saba, 2024). AA supporters believe that it also offers growers precise assessments and speedy “interventions,” beyond human abilities (Saba, 2024), and the ability to use data from a variety of sources and give directions for future plantings (TTControl, 2024).

A cautious view of AA credits the application of technology to include AI in robots, as well as sensors, drones, software and digital twin computer systems for monitoring fertigation. AA is presented as a solution to farmers and growers for a variety of issues with an underlying promise of greater control and predictability with fewer costs.

Nourish Labs, based in British Columbia, offers growers a fertigation management software system “designed to produce the most consistent, highest quality and yielding crops possible” (Nourish Labs). Their “nutrition formulations are “fresh, homogenized, PHbalanced plant nutrition formulations with milliliter precision to every plant at exactly the right time” (Nourish Labs). Nourish Labs offers growers control and precision. The pH balance remains stable with “uniformity” in plant feeding. The feeding itself is controllable by amount and time of application. The system increases ROI as it decreases effluent runoff, use of fertilizers, and use of water. It also decreases risk of human error, and with that is a matching decrease in worry, says Justin Valmont, Nourish’s chief product officer.

The company’s software is a “fifthgeneration platform that is completely modular,” said Valmont, with a “base system” for growers to which modules can be added as needed. Nourish Labs’ technicians can visit onsite to assess a growers’ needs as well as to review the system’s electrical, plumbing, and irrigation needs. Their software system is used by greenhouse staff members who have “management responsibilities” such as Master Growers and Operator Managers. Access is available remotely and the system works 24/7.

“Trust is a major issue when considering new technology,” notes Lynch. “Growers

are bombarded with many pitches and claims by companies offering amazing new technologies and have to filter out which ones have real value.”

Growers also have to consider ROI, performance, maintenance and support, and reliability. An issue with adoption of AA, Lynch observes, is that it is assumed that the current physical layout of greenhouses is what AA will be applied to. The future physical layout of greenhouses may be different. Additionally, greenhouse robots may have highly specialized functions such as watering, fertilizing, and pest removal. Alternatively, different functions may be found on one robot with different attachments. Plants may also change physically through breeding with smaller leaves and longer stems, for example, to ensure they can be successfully tended to by robots/ automated attachments.

Lynch cautions that “how we grow plants evolves and issues plants face evolve too, such as climate change and types of diseases.” The risk in adopting

AA, according to Lynch, may lie “in taking the risk today with technology that might not be ready or as highperforming as you want, versus waiting too long to adapt and having to catch up to the rest of the industry.” He foresees the potential for dependence on automation and AI to lead to future generations of growers with less intuitive knowledge and wisdom than their predecessors.

“Growers have an intimate knowledge of their crops and years of experience and insights that make them successful. We’re now training AI systems to learn and replicate that expertise and seeing amazing results,” says Lynch. “But, while you can ask a grower to explain his or her reasoning and then pass that information to the next generation, it is often impossible to do so with AI systems.”

When it comes to robots, AA “is a bit optimistic, but not overly ambitious,” says Dr. Medhat Moussa, PhD, P.Eng., Systems and Computer Engineering,

Promoters of Autonomous Agriculture (AA) state that artificial intelligence (AI) applications will facilitate “inferences, predictions and decisions” and will allow agriculture to become “hyper-optimized...”

INTEGRATED GROWING SYSTEMS FLEXIBLE INSTALLATION PROFESSIONAL, EFFICIENT SERVICE

Haygrove Growing Systems are renowned for their strength, ease of management and a superior agronomic environment allowing growers to reduce labor requirements, extend cropping seasons and boost yield and quality.

Pete Stefanos Sales Manager 805-441-7673 pete.stefanos@haygrove.co.uk

School of Engineering, University of Guelph. Innovations in technology, such as AI and sensors, that will eventually evolve into AA applications, begin as applications in cars and manufacturing. Some aspects of AA exist but for various reasons cannot be widely applied. Moussa notes that “autonomy” is one of the more ambitious elements of AA technology. Safety features and certification protocols used in industrial settings, such as cages for robots to work within or lasers to keep them on track, are being developed for robots to operate inside greenhouses. Expense is another issue. Hyper spectral cameras used to detect disease, for example, are still cost prohibitive for most growers as are robots that are specialised to provide their services to specific crops such as strawberries versus green peppers.

The varying needs of growers also influences the implementation of AA

in greenhouses, Moussa points out. The needs of a grower with 10 acres of greenhouses versus that of a grower with 200 acres are different, which affects AA adoption. The grower’s appetite for risk can also curtail the use of AA. Additionally, the power of AA such as is found in images taken of individual plants can provide “massive data,” Moussa notes, that exceeds the current abilities of most growers to work with that information. AA, Moussa believes, will have wider adoption in Canada in the next 10 years.

Connectivity is a strength and a weakness. The strength of AI gathered information may be slowed by weaknesses in “connectivity infrastructure” when 4G and 5G connections may be needed (TTControl, 2024). Additionally, there is

concern in the agricultural industry about the data new technology generates and the ‘bad actors’ that may find it worthwhile to steal or hold hostage. In the past three years Ontario Pork, Lactanet, a Canada-wide organization, Maple Leaf Foods, Agronomy Company of Canada, and JBS had ransomware attacks and data stolen (Martin & Rudolph 2024). Embracing AA means embracing data and computer system protections and restricting access to technology and information.

Current legislation is seen as inadequate to protect farmers and growers according to David Shipley, CEO of Beauceron Security (Connolly, 2024). Bill C-26 – An Act Respecting Cyber Security (2022) protects finance, telecommunications, energy, and transportation but did not include agriculture. It is hoped that amendments will enhance current protection for software and “smart” agricultural equipment.

Nourish Labs, based in B.C., has developed a precision fertigation system that employs a fifth-generation platform that is completely modular. The system has shown to significantly reduce effluent runoff, use of fertilizers, and use of water.

