AUTOMATE NOW PLUS

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson sjamieson@annexbusinessmedia.com

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid

energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls

SMART MOBILITY

Mobile robotics the unsung heroes of Smart Factory automation evolution

By Jim McMahon

Smart Factories are no longer visions. While different model factories represent the feasible, many plants exemplify how the Smart Factory functions.

Automation providers are taking Industry 4.0 to a new threshold. Leveraging interconnected automation with the latest controls technologies, they enable a more seamless production flow to be engineered and implemented, attaining the highest levels of operational predictability and production efficiency.

The exchange of data between production processes is facilitated by the Ethernet and the Cloud-based Industrial Internet of Things (IIoT). These systems also communicate and cooperate in synchrony with humans. This cyber-machine/human integration enables a much more efficient connection of processes and better organization within the production environment.

Robotics are a key operation of intralogistics and Smart Factory integration, delivering flexibility, speed and accuracy—making them ideal for productivity enhancements in a wide range of manufacturing and distribution applications.

From a safety perspective, robotics minimize the risk of fatigue and injury that human labor is subjected to in repetitive and hazardous applications.

Accordingly, manufacturing and distribution executives increasingly turn to robotics, and specifically automated guided vehicles (AGVs), as a

Automated mobile robots perform tasks that are not possible with other transport systems.

Grenzebach’s model OL1200S AMR positions loads to within a fraction of an inch of their designated targets with 360° autonomous mobility.

solution for transporting materials and parts between assembly, production, distribution and fulfillment operations.

The use of AGVs has played a pivotal role in facilitating process and throughput efficiency and supporting the integration to Industry 4.0.

Interfacing with multiple systems, AGVs provide reliable raw material and product handling, with near zero potential for product damage.

Utilizing a combination of logic software and wireless navigation, AGVs can perform tasks that are not possible with other transport systems.

This includes the uniform movement and positioning of loads to within a fraction of an inch of their designated targets, with minimal noise, and with a high degree of safety for workers and their operational environment.

One of the more recent developments of AGVs has been the rise of automated mobile robots (AMRs) to support goods-toperson picking.

The AMRs transport common load carriers like tables, carts, racks and shelves to specified locations throughout manufacturing and distribution facilities.

Their focus is to significantly reduce time and effort required for order picking, whether that be for raw materials, kitting parts for assembly, or parts and finished products for shipping. Order fulfillment for assembly line kitting and shipping spare

parts and finished products is a critical and labor-intensive process in manufacturing and distribution.

Most facilities utilize a person-to-goods model for order fulfillment. Workers walk or move a lift truck to where the inventory is located and manually pick items.

This is highly labor-intensive and leads to slow process flows where time is mainly spent locating and retrieving items to fill orders.

Manufacturing and distribution executives, looking for more efficient order picking solutions, have embraced automated goods-to-person systems where inventory is brought to the picker who is comparatively stationary.

Since the picker does not have to walk, up to a 60-percent reduction in travel time is realized.

Because operators are presented with only the goods needed for orders, goods-to-person systems reduce the chances that workers will pick the wrong items—improving accuracy and productivity, and reducing the high cost and disruption of customer returns.

One of the latest generation mobile robots, the model OL1200S AGV from Grenzebach Group (www.grenzenbach. com) performs tasks that are not possible with other transport systems.

This includes the uniform movement and positioning of loads to within a fraction of an inch of their designated targets with 360°

autonomous mobility.

The robot accomplishes this with minimal noise, with a high degree of safety for workers and the operational environment, while fully supporting Industry 4.0 interconnectivity.

Grenzebach is a global leader in the design and manufacturing of robotic handling applications, control technology, and complete fabrication lines for manufacturing, processing and automation in a multitude of industries.

With 650 specialized engineers, the company is capable of building customized AGVs for unconventional, difficult or hazardous production environments; heavy-duty AGVs for loads such as engines, drive trains or aircraft modules; long-load AGVs for transport of oversized goods and production parts; and AGVs for handling of sensitive IT infrastructure.

The company’s primary objective in the development of the OL1200S mobile robot AGV was to design nothing less than a new generation of autonomous goods transport vehicle.

Specifically, oen that delivers a higher level of goods-to-person functionality supporting both manufacturing and warehousing applications of goods receipt, production, storage, order fulfillment and dispatching, with complete intralogistics integration of Smart Factory Industry 4.0 connectivity.

The OL1200S mobile robot transports goods carriers (carts, shelves and racks) to destinations in production and warehousing autonomously and accurately for subsequent manual order ful-

AMRs transport common load carriers like tables, carts, racks and shelves to specified locations throughout manufacturing and distribution facilities.

AMRs support assembly line kitting and shipping spare parts and finished products.

fillment.

The robot frees workers from performing heavy-load and ergonomically-straining tasks, while providing a safe operating environment for workers.

The entire process is coordinated by a software ecosystem that not only controls the transport vehicles, but also ensures a maximally efficient workflow.

Here are the 12 key functionalities that make the OL1200S exceptionally robust, highly maneuverable, and quick mobile transport system for both production and warehousing applications:

• Lithium Power. Equipped with a 48 VDC lithium iron phosphate battery, providing up to 80 amperes charging current, the OL1200S delivers a top speed of 3.7-mph (one meter per second) when loaded, with a maximum uptime of six hours.

• 360° Mobility. The OL1200S is omnidirectional, with positioning accuracy ± 0.6 inches (15-mm). It can move freely in any direction and rotate on its axis while stationary, with maximum performance in the smallest of spaces. Narrow pathways, 90° curves, turning maneuvers and cross-docking with goods carriers are all easily accomplished tasks.

• Flexibility with Changing Tasks. With smart sensors and SLAM (Simultaneous Localization and Mapping) navigation enabling the vehicles to map out unknown environments, the OL1200S reduces static peripheral requirements to a minimum. It does not require permanently installed stations for the pick-up and delivery of goods carriers, thus creating ideal conditions for highly flexible production environments.

• Low Height. Due to its low construction height, the OL1200S can tunnel under a variety of different load carriers, including tables, carts, racks and shelves.

• 360° Travel Area Monitoring. A 360° 3D vision system detects disruptive factors with a minimum size of approximately two inches (50.8-mm). This prevents transportation damage caused by collisions with obstacles in the operating area, such as protruding components, partially open roller doors or forklift tines.

• Autonomous Load Carrier Detection. The OL1200S detects the position of inaccurately placed load carriers with a variance range of +/- 9.8 inches (250-mm). The vehicle locates the goods carrier placed in the transfer zone and automatically compensates for manual positioning errors.

• Long and Heavy Payloads. The maneuvering ability of the OL1200S makes it particularly suitable for long loads. The AGV can transport up to 1.3 tons (2,645 pounds) lengthwise or crosswise.

