CORRUGATED 360º

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson sjamieson@annexbusinessmedia.com

connectivit y

BOBST IS BOSS W

Converting machinery giant takes aim at North American e-commerce markets with new purpose-built EXPERTFOLD 165 configuration

ith retail e-commerce sales expected to reach an astonishing $7.4 trillion dollars worldwide by 2025, the need for converters to have the optimal equipment in place to meet the demand is increasing.

With this in mind, global converting machinery giant BOBST Group (www.bobst.com)has modified one of its most popular folder-gluers– the EXPERTFOLD series– with additional features to make it ideally suited for the demanding world of e-commerce packaging production.

Designed primarily for processing of litho-laminated boxes, the new EXPERTFOLD 165 e-commerce version is already making a big impact with converters across Europe.

Boasting two new modules—POLYVACUM and GYROBOX—the new machine already featured a highly configurable and modular design to delivering unmatched flexibility and versatility, with the modules adding significant benefit for applications in the world of e-commerce.

Designed to maximize versatility, the POLYVACUUM module’s bespoke upper transports allow for the installation of external application tools, while the lower vacuum transports ensure extremely stable transport of the blanks.

According to BOBST, POLYVACUUM enables the fitting of special folding devices as well as in-line applicators of strips and self-adhesive tapes required for e-commerce boxes.

For its part, GYROBOX helps converters to keep pace with heightened e-commerce demands.

The high-speed system can pivot blanks at any angle from 0° to 180° in the running direction—rotating boxes that normally require two passes in one single pass.

The system can rotate left to right or right to left—allowing for even most complex box shapes to run at speeds up to 250 m/min.

Even when GYROBOX is not used, the blanks can be folded and glued without any hindrance at full machine speed. This unique module enables the fast and cost-efficient production of specialty boxes, further increasing the great potential for diversification.

“Having made great waves in Europe, we are delighted to

launch the EXPERTFOLD 165 e-commerce edition in the North American market,” says Emilio Corti, market director at BOBST North America.

“We keep hearing from our customers that they need solutions that fulfil the unique demands of digital commerce.

“I think for converters, one of the most attractive aspects of the EXPERTFOLD 165 e-commerce version is that it can produce durable, returnable cartons in a single pass, which is essential for online retail.

“The flexibility of the double gyro module makes it simple to accomplish, while also allowing resealable tape and glue applications to be applied perpendicular to each other.”

The machine is also equipped with MATIC automation technology and remote control, improving efficiency even further. It is also extremely easy to operate, controlled via an innovative

HMI (human-machine interface), which allows users to save and retrieve settings on demand—enabling swift set-ups and changeovers.

Ready for the transition to Industry 4.0 manufacturing, the sleek new EXPERTFOLD is already available with Helpline Plus and BOBST Service apps, allowing remote access for fast and effective production monitoring and assistance.

“The speed of turnaround from click to delivery is central both to the customer experience and business success, and that begins with the right machinery in place,” says Corti.

“The EXPERTFOLD 165 e-commerce version can tackle even the most complex designs, producing a wide range of strong and solid boxes in a single pass, including fully recyclable packaging.

Says Corti: “The possible applications are endless: from shoes to coffee machine boxes, from pharmaceutical to FMCG (fast-moving consumer goods) and food-and-beverage containers.”

www.bobst.com

Designed for optimal flexibility and fast changeovers, the new Bobst EXPERTFOLD 165 e-commerce version folder-gluer can process even the most complex box shapes and designs at high running speeds of up to 250 m/min in a single pass.

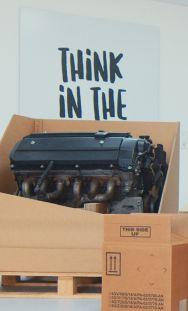

THINK BIG!

Helping industrial customers switch to heavy-duty corrugated packaging used to ship a variety of large or heavy industrial goods and consumer durables more efficiently and more sustainably

All big things should come in smart packages” is a clever and catchy marketing slogan for one of the world’s leading producers of heavy-duty corrugated packaging.

