fenestrationreview.com

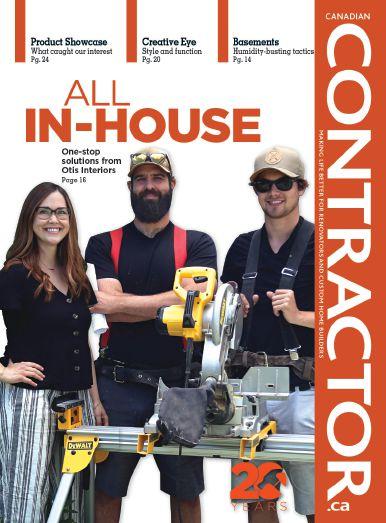

THE PEOPLE’S MAN

Gordon Seier’s journey in the window and door industry so far.

Grove Shims™ has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money.

* Contact us about eligible tariff fee reimbursements on the purchase of Grove’s shims only. “This ad applies to U.S. and Canada only. Offer expires 12/31/20.”

Need help? Just ask! We’re here to help. 978-534-5188 Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com

FreeSamplesareAvailableUponRequest. Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Fenestration Review 2020

Vol. 9 • Issue 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE EDITOR | Sukanya RAY GHOSH srayghosh@annexbusinessmedia.com 647.203.7031

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

NATIONAL ACCOUNT MANAGER | Amanda McCRACKEN amccracken@annexbusinessmedia.com 226-931-5095

ACCOUNT COORDINATOR | Stephanie DEFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

AUDIENCE DEVELOPMENT

MANAGER | Urszula GRZYB ugrzyb@annexbusinessmeda.com 416-510-5180

MEDIA DESIGNER | Curtis MARTIN

GROUP PUBLISHER, VP SALES | Martin MCANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN

ADDRESS TO CIRCULATION DEPARTMENT, P.O. 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

email: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

ugrzyb@annexbusinessmedia.com

416-510-5180

Fax: 416-510-6875 or 416-510-5180

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $22.00 (plus applicable taxes)

U.S.A. - 1 Year $50.50 (in CDN dollars) Foreign – 1 Year $58.00 (in CDN dollars)

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Tel: 800.668.2374

Occasionally, Fenestration Review will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. www.fenestrationreview.com

CANADA’S WINDOW AND DOOR MAGAZINE

16 6

4

EDITORIAL

Introducing Fenestration Conversations.

15

FGIA

The Fenestration and Glazing Industry Alliance shares lessons learned about online events..

6

INDUSTRY NEWS

Tariffs dropped… NGA extends GlassBuild Connect… Reg Pollard passes away…

16

A NEW PATH

Fanshawe College throws the doors open to train the next generation of window installers.

12 THE PEOPLE’S MAN

After 40 years in the window industry, Gord Seier knows the value of great colleagues.

Fenestration Canada went coast to coast with regionspecific education. 12 21

10

FIT & FINISH

The supply chain is disrupted; let’s keep communication chains open. by Chris Meiorin

19 PHILIBUSTER

Rising above prejudice: breaking barriers of race, colour and gender. by Phil Lewin

FENCAN REGIONAL WEEK

22 THAT’S RICH

Investing in a well-rounded sales team sets you up for success. by Rich Porayko

A new way to talk

by Patrick Flannery

We’re excited to launch Fenestration Conversations, our new podcast.

Keep your eye out for a lot more podcasts coming from Fenestration Review this year. I have to say I just love the format. For those of you who haven’t sampled this wonder of online communication, here’s a quick overview.

A podcast is really just a recorded conversation on a topic. It’s essentially a long interview with an expert or other noteworthy person, similar to what CBC radio does on shows like As It Happens or Steve Paiken does on The Agenda. Podcasts, though, can be even longer – some of them go two or even three hours. I won’t be going that long, but it isn’t hard to fill an hour with a guest that has good things to say.

The long-format conversation has a lot of advantages over a TV or radio interview. There’s a chance to really go back and forth and examine an issue. No one is getting cut off or having to condense their thinking into sound bites. You can go over as much terrain as the guest can cover and do so as thoroughly as the topic demands. When it comes to taking a deep dive into some area of interest, podcasts exceed even the ability of a print article to deliver lots of interesting points.

The other great thing about podcasts is the delivery model. You get podcasts by subscribing to them, usually for free, on a podcasting app. Apple and Android phones include one on the device and the big online services include SoundCloud, Spotify and Audible. Podcasts can also be played off any internet browser – ours will be posted online at fenestrationreview. com. To find the podcast you want, you simply open the app and search for the name. Once

you’ve subscribed, each episode of the podcast gets downloaded to your device, where you can listen to it at your leisure. On a plane or in a car with no WiFi? No problem. Unlike live broadcasts, you can stop the recording any time you want and start it again later. Since it’s voiceonly, the demand on your attention is less than video. Podcasts are perfect when you’re doing something else, like cutting the lawn, driving or working in your garage. I like to shut off the sound on a video game and listen to a podcast while I play.

Our podcast is called Fenestration Conversations and I’m going to use it to bring voices from the industry to you with information to help your business. One thing we will do is bring on the Fenestration Review columnists you read each issue to discuss their last column and expand and enhance their expert advice. We’ve already posted discussions about extrusion technology, software tricks, payables insurance, the new Fenestration and Glazing Industry Alliance association and more. And we’ll be bringing prominent window and door professionals on board to talk about their experiences and stories in the industry, and their opinions of the issues of the day. We’ll release a new Fenestration Conversation every month. If you are like me, you’ve viewed a lot of the social media out there these days with some skepticism. There’s a lot of talking going on and not much being said. I can promise Fenestration Conversations won’t just be part of the general noise you’d like to tune out. Whether you’re an experienced podcast listener or someone who only uses a phone to make phone calls, I hope you’ll give Fenestration Conversations a try.

