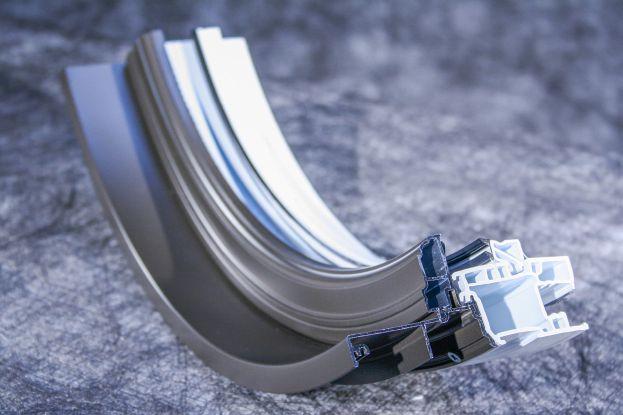

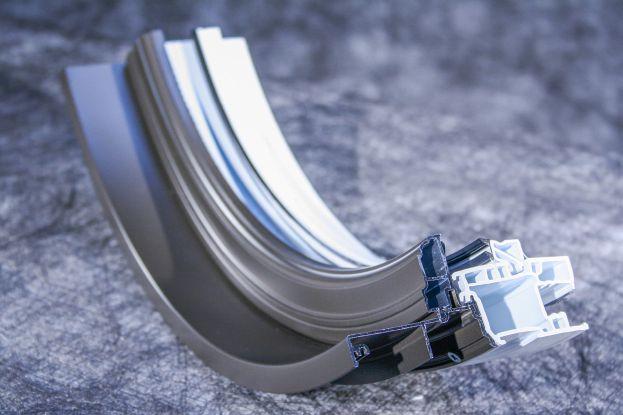

We do it all: Vinyl windows, wood windows, aluminum windows, wood jamb extension, curved wood trim and more. The customer service is one of our priorities. At PVC Architectural, you will enjoy fast delivery, high-quality products and courteous service.

We can shape more than 500 extrusions and we have them in stock. Our computerized workstations allow us to track your order at all times, which provides us with great flexibility and superior precision. PVC Architectural has a remarkable production capacity, thanks to its in-house equipment and outstanding team.

Contact us and see by yourself why PVC Architectural is the greatest leader in window shaping 1 888 404-2286 or info@pvcarchitectural.com years

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DEFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Gerry WIEBE

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

email: subscribe@glasscanadamag.com

Tel: 866.790.6070 ext. 201 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) $39.55 includes HST/QST

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

fenestrationreview.com

4

EDITORIAL

B.C.’s experience a cautionary tale in how not to implement NAFS. by Patrick Flannery

Shifting

18 LOOKING UP

THE NEXT BIG THING 3D printers are changing how fenestration profiles are designed.

Spectrum Skyworks is moving up the value chain as it takes on ever-morechallenging skylight projects. 21 FENSTRATION CANADA MEMBERS DIRECTORY

Updates on a successful 2014. by Skip Maclean

Your guide to Canada’s window and door industry.

THAT’S RICH Trade shows can help you if you do them right. by Rich Porayko

by Patrick Flannery

Good news out of B.C. recently: the provincial government is moving to standardize building requirements across the province in a new Building Act. The act, if passed in the legislature, will establish the provincial government as the sole authority to create building requirements. Presently, local jurisdictions (cities, counties and even smaller entities) have the power to make their own codes and interpret and enforce the provincial codes in ways peculiar to themselves.

The chaos this created over the past few years was predictable, especially with attempts to implement the North American Fenestration Standard (NAFS) in the province. NAFS was, to put it mildly, poorly understood by municipal building officials in B.C. despite the best attempts of organizations like Fenestration BC and Fenestration Canada to educate everyone. However, the leaky condo scandals in Vancouver lit a fire under everyone across the province to establish some kind of regulation of air and water ingress in new building fenestration. This, in an environment where building inspectors had, for the most part, not even been looking at doors and windows except to check for structural integrity. So we had a huge number (some estimates in excess of 80) of jurisdictions, each with authority to set their own building standards and desperate to avoid potentially budget-crippling lawsuits. They were hurrying to do something they had never done before with reference to a standard so complicated that few people actually building windows and doors understand it either. You probably could not have invented a situation more conducive to confusion, frustration, bureaucratic bungling and economic strangulation.

Some jurisdictions insisted on labels, without knowing what the labels should show and leaving it to individual inspectors to guess. Some accepted a letter from the fabricator

saying everything they make is NAFS-compliant and left it at that. Some invented their own labels. Some asked for certification of the installed window, not knowing that no standard exists for this under the NAFS (but one was put into the 2012 B.C. building code).

Installations got red-tagged. At least one fabricator took to making template labels and hand-writing in the test data so they would not have to make a different label for each area. Others contemplated the enormous sums they would have to spend on testing to meet each jurisdiction’s requirements and started looking for new markets. No one actually closed that I know of, but the mess has been expensive and not at all good for the B.C. fenestration industry, or the building industry generally. Let’s hope that is all behind us.

I had many interesting discussions about the B.C. NAFS experience at Windoor last November, and some of them were caught on video. You can see them online in our video Windoor recap. As you read through the digital document, you will notice there is a “play” button on some of the photos – just click that and you’ll get a clip of the interview with an option to play the full video. We have B.C. natives like Al Jaugelis and Todd Hassman telling a few, shall we say, “cautionary tales.”

Our spring edition of once again focuses on technology with a look at 3D printing, an idea that has been around for a few decades, but is showing new potential due to the exponential increases in computer processing power we now have. And we go inside Spectrum Skyworks, a Vancouver company that has done some incredible work on those windows that look straight up. You’ll find the Fenestration Canada 2015 Members Directory inside as well. It is a great resource for looking up your colleagues in the window and door industry across the country, and for finding suppliers who have demonstrated their commitment to Canadian fenestration.

Centennial Windows has been awarded the Energy Star 2014 Manufacturer of the Year by Natural Resources Canada. Founded in 1981 in London, Ont., Centennial Windows and Doors is a family-owned and operated business. In the early 1990s, Centennial began development of a window system that would later become one of the most energy efficient systems in Canada. The company expanded its product line in 2009 to include doors, and currently offers hundreds of Energy Star-qualified glass inserts for steel and fibreglass doors. The first window

company in Canada to promote and sell Canadian Energy Star-qualified windows, Centennial offers an end-to-end service: manufacturing, selling, installing and servicing its own complete line of energy efficient windows and doors. Its entire window line and 96 per cent of its door line is Energy Star-qualified. The number of qualified models offered by Centennial increased three-fold from 2012 to 2013. The company takes every opportunity to educate consumers on the benefits of energy-efficient products, using Energy Star as the basis for all its sales and marketing programs. It has also been an advocate of third-party testing and labeling of energy efficient products for decades and its windows were the first in Canada to carry the CSA label.

Centennial Windows & Doors has received four Energy Star recognition awards: twice as Manufacturer of the Year of fenestration products, once as Retailer of the Year and for Sustained Excellence in 2008.

In other Centennial Windows news, the company has just taken the wraps off a new, 80,000-square-foot manufacturing facility located just behind its previous plant and showroom in London, Ont. Centennial employs about 150 workers making Energy Star-qualified vinyl windows, fibreglass and steel doors and patio doors for the replacement/renovation markets.

“It’s amazing what we achieved,” owner George Warren told the London Free Press. “This has been a tremendous year. We are blessed. We have had phenomenal growth over the last five years.”

Started by Albert Spanier in 1936, Calgary Sash and Door has made high-end wood windows and doors in Alberta for 79 years. Now, Ralph Spanier, Gord Spanier and Lorie Gibson have announced the company will exit the window and door business, citing difficulty finding workers with the woodcrafting skills necessary to maintain their standards. The announcement was made in the following release addressed to “Friends”:

“After 79 adventurous years, we, the Spanier family, have decided the time has come for us to exit the window and door business.

“Consequently, Calgary Sash and Door Limited will cease accepting new orders as of 4:00 pm, Thursday, Feb. 12, 2015. This may seem sudden, but it is a decision we have been pondering for a very long time.

“The reasons are many, not the least of which is the absence of skilled workers to succeed the dedicated craftsmen who have been responsible for creating the finest windows and doors in any market.

“All orders currently in production will be completed by March 27, 2015. For orders presently completed please contact our office before March 6, 2015, to arrange for pickup. We ask that you submit all unpaid amounts within your normal terms of payment.

“Of course, any warranty obligations to our customers will be honoured as we expect our suppliers to honour all of their warranties to us.

“We are grateful for your loyalty and will always fondly recall all of the exceptional business we did together.”

Effective immediately, Azon will no longer produce the warm-edge spacer product Warm-Light for insulating glass.

According to David Mills, Azon CEO, “Even though we believe the product to be the very best spacer for thermal and structural performance, we simply are not able to produce the material in our plant in a cost-efficient manner and we are unable to improve margins and still remain competitive in the marketplace.”

The Michigan-based company is appreciative of the many customers who chose the product for use in fabricating insulating glass over the past 20 years.

Azon continues to be a leader in technology for the manufacture of thermal barrier aluminum fenestration, commonly referred to as the pour and debridge method with the growing network of aluminum extruders and window manufacturers worldwide.

Fenestration Manitoba continued its development program with the launch of the first of a series of seminars – the CSA Fenestration Installation Technician Level I - on January 28th at Red River College, headlined by David Mitten, executive director of SAWDAC.

“We see some inconsistencies in the installation activities in both new construction as well as replacements,” says Ryan Dudeck, president of Fenestration Manitoba. “We have even been asked to get involved by groups such as Manitoba Home Builders and the New Home Warranty program. We felt this was an excellent opportunity to deliver an established program.”

In attendance was a wide range of industry members, ranging from manufacturing owners to commercial glazing installers and managers to service managers, technicians and hands-on retrofit installation. There were 27 people in attendance, five installers and the rest window manufacturing staff.

