Driving demand for energy-efficient fenestration products

Driving demand for energy-efficient fenestration products

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available

Grove Shims has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Reader Service

Print and digital subscription inquires or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181

Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE

EDITOR | Sukanya RAY GHOSH srayghosh@annexbusinessmedia.com 647.203.7031

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

National Account Manager | Amanda McCracken amcCracken@annexbusinessmedia.com 519.429.5234

ACCOUNT

COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Curtis MARTIN

GROUP PUBLISHER, VP SALES | Martin MCANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $50.50 (in CDN dollars)

Foreign – 1 Year $58.00 (in CDN dollars)

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

4

EDITORIAL

Sometimes, being strict is necessary for our own safety.

7

18 18

12

SELLING EFFICIENCY

Industry experts discuss convincing Canadians to buy high-efficiency windows.

Dealing with continuous insulation can be a headache. 12

14

The Fenestration and Glazing Industry Alliance talks about transforming the Canadian marketplace.

6

INDUSTRY NEWS

Order of Canada for Fast… grants for energy efficiency… REHAU appoints Troeger CEO of Americas…Promax founder Royer passes.

16

BEYOND THE LAB

Field testing fenestration products is key to ensuring optimum performance.

15 FIT & FINISH

There are several ways to source good content. by Chris Meiorin

10 FENESTRATION CANADA

FenCan has new plans and moves to navigate 2021.

THROUGH THE WRAPPER

30

PHILIBUSTER

What will be the next big breakthrough in creating window screens? by Phil Lewin

by Patrick Flannery

The tension between collective action and individual responsibility has never been more evident.

Now over a year into the pandemic, we’re getting grouchy. I was inspired last spring by the spirit of determined cheer that our industry, and the country at large, brought to the huge challenges posed by COVID-19. Anyone in business is a problem-solver at heart, and while everyone acknowledged the lockdowns would generate a recession and a fiscal crisis for governments, many of us turned our natural positivity and optimism to finding creative ways to cope. By last summer, the most common reaction when I asked window and door manufacturers and dealers about the effects of the pandemic was a shrug. “We’re OK.” People trapped in their homes with their vacation dollars burning a hole in their pockets actually drove a boom in demand for renovations including new windows and doors. The biggest challenge so far has turned out to be on the supply side, with delayed deliveries of glass, lumber and other materials forcing us to mark up prices and turn work away.

But as time has gone on and the second wave of the fall hit, grumbling has set in and is growing louder. While the money from governments flowed quickly and easily to individuals, many of the business programs were marred by hasty decision-making and poor follow-up. The rentrelief program relied on landlords to apply and voluntarily take hits to their revenues. The partially forgivable and interest-free loans were still loans – and no one wanted to take on debt. Promised grants languished in bureaucratic limbo with no money flowing. The wage subsides were welcome, but the early looseness of the CERB program created a situation where workers were electing to stay home and collect cheques even when they could have come to work safely.

And as more information came out about just how the virus is transmitted, where the risks are greatest and who is most at risk, questions about the lockdown rules grew from a grumble to a

roar. School closures have been a special bone of contention in light of data showing young people hardly ever get very sick, don’t spread the disease very much and suffer worse consequences than adults from being home and isolated – not to mention the impacts on their parents forced to juggle at-home care while working from home. Big stores being open while the small retailer next door was forced to shut was a bad look. Out of all this has come calls for an end to mandated lockdowns and a reliance on individual judgement and responsibility. We all know enough about safety procedures now, the thinking goes, to go about our business without causing massive outbreaks. The ill and elderly can be given special protection while workingage people who are not generally at risk of serious illness can get on with life, carefully. The counterargument to this is that while freedom and individual responsibility are almost always the best approach to policy, there are certain circumstances where anything other than collective effort is the same or worse than no effort at all. The ugly fact, borne out in places where lockdowns have been absent or unevenly implemented, is that anything less than strict observance of protocols by almost all of the population leads to big spikes in infection. And once community spread is out of control, it becomes nearly impossible to protect the vulnerable.

It’s above my pay grade to assess what the impact of removing lockdowns would be, and whether the cost in lives lost to COVID would be worth the benefit in lives saved by a healthier economy and lifestyle. But I suppose you can chalk me up as a collectivist when it comes to collective threats. Call me naive, call me complacent, but I’m going to keep trusting the public health officials we hired to advise us on the right way through this thing.

With the combined expert resources of AAMA and IGMA, the Fenestration and Glazing Industry Alliance (FGIA) sets the standard for excellence in the glass and fenestration industries.

Our product certification programs provide a unified measurement of success, giving you the means to independently demonstrate to customers that your products meet the highest performance metrics across the board—from certified profiles and verified components to insulating glass certification and gold label certification.

Give your customers the confidence of FGIA. Learn more about Product Certification at FGIAonline.org/certification

Bill Fast, founder of Winnipeg’s Willmar Windows, has been appointed a Member of the Order of Canada. Fast will be formally awarded the honour in a ceremony at a later date. The Order is one of Canada’s highest civilian honours. Fast is receiving it in recognition “For his leading business acumen and for his philanthropic commitment to disadvantaged communities in Canada.” Fast and Willmar

were early supporters of IDE, a global charity promoting business startups in underdeveloped parts of the world.

“Here in the window business we’ve known Bill was a great guy for a long time,” said Al Dueck of Duxton Windows. “He was awarded the C.P. Loewen Award by Fenestration Canada in 2014.”

If you are happy for Bill, he’d probably want you to go check out IDE.

Rehau has announced the promotion of Thomas Troeger from CMO to CEO of the Americas region. The regional executive board of Rehau Americas, with headquarters in Leesburg, Va., includes Troeger, CEO; Theo Haast, CFO; and Terry Barnaby, head of operations. Haast, who headed the region as president and CFO since January 2019, has elected to refocus on his main and key responsibilities as CFO.

“We thank Theo for leading the region to improved profitability during the last two years, an important step in preparing the foundation for growth in the Americas,” said William Christensen, CEO of the Rehau Group.

During his 14 years with Rehau, Troeger has developed through various positions with increasing responsibility, primarily in the areas of marketing and sales. He became director of the furniture solutions business division in North America in 2013 and then vice-president of the division for the entire Americas region in 2015. Troeger joined the regional executive board in January 2019 as chief sales and marketing officer, with all the company’s non-automotive

business divisions reporting to him.

“We are very pleased to promote an internal candidate into this key leadership role,” said William Christensen, CEO of Rehau Group. “Throughout his Rehau career, Thomas has demonstrated an ability to zero in on market opportunities and inspire customer-focused innovation across all our divisions. As our Americas CEO, he will take on the additional challenge of championing our values of trust, reliability and innovation in support of our growth strategies.”

“When I consider the range of markets Rehau operates in, and the relatively narrow focus of our product portfolio, I believe we have huge untapped potential,” said Troeger. “And when I look internally, we have very qualified, loyal employees who I believe can reach new heights and find greater enjoyment in their work as part of an even more successful team. I look forward to showing customers and employees we are ready to live our claim of ‘engineering progress enhancing lives’ in ways they have not yet imagined.”

