FRESH AND EASY

Fresh produce packer leverages robust packaging automation to accelerate organic product growth

Story on page 32

Fresh produce packer leverages robust packaging automation to accelerate organic product growth

Story on page 32

NO. 3

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228 AJoseph@canadianpackaging.com

ART DIRECTOR

Brooke Shaw • (519) 428-3471 x264 bshaw@annexweb.com

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexbizmedia.com

CIRCULATION MANAGER

Barbara Adelt • (416)-442-5600 x3546 badelt@annexbizmedia.com

VICE PRESIDENT Tim Dimopoulos • tdimopoulos@annexbizmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

Canadian Packaging, established 1947, is published 11 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbizmedia.com

Tel: (416) 442-5600 ext 3555

Fax: (416) 510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $73.95 per year, Outside Canada $120.95 US per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

privay@annexbizmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2016

reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage for our publishing activities.

here are times when local events and developments have far-reaching implications and influence far above their natural weight and clout in the grander scheme of things.

It’s always been a source of wonder and amazement to yours truly how, for example, the results of a caucus straw poll in tiny Iowa or New Hampshire set the tone and momentum for eventual selection of nothing less than the leader of the free world.

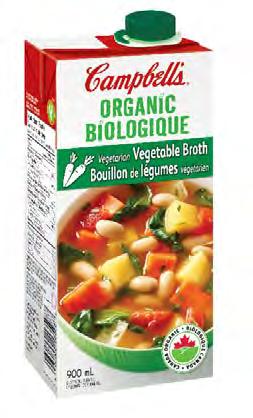

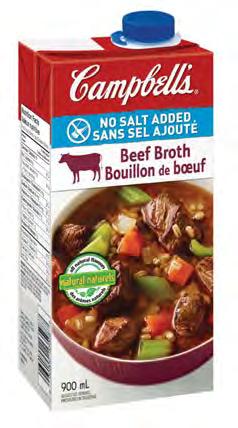

In similar vein, the recent decision by the Camden, N.J.-headquartered food multinational Campbell Soup Company to make a voluntary disclosure of any genetically-modified ingredients present in its products to comply with a pending legislation in the state of Vermont, effective July 1, 2016, has much broader implications for the entire North American food processing business.

If this disclosure was to be limited solely to Vermont, the move would hardly be the subject of numerous national news headlines across the U.S. earlier this year.

But in a bold breakaway from most of its food industry peers, Campbell publicly announced its full support for enactment of a federal legislation requiring full GMO (genetically-modified organism) disclosure on all packaged food products.

Given that until then the company had spent over US$1 million fighting efforts to impose similar mandatory labeling in California and Washington State, this decision puts the Campbell Soup directly at odds with its one-time allies at the Grocery Manufacturers Association, which had spent millions lobbying the U.S. Congress to pass a bill

that would make GMO labeling purely voluntary, while pre-empting any state regulations on the subject from coming into law.

“We will withdraw from any coalition that doesn’t support mandatory labeling,” Campbell’s chief executive officer Denise Morrison told The New York Times (January 8, 2016), explaining that having a federal legislation would prevent the far more chaotic and cumbersome state-by-state patchwork of same-but-different state laws that would ultimately cost food producers far more to comply with.

“We’re optimistic that a federal solution can be reached in a reasonable amount of time,” says Morrison, “but if that’s not the case, we’re preparing to label all our products across the portfolio.”

If that indeed turns out to be the case, it doesn’t take a great stretch of imagination to see such GMO labeling spilling over into Canada sooner rather than later, which may force Ottawa’s hand to address that matter on a federal level before some of the provinces decide it falls under their jurisdictions.

Under either scenario, though, Canadian consumers will be the ultimate winners by virtue of obtaining instant access to the secretly-guarded GMO product information they have long been denied. And in that light, full credit to Campbell’s for putting honesty first!

16 FROM PALLET TO

By Andrew Joseph Quebec vegetable processor leverages high-payload robotics to move its products into the marketplace.

22 STRENGTH IN NUMBERS By George Guidoni Canada’s fresh produce sector working hard to accelerate industry growth.

28 A SPIRITED ENDEAVOR By Andrew Joseph Distilled spirits giant makes a strong case for tankless adhesive applicating technologies.

35 READY TO SERVE By George Guidoni Iconic soupmaker’s new recipe for reconnecting with Canadian consumers.

36 MASTERING THEIR CRAFT By Andrew Joseph Ontario craft-beer startup relies on digital label printing to grow its market presence.

38 A SHOW LIKE NO OTHER A quick SIAL Canada 2016 pre-show primer.

40 CUT ABOVE THE REST By Ronnie Cons The right way to choose the right meat packaging equipment for your needs.

A cool climate may not naturally be a winemaker’s best friend, but that’s not really a problem for various up-and-coming vintners in southwestern Ontario’s Niagara Region that are truly devoted to their craft—like the Niagara-on-the-Lake-based Southbrook Vineyards.

Located on a 150-acre property boasting 60 acres of vines to grow a select variety of organic red and white grapes, the company’s recent launch of its new Seriously Cool red and white varietals marks a welcome recovery of the region’s grape crops back to their former glory days before the exceptionally harsh winters of 2014 and 2015 significantly reduced the local harvests.

Produced in strict adherence to the Sustainable Winemaking Ontario standards developed by the Wine Council of Ontario, the Seriously Cool label currently comprises two varieties of easydrinking wines now retailing across Ontario in 750-ml bottles made exclusively from recycled glass.

According to Southbrook Vineyards, the 2012 Seriously Cool Red is a dry, well-balanced, medium-body blend of Gamay, Pinot Noir and Zweigelt with flavors of juicy red fruit, cherry and cedar, enhanced with earth and smoky notes to create a savory foundation that “pairs beautifully with dried meat platters, steak frites, duck confit, and pizza and pasta with red sauce.”

For its part, the floral 2015 Seriously Cool Chardonnay Light is a light- to medium-bodied white wine with lush fruit on the palate and a whiff of oak that make it a perfect complement with fresh and bloomy rind cheeses, white bean spreads, pasta

with cream sauce, white-fleshed fish and roast chicken.

According to Southbrook Vineyards proprietor Bill Redelmeier, both wines make optimal use of the unique taste profile of locally-grown grapes boasting ripe concentrated flavors with vivid aromatics and zesty acidity on the palate.

“Continuing in the Southbrook tradition of producing the best quality wines with locally available grapes, we are very excited to showcase the Seriously Cool wines,” says Redelmeier, adding the Seriously Cool moniker for the wines was selected as a tribute to the local region’s “seriously awesome” suitability for high-quality agri-food production.

To get that point across graphically, Southbrook Vineyards retained the services of Toronto-based graphic design agency Messenger to create the suitable labels.

Composed of bold geometric patterns in vibrant colors that include near-fluorescent orange and pink mixed in with other vivid colors drawn from Southbrook’s palette used to describe grape varietals, the wallpaper-like labels are actually an extension of the artist’s Awesome Series art and design project she began in 2012, which pays homage to leading Bauhaus movement artists like Josef Albers, Gerhard Richter, Maya Hayuk and Herbert Bayer.

“One of the things I like most about these labels is that they are part of a series,” says Wills. “And the recipe for the series is simple: Pattern plus Color equals Happiness.

“People love patterns,” Will explains. “Think of

your favorite tie, your coolest socks, or the cushions on your sofa that you love and treasure.

“They exist for no other reason than that you like them, and on some level they bring you joy and a means of self-expression,” says Wills, relating that Messenger works with Toronto-based labeling converter A1 Label Inc. to produce the selfadhesive labels for Southbrook Vineyards using a Hewlett-Packard Indigo WS6000 digital press and the traditional methods of embossing and spotvarnish screening.

“The variable digital printing is one of the things that made this family of labels possible, because it enabled us to print the designs for each series together in a consecutive sequence right off the printer,” she explains. “Because the bottling, labeling and casing are all done simultaneously, it is possible to have all three designs featured inside each case of both the red and the white wines.

“The four-color Indigo digital press has an extended gamut of three special colors,” she adds, “which is how we were able to achieve such vibrant colors on the labels.”

Getting fresh fruits and vegetables to the point-ofsale in prime condition is a remarkable achievement of modern food science, and so is enabling them to virtually sell themselves well before their due date.

And thanks to some outstanding behind-thescenes work by the Mississauga, Ont.-based Chantler Packaging Inc., Canadian consumers and retailers alike are in for a real treat following last month’s Canadian commercial launch of the proprietary PrimePro Core ethylene absorbing film technology incorporated onto microfluted corrugated materials.

Made with special proprietary equipment, these ultra-light PrimePro Core -treated compact containers were specifically developed for retail-ready merchandising and displaying of four to 10 fresh fruits or vegetables per pack, according to Chantler, which first piloted the technology overseas in partnership with Flexomed, a package printing and graphics company based in Valencia, Spain.