And, it would appear the plan was correct. The classroom quickly sold out and FenMan proceeded to also bring in a local experienced expert, Brian Warkentin. “I’ve been involved in various parts of the industry from code development to actual hands on installation,” says Warkentin. This additional step will allow FenMan to continue delivering the program in the coming months to a range of additional interested parties, including even more window and door retrofit installers. “

“The man Fenestration Manitoba has chosen, Brian Warkentin, to do the training for them is excellent, very knowledgeable and also good at presenting,” Mitten reports. “He helped me the next day when I gave the same course again to a new Window Wise dealer in Winnipeg. I found that Brian relates very well to installers.”

Fernando Unrau, installations manager for KPL Projects commented, “I found ‘The House as a System’ to be one of the most interesting discussions although I really found the entire program very helpful. An additional benefit is simply the opportunity to exchange views with other experienced

Similar views were reflected by Jonah Trusty, sales representative for Armwood Windows and Doors, “I thought the seminar was very helpful for everyone. I would like to thank all the people who had a hand in putting this event together and look forward to more like it in the future. One of the highlights for me was having such a diverse and engaged group of participants. It really helped to bring healthy debate and insight to the event.”

All participants will receive course materials and a certificate for completing the course. Newly appointed manager, Kelsey Evans, was kept even more “on her toes” during the event as there was a water advisory in effect and emergency supplies of coffee and refreshments had to be obtained from a local Tim Horton’s!

This first course was run by SAWDAC. Future SAWDACFIT courses in Manitoba will be run by Fenestration Manitoba with Brian Warkentin as instructor. Everyone who attends and passes receives a SAWDAC-FIT certificate and are registered in the SAWDAC database. This is the same arrangement SAWDAC has with the AVFQ in Quebec. The SAWDAC-FIT course is SAWDAC’s property with Fenestration Manitoba and the AVFQ being authorized delivery agents.

Amesbury Truth has announced the hiring of its new director of marketing, Kevin Anez. With more than 21 years of experience in the building materials industry, Anez comes to Amesbury Truth from Viracon, where he was director of marketing and product management for the architectural commercial glass business. Prior to working for Viracon, Anez spent nearly 19 years with Andersen Corporation. He will report to Rolland Petersson, the senior director of sales and marketing for Amesbury Truth.

“Kevin’s impressive background in marketing and the fenestration industry will help position AmesburyTruth as the leader in providing high performance components to the window and door business,” says Petersson. “We are in an

important phase of merging two strong brands into one great company, and I’m confident Kevin’s expertise will help us stand out in our industry.”

“I look forward to joining the Amesbury Truth team. These are

exciting times for the window and door industry. The combination of the Amesbury and Truth businesses positions our company for success as we can now leverage the collective competencies to better serve our customers. I’m looking forward to being part of a company that’s advancing its innovative capabilities to meet the evolving needs of the window and door industry,” says Anez. “

Anez was an adjunct marketing instructor at Dunwoody College of Technology in Minneapolis. Proficient in the science of merging engineering with business, Anez has three degrees, including a Bachelors degree in Industrial Technology from the University of Wisconsin Stout, a Masters degree in Manufacturing Systems and an M.B.A. in Marketing from the University of St. Thomas.

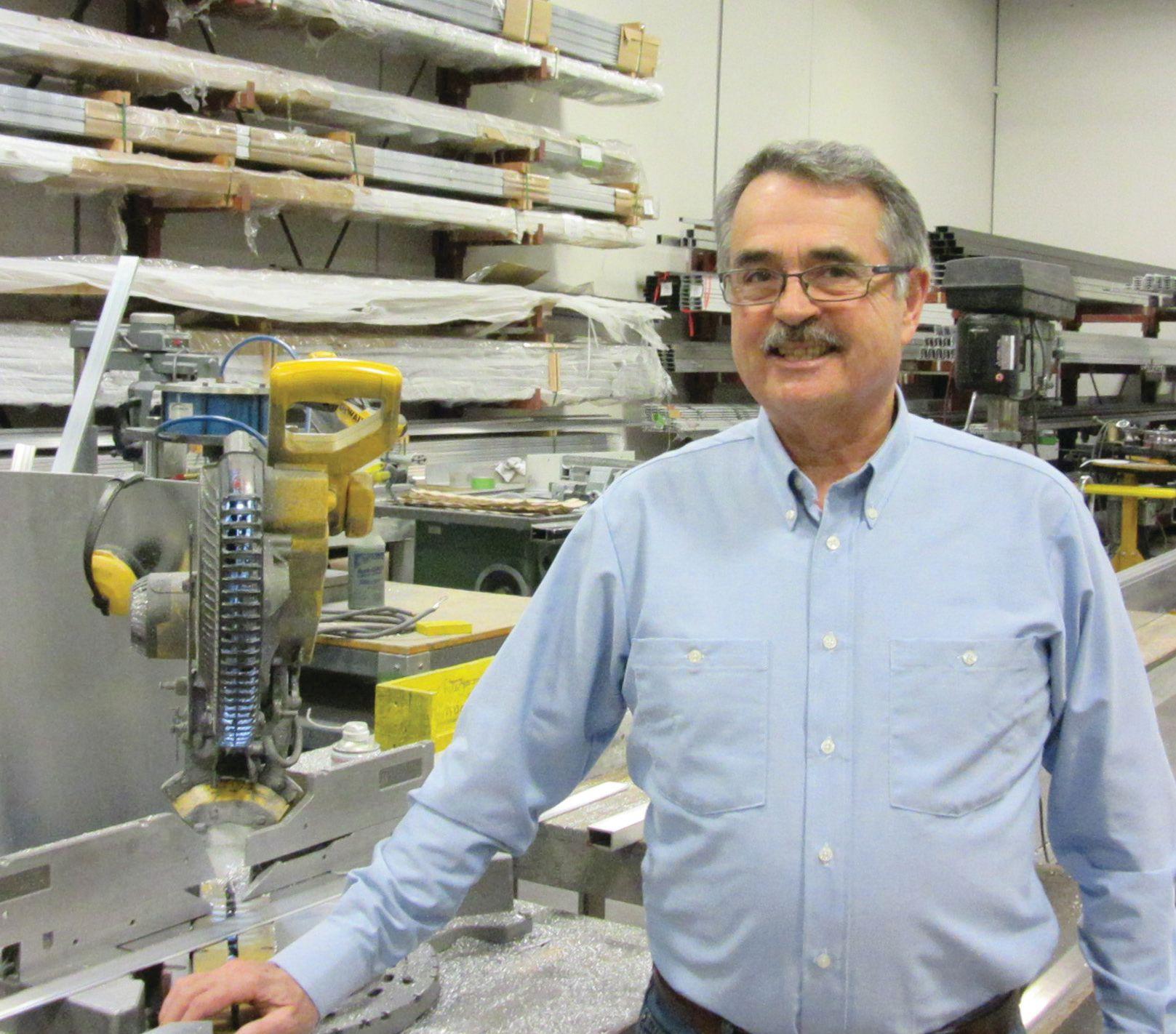

Long time SAWDAC member, Terry Bobiak, recently took SAWDAC executive director, David Mitten, on a tour of the Mastertech Door Systems factory. Mastertech, which began producing entry door systems in 1987, has outgrown two earlier plants in Hamilton and now resides in a new, 14,000-square-foot facility in Ancaster Ont. The business is owned by three partners: Terry Bobiak, Jim Campbell and Denny Islami. Jon Campbell, who is the company’s complete sales force, inside sales, outside sales and customer service told me that Mastertech’s success is based on providing quality products at the best possible value with an emphasis on personalized customer service.

Terry Bobiak runs a replacement window and door contracting company in the Hamilton area. It’s called QSI Windows and Doors and it started way back in 1976.

Given Terry’s retail experience, it’s no wonder that Mastertech approaches the business of providing entry door systems with a real understanding of their customers’ needs.

On the tour, it was obvious how well-organized the Mastertech plant is. The factory’s efficiency and attention to detail are instilled in the 18-member staff by plant manager, Denny Islami. The result? Over 5,000 entry door systems produced per year!

Vinyl Window Designs of Woodbridge, Ont. received

two awards from Energy Star: Sustained Excellence and Promotion of the Year. Centennial Windows and Doors of London, Ont., received an Energy Star award as Manufacturer of the Year. GEM Windows and Doors of Toronto received Pella’s Top Gun Award.

Drucker Research reports the U.S. new housing window market and the replacement window market are roughly equal in size at 30 million units each. The Canadian estimate is 3.5 million units going to each of these markets.

Fourth quarter 2014 Window Wise registrations were

almost exactly even with the same period last year. The increase in registrations monthly keeps us all optimistic that things within the industry are picking up. Window Wise Statistics for 2014

• Total number of installers trained: 40

• Total registered jobs: 4,752

• Total windows installed and guaranteed: 29,720

• Manufacturers participating: 15

• Installation companies/ contractors: 35

• Beingessner Home Exteriors, St. Jacobs, Ont.

• Beverley Hills Home Improvements, Stoney Creek, Ont.

• Consumers Choice Home Improvements, Scarborough, Ont.

• E-Star Windows and Doors, Windsor, Ont.

• George Kent Home Improvements, Mississauga, Ont.

• Long Life Windows and Doors, Vancouver, B.C.

• Lormac Renovation Centre, St. Jacobs, Ont.

• Platinum Home Design and Renovations, Scarborough, Ont.

• PM Windows and Doors, Kitchener, Ont.