Headquartered in Weighbridge, U.K., Mondi Group (www.mondigroup.com) is a leading European supplier of sustainable heavy-duty corrugated solutions.

With operting plants in Germany, Poland and Turkey, the company specializes in creating fit-for-purpose packaging for industries as varied as automotive, chemical, machinery, metal, solar energy, heavy consumer durables, white goods, home construction and fittings, and

sports and leisure.

According to the clompany, Mondi is making good progress in terms of integrating its new Turkish-based HD corrugated plants in Bursa, Corum and Gebze with its plants in Germany (Ansbach) and Poland (Simet), following the acquisition of Olmuksan in 2021.

In recent years, Mondi has invested in new capacity, technology and machinery at its Ansbach and Simet plants, which are now some of Europe’s largest full-service, state-of-the-art facilities.

Today, Mondi Olmuksan is one of the leading players in the HD sector in Turkey, further expanding the group’s capacity to serve a broader range of industries and geographies.

“Our customers have been impressed that a HD corrugated con-

A sampling of the purpose-built, heavy-duty corrugated packaging solutions manufactured by Mondi Group for a diverse customer base operating in a broad range of manufacturing and CPG (consumer packaged goods) industries worldwide.

tainer can withstand a tonne of top weight, or that a corrugated box can safely transport heavy items through hot and humid climates,” says Gerald Dörzbach, sales director at Mondi Wellpappe Ansbach.

“Once they realize that HD corrugated solutions are a viable alternative, they get really excited about all the added benefits of customization, handling and transport efficiencies,” Dörzbach relates.

“And, of course, switching to a lightweight, paper-based, recyclable material helps our customers achieve their own sustainability goals.”

As Dörzbach explains, Mondi fully supports itd customers in making the switch to HD corrugated packaging, working closely together from initial analysis to design and implementation.

The company’s new ThinkBox customer engagement centers are providing a dedicated space for collaboration and the development of solutions in the HD and industrial segment.

This collaboration benefits customers immensely with tailor-made, lightweight solutions that provide perfect fit for oddly shaped or heavy products, while increasing the number of items per pack

and maximizing the use of limited cargo space.

“Shipping large and heavy items is increasingly complex and costly, in addition to the environmental impact,” saysTarik Aniba, sales and marketing director at Mondi Corrugated Solutions.

“That’s why we believe ‘all big things should come in smart packages,” says Aniba, citing the mutiple benefits that HD corrugated packaging offers in terms of operational efficiencies, logistics and sustainability.

“We want to reach companies who may not have considered the possibility of a paper-based alternative to traditional crates and containers, “ Aniba states.

“We look forward to developing customized solutions that not only meet their needs,” he concludes, “but are sustainable by design.”

With annual sales of about US$10 billion, Mondi is a leading vertically-integrated global leader in paper packagins olutions, from managing sustainabl from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions.

www.mondigroup.com

The Mondi Group’s MonCorr range of corrugated packaging solutions produced for Warmhaus, leading manufacturer of home heating equipment based in Turkey.

