Colin Breukelman reflected on his decision, saying,

‘The

by Brett Ruffell

The future of water used by Canada’s agriculture industry requires nationwide attention, a think tank says. The Canadian Agri-Food Policy Institute (CAPI) is urging governments to develop a comprehensive national plan to sustainably manage and utilize water for the agri-food sector.

In its recently released report, titled A National Agri-Food Water Action Plan, the institute emphasizes the need for ambitious commitments from governments and partnerships with stakeholders to prioritize this critical natural resource.

Tyler McCann, the managing director of CAPI and co-author of the report, highlights the strategic importance of water for Canada.

He also emphasizes the need to understand its value and leverage it while also conserving and managing it effectively.

“With increasing pressures in Canada and around the world, we can no longer take water for granted,” he says.

The report, which is available for download at capi-icpa.ca, identifies water as the key agricultural issue of the century, and underscores the urgency of adapting a plan to produce more food sustainably while adapting to change.

“Amid current climate and geopolitical change, water quality and quantity will redefine production and trade of agri-

food products – it’s the challenge of the 21st century,” says CAPI’s Nicolas Mesly, who also cowrote the report.

The institute calls for immediate action to establish a foundation for effective water management, including uniformity in data collection, investment in research, and the formation of an expert panel. Furthermore, the report recommends using watersheds as the basis for research and innovation.

The institute calls for this because the current fragmented and siloed model for water management in Canada lacks standardized and complete data collection and reporting. It is crucial to address these issues and ensure standardized data collection and reporting.

“With increasing pressures in Canada and around the world, we can no longer take water for granted.”

The document emphasizes the need for a regular assessment of the state of water resources in the agri-food sector. It suggests the importance of providing a comprehensive overview of water usage in agriculture and food production across the country, as well as the measures taken to protect and manage this vital resource.

Additionally, the report highlights the significance of understanding the investments made

in water-related initiatives. Water plays a critical role in food production in Canada, and the country has been grappling with consecutive droughts, posing challenges for farmers. The report emphasizes the increasing occurrence of extreme weather events, including droughts, heavy rains, and floods, and underscores the importance of flexible infrastructure to effectively manage water supply.

At Canadian Poultry , we understand how important water is to the industry. That’s why we’ve once again put together our annual water issue.

The pages ahead are dedicated to helping producers better mange this vital resource. For example, in our cover story on page 10, three people who go the extra mile with water management share what’s worked well for their poultry operations.

In addition, on page 18 read about an exciting new made-inCanada app that helps poultry producers manage the water on their barns more effectively.

The issue also includes two insightful columns on water management. In her brooding column on page 8, Dr. Gigi Lin shares an interesting case report about a flock of chicks that suffered from dehydration due to an issue with the waterlines.

Complimenting this column, on page 24, water expert Mary Foy provides a helpful primer on cleaning your waterlines.

Enjoy the issue! And if you know of anyone else doing something outstanding with their water, I’d love to hear about it. Email me at bruffell@annexbusinessmedia.com.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Curtis Martin

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager Anita Madden amadden@annexbusinessmedia.com 416-510-5183

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada – 1 Year $32.50 (plus applicable taxes)

USA – 1 Year $91.50 CDN

Foreign – 1 Year $103.50 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

From the first day your chicks and poults are placed, water is one of the first things they look for, and for decades farmers and poultry have relied on our drinkers for a consistent flow of fresh water.

Our drinkers provide poultry the single most important ingredient for the BEST POSSIBLE START, AND HEALTHIEST LIFE DURING LAY PERIOD AND GROW-OUT.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc. Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

In the first complete week of November, several commercial flocks in British Columbia have been diagnosed with avian flu, contributing to the rapid spread of the disease among poultry farms in the region. The primary source of infection for both commercial and backyard operations in B.C. is believed to be the fall migration of wild birds. To prevent further spread of the disease, the chief veterinarian of B.C. issued two orders in October. Farmers were instructed to keep their birds indoors, and markets and auctions were halted.

The Livestock Research Innovation Corporation (LRIC) has secured a $2 million funding agreement from the governments of Canada and Ontario.

The Sustainable Canadian Agricultural Partnership, a five-year federal-provincial-territorial initiative, will provide support for LRIC’s activities on behalf of the livestock sector for the next five years. The agreement will allow LRIC to continue its work in industry intelligence-gathering, stakeholder engagement and collaboration.

To commence the holiday season, Think Turkey is shining a spotlight on underappreciated heroes of the holidays with the introduction of the inaugural Wishbone Awards. The program will acknowledge and support community champions who strive to provide holiday meals for those in need. In December, eight exceptional individuals will be honored.

The team of Greg Page, Chanelle Taylor, Kendra Vanden Ouweland and Brenna Tuer took the Most Persistent Swingers prize.

On September 6th, 2023, the Poultry Industry Council (PIC) held its annual fundraiser golf tournament at Foxwood Golf Club in Baden, Ont.

