AUTOMATE NOW PLUS

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com. CIRCULATION

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson sjamieson@annexbusinessmedia.com

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI

needs, whether it’s our

Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls

meters, contactors, motor controls, monitoring

or sensors, now available with IO-Link communications.

VALUE PROPOSITION

Prominent packaging machinery OEM raising operational flexibility to the next level with bold design features and diverse application versatility

By Andrew Snook

Smart. Flexible. Modular. When it comes to finding automated packaging solutions, these are qualities that many operations value above all else.

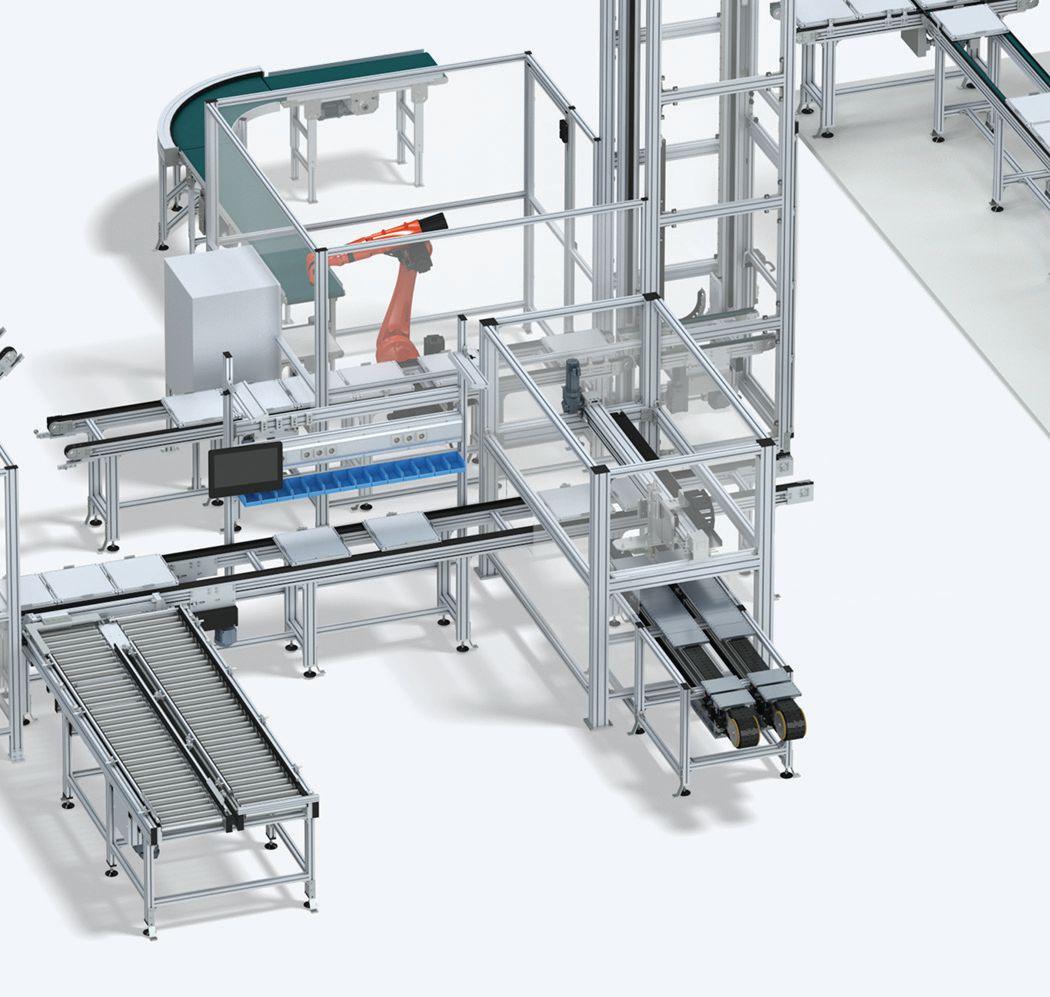

To help clients meet these automated packaging needs, R.A. Jones (www.rajones), a Coesia company, introduced its new-generation iFTS (Intelligent Flexible Transfer System) at the interpack 2023 global packaging exhibition in Düsseldorf, Germany this past May.

Making its North American debut at the recent PACK EXPO Las Vegas exhibition last month, the iFTS system was designed to offer solutions for automation challenges—from the simplest to the most complex.

According to R.A. Jones, the company has married the iFTS with its Criterion CLI-100 model intermittent cartoner to meet customers’ needs for a packaging machine with user-friendly operation and clean-up, as well as quicker and more repeatable changeovers.

The combination of the iFTS and the Criterion CLI-100 stems from over a century of experience.

“We’ve been designing cartoning and automatic product transfers for over 110 years, and we’ve been creating and implementing robotics in packaging along with other flexible automation for 30-plus years.

The new iFTS solution for R.A. Jones utilizes 3D-printed red shuttles and magnetic levitation technology to offer virtually unlimited flexibility in pick-andplace cartoning applications.

