LABELS 360º

The Power of Sustainable Packaging.

Today’s consumers are more environmentally conscious than ever — that’s why we’re committed to innovative solutions for labels that are good for the environment and the bottom line. At Sun Chemical, helping you meet your sustainability goals just comes naturally.

Request your copy of Sun Chemical’s Guide to Sustainable Packaging at sunchemical.com/poweroflabelpackaging.

working for you.

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson sjamieson@annexbusinessmedia.com

Tel: 416-442-5600

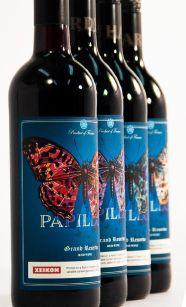

PANTHER’S PROWESS

New UV inkjet presses take Xeikon’s label portfolio

to the the next level of digital printing excellence

Digital printing press technology manufacturer Xeikon (www.xeikon.com)has unveiled the second-generation of its Panther UV inkjet technology with the launch of two new label presses to help label producers digitalize their print manufacturing processes.

As the company’s wide portfolio evolves in line with advances in technology, the new Xeikon PX3300 and Xeikon PX2200 printers feature breakthrough technological advancements in applications and data management, according to Xeikon, aa division of Luxembourg-headquartered global printing inks and consumables manufacturer Flint Group. (www.flintgrp.com)

“We are defining a pathway to full digitization of print production and manufacturing,” says Filip Weymans, vice-president of marketing at Xeikon America Inc. in Itaska, Ill.

“Responsiveness has become key for any business,” Weymans says, “and it can only be achieved effectively by digitalizing all print manufacturing processes—not just printing.

“The foundation for a digitalized environment lies with collecting data in a digital manner.

Says Weymans: “The Cloud-connected, machine-machine and man-machine interfaces of our UV inkjet presses will enable label printers to take operational excellence to the highest levels.

“They offer great potential to maximize overall equipment effectiveness (OEE), increase sustainability and make an operation robust for any future challenge,” he adds.

“The data volume, captured in real time, creates the information that is required by label converters to make fact-based decisions, while is the interfacing connections in production between machines and operators help to transfer job information between various production processes, or drawing the attention of operators when it is really required.”

As Weymans explains, the new Panther 2.0 series presses offers new opportunities for label

printers to expand their applications portfolio with Xeikon’s new robust substrate handles technology featuring a new splice table, advanced web detection capability and cooled roller at the curing section.

This makes it possible to print high-quality labels on a wider choice of substrates, including clear-on-clear face-stock, which requires a high-quality opaque white to make the design stand out.

Both presses can be configured with a fifth print station for white ink and can print on a wide range of self-adhesive media in addition to clear-on-clear, including coated paper, vinyl, PP, PE, PET and metallized stock.

The Xeikon PX2200 and PX3300 presses leverage the advantages of dedicated PantherCure UV inks, which meet the demands from brand owners for high-gloss, durable labels with high scuff resistance.

The Panther DuraCure UV technology produces high-gloss effects and stands out across the widest color gamut, while delivering exceptional longterm durability for multiple applications such as industrial, chemical and household labels, as well as high-end labels for the premium beer, spirit, beverage and health-and-beauty market sectors.

“Print is becoming more customized and valuable,” says Xeikon’s director of product management Jeroen Van Bauwel, “and with VariOne, Xeikon is taking a significant leap forward in its research and development and now offers completely new horizons for differentiation.”

“With VariOne it is possible to create thousands of unique and individual clips from a base design,” says Van Bauwel , “with limitless possibilities for producing unique images on both our dry toner and inkjet presses.

With Xeikon’s VariOne, personalized image creation can be fully automated within the printing process, with its robust software functionality achieves random selections from zero to millions.

This variable data application offers endless uses and endless variations, as VariOne can immediately process, format and print unique creative designs featuring variable patterns with random elements and the widest gamut of color combinations—enabling creation of unique designs on-the-fly and in minutes in a broad variety individual patterns.

According to Xeikon, “This new innovation is a breakthrough and a complete game changer.”