• 360° People Safety. Equipped with two LiDAR (light detection and range) laser scanners (front and back), the OL1200S provides safe operation for nearby workers.

• Scalable for Production Volume Changes. The OL1200S fleets are immediately and easily scalable to changing throughput requirements.

• Adaptability to varied environments. The mobile robot fleet is designed to integrate into existing environments, such as elevators, robotic cells, conveyors and packaging systems within a temperature range of 50° – 104° F (10° – 40° C). Due to the system’s SLAM naviga-

tion, there is no need to set up protected areas.

• Space Consolidation. The omnidirectional maneuverability of the OL1200S permits storage units to be located more compactly within tighter spaces.

• VDA 5050 Compatible. Dsegned to allow forMaximum freedom for plant planning, the OL1200S can be combined with automated guided vehicles from other manufacturers under a single software control center via the VDA 5050 interface.

Grenzebach’s OL1200S mobile robot AGV technology is dependent upon state-of-the art software solutions for all intralogistics functions within manufacturing and distribution.

The management and control software provides critical intelligence capabilities to seamlessly manage inventory and perform goods transport operations within the integrated intralogistics environment. These software systems encompass the following:

• Lightweight warehouse execution system (WES);

• Warehouse control system (WCS), with an integrated fleet manager system (FMS);

• Cloud-based IIoT platform SERICY;

• Application server, functioning as a modular control center.

The WES’s intelligent prioritization system, optimizes order processing at workstations. At the pick gates, the standard integrated pick-by-light and put-to-light system supports fast and process-reliable order picking, enabling the AGVs and employees to work together efficiently.

The WES manages requirements for same-day delivery, deadline dispatch, serial number tracking, and last-minute order changes, while providing process security for flow of goods, inventory and warehouse stock.

The Grenzebach WCS takes over warehouse management tasks in production and warehousing

The OL1200S, equipped with a 48 VDC Li-ion battery, provides up to six hours uptime.

environments for optimized control of logistical processes in the mobile robots’ automated transport of goods.

The software also serves as the interface between the company’s ERP (enterprise resource planning) and the Fleet Manager System.

Using the WCS, users manage goods carriers and items within the mobile robot AGV system and assign them to different storage locations.

In addition to the automatic creation of jobs, transport orders can be easily created via tablets at individual process stations.

More complex material flow sequences can be linked to conditions such as the selection of buffer and storage locations. The WCS also enables universal fleet management via VDA 5050. Grenzebach’s Fleet Manager System coordinates all transportation and handling tasks of the robotic AGVs.

Distances and cooperation of the fleet are continuously optimized, and the FMS provides for smooth integration into the plant’s software ecosystem, such as the ERP.

The software coordinates all vehicle movements based on transport orders and feedback given by the ERP, using robust algorithms to ensure an intelligent selection of vehicles and optimized deadlock-free route finding based on CAD.

It also controls the following functions:

• Energy management of the vehicles—monitoring of battery conditions and smart charging management;

• Alarm management—sending information about faults in the system;

• Management of rights —integration of a role-rights-concept carried out by the Grenzebach security manager;

• FMS interfacing to external periphery, such as external hardware like robots, hall doors, elevators, etc.;

• Providing controlled shutdown of the equipment following a pre-defined scenario in the event of fire.

A web-based user interface provides a comprehensive overview and visibility of the system, such as travel paths, vehicles, and logistics processes (picking stations, put wall, pick-by-light and put-to-light systems, safety equipment, charging technology and transfer stations).

For both warehouse and manufacturing, the Grenzebach’s SERICY platform controls, monitors and optimizes all processes with complete transparency.

The modular platform incorporates apps preconfigured for intralogistics that enable a holistic digitization.

In addition, SERICY brings the process data from all machines together for use in all departments within the company, including manufacturing, and distribution.

Linking the historical information system of the company by using standardized interfaces, SERICY can be used on-premises, or in a private Cloud, and it is arbitrarily scalable due to its architecture.

The software digitally integrates data and solutions, resulting in optimized mobile robot transport activities that guarantee reliable and in-time delivery of components to workers and assembly robots in manufacturing, and parts and finished goods to fulfillment for shipping.

Functioning as a modular control center, the application server proactively controls and directs all logistics sequences in manufacturing and distribution processes, while integrating transport equipment and devices.

The collaboration of automated mobile robot AGVs for goods transport, combined with intelligent connectivity, has enabled outstanding control and a better assurance of reliable product assembly and distribution.

All in all, Grenzebach’s OL1200S mobile robot technology gives manufacturers a truly holistic solution to intralogistics with a more ‘lean,’ efficient, productive and versatile process for goods transport in assembly and distribution operations.

Most importantly, this powerful technology firmly positions manufacturers to take advantage of the vast benefits available from Smart Factory Industry 4.0 intralogistics. www.grenzebach.com

Jim McMahon is a freelance writer specializing in industrial, manufacturing and technology issues.

Low-profile AMRs can tunnel easily under tables, carts, racks and shelves.

Coordination of all vehicle movements based on transport orders and feedback given by the ERP.

Web-based interface provides complete overview and visibility of the system.

TEST DRIVE

A conveyor OEM testing facility lets food packagers verify the performance of their product on tubular disc and cable conveyors

By Del Williams

Even when people love the look of a car or SUV, most would not complete a purchase before a test drive to confirm how the vehicle performs on the road.

Similarly, today an increasing number of food packagers are realizing the importance of “test driving” conveyor equipment at OEM test facilities, which use their actual product to ensure the equipment meets processor quality, flow, and cleaning requirements before they make the purchase.

In response, some OEMs have invested in state-ofthe-art test facilities that allow food packagers to run product on the same type of equipment they are considering for purchase, while benefitting from expert

AUTOMATE NOW PLUS

consultation to optimize their process.

“We encourage food processors to test their products [at our facility] and observe the results to ensure it meets their needs,” explains Larry Van Zee, recently-retired executive vice-president at Cablevey Conveyors (www.cablevey.com) in Oskaloosa, Ia.

“They can ask questions in real time. They can test for fines or degradation. They can see for themselves how the product flows in the conveyor and how easy it is to clean,” Van Zee states.

With system installations in 66 countries, Cablevey is a well-known mechanical conveyor manufacturer that serves the food packaging, specialty food, coffee, powder, nut, frozen food and pet food markets.

At its full-service product test center in Oskaloosa, the OEM has tested more than 1,900 products, including beans, rice, grains, cereals, coffee, chocolate, and caramel corn peanut snacks, for some of the largest global brands.

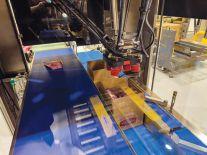

All products are run through a tubular disc and cable conveying system to observe the effects and fine-tune the results.

According to Cablevey’s product testing manager, Scott Berning, there are multiple reasons food packagers decide to visit the test center.

“Customers may have products that we know will run well on tubular cable conveyors, but they want to see it in operation with their own eyes,” says Berning.