Despite the hot weather, over 165 golfers from different sectors of the industry participated in a fun round of best ball.

is how many golfers from different sectors of the industry participated in the best ball tournament.

The team from Nieuwland Feed won with the lowest score of the day. The event also featured a unique “scared chicken” contest, where golfers had to hit a wooden chicken with their first shot. Sandra Palmer and Chanel Taylor both won prizes, with Taylor impressively using her putter off the tee.

The AGM and board of director’s meeting followed in late October, where some leadership changes were made.

Caroline Gonano remains as the chair of the board, while Dr. Kayla Price takes over as vice chair. Cathy Lennon continues to serve as treasurer.

The National Poultry Show made a successful return, and strategic projects were implemented to address education gaps in the sector.

PIC is excited to deliver its cornerstone events for the 2023-2024 year, which will focus on Poultry Health, Research Impacts, and Producer Updates, among others.

It will also extend their support to small flock owners by educating them on biosecurity practices and assisting them with any disease issues that could potentially impact the industry.

Gonano expresses her pride in leading an organization that is open to new ideas and ready to grow. PIC is well-positioned for success in the future.

The past fiscal year was marked by the concern of HPAI in the industry, but PIC played a crucial role in keeping the industry informed and prepared.

For full details from these events, visit poultryindustrycouncil.ca.

“On behalf of the Board of Directors of Chicken Farmers of Canada, I would like to extend to you our best wishes for a safe holiday season and a peaceful New Year.”

« Au nom du Conseil d’administration des Producteurs de poulet du Canada, j’aimerais vous offrir nos meilleurs vœux pour la saison des fêtes en toute sécurité et une nouvelle année paisible. »

Tim Klompmaker Chair, Chicken Farmers of Canada Président, Les Producteurs de

poulet du Canada

By Dr. Gigi Lin

Dr. Gigi Lin is a board-certified poultry veterinarian. She provides diagnostic, research, consultation, continuing education, and field services to all levels of the poultry industry in Western Canada. In this column, she will share case-based reviews of brooding best practices.

It was on a Monday morning that I received a call from a broiler grower who was concerned about his five-day-old flock, which had experienced a sudden increase in mortality (two per cent) over the weekend. The grower believed that the chicks had bacterial infection and was hoping to treat them with antibiotics.

He was convinced that the flock had bacterial septicemia because, upon opening up some chicks, he noticed their hearts were covered by a white sac – a lesion he learned about in a recent poultry disease webinar. I made a field visit to launch the disease investigation.

Before entering the barn, I performed an on-farm necropsy to confirm the cause of death. None of the chicks showed signs of bacterial infection; most had varying amounts of feed in the crop and gizzards.

All the chicks had gross lesions consistent with severe dehydration, including: sunken eyes; dry, shriveled, dark skin on the lower legs; dark and dry muscles; swollen, distended ureters; and pale kidneys.

The most prominent lesion was visceral gout, characterized by chalky, white deposits on the surface of the hearts (and sometimes on other organs such as the livers) – a lesion that can be mistaken for fibrinous pericarditis found in chicks with systemic bacterial infection.

To expedite a treatment plan and reduce losses, it is

important to obtain an accurate diagnosis from a poultry veterinarian or pathologist, as some of the lesions can have similar appearances. Visceral gout (chalky, white deposits) and fibrinous pericarditis (pale yellow cheese-like layer) are induced by different causes; therefore, both require different interventions.

Visceral gout, a condition resulting from the deposition of urates on various organs, is commonly found in young chicks suffering from dehydration. Although relatively rare, visceral gout can also result from kidney damage due to various primary causes such as infection, nutritional imbalance, and toxicity. Once again, it is crucial to emphasis that making an accurate diagnosis is the first and most important step of disease investigation.

Although the necropsy findings clearly showed that the chicks suffered from dehydration, I still conducted a comprehensive brooding assessment to ensure that there were no

factors deterring the chicks from accessing the water source. For example, as I discussed in my previous column, high carbon dioxide levels in the barn can induce huddling behaviour and reduce birds’ water and feed intake.

Based on the brooding assessment, the barn had excellent brooding conditions in general in terms of the temperature setting, feed supply, litter condition, air quality, and sanitation. All the waterlines were at the correct levels with clean water supply on both ends. However, upon testing all the drinking nipples, all five waterlines had sections with no water flow, accounting for over 25 per cent of the overall water supply.

Through further investigation, I found that the waterlines were unleveled for maintenance and drinking nipple replacement over the downtime period. These actions likely induced trapped air in the waterlines, creating air locks that restrict water flow in various sections.

Fortunately, dehydration is generally easy to treat simply by resuming consistent fresh and clean water supply. All the waterlines returned to full function after the grower flushed them and readjusted the water pressure. The flock returned to normal condition within 24 hours after the resumption of water supply.

Before flock placement, in addition to leveling and sanitizing the drinker lines, remember to trigger most of the drinking nipples to help identify clogged sections or areas of restricted water flow even after a round of high-pressure flushing.