The converter took the existing PrimePro shelf-life extension film technology—formulated to remove the ethylene gas plant hormone that the triggers the process of ripening and decay—and laminated it to corrugated trays and compact boxes in a simple process requiring no additional materials or extra labor for tying, sealing or gassing the produce.

“The produce industry is always looking for innovation and we are to proud to offer a new and competitive advantage in packaging”, says Francisco Vercher, international sales manager for PrimePro in Europe.

“What we have is something that is effective throughout the entire supply chain—even on the retail floor.”

Last summer, PrimePro Core won the Best Food Packaging 2015 award in the LiderPack Awards competition—held each year in Barcelona—celebrating excellence in packaging and point-of-sale advertising in Spain.

To enter the competition, PrimePro Core ’s efficacy had to go through extensive testing on various fruits and vegetables by Centro Tecnológico de la Conserva y Alimantacion (National Technology Centre of Packaged Food), which is acknowledged by the Spanish government as the country’s center of research and innovation.

“This new product and test results really show how versatile the PrimePro technology is, without any complicated application methods,” says Grant Ferguson, vice-president of sales and marketing at Chantler Packaging. “It’s not just your ordinary MAP (modified atmosphere packaging) technology.

“Convenience is key with PrimePro Core,” states Ferguson. “Its incorporation into rigid produce retail corrugate and paperboard easily extends shelflife, but more importantly, it reduces food that goes to waste.

“We are confident that this solution can help our friends in Canada, the U.S. and even South America,” says Ferguson, “and we’re excited to expand PrimePro Core to high-value commodities such as pears, cherries, stone fruit, and organics.”

There’s no better way to get into the consumers’ mindsets than to ask them directly what makes them tick or turns them off inside a retail environment.

And that’s exactly what market researchers at the Toronto-based BrandSpark International have been doing for the last 13 years as part of the company’s annual BrandSpark Canadian Shopper Study report that’s used to determine the winners of the companion Best New Product Awards (BPNA) competition.

“The sheer number of new products that appear on the store-shelves each year can be overwhelming,” says BrandSpark International president and chief executive officer Robert Levy.

According to Levy, this year’s Canadian Shopper Study surveyed more than 39,000 Canadians about a broad range of their shopping habits, with results then being used to determine the BNPA winners— resulting in 71 winning products across multiple categories in the health-andbeauty, food-and-beverage, householdcare and kids products segments. (See pictures above for products selected as having the best packaging)

“The competition and the study distinguish the products that are truly innovative,” says Levy, “while providing manufacturers with important insights about what Canadians look for while they shop.”

Here are some of the notable highlights that this year’s Canadian Shopper Study reveals about the Canadian consumers’ shopping patterns and behavior: Canadians embrace innovation and are willing to pay for new products that deliver results.

“We’ve seen Canadians’ interest in new products remain strong through economic ups and downs, with 75 per cent embracing innovation,” says Levy, adding that 67 per cent of survey participants are willing to pay “a little more” for a new product that truly appears to be improved.

Canadians split on household shopping trips.

According to survey results, more Canadians enjoy household shopping than not, with 52 per cent of shoppers saying that hunting for deals makes the trip fun; 56 per cent regularly shopping at multiple stores to get the best prices; and only 33 per cent saying that the convenience of one-stop shopping is more appealing than the lowest prices.

The “natural” over-the-counter health products resonate with 53 per cent of Canadians.

“Price is not always the only factor for over-the-counter health products,” says Levy, citing 55 per cent of Canadians willing to often spend a lot more for health products they know work.

“Despite the fact that 70 per cent of Canadians think that natural claims, which are not regulated like organic

claims, are often exaggerated, the promise of more natural products remains broadly appealing,” says Levy.

Canadian shoppers believe in organic food products but aren’t willing to pay for them.

According to the study, only 36 per cent of Canadians are convinced that organic food products are healthier, and only 23 of the surveyed consumers buy them on a regular basis. However, 60 per cent of Canadians stated they would buy more organic food products if they were less

expensive, with 42 per cent agreeing that organic products are better for the environment.

Brand loyalty is declining as Canadians become “deal hunters.”

The study finds that 45 per cent of Canadians shoppers are not as brandloyal as they were a few years ago, which is a 33-percent increase from the 2014 survey. “This decrease in brand loyalty appears to be driven in part by rising food prices and the low dollar, as we’re seeing promotions drive product switching more than ever,” says Levy, citing the 75 per cent of shoppers who regularly check the retailers’ weekly print flyers for low-price promotions. Robert Levy, President and CEO, BrandSpark International

n Custom paperboard packaging converter Beneco Packaging of Mississauga, Ont., and its Toronto-based subsidiary SoOPAK specializing in short-run offset folding-carton printing—have made the annual PROFIT 500 list of Canada’s fastest-growing companies, compiled by the Canadian Business and Profit magazines, for the second year in a row by placing 432nd overall and 81st among the fastest-growing manufacturing companies. “This achievement reflects the strength of our company and the dedication of our team,” says Beneco president Yajun (Carol) Jiang (see picture) , citing the company’s annual revenue growth of 91 per cent in the last five years. “We’re very proud of our technology, services and solutions and our excellent staff—all of which reflect our vision to serve the short-run packaging needs with unique, high-quality, attentiongrabbing promotional cartons.”

Founded in 2004, Beneco operates a state-of-the-art, 45,000-squarefoot facility offering a comprehensive range of advanced packaging capabilities from prepress and creative graphic design to waterbased and UV coating, embossing, window patching and gluing. “We work hard to make our customer experience very positive by keeping a ‘customer first’ mindset and using technological advances to facilitate easy folding carton order purchasing,” says Jiang, who also made last year’s prestigious W100 list of Canada’s top female entrepreneurs compiled by the Canadian Business and Châtelaine magazines. “We have dedicated knowledgeable folding carton consultants looking after every customer’s order [and] we’re the

first company with an online folding carton platform to make online ordering easy—providing instant quotes and live support from our product specialists—to bring added value to each customer.

n While a humble folding carton may not be synonymous with innovation, the way that California-based FoldedColor Packaging goes about producing its folding cartons online has recently earned it a selection as a finalist in the global 2016 Edison Awards competition, celebrating excellence in new product and service development worldwide. Said to be the only online folding-carton supplier with a fully-integrated web-based order entry system, FoldedColor allows customers to select box templates online, obtain instant pricing, edit online or offline, approve their design through an interactive 3D proof, order short print runs as low as 50 boxes, print unlimited spot colors at no additional charge, and receive their order in as little as five to seven business days. “We’re thrilled to be among this year’s Edison Awards finalists,” says FoldedColor president Jan Steiner, who will be in attendance at the Edison Awards Gala in New York City on April 21, 2016, when this year’s winners will be publicly revealed. “This recognition is a testament to our team’s innovation, and it further validates our position as

a game-changer in the folding carton space.” According to Steiner, all the ordered folding cartons are manufactured from fully-recyclable, SFI (Sustainable Forestry Initiative)-certified SBS (solid bleach sulfite) paperboard, using the company’s proprietary extended color gamut printing technology and a seven-color offset printing process that produces brilliant colors and graphics.

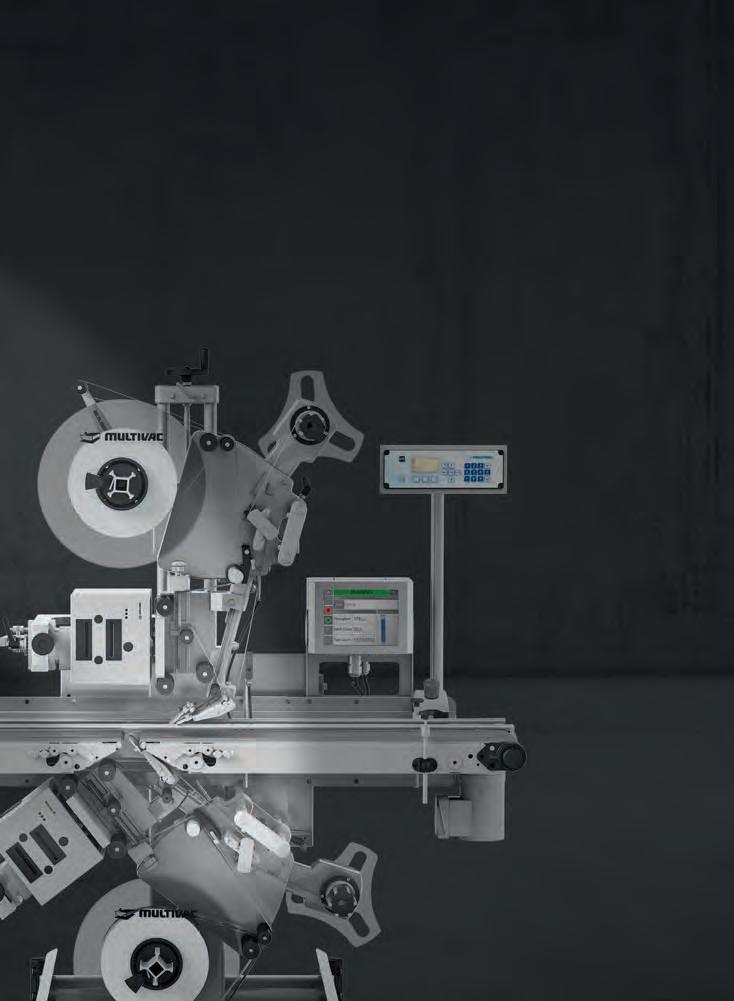

n Pro Mach, Inc., a diversified packaging equipment supplier headquartered in Cincinnati, Ohio, has completed two major acquisitions in the early part of 2016, including:

• EPI Labelers, a prominent manufacturer of high-performance labeling systems and solutions— including tamp, blow-on, wipe-on, two-panel, corner-wrap and printand-apply systems—based in New Freedom, Pa.

