SUSTAINABLY YOURS

Compostable trays give iconic Montreal grocer full green light to go green for greater good Story on page 14

Compostable trays give iconic Montreal grocer full green light to go green for greater good Story on page 14

Videojet 1860 Continuous Inkjet Printer

True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada

$156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s

Started up in earnest in the early 1990s, Ontario’s famed Blue Box curbside recycling program was never originally expected to evolve into a moneymaking machine—its primary initial mandate driven by an urgent need to address Ontario’s full-blown landfill crisis. And while it never claimed to be an ultimate cure-all for all of the modern society’s throwaway habits and excesses, it worked well enough at the outset to have been adopted as a general blueprint for recycling in 150 countries around the world, according to the program’s administrator Stewardship Ontario.

Inevitably, however, the program started showing signs of running out of steam in terms of its overall effectiveness, with recycling rates for household trash like newsprint, plastic and glass containers, aluminum and other packaging waste stalling in the mid-60s percentage range.

Furthermore, with many new packaging products coming on the market that were not around when Blue Box first got off the ground—think multibarrier stand-up pouches, single-serve coffee pods, combination blister-packs, etc.—Blue Box seemed unable to keep Ontario residents up-to-date on what household waste they could put in their Blue Bins without contaminating the recycling stream.

So it should not come as a shock to learn that about a third of all the waste collected through the Blue Box program nowadays ultimately ends up in the landfill anyways, according to a new report prepared for the provincial Ministry of Environment, Conservation and Parks, which urging a sub -

We

stantial overhaul of the existing Blue Box ecosystem over the next six years.

Authored by special advisor on recycling and plastic waste David Lindsay, the report identifies seven key areas that the government and all other key stakeholder must address in the next six years to preserve the Blue Box program’s viability.

This includes providing a common collection system for all Ontario municipalities, standardizing Blue Box contents, determining eligible sources for Blue Box materials, setting effective design targets and, most notably, making product manufacturers responsible for bearing the collection costs of their product packaging. Whereas municipalities and industry currently share the costs of Blue Box collection on 50-50 basis, Lindsay’s report urges the province to make consumer brand-owners and manufactures fund all the collection costs by 2025.

So far, at least, the government’s response has been fairly open-minded to the idea, especially in light of rising Blue Box costs estimated to increase by $10 million each year after 2019. According to the environment minister Jeff Yurek, “It’s clear that Ontario’s current Blue Box Program is unsustainable.

“Hopefully by the end of the day we create a new economy of recycled products here in Ontario because of the program that’s going to be put in place,” said Yurek, adding this would free up precious new funding for the municipalities.

“The cost of the program will be transferred over to the producers, businesses and industries creating the waste: they will be the ones who will be paying for the recycling program when this change occurs.”

We’ll see … in 2025?

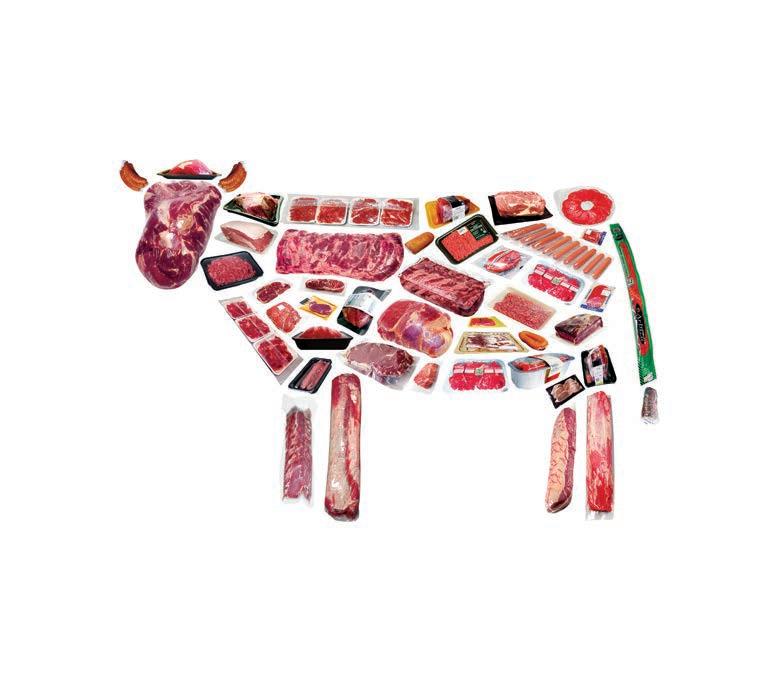

Iconic Montreal grocer embarks on a sweeping sustainability initiative with the help of compostable molded-fiber trays in its fresh produce aisles.

photography by Pierre Longtin

Bedding products supplier sleeping easier after installing

sensitivity metal detection system to keep unwanted debris at bay.

of packaging

on high-speed production lines.

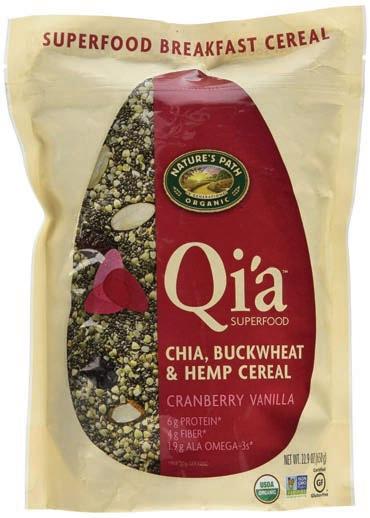

Dry

foods distributor hits the packaging sweet spot with award-winning recyclable stand-up pouches.

of a job.

Continued

With demand for plantbased protein products in Canada soaring through the roof, California-based Miyoko’s Creamery has picked an exceptionally opportune time and place for its first international expansion.

Having already established itself as something of a cult favourite in many U.S. markets, the leading U.S. plant-based butter and cheese brand made a tasteful Canadian market debut last month with the launch of its award-winning vegan butter at more than 1,000 grocery stores across the country last month, including Sobeys, Loblaws, Save-On Foods and Longo’s, as well as other smaller boutique grocers.

Produced and packaged at Miyoko’s processing facility in Petaluma, Ca., the company’s bestselling Organic European Style Cultured Vegan Butter is promised to melt, spreads, bakes, sautés and taste just like the highest-quality dairy butters, according to the company’s founder and chief executive officer Miyoko Schinner.

“Canada has really embraced the plant-based movement, with nearly 10 per cent of Canadians

considering themselves vegetarian or vegan,” says Schinner.

“What I find most heartening is how so many omnivores are enthused about plant-based food options and have been asking us to cross the border for years,” says Schinner, crediting Vancouver-based branding agency Fluid Creative for working with his company’s in-house package design team for all the translation work from English to French that had to be incorporated into the package design.

Already one of the most widely distributed vegan cheese and butter brands in the U.S. with distribution in more than 12,000 stores, Miyoko’s Creamery recipes use only real, whole food organic ingredients like nuts, legumes and plants, awhile eschewing fillers, additives or GMO ingredients.

The company also ensures that it partners with ethical and environmentally conscious suppliers, Schinner points out.

With cashews being a major ingredient in Miyoko’s cheeses and butters, the company has partnered with the Dutch supplier Tradin Organics to source organic

cashews from small farmer producers in Vietnam with the highest scores from third-party audits for working conditions and environmental standards.

As a result of these sustainability efforts, Miyoko’s products generate up to 98 per cent less greenhouse gases in production than their cow-based counterparts, according to Schinner.

“Consumers under 35 are the primary drivers for delicious plant-based food innovation: they want flavor and they don’t want to feel they’re giving up any of their favorite foods,” he states.

“They also get the importance of saving animals, the earth and preserving their health,” Schinner says, citing the new Canada’s Food Guide as validation of his company’s move into the Canadian market.

“We want to delight the palate of all butter loving Canadians who want a creamy, cultured, good-foryour-gut), buttery experience with zero cholesterol,” he states.

Schinner adds that Miyoko is planning to follow up the Canadian launch of its butter later this fall with the phased introduction of its artisan vegan cheeses across Canada, including the award-winning Double Cream Classic Chive, Fresh Vegan Mozzarella and its premium cheese wheels in flavors such as Aged Black Ash, Sharp Farmhouse and Smoked Farmhouse

One great beer ultimately deserves another, so after brewing only one style of beer for 19 years, Torontobased Steam Whistle Brewing has broken its original “one beer” premise of being a one-beer company by adding a new product to its flagship Steam Whistle label.

Packaged in distinct blue cans, the new Steam Whistle Premium Pale Ale is made according to the exacting standards of the Bavarian Purity Act of 1516—just like its original bestselling Steam Whistle Pilsner —at the company’s newly opened state-ofthe-art brewery in west-end Toronto.

Counting calories can be a real killjoy for consumers seeking relief from summer heat with a trusty old helping of ice cream. But thanks to companies like Montreal-based CoolWay, Canadians have never been as spoilt for choice as now in chilling out with a delicious lowcalorie ice-cream product without the guilt trip of high caloric content of most conventional frozen dairy treats.

Although it’s only been introduced to Canadian retail market just over a year ago, the company’s flagship CoolWay brand of low-calorie, high-protein ice cream is now available in 15 different flavors, following recent launches of the new Birthday Cake, Cherry Fudge Brownie, Chocolate Chip Cookie Dough, Lemon Cake, Maple Swirl, Mocha Brownie Fudge and Strawberry Cheesecake recipes.

