MANAGING MULTIS

Labor-Saving

Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Shims™ has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2020 Vol. 9 • Issue 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT

COORDINATOR | Stephanie DEFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

AUDIENCE DEVELOPMENT

MANAGER | Urszula GRZYB ugrzyb@annexbusinessmeda.com 416-510-5180

MEDIA DESIGNER | Brooke SHAW

GROUP PUBLISHER, VP SALES | Martin MCANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

ugrzyb@annexbusinessmedia.com 416-510-5180

Fax: 416-510-6875 or 416-510-5180

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $50.50 (in CDN dollars) Foreign – 1 Year $58.00 (in CDN dollars)

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.fenestrationreview.com

13

Joe Altieri did a great job trying to explain our industry on Shark Tank.

12 FIT & FINISH

13

PHILIBUSTER

14 MANAGING MULTIS

Low-rise and track housing is where the growth is. But serving this market has unique challenges.

A great cup of coffee says something about your brand. by Chris Meiorin 30

Windows that let air out can be just as problematic as ones that let it in. by Phil Lewin

THAT’S RICH Meetings are huge timewasters. Let’s discuss. by Rich Porayko

Swimming with the sharks

Flexscreen’s

Jby Patrick Flannery

Shark Tank experience contains some lessons.

oe Altieri of Flexscreen was on Shark Tank recently and it was fun to see a window guy trying to explain this industry to the sharks. It really highlighted how different manufacturing supply is from the flashy, sexy businesses they are used to – and revealed an aspect of our business that I think we should all be trying to change. The sharks were immediately blown away by Altieri’s product. Flexscreen makes custom screen with a plastic frame reinforced with flexible steel wire. All Altieri had to do was show them how it could be bent and almost folded to easily go in and out of windows without being destroyed like a regular aluminum frame and they were sold. That was the easy part.

They asked about sales and Altieri had a great story there, too. He told them how Flexscreen has gone from $400,000 in its first year to $5 million last year, just four years later, and was projecting $10 million this year. Kevin O’Leary was getting ready to throw a party. Then they asked Altieri what his profit was and even my jaw hit the floor when he said $40,000. The sharks all recoiled in horror. Altieri tried to explain that he’d been reinvesting but that drew the inevitable follow-up question about his margins. Altieri had to admit he’d only netted $700,000 on $5 million in sales and was only making 15 cents on the dollar on each unit. The sharks went nuts, especially after Altieri explained that Flexscreen was a custom product with no standard size. That by itself was a revelation about our business for the sharks – they were all under the impression that windows and doors are standard sizes.

Why isn’t he charging more for this product, they wanted to know. Why didn’t he go straight to retail? Why didn’t he sell it as a premium product and let his low-paying accounts drop away? He must have failed somehow in his negotiations with fabricators. One shark said he would have put a 100 per cent markup on the product.

Hearing that last bit, I could see the divide between the world the sharks swim in and the

world Altieri comes from. Fleecing customers for double the costs of your product might work at the concession stand at a movie theatre, but window manufacturers are going to take a harder look at that deal.

O’Leary, at least, was somewhat mollified by Altieri’s explanation that he had to achieve a certain market penetration before he could start to expand margins. “Oh, they wanted proof of market,” O’Leary nodded. Again, the image of the risk-averse window manufacturer loomed in my mind. Coming from the industry, Altieri knew that no one would take him seriously until he had a track record of successful installations over time. Conservative, thy name is fenestration.

Another revealing moment came when Robert Herjavec asked why this couldn’t be sold as a premium product for manufacturers to offer as an upgrade to regular screens. Altieri gulped, then answered, “Window manufacturers are not very good at marketing.” This caused Mark Cuban to yell at him for shifting the blame for his marketing failures to his customers. What Cuban doesn’t understand is that it would be hard for Altieri to directly advertise his privatelabelled product. His customers would complain that he’s helping their rivals’ businesses. Window manufacturers want their components to be secret sauce that only they can offer.

No, Altieri was right that the reason he can’t charge more for Flexscreen products is because fabricators don’t feel they can recover the charge on their sales. I don’t think this is a reflection on Flexscreen, I think it’s a reflection on our race to the bottom on prices and our unwillingness to invest in the marketing effort needed to get what we deserve. Our products are fantasic, but they do no one any good if we don’t communicate what is so great about them.

By the end, Altieri had three of the four sharks fighting over him and a fun moment when Lori Greiner essentially stole Barbara Corcoran’s idea to close the deal. Congratulations to Joe and Flexscreen.

INDUSTRY NEWS

Jaugelis is new FenCan technical director

Fenestration Canada has announced that Al Jaugelis has joined the Fenestration Canada team to act as full-time technical director. He replaces Jeff Baker. Prior to joining Fenestration Canada, Jaugelis was a senior fenestration specialist at RDH Building Science. In that role he provided consulting services on fenestration performance matters, initiated several research projects on window energy performance and supported window and door manufacturers with practical North American Fenestration Standard test planning and code-compliance challenges.

“I am honoured to have been selected to be the technical director for Fenestration Canada,” Jaugelis said. “This is a vitally important organization and I am eager to work with the board and our executive director to help our members succeed at a time of rapid change and innovation in this industry.”

Jaugelis is a voting member of the CSA A440 Committee, a member of the Natural Resources Canada Energy Efficient Fenestration Steering Committee, and the Fenestration Canada Technical Services Committee. Recognized as an authority on NAFS, he writes about it on the “NAFS in Canada” blog. In this role, Jaugelis will engage with Fenestration Canada members and support the industry by sharing his technical expertise, skill and insights into developing a world-class window and door manufacturers association. Jaugelis will also be an asset to the executive director and the board of directors to liaise with industry stakeholders and to provide the most up-todate information and expertise on federal and provincial industry regulations.

Fenestration Canada firmly believes the appointment of Jaugelis as technical director will allow the association to better serve its members and make a difference in the window and door industry.

Thibault named technical manager for FGIA

The Fenestration and Glazing Industry Alliance has announced the hiring of Nathalie Thibault, who will serve the organization as technical manager for glass products and Canadian industry affairs. Throughout 2020, Thibault will shadow Margaret Webb, glass products and Canadian industry affairs director, to prepare to take on her duties upon Webb’s retirement in early 2021.

“Nathalie comes to us with over 15 years’ experience in the insulating glass arena,” said Janice Yglesias, FGIA executive director. “With sales, project management and technical roles throughout her career, she is well-positioned to represent FGIA in various Canadian standards and regulatory arenas, as well as to guide the work of our Glass Products Council members. Her work ethic and experience

New location for Ecoline

Ecoline Windows opened its newest location in Ottawa in October 2019. The new Ottawa location offers vinyl window and door installations services in Ottawa and surrounding areas.

Ecoline Windows has additional locations across Canada, servicing Edmonton, Calgary, Winnipeg, Regina, Saskatoon and Vancouver. The company offers many window replacement options, including full-frame, retrofit and Energy Star vinyl windows. Window styles include casement, awning, slider, hung, bay, bow, shape,

plus her Canadian residency and fluency in French all came together to produce the ideal candidate for this role.”

“The glass initiatives of FGIA are critical to the new organization, so it’s exceptionally beneficial to have Nathalie on board so early in 2020, allowing us about a full year of operating together on all glass and Canadian activities,” said Webb. “We have the opportunity to travel together throughout this year to all relevant industry events, creating direct access to first-hand learning experiences. With the volume of knowledge and the vast array of contacts to be retained within this role, a comprehensive and coordinated plan executed over an ample timeframe is sure to create a seamless transition.”

Thibault lives in Riviere-du-Loup, Que., and will work from her home office.

combination and triplepane windows.

Door styles offered include steel entry doors, fiberglass entry doors and garden doors. Many different features and options are available. Triple-pane options are available on all models and the company has in-house installation crews. The windows are made in Canada.

SAWDAC

WINDOW WISE UPDATE

In 2019, window contractors certified under the Window Wise national certification program installed over 30,000 windows across Canada. Window Wise, now in its 24th year, has proven to be an invaluable asset for qualityconscious window dealers.