The iFTS product transfer system from R.A. Jones integrated with the Criterion CLI-100 intermittent-motion cartoning machine provides a wide range of new manufacturing and packaging applications with bag, bottles, cans, boxes and other types of packaging containers.

“This combining of technologies solves some key problems that the customers are facing daily,” explains Bob Burkhardt, product portfolio manager for cartoning, robotics and pouching at R.A. Jones.

“The iFTS we took to interpack and to Pack Expo Las Vegas is very similar to a solution we made for a customer five years ago, where they were putting pouches of spices in cartons.

“That solution worked,” he says, “but what we realized is that there are ways to do things more simply, particularly using some newer technologies that we’re demonstrating.”

The iFTS showcased in Las Vegas that can be integrated into a complete automated packaging solution offered by R.A. Jones in combination with other technologies from their parent company Coesia (www.coesia.com).

This kind of complete solution is highly sought-after by manu-

facturers with packaging operations.

“Companies are looking for suppliers that can provide complete solutions,” Burkhardt points out. “They want somebody that can provide the pouch machine, the transfer, the cartoner, conveyance, and the palletizer because they know we are then responsible for making it all work.

“They’re not having to go work with multiple companies where you can have arguments in the boundary areas about who’s responsible if something doesn’t work,” Burkhardt explains. “There’s a really big emphasis on this for us.

“It’s important because it meets the customer’s Operational Equipment Effectiveness (OEE) requirements with high system efficiencies.”

As Burkhardt relates, the iFTS is designed to offer customers a standard building block platform approach by offering it with a

wide range of fixed automation solutions, robot types and sizes, and standard or custom tooling.

In its most typical form, the iFTS receives products from upstream systems that can then be grouped, oriented, and layered for either side-load or top-load cartons or cases.

The unit is built to work alongside other Coesia and R.A. Jones packaging technologies, or be engineered for unique manufacturing applications that can include bags, bottles, bars, cans, cartons, components, medical devices, personal care, pouches, syringes, tubes and vials, and many others.

The automation options on the iFTS include smart conveyance (smart belts, indexing conveyors, two-trains), feeders, and collation, grouping and loading, which includes sweeps, pivot gates, rotary vanes, IndeCarts, and shuttle tables using magnetic levitation.

At interpack, R.A. Jones showcased a completely turnkey Pouch System that integrated the SI 280 Volpak horizontal stand-up pouching machine working alongside the iFTS, the Criterion CLi 100 intermittent cartoner, and the Flexlink RC12 cobot palletizer.

The Volpak SI 280 formed the pouches from rollstock, filled them with product, and then sealed them.

The iFTS solution then utilized 3D-printed red shuttles that were carried by magnetic levitation technology. The synchronized shuttles on the iFTS magnetic table received the pouch discharged from the Volpak pouch machine, as part of a total integrated solution.

One of the highlights of this solution is the new user-friendly HMI (human-machine interface) touchscreen to help companies manage their labor challenges.

“One thing we’ve seen coming out of COVID-19 and continuing to now is the scarcity of labor,”Burkhardt say .

“Our customers have a hard time getting workers to run these lines at times, “ he says, “and then to keep them after they get them.”

While the company has always trained customers’ employees on any new technologies they are supplying, and will continue to do so, R.A Jones believes the new HMI technology will help less experienced employees get up to speed faster.

“One of the reasons we’re going to newer technologies on our

“Companies are looking for suppliers that can provide complete solutions.”

controls for the system is because we want to have the ability to direct the new user,” says Burkhardt.

“We want to train them the first time, but like any of us, users learn through repetition and experience,” Burkhardt points out. “And since the HMI offers more guidance, that is a real benefit.”

“Our parent company, Coesia, is really leading the charge on this because that same interface on the screen will be the same between any Coesia machines,” says Burkhardt.

“And so if you have an operator running the cartoner, the iFTS, or the Volpak, the plan is for everything to have the same look and feel.”

Another innovative feature of the iFTS is the unit’s fault zone lighting option, where LEDs will light up any area experiencing a fault to help operations and maintenance staff save time in keeping the machines up and running.

“The machine will highlight that area to get them to address the issue,” Burkhardt notes. “Most of our customers choose that option these days, because it’s so beneficial,” Burkhardt says.

“And that’s one area where the technology has really advanced,’ he says.

“There’s no need to deal with glass light bulbs anymore, and in the world full of LEDs, it’s pretty affordable.”

The push-button changeover (i.e. Acc-U-Change Plus) is another important feature of the iFTS that customers have always wanted but weren’t always able to justify the cost. But with the recent labor shortages, things are changing.

“If your lines are not running because you don’t have trained people to run them, you can quickly see the cost benefit of the push-button changeover,” Burkhardt says.

“We’re actually seeing a trend where customers are more interested in the push-button changeover in general because of this feature,” he says. “With our machines, we offer different levels of

changeover assistance including Standard, Acc-U-Change, or Acc-U-Change Plus.”

Significantly, R.A. Jones has also integrated Coesia’s Performate IIOT (Industrial Internet of Things) platform for real-time machine monitoring into its iFTS and Criterion CLI-100 cartoner.