In some scenarios, inadequate water flow could be identified early if chicks are observed pecking at the water nipples aggressively or spending more time drinking. Young chicks are very susceptible to dehydration and will die quickly. This is especially the case beginning on the fourth or fifth days of life, once they consume the water and nutrients from the yolk sacs.

Thank you to turkey farmers across Canada, who help Canadians celebrate their tradition with turkey at the table.

Canadian turkey farmers are committed to ensuring the humane care and respectful treatment of their birds, while providing wholesome and safe food to consumers.

Ensuring top-notch water is a key element of success for these three poultry producers. By Ronda Payne

Water. It’s a vital necessity for all forms of life, including livestock. While humans consist of around 60 per cent H2O, chickens surpass that with a composition of 70 per cent water.

Even a slight decrease of 10 per cent in the essential fluid can prove fatal for a chicken. Therefore, it is crucial to deeply contemplate the significance of water in maintaining the health of birds.

Here, three producers who are well aware of the significance of water as a crucial input in their operations discuss the measures they take to ensure the purity, cleanliness, and healthiness of water for their birds.

Producing about 65,000 tom turkeys for consumer meat consumption, Steve Clark and his son Todd know more than a thing

or two about the elements that lead to great quality birds. Steve and his wife Kim purchased their farm in Embro, Ont., in 1997 and now take a slightly less active role as Todd and his wife Cassandra are running the business.

The family run operation works seven cycles of about 9,500 birds each per year, from one-day-old poults through to finish at about 16 weeks.

“Water, feed and good air movement in the barns are key to growing good quality turkeys,” says Steve. “Bad water can stunt a turkey’s growth and cause certain ailments that will affect the farm’s bottom line. Keep in mind, we have been growing RWA (raised without antibiotics) for the last seven years approximately, so making sure everything is of great quality is extra important, as we cannot medicate if a problem arises.”

About four years ago, the farm switched to using an organic acid, called MS Goldmix, to reach the desired pH. This

combined with Dutrion tablets that mix with water to achieve chlorine dioxide. The switch wasn’t a proactive one, but instead a response to some rather undesirable build up.

“In the late 90s and into the 2000s, water on the farm was good,” Steve says. “We could run your typical low doses of chlorine for pH along with low doses of peroxide to keep the waterlines free of biofilm. This achieved good water for the turkeys to drink.”

Then, about 10 years ago, something in the water table changed. There was a greater build up of slime and gunk in the filters. Of all the glamourous jobs in farming, cleaning and changing slimy filters more regularly and being concerned about the water isn’t a highlight.

“Eventually, it escalated to where our drinkers were gumming up with sliming biofilm and greatly reducing waterflow,”

he says. “We tried numerous different acid products and sanitizers to try and solve the problem but kept hitting dead ends.”

In a stroke of luck, they found advice from a veterinarian who encouraged them to try an organic acid with chlorine dioxide.

“The chlorine dioxide keeps the waterlines clean and free of biofilm buildup,” he says., “And since we started using the products, our filters need to only be cleaned once annually and our waterlines and water cups have never plugged up.”

“Water, feed and good air movement in the barns are key to growing good quality turkeys.”

The need for feed

It takes very little for water pH to go sideways and wreak havoc with turkey growth.

“A good pH is vital to a turkey’s health,” Steve notes. “Although farmers’ opinions vary on what is a proper pH to achieve, we like to have our pH in the brood barn just below a five. The lower the pH, the harder it is for E. coli and harmful bacteria to live in the turkey.”

The flip side, however, is that if pH is too low, the birds may stop drinking and subsequently stop eating. This would decrease bird growth and impact profitability.

Todd says since making the switch to organic acid and chlorine dioxide, the birds are achieving target weights more consistently. Flock mortality levels are also improved.

“When there are fewer water disruptions… I’d definitely say things are much better productivity-wise than before,” he says.

Steve says a big selling feature is that there is no restriction on water flow with this system and the chlorine dioxide is tasteless and odorless – a huge improvement over traditional chlorine.

“However, these products aren’t cheap,” he notes. “We spend at least $20,000 a

year. A similar-sized farm would probably spend at least 40 per cent less than us with other cheaper products.”

Implementation was simple and the pumps for the products work great. The chlorine dioxide pump sometimes has crystallization build up and needs to be

cleaned, but Steve says this is a quick, 10-minute job to get everything back in business.

Many sites, many solutions

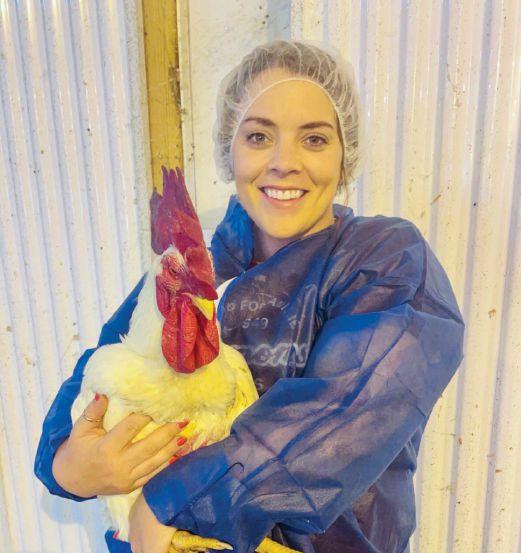

In Gentry, Ark., Samantha Beitia is the quality assurance manager of live production of broilers for Simmons Foods. Through several contract farms, the operation processes about four million birds a week.