INDUSTRY NEWS

Industry pioneer Reg Pollard passes

Reg Pollard, founder of Pollard Windows and Fenestration Canada Pioneer, has passed. Excerpts from the official obituary follows “It is with deep sadness that the family of Reginald Norman Pollard announces his passing on Aug. 5 at the age of 91. He had a deep love and commitment to his family. He exuded love and always tried to guide and support them throughout their lives. His deepest love was for his wife Carol. He was a visionary, entrepreneur and founded Pollard Windows in 1948 along with his parents and sisters. From the very beginning, Reg put his heart and soul into building the business. He was still very much involved in the company until just a few short years ago. Reg was extremely proud to have raised his family in Canada and to have founded Pollard Windows here. With his determination, passion and a

genuine work ethic he built a very successful business benefiting thousands of customers, suppliers and communities. Reg loved his business but more importantly loved all of its employees: the people that helped him every day to build the company and its good reputation. He successfully instilled in his family, a lasting commitment to its employees which he was truly proud of. Reg was instrumental in the development of the window and door industry in Canada. He was recognized in 2009 as ‘Pioneer of the Industry’ by the Canadian Window and Door Manufacturers Association. The Burlington Economic Development Corporation inducted Reginald Pollard into the Entrepreneur Hall of Fame in 2012. Also, in 2012, the Chancellery of Honours awarded Reginald Pollard with the Queen Elizabeth II Diamond Jubilee medal.”

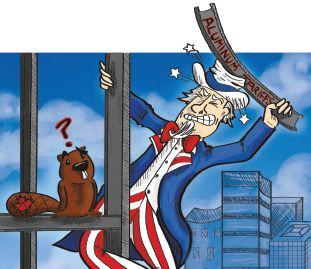

Tariffs dropped, retaliation avoided, but quotas implied

On Sept. 15 the U.S. government announced it was dropping a 10 percent tariff on Canadian aluminum exported to the U.S., hours before Canada was set to impose retaliatory tariffs on manufactured aluminum U.S. imports, including aluminum windows and door components. But the Americans are threatening to re-impose tariffs retroactively should Canadian aluminum exports exceed unilaterally imposed quotas. The U.S.-based Aluminum Association said it welcomes the end of tariffs and supports tariffand quota-free trade in aluminum products between Canada and the U.S. Trump has invoked Section 232 of the U.S. Trade Expansion Act to justify the tariffs, which would otherwise be in violation of the USMCA free trade agreement. Section 232 allows the U.S. to restrict trade where import of a product would imperil national security. So somehow importing aluminum from Canada is suddenly posing a threat to U.S. national security. Trump had announced on Aug. 6 that the U.S. was planning to put a 10 percent tariff on Canadian aluminum ingots entering

the U.S., effective Aug. 16. In response, Ottawa had threatened $3.6 billion in retaliatory tariffs on American aluminum goods entering Canada. “Aluminum doors, windows and their frames and thresholds for doors” were on the list of potential products targeted for tariffs, and were part of the retaliatory tariffs Ottawa imposed in 2018 in response to the U.S.’s 25 percent tariff at the time. Commenting on the move on Trump’s announcement on Aug. 6, Augustine Lo, an export attorney, sent the following analysis: The presidential proclamation affects only imports of unwrought, unalloyed aluminum from Canada, which are primary products made from raw bauxite, which are

used to fabricate downstream aluminum products. While seemingly narrow, this class of goods actually constitutes the largest share of Canadian aluminum exports to the United States. Assuming this 10 percent tariff proceeds, it could significantly impact the aluminum market, from competing U.S. producers of primary aluminum to producers of secondary aluminum from recycled goods that could compete with imported primary aluminum, and to downstream users of aluminum across all industries. Canadian aluminum products have became subject to whiplash in having tariffs variously imposed and removed. Initially, Canadian aluminum products, along with Mexican products, were exempt, possibly in consideration of ongoing negotiations to replace the North American Free Trade Agreement (NAFTA). Then, in June 2018, Canadian and Mexican aluminum products were added back onto the tariff list, which prompted Canadian and Mexican retaliatory tariffs on U.S. products.

SAWDAC Newsletter

84 Adam Street, Cambridge, ON N3C 2K6

NOT A HANDICAP, JUST A HICCUP

When the Canadian economy shut down in March due to the coronavirus, our members prepared for the worst. But the worst seemed to be a hiccup.

During the shutdown we received a lot of calls at the office here about consumers asking about their windows: if they were installed right and how long should they last. “We want new windows. Who would you recommend? What’s this Window Wise program?”And so on.

If someone told me a year ago we would have two to three million people out of work, “but don’t worry, home renovations would be fine,” I would have told them they were crazy. However, that’s what is happening. In actuality, business has increased faster than any time when there were not government rebates.

The coronavirus and the ensuing shutdown of the entertainment industry, the stay-at-home orders and remote working have many people thinking a lot about their homes and increasing the value of them through renovations, mainly windows and doors. Many people we have talked to know they won’t be traveling for a while and want to invest in their home instead.

We’re not just seeing the typical 45-plus crowd buying

windows, we’re seeing very young buyers come in and say, “I know nothing about window replacement but we want energy efficiency and to increase the value of our investment.”

“My parents told me to call you guys,” one consumer remarked to us at the office.

THE SILVER LINING

The Royal Bank of Canada just announced that the average house price in August is $569,000 in Canada and that is up 18.5 percent from July!

Increases in existing home equity over the last decade, combined with historically low interest rates are giving many homeowners the financial ability to upgrade. The window and siding industry being considered essential early on has kept our members moving all through the pandemic, with that hiccup in May.

Still, our members are struggling to deal with affordable quotes from a year ago as material and labour costs continue to rise. Lumber prices have risen to the highest point since 2004.

With low interest rates and people working from home likely to remain for the immediate future, SAWDAC members believe demand will remain strong at least through the rest of this year. But that does not mean we are necessarily confident about the future.

519-651-2812

TRAINING THE NEW GENERATION

519-658-4753

One of our members commented, “I keep thinking that we can’t have two million people out of work and spending on renovations and toys without it ultimately becoming a drain on the entire country.” To be able to handle all this growth in the industry we need installers. SAWDAC is very pleased to announce we have been working with Fanshawe College in London, Ont., to bring the first window and door installer program to continuing education.

The first cohort of 25 students started Oct. 1 and they will have a 16-weekcourse where they will learn everything from two of our great SAWDAC members.

1-800-813-9616

Northstar in St Thomas, Ont., will help out for the manufacturing end of things. They will then work with Douglas Windows in London on the sales, marketing, and install side of things where they will see what being a certified Window Wise dealer looks like and the benefits to being one.