This portal is designed to allow users to access production data, downtime analysis, real-time data, key production values, machine condition monitoring, technical documentation, remote assistance, and R.A. Jones’ Webshop online parts ordering portal.

Another advantage that packaging operations get when opting for R.A. Jones’ new automated solution is the ability to learn from the company’s depth of engineering experience on the cartoning side, which can offer a wide variety of flexible solutions.

“We call it a flexible transfer system on purpose,” Burkhardt states.

“It’s about bringing the right solution for the customer, and not trying to force them into what you have.

“We have the ability to offer both standard and custom designs with our experience in running production lines, 24-hours-perday, all-year-long with two or three shifts, and hitting those OEE efficiencies in the high 90s,” Burkhardt says.

“Some of the customers we’re working with are some of the biggest CPGs (consumer packaged goods) companies in the world, and they have extremely high expectations,” Burkhardt sums up.

“And so whether it’s those companies or medium-sized or small companies, our engineers bring that same experience and intellect to everything we do.

“We are an extremely large company with a great deal of capability.”

www.rajones.com

www.coesia.com

SOIL SAMPLES

Automatic end-of-line packaging machinery ensures optimal product protection and load stability for potting soil distributors

Serving the fast-growing market for potting soils such as peat, humus and alternative plant substrates, German-based OEM BEUMER Group (www.beumer.com) specializes in supplying tailor-made packaging solutions based on standardized machine concepts to pack these materials safely and ready for transport, despite the significant differences in their consistency and other physical characteristics.

“The corona pandemic has certainly fueled the demand for potting soil, peat, humus and alternative plant substrates considerably,” says Jörg Spiekermann, head of the Consumer

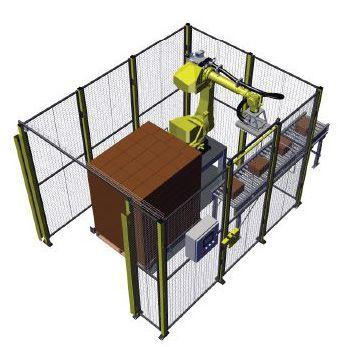

The BEUMER paletpac features a new modular design incorporating the same or similar components and modules now installed in all systems.

Goods Sales Division at BEUMER Group.

“During the pandemic people couldn’t travel anymore, so they took more care of their gardens and patios,” says Spiekermann, noting the trend is still continuing with no signs of slowing down soon.

The company’s customers—including include large retail chains, horticultural markets and owners of large garden areas who cultivate various types of vegetables in the professional and hobby sectors— turn to BEUMER for robust, durable and highly available systems that pack these products in stable and palletized product stacks.

The producers of potting soils come mainly from Europe, where the largest peat deposits are located.

The BEUMER Group supplies these producers with complete packaging lines, including high-performance palletizing and packaging machines.

For bagging and processing such as dosing, sieving and even chopping, the system provider works with partner companies, helping with selecting partners for proper consumables.

Essentially, customers receive everything from a single source.

“It’s the seasonal business that makes this industry special,” says Spiekermann, explaining that the machines have to run non-stop for several months, often in multi-shift

operation, to successfully transfer the usually enormous order quantities of different soil materials.

“The machines must always be highly available and powerful, he says, “with no downtime in this limited time frame.”

One of the biggest challenges for packaging is the different compositions of the soils. Peat, for example, behaves in a different way than humus, bark mulch and alternative plant substrates, which impacts the filling speed and the stability of both the bags and the palletized stack.

Peat is a form of humus that is a much sought-after raw material for many potting soils. It is formed in bogs, where due to the lack of oxygen under water and the acidic pH value from dead moor plants, peat is composed of incompletely decomposed and preserved plant remains, especially those of peat mosses.

These remains are saturated with water, because moors store a lot of rainwater or are fed from groundwater.

“Moist peat is particularly easy to bag,” says Volker Feldmeyer, business development manager at the BEUMER Group.

But it’s a different story for peatfree or peat-reduced soils, increasingly being used more often, because the plant materials deposited in peat consist largely of carbon compounds.

Peat is therefore an important

The BEUMER stretch hood

A is also a modular machine that allows the soil to be packed ready for transport and protected from environmental factors.

CO2 reservoir, removing carbon dioxide from the atmosphere that plants once absorbed from the air. This gas is released again during use, fueling the greenhouse effect.

It’s also a fact that peat is becoming scarce, with global reserves probably only be able to meet demand for a few more decades, and various regional mining restrictions also affecting the supply.

This is why substrates of wood fibers, compost, green waste, straw, perlite, lava, sawdust, various coconut fibers and bark humus are being increasingly used—fueling the market growth.

In addition to peat producers, more and more plants are being built in Germany that predominantly process these alternative municipal substrates.

“The materials are much coarser, and the water runs through,” says Feldmeyer. “And the coarser the earth, the more voluminous it is.

That’s why alternative plant substrates are much harder to bag and palletize.”

This is particularly the case with coarse bark mulch.

“We supply our customers with standard systems, which we adapt to the respective product,” says Spiekermann.