Initial implementation of AA is likely the most investment heavy stage in the lifecycle of AA in a greenhouse. “The main challenge in automating planting and seeding lies in the initial cost and complexity of integrating these systems into existing operations. Additionally, customization may be necessary to accommodate different types of seeds or planting patterns, adding to the expense and complexity” (Bernier, 2024). While AA is sometimes presented as a panacea technology is not perfect — there can be failures. “Implementing these systems can be complex, as they require detailed programming to adapt to the varying needs of different plants. There’s also a risk of mechanical failures, which could lead to under or over-watering, potentially harming the crops” (Bernier, 2024).

Before investing in AA, it is advised that growers consider doing a needs assessment; a cost versus benefit analysis; assessing integration with existing systems; scalability; technical support and maintenance; training and workforce transition; regulatory compliance; and market size (Bernier, 2024).

Reviewing business insurance policies for technology investment and failure coverage is also prudent as is establishing whether the business is covered for loses connected to cybersecurity.

The current state of AA is that its utility is in the eye of the beholder. Caution adoption of AA over time may be the wise choice for small to mid-sized growers. More widespread adoption in ten to twenty years from now, after the “kinks” in AA systems have been resolved may be the best ROI.

• Alam, H. (2023, Dec 11), A sustainable agricultural industry needs to start addressing mental health of farmers, says researcher, CBC.ca, 2023, https:// www.cbc.ca/news/canada/edmonton/ alberta-farmers-mental-healthanxiety-1.7055123

• Bernier, C. (2024, Feb 28), Robots in the greenhouse: Cultivating a new approach to agriculture, Cobot, https:// howtorobot.com/expert-insight/robotsgreenhouse-cultivating-new-approachagriculture

• Connolly, B., (2024, Sept. 2).

Canada’s food industry is vulnerable to cyberattacks, expert warns, https://www. ctvnews.ca/canada/canada-s-foodindustry-is-vulnerable-to-cyberattacksexpert-warns-1.7022867

• Martin, D., & Rudolph, J., (2024, May 30) Manitoba Co-perator, https://www. manitobacooperator.ca/news-opinion/ news/farm-risk-management-includescybersecurity/

• Nourish Labs https://nourishlabs.ca/

• Saba, R. (2024, June 16), CTV.ca, How AI could help farming become more efficient and sustainable, https://www. ctvnews.ca/business/how-ai-couldhelp-farming-become-more-efficientand-sustainable-1.6928768

• TTControl Hydac International, How Europe’s farmers can leverage the power of AI, machine learning, and automation to feed a changing world, https://www. ttcontrol.com/farmers-leverage-aimachine-learning-automation

• World Economic Forum (WEF) (2022, Jan 20), 3 ways autonomous farming is driving a new era of agriculture, https://www.weforum.org/ agenda/2022/01/autonomous-farmingtractors-agriculture/

www.horti-growlight.com

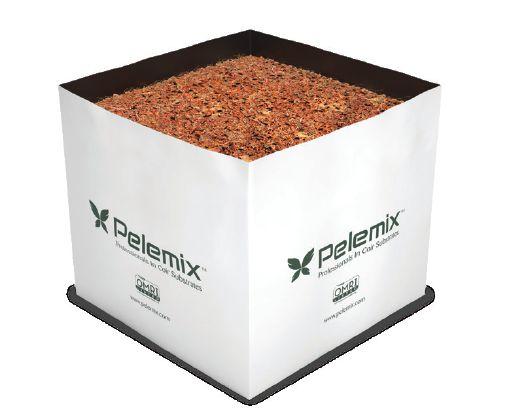

Ahealthy root system is crucial to the success of greenhouse-grown crops, and beneficial microorganisms have proven to be a valuable ally. Active ingredients, like mycorrhizae and Bacillus , help plants reach and absorb more nutrients and water, reduce stress and stimulate plants for a healthier root zone and stronger plant growth.

Researchers from across the industry and scientific community have found mycorrhizae to be a beneficial association between a mycorrhizal fungus and roots. Premier Tech, which produces and markets growing media and other products for the greenhouse industry under the PRO-MIX brand, conducts research around biological inoculants and biotechnologies for the horticulture industry to further prove these benefits.

The researchers have found that endomycorrhizae help plants reach and

absorb certain nutrients and water that would normally be unavailable to the plant. By colonizing the plant root system, mycorrhizae form hyphae threadlike structures that reach out to acquire nutrients, particularly phosphorus, and efficiently access and transfer these nutrients and water into the plant root cells. Additionally, the research team identified Bacillus as bacteria that’s “able to colonize plant roots and mycorrhizal fungus hyphae, [enveloping] the roots and creating a healthy environment.”

“Once the association between mycorrhizae and the host plant occurs, it lasts for the lifetime of the plant,” says Ed Bloodnick, Grower Services and Product Development Director – Horticulture North America, at the company, who says the goal has always been to improve the quality and performance of plants. “We can grow tomatoes and pep -

pers in a growing medium with mycorrhizae to inoculate the plants and then transplant these [into farmers’ fields]. These plants produce more tomatoes and peppers than their non-mycorrhizal counterparts, sometimes as much as a 19- to 21-per-cent increase in crop yield.”

In addition to boosting yield potential, Marc Béland, Senior Director –Agriculture North America, at Premier Tech, says the ingredients, especially when used in combination, enable plants to uptake more fertilizer. “The benefits of this include less plant loss, fewer diseases, and decreased use of pesticides, which benefit greenhouse workers and their exposure to chemicals,” he notes.

The improved fertilizer use efficiency has an extended benefit, as it reduces the amount of fertilizer

runoff into water sources – a common concern for waterfront properties. “This means that there are fewer algae blooms,” Béland adds, referencing the province of Quebec’s initiatives to decrease the impact of fertilizer runoff on fish and wildlife.

While each biological active ingredient has its individual strengths, Béland says the combination of mycorrhizae with Bacillus is a powerful match.

“The mycorrhizae increase root surface area that, in turn, increases the structure and nutrients. It works in partnership with Bacillus ,” he says, describing the two ingredients together as “1+1 = 3” – they work best together, and not just side by side. “They are part of a team to amplify plant health and productivity,” he emphasizes.