BACKGROUND

In the mid-’90s SAWDAC was challenged to find a solution to an epidemic of poorly installed windows. After consulting with many industry groups and carrying out market research, a quality assurance program with five key components (listed below) was developed. Window Wise was the answer that guaranteed a quality window, properly installed. Window Wise gave homeowners wanting to replace their windows a list of approved windows and a list of certified window contractors from a trusted, independent source. Window Wise program components:

• Approved windows

• Certified contractors

• Trained and certified installers

• Random job inspections

• A quality assurance guarantee

There are over 2,000 window manufacturers in Canada and over 15,000 window contractors. Many windows aren’t even tested according to the

CSA A440 standard and very few contractors have trained and certified installers. In 1995, no window installers were trained because no replacement window installation course existed. SAWDAC corrected that problem by creating a one-day window installation course for experienced installers, which included a 125-page manual and videos on proper installation methods.

All Window Wise-approved windows are Energy Starqualified. They are tested and must meet minimum performance standards, which vary from region to region. Window Wise-certified contractors have been in business a minimum of two years, carry $2 million in liability insurance, abide by the SAWDAC code of ethics and offer a minimum five-year workmanship guarantee. Window installers are trained through the Window Wise installation course and are certified by having their work randomly inspected. Every homeowner who purchases from a Window Wise contractor receives a five-year guarantee from SAWDAC that backs up the protection offered by the window manufacturer and the window contractor. Chris George, president of Douglas Window and Door in London, Ont., has been on the Window Wise program since it began in 2016. He says, “My company belongs to

Window Wise for two reasons: consistent workmanship and marketing. Getting all our installers trained and practicing the same methods greatly improved the production side of our business. Callbacks dropped off dramatically with a resultant decrease in service costs. Most importantly, the entire team seems to have an elevated sense of pride in everything we do. Our salespeople find that Window Wise causes an increase in closing ratio due to the enhanced customer confidence after the program is explained. Since we joined Window Wise, our sales have increased as well as the gross margins. I can confidently say that Window Wise is a very important part of our success.”

THE WINDOW WISE LARGE PROJECT PROGRAM

If, for example, 27 town houses in a condominium corporation decide to change all their windows, Window Wise

provides a cost-effective way of ensuring the job is specified correctly and installed properly. Window Wise dealer Beingessner of St. Jacobs. Ont., says, “Before Window Wise came along, numerous contractors would bid on large projects that typically had very poorly defined specifications. It was difficult for engineers and specifiers to define window quality and measure workmanship. Contracts were chosen primarily on price with the result that owners were often unhappy with their new windows. Window Wise sets a standard for the window and the installation method. A Window Wise inspector visits the work site when the work begins and at intervals thereafter. Many engineers and specifiers now invite only Window Wise-certified contractors to bid on this type of work, which makes it better for everyone involved.”

For more information about The Window Wise national certification program visit win-

INDUSTRY NEWS

Pries takes on new lines

Everlast Group and Westeck Windows and Doors have announced they have retained the services of Rick Pries (president of Fenestration Pro Consulting) to represent their products in western Canada. Pries brings over 30 years’ experience in the window and door industry. Starting in 1988 after graduating with a diploma in civil engineering, he has worked with some great companies in the past such as Gienow, Berlinex/ Veka and Skyreach. He has also volunteered time with Fenestration Canada as a past chair for the WinDoor show.

“Everlast looks forward to having Rick’s vast experience representing our Aluminum Altitude Plus

Rainscreen method update

Building engineering expert, Jon Eakes, is reporting that research projects are going forward on a new method to install windows using rainscreen principles. For the last year and a half, discussions at window conferences across Canada have led to research projects at George Brown College in Ontario and Red River College in Manitoba designed to define and quantify the role drainage paths and pressure equalization can play in providing more reliable (and possibly less expensive) residential window installations in new cold climate construction. A small preliminary project at George Brown College, supervised by Chris Timusk, is focusing specifically on what pressureequalization between the drainage plane and the forces of the wind can contribute to the control of moisture ingress in residential window installations. This project is considered a first step in preparing the larger Red River College project. The researchers are presently in the process of building the test wall. The project is moving forward because of College scheduling restrictions despite a current funding shortfall. Presently, it is $1,500 short of the initial budget and another $2,000 short of the dreamed-for budget. Any Ontario based (a requirement of the research-matching funding agency) window manufacturers or window installing companies who would like to support the effort are encouraged to contact the administrator, Arbab Khan, at 416-415-5000 ext. 3508 or arbab.khan@georgebrown.ca.

The project at the Building Envelope Technology Access Centre division of the Red River College in Winnipeg has recently had its first advisory committee meeting after securing its funding. It is presently projected to be a one-year project. They are going to undertake some initial THERM modeling, especially on the thermal contribution of the dead air space in a drainage plane –part of evaluating a payoff balance between insulation and

windows and storm doors in the western Canadian marketplace,” said Mike Bruno, Everlast president. “Everlast has been in business since 1960 and Rick’s knowledge and expertise is perfect fit to expand our sales force into Western Canada.”

Pries will also represent Westeck products in Alberta, Manitoba, and Saskatchewan. Westeck worked with Pries previously when he was the general manager for Veka. The company says it always found him very knowledgeable, friendly and ready to help when called upon. Westeck now looks forward to having Rick’s vast experience representing the many different product lines that Westeck offers, like the Rev XL Passive House lift-and-slide doors and swing doors in the Canadian marketplace.

drainage in a limited space. The George Brown College project should have wrapped up before plans are finalized for lab testing at BETAC, so whatever is learned at George Brown will be used there. Fenestration companies interested in contributing in some way to the Winnipeg project should contact Rob Spewak, technology centre manager, at 204-632 2357 or rspewak@rrc.ca .

In 2011, National Research Council research concluded that trying to stop the wind and the rain at the same place does not assure long-term durability of water control in residential window installations. Yet this is exactly what is attempted when installers caulk, tape and foam the window at the level of the mounting flanges. Eakes has been criss-crossing the country spearheading industry discussions into new installation methods that could reduce water ingress at the window/wall interface.

FenCon education streams announced

FenCon20 brings new flavours to its education streams May 12 and 13 at the RBC Convention Centre in Winnipeg. The new Something Colourful stream will hit an increasingly important issue: effectively and profitably meeting the demand for finish options. Content will address types of finish, finish process, different types of application equipment for different levels of operations, trends, handling and more. Something Lean brings more Continuous Improvement education but with additional focus on KATA and real-world implementation. Experts Ian Marshall of Canadian Manufacturers and Exporters Manitoba and Warren Peters, a 20-year veteran of Lean implementation will offer a combination of seminars including a practical industry “reporting back session” and workshops. Something Hot will take advantage of the later date for the show. Attendees will escape “Winterpeg” and get outside under beautiful blue skies. FenCon has also re-worked the schedule such that the first day of workshops on the 12th leads into the full conference day on May 13. Something New will help attendees punch up demand with more powerful marketing. New York marketing guru, Jeff Swystun,

Business and fun at WinDoor

WinDoor 2019 attracted a healthy crowd of window and door manufacturers and dealers to the International Centre in Mississauga, Ont., Nov. 20 and 21. The first day saw a big rush and crowded booths with things quieter on Day 2, as usual. The floor was smaller than past years, but the education sessions were well attended, especially the ones offering technical advice and codes and standards updates. But the big charge of energy came again from the Main Event dinner on the first evening, which saw over 500 sit down to eat, chat, honour the industry’s leaders and rock out to Destroyer, a Kiss cover band. It reinforces a trend toward shows becoming more about the networking and education and less about looking at products and finding suppliers. Feedback from exhibitors indicates they are actually fine with that, as the chance to connect with dozens of clients and potential clients in a couple days is very valuable.

will discuss ways to be on the cutting edge of products and to think about ways to bring them to market. Also, star economist and native Winnipegger, Glen Hodgson, returns to deliver an economic forecast and update that can’t be missed. Building It Right leader Murray Frank will deliver a workshop with live demonstrations of four to six different window installations. These sessions will focus on changes resulting from double two-by-four frame walls and walls with layers of exterior continuous insulation. Registration is open at fencon20.com.