As he explains, these systems shake the bags less or more during the filling process to achieve optimum distribution during bagging.

The height of the bag flattening belts and the pressure force must also be adjusted in the downstream palletizing system in order to force the residual air out of the bags.

Once perfectly adapted, the bags and finished product stacks come out of the machine dimensionally stable.

“The palletized stacks can be up to 2.4 meters high,” Spiekermann points out, “so the stacking

Massive loads of bagged potting soil are fully protected from environmental elements during outside storage by the tough layer of film wrapped around each load by the BEUMER stretch hood.

Top to bottom Jörg Spiekermann, Head of the Consumer Goods Sales Division, BEUMER Group.

Volker Feldmeyer, Business Development Manager, BEUMER Group.

pattern has to be just right.

“This is relatively easy with potting soil, with the finished sacks as solid as bricks.

“But it’s much more difficult with the coarse-fibered bark mulch,” he points out. “If the pressing height is not set correctly, the bags could straighten up again after the bag smoothing process, negatively affecting the stack pattern.”

To provide the right solution for different products, the BEUMER Group offers various palletizing solutions, such as the BEUMER paletpac.

The system provider equips the paletpac with either a clamping or double-belt turning device to match product requirements.

The device quickly brings the bags into the required position and keeps them dimensionally stable.

The palletpac palletizer series is not only robust, but it is also designed for a long service life.

The BEUMER Group has completely redesigned it with a modular design using the same or similar components and modules are now used in all systems. Fewer components means fewer number of spare parts and speedier their delivery times, which has a significant impact on availability.

According to Spiekermann, BEUMER assembles the modules individually to match the customer’s requirements, tests them in-house, and assembles them at the customer’s premises. This not only saves time and money, but also simplifies any subsequent modifications and increases in performance.

The containers, precisely stacked on pallets, can then be conveyed to the downstream packaging system—the BEUMER stretch hood—which also offers the same advantages of modular as the BEUMER paletpac.

The BEUMER stretch hood covers the palletized goods with a stretch hood film that adapts itself to each stack. It is very stretchable and fixes the material on the pallet by means of horizontal and vertical contracting forces.

This process thus offers a significantly higher load stability, whereby the goods are also safely protected against environmental influences such as sun, dirt and moisture— both during handling and external storage.

Operators can transport products to their customers in perfect condition, ready for presentation at the point of sale.

“More and more customers are coming to us and demanding stretch hood film with the highest possible recycled content of up to 30 per cent in order to conserve resources,” says Feldmeyer.

“In the case of sack film, up to 80-percent recycled material content is already possible.

“These films can all be processed reliably with our stretch hood series,” he asserts.

“Our robust machines are usually in operation for 25 years and sometimes for more than 30 years,” adds Spiekermann. “The experts continuously optimize the machines, like improving energy efficiency, for example

“Another important aspect is comprehensive customer support, which ensures the constant availability of the packaging lines,” Spiekermann continues.

“The support includes, among other services, a 24/7 hotline, a rapid supply of spare parts, and service branches all over the world enabling fast support for customers everywhere.”

Says Spiekermann: “After the season, our service department takes a close look at the customer’s machine.

“Our experts check whether repairs are necessary and make them fully operational for the following season.”

Spiekermann adds he is excited about a promising market trend that more and more operators and contract baggers are turning to wood pellets or similar products in the off-season.

“These can be handled in a similar way to potting soil,” he concludes, “enables them to run our packaging lines all year round.”

www.beumer.com

“ “

The Solution is Modular Systems

-

Ernst Blickle, Co-Founder

-

MASTERS IN MODULAR AUTOMATION SYSTEMS SINCE 1945

MOVI-C®

MODULAR AUTOMATION SYSTEMS FROM A SINGLE SOURCE

END RESULTS

How palletizers address the automation trends shaping the world of manufacturing and warehousing

By Shawn Semer

Wouldn’t it be nice if a single machine could solve all your operational challenges? Though a lot of modern equipment available on the market today can come pretty close, the assumption that a single tool can be a cure-all is an unrealistic one.

Automation and robotics have become indispensable in modern manufacturing and ware-

housing, driving efficiency, productivity, and cost-savings. But with so many variables in play, it can be overwhelming to determine where to start.

The easiest way would arguably be to implement a full end-of-line solution with automation components, which would offer the flexibility, scalability, and redundancy needed to improve productivity. Realistically though, budget plays a significant role in line equipment improvements.

For manufacturers interested in automation but hesitant due to budget considerations, palletizers can serve as a cost-effective and straightforward introduction.

Full system integrations should also be considered as an alternative to single automation investments, as the push to reduce labor continues to be a priority, even on a small scale. Why is this? Let’s look at the trends driving adoption of palletizers.

Today’s culture of rapid fulfillment has pushed many manufacturers out of their comfort zones.

With the number one goal to ship as much as possible as fast as possible, the evolving dynamic of mixed pallet loads has forced manufacturers to think outside the box to keep up with demand.

Manual palletizing, predominant in many mid-range operations and distribution centers, carries limitations of being time-consuming, labor-intensive, and error-prone— leading to inconsistencies and increased risk of load instability and damaged products during transit.