Unifying the two biological active ingredients into PRO-MIX growing media, allows growers to maximize their plants’ potential. The product, now called PRO-MIX AGTIV AMPLIFY, amplifies the root system and improves crop uniformity and consistency, provides better overall plant growth and healthier crops. Béland says this new branding clearly indicate the services each product provides.

The individual ingredients have also been rebranded to better reflect the benefits of each ingredient that is integrated into PRO-MIX growing media. Growers can now expect to see Premier Tech’s Mycorrhizae branded as PRO-MIX AGTIV REACH, referencing how the ingredient helps plants reach and absorb more nutrients and water.

Bacillus , formerly PRO-MIX BIOSTIMULANT, is now known as PRO-MIX AGTIV STIMULATE, referencing how the bacteria work to promote a healthy root zone.

Aside from the change in name, Bloodnick says growers can continue to expect the same results, with no changes to cultural practices or special handling required. Planting and transplanting can take place as usual.

“The active ingredients are incorporated into the PRO-MIX growing medium at specific rates,” he says. “They are quite robust and remain dormant in the growing medium until the growing medium is used and

plants are transplanted into the growing medium.”

Pairing the two biologicals together and uniting them with PRO-MIX growing medium improves retail shelf-life, which transfers further benefits to the consumer, Bloodnick says. “The beneficial mycorrhiza and Bacillus remain with the crop for life,” he notes. Besides better-performing plants, Bloodnick says growers can expect to see reduced transplant shock, more prolific flowering and fruiting, and overall healthier plants.

Premier Tech’s experts are available to provide agile and strategic advice, comments Scott Thornton, the company’s vice-president of sales – North America. “There is lots of information out there, and our company has a long-term perspective. Our Grower Services team delivers expert guidance on a variety of topics, including crop nutrition, water management, and the effective use of growing media. Growers can come to us for more details, and we can come to them as well.”

“Typically, growers look for assistance with crops that are more difficult to grow, or may be longer-term crops, such as poinsettia for example. But every grower is different, so we are equipped to assist all growers with any crop,” Bloodnick adds, noting that growers can access the Premier Tech sales and Grower Services team to arrange a demo. “We go on-site to set-up a growth comparison, monitor the crop(s) throughout the crop cycle, collect data, take pictures and provide a report. Growers then can see the results and determine if a switch makes sense for them,” he says.

To learn more about PRO-MIX with AGTIV technologies, visit try.pthorticulture.com/promixwithagtivcanada

BY DR. SAJJAD RAO AND JANE DE PAUW, ASSINIBOINE COLLEGE

Recent developments in greenhouse design technology and improvements in production systems to increase yields and economic returns have increased the area committed to greenhouse production worldwide. However, choice of structure, climate control and monitoring systems available determine the cost of design and technological input for a greenhouse. The selected production system requires intensive production practices and utilizes large amounts of energy and other inputs such as heating, fertilizer, and pesticides. The rising cost of heating the greenhouse is a main concern and has prompted the greenhouse industry to reconsider the possibility of reducing costs by using alternate, renewable energy resources, such as solar and geothermal energy. Amongst

ABOVE

the renewable energy sources, solar energy is the cleanest, most abundant and is relatively environmentally friendly. It also has a great influence on greenhouse micro-climate and cost-efficiency in colder climates, where heat sink technologies can increase indoor ambient temperatures in the winter months.

A three-year study was conducted in two south facing passive solar energy greenhouses, oriented eastwest at Assiniboine College, in Brandon, Manitoba (49ºN, 99ºW). The study was performed from November to April for each of the three years. Each of the passive solar energy greenhouses (experimental treatment) was equipped with different technological inputs

Research greenhouses at Assiniboine College in Brandon, Man., where researchers have conducted studies on solar energy.