Retailing across Canada at Walmart, Metro, No Frills, Longo’s, Whole Food Market, Farmboy, FreshCo and select Sobeys stores, the company’s diverse offerings—packaged in colorful 500-ml pint-size tubs designed by Bo Branding & Design Co. of Montreal—range from 280 to 390 calories per 500-ml container, which is about 1,000 calories less per pint than traditional ice-cream brands.

“We have grown to become the Number One craft beer in Canada with only one beer,” says Steam Whistle’s vice-president of marketing Tim McLaughlin, “but we have heard loud and clear from our customers that they would like to see more beers from us.”

McLaughlin says that Steam Whistle conducted an extensive research project reviewing the Steam Whistle brand earlier this year, which showed that 92 per cent of Steam Whistle Pilsner drinkers were willing to try another beer from Steam Whistle.

In fact, Steam Whistle has already used its new

brewery’s ample new production capacity to launch a brand new Von Bugle brand of Munich-style lager earlier this year.

However, the new Steam Whistle Premium Pale Ale is the brewer’s first new beer under the Steam Whistle label.

“In terms of the style of the beer, our pale ale is still easy to drink and crisp, but more hop-forward than our pilsner,” says McLaughlin.

“We will remain true to our standards of brewing a pure ale with no additives, preservatives or artificial foam enhancers.”

Faster on the market with your machines. Very

In addition to the new flavors offered in the pint-sized tubs—manufactured by Smithville, Ont.-based Stanpac CoolWay has also expanded its product portfolio with the introduction of 88-ml ice-cream bars. (See Picture)

Made with 100-percent Canadian milk sourced from a dairy in Halifax, N.S., the single-serve Cookies & Cream and Salted Caramel ice-cream bars contain only 80 calories per serving, and can be found in the freezer aisles of Quebecand Ontario-based stores operated by Walmart, Metro, No Frills, Longo’s, Whole Food Market and Farmboy.

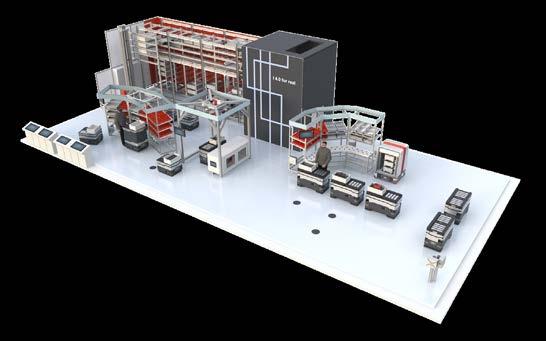

Schneider Electric‘s PacDrive 3 system delivers 50% more power and now syncs up to 130 servo axes including robot axes with new controllers. From now on, automate a large number of your machines with just one technology and thus get to the market faster. Made possible by the motion control solution PacDrive 3 from Schneider Electric.

nPrinting inks manufacturer INX International Ink Co. of Schaumburg, Ill., has announced completion of the expansion of its R&D (research-anddevelopment) complex in Chicago’s west end—nearly doubling the facility’s production space up to

70,000 square feet and prompting the hiring of about 20 new chemists and support staff to service the expanded on-site lab. (See Pictures) Commenced in the fall of 2017, the expansion project has provided critical new production space to house the company’s digital solutions offerings and other fastgrowing market segments, according to the company’s R&D director Mark Hill. “The expansion effort focused on growing specific markets such as energy curable inks and coatings and inkjet ink technologies of all types,” Hill explains. “With increasing demand for our products, we added 5,000 square feet to our digital print applications lab, which now houses several types of inkjet printers, printhead makers, and delivery systems for more complete ink testing capabilities.”

nLeading German plastic processing machinery manufacturer Arburg GmbH + Co KG has commenced a major 22,600-square-foot expansion of Arburg, Inc. facility in Rocky Hill, Conn., to create more space for building and acceptance testing of complete turnkey systems, customizing, stock machines to customer specifications, and house a significantly larger spare parts warehouse. “In recent years, our business in the US has developed significantly better and faster than expected [and] our U.S. headquarters is already reaching its capacity limits,” says Friedrich Kanz, managing director of Arburg, Inc. According to Arburg, the new building will be equipped with modern logistics and a gantry crane with a lifting capacity of 40 tonnes, while also housing additional rooms for customer training and technical seminars.

Jeff Greenwood, Reiser Packaging Specialist

nProtective packaging products manufacturer Pregis LLC has announced the opening of the company’s new Pregis IQ innovation headquarters in Aurora, Ill. Staffed with ISTA -certified lab engineers, the new 50,000-square-foot facility is fully equipped to provide customer-focused training, design and testing services using related testing protocols to develop performanceoriented, cost-effective protective packaging solutions, with special emphasis on e-commerce applications. “As a protective packaging thought leader and innovator, we will be using creative packaging design, material science, sustainability and automation services at Pregis IQ to help customers solve specific packaging challenges,” says Pregis chief innovation officer Tom Wetsch. “We will also be using a data and metrics-based approach to create advanced solutions that support market trends and meet customer needs.”

nLorenz Conveying Products Corp., manufacturer of pneumatic conveying products based in Cobourg, Ont., has completed the acquisition of Flow Valves International, Evanston, Ill.-based manufacturer of Syntron and SMS Iris brands of flow control valves. “The addition of the Iris flow valves to our product line is the perfect fit with our other products, and will allow us to service our customer base more effectively from the new location,” says Lorenz Conveying Products president Peter Lorenz, adding the newly-acquired plant in Normal, Ill., will now operate

under Lorenz Conveying Products USA Inc. corporate banner going forward.

nPretium Packaging, Chesterfield, Mo.-based manufacturer of plastic containers and closures, has completed a US$2-million installation of new reheat stretch PET (polyethylene terephthalate) blowmolding at its production facility in Troy, Ala. According to Pretium, the new equipment can produce both cold- and hot-fill PET plasic containers for condimenta, sauces and dressings—as well as readyto-drink teas, energy drinks, coffee and other beverages—in sizes ranging from six ounces to two-liter volume capacities. “While demand from small- to

medium-sized companies for condiment containers, as well as hot-fill bottles, continues to increase, many suppliers are not willing to provide smaller stock quantities that many of these processors and bottlers require,” says Pretium’s director of operations Randy Neibarger. “Our objective is to serve that niche.”.

nFood packaging equipment supplier Rovema North America, Inc. of Norcross, Ga., has been honored with the 2019 Supplier Excellence Award for Innovation from leading confectionary producer Hershey

Company in recognition of its efforts in the launch of Hershey’s Doy-type stand-up pouches for several of its well-known milk chocolate brands. The collaborative project involved multiple models of Rovema’s BVC series Flex Machines—continuous-motion vertical form, fill and seal (VFFS) unit that, in addition to the Doy-style bags specified by Hershey, can also produce pillow, gusseted and quad bags with or without zippers.

nLeading German industrial conglomerate Robert Bosch GmbH has announced plans for the sale of its Bosch Packaging Technology unit to a newly incorporated entity managed by the Luxembourgbased private equity fund CVC Capital Partners (CVC), which currently manages more than US$75 billion of assets worldwide. Under the agreement signed by both parties last month, Bosh Group is expected to transfer its entire global packaging technology business—including over 6,100 employees in 15 countries—to CVC by the end of the year, pending all the required regulatory approvals. “Bosch Packaging Technology is a strong company in an attractive market with long-term growth prospects [and] an excellent reputation for quality and innovation, a broad product range, a global footprint, and experienced associates,” says CVC managing partner Alexander Dibelius. “Together with the management team, we will work to take the business forward in the years ahead, and to make it even more competitive.”

The new QuickLabel QL-120X tabletop digital color label printer from AstroNova, Inc. is a flexible, highquality, efficient solution for on-demand digital color label printing, featuring economical high-capacity ink cartridges and efficient, dye-based inks. Equipped with next-generation printhead technology, the QL-120X prints three times more labels (over the life of the printheads) than the original QL-120 system, with its four individual, snap-in, color printheads facilitating rapid on-site changeover. The QL-120X enables users to print labels as narrow as 0.5-inch or as wide as 4.2-inches on the same device, using a wide variety of media types ranging from matte to high gloss paper and synthetics to deliver superior durability in a wide range of applications. AstroNova, Inc.

E. Hofmann Plastics has expanded its range of food-grade MAP (modified atmosphere packaging) trays with a new line of antimicrobial trays incorporating a special contact layer that can kill harmful bacteria such as Listeria and Salmonella on contact, according to the company, without sacrificing structural integrity. Made with #5 recyclable polypropylene, the trays were tested against conventional PP in an independent lab, where the trays were found to reduce antimicrobial activity by up to 96 per cent, while still providing a highly effective oxygen barrier layer to ensure optimal food freshness and shelf-life performance.