• Stork-Texwrap, manufacturer of the popular Texwrap brand of automated shrinkwrapping systems and related accessories— including L-bar sealers, side sealers, tunnels, infeed devices and conveyors—based in Washington, Mo.

“Texwrap has an excellent product line and talented people that complement our existing capabilities and customer base,” says Gary Evans, head of Pro Mach’s End of Line Group business unit. “Their knack for solving customer problems using cost-effective and proven technology makes them a great addition to our business—giving Pro Mach one of the strongest and most thorough distributed product lines in the industry and strengthening our position as a world leader in packaging machinery solutions and customer service.”

Chris’ strength lies in seamlessly on-boarding large customers with multiple SKU’s, supporting launches for private label brands as well as, overseeing significant retail campaigns for major Canadian food manufacturers, transitioning customers onto new and advanced structures, and, providing guidance and insight into his customer’s research and development endeavours. Additionally, Chris has deep experience in the pet food category where he gained a strong knowledge base of this market’s unique flexible packaging and marketing requirements. Through this engagement in the pet food Industry, he has played a vital role in supporting new and innovative flexible packaging research and development efforts.

Chris is enthusiastic about joining the TC Transcontinental Packaging team and sees their dedication to food safety, creation of innovative flexible packaging, research and development, and, most-significantly, to TC Transcontinental Packaging’s aggressive growth and acquisition strategy as significant market advantages.

Chris attributes his success in the flexible packaging industry to his core philosophies: You need to treat your customer’s business as if it is your own. The flexible packaging we produce for a customer is vital to their success, and as a business partner you need to be all in and stand behind the product.

Working closely with customers in their research and development efforts is important to remaining relevant, supporting customer success, and maintaining long-term relationships. Integrity and trust must be earned and worked for every day.

Chris’ philosophies are aligned with TC Transcontinental’s core values of innovation, teamwork, respect, and performance, which make him a perfect addition to the team.

TC Transcontinental Packaging offers concept to consumer flexible packaging solutions from design, production art, and plates through flexible print and laminating. Everything we do is geared towards creating a unique customer experience that supports their flexible packaging needs.

Capable of forming, filling and sealing laminated, metalized and polyethylene materials in a broad variety of shapes and sizes up to eight-inches-wide at speeds of up to 80 pouches per minute, the new VerTek 800 vertical form-fill-seal seal machine from WeighPack Systems Inc. features a compact design with a simplified swiveling mount for the vertical back seal for ensuring an even and precise seal, with the open-frame design facilitating quick access for maintenance and service. Equipped with a tool-less removable film shaft, forming collar, pull belts, and front and back jaw assembly, the VerTek 800 pouching system is equipped with an integrated encoder and a 10.4-inch color touchscreen interface for userfriendly operation.

WeighPack Systems Inc.

401

Designed to bring the Numatics 501 Series directional valve’s high-flow characteristics and compact size to pneumatic panel applications, the new Numatics 501 Series panel mount adapter plate from ASCO Numatics eliminates the need for complex tubing routing and bulkhead fittings, according to the company, while reducing custom machining and drilling requirements and simplifying panel layout. Well-suited for applications in the process in the process industries where directional control valves are installed in a cabinet due to environmental or packaging constraints—including food-and-beverage, pharmaceutical and packaging machinery—the high-strength panels are engineered to withstand a broad range of harsh environmental conditions to maintain optimal system integrity and reliability, according to the company.

ASCO Numatics 403

Designed for use with Graco Inc.’s InvisiPac TankFree hot-melt adhesive applicating systems, the company’s new LineSite remote monitoring solution enables operating personnel to check temperatures, review critical performance metrics, view how much adhesive each line is using, and monitor machine

diagnostics from a smart phone, tablet or computer by tracking and transmitting real-time data from individual InvisiPac systems onto a single, local storage device. Designed to capture all critical data in an intuitive graphical format for quick and easy review, the LineSite device allows users to view adhesive consumption over time to spot trends and make quick adjustments, view live temperatures, graph system parameters to analyze historical performance, and even link to detailed troubleshooting instructions from virtually anywhere by logging in from a local network or by enabling web access through the external portal. Graco Inc.

404

Comprising a high-speed blowmolder/ unscrambler, filler and labeler in one blocksynchronized machine, the new 3Bloc system from Krones AG subsidiary Kosme s.r.l. is available in two versions to suit the specific requirements of both PET (polyethylene trerephthalate) and HDPE (high-density polypropylene) containers in busy bottling environments. For PET bottles, the innovative block configuration with a blowmolder can be equipped with either a pressure-sensitive Flexa Sensicol labeling station or wraparound rollfed labeling for handling cylindrical, square and odd-shaped PET containers at speeds of up to 16,000 bottles per hour. For its parts, the HDPE-compatible version replaces the blowmolder with an unscrambler for erecting and placing the empty containers on the line as they are being fed in at robust throughput speeds of up to 25,000 bottles per hour.

Krones, Inc.