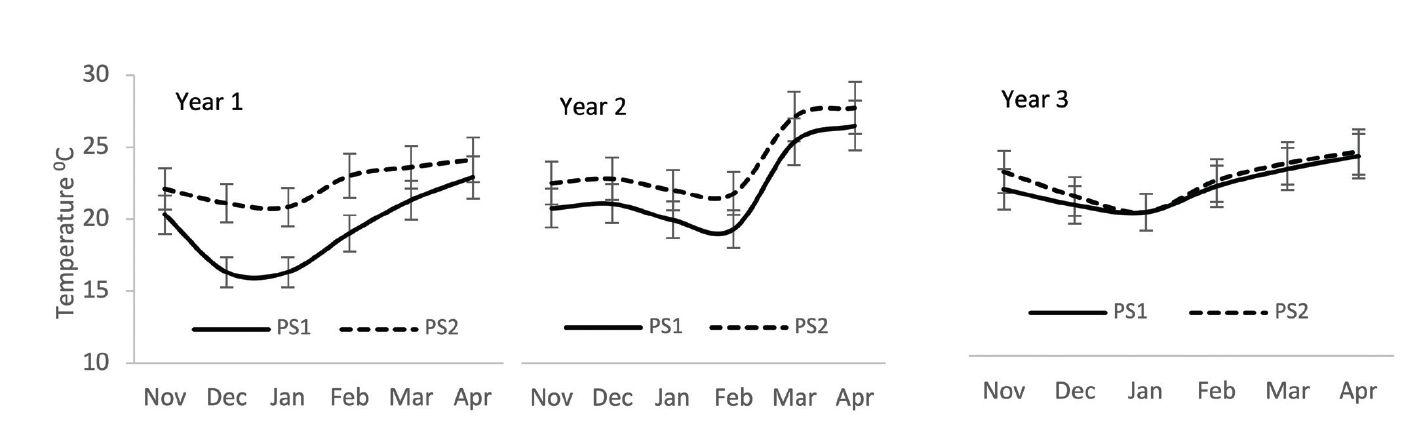

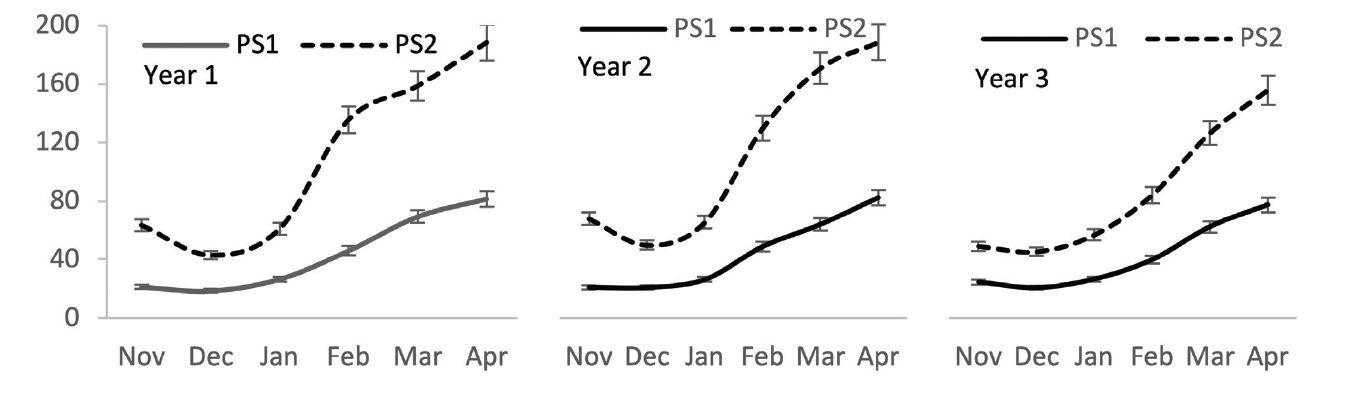

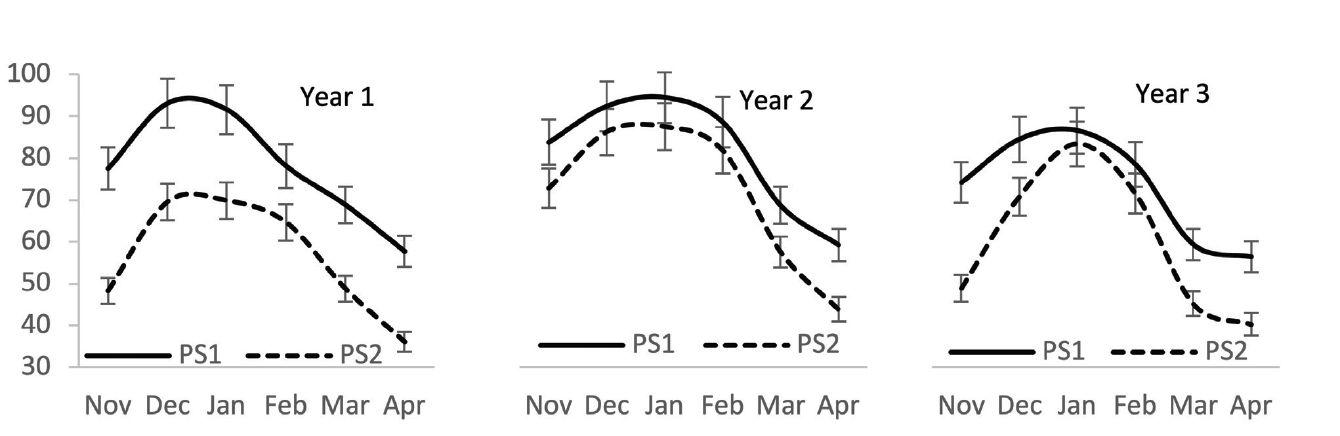

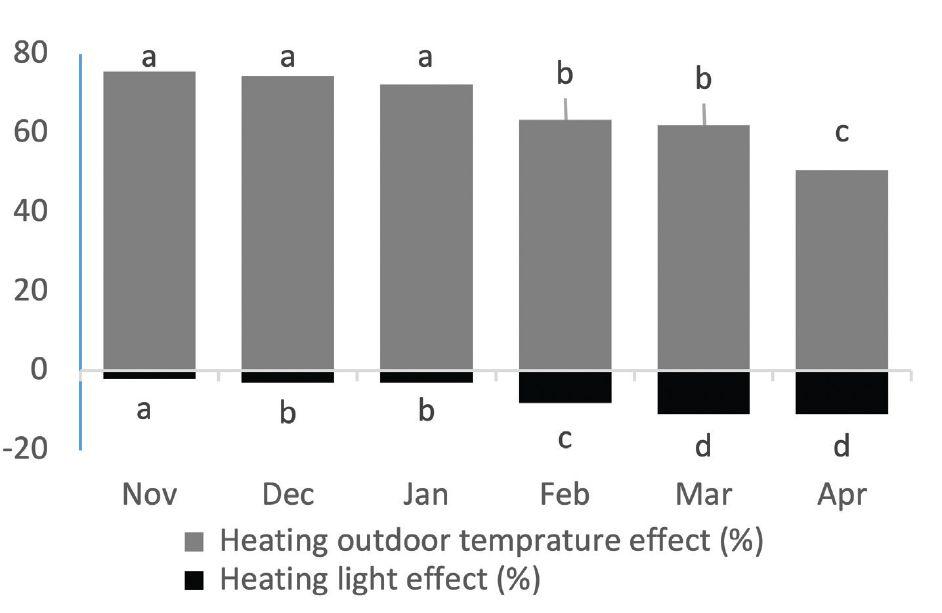

FIGURE 1

Greenhouse temperature variations in Passive Solar 1 (PS1) and Passive Solar 2 (PS2) greenhouses. Vertical bars ±SE (n=240, 248, 248, 224, 248, 240 for November, December, January, February, March and April respectively).

and were designated as Passive Solar 1 (PS1), a low input technology greenhouse, and Passive Solar 2 (PS2), a medium input technology greenhouse. Greenhouses PS1 and PS2 each have a section which is 9.5x6m (LxW) glazed with a 12-ounce 23 mil fabric clear tarp. Both greenhouses have steel framing, polycarbonate side walls, and an insulated north wall which is covered with 24ga black AMP painted steel material for conserving solar energy. Each unit also has one hydronic unit heater with glycol loops which connect to a propane boiler, controlled by the Argus Titan Control system to maintain target temperatures. PS2 has concrete floor and PS1 has a gravel floor. PS2 receives additional floor heating from the active solar heating panels, five sets of 30 SunMax Vacuum Heat Pipe (VHP)

solar evacuated tube collectors, installed on standing extruded aluminum frame in front of the greenhouse complex facing south. These solar collectors absorb heat from the sunlight and transfer the energy to a solar hot water tank in PS2 which provides energy for the in-floor heating system.

