The SF-200 benefits include:

• Up to 240 Bottles Per Minute

• Reduced Parameter Settings

• Programmable Recipes

• 21 CFR Part 11 Compliance

• Repeatable Quick Change Over

• Speed

• Accuracy

• Versatility

The Bambino benefits include:

• Designed to Fill, Plug, Cap, & Label

• Speeds up to 40 BPM**

• Recipe Driven Technology

• Fast & Easy Change-Over

• Compact Monoblock Design

• FDA Compliant

The Patriot benefits include:

• Designed to Fill, Plug, Cap & Label

• Speeds up to 60 BPM**

• Recipe Driven Technology

• Fast & Easy Change Over

• Compact Monoblock Design

• FDA Compliant

VOLUME 69, NO. 10

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198

SDean@canadianpackaging.com

ACCOUNT MANAGER

Adnan Shaw • (416) 510-5117 AShah@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227

GGuidoni@canadianpackaging.com

FEATURES EDITOR

Andrew Joseph • (416) 510-5228

AJoseph@canadianpackaging.com

ART DIRECTOR

Katerina Maevska • (905) 713-4389 kmaevska@annexweb.com

PRODUCTION MANAGER

Barb Vowles • (416) 510-5103 BVowles@annexbizmedia.com

CIRCULATION MANAGER

Anita Madden • (416) 442-5600 x3596 AMadden@annexbizmedia.com

VICE PRESIDENT Tim Dimopoulos • tdimopoulos@annexbizmedia.com

PRESIDENT & CEO Mike Fredericks

ANNEX BUSINESS MEDIA

80 Valleybrook Drive, North York, ON, M3B 2S9; Tel: (416) 510-5198; Fax (416) 510-5140.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

e-mail: rthava@annexbizmedia.com

Tel: (416) 442-5600 ext 3555 Fax: (416) 510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE): Canada $74.50 per year, USA $130.95 US per year, Outside Canada

$149.00 US per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

privacy@annexbizmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2016 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content

If we really are what we eat and drink, then Canadian adults are still falling short of setting a good example for future generations with their excessive caloric intake and sugar consumption, according to the latest empirical research and evidence.

For all the talk about portion control and healthy food-and-beverage options, Canadians by and large seem reluctant to forego their traditional sugar-laced beverages for the low-calorie versions of the same brand of LRB (liquid refreshment beverages) offered by many leading beverage producers.

To help change their minds, the Canadian Beverage Association (CBA) launched the wellintended Balance Calories Initiative just over a year ago, with the goal of reducing the daily per capita LRB calories consumed by Canadians by 20 per cent between 2015 and 2025.

While this may not seem like reaching for the stars, getting them to moderate their average daily intake of LRB calories from 142.5 down to 114 over 10 years is not as simple as it would be in a perfect world.

According to a new report prepared for CBA by The Conference Board of Canada, Canadian consumers have actually been able to lower the caloric intake from their LRBs by more than 20 per cent between 2003 and 2014, primarily by having more low-calorie beverage options being made available to them by leading beverage brand-owners and some savvy upstarts.

“That declining LRB consumption was initially driven by the introduction of lower-calorie options, which grew their market share by 15 percentage points between 1999 and 2009,” the report acknowledges.

“Since then, the market share for low-calorie LRBs has continued to grow, but at a reduced rate,” the study points out. “So although average calorie consumption per liter in 2014 was 28 per cent lower than in 1993, about three-quarters of this improvement had occurred by 2008.”

In other words, the next 20-percent reduction will be a far more challenging task, the report contends, requiring “further industry efforts to reduce LRB calories/capita/day by an additional 9.5 percentage points beyond that which can be expected through forecast market trends.”

This challenge is made ever more daunting still by the increasingly sedentary work and home environments that continue to produce more overweight Canadian adults and adolescents, the report notes.

“Today, Canadians are less likely to work in physically demanding jobs, while adolescents have access to a range of technological amusements (e.g. social media, games) that have partly displaced traditional forms of exercise,” The Conference Board points out.

With an estimated 53 per cent of Canadian adult population and 21.9 per cent of our adolescents deemed to be overweight, according to the report, the LRB industry certainly has what it takes in product innovation and packaging savvy to help reverse the unhealthy drift to excessive weight gain across Canadian population, even if it’s not the biggest culprit behind it.

According to the Balance Calories Initiative, there are four ways in which it can do its part:

• Product Innovation. Introduce more low-calorie beverage products to the market.

• Packaging and Labeling. Introduce smaller-format packaging and provide clearer labeling of calorie content.

• Distribution. Limit distribution of high-calorie offerings in schools and feature more low-calorie offerings more prominently in stores.

• Marketing. Restrict marketing targeted at children and promote low-calorie beverage choices. There’s no denying that at the end of the day it’s up to consumers themselves to make the healthy choice, but there is nothing wrong with the industry pinching in to help them do so through better product variety, clearer product messaging and, ultimately, a bettertasting beverage experience all-around. Cheers!

George Guidoni

12 FILL THE BILL By Andrew Joseph Venerable Ontario craft brewer steps up to the plate with a turnkey brewhouse operation and new filling line installation to pursue its ambitious growth targets. Cover photography by Naomi Hiltz

3 UPFRONT By George

Guidoni

4-6 NEWSPACK Packaging news round-up.

6 NOTES & QUOTES

Noteworthy industry briefs & updates

8-9 FIRST GLANCE Highlights

part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

18 FIGHT THE GOOD FIGHT By Andrew Joseph Vaping industry pioneer gearing up for future growth with an integrated filling-and-cappng line to keep up with fast-growing market demand.

22 ON TOP OF THE WORLD By Andrew Joseph Alberta meat processor climbing up the industry food chain with globally inspired recipes and world-class packaging technologies.

26 THE REAL VEAL DEAL By Andrew Joseph Quebec veal processor using cutting-edge vacuumskin packaging machinery to serve up a feast for the eye s and stomach. 30 GEORGIA ON THEIR MINDS

A sneak preview of the upcoming 2017 IPPE exhibition in Atlanta.

32 ROCKING IN THE U.S.A.! By George Guidoni Industrial automation supplier strengthens its hold on North American markets with major capital expansion and growing product portfolio.

Choosing between all or nothing is not really much of a choice, and for millions of Canadians who love the great taste of Coca-Cola, the soft-drink giant’s new Coca-Cola Life brand offers a sweet new option for moderating their sugar intake.

Naturally sweetened with a proprietary blend of stevia extract and cane sugar, the new drink’s distinct green packaging and product labeling offer consumers a clearly identifiable middle-ground option between the traditional high-sugar content Coca-Cola and the zero-sugar Diet Coke and Coca-Cola Zero brands.

“As leaders in innovation, we know Canadians love our brands and want more choices in flavors, package sizes and sweetener options,” says Michael Samoszewski, vice-president of Coca-Cola Ltd.’s sparkling business unit.

“Coca-Cola Life fills a very clear gap among Canadians looking for a great-tasting, reduced-

Buttering up Canadian consumers with healthy dairy products comes naturally to leading Quebec dairy co-op Natrel, whose latest innovation promises to bring many festive cheers this holiday season to both organic ‘foodies’ and to lactose-intolerant consumers.

Launched across eastern Canada last month, the company’s new Natrel Lactose-free butter was developed as a first-ever appetizing butter option formulated specifically for the dietary needs of an estimated seven million lactose-intolerant Canadians, according to the company, which is the only Canadian dairy producer to use real sea salt for butter products.

Produced with special lactose-free cream at the parent company Agropur’s production facility in Mirimachi, N.B, the 250-gram block of butter are packaged inside traditional foil bricks decorated with fresh and clean graphics designed by Montrealbased branding specialists lg2 boutique, which also created the same-but-different green-tinted design for the companion Natrel Organic Butter product,

With short-run flexibility a prized commodity with today’s ever-growing SKU (stock-keeping unit) proliferation and accelerated speed-to-market requirements, flexible packaging converter and co-packer Swiss Pack Canada is making all the right moves to retain its competitive edge in the increasingly digital world.