“They want to ensure the product will run properly, and their quality department typically checks as part of their due dili-

gence before purchasing equipment.”

Berning adds that when Cablevey’s applications department designs and quotes a conveyor and the manufacturer lacks sufficient experience conveying a specific product, the email quote states it is “pending successful product testing.”

Some food packagers want to evaluate tubular cable conveyors against other conveying options they may also be considering, such as bucket elevators or chain conveyors.

Others are already familiar with tubular cable conveyors based on experience, and want to show their managers that a similar solution could be implemented at their current facility.

Once the food packager is at the site, Cablevey product specialists and engineers typically consult with the customer to determine their specific goals and issues to be resolved.

Once done, they can proceed to design a conveyor with a set of features that addresses specific challenges.

“Our technicians and engineers can diagnose and prescribe a solution whether the concern is breakage, temperature, stickiness, abrasiveness or other issues,” says Berning.

He notes that when food packagers test products at the facility, they are provided with full documentation of the results, including a detailed report with video and recommendations.

According to Berning, testing for product fragility and damage is usually the primary concern for food packagers.

Top to bottom

All products are run through a tubular disc and cable conveying system to observe the effects and fine-tune the results.

Technicians and engineers can diagnose and prescribe a solution whether the concern is breakage, temperature, stickiness, abrasiveness, or other issues.

“No matter the product —whether it’s a cereal, crackers or nuts—processors want to keep their product intact and avoid damage during conveying,” says Berning.

He points out that tubular drag cable conveyors excel at reducing product damage, since the units gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop.

Featuring solid circular discs (flights) attached to the cable— pushing the product through the tube without using air pressure—these conveyors can transport delicate, precise blends for a wide variety of food types, at up to 2,000 cubic feet per hour of materials, in versatile layouts and configurations.

Still, quality assurance checks can be essential for packagers even those transporting products that seem hard to damage, like flour.

“For flour, it can be hard to tell if it is being damaged, but maintaining the particle size is important,” Berning explains.

“If flour is transported too roughly, the particles can become finer, leading to inconsistent recipes and cooking results.

“So, there is a lot of science that goes into the testing.”

Reducing product loss and maintenance is also important to packagers, according to Berning.

“Processors want to place their material in an inlet and then have all of it emerge from the discharge with minimal losses,” he says.

“Since tubular cable conveyors are sealed from end-to-end, with product traveling one way in enclosed tubes, there is essentially no product loss and no issue with carry-back.”

The ease of cleaning the conveyor is also a top priority for food packagers, many of who visit the facility primarily to witness how easily the conveyor can be cleaned.

“People come here from across North America just to watch me perform a conveyor wet-clean and washdown, even though it is something I have to do every day,” says Berning.

“Traditional alternatives like screw conveyors can be difficult to clean and require time-consuming disassembly, as well as some heavy lifting after each product changeover,” he says.

“One food processor told me that it took six of his technicians

With easily accessible, advanced product testing facilities, food packagers can view and verify in real-time that their investment in new conveying equipment will meet their requirements.

about eight hours to clean their screw conveyor system,” Berning relates. “They had to pull a big auger out of the screw conveyor, which was dangerous to handle.”

In contrast, tubular drag cable conveyor systems offer easier, safer options for dry and wet tube conveyor cleaning. Equipment such as brush boxes, urethane wipers, air knives, inline sponges, and inline bristle brushes can facilitate multi-step, essentially automated, Clean-In-Place (CIP) wet cleaning.

The wet cleaning process internally cleans the cable conveyor tube in several steps, starting with a water rinse and followed by introdcution of foaming agent, a sanitizing rinse, and a final water rinse. Once the system is thoroughly flushed out, drying is achieved by attaching urethane wipers to the tubular conveyor’s discs, which act like a ‘squeegee’ to remove any residual water.

For those unable to visit the test facility in person, Cablevey now offers the ability to view and respond to product testing live via a virtual visit with a link to real-time video and a Zoom meeting-type format—an option developed during the COVID-19 pandemic.

With this technology, the tubular cable conveyor manufacturer can host both in-person and virtual visits simultaneously, which is helpful when larger work groups such as quality assur-

ance teams have an interest in evaluating the conveyor.

“In one recent product test, a team of four visited our facility in person, while 12 others watched virtually,” says Berning.

For those who wish to experience the world-class facility in greater detail, Cablevey has created a 360-degree immersive virtual tour of the product test center on its website, featuring an embedded virtual reality (VR) experience with full product information and videos.

The video library demonstrates how tubular cable conveyors transport different materials such as coffee beans, grains, bird seed, tea leaves and breakfast cereals. For their part, the ccompanying how-to videos illustrate potential layouts, components, technologies, cleaning, and maintenance options.

With easily accessible, advanced product testing facilities, food packagers can view and verify in real-time that their investment in new conveying equipment will meet their requirements.

Packagers who “test drive” their product in this way will not only enhance their product quality and productivity, but also experience a significant advantage over competitors. www.cablevey.com

Del Williams is a technical writer based in Torrance, Ca.

Packagers who “test drive” their product in this way will not only enhance their product quality and productivity, but also experience a significant advantage over competitors.

“ “

The Solution is Modular Systems

-

Ernst Blickle, Co-Founder

-

MASTERS IN MODULAR AUTOMATION SYSTEMS SINCE 1945

MOVI-C®

MODULAR AUTOMATION SYSTEMS FROM A SINGLE SOURCE

PRIME TIME AT PRANA

Organic snack-food trailblazer raises its packaging game with integrated end-of-line turnkey packaging solution

By George Guidoni, Editor

Photos by Pierre Longtin

While the fledgling Triple Bottom Line (People, Planet and Profit) movement may not yet be the mainstream cause célèbr e its proponents and early adopters hope it will become, its underlying notion of building a healthier and more sustainable world through responsible choices on everything related to food—from farming to consumption—is an idea that millions of Canadians could easily

PRANA Biovegan’s vie-president of operations Julie Séguin proudly shows off some of the company’s high-end organic and natural snack products primarily packaged in vibrant signature resealable stand-up pouches adorned with eye-catching graphics for high-impact shelf presence.

get behind.

In fact, many of them have already done so for the better part of the 21st Century—consciously or not—by switching to organic, minimally processed food sources that naturally promote healthy eating and nutritional habits, with minimal impact on the environment.

Founded in 2005, Montreal-based company PRANA Biovegan Inc. is a bona fide corporate poster child for the 3Ps business model that embraces integrity, transparency, and social and environmental responsibility at the core of its everyday business operations.

Co-founded by the husband-and-wife team of Alon Farber and Marie-Josée Richer, who met each other while backpacking through India about 20 years ago, the company is one of Canada’s fastest-growing processors of organic snack products such as nuts, seeds, dried fruits and berries, cocoa, granola and trail mixes, and other plant-based vegan foods sourced from around the world.