Choe of Trimlite. “We had some engaging conversations with our customers, so job well done.”

“We saw everybody we wanted to see,” said Jean Marois of Energi. “That was the goal. We made sure we were meeting our customers because it is a good time to wrap up the year with them and talk about next year.”

“The first day was very busy,” said Luca Toscetti of INT Machinery. “We had people who were starting to investigate and people who already knew what they were looking for. We had very good interest on our paint line for painting on lineals.”

“This was better than the last three years,” said Erdem Gogceloglu of Klaes.

“The show this year has been great,” said Carrie Scheetz of Quanex. “We got to see a lot of our customers which is why we love coming to WinDoor. We get to see a lot of customers we don’t see anywhere else.”

“I thought the show was really well attended with a good flow of traffic and minimal downtime,” said Eddie

WinDoor returns to Montreal Nov. 18 and 19 this year at a very special venue: Olympic Stadium!

FIT & FINISH

Coffee culture

It’s like a big steaming mug of business success.

by Chris Meiorin

Anyone that has visited our office here at EuroVinyl Windows knows we take our coffee seriously – and we aren’t talking about a drip filter coffee that’s been baking for hours. More along the lines of high-quality espressos, macchiato’s and lattes, thoughtfully and carefully prepared using the highest quality bean and hand-crafted Italian equipment. Now, before you consider this column nothing more than a muse, reflecting on yet another obsession, think again.

The significance of coffee our workplace stems back over 20 years when it wasn’t at all uncommon to be working with fenestration installers and business owners of Finnish origins. On one occasion, I offered one such installer a coffee, and he gladly accepted my offer. While enjoying his coffee, he asked, “Do you know which country has the highest coffee consumption per capita?” As you can well appreciate, I just assumed it was Italy, and when he informed me it was Finland, I had to take his word for it as Google didn’t yet exist. He explained that it was considered rude not to offer a guest a coffee and equally rude to refuse one. With this information, I made it a point to offer our guests and visitors a coffee, and worked hard over the next 20 years to make each coffee a memorable one. You might ask “What does this have to do with anything?”Let me explain.

Coffee has become an important part of how we do business. Most every morning starts with coffee. It could be short shot of espresso with production. An oat milk latte with the marketing manager or a strong espresso macchiato with our ERP engineer. Consider it an elevator-pitch length of time for a map of the day, except the short espresso is more like an escalator and the latte a gondola. Guests and customers get a coffee, as well. This, however, is a very different experience. Much like the morning coffee, this tends to be

a little slower. It’s an opportunity for us to get to know our guests better, and for our guests to know us for the things we do and what we stand for. It’s a balancing segue into what might follow. A vendor meeting. A plant tour. An architectural presentation. All of the above. The act of preparing and appreciating a coffee sets the tone. If there is any doubting this, look to high-end luxury retailers like Louis Vuitton, Lexus and Emirates. They all subscribe to this business culture. In retail, it’s used to increase “dwell time” – basically keeping the customer in the store longer so they will buy more. Or it might be at the back end of the sale while you’re waiting to settle up for the new Rolex. Either way, the act of extending a co-worker, a customer or a guest a coffee that you took the time to prepare and serve is an opportunity. It’s an opportunity to talk. An opportunity to communicate. An opportunity to share ideas. An opportunity to get to know someone. An opportunity to learn.

There’s a branding message here, of course. Do you want your customers to feel like they are in Home Depot or a BMW dealership?

Let’s just say the difference between those two feelings could be the difference in how much money they are willing to fork out for your products. Getting the quality message across for better fenestration products is a challenge we all face. You need to set an atmosphere that encourages people to slow down and take the time to look at something except the price tag. And keep them awake at the same time. Coffee kills both birds with one stone.

All of this was learned over a cup of coffee almost 20 years ago, and to this day holds truer than ever. So, when a Finn offers you “santsikuppi” (another round of coffee), say yes.

Chris Meiorin is president of EuroVinyl Windows and Doors in Woodbridge, Ont.

Letting the air out

by Phil Lewin

Irecently participated in an online discussion that reminded me of an experience I had many years ago that is still a relevant window service issue today. In our industry there is a lot of attention paid to air infiltration. Of course, no one wants to be standing next to a closed window and be standing in a cold breeze blowing right through it. That cold air will ultimately result in the thermostat turning on the home’s heat source, costing money and wasting energy.

Instead, one wants to be standing next to a closed window in the dead of winter and feeling warm and toasty. So, you may be surprised when I tell you that warm and toasty feeling may be a symptom of a problem not unlike the cold breeze from air infiltration!

Many years ago, I was asked to go to a farmhouse in the dead of winter where one of the dealers I worked with at the time had installed a single window. The homeowner was unhappy with the window’s performance and the dealer could not see anything wrong with either the product or the installation.

After a trip to the middle of nowhere, I arrived at the farm house in the middle of an open field. The word “desolation” comes to mind. The owner was pleased to see me and explained that this was the sixth window, each from a different company, that she had installed and not one of them was acceptable. She did show me one window that she liked but was unable to find again. It was warm standing in front of this window.

I was then directed to my window. Truthfully, I could immediately tell that it was not as warm to stand near it. I had brought a laboratory-quality smoke gun with me. These look like a glass tube with a rubber bubble at one end. Squeeze the bubble and out of the tube will come a smoky substance that hangs in the air unless the air itself is moving. They’re great for locating drafts. Using the smoke gun, I checked the complete perimeter of the window. Then I checked the casing. I checked the hardware. There was no air leak to be found. The only air movement was a slight drop. That is normal because as air near cold glass cools, it becomes more dense and gravity pulls it down. The homeowner was not impressed, reminding

me that something had to be wrong and once again mentioning the other window.

I admit I really wasn’t thrilled to be asked to use my smoke gun on a product from another company, but the homeowner insisted that I do it. She suggested that the dropping air on my window was the problem and would not be a factor on her one prized window possession. With the smoke applied, at first glance, I didn’t see any air infiltration. Then, I looked down through the window. What I saw looked like a miniature Niagara Falls of smoke coming out the sill of the window! In fact, the window was taking all my smoke and shoving it outside. So, as the air adjacent to the window was leaving the building faster than Elvis, it was obvious what was happening. Air next to this window never had a chance to cool off before it was exfiltrated from the home. In reality, standing next to the window was a matter of standing in a warm draft of heated air. Yes, nice and toasty, but a source of significant heat loss and energy wastage.

Now I had a new problem as I had to explain to the homeowner that her most prized window was not the star that she believed. People can be so resistant when confronted with unpleasant truths. Here is what I told the homeowner: for the air pressure in your home to remain basically constant, for any air that is added, an equal amount of air has to leave. I pointed out that even in her old home, she had air return grates built into her floors. Hot air enters a room and the colder air is expected to leave, back into the system where the remaining heat would be recycled. Her home was not circulating air efficiently and heat was being lost through the windows.

It all came down to air flow. The moral of the story is, when trying to diagnose an issue, one has to look at the entire building envelope and not just a single component in order to get an accurate picture.

Phil Lewin is sales and marketing manager for GEM windows. He’s been annoying people in the window industry since 1984.