Being the first Canadian co-packer to install a brand new HP Indigo 20000 digital printing press at its production facility in Burlington, Ont., is just the latest milestone in the company’s proud record of continuous process improvement and proactive capital investment.

Manufactured in Israel by Hewlett-Packard, the new press has enabled Swiss Pack to help Canadian

calorie soft-drink that is sweetened from natural sources.”

Extensively supported by a multifaceted marketing campaign including television advertising, a

Although it’s been around Europe for decades, shelf-stable milk is still a relatively new concept in North America, despite its vast shelf-life superiority

Making optimal use of the 740x1,1000-mm image coverage to print flexible packaging, pressuresensitive labels, shrinksleeves, and in-mold labeling (IML) on a broad range of substrates from 10 to 250 microns, the Swiss Pack plant now produces dozens of different jobs daily in one-pass, full-color process at speeds of up 42 linear meters per minute.

small businesses enter the flexible packaging market with cost-effective, high-quality packaging at low minimum order quantities.

“Our investment in the HP Indigo 20000 enables us to help companies, especially those in the food packaging industry, make the transition into shortrun digital printing,” says Swiss Pack general manager Philippe St-Cyr. “We pride ourselves in being a local print service provider producing high-quality products with sustainable substrates to help others take their first step in custom-printed packaging.”

Buoyant demand growth in the pharmaceutical sector will keep domestic shipments of U.S.-built packaging machinery growing at a healthy pace in upcoming years, according to a major new report from PMMI, The Association for Packaging and Processing Technologies, reaching US$8.5 billion by 2020.

According to the association’s 2016 State of the Industry U.S. Packaging Machinery Report—released at the start of last moth’s PACK EXPO International 2016 exhibition in Chicago—U.S. based packaging machine-builders will enjoy a compound annual growth rate (CAGR) of 2.4 per cent between now and 2020, with food and beverage industries accounting for more than half of total growth.

“The forecast for the packaging machinery market is strong, as we continue to anticipate growth in major market segments such as pharmaceutical and beverage,” said PMMI’s vicepresident of market development Jorge Izquierdo.

According to PMMI’s findings, domestic U.S. demand for packaging machinery will grow at an average of 2.8 per cent for the forecast period, followed by the average of 2.4 per cent for the beverage sector.

“Factors such as changing consumer habits, new regulations and general economic growth are fueling this development,” said Izquierdo, adding that labeling, coding and decorating

machinery will grow fastest of all the 28 packaging machinery categories surveyed by PMMI, recording average CAGR increases of 3.9 per cent.

“The rapid growth anticipated in the labeling, decorating and case handling segment is largely a result of new legislation demanding increased labeling and coding, continuing developments in printing technologies, and the proliferation of SKUs (stockkeeping units),” Izquierdo said.

With U.S. being the largest market in the world for pharmaceutical and medical devices, PMMI expects suppliers of packaging systems, materials and services to these sectors to benefit

• Increase the flexibility of your robots by adding the ability to use more than one end-effector in an application.

• Production line tooling changed in seconds for maximum flexibility.

• Change tools in seconds for maintenance and repair.

• Increase operator safety by changing tools automatically.

• Million-cycle tested for reliability.

• Food-handling models available.

from buoyant demand in these sectors in coming years.

According to second companion PMMI study released during at last month’s PACK EXPO International 2016 show, “Contract manufacturing and packaging for pharmaceutical products in developed markets are forecast to grow at six percent CAGR through 2018.

“Mergers and acquisitions will also remain a major component of strategic growth—with mergers up 66 per cent from 2014 to 2015—and predictions of strong continued activity,” PMMI states in its Pharmaceutical and Medical Devices: Trends and Opportunities in Packaging Operations report.

“As the global demand for medicines and devices rise, processors are concerned with issues such as changing consumer demographics, regulatory issues, the need for cost containment, advances in 3D printing and updating legacy lines,” the report notes.

“Pharmaceutical manufacturers face many of the same opportunities that other packaged goods manufacturers are challenged with,” added Izquierdo, “such as sustainability, smart packaging, 3D printing, track-and-trace and coldchain logistics.

“With two out of three companies predicting the need to spend more on capital equipment in the next 12 to 24 months, there are great opportunities for OEMs in both pharmaceuticals and medical devices.”

n Toronto-based nutrition bar manufacturer Riverside Natural Foods Ltd. was chosen as one of 11 companies to receive a 2016 Ontario Export Award after being selected as the winner in the Food, Beverage & Agriculture category of the annual Ontario Export Awards competition—produced by Annex Business Media— celebrating exporting excellence among Ontario businesses. Recently featured as a cover story of the Canadian Packaging magazine in the publication’s May 2016 edition, the family-owned company grew from a tiny six-employee startup in 2013 into a thriving manufacturer of the MadeGood brand of organic, non-GMO, gluten-free granola bars and mini-snacks retailed across Canada and exported to growing international markets in the U.S., Japan, Australia, Chile, Holland, U.K., Dubai, Singapore and Hong Kong, among others, along with producing a broad range of store-brand cereal bars for many leading North American grocery retailers.

n Leading global chemicals group BASF SE has announced plans to invest over US$200 million in its plastic additives business worldwide, including a major expansion of its manufacturing facilities in McIntosh, Ala., (picture above) where the company produces the fastgrowing Tinuvin range of light-stabilizing additives widely used in industrial coatings, adhesives and sealants. According to the German-headquartered BASF, the investment reflects major expansion of polyolefin production in the U.S. by existing and new producers taking advantage of low-priced natural gas feedstock in the region.

Squid Ink’s new family of CoPilot Printing Systems offers 3 different print heights for your different applications.

Squid Ink’s CoPilot 128 is a proven choice for printing small character codes or barcodes on egg cartons, PVC pipe, corrugate cases or more. The CoPilot 382 is ideal for replacing costly print and apply labels or printing GS1 barcodes on the side of a box. The CoPilot 256 fits right in between, making Squid Ink’s CoPilot family the ideal solution for your specific coding and marking applications.

For more information visit www.squidink.com or call 1-800-877-5658 for your local Authorized Squid Ink Distributor today.

Leading automated material handling solutions provider Intelligrated unveiled the company’s new IntelliGen palletizing software for enabling operators to easily adjust pallet load configuration without the need for extra programming or cumbersome integration.

Designed to ensure enhanced flexibility, speed and load integrity, the new software allows operators to simply adjust load patterns and stacking characteristics based on changing product dimensions and other variables.

Integrated with the robotic cell’s standard control system to allow facility operations personnel to select user-defined load configurations—greatly simplifying product changeovers—the software’s advanced functionality also includes row-forming and case-turning to facilitate multiple-piece picks and drops on multiple rows.

“As SKU proliferation and packaging evolution continue, managing the product variability in palletizing operations demands simplicity,” said Matt Wicks, vice-president of product development for manufacturing systems.

“The IntelliGen tool simplifies the process of updating the robotic palletizing cell with the necessary flexibility to support a wider range of products, while maintaining load quality at high rates.”

The IntelliGen platform offers wide-ranging compatibility with major robotic arm brands and supports a variety of customized end-of-arm tooling—reducing integration time and providing the ability to handle a variety of packaging types, including corrugated cases, plastic totes and bags.

Intelligrated 401

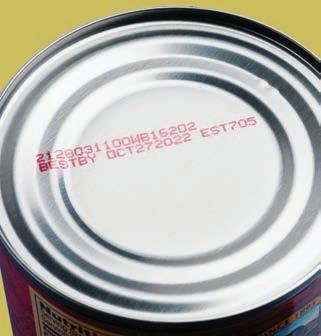

Leading product coding systems supplier ino Amjet Inc. unveiled the world’s first high-speed fiber laser coder developed specifically for inline coding of filled aluminum beverage cans of beer, soft-drinks and other beverage products.

Fully protected in IP 65-rated enclosure to enable its use in extremely harsh, humid and temperature-challenging production environments up to 45°C/ 113°F, the robust F720i fiber laser delivers exceptional operating speeds of up to 90,000 cans per hour for standard product codes, and up to 42,000 cans per hour for complex codes and promotional data of more than 60 characters—even on concave or curvy surfaces of the can bases.