Manufactured by EndFlex, the BOXXER case erector is an integral part of Paxiom’s end-of-line packaging solution developed to improve efficiencies and productivity on PRANA plant’s stand-up pouch line.

Sorted, processed and packaged at the company’s SQF -certified, 60,000-square-foot production facility in the Montreal suburb of Saint-Laurent, the PRANA brand organic products are nowadays readily available across Canada at most leading supermarket chains and independent grocers, in addition to being distributed as private-label store brand offering throughout major Canadian and U.S. markets.

Such fairly quick rise to market prominence is especially impressive in light of the company’s humble origins and early days.

After arriving to Canada from India in 2005, Farber and Richer decided to open up their own business specializing in fresh hummus, tofu, hazelnut spreads and ready-to-eat vegan dishes, which they would cook at home and hand-deliver to local specialty restaurants, health-food stores and farmer’s

markets.

At a time when organic foods were still a very narrow market niche across North America, the fledgling start-up had a hard time getting significant capital backing from potential investors, Farber recalls, prompting its co-founders to strive to become entirely self-sufficient through hard work and word-ofmouth marketing.

Despite all its limitations and challenges, the company managed to generate about $100,000 in revenues in its first year of operation, according to Farber, growing to about $250,000 in its third year.

“It was all work seven-days-a-week in those early days,” says Farber, adding the couple originally used Richer mother’s kitchen to create the earliest products, before renting out space at the back of a local coffee shop.

“Not having access to a lot capital was definitely a disadvantage,” he notes, “but it also had the advantage of forcing us to learn to be frugal and not be too shy about putting in real hard work.

“So it was a really good learning experience that way.”

Close-up of a corrugated blank (foreground) being formed into a shipping box by the BOXXER case erector manufactured by EndFlex, one of several packaging machine manufacturing sister companies operated by Paxiom Group worldwide.

But after three years of hard around-the-clock wok, Farber and Richer decided they would need to change the company’s product portfolio and market focus to grow the business further.

“After couple of years we realized that making and managing all these perishable products was a complicated endeavor that required a much more sophisticated supply chain than what we had,” says Farber, “so we decided to get out of the perishables to concentrate on selling non-perishable organic foods.”

With solid knowledge of the agricultural business obtained from growing up and being raised on a farm in his native Israel, Farber put that knowledge to work by identifying and sourcing the organic nuts, seeds, fruits and other ready-to-eat crops that would appeal to the growing segment of population becoming more aware and better-informed about organic food production in general.

Around the same time, the company hooked up with a major local food distributor in a partnership aimed at expanding its customer base.

“Our ability to continue our growth trajectory and reach more customers was limited without expanding our distribution network,” Farber explains, “so it was important for us to start looking elsewhere.

“They asked us if we could supply them with some packaged nuts, seeds and dried fruits,” he recalls, “and that quickly became an important business focus.”

Says Farber: “Right from the beginning, we had the mindset to supply products that would provide a responsible alternative to the food choices available to consumers in Canada.

“That became our mission,” Farber asserts, “and we were lucky in the sense that the health-food movement was just beginning to get traction here in Quebec, and across Canada, to drive growth in demand for cleaner, organic products.

Manufactured by Valtara, the PKR Delta 1300 modular robotic pick-and-place cell provides exceptionally gentle product handling at robust throughput speed of up to 180 picks per minute.

“It was hard work to get the message out,” he says, “but it all paid off by resonating with the Canadian consumers.”

It certainly has, with sales of the company’s flagship PRANA Organic brand not only catching fire across Canada since its 2005 launch, but also earning a fast-growing market share in the U.S.

“Hence, we wanted to position ourselves as a brand that cares about the environment; cares about the quality of nutrition consumers get; cares about the suppliers, the farmers and everyone else in the supply chain—all the things that we believe are important.

With keen focus of continuous product innovation and experimentation, the PRANA Organic brand

family itself has grown exponentially over the years to comprise dozens of different product blends and flavor varieties. Packaged primarily in high-quality resealable plastic standup pouches incorporating high-impact product photography and imagery of the many exotic healthy foods and ingredients used to make the product, the PRANA product portfolio covers a broad array of inspired and unique offerings ranging from granola bars and chia seeds to varied trail mixes, salty and savory snacks, chocolate treats, cookies, dried fruits and many other imaginative snack-food creations.

A METTLER TOLEDO Safeline metal detector performs a rigorous quality check to detect any possible contaminants inside each stand-up pouch making its way to the end-of-line packaging area.

As one of the earliest Canadian food businesses to receive the vaunted global B Corp certification for “meeting the highest standards of verified social and environmental performance, public transparency, and legal accountability to balance profit and purpose,” PRANA goes through great lengths to ensure that the lion’s share of all the different raw ingredients it sources worldwide meet its exacting criteria for non-GMO origins, Fair Trade practices, ethical working conditions, and minimal carbon footprint.

Not surprisingly, PRANA’s earnest and genuine commitment to environmental sustainability applies to everything that unfolds on the production floor of its new production facility in Saint-Laurent, where the company moved in 2019 to accommodate its growth plans.

Aiming to become a food waste-free facility by the end of the year, the modern high-ceiling facility houses three packing lines and 80 full-time employees working on a two-shift, five-day

detect any possible

A METTLER TOLEDO Safeline metal detector performs a rigorous quality check to

contaminants inside each stand-up pouch making its way to the end-of-line packaging area.

weekly production schedule to churn out ever-growing quantities of the company’s branded and private-label products.

With one line dedicated to pillow bags and second one to stand-up pouches, the plant employs two fully-automatic multihead weighscales and two high-performance vertical pouch bagging machines running at average speeds of up to 120 pouches par minute.

Until recently, the relatively high level of automation at the front end of the process presented a real challenge for the downstream personnel at the end of the stand-up pouch line, who were tasked with the grueling and repetitive jobs of removing the incoming pouches off the conveyor belt and placing them inside the corrugated shipping carriers used to ship the product to customers.

Employing up three people to keep up with the product flow, the manual process was in dire need of a switch to more automated mode of operation, according to Farber, to enable better line efficiencies and a more productive use of the company’s personnel to perform more value-added tasks elsewhere in the plant.

“With the cost of labor becoming more expensive, and finding people to do these kinds of jobs becoming harder to find, end-of-line packaging has been an area of concern for some time,” Farber acknowledges.

“The whole COVID pandemic experience only accelerated our need to invest in additional automation.”

Buoyed by substantial government assistance from the Quebec Ministry of Agriculture, Fisheries and Food (MAPAQ) as part of the ministry’s Food Transformation Program: Robotization and Quality Systems , Farber finally had the required funding in place to address the end-of-line shortcomings.

Before long, Farber approached renowned local packaging machine-builder Paxiom Group (www.paxiom.com) to find an effective way to automate the end-of-line packaging process for the stand-up pouch line.