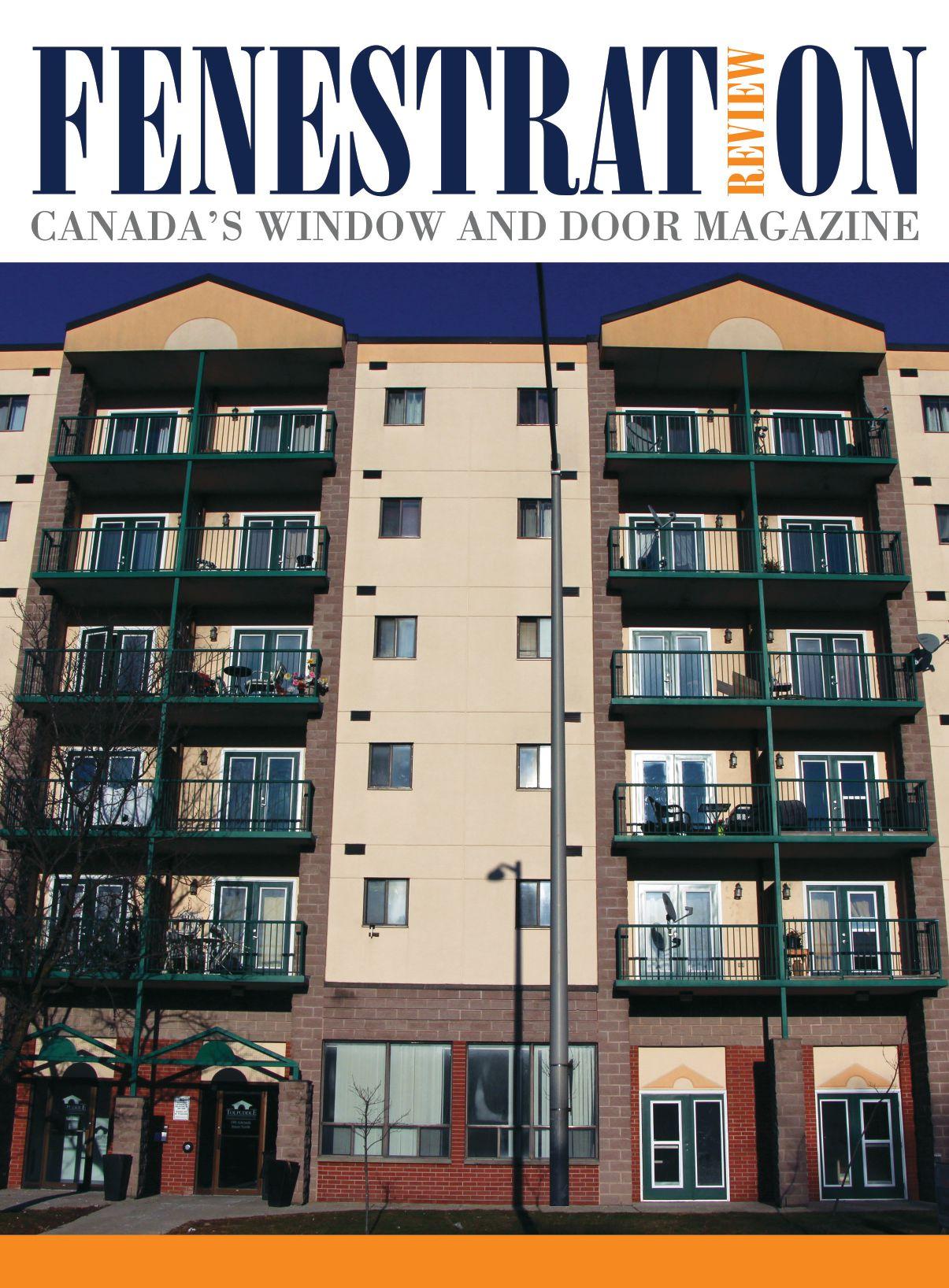

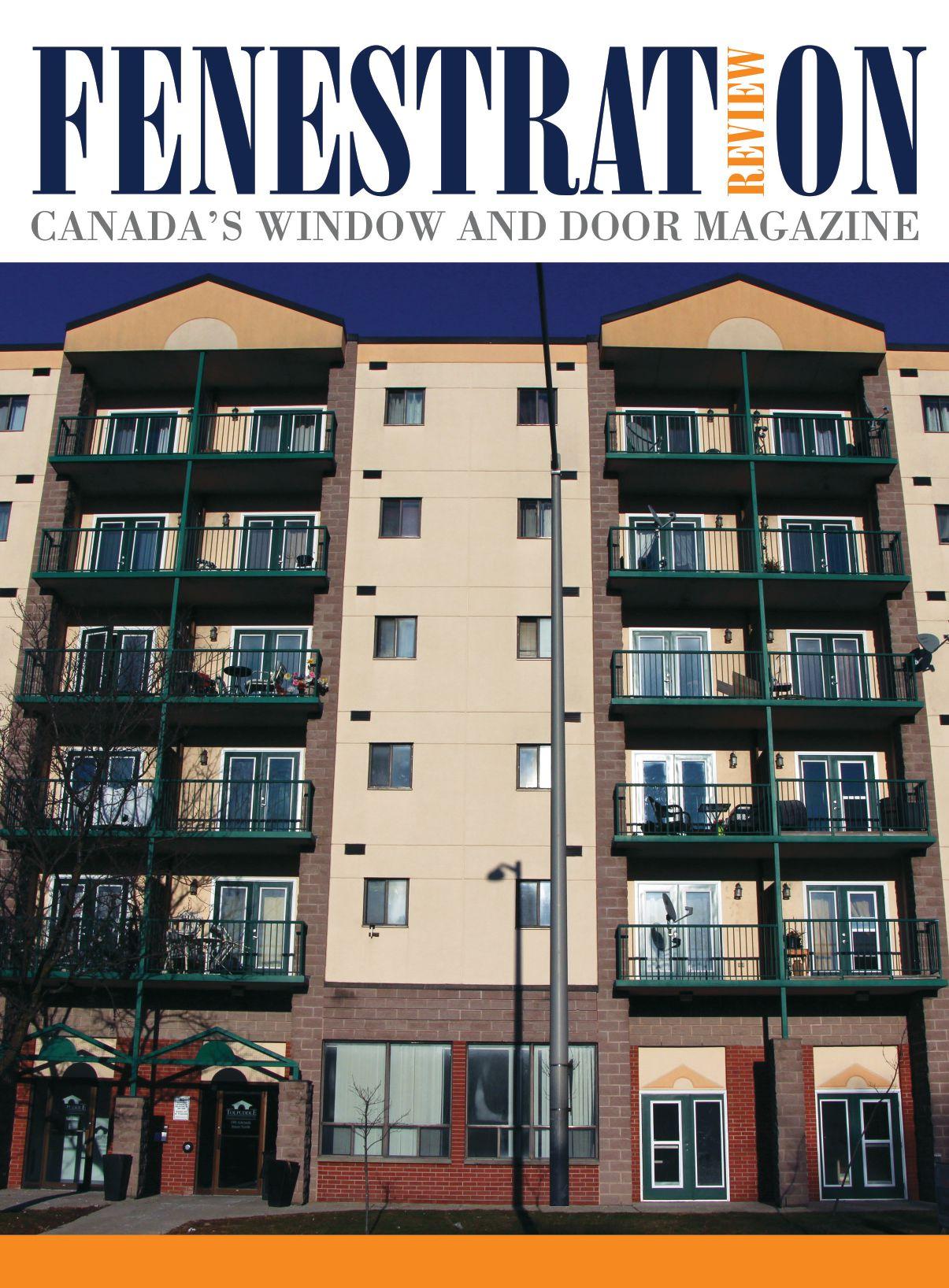

COVER STORY

MANAGING MULTIS

What’s the difference? A lot.

When it comes to supplying single-family homes and multi-unit projects, manufacturers and installers are dealing with two very different beasts.

by ANDREW SNOOK

From project planning and design to quoting, installation, servicing and logistics, there can be many different challenges for installers and manufacturers to take into consideration.

“When doing a single-family home supply, you do the quotes, do the job, ship to site, and you’re basically done,” says Terry Adamson, president of Fenestration Canada and technical director at Westeck Windows & Doors in Chilliwack, B.C. Adamson’s company focuses on the single-family home market. He says multi-unit projects in B.C. require a great deal more planning, including pages and pages of specifications to review, engaging the services of engineers, field shop drawings, and on-site testing after products are delivered and installed. And to make things even more challenging, it’s a price-driven market.

“It’s a very challenging market to be in,” he says. “If you’re doing spec multi-family – three-, four-, five-storey residential – price is everything. If you have a problem at the end of the job, you’re not making any money.”

KNOW THE CODE REQUIREMENTS

When it comes to code requirements, there are differences that manufacturers need to consider when suppling windows for single-family homes and buildings up to three storeys (Part 9 of the National Building Code), compared to supplying multi-family units (Parts 3, 4 and 5).