Unlike conventional fiber lasers, the 3D power concentration of the F720i generates a highly focused beam distributed in short intense pulses, according to Domino, resulting in vastly increased marking speed.

The system’s high-quality optical laser beam also enables it to create intricate, but robust permanent characters with superior resistance to vibrations or water condensation.

“At Domino, we are continually looking to set new industry standards with our laser coding technology, and the introduction of the F720i continues to stretch the boundaries of innovation to deliver ever greater operational efficiencies for our customers,” said Domino’s laser product marketing manager Jon Hall.

“The new F720i not only meets current coding demands within the beverage canning sector, it also provides the flexibility to cater to future customer requirements,” Hall explained.

“These include even faster production speeds, more intricate and detailed promotional marketing codes, as well as meeting key legislative requirements for clear, legible and long-lasting characters.”

Domino Amjet Inc.

THE HUMAN TOUCH

402

ABB Robotics showcased the company’s recently-launched YuMi collaborative robot, claimed to be the world’s first collaborative dual-arm industrial robot that can safely work alongside humans to speed up and automate a diverse range of manual

tasks ranging from bag filling/sealing and box loading to small parts and electronics assembly.

Featuring seven axes and 500-gram payload capacity for each arm, the YuMi robot can be outfitted with a broad range of grippers to suit the task at hand, while its inherently safe design—featuring a lightweight yet rigid magnesium skeleton covered with a floating plastic casing wrapped in soft padding to absorb impacts—is enhanced with humanlike dimensions and movements to make human co-workers feel safe, comfortable and at ease. “The new era of robotic co-workers is here, and it is an integral part of our ‘Next Level’ strategy,” said ABB’s chief executive officer Ulrich Spiesshofer.

“Our new YuMi makes collaboration between humans and robots a reality. It is the result of years of research and development, and will change the way humans and robots interact.

“YuMi is a key element of our Internet of Things, Services and People strategy for creating an automated future together.”

Exceptionally fast and precise, the YuMi robot can return either one of its arms to the same point in space over and over again to within 0.02-mm accuracy and moving at a maximum velocity of 1,500-mm per second, while completely pausing its motion within milliseconds of accidental contact with a co-worker or another object.

ABB Robotics 403

Product inspection and quality assurance specialists Mettler Toledo Product Inspection Group managed to highlight all of the company’s comprehensive expertise in metal detection, checkweighing, vision systems and X-Ray detection in a simulated production line integrating the aforementioned technologies to demonstrate how different product defects are detected by different system to be rejected off the line.

Passed down a looped conveyor, the diverse range of test products—some containing contaminants and/or with defective labels or packaging—were tested through a series of the company’s most advanced inspection systems comprising:

• A Profile Advantage metal detector to inspect for metal contaminants within raw materials and finished products;

• A C3570 inline checkweigher to weigh packaged products to ensure they match the weight shown on labels;

• A model X37 X-Ray inspection system to inspect for bone, plastic, stone, glass and other contaminants.

• A V2410 Mosaic paneled vision system to view and verify product labels to ensure they are complete, correct and readable.

“As the final food safety regulations set out in the Food Safety Modernization Act (FSMA) come into full effect and consumers continue to focus on the safety of the packaged foods they purchase, food processors and manufacturers recognize that they need to maximize their efforts to ensure the safety of their products,” said market communications manager Sarrina Crowley.

“It is much less costly to reject a contaminated raw material before it becomes part of a finished product, for example, or a contaminated product before it is packaged,” she explained.

“This has resulted in an increase in the number of multiple different inspection systems being installed on processing and packaging lines, and we are proud to offer them all the right product inspection systems for their specific needs.”

Mettler Toledo Product Inspection Group 404

Diagraph Marking and Coding used the occasion for a North American launch of the company’s high-speed Allen MLi-TE multihead thermal-transfer printer designed to provide cost-effective, multilane, multiline printing of graphics, alphanumerics and barcodes on thermoformed packages.

Featuring up to 12 printheads integrated on one common platform using a single controller, the Allen MLi-TE provides high-resolution, 300- dpi printing of printing of static and dynamic information such as product identification text, date/lot/ batch codes, and company logos on packages such as sachets and stick-packs for a wide variety of applications, including food (condiments, sugar, spices, processed meats, cheeses, pouches, candy bars); beverage (coffee, drink mix); pharmaceutical (blister packages); and medical devices (syringes, sutures, IV bags, catheters).

The robust Allen MLi-TE coder generates bold, indelible print on a variety of substrates at speeds up to 70-mm per second for each printhead, using a special thermal-transfer ribbon to produce highquality print on porous and non-porous substrates alike. Moreover, its innovative ribbon-saving mechanism ensures minimum gaps between prints to yield up to 50-percent reduction in ribbon waste, depending on application.

Equipped with an intuitive color touchscreen interface to facilitate simple, centralized message editing for individual and batch messages for up to 12 lanes of print, the Allen MLi-TE printer allows users to program and save all the key settings— printing formats, print speeds, contrast, ribbon sav-

ing commands, and print position—for quick and easy recall in seconds, while also facilitating quick repositioning or printheads by sliding them along the T-slot to its new positions.

The new printer’s modular, single-unit, smallfootprint design with minimal interface cabling ensures quick and simplified integration into both vertical and horizontal form/fill/seal (FFS) machines—including horizontal flowwrappers, sachet machines, blister-pack machines, four-side sealing machines and thermoformers—with flexibility to be positioned either parallel or perpendicular to the flow of the packaging film in the host equipment. Diagraph Marking and Coding 405

Operating as a semi-automatic stand-alone machine or as a fully-automatic sys tem with an integrated case erect or and sealer, the new Raptor top-load case packer from Edson Packaging Machinery is a compact machine designed for high-speed picking and loading of pouches, bags, flow-packs and other flexible packaging formats at speeds of up to 20 picks per minute and up to 10 cases per minute, depending on application. Controlled by an intuitive HMI (human-machine interface) terminal, the Raptor is compatible with a wide range of case types, and features streamlined SKU (stock-keeping unit) changeover for enhanced throughput and minimal downtime.

“Customers looking to expand their business into new markets and to satisfy growing demand in existing markets are going to find the new Raptor exactly what they are looking for,” said Edson’s vice-president of technology Jeff Werner.

“The Raptor is a flexible and rugged machine that can grow in capability as product demand increases,” Warner said.

“A lot of engineering went into the machine to ensure this exceptional level of price and performance.” Edson Packaging Machinery (Div. of Pro Mach, Inc.) 406

Losing packaging weight is one of the surest ways to notable carbon footprint reduction for one’s products—especially those packaged in Club Store supersized formats.

But simply switching from glass to lightweight plastic has been a tricky proposition for many hot-fill food processors traditionally using mason-style glass jars capped with metal lug closures to package their jams, jellies, salsas, applesauce, pasta sauces, etc.

No such problems though for the Orange, Ca.based MegaMex Foods, LLC, which became the first company to use a breakthrough new plastic container developed by Amcor Rigid Plastics of Ann Arbor, Mich.

Operating as joint-venture company of Hormel Foods and Mexican-based agrifood group Herdez del Fuerte, S.A. de CV, MegaMex recently used Amcor’s new 24-ounce APEX hot-fill PET (polyethylene terephthalate) plastic containers with metal lugs to launch its newest La Victoria organic salsa product at Costco club stores on the U.S. West Coast.

“Since Costco has been at the forefront of many

trend-setting packaging developments, we thought it made sense to test our latest La Victoriabrand salsa in a 24-ounce PET container at the Club Store level,” says MegaFlex Foods brand manager Stephanie Bloch.

According to Bloch, the APEX jars with metal lug closures—retailed in two-packs—project the same level of authenticity and refinement as their glass counterparts.

“Consumers who are familiar with the look and quality feel of a glass jar with a metal lug closure can now enjoy the same quality and reassurance of the fresh ‘pop’ of a metal lug closure on a lightweight, shatter-proof PET jar,” says Bloch, adding the highbarrier containers provide optimal sealing integrity and meet the industry average for removal torque (ease-of-opening).