If you are interested in hiring one of these students, please send me an email and we will help get you in contact. This is an exciting program for our industry and we will need your help moving forward to keep this going. We have many more items to cover but we will save that for the next edition.

If you have any questions please drop me a line at jason@sawdac.com

INDUSTRY NEWS

FenMan hosts short, robust virtual AGM

Fenestration Manitoba’s 2020 AGM was conceived with a view to increase the level of virtual attendance based upon an interesting, fast moving agenda. And, based upon the feedback, the mission was mostly accomplished with positive feedback from a sizeable group of virtual attendees. Patrick Flannery of Fenestration Review launched the event with an informal interview/feedback opportunity on the impact of Covid-19 plus a few additional questions to a panel consisting of Laverne Dalgleish of Building Professionals; Aynsley Dueck of Duxton Windows and Doors; Al Babiuk of Loewen Windows and Stephen Segal of Polar Windows. Babiuk encapsulated the discussion, noting, “The industry trends were extremely strong heading into the COVID phase and we think that strength should lend to a strong recovery as things open back up. The trends towards increasing energy codes are a positive for getting better quality products to the market, but there is a cost to meeting the higher standards and consumers’ budgets will become a challenge at a certain point.” It is perhaps somewhat reflective of the low levels of COVID-19 in Manitoba to date that the attitudes were generally relatively positive. Flannery noted, “While everyone on the panel acknowledged there will be challenges, it came across quite clearly that Manitoba’s window and door makers welcome the chance to build and market higher-quality products.”

The panel was followed up with a set of highly qualified, professional five-minute presentations

from Glen Hodgson, an economist; Jeff Swystun, a marketing professional; Ian Marshall, a CME Lean trainer and Terry Adamson, president of Fenestration Canada. Hodgson’s feedback included, “As an outsider, the event provided an excellent overview of how the pandemic and shutdown has affected the fenestration industry – both the business impact of the pullback, and the prospects for sustained recovery in housing and commercial property markets.”

Adamson brought a valued connection to the national association and noted, “Today more than ever, the value of a manufacturers relationships to our industry associations is paramount. Facing challenges over the next several years that will require development and design to meet difficult performance targets is a must, and associations have the resources and connections to help manufacturers conquer these hurdles. Together the industry can become world leaders in fenestration development.”

Rob Spewak of Red River College also provided a short update on the window installation testing program that has just been launched at the college with the window donation by Jeld-Wen. The final element before completing a closed member’s meeting was a short set of elevator pitches delivered by a small set of sponsors.

Vince Porcelli from Everlast noted, “The event was a great platform in challenging times that had a welcoming casual feel with great information and insight on relevant topics from respected professionals.”

NGA extends GlassBuild Connect through 2020

The National Glass Association has announced that GlassBuild Connect will continue through December 2020, providing registered attendees on-demand access to more than 70 education presentations and products and services from more than 300 exhibiting companies at glassbuild. com. The announcement comes at the conclusion of the month-long glass and fenestration online event that drew thousands of attendees from across the world.

“GlassBuild Connect was such a remarkable and collaborative endeavor,” said Nicole Harris, NGA president and CEO. “Our exhibitors, sponsors, speakers, industry partners

and NGA staff built something truly valuable in scale and caliber.”

NGA produced GlassBuild Connect in collaboration with more than 300 companies serving the glass, window and door industries. Organizations representing all facets of the industry joined the effort, including the Fenestration and Glazing Industry Alliance; the American Subcontractors Association; the Facade Tectonics Institute; the Window and Door Manufacturers Association; Glass Canada and Architectural Record.

“In this year of in-person event cancellations, we’re grateful that the industry has been able to come together

at GlassBuild Connect,” added Harris. GlassBuild Connect is free to access, though registration and site log-in is required. Select webinars and events will continue to be held live on the site throughout the remainder of the year. Products, demos and webinars, including 14 AIA-accredited sessions providing 17 AIA Continuing Education learning units, have been curated to ensure the most timely and relevant content is easily accessible on demand. Information and registration for GlassBuild Connect is available at glassbuild.com. The next GlassBuild America is planned for Sept. 13 to 15, 2021, at the Georgia World Congress Center in Atlanta.

Screenco partners with Lolex

Screenco has announced it has engaged Lolex to represent its products in Quebec and the Atlantic provinces. Lolex is an independent sales agency headed by Mathieu Hebert, a sales professional with over 22 years’ experience in the industry. Prior to forming Lolex, Hebert was Canadian national sales director for AmesburyTruth. He operates out of Trois Ruisseaux, N.B.

“We’ve known Mathieu for many years and have always been impressed by his professionalism and great relationships,” said Craig Stewart, COO of Screenco. “Mathieu will be a great asset to Screenco’s Promax division in Quebec and eastern Canada. He is bilingual and his core values align perfectly with ours.”

“I’m excited to be partnering with a North Americaleading manufacturer of high-quality screen products,” Hebert said. “Our partnership is well-positioned to assist customers with the implementation of best-in-class solutions, as we can now leverage our broad capabilities to better serve the needs of the eastern Canadian market. I’m looking forward to making a difference.”

Keystone Certifications receives SCC accreditation INDUSTRY NEWS

Keystone Certifications recently achieved Standards Council of Canada accreditation for the Fenestration Certification Program. This credential enables the program to demonstrate product compliance with Canadian national and provincial building codes as well as the National Energy Code of Canada and the Canadian Energy Star Program. Keystone becomes the first U.S. fenestration certifier to hold both U.S. (ANSI) and Canadian (SCC) accreditations and to offer associated certification services on both sides of the border. Program referenced standards include the NAFS and CSA A440S1 structural performance, ASTM impact resistance and CSA A440.2 energy performance. Keystone Certifications is based in New Cumberland, Penn., and has been certifying fenestration products since 1998 as an ANSI-accredited certification body and an NFRC-licensed inspection agency.

FIT & FINISH

Chain reaction

by Chris Meiorin

For years we have been blessed with a supply chain that remained relatively stable. Although we have seen short term interruptions over the past 30 years, notably with logistics, oil prices, terrorism, free trade agreements and global events, I can’t recall any situation that can compare to the rapid dismantle of the supply chain like what we have seen with the COVID-19 pandemic.