• West Windows and Doors, Burlington, Ont.

by TREENA HEIN

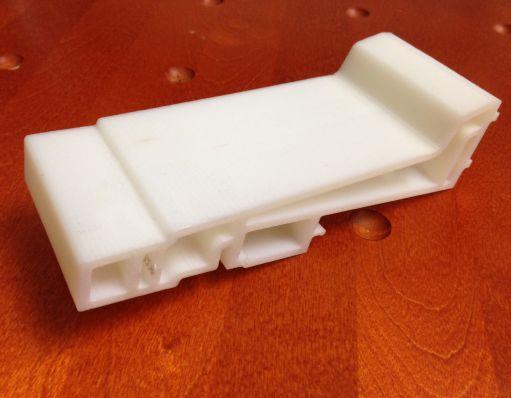

3D printers are changing how fenestration profiles are designed, and may one day change how they are manufactured.

If one thread runs through the conversations that we’ve recently had with window and door manufacturers about their 3D printers, it’s that they could not do without them.

These high-tech tools are simply indispensable, speeding up the manufacturing process, providing flexibility in design and allowing companies to more easily produce exactly what customers want. Window and door manufacturers are clearly very pleased to have this technology – and are looking forward to expanded applications and material selection in the future.

There are many present uses for a 3D printer in the glass industry, including much quicker production of tooling compared to traditional methods, says John O’Hara, sales manager at Chicago-based 3D printer maker Sciaky. “These tools can be used,” he says, “to form vinyl, aluminum and stainless steels into parts of windows or doors.” Reuben Menezes, a 3D printing solution specialist at Proto3000, lists other industry applications to include design testing, marketing of new concepts, production of jigs and fixtures for inspection or assembly, and extrusion test moulding. Multi-material printing, he adds, can allow for testing of seals without a two-step process.

3D printers also allow window and door manufacturers to meet demands for increasing efficiency and durability/structural integrity, explains Matt Havekost. “The ability to prototype quickly before cutting expensive extrusion die tools allows [manufacturers] to stay flexible with designs until they have been proven,” adds the director of additive manufacturing sales at Advanced Technology Systems of St. Paul Minn., a U.S. distributor for Stratasys 3D

printers. He says most manufacturers use the technology for some functional lab testing, such as evaluating how the adhesives flow inside the channels between the extrusion profiles and the corner keys.

Andersen Windows has several large Stratasys 3D printers which run non-stop. The company does a significant amount of business in re-modelling old homes, where new windows need to match the size of those being replaced, as well as match the hardware finishes, grill patterns and so on. Their large printers were purchased over the last few years for use at their larger facilities, and a few small desktop printers are also in place at some of their smaller facilities. “We use the printers primarily to prototype parts to verify fit and function, figure out how things will be fabricated, and to build small window units for testing,” says manager of Window Product Development, Dale Fitterer. “We have a tough time if the machines are down. They also help with attachment methods, making quick physical displays and doing test fits for presentations and for marketing. Customers can get a quick feel for what we have in mind, give us their feedback and we can look at ideas or make changes. It all helps in making customers happy.” The printers are also used at Andersen to build parts that are used by production, like temporary fixtures

or brackets.

Over the time they’ve had the printers, Fitterer and his colleagues have seen industry applications expand significantly. “The newer large printers offer more materials and more colours than before, and the materials are stronger than the ones we previously used,” he explains. “The desktops can use a few different types of material as well. It allows us more flexibility to get better strength properties in parts, and the different colours mean it’s easier to see how things go together.”

In the future, Fitterer expects 3D printing applications to keep growing. For example, he foresees that they’ll be used for making more detailed pieces to

do even smaller fit and function. They will also help in building more units for testing and for better prototyping. “We have a Stratasys fused-deposition model that provides relatively good definition,” he explains. “We outsource now to access different materials to get smoother, more aesthetic finishes than what we can achieve, but we’ll be able to do that in-house someday. As material selection increases, we’ll be able to do some structural tests on prototypes as well. If you can skip the machining, it’s much more efficient.”

All Weather Windows in Edmonton first purchased a 3D printer (a Stratasys Dimension 1200es) in early 2011 in order to build prototypes. “It was a sig-

nificant investment at the time but it’s proven to be very capable and reliable,” says Jesse Tufts, product development engineer. “It prints in ABS, which is reasonably strong so the finished pieces can also be functional (for testing). The material comes in cartridges which are easy to load and handle, but quite expensive at around $5 per cubic inch of printed material. Despite the operating cost, it’s usually used several times per week.”

3D printing means the All Weather Windows team can produce a window profile prototype in hours instead of the months it can take for a PVC extrusion die. Tufts notes that getting a die cut is obviously very costly if there has been a

mistake, and 3D printing means the details of how things fit together are all sorted out before that point. “It also requires no special skill versus hand-building a prototype,” he notes. “The biggest advantage for me is it allows me to go through multiple design iterations in a single day. For parts that need to fit and function with other parts, this is invaluable and allows me to make better design decisions before sending something off for production.” He adds, “Things like doorsills can be visualized on the screen, but until you actually hold it in your hands, you can’t be completely sure about fit.” Tufts believes the speed and the cost savings that 3D printers offer provide a competitive advantage to window and door companies which own one or more of them.

Aside from prototyping, another common use for the All Weather Windows 3D printers is creating machining jigs and router templates which are often used for low-volume production on the floor. “For low-volume small plastic parts, it can actually make sense to 3D print the parts themselves instead of paying for an injection mould,” says Tufts. “Small caps, plugs and clips can function just fine as 3D printed parts and can usually be printed reasonably quickly and economically.”

To Tuft, another big advantage to having in-house 3D printing is the ability to create full-sized functional parts and use them to build windows or doors for lab testing. “I’ve 3D printed entire door sills from several pieces and tested them full scale,” he says. Their newest printer, a Makerbot Z18 purchased in August 2014, has been “very useful” for printing large prototypes and can print pieces that are 50 per cent

longer than those that can be made with their older printer. The firm also wanted a second printer because delays in getting projects finished were occurring when the 1200es was tied up. “We were looking at other more expensive options to expand our capability when MakerBot announced the Z18,” Tufts remembers. “It has a larger print volume, higher resolution and uses much less expensive (about $1 per cubic inch) PLA filament which comes in simple rolls. Its purchase cost was also about one-sixth of our original printer, so it was relatively low-risk.” He says subsequent software and firmware updates gave the brand new Z18 better functionality and print quality in the months after purchase. Tufts notes the PLA material isn’t as quite durable as the ABS, but prints are still functional.

In terms of the future, Tufts turns to materials, noting that some new Stratasys printers can print in nylon, and therefore provide increased possibilities for doing small production runs of custom parts. “We have a lot of aluminum extrusion profiles as well as PVC extrusions,” he adds, “and a 3D metal printer could speed up the prototyping process for these designs. As this technology develops, I can see 3D metal printing becoming a lot more common and preferable in some ways to CNC machining or wire EDM due to the material efficiency.” He points to multi-material 3D printing as another area of advancement. “We can’t do it here but we often send out weatherstrip designs to be 3D printed in rubber-like materials before getting dies cut,” Tufts explains. “They can print combinations of flexible and rigid materials on the same piece, for example a weatherstrip with a stiff base and a more flexible top, or a prototype of a rigid plastic extrusion with a co-extruded gasket.”

Combinations of materials is why Rehau is currently exploring 3D printer purchase options. The company is quite interested in a CubePro Duo made by 3DSystems, which can print multiple materials (e.g. PLA and ABS) in the same part. “The reason we are just now looking into this relates to a new development we are currently working on,” says

Rehau’s Window and Door Division designer, Justin Taylor. “This development has several mechanical parts, both plastic injection-moulded and zinc die-cast. As we have inquired about outsourcing prototypes, the price to have these parts produced triggered us to look more heavily into bringing prototyping in house.”

Although Rehau only extrudes the lineal for windows and doors, the company often works closely with hardware and moulding companies in order to provide all the required components for a window or door system, and 3D printing will also come in handy with this work. “The use for [the technology] is not only for prototyping these components, but will allow us to ensure accuracy in various fabrication or processing steps,” says Taylor. “For instance, a window unit that requires a T-mullion will need a certain end mill procedure to fit into the contours of a frame. Being able to replicate our design of the end mill on a 3D printer allows us to test fit and function before sending the design out for tooling a cutter stack on an end-mill machine.” Tooling can be very expensive so it’s imperative to have a prototyping phase in the design to reduce the chances of tooling changes.”

Echoing others, Taylor notes that 3D printing will assist Rehau in not only increasing the precision and accuracy of

3D printing is actually a blanket term for several different additive manufacturing processes. The core concept is that instead of taking material away from a block, as in machining, material is added in precise layers and gradually built up to create the finished shape. CAD/CAM software is used to model the desired shape and output machine control instructions to CNC actuators that position the manufacturing heads. What those heads actually do is where the various 3D printing methods diverge.

xtrusion deposition

Extrusion deposition printers use a nozzle head to heat and extrude tiny quantities of thermoplastic filament or metal wire that hardens quickly once it is laid down. It is the least expensive 3D printing technology on the market now, but has some restrictions on the shapes it can produce.

Selective fusing

Another approach is aim a laser at a bed of granular material, hardening the material only where the laser is focused. Once a layer is printed, another layer of material is spread over top and the laser prints the next layer, fusing it to the shape beneath. The material can be sintered, or completely melted. For extra-strong metal parts, a high-energy electron beam can be used. An inkjet-like process also exists where the nozzle head spreads a binder on a powder causing it to harden in the correct pattern.

parts, but in getting products to market much faster. “In our current situation, a part can be designed in a matter of days, then quotes need to be obtained for outsourcing prototypes,” he explains. “Once the administrative side is complete, it can be a week or more before we see the actual part. Having our own printer dramatically decreases that time, especially if the part requires revisions and a second or third prototype is required.”

Tufts at All Weather Windows says having a 3D printer “makes so much sense” and believes that as things advance, the advantages become greater. “It’s the next step,” he notes. “We went from hand-drafting to Autocad to 3D drafting to 3D modeling. It’s a breakthrough change. It’s not completely essential to buy one, as there are companies that can do it for us and we can have the part in two to three days, but the printers are becoming so inexpensive that they pay for themselves quite quickly. If you do a lot of design work and you need to visualize and hold things in your hand, it’s a no-brainer.” Tufts notes that with each new generation of printers coming onto the market, purchase price, speed, accuracy, print quality, and material selection are all improving. “I can’t imagine how we got along without it for so long,” he says.