405

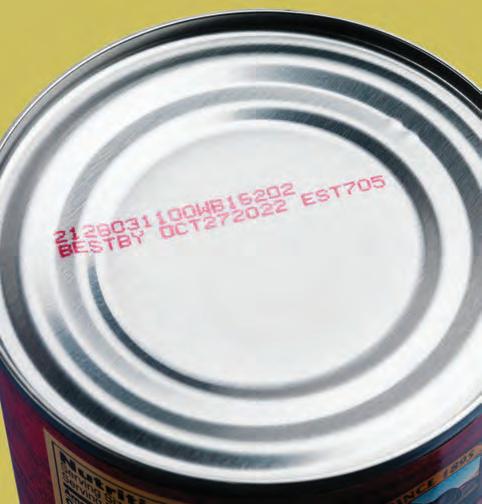

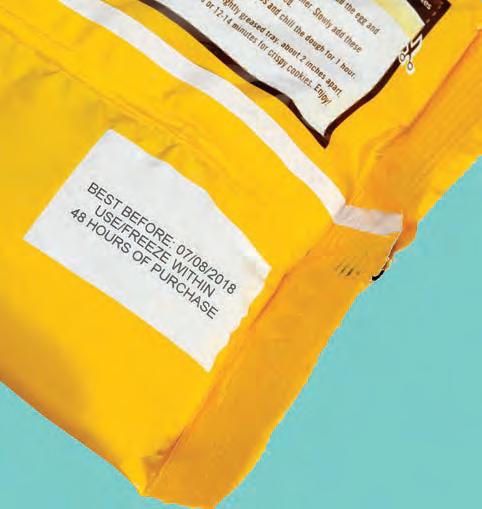

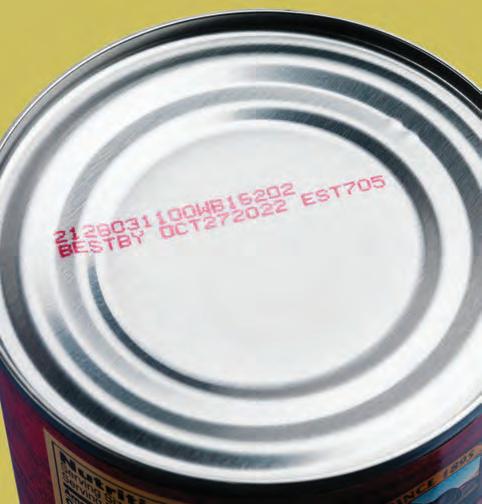

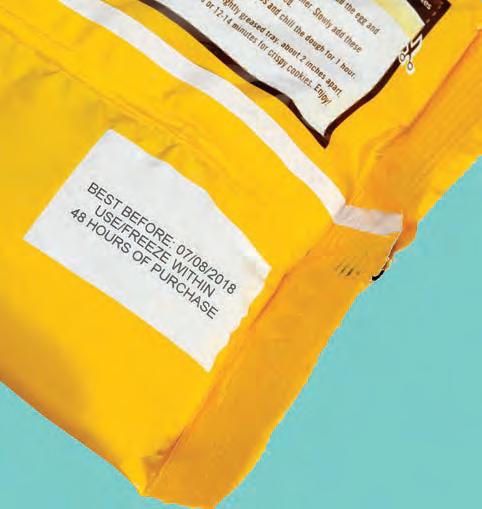

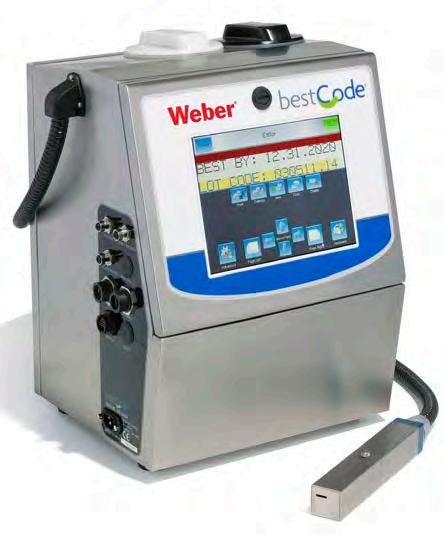

Manufactured by BestCode Products and distributed by Weber Packaging Solutions, Inc., the new BestCode Series 8 industrial marking and coding systems are designed for highly reliable and legible CIJ (continuous inkjet) printing of best-by, lot code, sell-by, expiration codes and other important identifying marks and codes on industrial and consumer goods to ensure product traceability with high-speed, non-contact, instantly dry marks and codes on a wide range of substrates, including plastic, glass, paper and more.

Weber Packaging Solutions

406

Cognex Corporation’s newly-released In-Sight 2000 series product line is said to combine the power of the company’s advanced In-Sight vision systems with the simplicity and affordability of a vision sensor for solving a myriad of errorproofing applications with the benefits of a simple set-up and a modular design with interchangeable lighting and optics. Featuring an integrated, high-performance image formation system consisting of field-interchangeable lenses and a patent-pending LED ring light that produces even, diffuse illumination across the entire image, the In-Sight 2000 eliminates the need for costly external lighting, while allowing users to easily swap out the lens and change the color of the integrated ring light as needed for their application.

Cognex Corporation

407

mk North America has expanded the company’s VersaMove pallet handling and conveying systems to offer three different pallet system platforms— including VersaMove Standard, VersaMove Plus and VersaMove Ultra —to accommodate a broad range of load requirements from 80- up to 700pound pallet loads. Fabricated from extruded aluminum, each of the three highly flexible systems allows for easy expansion and redesign, according to the company, via quick and easy mounting of required hardware and components onto the conveyor frame. Designed for easy integration into the existing workflow of fast-paced automated assembly and other mass-production environments, each system is versatile enough to handle lighter-duty conveying applications.

The new Raptor HPL turntable stretchwrapping machine from Muller is a heavy-duty, semiautomatic turntable that can wrap up to 35 loads per hour. Equipped with a user-friendly control panel to provide full flexibility to create customized wrap patterns for each unique application, the Raptor HPL model stretchwrapper utilizes patented strain gauge technology to enable electronic film feed and corner compensation, while its motorized power pre-stretch system provides up to 250-percent adjustable film tension control to ensure optimal film usage, facilitate superior load containment, and minimize the risk of product damage. In addition, the Raptor HPL turntable now features Muller’s patented Logo Wrap enhancement—previously available only on its Octopus series ring-style stretchwrappers—to enable valueadded branding and custom messaging functions. Muller 409

The new model CH-100 tamper-band applicator from American Film and Machinery is a fast, high-efficiency butterfly mandrel style tamper band applicator designed for continuous, 24-hour operation at low to medium speed rates across a broad range of food-and-beverage, pharmaceutical, nutraceutical, health-and-beauty, consumer goods, household chemicals and other manufactured goods industry applications. With the applicator’s compact housing constructed from 304 grade stainless steel and anodized aluminum to provide strength, reduce vibration and ensure quiet operation, the CH-100 model boasts a touchscreen control interface for programming product runs with quick set-up, while its single-blade guillotine cutting mechanism provides extremely smooth and effective cutting motions for a diverse range of plastic banding options up to 50 to 70 microns in thickness. The new model comes complete with stepper motor-driven, single-film unwind with tension control, cutter assembly, and pneumatic cylinder to provide accurate and consist-

ent tamper-band application, along with a photoeye sensor system to allow for precise register cutting, as well as an innovative quick-change system for switching the machine’s mandrels with a simple turn of the knob.

American Film and Machinery

410

Designed for high-performance packaging, cartoning and kitting applications, the MPP3H robot from Yaskawa Motoman features a parallel link arm configuration with a direct-driven rotary axis to simplify design and increase reliability, with its robust MotoPick software optimized to perform high-speed picking operations by synchronizing multiple robots, vision systems and multi-part conveyors. According to the company, the MPP3H robot has several key features to facilitate easy line integration—notably a large, 80-mm thru-hole at the base for allowing endof-arm tool cables to be routed through the center of the robot, thereby facilitating less complex cabling and reduced cable lengths. The thru-hole can also be used to mount the valve pack at the base of the threekilogram payload robot—thereby reducing the payload the robot has to carry.

Yaskawa Motoman 411

Columbia Machine has completed the redesign of its HL (High Level) family of palletizers— including the pictured HL6200, HL7200 and HL9200 series—to enhance safety, flexibility and performance with a contemporary, completely modular, and exceptionally user-friendly palletizing machines equipped with highly advanced safety and guarding systems. Designed for continuous around-the-clock operation, the redesigned HL6200 model palletizer is equipped with an operator-friendly Product Manager interface terminal to create and modify layer patterns, view and export production reports, adjust drive speeds and timer settings, and to access manuals and schematics through a single control terminal. Moreover, the machine’s bi-parting stripper apron and case stops enable the HL6200 to create gaps both frontto-back or side-to-side to palletize up to 120 cases per minute depending on the selected stacking pattern, according to the company.

Columbia Machine 412

For a tiny country like the like the Baltic state of Estonia in northern Europe, little steps forward in packaging sustainability often have a big positive impact for business enterprises like the Valio Eesti dairy.

Founded in 1992 soon after Estonia achieved its independence from the former Soviet Union, Valio Eesti has been producing over 150 different milk and cheese products for the Baltic region and Italy—making it one of the largest dairy companies in the Baltic region.

Aware of its growing carbon footprint, a few weeks ago the dairy switched the packaging of its popular Valio brand of probiotic yogurt and kefir drinks to the lightweighed HDPE (high-density polyethylene) bottles developed by Greiner Packaging, its long-time supplier of thermoformed dairy cups.

“We were able to use our comprehensive know-how of different plastic-processing technologies to implement a sustainable and costoptimized product solution for our customer,” explains Günter Ausserwöger, sales director at the Kavo division of Greiner Packaging in Kremsmünster, Austria.

The new blowmolded HDPE bottles (see picture)

are “not only practical and consumer-friendly,” Ausserwöger relates, “but they also but also stand out in respect to sustainability due to their low weight and optimized use of plastic material.

“We even developed a unique injection-molded cap specifically for this customer’s 100-ml bottles, as the requested standard solution did not exist in the market.”

In addition to the 100- ml containers of kiwi, strawberry-banana, plum and tutti-frutti yogurt flavors and 300- ml bottles of blueberry, cappuccino and chocolate-mint kefirs, the dairy also started using Kavo-made 275- ml bottles to package its brand new line of yogurt smoothies.

Produced in banana-strawberry-kiwi, mango-passion fruit, pear-apple-banana flavor combinations, the new yogurt smoothies—a first in the Estonian market—are targeted primarily at families with children and sold all over the Baltic region.

“Healthy eating is booming and the demand for berry flavor, vitamin-rich drinks and smoothies is increasing all over the Baltics,” says Ausserwöger. “These resealable bottles also perfectly suited for enjoying these healthy beverages on the go.”

Leading German medical device manufacturer

Gerresheimer AG has launched what the company claims to be the world’s first fully renewable plastic tablet packaging made from sugarcane.

Unveiled at last month’s Pharmapack Europe 2016 pharmaceutical industry exhibition in Paris, France, the new Biopack container features a distinct spacesaving rectangular design to facilitate more efficient packaging for transportation, while its internal leaflet compartment (see picture) creates additional surface space on the outside to provide for more effective branding that would otherwise be used to print the required product information.

“By using biomaterials our customers contribute to the reduction of greenhouse gas emissions, thereby protecting the environment and avoiding unnecessary waste,” says Niels Düring, Gerresheimer’s global executive vice-president for plastic packaging.