“We looked around and it seemed that no one had the machine we needed to take care of our specific requirements on that line,” Farber recalls.

“But with Paxiom being a local company, we felt comfortable to work with a local partner to develop a solution that would meet our needs.”

Happily for PRANA, his hunch to engage Paxiom as a partner in this endeavor turned out to be a perfect call.

As Paxiom’s territory manager Andre Strul recalls, “Their main objective was to reduce the number of employees hand-packing the product off the line, and thus avoid having them do repetitive motions all day long.

“Moreover, their existing hand-packing method allowed them very little control over their pouch alignment and feeding

consistency, as well as quality of their corrugate boxes,” Strul adds.

“Being a local company, we were happy to take on the challenge of offering them cutting-edge technology to resolve their issue.”

Installed on the stand-up pouch line’s downstream area just past the METTLER TOLEDO combination metal detection/ checkweighing station, the customized turnkey packaging solution provided by Paxiom is actually a fully-integrated turnkey system comprising three high-performance packaging machines manufactured by two different Paxiom manufacturing sister companies, Valtara SRL in Italy and EndFlex LLC in the U.S.

Installed and commissioned about four months ago, the fully-automatic turnkey solution incorporates:

• The PKR Delta 1300 modular robotic pick-and-place workcell supplied by Paxiom’s Italian-based sister manufacturer Valtara.

Designed for automatic top-loading of flexible bags and pouches into corrugated case or trays, the servo-driven system can be integrated with any case or tray former to reduce labor costs by eliminating manual packing stations, according to Paxiom.

Boasting a compact footprint that easily fits into any packaging line for precise top-loading of products in single or multiple layers, the PKR Delta 1300 is designed to provide exceptionally gentle product handling with vacuum or mechanical product pick-up to ensure optimal product integrity and consistent case/tray loading in a wide variety of sizes and pack patterns.

Deploying a multi-axis Delta robot capable of up to 80 picks per minute—depending on weight, distance, product and pack style—the PKR Delta 1300 is fully outfitted with advanced Omron controls, electronics, sensors, HMI (human-machine interface) control terminal, smart machine vision camera, and other essential automation componentry for optimal machine performance.

• The automatic BOXXER case erector developed by Paxiom’s Florida-based EndFlex LLC manufacturing sister

A finished pallet loaded with five-layer stacks of filled corrugated boxes ready for shipping.

company.

Designed to transfer the knock-down RSC or HSC blanks from the hopper magazine to the erecting station, the machine uses vacuum cups to pull the blanks out of the magazine, fold the two minor flaps into the case, and erect the case within a blink of an eye.

Once done, the machine’s dual belt drives drive the erected case through the taping section, where the built-in tape head secures the bottom of the case and discharges the case towards the PKR Delta 1300 cell for loading.

Outfitted with reliable SMC pneumatic components and an Omron PLC (programmable logic controller), the BOXXER case erector utilizes venture vacuum technology to ensure highly reliable and repeatable case-erecting at speeds of up to

18 cycles per minute, depending on the model.

• The automatic EZTAPE CS-C50 uniform case closer and top-and-bottom sealer.

Also manufactured by EndFlex, the EZ TAPE CS-C50 is a user-friendly, fully adjustable machine incorporating dual masts to ensure optimal stability during the entire sealing process, along with heavy-duty side-belt drives to ensure perfectly squared cases and tight seals.

Designed for quick changeovers and height adjustments without any special tools, the EZ TAPE CS-C50 features toolless tape heads for accurate and consistent sealing, with easily removable tape cartridges.

According to PRANA’s vice-president of operations Julie Séguin, working with Paxiom to resolve the plant’s end-of-line packaging issues has already had a big impact on the stand-up pouch line’s efficiencies and productivity.

“We have been able to completely optimize our team at that step of our process,” Séguin states.

“Whereas we used to have a team of three people doing some very physical and repetitive work, were are now doing the job with an equivalent of 1.5-persons, with all the repetitive movement being completely eliminated.

“As a result, we were able to relocate our team members elsewhere in our production to support our ongoing growth,” she points out. “This is a big plus at a time when the workforce market is so competitive.”

Says Séguin: “At first, we were a bit reluctant about adding robotic technology to our facility because our team had never worked with this type of equipment.

“However, this line is very lean and simple to operate,” Séguin states. “The system’s footprint fit perfectly into our available space,” she relates, “and Paxiom also provided full training and continuous support, which was an important part of our decision-making.

“We met a couple of suppliers from the Montreal region to see what was available on the market,” Séguin confides, “and Paxiom ultimately offered what we were looking for.

“The process of validation of our product running on their equipment was very clear,” she relates, “and we worked closely

with Paxiom through each step of assembling the line.

“Moreover, Paxiom worked with us in providing the critical parts and user manuals we would need to do preventive maintenance on the equipment,” Séguin adds. “They trained our staff and were available at start-up and during our learning curve.

“We have had excellent support from the entire Paxiom team,” says Séguin, adding that PRANA is currently exploring the possibility of purchasing an additional VFFS (vertical formfill-seal) bagger from Paxiom.

“With their complete packaging equipment portfolio, they will certainly be part of our future growth projects,” she states.

Such ringing endorsement is naturally sweet music to Paxiom’s territory manager Strul, who says he thoroughly enjoyed the experience of working with a progressive and fast-growing customer like PRANA.

“We were very happy to provide full support during their learning curve as they reached full ownership of the new system,” Strul says.

“We educated the client on how to improve their overall system efficiency and to standardize their end-of-line packaging quality,” he adds.

“I am certain they will achieve quick ROI (return-on-investment) thanks to reduced manpower requirements and having tangible data on their production efficiency going forward,” he points out.

“PRANA quickly understood the areas they needed to improve to facilitate the integration with their existing line,” Strul concludes, “and they also invested the time to learn the new equipment.

“As a result, they were able to run production on Day One and they have not stopped since.”

www.paxiom.com

Please see a video of Paxiom’s turnkey end-of-line packaging solution in action at the Prana production facility in Montreal on Canadian Packaging TV at www.canadianpackaging.com

Close-up of the retail-ready display trays manufactred by Mitchel Lincoln are used for shipping PRANA products to Costco stores.

UNTROUBLED WATERS

Beverage processing systems powerhouse modernizes its stretch blowmolder control unit to prevent unplanned downtime

It is the brains of a machine: without a control unit your bottling system can neither mold nor fill your containers.

When suppliers notify a discontinuation of such components —such as the control unit on the KHS InnoPET Blomax Series III—in the worst case production can grind to a halt.

In order to avoid this dilemma, and the unnecessary costs, the Dortmund, Germany-headquartered beverage filling systems specialistts KHS GmbH (www.khs.com) is now offering a comprehensive upgrade for its stretch blowmolder.