“One thing I love most about my position is that I work with water quality,” she says. “There isn’t a one-size-fits-all program, so understanding the needs at each farm is important.”

She explains that water is the number one nutrient birds consume. More than feed. She refers to a study that says for every pound of feed a bird eats, they will drink 1.7 pounds of water.

Beitia understands that flock performance often improves when water is right and considers the challenges of various minerals and specifics to a farm’s water source.

Enhancing the system

“The first thing I’m going to do is I’m going to take a sample from the source, the control rooms and at the end of the line,” she says. “I’m going to look for bacterial contamination and I’m going to

see what that looks like at each stage of the sampling. Also, a mineral analysis, as it’s typically a well, to see if there are any underlying problems.”

These tests help determine if there is a mineral issue, microbial

Continued from page 26

Enjoy peace of mind monitoring while staying in control of monthly fees!

The DOL 2400 alarm system can be connected to traditional landline or utilize the cell network for alarm notifications. Unlike some other systems where you are locked into a contract for your monthly fees the DOL 2400 can use any mobile GSM carrier, and if you want to switch providers you simply insert a new SIM card.

Available with 7" or 10" touchscreen. Base units come configured as ten inputs and outputs, expandable to 100 by adding expansion boxes or slaves. Connect multiple barns using master / slave mode which allows all units to utilize one dialer (less monthly fees)

• Wide variety of sensors available including, temperature, humidity, CO2, ammonia, dry contact, power failure

• Phone call or text message (GSM units) notification options, as well as siren, flashing light or silent (burglary)

• Status reports via text message (GSM units) NO DATA OR INTERNET REQUIRED

• Can activate backup equipment in case of alarm (outputs)

• Self learning temperature curves for alarm set-points

• Optional fingerprint scanner for additional security

County Line Equipment Ltd. sales@county-line.ca | www.county-line.ca

Listowel 8582 Hwy 23 N., Listowel ON N4W 3G6 (800) 463-7622

Hickson 596202 Highway 59, Woodstock, ON N4S 7W1 (800) 463-7622 ext 4

By Jane Robinson

Research is just scratching the surface to understand how nutrition can bring pullets into lay in optimum body condition, according to Dr. Martin Zuidhof. “What’s really missing in the literature is information on how pullet rearing strategies impact long-term egg production,” says Zuidhof, who’s in charge of poultry systems modeling and precision feeding in the Agricultural, Food and Nutritional Science Department at the University of Alberta.

The multi-feed precision feeding system he created is proving to be an invaluable research tool for evaluating nutritional strategies during pullet rearing. “One of the advantages to using precision feeding stations is the efficiency for studying various diets, and the ability to apply treatments to individual birds and gather data on them in a free-run environment,” he says. “We wanted to look specifically at the impact of energy and protein during rearing.”

Zuidhof’s graduate student Jo Ann Chew is working on the underlying mechanisms that bring pullets into lay for her PhD. “My project is looking to determine pullet rearing optimization strategies –what we feed a growing bird and how that impacts their lifelong health and productivity,” says Chew.

The project was split into two parts looking at dietary energy and protein/ amino acid levels separately. Another one of Zuidhof’s PhD students, Thiago Noetzold, was also involved in the dietary energy study.

The first trial focused on how different levels of energy affected egg production and ran from April 2021 until December 2022. Three dietary energy levels were compared – 2,800 kilocalories per kilogram (industry standard), a lower level at 2,600 kilocalories and a higher level at 3,000 kilocalories. Diets were fed to pullets in multi-feed precision feeding stations on an unrestricted or restricted basis.

“Each bird was fitted with a radio

frequency identification (RFID) tag to align with the diet and feeding frequency assigned,” says Chew. “When the birds enter the feeding station, the RFID tag is read, and the appropriate diet is dispensed.”

Birds assigned unrestricted feeding received a meal any time they enter a feeding station, while birds on restricted access feeding received a meal based on a frequency that kept them on the lower end of the breeder recommended body

Visit eggs.ca for fun and festive recipes to help you savour the celebration.

Season’s greetings from Egg Farmers of Canada.

Visitez lesoeufs.ca pour savourer le temps des fêtes avec des recettes amusantes et festives.

Joyeuses fêtes de la part des Producteurs d’œufs du Canada.

weight trajectory for pullet growth. “We looked at a bit of feed restriction in this study to see if we could save a little on feed and still come up with the body condition at lay that would support a productive laying cycle,” says Zuidhof.