The total value of building permits decreased 4.1 percent to $9.1 billion in December, following a month during which several high-value permits were issued. Declines were reported in every component except single-family dwellings. Gains in seven provinces, led by Newfoundland and Labrador, were largely offset by a significant decrease in Ontario (13.2 percent). Single-family homes rose seven percent to $3.1 billion, surpassing the previous record of $2.9 billion set in October 2016. Six provinces posted gains in this component, led by Ontario (6.8 percent) and Quebec (11.1 percent). The rise in Ontario was mainly due to the census metropolitan area of Toronto (51.9 percent), while the gains in Quebec were largely due to municipalities outside of CMAs. The national value for multi-family dwellings declined 7.2 percent to $3.3 billion, largely because

of a 12.8 percent drop in Ontario. Four other provinces also reporting a decrease in this component. Overall, the residential sector edged down 0.9 percent to $6.4 billion after posting a record-setting month in November. Quarterly gains observed in the residential sector were enough to offset a decrease in the non-residential sector. As a result, the total value of building permits in the fourth quarter of 2020 reached $27 billion, up 5.4 percent compared with the third quarter, surpassing the previous record high, which was set in the second quarter of 2019. Single- and multifamily dwellings both posted record highs in the fourth quarter of 2020. This marked the second straight quarter of record-setting numbers for multi-family dwellings, while single-family homes surpassed the previous high set in the fourth quarter of 2016.

The SAWDAC team is evolving! We are pleased to announce two big moves that we think will really be positive for the association going forward.

Jennifer Beingessner has been elected president of SAWDAC. Here is her story in her own words.

“When SAWDAC director Jason Neal asked me to write something for the newsletter, lots of ideas came to mind. But nothing I thought was particularly interesting to the SAWDAC membership. And maybe that is the point: while I may not find my story interesting, others might. For those who may not be familiar with my company, Beingessner Home Exteriors was started in 1967 by my grandfather, Harry Beingessner, in the days of aluminum siding, storm doors and windows. The twoman business was suddenly taken over by my father, Doug Beingessner, when my grandfather passed unexpectedly. A few decades later, I was work-

ing alongside my father, learning the ropes and being mentored into an eventual thirdgeneration owner. This is an accomplishment I am proud of, since only 30 percent of second-generation businesses succeed and a mere 10 percent see success into the third generation. Maintaining the triedand-tested systems we already had in place that brought us more than 50 years of success was more important than reinventing the wheel. Watching my father’s involvement with SAWDAC and Window Wise over the years showed me that dealer participation, and not just a membership, is a win-win. In the early years of SAWDAC, local chapter round table discussions were highly attended and gave dealers the opportunity to discuss issues or opportunities they faced within their business with other dealers. Collectively, our membership has a wealth of knowledge and experience. Without dealer participation, the depth of the organization would be greatly limited. While the dealer benefits from the numerous services and support SAWDAC offers to its members, making business contacts and staying current with the changes within the industry is a huge asset to a window and siding business owner. Being involved on the SAWDAC board of directors is akin to the round-table brotherhood, with a few added

sisters at the table. When the SAWDAC board of directors appointed myself president in June, I was humbled and excited. Working closely with the other board members including outgoing president Fred Hamilton, the membership, and Jason and Ronda is an opportunity to help continue to grow and develop SAWDAC. Twenty years ago, my father held the same position as president of SAWDAC. It is nice to follow along in his footsteps once again.”

Phil Lewin has joined the SAWDAC team as technical director. Prior to joining SAWDAC, Phil’s career has been as a technical marketer for both manufacturers and dealers. He provided information on fenestration performance matters, initiated several technical projects on window energy performance and supported window and door manufacturers on code compliance issues.

Phil says, “I am privileged to have been selected to be the technical director for SAWDAC. This is a fundamentally important association and I am excited to work with the board and our executive director, Jason Neal, to help you, our members, succeed at a time of uncertainty and explosive growth in our industry.”

Phil is a voting member on CSA A440 committees and a member of the NRCan Energy Efficient Fenestration Steering Committee, among others. He is a columnist with a technical focus for Fenestration Review magazine and is recognized for his knowledge of the many industry standards. In this role, Phil will connect with SAWDAC members and support the industry by sharing his technical expertise, skill and insights into our ongoing development as a world class siding, window and door association. Phil will also be an asset to the executive director and board of directors to interact with industry shareholders and to provide the most up -to-date information and expertise on federal and provincial industry regulations. SAWDAC firmly believes the selection of Phil as technical director will allow the association to better serve its members and make a difference in the industry.

Jennifer Beingessner EXECUTIVE-DIRECTOR Jason Neal

Harold Orr, a Saskatoon engineer who was a pioneer in building energy efficient homes, was named to the Order of Canada in January this year. During an ongoing energy crisis, Orr was a member of the team that created the Saskatchewan Conservation House project in 1977. The team from the Saskatchewan Research Council had been asked to build a solar house that would fare well in Saskatchewan extreme winter and summer conditions. Fenestration Review’s sister magazine Canadian Contractor paid a tribute to Orr in its April 2018 issue.

“When we looked at conventional houses, we identified three major components to heat loss: the insulated portion of the building (windows, walls and ceiling), the basement and air leakage,” recalled Orr during that interview. “Adding insulation alone only reduced the heating needs by about 30 percent.

We had to deal with the other two components: basement and air leakages.”

These were handled in a straightforward manner. First, a grade-beam and pile foundation was used, thereby eliminating the basement. Second, given his expertise on air leakage, Orr agreed to personally install the project’s air barrier. The result was an air tightness level that was extraordinarily high for a home anywhere in the world at that time. While home construction costs were modest for 1977 at approximately $60,000, the solar system added another $65,000. Orr contrasted that substantial additional capital cost with his estimate that heating the home conventionally with natural gas instead would have cost only $25 per year. The lesson learned was that by insulating the windows, walls and ceilings concurrent with insulating (or eliminating) the basement and installing an effective air barrier, the home’s energy consumption could be reduced by 90 percent.

The Fenestration and Glazing Industry Alliance has updated a mulled assemblies document. AAMA 450-20, Performance rating method for mulled combination assemblies, composite units and other mulled fenestration systems, was last updated in 2010. This FGIA performance rating method describes procedures and requirements for determining the air leakage, water resistance and structural performance of mulled fenestration systems. The method also describes test procedures and calculation procedures for determining the performance of mulled fenestration systems. Mulled fenestration systems may be factory assembled or knocked down for field assembly with parts and instructions supplied by the fenestration product manufacturer.

“The North American Fenestration Standard says that ‘mullion ratings shall be determined according to the requirements and procedures of AAMA 450 for both composite units and mulled combination assemblies.’

However, until now, AAMA 450 provided no guidance for composite units,” said Dave Goldsmith (PlyGem), co-chair of the FGIA requirements for mulled and combination window assembly update task group.

Composite units have been brought fully into the scope of the standard, together with storefront and curtainwall fenestration products and side-hinged doors.

“This will put powerful new tools into the hands of engineers to assist them in determining how to construct structurally sound and weatherproof fenestration products in the most economical ways, and should also drastically reduce the amount of testing required to validate a large variety of composite unit configurations,” said Goldsmith.

AAMA 450-20, as well as other AAMA documents available from FGIA, may be purchased from the online store at the discounted member rate of $20 or the nonmember price of $60.

Screenco has announced that Daniel Royer, former owner of Groupe Promax, a division of Screenco in Quebec City, passed away on Jan. 2, at an early age of 71. Royer had a long history in the Canadian fenestration industry. He founded the successful steel door company, Celco Doors, in 1985, and sold it to Premdor (now Masonite) in

1997. In 2004, he joined founder of Groupe Promax, Daniel Aubert, as a partner in the business. He helped grow the operations and took over entirely in 2013. Royer was recognized as a Fenestration Canada Pioneer in 2010. In 2018, Screenco acquired Promax and Royer retired.

“My last contact with him was in September of this year

(2020) when we communicated about the crazy COVID year and its effect on business and supply chain. He was in good spirits and looking forward to his RV trip to Gaspesie. From the entire Screenco and Promax families, we extend our deepest condolences to his loved ones,” said Jennifer Small, president of Screenco.

