Establish

by Brett Ruffell

Establish

by Brett Ruffell

It’s been a year I think most people would like to forget. And yet, based on my 2020 in review interviews with representatives from different poultry sectors, there have been a few beacons of light for the industry in the midst of the pandemic.

I spoke with leaders from Chicken Farmers of Canada (CFC), Egg Farmers of Canada (EFC) and Turkey Farmers of Canada (TFC) about their thoughts on the year that was. And while challenges brought on by COVID-19 dominated those discussions, each person noted some promising takeaways from the experience as well.

All three organizations reported a significant hit to the foodservice side of their business due to pandemic restrictions, accompanied by a surge in retail sales that was still a far cry from making up the gap. “We were significantly affected by a decline in the foodservice side, which represents 40 per cent of our business,” says Lisa Bishop-Spencer, CFC’s director of brand and communications.

Still, she says the collaborative and orderly way the sector responded, aided by supply management, is a positive takeaway from the unfortunate situation. “We were able to show the flexibility we needed to adapt production so that we could still meet

consumer demand but also the capacity of everybody in the value chain,” Bishop-Spencer says, adding that the board reduced its production for the May/June and July/August periods by about 12 per cent nationally.

The egg sector also saw a significant increase in demand at the retail level, aided in part by an uptick in home baking. The upsurge peaked at about 25 to 27 per cent. Those numbers eventually leveled out to about a four per cent increase for the year.

EFC CEO Tim Lambert hopes to sustain that trend even after the pandemic in order to reach the organiza -

“We were able to show the flexibility we needed to adapt production.”

tion’s broader goal of making Canada a world leader in per capita egg consumption. Canadians consume around 250 eggs per person annually, Lambert says. In comparison, the world’s largest egg consuming countries – Mexico and Japan – consume around 350 eggs per person each year.

Lambert thinks by continuing the upwards trend in home consumption, Canada could eventually join the world leaders. “Ambitiously, we think we can get there,” he says, noting that the sector

has a strong story to tell around the nutritional quality and flexibility of eggs.

On the turkey side, the sector was already in a tight marketplace. The pandemic, which hit right before Easter, an important time for the sector, made things that much more challenging. “We’ve seen a slight increase in retail but it never made up for the loss that we had in the full-service deli and foodservice industries,” TFC chair Darren Ference says.

As a result, in May the sector adjusted its market downward by seven per cent. That amounts to a decrease of about 10 million kilograms nationally and a loss of $23.3 million for producers’ farm gate. Still, there was some hopeful news.

Despite warnings against gatherings this past Thanksgiving, smaller turkeys and parts proved popular, which helped soften the pandemic’s blow. “So far without the final numbers, Thanksgiving was okay,” Ference says. “So, we’re hoping for the same now with our largest market at Christmas.”

To hear my full year in review conversations with Bishop-Spencer, Lambert and Ference, visit canadianpultrymag.com/podcasts.

We discuss many othertopics, including compensation for trade deals, research and innovation, what a Biden presidency could mean for the Canadian poultry sector and more.

Until next time, Happy Holidays!

December 2020 | Vol. 107, No. 10 canadianpoultrymag.com

READER SERVICE

Print and digital subscription inquries or changes, please contact Anita Madden, Audience Development Manager

Tel: 416-510-5183

Fax: 416-510-6875

email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Associate Publisher Catherine McDonald cmcdonald@annexbusinessmedia.com Cell: 289-921-6520

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Curtis Martin

VP Production/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes) USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

When you choose to install the LUBING 4023 Maximum Flow, All-Stainless Nipple with 360 degree action, you choose a real winner! It is constructed 100% from high grade, precision machined, stainless steel and is virtually indestructible.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

This nipple is designed to be used with our one-arm LitterGard cup and has a wide range of flow that can be adjusted down for small 4 lbs. birds or adjusted up to over 100 ml for large 9.5 lbs. birds. You can decide the flow you want! Combine this nipple with our 28 mm (1.10-in) drinker pipe, the largest on the market, and you have the water volume you need 24/7.

Join the club of thousands of growers that have enjoyed the longevity and performance of this nipple/cup combination that has been proven time and time again for well over 20 years.

Got Lubing? You can’t afford not to!

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

At its October 22, 2020, annual general meeting, Poultry Industry Council elected two new members and one returning member to its board of directors. Board chair Ed Verkley announced that the following new individuals had joined the board: Cathy Lennon, general manager of Ontario Federation of Agriculture; and Kayla Price, poultry technical manager for Alltech. Returning board member Babek Sanei, national business and technical manager for Zoetis, was also re-elected to serve for another term.

In October, dozens of workers at a southeastern Manitoba poultry plant tested positive for COVID-19, while many more people linked to the plant self-isolated. The first case of the illness at the Exceldor Cooperative plant in Blumenort, Man., was detected in early October. Exceldor merged with Granny’s earlier this year, the Manitoba-based company’s website says.

Cobb-Vantress has released a new Hatchery Management Guide that includes the company’s latest recommendations based on breed performance, current scientific knowledge and practical field experience from around the world. The guide covers such topics as hatchery humidity, machinery and cooling systems and has extensive new information as well as important updates. To access this resource, visit cobb-vantress.com/resource.

Farms’ Sandra Dyck (pictured to the right) of Springstein, Man., is one participant in a program Egg Farmers of Canada created for women in the egg industry.

Sandra Dyck wasn’t born a farmer. Her career began in healthcare, in fact – but everything changed when she married fourth generation egg farmer Eric Dyck and got involved in the family farm. Dyck has been working full-time on the Dycks’ 4D Farms in Springstein, Man., since 2013. And she loves it.

“It’s been amazing – I love agriculture,” Dyck says.

education opportunities, take part in networking and industry events to build connections and share experiences and support each other through a mutual mentorship program.