E. Hofmann Plastics

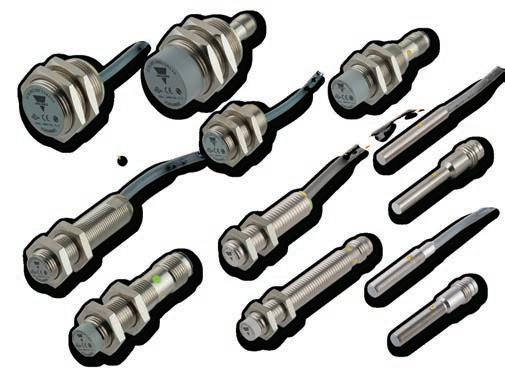

Metal Detector for installation on conveyor belts

Innovative user interface

Best metal detection performance with Multi-Simultaneous-Frequency-Technology

Specialized Compliance Mode software

Active detection performance displayed via Detection Forecast Algorithms

The paperboard division of Rayonier Advanced Materials has announced the launch of its new folding-grade Kallima box coated paperboard as a low-weight option for a broad range of packaging, cartoning, POP display and other projects requiring foldable, printable and boxable solution. According to the company, the Kallima box is the only FBB (folding boxboard) grade currently manufactured in North America. Coated on one side and available in 14-, 16- and 18-pt grades in sheets and/or rolls, the Kallima box paperboard’s low-density, multi-ply board characteristics bring significant savings due to the basis weight advantage over competing SBS (solid bleached sulphite) products, while facilitating consistent printability and reliability on the press.

Rayonier Advanced Materials

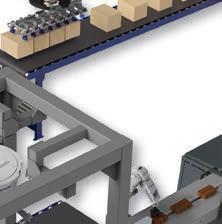

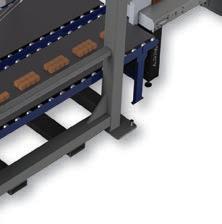

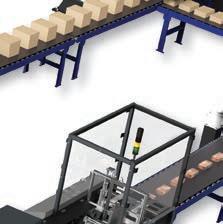

Designed for mid-range applications, the new M236 case sealer from A-B-C Packaging Machine Corporation—available in tape and adhesive sealing models—offers many high-performance features to ensure highly reliable operations in speed range of 15 to 25 cycles per minute. The machine’s metering roller feed accepts cases back-to-back or spaced and automatically aligns with changing line speeds, while the powered minor flap tucker ensures positive inner flap closing and the outer flaps are closed by contoured flap folders that fold the flaps squarely—even when running cases with poor or undefined scores. Moreover, the adhesive sealing Model 236 has a sealing section with rollers that compress against each case to ensure secure adhesive bonding even when running cases with minor case height variations.

A-B-C Packaging Machine Corporation

Designed to deliver high flow rates and reliable compressed air pressure control in a range of harsh environments with corrosive atmospheres, extreme temperatures or explosive zones, Festo’s new filter regulator combines filter and pressure regulator functions in a single space-saving design with patented seal technology protects against back flow and ensures reliable exhausting without special accessories. With its housing and interior made entirely of premium stainless steel to ensure high corrosion resistance, the UV-resistant PCRP functions reliably outdoors at temperatures ranging from -60°C to +80°C, with its rugged construction making it suitable for use in potentially explosive zones 1, 2, 21 and 22, according to Festo.

Festo, Inc.

A new ultra heavy-duty bulk bag filling system from Flexicon Corporation is designed to provide reliable intake of abrasives, highdensity solids and other difficult-to-handle bulk materials from upstream processes or storage vessels and fills the material by weight into bulk bags. Intended for mining, glass, ceramics and other demanding industrial applications, the system is comprised of heavygauge variants of the company’s patented TWIN-CENTERPOST filler and FLEXICON flexible screw conveyor consolidated on a robust skid with integral forklifting tubes for mobility. The filler is equipped with fill head height adjustment to accommodate all popular bag sizes, pneumatically retractable bag hooks and an inflatable connector to seal the bag inlet spout, with an optional feed chute outlet port featuring a high-efficiency filter sock for dust-free air displacement during filling. The FLEXICON conveyor consists of a steel outer tube with a rugged flexible screw that self-centers as it rotates to preventing material from grinding between the screw and tube wall, while eliminating the need for a bearing at the intake end.

Flexicon Corporation

Requiring just one operator and designed to improve the efficiency of distribution operations, the new Series 2300 large-volume sorting conveyor from Eaglestone Equipment is outfitted with adjustable-speed pneumatic sorting arms that automatically divert products into containers, and then shift to a different receptacle when cartons are full. Featuring bright LED lights to indicate when each container is nearly or completely full, the Series 2300 conveyor can sort both random and single product production batches through the use of eye safe infrared scanners to identify barcodes. The Series 2300 can be supplied with numerous options to suit various application requirements, including retracting ends, diverting chutes, blast gates, push-offs, stainless-steel casters, etc.

Eaglestone Equipment

An major new life-cycle assessment (LCA) study from German environmental researchers claims that singleuse beverage cartons compare favorably to reusable glass bottles, while also strongly outperform ingsingle-use PET (polyethylene terephthalate) plastic bottles across the fresh milk, juice, and UHT milk market segments.

The LCA study is based on an analysis of the German beverage packaging market, with expert reviews by the German Federal Environment Agency (UBA)

The conclusions are globally relevant and support the findings of previous reviewed LCAs that beverage cartons offer environmental advantages to alternative forms of packaging, according to a leading German beverage carton

Next-generation leadership performance

Hitachi’s UX Series continuous inkjet printers represent the pinnacle of innovation in marking and coding technology, all while showcasing Hitachi’s reputation for Reliability, Efficiency, and Ease of Use.

Environmentally friendly while realizing a low running cost

High reliability, and reassured maintenance and service networks

Simple touch panel operation and maintainability

producer SIG, a member of the German Beverage Carton Association FKN, which commissioned the LCA study to support informed decisions on packaging by food producers, consumers, and policy-makers.

“The latest LCA confirms once again that beverage cartons are the preferred environmental choice for milk and juice packaging,” says SIG’s chief executive officer Rolf Stangl.

“These results are based on standard beverage cartons that are around 75 per cent renewable and SIG already offers customers innovative products that are linked to up to 100-percent renewable content,” Sangle says, stressing that science-based LCA is fundamental to SIG’s approach to product responsibility.

As Benedikt Kauertz, scientific director at IFEU, explains: “The results show that beverage cartons for milk and juice are advantageous compared with single use PET bottles.

“For milk, beverage cartons are even better than the reference system, reusable glass bottles, and for juices beverage cartons perform on a par with the reference system,” Kauertz points out.

“For UHT milk, where no reusable packaging option is available, beverage cartons perform better than the singleuse PET bottle alternative.”

Reusable packaging options, such as glass bottles that are returned to producers to be used again, are assumed to be the best option, the LCA study notes.

That is why reusable options, where available for a particular market, are used as the reference system for comparison.

Based on an analysis of all three-market segments, the beverage carton performs as well, or in the case of fresh milk, even better than reusable glass bottles.

In fact, cartons have been found to perform significantly better than the alternatives on climate change––the category given highest ecological priority by the UBA.

The climate results for cartons are 78 per cent lower than reusable bottles for fresh milk, 37 percent lower than reusable glass bottles for juices, and 71 percent lower than PET bottles for UHT milk, according to the study.

The high proportion of renewable material used to make cartons contributes to their environmental performance, together with their design, which reduces impacts from transport and distribution.

The results are underpinned by the industry’s commitment to sourcing from responsibly managed forests, according to the report, which plces high value on the positive contribution that renewable materials make to the environmental performance of beverage packaging.

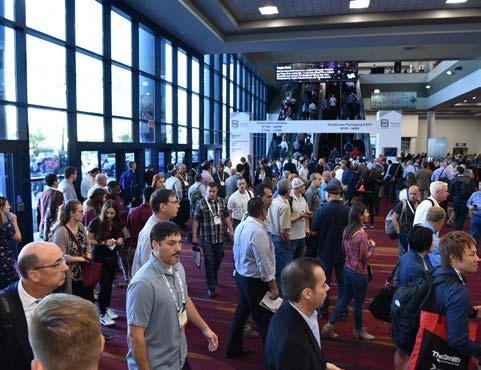

Sept. 17-18

Hartsville, S.C.: 2019 Sustainability and Food Waste Summit, international conference by Sonoco FRESH (Food Research Excellence for Safety and Health). To register, go to: www.sonoco.com/form/sustainabilitysummit-enrollment

Sept. 23-25

Las Vegas, Nev.: PACK EXPO Las Vegas, international packaging technologies exhibition by PMMI, The Association for Packaging and Processing Technologies. Concurrently with Healthcare Packaging EXPO. Both at the Las Vegas Convention Center. To register, go to: www.packexpolasvegas.com

Sept. 24-27

Brussels, Belgium: Labelexpo Europe 2019, labeling technologies exhibition by Tarsus Group plc. At Brussels Expo. To register, go to: www.labelexpo-europe.com

Sept. 30 – Oct. 2

Monaco: Luxe Pack Monaco, luxury products packaging exhibition. At Grimaldi Forum. To register, go to: www.luxepack.com

Oct. 5-9

Cologne, Germany: Anuga 2019, international food and beverage industries exhibition by Koelnmesse. At Koelnmesse fairgrounds. To register, go to: www.anuga.com

Oct. 10-12

Manila, Philippines: Pack Print Plas Philippines, packaging, printing and plastics trade show for the ASEAN region by Messe Düsseldorf Asia. At SMX Convention Center Manila. To register, go to: www.mdna.com