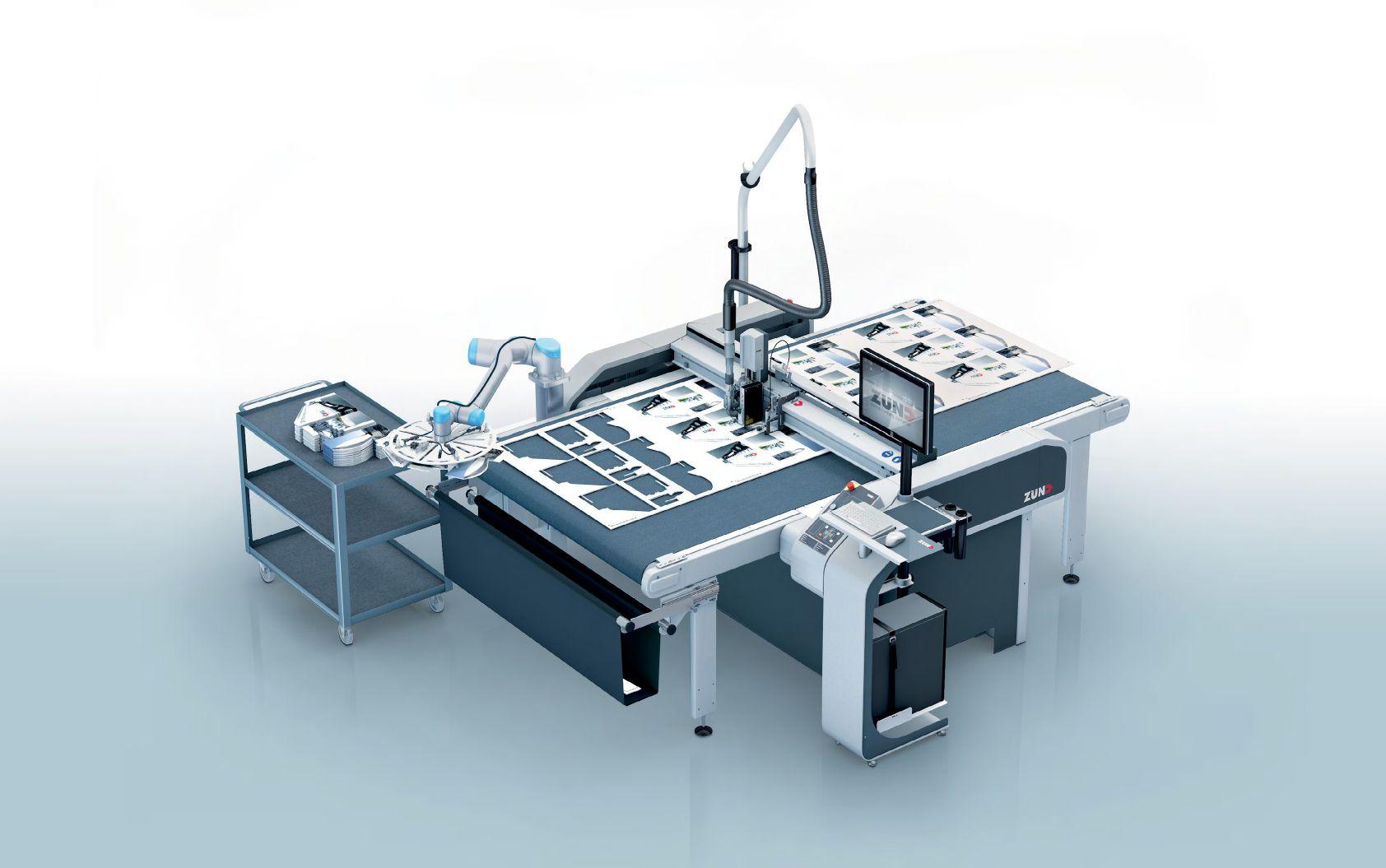

– Prepress and meta-data based production-workflow automation – Continuous productivity monitoring and KPIs with Zünd Connect

– Semi- to fully automated/robotic material-handling options #Letstalkworkflow: Call us now and visit us at ISA Sign Expo – Atlanta, May 4–6, Booth 4331.

THE PAPER TIGER

High-caliber engineering enables seamless automatic void-fill paper cushioning

Global protective packaging pioneer Pregis LLC (www.pregis.com) has engineered the first-of-its-kind paper cushioning conveyance system using air ducts.

This means that Pregis’ paper cushions created by its Easypack Packmaster Pro machines—designed to deliver a range of lightweight, robust paper cushions on demand that are easily molded around any product—can be conveyed via air blowers/aluminum ducting to a conveniently located overhead delivery hoppers.

The new delivery system significantly improves worker ergonomics and packing speed, according to Pregis, while reducing capital equipment expenditures.

“Typically, paper packaging machines are dedicated to either one or two packing stations,” explains Paul van Dijk, senior product manager paper systems at Pregis Europe in Heerlen, The Netherlands.