The study also included a “choice” group where birds had access to all three energy level diets when they entered the feeding station. For comparison, the project also included a conventional feeding system with birds in treatment pens – one for each energy level diet. The choice group was omitted in the conventional feeding study.

All birds were monitored through rearing for body fat, body weight, feed intake, age at first lay, egg production and egg quality. They were monitored throughout the lay period, although the feeding treatments ended when they came into lay; all birds received the same diet during the egg-laying phase.

While the results are still preliminary, there are a few clear findings when comparing energy levels and feed access options in pullet rearing.

Layer pullets with unrestricted access to feed came into lay earlier than birds with restricted access to feed. There was no difference between the three energy levels fed with the precision feeding system for the age at first lay. Birds fed the standard level of energy (2,800 kilocalories per kilogram) showed the most promising results if fed unrestricted. Birds fed the standard diet with restricted access performed lower.

“If you think about the application to industry, the birds fed the standard energy diet were most promising when feed intake was not restricted in any way,” says Chew. “If access to feed is restricted, as we simulated with precision feeding, birds

will perform at a lower level,” says Chew.

The bottom line. “The industry has it right for layer pullets when it comes to energy level in the diet and providing pullets with unrestricted access to feed,” says Zuidhof.

The protein portion of the study started in May 2023 and is taking a slightly different approach – looking to find the level of protein pullets need to obtain their max imum rate of gain prior to sexual matura tion. The precision feeding stations are being used to assign different diets but there is no feed restriction component.

“We are comparing brown-feathered and white-feathered strains to see if opti mum protein levels during rearing are strain-dependent,” says Chew. “We’ll also look at how differences in body compos ition influence the onset of lay between the brown- and white-feathered birds.”

Results of this study are expected in early 2024.

feeding system producers are using, there is no need for precision feeding in a commer-

layers, just maybe not in his lifetime. “When we feed an animal what it needs,

The question now is whether precision feeding will become the new normal in layer pullet rearing as it has already shown promise in broiler breeders. Not just yet, says Zuidhof.

The precision feeding system serves up a solid research role but there are no clear benefits for the layer industry at this time. “There is still so much we need to know about what individual layer pullets need from a nutrition point of view,” he says. “We need to figure that out before precision feeding would make sense for commercial layers.”

Considering that this research showed no advantage to restricting feed when rearing pullets, compared to the conventional

Everyday stressors from environmental or feed changes to handling and socialization can impact poultry health and productivity. This stress can lead to reduced feed intake, fertility and productivity — just to name a few of its effects. But it doesn’t have to be this way.

KemTRACE® Chromium from Kemin helps alleviate the negative impacts of stress for improved maintenance, reproduction, growth and immunity. In fact, supplementing with KemTRACE Chromium can lead to a 2-point improvement in feed conversion ratio.

LEARN MORE AT kemin.com/ktchromium

By Jane Robinson

Water quality plays an important role in overall flock health and performance. But every farm has a unique water supply and system so providing general guidelines about water management is generic at best.

A group of Alberta poultry researchers set about to construct a customized decision-making tool that could streamline the resources available for poultry producers looking for customized solutions to drinking water issues to improve productivity.

“We knew there is a wealth of information on water management in poultry farms, but no systematic way to identify and address specific types of water challenges on an individual farm,” says Mohammad Afrouziyeh, research associate with the Poultry Innovation Partnership (PIP) and sessional university lecturer in animal nutrition at the University of Alberta.

Afrouziyeh led a collaborative team that drew on the expertise of researchers, industry and producers to create what they believe to be the first Made-in-Canada app for drinking water management on poultry farms.

He credits Dr. Val Carney, PIP leader and associate professor at the University of Alberta, for the idea behind the project based on stories she was hearing at producer meetings about challenges in bird

performance and liveability related to water management.

Afrouziyeh began the project by reviewing existing resources on water management for poultry farms. He collaborated with poultry water management experts to be sure their net was cast wide enough to capture relevant water management knowledge when building and powering the app.

“I distilled all this information into a user-friendly format to create an app that would identify challenges and help producers make informed decision about the actions needed to manage and treat water,” says Afrouziyeh.

The resulting app – the PIP Poultry Water App – uses a decision-tree style to gather input from the user and provide solutions geared to individual challenges identified by farm. The app is applicable for all types of poultry operations.

There are two key components to the app. The first part consists of 63 multiple choice questions in five sections that cover observational, mineral and microbiological test results, plus on-farm water testing procedures and water system maintenance. Based on answers provided, the app generates recommendations for each section, including solutions and actions as needed.

The second part contains resources on water quality that include video protocols on water sampling, microbial treatment and water sanitation, waterline cleaning during and between flocks, biofilm cleaning, drinking water vaccination, well shock chlorination and onfarm water test tools.

“The app represents a significant

advancement for poultry farmers, giving them the tools to manage drinking water systems efficiently that will result in healthier birds, increased productivity and reduced costs,” says Afrouziyeh.