In 2019, Dyck was paired with mentor Kelly Clarke, who has been farming in Nova Scotia for two decades. Dyck sings the program’s praises.

77K is the number of women working as farm operators in the country, according to Statistics Canada.

Across Canada’s agriculture sector, over 77,000 women are farm operators – a higher proportion than existed just 20 years ago. Today, nearly one-third of Canadian farm operators are women, according to Statistics Canada.

“The most welcoming community to me, as a female farmer, has been other farmers,” Dyck says. In that spirit, Egg Farmers of Canada (EFC) created its new women in the egg industry program. Now in its second year, the program participants – including Dyck –are nominated by egg boards from across Canada.

Throughout the program, delegates engage in continuing

“I’ve asked Kelly questions about everything, from human resources to specific barn questions,” she says. “We set goals for our relationship for our year. It’s a great relationship – the chance to learn from someone living a parallel life to you. Networking with these women gives me confidence to take on more roles, to consider getting involved at a higher level.”

The aim of the program is to inspire and help prepare the next generation of leaders in Canadian agriculture, while enhancing connections across our sector – and acknowledging the particular challenges women juggle as farmers.

Christine Nicol is a highly regarded author, academic and researcher based in the U.K. She is a professor of animal welfare at the Royal Veterinary College and has honorary appointments at the University of Oxford and the University of Lincoln. We asked her five questions.

Tell us about your background. I always had an empathy with animals. I initially thought I’d like to be a vet and, as a schoolgirl, I worked in a companion animal veterinary practice. Ultimately, this had a deterrent effect. The work seemed repetitive and was not addressing bigger questions around human-animal relationships and interactions. I decided to study zoology instead. After completing my degree at Oxford University, I spent a year working with horses, then returned to Oxford to study for a PhD.

Why animal welfare?

I’d always had a concern about how individual animals were treated by humans but I didn’t realize that this could form the basis of any kind of scientific study. It was only when I met Marian Dawkins that I saw a way ahead. Marian was my college tutor and I helped with some of her experiments on laying hen welfare. I discovered that it was possible to use preference testing to obtain information on animals’ preferences and priorities.

Explain the triangulation approach to chicken welfare. For many years, scientists have pursued different approaches to assessing animal welfare in relative isolation. The first

“welfare indicators” method involves measuring a range of animal responses. Based on analogy with ourselves, we draw conclusions about bird welfare. The second method is to ask the hens themselves which system they prefer, by letting them choose between systems or elements of systems (e.g., perch type), or seeing how hard they will work to access a specific resource. The third approach is more recent, and it involves examining the general mood state of hens kept in different systems.

Which method is most effective?

No one method can be considered a gold standard. Our triangulation approach looked at how these three different methods inter-related with each other in a study of hens kept in different environments. There were areas of strong correlation between the first two methods, but the third method was something of an outlier and may be measuring something other than animal welfare.

Any observations on poultry welfare research in Canada?

Poultry welfare research in Canada is thriving. I was due to spend time with the group at the University of Guelph in September, but due to the pandemic this visit had to be cancelled. I was looking forward to hearing more about the important work this group is doing on feeding strategies for broiler breeders. The work at the University of Saskatchewan on the effects of beak trimming on beak morphology and function also has wide-ranging welfare implications, and I hope for a rescheduled visit.

DECEMBER

DEC. 9

PIC Producer Update, Webinar poultryindustrycouncil.ca

JANUARY 2021

JAN. 25

PIC Science in the Virtual Pub poultryindustrycouncil.ca

JAN. 25-29

IPPE, Virtual Event ippexpo.com

JAN. 27-FEB. 10

Processor Member Sector & POTC Meetings, Virtual Event cpepc.ca

FEBRUARY

FEB. 9-12

Eurotier, Hanover, Germany eurotier.com

FEB. 10

PIC Poultry Producer Update, Webinar poultryindustrycouncil.ca

FEB. 23

Canada’s Agriculture Day Ottawa, Ont. agriculturemorethanever.ca

FEB. 24

PIC Poultry Producer Update, Webinar poultryindustrycouncil.ca

FEB. 24-26

Ag Expo, Lethbridge, Alta. exhibitionpark.ca/annual-ex-events

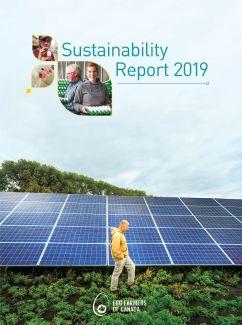

Egg Farmers of Canada (EFC) has released its first Sustainability Report, outlining how egg farmers across Canada are investing in and implementing sustainable agricultural practices. The docu-

ment also covers initiatives and programs that set out new opportunities for the future of egg farming.

“This inaugural report shows how egg farmers have positioned themselves as leaders by living sustainably every day, through every choice they make,” says Roger Pelissero, EFC’s chair. “It sets out a blueprint for how we can build on our current practices as we grow our industry, putting egg farming at the forefront of sustainable agriculture.”

The report further defines EFC’s commitment to sustainability and presents concrete ways in which egg farmers are moving toward becoming more sustainable, while also highlighting the industry’s recent advances.

The approach is built around five pillars, including: protecting the health and welfare of our hens; delivering safe, high-quality eggs; finding new ways to make egg production more environmentally sound; enhancing the well-being of others; and

empowering our people.

“With the wide-spread and growing uses of eggs comes the responsibility to produce eggs sustainably,” says Tim Lambert, EFC’s chief executive officer.

“We’re very proud of this report, and are confident it will help egg farmers communicate their past successes and challenges so our industry continues to contribute to domestic and global efforts to produce more food with fewer resources.”

Mary Katherine Foy is the director of technical services for Proxy-Clean Products of Melissa, TX. The Water Smart Program is a step by step plan of action for providing quality water to animals on the farm. It is an initiative developed by Weeden Environments of Woodstock, Ont., who is the manufacturer’s representative for Proxy-Clean in Canada and Jefo Inc., of Saint Hyacinthe, Que., who is the national distributor.