Not to mention the liability and risk of injury to the workers doing this repetitive task.

By removing the manual aspect of palletizing, manufacturers can refocus their attention on the root goal—creating an efficient process that produces the highest throughput as quickly as possible. Implementing a core palletizing solution helps address another struggle across many industries: the ongoing labor shortage.

Labor challenges, including higher wages, turnover, and manual inconsistencies, have prompted many manufacturers to look toward automation to fill the resulting gaps in the production line.

Modern manufacturing emphasizes customization and real-time diagnostics to optimize performance.

Developing an overall system solution that leverages intrinsic knowledge of other components throughout the entire production line is key to achieving maximum efficiency.

Real-time diagnostics enable continuous monitoring and adjustments, ensuring the palletizer performs at its best and adapts to changing production requirements.

This level of customization and adaptability allows for seamless integration into existing systems and processes, further enhancing the overall automation strategy.

To keep up with the growing demand for palletizers, there has been a notable shift toward pre-wired systems to improve installation time-frames and minimize downtime.

With advanced software and robust equipment, robotic palletizers have become a versatile solution for operations with multiple SKUs requiring variable stacking patterns.

The varying speed capabilities of these machines and customizable intuitive interfaces make them an ideal option for high-volume production lines.

It’s important to note that not all palletizing solutions are created equal, and careful consideration is required for optimized performance and longevity. Several factors must be taken into consideration when choosing to upgrade or integrate new equipment.

Selecting the right palletizer involves careful consideration of factors such as Overall Equipment Efficiency (OEE), as well as the ability to handle cases out of specification or damaged pallets.

It is essential to evaluate the product history and determine whether a single tool or a combination of tools is needed.

Working with an OEM that has a deep bench of engineers with extensive industry experience can help reduce the stress of this often-confusing process.

This consultative approach allows for tailored solutions based on modified standards and customized tooling to meet specific requirements.

Adjustability and versatility of the software and tooling are also critical, as varying product types may require different handling methods.

While integrated systems can have multiple robots in tandem to form layers and move pallets, it’s worth considering that more automated tasks introduce more potential points of failure.

This is where the benefit of pre-installation testing comes into play.

By replicating real-world transit conditions in a controlled setting, customers can learn how their specific product can be packaged and shipped more efficiently and cost-effectively.

Finding a transit packaging partner who offers this through an ITSA-certified testing lab helps manufacturers verify opportunities for automation before investing in and implementing them across their operations.

Once a palletizer, or any new machine, has been integrated into the production line, it’s important to be sure it’s regularly

Modern manufacturing emphasizes customization and real-time diagnostics to optimize performance.

maintained and serviced promptly when necessary.

An OEM with a team dedicated to post-installation service and support helps keep your equipment operating at peak performance, minimizing downtime and keeping operations running smoothly.

Empowering manufacturers and warehouses to enhance their operations, palletizers have emerged as a strong introductory option to the world of automation.

The next generation of manufacturing innovation is upon us, and it’s crucial to recognize the increasing role that automation and robotics will play in improving efficiency, productivity, and cost-effectiveness.

While the transition to automation can seem overwhelming, partnering with a transit packaging leader can simplify the process.

By focusing on specific pain points and implementing targeted solutions, businesses can reap significant benefits and gain a competitive edge in their respective industries. www.signode.com

SHAWN SEMER

is the director of sales and marketing for Signode’s Global Automation division.

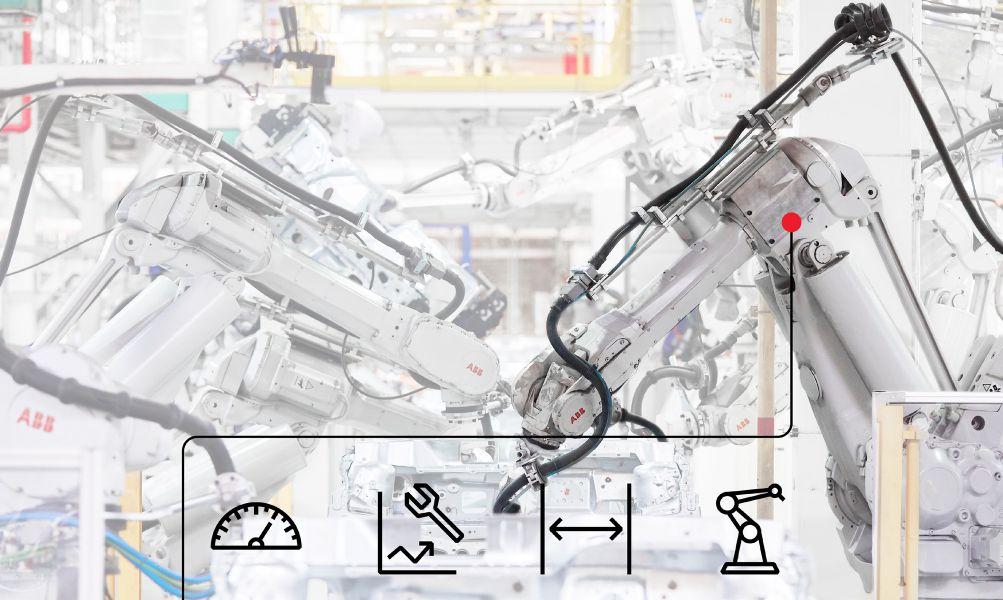

PREDICTABLE OUTCOMES

Innovations in predictive maintenance and artificial intelligence shaping the future of the packaging industry’s unfolding transformation