By conveying the paper void-fill cushions to an overhead hopper which feeds up to six packaging stations, the need to take up valuable floor space with multiple machines is eliminated,” he says.

“Additionally, packers who are using the new conveyance system tell us that it is more ergonomic for them. Finding people to staff open positions is problematic in many countries.

The Easypack Packmaster Pro machines used to manufacture 100-percent recyclable void-fill material used to provide optimal product protection for loose products shipped in corrugated boxes.

This makes creating a work environment that supports packer satisfaction more important than ever,” says van Dijk, citing cutting-edge proprietary engineering incorporated into the design of the air duct conveyance system to enable efficient operation.

Unlike other delivery systems which use conveyor belts and/ or structural poles, the Pregis conveyor-less approach is more cost-effective, uses less energy, frees up floor space and is lowmaintenance.

The air ducts move fan-folded paper, which has been created from a roll with nearly five kilometers of paper, depending on paper weight.

This significantly reduces roll changes per shift, van Dijk points out, adding significantly to process efficiency.

“For more than a decade, Pregis has a significant track record in providing overhead delivery systems for inflatable materials,” van Dijk says.

“We have taken much of the knowledge gained with those applications and applied it to our 100-percent recycled paper solutions,” van Dick adds.

“Moreover, the way we have engineered the paper conveyance ducting will allow it to work side-by-side with an air pillow system overhead for operations requiring both packing solutions at each pack station to accommodate a variable mix of items

Headquartered in Deerfield, Ill, Pregis LLC is a customer-driven solutions provider of innovative flexible packaging, protective packaging materials, equipment systems and surface protection. As a material-neutral company, the company works with its customers to find the right solution to solve their business challenges.

Dedicated to minimizing impact on the environment The company serves a wide variety of consumer and industrial market segments including food, pharmaceutical, healthcare, medical devices, agricultural, e-commerce, retail, automotive, transportation, furniture, electronics, building, construction and military/aerospace.”

www.pregis.com

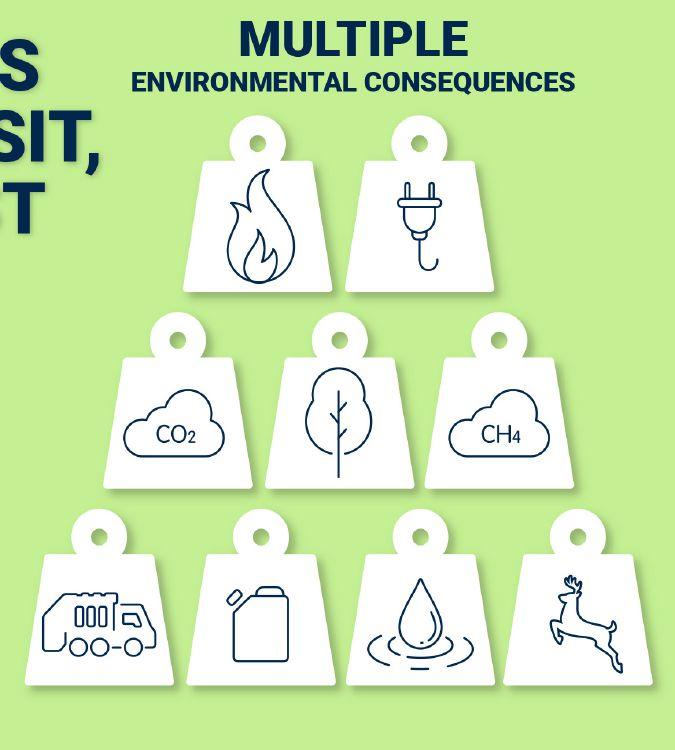

WHEN A PRODUCT IS DAMAGED IN TRANSIT, IT COMES AT A COST

BY ROYAL DECREE

Venerable independent box producer invest into a colorful future with massive single-pass press to enable high-quality mass customization

Founded almost 100 years ago in Cicero, Ill.,

The Royal Group (TRG) ranks among the largest independent corrugated box and display manufacturers in the U.S., operating over 30 locations nationwide.