Water lines contain entire communities of organisms that producers must manage to protect flock vitality.

By Mary K. Foy

When you enter a poultry barn, how often do you walk to a water line and open it? Have you ever had the water tested for minerals or bacteria? Do you see the birds at the drinkers and assume that all is well? That incorrect assumption can have a significant impact on your bird’s performance and, ultimately, your bottom line.

The problem is, even when you open the water line and look inside, it doesn’t look too bad. So, what exactly could be happening in there? Much more than you realize!

Think of the water line as its own world with entire communities living there. These communities are made of living organisms that have jobs and neighbors. They use the available resources to replicate and thrive. They even have defense mechanisms that protect them and those around them. This versatile group of living organisms could be having a detrimental impact on the vitality of your birds.

Source of problems

Your first thought may be that the

microorganisms in the water line must be coming from the well or the source water. Sometimes, the source water contributes to the flora in the water line. But most often, the microorganisms in the water line come from the birds’ environment inside the barn.

Microorganisms can arrive via the litter, through the ventilation, from rodents in the barn, from the birds themselves and even from us. Whatever is in that barn, be it a bacteria, yeast, mold, fungi, algae or virus, it can become airborne. And when they land on the drinking system, microorganisms have multiple methods of movement. They move up and down the water line, often carrying a “friend” with them, like a mold spore, for example.

Some of these organisms move so well that they can actually travel backwards in the system, against the flow of water. They can get into the filters and work their way back to the well. Several times, we have seen a well contaminated not by run-off from the surrounding land but by microorganisms that have worked their way from the barn backwards into the well.

Microorganisms take hold

Once these microorganisms have gotten into the water line, they will then use their flagella and something called “pili” to attach to the waterline, rubber seals or regulator diaphragms. These are hair-like structures that allow them to cling to a surface while they produce a polymeric layer to more permanently affix themselves to the

waterline and to protect them from environmental factors.

Here, in this polymeric layer (the beginning of the biofilm), they begin to multiply.

If you do not have a water treatment program, it is at this point that you can begin to lose the battle against microorganisms in your water line. A biofilm can start within 18 hours of bacteria attaching to the waterline.

They then begin to signal to other bacteria by using something called cell-to-cell signaling. This communication can go on between all different types of bacteria, creating a diverse community that includes Salmonella, E.coli, Pseudomonas or Campylobacter , just to name a few. Even molds, algae, yeasts and fungi can contribute to this community.

These organisms are especially good at producing copious amounts of organic material in which bacteria can easily join for protection, then colonize and thrive. This biofilm can attach in small deposits along the line or, if left alone to grow, it can completely cover the inside of the water system. Over time, the biofilm grows and pieces of it will begin to slough off releasing microorganisms back into the flowing water.

At this point, birds can consume the microorganisms as they drink. The microorganisms can also move in the water system to reattach and begin a new section of biofilm. Some bacteria produce a hard, clear biofilm that may not be visible, similar to the plaque on our own teeth. Sometimes, the only way to

Mold spores are often carried up and down water lines by microorganisms.

know that biofilm is present is to have a bacteria test of the water done.

There are several factors that you, as a producer, have control over when it comes to the environment inside the water system. Controlling minerals can be a good first step, as all of our source water contains minerals, even municipal water.

These minerals can impact bird health – magnesium, for example, can cause birds to flush. These minerals can seal over drinkers, deposit in the water line creating scale and they can be a great source of food for some bacteria as well.

E. coli, for example, can actually use iron as a source of energy. The mineral scale in a water line creates a rough and uneven surface that becomes an easy grabbing ground on which the bacteria can stabilize itself and begin to produce the polymeric layer that creates the biofilm.

Therefore, reducing minerals in the water can have multiple positive effects not only on the functioning of the equipment but also on the health of the birds and the reduced ability for microorganisms to thrive.

The source water can bring problems, but

what are you adding to the water line that may be promoting the growth of microorganisms? Just about everything we add to the water line can be used as a food source for microorganisms. Vitamins, electrolytes, stabilizers for vaccines, organic acids and even supplements such as copper sulfate can be used as an energy source for microorganisms.

Our intention is to improve performance, but at the same time we may be inadvertently helping entire communities of microorganisms to flourish. Even supplements that kill some of the microorganisms

in the water line, such as iodine, copper sulfate or organic acids can allow other groups of organisms to survive.

There are acid loving bacteria called acidophiles and then there are the bacteria that can adapt to the acidic environment such as E. coli. These acid-loving and adaptable microorganisms can overtake the flora of the water system in the absence of the competing bacteria. Molds and algae are particularly good at this and tend to clog a line quickly with their effusive production of organic material.

There is valid evidence that numerous

types of supplements, including organic acids, can improve bird performance. We just have to make sure that after the use of these supplements in the water system, we have a planned water treatment program to combat any growth we may have promoted inside the water line.

Keep in mind, when you are using the water line to administer a supplement that will help the bird grow, you are also administering a supplement that will help the microorganisms grow.

There are three vital times to pay attention to and treat the water.

The first is during the initial few weeks of the bird’s life. During this time, the water is warm and moving very slowly with the birds continuously hitting the drinkers and “re-inoculating” the water line. This environment is ideal for microorganism growth.

The second vital time is following the addition of a supplement or 24 hours after the completion of a vaccination program through the water line.

The third vital time, but definitely not the least important time, is when the facilities are empty. This is your chance to properly clean the water lines and begin the next grow-out with a water system you would take a drink out of! I emphasize properly here – read instructions, get the proper tools and be prepared to do a good job of cleaning the lines when the birds are gone.

Throughout the life of a flock, every producer should have ongoing water treatment or a plan that occurs at least on a weekly basis for 48 hours. It should include cleaning the lines with a proven water line cleaner when the facility is empty.

