COLD TURKEY

Ontario turkey processor spreading its wings with flexible thermoform packaging technology Story on page 33

Sean Maguire, Sales & Operations Manager, Hayter’s Farm

Lindsay Hayter, Human Resources Manager, Hayter’s Farm

The smarter way to print is with true CIJ innovation

Videojet 1860 Continuous Inkjet Printer

True predictability

Industry-first ink build-up sensor provides true predictability and warnings of possibly degrading print quality, even before a fault occurs.

True remote services*

Multiple access options (Ethernet™, WiFi) and secure VPN communication meet highest standards in the industry as part of VideojetConnect™ Remote Service, and help to improve machine uptime and customer experience.

* Subject to availability in your country

True IP rating

Optional IP66 rating for entire cabinet and hygienic design following industry guidelines; easier integration with slanted printhead design.

True scalability

Workflow modules help to customize the printer to perform the exact need required. It is easy to adapt the printer with new capabilities and functionalities, and to meet growing demands.

OCTOBER 2019

VOLUME 72, NO. 10

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

ASSISTANT EDITOR

Alanna Fairey • (416) 510-5228 afairey@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbusinessmedia.com

VICE PRESIDENT

Tim Dimopoulos • tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging,

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3555

Fax: 416-510-6875 or 416-442-2191

TOAST TO A PROMISING CHEERFUL FUTURE

The glass is always halffull, at the very least, in Ontario’s thriving craft beer industry. While the country’s traditional Big Three beer triumvirate comprised of Molson Coors, InBev (Labatt) and Sleeman seems to be constantly struggling with the reality of a mature and flat market for mass-produced beer products, the province’s craft brewing community continues to grow in leaps and bounds.

Currently accounting for 10 per cent of all beer sales in the province, according to the Ontario Craft Brewers (OCB) association, the province’s craft beer producers appear to have taken full advantage of the long-awaited regulatory changes to allow for limited beer sales at some grocery outlets across the province to maintain the sector’s stellar, double-digit annual growth that has evloved it into an important contributor to Ontario’s economy and job market.

And according to OCB president Scott Simmons, the industry can double its sales and market share within a couple of years if the provincial government allows for further relaxation of rigid rules still governing the sale and distribution of beer products in Ontario by opening up convenience stores and other channels. In fact, Simmons has some very interesting ideas on how the government could go about it, which he shares with Canadian Packaging in a special report starting after page 10 of this issue.

As for proof of the industry’s remarkable growth track record so far, OCB’s decision to move its annual Ontario Craft Brewers Conference and Suppliers Marketplace from its traditional host venue of

Beanfield Centre at Toronto’s CNE fairgrounds to the Scotiabank Convention Centre in Niagara Falls this year neatly sums up the sector’s progress.

“The truth is that we simply outgrew the Beanfield Centre in terms of being able to fit all the exhibitors that want to be a part of the Suppliers Marketplace trade show,” Simmons explains. “We had to find a bigger place and the new Scotiabank facility in Niagara Falls checked off all the boxes for us.”

Running from Oct. 28 to 30, 2019, this year’s event promises to eclipse all other previous editions, according to Simmons, with well over 200 exhibitors and more than 1,200 visitors, who will be treated to a world-class conference featuring some of the global craft beer industry’s leading lights.

As Simmons points out, the choice of Niagara Falls also happens to carry a fair bit of symbolic significance on the account of the venue’s proximity to the Niagara College of Applied Arts and Technology, home to the renowned Brewmaster and Brewing Operations Management diploma program that has already produced some of the country’s top professional brewmasters.

Says Simmons: “The DNA of the craft brewery business matches up very well with the DNA of today’s young people, specifically millennials, who find the working environment well aligned with their own personal beliefs that stress the importance of being very supportive of one another and really caring about the people behind the product, rather than solely the product itself.

“It’s just part of the nature of the industry.” Amen.

Davor Djukic

37 ALL GOOD IN THE HOOD Organic foods producer using stretch hood packaging to keep the pests at bay.

PLASTICS INDUSTRY GROUP CLAIMS THAT CANADA CAN RESOLVE ITS OWN RECYCLING SHORTCOMINGS

The closing of Chinese and other overseas markets to Canadian-made plastic waste does not have the calamitous consequences for Canada’s plastic recycling infrastructure that would require governments to introduce outright bans or other drastic measures deemed to be necessary to solve the country’s plastic waste problem, according to a new report prepared for the Canadian Plastics Industry Association (CPIA)

Released in late August, the 2017 Post-Consumer Plastics Recycling in Canada report says that most of the recyclable plastic material collected in Canada remained in North America for reprocessing into new products, rather than being shipped to overseas markets.

Complied by highly respected California-based recycling consultancy More Recycling, the study found that 88-per cent of collected plastic material in 2017 was reclaimed either in Canada or the U.S., with only 10 per cent being diverted to overseas markets, with the remaining two per cent of that total unaccounted for.

While CPIA acknowledges that the Chinese

government’s new ‘National Sword’ policies— introduced in 2017 to block plastics and other recyclables from entering the country—has led to a “significant tightening” in the market for recycled waste, the Mississauga-headquartered industry states that Canada already has all the resources it needs to solve its plastic waste challenges domestically through enhancements to its existing recycling infrastructure.

“Despite this [export market closing], Canadians continue to recycle, and recycling programs continue to send these materials to end markets, the majority of which are in North America,” CPIA states.

“By converting the plastics to new packaging and consumer and industrial goods, they are continuing to support strength in overall recovery rates.”

According to CPIA president and chief executive officer Carol Hochu, “This study again proves that by developing and maintaining strong domestic markets for recycled commodities we can continue to offer Canadians viable programs to recycle plastics.

“This is important because Canadians have demonstrated they are fully committed to and want to continue to recycle,” Hochu states.

As always, plastic bottles continue to be the coast-to-coast leaders in recycling, the study finds, with 63 per cent of used plastic containers being collected at curbside or returned to depot for recycling

Following their first and potential reuse, PET (polyethylene terephthalate) plastic bottles continue to be reprocessed to generate plastic fibers for textile products, as well being converted into new bottles.

For their part, the HDPE (highdensity polyethylene) plastic bottles are most often converted into new bottles, along with being used to manufacture lumber, decking and lawn–and-garden products.

“Despite the challenges over the past two years, the mainstay programs for HDPE and PET jugs are very close to what we saw in previous year, before China’s National Sword policies came into effect,” says Hochu.

“It’s a testament to the strength of the North American reprocessing industry that recycling of materials from Canada stayed strong at 88 per cent per cent during this difficult period.

“Not only that, but Canadian recyclers were managing more materials generated in the U.S. as well.”

Contrary to the positive outlook for traditional plastic bottle packaging, the tightening international markets have impacted plastics recycling rates across the board, as reflected by a five-percent overall decline in recovery rates through 2017.

According to the report, plastic film recycling was most profoundly affected

by export restrictions and a need for new domestic markets— particularly those able to process post-consumer materials from curbside programs.

While many other materials were also subject to reductions, most were just slightly off from a year before.

According to CPIA, solving these shortcomings will require continued commitment to recycling by the public and accelerated innovation by the producers of plastic packaging.

“The CPIA team is working diligently with municipalities, industry and regulators to seek new ways to recover and derive continuing value from all types of plastic packaging, including recycled content in new products and packaging,” says CPIA’s vice-president of sustainability Joe Hruska,

“When new and evolving packaging formats come along,

like the new and emerging film and laminated plastics, there’s often a lag in technology to manage this more complex material,” Hruska explains.

“But I’m excited to see the huge growth in recovery technology now, with new systems available to recycle curbside film, polystyrene and much more,” Hruska states.

“With that, we’re confident that the declines of 2017 will be offset over the years to come,” says Hruska, citing a significant increase in new Canadian processing capacity.

In addition to more traditional mechanical recycling capacity, Hruska says the introduction of new-generation ‘resource recovery’ technologies will help recyclers to recover the value from plastic materials and to ensure they don’t go to litter or landfill.

Mike McCann. Application Specialist. Packaging Expert.