Driven by the powerful Xeikon X-800 DFE (digital front end), the new Panther UV inkjet presses offer superior and consistent print quality at highest industry speed levels, while facilitating seamless Cloud connectivity to provides access to both machine data and job data, such as ink consumption, printing time, etc.

The latest generation of Xeikon’s X-800 enables unique applications on the Panther series, such as haptic printing. This tactile layer of white to deliver the sought-after embellishing effect inline with full color printing for designing labels with enhanced tactility and luxury feel.

According to Xeikon, label printers will also benefit from the powerful variabilization capabilities— from black-and-white and color numbering and to the most complex full color variable data application through Xeikon’s new VariOne data generation tool.

This integrated software innovation can immediately generate and print unique creative designs, based on an image or on vector graphics, in endless complex patterns— achieving the highest levels of variable imagery possible today.

With the addition of two new presses, the Panther 2.0 series now comprises seven different UV inkjet presses in various configurations up to eight print stations.

With high-performance levels and low-energy consumption, Xeikon’s Panther 2.0 series of presses are equipped with Cloud connectivity and next-generation HIMI (human-machine interface) to helps operators monitor the workflow to maximize productivity—by avoiding downtime and bottlenecks—and make changes on-the-fly while maintaining full color control.

The new Xeikon interfaces also allow presses to communicate with other equipment, such as Xeikon’s finishing and embellishment units, Weymans points out.

“Xeikon’s UV inkjet presses can address any request from label converters,” says Weymans.

“This can mean replacing an older UV flexo press to be more effective, being cost competitive within the high-end to medium-run label market, expanding the digital application space of existing liquid toner businesses, or providing entry-level investments that allow any printing company to embark into the digital label space.”

CHANGING LABELS

Labeling industry expert explains how product labels are becoming more sustainable and flexible

In light of increasing regulatory demands globally, labeling today is a highly intricate process that is even more vital to products than ever before.

Leading food and beverage industry players are particularly concerned about the costs of materials today, and are hence very keen to optimize their investment while increasing brand recognition. With 45 years of experience in the labeling industry and over 5,000 machines installed worldwide, French packaging machine-builder Sidel (www.sidel.com) is one of the leading players in the market—providing a vast pool of technical knowledge and expertise to meet all the labeling needs of today’s rapidly changing global consumer marketplace.

Artem Krukov, director of business development at Sidel, a division of global engineering/industrial group Tetra Laval (www.tetralaval. com), talks about new labeling and how a greater focus on sustainability and flexibility is changing the way labels are created and applied.

The highly versatile Sidel EvoDECO Multi labeling system offers several labeling applications in one multi-technology machine.

What are the most important challenges in labeling for the beverage industry?

Similar to the manufacturing industry as a whole, beverage producers are searching for greater efficiency and lower TCO (total cost of ownership) for their labeling equipment. There is also a significant focus on sustainability. The label is one of the main interfaces for communication with the consumer, and companies are changing their labels constantly to respond to fastchanging consumer preferences.

How is labeling becoming more sustainable?

It is our goal to help customers cut costs on everything from material consumption to maintenance costs. By reducing label thicknesses and surface areas, customers can cut costs and improve the carbon footprint of label production and the labeling process. Label producers are also working to ensure that labels do not affect PET recycling.

Another important trend is the conversion of labels from shrinksleeves to BOPP labels—plastic rollfed labels for wraparound applications.

This is a very important step in bottle labeling, since containers labeled with shrinksleeves are difficult to recycle.

Hence, the shift to BOPP labels not only provides recycling capabilities, but also helps companies reduce their carbon footprint even further.

What do you mean by that?

Historically, labels have caused issues with PET recycling to food-grade standard because the label or the glue has affected the recycling process. Today there are several initiatives that can minimize this impact, namely label surface/size reduction, wash-off glue development, and glue application minimization.

All drinks manufacturers focus a lot on glue characteristics.What is the reason for this?