“Most residential window manufacturers are supplying single-family homes – maybe townhouses, maybe small multi-family projects that aren’t too large, up to three storeys – they’re basically selling windows, factory tested, with labels on them. They don’t normally have to get engineers involved in what they’re doing. The energy

performance requirements are stated in the code, their products should be labelled with those values, and it’s a fairly simple business compared to doing work on larger, multi-family unit buildings that are designed under parts 3, 4 and 5 of the code,” explains Al Jaugelis, technical director with Fenestration Canada. “At that point, you’re dealing with architects and, depending on whether you’re getting into mid- or high-rise buildings, you’re dealing with higher wind loads. You’re probably going to have to provide shop drawings with those windows. You might need to have an engineer review the drawings and the glass, and how the windows and doors are attached to the building. You may also have enclosure engineers very concerned about how you install those products on that building. You have more professionals looking at what you’re doing and expecting you to know more about how you comply with the code when dealing in the big leagues.”

QUOTING CONSIDERATIONS

When it comes to the standards testing for products, Jaugelis says there’s no real difference in either market; however, you may be required to submit different types of compliance documentation.

“They might want you to anchor your projects differently. They may want you to use thicker glass, stronger than you’re using in Part 9. When bidding those projects, it’s a little bit of a different ballgame because you’re going to submit to more requirements. The standard things you do in Part 9 and the standard glass you’re using are probably not adequate for those projects,” he says. “You can end up facing unexpected costs to have to upgrade things like glass that you may never have thought

you’d have to do, if doing this for the first time.”

Jaugelis says that companies that are used to bidding on jobs for larger multiunit projects know what to expect, but some companies jumping into the market for the first time get hit with very unexpected and expensive results.

“In much of Canada, it is the expectation that the window supplier has a registered professional engineer – registered in the province that they’re working – that will review their shop drawings and make sure that the right glass strength is there,” he says. “They will look at how your products are anchored and how many screws you need and tell you how to fasten them. You may not be able use your standard anchoring method. The engineer may be obliged by professional responsibilities under Part 4 of the code to deal with things like guard loads on glass and has to upgrade the glass so that the glass is strong enough to handle the specified guard load that would apply to the windows.”

Project teams in charge of these types of larger builds will expect the window and door manufacturers and installers to know these types of things, so companies have to

make sure they’re prepared and bid accordingly. Jaugelis suggests that companies cultivate relationships with the engineers in their areas who handle window and door products for these types of buildings.

“Discuss with an engineer the kinds of things you’re going to do, because if you’re going to bid your first job, you better have that engineer approve your glass that you’re planning to include in your quote. You better have the engineer approve what you’re going to do, because you may be seriously underbidding what will be expected,” he says.

Shannon Ruffell of Heritage Renovations based in London, Ont., says that one of the other challenges related to quoting larger projects is that you’re trying to find the best product match based on a group of people instead of a single family.

Benoit Dubord’s company, Portes et Fenetres President in Longueuil, Que., which specializes in the replacement and renovation condo market (up to four storeys), experiences similar challenges. He says the big difference between serving the single-family home market and multi-unit projects is related to ownership.

“The decisions are taken by multiple

owners who don’t necessarily have family ties and may have different interests. Some of them are retirees who want to live there for the rest of their lives, and some are younger families who will move within the next two years,” Dubord says. “Some might be focused on immediate cost of replacement and others on maintenance in the future. It’s a challenge because all condos don’t work the same. If you have six owners, you have six involved in the process.”

INSTALLATION CHALLENGES

When it comes to installing windows, multi-unit projects typically present far more challenges.

“The scale is the major difference,” says Ruffell, who adds that coordinating installation for 100 to 150 window and door replacements across multiple units, tenants and owners can present a variety of challenges when trying to complete a project in a timely fashion. “People are going on vacation, some people are there or not there, some people are owners while others are renting.”

Dubord says the “human aspect” of installations in existing buildings is a major factor to consider.

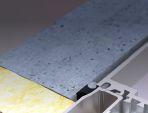

Gearing up to supply multi-unit projects can demand changes to your designs, your installation methods, your shipping and your sales approach. Plus, you’ll have to learn a whole new code language. Photo: Heritage Windows and Doors

PROUDLY CANADIAN SINCE 1989

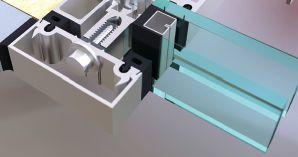

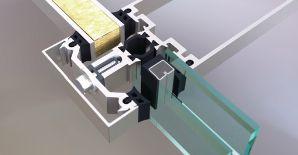

COMMDOOR ALUMINUM: RESHAPING BOUNDARIES

THE SPECIALIST IN CURTAIN WALLS, WINDOWS AND DOORS

With our transparent approach, we have been serving the commercial and industrial demand for architectural aluminum products since 1989. A proud member of the Toro Aluminum Group of Companies.

CURTAIN WALL

FIXED WINDOW SERIES

HIGH PERFORMANCE CURTAIN WALL

ENTRANCE FRAMING

OPERABLE WINDOWS

SLIDING AND BI-FOLD

SWING DOORS

MISCELLANEOUS PRODUCTS

QUALITY PRODUCTS, INNOVATIVE DESIGNS AND A LASTING RESULT.

With a long and successful history in the commercial glazing industry, Commdoor Aluminum provides high-quality architectural aluminum building products for engineers, architects, glazing contractors, designers and building owners.

COVER STORY

As with single homes, multi-unit projects exist on a spectrum from basic to luxury. Your skills as a custom builder can translate in some cases. Photo: Westeck Windows and Doors

“You get into people’s homes, living rooms, bedrooms, so people often need to understand how we will manage the work, the schedule, and what we have to do,” he says, adding that you need to have a plan in place to answer those questions when bidding for these types of multi-unit projects.

Dubord adds that new builds tend to offer much simpler installation than renovations and replacements on existing builds.

“The landscaping has not been done; you can use a crane whenever you want to manoeuvre around the building. In the renos that can sometimes be challenging,” he says. “Some places where you’ll have to use a ladder or a product you will assemble on site. You have to have a system for new builds and a system for existing markets, they’re two different beasts.”

Mike Bruno of the Everlast Group of Companies in Etobicoke, Ont., agrees that there is a difference between the two types of installations.

“It’s great to bring in eight-foot by eightfoot sliding doors when under construction, but when the house is completed, it’s a little bit different to manoeuvre in there. Typically you’ll have narrow stairs that are steep, and when you walk up the stairs you hit a wall, which is now going to increase your service fees,” he says. “We’re having a challenge right now on multis where we

Logistics is one main difference in the multi-unit business. Bigger batches, bigger shipments and bigger warehouses are all part of the

don’t have elevator access. The entry points are farther from the units with not enough room for installation trucks. Storing windows on site becomes challenging.”

One exception when it comes to single-family homes offering bigger challenges can be in the custom-built market. Adamson’s company focuses on a lot of custom installations for single and smaller multi-family units.

“Five years ago, we were doing a lot more apartment style, multi-units but the margins were so slim we just got out of it,” he says. “We do more Passive House projects: multi-unit projects that are unique and something custom that other spec-type suppliers aren’t prepared to offer.”

Adamson says expectations for these types of installations and future servicing differ a great deal from installation a typical spec window.

“When you’re doing simple windows, they’re less problems,” he says. “Revenue for a single-family [custom] job can be significant, but that can lend itself to challenges after the fact. When you’re spending $150,000 on a window and door package for an upper-end client, expectations are different.”

LOGISTICS

Single-family projects come with simple shipping solutions due to the small amount

of product typically being moved. Multiunit projects are another matter.

“In a lot of cases, we’re having to send out frames on one truck, send out glass on another truck, and have more people unload the product,” Bruno says.

Heritage Renovations recently invested in a new warehouse to accommodate their larger orders.

“We just moved into a new 25,000-square-foot facility, so we’re able to warehouse larger projects,” Ruffell says. “Before we would take in quadrant by quadrant, or floor by floor, but now we can take in more product.”

MARKETING

When it comes to marketing your company to the single-family and multi-unit markets, the key is to treat all your clients as potential returning clients, regardless of size, and let them do the marketing for you, according to Ruffell. She says that Heritage Renovations relies a great deal on building on its good reputation and growing through word of mouth, and that her company has been recommended for larger projects by both clients and manufacturers.