In a call with Fenestration Review, Ontario Minister of Labour, Training and Skills Development, Monte McNaughton, laid out the ministry’s plans to cap Workplace Safety and Insurance Board premium hikes and to recognize working at heights training certificates held by workers from Newfoundland and Labrador. According to McNaughton, the ministry will move to cap 2021 WSIB premium increases on Ontario businesses at two percent. The action is necessary, he said, in order to offset a statistical rise in the average price of labour in Ontario due to the pandemic. COVID-19 has caused lower-wage workers to be laid off in higher numbers than higher earners. The combination of fewer workers at higher wages would have driven a WSIB premium increase of nine percent without intervention. Benefit payments for workers will not be affected, McNaughton says. The cap applies to the 2021 calendar year.

“We listened to small business owners, many of them

contractors with six to eight employees, who told us they might have to mortgage their houses if rates go up,” McNaughton said. “We’re going to save small businesses $40 to $50 million with this.” McNaughton said the rates will “self-adjust” back to normal when pandemic measures are lifted and workers get back on the job.

The other measure McNaughton announced was an amendment to Ontario’s Occupational Health and Safety Training law to automatically recognize working-at-heights training received and certified in Newfoundland and Labrador. McNaughton referenced especially a “huge” shortage of boilermakers, saying he was responding to requests from automotive manufacturers, nuclear plants and Sarnia’s petrochemical industry to enable 750 boilermakers from Newfoundland and Labrador to work immediately upon arriving in the province.

“We are knocking down barriers to increase labour mobility,” McNaughton said.

Earlier this year, the Western Retail Lumber Association invested in an economic impact study to justify a home renovation tax credit as a strategy to support economic recovery. The Saskatchewan government took this information as the basis to build its recently announced program. The program runs retroactively from Oct. 1, 2020 to Dec. 31, 2022. WRLA will continue to advocate for an HRTC in other provinces in the meantime. The federal government, as part of its 2020 fall economic statement, also announced an energy retrofit program. The WRLA, in addition to several partnering stakeholders, advocated for an eco-retrofit program either in the form of tax credits or grants. The 2016 census identified 4.5 million dwellings that require minor or major repairs. WRLA noted that it is pleased to see that the federal government listened to recommendations from the industry and its partners and will support economic recovery while taking action towards climate strategy. The proposed program will provide $2.6 billion over seven years to help homeowners make energy-efficient improvements to their homes.

In its Nov. 30 fall economic statement, the federal government included a promise to support energy-efficient home retrofits.

“Buildings, including our homes, account for 17 percent of Canada’s greenhouse gas emissions, so helping Canadians make their homes more energy efficient can support our environmental objectives while making homes more comfortable and more affordable to maintain. And will create good, middle-class jobs in their communities,” it said.

Natural Resources Canada has released some details of the Our Action Starts at Home initiative will look like, though the program is not available to homeowners yet. According to the NRCan website, the program will be retroactive, covering retrofits started as far back as Dec. 1, 2020. It will “complement” efficiency rebates offered by provinces and other jurisdictions. The initiative will provide 700,000 grants of up to $5,000 for eligible retrofits and one

million free EnerGuide energy assessments. Homeowners will have to get an EnerGuide audit before becoming eligible for the grants. They will also have to document the work done, including before and after photos. The website states NRCan is working to train enough auditors to meet the anticipated demand. The organization is also promising low-interest financing options in addition to the grants. No word on when the initiative might actually launch.

by Stephane Labelle

Ithink everyone can agree that 2020 was a special year. A year that forced us to rethink everything on a personal and a professional level. First and foremost, I want to thank all our members and sponsors for keeping Fenestration Canada strong despite this weird situation. There is a lot to be said about the resiliency of our business owners and employees who clearly went the extra mile last year.

This year is one of hope. We all hope we will be able to travel and meet in person again. Let me assure you that we are exploring all possible options to get back to an in-person experience as soon as possible. As we speak, we plan to host WinDoor in-person even if it will probably have to be a little different than usual. In the meantime, we have one full year of online content planned for you on the Marketplace where you can still visit our exhibitors all year long.

Tech Talks and Fenestration in Canada are also back with tons of educational content and interesting interviews. Simply put, even if we needed to keep everything online this year, we would still be able to make sure that we do everything possible to support the industry, but

“This year is one of hope. We all hope we will be able to travel and meet in person again.”

membership with Fenestration Canada includes a full membership with CFIB, for free. Thanks to this alliance, we now have access to even more pull and resources when needed. Make sure to make sure to use these benefits!

As you saw last year, we are also supporting our partners in their mandates whenever they need us. Last year we worked with several regional industry associations as well as the major associations in the United States. We also work closely with other stakeholders organisations such as the Canadian Home Builders Association, The Vinyl Institute of Canada, Passive House Canada and many more. Our regional committees did an excellent job last year and we are now starting 2021 with two new chairs. Marie-Pier Houle and Marco Greco will respectively chair the Quebec and the Ontario committees. We are excited to welcome new blood to the team and are very excited to serve all the regions of our beautiful country. Please make sure to reach out to your respective chair if you want to join a regional committee, or simply let us know at the office.

This year is also a Toronto WinDoor year, which means that the C.P Loewen Award will be presented. Keep an eye out for the nomination forms later this year.

Last year, due to COVID-19, the board of directors remained unchanged, but this year we are getting back to business as usual. So keep an eye out for the call for nominations if you are interested in joining the board. Now more than ever we welcome fresh input that will help us grow as an organisation. Our president, Terry Adamson, will pass the pepper grinder to Mike Bruno, who acted as first vice-president of the board.

we would definitely like to see all of you again. In the meantime, our technical director, Al Jaugelis, and I are working closely with NRCan as members of the Advisory Council and the experts team. Our technical team is also active on different fronts, including the different standards committees in the industry.

I also want to mention again that your

As we are looking forward to the end of this pandemic I can only hope that we eventually get back to some sort of normality. But we will make sure to leverage everything we were forced to change so we keep offering more and more. We have exciting new announcements coming up in the next few weeks, stay tuned!

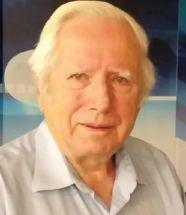

Marketplace by WinDoor was launched in November 2020 and has been a great success so far with education sessions, showcases and of course, exhibitor booths. The platform is still open and will continue to stay open until November 2021. The Marketplace will be the main educational platform for 2021 as well as updated exhibitor booths which can be viewed at the attendee’s convenience.

Join us in the Marketplace by registering on our website www.windoorshow.ca

Please contact me at laine@fenestrationcanada.ca for more info about the Marketplace and for sponsorship opportunities.

Laine Atkins Events Manager

Industry experts reflect on solutions to drive demand for high-performance fenestration.

For several decades now, environmental advocates have wished Canadians would spend more on their windows. But the math hasn’t worked out for homeowners. Now, the question of how to move the market upstream has gained new urgency.

by TREENA HEIN

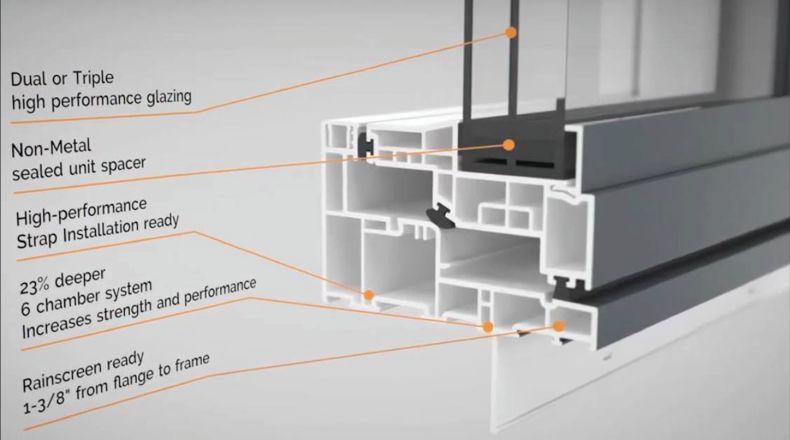

RIGHT: The industry is working towards transforming the Canadian window market into something that’s more accepting of higherperforming products. This picture illustrates how the concept of energy efficient windows can be explained to customers. Illustration courtesy of Westeck Windows and Doors.