Think every day where you want your birds to use their energy. If they are having to use it to fight bacteria every time they get a drink, they won’t be able to use that energy for feed conversion and growth rate.

Everyone needs to have their water tested for minerals and bacteria and set up a water treatment program. The plan should include treating water while birds are in the barn and a thorough cleaning of the

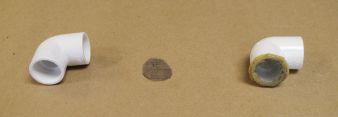

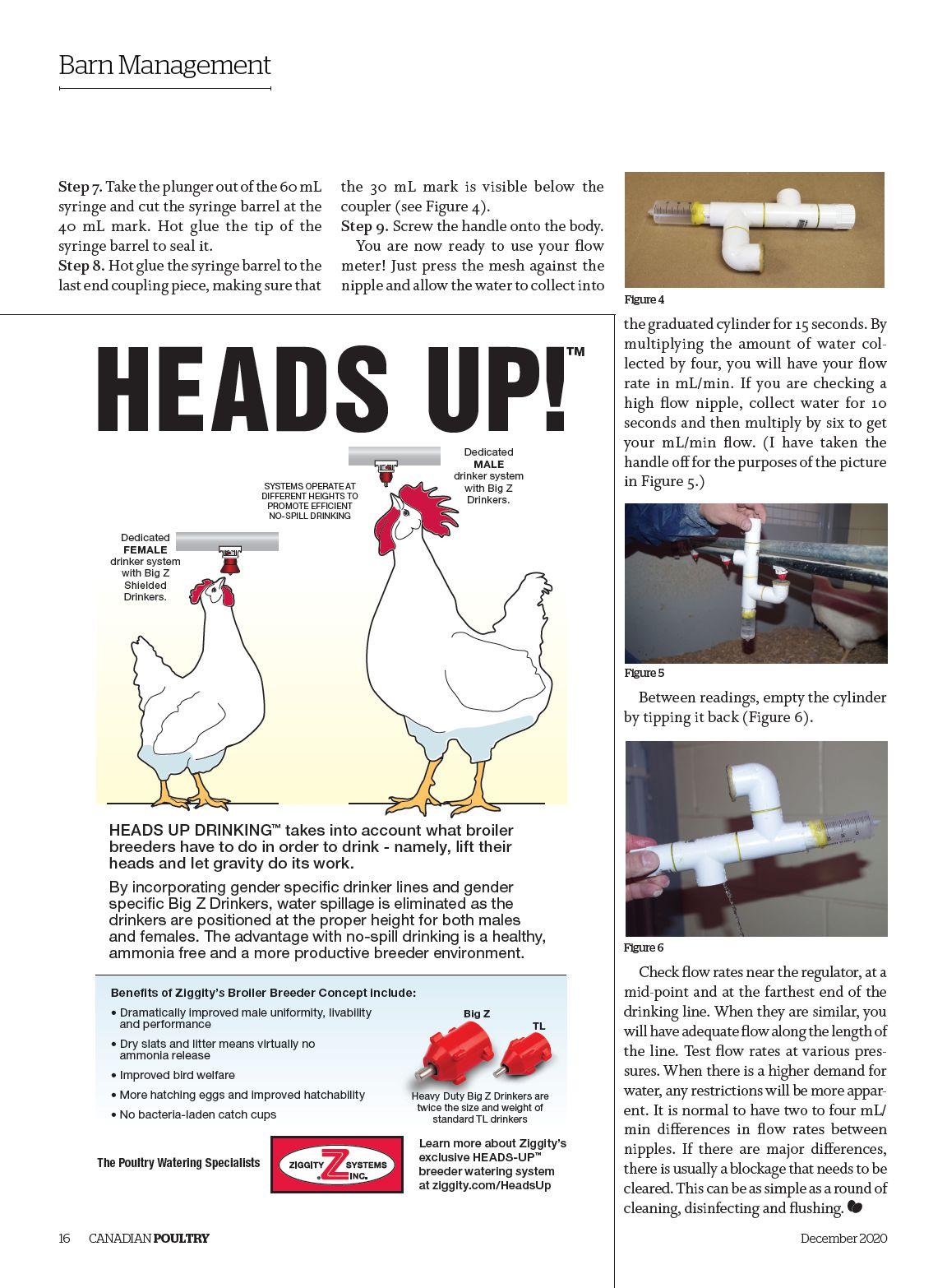

Building a low-cost water flow meter for coffee money.

By Al Dam

Awater flow meter is a simple, reusable device that allows a farmer to check the flow rate from drinking nipples at different areas in the barn. It is quite easy to build a flow meter and it can be sanitized and used repeatedly.

Checking water flow rate is important to make sure that all the birds are getting adequate amounts of water and that your water lines are working properly. Birds require twice as much water, by volume, as feed that they consume.

In hot weather, water requirements will increase substantially – up to almost twice as much as the regular amount. Thus, any restriction on flow means lost income and productivity and can have a significant effect on bird health and welfare.

Producers can build a simple flow meter with about 10 dollars’ worth of PVC tubing, tees, elbows, a syringe and a piece of mesh screen.

To begin, you will need to go to a local hardware store to acquire the necessary supplies, which are laid out in Figure 1. You’ll need:

• A five cm by five cm piece of mesh screen (metal mesh, as it needs to be stronger than fly screen).

• A 60 ml syringe (a 20 ml syringe if you want to use the rubber plunger tip as a plug for the handle).

• A hot glue gun (herein referred to as “hot glue”).

• Standard yellow PVC cement (herein referred to as “glue”).

• A saw or cutter.

• A one by half inch CPVC CTS slip x

MPT male adapter.

• A two by half inch CPVC CTS slip x slip x slip tee.