Oct. 15-17

Indianapolis, Ind.: International Robot Safety Conference, by the Robotic Industry Association (RIA). At JW Marriott Indianapolis. To register, go to: www.robotics.org

Oct. 16-23

Düsseldorf, Germany: K 2019, world fair for plastics and rubber by Messe Düsseldorf GmbH. At Messe Düsseldorf fairgrounds. To register, go to: www.mdna.com

Oct. 23-26

Shanghai, China: E-PACK TECH 2019, ecommerce technologies and packaging solutions exhibition by Ipack Ima. At Shanghai New International Expo Centre (SNIEC). To register, go to: www.epacktech2019.com

Oct. 28-30

Niagara Falls, Ont.: Ontario Craft Brewers Conference & Suppliers Marketplace 2019, by Ontario Craft Brewers (OCB). At Scotiabank Centre. To register, go to: www.ontariocraftbrewers.com

Oct. 28-30

Charlotte, N.C.: Time is Money, annual fall conference of the Flexographic Technical Association (FTA). At Sheraton Charlotte Hotel. To register, go to: www.flexography.org/fall19

Nov. 4-6

Paris, France: Sustainable Cosmetics Summit Europe, conference and exhibition by Ecovia Intelligence. At Hotel Marriott Champs-Élysées.To register, go to: www.sustainablecosmeticssummit.com

Nov. 12-13

San Jose, Ca.: Collaborative Robots, Advanced Vision and AI (CRV.ai) conference by the Association for Advanced Automation (A3), Advanced Imaging Association (AIA) and the Robotics Industry Association (RIA). At Doubletree by Hilton San Jose.To register, go to: www.visiononline.org

Nov. 19-22

Milan, Italy: SIMEI 2019 (International Enological and Bottling Equipment Exhibition), by Unione Italiana Vini. At Milano Fiera-Rho. To register, go to: www.simei.it

Nov. 29-30

São Paulo, Brazil: Sustainable Foods Summit, international sustainability conference by Ecovia Intelligence. To register, go to: www.sustainablefoodssummit.com

Dec. 5-7

New Delhi, India: drink technology India, beverage, dairy and liquid food industries trade show by Messe München GmbH. At Pragati Maidan grounds. To register, go to: www.messe-muenchen.de

Dec. 9-11

Cairo, Egypt: Pacprocess MEA, packaging exhibition for the Middle East Africa (MEA) region by Messe Düsseldorf GmbH. At Egypt International Exhibition Center. To register, go to: www.pacprocess-mea.com

BY GEORGE GUIDONI, EDITOR PHOTOS BY PIERRE LONGTIN

Genuine packaging sustainability does not happen overnight or in isolation.

Which is why progressive retailers who truly believe in the virtues of reducing their carbon footprint have much to gain from hooking up with business partners with extensive experience in developing effective sustainable packaging solutions.

Founded in 1954 in Montreal’s famed Little Italy district, independent grocer Fruiterie Milano offers a compelling proof of the benefits of such strategic alignment.

Celebrating its 65th anniversary this year, the popular grocer has long been acknowledged as one of eastern Canada’s best shops to purchase authentic made-in-Italy specialty foods and delicacies—ranging from olive oils and fresh pastas to buffalo mozzarella and other gourmet cheeses, along with a broad array of Italian deli meats such as capicolo, prosciutto,

sopressata, mortadella and numerous salami varieties.

Considered a landmark Saint Laurent Boulevard institution by the area’s residents, many of them descendants of early Italian newcomers to Canada during the early 20th Century, the thriving family business has expanded nearly a dozen times since founder Vincenzo Zaurrini first opened its doors as a small boutique specializing in imported Italian-made foods.

Nowadays, employing about 100 people and stocking a broad selection of mainstream food and beverage products in addition to its Italian novelties,

Above: Founded 65 years ago by Vincenzo Zaurrini, Fruiterie Milano has continued to operate from the same location in the city’s Saint-Laurent street district, having gone through numerous facility expansions over the years to establish itself as one neighborhood’s landmark institutions and favourite meeting places.

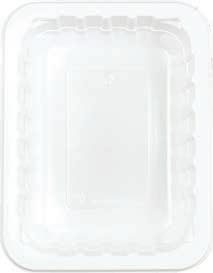

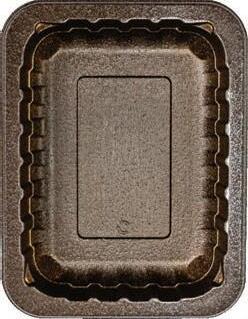

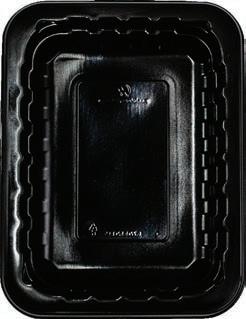

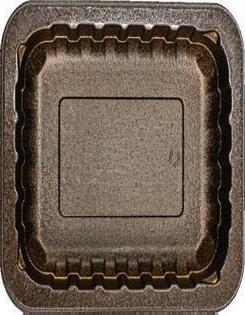

Left: Fruiterie Milano store manager Nadia D’Amour proudly showing off the compostable EarthCycle™ trays, manufactured in Canada by CKF Inc. and distributed by Veritiv, that the iconic store began using earlier this year to package pre-portioned fresh produce as part of the company’s ambitious and far-reaching sustainability initiative.

Fruiterie Milano has recently embarked on a quest to raise its community profile by embracing newer and more eco-friendly product packaging than it has in the past.

According to store manager Nadia D’Amour, the primary impetus for this change came primarily from the store’s own loyal customers, who would often express their concerns over apparent product overpacking and other packaging excesses to the store management and employees.

Upon seeing these comments becoming more common and frequent, current owners Celia and

Mario Zaurrini recently decided there was no better time than the present to turn over a new green leaf in the company’s illustrious history.

Just as the Fruiterie Milano owners began identifying opportunities for introducing more sustainable packaging to their operations about a year ago, they got a well-timed call from a sales representative at Veritiv Canada, Inc.’s Montreal office inquiring about their packaging needs and requirements.

“It was a case of very good timing for both ourselves and Fruiterie Milano,” according to Pascal Lacasse, Veritiv Canada’s director of packaging sales for Quebec and eastern Canada.

“We contacted them just as they started looking for a partner to supply the right packaging products that would help improve their environmental profile,” Lacasse told Canadian Packaging in a recent interview.

Specifically, they wanted to replace all the polystyrene foam trays they were using with something that did not end up going to landfill and stay there forever.

“As it happened, we also just began stocking an exciting new alternative solution to the traditional foam trays commonly used by grocery retailers for packaging smaller quantities of fresh fruits and vegetables,” Lacasse relates. “It was a very happy coincidence.”

“Once they saw what we had to offer, they wasted no time in placing the initial order and proceeding to move ahead with their sustainability program.”

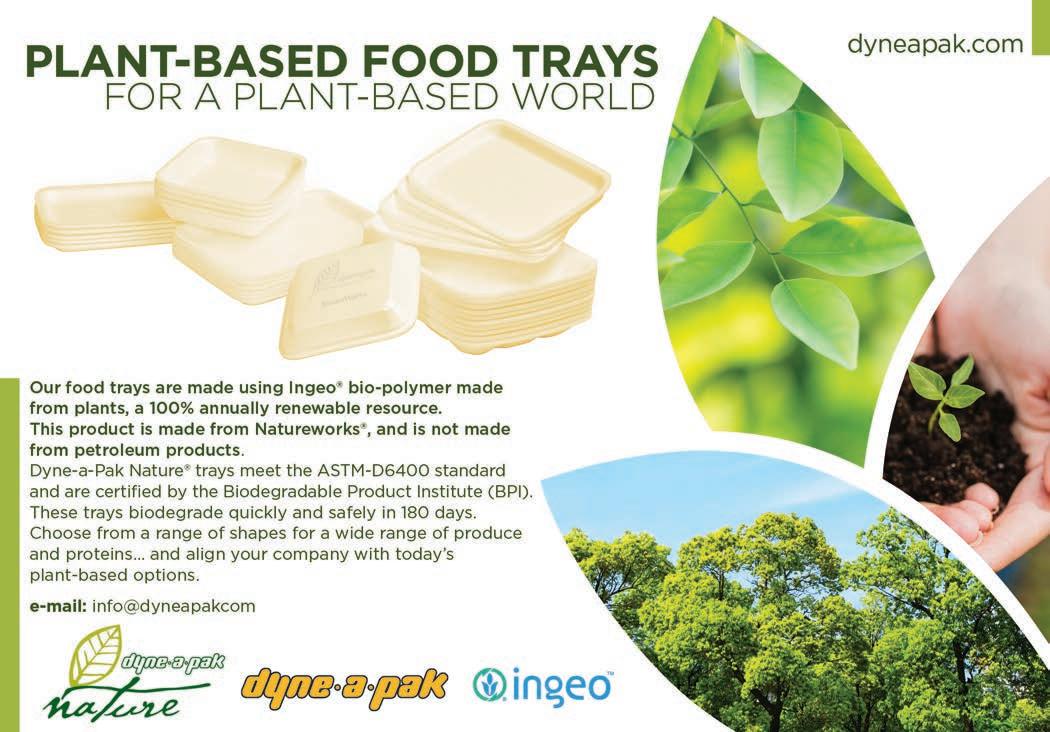

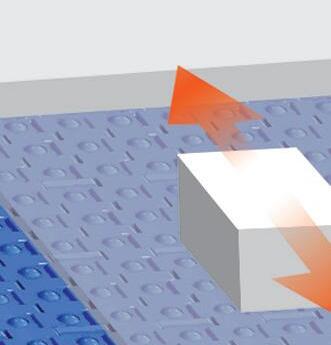

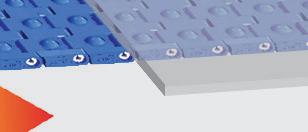

Manufactured in Canada by Hantsport, N.S.-headquartered CKF Inc., the EarthCycle™ brand thermoformed pulp trays distributed by Veritiv are made from a blend of wood fibers— using a proprietary process to create fully compostable, renewable and recyclable trays with outstanding shelf-life properties for the top-sealed products placed inside them.