First of all, customers around the world are eager to reduce the amount of glue for three reasons: more glue equals higher costs; less glue usage positively impacts

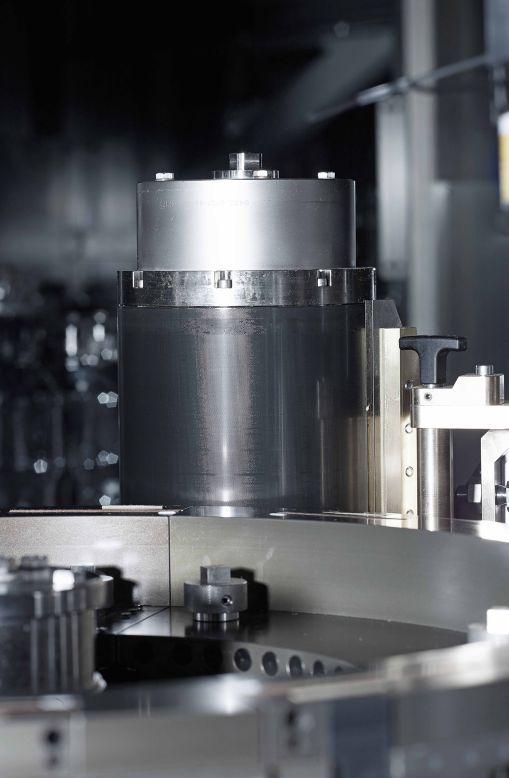

Artem Krukov, Director, Labeling Business Development, Sidel Close-up of inline labeling application on a bottling line.

A vertical melter incorporated into the Sidel EvoDECO Multi lableing system.

machine cleanliness, which leads to higher efficiency; and glue affects the recycling process.

Most importantly, customers want to address all of these factors without sacrificing product quality.

There is also a second trend playing out in some countries where customers want to increase glue distribution to make label application more solid and stable.

Sidel has developed a unique solution that fulfils both requirements by leveraging the BOPP solution—namely by developing a laser-engraved glue roller (a standard scope for the roll-fed machine portfolio), to ensure better control of glue distribution and repeatability. As a result, the label can still maintain its optimal quality even with less glue. At the same time, we can also manage higher glue quantity by distributing more efficiently over the entire glue strip surface.

How does Sidel integrate sustainable solutions in labeling?

Sustainability is always at the heart of Sidel, where we make every effort to minimize the impact on the environment.

For example, our renowned Sidel EvoDECO labeling solutions minimize electricity and glue consumption via the new melter and glue distribution control. With an integrated glue tank in the roll-fed labeler, a patented vertical melter and heating control, glue is melted on demand and always circulated at a precise temperature and in smaller quantities—improving the quality of label application.

This enables reduced glue consumption and prevents glue degradation, glue filaments and glue splashing for better overall quality and improved sustainability.

The solution requires 40-percent less electricity consumption

and it also needs no gears and transmissions—and therefore no lubrication.

How has the move towards lighter bottles affected labeling?

Packaging design has a critical impact on the efficiency of the entire supply chain. Over the past 30 years, we have more than halved the weight of a 1.5-liter PET bottle, while increasing output speeds by 2.5 times, with considerable savings in terms of raw materials and gains from a productivity perspective.

Therefore, it is a story about “rightweighting”—making sure that the package is minimized, while still maintaining its technical performance and high consumer appeal.

Some manufacturers use nitrogen to add resistance and stability to the bottle. Sidel has designed its labelers so that they can manage the extra demands of bottle lightweighting, with or even without nitrogen.

The most advanced solution for handling lightweight bottles is the Super Combi machine, where the labeler is placed in between the blower and the filler as part of an all-in-one solution. With this setting, the labels are applied on the empty bottles handled by the neck—reducing the risk of scratching and improving overall bottle quality.

Another crucial factor in labeling is flexibility, and this relates to product personalization. What is it, and how does it affect labels?

Labels are key components of any brand marketing mix, allowing manufacturers to differentiate their products and give end consumers the information they need and increasingly expect.

A laser-engraved glue roller enables precise label application and placement.

The growing variety of beverage types and bottle formats has made labeling increasingly challenging because, more than ever, flexibility has become a valuable benefit to beverage producers. Their top priorities today are focused on faster product and format changeovers, simple operations, and optimized processes that use the same equipment for different label types, while still ensuring consistent uptime.