Photopolymerization

In a process similar to the old idea of stereolithography, liquid polymers are exposed to controlled lighting, causing them to cure at the focal point. The vat of liquid is then moved down incrementally, building up layers. A version of this method using lasers can make extremely small parts, and parts with complex internal workings.

by Chris Meiorin

Icame across a recent online editorial discussing how well recent fenestration labeling is being received by manufacturers, which begged the question “What manufacturers exactly is she referring to and what is she smoking in her e-cigarette?” Almost without exception, the small shop fabricator makes like a deer in the headlights when the topic of NAFS and fenestration labeling comes up. With small and medium-sized companies (SMEs) accounting for over 75 per cent of all private jobs over the last decade, and representing almost 70 per cent of the private-sector labour force in Canada, one might think it would be in the best interest of the economy to cater to this segment of the industry. With the limited financial and human resources available to SMEs, especially after a couple of belt-tightening years, the scope of work involved in initiating and maintaining a fenestration labeling program is daunting to say the least.

I came across another recent article on the Dot-Bong boom. It discussed how the medical marijuana industry is the next big thing and there has been no shortage of investors rushing to cash in on a grow op – the only problem being Health Canada’s continued changes to how the game is to be played. This has left only the largest of companies – in some cases, publicly traded companies – as the only ones able to weather the storm of knee-jerk regulatory changes. “They keep moving the goal posts,” one West Coast-based applicant said of Health Canada’s evolving review process. I could not help but think of how the fenestration industry is faced with the same challenges.

On the surface, it is easy to see the value in fenestration labeling. It’s all about offering

the consumer the most energy-efficient products available for the application. In theory, not a bad idea, however what is lost is how the product performs after it has been installed. No mention is given to how the product is made. No mention of the materials used and how they actually perform in the long run. How they might hold up in our harsh climates. It’s all about energy modeling and how one product is slightly better than the next, using a rather narrow criteria. Yes, fenestration labeling has brought some value to industry but any of the men and women I have had the pleasure of associating with over the years made great products long before labeling came into effect. In fact, the argument can be made that labeling has the potential to decrease how the product performs in the field. Take steel reinforcing out of the window and earn energy points. Narrow down a profile, more points. Use a non-structural spacer and you’re on an energy roll. Yes, it all looks good on paper but the windows I would make for my own home will work for generations, and the same cannot always be said for energy-efficient windows. Unlike our American counterparts, we’re a fragmented industry here in Canada with a lot of small players working hard to make a good product. The cost entry of the labeling requirements puts the small and mediumsized fabricators on the same playing field as the big guys. This effectively shuts out a lot of good companies from playing the game and sometimes forces good companies underground just to survive – a problem faced not only by window fabricators, but with Health Canada and pot growers alike.

Chris Meiorin is the owner of Euro Vinyl Windows and Doors in Woodbridge, Ont.

Windoor 2014 capped off what was, for most, a pretty good year overall.

by SKIP MACLEAN, FENESTRATION CANADA PRESIDENT

All of the tasks and housekeeping chores that were put off due to a rather healthy and hectic fall season are now clearly staring us in the eyes and begging for attention. What exactly will this New Year bring? There are certainly no signs of the dreadfully slow start experienced for most of us last year.

Windoor 2014 capped off what was, for most, a pretty good year overall. Attendance at the 20th anniversary show, although hindered by horrific weather to the south, was fairly representative of previous years. Opening night celebrations included recognizing our 20 year exhibitors: Amesbury/Truth, IGMA, Novatech and TrimLite, as well as several pioneers of the show.

Congratulations to the show committee and management for a job well done. Results of a survey sent to exhibitors and attendees will help shape this year’s show and maintain Windoor North America as Canada’s window and door showcase.

Congratulations to our winners from the survey respondents. Exhibitor winners were Brian Belzberg of Aribell and Bob Borkoski of Veka. Attendee winners were Jessica-Ann Runte of Patrick Morin Inc. and Kevin Becessar of Marvin Windows. There were quite a few suggestions and comments on how we can change and improve the show to keep it a must-see event. Look for more news concerning Windoor on the Fenestration Canada and dedicated Windoor websites.

The Fabricators Council held an open forum meeting at Windoor with the purpose of clarifying and bringing a common understanding and interpretation of NAFS compliance testing requirements between labs and certifying agencies. Lisa Bergeron of Jeld-Wen and Greg Dickie of Atlantic Windows presided over the meeting which was chaired by none other than Morgan Hanam (Fenestration Services). Morgan has been instrumental in helping us develop this guideline and continues to assist us in technical issues. The meeting was attended by representatives of all of the certifying agencies and test labs either at the show or by teleconference and should go a long way to demystifying testing requirements and procedures.

Skip Maclean is president of Fenestration Canada. He is business development manager for Tru-Tech Doors and has over 40 years’ experience in the window and door industry.

A Technical Committee session was held at Windoor and the committee continues to do the spade work of code interpretation and keeping up with developments on the National Building Code and energy code fronts across the country. A number of technical bulletins are being planned for release in this current year. Work is underway to develop a North American Fenestration Standard FAQ section which will be posted on the association’s website to help members better understand the standard, testing and compliance requirements. Co-chairs Jean Marois of Royal Plastics and Robert Jutras of Air-Ins along with our technical advisor, Jeff Baker, continue to provide dedicated and valuable guidance on everything technical.

The Membership and Marketing Committee, chaired by Laura Weil of Euro Vinyl Windows, is about to announce the launch of our new website (oops, looks like I scooped them!) The new platform promises to be more user-friendly and current. Updates will soon be done internally allowing information and news to be current and timely. Members will also have access to update their information and profile. The new-look site was preceded by the creation of an improved prospect brochure and the committee is working hard to promote membership value. A newly formed committee was enacted to plan, organize and promote our upcoming AGM, being held in the breathtaking city of Vancouver. The planning process is well underway and details of the programs are expected shortly. Thanks to Terry Adamson of Westeck Windows and Fenestration B.C. for their support and contribution in organizing this event.

I would like to wish everyone a very healthy, prosperous and happy 2015. If you are a Fenestration Canada member, thank you! Please stay involved. It is only with your input and effort that we can truly represent our industry.

Here’s your spring roundup of new products in the window and door industry.

8pidbooks.com

PID Books has introduced Service Life Prediction of Exterior Plastics: Vision for the Future, a collection of chapters derived from the Fifth International Symposium on Service Life Prediction edited by White, Martin and Chapin. Risk permeates every aspect of product commercialization. How risk is assessed, therefore, is critical to the ability and rapidity of an industry to innovate. This volume updates progress in delineating advances in the state of the art in service life prediction for polymeric materials exposed outdoors. Accurate in-service performance estimates would greatly reduce risk in introducing a product into the marketplace. By increasing the reliability of the predictions for polymeric materials, the pace of innovation in industries that rely on these materials will also increase. The symposium from which this book is derived focused on service life prediction for a variety of materials and products, as well as standard testing requirements. The objectives of all sessions were to critically

examine current prediction methodologies and to present advances in laboratory testing, field exposure and modeling approaches, together with implementation strategies and outstanding issues related to these advances. Written for an audience of professionals and researchers, the book contains more than 150 illustrations including 80 in colour. The wide range of materials examined range from vinyl siding products to protective films and coatings and components in solar energy applications.

8weiserlock.com

Weiser has introduced Android compatibility to its Kevo smart lock. Consumers with Android 5.0 Lollipop (L) software on supported devices can download the beta Kevo app on the Google Play store to

experience Kevo’s functionality. Android L devices are the first from Android that fully support Bluetooth Smart peripheral mode, which is needed for Kevo compatibility. Bluetooth Smart technology ensures a low energy, seamless connection from the Kevo deadbolt to authorized devices. No more fumbling for keys, users simply touch the lock to open with an authorized Android device in their purse or pocket to open the door. EKey management is another feature. Send or delete electronic keys (eKeys) from the beta Kevo app to grant or revoke access from the smartphone at any time. Guest eKeys allow users to give recipients access to the home for a 24-hour period, while Anytime eKeys give guests unrestricted access and Scheduled eKeys let users set day and time restraints for someone who needs regular, pre-determined access. A history of the lock’s activity may be viewed through the Kevo mobile app. The history log provides the times and dates that eKeys were sent and received as well as when eKey holders locked and unlocked the door for ultimate peace of mind. Kevo offers patentpending positioning technology that detects whether an authorized user is inside or

outside of the home before granting access, to help prevent unauthorized entry.

ODL Inc. has launched its line of Spotlights doorglass, adding to its extensive doorglass collection. Spotlights doorglass is suitable for any flush door purchased from a distributor or door shop. The Spotlights collection was created to enhance the unique style of existing homes, such as Georgian Revival, Mid-Century Ranch, Dutch Colonial, Bungalow or even Contemporary. As more homeowners opt to renovate their homes, Spotlights designs help them stay true to their roots, while enhancing curb appeal. The white, low profile PVC frame assists in this process as it can be painted to match any colour. The Spotlights collection is comprised of three doorglass sizes: 7.5 by 7.5, 12 by 12 and 22 by 3.5 inches. Each size is available in any of four

glass options: chain link, cubed, frosted and clear. Configuration possibilities are endless, as both horizontal and vertical arrangements are available, in addition to varying options for quantity and orientation. Size and glass options can be mixed and matched to complement various home aesthetics ranging from those built in the 1920s to today. The four glass options provide a range of privacy levels. Chain link glass, cubed glass and frosted glass allow for heightened privacy, while clear glass provides complete transparency. Not only does Spotlights doorglass upgrade the style of existing homes, but its insulated glass and well-constructed frame units also make it an energy-efficient choice. And because architects, builders and remodelers can vary their choices in style, shape and size, pricing is particularly flexible.