• A one by half inch CPVC CTS 90-degree slip x slip elbow

• A one by half inch CPVC CTS slip x FPT female adapter.

• A one by half inch CPVC CTS end cap (optional for handle).

• And one meter (three feet) of half inch CPCV pipe (optional for handle).

Note that if you are an egg farmer with a cage system, you could simply just glue a piece of mesh screen to the top of a syringe and glue the needle end shut. Or, if you do not want a handle, you can opt out of the three feet of pipe, but you will need four pieces of half inch diameter CPVC, each one and a half inches long. The handle is meant for ergonomics so that you can check the line when it is set and close to the ground without having to be on your hands and knees.

Step 1. Take the three-foot-long PVC pipe and cut off four pieces that are one and a half inches long.

Step 2. Glue the end cap to the long PVC pipe. This will be used as your handle for

the flow meter.

Step 3. Take the CPVC CTS slip x MPT male adapter and put a plug into the threaded part (e.g., a rubber stopper from a 20 mL syringe or a bottle cap that is hot glued in place).

Step 4. Glue the CPVC CTS slip x MPT male adapter with the plug onto the other end of the long PVC pipe used for the handle. Now you can screw the handle into the flow meter you will make next.

Step 5. Glue the pieces together as Figure 2 shows.

Step 6. Cut the mesh screen to cover the open end of the elbow and hot glue it in place, as seen in Figure 3.

Premium motors engineered to be direct replacements for your existing equipment. Every GrowerSELECT motor comes with the industry’s best 2-YEAR WARRANTY and is backed by our network of local stores.

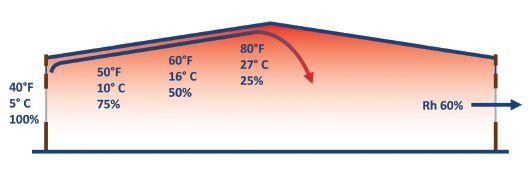

Establish and maintain an optimal barn environment during the winter using negative pressure.

By William Alexander

As the season changes, it’s important to prioritize cold weather ventilation to ensure the well-being and performance of your flock. This article explains how to establish and maintain an optimal environment inside your poultry house using the concepts of negative pressure ventilation.

The foundation of minimum winter ventilation begins by having a tight house. Then, once we’ve created proper airflow and direction we can use fans as a water pump to remove moisture.

To test the tightness of a house, you need to first close all openings, which include curtains, inlets and doors. Next, turn on minimum fans to as close as possible to one cfm per square foot of your barn. Then measure the static pressure with a magnehelic. Experts recommend a minimum of 0.15” static pressure

(SP) for older or renovated houses through 0.20” SP or greater in new houses. The tighter the house, the more efficient it will function. If static pressure is outside these recommended ranges, common problem areas are as follows:

• Unsealed curtains: Attach curtain seals to the top of the curtains to prevent air leakage. You can also consider fastening the bottom of the curtain to the barn to avoid any additional air leakage.

• Unused and dirty fans: Remove built-up dust and dirt that may be preventing fans from closing properly. Consider covering fans that are not in use during cold weather with plastic, insulation board or plywood to eliminate unwanted drafts.

• Improperly sealed end doors: Thoroughly weather strip the perimeter of end doors to prevent air leakage. This is one of the most overlooked areas, even in newer barns!

To create both air pressure and air volume that project and condition the incoming air, start by having the correct number of fans and inlets. These numbers depend on the size of a house.

The objective is to bring in cold air from the outside and have it travel along the ceiling to gradually warm and increase its water holding capacity. When done correctly, you will find that for approximately every 11oC we warm the incoming outside air, we decrease the humidity by half.

Consider an example where the outdoor temperature is 5oC with 100 per cent relative humidity (RH). If we warm the air as it comes into the barn to 16oC, then the relative humidity drops to 50 per cent. If we can continue to warm to 27oC, then the relative humidity drops to 25 per cent (see Figure 1).

The idea behind this conditioning of incoming air is that you use fans to create a water pump. For example, if we take a

The Premium+® laying nest is the number one selling nest worldwide. Its high nest acceptance, minimal amount of floor eggs and use of high quality materials are reasons why many farmers worldwide favour the Premium+® laying nest.

Maximum number of first class hatching eggs

Optimal hygienic conditions www.jpe.org Follow us on:

house with an internal temperature of 27oC and 50 per cent RH, using a 10,000 cfm fan for 30 seconds on out of five minutes, you can remove 2.8 gallons (10.6 L) of water per hour. In a 24-hour period, that equals 67 gallons (254 L). Our goal is to keep relative humidity below 60 per cent. By adjusting the amount of fan run time, you can regulate the amount of moisture inside the house. By having the correct number of fans and inlets, you can create the appropriate air flow. To calculate the correct number of inlets for your desired fan capacity please contact Hybrid Turkeys to obtain a copy of their ventilation calculator.

A good rule of thumb is for every one point of static pressure, air can be thrown 2-2.5’ (0.6-0.75m). Our goal is to get the air as close to the middle of the house as possible. Depending on the width of the house, the range can be from 0.09-0.12” SP to achieve our airflow goals.

Smoke emitters are a great tool, depending on the style and

“This method of ventilation reduces drafts and prevents air leakage.”

Highest possible nest acceptance

Reduces the amount of floor eggs to a minimum

For more info contact our local dealers: Avipor | Meller Poultry Equipment | United Agri Central Agri Systems | LBJ Farm Equipment

placement of inlets, to fine-tune the amount of inlet opening and air direction. Circulation fans are another great tool to ensure optimal condition in a barn. Use of circulation fans help to mix cold and warm air together to reduce humidity and improve litter conditions. They are also a great tool to help prevent drafts in loose houses with poor air direction.