First used on the USDA-certified organic La Victoria Pineapple, Mango and Habanero brand salsa (see picture), the blowmolded APEX jars are hot-fillable up to 205°F (96°C) and feature a 63-mm finish with a functional ‘pop’ tamper-evident indicator button on the closure.

“The new APEX container is a game-changing development which firmly positions PET hot-fill containers in the food packaging industry,” says Amcor Rigid Plastics senior marketing manager Bunlim Ly.

“We’ve filled an important need for consumers and brand-owners who seek the benefits of PET containers with metal lug closures, delivering the same quality and freshness associated with glass along with significant performance, manufacturing and sustainability benefits.”

Easily adapted to most existing capping and filling lines, the 24-ounce APEX plastic containers offer 85-percent material reduction per jar compared to glass, according to Amcor, along with 36-percent energy savings—an equivalent of one-year electricity use by 278 homes—and removal of 2,024 tonnes of carbon-dioxide emissions.

“The weight reduction results in major transportation cost benefits,” states Amcor, “including shipment of 30 per cent more product by weight per truck.”

While seamless recyclability is likely to remain a formidable challenge for flexible packaging for some time to come, recent work by companies like the Atlanta, Ga.-based Printpack suggest that solving that challenge may well be a question of when, rather than if.

Displayed at last month’s PACK EXPO International 2016 packaging exhibition in Chicago, the company’s new easy-tear polyethylene pouch was designed specifically for compliance to the fast-growing How2Recycle store drop-off recycling stream in the U.S., which now comprises over 50 participating retail companies and major consumer brands.

Introduced in early 2012 by the Sustainable

Packaging Coalition (SPC), the How2Recycle voluntary labeling system has recently partnered with the American Chemistry Council ’s Flexible Film Recycling Group, whose own Wrap Recycling Action Program (WRAP) aims to boost the recycling of polyethylene film in the U.S. by expanding public awareness and boosting the number and proficiency of store drop-off locations throughout the U.S.

According to Printpack, the pouch’s recyclability stems from its single-material structure—unlike films with multiple materials can contain a combination of recyclable and nonrecyclable layers.

“Consumers are increasingly concerned about the impact of packaging waste on the environment, but they do not want to compromise on convenience

and product quality,” says Printpack’s director of technology and innovation Mark Brogan.

“By providing them with packaging that is easily recyclable and free of significant learning curves or sacrifices to convenience and product protection, brand-owners can live up to their sustainability promises and build greater brand loyalty.”

Well-suited in applications for multi- or singleserve snacks such as nuts, cookies, crackers and chips, the pouch can also be outfitted with combinations of coatings, barriers and closures to preserve food product flavor, color and aroma, adds Brogan, as well as minimizing food waste.

As the global market for drinkable yogurts continues to grow in mighty healthy leaps— with a new Technavio study projecting seven-percent annual growth (approximately US$13 billion in total) through 2020—progressive dairy producers are already taking steps to minimize the product’s potential environmental footprint.

For leading Swedish-based dairy co-op Skånemejerier, the recent launch of its flagship Drick Yoghurt brand of fruit-flavored yogurt beverages in the bottle-shaped Tetra Top 330 Mini Nallo paperboard cartons from Tetra Pak sets an early benchmark for others to up to.

“In the past, drinking yogurt was packaged in plastic bottles, which has a far greater environmental impact than carton packages,” says Skånemejerier’s sustainability manager Armina Nilsson, noting the new

330-ml containers are made from paperboard sourced exclusively from FSC (Forestry Stewardship Council)-certified forests.

“Switching 2.1 million packs of our drinking Yoghurt to paperboard means we are cutting the use of plastic by more than 45 tonnes per year,” says Nilsson, citing remarkably positive feedback from Swedish consumers.

“This move is part of our wider commitment to care for animals and nature, and we are delighted that consumers are responding in a very supportive way,” Nilsson states.

“Consumer tests proved that they prefer these carton bottles to plastic packages, particularly from an environmental perspective.”

With a V-shaped panel on one corner, Tetra Top Nallo also allows brand-owners to highlight their messages in

the packaging design to make their product stand out on the shelf, according to Tetra Pak, while its tall and slender profile provides a good natural handgrip for the consumer.

In addition, the bottle’s resealable wide-mouth cap with one-step opening ensures a smooth drinking experience.

“The new Tetra Top 330 Mini Nallo is one of our latest innovations for younger generations,” says Charles Brand, Tetra Pak’s vice-president of product management and commercial operations.

“It has taken all aspects of their needs into account: their increasing interest in the environment; their demand for an appealing appearance; and their desire for a convenient package that they can drink from, reseal, and carry around while on the go.”

Early Bird Date – November 30, 2016

Entry Deadline Date – January 30, 2017

Package submissions to judging site – February 2, 2017

Finalists Announced – February 21, 2017

Winners celebrated at Awards Gala on May 2, 2017

Canada’s oldest craft brewer leaps into the future with new high-tech filling lines to boost productivity and reach a larger audience

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

The North American craft brewing industry has been experiencing fantastic growth over the past decade —providing grateful beer connoisseurs with quality, variety and flavor akin to the days of yore, when every self-respecting drinking establishment brewed their own house beer right on the premises. Over the past 20 years or so, t he Canadian craft beer industry has evolved from guys in the basement producing home-brewed suds into a professional industry where quality and consistency of taste is as important as the desire to produce beer varieties beyond the norm of the industry’s

multinational mass-production giants.

Wellington Brewery, located on the northwest edge of Guelph, Ont., is Canada’s oldest independentlyowned craft brewery. Established in 1985, the company now employs 50 full- and part-time employees to produce its popular beer brands.

“We were part of the first wave of Ontario microbreweries that started up after changes to an outdated provincial law allowed small breweries to operate,” Wellington Brewery president Brent Davies told Canadian Packaging magazine during a recent visit to the 19,000-squarefoot facility, which was expanded and

overhauled over the past year to add 12,000 square feet of additional production space.

To accommodate the expansion, brewery moved its administration offices across the street from the brewery plant.

Also operating a distribution warehouse in Toronto, Wellington Brewery had been producing between 20,000 and 25,000 hectoliters of beer over the past few years, but Davies now expects that total to quadruple to about 100,000 as a result of the expansion and comprehensive equipment upgrades.

“Industry trends show that nowadays customers prefer their retail beer purchases to be packed in cans over bottles,” notes Davies, “which is why 50 per cent of our production is geared towards cans, 30 per cent for draught beer in kegs, with the remaining 20 per cent in bottles.”

Core brands from Wellington Brewery are its best-selling S.P.A (Special Pale Ale), Trailhead Lager, County Brown Ale, Arkell Best Bitter, Kickin’ Back Dry-Hopped Session Ale, Iron Duke Strong Ale, and the Imperial Russian Stout —in 355- ml bottles and 473- ml cans, and can be found at the LCBO (Liquor Control Board of Ontario), the Beer Store, participating grocers, and over 400 active accounts with bars and restaurants across southern Ontario.

Wellington Brewery founder Phil Gosling’s plan was to only produce English-style real ales (also known as Cask Conditioned Ales), an unfiltered, unpasteurized, naturally carbonated beer served from a cask without adding nitrogen or carbon dioxide pressure.

Davies notes that its Imperial Russian Stout is patterned after the highly-fortified stout that Great Britain exported to Russia in the 1800s, so the English link remains.

“Wellington Brewery was one of the first modern brewers in North America to produce caskconditioned ales,” relates Davies, adding that the taste profile has become very popular over the past decade or so.

“Because Gosling wanted our beer recipes to closely match the flavor and character of the British Ales, our original brewhouse and most of the brewing equipment was shipped directly from England to Guelph,” says Davies who first joined the brewery in 1991 through 1996.

Success came quickly for Wellington Brewery, with the company winning local and national brewing awards as early as 1987.

Davies was coy as to the naming of the brewery: either arising because Guelph is located in Wellington County, or perhaps it was named after the Duke of Wellington, or perhaps because everyone thought the boots were kind of neat.

“It’s a lot of each, actually,” says Davies. “We are phasing out the brand’s former image of the Duke of Wellington, and are utilizing the tag line of ‘Try a Welly on’ with the famed rubber boot being standard footwear on our staff, as well as on our beer packaging and promotional items.”