“All of our customers we really work with based on them being repeat business, everyone has that potential. We always try and go above and beyond,” Ruffell says.

picture. Photo: Portes et fenetres President

Introducing FGIA

by Margaret Webb, director of glass products and Canadian industry affairs

As of Jan. 1, the Insulating Glass Manufacturers Alliance and the American Archiectural Manufacutrers Association have combined to evolve into the Fenestration and Glazing Industry Alliance following two years of widely publicized discussion, intense dialogue, shirt sleeves rolled up and member presentations. The staff and boards of directors of both organizations have been in high drive, bringing the best of the two organizations together, nominating the FGIA inaugural board of directors and the Steering Committee members. It’s been a lot of activity leading up to Dec. 31 so that FGIA was ready to launch Jan. 1, and launch we did.

The face of the industry has changed over the past 20 years. There are a lot more product offerings not only in traditional double-glazed insulating glass units but also dynamic glazing, increased stringency in building and energy codes, material sustainability and more.

I started with the Insulating Glass Manufacturers Association of Canada prior to its merger with the Sealed Insulating Glass Manufacturers Association. It was a time of great change for the Canadian and U.S. members of both associations. It was a successful transition combining not only the two organizations but the cultures as well. That transition, merging the two cultures, took about 18 months. In spite of some of the member concerns about what the new organization would look and feel like, IGMA was a very successful undertaking.

It was a very different time in 2000 compared to today. Every aspect of FGIA was discussed and planned down to the smallest detail prior to balloting the two memberships. (In the case of the IGMAC-SIGMA merger, nothing was heavily planned in advance.) The 18 months following the successful vote was dedicated to establishing the new management, the new structure and determining staff positions. In establishing FGIA, we are well ahead of the game.

While FGIA is the name of the new organization, the IGMA, IGMAC and AAMA

brands are continuing indefinitely and will serve as the lead brands for publications and product certification. We may have a new name but, in reality, all programs and services including task groups will continue the same as they have. The IGMAC certification program also continues as it always did – task groups are continuing to meet and work on their documents and the IG Fabricator Workshop is scheduled for Nov. 10 to 12. I believe there will be more things familiar than different.

So, as my position as IGMA executive director winds down and my role as the FGIA glass products and Canadian industry affairs director gears up, I find myself reflecting on the past 20 years. IGMA started with two committees and a handful of task groups. Since 2001, we have increased our scope of activity to include codes and standards in Canada and the U.S. as well as participation in the ISO standards development world. We are engaged in research and development funded by the membership and have embraced new training methods while keeping some of the past. While we increased our scope dramatically, the size of the staff did not increase. A number of activities by necessity had to go on the back burner. Two staff can only handle so much. Now, with the resources of FGIA, the vision of what IGMA could have been will be realized.

The next year will bring changes but not as many as some may fear. Much has been retained: the research projects, certification programs, services, workshops and of course the staff. We’re located at the same offices and have the same phone numbers. Emails will change but the old ones will still work. If you have a question, give me a call – we’re here for you.

Change is inevitable. However, change managed properly opens new avenues and opportunities for growth. IGMA and AAMA will be stronger together and provide a powerful voice for the fenestration industry on both sides of the border.

Come join us. Be the voice of change and have a voice in the future.

FENESTRATION CANADA

What a year

2019 saw huge progress. We’re looking to build off that.

by Stephane Labelle, Fenestration Canada executive director

What a year 2019 was! It went by so fast and yet we got so much done. In the span of 12 months, Fenestration Canada strengthened its presence all across the country with the addition of the regional committees, protected our members interest while making sure our industry evolved and stayed relevant and hosted several successful events in Canada and the United States.

When Terry Adamson took over as president, he made a point of making sure Fenestration Canada would be the voice of our industry in the whole country. Our efforts paid off with several new members from all across Canada. This year, we are pushing it even further by offering 10 regional events, for free, for all members. This is the perfect occasion for all of you and your staff to stay up to date with the constant changes happening in our industry. It is also where you will be able to meet with our new technical director, Al Jaugelis. Prior to joining Fenestration Canada, Al provided consulting services on fenestration performance matters, initiated several research projects on window energy performance, and supported window and door manufacturers with practical NAFS test planning and code compliance challenges. Al is also a voting member of the CSA A440 Committee, a member of the NRC Energy Efficient Fenestration Steering Committee and the Fenestration Canada Technical Services Committee.

Recognized as an authority on the North American Fenestration Standard (NAFS), he writes about it on the “NAFS in Canada” blog. His role with Fenestration Canada is to support the industry by sharing his technical expertise, skill, and insights into developing a world class window and door manufacturers association. Al is also a great asset to myself and the board to liaise with industry stakeholders and to provide

the most up-to-date information and expertise on federal and provincial industry regulations.

On my side, on top of my regular management duties, I will keep traveling from east to west to make sure I get a chance to talk with as many of you as possible. It is a priority for me to always have a clear picture of what is going on on the field so we can adjust our initiatives to serve you in the best way possible.

As Terry Adamson becomes past president in June, Mike Bruno will take over the role of president. Mike was always vocal about the fact that manufacturers should be as involved as possible in Fenestration Canada’s activities and that our suppliers should support us in keeping the industry healthy. We need everyone’s input and support to keep this organisation strong and that is what we ask from you: involvement and support. I am really grateful for everything we accomplished in 2019 and also really excited about everything that is coming in 2020.

Mark your calendars for these upcoming Fenestration Canada events...

Our Spring Conference takes place June 3 to 6 in beautiful Charlottetown, P.E.I. This location has created a buzz! Everyone is looking forward to the relaxed atmosphere and scenic beauty of the Island. Come for the lobster, stay for the exclusive networking and education opportunities guaranteed to help your business.

Speaking of buzz, everyone’s going to be talking about WinDoor 2020. Why? We’re holding it at a very special new venue: Olympic Stadium in Montreal! That’s right, you are going to be able to shop for new hardware on the very ground where Larry Walker and Vladimir Guerrero played.

Dates and locations for our regional events will be coming to your inbox soon. Come out, get a free lunch and an update on the association and industry issues.

See you there!

A & D PRÉVOST

305 12e avenue Richelieu

Richelieu, QC, J3L 3T2

Tel: (450) 658-8771

Contact: Claude Cardin

Email: ccardin@prevost-architectural.com www.adprevost.ca

AABEN WINDOWS AND DOORS LTD.

700 Progress Ave

Kingston, ON, K7M 4W9

Tel: (613) 384-3163

Contact: Michael Braby

Email: michael.braby@aaben.com www.aaben.com

ADFAST CORP.

2685, Diab street

St-Laurent, QC, H4S 1E7

Tel: (517) 617-1579

Contact: Denis Perron

Email: denis.perron@adfastcorp.com www.adfastcorp.com

AERLOC INDUSTRIES LTD.

64 Head Street

Dundas, ON, L9H 3H7

Tel: (905) 628-6061

Contact: Edward Laman

MEMBER DIRECTORY

AMERI-CAN MACHINERY

5-2650 Meadowvale Blvd Mississauga, ON, L5N 6M5

Tel: (905) 542-2055

Contact: Yolanda Sangiuliano

Email: yolanda@ameri-can.ca www.ameri-can.ca/

AMESBURYTRUTH

125 AmesburyTruth Drive Statesville, NC, 28625

Tel: (800) 866-7884

Contact: Donna Cockrell

Email: donna.cockrell@amesburytruth.com www.amesburytruth.com

Andersen Corporation

100 FOURTH AVENUE NORTH

Bayport, MN, 55003-1096

Tel: (651) 264-5570

Contact: Mark Mikkelson

Email: mark.mikkelson@andersencorp.com www.andersenwindows.com/

ANDERSON WINDOWS

46 Cheryl Crescent, P.O. Box 510 Sundridge, ON, P0A 1Z0

Tel: (705) 384-5341

Contact: Cheryl Anderson

Email: sherianderson@bellnet.ca www.andersonwindows.ca

ANIG WINDOW MANUFACTURING

LIMITED

2040 Ellesmere Road, Unit # 1 Scarborough, ON, M1H 3B6

Tel: (416) 438-7213

Contact: Enzo Angheloni

AGC GLASS NORTH AMERICA

11175 Cicero Drive, Suite 400 Alpharetta, GA, 30022

Tel: (647) 216-9743

Contact: Marilyn Moore

Email: marilyn.moore@ca.agc.com www.us.agc.com

ALL WEATHER WINDOWS LTD.