Since its start, TRG (www.teamtrg.com) has grown its offerings from packaging to a wide assortment of products and services including ‘Big Box,’ protective packaging, retail-ready packaging, displays, co-packing, fulfillment, and shipping supplies.

Firmly committed to fulfilling its mission is to provide value added solutions to the most demanding customers, earlier this year, TRG invested in a state-of-the-art Delta SPC 130 Automatic single-pass press from Koenig & Bauer Durst (www.koenig-bauer-durst.com) to pro-

The Royal Group’s regional mid-Atlantic manufacturing site just outside of Philadelphia, Ps., is one of more than 30 manufacturing facilities operated by the independent

boxmaker across the U.S.

vide mass customization and high-volume, fully-automated digital production to its customers.

The six-color press, now installed at TRG’s mid-Atlantic packaging site near Philadelphia, gives customers the flexibility to print unique versions of high-quality graphics for brands and brand extensions, allowing for mass customization at a large scale.

It’s one of many TRG solutions, which range in scope from industrial packaging and brown box shipping containers to high-end graphic packaging, ecommerce, in-store displays and shelf-ready packaging.

These products serve a diverse array of markets, including retail, food-and-beverage, pharmaceutical, health and beauty, agriculture, consumer electronics and home goods, among others.

With its sustainable, food-grade certified water-based ink technology, the Delta SPC 130 Automatic, provides specific solutions for the food and retail packaging and display industry.

Most notably, the new single-pass press reduces lead times and provides excellent print quality, equivalent to flexo and offset production.

Transferring work from traditional to digital production will empower TRG to meet customer needs as the demand for both corrugated packaging and speed to market grow.

The printer’s expanded color range, adding orange and purple to the CMYK color wheel, allows it to achieve more than 90 per cent of the 3,000-plus Pantone colors, including spot coloration for specific brands.

“As both a producer and a converter of corrugated packaging, The Royal Group has made significant investments to acquire the best machinery available in the industry,” says TRG’s chief executive officer Bob McIlvaine.

“The investment in the Delta SPC 130 for our Mid-Atlantic site underpins our commitment to process improvement,” McIlvaine states. “It will enable us to provide highly automated, world-class printing capabilities at high speed s, while remaining as flexible as possible for our clients as we continue to grow our business.

“Digital packaging is the future,” McIlvaine prolcaims, “and we aim to satisfy our customers and meet their needs with innovative solutions.”

Adds Koenig & Bauer Durst managing director Robert Stable: “Successful companies such as TRG embrace trends and offer high-impact solutions for their customers.

“Brand owners want shorter lead-times, sustainable manufacturing practices, and products that freally stand out from competition.

“The Delta SPC 130 Automatic meets all those needs ,” Stable asserts, “while providing customers with the latest, most reliable, and cost-effective production method available.

“We’re happy to deliver a solution that gives both TRG and its customers the capability and competency to mass customize without compromising quality.”

Operting a as joint-venture company equally owned by Koenig & Bauer and Durst Group, Koenig & Bauer Durstdevelops, manufactures and markets single-pass digital printing presses for folding box and corrugated board production by leveraging technological focus and market expertise of the two parent companies —both in the development of digital printing systems and in mechanical engineering.

www.teamtrg.com www.koenig-bauer-durst.com

A side view of the new Delta SPC 130 Automatic digital press from Koenig & Bauer Durst installed at The Royal Group’s mid-Atlantic boxmaking facility.