Both external and internal greenhouse environmental conditions were controlled and recorded using Argus Titan system version 718. A Titan WS2 weather station, installed at the top of the greenhouse complex, was configured to record on-site weather information for outdoor temperature (ºC), light energy (W/m2), wind speed and direction. This same control system was configured to deliver the amount of heat needed to maintain the target temperature based on the rate of the loss recorded.

FIGURE 2

Photosynthetically active radiation variations in Passive Solar 1 (PS1) and Passive Solar 2 (PS2) greenhouses. Vertical bars ±SE (n=240, 248, 248, 224, 248, 240 for November, December, January, February, March and April respectively).

FIGURE 3

Temperature heating required (%) variations in Passive Solar 1 (PS1) and Passive Solar 2 (PS2) greenhouses. Vertical bars ±SE (n=240, 248, 248, 224, 248, 240 for November, December, January, February, March and April respectively).

The unit’s calculation was based on the Heating Required Temperature (HRT %), which considers current temperature conditions in relation to the target set point temperature and develops a proportioned result from zero to 100 per cent. At zero per cent, no heat is required for temperature management; at 100 per cent, the maximum heating resources are required to meet the current demand.

The study showed, both PS1 and PS2 greenhouse technologies created varied microclimates (Fig. 1, 2) and had a different effect on HRT (Fig. 3). Maximum temperatures exceeded set points in both greenhouses in February, March and April, whereas PS1 maintained lower day and night temperatures than the target set points through November to February. The increase in greenhouse climate temperature in PS2 was observed in most months (Fig. 1) and was possibly due to

ABOVE

Research from Assiniboine College (facilities pictured above) found that a greenhouse designed with a concrete, in-floor active solar heating system provides an optimum crop production environment for winter months with reduced heating cost.

FIGURE 4

the heat sink strength of the north wall, concrete floor and PS2’s in-floor heating solar heating system that PS1 did not have.

Photosynthetically active radiation (PAR) increased in December onward in both greenhouses as outside solar radiation increased. PS2 greenhouse recorded significantly higher PAR over three years in each month and between months for each individual Year (Fig. 2). The highest PAR intensity was measured in April followed by March in Year 2 in PS2, whereas highest PAR in PS1 was recorded in Year 1 months for April and March. Higher PAR in PS2 resulted from the concrete floor reflection as compared to the gravel floor in the PS1 greenhouse. This may also have contributed to a higher temperature in PS2 as solar radiation had more influence on the greenhouse temperature compared to outdoor temperature. The lower light levels in PS1 were possibly due to the absorption of diffused light by the gravel floor surface. The required heating temperature for each PS1 and PS2 greenhouse was measured daily over three growing seasons. PS1 required significantly higher heating to maintain target inside temperature than PS2 in each month over the three years. A non-significant heating requirement between the two greenhouses was recorded only for the month of January in Year 3 compared to other months where heating demand were

significantly higher in PS1 greenhouse (Fig. 3). A non-significant outdoor temperature effect was measured between November through January, and between March and April months, whereas a negative heating light effect was measured in April, which was significantly different from rest of the months except March. The heating outdoor temperature effect was significantly lower in April than March, whereas non-significant value was measured for heating light effect between March and April months. Heating outdoor temperature and heating light had a non-significant effect over three years for December and January months.

Monthly heating outside temperature effect and heating light effect on heating temperature required in two greenhouses. Different letter on mean bars indicate the significant difference (p<0.05), according to LSD test. Data presented are means of three years. ABOVE Amongst

This three-year study revealed a negative impact on temperature heating required with decreasing outdoor temperature effect and increasing light effect for both PS1 and PS2 greenhouses (Fig. 4), and this climate energy effect was statistically significant between the two greenhouse technologies in each month. The PS2 greenhouse temperature heating requirements were 28 per cent, 16 per cent, 11.5 per cent, 11.2 per cent, 22.9 per cent, and 30 per cent lower than PS1, in November, December, January, February, March and April respectively. This lower demand of required heating in PS2 resulted from the high temperature generated through the combined climate energy effect, outdoor temperature and light effect, average daily energy storage and release by the north wall, soil surface and in-floor heating system; consequently, maintaining a higher climate temperature in PS2 than PS1.

This study demonstrates that a greenhouse designed with a concrete, in-floor active solar heating system provides an optimum crop production environment for winter months with reduced heating cost. No difference was found for outdoor light and temperature energy impact for the months of December and January. Therefore, growers can adjust their growing cycle based on the results of outdoor solar energy effect in winter months. This study also shows, photosynthetically active radiation was higher in a greenhouse with a concrete floor compared to a gravel floored greenhouse, which enhanced the greenhouse microclimate.

Transform your greenhouse operations with Ridder’s cutting-edge solutions

Our innovative solutions boost the efficiency, sustainability and productivity in your greenhouse. Interested? Visit us at the Canadian Greenhouse Conference, at booth 210, or explore our website to discover more.

Climate Screens

Optimize your growing climate with the high quality flame retardant screens from Ridder.

HortiMax-Go!

Affordable and modular operating system for climate and irrigation automation.

Can’t make it to the conference?

Then explore our website for more information!

Labour Management

Labour Management

Boost your labour insight, efficiency, and control.