Product personalization is about being able to produce smaller batches of products with their own labeling in a very short time. Hence, the main challenges are the short time-frame for creating customized graphics and labels.

Personalizing the label is a difficult process, as there are so many different elements involved. The change usually starts with marketing and then has to go through design and production phases and, eventually, out for storage and transport. In fact, the standard process for a label change can easily take over four months.

There is no doubt that the rise of online shopping has brought up a host of new challenges for supplying consistent, unique and durable packaging and label solutions, but it has also opened up new opportunities to offer personalized packaging solutions for protecting the product during shipping by rightsizing the packaging and making sure that it provides a seamless brand experience for consumers.

This is the reason why we also provide consultancy for customers regarding packaging design—not just bottle design but also labels, secondary packaging, etc.

Sidel’s packaging experts are ready to support our customers in figuring out the best option that fits the company’s brand identity and responds best to consumer preference.

“Personalizing the label is a difficult process, as there are so many different elements involved.”

standardized carousel that can be equipped with up to four different labeling technologies, including hot-melt, rollfed, self-adhesive and cold-glue. Moreover, switching between various labeling modules is quick and easy thanks to ‘plug-and-play’ connections, offering producers the freedom of labeling choice and total flexibility. When set up as g part of Sidel’s Super Combi settings, the labeler can run at up to 90,000 bottles per hour (bph).

What are your observations on the impact of the pandemic on the labeling industry?

How does Sidel react and help customers face this challenge?

We fully understand the challenge, and that is why we have flexibility in mind. With Sidel’s EvoDECO labeling solutions, manufacturers can deliver different stock keeping units (SKUs).

They might either include several labeling applications in one multi-technology machine, or as a single labeling application through dedicated equipment for optimized uptime, reduced footprint and low total cost of ownership (TCO).

So manufacturers can use one machine for different labels?

Exactly. It gives businesses the flexibility they need and allows them to produce most product types on a single machine. Thanks to the modular design and a variety of technologies, they allow companies to adapt multiple application methods in one compact machine.

What is the most up-to-date Sidel labeling solution with high flexibility?

The most flexible labeling solution to date from Sidel, the EvoDECO Multi, brings next-level modularity into labeling. It offers a

During the pandemic, many people reduced their daily spending due to economic reasons. This has resulted in stagnating sales for certain premium products in the beverage sector, and manufacturers have been forced to reduce packaging costs. For instance, the second-tier beverage producers have shown significant interest in converting from shrinksleeves to BOPP labels to save cost. That is the reason why low-cost beverages have been popping up recently in the market.

Lastly, would you share with us what milestones Sidel has achieved and Sidel’s next step in labeling?

Sidel has been working continuously since 1976 to ensure and promote the image of various leading global brands, with our dedicated labeling plant in Mantua, Italy, not only manufacturing labeling equipment, but also providing outstanding services to support its customers worldwide. We are proud of our latest milestone— installing the 5,000th labeler for Ting Hsin International Group in China this year—as we aim to be the leading end-to-end partner in sustainable labeling for our existing and future customers.

THE CLASS OF GLASS

New decorating technology for beverage containers promises a more sustainable future with virtually zero labeling waste

ACTEGA , a prominent German manufacturer of specialty coatings, inks, adhesives and sealing compounds for the print and packaging industry has formally launched it breakthrough pioneering Signite decorating solution, designed to significantly reduce and, one day, eliminate waste in label production for beverage containers.

Depending on the decoration design, the patented new technology can currently reduce label waste by over 50 per cent compared to a similar footprint pressure sensitive label by elimination the label matrix, reducing the decoration thickness to about a third of that of a typical clear pressure-sensitive label, and eliminating label media plastic in nonprint areas.

Furthermore, with Signite decorations comprising substantially less material mass than traditional pressure-sensitive labeling and shrink sleeves, this novel alternative is much more accommodating to current recycling processes and the expanding brand-led container reuse programs beginning to dominate single-use glass packaging throughout the world.

The ground-breaking Signite decorations represent a true alternative to “no-label look” labels, bringing the look and feel of direct-to-container screen or digital printing with the efficiency of pressure-sensitive labeling.