8 quanex.com

To help increase energy efficiency and align with the changing needs of entry door producers and installers, Quanex Building Products has expanded its line of thresholds to help customers achieve their performance, installation and budgetary goals. The 5C Can-Am Sill is designed for high-end applications in Canada that require the very best performance and longterm durability. The 5C sill is adaptable, allowing the installer to expanded or contract widths, virtually eliminating air and water infiltration.

“Our 5C sill is made specifically to meet the demands of the Canadian market,” says Jim Meeks of Quanex Building Products. “We designed the 5C sill for simplified installation, while meeting all the performance requirements of our customers, including eliminating air and water infiltration, resisting weathering, and providing a long-lasting natural

appearance.”

In addition to the 5C Can-Am sill, Quanex offers the 5Y High-Performance Threshold, incorporating patented ImperiSeal technology, eliminating any chance of water intrusion through the threshold. Also, the 5H Hybrid-Technology Threshold, providing balance between economy and performance, and the Imperial 5E Rail Over Dam Threshold, ideal for secondary doorways, such as garage entrances.

8 thermatru.ca

For more than 50 years Therma-Tru has specialized in providing estheticallypleasing, award-winning door options and entrance solutions from a single supplier. In 2014, Therma-Tru launched an assortment of new doors, features and glass styles aimed at providing builders and remodelers with enhanced options for increasing their business. On-trend new door styles encouraged Therma-Tru to expand the Fiber-Classic Mahogany Collection to satisfy homeowners. New doors and sidelites include deep mahogany graining and high-definition panel embossments that are designed to complement rich wood tones in the home’s interior, extending the hardwood look to entry, patio, house-to-garage and service doors. The expansion also introduces the mahogany grain to the Therma-Tru vented sidelite offering. Launched in 2013, the Pulse series of contemporary doors now adds a mahogany-grained fiberglass

option along with a new Echo design option for doors and sidelites. Delivering clean lines and crisp right angles, Pulse meets new construction and remodeling market needs for homeowners seeking modern and eclectic entrances. The new mahogany-grained fiberglass offering joins the original oak-grained fiberglass, smooth fiberglass and steel product line options. New configurations within the Echo design provide a total of 12 new door styles and four new sidelite choices available in a variety of glass designs and material offerings. Pulse doors and sidelites are available in six-foot, eight-inch and eightfoot heights. Available in full- and half-lite styles, low-E internal blinds provide both energy efficiency and privacy to home entrances. Cordless operation allows homeowners to control the desired level of light and privacy with the simplicity of a single handle. Blinds are enclosed between glass and remain dust-free for homeowner convenience.

Daylight affects people in numerous ways: psychologically, physically and systemically. We require access to natural light for our health, performance and eyesight – especially those responsible for complex tasks.

by RICH PORAYKO

Enter Spectrum Skyworks. Founded in 1992 in Port Coquitlam, B.C., Spectrum specializes in specialty skylights, canopies and other types of overhead and sloped glazing. “We bought Spectrum in 2008,” says managing partner, Ken Boyce. “What attracted us was the potential. We saw this as an opportunity of getting into a niche part of the glazing industry. At the time, Spectrum didn’t do any storefronts or curtain wall and we’ve grown it from a small business to an almost $7 million a year company.

Control of their materials and systems has helped Spectrum to grow. “I really enjoy the problem solving aspect,” says Boyce, a 30-year building envelope veteran including working for Fortune 500 companies in the U.S. while commuting out of Vancouver. “A skylight is basically a window on the roof. If it is not installed properly, it’s going to leak or fail and can be a major problem. We see it all the time. We solve those problems. We have our own extrusions for our skylight systems. And because of that, we enjoy a fairly stable repeat business.

It is a good thing Boyce enjoys problem solving. Spectrum serves high-end residential customers who often have ideas bigger than their budgets. “We also install skylights in a lot of high end homes, however residential is different,” says Boyce. “With commercial you have drawings to look at. With residential, there is no spec, just a hole. The industry has also been backed into a corner with free estimates. When was the last time an electrician provided free estimates? They charge a service call. Every

time we get a residential call, we have no idea what to expect. We’ll send a sales consultant to site and a big part of that is to help set expectations. A home owner might want a 20-foot-long by eight-foot-wide ridge skylight down the front of their house, however they have no idea how much something like that would cost so we help them set a budget and we provide a hard number for supply and install. In all cases, we have stamped engineering drawings.”

Like most successful business owners, when asked how he does it, Boyce points to his staff. “The people here are amazing people,” says Boyce. “Everyone is well trained and loyal. We have sales, estimating, design engineering, AutoCAD, finance, fabrication, powdercoating and installation teams. Even Sunshine the company cat has a place. Together, we’ve installed 8,000-10,000 skylights over the past 25 years.”

Spectrum Skyworks is also the parent company of Langley based Dayliter Skylights, a true manufacturing business with no installation services. “Dayliter has been a good business for us. Roofers will drop by and pick up five twoby-four-foot skylights at a time.” The vinyl frame skylights come in opening and fixed options with glass, acrylic or “insulite” fill. Insulite is a combination of a Cardinal low-E 366 base topped by an acrylic dome. The dome creates an airspace that greatly improves thermal performance.

Spectrum’s restless search for new markets has led it in some unusual directions. “Roof doors are a growing market for us. We have designed our own proprietary system,” says

BY

Spectrum stocks its own aluminum extrusions and has full in-house design engineering, metal fabrication, welding and powder coating capabilities. This is managing partner, Ken Boyce.

Boyce. “The frame is structurally reinforced and has a continuous stainless steel hinge with dual-keyed locks and locking pistons. We ship them all over North America. It’s a solution for people who want to get up on top of their flat roof area. Typically there is a height restriction. If you build a staircase with a dog house and a seven-foot walkout door, the neighbours aren’t going to like it. Roof doors have caught on big time. We’re installing roof doors on the top condo units for a project called the Radius with Marcon. We are installing another 36 roof doors on an Onni project. People love to get outside.

Architects know this and a flat roof which can be dead space or they can get a lot more money for them.”

Boyce sees a big future in commercial glazing for Spectrum. “About a year and a half ago, we expanded our wings with the Bloedel Conservatory, a big geodesic dome with 1,488 panels of which there are 32 different sizes. It is very unique. It went very well. No incidents. No accidents. They only lost two days of business at the Conservatory during the whole project: the day we lifted the two 180-foot spline beams into place and the day we removed them. It was supposed to take nine months but it only took

seven.” Bloedel Conservatory launched Spectrum into looking into larger projects. “We’ve expanded our capabilities and horizons,” says Boyce who is also an engineering technologist. “Leaky condos are a big part of our business, approximately 60 per cent. We work with Morrison Hershfield, RJC and RDH a lot. We recently changed out the top four stories of sloped glazing at a 26-storey building in Vancouver called Crystallis. That was a big job.”

Boyce continues, “We also supply and install around $1.5 million in custom railing each year. It all ties together. Almost every large building restoration

market as well as with its products. The company takes on everything from mass produced standard skylights for the DIYer to custom-built architechtural marvels like the Bloedel Conservatory in Vancouver.

job will have skylights at the top, some sort of a railing component and a number of canopies to protect the doors. Which is one reason why these buildings failed, there was no overhang and the water just drove in. It was that period of time. Restoration is a big scope of our work.”

“Glazing wise, we’ve completed a number of high end homes last year and we’re getting more into it,” says Boyce. “We hope that going into 2015, our new relationship with Kawneer as a dealer will allow us to do more glazing work. Window wall, curtain wall and storefront are fairly competitive markets. We are a niche [supplier] so depending on the size of the building,

we can be a one-stop-shop which the general contractors love. Or if it is a smaller project, I’ll take it on as a general contractor. If it’s mostly about glazing and all I have to do is hire a roofer, I’ll do that. That’s the scope in how we’ve expanded. Metro Vancouver, Vancouver Island, Whistler, Kamloops. We have completed six or seven Browns Social Clubs in B.C. and Alberta including Calgary, Edmonton, Red Deer and Lethbridge.”

From high-end residential custom builds to mass-produced, off-the-shelf skylights to engineered landmark projects, Spectrum Skylights has built competency across just about every kind of fenestration there is.

MARCH 23 - 25

NFRC Spring Committee Week Annapolis, Md. 8 nfrc.org

MAY 14

Fenestration BC Golf Tournament Surrey, B.C. 8 fen-bc.org

JUNE 4 - 6

Fenestration Canada

Annual General Meeting Vancouver, B.C. 8 fenestrationcanada.ca

JUNE 24

Fenestration Manitoba Golf Tournament Winnipeg, Man. 8 fenestrationmanitoba.ca

JUNE 28 - JULY 1

AAMA National Summer Conference Seattle, Wash. 8 aamanet.org

SEPT. 16 - 18

GlassBuild America Atlanta, Ga. 8 glassbuildamerica.com

SEPT. 21 - 23

NFRC Membership Meeting Location TBD 8 nfrc.org

OCT. 18 - 21

AAMA National Fall Conference Cambridge, Md. 8 aamanet.org

NOV. 3

Windoor Toronto, Ont. 8 windoorshow.com

DEC. 2

Construct Canada Toronto, Ont. 8 constructcanada.com

360 INNOVATIONS

182A Iberville Boulevard

Repentigny, QC, J6A 1Y8

Tel: 888-654-3287

Fax: 450-654-8483

Contact: Serge Rondeau

Email: srondeau@360-innovations.com

3M CANADA COMPANY

300 Tartan Drive

London, ON, N5Y 4M9

Tel: 519-452-6178

Fax: 519-452-6286

Contact: S.P. Gillis

Email: sgillis@mmm.com

ACCURATE DORWIN CO.