Boost the insight, efficiency, and control over your labour.

Labour Management

Boost your labour insight, efficiency, and control. SmartDrive

Achieve precision control and efficiency with our groundbreaking SmartDrive.

An update on what’s working — and what’s not when it comes to managing this devastating pest in the greenhouse

BY SARAH JANDRICIC (OMAFA) AND JUDY COLLEY (PLANT PRODUCTS)

Most of the conversation around the invasive pest Thrips parvispinus (Fig. 1) has centered around chemical control since it was found in North America four years ago. This is hardly surprising, given the extensive damage they cause, the high value of the crops it attacks (mainly tropical flowering plants), and quarantine issues in the U.S.

Given our experiences with Bemisia whitefly and western flower thrips in the ornamental industry, we all know that control of insects with chemicals alone is not sustainable in the long run. Previous articles on the ONfloriculture.com blog have touched on using mass trapping to help control T. parvispinus But what about biocontrol? Is anything working for this pest? Here, we share information from European studies, as well as on-farm trials in Ontario.

RESEARCH TRIALS IN THE NETHERLANDS: ANTHURIUM

Research at Wageningen University by Dr. Sophie Le Hesran (Postdoctoral Fellow) tested multiple foliar and soil-dwelling natural enemies against T. parvispinus on anthuriums (Fig. 2).

In preliminary lab trials, the commercial predators that consumed the most T. parvispinus larvae were Chrysoperla carnea and Amblyseius swirskii. Dalotia coriaria consumed more than 90 per cent of T. parvispinus pupae provided. Orius species were not tested in these trials, but are now underway.

scimitus paired with A. swirskii, Neoseiulus cucumeris or the foliar mite Transeius montdorensis , which is not available in Canada). Unfortunately, in these tests using loose product, none of the biocontrol agents were able to satisfactorily control T. parvispinus . Tests also showed foliar-dwelling mites did not establish well on anthurium, as few were recovered at the end

Since tests in Petri dishes don’t necessarily tell us what will happen in the greenhouse, trials were scaled up to whole-plant trials in cages. Several natural enemies were tested individually ( A. swirskii, C. carnea, D. coriaria ) or in combinations ( A. swirskii + C. carnea , or Stratiolaelaps

female (right).

of the trial despite repeated introductions at relatively high rates.

Other tests with the fungus Beauveria bassiana GHA did not show efficacy as a soil or a foliar treatment.

Ultimately, the only trial that showed success in the Netherlands used sachets of T. montdorensis . In all cages where sachets were present (at a rate of one sachet per 12 plants), the number of T.parvispinus was very low (less than five T. parvispinus per cage, with less than <20 per cent leaf area damaged). Although this species of predatory mite is not available in Canada (and won’t be for the foreseeable future due to regulatory issues), this does give us hope that effective biocontrol programs may be found for T. parvispinus

Similar to results in the Netherlands, trials in an Ontario greenhouse have shown that predatory mites A. swirskii and N. cucumeris are not effective against T. parvispinus . In the first year T. parvisinus was found in Ontario, high numbers of N. cucumeris , along with sprays of microbial pesticides containing Beauveria bassiana GHA were applied, but 60 per cent of the mandevilla crop was lost.

In a subsequent year, high levels of A. swirskii were applied (in the form of sachets as well as weekly broadcasts), and supplementary food provided. Despite our best efforts, Kelly Smith from Biobee Biological Solutions (Canada) confirmed in tests that mites could not be recovered on mandevilla plants a week after application. This suggests mites do not do well on the waxy leaves of this crop – similar to the results in anthurium.

In other tests, we dipped the unrooted mandevilla cuttings

FIGURE 3

Thrips parvispinus exhibits strong variety preferences in both anthurium and mandevilla / dipladenia (pictured). This can be used against the pest, by growing more susceptible plants in different areas and/or using them as indicator plants when scouting.

(which arrive in July) in insecticidal soap and Beauveria bassiana GHA to reduce incoming thrips. We also did a second, experimental dip of rooted cuttings in Metarhizium brunneum M52 before planting. This reduced initial populations of thrips by roughly 50 per cent before potting (in late August). We then focused on non-mite biocontrol agents, i.e. high rates of Orius applied weekly, regular applications of S. scimitis, C. carnea, Dalotia and drenches of the nematode Steinernema feltiae

Although control proved better than previous attempts with predatory mites, we were only able to supress T. parvipsinus populations with these biocontrol agents. Despite thrips numbers being reduced to less than five thrips/nine-inch plant on average from early September to late October (down from 10 thrips/plant in previous years efforts), this was not enough to prevent damage. Even a small number of larvae feeding on growing tips prevents mandevilla from growing properly. And, even if the program had been successful, it would have still been too expensive to be feasible.

Although all IPM trials in mandevilla to date have necessitated changing to a chemical program in late Fall to ensure sale of the crop in May, we are continuing to narrow down the efficacy of current control options and examine new solutions. Several collaborative projects with the Vineland Research and Innovation Centre, OMAFA and AAFC are currently underway to find alternative approaches to chemicals for T. parvispinus.

The good news part of this story is that biocontrol strategies developed in Ontario by Plant Products with existing biocontrol agents are working in anthurium. Success is likely better in this crop than mandevilla because the

4

Testing of various sticky card colours to trap T. parvsipinus at an Ontario farm, with large mass traps along post rows. Mass trapping is an important part of an IPM program for this pest and can reduce movement between varieties.

damage threshold is likely higher, and the simpler architecture of this plant allows for better spray coverage with microbials. The plants are also spaced closer together creating the perfect micro-climate for microbials to survive.

Current programs developed in Ontario involve initial applications of Success (spinosad), Kontos (spirotetremat), and Lalguard M52 ( Metarhizium brunneum strain M52) to knock back T. parvispinus populations arriving on propagative material. Spinosad and Kontos also provide residual activity against any larvae hatching out during the propagation phase. Overall, two Success applications are done, and one Kontos drench (all seven days apart), followed by three applications of M52 (also seven days apart) in propagation.