“Biomaterials are the renewable alternative to conventional PE (polyethylene) and PET (polyethylene terephthalate), and sugarcane is one of the more attractive substances used to make biomaterials.

“It produces a material with exactly the same characteristics as conventional plastics, while also being fully recyclable.

A year may not sound like a really long time, but for progressive companies like the global processing and packaging equipment group Tetra Pak, one year can make a huge difference in packaging sustainability.

Introduced in Europe in January of 2015, the company’s Tetra Rex Bio-based drink carton has made its North American debut a few weeks ago in the U.S. with the launch of the Tetra Pak Gable Top Bio-based carton, which was especially adapted for the needs of the U.S. market.

“Environmental excellence is one of Tetra Pak’s strategic priorities and a driver of our product development activities,” says Carmen Becker, president and chief executive officer of Tetra Pak Inc. in Denton, Tex.

“We are proud to be the first to offer a fully renewable carton package to the U.S. market because we believe that increasing the renewable content of our packages is not only good for the environment, but

also offers our customers a competitive advantage.”

According to Tetra Pak, the new cartons are made solely from renewable materials—defined as natural resources that can be replenished over time—developed from a combination of paperboard and sugarcane-derived plastics.

“We’re proud to be the first to offer a fully renewable carton package to the U.S. market and believe that increasing the renewable content of our packages is not only good for the environment, but also offers our customers a competitive advantage.”

Notably, Tetra Pak customers currently using the standard half-gallon gabletop with or without closure can easily transition to the new bio-based version without the need for any additional investment or modification to their existing filling machines, according to the company.

The successful U.S. launch of the Tetra Pak Gable Top Bio-based package follows a long line of successful innovations in sustainability at Tetra Pak over the last year, including the launch of the fully renewable Tetra Rex Bio-based package in Europe; the global launch of the industry’s first bio-based cap; and the successful introduction of bio-based coatings for all the Tetra Pak cartons produced in Brazil.

All told, the company’s sustainability efforts have been recognized with seven prestigious awards in that time-frame, including first-place ranking in the Sustainable Category of the global Ethical Corporation Responsible Business Awards competition.

Remarkably, the company expects to ship more than 100 million of Tetra Rex Bio-based cartons to customers during the course of 2016, citing a fastgrowing customer base across Scandinavia that already comprises leading regional dairy producers such as Valio, Arla Foods, Wermlands Mejeri and TINE AS.

“We believe that growing our business sustainable is not just good for the environment, but also improves our competitiveness by providing effective product differentiation,” says Bjørn Malm, director of corporate responsibility at TINE in Oslo, Norway.

“Thanks to the Tetra Rex Bio-based packaging, we have been able to take a significant step towards our own environmental goals and have committed to making all our milk cartons renewable from next year forward,” he adds.

“The success of Tetra Rex Bio-based in its first year is extremely encouraging for us,” says Tetra Pak’s executive vice-president of product management and commercial operations Charles Brand.

“We are very proud to be the first company to deliver a package made entirely from plant-based materials.

“Every package is traceable to its origin—helping customers to enhance their brand and to communicate with consumers,” Brand concludes.

“This is a significant milestone in Tetra Pak’s longterm ambition to provide 100-percent renewable packaging across our entire product portfolio.”

Residential recycling bins and organic waste containers have become so ubiquitous and commonplace in the last few years that it’s easy to forget that someone actually has to manufacture these essential workhorses of successful waste diversion programs.

And by any objective measure, leading injection-molded plastic products manufacturer IPL Inc. clearly succeeded in its recent epic undertaking involving the manufacture, distribution and delivery of over 1.2 million rolling carts and kitchen containers to 317,000 homes located in the Regional Municipality of Peel, the second-largest municipality in the province of Ontario after Toronto.

Headquartered in Saint-Damien, Que., IPL was awarded a $45-million contact in 2014 to supply residents of the fast-growing cities of Mississauga, Brampton and Caledon with three kinds of carts—including waste carts, organics carts and recycling carts—as well as provide all the related maintenance support over a 10-year period.

In order to deliver such a high number of carts, the IPL plant in Saint-Damien pushed the limits of its manufacturing and distribution capabilities to produced the carts and ensure their timely delivery to a central distribution center in Mississauga.

To ensure efficient distribution of the carts to 317,000 homes in such a short time, IPL also used a new technology utilizing smart phone scanning, whereby every produced cart was initialized with a unique chip containing the cart’s serial number, GPS (global positioning system) coordinates and the home address, with files uploaded upon delivery.

Using RFID (radio frequency identification) technology, the delivery team could scan the cart with a smart phone to know exactly where and how to deliver each cart—making the delivery process much easier and faster.

Using the same technology, the management team was able to do live monitoring of the delivery process.

“This project allowed us to position ourselves a notch above any North American competition,” says Paul Palazzo, vicepresident of sales and marketing at the company’s IPL Environmental division, which was the responsible for the project.

“Not only were we faster and more efficient than any of our competitors,” Palazzo notes, “but the technology used in this project will also help us manage the Peel Region’s ongoing growth and the 10-year maintenance and service agreement that is also an integral part of this project.”

Says Palazzo: “Because the IPL carts were actually made in Canada, they were specifically designed to withstand the various extremes of the North American climate.

“These smartly designed and cost-effective containers come in a range of practical sizes to provide effective solutions that work, furthering IPL’s 70-year tradition of manufacturing excellence, while protecting the environment.”

Cutting corners may not always be the best route to packaging innovation, but the new revolutionary technique developed by leading Swedish pulp and paper producer SCA (Svenska Cellulosa Aktiebolaget) to produce round corrugated board packaging is an inspired example of out-of-the-box thinking on many levels.

Unveiled last month, the new Arcwise packaging design combines nature’s robust round geometries with the high rigidity of corrugated board is said to enable impressive package stability, while reducing the packaging weight by up to 30 per cent to improve environmental performance for a broad range of transport packaging, retail-ready and consumer packaging, according to the Stockholm-headquartered company.

“The technique opens up totally new possibilities for packaging designs that are attractive to both customers and consumers,” says Arcwise business manager Rickard Hägglund.

“Our surveys show that people generally prefer rounded shapes to angular ones,” says Hägglund, noting that the Arcwise process can be easily deployed in standard corrugated board production facilities.

“Because round packaging is so eye-catching and attracts consumer attention in the retail environment, we think both designers and brand-owners will find these new opportunities very interesting,” says Hägglund, adding that the patentprotected process is now available to packaging manufacturers worldwide under license.

September 27, Golf at Legends on the Niagara

What emerging concepts, packaging innovations and technologies will flourish in 2025? Omni-channel, big data, analytics, virtual, 3D, digital printing, interactive, robotics, artificial intelligence, computer-aided design, drones, technical and biological nutrients, nanotechnology.

PAC invites you to register today for this forward-thinking conference. Early adoption and implementation of these emerging trends, ideas and innovations will be the difference between winning market share or the threat of business survival.

Visit www.pac.ca/2016-conference.html for more information or email labraham@pac.ca

March 22-24

Toronto: FABTECH Canada, metal forming, fabricating, welding and finishing exhibition by SME. At Toronto Congress Centre. To register, go to: www.fabtechcanada.com

April 4-7

Atlanta, Ga.: MODEX 2016, international supply chain exhibition and conference by MHI. Concurrently with Supply Chain & Transportation USA. Both at the Georgia World Congress Center. To register, go to: www.modexshow.com

April 10-12

Scottsdale, Az.: 2016 Executive Leadership Conference, by PMMI-The Association for Packaging and Processing Technologies. At Hyatt Regency Scottsdale Resort & Spa. To register, go to: www.pmmi.org.elc

April 12-14

Calgary: Growing Strong, annual convention and trade show of the Canadian Produce Marketing Association (CPMA). At BMO Centre. Contact Selena Karkash of CPMA at (613) 226-4187, ext. 213; or go to: www.convention.cpma.ca

April 13-14

Green Bay, Wis.: Converters Expo, package converting technologies exhibition by Packaging Strategies. At Lambeau Field Atrium. To register, go to: www.ConvertersExpo.com

April 13-15

Montreal: SIAL Canada 2016, North America’s food innovation show by Expo Canda France Inc. Concurrently with the SET 2016 food industry equipment exhibition. Both at Palais des congrès de Montréal. To register, go to: www.sialcanada.com

April 13-17

Tehran, Iran: IranPlast 2016, international trade fair for plastics, rubber and packaging by the National Petrochemical Company (NPC). At the Tehran International Permanent Fairground. To register, go to: www.iranplast.ir

April 14-15

Vienna, Austria: Global Release Liner Industry Conference & Exhibition 2016, by AWA Alexander Watson Associates. To register, go to: www.awa-bv.com/events