As a result, customers such as Slovenian bottler Atlantic Droga Kolinska are profiting

from KHS’ holistic services by not only increasing their production reliability, but also significantly boosting their efficiency. Proactive installation of the KHS ReDiS remote maintenance system in the course of the conversion also helps to further cut process costs.

Many customers across the globe value the many years of service life provided by KHS-

built machines.

This is no different when it comes to the third-generation of KHS stretch blowmolding technology, which was already heralded as one of the pioneers on the market back at the turn of the century.

Hundreds of these machines are still in successful operation at customer plants all over the world.

For its existing clients, KHS now offers a conversion of the control unit to modern components, a step made necessary by the discontinuation and thus cessation of production of

Dennis Jacobi, service sales manager and expert for conversions at KHS in Hamburg, Germany. The InnoPET Blomax Series III is the third generation of KHS stretch blowmolding technology, with hundreds of these machines are still in successful operation worldwide.

the same by the former supplier.

The number of available spare parts will thus decrease as a result. If there is a machine failure, downtimes could last longer and repairs may not always be possible, or may take up a vast amount of time and effort.

“We therefore urgently advise all users to replace their control unit. Ignoring this could prove expensive,” says Dennis Jacobi, service sales manager and expert for conversions at KHS in Hamburg, Germany.

One of the first customers to opt for a machine conversion on one of its two InnoPET Blomax Series III stretch blowmolders at its Rogaška Slatina plant in the east of Slovenia is the afore-mentioned Atlantic Droga Kolinska.

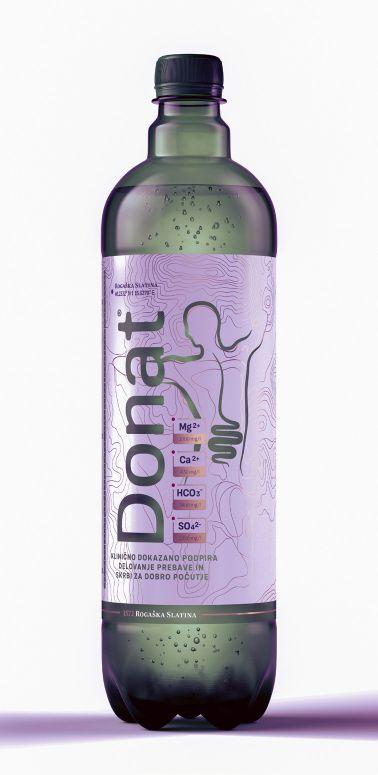

Here, premium Donat mineral water is filled into non-returnable PET bottles, holding between 0.5- and one liter, that comes from the springs of Rogaška Slatina and is named after the nearby mountain of Donačka Gora. It is valued as a healthy product for its combination of trace elements and good digestive properties.

In order to safeguard the continuing production of perfect containers in the future, the control unit on the stretch blowmolder – now more than 20 years old – was recently replaced.

“Mechanically it’s in a sound condition; it’s the electronics that are showing their age,” says Matic Javornik, manager of process automation for the Slovenian bottler.

“We wanted to carry on using our stretch blowmolder for a good few years more despite its vintage.

“The conversion has now greatly reduced the risk of unplanned downtime,” says Javornik. “We’ve also ensured the reliability of production.”

As Javornik relates,Tthe modernization project was successfully completed in less than a week. As as part of its extensive range of services, KHS experts supervise production on converted machines on-site for five days in order to reliably adapt all processes on the machinery.

“The support above and beyond this phase is equally exemplary,” Javornik extols.

By converting its plant engineering, the Slovenian beverage producer has secured the availability of parts in the long term, while benefitting from lower costs for any necessary spare parts.

Moreover, both the software and visualization have been brought up to the minute, thus making operation easier thanks to the intuitive operator panel, for example.

KHS also offers its existing customers further advantages above and beyond the actual conversion.

“With the new control unit we’ve gained lots more functions that are comparable with newer-generation machines,” claims Javornik.

Unlike its predecessor, the installed system now has a Bluetooth link, instead of rotary connectors that were something of a challenge to maintain.

While replacing the control components, the systems provider also installed the intelligent ReDiS remote maintenance system free of charge.

“As with replacement of the control unit, this reduces the risk of machine downtime, as remote maintenance enables advice and support from service engineers to be given regardless of the actual location,” Jacobi explains.

“Any errors in the production process can therefore be detected in good time and remedied much more efficiently.”

Costly travel arrangements for assignments on site are also a thing of the past.

“We offer our customers an attractive complete package that not only increases production reliability but also boosts process efficiency,” Jacobi states. “They also receive intensive support from their initial inquiry through to implementation.

“We have exactly the right solution for each container and beverage segment in our discontinuation management program.”

Ultimately, however, it’s not just the service provided by KHS that has the Slovenians convinced but also the machines themselves. This is why Atlantic Droga Kolinska is planning on further modernizing its production set-up in the near future together with KHS. www.khs.com

Atlantic Droga Kolinska process automation manager Matic Javornik.

GREEN LIGHT GO!

Global automation showcase to highlight the sustainability upside of the automation revolution across broad spectrum of manufacturing industries

There is little doubt about the urgent need to achieve the significant carbon reduction goals that the UN (United Nations) and numerous manufacturing companies have set for themselves. There is also no doubt that implementation of the required steps and measures to achieve that goal will be ambitious and expensive.

On the bright side, concerted sustainability efforts are also creating entirely new markets— generating attractive new business models that offer great opportunities for key modern-day technologies like robotics and automation.

For progressive companies concerned about long-term sustainability of their business as well as the planet, next month’s automatica 2023 global industrial automation show in Munich, Germany (June 27-30, 2023, at Messe München) will present a vast wealth of opportunities for profitable and sustainable production.

Smart automation can make a significant contribution to achieving the set climate goals by improving the energy efficiency of production facilities, or by facilitating resource-conserving manufacturing processes through the minimization of reject parts.

Green technologies in the fields of power generation and mobility—photovoltaics, wind power, fuel cells, and e-mobility—are widely held up as the new economic drivers of automation technology.

The social transformation towards sustainability and climate neutrality generates new business because robotics and automation are key technologies driving this transformation. This correlation is already reflected in the increased demand currently experienced by automation and robotics suppliers.

As Volker Spanier, head of industrial robotics at Epson, realtes: “We have recently seen an increase in leads from the area of battery and

fuel cell manufacturing.

“And we will soon see the volumes rise to current photovoltaic industry levels,” Sanier says. “The decisive factor for Europe will be the future location of this business.

“For the time being, almost all equipment suppliers for giga factories are located in Asia,” Sanier notes, “but maybe automatica will show promising approaches here, especially for the emerging fuel cell manufacturing sector.”

Amidst all the enthusiasm about the scope of application for robots, an important question often pops up: Are standard robots at all suitable for lithium-ion battery and fuel cell production?