Greefa grading machines are a perfect balance between fruit-friendliness, efficiency and ease of use, with different models available to cover a wide range of fruits and vegetables.

We offer integration for complete packing lines, including custom washers, waxers, dryers, dry and wet dumping systems, container handling, and packing equipment. As well as water filtration and purification systems.

with a large range of

Applications of Success and Kontos are appropriate in this situation since predatory mites are not part of the biocontrol program (with spinosad having a long residual toxicity time for mites).

The biocontrol program from potting-up until finish relies on weekly releases of Orius insidiosus . Unlike in vegetables, we are not counting on Orius to establish and reproduce in the crop. Rather, we are counting on the adult Orius to do most of the heavy lifting (especially in winter months), with a next generation of nymphs as an added bonus. By using Success/ Kontos and M52 in propagation, the effective rate of Orius is 2.5 /m2 weekly (or 0.25/sqft).

Control is also possible if pesticides are not used in propagation. Regular applications of S. scimitus and nematodes can be added instead. However, higher rates of Orius are needed to be effective (5.5/m2), but particularly susceptible varieties may still be damaged. This means the overall cost of the program is higher, for less payout.

What we’ve both learned by working with this pest for over three years is that biocontrol will likely never be effective on its own for T. parvispinus . Along with the use of pesticides, other tools in the IPM toolbox are an absolute necessity.

In anthuriums, cultural control (altering the environment be less favourable to the pest) have proven to be a critical part of the program. Research from Dr. Le Hesran in the Netherlands confirmed our observations that anthurium varieties show strong differences in susceptibly to T. parvispinus , with certain

varieties not allowing for the survival of larvae. Eliminating the top susceptible varieties has made a huge difference in the level of quality product produced by Ontario growers.

Similar variety preferences have been observed in mandevilla (Fig. 3), with certain white varieties showing the highest T. parvispinus populations and plant damage year after year. Until investigations into less-preferred varieties of white mandevilla can be done, we recommend eliminating this flower colour, if possible. If not, then it’s necessary to grow white varieties in a separate area of your greenhouse, where control tactics can be concentrated and the risk of spill-over of T. parvispinus into less susceptible varieties is minimized.

Mass trapping – a physical control – is responsible for around a 20- to 30-per cent reduction of T. parvispinus in the crops we’ve assessed. So far, dark blue cards seem to work best in anthurium. In mandevilla, dark blue cards are most effective in winter, with yellow highly effective in the spring/summer (Fig. 4).

The most effective mass trapping card colour varies by facility and season, so be sure to test these colours (or different ones) yourself. Trap plants, such as sweet alyssum (var. Gigi white) can also be used as an indicator plant or can be sprayed regularly to reduce T. parvspinus numbers in the crop.

Microbial pesticides are also going to be an incredibly important part of T. parvispinus control. Along with the success seen in anthuriums with this product, we had promising results using “sprenches” of Lalguard M52 to control T. parvispinus outbreaks in mandevilla, suggesting this product can be used effectively in pesticide rotation programs. This will reduce the potential for insecticide resistance. However, the use of microbials is less effective in winter months, as spore germination drops off sharply below 20ºC. It can help if GH temps are kept above 20ºC in winter (or if flood floor heating is kept at a minimum of 20ºC).

TAKE-HOME MESSAGES:

• Standard predatory mites (Cucumeris, Swirskii) just don’t work – even at high levels. The jury is still out on larger or more voracious mites, such as Anystis, Limonicus or Degenerans. However, all of these species would add significantly to biocontrol costs.

Dutch contemporary design

Most efficient LED fixtures

Superior light distribution with high efficacy

• Pesticides will likely still be needed in i) propagation, ii) when the growing temperatures are too hot/cold for biologicals to work effectively and iii) for crop clean up. But using biocontrols between these times will reduce the chance of resistance and phytotoxicity.

Compact & robust dimming solution to optimize yield

Biocontrol success will likely be crop-dependant. Nonvining plants, such as anthurium, with their more open structures and smaller stature have a better success with Orius and microbial pesticides.

Biological-based IPM programs for larger tropical plants, such as mandevilla, are likely prohibitively expensive at this time. The focus should be on delaying chemical pesticides as long as possible, possibly by using high levels of biocontrol in propagation and incorporating microbial pesticides. Tests are ongoing.

• Cultural and physical controls, such as variety selection, trap/indicator plants and mass trapping are also an important part of an IPM program for this pest.

Alberta and Saskatchewan growers gather to explore new varieties and plan for 2025

BY MICHIEL VERHEUL

Since 2018, Morinville, Alberta has been the setting for a new tradition in Canadian horticulture. The event is called New Blooms and takes place every summer in July. It is a day where members of the industry gather to learn about the new varieties being offered by several breeding companies

New Blooms is the result of years of collaboration and partnership between High Q Greenhouse, where all the product for the event is grown, Deb’s Greenhouse where the finished product is showcased, and for the last two years, the Canadian sector of Express Seed Company head office in British Columbia.

For 2024’s New Blooms event, 10 breeding companies participated by providing unrooted cuttings to High Q Greenhouses, a young plant facility with root and sell contracts with several breeders. The companies featured at this year’s

ABOVE AND RIGHT

Some of the plant material showcased at Deb’s Greenhouse in Morinville, Alta. for New Blooms 2024.

Ready for better crop yields and bigger savings? Set your greenhouse up for long-term growth with retrofit incentives from Save on Energy.

event include: Beekenkamp, Schoneveld, Bull Genetics, PanAmerican Seed, Green Fuse, Syngenta, Danzinger, Westhoff, Think Plants, and DeVry Greenhouses

The plants are grown by traditional grower methods, with a bit of pinching and a regular feeding program.

This year, more than 250 varieties and species were on display at Deb’s Greenhouse and in early July, close to 100 growers and industry professionals gathered to learn about these new varieties and how to manage them.

It was a great event where small groups rotated through the greenhouse visiting the different stations to find out what’s new and exciting for the 2025 season.