“I’m Mike McCann and I’m part of the Reiser team of Packaging Specialists who work with customers to improve the packaging of their products. I can help you every step of the way –from evaluating your product, your customer, and your goals to assessing your various packaging machine options. With decades of experience, I can help you select the very best packaging solution for your specific application. Are you ready to produce a better package? Let me show you how.”

Watch Mike’s video

NOTES & QUOTES

Endress+Hauser Canada general manager Anthony Varga (sixth from left) hosted the groundbreaking ceremony that also included (from left) Burlington city councillor Paul Sharman; Harold Reinders of construction manager Maple Reinders; local member of parliament Pam Damoff, Drew Hauser of mcCallumSather (project architect and mechanical engineer); Burlington mayor Marianne Meed Ward; Todd Lucey, corporate sales director of Endress+Hauser North America; and Bill Poland of Genesis Property Management.

nLeading German industrial instrumentation and measurement technologies group Endress+Hauser Group has formally broken ground on its new $28-million Endress+Hauser Canada facility in Burlington, Ont., last month. Scheduled for completion next year, the new 47,000-square-foot building will serve as the company’s Customer Experience Centre for central and

eastern Canada—offering clients from Manitoba to the Maritimes a state-ofthe-art training and support hub for selecting and familiarizing themselves with the company’s latest innovations for process automation. “Providing great customer experiences is a key differentiator for Endress+Hauser,” says Endress+Hauser Canada’s general manager Anthony Varga, adding the new building will be designed and built in accordance to LEED Gold standard green building certification for net zero energy and emissions. “This is a strong endorsement of the continued growth and strong potential for Endress+Hauser in the Canadian market.”

nMiraclon, Rochester, N.Y.-based supplier of Kodak Flexcel platemaking equipment for flexographic printing applications, has received the prestigious 2019 InterTech Technology Award of the P rinting Industries of America (PIA) in recognition of the innovative Kodak FLEXCEL NX Ultra Solution plate-making system for solvent-free flexo plate processing.

“At Miraclon, we are committed to delivering technology solutions that drive efficiency, consistency and quality in flexo printing,” says the company’s chief technology officer Zaki Ali. “The FLEXCEL NX Ultra Solution checks all those boxes, and more, by allowing the preparation of a pressready plate in under one hour, while removing the hurdles and challenges that have plagued aqueous platemaking solutions for the last 25 years.”

nHoffmann Neopac, Swiss manufacturer of tube packaging solutions for a diverse range of global industries, has recently received several highprofile awards for tube solutions in the

healthcare sector— each utilizing the company’s proprietary high-barrier Polyfoil technology designed to ensure superior protection for the packaged product against moisture and oxygen. Most recently, the company’s its Voltaren No Mess tube and applicator—developed in conjunction with GlaxoSmithKline and Nypro —received a 2019 WorldStar award of the World Packaging Organisation (WPO) for providing a cleaner, more hygienic method of applying pain relief medicine, whereby the intuitive pull/push mechanism of the No Mess tube allows the massage tip to close by itself after the application of gel to the skin. Prior to winning this year’s WorldStar award, the No Mess tube also picked up the 2018 Dow Packaging Award, ETMA Tube of the Year award, and Pharmapack Award 2018

nWayne, Pa.-based packaging products manufacturing group Tekni-Plex, Inc. has completed the acquisition of MMC Packaging Equipment Ltd., an established manufacturer of including cap lining, slitting/folding, assembling and closing systems based in Montreal. Currently employing about 70 full-time staff, MMC will become part of Tekni-

Plex’s fast-growing TriSeal business, according to Tekni-Plex president and chief executive officer Paul Young. “The acquisition of MMC allows us to bring an expanded array of solutions to the caps and closure packaging segment, as well as other markets,” Young states. “As experts in designing, assembling and supplying leading-edge, high-speed, post-molding automation systems, MMC’s global business perfectly complements Tri-Seal’s worldwide manufacturing footprint with their innovative products and excellent manufacturing capabilities.

nChicago-headquartered rigid packaging products group Berlin Packaging has completed the acquisition of Vincap B.V. and Adolfse Packaging B.V., Dutch-based manufacturer of food and beverage closures and pharmaceutical packaging to a well-established client base across northern Europe. A prominent supplier of plastic, cork, and metal closures and plastic packaging in the Benelux (Belgium, The Netherlands and Luxembourg) region strategically located in Utrecht, Vincap & Adolfse will be integrated into Berlin Packaging’s Bruni Glass business, headquartered in Milan, Italy, marking marks

Berlin’s tenth overall acquisition since 2010 and the fourth in Europe since 2016. “As Berlin Packaging continues to acquire companies that share our commitment to quality, service, and bottom-line growth for our customers, we further separate ourselves from the competition with a tremendous global footprint, an unparalleled product and service offering, and a long history of double-digit organic growth,” says Berlin Packaging’s chairman and chief executive officer Andrew Berlin.

nDIC Corporation, parent company of Sun Chemical Corporation, has reached a definitive agreement to acquire BASF Colors & Effects (BCE), the global pigments business of leading German chemicals producer BASF SE , for an undisclosed amount. According to DIC, the acquisition will broaden DIC’s portfolio as a global manufacturer of pigments, including those for electronic displays, cosmetics, coatings, plastics, inks and specialty applications. “Our acquisition of BCE brings together complementary resources and expertise of two recognized leaders in innovation, product stewardship, regulatory leadership, application support and manufacturing,” says DIC president and chief executive office Kaoru Ino. “It will allow us to expand our offering as one of the leading pigment suppliers globally, while providing our customers with even more versatile solutions.”

Ink Jet Printer

FIRST GLANCE

TAKEN TO TASK

The new TaskMate robotic systems from ESS Technologies, Inc. incorporate FANUC America’s new line of SCARA robots to create an ultra-compact robotic cell that integrates easily with cartoners, case-packers and monoblock fillers/cappers for effective collation and machine loading and unloading. According to the company, the TaskMate systems leverage the small size and flexibility of the FANUC robots to place the robot within the machine frame— unlike the larger robots that require a separate robotic cell with additional safety guarding—to reduce the system footprint, cost and guarding requirements. Fully compatible with the company’s broad range of custom end-of-arm tooling (EOAT) for each application, TaskMate robotic systems can handle a variety of shapes and sizes to allow the robotic cell to be used in a wide range of applications for kit packing, collation, loading, unloading, material handling, and product assembly.

ESS Technologies, Inc.

THE INCREDIBLE BULK

A new ultra heavy-duty bulk bag filling system from Flexicon Corporation is designed to provide reliable intake of abrasives, high-density solids and other difficult-to-handle bulk materials from upstream processes or storage vessels and fills the material by weight into bulk bags. Intended for mining, glass, ceramics and other demanding industrial applications, the system is comprised of heavy-gauge variants of the company’s patented TWIN-CENTERPOST filler and FLEXICON flex-

ible screw conveyor consolidated on a robust skid with integral forklifting tubes for mobility. The filler is equipped with fill head height adjustment to accommodate all popular bag sizes, pneumatically retractable bag hooks and an inflatable connector to seal the bag inlet spout, with an optional feed chute outlet port featuring a high-efficiency filter sock for dust-free air displacement during filling. The FLEXICON conveyor consists of a steel outer tube with a rugged flexible screw that self-centers as it rotates to preventing material from grinding between the screw and tube wall, while eliminating the need for a bearing at the intake end.

Flexicon Corporation

LIVING LARGE

Requiring just one operator and designed to improve the efficiency of distribution operations, the new Series 2300 large-volume sorting conveyor from Eaglestone Equipment is outfitted with adjustable-speed pneumatic sorting arms that automatically divert products into waiting containers, and then and shift to a different receptacle when previous cartons are full. Featuring bright LED lights to indicate when each container is nearly full or completely full, the Series 2300 con-

veyor can easily sort both random and single product production batches through the use of eye safe infrared scanners to identify barcodes. The Series 2300 conveyor can be supplied with numerous options to suit various application requirements, including retracting ends, diverting chutes, blast gates, push-offs, stainlesssteel casters, etc.