A fter new ownership consisting of Mike Stirrup and Doug Dawkins came aboard in 2000, Davies was back in the saddle in 2010 when he bought out Stirrup who was retiring.

“Doug passed away this June, and while I am loath to assume his job title, I have, as of September, assumed his duties,” mentions Davies.

W hile the passing of the company president and

friend was jarring to say the least for the genial Davies, his stress levels were further increased because his Wellington Brewery was in the midst of its first large-scale expansion, though he points to operations manager Chris Sheppard as being a key person in maintaining the positive momentum of the expansion plans.

“It was back in 2011, when it became evident that the current amount of capacity for the brewery was found wanting for both brewhouse and packaging, operating at capacity,” mentions Sheppard.

To increase brewing capacity, in 2011 the Wellington Brewery installed a pair of new 150 hectoliter tanks (there are 100 liters in one hectoliter). In January of 2013, four more similar-sized tanks were added to keep up with the growing demand.

“We took over the next door area and then rebuilt to suit our needs,” says Sheppard, adding they took occupancy in April of 2016.

T he packaging line was installed in May, with a new brewhouse installed in late August.

P urchased from Newlands Systems Inc. (NSI),

a company located in Abbotsford, B.C., and recognized as a distinguished manufacturer and supplier of premiere brewing equipment in North America.

“We wanted to go as Canadian as possible,” notes Davies.

However, when it came time to opt for new bottle and can filling lines, Davies was happy to deal with the Canadian arm of Germany-headquartered Krones Machinery Co. Ltd., who design and manufacture filling and process technology for the food and beverage industry.

“Why Krones? An easy enough answer is that Krones has been known to be the best in the industry for its filling and capping equipment,” Davies says with a knowing chuckle.

“We approached Krones, and they worked with Chris to create a turnkey system specific to the current and future needs of Wellington Brewery.”

According to Chris Sheppard, “We were originally looking at adding a pair of small units for the canning and bottling lines, but Krones correctly pointed out that what we had planned for the next

five years, was inadequate.

“We were thinking too small in our big-thinking plans, which is how we purchased a Krones-Kosme hybrid line.”

“For us, moving up in scope, it was important that we not sacrifice quality,” notes Sheppard, “ and we didn’t.”

“The new lines provide us with everything we wanted: an ability to create great tasting beer in an efficient and safe manner; and, of course, to produce much more of it.”

T he can and bottle filling lines were purchased as turnkey operations from Krones, and consist of its own Krones and Kosme brand machines, as well cherry-picked equipment from other well-known and respected suppliers.

Both lines are supplied empty packaging options of cans or bottles from a Kosme Solution by Apsol depalletizer capable of easily moving some 2,250 glass bottles or 5,086 cans per skid onto the conveyor line powered by Bonfiglioli electric motors controlled by Rockwell Corporation’s AllenBradley brand PanelView Plus 600 interface.

T he palletizer is a pneumatic system, with air

pressure causing the cylinders to clamp on and move the bottles smoothly onto the conveying line for label application and filling.

T here are even robotic applications with suction grippers on the depalletizer that removes the pallet protective lidding out of the way.

T he conveyors transport the bottles past a Kosme Flexa Sensicol labeler that applies pressure-sensitive labels to the front and back of the bottle, after which date coder then applies the proper lot code and bestbefore data onto the rear label.

T he conveyor then moves the bottles, carefully flipping them upside down to be rinsed with water, purged with a jet of carbon dioxide, dried, and then righted again before being filled by a Kosme Barifill R-FC (rinser, filler, and capper) 16-valve unit.

T he Kosme Barifill R-FC utilizes robust, pneumatically-actuated Krones filling valves that allow for a fast, non-foaming filling process that helps maintain product integrity.

A s the bottle enters the filling sequence, a probe is placed into it, and the bottle is bottom-filled with beer. Once the beer makes contact with the probe, it creates an electrical charge that informs the fill

system that the bottle is at the optimum fill height.

T he Barifill uses:

• a n isobaric filler with electropneumatically-controlled filling valve functions;

• a compact valve manifold;

• a r inser with several capping systems for diversity;

• no sharp corners that could allow dirt to congregate.

A short conveyor ride later, the bottles are handpacked into six-pack paperboard trays, which are loaded inside corrugated two-four 24-bottle cases that are stacked onto shipping pallets and secured into finished, ready-to-ship loads by a Phoenix model P2150 semi-automatic stretchwrapping machine from Doverco.

“For cans, it’s not too much different,” says Davies. “After the initial depalletizing, the cans travel along the same conveyor line are then diverted towards the canning equipment.”

T he pre-printed cans are open at the top, and are flipped upside down and rinsed by a McBrady can rinser.

The cans are then filled by the 24-valve Krones CraftMate can filler featuring a four-head Swiss-

made Ferrum F 404G-TI seamer that adds and seals the can’s lid.

T he modular-designed, easy-toclean Ferrum seamer works equally well on aluminum cans as well as steel, plastic and composite applications, able to seal cans—depending on size—at speeds of 80 to 360 cans per minute.

“The Ferrum sealer was a very important piece of the turnkey system we purchased from Krones,” acknowledges Davies. “Having a perfect seal helps us ensure a quality product is being delivered to the consumer every time.”

T he cans are then conveyed through a Krones Checkmat 707 F-X inspection system—a machine that utilizes X-Ray technology to ensure the fill height of the product remains within the brewer’s realm of tolerance.

For Wellington Brewery, the Checkmat 707 F-X line also verifies the presence of a properly applied lid.

“If the fill height does not match the required volume, or if the lid

provides a faulty seal, the Checkmat pneumatically push-rejects the can,” explains Davies.

“The Checkmat helps increase the efficiency of our packaging line, and helps guarantee that our customers get what they are paying for,” Davies notes.

To remove any can sweating caused by the cool beer contents, the cans pass through a can warmer supplied by Lagrotta Packaging Group, an innovative custom-design manufacturing company headquartered in Kitchener, Ont.

T he cans are then hand-packed onto corrugated trays, have a sheet of heat-sealed plastic adhered to it and then skidded atop a pallet.

“The CraftMate is a volumetric can filler with 24 filling valves, specifically targeted for the North American craft brewing market,” notes Davies. Before the release of the CraftMate, Krones did not have a range of can filling equipment designed specifically for the craft beer market, work-

ing with a minimum of 36-valves.

T he CraftMate fills cans at a small production rate of 12,000 containers an hour—based on a 16 ounce can—and comes with a capping system with four capping heads.

A nd, for those times that a third-party contracting company wants to use a can of a different size or format from the typical Wellington Brewery sizes, the CraftMate can easily handle it—not to mention working with beer as easily as it does carbonated beverages.

Featuring innovative technology, the CraftMate offers:

• 24 electropneumatically-controlled filling valves;

• pressing-on and pressurization of the cans via a double-acting cylinder and differential pressure chamber;

• exact filling quality determined by inductive flow meter;

• h igh technological standard for oxygen pick-up and carbon dioxide consumption;

• m anual carrousel height adjustment.

“We also find that the CraftMate is very easy to maintain as far as cleanliness,” notes Davies.

T he first real new brew was produced on September 18, 2016, and despite the relative short operating time, Davies was quite impressed with the new set-up.

“With the old brewhouse and packaging line, we had to run 24/7 over the past three years in order to keep up with demand,” relates Davies.

“With the new set-up, we work fewer hours— just two shifts—to maintain our production output, as the filling line is very quick.”

Wellington Brewery’s conveyor lines use System Plast NG belting manufactured by Regal Beloit to move the cans and bottles to and from the packaging line’s various systems with key smooth handling and transfer.

Other suppliers servicing the Wellington Brewery include:

• TricorBraun designs and supplies the glass bottles;

• Toronto headquartered Tapp Label provides the pre-printed pressuresensitive labels applied to the bottles;

• Custom Drink Carriers of Dundas, Ont. supply the paperboard six-pack containers;

• the 24-bottle motherpacks that hold four six-packs each are supplied by the Concord, Ont.-based paperboard and corrugated packaging converter Packaging Technologies Inc. (PTI).