April 19-20

Oakville, Ont.: CPES2016, conference by the Canadian Printable Electronics Industry Association (CPEIA). At Sheridan College conference center. To register, go to: www.cpes2016.ca

April 26-27

Mississauga, Ont.: Partners in Prevention 2016, national occupational health and safety trade show and conference by Workplace Safety & Prevention Services (WSPS). At The International Centre. Contact WSPS Customer Care Department at 1 (877) 494-9777; or go to: www. PartnersinPreventionConference.com

May 1-3

Mississauga, Ont: Bakery Showcase 2016, national baking industry trade show and conference by the Baking Association of Canada. At The International Centre. To register, go to: www.bakingassoccanada.com

May 10-12

Rosemont, Ill.: Food Safety Summit, conference and exhibition by BNP Media. At Donald E. Stephens Convention Center. To register, go to: www.foodsafetysummit.com

May 17-20

Mexico City: EXPO PACK México 2016, packaging technologies and materials exhibition by PMMI-The Association for Packaging and Processing Technolo -

gies. At Centro Banamex. To register, go to: www.packexpo.com

May 23-25

Indianapolis, Ind.: ANTEC 2016, international plastics technical conference of the Society of Plastics Engineers (SPE). At JW Marriott Indianapolis. To register, go to: www.antec.ws

June 7

Mississauga, Ont.: Top 50 Packaging Ideas Expo, tabletop exhibition and networking event by the Canadian Packaging magazine. At Mississauga Convention Centre. Contact Stephen Dean at (416) 510-5198; via email sdean@canadianpackaging.com , or please go to: www.top50packagingideas.com

Fresh veggies processor rebounds from unforeseen setbacks to reach new levels of production efficiency with high-speed, high-payload robotic palletizing

ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY JOHN PACKMAN

For any manufacturer or processor, regardless of the industry, keeping things fresh is key in gaining and maintaining one’s customer base. Within the produce industry, freshness is even more important with the requirement to keep the product and brand ideas as fresh as the fruits and vegetables offered to the customer base. Bonduelle Group —a globally-dominant processed vegetable producing company headquartered in Villeneuve d’Ascq, France and all its international divisions, including Canada—is just such a business. Founded in 1853 by Louis-Antoine Bonduelle and partner Louis Lesaffre-Roussel, it began life as Lesaffre et Bonduelle, Alcools de l’Abbaye, a grain and juniper berry distillery situated in the northern part of France.

Eventually in 1926, at the company’s birthplace, brothers Pierre and Benoît Bonduelle turned an old barn into a cannery and installed a pea sheller, copper containers, a canning machine and sealer. This is where the company’s growth really took off, producing about 1,000 tonnes of canned peas a year, but with the harsh realities of WWII, oper-

ations were suspended in 1940.

When the war ended in 1945, and its own farms unable to satisfy customer demand for its canned peas, Bonduelle began to buy fresh vegetables from other local farms to supplement its own harvests, and created its own brand.

In 1963, a new plant was built in Estrées, France, and with continued growth it is now the largest vegetable cannery in the world, with approximately 2.15-million square feet of covered production space.

Since the conclusion of WWII, the past 70-plus years have seen Bonduelle enjoy rapid and steady growth in the canned and frozen vegetables industry, selling its products through supermarkets, restaurants and institutional food services everywhere.

The 1960s saw the company improve the exports of its veggies and the freezing of its veggies, including adding subsidiary companies in Germany, Italy and the U.K., with exports accounting for about 50 per cent of the company’s turnover.

After setting up a commercial presence in Brazil in 1994, Bonduelle later built a huge facility there—its first in the Americas.

With multiple acquisitions in-between, Bonduelle officially entered the fresh produce sector when it purchased the France-based Salade Minute and its

four dedicated plants in 1997.

In 2007, Bonduelle expanded its operations into Canada when it acquired Aliments Carrière and its Arctic Gardens brand—a well-known leader in veggies and frozen foods that also provided the company with access to an additional 39,500 hectacres of prime farmland.

Arctic Gardens remains a key brand for Bonduelle

in Canada.

Nowadays, the Bonduelle Group is broken down into four specific units: Bonduelle Europe Long Life; Bonduelle Fresh Europe; Bonduelle Americas; and Bonduelle Development, and is led by the sixth-generation of the Bonduelle family, Christophe, who serves as its chairman and chief executive officer.

Part of the Bonduelle Americas division, the Canadian headquarters is located in Montreal, and features: two canning and two frozen facilities in Quebec; two frozen plants and a canning facility in Ontario; and a mainly frozen vegetables operation in Lethbridge, AB.

“We receive vegetables from within a 200-kilometer radius from wherever in the world a Bonduelle plant is located,” Bonduelle Americas project engineer for Ontario, Sergio Murcio told Canadian Packaging during a visit to the huge Tecumseh, Ont. facility that packs mostly frozen vegetables, but also does canned vegetables, too. “With a tight radius, it ensures we receive the freshest vegetables for our plants to process and pack and get to the consumer.

“Bonduelle contracts with local farmers, but for items we do not grow, we do purchase as required from around the world.”

All told, however, Bonduelle has some 128,000 hectares of land throughout the world which is either farmed by itself or by its agricultural partners, and considers itself to be the world leader in ready-to-use vegetables offering: canned vegetables; frozen vegetables; processed fresh vegetables;

and prepared vegetables in the form of salads.

According to Murcio, the Tecumseh facility packs its own Arctic Gardens brand, but also copacks for many Canadian retailers.

Frozen vegetables used for the Arctic Gardens brand includes: sweet carrots, green beans, corn super sweet, peas, wax beans, asparagus, broccoli, edamame, cauliflower, green beans, spinach, red and green peppers, mushrooms, onions, sugar snap peas, water chestnut, bok choy, green and yellow zucchini, lima and romano beans, potatoes, as well as flavored and fried potatoes—used by Bonduelle to create some 25 SKUs (stock-keeping units) of Arctic Gardens vegetable mixes for various soup and stir fry recipes, as well as individual veggie product bags.

“Overall, the Tecumseh facility produces approximately some 60 SKUs,” notes Murcio.

The Arctic Garden frozen vegetables come in standup foil packs of varying sizes, from 300-grams, 500g, 600g, 650g, 750g and 1.75-kilogram. Excluding the largest package format, in most instances, the key difference in package weight is because of specific vegetable product density.

“We produce simple polybag formats, a vertical bag format, sealed upright DOYpack, as well as a vegetable-in-sauce line,” mentions Murcio.

Murcio reveals that, “Bonduelle is the largest supplier of canned and frozen vegetables in Canada, and we continue to expand in to the U.S. as well.”

The Tecumseh plant was originally home to a

Green Giant canning factory when it opened in 1931 and after several years and different owners, a freezer tunnel was added in 1968 and it began to pack frozen vegetables for the first time.

Bonduelle took possession of the plant in 2007, and with its quality Arctic Gardens brand made significant inroads into the Canadian marketplace.

While a massive fire devastated the Tecumseh Bonduelle plant in July of 2014 causing approximately $50-million in damages, the company confidentially suggested it would reopen within two weeks—and it did.

Nowadays, the HACCP (Hazard Analysis Critical Control Point) -certified, BRC (British Retail Council A-rating)-audited and GMP (good manufacturing policies) plant—also organic-certified and Kosher—with 80-million pounds of capacity employs some 100 full-time employees, increasing to include over 400 seasonal workers between June and December.

“Bonduelle operates the packaging facility 24-hours-per-day, seven-days-a-week from Labor Day to Easter—our peak demand periods,” mentions Murcio, adding that the rest of the year chugs along nicely with three-shifts-a-day, five-days-aweek.

“Approximately 80 percent of our production at the Tecumseh plant is for individual or mixed frozen vegetables in the stand-up and pillow-type packaging, as well as a third variety featuring the veggies and a sauce in a bag,” says Murcio.

“The remaining 20 percent of the operation is dedicated to vegetable canning,” he notes.

“The bag packaging is a year-round operation for us at the Tecumseh plant, while we only do canning for about two or three months a year,” Murcio relates. “We pack vegetables, of course, but we also pack rice and pasta to ensure we are constantly running,” notes Murcio.

The facility houses four canning production lines, and an additional four frozen packaging lines with a fifth line to be up and running soon, notes Murcio.

“We’re always open for technological improvement at Bonduelle,” he offers, “with a focus on health and safety for our employees, but also for our customers.”

It was after the fire, where all of the plant’s frozen warehouse and shipping docks and packaging lines were destroyed, that Murcio sought out a new palletizer to place the sealed cartons of product packages on a wooden pallet and prep for customer transport.

“I was the one who wanted to ensure our palletizer was robotic,” he says.

Opting to work with Grimsby, Ont. headquartered Jantz Canada —a leading systems solutions provider and machinery integrator specializing in high-quality builds of machinery, conveyor systems and robotics for the food industry—the new palletizer utilizes an ABB IRB460 palletizing robotic system, what ABB and Jantz acknowledge as the fastest palletizing robot on the planet.