Eaglestone Equipment

RADIO WAVES

Designed to simplify data collection in high-throughput production facilities, the new Ultra High Frequency (UHF) handheld RFID reader from Balluff Inc. offers superior flexibility in both close and long-range applications, according to the company, in addition to reliable 2D (twodimensional) barcode scanning. Equipped with a high-speed processor to allow which allows for expeditious reading of multiple tags in the field, the handheld system comes with a Microsoft Windows Embedded Compact 7 operating system; an intuitive user interface that minimizes deployment time and eliminates the need for complex programming; and an optional software development kit for custom applications.

Balluff Inc.

TOUGH LUCK

The new TOUGHBOOK 55 industrial laptop from Panasonic Corporation offers welcome versatility and ruggedness thanks to the superior flexibility of its its modular expansion packs and accessories that ensure users can customize the design of the laptop to accommodate the changing way they work in harsh industrial environments. Designed to help shorten lead times and decrease downtime, the TOUGHBOOK 55 has the longest battery life of any Panasonic TOUGHBOOK introduced to date with the ability to hot-swap an optional second battery without powering down, while also being the thinnest and lightest in its class. The TOUGHBOOK 55 includes an optional 1000 nit touchscreen, AMD dedicated graphics, and the latest Intel 8th Gen quad core i5 and i7 processors. It is also the first TOUGHBOOK to offer a USB Type-C port, HDMI 2.0 and Bluetooth 5.0. Moreover, it is claimed to be the first laptop with tetra-array microphones, as well as the first Panasonic laptop that to offers faste WiFi, louder speakers, enhanced brightness and a color-selectable backlit keyboard. Panasonic Corporation

GETTING A GRIP ON RECYCLING

WaveGrip, a company of Berry Global, is providing a packaging solution and carrier return plan for the Atlanta, Ga.-based craft brewer Orpheus Brewing to help reduce its packaging waste as part of a larger company effort to slash its annual packaging footprint.

Orpheus Brewing operates a 16,000-squarefoot brew house and tap oom focusing on four core beers and an endless range of specials, with flavors ranging from tart sours to strong barrelaged stouts.

Aiming to reduce its overall packaging footprint, the WaveGrip beer can carriers provided a perfect place to start. Weighing only 3.5-gram for a standard six-pack carrier, WaveGrip provides an 85-percent reduction in material usage when compared to HDPE plastic handles, and a 10-percent savings when compared to traditional ring carriers.

Compared to standard HDPE carriers, WaveGrip allows for up to 370 per cent more carriers per pallet, thereby reducing overall shipment cost, as well as fuel consumption and related greenhouse gas emissions..

Being made from LDPE, WaveGrip carriers are recyclable, but the challenge remained to ensure that the carriers were collected for recycling. This, together with understanding the differences in recycling capabilities across the U.S. states, led to the ‘Orpheus Carrier Recycle Program’.

Under the scheme, Orpheus customers can now return their used carriers to any of their taprooms and get an incentive off future Orpheus purchases. Once a sufficient number of carriers have been returned, they are collected in bulk by WaveGrip and recycled into a diverse range of products such as decking, road paving and other types of packaging, including brand new WaveGrip carriers.

“The sustainability of WaveGrip was fundamental to our choice of carriers and has helped to significantly reduce our packaging usage,” says Orpheus Brewing’s chief executive officer Remco Bos.

Adds WaveGrip’s managing director Aaron McIvor: “We know how important sustainability is to our customers and it is integral to our WaveGrip products and development.

“We are therefore delighted to support this initiative by Orpheus Brewing and ensure that WaveGrip carriers are collected as part of a circular approach to packaging,” McIvor states.

“We very much hope that this is the first step in launching a wider collection plan across the U.S. carriers in coming months.”

CANADIAN SCHOOLS TO PREPARE FOR NEW RECYCLING CONTEST

To educate students, teachers and communities about maintaining healthy bodies and a healthy environment, TerraCycle has launched the 2019 Collection Craze recycling challenge in partnership with the Schneiders Lunch Mate and Maple Leaf Simply Lunch brands of the Mississauga, Ont.-headquarted food products giant Maple Leaf Foods

Throughout November, participating schools collect waste from their Schneiders Lunch Mate and Maple Leaf Simply Lunch kits including plastic film, content packaging and plastic trays and send them to TerraCycle in exchange for credits.

During the “Collection Craze” contest period, students, teachers and the surrounding community are encouraged to vote for their school of choice once a day during the promotion timeline on the contest page. Each vote counts as one credit.

The contest will be judged based on the quantity of recycled packaging collected and the number of credits earned. The top 10 schools that earn the most credits by Nov. 31 will win a share of $3,700 in TerraCycle points.

To win an extra $1,000 in TerraCycle points, participating schools are invited to enter in a photo sweepstakes by submitting a photo to TerraCycle’s sweepstakes form of their recycling bin or station.

“The Collection Craze offers schools a viable way to divert waste from landfills, engage their communities and be rewarded for their effort,” explains TerraCycle founder Tom Szaky.

“By participating, students gain valuable knowledge about sustainability, how to make a difference within their school and community and how to protect the environment through recycling.”

GRASS JUST GOT A LITTLE

GREENER

For the first time ever, 100-percent grass-fed organic milk is now available in shelfstable, single serve cartons. Oranic dairy producer Maple Hill of Kinderhook, N.Y., recently hooked up with leading aseptic packaging producer SIG to create and exciting new innovation in for a growing product category that has been quiet far too long.

As a result of this joint endeavor, the Maple Hill brand 100-percent grass-fed organic whole milk and chocolate milk, made with certified Fair Trade Cocoa, are now available in eight-ounce combismile cartons from SIG. According to SIG, the cartons provide a convenient, on-the-go option in a shelf-stable package that does not need to be refrigerated until after it is opened. Instead of a straw, the fully-recyclable package features a reclosable cap with a leak-proof and tamperevident spout. The packages are fully recyclable.

“There has not been an innovation in shelf-stable milk for years, but for the first time ever, consumers will be able to get 100-percent grass-fed whole milk and chocolate milk on the shelf and in eco-friendly packaging,” says Maple Hill president Carl Gerlach. Adss Gerlach: “SIG has been an integral partner in bringing this product to the market in the right way.”

LET IT BEER

Canada’s craft brewers serve up packaging masterclass

CULTURAL LINKS

Consumer choice and convenience on top of busy agenda for OCB president

BY GEORGE GUIDONI, EDITOR

Golf and beer make remarkably good bedfellows for vast numbers of Canadian summer weekend warriors, so it’s more than fitting that Scott Simmons, president of the Ontario Craft Brewers (OCB) association, would have a remarkably close professional affinity to both fields.

Having served for 10 years as chief executive officer of Golf Canada from 2007 to 2017, preceded by a six-year term as vice-president of marketing and business development of The Beer Store beer retail distribution network, Simmons says he is consistently thrilled and honored to be heading a dynamic and buoyant industry group representing one of the province’s fastest-growing industries in any GPG (consumer packaged good) business.

“Like the old saying goes: If you love what you do, you never really work a day in your life,” says Simmons, a graduate of the Ivy Business School at the University of Western Ontario in London, Ont., who began his career with Procter & Gamble Inc., gaining valuable insight into consumer goods business.

That said, the father of four daughters finds himself spending a lot of time on the road crisscrossing the province as the head of OCB to promote products brought to the market by OCB members and other fellow Ontario craft brewers in a concerted effort to maintain the industry’s brisk growth going forward.

Founded in 2003, OCB was formed by 12 craft brewing companies operating in the province at the time to provide a unified voice for the then-fledgling sector that has grown to nearly 300 companies since those early days.

“I’m on the road pretty much every day dealing with the government on the provincial level and, of course, doing a lot of interaction with our members on a daily basis, as well as traveling all over the province to meet with our customers and other third-party industry stakeholders,” says Simmons, who officially took over as OCB’s second-ever president in August of 2017 following retirement of the group’s founding president John Hay.

“Interestingly enough, I first met John Hay in 2002 when I was working at The Beer Store,” Simmons told the Canadian Packaging magazine in a recent

interview. “Little did I know at the time that I would be heading this association one day, but here I am, more than two years later.”

Says Simmons: “I have a genuine passion for the industry because its people, like myself, really love what they do.

“Their craftsmanship is amazing, bus so is their meticulous attention to quality and the high ethical standards that they put into their practice on a daily basis,” Simmons extols.