Early on in this current pandemic, I came across a special report published by the Harvard Business Review titled “Preparing for a Pandemic:”. I was surprised at the speed at which this paper was published, given that it was so early on in the unfolding of current events, only to realize it was published in 2006 and used the H5N1 bird virus as a discussion point. None the less, I read (listened) to the paper just to see how close they got it in 2006, relative to our current scenario, and had to stop listening to the publication as it discussed our current scenario in almost perfect and striking detail. Had I read this paper a year ago, I would have dismissed it as a “worst case scenario” that modern research and medical advancements would make unlikely. As you can appreciate, I felt as if the future was unfolding before me and I was a little intimidated.

This HBR paper discussed, in detail, everything that was happening at that current moment. Looking forward, it also discussed the impact a pandemic would have on the global supply chain, and although it may not immediately surface, as demands surged and inventories depleted, manufactures would run into problems obtaining parts and have to scale back production to adhere to COVID-19 safety protocols – and as I write this, this is our new day-to-day reality. There is no point on expanding on any of this as we are all too familiar with the scenario. That said, one point that stood out was leadership and, more importantly, communication.

Effective communication has to come not only from our elected officials, but business leaders as well. As business leaders, we have an obligation not only to our staff, but to our customers and vendor partners as well.

Internally, it is important to communicate to staff and team members that their safety comes first. This message can be communicated downstream as well so that both customers and vendors know we have their personal best interests in mind. It is equally important that, as a company, we maintain constant communication with vendors to better understand the potential for supply interruption and share this information downstream to the best of our abilities. With the dynamic unfolding of supply chain interruptions, pent-up demand and labour disruption, it is sometimes near impossible to communicate a clear and concise message. But to say nothing is completely irresponsible.

Communication is a something I have followed diligently through this pandemic. I have come to appreciate very much the efforts of our elected leaders in communicating a clear message, but have come to appreciate even more the efforts of company leaders who step up and do their best to communicate to all stakeholders as clear a message as current information affords. That message may not always be perfectly accurate, but my complete admiration and compliments go out to those who stepped outside of their comfort zone to share their knowledge, knowing that the message may not always be accurate given the dynamic and rapidly changing scenario.

Interestingly enough, I’ve followed both large and small companies’ communications and consistently have been impressed with those small and medium-sized enterprises who have worked hard, without the resources of communication departments and PR firms, to communicate their respective message. In contrast, I’ve also witnessed large companies, those with entire departments devoted to nothing but communication, fall silent, and leave those dependent on their products and services completely in the dark. To those companies I say, shame on you.

Chris Meiorin is president of EuroVinyl Windows and Doors in Woodbridge, Ont.

Join now as a 2021 new member and enjoy membership benefits for the rest of 2020—for FREE.

With the combined expert resources of AAMA and IGMA, the Fenestration and Glazing Industry Alliance (FGIA) brings industry leaders together to improve home and building performance through better glass, window, door and skylight technologies and standards.

An FGIA membership gives you access to an indispensable support network of peers, product certification from the industry leader in standards, and discounted rates on training, certification and professional development.

Whether as an individual or business, joining FGIA will give you a leg up in an increasingly competitive industry. Join the alliance today at Join.FGIAonline.org

THE PEOPLE’S MAN

A living legend

in

the Manitoba window manufacturing community shares his stories.

Industry veteran Gordon Seier currently works as an architectural consultant at AGM Glass Fabricators located in Manitoba. Having spent over 40 years in the window and door industry, he has a plethora of stories to tell from his journey so far.

by SUKANYA RAY GHOSH

Seier was first introduced to the industry through his father. His father worked for a company called Willmar Windows. Seier often worked there full-time during the summers and sometimes part-time during the year to make some income. After finishing a course in industrial engineering technology in college, he went on to work full-time at Willmar Windows in the spring of 1977.

Seier had been looking forward to working and learning from his father, who was wellestablished in the industry. However, fate had other plans for him.

“Shortly after I started, my father, who was the production manager in the company, was diagnosed with a brain tumor. It was my intention to work in Willmar Windows full-time to try to understand how the window business operates. When my father fell ill, they asked me to take up work there and take a position within the manufacturing part of the team to help it grow,” he says.

FOSTERING GROWTH

Seier had been brought in full-time into Willmar Windows to help the manufacturing team grow. As he looks back at his time during this period, he says the contribution he made has helped create an environment that encouraged good people and a good work culture.

“They were all good people. They always came when we needed them most. I also helped in organizing the team. I made sure that we had not only the know-how to make the windows,

but also the know-how to control the inventory; how to do the production scheduling. I made sure that they had the know-how go ahead and make sure that the human resources work properly at the right times because we had to consider the very cold winters and construction slow-downs,” he notes.

He adds that he worked on concerns such as how to keep good people, how to do the training, the cleanup and everything else during the slow times. His contribution was combining all these processes, trying to ensure that everything would get done and also ensuring that the products were being produced properly.

Seier says that he got to work with a good team. There were good people when he started and he was able to find other good people to develop alongside them. As the company grew, they all went on to became significant players in the organization.

Besides a good team, Seier also had a good boss. His name was Bill Fast and he was the owner of the company. “He supported us all. He was significant in designing a lot of the products that were brought out. He was significant in helping us decide on new equipment and the processes for that equipment.”

Seier also recalls the company having good business and engineering people on board who helped advance the company’s business.

From his time at Willmar, Seier says a big takeaway has been how important people are, especially those that are ambitious and hard-

working and want to give back to the company. “When I look back, I think about the people that helped along the way,” he says. The thought of losing good people often kept him awake at night. Good people moving away to other companies was his greatest fear.

A FAMILY AFFAIR

Besides his father, Seier’s brothers have also been a significant part of the window industry and Willmar Windows. “When my father passed away, I have three brothers I worked with. They all had significant input in the work that we did.”

Seier’s older brother Martin was the vicepresident of operations and also sort of a general manager. Another brother looked after the branch in Edmonton when Willmar expanded. And his other brother worked in the transportation, logistics and shipping area.

The Seier brothers worked as a team in the company which had an undeniable advantage.

“We would discuss if any problems cropped up or if there were some improvements to be made or what we

could do to improve the business. We discussed what we could do to make sure that we listen to the customers and that we implement procedures to satisfy those customer needs,” says Seier. He adds that it was a family discussion a lot of the time. Where most families talk about politics, the Seier brothers talked about work during their frequent family dinners.