Today, label decorations are typically produced using slightly reconfigured narrow-web flexo or hybrid digital printing processes running at standard narrow-web printing speeds.

Small to mid-sized brands have the potential to utilize these new or modified variations of their printing assets immediately—allowing for rela-

tively seamless scaling of their decoration production as the Signite technology continues to commercialize.

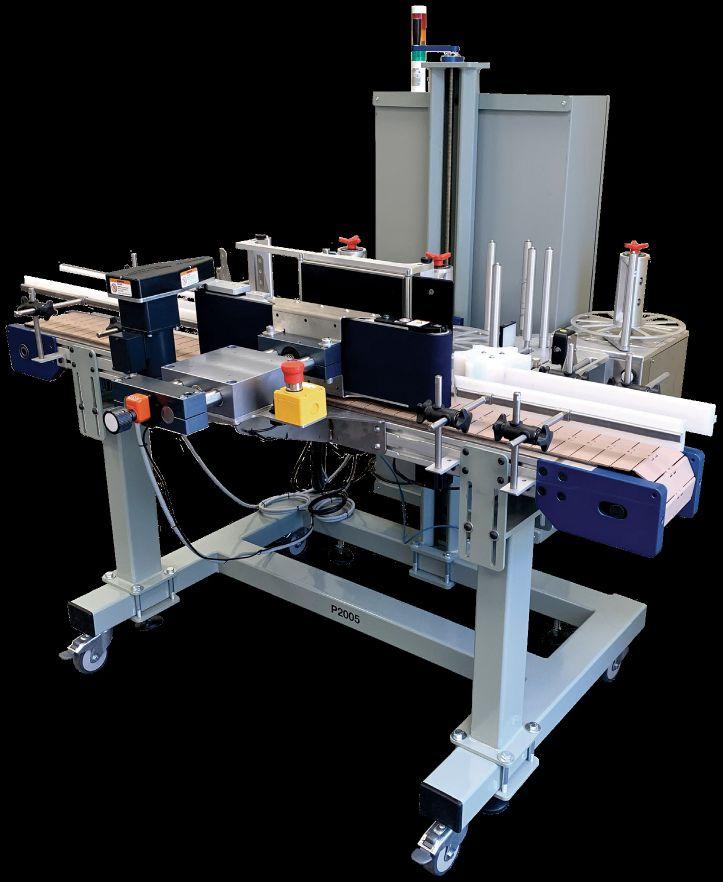

Transfer of the Signite decorations to containers requires designed-for-purpose variations of pressure-sensitive labeling equipment.

The first Signite inline applicators launched into the market address rigid cylindrical containers running at lower throughput speeds.

Subsequent system designs, currently in different stages of prototype development, will address aluminum and asymmetrical containers along with thin-walled container types requiring inflation for decoration transfer.

According to ACTEGA, high-speed Signite applicator machines and corresponding decoration media are planned as an inherent part of the technology roadmap and are anticipated to move into prototyping in 2022.

“Brands are taking a leadership position on Depending

sustainable packaging solutions, with ambitious waste reduction goals and a drive to increase the efficiency and scale of container recyclability,” explains Anthony Carignano, technical director of marketing for the Signite brand at ACTEGA (www.actega.com)

“At the same time, these companies are seeking ways to unlock new high-quality label aesthetics and tactile experiences for premium products.

“Signite offers these brands the best possible chance to meet all of these objectives,” Carignano states.

“The solution is truly game-changing with no other technology delivering plastic waste reduction on this scale.

“Plus, as the solution advances and becomes compatible with other production processes, such as digital inkjet, the impact on the industry and ultimately, the environment, will only become more significant.”

According to ACTEGA, operating as a division of global specialty chemicals group ALTANA, the Signite technology promises to be a pioneering solution for numerous market sectors, and that the company aims to develop new applicators to the high-volume production volumes required by high-profile brands in the near future.

For now, however, Signite offers an ideal solution for small-volume contract decorators and specialty brandowners looking for a substantial differentiator that strengthens their competitive edge.