“These are small businesses contributing to Ontario’s economy by creating jobs, generating tourism and making positive economic impact.

“A lot of them are located in rural Ontario,” he continues, “where many have become the largest local employers in the small towns—giving back to the communities where they work and live, where kids can have summer jobs in the communities they grew up in, instead of leaving for the ‘Big City.’

“There are so many things to be passionate about with this industry,” Simmons says, “that it really makes going to work fun for me every day.”

For all the fun that goes with the job, however, Simmons is fully aware of the serious burden of responsibility in advancing the industry’s interests among the province’s lawmakers through relentless lobbying and advocacy.

With OCB member-companies accounting for about 95 per cent of the volume of craft beer produced in Ontario annually, Simmons says the Ontario craft beer sector has more than earned the right to enjoy easier access to consumer through opening up more sales channels and the loosening of many legal restrictions still hampering their efforts to reach more Ontario consumers.

“Our government advocacy at Queen’s Park does not stop at the Premier’s Office,” says Simmons, while acknowledging that having a premier like Doug Ford in office is promising for an industry once mired in red tape and heavy-handed government regulations governing beer sales and distribution for the craft sector.

“We also work with the ministries of the environment, tourism and economic development, among others, on many issues affecting the industry,” he relates.

Simmons says he is satisfied that the current Progressive Conservative government is listening to his industry’s concerns, citing several recent lobbying successes that include allowing the craft brewers’ storefront taprooms to stay open for business until midnight, instead of closing at 9 p.m., allowing them to sell beer to the public starting at 9:00 a.m. in the morning, and eliminating the maximum serving requirement of 12 ounces.

However, there is clearly much more to be done to put craft brewers on a more level playing field with the country’s Big Three mass beer producers that jointly

Scott Simmons, President, Ontario Craft Brewers (OCB)

The Scotiabank Convention Centre in Niagara Falls will be the host venue or this month’s annual OCB Conference and Suppliers Marketplace industry showcase running Oct. 28-30, 2019.

co-own The Beer Store distribution network.

According to Simmons, addressing this market accessibility imbalance comes down to allowing craft beer producers to sell their products at more retail locations than the relatively few select supermarkets that the Ontario government designated about two years ago.

“It’s really all about choice and convenience,” Simmons states. “The craft industry has enjoyed tremendous success at the new retail channels so far, with craft beer account for 20 per cent of all beer sales at these locations, compared to 15 per cent at the LCBO (Liquor Control Board of Ontario) outlets and only two per cent at The Beer Store.

“We feel that expanding choice and convenience for Ontario consumers is the right thing to do, whether it is at grocery stores, convenience stores, Big Box stores, specialty alcohol stores, or even letting craft brewers operate their own satellite stores in addition to the ones they operate on-site,” Simmons explains.

“If the provincial government continues with its expansion of the retail opportunities,” Simmons says, “that will allow us to realize the full potential that our industry has in this province.

“You could easily see someone like Muskoka Brew-

ing or Steam Whistle open up a half-dozen or so stores in key Ontario markets,” he argues, “with smaller ones opening up one or two parallel stores in nearby communities.”

As Simmons asserts, the current law allowing microbrewers to sell their products only from locations with an on-site operating brewery are inherently unfair to craft producers, the Ontario consumers and, ultimately, the province’s economy.

“Helping the craft industry in Ontario grow is good for all stakeholders because it would help create more jobs and boost the economic impact even further,” Simmons states.

“We are talking about 300 small businesses, Canadianowned businesses to boot, that could provide more job sand the tax income the government needs to reinvest in social services, reducing the deficit, upgrading infrastructure and all those other important causes,” Simmons continues.

“For a government claiming to be supportive of small businesses, supporting this industry falls right into their mandate of growing Ontario’s economy.”

As Simmons notes, Ontario craft brewers are already making a substantial contribution to the provinces economy with a combined 2,500 direct full-time jobs, an estimated 9,000 indirect spin-off jobs elsewhere in the economy, and about a $2-billion annual contribution to the province’s annual GDP (Gross Domestic Product).

But even with such numbers in hand, craft beer sales still account for only a 10-percent share of total $3.5 billion in annual beer sales in the province overall, according to Simmons.

“I truly believe that number can double in the next couple of years with the right retail environment, where craft brewers can operate and compete without handcuffs on,” Simmons says, noting that while the total annual output of Ontario’s entire beer industry has been stalled at about eight million hectoliters for several years, production volumes in the craft beer segment are continuing to grow at double-digit rates.

with their high product quality and beautiful packaging, that when you put consumers in an ‘open shopping’ environment where they can shop the entire category, they are clearly choosing craft beer in growing numbers,” he states.

“There are a lot of consumers who want to support local and homegrown businesses,” he says, “and we want them to have that choice and convenience.”

As part of that, Simmons says OCB wants the government to make retailers open up 30 per cent of their available beer shelf-space to Ontario craft beers, compared to the current 20-percent requirement.

“As it is, most of retailers have already moved beyond 20 per cent because of consumer demand,” he notes, “so we don’t really see that as a major hurdle.

“Some retailers are even creating dedicated sections within craft beer sections to showcase local producers, so that a store in Mississauga will make sure to carry products made in Mississauga or Oakville, for example.

“The growing volumes and market share speak for themselves,” he states. “Not only are these brewers are growing their own share domestically, but some are also venturing into export markets and doing very well there.”

Simmons says he personally enjoys heading a business community as free-spirited and diverse as Ontario’s craft beer sector.

“You’re talking about 300 companies that they come in all different shapes and sizes,” he states.

“There are some that just want to do business in their local communities and sell at their storefront taprooms, while some have a retail footprint right across the province and also into export markets.

“These people do such a great job with their products

“When you total them all together, you get this 15- to 20-percent growth, both domestically and internationally.”

For all that growth, Simmons insists the Ontario market is nowhere near the saturation point yet.

“We need to continue to grow the industry so that it can double or more in the next few years,” he proclaims.

“In British Columbia the market share for craft segment is already at 20 per cent,” he points out, “and there are many U.S. states where crafts account for 25 per cent.

“A lot of that has to do with the more open local retail environment for craft producers, and that is exactly what OCB is aiming to achieve for our members and other craft brewers who we hope will become our members when they’re ready.

“Many of these brewers have only been around for two or three years, so in many ways we are trying to catch up,” he says.

“But while we are constantly trying to grow our membership, we also have very high standards a brewer must meet to become an OCB member.

“But at the end of the day,” Simmons sums up,“there is no question that we are all stronger as a collective unit than individually.”

BEHIND THE BENCH

Upstart Ontario craft brewer serves up an eclectic selection of sour beers

paying faithful homage to their Fruit Basket origins

BY GEORGE GUIDONI, EDITOR

PHOTOS BY NAOMI HILTZ

There’s nothing wrong with making lemonade when lemons are all that life gives you. But when you’re spoilt for choice with juicy and tender peaches, grapes, cherries, plums and other sweet crops harvested in Ontario’s famed Niagara fruit basket, the possibilities for creating memorable new beverage experiences are virtually limitless.

And indeed, sky appears to be the limit for Matt Giffen, founder and president of Bench Brewing Company in Beamsville, Ont.

Despite being a relative latecomer to Ontario’s burgeoning craft brewing industry—commencing its own brewing operations in earnest in early 2018— the upstart beermaker already has few equals in the segment in terms of product diversity or originality.

“We currently have a portfolio of 45 beers and we’re just getting started,” Giffen told Canadian Packaging on a recent visit to the 16,000-square-foot microbrewery housed behind a two-storey, red-brick structure originally erected as a wooden shchoolehouse way back in 1832, upgrading to a brick structure in 1864.

Fronted by a chic 6,000-square-foot tap room and full-service kitchen inside the former Maple Grove Schoolhouse—along with an adjacent beer garden overlooking neighboring farms, orchards and vineyards—the brewery already employs 29 fulltime and 35 part-time people at the eight-acre site, which including a three-acre hops field used to grow unique specialty hops used in many Bench Brewing brands.

Bench Brewing Company founder and president Matt Griffen strikes a cheerful pose inside the company’s large and bright storefront taproom with a selection of highquality bottled sour craft beers produced at the company’s brewery in Beamsville, Ont.