By Tom Egan

The packaging industry has always been at the forefront of innovation, constantly evolving to meet the demands of consumers and optimize operational efficiency. In recent years, the convergence of predictive maintenance and artificial intelligence (AI) has emerged as a game-changer, revolutionizing the way packaging and processing operations are conducted.

As stated in the new Challenges and Opportunities for Packaging and Processing Operations report, produced by PMMI, The Association for Packaging and Processing (www.pmmi.org), the integration of these technologies offers immense potential for cost savings, enhanced productivity, and improved overall equipment effectiveness (OEE).

Traditionally, packaging operations have relied on preventive maintenance, following a predetermined schedule of inspections and component replacements.

However, this approach often leads to unnecessary downtime and costs, as maintenance is performed even when equipment may not require it.

Predictive maintenance takes a more proactive stance, harnessing data-driven insights to predict and prevent failures before they occur.

One of the primary advancements in predictive mainten-

Effective predictive maintenance strategies leverage the power of artificial intelligence to help maintenance teams identify machine anomalies and trouble spots before they cause equipment breakdowns and production downtime.

WHERE CPG COMPANIES STAND

ance is the Internet of Things (IoT).

By equipping packaging machinery with sensors, it becomes possible to monitor various parameters in real time.

These sensors collect data on temperature, vibration, pressure, and other vital metrics, which are then analyzed using machine learning algorithms.

As a result, maintenance teams can identify patterns and anomalies, enabling them to intervene promptly and prevent equipment breakdowns.

Moreover, the integration of predictive maintenance with AI offers a higher level of accuracy and efficiency.

Machine learning algorithms can analyze vast amounts of historical and real-time data to detect subtle patterns that human operators might miss.

By continuously learning from data, AI-powered predictive maintenance systems become increasingly accurate over time—optimizing equipment performance and minimizing unplanned downtime.

PACKAGING MACHINERY DOWNTIME

Artificial intelligence is revolutionizing the packaging industry in numerous ways by enabling the automation of complex tasks, enchanting quality control, and streamlining production processes.

Here are some of the most impactful AI applications in packaging to date:

• Quality Control and Inspection. AI-powered vision systems can inspect packaging materials quickly and accurately, ensuring quality standards are met.

These systems can detect defects such as scratches, dents or printing errors in real time, significantly reducing the risk of faulty products reaching the market.

• Intelligent Robotics. AI-driven robots are transforming packaging operations, increasing speed and precision.

These robots can handle repetitive tasks like picking, placing, and packaging items, freeing human workers for more value-added activities.

Advanced AI algorithms enable robots to adapt to

changing conditions, making them highly versatile in various packaging scenarios.

• Supply Chain Optimization. AI algorithms can analyze vast amounts of data, including sales, inventory, and market trends, to optimize supply chain operations.

By predicting demand patterns, AI systems help streamline inventory management, reduce waste, and ensure optimal stock levels.

Additionally, AI-powered route-optimization algorithms optimize the delivery process, minimizing transportation costs and improving efficiency.

• Personalization and Customization. AI allows packaging manufacturers to cater to individual consumer preferences.

By analyzing consumer data and preferences, AI algorithms can generate customized packaging designs and produce them efficiently.

This level of personalization fosters consumer engagement, brand loyalty and, ultimately, increased sales.

While the advancements in predictive maintenance and AI present a promising future for the packaging industry, there are challenges to overcome.

One of the primary obstacles is the collection and analysis of vast amounts of data generated by sensors and machines.

This requires robust data infrastructure and analytics capabilities to ensure accurate predictions and preventive actions.

Furthermore, the implementation of predictive maintenance and AI requires skilled personnel who can manage and interpret the data effectively.

Upskilling the existing workforce and attracting new talent with expertise in AI and data analytics will be critical for organizations to fully harness the potential of these technologies.

However, the opportunities presented by these innovations are substantial

According to PMMI’s report, companies adopting

IMPLEMENTATION

HARDWARE

Using smart sensors to collect useful data for OEMs and system integrators.

BENEFITS

Reduced downtime and increased machine lifetime.

REVENUE

Shifting to MaaS pricing models, offering middle ground for end users and OEMs.

CYBERSECURITY

A valid concern and key barrier to allowing remote access.

MOST USEFUL DATA TYPES

Machine learning algorithms can analyze vast amounts of historical and real-time data to detect subtle patterns that human operators might miss.

predictive maintenance and AI can expect significant cost savings, reduced downtime, and improved OEE.

By preventing equipment failures, businesses can avoid costly repairs, maintain consistent production levels, and enhance overall operational efficiency.