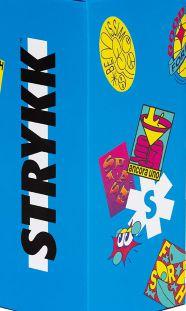

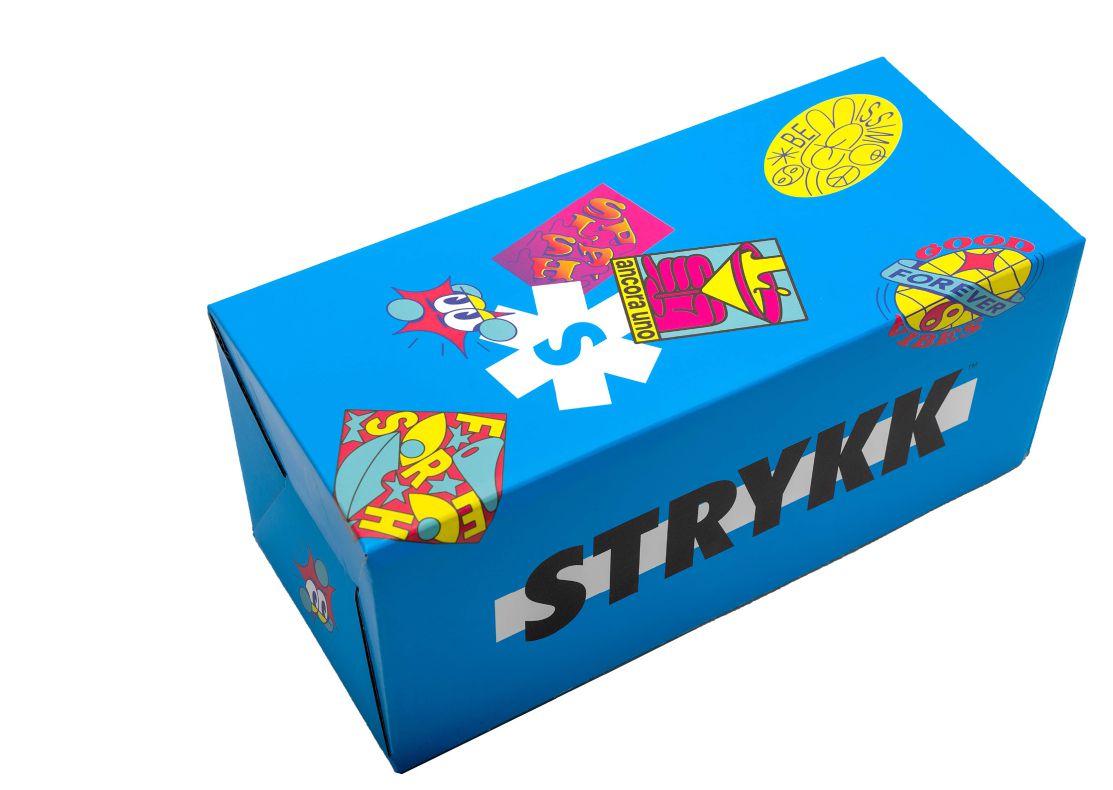

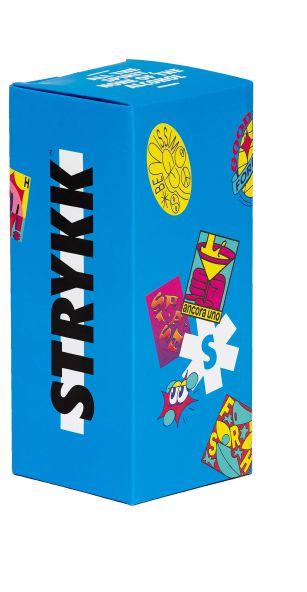

STRYKK-ING GOOD LOOKS

Bespoke corrugated packaging solution helping upstart non-alcoholic cocktail maker shake things up in the fast-growing beverage category

Founded in 1999 by Alex Carlton in London, England, Funkin Cocktails is a true innovator in the fast-growing global market for nonalcoholic spirits. A genuine bar world veteran with over two decades of experience under his belt, Carlton’s passion for new product development has resulted in a long series of exciting new brand launches— most recently the Strykk brand of alcohol-free spirits distributed around the world by various online e-commerce channels. Back in September of 2020, Carlton was in need of some expert help and guidance in developing a new drinks packaging for the brand—leading him to discover the website of U.K.-based Saxon Packaging (www.saxonpackaging. co.uk).