What’s truly unique about this app is the big picture, whole farm view. “We need to connect the dots and look beyond just microbiology or mineral tests when it comes to water management,” says Afrouziyeh. “The app is much more robust than a lab test report because it includes other aspects of water management to determine where any problems are coming from.”

During the development and testing of the PIP Poultry Water App, the team connected with about 30 poultry farmers in Alberta to test it and provide feedback to refine and enhance the functionality of the tool.

And in 2024, Afrouziyeh and PIP will be working with the Egg Farmers of Alberta to conduct on-farm research to measure and evaluate the real-world impact of the app on about 10 poultry farmers in the province. “We expect this research will give us valuable insights about how the app is recognizing potential water-related challenges, improving water quality and quantity, and overall farm productivity,” says Afrouziyeh.

While they don’t have data on number of app users yet, Afrouziyeh says they are actively monitoring user engagement and feedback on the website, that includes a user feedback section to help the team continue to refine the app. Poultry producers in Europe and the U.S. have also shown interest in the app.

The PIP Poultry Water App is available at pippoultrywaterapp.com for a one-time fee of $49.

Poultry Innovation Partnership is a consortium of government, university and industry focused on making knowledge and information available and translatable into action for end users. The PIP Poultry Water App project received funding from Results Driven Agriculture Research (RDAR) and the Canadian Agricultural Partnership (CAP).

Can a barn get too clean? A look at the science.

By Lisa McLean

Canadian broiler producers are required to deep clean their barns with chemical disinfectants at least once per year, but how they clean between flocks is a little more fluid. Some producers opt for a full disinfectant with every cleanout, while others may choose to wash with just water between flocks.

It’s an important biosecurity decision that has the potential to impact food safety and flock health. Now, for the first time, research looks at how both options impact chicken gut health.

Dr. Yi Fan, Department of Agriculture, Food and Nutritional Science at the University of Alberta, has completed a study evaluating the effects of barn cleaning methods on various factors affecting broiler health. His results suggest that, for barns that have had no challenges with disease outbreaks, a water wash may be healthier.

“Our results suggest that water wash may result in enhanced activity of the gut microbiota and they seemed to be more naturally resistant to pathogenic bacteria,” says Fan.

The study involved 28 production flocks raised in barns without any prior history of disease outbreaks. A commercial broiler facility in Alberta provided the chickens and facilities for the project, including seven cement-floored production houses at two locations. Over a 10-month period, the researchers studied 14 flocks raised in barns that employed each cleaning practice.

In all of the flocks studied, barns had been cleaned thoroughly. Chicken manure, used litter and organic matter were completely

removed. The full disinfection cleaning practice included foam and high-pressure and low-pressure wash and air drying. The water wash process included low-pressure water rinse and air drying.

The researchers tested litter samples, feeding pan samples, drinker samples, and shoe-cover samples. They also evaluated broiler performance and gut health indicators such as the composition of the cecal microbiota, Campylobacter and Salmonella occurrence, and short-chain fatty acid composition.

“Our results revealed that barn cleaning methods had little impact on the 30day body weight and mortality rate of broiler chickens, which would also suggest an absence of subclinical infection,” says Fan. “From the beginning to the end, we did not recover any salmonella from the environment or the chicken gut.”

Most tellingly for Fan, was the subtle but

significant effect on the broiler cecal microbiota that resulted from the two cleaning practices. The full disinfectant treatment showed increased abundance of cecal Campylobacter associated with decreased concentrations of short-chain fatty acids (SCFA).

In general, the gut microbiota-derived short-chain fatty acids increases the gut acidity, which creates an environment that is less favourable for many pathogens. Fan notes these fatty acids also act as fuel for intestinal cells, and play an important role in modulating immune responses.

“This would support the adoption of water wash as a standard practice, because compared to full disinfection, water wash can be beneficial to the broiler chicken by altering the gut micro-environment towards a more homeostatic state with reduced cost and labor of cleaning,” says Fan.

To understand why this might be the case, Fan suggests it’s important to look at chickens

in natural environments. In nature, chicks are hatched by hens, and the parental flock passes their microbiome to the chicks. Fan notes that in modern production systems, eggs are collected and transferred to a clean hatchery, and then chicks are transported to barns.

“In our modern production system, we artificially cut the beneficial microbiome connection between hens and their chicks,” says Fan. “Using chemical disinfectants removes a high proportion of microbes, but it may also reduce the transmission of beneficial microbes between flocks. This could lead to a potential loss in the microbes that can outcompete pathogens in the environment.”

There’s value in a good clean Whether producers opt for once a year or a more regular full disinfection, it’s important to get it right. Michael Ryan is the owner

and general manager of Jeni Mobile Wash Ltd, an Ontario-based cleaning service.

“The goal of a proper wet wash with detergent and disinfectant is to get the disease threshold in the barn as low as possible.” Ryan says. “If the wet wash isn’t done well, all you’re doing is getting the bacteria in the barn wet.”

Ryan says some producers call in his experienced crew once they’ve run into a disease challenge. It takes time to clear up the problem.