As we move on from the hallmark year of 2020, governments around the world are under more pressure than ever to ensure carbon emissions within their borders are minimized or reduced. The government of Canada, along with others that signed the Paris Climate Agreement, wants its companies and its citizens to use less energy. With citizens, there’s a focus on high-performance windows so that the energy used to heat and cool houses is minimized.

It was already five years ago that Natural Resources Canada launched the Market Transformation Initiative which aims to encourage more uptake of high-efficiency windows. Will this initiative work? What

roles should the government and the fenestration sector play in making the use of these windows more common? This topic was the focus of a recent panel discussion at the 2020 Fenestration Canada WinDoor event. Panel host and Fenestration Review editor Patrick Flannery noted that through better windows, huge building envelope efficiencies can be made. But while you can legislate what types of windows must be used in new builds, he asked, “what do you do about renovations and the rest of the market? Governments are looking for answers from the industry on how we’re going to transform the Canadian window market into something that’s more accepting of higher-

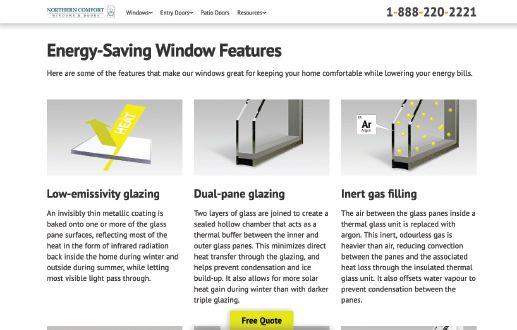

Examples of company websites promoting energy-efficient windows. Including educational content is a good idea.

performing products.”

The panel experts span a range of stages in marketing these products. Thermoproof Windows and Doors on Vancouver Island (Cam Drew, managing partner) has just recently started; Euro Vinyl in Woodbridge, Ont. (Laura Weil, vice-president) has been selling them for some years and Tiltco in Toronto (Jay Madha, president) has been doing it for decades, though he’s shifted to commercial in recent years. Perhaps the first step to having more uptake in high-efficiency windows is to ensure there are a number of products to choose from. Like many other firms, Euro Vinyl is increasing its highefficiency product lineup. It now offers a sliding door that can take triple panes and will be offering an enhanced casement system next year. Thermoproof is currently testing a new double-triple slider and a triple casement, but Drew notes that “we have a two-tier rebate system for renovations here in BC, with the second tier for windows of a U value 1.22 or lower…but our window for the second tier is in testing.”

Weil adds that demand continues to grow for larger windows which can’t always include more efficient glass, and discerning customers with high incomes will beef up their heating system if that’s what they have to do to have more glass in their homes. Madha echoes these thoughts, noting that customers will say “I want energy efficiency but I still want my glass and my views; so it’s a compromise.”

Weil explains that customer discussions about window performance usually focus on comfort.

Customers are looking for narrow frames and large windows first, and energy efficiency is typically later in

the conversation. “It’s about comfort, how much floor space do you want to be able to use, how close do you want to be able to get to the window in winter, how do you want the place to feel,” she says. “I find that’s a much better way of talking about thermal efficiency.”

Drew agrees, explaining that he approaches these discussions in a similar manner to how weather forecasters in some parts of the world talk about the day’s weather in comparison to the day before. “I think it’s brilliant,” he says. “So, we talk to them about their current home. They point out where it’s warm and we look at why and where it’s cold. You put them in their current state so that they can talk about their future state.”

There have been several rebate programs over the years at the provincial and federal levels to encourage purchase of high-efficiency windows. In Ontario a few years ago, the GreenON program offered $500 per window and got overwhelming traction. A current rebate program in BC of $50 for a double-pane window with a U-value of 1.40 or less, and $200 for a window that meets 1.22 or less, says Drew, has not had the traction that the government would have liked to see. “There were a lot of steps to getting to the rebate and that put homeowners off,” he says. “Interest is picking up and some companies are doing a much better job [of promoting it] depending on their inventory.”

Drew adds that the Home Performance Stakeholders Council (funded by the B.C. government, BC Hydro and natural gas firm, Fortis) has

discussed the idea that every house put up for sale could be required to have an energy advisor’s report, an EnerGuide number, so that potential buyers could understand the energy rating of their choices. Windows would factor in and this system might incentivize some sellers to put in high-efficiency windows, but Drew is not sure the idea “is ever going to fly.”

Drew, Weil and Madha all agreed that window costs need to come down if high adoption rates of energy-efficient windows is ever to occur.

“I like the 1.05 U-value window because it allows most manufacturers to keep manufacturing, but that’s my personal perspective,” says Drew. “I know we’ll meet 1.05 and we’ll get lower than that, but meeting 0.8 is where the cost curve starts to go up.”

Weil notes that from a big-picture perspective, with other things like lighting and vehicles, energy efficiency gains have been made, and it will further progress. Windows are no different.

“We’ve made progress and it’s part of the general conversation,” she says. “I think most homeowners want to have an energy-efficient home because it feels good and it’s ethical, but moving that needle has to be methodical. There has to be accessible technology available to us and, as our industry changes as a whole and smaller manufacturers are bought up by larger groups, there’s going to be a lot more money available to our industry to develop new products. I think the changes will align and create a retrofit program that’s attainable and realistic. I’m sure that needle will move. It’s just going to take some time.”

by Margaret Webb, FGIA glass products and Canadian industry affairs director

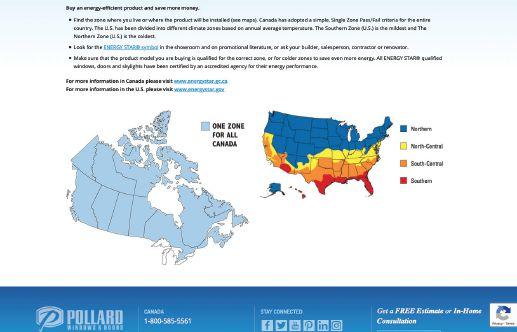

In the summer of 2018, governments released Paving the road to 2030 and beyond: Market transformation roadmap for energy-efficient equipment in the building sector. The Roadmap set 11 aspirational goals for the energy performance of three key technologies in the building sector – space heating, water heating, and residential windows – focusing on these products and their significant opportunities to reduce energy use.

Starting in 2017 and through to the summer of 2019, NRCan met with industry stakeholders to identify opportunities and barriers to achieving the aspirational goals. High priority initiatives to move the industry towards these goals were:

• A single information portal developed by NRCan regarding window benefits and available window incentive programs

• Sustainable GST/HST tax rebates for installations

• Mandatory disclosure of energy and green house gas emissions performance of homes for sale

• Facilitate training for window installers and certification programs

• Develop codes for new construction that involve the use of highly efficient windows

• Other recommendations including tiered incentive plans, enhanced glazing materials testing funding support, labeling simplification and glass inventory

They are aspirational goals for each of the three identified sections. The windows performance targets are ambitious. And while there are products in the Canadian marketplace that have achieved these goals, they are not readily available nor necessarily affordable for the Canadian homeowner.