18550 - 118A Avenue NW Edmonton, AB, T5S 2K7

Tel: (780) 451-0670

Contact: Tracy Nadiger

Email: tnadiger@allweatherwindows.com www.allweatherwindows.com

ALLSCO WINDOWS AND DOORS

70 Rideout Street

Moncton, NB, E1E 1E2

Tel: (506) 853-8080

Contact: André Doiron

Email: adoiron@allsco.com www.allsco.com

AMBERWOOD DOORS INC.

191 Attwell Drive, Unit 3 Toronto, ON, M9W 5Z2

Tel: (416) 213-8007

Contact: Colin Fraser

Email: cfraser@amberwooddoors.com www.amberwooddoors.com

Email: enzo@anigwindows.com www.anigwindows.com

AQUASURTECH OEM

2148 Trans-Canada Highway Dorval, QC, H9P 2N4

Tel: (514) 684-2628

Contact: Michael Braeuel

Email: mbraeuel@aquasurtech-oem.com www.aquasurtech-oem.com

ARMWOOD WINDOWS & DOORS Highway 1A West, P.O. Box 8

Portage la Prairie, MB, R1N 3B2

Tel: (204) 856-2320

Contact: Brent Otsuji

Email: brent@armwood.ca www.armwood.ca

ATIS

Solar-3400 Rue de l’Éclipse-Local 420

Longueuil, QC, J4K 5G4

Tel: (418) 881-3950

Contact: Francois Lafortune

Email: francois.lafortune@atisgroup.ca www.atiscanada.com

ATLANTIC WINDOWS LTD.

49 East Main Street

Port Elgin, NB, E4M 2X9

Tel: (506) 538-2361

Contact: Greg Dickie

Email: greg.dickie@atlanticwindows.com www.atlanticwindows.com

AURORA WINDOW SYSTEMS INC.

535 Manitou Rd. SE, Calgary, AB, T2G 4C2

Tel: (403) 291-2851

Contact: Kent Schultz

Email: kent@aurorawindowsystems.ca www.aurorawindowsystems.ca

BASCO WORLD

1141, rue Reynald

Laval, QC, H7W 1N2

Tel: (514) 241-9686

Contact: Nathalie Gaudreau

Email: marketing@bascoworld.com www.bascoworld.com/

BERDICK WINDOWS & DOORS

404 Roblin Boulevard Winkler, MB, R6W 0N4

Tel: (204) 325-8053

Contact: Victor Soto

Email: victor@berdick.com www.berdick.com

BONNECHERE VALLEY WINDOWS LTD.

2824 Fourth Chute Road, RR# 6

Eganville, ON, K0J 1T0

Tel: (613) 628-3056

Contact: Andreas Vornweg

Email: andreas@b-v-w.com www.b-v-w.com

BROWN WINDOW CORPORATION

185 Snow Boulevard

Concord, ON, L4K 4N9

Tel: (905) 738-6045

Contact: Dennis Ostapovich

Email: info@brownwindow.com www.brownwindow.com

CADWIN LTD.

180 Trowers Rd, Unit 27

Woodbridge, ON, L4L 8A6

Tel: (905) 264-8270

Contact: Robert Casinelli

Email: robert@cadwin.ca

CAN-BEST TESTING LABORATORIES

38 Regan Road, Unit 4

Brampton, ON, L7A 1C6

Tel: (905) 840-2014

Contact: Elie Alkhoury

Email: elie@can-best.com www.can-best.com

CARDINAL GLASS INDUSTRIES

534 Wasaga Crescent

Waterloo, ON, N2V 2Y8

Tel: (519) 590-3194

Contact: Mike McAndrew

Email: mmcandre@cardinalcorp.com www.cardinalcorp.com

MEMBERDIRECTORY

CARTONS CORRUGUARD

101 Des Ateliers

Lavaltrie, QC, J5T 3R3

Contact: Marie-Helene Hotte

Email: mhhotte@cartonscorruguard.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Rd

London, ON, N5V 4K8

Tel: (519) 451-0508

Contact: George Warren

Email: george.warren@centennialwindows.com www.centennialwindows.com

CERTIFICATION CONSULTANT

562 Fallingbrook Drive

Waterloo, ON, Tel: (519) 570-6917

Contact: Pauline Richards

Email: prichards.ap@gmail.com

CLEARBROOK GLASS 2007 LTD.

33470, South Fraser Way

Abbotsford, BC, V2S 2B5

Tel: (604) 854-1327

Contact: Bruce Friesen

Email: bruce@clearbrookglass.ca www.clearbrookglass.ca

CLEARVIEW INDUSTRIES LTD.

45 Fenmar Dr. Toronto, ON, M9L 1M1

Tel: (416) 745-6666

Contact: Tom Marsala

Email: tmarsala@clearview.on.ca clearview.on.ca/

CLEB LABORATORY INC.

1320, Lionel-Boulet Blvd. Varennes, QC, J3X 1P7

Tel: (514) 923-6611

Contact: Robert Jutras

Email: rjutras@cleb.com www.cleb.com

COLOUR ALLIANCE INC.

8 - 60 Healey Rd

Bolton, ON, L7E 5A6

Tel: (905) 857-8072

Contact: James Martin

Email: james@colouralliance.ca

COMPONEX

Unit 6 - 329 Rayette Rd

Concord, ON, L4K 2G1

Tel: (647) 367-0006

Contact: Maxim Zolotarev

Email: info@componex.ca www.componex.ca

CONTINENTAL

Salinenstrasse 1 Weissbach, 74679 Germany

Tel: (540) 550-4596

Contact: Marco Patterman

Email: marco.patermann@gapser.com www.skai.com

CSA GROUP

178 Rexdale Road

Toronto, ON, M9W 1R3

Tel: (866) 797-4272

Contact: Mohamadou Diallo

Email: mohamadou.diallo@csagroup.org www.csagroup.org

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue

Dartmouth, NS, B2W 6A2

Tel: (902) 462-6114

Contact: Dan Darcy

Email: dan@darcyasscs.ca

DEL WINDOWS & DOORS

241 Arvin Ave

Stoney Creek, ON, L8E 2L9

Tel: (905) 561-4335

Contact: Ed Bremer

Email: ebremer@delwd.ca delwd.ca

DOORCOM

285 Vaughan Valley Blvd. Woodbridge, ON, L4H 3B5

Tel: (905) 850-5352

Contact: Daniel Sardella

Email: daniel@wintek.ca www.doorcom.ca

DOORSMITH (A DIVISION OF CANSAVE)

411 Bayview Drive

Barrie, ON, L4N 8Y2

Tel: (705) 722-7283

Contact: Ryan Eccleshall

Email: ryane@cansave.ca www.cansave.ca

DORPLEX INDUSTRIES LTD.

100 Norfinch Drive

Toronto, ON, M3N 1X1

Tel: (416) 744-3667

Contact: Paul Moseley

Email: paul@dorplex.com www.dorplex.com

DUFFERIN WINDOWS LIMITED

115 Centennial St.

Shelburne, ON, L9V 2Z4

Tel: (519) 925-3111

Contact: Karen McCabe

Email: karen@dufferinwindows.ca www.dufferinwindows.ca

DURABUILT WINDOWS & DOORS INC.

10920 178 Street NW Edmonton, AB, T5S 1R7

Tel: (780) 577-2004

Contact: Sami Sakalla

Email: samis@durabuiltwindows.com www.durabuiltwindows.com

DUXTON WINDOWS & DOORS

45 Higgins Avenue Winnipeg, MB, R3B 0A8

Tel: (204) 339-6456

Contact: Al Dueck

Email: apdueck@duxtonwindows.com www.duxtonwindows.com

E J MACHINE SALES & SERVICE INC.