“It’s more challenging to control a disease in a barn that hasn’t been washed properly in a while because things build up,” Ryan says. “And when you don’t have the option of using antibiotics, it becomes more important to start with a clean barn, and give those birds the best start possible.”

Decisions are personal Fan admits it’s a “great responsibility” to

advise growers on biosecurity decisions, especially without the tool of antibiotics if an outbreak occurs.

“For producers who feel confident in their flocks, who have not had a previous disease challenge in their barns, this gives them the confidence to continue cleaning between flocks with a water wash, and the research supports they should not lose chicken performance or see increased mortalities,” says Fan.

All of the barns in this study were from a nonchallenging commercial production setting. He says further studies examining other barn disinfection practices, and testing for other pathogens are warranted to identify the best practices to minimize pathogen load and maintain animal performance.

This research was supported by the Alberta Livestock and Meat Agency, the Alberta Chicken Producers, the Results Driven Agriculture Research, and the Canadian Poultry Research Council.

Season’s Greetings from the Board of Directors and Staff

Meilleurs Voeux du Conseil d’administration et du personnel

By Mary K. Foy

We hear it all the time when it comes to getting our farms ready for a flock to be placed – clean the water lines. The assumption is that everyone just knows how to do this. Well, if you feel like you missed the memo on how to clean water lines, or if you just want a refresher course, we have you covered here.

Equipment you will need Cleaning product

Find a product that specifically says it can be used to clean agricultural water lines. Some products are very harsh on the rubber components and stainless-steel components of our water systems. Read the label!

Sump pump or proportioner pump

Most products call for a two or three per cent solution. This cannot be achieved with a 1:128 medicator. Some growers have an adjustable medicator that can go up to these percentages. There are special proportional pumps called Qwik-Blends that will inject the three per cent directly from the container, or you can use a barrel with 30 gallons of water, one gallon of cleaning product and a sump pump to create a three per cent solution that is pumped directly into the waterline with the sump pump.

Gloves

Protect your hands!

Bucket

You’ll need one if you do not have flush hoses installed at the end of the waterlines.

Steps for cleaning your lines

1. Start with an empty barn.

2. Lower the waterlines so the drinkers will be easy to trigger by hand

3. Adjust your medicator to the two or three per cent level, install the QwikBlend proportioner pump, or set up

“Clean the waterlines between every flock to give each placement of birds a fresh start.”

your sump pump/barrel of solution to deliver the recommended solution into the water system. (A Qwik-Blend will go onto the system right where your medicator is – unscrew the medicator hoses and screw in the Qwik-Blend hoses. Qwik-Blends are only to be used when no animals are present. A sump pump will just need one access valve into the system to screw in the hose from the sump pump into the system – close all valves before the sump pump location so there is no back flow)

4. Open overhead clean-out hoses or

attach a flush hose to the end of the line and open valves. You can also place buckets at the end of the waterline.

5. Dye that does not contain a stabilizer (vaccine dyes have stabilizers in them) may be added to some products at this point to indicate product location in the system.

6. Turn on water in the anteroom and begin flushing. It may take 15 to 20 minutes for the system to be full of the cleaning solution.

7. While the lines are filling with cleaning solution, walk the barn and trigger every drinker. This is an essential step to cleaning the system properly.

8. Watch for fizzing (if using a hydrogen

peroxide) or the dye color change on the ground outside where the hoses empty or in the catch bucket at the end of the waterline if you do not have flush hoses.

9. Hang the flush hose up high to prevent solution from syphoning out of

the line. If you have overhead cleanouts, leave the valves partially open to provide adequate ventilation.

10. Allow solution to sit the recommended time that is on the label of the product. Please pay attention to this. Some products only stay for 6 hours,

some can stay for 24 hours depending on how harsh they may be for your equipment

11. After the recommended amount of time has passed , flush fresh water into waterlines and trigger each drinker again. You must trigger the drinkers again to make sure fresh water is in the drinker wells for the incoming birds. This may take 30 to 45 minutes.

Before you start, make a plan. What product will you use? Read the label to help fine tune your plan. Remember, the amount of product you use during a flock will be different than the amount you use cleaning waterlines. Read, read, read.

How much product will you need? Calculate the volume of your waterlines and what it will take to have a two or three per cent solution of cleaning product put into those lines. Product manufacturers with experience in poultry may be able to answer this question for you based on your barn size and waterline diameter.

When will you do this? It is recommended that cleaning the waterlines be done a couple of days before birds are placed.

If the lines have never been cleaned or if it has been several years, plan to repeat the process and give yourself enough time to do that before the birds are placed.

Carrying contamination in the waterline from one flock to the next flock is one of the most common missteps when raising birds. Clean the waterlines between every flock to give each placement of birds a fresh start.

Continued from page 8

issue, or both. She also makes use of a water camera to look at the line for visual factors.

“For Simmons, I’d say 90 per cent of our farms pull from a well and then we require storage tanks for animal welfare purposes,” she explains. “Typically, the well water goes through the storage tanks, through the underground lines and into the water control room. From the water room, we go through an inline filter, then you’re going into the house for the birds to consume.”