1535 Seel Avenue

Winnipeg, MB, R3T 1C6

Tel: 204-982-4640

Fax: 204-663-0020

Contact: Rob Johnstone

Email: info@accuratedorwin.com

AGC GLASS COMPANY NORTH AMERICA

191 Coronation Street

Woodbridge, ON, L4L 6M4

Fax: 905-738-1177

Contact: Peter Virgili

Email: peter.virgili@agc.com

AIR-INS INC.

1320 boul. Lionel-Boulet

Varennes, QC, J3X 1P7

Tel: 450-652-0838

Fax: 450-652-7588

Contact: Robert Jutras

Email: r.jutras@air-ins.com

ALL WEATHER WINDOWS LTD.

18550-118A Avenue North West

Edmonton, AB, T5S 2K7

Tel: 708-451-0670

Fax: 780-454-7474

Contact: Henry Banman

Email: henryb@allweatherwindows.com

ALLSCO WINDOWS AND DOORS

70 Rideout Street

Moncton, NB, E1E 1E2

Tel: 506-853-8080

Fax: 506-386-4292

Contact: André Doiron

Email: adoiron@allsco.com

ALUMICOM INC.

8161 Keele Street, Unit 14-15

Vaughan, ON, L4K 2N2

Tel: 905-761-8554 ext 221

Fax: 905-761-8228

Contact: Rufina Melichov

Email: rufina@alumicom.ca

AMBERWOOD DOORS INC.

80 Galaxy Boulevard, Unit 16 Toronto, ON, M9W 4Y8

Tel: 416-213-8007

Fax: 416-213-8009

Contact: Colin Fraser

Email: cfraser@amberwooddoors.com www.amberwoodoors.com

AMESBURY TRUTH

700 West Bridge Street

Owatonna, MN, 55060

Tel: 507-444-4622

Contact: Kevin Anez

Email: kanez@amesburytruth.com www.amesburytruth.com

ANDERSEN CORPORATION

100 Fourth Avenue North Bayport, MN, 55003-1096

Tel: 651-264-5570

Fax: 651-351-3396

Contact: Mark Mikkelson

Email: mark.mikkelson@andersencorp.com

ANDERSON WINDOWS

46 Cheryl Crescent, P.O. Box 510

Sundridge, ON, P0A 1Z0

Tel: 705-384-5341

Fax: 705-384-7514

Contact: Cheryl Anderson

Email: sherianderson@bellnet.ca

ANIG WINDOW

MANUFACTURING LTD.

2040 Ellesmere Road, Unit 1 Scarborough, ON, M1H 3B6

Tel: 416-438-7213

Contact: Enzo Angheloni

Email: eangheloni@bellnet.ca www.anigwindows.com

AQUASURTECH OEM- HEAD OFFICE

2148 Trans-Canada Highway

Dorval , QC, H9P 2N4

Tel: 514-684-2628

Fax: 514-684-2620

Toll Free: 1-888-884-8982

Contact: Michael Braeuel

Email: mbraeuel@aquasurtech-oem.com

AQUASURTECH OEM

TORONTO OFFICE

57 Ashbridge Circle, Unit 1 Woodbridge, ON, L4L 3R5

Tel: 905-856-6336

Fax: 905-856-0895

Toll Free: 1-888-884-8982

Contact: Michael Braeuel

Email: mbraeuel@aquasurtech-oem.com

ARMWOOD WINDOWS & DOORS

Highway #1A West, P.O. Box 8

Portage La Prarie, MN, R1N 3B2

Tel: 204-856-2320

Fax: 204-856-2339

Contact: Brent Otsuji

Email: armwood@armwood.ca

ARTISAN DOORS CANADA

30 Pinetree Drive, South West

Calgary, AB, T3Z 3K4

Tel: 403-471-7123

Contact: Catherine Connolly

Email: cconnolly@gistsolutions.com

ASHLAND HARDWARE

116 Exmore Road

Mooresville, NC, 28117

Tel: 704-696-5123

Contact: Allison Guilfoyle

Email: allison.guilfoyle@ashlandhardware.com

ATIS GROUP

39 rue Industrielle

Saint-Apollinaire, QC, G0S 2E0

Tel: 450-477-1111

Fax: 418-881-3920

Toll Free: 1-800-463-1922

Contact: Bertrand Nadeau

Email: bnadeau@atisgroup.ca

ATLANTIC WINDOWS

49 East Main Street

Port Elgin, NB, E4M 2X9

Tel: 506-538-2361

Fax: 506-538-7603

Contact: Greg Dickie Email: greg.dickie@atlanticwindows.com

AURORA WINDOW SYSTEMS INC.

4215B - 11 Street North East Calgary, AB, T2E 6K4 Tel: 403-291-2851

Contact: Kent Schultz Email: awsinc@telus.net www.aurorawindowsystems.ca

BERDICK WINDOWS & DOORS

404 Roblin Boulevard, P.O. Box 1059 Winkler, MB, R6W 4B1

Tel: 204-325-8053

Fax: 204-325-5516

Contact: Dan Friesen

Email: dan@berdick.com

BONCOR BUILDING PRODUCTS

3886 Commerce Road

London, ON, N6N 1P6

Tel: 519-644-2626

Fax: 519-644-2662

Contact: Dave Nuttall

Email: dave.nuttall@royalbuildingproducts.com

BONNECHERE VALLEY

WINDOWS LTD.

2824 Fourth Chute Road, R.R. #6

Eganville, ON, K0J 1T0

Tel: 613-628-3056

Fax: 613-628-9070

Contact: Andreas Vornweg

Email: andreas@b-v-w.com

BROWN WINDOW CORPORATION

185 Snow Boulevard

Concord, ON, L4K 4N9

Tel: 905-738-6045

Fax: 905-738-1342

Contact: Eros Gerardi

Email: pinom@brownwindow.com

C&L AGENCIES LIMITED

458 Keltic Drive, Unit A, P.O. Box 1493, Station A

Sydney, NS, B1P 6R7

Tel: 902-564-4911

Fax: 902-564-1039

Contact: Bradley Latham

Email: bradleylatham@eastlink.ca

CALDWELL MANUFACTURING CO. NORTH AMERICA LLC

P.O. Box 92891

Rochester, NY, 14692-8991

Tel: 585-352-2810

Fax: 585-352-3729

Contact: Nancy Bostwick

Email: nbostwick@caldwellmfgco.com

CANADA WINDOWS & DOORS

119 Consumers Drive

Whitby, ON, L1N 1C4

Tel: 905-665-1506

Fax: 905-665-9381

Contact: Isabel Mendicino

Email: isabelm@canwindows.com

CAN-BEST

38 Regan Road, Unit 4

Brampton, ON, L7A 1C6

Tel: 905-840-2014

Fax: 905-840-0847

Contact: Elie Alkhoury

Email: elie@can-best.com

CAN-SAVE SUPPLY AND DISTRIBUTION

411 Bayview Drive

Barrie, ON, L4N 8Y2

Tel: 705-722-7283 ext. 2258

Fax: 800-668-6886

Contact: Dan McArthur

Email: danm@can-save.ca

CARDINAL IG COMPANY LTD.

775 Prairie Center Drive, Unit 200 Eden Prairie, MN, 55344

Tel: 952-229-2600

Fax: 953-935-5538

Contact: Mike McAndrew

Email: mmcandre@cardinalcorp.com

CENTENNIAL WINDOWS & DOORS

687 Sovereign Road

London, ON, N5V 4K8

Tel: 519-451-0508

Fax: 519-451-8582

Contact: George Warren

Email: george.warren@centennialwindows. com

CHANTECLER PORTES & FENÊTRES

35, boulevard Desrosiers, C.P. 763 Gatineau, QC, J8P 6J3

Tel: 819-663-5301

Fax: 819-663-4209

Contact: Jean- Philippe Henri

Email: jphenri@chantecler.biz

CODEL ENTRY SYSTEMS

1510 St. Paul Avenue Tacoma, WA, 98421

Tel: 253-536-9655

Fax: 253-536-9662

Contact: Brian Smith

Email: bsmith@codeldoors.com

COSSINS WINDOWS LTD.

2908 - 18th Street North East Calgary, AB, T2E 7B1

Tel: 403-291-3960

Fax: 403-291-3961

Contact: Chris Cossins

Email: chris@cossins.com

CSA GROUP

178 Rexdale Boulevard

Toronto, ON, M9W 1R3

Tel: 416-747-2688

Fax: 416-401-6536

Contact: John Glowacki

Email: john.glowacki@csa-international.org

C-SKY WINDOWS LTD.

5662 Goring Street

Burnaby, BC, V5B 3A3

Tel: 604-759-2759

Fax: 604-759-2758

Contact: Jeffrey Wu

Email: jeff@csky.ca

CUSTOM WINDOW DESIGNS

3495 Laird Road, Unit 1 Mississauga, ON, L5L 5S5

Tel: 905-569-1329

Fax: 905-569-1259

Contact: Peter Petrovski

Email: peterp@customwindowdesigns.ca

DALMEN PRODUCTS LTD.

5630 Ste-Catherine Street, Box 220

St. Isidore, ON, K0C 2B0

Tel: 613-524-2268

Fax: 613-524-3070

Contact: Jacques Ménard

Email: info@dalmen.com

DALTON TIMMONS INSURANCE GROUP INC.

35 Stone Church Road, 3rd Floor

Ancaster , ON, L9K 1S5

Tel: 905-304-2355

Fax: 905-648-9295

Contact: Michael Daou

Email: michaeld@daltontimmins.com

DAN DARCY & ASSOCIATES INC.