Bench Brewing’s 16,000-square-foot brewery in Beamsville was built as an addition to the historic Maple Groove Schoolhouse building that has been converted into a modern 6,000-square-foot taproom and beer garden.

Built over a busy 18-month stretch from the start of 2017 up to the Canada Day long weekend of 2018, the brewery is currently prducing about 12,000 hectoliters of beer annually, according to Giffen, a former banker clearly enthused by his chosen new career path.

Like many of its industry peers, Bench Brewing initially started out in 2016 by using other established Ontario microbrewers to co-pack its brands, taking the due time and diligence to find a perfect home for bringing Giffen’s vision of a ‘Beer from Wine Country’ to life.

“We are so proud of our unique beer produced from ingredients sourced from Niagara’s Twenty Valley that we want to make sure that we share it with beerlovers across Ontario, Canada and around the world,” says Giffen, stressing critical importance of the “unique terroir of the region” captured in many locally-sourced ingredients.

Modeled after the traditional farmhouse brewing operations found across Belgium, Bench Brewing takes a lot of pride in leveraging the region’s unique history and geography as core competitive advantages in an increasingly competitive and crowded domestic market for Ontario craft beer.

“It is a competitive marketplace,” Giffen acknowledges, “but one that we are happy to be a part of.

“We are proud to be a part of a brother/sisterhood that is starting to really draw attention to Ontario and all the great brewers we have in the province.

“As a relatively new entrant to craft beer scene, we don’t view other craft breweries as competitors, but rather as partners and collaborators in the great Ontario craft marketplace,” Giffen relates.

“We believe that the craft sector will continue to grow as more Ontario beer drinkers shift their preference to the superior taste and quality that the craft category provides.”

Sold at LCBO (Liquor Control Board of Ontario) outlets, select grocery stores, and bars and restaurants across Ontario, Bench Brewing brands are also distributed in British Columbia, Alberta, Manitoba, Saskatchewan and Quebec, Giffen relates, as well as some markets in the U.S. and China.

“Some of our most popular products are our Community Range beers that pay homage to important landmarks in an around Niagara’s Twenty Valley,” says Giffen, citing the company’s flagship Ball’s Falls Session IPA brand, along with other popular labels such as Jordan Harbour Belgian Pale Ale, Short Hills East Coast IPA, Stone Road White Ale, and Twenty Mile Farmhouse Ale

All of these brands are packaged in 473-ml Tallboy-style aluminum cans purchased from the U.S.-based Ball Corporation and filled on the brewery’s CFT canning line running at operating speeds of about 100 cans per hour.

Manufactured by the Italian-based CFT Group, the 10-head rotary filler is located in the brewery’s so-called Clean Side of the operation, as opposed to the fully-separated Funk Side dedicated to bottling fruit-infused sours and other less conventional specialty beers.

“We use cans and bottles for different reasons,” Giffen explains. “Sealed cans can help beer destined for travel to stay fresh longer by helping maintain required carbonation levels and preventing light from striking and oxidizing the beer.

“Bottles, on the other hand, are better containers for beers that are meant to be cellared or bottle-conditioned—just like you would with fine wines.

“These types of beer can still contain small amount of yeast that continues to

Supplied by Ball Corporation, the direct-printed cans of Bench brand craft beer are moved towards the Adamark air knifes, supplied by R.E. Morrison Equipment Inc., to remove moisture and condensation from the cans’ surfaces.

The CFT canning line at the Bench Brewing facility is equipped with an automatic Filtec container vision inspection systems that ensures precise filling of each 473-ml aluminum can filled and capped on the high-speed line.

Custom-designed glass beer bottles, supplied to Bench Brwing by Bruni Glass, get a thorough rinse on the GAI MLE 881 BIER bottling line, supplied by Prospero International, prior to the filling and seaming process.

The busy brewhouse is outfitted with a number of large industrial fans, manufactured by Big Ass Fans Company, to keep the facility well ventilated and comfortable for the plant’s production personnel.

work away over time,” Giffen relates, “resulting in more complex and interesting flavors.”

One of those interesting flavors, Plum Grove, has in fact gained priceless worldwide recognition earlier this year by picking up the coveted Best in World honors in Sour Beer category of the 2019 World Beer Awards competition in Brussels, Belgium.

While Giffen is naturally proud of this “extraordinary achievement,” such industry acclaim is quickly becoming second nature to Bench Brewing.

“This year we have also received awards for our beers in various styles and categories at the Canadian Brewing Awards, Ontario Brewing Awards, and U.S Open Beer Championship,” Giffen says, citing several winning competition entries that include bottled sours such as Citra Grove Dry Hopped Sour, Clean Slate Brett Saison, Folklore Dark Sour, Plum Grove Fruit Sour and Strawberry Grove Fruit Sour.

“We’re honoured to be recognized for our beers around the world, and can’t wait to share more of what’s to come,” he states.

While Giffen says he understands practical reasons behind the industry’s trend to migrate to cans at the expense of glass bottles, he says that aluminum cans simply can’t match the efficacy of glass bottles when it comes to packaging sour and other specialty beers produced on the brewery’s Funk Side, such as the award-winning Plum Grove series named as a symbolic nod to the historic Maple Grove Schoolhouse.

“We produce these beers using our own in-house blend of yeasts to create approachable sours that get better with age as they bottle-condition,” he explains.

“We also use the same mixed-fermentation base and add whole local fruits to create award-winning fruit sours.

“True to our farmhouse style, we only use whole strawberries, plums, cherries and peaches sourced from our neighboring farmers within a five-kilometer radius.”

As Giffen points out, having two separate beermaking operation under one roof

enables Bench Brewing to overcome the seasonal demand fluctuations that are part and parcel of the craft beer business, thereby maintaining a steady five-daysper-week production schedule throughout the year.

“Most breweries will see production slow down in the winter and peak in the summer,” he notes, “but we don’t really have a slower season at Bench.

“We take advantage of the time off-season to build up our Funk Side inventory, which takes several weeks or months longer than our Clean Side product to ferment and bottle-condition in our wood cellar.”

Bench Brewing spared no expense in outfitting its brewery with a world-class four-vessel 50-hecotleter brewhouse—manufactured in British Columbia by Newlands Systems Inc. (NSI)—along with eight 100-hectoliter fermenters; four 50-hectoliter fermenters; three 100-hectoliter brite tanks; two 50-hectoliter brite tanks; and 14 Douglas fir wooden 95-hectoliter foeders; and over 350 wooden wine barrels used to create sour and mixed-fermentation beers.

“Since startup, we have also added three more 100-hectoliter fermenters and one more 100-hectoliter brite tank,” Giffen notes, while also crediting a poststartup installation of the CFT rotary filler for significantly boosting productivity on the canning side of the business.

“Moving from a four-head inline canning line to a 10-head rotary CFT canning line which operates at 100 cans per minute has allowed us to cut down roughly 10 hours of run time and 16 hours of part-time labor per run,” he says.

“It has enabled us to pack 10,000 liters in roughly three-and-a-half hours, give or take, which works out to 21,142 Tallboy cans of Bench beer.”

Equipped with an integrated Filtec vision inspection system, the compact CFT canning line also takes care of all the necessary quality control checks to ensure optimal product consistency and line efficiencies, according to Giffen, while eliminating costly overfilling.

“We no longer need an need an operator to watch the filler for fallen cans, low fills and bad seams,” he says.

“Moreover, the filler’s full oxygen purge, patented separate air return, counter-

Filled and crowned 500-ml glass beer bottles of Bench brand sour craft beer making their way into the GAI rotary series 7400 labeling system for quick and precise label application.

Bench Brewing’s in-house graphic designer Julie Seo showing off the classy and elegant label graphics she developed for Bench Brewing’s bottled products inside the brewery’s taproom.

Bench Brewing uses high-strength corrugated trays supplied by Cascades Inc.to ship it canned products to market.

A close up of Festo’s industrial instrumentation and controls deployed throughout the brewery’s packaging equipment.

The brewer makes extensive use of packaging tapes and other essential supplies distributed by Uline Canada Corp.

pressure filling, short transfer to the seamer, and under lid-gassing all contribute to the lowest documented DO (dissolved oxygen) oxidation levels in the industry.”