One aspect that seems to be top of mind for breeders going into 2025 is the distance that some of this product has to travel to get to growers. A stable government and clear and good roads to the airport, as well as a continued cooling chain, are needed to support that.

Additionally, we noticed colours are getting stronger and stronger and patterns are going to be more ‘out there.’ W’re seeing more speckles and colour-changing plants and flecks on flower petals, like the Westhoff’s Calibracoa Caliloco Graffiti.

Big hits for 2025 are the Sunbeckia from Bull

Designed for both students and practitioners in the Green Industry, this book offers full coverage of the calculations necessary to effectively, safely, and economically manage a Green Industry operation.

The authors provide clear explanations of all relevant mathematical principles and cover calculations inherent in all aspects of the Green Industry, from determining area and volume, to the application of

pesticides, and growth regulators, to preparing design and installation cost estimates.

Genetics: They were well received by the growers and customers. There was a soft launch of this variety in 2024 but the interest is building. The new Kanga from Greenfuse is amazing and we hope supply can keep up with demand.

The New Blooms event even hit the road this year, visiting Central Botanical Growers, located in Saskatoon, Sask., where an identical set of varieties and species were grown for display and comparison. New Blooms Saskatchewan, as this neighbourly event is being called, also hosted a grower expo featuring the products and services of 15 industry supply companies. The event here was attended by 50 companies and staff. Again, this was a huge success with Dr. Ken Fry, a renowned entomologist from Olds Colleges in Alberta, spoke in a session that allowed growers to obtain credits for their pesticide licence.

A huge thank you to the staff of Express Seed Company for their coordination efforts, High Q greenhouses for presenting the event and Central Botanical Growers and Debs Greenhouse for hosting.

Michiel Verheul is the owner and operator of High Q Greenhouses in Sturgeon County, Alta. He is also the president of the Alberta Greenhouse Growers’ Association. He can be reached at mverheul@ highqgreenhouses.com

GARY

JONES | greenhousewolf@gmail.com

Have you looked at the Speaker Program for the 2024 Canadian Greenhouse Conference (CGC) yet?

This year’s theme is ‘Smart Growing’, and there’s an action-packed program of presentations, including a great selection of talks with a focus on energy. For example, Wednesday presentations include:

• Xiuming Hao, Agriculture & Agri-Food Canada; Pepper lighting trials

• Andy Lee, Grodan; Where next in energy saving for high-tech greenhouse horticulture?

(Incidentally, the write up ‘trailer’ says the work Andy is reporting on has achieved >50 per cent lower total heat input compared to a reference tomato crop – want to know more, don’t you?)

• Camille Hanna, Skytree; Transforming CO2 for Canadian CEA.

Thursday sounds equally educational and intriguing with some of the talks being:

• Ajwal Dsouza, U. of Guelph; Closing the loop: biowaste management & resource recovery for urban vertical farms

• David Lubitz, U. of Guelph; Accessing technologies and operating protocols for reducing fossil fuel use in Ontario greenhouses, and

been a significant reduction over the past couple of decades.

Of course, I doubt that there’s any single ‘silver bullet’ fuel replacement for natural gas. Likely the greenhouse in a couple of decades from now will be using multiple fuels, each with unique benefits and contributions to the de-carbonisation conundrum.

But I was also wondering how level is the playing field compared to other countries? “The European Green Deal (EGD) strategy was developed in response to the escalating environmental issues and the growing public and institutional awareness of this phenomenon, which has given renewed impetus to EU-level CC policy and action. The EGD is a set of policy initiatives that attempts to support and motivate sustainable production and put the EU on a green transitional path, with its final objective of achieving carbon neutrality by 2050.”

The ‘Climate Action Tracker’ website offers insights into the GHG emission targets – and achievements - of many countries. It reports that “The current US target of 50–52% reductions below 2005 by 2030 is not 1.5˚C compatible.” “Australia has a net 2030 emissions target of a 43% reduction below 2005 levels.” And “…in November 2022, Norway slightly strengthened its 2030 emissions target to a reduction of at least 55% below 1990 levels.”

“How level is the playing field compared to other countries?”

• Wael Ahmed, U. of Guelph; Carbon Capture and Utilization System for Sustainable Greenhouse Farming; Improved Production while Mitigating GHG Emissions.

There are also more than half a dozen presentations over the two days focusing on robotics, automation, or autonomous growing. Energy is certainly centre stage, but of course, there is so much more of interest, and as always, there’s a lot going on at CGC.

There’s currently a huge push to find options to reduce Greenhouse Gas (GHG) emissions and any potential alternatives to fossil fuels. You may not agree, of course, but I believe it is critical to do this for the sake of our kids and grandkids.

But don’t overlook the fact that the greenhouse industry has been exploring energy options for many years and is known for making constant improvements in the efficiency of producing delicious, healthy, local produce. I tried to find data of the ‘carbon footprint’ for each kg of greenhouse peppers or tomatoes for 2024 c.f., say, 1994, but failed miserably. Sorry. However, I’m sure there has

Incidentally, Norway now “leads the world on electric vehicle (EV) adoption thanks to a long track record of government support and regulation. It is on track to achieve its 2025’ [next year!] ‘phase out of fossil fuel vehicle sales well ahead of schedule, with the market sales share of zero emission vehicles and plug-in hybrid vehicles combined reaching 86% in February 2022.”

This all highlights a very important aspect of finding energy alternatives. That is, much of the solution will be fixing regulatory and policy issues, not technical ones. For example, permitting CHP/CoGen in some provinces to allow ‘surplus’ electricity to be put into the grid. I’m also sure that Norway is achieving its goals because of very high level, guaranteed government support. There has to be strong political will (and incentives), not just government direction (and repercussions).

But perhaps the first step toward any solutions is the research and sharing the findings. If it’s not too late, why not get along to the CGC and find out what’s going on. We’ll all be better for it.

Gary Jones sits on several greenhouse industry committees in BC and welcomes comments at greenhousewolf@gmail.com.