Negative pressure ventilation plays a key role in establishing a comfortable environment for your flock to thrive, especially during cold weather. In addition to improving environmental conditions, it reduces drafts and prevents air leakage, allowing for more efficient use of fuel and lower operation costs. Effective removal of moisture from a barn results in drier litter, lower levels of ammonia and lower levels of other gases in the air.

This article is based on a presentation given by William Alexander, during the virtual Poultry Service Industry Workshop on October 7, 2020. For more information, visit hybridturkeys.com.

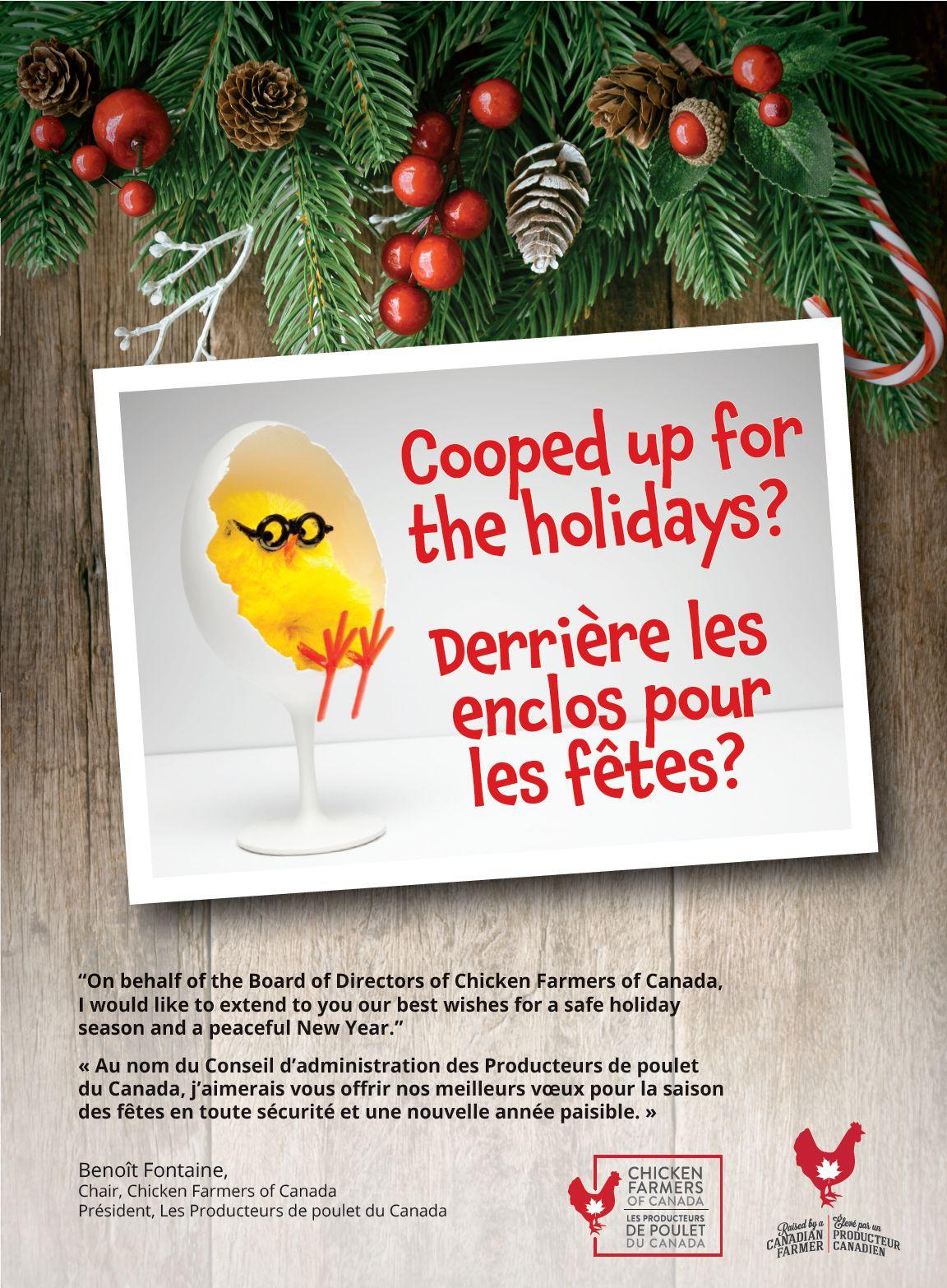

Visit eggs.ca to get inspired with dishes that bring warmth and joy to your table. Happy holidays from Egg Farmers of Canada!

Visitez lesoeufs.ca pour trouver des recettes inspirantes qui amèneront chaleur et joie autour de la table. Les Producteurs d’œufs du Canada vous souhaitent de joyeuses fêtes!

By Jane Robinson

As more of Canada’s laying hen population transitions to new housing systems, it’s clear the switch is about much more than the physical surroundings. Tina Widowski has been studying how new housing systems impact a bird’s behaviour, and how to minimize the challenges and optimize the opportunities for birds to thrive in new aviary systems.

“Consumers expect a very quick transition, but the sheer magnitude of moving Canada’s 27 to 30 million laying hens from conventional cages to enriched colonies and non-cage housing is enormous,” says Widowski, professor of animal biosciences at the University of Guelph and Egg Farmers of Canada chair in poultry welfare.

“Some of the biggest challenges are about the complex environment that aviary systems create. Hens have to find food and water and nest boxes on different tiers. They may be kept in groups of upwards of

15,000. And more freedom means more opportunity to get in trouble.”

Since both genetic selection and management were customized for laying hens living in confined environments for decades, Widowski is interested in how to create a laying hen that can adapt to the new systems that bring new risks for injury, piling and smothering. “You need a calm, smart and physically fit bird to thrive in an aviary system,” she says.