The goals for windows provide the future targets for the industry:

• By 2020, residential windows for sale in Canada meet an average U-factor of 1.61

• By 2025, residential windows for sale meet a U-factor of 1.22 and on the R&D front, residential windows with a U-factor of 0.8 can be manufactured and installed cost-effectively

• By 2030, all residential windows for sale in Canada meet a U-factor of 0.8

In addition to identifying market strategies, stakeholders also identified barriers to transforming the market under availability, accessibility, awareness, affordability and acceptance. Also, there isn’t a lot of information available to the average homeowner about the benefits of highly efficient windows.

More affordable windows with a U-factor of 1.6 are readily available, with sufficient information for public awareness. The technology exists for windows with a U-factor of 1.2. While they are available, there is again very little awareness of the technology to fabricate the product, and the affordability is not mainstream. Manufacturing windows with a U-factor of 0.8 will require triple-glazing. Approximately 88 percent of the IGMAC certification program participants certify a tripe-glazed unit, so this is readily available in all areas of Canada. As the market moves towards triple-glazing, affordability will be realized as economies of scale are realized.

Work was delayed on the three identified sectors for the last half of 2019 due to the Canadian federal election. NRCan was focused on space heating and water heating for the majority of 2020. In August 2020, however, the windows advisory council met to review their operating guidelines and objectives. The council will review updates from the window experts team, draft the annual report and provide updates to the Roadmap advisory council.

The first meeting of the window experts team reviewed the background and provided information on how the team will operate. The team is expected to meet monthly to review the specifics of transforming the market.

So, what can you do? NRCan will be scheduling regional stakeholder workshops to solicit information and feedback on achieving the aspirational goals for 2030. All industry organizations will be advertising these workshops and your participation is critical to ensuring that the goals are achievable and do not penalize or favour any single stakeholder group.

by Chris Meiorin

Good creative content can give you that competitive edge.

Have you ever read a business valuation that lists content as an asset? Not “contents,” but rather, “content”?

Creative content is an asset. Anyone who takes advantage of successful digital marketing knows full well the value of good content. In fact, value-added content, in itself, is another form of content that can be leveraged effectively via just about any medium, digital or otherwise. There are fenestrators who get it. They understand the work involved in mining good creative content. The companies with the best content make digital marketing look easy and, more importantly, believable. And its not about the budget either, as really good content is often created with the only outlay being considerable time.

If you have any doubt about the value of content, just look at Netflix. In its early years, it acted primarily as the distributor of content, namely motion pictures. This was Netflix’s business model for most of its first 10 years and the stock price averaged below ten dollars. Then in 2013, Netflix began creating its own content using the term “original,” and its share value has since climbed to over $500. Entire brands have been built on nothing but good creative content and good content channels need a lot of fuel to exist. So, if you’re not already living in a hype house, where do you start?

Creative content comes in different forms: blogging (this column is ultimately a blog); visual (videos, photographs and movies); case studies (the combination of a blog and visual content); even webinars (who hasn’t done at least one during COVID?). All of these make for good base content to land, but without the actual content to plug in, you having nothing. Recently I had a conversation with a fellow business owner and the topic of social media came up. Their partner had recently left their job and wanted to start a social media campaign using visual channels (Instagram).

The only problem was that they had no fuel. Nothing to plug in. They had no content.

If you don’t already have a highly organized library of creative content, where do you begin? For starters, find someone to who has good content and ask if you can share. Creating your own content is often the most effective, but so is user-generated content. User-generated content allows you to leverage the creativity of your customers and fans –and it is authentic. Nothing is worse than watching a company farm out their media campaigns with generic and unauthentic content. If you can’t beg or borrow, then create your own.

Canon Camera might have an interesting solution. It’s safe to say that Cannon’s equipment has been used to create a quintillion bytes of content. The only problem was they didn’t really own or have direct access to the huge amount of content their equipment created. For that they created the Canon Ambassador Program. Over the years, this program has taken different shapes, but for the most part, Canon would sometimes offer promotional gear (or sometimes nothing more than promotion) in exchange for customer generated content. For their efforts, Canon has enough user generated content to last an eternity, just for asking.

Practically all of us have the necessary tools to immediately start to create content. Today’s mobile phones serve not only as a medium to broadcast content, but as a tool to create, with the advanced features of both photography and video. Photograph your jobs, your team or anything else you think your audience might find interesting. Talk about your topic, not just your brand. Share other people’s content. Engage with your audience. Participate in Q&As, and, above all else, create content!

Chris Meiorin is president of EuroVinyl Windows and Doors in Woodbridge, Ont.

Performance-path code compliance means field testing is getting more important.

Because they are critical components of a building’s weatherresistant barrier, fenestration products are often the focus of investigations of real or perceived water penetration or excessive air infiltration.

by Jason Seals

However, faulty fenestration design is not likely to be the cause of such leakage problems. Products that meet the appropriate performance class defined by the code-mandated North American Fenestration Standard, must pass laboratory water leakage tests of increasing stringency, depending on the product’s performance class and grade. Regardless, water penetration at an installed fenestration product may actually be attributable to poor installation, as well as shipping, handling, acts of subsequent trades, aging and other environmental conditions.

Because installed fenestration can be very difficult and expensive to fix after the building envelope is complete, specifiers and contractors are well advised to require field testing during or immediately after installation begins. The FGIA publishes field testing methods to aid in this mission. Of these, AAMA 502, Voluntary specification for field testing of newly installed fenestration products is the proper test method for determining water penetration and air leakage resistance of any type of newly-installed (prior to issuance of the building occupancy permit but no later than six months after installation of the fenestration product) factory-built windows, doors and skylights. It is based on ASTM E783, Standard test method for field measurement of air leakage through installed exterior windows and doors and ASTM E1105, Test method for field determination of water penetration of installed exterior windows, curtain walls and doors by uniform or cyclic static air pressure difference. Newly installed curtain walls and storefronts are tested per AAMA 503, Voluntary specification for field testing of newly installed storefronts, curtain walls and sloped glazing systems.

AAMA 502 specifies that one percent of the fenestration products to be installed on the project, but no fewer than three, shall be tested as soon as possible after installation begins to verify performance of both the fenestration product

and its installation. To test for resistance to air leakage per ASTM E783, a differential pressure is created across either the interior or exterior of the test specimen using a chamber erected on site. The differential pressure should be equivalent to that originally used in the laboratory: a minimum uniform static test pressure of 75 pascals (or as specified for the project) but not to exceed 300 pascals. Unless otherwise specified, the allowable rates for field-measured air leakage must be a maximum of 1.5 times the applicable NAFS rate for the product type and performance class. Using this same chamber, the water penetration test is performed in accordance with ASTM E1105 procedure “B” (cyclic static air pressure difference), except AW-class windows are tested per procedure “A” (uniform static air pressure difference). AAMA 502 specifies the static water test pressure differential should not exceed two-thirds of that used in the laboratory. These reductions in air leakage rate and water test pressure are considered a reasonable adjustment for the differences between conditions found in a laboratory test environment versus those found in the field.

A newly-released 2021 edition of AAMA 502 is a significant revision from the previous 2012 version, with major changes including:

• All testing must be conducted by an FGIAaccredited laboratory or field test agency (FTA) that meets the requirements of FGIA/ AAMA LAP-3, Laboratory accreditation program operations manual - Laboratories and test agencies performing on-site testing of fenestration products. Additionally, key personnel must be a currently registered FenestrationMaster or FenestrationAssociate.