According to CKF’s director of market development Shannon Boase, “Being certified home-compostable and also widely recyclable in most common

paper waste streams gives EarthCycle packaging a lot of environmental credibility.

“It is a terrific sustainable alternative to help retailers reduce their dependence on single-use plastics and other non-recyclable materials.”

Developed as an alternative for plastic packaging used for smaller-sized fresh fruit, vegetables, berries and mushrooms, the home-compostable EarthCycle packaging received widespread global acclaim earlier this year at the massive Fruit Logistica 2019 international trade fair for fruit and vegetable marketing in Berlin, Germany, where it picked up a bronze (third place) Fruit Logistica Innovation Award from hundreds of entries submitted to the competition.

For store manager D’Amour, who joined Fruiterie Milano a little over a year ago, the multiple environmental benefits offered by EarthCycle packaging made it a very easy sell.

“We had set ourselves a goal of zero waste in 2019,” says D’Amour, “and these EarthCycle trays provided a perfect starting point for us.”

“When I came on-board, I heard many customers asking us in-store whether it was possible, for example, to replace the non-recyclable trays we used for fruits, vegetables and meat,” she recalls.

“I also came across many of the same types of comments being made on the social networks.”

“We realized then that we had to change our way of doing things,” D’Amour relates, complimenting the grocer’s owners for initiating the company’s drive to embrace sustainable packaging solutions—starting with the fresh produce aisles.

“So we introduced one format, then a second immediately after, and before long our customers soon realized that we were using a new type of tray to

WestRock Automated Packaging Systems’ innovative shelf- and retail-ready packaging design to automation solutions reduce the need for third party repackaging and the associated packaging and freight redundancies. Efficiently run one- and two-piece structures in-house while satisfying multiple retailer requirements and increasing your sales lift.

Learn more by visiting us at PACK EXPO, Booth C-2223 and see Meta® Duo in action, our newest two-piece SRP technology for multi-channel, in-house automation.

westrock.com/aps aps@westrock.com

package our fruits and vegetables,” D’Amour recalls.

“Naturally, they wanted to know the characteristics of our new trays, and when we explained to them that they were recyclable and compostable, their reactions were overwhelmingly positive.”

Fruiterie Milano currently uses eight different sizes of EarthCycle trays to pack its fruits and veggies onsite in overwrap stretch film that is also supplied by Veritiv Canada via the company’s local sales reps.

“We also made it a point to use film that could be recycled, assuming that it ends up in the right waste stream,” D’Amour says, “because we are very serious about achieving our zero waste targets.

“We have been very fortunate to be able to count

on the great advice we received from Veritiv sales reps, who are continuing to guide us through our search for more sustainable packaging products.”

According to D’Amour, she is currently working close with Veritiv to introduce new sustainable packaging for the hot soups and meals that Fruiterie Milano also sells on-site from its busy deli counter.

“Our collaboration with Veritiv Canada is enabling us to launch all kinds of initiatives to meet the demands of our customers by reducing our environmental footprint,” D’Amour states.

“We are very keen on maintaining this relationship because we want to continue to innovate in grocery packaging.”

“Our interest in compostable and recyclable packaging products demonstrates how serious we are about making sustainability our core business value proposition.”

According to Veritiv Canada’s Lacasse, Fruiterie Milano’s sustainability program provides an accurate reflection of the urgency of introducing more sustainable packaging by virtually all Canadian grocery operators large and small.

“We have been carrying what would be considered sustainable packaging options for about 15 years now,” Lacasse notes, “but it is in the last two years that the demand for more environmentally-friendly packaging solutions has really taken off in a big way across the grocery sector.”

Grocery retailers have long been a significant and important customer base for Veritiv Canada, whose vast inventory comprises different packaging, printing and facility management products sourced from various suppliers.

“In the past, prospective customers would begin their inquiries with questions about price, quantities, deliveries and all the other standard purchasing questions,” he says, “whereas today sustainability either tops the list or comes very near it.”

Says Lacasse: “I think that after 15 years or so that environmental sustainability has finally become a real public issue, consumers are finally realizing how urgent and important this issue really is for all of us, and they are finally using that knowledge to put pressure on their brands and retailers to address these concerns.

“Veritiv is excited to provide innovative sustainability solutions to its customers so that we can all become better stewards of this planet,” Lacasse sums up.

Entering the distilling market is a long-term venture and understanding product development is an investment. Once a distillery has a range of products and a market, then follow these 4 tips for determining production requirements:

Pick the Right Partner Work with an integrator that sees your vision. The process design needs to allow the distiller to input artisan touches to products but be sophisticated enough to be exible and enable the distiller to concentrate on meaningful variables while minimizing basic control.

Equipment Production design needs to include equipment that will last and is repeatable. Distillers need to have a process and equipment that can reproduce a successful product – from brewing and the stills to the distillation equipment. They need automation to capture the movement and trends as well as document the process for review and duplication.

Control System A controls platform needs to be exible, stable and stand the test of time - to expand and grow with the distillery business. It needs to be able to capture and manage data, handle recipe management and inventory control. The key is to have data available at the time of production and a way of storing it for future planning.

Plan for the Future It is critical for a distillery to have a long-term plan so that when elements of the process change, the automation framework is in place to allow for growth and continuous improvement. Plan for the future versus having to rework or redesign the process down the road.

Operating inside a fully-renovated 184-year-old historically designated stone building in downtown Guelph, Ont. since the start of the year, the Spring Mill Distillery houses a world-class arsenal of distilling equipment, including the towering stainless-steel fermenters (inset) rising almost the entire height of the building, for the production of premium-quality craft whiskey, vodka and gin products.

Upstart craft distiller blends its brewing expertise with process control automation to put itself on solid gowth path

BY GEORGE GUIDONI, EDITOR PHOTOS BY NAOMI HILTZ

Patience may be an increasingly rare virtue in today’s world of instant consumer gratification, but for companies focused on the timeless pursuit of quality, purity and craftsmanship, the ultimate rewards are more often than not well worth the wait.

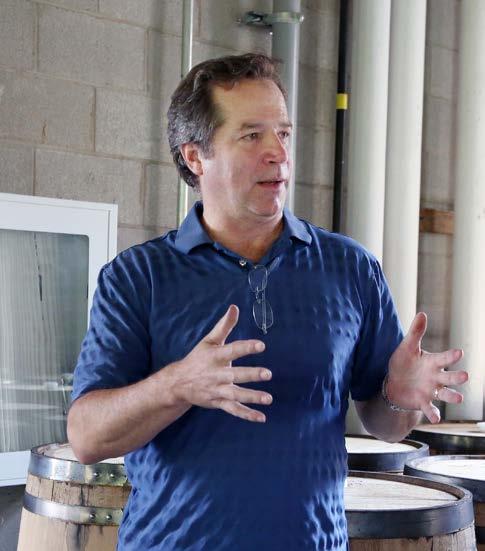

As a founder and former owner of one of Canada’s most successful beer companies of all time, John Sleeman is a living personification of everything that is good and noble about artisanal authenticity in the production of high-quality, well-crafted and cleverly packaged products for which Canadian consumers will happily pay a well-earned premium in a compelling display of brand loyalty and appreciation.

Having steered the Guelph, Ont.-based Sleeman Breweries from its humble beginning in 1988 through its emergence and pre-eminence as one of Canada’s first large-scale craft brewers right up to its astonishing $400-million sale to global Japanese brewing giant Sapporo Breweries in 2006, Sleeman has definitely more than earned his right to coast and bask in the golden afterglow of an extraordinary career.

But that just wouldn’t be John’s style. Rather, in addition to faithfully carrying on with his duties as a Sleeman Breweries chairman of the board, the 65-year-old entrepreneur is on a quest to replicate his remarkable success in the beer business with the new craft-spirits venture called Spring

Also located in Guelph, the recently-launched distiller is an independent, privately-funded enterprise co-owned by 14 individual investors—with Sleeman owning the biggest minority share—aiming to position itself as one of the country’s top producers of craft whiskey and other distilled spirits such as vodka and gin.

“John and I had initially started discussing this idea back in 2010,” says Spring Mill’s vice-president of operations and master distiller Doan Bellman, one of the distillery’s founding co-owners and, notably, the very first brewmaster that John Sleeman hired way back in 1988 to start his then-fledgling microbrewery in Guelph.

“We are both fans of fine whiskeys made around the world,” says Bellman, “and naturally we have plenty of background in alcohol beverage production that we think will give us a competitive edge in the growing market for craft whiskey.