To find that kind of bird, Widowski and research team members Leanne Cooley and Mariana Roedel Peixoto started at the very beginning, in the layer breeder flock. “We are interested in how the experience of the mother can change the composition of the egg, the developing embryo and ultimately the behaviour, physiology and health of the new laying hen for her entire life,” Widowski says. “When you consider that every breeder hen produces 150 laying

hens, it is surprising that no one has really studied this before.”

The biggest differences Cooley found were related to the age of the mother. “We know that egg composition changes with the age of the mother – the amount of yolk, hormones and nutrients in the eggs change as a hen gets older – and these changes affect the developing embryo,” Widowski says.

“We found that the eggs of younger hens had less yolk, more albumen and more testosterone. Their offspring were more anxious and responded differently to tests for fear and stress than offspring from older mothers.”

It’s not practical, actionable advice at this point but Widowski says it’s the first time they’ve looked at the impact of the age of breeder hens. She knows farmers often have multiple barns that are all managed the same but the flocks don’t all perform as well

rearing aviary systems that offer different levels of environmental complexity and types of exercise – continuing the search for a calm, fit bird that will thrive in a non-cage environment. She’s leading a large, multi-disciplinary research team looking to identify practices for housing and managing different strains of pullets that will help birds adapt to a complex housing system and stay healthy until the end of lay.

Osteoporosis and the associated welfare problems for hens is one of the areas Widowski and her research team are focused on. It’s a given that hens develop osteoporosis with the constant depletion of calcium from laying that can’t be replaced in the diet, so Widowski is looking at the impact of exercise during skeletal development on bone health.

“We’re trying to figure out how to alleviate keel bone fractures and osteoporosis in

hens, and we’ve teamed up with human medicine experts,” she says. “We know that bones grow differently – bigger and stronger – if hens are raised in an environment that provides a lot of exercise. And we know in humans that osteoporosis is generally considered a pediatric problem and that more exercise as a child leads to better bone strength as an adult.”

Widowski is collaborating with researchers Bettina Willie and Svetlana Komarova at Shriner’s Hospital in Montreal – specialists in human bone diseases – to look at early exercise in pullets and the impact on bone strength for hens. “I am rearing pullets in different housing environments with varying levels of exercise. Colleagues at Shriner’s are then analyzing live birds to see the differences in bone responses to mechanical loading based on their genetic strain and activity level in the different environments.”

She’s expecting to find that the early impact of jumping down in tiered housing will help birds develop stronger bones. “Adding perches and providing more space and opportunity for running and flight during the first few weeks of life might improve bone strength in adults and be an important consideration in barn design,” Widowski says.

The ultimate success of housing hens in non-cage systems depends on how well they function in a more complex environment that appears to be as much about genetics as the opportunity for different types of movements – running, perching, climbing and flying – at different stages of development to build calm and healthy birds from pullets to laying hens.

For layer breeders and egg farmers, paying more attention to early life experiences – especially pullet housing and management – is turning out to be as important as the experiences for birds in adult housing.

This research was funded by Agriculture and Agri-Food Canada, Canadian Poultry Research Council, Egg Farmers of Canada, Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), and in-kind contributions from Hendrix Genetics and Lohmann Tierzucht.

Skills Knowledge Community Connection

In this new way of doing business, Poultry Industry Council is helping you stay connected to the information and resources you need.

Success in the poultry industry relies on continuous improvements based on gaining new skills and knowledge on an ongoing basis.

Since 1997 Poultry Industry Council has served its members and the industry to ensure the best, most up to date information and knowledge is shared effectively. Membership is the best way for you to access the information, resources and events you need.

Contact us to learn more about membership today!

Women discussed leadership, communication and balance at the inaugural IWCA Summit.

By Alex Barnard

On Oct. 20, more than 200 women attended the inaugural Influential Women in Canadian Agriculture (IWCA) Summit, a virtual event featuring 11 outstanding women who’ve made contributions to Canadian agriculture.

Developed by the agricultural brands of Annex Business Media that comprise AgAnnex – Canadian Poultry, Fruit & Vegetable, Manure Manager, Potatoes in Canada and Top Crop Manager – IWCA began as a recognition program for outstanding women making a difference in Canadian agriculture. Bayer, Farm Credit Canada and the Women Entrepreneurship Knowledge Hub (WEKH) provided gold sponsorships for the IWCA Summit, and Egg Farmers of Canada and Wine Growers Ontario were the event’s bronze sponsors.

The Summit kicked off with live remarks from the Minister of Agriculture and AgriFood, Marie-Claude Bibeau. The first woman to hold this role, Bibeau has focused on supporting and empowering women in agriculture during her tenure. “If you give women the tools and power to succeed, the sky is the limit,” she said.

Each of the three panels, organized around the themes of leadership, communication and balance, began with a quick audience poll. The leadership poll determined 59 per cent of the audience are

currently managers or mentors, 17 per cent were in the past, and 29 per cent intend to pursue leadership positions in the future.

Politics and advocacy are where Peggy Brekveld, Ontario Federation of Agriculture vice-president, found her niche. She emphasized agriculture is relevant to everyone, and it’s important to have people who understand ag in politics and can represent agriculture and producers in policy discussions.

Kristen Phillips, Manitoba Ag Days’ general manager, discussed the importance of adapting your communication style to the situation. Since the pandemic began and the world has shifted to digital

communication, Phillips says she makes sure to be more positive in communicating with others and offer a light at the end of the tunnel. Talking through a screen is different from speaking together in person, so changing your style to suit is part of communicating effectively.

The panels also addressed issues specific to women in agriculture. Being overlooked in the decision-making process, having to choose between work and family, being the only woman in the room: each woman, panelist and moderator, had experiences marked by being a woman in agriculture.

Gillian Flies, co-founder and owner of the New Farm, advocated for unapologetically being a woman in ag, but noted women have to develop a hard shell, too.