• Prior to testing the FTA, the tester, in conjunction with the specifying authority, must

issue a field test plan that summarizes test methods, failure criteria, number and type of products to be tested and locations, among other things;

• The fenestration manufacturer and the installer are allowed to perform an inspection and correct any deficiencies prior to testing;

• A new section concerning calibration and validation of test equipment (previously found only in LAP-3) is included. A diagram has been added depicting the appropriate validation apparatus;

• More precise parameters for describing observable water penetration are provided, as are new illustrations showing the planes of controlled and uncontrolled water penetration for various installation types and flashing conditions;

• Finally, the list of required information to be included in test reports has been expanded, notably requiring photographs of the test specimen and other relevant details.

To facilitate its use, AAMA 502 conveniently provides a recommended short-form model specification that allows the specifier to

prescribe essential information such as the number of products to be tested; the test pressure for both air leakage resistance and water penetration resistance testing; and the pass and fail criteria.

Understanding field testing methods for air/water ingress is likely to become more urgent for window and door providers in the future. This is because, as energy efficiency rules tighten, homebuilders may begin to show more interest in wholehome performance-path compliance options. Jurisdictions such as B.C. and Ontario already offer builders the option to show compliance with energy regulations through modeling and testing of entire houses. The 2020 National Energy Building Code will offer compliance with higher tiers on a performance path measured against a reference building. The Canadian Commission on Building and Fire Codes had instructed the standing committees to defer airtightness testing requirements to future code development. The Standing Committee on Energy Efficiency included these testing requirements in the 2020 code recommendations. At the urging of CCBFC to remove airtightness requirements, SC-EE struck a working group from its members.

The conclusion was to retain airtightness testing in the current code cycle. This recommendation will be forwarded to CCBFC and the industry will have the opportunity to appeal this inclusion. Airtightness will be further addressed in future editions of the National Building Code, requiring compliance with various levels of air changes per hour, normalized leakage area and normalized flow rate.

Sometimes prescriptive paths to compliance will remain, but as builders look for savings and creative ways to hit higher efficiency targets, they may wish to work with fenestration suppliers to find trade-offs. Could better quality windows enable them to install a less expensive HVAC system? Could continuous insulation enable them to install double-glazed rather than triple-glazed units? Could a tighter installation method help them pass air/water ingress requirements with little cost added? Field testing of models and one day even renovation projects will be needed to answer these questions.

AAMA 502-20 and AAMA 503-14 may be obtained by visiting the FGIA online store.

Jason Seals is FGIA’s certification services manager for fenestration.

Continuous insulation and its challenges for window installers.

It’s no secret that energy efficiency requirements for low-rise and high-rise construction are becoming greater and will only continue to do so. One of the ways builders are meeting higher R-value demands is through the use of continuous insulation.

by ANDREW SNOOK

Why continuous insulation? Well, according to George Torok, facade specialist at Morrison Hershfield, there are two reasons for choosing continuous insulation. The first is that it just makes sense.

“Typically, in low-rise, you’re using wood frame construction still – sometimes steel frame. And, traditionally, the frame elements have bridged from the inside surface of the walls to the outside surface of the walls. So, on the inside you would have the poly and the drywall, and, on the outside, you have sheathing and moisture barrier and the cladding materials. So, the studs – whether they’re wood or metal – are thermal bridges. They’re very much more conductive than the insulation material between the studs. It’s an old issue,” Torok explains, adding that it was recognized as an issue by the folks at the National Research Council. “It degrades the heat loss through the studs, effectively reducing the insulation value provided by the insulation between the studs. So, you might look at a traditional two-foot by four-foot wall where you would have R12 as an exterior insulation, but when you count into the effect of the studs then you’re reducing the effective value of that insulation. So, the term you often hear today is ‘effective R-value’ of a wall or ‘effective U-value’ of a fenestration assembly.”

The terms effective R-value and U-value recognize that some components of a wall system or fenestration system are more conductive than others.

“Therefore, when you look at the whole, your actual R-value or U-value is higher or lower than

you would expect from a traditional analysis,” Torok says.

Builders counter this issue by placing insulation across the exterior of a structural wall assembly, which can be performed by placing insulation on the outside of the exterior sheathing and having the cladding beyond that. Or, instead of putting the sheathing in place – in the case of a house that would typically be OSB across the outside of the house – you can put rigid insulation material directly against the outside of the studs, such as extruded polystyrene or expanded polystyrene, Torok explains. He adds that it reduces the amount of heat loss to the studs and recovers some of the lost value of the insulation from in between the studs.

“It’s a smart move in terms of trying to increase the thermal performance of the envelope,” he says. “It’s a requirement of code these days. In Ontario, we have the supplementary standard SB-12 to the Ontario Building Codes which gives a number of compliance packages. To me, they’re energy performance targets for the exterior wall. Typically, they require insulation across the exterior of the stud frame to reduce thermal bridging.”

Torok says that a similar issue occurs in highrise construction.

“A lot of apartment buildings we typically build with reinforced concrete frames. There are, of course, the newer wood frame construction technique as well. And you can build with steel and composite steel and concrete frames. That creates a grid work of structure you have to infill between the floors and vertical elements

like columns and sheer walls to create the exterior walls. That’s typically done, again, with a [steel] stud assembly,” he says. “But if you have steel stud that spans from the interior drywall to the interior sheathing with no insulation on the outside of it, you have thermal bridges for that stud frame and that degrades the value of the insulation you put within the stud cavities. So, to meet energy performance targets, you need to insulate on the outside of the stud frame and on the outside of the building structure – the concrete frame or whatever has been used to make up the structure of the building. And again, that is picked up again in the Ontario supplementary standard SB-10, where continuous insulation is typically required within the exterior walls. So, it’s a combination of good building science that’s been translated into legislation in the form of building code requirements.”

The use of continuous insulation isn’t new – builders have been using it for more than two decades – but its popularity has been trending upwards. Once thought of as a more niche product for meeting energy efficiency requirements for green building, continuous insulation is now becoming a more regularly used tool in the belts of industry professionals.

Ben Polley, president of Evolve Builders Group based out of Guelph, Ont., says that there has been a significant increase in demand for energy efficient homes

both from an economic and an environmental perspective.

“There’s big interest in ultra-performing homes. It’s just completely on a different scale now,” he says. “People want you to build something they understand will be favourable for their pocketbooks and to the next generation for not doing more harm [to the environment].”

James Higgins, associate building science technologist for RDH Building Science in Burnaby, B.C., says emerging technologies have played a role in the upward trend in the use of continuous insulation.

“There has been emerging technology for rigid insulation layers and cladding attachments through these rigid layers, so we have the ability to add a scalable amount of insulation depending on the needs of the building. We’ve seen up to eight to 12 inches of exterior insulation,” he says. “It’s an efficient way to insulate the walls and other areas of the building as well. That’s why we see that trend and we’re seeing it all over.”

Higgins adds that he likes the trend towards increased use of continuous insulation because it will aid builders in the future.

“I like it because, here in 2021, we’re making sure we can install it properly and we’ve got the right detailing. But it’s scalable for 2030 and 2040 when, if

things continue, we will have even more insulation or be ready for what people call ‘future-proofing’ these assemblies. We’re not having to re-invent the insulation approach every time energy requirements increase or change,” he says. “It’s also a pretty elegant solution where we have this dedicated layer. You have to add a few more components to make sure you attach the cladding on the outside properly. It’s a pretty cool way to insulate the wall, for sure.”

Torok says the challenges for using continuous insulation for window installations are often the same for high-rise and low-rise construction.

“As you push the window further to the outside, you create a dead air pocket over the inside face of the window. That dead air pocket can become cooler and you increase the likelihood of condensation,” he says. “When we introduce insulating sheathing on the outside of a wall assembly, the problem is the window is so much narrower than the overall wall that if you keep that window close to the inside surface, then there are going to be other elements of the wall framing that are protecting beyond the window. Those can act as thermal bridges.”