Similarly, the GAI MLE 881 BIER bottling line employed in the brewery’s Funk Side packaging area—manufactured in Italy by Prospero International s.r.l.—comprises a high-performance six-valve filler, an eight-head rinser and a single-head crowner that can reach output speeds of up to 1,500 bottles per hour, depending on beverage temperature and style.

As with the CFT can filling line, the bottle filler’s compact, space-saving monobloc design provides plenty of opportunity for further automation of the case-packing and palletizing functions down the road once production volumes justify the investment, according to Giffen.

For now, both the cans and the 500-ml custom-shaped wine-style glass bottles—supplied by Laval, Que.-based United Bottles & Packaging are hand-packed inside high-strength, pre-printed corrugated trays and boxes manufactured by Canada’s leading paperboard producer Cascades Inc.

“We try to work exclusively with Canadian agents and suppliers whenever possible,” says Giffen, also extending credit for Bench Brewing’s stellar overall packaging execution to Cask Brewing Systems (cans); Schawk Canada Inc. (can artwork design); ASL Print FX and A-1 Label (labels); and North Keg (keg leasing services).

As for the branding aspect of its packaging, Giffen is happy to lavish praise on the company’s in-house graphic designer Julie Seo for creating the elegant, eye-catching graphic artwork for both the direct-printed cans and the self-adhesive paper labels placed on the glass bottles.

“We wanted to reflect our simple farmhouse approach in our brewing with our packaging,” Giffen explains. “Nothing elaborate or fancy—just clean, crisp and simple.

“Our beer is enjoyed equally by both men and women so, so we aimed to maintain an authentic style and culture that appeals to everyone.

Ryson Vertical Conveying Solutions

Ryson has the Right Vertical Conveying Solutions for the Beverage Industry.

Whether you are handling cases, trays and packs or bottles and cans in mass or a single file, we can help. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Ryson Spirals are powder coated carbon steel with choice of any standard RAL color. They are also available in hybrid versions suitable for wet environments or stainless steel versions for washdown applications.

Quality and service come first at Ryson. We are the number one spiral manufacturer in the USA. For application assistance or more information, give us a call or visit www.ryson.com

Finished six-packs of canned Bench brand beer are held together by the convenient and fully-recyclable PakTech snap-on plastic carriers featuring built-in carrying handles.

ment in packaging to ensure the best product possible.

“That means supplying best-in-class packaging to ensure freshness, high quality and consistency in all of our beers for the consumers in Ontario and elsewhere,” says Giffen, adding the company is already exploring possible new exporting opportunities in Europe and new Asian markets.

“Quality, consistency, experience and our relationships are all high priorities and something we work hard at every day to maintain,” Giffen proclaims.

“On the brewing side of things, we have strict SOPs (standard operating procedures) that help us to maintain a consistent product tank after tank.

“As we continue to learn and grow as a company, we have been finding efficiencies across the board when it comes to time management, product output and transport, in large part due to our improvements in process and communication.”

room to grow still.

“We believe that sours, especially fruit sours and barrel-aged beers, will continue to be a fast-growing segment around the world and now in Canada,” Giffen concludes,“making us very optimistic about the future.”

SUPPLIERS

“It’s simple and fun design with a nod to our wonderful home and agricultural roots,” says Giffen, noting the classy wine-inspired motifs running through the Grove series label artwork.

As Giffen points out, “We made a significant invest-

With Ontario craft brewers accounting for about an eight-percent share of the domestic beer market, Giffen says Ontario craft beer producers still have a lot of good opportunities for growth in coming years, despite flat overall growth in North America.

“There are other provinces and U.S. states where 12 to 30 per cent of the domestic beer consumed is craft beer,” Giffen points out, “so there is plenty of

Canada Inc.

ASL Print FX A-1 Label CFT Group

Prospero International Filtec Uline Canada Corp.

R. E. Morrison Equipment Inc.

•

•

•

•

Bench Brewing brewmaster Mark Horsley (left) join Matt Griffen inside the brewery’s cellar housing giant 95-hectoliter wooden folders and over 200 recondition wooden wine barrels used for making sour and mixed-fermentation beer.

LOCK AND LOAD

Nova Scotia craft brewer leverages advanced shrinksleeve labeling technology to establish ban fide industry leadership credentials

BY GEORGE GUIDONI, EDITOR

PHOTOS BY BÉATRICE SCHULER

There are many ways to unlocking your true potential in the burgeoning Canadian craft beer industry, but some companies just seem to have a natural knack for doing it faster and with bigger aplomb than others.

Although it only came online only a brief threeand-a-half years ago, Dartmouth, N.S.-based microbrewer Nine Locks Brewing Co. has wasted little time in establishing itself as one Nova Scotia’s top craft beer producers—no small feat in a province boasting the distinction of having the most breweries per capita in Canada.

“We haven’t stopped expanding since we opened,” says company founder and president Shaun O’Hearn, a restaurateur operating a popular Halifax pub and eatery called Your Father’s Moustache.

With the restaurant’s on-site brewpub cultivating a loyal local fan base among the region’s craft beer aficionados, O’Hearn saw good opportunities in the province’s then-fledgling marker for craft beer for his own product that, in compliance with local regulations, could only be sold on-site.

So after one particularly inspired beer-tasting evening around a family backyard firepit with his cousin Danny O’Hearn in the summer of 2014, Shaun did what many of his brewpub patrons have been urging him to do for years and proceeded to look for a good nearby location for his own brewery.

Soon enough, the O’Hearns found themselves building that brewery in the municipality of Dartmouth, a renowned “City of Lakes” that was amalgamated into the metropolitan Halifax urban core back in 1996.

The founders drew inspiration for the brewer’s name from the nine locks built along the nearby historic Shubenacadie Canal—completed in 1861 to transport goods across the province for 10 years before the railroad was built—which is nowadays primarily used for pleasure boating, sailing, canoeing and kayaking.

Available only in 473-ml aluminum cans, the company’s flagship Nine Locks product range today includes the Nine Locks Cream Ale, Nine Locks IPA, Nine Locks Fathom Double IPA, Nine Locks Pale Ale, Nine Locks Porter, Nine locks ESB (Extra Special Bitter), Nine locks Watermelon Blonde; and the award-winning Nine Locks Dirty Blonde wheat beer.

The brewer also has a selection of seasonal Nine Locks products released at different times of the year, including Harvest Pumpkin Ale, Vanilla Porter, Apricot Blonde, Double Chocolate Stout, Scotch Ale and Bohemian Raspberry Sour, to name just a few.

Nine Locks Brewing founder and president Shaun O’Hearn proudly displays a piece of branded merchandise sold at the Dartmouth brewery’s frontstore, which also carries a varied selection of the company’s popular canned premixed cocktails and vodka soda products.

Manufactured by Montreal-based Aesus Packaging Systems and utilizing Omron controls (inset), the Compact Premier model shrinksleeve labeler takes care of all of the brewery’s current labeling needs, while boasting a lot of extra throughput capacity to accommodate the company’s requirements for higher-speed throughput in the near future.

Alas, Canadian craft beer enthusiasts can only find these beers in the Maritimes provinces, Shaun O’Hearn relates, at least for the time being.

“Our beer is currently sold across the province in the Nova Scotia Liquor Commission stores, as well as at four privately owned wine and beer speciality stores in Metro Halifax, and at our own retail store at the brewery in Dartmouth. We can also be found at numerous bars and restaurants across the province,” says O’Hearn, citing the operation’s limited annual capacity of about 15,000 hectoliters.

“We are already at maximum capacity in our current facility and can’t expand our current distribution if we wanted to,” O’Hearn explains.

“However, we are currently planning a new brewery for the spring of 2021 that will significantly increase our capacity,” says O’Hearn, noting the extra output will enable the Nine Locks to expand its geo-

graphic market reach.

That will be good news for craft beer fans in other parts of the country who like their beers natural and wholesome.

“All of our beer is made from all-natural ingredients,” O’Hearn proclaims, “and we don’t filter or pasteurize our beer.

“We brew all our beer in a full mash brewery— meaning that we start with the basic ingredients of malts, hops, and yeast to make our beer,” O’Hearn relates.