Establishing priorities was also discussed; several women mentioned how their priorities differed from those traditionally held, and how this isn’t a bad thing. For instance, soft skills, such as communication, critical thinking and teamwork, are often disregarded in male-dominated industries in favour of hard, more teachable skills. However, soft skills are essential in many ways, and often someone with strong interpersonal skills can be trained on hard skills, but not the other way around.

Michele Rogalsky, director of the school of agriculture at the University of Manitoba, described a time she had to take a step back from her position for her family. She was concerned about adapting to a new role, but developed confidence in her abilities and transferable skills by doing so.

The balance panel addressed how guilt can motivate your decisions. Learning to say no, understanding the difference between hard and soft deadlines, setting boundaries and focusing on mental health were ways the panel recommended for maintaining balance while fighting the power of guilt.

Laura Van Eerd, professor of sustainable soil management at the University of Guelph Ridgetown Campus, also noted how balance is a privilege. When the work has to be done – whether it’s harvest, livestock care, research, or any of the other diverse responsibilities in ag – there isn’t time to worry about maintaining balance. However, in these instances it’s even more important to have strategies to maintain balance to keep from burning out.

Many aspects of agriculture emphasize long-term thinking, where the benefits of many practices might not be seen for years, or even decades. Barbara Cade-Menun, research scientist with Agriculture and Agri-Food Canada (AAFC), commented that all the produ-

cers she works with consider themselves stewards of the land. Maintaining balance in life also requires this mindset.

To continue the conversation, a full re -

cording of the IWCA Summit can be found online at AgWomen.ca, along with more content to highlight several other progressive Canadian women working in agriculture, sharing their unique experiences, challenges and successes.

By Kayla Price

Antibiotic resistance continues to be an important topic globally that covers the human, livestock and pet health areas. Over the past several years, there has been more action, whether regulated or voluntary, in some countries to manage antibiotic resistance – especially in the livestock arena.

The poultry industry has been one of the more notable livestock sectors to take a strong stand toward managing antibiotic resistance. However, the degree of action is different depending on the country.

At the end of the day, the groups within poultry production that will have an active role to play in reducing antibiotic resistance, while ensuring the health and welfare of the flock, will be all of the stakeholders that are involved in producing the meat or eggs

for the consumer. These groups would include the producers, veterinarians, nutritionists, feed representatives, processors, hatcheries and so on.

Many countries have observed antibiotic resistance in poultry production. However, there are often country-specific trends.

Poultry in the U.K., specifically broilers, are raised in a similar fashion to poultry in Canada with a clean-out between flocks and generally using fresh litter. The EU banned antibiotic growth promoters in 2006 (including bacitracin) and they further plan to reduce preventative antibiotic use by 2022. From 2006 onward, many U.K. producers still used antibiotics in their flocks for medicinal use.

The U.K. poultry industry looked at antibiotic use and in 2012 began a voluntary ban on

The poultry industry has been one of the more notable livestock sectors to take a strong stand toward managing antibiotic resistance.

in-feed antibiotics considered important for human medicine (not including anticoccidial drugs). Around this time, the U.K. poultry industry and veterinary associations came out against routine preventative treatment with antibiotics. Initially, by 2013 the total antibiotic use levels (including inwater) increased as the industry adjusted to the changes.

After the U.K. industry accepted the holistic changes required to produce birds with no preventative antibiotics, its total antibiotic use (in-water and in-feed) decreased. From 2012 to 2019, the U.K. poultry industry had a 76 per cent reduction in the total use of antibiotics and a 97.3 per cent

reduction in the use of critically important antibiotics. Nevertheless, there are minor increases in antibiotic use depending on disease challenges but not to the same extent as pre-2012 levels.

In terms of antibiotic resistance tracking in the U.K., there is steady and slightly decreasing proportion of resistant Campylobacter and the percentage of susceptible E. coli strains are increasing while resistant strains are decreasing. Essentially, in terms of decreasing resistance, the program is working for some resistant bacteria in poultry production.

The U.S. poultry industry made a regulated as well as voluntary decision to phase out medically important antibiotics for production purposes in 2017. It only allowed the use of antimicrobials under the supervision of a licensed veterinarian. During this time, there was a shift from drugs considered medically important to humans to those that were not considered medically important to humans.

Based on a study Mindwalk Consulting Group completed for the U.S. broiler and turkey industries, bacitracin use in broilers based on bird live weight remained relatively steady from 2013 to 2017. At the same time, avilamycin and bambermycin use increased.

Conversely, based on broiler liveweight, antibiotics considered medically important to humans decreased from 2013 to 2017 in all classes. However, there was still room for improvement in turkey production in the macrolide

Merry Christmas to our poultry friends...

Wishing you a season of blessings.

In countries that have acted, there has been a general decrease in the proportion of resistant E. coli for most medically important antibiotics.

May the joy and peace of Christmas be with you throughout the year.

- Alberta Chicken Producers Board and Stafff

Location: Abbotsford, B.C.

Sector: Layers

The business

Nest Egg Poultry is a third-generation egg farm. Andrew Penner bought the business from his father about a year and a half ago. He now runs the day-today operations along with one employee who helps collect eggs. The producer has quota for just over 20,000 hens.

The need

Penner grew up two doors down from the farm and worked there off and on for years. That’s why when he bought the business he already knew it needed upgrading. Adding to that need to expand was a six per cent quota increase. “I realized we were completely maxed out in the existing facilities,” Penner says.

The barn

Working with AgPro West Supply, Penner replaced the aging conventional barn with a new aviary facility large enough to house 40,000 hens – plenty of room for future growth. The barn is the first in North America to include Big Dutchman’s NATURA Step XL system. It’s similar to the NATURA Step only longer and wider, with larger nest boxes that are surrounded by dual egg belts on each side. The facility includes two barns under one roof with two rows of equipment on each side. Penner says the free-run barn allows him to keep a closer eye on his flock. “In an aviary barn, you’re really watching what they’re doing, how they’re interacting and how comfortable they are,” Penner says.