And which features of four- and six-axis robots are particularly useful for these applications?

Fuel cell production has many particularities, and it would not be where it is without robots. For example, each of the 400 to 500 bipolar

plates in any given fuel cell stack must be layered with utmost precision and care.

This does not merely require extremely fast robots. They must also be qualified for the corrosive environment they operate in.

At automatica, multiple robot manufacturers will show if they can supply robots for such specific use cases.

Peter Pühringer, managing director of Stäubli Robotics Germany, is not worried: “I am sure that several leading manufacturers offer

ro-

bots capable of meeting these requirements.

“Stäubli Robotics will showcase four-axis and six-axis robots for deployment in hyper-dry environments, as well as special designs for operation in corrosive conditions,” he says.

“Thus, we are in a position to supply robots for both markets—lithium-ion batteries and fuel cells.”

The recycling of electrical devices and batteries is another promising market for robotics and automation.

In this context, Kuka has an electronic waste separation project currently going on in Ireland, where the staff are not exposed to hazards posed by gases and sharp-edged parts.

Here, electronic waste is separated and processed to become a valuable resource with a ‘second life’ in the circular economy.

Electric vehicle battery recycling is another application brimming with promising future prospects.

As EVs increasingly populate the streets, the question arises as to what happens with their batteries at the end of their life cycle.

According to Dr. Joachim Döhner, senior director of global sales for battery products at Kuka, “The required automation level in battery disassembly, and the recovery of valuable

resources, will produce new know-how and lead to new robotics business segments.”

Climate-neutral production trends and new fields of application for robotics and automation are expected to be the subject of intense discussions at automatica.

The new EU (European Union) directive CSRD, applicable throughout the EU from 2024 onwards, puts the topic of ‘sustainable automation’ in the spotlight even more.

The CSRD—an acronym for Corporate Sustainability Reporting Directive—requires companies above a certain size to submit a sustainability report and to assess the sustainability of their production in this context.

All in all, robotics and automation have enormous potential to improve environmental footprints, as modern assembly plants and robots greatly contribute to the associated efforts through improvements in service life, energy efficiency, and flexibility.

As Hahn Automation’s chief executive officer Frank Konrad sums up, “In modern assembly plants with a modular design, it usually suffices to make some simple modifications and to reprogram the robots to get the required conversion done.

“That saves time, resources and enegy.” www.automatica-munich.com

AUTOMATIC RESPONSE

Prominent CPG industry stakeholders reflect on new post-pandemic realities driving demand for further capital investment in new-generation industrial automation technologies

By George Guidoni, Editor

Saying that CPG (consumer packaging goods) companies need more automation to improve their manufacturing competitiveness is much like declaring that water is wet, but despite the virtually unanimous agreement on the importance of automation and digitalization as vital strategic assets and competencies, there remains much disparity in the success of their implementation to date across many manufacturing sectors.

Despite the billions of dollars spent by goods-producing industries on the latest robotics, artificial intelligence (AI), manufacturing software and other new-generation automation technologies, the gap between optimizing their full potential and the actual advances in process efficiencies and productivity on the shop floor

The Canadian Packaging magazine’s recent AUTOMATE NOW 2023 Rountable forrum was a hybrid event featuring in-person and online participants offering their views on the current state and the future of packaging automation technologies.

Left to right:

PMMI vice-president of industry services Tom Egan co-moderating the Automate Now 2023 Roundtable discussion earlier this year at the Toronto headquarters of Annex Business Media, which owns the Canadian Packaging magazine along with dozens of other leading Canadian B2B publications.

Alexander, V-P,

Wes Garrett, Executive Director, Global Accounts, Food & Beverage, FANUC America Corporation.

AREAS OF AUTOMATION FOCUS

CPG’s tend to focus on packaging and processing due to their existing knowledge and the skillset of their workforce.

still leaves a lot of room for improvement, according to numerous studies on the subject.

For packaging and related processing industries, this gap was comprehensively outlined in the recent landmark report, titled The Future of Automation in Packaging and Processing, released by PMMI, The Association for Packaging and Processing Technologies, during the latest PACK EXPO International global packaging industry showcase in Chicago in November of 2022.

Based on extensive interviews with leading executives at 105 prominent CPG manufacturing companies across North America, the study confirms that while senior management is largely committed to further investment in automation technologies to support future business growth, many corporate leaders remain unimpressed by the concrete results those investment have yielded so far.

To explore this state of affairs in more detail, the Canadian Packaging magazine has recently invited some of North America’s leading automation providers and their manufacturing customers to a roundtable discussion at the publication’s offices in Toronto earlier this year, focusing on how manufacturers can better leverage the existing and forthcoming packaging automation technologies and strategies to boost their competitiveness.

Doug

Sustainability, Belmont Meat Products Ltd.

ROBOTS HELP ADDRESS LABOUR SHORTAGES

Sponsored by leading packaging automation providers Syntegon, FANUC, Festo and igus, the timely discussion highlighted the emergence of a game-changing new narrative in the manufacturing business that rarely featured so prominently in most conversations about automation before the outbreak of the global COVID-19 pandemic in the spring of 2020.

Whereas the need to replace manual labor on production and packaging line used to be cited as a key raison d’être and end goal in and of itself in pre-pandemic days, the severe labor shortages across many manufacturing industries prompted by the pandemic have made the imperative to automate an increasingly urgent priority for manufacturers large and small—in virtually every industrial sector and segment.

In addition, the hybrid roundtable discussion—featuring in-person and online Zoom-connected participants—reflected on the growing importance of industrial automation as a means of reducing the manufacturing industry’s environmental footprint in light of increasingly vocal calls for action to address global climate change.

Using the aforementioned PMMI report as the backdrop to launch the discussion, PMMI’s vice-president of industry services Tom Egan cautioned that some of the report’s findings were based on responses received before the end of the pandemic, thereby leaving a certain margin of ambiguity for some specific questions and responses.

For the most part, though, the report’s finding were largely in tune with what PMMI was expecting and researching over the last couple of years, according to Egan.

“It is not surprising that the highest areas of automation focus predominate in the packaging

and processing areas at consumer packaged goods firms,” said Egan, noting that 55 per cent of the respondents cited these two areas as the most viable candidates for continued automation.” (See graph below)

According to Egan, processing and packaging functions appear to be getting the bulk of automation investment allocation because that’s where many companies feel most comfortable to bring in new automation.

But such familiarity and comfort levels drop significantly (13 per cent) when it comes to automating their distribution, warehousing and fulfillment operations, noted Egan, with less than a third of respondents (31 per cent) agreeing that both upstream areas present good opportunities for further automation.

As the PMMI survey reveals, many of the secondary and tertiary production processes related to warehousing and inventory management are still relying on manual methods of operation to a surprisingly high extent.