Since then, Saxon Packaging’s internal sales coordinator Emma Bishop has been working closely with Carlton and his team to create the perfect drinks packaging solutions for the Strykk brand family.

Together with the rest of the team at Saxon, Bishop has been able to support them in realizing their ideas and goals for the brand and transform these into outstanding packaging designs.

“To date, we have helped the Strykk team with 15 unique packaging orders and we are already working on some new designs for their future plans,” Bishop relates.

“The Strykk brand products are really making waves in the non-alcoholic drinks industry and we are proud to be supporting them as they continue to thrive.

“One of the very first projects we worked on with Strykk was for their single bottle premium drinks packaging,” Bishop relates.

“They had visions of a simple gin gift box, but they needed it to encompass a luxurious, premium feel and stand out from the fierce competition.”

As Bishop recounts, Strykk asked for a packaging solution that would not only raise brand awareness, but also deliver a moment of excitement to their customers when they receive their orders.

“In other words, they were looking for ‘the perfect unboxing experience.’

Just few weeks later, Saxon delivered “exactly what Strykk asked for,” according to Bishop.

“Happy clients are our favorite thing to see, and we are pleased to say that Alex and the Strykk team were blown away by their new premium drinks boxes,” Bishop extols. “The finished product was arguably one of the most vivid packs that we’ve seen roll out of our factory doors in quite some time.”

In the early stages of this project, Bishop spent a lot of time getting the structural packaging design just right.

“Working closely with our in-house design team at Saxon Packaging, we were able to deliver Strykk various design samples before settling on a preferred style,” she relates.

“In the midst of all this creativity, there were some challenges around which packaging material would be most suitable,” Bishop expands.

“ At the time, the print process for the project had not yet been decided, so it was difficult to choose which material grade and flute profile would work best,” Bishop says.

“Our specialist packaging team discussed all the

options available and the ultimate goal for this project.

“Originally, the premium single-bottle gift packs were intended to be printed digitally,” she says.

However, after reviewing the final artwork, the desired quantity of units and the overall purpose of the packaging, Strykk opted to go for the more premium and cost-effective lithographic (litho) print process.

As Bishop explains, litho-printed packaging is produced with a versatile print process that is commonly used for premium and luxury products.

It has the ability to produce eye-catching, top-quality graphics with the same level of finish and detail often seen in high-end, glossy magazines.

This level of printing is an absolute must for brands looking to position themselves as the premium choice in the market, according to Bishop.

With up to eight colors to work with, litho printing allows brands to showcase intricate high-resolution artwork on their packaging of choice.

Because litho-printed packaging can be coupled with a variety of print finishes and visual embellishments to enhance the packaging further, it offers an excellent solution for delivering a show-stopping experience to potential consumers.

With Strykk’s drinks packaging designed and ready to go, it was time to consider how these boxes would arrive to the customer and how we would create that wow-factor unboxing experience.

The single bottle gift boxes were accompanied by what is known in the packaging industry as an ‘outer’ box, whose primary purpose is to protect the contents inside from any damage or abrasion that can occur during the transit and delivery process.

With the unboxing experience at the forefront of the design process for this packaging solution, Strykk strategically created special artwork for the outer box that was relatively understated compared

to the box that would be packed inside.

The idea was that Strykk could now reveal a surprise-and-delight experience to those customers who opened the outer packaging with an extravagant litho printed gift box inside.

This fulfilled the design brief’s requirements and resulted in a perfect unboxing experience, according to Bishop.

“Rest assured, the outer packaging still ticks all the ‘boxes’ when it comes to helping to raise brand awareness,” she says, citing the unapologetically bold typography used for the box graphics.

“With the help of our design and production teams, the finished product is a standout example of premium packaging that we are certain will help Strykk both build their brand profile and delight their customers,” says Bishop.

“This single bottle luxury gift pack boasts the sort of color vibrancy that would make the likes of Andy Warhol turn his head!”