46 Diana Grace Avenue

Dartmouth, NS, B2W 6A2

Tel: 902-462-6114

Fax: 902-462-6118

Contact: Dan Darcy

Email: dandarcy@accesswave.ca

DELOR WINDOWS INCORPORATED

185 Trowers Road, Unit 7&8

Woodbridge, ON, L4L 5Z5

Tel: 905-851-3040

Fax: 905-851-3084

Contact: Renso De Pellegrin

Email: renso@delorwindows.com

DELUXE WINDOWS

25 Milvan Drive

Toronto, ON, M9L1Y8

Tel: 416-743-0633

Fax: 416-743-9442

Contact: Roman Weig

Email: r.weig@deluxegroup.com

DE-MAR WINDOW HARDWARE INC.

128 Adesso Drive, Unit 1

Concord, ON, L4K 3C3

Tel: 905-532-0070

Fax: 905-532-0077

Contact: Marcello Demarco

Email: info@demar.ca

DOOR COM DISTRIBUTION

285 Vaughan Valley Boulevard

Woodbridge, ON, L4H 3B5

Tel: 905-850-5352

Fax: 905-850-5071

Toll Free: 1-866-677-8311

Contact: Daniel Sardella

Email: daniel@wintek.ca

DORPLEX INDUSTRIES LTD.

100 Norfinch Drive

Toronto , ON, M3N 1X1

Tel: 416-744-3667

Fax: 416-740-1728

Contact: Paul Moseley

Email: info@dorplex.com

DUFFERIN WINDOWS LIMITED

115 Centennial Street

Shelburne, ON, L9V 2Z4

Tel: 519-925-3111

Fax: 519-925-5425

Contact: Karen McCabe

Email: karen@dufferinwindows.ca

DUXTON WINDOWS & DOORS

45 Higgins Avenue

Winnipeg, MB, R3B 0A8

Tel: 204-339-6456

Fax: 204-334-1800

Contact: Al Dueck

Email: apdueck@duxtonwindows.com

ELTON MANUFACTURING

8400 Lawson Road, Unit 2

Milton, ON, L9T 0A4

Tel: 905-302-6960

Fax: 905-878-9211

Contact: Andrew Beavan

Email: andrew@eltonmanufacturing.com

ENTRYGUARD DOORS INC.

8150 Keele Street

Concord, ON, L4K 2A5

Tel: 905-532-0740

Contact: Frank Luccisano

Email: frank@entryguarddoors.com www.entryguarddoors.com

EURO VINYL WINDOWS & DOORS INC.

167 Caster Avenue, Unit 8

Woodbridge, ON, L4L 5Y8

Tel: 905-851-9711

Fax: 905-851-9712

Contact: Laura Weil

Email: laura@evw.ca

EVERLAST GROUP OF COMPANIES

299 Carlingview Drive

Etobicoke, ON, M9W 5G3

Tel: 416-241-8527

Fax: 416-245-2629

Contact: Mike Bruno

Email: mike@everlast.biz

EVOTECH INDUSTRIAL COATINGS

2503 De La Métropole

Longueil, QC, J4G 1E5

Tel: 450-670-8930

Fax: 450-670-8930

Contact: Pierre Charbonneau

Email: pcharbonneau@evotechind.com

EXOVA INC.

2395 Speakman Drive

Mississauga, ON, L5K 1B3

Tel: 905-822-4111

Fax: 905-823-1446

Contact: Jordan Church

Email: jordan.church@exova.com

EXP SERVICES INC.

1595 Clark Boulevard

Brampton, ON, L6T 4V1

Tel: 905-793-9800

Contact: Greg Hildebrand

Email: greg.hildebrand@exp.com www.exp.com

EXTREME WINDOW AND ENTRANCE SYSTEMS

80 Loftus Street, Moncton Industrial Park Moncton, NB, E1E 2N2

Tel: 506-384-3667

Fax: 506-854-5905

Contact: Darren Bannister

Email: dbannister@extremedoors.ca

FENESTRA PURCHASING COOPERATIVE LTD.

140 Fullarton Street, Suite 208

London, ON, N6A 5P2

Tel: 902-679-9655

Fax: 519-518-3077

Toll Free: 1-888-713-6282

Contact: Brian Hermiston

Email: bhermiston@fenestra.coop www.fenestra.coop

FENESTRATION CANADA

P.O. Box 62060

Ottawa, ON, K1C 2S0

Tel: 613-424-7239

Fax: 613-424-7238

Contact: Robert Rivard

Email: rrivard@fenestrationcanada.ca

FENESTRATION COMPONENTS INTERNATIONAL INC.

202 Sheep River Lane

Okotoks, AB, T1S 1N8

Tel: 403-938-1064

Fax: 403-938-1082

Contact: Ted Paetkau

Email: ted@fci-inc.ca

FENZI NORTH AMERICA

11 Dansk Court

Toronto, ON, M9W 5N6

Tel: 416-674-3831

Contact: David Devenish

Email: info@fenzi-na.com www.fenzi-na.com

FERCO FERRURES DE BÂTIMENT INC.

2000, rue Berlier

Laval, QC, H7L 4S4

Tel: 450-973-1437

Fax: 450-973-7661

Contact: Yvon Soucy

Email: soucy.y@ferco.ca

FIBERCRAFT DOOR COMPANY

321291 Concession 2 SDR, R.R. #1

Hanover, ON, N4N 3B8

Tel: 519-506-2117

Fax: 519-506-4776

Contact: Bruce Schaus

Email: fibercraft@wightman.ca

FUSION GLASS WORKS

50 Irondale Drive

Toronto, ON, M9L 1R8

Tel: 416-739-7794

Fax: 416-739-9780

Contact: Michael Gabbana

Email: michael@fusion-glass.com

GALAXY WINDOWS LTD.

8220 Davies Road North West Edmonton, AB, T6E 4N2

Tel: 780-468-1263

Fax: 780-468-1202

Contact: Jim Roth

Email: galwind@telusplanet.net

GENTEK BUILDING PRODUCTS LIMITED

6320 Colonel Talbot Road

London, ON, N6P 1J1

Tel: 519-652-3246

Fax: 519-652-9591

Contact: Kevin Gain

Email: kevin_gain@gentek.ca

GLOBAL TECHNOLOGIES WINDOW MFG LTD.

810A Rowntree Dairy Road

Vaughan, ON, L4L 5V3

Tel: 905-264-9020

Fax: 905-264-9521

Contact: Joe Amaev

Email: info@gtwindowmfg.com

GLOBAL WINDOWS AND DOORS

128 Industrial Park Street, P.O. Box 2823

Richibucto, NB, E4W 4A4

Tel: 506-523-4900

Fax: 506-523-7003

Contact: Allan Doyle

Email: allan@globalwindows.ca

GROUPE PROMAX

2435, avenue Watt, bureau 2 Quebec City, QC, G1P 3X2

Tel: 418-650-7889

Fax: 418-650-5872

Contact: Daniel Royer

Email: info@groupepromax.com

GUARDIAN INDUSTRIES CORP.

2300 Harmon Road

Auburn Hills, MI, 48326-1714

Tel: 734-654-4822

Contact: David Cooper

Email: dcooper@guardian.com

HENNIGES AUTOMOTIVE SCHLEGEL CANADA INC.

514 South Service Road East, P.O. Box 218 Oakville, ON, L6J 2X6

Tel: 905-845-6657

Fax: 905-845-6558

Contact: Cathy King

Email: cathy.king@hennigesautomotive.com

HERR WINDOW & DOOR

6011-103A Street Edmonton, AB, T6H 2J7

Tel: 780-453-5929

Fax: 780-401-3038

Contact: Randy Stauffer

Email: herr@shaw.ca

HI-TECH ENERGY WINDOWS LTD.

1675 Inkster Boulevard

Winnipeg, MB, R2X 2W7

Tel: 204-783-9945

Contact: Drew Dudeck

Email: ddudeck@hitechwindows.com www.hitechwindows.ca

HOME’S EXCLUSIVE STEEL ENTRANCE SYSTEMS

281 Lancaster Crescent, P.O. Box 40

Debert, NS, B0M 1G0

Tel: 902-662-4204

Fax: 902-662-4205

Contact: Steve Emery

Email: steve.emery@homehardware.ca

HOPPE NORTH AMERICA INC.

6345 Netherhart Road, Unit 1

Mississauga, ON, L5T 1B8

Tel: 905-564-7344

Fax: 905-564-7301

Contact: Michael Pasternak

Email: mike.pasterbak@hoppe.com

INKSTER PARK MILLWORK LTD.

1512 Church Avenue

Winnipeg, MB, R2X 1G6

Tel: 204-694-0101

Fax: 204-694-9459

Contact: Gary Glowa

Email: inkster@inksterpark.ca

INLINE FIBERGLASS

30 Constellation Court

Toronto, ON, M9W 1K1

Tel: 416-679-1171

Fax: 416-679-1150

Contact: Bernard Rokicki

Email: brokicki@inlinefiberglass.com

INTERLOCK USA INC.

1105 South Rock Boulevard, Suites 120123

Reno, NV, 89502

Tel: 775-852-8808

Fax: 775-852-8867

Contact: Axel Husen

Email: axel.husen@interlockna.com

INTERTEK TESTING SERVICES NA LTD.

6225 Kenway Drive Mississauga, ON, L5T 2L3

Tel: 905-678-7820

Fax: 905-678-7131

Contact: Claudio Sacilotto

Email: claudio.sacilotto@intertek.com

JELD-WEN OF CANADA LTD.

485 Watt Street

Winnipeg, MB, R2K 2R9

Tel: 204-694-6012

Fax: 204-663-1072

Contact: Lisa Bergeron Email: lisabe@jeld-wen.com

JELD-WEN OF CANADA LTD. DIVISION DONAT FLAMAND

90, rue Industrielle St-Apollinaire, QC, G0S 2E0

Tel: 418-881-3974

Fax: 418-881-2029

Contact: Patricia Trottier

Email: patriciat@jeld-wen.com

JRC MACHINERIES INC.