• Philadelphia-headquartered Crown provides the majority of the preprinted cans, though Davies says that U.K.-based Rexam with offices throughout the Americas is also a supplier;

• Royal Containers convert the trays used to hold 24-packs of cans and bottles.

Without going into specifics, Davies acknowledges that the contract brewing business Wellington Brewery has helped the company pick up capacity.

“It wasn’t too long ago that we actually used a local brewery to produce and bottle -pack our own beer,” says Davies. “Although, we have always produced and packaged our cans and kegs.

“Everything, from our private-label business to our own beers has been one continuous cycle of growth,” says Davies. “Steady, manageable growth.

“It’s also one of the reasons why we felt comfortable in making such a huge capital investment.”

According to Davies, even though Chris Sheppard was doing yeoman’s work with getting the expansion project into gear, “we utilized a consultant to work on our behalf between Wellington Brewery and Krones during the design and install process.”

Chiming in, Sheppard says that “whenever we did have design changes, Krones was quick to point out both the pros and cons on the line of whatever question we had.

“The level of support we received to get the project started, and continue to receive from Krones has been astounding,” observes Sheppard.

Davies concurs: “There’s nothing wrong with becoming a larger brewing entity with the best brewing and packing equipment on the market.

“It’s just good business sense, and we’re just going about it in a more efficient manner now.”

Please see the online video of Wellington Brewery on Canadian Packaging TV at www.canadianpackaging.com

Fabbri_2017IPPE_MeatPkgAd_PoultryDrumsticks_CP_Layout 1 10/28/16 12:56 PM Page 1

Fabbri Automatic Stretch Wrappers produce highly attractive packages that make your products look fresh and “just packed”. Fabbri Stretch Wrappers use stretch film to package fresh meat products in preformed trays to provide an in-store wrapped appearance. They employ four-way stretch technology to produce tight, over-the-flange, wrinkle-free packages with securely sealed bottoms and a superb case presentation.

And here’s something you might find even more attractive: Fabbri Stretch Wrappers can help increase your profitability. Fabbri packaging is produced using low-cost packaging materials. And when you factor in its Best in Class low cost of ownership, the Fabbri Stretch Wrapper is your most economical and affordable packaging solution.

Compact and robust servo-driven Fabbri packaging machines are built for speed, versatility and the highest levels of productivity. Fabbri Stretch Wrappers can handle a wide range of tray sizes with no changeovers, producing up to 62 packs per minute. All models feature a user-friendly full-size control panel for easy operation and maintenance. Test the Fabbri at our Reiser Customer Center and see for yourself how it can improve your packaging. Contact Reiser today.

Canadian vape liquid manufacturer boosting its productivity levels to new heights with fully-integrated filling, capping and labeling capabilities

BY ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY COLE GARSIDE

It’s not quite true that nobody loves a quitter, because the vape industry surely does.

Canada Census calculates that of the approximately 35 million people in Canada, about five million of them are active tobacco smokers who help fuel the $16.86-billion Canadian tobacco industry— putting a lot at stake for companies in the business of helping people quit smoking.

With researchers comparing the addictive quality of tobacco to that of heroin, many people have found the allure of cigarettes a very tough habit to quit.

While some people trying to quit tobacco have been able to do so ‘cold turkey’ via medical aids, or by using nicotine patches and nicotine gum, many have found themselves drawn back into using tobacco products days, weeks and even months later.

“People looking to wean themselves from smoking are now looking to the vaping industry for a success story,” Vape Brands International Inc. chief executive officer and founder Beju Lakhani told Canadian Packaging during a recent visit to the vape e-liquid manufacturer’s new facility in Mississauga, Ont.

While mainstream media describes vaping as a form of electronic cigarette (e-cigs), Lakhani notes, vaping doesn’t even come close to resembling cigarettes.

Vaping involves the inhalation of heated flavored liquid that form a vapor, with Lakhani noting that the liquid may or may not contain nicotine, depending on the vaper’s choice.

When the vapor is exhaled, there is no smoke. It’s all vapor created by the heated liquid—that is often whimsically-scented to add flavor.

“Vaping is a relatively new technology that is considered to be a safe way to help smokers kick the nicotine habit,” relates Lakhani.

Vape Brands International is one of the largest vape e-liquid manufacturers in Canada, producing some 25,000 bottles of vape e-liquid per month, but Lakhani insists the opportunity is there to produce and sell far more than that.

According to Lakhani, the vape industry is growing by leaps and bounds globally—all thanks to the plethora of people who are using vape products to help them quit smoking tobacco.

“Consumers everywhere have accepted the vape industry,” Lakhani states. “They’ve tried the patch and the gum, but they have also heard the testimonials of the many people who have successfully used vaping to help them stop smoking.

“That’s why vaping is a growing industry.”

Lakhani says that within Canada alone, there are

A close-up view of the newly installed CF-2P dual filling component, manufactured by Montreal-based Capmatic, performs precision-filling of 30-ml glass containers of vaping liquid at the

around 1,000 shops catering to the vaping industry, with Vape Brands International distributing its e-liquid products to about 540 of them.

Vape Brands International is certainly counting on the trend continuing.

“I would say that since 2015, the vape market has doubled—nearly tripling in size,” says Lakhani. “In the U.S., there are over 6,000 different brands of e-liquid, just to give you a scope of how large and how popular the vape industry has become.”

Vape Brands International was formed in 2013,going live in 2014, producing a single vape e-liquid: Moshi E-Liquid.

Since then, Lakhani and his team have grown the Moshi brand into one of the top-selling vape e-liquids in Canada,with keen penetration into the U.S.,European andAsian vape markets

There’s actually a Moshi Standard and a Moshi Cloud line, with the chief difference being that the Cloud line contains 30 percent more vegetable glycerine, which

helps the vaper produce larger bursts of vapor cloud output.

The Moshi Standard line is named after local Torontoarea communities—each with their own distinct flavor and vibe: Baldwin Village; Black Creek; Bloordale; Centre Island; Chudleigh’s; Danforth; Don Valley; Dovercourt; Dundas Square; Echo Beach; Exhibition; Forest Hill; Fort York; Gladstone; Guildwood; High Park; Kensington; Leslieville; Mimico; Morningside; Mount Pleasant; Old Mill; Ossington; Parkdale; St. Clair; St. Lawrence; Summerhill;

Sunnybrook; The Annex; The Beaches; The Junction; Trinity; Union Loop; and Yorkville.

For the Moshi Cloud line-up,Vape Brands International only offers seven flavors: High Park; Leslieville; Rosedale; St. Clair; The Junction; Union Loop; and Yorkville.

“We also just released two new brands this past November,” relates Lakhani.

The new Origins line-up consists of three flavors of 30-ml taste: Pomegranate & Kiwi; Aloe; and green Candy Apple. The new Ohana line is currently just one flavor—fruit punch.

“Ohana is the Hawaiian word for ‘family’,” explains Lakhani, whose dad is also involved in the company. “The brand is our first go at producing our own product in the larger 60-ml bottle, even though we have created product in even larger sizes for other vape manufacturers.”

Lakhani says the company is proud to have the fulltime services of Andrew Vecchio, to create the recipes for them.

“Before joining Vape Brands International, Andrew was a professional chef for 11 years,” Lakhani reveals. “His sense of knowing how long various combinations of ingredients need to steep in order to create the final flavor profile we are after, is uncanny.”

To produce the e-juice, Vape Brands International utilizes hand labor: careful measurement of the ingredients featuring the mixing agents such as a flavorless base or propylene glycol or vegetable glycerine—a concentrate of flavorings for enhanced taste and smell; and if desired by the vaper, various controlled amounts of liquid nicotine.

Each variety of Moshi brand e-juice is available with different amounts of nicotine to help the smoker quit, all the way down to a vape e-liquid containing zero nicotine for those who just enjoy vaping.

After the ingredients are all mixed, steeping is required for anywhere up to a month, depending on the flavor profile or product manufactured, with a daily agitation via bottle shake as part of the plan.