Jantz Canada manager of robotics and applications Garth Dangerfield has been involved with the Bonduelle project from the start.

“Jantz was chosen out of eight bidders on the project because we offered a full turn-key supply.

“It means that everything we supplied was designed and manufactured under one roof,” relates Dangerfield.

“Along with costing, we were able to provide a lead time that met Bonduelle’s needs.

“In the end, I believe it was also comfort in having local representation and support that played a large role in Jantz Canada being allowed the opportunity to work together with Bonduelle.”

Prior to its installation in September of 2015, Bonduelle had been using three workers to stack cartons onto the pallets, but as Murcio says, “robotics enabled Bonduelle to better utilize our employee talents, while giving us a faster production line.”

Jantz Canada designed and built a custom palletizing solution for Bonduelle that is able to handle a range of carton sizes and the single-sized wood pallet it prefers to use.

The palletizing solution features: a cell, a PLC (programmable logic controller)—an operator interface that includes an operator display with the whole cell set-up and run; the IRB460 palletizing robot; a special end-of-arm

tool designed by Jantz; an infeed conveyor; pallet build and exit conveyors; and a perimeter guard with gates and light curtains.

“The infeed conveyors, pallet handling and pallet dispenser system were designed and manufactured at Jantz Canada,” notes Dangerfield.

“We also designed and manufactured a clamp-style endof-arm tool that allows the robot arm to better grip the cartons one-at-a-time for placement on the waiting pallet,” Dangerfield says, adding that “anyone can contact me for their automation needs and I’ll make sure they receive exactly what will work best for them.”

After a pallet is filled with neatly stacked cartons in a specific pattern, the system indexes the finished pallet out of the work cell for fork-lift pick-up while a new pallet is deposited from the pallet dispenser onto the pallet conveyor to move into the build station to begin anew the palletizing routine.

It’s not a box. It’s a billboard.

“We love the new robotic system built for us by Jantz Canada,” says Murcio. “It offers low maintenance and flexibility while making our overall production line run more efficiently without costly bottlenecks.”

The IRB460 certainly lives up to its unofficial moniker as the fasted palletizing robot in the world, able to work with 60-kilogram cartons at 2,190 cycles/hour or 2,040 cycles/hour with 110-kilogram loads—which ABB claims is some 15 percent faster than its nearest rival.

The robot system utilizes RobotStudio Palletizing PowerPac software from ABB, that allows users to configure, simulate and program the IRB460 and its gripper—all with little to no robot experience for the operator.

Murcio acknowledges that it is a combination of gripper, software and the ABB robot that makes the IRB460 palletizing system such a fast option for Bonduelle.

The IRB460 is the smallest member of the ABB palletizing family, yet possesses a reach of 2.4-meters with a carry-

ing capacity of up to 110-kilograms.

With four axis, it offers a compact design for an efficient use of floor space—1,007-mm x 720-mm.

“The four axis robot is optimized for palletizing, providing a shorter cycle time, lower weight of robot arm, higher payload, and low complexity,” opines Dangerfield, noting that ABB has nearly 30 years of experience in the palletizing sector.

For Bonduelle, having a robot arm capable of picking a payload of 110-kilograms was more than enough lifting power but, says Murcio, “it’s always good to have capacity even though we are currently using the IRB460 to palletize three cartons per pick-up for a total of 18-kilograms.”

Some of the other equipment used by Bonduelle at the Tecumseh facility includes:

• Safeline PowerPhase Pro metal detection systems manufactured by Mettler-Toledo;

• Nordson ProBlue glue application units utilizing hotmelt adhesive from Technical Adhesives;

• 3M manufactured 3M-Matic tape carton sealers;

• Eriez Magnetics vibratory shakers;

• Markem-Image S martDate X60 for high-resolution thermal transfer printing.

“Our current facility has had many major upgrades over the past several years,” explains Murcio. “We recently installed a new horizontal form/fill machine in 2010 to help us meet and exceed customer demands.

“As well, we are in the final stages of completing a new 100,000-squarefoot warehousing complex on the property,” sums up Murcio.

Nothing keeps your product fresher than MAP packaging produced on a Ross IN inline tray sealer.

n Produces MAP packages using preformed trays of almost any size or shape –easily packages your entire product line.

n Consistently produces packages with reliable, high-quality seals that extend shelf-life.

n Fast, highly flexible, and extremely easy to operate.

n Innovative tool/storage cart allows rapid, tool-less changeovers between tray sizes in 10 minutes or less.

n Stainless steel washdown construction and IP67 components.

n Compact footprint allows it to fit into tight areas.

n Test the Ross IN for yourself. Contact us to set up a demonstration at the Reiser Customer Center.

“Things have been moving along quite well for Bonduelle in general, and in Canada specifically.

“Thanks to the great work put in by Jantz Canada on our robotic palletizing unit, it has helped make our end-of-line operation that much more efficient.

“It has certainly helped us to get our product out the door faster to our customers.”

BY GEORGE GUIDONI, EDITOR

If the nation’s economic health is an accurate reflection of that nation’s eating habits, then Canadians still have a bit of work ahead of them to improve their daily diets in the years ahead for the sake of their own economic prosperity, according to current chairman of the venerable Canadian Produce Marketing Association (CPMA) in Ottawa.

The good news is that doing so is as easy as having an extra apple or so a day and adding a few extra veggies to their dinner plate, says Mike Furi, manager of procurement and pricing at The Grocery People Ltd. (TGP) subsidiary of the Saskatoon, Sask.-headquartered industrial products and services group Federated Co-operatives Limited.

“We’re eating more fruits and vegetables than Americans but less than the Europeans,” says Furi, noting that the country’s current per capita consumption of fruits and vegetables of 4.38 servings per day still falls considerably below the seven to 10 daily servings recommended by the Canada’s Food Guide nutritional guidelines formulated by Health Canada a few years ago.

“The economic burden of low fruit and vegetable consumption, estimated at more than $4 billion per year, is a result of us not only being unable to drive the economy forward as well as we could, but also due to the added health costs traced to bad dietary habits that manifest themselves in high numbers of overweight Canadians and epidemic obesity levels,” Furi states.

“This works out to about $127 for every Canadian each year, simply because we’re not as healthy as we could be or should be,” Furi told Canadian Packaging in a recent interview about various recent initiatives launched by the 91-year-old CPMA under his one-year tenure as the group’s chairman.

“If every Canadian was to increase their fruit and vegetable servings by one portion a day, it would add $3 billion to annual spending on fruits and vegetables in Canada, which in turn would create about 30,000 new jobs,” says Furi, citing recent research on the subject conducted by The Conference Board of Canada.

“But even beyond the jobs and tax revenues generated,” Furi expands, “what is really important is the relationship between the health of our industry, which is a major economic engine, and the health of the nation at large.”

With a few weather-related or seasonal exceptions for some commodities—such as the current shortage of strawberries during the El Nino year—supply of plentiful fruit and vegetable options is rarely a problem these days for Canadian consumers willing to do their part, Furi asserts.

“The world is so small today, that whatever consumer wants, we (suppliers) can get it: there are very few items today that you can’t get 52 weeks of the year,” he states.

“With air freight delivery and sophisticated container ships we can easily move product from places

Originally formed in 1925 in Montreal under the Eastern Canada Fruit and Vegetable Jobbers monicker, the Canadian Produce Marketing Association represents all the major growers, shippers, packers, importers, exporters, distributors, wholesalers, shippers, retailers and foodservice operators that are responsible for more than 90 per cent of all the fresh produce sales across Canada each year.

like South Africa and Australia to anywhere in Canada, under conditions that prevent the product from deteriorating.

“It’s quite amazing what we can do today with the technology we have, and it’s only going to get better,” says Furi, citing innovations such as climate-controlled, in-store shipping containers and igloo-style greenhouses that enable crop cultivation even in Canada’s extreme north.

While Furi acknowledges the general rise in prices for many imported produce commodities—largely tied to the low Canadian dollar— most fruits and vegetables retailing across Canada are hardly out of reach for most consumers.

“If you spend two dollars on fresh apples instead of a bag of potato chips, and then slice them up to feed to your children as a snack, it’s a win-win all around,” Furi reasons.

“It is healthier for them; it will fill them up better; it’s good for our farmers and our economy; and it’s a cost-saving opportunity for the consumer,” Furi states, pointing to lack of effective consumer education and communication as the biggest roadblocks to more widespread fresh produce consumption.

“Part of it is the general misunderstanding that it’s not that hard to eat healthy,” says Furi, citing CPMA’s recently-launched Half Your Plate marketing campaign, developed to encourage Canadian consumers to make fruits and vegetables count for half of their daily food intake.