“The process starts with milling the grain, whereby we use premium two row malt and blend it with speciality malts,” O’Hearn continues. “Those malts are cracked in our mill in order to extract the fermentable sugars.

“The cracked malts, now called ‘grist,’ is then transferred to a mash tun, where it is mixed with hot water

in a process called mash conversion, which uses the natural enzymes in the malt to break the malt’s starch into sugars.

“The mash is then transferred to a lauter tun, where the liquid, now called ‘wort,’ is separated from the grain husks.

“The wort is then transferred to the kettle, where it is brought to a boil and the hops are added in,” O’Hearn relates. “After boiling, the wort is transferred to a whirlpool, where the liquid is separated from any malt or hop particles.

“The liquid is then transferred to a fermentation tank, where we will pitch yeast that will convert the sugary wort into beer by producing alcohol.”

O’Hearn says the company also “dry hops” some of its beer in the fermenting tanks by adding different hops in the latter stages to give the finished beer different aromas.

Once the fermentation is complete and the beer is given some time to mature in fermentation tanks, the product is transferred to the bright tanks to be carbonated, after which it is either kegged or canned.

“We decided to package all our beer in cans for a few reasons.We feel that cans better protects the product from light and air than glass bottles, (beer’s worst enemies),” O’Hearn says. Cans are also easier to carry, you can throw a few in your backpack for a hike, or in a cooler to bring to your campsite without concern of broken glass ruining your trip.

“Being lighter than glass, cans also cost less to transport,” he adds. “Moreover, it takes less energy to recycle aluminum compared to glass, which makes it better for the environment.”

Adds O’Hearn: “In the past number of years there

A sampling of high-quality UV flex-printed shrinksleeve label rolls supplied to the Nine Lock Brewing operation in Dartmouth by Spectral Inc. of Mississauga, Ont..

has been a transition from craft beer mainly being sold in bottles to now mainly being sold in cans.

“I think that in the past there was a stigma about canned beer being of lower quality, but now people are accepting cans as a better vessel for their beer.”

Housing a 7,000-square-foot brewhouse and a 7,000-square-foot storage and sleeving area, the Nine Lock brewery employs a DME kegging line—manufactured by DME Process Systems Ltd. in Charlottetown, P.E.I.—to fill about 40 kegs per hour.

For the canned product, Nine Locks uses a Cask ACS canning line—manufactured by Cask Global Canning Solutions of Calgary, Alta.—that runs at approximately 25 cans per minute.

“Both the kegging machine and the canning line run roughly 10 hours a day, five to six days a week, in the busy summer season,” O’Hearn relates.

“Summer is always the busier season for beer companies as there are more barbeques, trips to the cottage, and open patios that time of the year,” O’Hearn notes.

“It is no different for our brewery: production usually ramps up in April and we run flat-out till the end of August.

“Even then, we are getting ready for our autumn seasonal beers being released in September and October,” says O’Hearn, adding Nine Locks is always looking for ways to optimize its output to match any fluctuations in market demand.

“We are currently in the market for a new canning line that would run between 120 and 160 cans per minute,” say O’Hearn, noting similarities between his company’s growth and that of the craft brewing industry in general.

“The craft beer industry has exploded in the past 10 years in Nova Scotia and across the country,” he states.

“In the past 10 years the number of breweries in Nova Scotia has grown from around 10 to over 50 companies,” says O’Hearn, citing the province’s other leading craft brewers such as The Propeller Brewing Co., Garrison Brewing Co., Breton Brewery, Big Spruce Brewery, Boxing Rock Brewery and Tatamagouche Brewery

“There are world-class quality beers being pro-

duced in Nova Scotia,” says O’Hearn, citing the bronze medals picked up by the Nine Locks Dirty Blonde brand in the recent 2019 Canadian Brewing Awards competition.

“Dirty Blonde, along with our 2018 Barley Wine, aged for 12 months in single malt whiskey barrels from Nova Scotia’s own Glen Breton Distillery, received the only awards in 2019 that went to Nova Scotia,” he points out.

Says O’Hearn: “Says O’Hearn: I feel like we have

The aluminum silver bulletTallboy-style cans entering the Aesus rollfed Compact Premier shrinksleeve labeling system to have the labels applied and securely heat-sealed around the entire surface prior to filling.

A machine operator (background) performs a quick roll changeover on the Aesus shrinksleeve labeling system used for decorating the silver bullet aluminum cans with colourful full-body wraparound labels.

A can of beer exiting the patented hybrid Aesus shrink tunnel that employs both infrared and steam heating methods to ensure perfect wrinle-free application of every label to the cans’ surfaces.

done very well in such a short time in Nova Scotia because we have a range of solid beers that are as true to their styles as possible. We don’t try to over hop our IPA’s or create a beer that is overly malty. Not that there is anything wrong with super hoppy or malty beer, many people love them, it’s just that ours might appeal to more people.

“Our flagship beer Dirty Blonde is a very approachable wheat beer that is full of flavor but also easy to drink and appeals to a very wide range of beer drinkers,” O’Hearn cofides. “We have definitely converted a lot of mainstream beer drinkers to craft beer drinkers with Dirty Blonde.

“Our head brewer Jake Saunders is extremely passionate about his craft and has extensive knowledge of beer in general,” O’Hearn relates.

“On top of making fantastic beer, our team has done a great job designing attractive cans that showcase Dartmouth and Nova Scotia,” says O’Hearn, extending credit to Halifax-based graphic designers Prime Creative for spearheading the development of attractive, streamlined beer labels boasting color-coded logos depicting a stylized picture of a rowing kayaker—set against a sliver backdrop showing close-ups of the map of Nova Scotia.

“Packaging plays almost as important a role as the product that we put in the cans,” says O’Hearn,” adding the brewer’s canned products are currently sold in individual cans and four-packs.

“The quality of the package is a reflection of the product that is going in it.

“The basic message of this design is that that we are a local Nova Scotia company that loves where we are from and are proud to call Nova Scotia home,” O’Hearn proclaims.

To get that message across loud and clear on every can of beer produced at Nine Locks, the brewer employs a Compact Premier shrink labeling system manufactured by Montreal-based Aesus Packaging Systems—purchased about a year ago— and high-quality shrinksleeve labels printed by labeling converter Spectrol Inc. of Mississauga, Ont.

According to O’Hearn, having in-house shrink-sleeving capabilities provides the brewer with operational flexibility to package its product in true on-demand JIT (just-in-time)fashion, without having to maintain a large inventory of pre-printed

A birds’-eye view of the Nine Locks Brewing plant’s canning operations housing the Compact Premier shrinksleeve labeling system and a hybrid shrink tunnel manufactured by the Montreal-based machine-builder Aesus Packaging Systems.

Each of the label rolls shipped to the Nine Locks brewery by Spectrol Inc. contains 4,500 individual sleeve labels designed by the Halifax-based graphic design studio Prime Creative.

LABEL OR NO LABEL?

Yes indeed, this Collective Arts can is sporting a Spectrol shrink sleeve label.

Replace excessive decorated container inventory with our shrink sleeve labels! Save money and look great. You’ll be amazed what high impact shrink sleeve labels can do for your product on retail shelves. Spectrol Inc. has invested in the highest quality flexographic printing equipment to produce shrink sleeves and roll labels for all your packaging requirements. Call today to meet with a representative and see

or pre-sleeved cans.

“The Aesus sleeve applicator allows us to purchase blank cans in bulk and then sleeve them as needed,” O’Hearn states.

“This saves us money by not having to store a number of pre-sleeved cans off-site, and by being able to order sleeves in the quantities that we require. With printed or pre sleeved cans, there are often minimum orders required, which could result in unused cans.”

Adds Aesus vice-president of sales Stephen Mons: “Nine Locks was looking for a small-footprint machine that could automatically apply shrink labels onto the ‘silver bullet’ cans at speeds up to 150 cans per minute, as well a shrink tunnel that could shrink the film in a fashion that the consumer would think that the decoration is printed onto the can.

“It turned out that Aesus had the very machinery

they needed,” Mons recalls. “The model Compact Premier shrinkleever has one of the smallest footprints in shrink labeling, and it uses servomotors to draw down the film and high-speed rotary blades to cut the film with unerring precision.”