20 Barr Rd.

Ajax, ON, L1S 3X9

Tel: (905) 427-3400

Contact: Melissa Colquhoun

Email: melissac@ejindustries.ca

ELEMENT MATERIALS TECHNOLOGY

INC. CANADA (FORMERALY EXOVA) 2395 Speakman Drive

Mississauga, ON, L5K 1B3

Tel: (905) 822-4111

Contact: Jennifer Wren-McDonald

Email: jennifer.wrenmcdonald@element.com www.element.com

ELTON MANUFACTURING

8400 Lawson Road, Unit 2 Milton, ON, L9T 0A4

Tel: (905) 876-1290

Contact: Andrew Beavan

Email: sales@eltonmanufacturing.com www.eltonmanufacturing.com

ENDURA PRODUCTS INC.

8817 W. Market St. Colfax, NC, 27235

Tel: (336) 668-2472

Contact: Mark Fortun

Email: mfortun@enduraproducts.com

ENERGI FENESTRATION SOLUTIONS

3035, boul. Le Corbusier Laval, QC, H7L 4C3

Tel: (450) 687-5115

Contact: Diane Loisel

Email: diane.loisel@energifenestration.com www.energifenestration.com/

ENTRYGUARD DOORS INC.

8150 Keele Street Concord, ON, L4K 2A5

Tel: (905) 532-0740

Contact: Frank Luccisano Email: frank@entryguarddoors.com www.entryguarddoors.com

EUGÉNIE WORLD INC.

1167 rue Nationale Terrebonne, QC, J6W 6H8

Tel: (450) 964-1616

Contact: Jonathan Chauvette

Email: jonathan@eugenie.world

EURO VINYL WINDOWS & DOORS INC.

167 Caster Avenue, Unit 8 Woodbridge, ON, L4L 5Y8

Tel: (905) 851-9711

Contact: Chris Meiorin

Email: chris@evw.ca www.evw.ca

LOTHAR’S INDUSTRIAL SALES

2717 Rena Rd.

Mississauga, ON, L4T 3K1

Tel: (905) 678-2397

Contact: Sarah Colberg

Email: info@lothars.ca

LUX WINDOWS AND GLASS LTD.

6875 - 9 St. NE

Calgary, AB, T2E 8R9

Tel: (403) 276-7770

Contact: Norma Ambrogiano

Email: norma@luxwindows.com

MARITIME DOOR & WINDOW

118 Albert Street

Moncton, NB, EIC 1B2

Tel: (506) 383-7114

Contact: Michael Mann

Email: mike.mann@maritimedw.com www.maritimedw.com

MARLBORO WINDOW & DOOR MFG. LTD.

2370 Stevenage Drive

Ottawa, ON, K1G 3W3

Tel: (613) 736-1441

Contact: David Dubrofsky

Email: david@marlborowindows.com www.marlborowindows.com

MARTIN WINDOWS AND DOORS

205 Fraserville

Riviere du Loup, QC, G5R 5M3

Tel: (418) 867-3222

Contact: Martin Emond

Email: memond@windowsmartin.com www.windowsmartin.com

MARVIN

1455 Courtneypark Drive E Mississauga, ON, L5T 2E3

Tel: (905) 670-5052

Contact: Brad Fevold

Email: bradfev@marvin.com www.marvincanada.com

MASONITE INTERNATIONAL

2771 Rutherford Road

Concord, ON, L4K 2N6

Tel: (800) 798-3667

Contact: Mark Woolnough

Email: mwoolnough@masonite.com www.masonite.com

MASTERGRAIN C/O WEBER

MANUFACTURING TECHNOLOGIES INC.

16566 Highway 12, P.O. Box 399

Midland, ON, L4R 4L1

Tel: (416) 917-1007

Contact: Lyn Jauncey

Email: lyn.jauncey@mastergrain.com www.mastergrain.com

MEMBERDIRECTORY

MAXAM/MAXFEN

C.P 252

Saint-Bruno, QC, J3V 4P9

Tel: (450) 723-1257

Contact: J.F. Kogovsek

Email: jfk@maxammarketing.com www.maxammarketing.com

MENNIE CANADA

111 Advance Blvd.

Brampton, ON, L6T 4H8

Tel: (416) 748-0088

Contact: Kinson Cheung

Email: kinson@menniecanada.com menniecanada.com/

MENUISERIE BASQUE & FILS LTEE.

390, rue Snowball, C.P. 3609 Succ. Bureau

Chef

Tracadie-Sheila, NB, E1X 1G5

Tel: (506) 395-2733

Contact: Alderic Basque

Email: mbf@nbnet.nb.ca

MILLCRAFT SYSTEMS INC.

369 Concession Rd 6 E

Millgrove, ON, L0R 1V0

Tel: (905) 689-9502

Contact: Lauren Malek

Email: lauren@millcraftsystems.ca millcraftcustomwindows.com

MORRISON WINDOWS LTD. 8400 124 Street

Surrey, BC, V3W 6K1

Tel: (604) 539-1315

Contact: Gurtej Dhillon

Email: gdhillon@morrisonwindows.ca www.morrisonwindows.ca/

MOUSTIQUAIRES MSA SCREENS

690, chemin Olivier

Levis, QC, G7A 2N2

Tel: (418) 831-3035

Contact: Jean-Robert Mathieu

Email: jrmathieu@moustiquairesmsa.com www.msascreens.com

MSR WEATHERSTRIPPING INC.

115 Cowan Court

London, ON, N6C 5E3

Tel: (519) 871-5088

Contact: David MacDougall

Email: msrweatherstripping@gmail.com

NAMI INC.

4794 Washington Memorial Highway

Hayes, VA, 23072

Tel: (804) 684-5124

Contact: Account Payable

Email: nami@namiinc.com www.namicertification.com

NATURAL RESOURCES CANADA

Contact: Maggie Johnston

Email: maggie.johnston@canada.ca

NEWMAR WINDOW MANUFACTURING INC.

7630 Airport Road

Mississauga, ON, L4T 4G6

Tel: (905) 672-1233

Contact: Carlos Martins

Email: cmartins@newmar.com www.newmar.com

NIRI HOME LTD. / DOOR DEPOT CANADA

3620B Laird Road, Unit 9

Mississauga, ON, L5L 6A9

Tel: (905) 820-5757

Contact: Adam Jiang

Email: adamj@doordepotcanada.com www.doordepot.canada.com

NORTH STAR WINDOWS & DOORS

40684 Talbot Line

St. Thomas, ON, N5P 3T2

Tel: (519) 637-7899

Contact: Gary Husen

Email: ghusen@northstarwindows.com www.northstarwindows.com

NORTHERM WINDOWS & DOORS

1-17 Burns Road

Whitehorse, YT, Y1A 4Z3

Tel: (867) 668-5088

Contact: David Borud

Email: dart@northerm.yk.ca

NOVA DOORS AND WINDOWS LTD.

46 Williams Avenue, Burnside Industrial Park

Dartmouth, NS, B3B 2B3

Tel: (902) 221-2406

Contact: Jason Sadler

Email: jason@novadoorsandwindows.com www.novadoorsandwindows.com

NOVAGARD SOLUTIONS

5109 Hamilton Avenue

Cleveland, OH , 44114

Tel: (330) 461-3500

Contact: Joe Borak

Email: jborak@novagard.com www.novagard.com

NOVATECH GROUP INC.

160, rue de Murano

Sainte-Julie, QC, J3E 0C6

Tel: (450) 922-1045

Contact: Robert Latour

Email: robert.latour@groupenovatech.com www.novatechgroup.com

NZP FENESTRATION

2459 rue de la Province

Longueuil, QC, J4G 1G3

Tel: (514) 360-9215

Contact: Alain Dorais

Email: a.dorais@nzpfenestration.com www.netzeroperformance.com

OCEANVIEW PATIO DOORS LTD.

5145 Steeles Ave. W., Suite B, Unit 4 Toronto, ON, M9L 1R5

Tel: (416) 741-2600

Contact: Frank Nicolazzo

Email: fnicolazzo@oceanviewdoors.ca www.oceanviewdoors.ca