Featuring popular celebrity chef Michael Smith as the program’s “culinary ambassador,” and formally endorsed by the Canadian Public Health

Association (CPHA), Canadian Cancer Society and the Heart & Stroke Foundation, the Half Your Plate initiative has been extensively communicated via various social media channels “to reach out to the millennial generation,” says Furi.

“Even though the program is less than a year old, it already has very strong support within the retail industry,” Furi relates, pointing out that many leading supermarket chains like Walmart, Sobey’s, Loblaw’s, Safeway and Longo’s prominently display the program’s distinct graphic logo in their weekly flyers. (See Above)

“Ultimately, we hope that the new [federal] government also adopts it as part of a new national food policy in the near future,” Furi says.

“It already has strong support among the [Health Canada] bureaucrats as a great additional way to educate the consumer about all the benefits of greater fruit and vegetable consumption.”

Furi says the recent demographic shifts in the Canadian population make-up allow for a unique opportunity for the campaign’s message to get traction with the general public, especially with the ever-

Smart describes the precision mandrel-forming technology from WestRock. Whether it’s our high performance Meta® Tray 8 – which outperforms any other tray in the produce market – our 2-piece Meta 8 telescoping case design or our high performance Meta RCT 8, the Meta System is versatile to meet the needs of your operation.

To learn more about our precision mandrel-forming technology, contact WestRock Automated Packaging Systems at 407.843.1300.

Of all the great food industry trade shows taking place in Canada every year, the annual CPMA Convention and Trade Show of the Canadian Produce Marketing Association (CPMA) truly stands out as a benchmark of excellence for shelf-life and longevity.

With the show’s 91st edition scheduled to kick off soon at the BMO Centre at Stampede Park exhibition centre in Calgary—April 12-14, 2016—this year’s show takes on an even bigger significance than usual, by virtue of bidding farewell to Calgary as one of the event’s regularly scheduled host cities.

vegetable sector.”

According to Furi, the show will provide an ideal opportunity for packaging manufacturers and suppliers to showcase their latest packaging innovations directly to key corporate decision-makers in the retail sector.

“There will be a lot of retailers looking at a lot of packages to find something unique to give them the extra edge they need in the marketplace,” he states.

growing variety of fresh produce available on the grocery shelves.

Says Furi: “For one thing, Canadians have started to travel around the world a lot more, discovering new products like mangoes and other commodities that they wish to enjoy at home, and our retailers have responded in kind by making them widely available.

“Alas, the show has simply outgrown the Calgary market,” CPMA chairman Mike Furi told Canadian Packaging in a recent interview explaining the group’s decision to begin rotating the annual fresh produce industry get-together between the larger municipal centers of Toronto, Montreal and Vancouver.

“It was a really bittersweet decision because Calgary is a really cool and beautiful city, offering many charms and things for visitors to do any time of the year,” says Furi, a frequent business traveler to Alberta’s largest city as manager of procurement and pricing for The Grocery People (TGS) business unit of Federated Cooperatives Limited in Saskatoon, Sask.

Organized under the theme Growing Strong, the three-day event is once again expected to draw over 3,000 fresh produce industry professionals from across Canada and 22 other countries, according to CPMA estimates to date.

“This keystone event will provide a unique forum for industry leaders to enhance their business opportunities in Canada through an exceptional combination of education and networking opportunities,” CPMA states.

“Our show regularly attracts key decision-makers and customers from the fresh produce sector, including industry executives, members of the fresh produce supply chain, and government representatives who are directly or indirectly involved in the Canadian fresh fruit and

“Even though the show is a completely Canadian event designed for the Canadian marketplace, it continually draws people from all over the world because of the massive and focused networking opportunities it provides.

“You have a much better opportunity to network with 3,000 people rather than 30,000 to 40,000 people,” he points out, noting the show’s revised Tuesday-toThursday schedule being introduced this year to facilitate more convenient business travel for the attendees and exhibitors alike.

“We have made several changes to the show that our membership has asked us to address,” Furi notes, “and as a result the Calgary show is already selling out very fast.

Featuring a Canadian celebrity entrepreneur, business leader and television personality Arlene Dickinson—of the Dragons’ Den television series fame—as a keynote speaker, along with an extensive conference and educational program, the Growing Strong theme is a fitting tribute to the quality of this year’s event, according to Furi.

“The theme Growing Stronger is all about exploring how we can all network and connect to make the whole industry stronger, and also to make our next generation and their children stronger by teaching them to consume more fruits and vegetables.”

For more information on attending the CPMA Annual Trade Show & Convention in Calgary, April 12-14, 2016, go to: www.convention.cpma.ca

mk North America is a leading worldwide manufacturer of aluminum conveyors, workpiece pallet conveyors, stainless steel conveyors, and extruded aluminum framing. With over 25 years of diverse industrial know-how, superb quality, constant innovation and application engineering excellence, mk North America, Inc. offers you a perfect solution for any application.

“The other thing is the big demographic shift unfolding in Canada, whereby we expect about a million new Canadians to arrive to our country by 2020,” he continues. “A thing like mango is a staple for them, not an exotic fruit, and they expect to find it at their grocers at any time of the year.

“As a result, what used to be seasonal is now a conventional listing for most of our major retailers,” Furi points out.

“We are seeing bigger produce sections at many supermarkets because we’re eating more produce and a bigger variety of it.

“That variety is expanding because that’s what the consumers want,” Furi notes, “but as our accessibility to more product variety has changed, we need to see that Canadian consumers are willing to change their eating patterns along with it, so that they can get the full health benefits of that change.”

To facilitate that change, Furi says the industry is looking forward to the impact of pending amendments to the current Safe Food for Canadians Act regulations, notably in respect to allowing produce distributors greater flexibility to making health claims for some of their commodities.

Furi explains: “The government currently does not allow us to advertise the presumed benefits and ‘health claims’ for bulk format produce unless it is accompanied by a whole lot of scientific documentation.

“The new changes, which we are expecting to be implemented in coming months, would in fact allow us, for example, to make a generic comment that oranges are healthy for you as a good source of Vitamin C, without having to go through all that extensive documentation and validation process.

“It may seem like a little thing, but it can make a big difference in the marketing of our products,” says Furi, crediting CPMA for its proactive lobbying efforts in bringing such change forward.

“The CPMA has been instrumental in getting this change,” Furi says, praising the association, comprising over 800 membercompanies nationwide, for its highly effective advocacy work on the industry’s behalf in general.

Says Furi: “The CPMA is really unique in terms of representing Canada’s entire produce food chain literally from field to fork, including retailers, growers, distributors, importers, logistics, packaging suppliers and everyone else in between.

“This enables CPMA to address issues on an industry-wide level, rather than a specific group level, which in turn helps us to make the politicians understand the

40 years with collaborative service, speed to market, food safety confidence and flexible packaging that stands out on the shelf.

• Packaging PrePress & Design • Flexographic Printing • Rollstock

• Lamination • Converting: Bags & Pouches

• Package Engineering & Development • Industry-leading Food Safety Processes, and much more!

Product packaging is playing an increasingly important role in the marketing of an ever-growing variety of fresh fruits and vegetables retailed across Canada, with consumer convenience, extended product shelf-life, carbon-footprint reduction, and the health-and-wellness trend expected to drive greater per-capita consumption.

entire Canadian marketplace better,” he explains.

“Our advocacy efforts have changed in the last five years insofar that we are now more focused on making more contact directly with the politicians, which has enabled us to be very successful in getting our message across with maximum impact.

“Moreover, the CPMA provides a whole range of valuable resources, including many educational tools and networking opportunities through the work of multiple committees made up of people from all the different links of the food chain.”

As Furi points out, “Our membership retention rate is well above 90 per cent, which is a pretty good indicator of the value that CPMA membership offers to our members.”

According to Furi, CPMA membership offers tremendous networking opportunities to packaging suppliers of all types looking to serve the multibillion-dollar produce sector.

“The packaging function is extremely important in today’s marketplace that is all about convenience,” he notes.

“The more convenient we can make it for consumers, the more opportunity there is for them to purchase it, the healthier they can get, and the more prosperous the industry can become.

Says Furi: “Today’s packaging innovations make it possible for consumers to just pick up a bag of precut salad and be on their way, or to ship produce in breathable bags that extend product shelf-life by letting good air in and bad air out, which greatly reduces product spoilage and food waste.

“We are also starting to see more top-sealing in Canada, whereby bagged produce is topped with a sealed layer of film instead of rigid plastic lidding,” Furi relates, “which notably reduces the environmental footprint throughout the supply chain.

“They have had great success with this packaging in Europe,” he points out, “and this is going to become a huge thing in the Canadian produce sector in coming years.”

While Furi acknowledges that Canada will continue to rely on imports for a significant portion of the fresh fruits and vegetables consumed in this country for the foreseeable future, “The products