Seier notes that these discussions were a result of their father’s influence who was very much involved in the company, was very industrious and was a smart man. He instilled in his sons the will to work hard and do what is necessary to ensure the company’s success. Seier regrets that he did not get the opportunity to work with his father. He passed away at the age of 52, just after Seier started working full-time in the company.

THE COMPETITIVE EDGE

Seier remained at Willmar Windows for 21 years, until 1998. His time there was spent in helping the company thrive consistently.

He recalls that Willmar was making wood windows out of hemlock at that

time and it worked very well for them. Almost all competitors at that time were making windows out of pine or fir. Using hemlock worked well for Willmar because its price was more stable. The lumber came from Vancouver Island. “That was an innovation that we did with wood windows. We developed the process for our millwork to do those things properly,” Seier explains.

Willmar Windows had also been an early adopter of heat mirror insulated glass units in Manitoba. Talking about how it came to be, Seier narrates, “I happened to be watching a program called This Old House on TV one day. On that program, they were installing a window that had a special low-E coating on it to have a higher R-value.”

Seier thought that was interesting. The show mentioned the name of company where the coating was made. He went back to work the next day, phoned them and asked them to tell him about it. They sent him some information and they had some conversations. About a month later, they came in to Winnipeg in the dead of winter. Facing the harsh –30 C made

them understand why Willmar offered triple glazing and why so many triple units were being produced. Willmar Windows started making heat-mirror shortly after this meeting.

“It was a great tool we had that said triple is not the standard anymore. The low-E product will be now the standard. A lot of our competitors would call us and said that there was so much pressure on the glass companies because of what we were doing with the low-E heatmirror units,” notes Seier. Willmar’s competitors were all racing to develop low-E type of product on glass for residential windows.

His takeaway from Willmar Windows came from Bill Fast. “What I learned was that you can go ahead and you can design a product that is not bulky, that is slimline, that is streamlined to manufacture and that will perform very, very well.” The thing that he got out of it all is when he takes a look at products, especially coming from the manufacturing side, he looks at it to understand how well it can be produced, how well it is engineered, how well it can perform in the market place and how affordable it can be compared to other products that are there.

THE NEXT CHAPTERS

After Seier left Willmar, he had a stint in a millwork company. When the millwork

industry took a hit after 9/11, he went back into windows.

PVC profile windows were continueing to be on the rise. So, Seier became a consultant, helping entrepreneurs start window companies. He would help them buy the equipment. He would help them with whatever was necessary to get into the business. Seier helped start up 14 new companies.

The person who helped Seier during this phase was his mentor, Peter Turner, who has since passed away. “When I asked Peter what am I going to be remembered for in this industry, he said it would be for all the window companies that I helped start up,” he recalls.

Although this chapter was quite successful, PVC wasn’t something that Seier really loved. Eventually, he moved on to the commercial architectural glass industry when he joined AGM Fabricators. He has been there for six and a half years now.

Architectural glass is where Seier plans to end his career. He loves the type of work and has been blessed with two good owners that he works for. “They are entrepreneurs; they are smart guys and are doing very well,” he says.

Through all these changes in his career path over the years, Seier says he has seen the industry transition from making aluminum windows, to making vinyl

sliding windows, to wood windows. Then came the full PVC windows. He has seen improvements in the designs and profiles of the PVC windows over time. Then came fibreglass, which has been able to make great inroads in the light commercial side and the residential side. Seier notes that he is amazed at the progress that has happened in the last six or seven years, especially in Canada. The designs have improved, not only to perform but also to manufacture.

Seier additionally supports the industry he has been a part of for so many years by being actively involved with Fenestration Manitoba.

“I’m not a window manufacturer; I work with window manufacturers. So, I carry a different type of perspective,” he says. He believes that the next big breakthrough will come from the glass industry. He works with FenMan so that the industry ends up with better products and ideas, working through it not only from the side of the window manufacturing process, but also through the glass industry. Seier shares his expertise on the glass part of things.

When asked about his vision of the industry’s future, Seier says that he wants the industry to be strong and get creative and innovative in terms of colours, operation ,designs and performance.

by Janice Yglesias, FGIA executive director

Lessons learned online

The global pandemic has put the need for public health and safety at the forefront, causing many in-person events to move online, at least temporarily. Although a virtual event cannot fully replace live events, it does allow for connection.

FGIA’s first virtual conference this summer provided a great opportunity to learn about what makes a successful virtual event and how to improve on future virtual conferences.

FGIA’s Virtual Summer Conference included well over a hundred new participants who had never attended an in-person FGIA event before, showing an unexpected silver lining to the fallout of the current crisis. We need to be prepared for this surge, especially with respect to establishing a strong and proactive strategy for conducting regular follow-up after the event to retain the engagement of these individuals.

One of the biggest takeaways from the conference was the importance of breaks between sessions. Allowing some time to step away from the screen or to get other work done keeps participants fresh and allows for a less disrupted workflow. Structuring the schedule with relevant time zones in mind allows for practical start and end times as well as reasonable accommodations for lunch breaks.

Virtual happy hours are popular as a way to connect with peers in a more casual environment. Keep these sessions purely social and structure them to allow participants to move between virtual rooms and enjoy different themes. Consider assigning a facilitator to each “room” to ensure the conversation flows easily. Roundtable discussion sessions are another option for creating engagement opportunities. Facilitate these with a mix of technical topics and other areas of discussion chosen ahead of time.

For sessions with larger attendance, use of the Q and A feature in your selected virtual platform is likely the most efficient option with a moderator serving up questions to the

presenter. In a virtual environment, ensuring that everyone’s questions are acknowledged can be a challenge. Have a system in place for addressing any unanswered questions following the session and share this follow-up strategy with the participants.

Most important of all is preparing to manage the technology. Hosts or presenters fumbling through a session with continual bouts of “technical difficulties” can detract from the event and leave a lasting negative impression. Identify a team member or external resource with extensive knowledge of the virtual platform to guide training and manage the live broadcast. Host session planning meetings and dry runs with staff and presenters to review each session’s flow, work out technology glitches and reduce anxiety. This is also a good time to review available features of your virtual platform such as live polling. These preparations build confidence among those involved in running the session.