Moreover, the integration of predictive maintenance and AI can lead to more sustainable packaging practices.

By optimizing production processes, reducing waste, and improving resource management, packaging manufacturers can minimize their environmental impact and contribute to a greener future.

The packaging industry is undergoing a transformative journey driven by innovations in predictive maintenance and artificial intelligence.

The convergence of these technologies enables organizations to unlock new levels of efficiency, productivity, and sustainability.

By leveraging the power of predictive maintenance, packaging operations can transition from reactive to proactive maintenance approaches, significantly reducing downtime and costs.

Furthermore, AI applications across the packaging value chain enhance quality control, improve supply chain management, and support personalized packaging experiences.

As PMMI’s report highlights, organizations that embrace these innovations stand to gain a competitive edge

in an increasingly dynamic marketplace.

With proper investment in infrastructure, talent development, and collaboration with technology providers, packaging companies can embark on a transformative path toward a more efficient and sustainable future. The possibilities are vast, and the time for embracing these innovations is now.

www.pmmi.org

TOM

KEEP IT CLEAN

Mobile ‘smart cart’ automates food conveyor CIP procedures for food packagers using tubular conveyors

By Del Williams

To promote food safety and sanitary compliance, food packagers are increasingly seeking the ability to Clean-in-Place (CIP), an automated method of cleaning the interior surfaces of tubular drag conveyors without disassembly.

Now, with the advent of mobile tools like an innovative “smart cart” that quick-connects to any tubular conveyor and enables simple, customizable “single button cleaning recipes,” CIP is becoming easier, faster, less labor-intensive, more repeatable, and almost fully automated.

Tubular drag conveyor systems gently move product through a sealed, enclosed tube using a drag cable and circular discs pulled through on a loop, so are ideal for delicate items.

In a wet CIP process, the system is flooded with water, flushed, rinsed, cleansed, and thoroughly sanitized.

The process thoroughly flushes out any potential allergens like nuts or

The smart cart is designed to store and utilize pre-programmed CIP recipes to flush various residual materials from the tubular drag conveyors in a facility before new production runs.

For an automated, wet Clean-in-Place process, a technician can push a cart with pre-programmed recipes and integrated water line hookups to tubular drag conveyors, facilitating quick sanitary compliance and production changeover.

gluten from conveying equipment and can be used with a variety of food types such as nuts, grains, cereals, powdered soups, and frozen fruits and vegetables.

Although the CIP process is very effective, streamlining its automation and simplifying the process for all of a facility’s tubular drag conveyors has been a priority for leading innovators in the industry.

“The standard system required port hookups to water lines and installing piping,” says John Adair, engineering and quality director for Cablevey Conveyors (www.cablevey.com), Oskaloosa, Iowa-based conveyor manufacturer

that has designed, engineered, and serviced enclosed cable and disc tube conveyors for 50 years.

“The processor also had to make decisions such as which water temperatures to utilize, or whether to use a cleaning solvent - and the correct amount to add manually,” Adair points out.

To simplify the wet cleaning process, Adair and his engineering team at Cablevey have developed a small, mobile “smart cart” with integrated water line hook-ups that a single technician can easily take to any tubular drag conveyor in a facility.

The cart is specifically designed to be a fraction of the size of similar carts on the market to facilitate mobility.

When the cart is in position and connected to water lines, the CIP process is automated and controlled by a programmable logic controller (PLC) that reduces the need for manual labor and virtually eliminates the risk of improper cleaning.

“Once it is set up, all you do is press a button and it will bring in the required amount of water at the correct temperature with the necessary amount of solvent for cleaning,” says Adair.

The ‘smart cart’ is designed to store and

utilize pre-programmed CIP recipes to flush various residual materials from the tubular drag cable conveyors in a facility before new production runs.

The cleaning recipes enable even those with very little training to use the cart.

This is helpful in today’s tight labor market and allows the technician to move on to other tasks once the cleaning process begins.

The use of easily executable recipes ensures a superior, repeatable clean that essentially “error proofs” the process.

This is particularly important when the technician may be new or less familiar with the

Close-up of the integrated water line hook-ups to tubular drag conveyors.

production equipment.

“Depending on the product being conveyed, sometimes all you need is a wet rinse, or sometimes you need a specific cleaning solvent,” says Adair.

“All that information is saved, so after the first cleaning, it can be automatically repeated.

“Just push a button to start the appropriate recipe, whether you have one conveyor running multiple products, or dozens of conveyors running various products.”

To facilitate food safety compliance, the smart cart also documents all critical CIP information such as water volume and temperature, chemicals used, and cleaning time by date in an easily retrievable data log.

Since decreasing production downtime between conveyor cleanings is a priority for food packagers, Cablevey provides new capabilities with the cart that expedites the CIP process.

Currently, the CIP process floods the tubular conveyor system but is not designed to specifically clean the discs.

“Operators would manually clean each disc and advance the system disc by disc when the discs had to be cleaned of particularly viscous substances,” says Adair.

Now, as an option on the cart, a disc washer can be integrated with the conveyor turnaround to spray a pressurized cleansing solution on the discs.