Torok says that ensuring the window is properly supported is a big challenge when

pushing the window further outward.

“When you push it further outward, some of the window is going to be sitting over some of the exterior insulation. So how do you now support the weight of the window and how do you anchor it back to the actual structural frame?”

Over time, industry professionals have developed a few different approaches. In high-rise construction, where there is a steel stud frame, people often line the steel stud opening with plywood that is three quarters of an inch or thicker, according to Torok.

“The plywood protects beyond the outside base of the stud and the surrounding sheathing as far as it needs to, to support the window. That allows the window to be slid further outward. The window is typically anchored directly into the plywood, and that plywood is anchored into the stud. So, you have an indirect load transfer in terms of wind load, structural load from window to plywood to stud frame, and then on into the building structure. The plywood is typically covered on the exterior underneath the window with a peel-and-stick membrane… the idea there is that the membrane waterproofs the plywood, so if there’s any water that might get into the exterior insulation, then the wood is protected.”

Torok says that plywood is also used sometimes in low-rise residential. Another approach is simply to add a picture frame of dimensional lumber around the outside – for instance, a two-by-threefoot frame added to the wall to outline the window opening. This would also be covered by membrane.

“The window would be set into the opening generally above that lumber frame and then the membrane would be brought in over the wood and sealed to the inside perimeter of the window. Then the exterior would be sealed to the waterresistance barrier and the surrounding wall assembly,” he says.

Another option is using one of the many liquid-applied products available in the marketplace.

“They essentially come in a caulking tube and you spread them out over the wood frame in a way sort of like a paint,” Torok says. “You have to achieve a certain thickness, so you could use a thickness gauge to measure it and even still need to seal that membrane with a caulking material usually to the inside perimeter of the frame, and that liquid-applied material would be travelled onto the surrounding water-resistant barrier.”

Rigid insulation can also be used for low-rise residential applications.

“If you’re using a rigid installation, like extruded polystyrene, and the window incorporates a perimeter mounting flange or nail flange, then it’s possible to nail directly from the flange through the extruded polystyrene directly into the frame. And then you still have to apply a water-resistant barrier around the window opening,” Torok says, adding that this is a proprietary solution and that the insulation manufacturer would need to approve its use. “You wouldn’t want the insulation to sag or move downwards.”

Polley’s company, Evolve Builders Group, has been working with continuous insulation in various forms for around 15 years, including rigid insulation. He warns that if the installer is using metal fasteners it can destroy the added R-value they are trying to achieve.

“If when installing continuous insulation – which is commonly 1.5-inch rigid polystyrene – that insulation is installed with a series of metal screws or metal nails, then there’s a real question as to whether or not a significant benefit has been gained; given that screws, for example, depending on the metal of which they’re made, can have a conductivity of thousands of times more than the surrounding insulation,” he says. “Each one of those screws might have a diameter of 3/16 inches, but it’s actually like the equivalent of three inches or four inches of a hole in that insulation because of how conductive that metal is. It’s not unlike taking a hole saw and drilling a bunch of holes in the insulation. That’s how it’s going to perform.”

Polley says the same issue exists for the window installation.

“If we build out a significant wooden frame to suspend or to support the window that is now breaking up the so-called continuous insulation, then we’re doing the same thing. It won’t be worse than building conventionally, but there’s the risk that we’re doing something that has limited benefit.”

Polley offered installation tips from both a design and construction perspective.

From the design perspective, he says to never rely on anecdote when it comes to your construction details. Get them tested.

A-1 WINDOW MFG LTD

#1 8038 Glenwood Drive

Burnaby, BC, V3N 5E9

Tel: (604) 777-8000

Contact: Sarb Kaler

Email: sarb@a1windows.ca www.a1windows.ca

A+W SOFTWARE NORTH AMERICA

One Parkway North, Suite S-400 Deerfield, IL, 60015

Tel: (847) 220-5237

Contact: Chris Kammer

Email: chris.kammer@a-w.com www.a-w.com

AABEN WINDOWS AND DOORS LTD

700 Progress Avenue

Kingston, ON, K7M 4W9

Tel: (613) 384-3163

Contact: Michael Braby

Email: michael.braby@aaben.com www.aaben.com

ADDEV PROFOM

1055 Autoroute 440 West Laval, QC, H7L 3W3

Tel: (438) 823-0953

Contact: Stephanie Morin

Email: s.morin@addevmaterials.com www.addevmaterials.us/en/

ADFAST CANADA INC.

2685, Diab Street

St-Laurent, QC, H4S 1E7

Tel: (514) 616-7536

Contact: Christian Guerard

Email: cguerard@adfastcorp.com www.adfastcorp.com

AERLOC INDUSTRIES LTD.

64 Head Street Dundas, ON, L9H 3H7

Tel: (905) 628-6061

Contact: Edward Laman

Email: edwardlaman@aerloc.com www.aerloc.com

AGC GLASS NORTH AMERICA

11175 Cicero Drive, Suite 400

Alpharetta, GA, 30022

Tel: (905) 738-9400

Contact: Marilyn Moore

Email: marilyn.moore@agc.com www.agcglass.com

ALBERTA VINYL WINDOWS AND DOORS LTD.

5920 - 30th Street S.E., Unit 6 Calgary, AB, T2C 1X8

Tel: (403) 863-0197

Contact: Ron Steppacher

Email: ron@avwd.com www.avwd.com

ALL WEATHER WINDOWS LTD.

18550 - 118A Avenue NW Edmonton, AB, T5S 2K7

Tel: (780) 451-0670

Contact: Tracy Nadiger

Email: tnadiger@allweatherwindows.com www.allweatherwindows.com

ALLSCO WINDOWS AND DOORS

70 Rideout Street

Moncton, NB, E1E 1E2

Tel: (506) 853-8080

Contact: André Doiron

Email: adoiron@allsco.com www.allsco.com

AMBERWOOD DOORS INC.

191 Atwell Drive, Unit 3

Etobicoke, ON, M9W 5Z2

Tel: (416) 213-8007

Contact: Colin Fraser

Email: cfraser@amberwooddoors.com www.amberwooddoors.com

AMESBURYTRUTH

3600 Minnesota Drive, Suite 800 Edina, MN, 55435

Tel: (800) 866-7884

Contact: Donna Cockrell

Email: donna.cockrell@amesburytruth.com www.amesburytruth.com

ANDERSEN CORPORATION

100 Fourth Avenue North Bayport, MN, 55003-1096

Tel: (651) 264-5570

Contact: Mark Mikkelson

Email: mark.mikkelson@andersencorp.com www.andersenwindows.com

ANDERSON WINDOWS

46 Cheryl Crescent PO Box 510 Sundridge, ON, P0A 1Z0

Tel: (705) 384-5341

Contact: Cheryl Anderson

Email: sherianderson@bellnet.ca www.andersonwindows.ca

ANIG WINDOWS

240 Ellesmere Road

Scarborough, ON, M1H 3B6

Tel: (416) 438- 7213

Contact: Luisa Angheloni

Email: luisa@anigwindows.com www.anigwindows.com

AQUASURTECH OEM

2148 Trans-Canada Highway

Dorval, QC, H9P 2N4

Tel: (514) 684-2628

Contact: Michael Braeuel

Email: mbraeuel@aquasurtech-oem.com www.aquasurtech-oem.com

ARMWOOD WINDOWS & DOORS

Highway 1A West, PO Box 8

Portage la Prairie, MB, R1N 3B2

Tel: (204) 856-2320

Contact: Brent Otsuji

Email: brent@armwood.ca www.armwood.ca

ATLANTIC WINDOWS LTD.