“We also have an ultrasonic agitator that we could use to do the same month-long process in just a few hours,” says Lakhani, “but that will come in handy as we get closer to reaching our capacity or if we have an emergency request for product.”

After the e-liquid has been steeped for the requisite amount of time, the plastic jug containing the flavor to be bottled is taken to its packaging room.

Also by hand, in the early days of Vape Brands International, the company then would fill the 30-ml bottles, add a liquid dropper and cap, twist to close, and add a label hoping it was placed perfectly straight.

“By the end of 2015, it was pretty obvious we had outgrown our 3,500-square-foot facility, so we moved into our new 13,000-square-foot manufacturing center in March of 2016,” explains Lakhani.

At the same time, the manufacturing business began to evolve,“as we outgrew our domestic distribution and established very strong relationships with other vape e-liquid brand owners in an effort to create and expand our international business,” Lakhani notes, adding that in August of 2016 the company launched a private-label business—a brand new direction for the company—as Lakhani has paid close attention to the boom in vape shops opening across Canada and North America.

Thanks to its automated nature, in-house label design with on-site printing, as well as a wide variety of stock bottles and caps, and an uncanny knack to create or recreate customer vape recipes, Vape Brands International has a full-time flavor creation team

available to turn ideas into reality.

“Having us provide private-label manufacture of vape e-liquid for businesses in California looking to distribute in the east is smart,” suggests Lakhani.“Certain taxes and the cost of transportation can immediately be eliminated when Vape Brands is involved.”

He says that Vape Brands International is already working with partners in several countries “to help facilitate the smooth distribution of vape products in many markets.”

He says the company also has manufacturing partnerships in the U.S., U.K. and China, and can produce and distribute products that meet the challenges of various regulatory requirements. Lakhani says his company represents 15 brands domestically in Canada, and six brands internationally, “and since all of this business has occurred after a mere three months, you know we are going to continue to grow those numbers.”

In favor of proper government legislation regarding the manufacture of vape e-liquid products, Lakhani

takes a serious role when it comes to product safety.

The new ISO: 9001 facility includes an enclosed 1,600-square-foot ISO 8 Cleanroom and a new filling, labeling, capping line with a safety seal application that givesVape Brands International the capacity to produce 1.2 million bottles a month, a challenge that Lakhani is more than ready to exceed over next couple of years. Vape Brands purchased a Capmatic CF-2P dual filling line with a Capmatic Jolly capper, Capmatic LabelStar System 1 ECO labeler, and a Capmatic BandStar 50 safety seal application system, as well as associated conveyors and a rotating accumulation table. Other equipment purchased through Capmatic includes:

• a Videojet DataFlex 6420 industrial thermal transfer printing system that burns easy-to-read information onto dark surfaces, such as the black labels used by Vape Brands International;

• a heat tunnel manufactured by JDA Progress of Woodbridge, Ont. featuring a Dayton blower that heat seals the plastic film applied over the head and

After a layer of plastic film is attached to the head and neck area, the bottles are conveyed through a JDA Progress heat tunnel, with a Dayton blower, to have a safety seal applied. The high-speed

neck of the bottle applied by the Capmatic BandStar 50

“We only just recently installed the line, and have been working with it on our own since early November 2016,” says Lakhani.“Before that, we had a Capmatic specialist in our facility working with the machine and training us to use it optimally.”

Capmatic calls its automatic CF-2P liquid filler versatile, featuring variable speed control, while being able to dispense and fill liquid or semi viscous products.

“The Capmatic website actually singles out the CF2P as being the ideal filling equipment for vape e-liquid

production,” relates Lakhani.

The CF-2P dual filler—it fills two 30-ml glass bottles at a time from the bottom-up to avoid inclusion of air bubbles—works at a speed of up 60 bottles per minute.

The new Capmatic line is not truly automatic, as the next phase involves two Vape Brand International employees adding an eyedropper cap to the bottle, and partial twist to close it.

After the line workers place the bottles back onto the conveyor, Festo pneumatics help guide the bottles to the Jolly capper. The capped bottles are positioned accurately within the machine thanks to an indexed starwheel, as the machine tightens the bottle’s cap with a very accurate torque.

Continuing on its path, the bottles pass through the LabelStar System 1 ECO labeler that applies an adhesive label around each bottle up to 80 containers a minute. Just prior to label application, a Videojet DataFlex 6420 industrial thermal transfer printing system quickly scribes lotcode numbers and best-before date onto each label.

According to Capmatic, the LabelStar System 1 ECO labeler is an economic labeler similar in function and features to the regular System 1 labeler, but operates at a slower speed for less demanding applications like those at Vape Brands International.

The conveyor then moves the bottles individually through the Capmatic BandStar 50 to apply a clear plastic band over the top of each bottle, before it travels

through the heat tunnel to provide a safety seal to help prevent product tampering.

“While no one likes to think their industry could be the target of product tampering, our company believes it is better to be safer, rather than sorry,” notes Lakhani.

“This is a very competitive industry,” he continues, “and if something negative should occur, we can at least say that we did a good job of protecting our product and the consumer.”

Lakhani says that Vape Brands “puts an emphasis on customer service—it’s more than just manufacturing a product to a customer’s specs; it’s about looking after the customer regardless if they are a liquid brand owner, a retail shop operator or a vape consumer.

“We create a product in a safe manner that ensures the consumer can ultimately enjoy it in safety. It’s why we chose to purchase our line from Capmatic.”

According to Lakhani, he put out a call for submission for a filling line, receiving project quotations from across North America and Europe.

“There were a lot of criteria on our list that we wanted taken care of, and Capmatic was the one company that fulfilled all of our needs on the first presentation,” recalls Lakhani.

Lakhani admits that Capmatic wasn’t the least expensive option presented to Vape Brands, but “price certainly wasn’t everything to us because we are aware that one often gets what one pays for.

“Capmatic’s after-sales service, and knowledgeable history of pharmaceuticals was quite impressive,” reels off Lakhani, adding that the decision was a close one with several excellent companies coming down to the final selection “but what we found, was that we could actually trust Capmatic more than others.

“We just felt that Capmatic would serve us best.”

We

Alberta meat processor turns on the heat with a fully-integrated packaging line installation to kickstart its next stage of accelerated business growth

BY ANDREW JOSEPH, FEATURES EDITOR PHOTOS BY AIDAN CAMPBELL

Because it’s there. That’s why people climb to the top of a mountain.

For one Alberta-based family-run food processing company, the mountain top is a journey always within sight as it continues to grow its consumer base with a variety of healthy food options featuring global appeal.

Mountain Top Foods Ltd. located in the town of Nanton just south of Calgary, Alba, is a growing enterprise that quickly found its niche in the food processing segment by creating international flavors, particularly those with an Asian flair, for dinner tables from across Canada with plans to enter the U.S. market early in 2017.

And it all began with beef jerky.

Starting out in 1994 as Three City Foods in Nanton, “We created beef jerky for the local market in our provincial meat processing plant,” Mountain Top Foods plant manager Jason Calvert told Canadian Packaging magazine.

The business was started up by Kin and Sylvia Leong, who added more family members to the management team as the business grew. These additions include Corrine and Fortune Anchoris, and the owners’ daughter Juanita, the current president of Mountain Top Foods and the wife of Jason Calvert.

“While business was steady, our focus

The complete packaging line purchased by Mountain Top Foods from Heat and Control Can-ada of Cambridge, Ont., includes a food-grade incline conveyor that swiftly moves the product from floor level to a mezzanine for portioning prior to bagging..

changed in December of 2001, when we purchased a federally-inspected meat plant in Nanton, 92 kilometers south of Calgary,” Calvert recalls “That was when we changed our company name to Mountain Top Foods”

While Nanton lies near the Canadian Rocky Mountains range but not actually in it,Calvert says the MountainTop company moniker is highly emblematic of the way the company runs the business.

“Our products are made to be at the“top”of quality and affordability for our customers,” he relates.

Although the company still processes beef jerky products, its focus has gradually evolved to take on a more global dimension of preparing fullycooked, ready-to-eat frozen beef, chicken and pork and marinated raw meats, with or without sauces/ seasonings,for various restaurant applications

“Nanton is where our family is from,”notes Calvert, “and as our business has grown over the years, we are happy to continue to employ more and more people from Nanton and the surrounding area.