“In this first phase of the technology’s launch, we have a strong and clear focus on advancing this solution for the glass packaging sector,” Carignano explains.

“The end customers initially benefiting from this solution will therefore include producers of craft distilled spirits, micro- or mid-sized winery products, specialty food and non-alcoholic beverages, natural and nutraceutical pharma products, and home glassware, such as candles,”Carignano continues.

“With several beta customers already in operation working with glass containers, and additional versions of the technology targeted for rigid PET containers and aluminum beverage cans anticipated over the next few months, we expect the demand for this solution to accelerate its success and rollout across the industry,” Carignano states.

Adds ACTEGA division president Thorsten Kröller: “This is an exciting time for ACTEGA and the industry in general.

“We are developing and bringing to market a solution that helps brand-owners achieve their sustainability targets as well as achieve unique aesthetics for premium labeling,” Kröller states.

“Although it is still in its infancy, Signite represents a huge milestone for the industry and on ACTEGA’s sustainability roadmap.”

PLENTY ON THEIR PLATE

A revolutionary plate-making system enables label converter to achieve superior print quality and strong market share growth

Ayear after the KODAK FLEXCEL NX Ultra Solution went into production at Dion Label

Printing , John Dion has a very positive verdict on the solvent- and VOC-free flexo plate-making solution.

“We’re wildly satisfied!”, says the co-president of the Westfield, Mass.-based producer of custom high-quality labels and packaging.

“We expected good things of the system, and it’s more than lived up its billing as a game-changer.”

Soon after John’s father, John Dion Sr, started the business in the cellar of the family home in 1969, Dion Label quickly acquired a reputation for printing label jobs that were both complex and had to get to market fast.

That philosophy hasn’t changed since, as general manager Randy

Dion Label Printing general manager Randy Duhaime (left) posing for a picture alongside company co-president John Dion in front of the office entrance in Westfield, Mass.

Duhaime, one of the senior management team along with John and brother Dave Dion, explains.

“Labels keep getting more and more complex—it’s almost like designers are trying to find colors we won’t be able to reproduce,” Duhaime states.

“But we always step up, because of our pride in producing the highest quality.”

High-end pressure-sensitive labels account for around 80 per cent of Dion’s design-to-dispatch production. The company also produces extended content labels for a wide variety of end-user applications, with over-the-counter (OTC) pharmaceuticals currently showing the fastest growth.

Other markets include food and beverage, personal care, household products, medical and specialty printing, with total products split roughly 50/50 between flexo (waterbased & UV) and digital.

Supplied by Rochester, N.Y.-headquartered Miraclon Corporation ( www.miraclon.com ), The FLEXCEL NX Ultra Solution is a solvent-free, VOC-free, water-based processing solution that allows printers to create a pressready plate in less than an hour.

Enabled by patented KODAK Ultra Clean Technology developed by the Miraclon team, the FLEXCEL NX Ultra Solution is the first aqueous solution that provides consistent, high-performing plates in a high-volume, low-maintenance environment.

The story behind the arrival of the FLEXCEL NX Ultra Solution to Dion Label Printing in June of 2020 is one of

patience and a degree of experimentation.

Says John Dion: “We’d been tracking the FLEXCEL NX technology for some time and had no doubts about the production and quality benefits, but we believed that solvent-free plate-making is the way forward and decided to wait for that solution.”

The decision was helped by the results of trials of other alternatives, he continues.

“We had a small solvent system, but it had limitations in terms of the fineness of screens and the consistency of screening from one end of the plate to another, particularly in highlight detail,” Dion relates. “So as jobs became more complex and difficult, we had to break some out and figure what we could do.

“We also tried a thermal solution, but that had issues that we couldn’t overcome—specifically, the way the plates swelled when the UV inks warmed up—so we needed extra plates on long-run jobs.

“Plates also deteriorated between runs, which meant we had to make new sets for reorders,” Dion says, “and an earlier experiment with water-based processing showed it was inadequate from a quality standpoint.”

Dion’s prepress manager Brent Berthiaume, the man tasked with getting the most out of the FLEXCEL NX Ultra Solution , vividly describes how the technology has impacted the company’s production.