This helps to remove stickier substances like chocolate that could remain after routine CIP cleaning.

“The disc washer sprays high-pressure water directly on the discs, so it acts like an automatic car wash,” Adair explains.

“At the push of a button, the discs and cable are run through and spray-cleaned, which reduces CIP time and eliminates the need to manually clean the discs.”

To further reduce downtime, Cablevey also offers a new sanitary blower option.

“After the wet CIP process, a sanitary blower attachment on the smart cart can dry the discs and other parts of the system 75 per cent faster than typical air drying,” says Adair.

“The faster that the conveyor is cleaned and dried after a product change,” Adair points out,

“the sooner it can be put back into service. While the food packaging industry is aware that automated CIP can improve conveyor system production uptime, barriers to implementation have slowed adoption.

Utilizing a mobile smart cart with integrated water hook-ups can help many food packagers to easily implement CIP in tubular drag conveyors throughout their facilities, thereby expediting conveyor cleaning, speeding up the production changeovers, and end insuring full sanitary compliance.

www.cablevey.com

DEL WILLIAMS is a technical writer based in Torrance, Ca.

The cart is specifically designed to be a fraction of the size of similar carts on the market to facilitate mobility.

The use of easily executable recipes ensures a superior, repeatable clean that essentially “error proofs” the process.

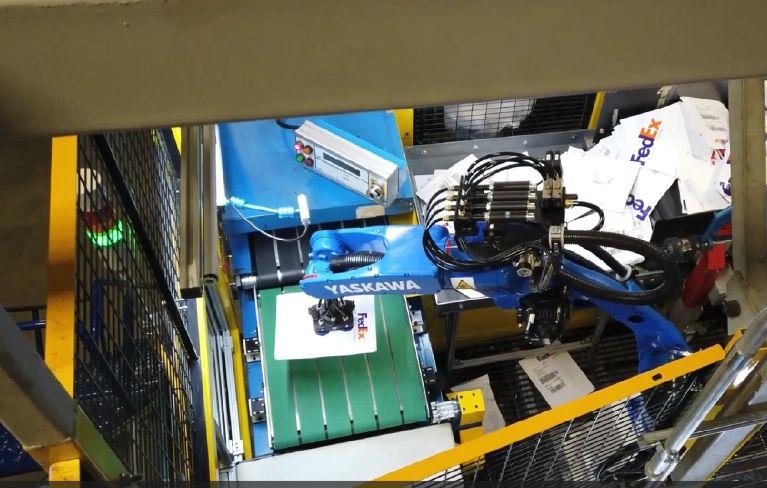

EXPRESS MAIL

Vision software helps FedEx keep the parcels moving with near-perfect accuracy and efficiency

Plus One Robotics (www.plusonerobotics.com) , a provider of advanced AI vision software and solutions for robotic parcel handling based in San Antonio, Tex., has announced customer programs using Yaskawa Motoman (www.motoman.com) robots for Plus One’s induction and mixed depalletizing solutions.

This deployment of Plus One and Yaskawa robotic solutions consists of 12 new induction systems acquired by FedEx Corp.— building upon the four existing robotic systems in use at the FedEx Express Hub in Memphis, Tenn.

Additionally, Plus One successfully introduced its mixed depalletizing systems at the FedEx facility in Reno, Nev., to allow for more efficient movement of cases from palleted shipments throughout the FedEx facility with the use of Plus One’s human-in-the-loop software Yonder that allowing for remote supervision of

the robots.

“The technology in these depalletizing arms helps us move certain shipments that would otherwise take up valuable resources to manually offload,” said Brian Marflak, FedEx vice-president of global engineering, research and technology.

“Having these systems installed allows team members to perform more skilled tasks such as loading and unloading airplanes and trucks.

“This has been a great opportunity for robotics to complement our existing team members and help them complete tasks more efficiently.”

“We’re proud that the Plus One solutions not only achieve the throughput necessary to fill the workforce gap experienced by all distribution centers, but do so with near 100-percent fulfillment accuracy,” says Plus One chief executive officer and co-founder Erik Nieves.

“This not only keeps the operations running 24/7, but also provides benefits like ergonomics, safety, and the flexibility to handle the variance associated with seasonal shipping schedules.”

Key to Plus One Robotics’ effectiveness is its remote supervision software Yonder. Utilizing human-in-the-loop capabilities employees, or Crew Chiefs, it can supervise multiple robots from any location allowing robots to handle a pick exception and return to autonomous operation within seconds.

Utilizing Crew Chiefs to remotely supervise the robots helps organizations reduce downtime and creates a workforce multiplying effect that keeps parcels moving while freeing up on-site employees for other higher-value work. The software then uses this data to improve the machine-learning model for future picks.

“With Plus One’s incredibly fast image acquisition and processing, Yaskawa robots can achieve maximum production potential,” states

Doug Burnside, Yaskawa Motoman vice-president of North American Sales and Marketing. “This, combined with the intuitive Yonder remote supervisor support helps to efficiently and accurately manage robot operation for more fluid production.”

www.plusonerobotics.com

www.motoman.com