“The fact that most of our staff typically has commute time of about five minutes,staff retention has not been a significant issue for us ”

In addition to growing its own brand label, the company has also made big strides in its private-label business,Calvert relates,enabling MountainTop Foods to maintain steady growth over the years.

“The last time Canadian Packaging did an article on us was in 2007,”recalls Calvert,“we had 27 employees here.

“We have nearly double our staff since then, nowadays employing 50 people” Calvert credits that strong growth on the private-

label side of business with enabling Mountain Top Foods to move most of its production capacity into a new 18,500-square-foot facility in early 2016.

“We maintain our sales office in Calgary, and we use our Three City Foods facility as our third facility to produce sauces, while the previous 7,000-squarefoot federal plant remains in operation to produce marinated meat items for retail and foodservice,” he explains.

According to Calvert, pork account for about 60 per cent of all the animal protein processed by Mountain Top Foods is pork, with 20 per cent each for beef and chicken.

Calvert says that roughly 60 per cent of the company’s revenues are generated in the retail markets, with HRI (hotel, restaurant and institutional) industries accounting for the remainder of sales.

“Since the last time we talked,” he reflects,“Mountain Top Foods has grown what I would describe as a medium-sized business, capable of processing up to 1,500 kilograms of cooked meat products per hour.

“We now have the capabilities to react fairly fast to any new industry trends and various customer requirements for a specific product,” he relates.

“These types of products will often have an initial lower volume that larger businesses would typically not entertain taking on,” he states, “but we are vary happy to do it.”

Calvert notes that while Mountain Top still produces its signature Sylvia’s International Cuisine line-up, the company was also keen to diversify its product portfolio with two new brands.

“We now also produce appetizers under the new Muldoon’s Pub Classics label and a growing range

of Asian-inspired foods under the Asian Inspirations brand name,” says Calvert, adding both brands soon be retailing nationally starting in early 2017.

The Muldoon’s Pub Classics pub style appetizers range comprises the Salt & Pepper Dry Pork Ribs, Buffalo Chicken Bites, and Boneless Dry Pork Bites, Calvert relates, while the rebranded Asian Inspirations product family offers a diverse offering of global flavors such as Thai Sweet Chili Chicken, General Tso Tempura Style Chicken, Pineapple Lemon Tempura Style Chicken, Ginger Beef, Vietnamese Style Beef, Ginger Tempura Style Chicken, Mango Chili Tempura Style Chicken, Sweet & Sour Pork, and Sweet Sriracha Tempura Style Chicken.

Mountain Top Foods also produces large volumes of products for other companies brands, with the privatelabel business now accounting for 55 per cent of its total sales.

“We are always looking for interesting flavors to provide more choice to the consumer,” Calvert relates, adding that the company’s sales manager is also a professional chef who and plays an active role in its R&D (research-and-development) activities.

“One of my roles is to take those ideas and turn them into a large-scale production proposition,” says Culvert, citing the company’s genuine commitment to producing high-quality products at an affordable price-point for both consumers and corporate/ institutional clients.

“During processing,” he says, “we produce all of our own sauces in-house and source the best-quality ingredients only from reputable suppliers.”

While the company’s main production line is housed within the new facility, the other lines are set up in two secondary buildings on company’s property nearby.

“With this new facility being both SQF- and HACCP-certified,” relates Calvert, “we designed it with the equipment in mind first, with the rest of the building then constructed around it so that the raw materials enter at one end of the facility, and exit at the opposite end in the shipping department as a fully finished product.

“This allows for complete and total segregation of raw and ready-to-eat areas, with staff having separate points of entry for each,” Calvert explains.

“All our floors and doors are colored red with signage for those working in the raw section,” he relates, “while the ready-to-eat area has green doors and appropriate signage.”

Hitachi Continuous Inkjet Printers have set the standard for reliable, user friendly, and cost effective product coding and marking for more than 35 years. With a reputation for relentless reliability and up to 50% less fluid consumption than other brands, our printers keep your uptime up and your operating costs down. Call us at 1-866-583-0048 or visit us online at www.hitachi-america.us/ice/inkjetprinters/.

According to Calvert, constructing the facility from the processing equipment on out was a thoughtful process, brought on by a desire to begin the next phase of Mountain Top Food’s journey with brand new equipment that would “propel our business to the next level in food manufacturing and food safety.”

For Mountain Top Foods, the complete packaging line was delivered to them by the Canadian subsidiary of the Hayward, Ca.-headquartered Heat and Control, a leading global manufacturer and supplier of automated processing and packaging machinery for food and non-food industries.

Located in Cambridge, Ont., Heat and Control Canada, Inc. markets itself as a true single-source for Canadian companies looking grow their food processing business.

The full line of equipment from Mountain Top Foods was installed by June of 2016, according to Calvert, with the first production run taking place in July.

With the ready-to-eat production line capable of robust running speeds of up to 1,500 kilograms per hour, Calvert says he has been extremely happy with all the equipment supplied by Heat and Control.

“Heat and Control offered a complete packaging line from the discharge of the freezer right up to checkweighing,” says Calvert, “and it all runs exceptionally well.”

From the moment product the leaves the cooking area, it is continually inspected for any defect while still on a conveyor prior to entering the spiral freezer purchased from the Vancouver-based FPS Food Process Solutions

“In my opinion, this freezer has to be one of the top spiral freezers in the world,” Calvert extols. “We really appreciate the highly sanitary and robust design of the freezer, and the level of service provided by FPS has been first-class”

After leaving the spiral freezer, the product moves along the first piece of equipment supplied by Heat and Control—the Fastback horizontal motion conveyor system that is capable of moving heavy loads at a safe but quick transfer.

“I’ve been very pleased at how gently the Fastback moves product along to the incline conveyor,” notes Calvert.“It’s an easy piece to disassemble and clean after production.”

Although the incline conveyor had some initial technical challenges, they were all resolved through Heat and Control’s excellent

After the bagged food product is packed into boxes by a Consolidated Technologies carton former, the finished packs are moved along a conveying system from Heat and Control Canada to refrigerated storage to await shipment to customers.

After emerging from the oven, the pre-cooked chicken pieces are visually examined and separated by a plant employee to ensure consistent product quality, moving along a conveyor system suppled by Heat and Control Canada. service.

“There was obviously a lot of thought put into this machine’s design in respect to sanitation and accessibility,” he notes.

After exiting the incline conveyor, the product en-ters a customized vibratory screening system, where any off-sized product is discharged out the side and down a chute to the ground level

After the vibratory screening, the product moves

onto two synchronized accumulation conveyors: one used to accumulate the product and the second one to feed the product to the weighing unit.

“If, for whatever reason, the weigher feed conveyor stops and begins to accumulate product, once it reaches a certain height, it will signal the accumulation conveyor to close a ramp,” explains Calvert.

“The accumulator will continue to fill until it reaches a pre-programmed level, at which point it communicates to the weigher conveyor to open a diversion spiral chute so product can flow to a secondary storage area, where product can be incorporated later after the problem issue has been resolved.”

The weigher feed conveyor supplies product to a Heat and Control-supplied big-bucket CCW-RV weigher, manufactured by Ishida Co.

Positioned on the plant’s upper mezzanine level, the fully-automatic 14-head Ishida scale is “an excellent and super reliable piece of equipment,” says Calvert, praising its high accuracy and consistency.

Calvert notes that Mountain Top Foods also purchased specially-designed washracks used specifically for the dispensing buckets to reduce the risk of damage during the robust sanitation process.

“Our staff really appreciates the operator touchscreen that is mounted in close proximity to the bagger on the lower level,” mentions Calvert. “The Ishida has a camera on it that projects the images of what is happening above to the screen below to help with any possible trouble shooting—saving our employees from having to run up and down the mezzanine stairs to observe what is happening at the Ishida scale.

“Personally, I just love how user-friendly the touchscreen is to operate when calling up recipes,” says Calvert. “Not to overdo it, but I’m really happy with this purchase and the bagger.”