“The difficulty is having to wait for three years to have a sellable [whiskey] product,” says Bellman, citing the patient aging process required to produce a quality whiskey, “whereas a startup brewery can have a sellable product in three weeks’ time.

“Hence this is a very patient money enterprise built on a lot of patient capital,” says Bellman, citing “many millions” of dollars spent on renovating and retrofitting the landmark 184-year-old building where Spring Mill has commenced production of its flagship Spring Mill brand of craft vodka and gin in early spring this year.

“We spared no expense in putting together what we think is the finest craft distillery in Canada,” Bellman told Canadian Packaging on a recent visit to the 20,000-square-foot operation housing two towering, four-meter-high copper pot stills hand-craft-

The clear custom-shaped 750-ml glass bottles supplied to Spring Mill by Bruni Glass are decorated using a high-end ACL (spliced ceramic label) printing process by Stanpac.

ed in Scotland by the famed distillation equipment specialists Forsyths

“It was a hugely capital-intensive project.”

Also housing two giant custom-built wooden “washback” vats made from the Douglas fir trees grown in Western Canada and shipped to Scotland for hand assembly, the designated Heritage Building facility has been making exceptionally good use of all the impressive best-of-breed distilling and processing equipment expertly laid out for optimal production throughout the building’s four storeys.

“We’ve been getting very good feedback right now on both our vodka and gin products,” says Bellman, adding the company is actively expanding its current limited base of about 100 LCBO (Liquor Control Board of Ontario) outlets carrying the premium-priced Spring Mill vodka and gin brands.

Currently retailing for $39.95 for a 750-ml bottle, the Spring Mill vodka and gin are packaged in shapely clear custom glass bottles supplied by Bruni Glass and deftly decorated via the high-end ACL (applied ceramic label) printing process by Stanpac in Niagara Falls, with Erin, Ont.-based A.O. Wilson Ltd. completing the packaging ensemble with tight-fitting wood-top bottle closures and the colored polylaminate bottleneck seals.

As Bellman readily agrees, the whole see-through look of the package is a nod to the once-revolutionary clear-glass beer bottles introduced to the Canadian beer market by Sleeman Breweries to great effect back in the 1990s to break up the decades-long stranglehold on Canadian beer bottle design by the so-called “stubby” bottles favoured by the country’s two dominant brewers Molson and Labatt’s “John always had a keen appreciation for the role that packaging plays in product marketing,” Bellman says, “and playing up the transparency angle with this see-through packaging look just seemed like a natural fit and compliment for our premium products that, in my opinion, are as good as any other established brands out there.”

As Bellman relates, “We are proud to be continuing on with the philosophy John started at the [Sl-

Spring Mill’s vice-president of operations Doan Bellman (left) and Jeremy Meyer, territory account manager for central Canada with Omron Automation Americas, taking a look at live equipment status reports displayed in real time on the Omron touchscreen HMI (human-machine interface) terminal embedded into the plant’s main control panel.

eeman] brewery, which is based on the belief that having the right equipment, the right ingredients, and the right know-how can enable us to produce some of the finest products in the world.”

Says Bellman, “My experience as the Sleemans brewmaster and, in later years, as vice-president of technical services in charge of all the engineering, quality assurance and brewing, enables me to bring a lot of attention to detail in the brewing process that precedes the distillation stages of spirits production.

“Most people don’t know this,” Bellman explains, “but you need to be able make high-quality beer [on-site] before you can proceed to use that beer to make high-quality whiskey, or any other distilled spirit.

“You may have the best stills with the best separation technology,’ Bellman states, “but the stills will not fix any mistakes you may have made in the brewhouse earlier in the process.

“That’s why attention to detail in the brewing process is critical to translating that know-how into the quality final product.

“It is not the stills alone,” Bellman proclaims. “It is the whole process: from start to finish.”

To illustrate the point, Bellman likens operating a still to playing a complex musical instrument like the organ, “whereby you use different pieces of equipment to heat the liquid to release alcohol from the original [beer] solution and then condense the alcohol vapor back into the liquid form.

Measuring

“You can play that tune in many different ways in terms of using different ingredients and all the different valves and other instrumentation to reach the desired boiling temperatures,” says Bellman, “which is why you have so many different vodkas out in the market, for example.

“There is a multitude of combinations and permutations of what you can do to effect the end product,” Bellman notes, “but it is the know-how behind the mechanical process of distilling that has the most important bearing on the final product quality.”

According to Bellman, Spring Mill goes through a lot of effort to source soft winter wheat to use as the base grain for its distilled products, along with many sought-after botanicals from around the world used for flavoring.

As for getting the distillery’s stills to perform like a fine-tuned organ, Bellman knew that the operation’s long-term success would be heavily dependent on installing the right process control solution, along with all related instrumentation and hardware, that would withstand the test of time and the vastly increased output down the road once the barrelled whiskies reached their maturity.

After trying several different engineering firms, Bellman eventually settled on proceeding with the project with LSI Control Systems Integration Canada ULC of Aurora, Ont., which has extensive experience of working with breweries and utilities that supply them with water and electricity.

“I have known Doan for a long time since Sleeman Breweries first opened up,” says LSI’s brand

manager Ian Richardson, who spearheaded the fairly complex automation and integration project at the distillery that commenced in early 2018.

As Richardson relates, integrating automation at a retrofitted facility, rather than at a brand new one, presented a number of unique technical challenges to address.

“This was a brownfield site in a historic building,” Richardson says, “so Spring Mill had a lot of architectural issues for the trades people to work on, such as routing for electrical supplies, process piping and utility piping.”

While that was being addressed, LSI began working on budgeting and preliminary drawings of how the system would operate, which Bellman quickly endorsed.

“Once we developed the process and instrumentation drawings, equipment lists, instrumentation selections and utility requirements, we started the automation discussions [and] by early 2018 we had a good handle on how the place was going to operate,” Richardson recalls.

While Spring Mill insisted on maintaining an artisanal hands-on approach to its production, “We both knew that there were many features that could be automated and displayed that could assist in their production, but still give them the autonomy of controlled production.”

According to Richardson, this included automating the brewing process that supplies the base alcohol, as well as utilities and grain feeds.

Says Richardson: “There was always going to be

a learning curve as to the distilling of alcohol [and] the best way to learn was to start with most configurations in manual.

“As the knowledge expands and we become more comfortable with the process, we could then decide which features could be automated.

“We anticipated that long-term we could automate most functions,” Richardson states, “so we needed the hardware in place so we could convert easily.

“Therefore we needed to be flexible in the design,” says Richardson, explaining LSI’s decision to select Omron’s well-proven Sysmac machine automation platform for the distillery’s process control infrastructure.

“We looked at several platforms and evaluated them based on installed base, flexibility, support capacity, ease-of-use, and our experience on the platforms,” he recalls.

“But understanding Spring Mill’s goals was imperative,” Richardson says, “which is why the automation platform had to be flexible.

“In the long term, they want to produce high-end whiskey products that could be aged five to eight years or longer, so they would need a platform that wouldn’t be obsolete by the time they put their first high-end products on the market.”

Richardson says LSI worked closely with electric components distributor Aztec Electrical Supply Inc. of Mississauga, Ont., and Omron Automation Americas to identify and validate all the key automation components and devices that would be

one integrated module could easily divert, transfer and sort multiple package types?

Very small packs? Polybags? Not a problem for Modsort® divert and transfer conveyor modules! The Modsort module can do left and right sorting on the fly for a wide range of package types and sizes. It is safe, quiet, versatile and cost effective.

Let our experts support you choosing the right system for your application or check it out at: regalbeloit.com/packaging www.regalbeloit.com Creating a better tomorrow™...

installed at the distillery.

“We asked a lot of tough questions of Aztec and Omron,” Richardson relates. “From our perspective the risk in the learning curve lay in being able to program the project, as we were working with intrinsically safe devices, explosion-proof devices, standard devices, and a variety of suppliers of instruments and equipment.”

After a series of live tests and demonstrations, Richardson became increasingly convinced that the Omron Sysmac platform would provide the best solution for Spring Mill’s process control needs.

“In the end, it was not so much a question of how much this will cost, but more a consideration of how much support Omron was willing to provide,” he states.

“Our mandate at LSI is to exceed expectations of the customer,” he says, “I was only willing to promote this op-

Omron controllers, I/O terminals and other automation devices were expertly configured and programmed by LSI Control Systems in a way that will enable the distillery to ramp up its production capacity and throughput down the road without any major downtime or interruptions.

tion if I knew that this was going to be a real partnership.”

With flexibility being a critical consideration, Omron supplied high-performance automated valves with modular components to accommodate any future changes, along with instruments capable of performing variable duties.

“In many cases we selected instruments that had a bigger range in anticipation of a bigger potential operating window,” he says.

“We also used Omron’s remote I/O blocks that could be easily expanded as required—keeping wiring local to the change but the process connected to the main PLC (programmable logic controller).

“It has been proven to be a learning experience,” he says, “and we have had to change our logic to accommodate the operations.

“But with a flexible platform, most of our changes are code-related, rather than hardware-related, which keeps the new capital costs down.”

In the end, the Omron Sysmac automation platform proved to be a cost-effective solution with plenty of flexibility to accommodate Spring Mill Distillery’s future production needs, states Richardson.

“I think it is fair to say that it was success story for both Spring Mill and LSI,” Richardson says.