As for the shrinking part of the process, the patented hybrid shrink tunnel supplied by Aesus uses a combination of dry infrared curing and steam to provide a cost-effective and energy-efficient solution for the brewer’s labeling needs.

“The steam is generated by the on-board steam boiler that Aesus provides with the tunnel,” Mons explains. “Using very little steam, there is no need for costly large boilers, floor drains or other installations.

Says Mons: “For many craft brewers, it is far more attractive to apply decorative sleeves onto blank cans than having to purchase pre-printed cans, with minimum order quantities of 100,000 cans.

“Purchasing machinery that can allow you to automatically apply decorative shrink labels onto cans allows you to sleeve as many cans as you like and need.

“So if a brewery only needs 5,000 cans of a seasonal beer, it can purchase one or two rolls of that particular flavor and sleeve the required amount of cans as needed.”

Brett Stegmaier, head of product and business development at Spectrol, says his company worked closely with both Nine Locks and Aesus to ensure “flawless” installation and startup of Aesus equipment at the brewery.

“We worked with Aesus on all the specifications, roll orientation and casting to validate the Aesus system for final quality,” says Stegmaier, adding the Nine Locks label are UV flexo-printed in one pass on Spectrol’s Gallus Arsoma 510 and Gallus ECS 340 printing presses in up to 10 colors.

Stegmaier says these advance printing technologies allowed Spectrol to develop a unique textured finish on the cans’ backsides to replicate the feel of a wooden surface for consumers holding the can.

Shaped to resemble the blade of a kayak paddle, the touchy-feely graphic also contains the basic recipe

and origins of the beer inside the can, printed in artisanal font to emphasize the product’s purity and authenticity.

“The surface granular varnish used in the process has a tactile feel so that a consumer would feel like their fingers are touching a wooden blade of a paddle,” Stegmaier.

“This tactile surface effect provides consumer with an interactive experience and enhanced interaction with the product,” says Stegmaier, adding that Spectrol has by now shipped swell over a million such partly textured shrinksleeves to Nine Locks since the Aesus equipment installation.

“Our printing equipment gives us the ability to print on both sides of the web at the same time,” Stegmaier relates, “so as we apply ink on the inside of the film we also put the tactile finish on the outside of the film, albeit only in the registered area of the canoe blade graphic.”

Says Stegmaier: “We are proud to be a label supplier of choice supplier to a lot of other craft brewers, which is becoming a very important and fast-growing market for Spectrol.

“Our extensive knowledge of application technologies enables us to provide our customers with everything they want in the label.

“We are very pleased that Nine Locks was happy with the final outcome,” he concludes, “and we look forward to continuing our relationship with them as they grow their production volumes at their new facility.”

SUPPLIERS

Aesus Packaging Systems

Spectrol Inc.

Gallus Holding AG (Division of Heidelberger Druckmaschinen AG)

Videojet Technologies, Inc.

PakTech

A Nine Locks Brewing employee placing cans of beer inside high-strength corrugated cases for storage and shipment.

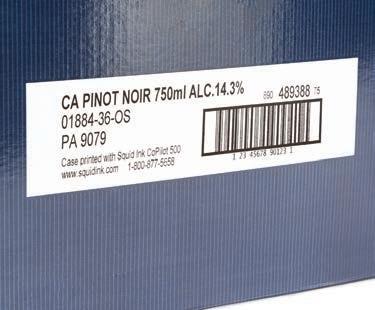

The Nine Lock plant employs a Videojet continuous inkjet (CIJ) small-character coder to apply the date of production and lot numbers to the bottom of each filled can of beer.

The four-packs of Nine Lock brand beer cans utilize black PakTech snap-on plastic beer carriers to hold the cans together inside the corrugated trays used for shipping the Nine Locks Brewing products to market.

SMOOTH MOVES

Grassroots brewery adds an impressive custom-designed, dry-running canning line to their collection

BY ALANNA FAIREY, ASSISTANT EDITOR

PHOTOS BY CANADIAN PACKAGING

Since its inception back in 2013, Hamilton, Ont.-based Collective Arts Brewing has made a name for itself, thanks to its continued efforts in bridging together the craft beer and arts sectors with its wide selection of craft beer and uniquely designed cans.

Even though their eye-catching full-body shrinksleeve cans–– designed by Mississauga, Ont.-based Spectrol Inc.–– do not need to be updated, it became evident to Collective Arts staff that some of their equipment did.

Back in 2018, the grassroots brewery was in the middle of installing a new filler, with the intention of producing more cans of beer.

The addition of a new filler also meant that Collective Arts needed to expand their current canning lines.

Simultaneously during this time, Collective Arts also came to the realization that they would need to install a modern, high-performance canning line that was worthy of the 65,000-square-foot plant.

With the brisk consumer demand outpacing the original canning line’s capacity to keep up, Collective Arts found itself in need of a better system to package its popular canned beer brands such as Lunch Money, Jam Up the Mash, Stranger Than Fiction, and their flagship IPA Ransack the Universe

“Previously, the canning line we were using was much smaller,” says Graeme Bell, project manager for Collective Arts.

“To increase our capacity, we started looking at alternatives for this kind of conveyor.”

To get this done in the most efficient and expedient manner, Milton, Ont.-based Merley Chains Ltd., who are the Canadian distributors for conveying system specialists Regal Beloit and their System Plast brand, were brought in to provide their expertise.

An importer and marketer of a wide array of chains, belts, sprockets, conveyor components and accessories, Brad Gillis, sales manager for Merley Chains, began to quickly survey the conveyor system and belt Collective Arts was using.

“Collective Arts had a lot of used conveying equipment that were in need of repair and refurb,” recounts Gillis.

“They had a mishmash of different types of chains and belts––there was some with stainless steel, and some with plastic.

“New conveyors had to be built to expand the line to accept the new higher filling capacity.”

After assessing what the best possible option would be for Collective Arts, Gillis recommended System Plast NGE Plastic chain & Modular belt on the complete line from start to finish, with sections of the con-

veyor built by Galick Packaging

NGE material offers lower coefficient of friction properties, thus eliminating the need for chain and belt lubrication, therefore acting as a genuine dry running conveyor system.

“Typically in this kind of environment at Collective Arts Brewery, they are running cans of beer and previously had to reduce friction on the conveyor chains by ” Gillis explains.

“The NGE system is able to run the cans dry with-

Merley Chains sales manager Brad Gillis (pictured left) discusses the best conveying solutions with Collective Arts Brewing’s maintenance manager Scott Dumbreak at the Hamilton, Ont.-based brewery for their canning line.

Mississauga, Ont.-based Spectrol Inc. are the creative forces behind the attention-grabbing full-body shrinksleeve cans at Collective Arts Brewing, pictured on the System Plast NGE Conveyor.

out lubrication and the benefits of that are elimenating the costs of lubrication, reducing the amount of water used and it also reduces wear and tear on surrounding equipment by keeping things dry.”

Asides from less maintenance, other benefits to the presence of the System Plast NGE include cost savings, an increased wear life, as well as an enhanced and safer working environment.

The many advantages of the System Plast NGE’s presence were not lost on Bell.

“We chose this System Plast conveyor because the alternatives of this machine were superior and it did not require any kind of lubrication,” Bell says with confidence.

“The System Plast conveyor is a huge factor in the overall improvement of the line.”

In addition to the System Plast NGE material, Collective Arts was also supplied with a magnetic chain and Toptrac magnetic corners for the curved sections of the conveyor.

According to Gillis, these are vital components to the overall operation.

“The magnetic chain retention allows you to lift the chain out of the tracks for cleaning and maintenance without having to take the chains apart,” Gillis elucidates.

“The Toptrac magnetic corner system is new from System Plast and offers the best corner track solution in the industry.”

As a fairly new design, the biggest selling point of the Toptrac magnetic corners was its ease of maintenance and hassle-free care.

Gillis explains that in older magnetic tracks, when a magnetic corner needs to be maintained and replaced, trained mechanics have to remove the whole corner and change it over.

Thankfully for Collective Arts, the Toptrac provides them with a much more manageable upkeep solution moving forward.

“Before installing the Toptrac, operators would have to shut the brewery down for several hours get a mechanic to come and remove the corner, put a new one in and then put the corner back into place,” Gillis explicates.