Don’t forget about addressing technology management for participants. Prepare a brief tutorial video for participants or utilize free content available from your virtual platform provider. Keep the steps for joining sessions simple and straightforward by including links in a pre-conference email or adding links directly to the conference schedule to provide a simple roadmap for participants. The smoother the technology experience is for everyone, the more focus there will be on the valuable content being delivered and the professionalism of your organization.

Going virtual is no small feat, but with the necessary preparation, it can be successful. Online events can also still be fun, connecting experiences with the right strategies and a bit of creativity. For the time being, virtual events are the safest option, respecting the policies and priorities that companies have in place. However, FGIA is looking forward to welcoming attendees back to in-person conferences in the future.

by TREENA HEIN

A NEW PATH

Fanshawe college is set to train the next generation of installers.

This month, the first group of students will begin a complete window and door installer program in London, Ont. This is an exciting and bold step forward in filling the industry labour gap.

Let’s get to the big news first, in case you haven’t already heard: Fanshawe College in London Ont., in collaboration with North Star Windows, Heritage Renovations and other industry members, has launched a fivemonth window and door installer training course this month (October 2020). Twentyfive graduates will be ready the day after their graduation to start work.

It’s actually a good bet that they’ll all be hired before they graduate. The lack of skilled installers, as everyone in the industry knows, is extreme, but finally something concrete is being done about it. “The regional demand for qualified installers is so high that one company like ours could hire all of the graduates from this program,” notes James Baker, the program instructor and vice-president

at Heritage Renovations, a large window and door installation firm in southwestern Ontario. “Over 15 companies have already expressed interest in hiring graduates.”

His sister, Shannon Ruffell, vice-president of strategic planning and implementation, adds that “we’ve had a sign out front for quite some time that says ‘Hiring Experienced Installers’ and have about 100 people a year apply that way, but we only hire the very best, and we’ve only hired about two through that avenue. Most hiring is being done through highly competitive networking.”

This program is one of very few in Canada and the only one being offered at a postsecondary institution. For the most part, installation skills are learned on the job, sometimes passed down from generation to

The first batch of students attend Fanshawe College’s Window and Door Installer training program. After completing the five-month training, they will be ready to step into the real world of window and door installation.

generation and there are gaps in the skill level across the country.

It’s hard to attract people to the industry, adds Ruffell, as there’s a perception that it’s hard work that doesn’t pay particularly well. But, she explains, “It’s lucrative, stimulating and challenging year-round work that’s very rewarding. Installers in southwestern Ontario make over $100 000 a year, and they have unmatched job security.” Baker adds that “our company has grown aggressively the past five years, and it’s been impossible to keep up with demand. Labour has stalled our growth and we’re very excited about this program.”

Before we get into how the program came about and its exciting details, here are the nuts and bolts.

The five-month window and door installer training program is funded

in part by the governments of Canada and Ontario through the Skills Catalyst Fund. “This Fund supports the development and implementation of initiatives that test new and emerging approaches to labour market challenges,” explains Christine Spicer, project lead at Fanshawe. “It provides one-time project-based funding, and participants that enroll this fall must be part of traditionally-underrepresented groups: women, indigenous peoples, newcomers, persons with disabilities, veterans and youth.” The Ruffells say that due to overwhelming demand, an equal representation of all groups will be accepted to make up the 25 qualified applicants.

PROGRAM BIRTH

The idea for the program was presented to Fanshawe about two years ago by Sheldon Dyck, general manager

at North Star Windows in St. Thomas, Ont. “The new Ontario government said it wanted to support the trades, and so that really got things going,” he says. “A consortium formed to develop the program, which includes North Star, Heritage Renovations and some other private companies, Window Wise and some recruiting agencies. There are three groups within the consortium that focus on orientation, curriculum and employment follow-up. I’m very excited about it. It’s the start of making sure we have enough labour support for the industry.”

Baker adds, “We had had some meetings with North Star and Fanshawe over the last few years about getting a program going and it was very exciting to get the green light in March.”

Yes, although the basics for the course were in place in March, the

entire team had only a few months to nail down exact learning outcomes, how students would gain each required skill and much more. It was decided that students will visit manufacturing plants to see raw materials and how products are built, and they will also visit Heritage Renovations’ large showroom to learn about the range of windows and doors available on the market.

COURSE DETAILS

“It’s a one-of-a-kind program for Canada and we wanted to be very technical and detailed,” Baker explains. “We want graduates to be able to start installing the day after graduation. So their train-

ing will include real-world conditions: working at heights, inclement weather, removing old rotten windows – everything. A high level of thought has gone into the content, implementation and structure to ensure all participants will obtain a high level of proficiency. They will experience what install days are really like and be able to perform all tasks exactly as if they were on a real job site.” In light of the pandemic, the entire course will include as much physical distancing as possible, and other protocols will be similar to those being used right now on job sites across Canada.

Speaking of those real-world con -

ditions, during the last few months, Ruffell and Baker have been constructing a model installation wall. It will be moved outside so that students are exposed to the elements, heights and so on, as Baker has explained. “They will have different challenges every day and learn a variety of techniques,” says Ruffell. “They will practice with windows, bays, bows, patio doors and entrance doors.” Students (not that they will need it) will also receive training in getting a job: resume writing, mock job interviews and so on, both from Heritage Renovations and career placement agencies.

LOOKING FORWARD

The plan is for the course enrollment to be expanded for fall 2021 and for the course content to be honed by that point to incorporate feedback from companies that will have hired the first graduates earlier that year. Ruffell and Baker both can foresee that this window and door installation course will be available in every province and that, eventually, it will become a formally recognized skilled trade.

Baker can’t wait to begin. “I’ve met people at all levels and there is always the complaint and frustration about labour and everyone was waiting for someone to do something,” he says. “We’re very excited to be part of the team that’s taken action.”

He believes that moving forward, there will be no limit on growth and expansion across the window and door industry, from manufacturing to shipping, sales and service to installation. “This program will have a significant impact on the economy of this region,” he says, “and eventually, other regions in Canada.”

by Phil Lewin

Breaking barriers

Inever ran into anti-semitism personally until I got to Canada and started selling windows in smaller Ontario towns and cities. (You knew how many salespeople had come before you by how many phone booths it took before you found a yellow page that didn’t have the windows section already removed.) I made a cold call to a substantial company in Guelph. The owner’s son met me at the door and after I explained I was there with a new vinyl window, he brought me to his father. The father asked one question. He asked the name of the owner of the company I worked for. I responded, “Goldenberg.” He responded, “A good Scottish name. There’s the door!” His son had the embarrassing task of taking me back to the door in silence.