“The platform has proven to be flexible enough to handle the many changes and additions as we walk down the learning curve, and the displays satisfy all the customers concerns, and addition to being customized as we go on.

“We are already in discussions about doing data acquisition down the road,” Richardson adds. “With the platform is already set up for it, it’s just a case of selecting what data and how to present it.”

For his part, Bellman says he is very satisfied with the flexibility offered by the Omron Sysmac automation platform in terms of accommodating further growth in the company’s product portfolio and capacity.

“Our stills were designed to produce a wide range of products,” Bellman says, noting that the distillery has everything in place to produce the four main whisky types that include the Old World-style Scottish and Irish whiskies; the traditional American-style bourbons; and the Canadian-style rye whiskey.

“We will definitely continue to look at other products to produce here that can stand on their own in the marketplace,” says Bellman, “but the main focus for now is supporting our existing two brands and gearing up towards the launch of our first whiskey products to celebrate our three-year anniversary.”

According to Bellman, the timing for the company’s phased entry into the craft spirits market could hardly be better.

Says Bellman: “As the population ages, people tend to drink less but they tend to drink better.

“Today’s consumers are increasingly choosing quality over quantity,” he says, “and we want to tap into that mindset.

“We have seen this happen in the beer industry with the rapid growth of the craftbrewing segment,” he concludes, “and we are already seeing this trend unfolding in the craft distillery business, where we believe Spring Mill will have a strong role in the sector’s continued growth.”

BY ALANNA FAIREY, ASSISTANT EDITOR PHOTOS BY NAOMI HILTZ

No good night sleep is complete without the perfect fluffy pillow, an art that North York, Ont.-based Hollander Sleep Products has mastered in their 100-year long history of developing high-quality bedding products.

Founded by Leo Hollander, the U.S.-based business predominantly focused on making luxury pillows, which quickly expanded into making other sleep products as the business took off.

Today, Hollander is owned by private equity and has two manufacturing facilities in Toronto and the other is in Montreal, while there are at least seven manufacturing facilities in the U.S. as well, servicing the U.S. marketplace.

“Canada is a unique market,” observes Chris Matukas, vice-president of sales.

“We just strive to make a great pillow and great products and great duvets and mattress pads for the Canadian marketplace.”

For a number of years, Hollander has been a proud supplier to warehouse dynamo Costco Canada, distributing their Beautyrest, Pacific Coast Feather and Great Sleep brands.

Hollander is committed to its procedures in safety and overall quality assurance, as Matukas and shares that there is always a risk that a broken sewing needle could accidentally end up in the pillow and his team needs to be prepared to rectify the situation.

“Even though we have needle guards on sewing machines and we have very experienced sewers, needles do wear out and they do break––it’s very rare, but it does happen,” Matukas told Canadian Packaging during a recent visit to the 135,000-square-foot, 85-employee operation working two shifts on multiple machines to keep pace with orders.

“At that moment, we can quarantine that particular sewer station and do a full inspection.

“We collect all of the pieces of the broken needle and put it in our broken needle record book, so that we have an actual assessment and categorization of that broken needle or replaced needle.”

Matukas is not the only one who takes the risk of contamination very seriously.

Due to a number of quality and safety require-

Vice-president of sales Chris Matukas poses proudly with a pillow that had been successfully run through the Fortress STEALTH Metal Detector System at Hollander Sleep Products’ 135,000-square-foot facility based in North York, Ont., which houses 85 full-time employees.

ments as per their agreement with Costco Canada, Matukas and the QA (Quality Assurance) teams had to re-evaluate the metal detection systems that Hollander had in place.

“We found that the metal detection machines that we had that we purchased from China were inferior,” Matukas recalls.

“They weren’t doing the job that we needed, they weren’t detecting to the level that we needed, and therefore we had to find another source to help us maintain our level of quality for Costco Canada.”

In their search for a more efficient metal detector, Matukas began consulting with Fortress Technology Inc., with discussions going back and forth for about a year’s time.

After much deliberation, Hollander decided to

Hollander operators have praised the Fortress STEALTH Metal Detector system for its user-friendliness and accuracy, a major upgrade from the metal detectors that the facility had been using previously.

ing a better chance of catching small and minute needles.

“We had to get quite finite in our detection and found that the Chinese machines that we were using were not detecting to the level that we required,” Matukas explains.

“Working with Fortress and the technology that they’re using provides a far better detection scenario.”

Prior to installing the STEALTH Metal Detector, Matukas and his operators would have to do ninepoint tests on the metal detector systems to ensure that they are still operating at peak performance. Now, they do not have to do that.

“We now do a simple single test where we put the actual test card in the middle of the track and we let it go through the machine because the center is the weakest point of the machines detection,” Matukas elucidates.

“If it detects it at the weakest point, we know that the machine is operational and we can go back into production we do that every two hours during the course of the day to ensure that the machines are at peak operating condition.

“If it isn’t, we stop and recalibrate.”

In the synthetic pillow process, Hollander sources synthetic fibre that’s inside the pillow from North American sources, predominantly in the U.S., while the shells come from china, and poly bags, cartons and the corrugate are all sourced from Canadian companies that Hollander has partnered with.

lease a Fortress STEALTH Metal Detector system, as they continue developing machinery or metal detection, more specific to their requirements with Costco Canada.

“It provides us the certainty that we’re catching everything that we possibly can from a metal perspective,” Matukas explains.

“We’re really trying to mitigate any kind of metal source that may have fallen into the manufacturing process.”

Renowned for its superior accuracy and reliability, the STEALTH Metal Detector has built-in data software that helps to catch product contamination.

A feature that is unique in Matukas’ eyes is the way the STEALTH Metal Detector does detection, due to the system’s lower aperture and smaller opening hav-

When the raw materials arrive at the facility, the factory workers then promptly fill the pillows onsite.

The pillows are then run through the STEALTH Metal Detector, to ensure that it is free from any broken needles that may have inadvertently made its way into the product.

Once it successfully passes through, operators then package the pillows in the corrugate, put it on the pallet and then it is shipped off to the customer.

In the event the STEALTH Metal Detector catches a contaminated pillow, the machine makes a loud beeping sound and the belt that carries the item through the aperture stops automatically.

The workers there call in the QA department and they perform a full inspection to see where the con-

the event a needle inadvertently

tamination might have occurred.

“It really helps us have a second set of eyes to mitigate any metal falling into the pillow,” Matukas reflects.

While the STEALTH Metal Detector has only been installed at the facility for just a couple of months, Matukas has already seen a noticeable difference in the overall quality of Hollander’s pillows.

“They run more efficiently than the Chinese metal detection machines that we have so it actually has enhanced our production cadence,” Matukas extols.

“Because of the sensitivity of the machines, we are going to catch more potential issues and therefore we

have a far higher level of confidence that the machines are doing what they’re meant to do.”

Since the installation, the partnership between Fortress and Hollander has been smooth sailing thus far.

Praising the smooth process and straightforward lease agreement, Matukas has been impressed by the customer service that Hollander has received from Fortress.

“They came in and installed machines, gave us training, and they have a contact that our QA manager can call in case they’re really stuck,” Matukas shares.

While the STEALTH Metal Detector is currently on lease from Fortress, Matukas shares that Hollander’s

Montreal facility purchased the system, which fortress built on their behalf based on their specifications for mattress pads.

Because of the experience in Montreal and through leasing with them, Matukas says that there is a good chance that the Toronto-based Hollander facility will end up purchasing from Fortress altogether.

For now, Matukas shares that the number one priority for Hollander is to maintain their business and to continue to grow in an ever-competitive marketplace, knowing that retailers choose their suppliers based on the overall quality of the product.

“There are many players out there manufacturing pillows and coming from various sources,” Matukas says.

“We’re fortunate enough we can manufacture in Canada and supply our Canadian customers with a quality product and that’s one of the reasons why we still have manufacturing in Canada.

“We can control the whole process and therefore we know that the customer is receiving product that is built by Canadians for Canadians.”

With several internal and retail awards accredited to their commitment to safety and superior products, they serve as a testament to Hollander’s commitment to giving their customers the bedding commodities that they deserve.

“Quality control has to be on top of things, because you’re trying to protect the public,” Matukas reiterates.

“It’s just like the food that you buy––you trust the food that you’re buying, so you need to trust the products that you’re buying as well.

Concludes Matukas: “Especially if you’re sleeping on it like a pillow.”

Yes, we can solve that too.

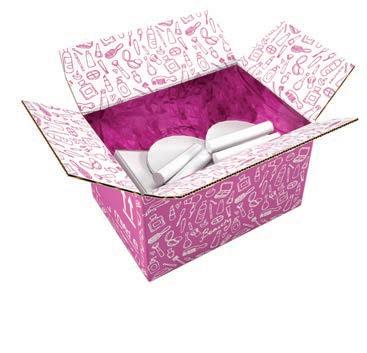

WestRock Automated Packaging Systems’ innovative e-commerce packaging design to automation solutions help streamline your process, improve your supply chain and lower your total cost.