Says Bishop: “This was a great project to work on. While it did have its challenges along the way, we worked through them all.

“The result of Strykk’s litho-printed packaging is one that is really amazing and will no doubt stand out amongst competitors.”

Molly Bray from the Strykk team adds: “We were really pleased with it!

“The quality of the print was spot on and we can’t wait to start sending them out to our customers.”

Founded in 1986, Saxon Packaging is one of leading designers and manufacturers of high-quality corrugated packaging in the East Anglia region of the U.K., operating as a wholly-owned subsidiary of leading global paper-based packaging producer Smurfit Kappa Group.

www.saxonpackaging.co.uk

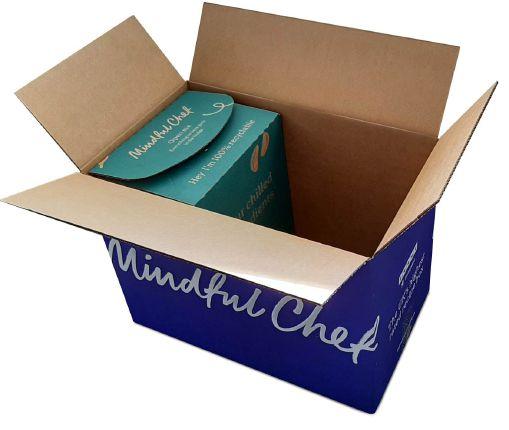

MINDFUL MANNERS

Smurfit Kappa adds the missing ingredient to sustainable recipe box

Operating as a certified carbon-neutral company since 2020, leading U.K. recipe box company

Mindful Chef has recently collaborated with paper packaging experts at Smurfit Kappa (www.smurfitkappa.com) to reduce the company’s carbon footprint even further by making their packaging more sustainable.

Having experienced a huge surge in increase in demand for its home-delivered recipe kits during the COVID-19 pandemic, the company has made it a core mission to making every aspect of its business as sustainable as possible—including packaging.

Its previous recipe box consisted of insulation pouches combined with gel ice-packs which, while effective at keeping the contents cool, were not easily recycled.

To address this issue, experts at Smurfit Kappa’s Experience Centre in Yate came up with a 100-percent recyclable alternative that was better for the environment, while still maintaining the required temperatures over extended periods.

The new solution encompasses corrugated cardboard insulation packs, with a 30-percent lower carbon footprint than the previous insulation, housed in a snug, two-piece telescopic design.

The new packaging solution was thoroughly tested at Smurfit Kappa’s International Safe Transit Association (ISTA)-certified testing lab in Northampton to ensure that it met the strict requirements for fresh food transportation.

During testing, the new packaging solution demonstrated that it kept the ingredients under 8°C for over 30 hours in ambient conditions.

Commenting on the collaboration, Eddie Fellows, chief executive officer of Smurfit Kappa for UK and Ireland, says: “We were delighted to partner with Mindful Chef on this exciting project, which resulted in improved product protection and an eye-catching packaging solution that is better for the planet.

“Many of customers are looking for tailored e-commerce solutions that meet the growing consumer demand for sustainable packaging,” Fellows states. “The teams at our Experience Centre and ISTA lab were able to create something special for Mindful Chef that meets the highest standards of social and environmental performance, alongside enhancing the brand.”

Mindful Chef’s buying manager David Waller adds: “Working in close collaboration with Smurfit Kappa has helped us in achieving our goal of becoming even more sustainable.

“Our new insulation packs are perfect for keeping our food fresh during transportation,” Waller states. “This helps to ensure that we meet our customers’ expectations which in turn ensures an excellent experience when they receive their orders.”

Headquartered in Dublin, Ireland, Smurfit Kappa, is one of the leading providers of paper-based packaging solutions in the world, generating annual revenues of about US$9.9 billion.

Employing approximately 46,000 people in over 350 production sites across 36 countries, the company prides itself on manufacturing 100-percent renewable packaging products to serve a highly diverse customer base worldwide.

www.smurfitkappa.com