“With thermal, we were stuck using 133- to 150-lpi (lines per inch) screens, largely due to the dot gain,” he says.

“If we went to 175-lpi on a long run we were into a second

The solvent-free FLEXCEL NX Ultra Solution developed by Miraclon has enabled Dion Label Printing to improve its production capabilities and maintain consistently high print quality.

set of plates for almost every job.

“With FLEXCEL NX Ultra we’ve yet to make a single plate under 175-lpi, and that includes running several 80,000-foot jobs on a single set of plates,” Berthiaume relates.

“That’s the Number One benefit—holding consistency throughout the run, while producing high-quality linework.

“It’s an exponential improvement.”

According to Mraclon, the KODAK FLEXCEL NX Ultra Solution pairs the proven FLEXCEL NX System for world-class imaging with the FLEXCEL NX Ultra Processing System and FLEXCEL NX Ultra Plate in a a complete end-toend plate-making solution that combines exposure, washout, drying and finishing in an easy-to-use, robust system with automated cleaning cycles.

For their part, the FLEXCEL NX Ultra Plates utilize the proven flat-top dot structure, KODAK NX Advantage technology and patented Advanced Edge Definition to achieve an unprecedented level of ink transfer control during printing.

As Dion attests: “Being able to maintain brand-compliant colors across multiple platforms is also a major benefit.

“When you compare conventional flexo with digital output you can usually see the difference, but now the colors hit the targets whatever the process,” Dion explains.

“We have a parallel relationship between the two platforms, so if workload means we have to switch a job from one process to another we’re confident the results will be fine.”

Commenting on the KODAK NX Advantage

Patterning technology, John Dion cites a “Miracle ... in the way it solves the flexo conundrum of how to achieve strong color using pigments that are not as intense—reds and greens, for example.”

Says Dion: “Normally you have to lay down a thicker ink film, which means the quality deteriorates, especially in screens, so we’d have to break out screens from solids to achieve the right results.

“That’s no longer the case, because NX Advantage Patterning allows greater efficiency by enabling improved ink laydown and transfer to the substrate at a higher concentration, while still combining screens,” Dion explains.

“We’re also able to use smaller-volume aniloxes on a larger number of jobs and achieve our objectives—controlling dot gain, maintaining color consistency throughout the run, and so on,”

Dion concludes. “We can also increase the white opacity with one hit, whereas it previously took two.”

“I find this quite remarkable—my wildest dream, looking back 20 years, has been to be able to do what we’re doing today.”

Dion Label Priniting’s prepress manager Brent Berthiaume is full of praise for the FLEXCEL NX Ultra system’s ability to maintain consistent high-quality printing throughout the entire production run.

A close-up view of the NX Ultra Plate made with Milacron’s KODAK FLEXCEL NX Ultra Solution plate-making system.

CENTER OF ATTENTION

New global hub for labeling innovation aiming to foster diverse talents to support Industry 4.0 future

Leading global label manufacturer All4Labels, headquartered in Hamburg, Germany, has commenced operations of the company’s new Center of Excellence (CoE) in Salerno, just southeast of Naples, Italy, focused on fostering new ideas and knowledge among talents, customers, universities and start-ups to develop sustainable products and technologies for the new Industry 4.0 manufacturing era.

The Salerno CoE aims to undertake new R&D investments over the next five years, totalling approximately $4 million per year, focusing on AI (artificial intelligence), IoT (Internet of Things) and biomimetics technologies to steer co-development for new interactive and functional packaging solutions.

According to All4Labels (www.all4labels.com), the CoE will operate as “An open ecosystem, designed to promote and support innovation both inside and outside of All4Labels, strengthening the company’s leadership in the market and seeking to become a model of growth for all companies.”

The aim is also to achieve a higher level of digitization, All4Labels

relates, leading to the creation of new business models that have the potential to inspire labeling and packaging sectors worldwide.

Reflecting the culture and values of All4Labels, the CoE will also focus on personal development and growth–empowering the talents of its employees, including the high-level scientific and technical team mandated to develop patents and ensure the protection of intellectual property.