3382-A Jacob-Jordan Terrebonne, QC, J6X 4J6

Tel: 450-477-1286

Contact: Jonathan Chauvette

Email: jonathan@jrcmachinery.com www.jrcmachinery.com

KEHL WINDOW SYSTEMS INC.

370 King Street West, P.O. Box 222

Harrow, ON, N0R 1G0

Tel: 519-738-2110

Fax: 519-738-9465

Contact: Richard Kehl

Email: rkehl@mnsi.net

KENTO LTD..

1641 Topsail Road

Paradise, NF, A1L 1V1

Tel: 709-782-1556

Fax: 709-782-7423

Contact: Don Kennedy

Email: donkennedy@acanwindows.com

KOHLTECH INTERNATIONAL LTD.

583 MacElmon Road, P.O. Box 131 Debert, NS, B0M 1G0

Tel: 902-662-3100

Fax: 902-662-2154

Contact: Kevin Pelley

Email: kpelley@kohltech.com

KP BUILDING PRODUCTS LTD.

300 MacDonald Boulevard Alexandria, ON, K0C 1A0

Tel: 613-525-3065

Fax: 613-525-2948

Contact: Richard Séguin

Email: r.seguin@farleywindows.com

LAURELWOOD MILLWORK LTD.

1509 Snow Valley Road, R.R. #3

Minesing, ON, L0L 1Y3

Tel: 705-737-5315

Fax: 705-728-6043

Contact: Rob Rodgers

Email: info@laurelwoodmillwork.com

LOEWEN WINDOWS

77 Highway 52 West, P.O. Box 2260 Steinbach, MB, R5G 1B2

Tel: 204-326-6446

Fax: 204-326-5227

Toll Free: 1-800-563-9360

Contact: Gary Blad

Email: garyblad@loewen.com www.loewen.com

LUX WINDOWS AND GLASS LTD.

6875 - 9 St. North East

Calgary, AB, T2E 8R9

Tel: 403-276-7770

Fax: 403-276-7792

Contact: Norma Ambrogiano

Email: lux@luxwindows.com

MARITIME DOOR & WINDOW

118 Albert Street

Moncton, NB, E1C 1B2

Tel: 506-383-7114

Fax: 506-383-1420

Contact: Michael Mann

Email: mike.mann@maritimedw.com

MARLBORO WINDOW & DOOR MFG. LTD.

2370 Stevenage Drive

Ottawa, ON, K1G 3W3

Tel: 613-736-1441

Fax: 613-736-1220

Contact: David Dubrofsky

Email: david@marlborowindows.com

MARTIN CONSULTING

285 Vaughan Valley Boulevard Woodbridge, ON, L4H 3B5

Tel: 416-315-0190

Contact: Bernice Martin

Email: bernice.e.martin@gmail.com

MARVIN WINDOWS & DOORS

1455 Courtney Park Drive East

Mississauga, ON, L5T 2E3

Tel: 905-670-5052

Fax: 905-670-0364

Contact: Knut Holmsen

Email: marvincanada@bellnet.ca

MASONITE INTERNATIONAL

2771 Rutherford Road

Concord, ON, L4K 2N6

Tel: 800-798-3667

Fax: 888-329-2783

Contact: Mark Woolnough

Email: mwoolnough@masonite.com

MASTERGRAIN C/O WEBER MANUFACTURING TECHNOLOGIES INC.

165666 Highway 12, P.O. Box 399

Midland, ON, L4R 4L1

Tel: 705-527-2973

Contact: Ken Kussen

Email: kenkussen@mastergrain.com www.mastergrain.com

MAXAM MARKETING

C.P. 252

Saint-Bruno, QC, J3V 4P9 Tel: 450-723-1257

Fax: 450-723-1258

Contact: Jean-François Kogovsek Email: jfk@maxammarketing.com

MAXDOR INC.

2180 Highway 7, Unit 18

Concord, ON, L4K 1W6

Tel: 905-738-2358

Fax: 905-738-5619

Contact: Zeev Dabelman

Email: info@maxdorinc.com

MENNIE CANADA LIMITED

5145 Steeles Avenue West, Unit 3 Toronto, ON, M9L 1R5

Tel: 416-748-0088

Contact: Maria Fermin

Email: maria@menniecanada.com www.menniecanada.com

MENUISERIE BASQUE & FILS LTEE

390, rue Snowball, C.P. 3609 Succ.Bureau

Chef Tracadie-Shelia, NB, E1X 1G5

Tel: 506-395-2733

Fax: 506-395-1925

Contact: Alderic Basque

Email: mbf@nbnet.nb.ca

MILGARD WINDOWS & DOORS

P.O. Box 881

Bellingham, WA, 98227

Tel: 360-599-6326

Contact: Dennis Michael

Email: dennismichael@milgard.ca www.milgard.ca

MMM GROUP

582 Lancaster Street West

Kitchener, ON, N2K 1M3

Tel: 519-743-8777 ext. 2428

Fax: 519-743-8778

Contact: Michael Barclay

Email: mbarclay@enermodal.com

MOUSTIQUAIES MSA SCREENS

690 chemin Olivier

Lévis, QC, G7A 2N2

Tel: 418-831-3035

Fax: 418-831-3043

Contact: Pierre Pageau

Email: pageau.pierre@videotron.ca

NATIONAL ACCREDITATION & MANAGEMENT INSTITUTE INC. (NAMI)

4794 Washington Memorial Highway Hayes, VA, 23072

Tel: 804-684-5124

Fax: 804-684-5122

Contact: Tanya Wix

Email: tanya@namiinc.com

NEWMAR WINDOW

MANUFACTURING INC.

7630 Airport Road

Mississauga, ON, L4T 4G6

Tel: 905-672-1233

Fax: 905-672-1076

Contact: David Wren

Email: dwren@newmar.com

NEXTRUSIONS INC.

10 500, Rue Colbert

Montreal, QC, H1J 2H8

Tel: 514-881-2090

Fax: 514-881-2089

Contact: Gérald Gravel

Email: ggravel@dynaplastinc.com

PVC ARCHITECTURAL INC.

220, rue Industrielle

Saint-Apollinaire, QC, G0S 2E0

Tel: 418-881-2286

Fax: 418-881-2082

Contact: Guy Leclerc

Email: guy@pvcarchitectural.com

QUALIGLASS WINDOWS AND DOORS LTD.

6605 82 Avenue

Edmonton, AB, T6B 0E8

Tel: 780-466-3938

Fax: 780-463-5394

Contact: Chris Eckert

Email: qg@qualiglasswindows.com

QUALITY AUDITING INSTITUTE LABORATORIES LTD.

211 Schoolhouse Street, Unit 16

Coquitlam, BC, V3K 4X9

Tel: 604-527-8378 ext 234

Fax: 604-527-8368

Contact: Kevin Saito

Email: ksaito@qai.org

QUANEX BUILDING PRODUCTS

800 Cochran Avenue

Cambridge, OH, 43725

Tel: 603-661-4096

Fax: 740-439-0121

Contact: Tracy Rogers

Email: tracy.rogers@quanex.com

R.M. LANDRY & SON LTD.

554, Highway 247, Grand Greve, P.O. Box 223

St. Peters, NS, B0E 3B0

Tel: 902-535-3346

Fax: 902-535-3662

Contact: Jason Landry

Email: jason@rmlandry.com

RANGATE NORTH WOODWORKING SOLUTIONS INC.

311-1220 Pender Street East Vancouver, BC, V6A 1W8

Tel: 888-810-2522

Fax: 888-750-6940

Contact: Christopher Chan

Email: chrisc@rangate.com

RDH BUILDING ENGINEERING LTD.

224 West 8th Avenue

Vancouver, BC, V5Y 1N5

Tel: 604-873-1181

Fax: 604-873-0933

Contact: Al Jaugelis

Email: ajaugelis@rdhbe.com

REHAU INDUSTRIES INC.

1149 Pioneer Road

Burlington, ON, L7M 1K5

Tel: 905-335-3284

Fax: 905-335-1112

Contact: Emanuel Pivniceru

Email: emanuel.pivniceru@rehau.com

RELIANCE WINDOWS INC.

111 Carlauren Road

Vaughan, ON, L4L 8A8

Tel: 905-889-0358

Fax: 905-889-0365

Contact: Lou DeLellis

Email: lou@reliancewindows.ca

RICHERSONS ENTERPRISE LTD.

388 Granton Drive

Richmond Hill, ON, L4B 1H7

Tel: 905-889-4406

Fax: 905-889-4997

Contact: Danny Lin

Email: d.lin@richersons.com

ROTO FASCO CANADA INC.

6625 Ordan Drive, Unit 1

Mississauga, ON, L5T 1X2

Tel: 905-670-8559

Fax: 905-670-8560

Contact: Chris Dimou

Email: sales@fasco.ca

ROYAL WINDOW AND DOOR PROFILES

30 Royal Group Crescent

Woodbridge, ON, L4H 1X9

Tel: 905-652-6207

Fax: 905-652-3136

Contact: John Grandoni

Email: grandonij@royalbuildingproducts.com

S.I.L. PLASTIC

30 Whitmore Road

Woodbridge, ON, L4L 7Z4

Tel: 905-264-8845

Fax: 905-264-8849

Contact: Stefan/David

Email: silsales@silplastic.com

SAINT-GOBAIN ADFORS AMERICA

1795 Baseline Road

Grand Island, NY, 14072, USA

Tel: 716-404-6352

Contact: Julie Spatholt

Email: Julie.Spatholt@Saint-Gobain.com www.adfors.com

SCREENCO MANUFACTURING LIMITED

290 Millway Avenue

Concord, ON, L4K 3W4

Tel: 905-669-9440

Fax: 905-669-9480

Contact: Jennifer Small

Email: jennifer@screenco.ca

SCREENS”R” US

275 Gaspé

St-Apollinaire, QC, G0S 2E0

Tel: 418-881-1328

Fax: 418-881-0179

Contact: Tony Lambert

Email: tlambert@screensrusonline.com