Happily, that incident in the mid ‘80’s was the only time in my decades in the fenestration industry that this ever happened to me. Overall, I have always loved cold calling because you never know what you’re going to find when you walk through a new door. Does that mean that our industry is free from prejudice and glass ceilings? I suspect not, but I also see that we are one of the industries where I plainly see that sex, colour and race has not prevented many people with different backgrounds from advancing. Working for Canadian Thermo Industries, there were few office positions anyway. However, the supervisors in the factory came out of the general labour population, based on ability. Next, I worked for Acan Windows, which most people knew was owned by a large Korean corporation. As national sales manager, I would be the first to interview prospective sales personnel and to make recommendations to the top management, which was all from the corporate owner. At one point I recommended a woman for sales. This was at a time when I was not aware of any women in sales. I think she was a great candidate, but she was rejected before a second interview. This was in the early ‘90s. I considered recommending a young black man whose only experience was working in a liquor store. I expected him to be eaten alive in the field, going to smaller Ontario towns. I did not want to do that to him. To this day, I question myself over

whether I did the right thing or whether I was behaving in a prejudiced manner myself. For balance, there were many fine characteristics in working for the Koreans. At one point I made a notable financial mistake and when I confessed my crime to the company’s president, he replied, “You represent the company. We must honour your commitment as it is the company’s commitment.”

Next was a five-year stint working for Gem Windows in Toronto. This small family business, run by second-generation Spiros Christopoulos, was colour blind and sex blind, among other things. One woman who worked in sales had a bit of a moustache. She did her job well enough and no one said or thought anything. One day Spiros received a phone call from a potential customer who had met the woman in question as his assigned sales rep. He was very upset at the idea of being served by a woman with facial hair and requested another sales person. I also think he recommended that Gem get rid of the woman. Spiros’ response was to tell the would-be customer where to go.

Next on my employment travels was Vinyl Window Design. By 2001, man or woman, white, brown or black skin made no difference. Only ability seemed to be considered as numerous women were department heads at one point or another both in the factory and in the office.

In my many years working with various industry associations I have appreciated the increased role of women and people of a rainbow of colour. Over the years, I have known women owners of factories and retail establishments. I have enjoyed working with black and Asian customers. More recently, Arabic people have contributed to our industry. Overall, I’m not saying there are no racial or sex-based barriers, however when I look at where the world is today, I am pleased and proud at who we have become in fenestration as a Canadian industry.

Phil Lewin is now a semi-retired consultant who intends to continue his quest to point out when the emperors of the fenestration world are not wearing clothes.

FENESTRATION CANADA

All in this together

by Terry Adamson, Fenestration Canada president

Another summer in the books. Without a doubt the most unique summer any of us have ever experienced. Finding our way through all the difficulties faced by our industry, and by so many others, has taken a toll on everyone. I have tried to take a break from the news, social media, and the ever present “so how are you managing COVID?” question. Like everyone, I’m tired of it. Take a break. It helps. Unfortunately, it’s not done with us. So, we carry on doing our best to stay positive and move forward. FenCan has kept busy over the summer holding a few FenTalks online sessions with Al Jaugelis, FenCan technical director. These sessions continue to be well-received and informative, engaging online offerings. These have now become a staple of value for members and we will continue to develop and research new topics of interest to bring us together to discuss and debate. And of course, if you have questions or topics you would like us to address, let Al know at al.jaugelis@fenestrationcanada.ca Midsummer, we released the format for the WinDoor Marketplace event coming in November that we are holding in place of an in person WinDoor that had been scheduled for Montreal. Even with all the other online events held by numerous associations over the summer we are still seeing plenty of interest and expect that our show, scheduled for Nov. 18 and 19, will be a great success. The Marketplace component to the show that will carry on throughout the following year has attracted many suppliers, as it allows them to promote and update their booth long after the WinDoor show portion is over. If you are interested, reach out to Laine at laine@fenestrationcanada.ca.

Our committee activity has slowed a little over the summer, but we will see that we pick up moving into the fall. A committee that remains very active is our membership committee, holding several meetings during the summer. A number of our members have incurred stresses that impact their ability to maintain active membership. We understand these difficulties and are working with them and will do whatever we can to make sure they continue to receive our valuable content.

Members that need to drop their membership are encouraged to reach out as soon as their situation improves so we can make sure they continue to receive as much support as is possible. We must do our best to retain our membership and to ensure active members continue receiving the value they pay for. If you want to discuss your membership, reach out to Jason Wadel, jwadel@veka.com, membership committee chair.

In late September we held our Regional Week. This was a fast-paced virtual event taking place each day during the week of September 28. The focus was on each geographical region across the country represented by the regional committees. It is clear we have unique businesses and regional variations as we move across the nation. Content ranged from very specific challenges that each region faces, such as the Step Code in B.C. to the Tiered Code headed for Ontario. We addressed managing multi-unit engineered projects in the prairies as well as cold climate installations. The topics varied as much as the weather. Al delivered region-focused presentations on some of these challenges we face, as well as more national topics like the Market Transformation Roadmap details that will impact all of us. We had lighter sessions like the Manufacturer Spotlights, that allowed a member manufacturer to tell us about who they are and what they do. Always interesting to hear your peers tell us how they see the industry and what unique things they do. The Regional Week was well received with great attendance and interesting discussions. We extend our thanks to Veka and Everlast for their sponsorship participation – we really appreciate it. And the always entertaining Patrick Flannery for his Spotlight interviews. From its success we are committed to making the Regional Week an annual event moving forward.

Undaunted, Fenestration Canada continues to move forward developing programs, education and partnerships to provide the very best member value during these difficult times. We are here for you and your business. Do not hesitate to reach out to Stephane, Al, Laine or myself. We are all in this together, let’s help each other.