Learn more by visiting us at PACK EXPO, Booth #C-2223 where you can watch live demos of two of our newest e-commerce package right-sizing automation innovations, BoxSizerTM and Pak On DemandTM Pouch System.

westrock.com/aps aps@westrock.com

Dutch cookie manufacturer sees the sweeter side of life thanks to ultramodern integration line

BY ALANNA FAIREY, ASSISTANT EDITOR

PHOTOS BY NAOMI HILTZ

Family-owned Schep’s Bakeries Ltd. has come a long way since its humble beginnings as a small business for small specialty stores over 35 years ago.

Founded by Dutch-born Arie Schep, Schep’s Bakery quickly blossomed into the only stroopwafel manufacturer in North America, distributing the Double Dutch waffle cookie assortments into larger retail stores in Canada and the U.S. market.

For the past eight years, the Norwich, Ont.based Schep’s Bakery facility stands at an impressive 50,000-square-feet, where they are conveniently at the centre of a predominantly Dutch community.

“We’ve grown from a smaller shop to a bigger shop,” says Schep’s Bakery president Jacco Schep, who has taken up the mantle from his father and has continued to oversee production of only the best waffle cookies, credited to a tightly guarded family recipe.

“Making waffle cookies is what we do––it’s our main focus,” extols Schep.

A true Dutch delicacy, a stroopwafel is a wafer made from two thin layers of baked dough with a golden caramel syrup filling in the middle. While it was first made popular in the Netherlands, nowadays stroopwafels are enjoyed worldwide.

While most stroopwafels are traditionally filled with caramel, Schep’s Bakery has created glutenfree and organic varieties, and a plethora of flavours requested by their customers, which include fan favourite, Cookies & Crème.

“If demand is there, we will create it,” Schep told Canadian Packaging during a recent visit to the lively 55-employee facility working on two-shifts, six-days-a-week schedule throughout most of the year, with steady demand upticks throughout the year.

“Everything changes daily––there’s trends and there is necessary changes.

“As a business, you try to go along with it as much as you can based on how big the market is for that particular trend.”

To show their commitment to producing high quality stroopwafels, the Schep’s Bakery plant has earned the internationally recognized GFSI (Global Food Safety Initiative) and BRC (British Retail Consortium) certifications, while the stroopwafels are Kosher, gluten-free, and only use Non-GMO and sustainably sourced ingredients.

According to Jonathan Schep, the younger of the two Schep brothers, consumers have provided them with glowing reviews of their stroopwafels.

“Customers just love the product,” says Jonathan. “We look at the quality more than at the quantity

of what we do.”

“It’s always about how it tastes, and how it looks.”

Adds Jonathan: “We have our own in-house R&D (research-and-development) lab to develop new flavours and waffle types.”

Although Schep’s Bakery will continue to make top-notch stroopwafels, the Schep brothers are mindful that they are doing business in an increasingly competitive market.

“The industry is competitive, ” Schep reiterates.

“Even though we are the only stroopwafel manufacturer in North America, there is definitely competition out of other parts of the world, which keeps the business interesting.”

To stay afloat in an increasingly competitive and demanding market, the Schep

brother’s sought the help of Propack Processing & Packaging Systems Inc., a leading supplier of custom robotic packaging solutions.

Specializing in high-speed pick-and-place structures for applications such as cakes, cookies, candy, granola and snack bars, Propack has been a faithful partner of Schep’s Bakery for over a year and a half.

“A lot of machines were considered during the process of making the decision on which company to use and why, and I think that in the end, Schep’s Bakery chose Propack,” says Joseph Bradley, a technical sales representative for Propack.

“We were able to work together as a team, and as a team we developed a system that we believe is beyond what’s available in the market as a standard offering.”

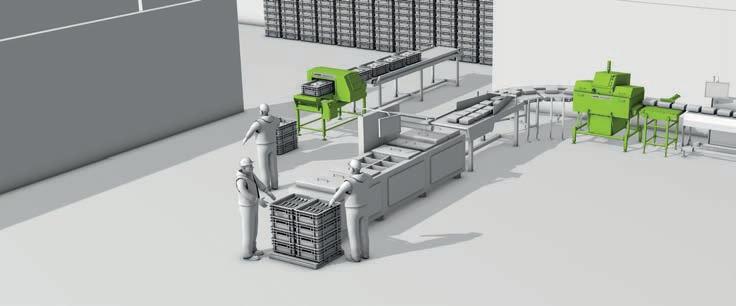

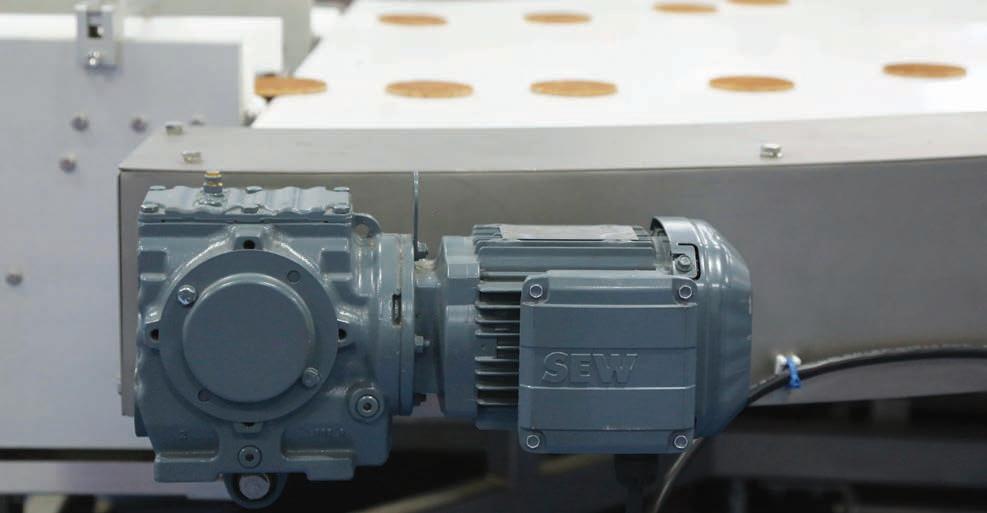

The Propack Row Distribution System (RDS), which has been installed at

the plant for about six months, uses AC motors and servo technology to receive rows of prepared stroopwafels from upstream processing equipment and coordinates product delivery on-time, on-demand to low, medium, or high-speed wrapping machines.

A flexible machine, the younger Schep brother has no qualms about singing its praises.

“The RDS distribution system that we have is one of the most advanced in the world,” Jonathan shares. “There really is nothing else out there like it with all of its capabilities.”

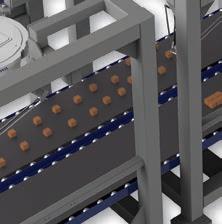

Prior to being distributed and sold throughout North America, the waffle is baked as per the family recipe’s instructions, the waffles are filled with the syrup and it is then cooled.

Once they have cooled, the waffle cookies are promptly distributed in rows on the RDS’ main belt, where the central panel controls system determines which line the cookie will go.

“The system has the ability to deliver those rows to multiple packaging streams simultaneously or independently,” Bradley explains.

“This includes distributing stroopwafels to high speed wrappers and then sending them further downstream to robotic carton loading.

“Or, the RDS can make a decision to deliver products to the scale and bagging system instead of to the wrappers.

“We can also wrap the product and then send it to the baggers instead of going to the cartons.”

Having met in the initial stages of Schep’s Bakery looking for a partner, the Schep brothers were very clear about what they wanted the overall line to look as an integrated packaging line as one system from Propack.

Suffice to say, Propack provided everything and more in the eyes of Schep’s Bakery.

“Everything had to be integrated along with all of the programming and Propack took care of everything from start to finish,” Jonathan says.

“From purchasing the machines, to getting them all here, to installing it and setting it up, and commissioning it, everything has been good––what more can we say?”

Supplied from The Paxiom Group, Schep’s Bakery uses a state-of-the-art Swifty Bagger 3600 for their stand-up pouches as well as a PrimoCombi multihead weigher, which were seamlessly integrated into Propack’s Row Distribution System (RDS)

The PrimoCombi multihead weigher’s two main goals are to achieve high accuracy requirements and high production rates.

When the center of the PrimoCombi multihead weigher is filled in bulk with stroopwafels, the feeder pans promptly transport the finished product to the weigh bucket where it is then weighed and measured before it is sent to the Swifty Bagger 3600.

Specifically engineered for dispensing snack foods and baked products, the PrimoCombi multihead weigher has been praised for its accuracy and is guaranteed to deliver stroopwafels to the bags within a set range.

Engineered for medium to high production rates, the Swifty Bagger 3600 offers speeds of up to 35 pre-made bags per minute, which greatly excels production for Schep’s Bakery.

The Swifty Bagger 3600 also includes a comprehensible bag magazine for pouch loading, automatic zipper opening device,

and bag shaker at the fill station for product levelling and an integrated exit conveyor.

This system is able to accept pre-made pouches of multiple sizes, of length and width, and several different styles of bags.

The Swifty Bagger 3600 will also accept bags with or without a zipper feature, depending on the request of the customer.

According to Jonathan, the Swifty Bagger 3600 has been an asset to Schep’s Bakery, thanks to its flexible and user-friendly interfaces.

Schep’s Bakery has not only reaped the benefits of Propack’s flexible integrated line, but also from their professional aftercare services and support.

In the event of a malfunctioning machine, skilled technicians from Propack are available to assist Schep’s Bakery, no matter the time or situation.

“We’re about an hour away, so it gives us quick and easy access to react,” Bradley explains.