“At All4Labels, mentoring and developing talents is and has al-

ways been one of our primary goals, enabling people to make a difference and be part of our DNA for success,” says chief operating officer said Günther Weymans.

“With the CoE we want to equip and stimulate specialists to conceptualize, create and prototype the best and most sustainable packaging solutions, keeping in mind the needs of the consumer of the future,” Weymans states.

“We pursue excellence in everything we do, and the CoE is further evidence for that,” Weymans adds.

“All4Labels wants to succeed in being a pioneer in the industry, helping to boost innovation within Industry 4.0.”

Consistent with the All4Labels philosophy, every single action at CoE will also be guided by respect for sustainability principles— one of the most important pillars of the company´s operating model.

As such, All4Labels says it will continue to rethinks labeling and packaging to spur further innovations in the context of the Circular Economy model, which includes considering different regional regulations on recycling, promoting dialogue, and sharing ideas with the entire value chain, according to the company.

PRETTY IN PINK

Beauty products brand marks company milestone with hot pink packaging and labeling upgrade

Corporate anniversaries are a great opportunity for companies to update their product packaging and labeling to make it more eye-catching for consumers, and leading skin-care and cosmetic products brand Soap & Glory has certainly used the product line’s 15th anniversary earlier this year with dazzling creative aplomb.

To mark the occasion, brand-owner No7 Beauty Company partnered up with color management solutions provider X-Rite, Inc. (www.xrite.com) of Grand Rapids, Mich., to create a new bespoke pink color that would be instantly recognizable across its packaging supply chain, while significantly reducing color variance across print suppliers and packaging and labeling materials.

In implementing X-Rite’s i PantoneLIVE and ColorCert Suite digital color management solutions across its packaging supply chain, the brand established one clearly specified digital target and a marching print quality control program for suppliers to follow.

“Moving from physical color references and visual evaluation to a digital color program has dramatically improved Soap & Glory’s printed packaging color consistency,” says Craig Davids, global artwork and print manager at No7 Beauty Company.

“Instead of spending time and money relating to the subjective acceptance or rejection of printed colors from Soap & Glory printers from around the world, we can now monitor print quality across multiple sites through X-Rite and Pantone’s connected software solutions.

“Giving printers ownership over print quality means they don’t ship if color isn’t right, preserving our brand identity on the shelf,” Davids says. “It’s a win-win for everyone.”

The Soap & Glory’s new distinctive pink color draws customers to the brand’s indulgent bathing, skin-care, cosmetics and gift products that previously used a physical reference to communicate color expectations and get quick alignment from print suppliers.

Initially based on Pantone 701C, this Pantone color reference helped simplify brand color communication for print suppliers at first, but over time Soap & Glory noticed a lack of color consistency across printed labeling, packaging, point-of-sale, merchandising and marketing materials.

Working with the X-Rite and Pantone teams, No7 Beauty Company selected a new, bespoke pink brand color for Soap & Glory as part of a larger comprehensive brand visual identity (BVI) redesign project.

The new brand standard was digitally defined by X-Rite and stored in the PantoneLIVE Cloud for easy access by everyone in the design, artwork creation, and packaging production workflow.

The digital PantoneLIVE standard enables the entire packaging supply chain to understand the achievability of the Soap &

Glory pink on 30 different print process and substrate variables, enabling printers to also access spectral data for ink formulation and print quality checks.

With the X-Rite ColorCert Scorecard Server installed to evaluate and control printed packaging colors, print suppliers can measure production into ColorCert and submit a job score into the No7 Beauty Company Scorecard server.

This in turn empowers No7 Beauty Company to view supplier performance and printers to monitor their own print quality.

“By using X-Rite digital color standards and workflow solutions, No7 Beauty Company can ensure brand consistency across multiple products, packaging materials and suppliers,” says Cindy Cooperman, X-Rite’s vice-president of brand global strategic accounts. “Having access to objective color results enables brand manager to work directly with print suppliers to identify areas for improved efficiencies and cost-savings.”

The new IntelliTrax2 Pro and eXact Auto-Scan Pro scanning systems from X-Rite feature seamless connectivity to ColorCert Scorecard Server, which saves the operator time by not having to switch between software.