VIRTUAL EVENTS

NOT LIVE, BUT LIVELY

Fenestration Canada’s information-packed Regional Week was a big success.

by SUKANYA RAY GHOSH

Not bound by the constraints of venue location anymore, Fenestration Canada successfully carried out its Regional Week from Sept. 28 to Oct. 2. With every region’s unique set of requirements, the association put together a day of information-heavy sessions each catering to the five regions – British Columbia, the Prairies, Ontario, Quebec and the Atlantic.

Moving from the west to the east, the Regional Week kicked off with B.C. day. Interestingly, though the content was often region-specific, there were sessions that could be attended by other regions as well. An education item that featured on all the days was the Market Transformation Roadmap update and the National Building Code public review update presented by FenCan technical director, Al Jaugelis. Attendees heard from Jaugelis that all NBC code changes are focused on stricter energy performance requirements in large and small buildings and the introduction of defined tiers of better-than-base-code.Fenestration Canada and other associations commented on the changes to the National Energy Code for Buildings and to Part 9 in the public review. The publication of the 2020 NBC has been postponed to December 2021.

During the presentation on the MTR Roadmap, Jaugelis discussed the background: how the industry got there, the drivers that helped develop the

Ever since industry events have gone virtual, there has been a constant effort from everyone to offer something different that can keep attendees hooked to their screens.

roadmap and the process taken to develop it. He then focused on where the industry was headed with its implementation, what the governance structure is, what is supporting implementation and what the next steps are.

During the Prairies event, Dave Goldsmith; Randy Krebes, director of practice for the Alberta Architects Association; and Al Jaugelis all came together to discuss the roles of architects and engineers in non-exempt buildings. The topics touched during this session included why the North American Fenestration Standard is in the code, whether NAFS testing is sufficient to address Part 5 requirements and whether professional design and field review is necessary for windows and doors in nonexempt buildings.

Window testing and labelling in Canada was another interesting topic covered on multiple days. Jaugelis noted that he developed this presentation in response to a request from the Atlantic committee. They were asking for a presentation or a document that would simplify or help people to understand what’s required for NAFS testing. They wanted something that could be used to educate building officials as well as manufacturers about what the code requires in the way of performance testing and labeling. This presentation, he said, could be used for

that purpose.

On Atlantic day, Jaugelis offered a session on what was new for windows in the National Building Code 2015. During the presentation, he reviewed the products that are in and outside the scope of the NAFS standard. The next focus was on what the 2010 code had to say about windows and the problems that created for industry. The third point discussed was the new subsection dealing with other fenestration assemblies that was introduced in the 2015 National Building Code. And finally, Jaugelis provided tips for using the fenestration performance calculator available on the Fenestration Canada website.

Attendees also had the opportunity to video tour the Veka facility where they were shown how their profiles were created. Additionally, Patrick Flannery from Fenestration Review had interesting conversations with Everlast and Thermoproof during the “Manufacturer Spotlight” sessions.

It was not all work during the Regional Week. To end the informative and educational week on a high note, attendees were invited to a Trivia Night. All five regions shared a cocktail recipe each to keep up the cheer. Hosted by Flannery, it was the right mix of fun and friendly competition and a perfect ending to a eventful week.

RICH

Hunting and gathering

by Rich Porayko

The fall is hunting season. It’s a time when a very small yet driven percentage of the population head out into the field in search of sustenance to feed their families. Nonhunters really have no idea how hard it is. You need to find the right age of the right sex of the right species at the right time in the right place.

The “Golden Hour” is the hour at sunrise or sunset. Many seasoned hunters only hunt during this productive period and spend the warm noon weather scouting new locations, setting up blinds, checking game cameras and taking a nap. In order to maximize the “Golden Hour” you need to get up really early. The more time and effort you spend in the field, the more payback you’re going to get. After scouting for hours, days even, you finally see a huge buck. Excitement. You count the points. Only three on each side. Too small. Disappointment. Even when all of the planets for a shooting opportunity align, you still need to take the shot. If you choke, the animal can get spooked and bolt or, even worse, you miss or wound it.

A former mentor used to split sales reps into two categories: hunters and order-takers. I always thought the phrase “order-takers” was a bit harsh and prefer the term estimators but it’s the same idea. One group is proactively reaching outwards seeking sales (technically, commissions). The other group reactively waits for RFQs and orders to come in. My mentor was right: there is a big difference between the two groups.

I thought hunting would be easy. I was wrong. I thought sales would be easy, too. I was wrong again. Being a professional salesperson is hard, often thankless work. It’s full of rejection and disappointment.

Don’t get me wrong. Estimators are key. There needs to be experienced and knowledgeable resources available to support the outside team. Estimators and inside sales assist the sales process but they do not drive sales. For an organization of any decent size, there really needs to be both. An outside sales representative cannot be sending quotes, entering orders, babysitting orders and visiting customers.

My mentor was right about the hunter/gatherer analogy. When there isn’t a global pandemic,

successful sales reps need to be hustling out in the field. Cold calling new customers. Scouting new markets and opportunities. Qualifying prospects. Asking for orders. Some people have it naturally. Others can be trained. But most will fail or never pretend to try.

Sales is the ultimate numbers game. As with hunting, there is a direct parallel between productivity in the field and the return on investment. You’re never going to harvest a deer sitting on your couch. Sales don’t close themselves either.

Even after finding a prospect and being invited to bid on an active opportunity, you still need to close the sale. The customer may get spooked at the price and run. Or a competitor might swoop in and snipe the job from underneath you.

Which leads me to the well-known miserable feeling of disappointment going home empty handed. Nothing in life is guaranteed.

When quotes are turned into orders, quite often this is where the tedious and often unnecessary heavy lifting begins. Sales representatives are advocates for their customers with regards to lead times and quality issues, among other things. Although reps need to be aware of issues, customer support needs to be driven on the inside by inside sales, estimators or other customer support resources.

Sales representatives need to be hunting and gathering. Remove obstacles in the way of them doing their job. Take care of them and they will take care of you.

The market is already very competitive. Investing in your sales team and developing an aggressive commission structure so they can do more than just provide for their family is a surefire recruitment, retainment and growth strategy. If operations can keep up.

Another mentor used to say that if you aren’t in sales, you’re overhead. It is not an easy gig but if you set your sales team up for success, your company will follow.

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company in Metro Vancouver. richp@constructioncreative.com