49 East Main Street

Port Elgin, NB, E4M 2X9

Tel: (506) 538-2361

Contact: Greg Dickie

Email: greg.dickie@atlanticwindows.com www.atlanticwindows.com

BASCO WORLD

4064 Alfred-Laliberté

Boisbriand, QC, J7H 1P8

Tel: (514) 241-9686

Contact: Jenny Desjardins

Email: marketing@bascoworld.com www.bascoworld.com

BAVARIAN WINDOW WORKS

2236 Shirley Drive

Kitchener, ON, N2B 3Y1

Tel: (519) 578-3938 Ext. 229

Contact: Jordan Stewart

Email: jordan@bavarianwindows.com www.bavarianwindows.com

BETHEL WINDOWS AND DOORS

1504 12th Street

Coaldale, AB, T1M 1M3

Tel: (403) 345-4401

Contact: Samuel Van Seters

Email: sam@bethelwindows.ca www.bethelwindows.ca

BROWN WINDOW CORPORATION

185 Snow Boulevard

Concord, ON, L4K 4N9

Tel: (905) 738-6045

Contact: Pino Marinelli

Email: pinom@brownwindow.com www.brownwindow.com

CALDWELL MANUFACTURING COMPANY

2605 Manitou Road

Rochester, NY, 14624

Tel: (585) 352- 3790

Contact: Emily Mount

Email: emount@caldwellmfgco.com www.caldwellmfgco.com

CAN-BEST TESTING LABORATORIES

38 Regan Road, Unit 4

Brampton, ON, L7A 1C6

Tel: (905) 840-2014 Ext. 201

Contact: Elie Alkhoury Email: elie@can-best.com www.can-best.com

CARTONS CORRUGUARD

101 Des Ateliers

Lavaltrie, QC, J5T 3R3

Tel: (450) 586- 0666

Contact: Marie-Helene Hotte

Email: mhhotte@cartonscorruguard.com www.cartonscorruguard.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Road

London, ON, N5V 4K8

Tel: (519) 451-0508

Contact: Lindsay McGhie

Email:

lindsay.mcghie@centennialwindows.com www.centennialwindows.com

CLEARVIEW INDUSTRIES LTD.

45 Fenmar Drive

Toronto, ON, M9L 1M1

Tel: (416) 745-6666

Contact: Tom Marsala

Email: tmarsala@clearview.on.ca www.clearview.on.ca

CONTINENTAL / KONRAD HORNSCHUCH AG

Salinenstrasse 1

Weissbach, 74679

Tel: (540) 550-4596

Contact: Marco Patermann

Email: marco.patermann@gapser.com www.skai.com/en/exterior/

CORNERSTONE BUILDING BRANDS

40684 Talbot Line

St. Thomas, ON, N5P 3T2

Tel: (519) 637-7899

Contact: Gary Husen

Email: ghusen@northstarwindows.com www.cornerstonebuildingbrands.com

CSA GROUP

178 Rexdale Road

Toronto, ON, M9W 1R3

Tel: (866) 797-4272

Contact: Mohamadou Diallo

Email: mohamadou.diallo@csagroup.org www.csagroup.org

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue

Dartmouth, NS, B2W 6A2

Tel: (902) 462-6114

Contact: Dan Darcy

Email: dan@darcyasscs.ca

DAYSIDE WINDOWS & DOORS

441 Henry Street, Unit 2

Brantford, ON, N3S 7V6

Tel: (519) 759-5222 Ext. 213

Contact: Sarah deBoer

Email: sarah.deboer@daysidewindows.com www.dayside.ca/

DEL WINDOWS & DOORS

944 South Service Road

Stoney Creek, ON, L8E 6A2

Tel: (905) 561-4335

Contact: Edward Bremer

Email: ebremer@delwd.ca www.delwd.ca

DOORCOM

285 Vaughan Valley Boulevard

Woodbridge, ON, L4H 3B5

Tel: (905) 850-5352

Contact: Daniel Sardella

Email: daniel@wintek.ca www.doorcom.ca

DOORSMITH

(A Division of Can-Save)

411 Bayview Drive

Barrie, ON, L4N 8Y2

Tel: (705) 722-7283 Ext. 2258

Contact: Ryan Eccleshall

Email: ryane@cansave.ca www.doorsmith.ca

DORPLEX INDUSTRIES LTD.

100 Norfinch Drive

Toronto, ON, M3N 1X1

Tel: (416) 744-3667

Contact: Paul Moseley

Email: paul@dorplex.com www.dorplex.com

DUFFERIN WINDOWS LIMITED

115 Centennial Street

Shelburne, ON, L9V 2Z4

Tel: (519) 925-3111

Contact: Karen McCabe

Email: karen@dufferinwindows.ca dufferinwindows.ca

DURABUILT WINDOWS & DOORS INC.

10920 178 Street NW

Edmonton, AB, T5S 1R7

Tel: (780) 577-2004

Contact: Sami Sakalla

Email: samis@durabuiltwindows.com www.durabuiltwindows.com

DUXTON WINDOWS & DOORS

45 Higgins Avenue

Winnipeg, MB, R3B 0A8

Tel: (204) 339-6456

Contact: Al Dueck

Email: apdueck@duxtonwindows.com www.duxtonwindows.com

ELEMENT MATERIALS TECHNOLOGY CANADA INC. (FORMERLY EXOVA)

2395 Speakman Drive

Mississauga, ON, L5K 1B3

Tel: (905) 822-4111 Ext. 11582

Contact: Jennifer Wren-McDonald

Email: jennifer.wrenmcdonald@element.com www.element.com

ELTON MANUFACTURING

8120 Lawson Road

Milton, ON L9T 5C4

Tel: (905) 876-1290

Contact: Andrew Beavan

Email: sales@eltonmanufacturing.com www.eltonmanufacturing.com

ENDURA PRODUCTS INC.

8817 West Market Street

Colfax, NC, 27235

Tel: (336) 668-2472

Contact: Mark Fortun

Email: mfortun@enduraproducts.com www.enduraproducts.com

ENERGI FENESTRATION SOLUTIONS

3035, boul. Le Corbusier

Laval, QC, H7L 4C3

Tel: (450) 687-5115

Contact: Martin Boulanger

Email: marketing@energifenestration.com www.energifenestration.com

ERDMAN AUTOMATION CORP.

1603 South 14th Street

Princeton, MN, 55371

Tel: (763) 389-9475 Ext. 6109

Contact: Jessica Metz

Email: jmetz@erdmanautomation.com www.erdmanautomation.com

EUGÉNIE WORLD INC.

1167 rue Nationale

Terrebonne, QC, J6W 6H8

Tel: (450) 964-1616

Contact: Jonathan Chauvette

Email: jonathan@eugenie.world www.eugenie.world/

euro + glasshaus

167 Caster Avenue, Woodbridge, ON, L4L 5Y8

Tel: (905) 851-9711

Contact: Chris Meiorin

Email: info@evw.ca www.euroglasshaus.com

EVERLAST GROUP OF COMPANIES 299 Carlingview Drive Etobicoke, ON, M9W 5G3

Tel: (800) 897-5118

Contact: Vince Porcelli

Email: Vince@everlastproducts.ca www.everlastproducts.ca

EXP SERVICES INC. 1595 Clark Boulevard Brampton, ON, L6T 4V1

Tel: (587) 226-3220

Contact: Norris Jia

Email: norris.jia@exp.com www.exp.com

EXTREME WINDOW & ENTRANCE SYSTEM

80 Loftus Street Moncton, NB, E1E 2N2

Tel: (506) 384-3667

Contact: Darren Bannister

Email: dbannister@extremedoors.ca www.extremedoors.ca