The inline filter is the “tell” in the system. Beitia uses visual observation to adjust as needed.

“If we didn’t have that filter, I wouldn’t know,” she says. “It could be a slime bloom. If you watch your filters, it could be your first line of defense. You know you need to get something in the water.”

She says problems can crop up quickly without warning. Her starting point is flushing the lines with fresh water to move the concerns out, then follow with a sanitation chemical to counteract the slime or other contaminants.

“Our water systems are vulnerable,” she says. “They can be a challenge to our birds. Our systems can harbour bacteria that can harm our birds.”

826 Nanticoke Creek Parkway, Jarvis, Ontario, N0A 1J0 Call us on: 519-587-2667 www.meller.ca • mellerpoultry@gmail.com

While she feels getting to optimal water quality is relatively simple, she is also aware that some farms have more significant challenges.

tiers. This system requires fewer aisles, resulting in maximum house utilization and maximum egg production.

The quest for the Holy Grail

Jordan Fois, farmer with Fois Poultry Farm in Wellenport, Ont., says he thinks all farmers and businesspeople look for the edge that advances them.

“I always thought water was the Holy Grail. It took me about four years to find the right person,” Fois says. “His name is Walter.”

Fois connected with Walter Bauer of Bauer Energy Design about 15 years ago to help with his broiler farm and he can’t say enough good things about how the water has improved since that time. In fact, it’s so good, he doesn’t think much about his water anymore.

In Fois’ large cistern, one of Bauer’s mixers slices through the water to “change the molecular structure,” Fois says. From there, the water is chlorinated in contact tanks for about 30 minutes, then runs through two green sand filters, a UV

system and then one last filter before making its way to the holding tanks.

“But it leaves all the minerals in the water,” he clarifies. “UV lights, I change once a year. I had one break down. After 10 years, I had to change a constant pressure pump. The system has been bulletproof.”

He told Canadian Poultry that he’d found the key to healthier water with this system in an interview about four-and-ahalf years ago. Is it still just as good?

Absolutely.

“I don’t believe I would change anything,” he says. “I believe the benefits outweigh the costs when you have an ROI of less than five years. There’s hardly any ammonia in the barn, though, that’s not very scientific.”

He adds that the other benefit is that there is a great reduction in antibiotic need in the flock as well as with baby chicks. With five crops a year on a 10-week cycle,

and about 200,000 kilos a quarter, the results speak for themselves.

He’s adamant about not just good, but great, quality water.

“We use this water to drink and to shower in as well,” he says. “My family comes first, the chickens come second. I collect water off the roofs of the barns and I also truck a lot of water in that comes from Lake Ontario.”

He doesn’t test his water much anymore. He walks into his water room and knows what to look for.

“You’re always looking for that edge and the edge for me was putting that system in,” he says. “Not only for me and my family’s health, but also for my bottom line. I think in North America in general we take water for granted. I think we should take a real hard look at water and the benefits of clean water. It’s so important.”

Broiler Nutrition serves as a follow on from Chicken Nutrition, published in 2013, which was intended to function as an introduction to poultry nutrition for nutritionists and poultry professionals.

The book is focused purely on the science of feeding rapidly-growing broiler chickens. The rapid developments in both the genotype of the bird; in production and commercial systems; changing consumer perceptions and demands; and advances in our understanding of the various aspects of broiler nutrition have meant that – as an industry – we are required to rethink many of our current practices.

Sector

The business

Daybreak Farms, located in the secluded town of Terrace, B.C., is a thriving egg operation. Comprising of layer barns, a grading station, and a feed mill, the farm employs about a dozen staff members. Following the unfortunate passing of her father, Kieran McKeown assumed control as general manager of the farm.

The need

Upon inheriting the business, McKeown promptly shifted her focus towards replacing the farm’s deteriorating conventional barns. She recognized the industry’s shift towards enriched housing. She also felt that her community prioritized affordability over whether hens were cage-free. So, she embarked on a decade-long modernization project, investing millions into the development of a state-of-the-art enriched housing facility.

The barn

McKeown had a single expansive facility built comprising of six interconnected barns, each equipped with its own separate production unit. Opting for a mega structure instead of three individual barns proved to be a more efficient choice, as stated by McKeown. Each barn is furnished with enriched, stackable housing and possesses its own ventilation system, climate control, manure removal, and feeding system. However, they all benefit from a shared conveyor belt, enhancing the efficiency of egg collection and sanitization.

The Clostridium Perfringens Type A vaccine is the only mass-administered vaccine available for controlling necrotic enteritis (NE) in chickens. Using RASV technology, it stimulates an immune response against both α-toxin and Netb toxin of C. perfringens Type A.

Proven effective for the vaccination of healthy chickens at day of age or older against NE due to C. perfringens type A.

Talk to your Huvepharma sales representative or contact customer service at customerservice@huvepharma.ca