For example, 68 per cent of respondents identified the receiving and storage of packaging materials as being “highly manual” at their plants, along with raw materials receiving and

storage (61.3 per cent), and pallet transfer and storage retrieval (58.8 per cent).

“These seem to be the areas that are ripe for automation,” Egan said, “including robotic automation.”

Conversely, just over a third of respondents thought of their shipping/distribution, secondary packaging and warehouse management as being highly manual—representing considerable progress in these areas in recent years.

The big surprise here, according to Egan, was to see secondary packaging, such as cartoning, still being a largely manual task for nearly twothirds of the surveyed companies.

“That would indicate that many companies who have already automated their tertiary packaging (palletizing and stretchwrapping) are working backwards up the line to secondary packaging to bring in higher levels of automation,” Egan noted.

Indeed, seeing teams of workers manually hand-packing corrugated shipping containers with finished packaged goods is still a common sight at many production plants for a variety of reasons, despite the widespread availability of many leading-edge robotic systems available to

Emilie Alen, Vice-President, Logistics, Biscuits Leclerc.

Michael Butler, Robotics Product Owner, Syntegon

automate these process steps.

While the use of industrial robotics has soared across many industries in recent years— particularly in upstream primary packaging and processing areas—the introduction of so-called cobots (collaborative robots) into the manufacturing process has so far failed short of the widespread adoption that robotics manufacturers have been hoping for.

As Egan pointed out, 51 per cent of the survey respondents said that cobots only offer a small improvement to their existing processes, with another seven per cent saying they offered no improvement at all.

On the bright side, Egan noted that the continued chronic labor shortages and stricter focus on workplace safety should reverse this imbalance in coming years, as manufacturing companies realize the benefits of having the smaller, intrinsically-safe cobots working alongside humans without the additional expenses of wiring and safeguarding the larger industrial robotic systems that take up far more valuable floorspace.

Moreover, most cobots produced today are designed as exceptionally user-friendly and highly mobile mechanical servants outfitted with powerful machine learning capabilities to make them valuable productive assets working in tandem with their human counterparts.

“When you look at the forecast for 2026, you will see chemical, pharmaceutical and food-and-beverage sectors showing robust growth for the use of robots in their production operations,” Egan said.

“It’s expected that cobots will continue to grow in those areas to show some pretty significant growth as we go into 2026.” (See graph on next page)

Doug Alexander, vice-president of sustainability at Belmont Meat Products Ltd., said he sees continued growth in the number of cobots being added to all kinds of food processing operations due to their compact design, mobility and the ability to work safely with humans side-by-side.

“One of the constraints we’ve had historically with traditional robots is where to put them,” Alexander said. “So if you have a giant palletizing robot, you needed a very large footprint.

“Food plants have typically advanced over the decades to the point where they don’t have the space large gargantuan robot systems,” he said.

“Cobots make it much more safe for (human) labor and machinery to work together in a smaller footprint,” he said, “and that really opens the door for more automation.”

As Alexander pointed out, “One of the challenges we have in food processing is that it is incredibly labor-intensive, so the significant improvements in the dexterity, tooling and machine learning tooling now provides the ability to have cobots interact between the steps that are traditionally manual.

“That natural interplay between the two allows for more introduction of automation even earlier, perhaps, than with traditional automation robots.”

For Wes Garrett, executive director of global accounts for food and beverage business at leading robotic systems manufacturer FANUC America Corporation , the double-digit global growth in the sales of collaborative robots in recent years is compelling proof of the cobots’ viability at modern manufacturing enterprises. Since launching the company’s CRX series collaborative robotic arms in 2019, FANUC has

expanded the CRX cobot range to five models with different reach capabilities and payload capacities from five to 25 kilograms.

While cobots are not intended to replace the towering high-speed, high-capacity industrial robots employed on high-throughput product ion lines of large-scale mass manufacturing operations, “When we’re talking about small to medium-sized manufacturers, cobots can be a really good fit,” Garrett proclaimed.

“We have found that many smaller manufacturers tend to have a lot of product mix, rather than a lot of high volumes, so the flexibility of cobots really comes into play for them,” Garrett noted.

“So even if they can’t have a cobot at every single line running around the clock, they can literally move their cobots to a different line as they need to,” he explained, noting that their ‘plug-and-play” operability allows for continuous redeployment of the collaborative robotic arms to wherever they are needed without much process interruption or line downtime.

In addition to their flexibility, cobots also offer a fairly economical alternative to permanently-mounted industrial robots because they do

not require all the safety wiring and guarding systems to prevent close physical proximity to human workers.

“I think that our cobots are already fairly cost-competitive in the marketplace,” Garrett stated.

“I don’t know if the pricing is going to keep going down much further,” he acknowledged, “but it really comes down to the sheer amount of additional safety requirements for traditional robots,” such as safety light curtains, CG laser safety scanners and the actual protective fencing/wiring.

According to Nicholas Taraborelli, vice-president of prominent manufacturer of automated packaging machinery Paxiom Group, close collaboration between automation suppliers and end-users has a direct impact on the success and ROI (return-on-investment) of any capital investment project involving robotics, traditional or collaborative.

“While the costs of robots may not be decreasing, the costs of labor are increasing quickly,” he said.

“So for us, as a machine manufacturer, offering different robots across our whole product line is really important.”

Nick Fleuriot, Business Development Specialist, Festo Inc.

Nicholas Tarobarelli, Vice-President, Paxiom Group.

Said Taraborelli: “All applications are unique, but all businesses are the same: they are all tasked with providing shareholders with value.

“And that value will come from greater efficiencies, better cost control, and delivering more product to market.

“So I think it’s important to work with every client by working in reverse and asking, ‘What are your needs? What are your pain points? Where can you save costs? Where can you find that value-added?’

“And then you build your machine solutions around those new pieces of automation,” he said.

“It’s not just about the straight ROI in terms of how many people I can reposition within my facility to justify the investment,” Taraborelli stated. “These days I find that employee reliability, just in terms of basic attendance, is becoming the biggest issue in preventing manufacturers from scaling up their business.

“You also need to be flexible enough to realize that sometimes less (automation) is actually more,” Taraborelli pointed out. “If the company’s marketing is driving its innovation, you may not want to automate you process to the gills because that is going to have a direct effect on the product (variety) that you’re delivering to the marketplace.

“You can’t just ram automation down people’s throats.”

Emilie Alen, vice-president of logistics at Canada’s leading baked goods manufacturer Biscuits Leclerc Ltée , says that continuous investment in automation technologies has played a major role in the company’s growth and expansion over the last couple of decades.

“We have an automated warehouse at four of our (eight) plants,” Alen revealed, “and we are now planning to automate the warehouse at our

Brockville, Ont., plant automated as well.

“We have a lot of industrial robots doing palletizing at these plants,” she said, “as well as some cobots.

“We (Leclerc) have been investing in automation for the last 20 because it is a priority for us,” she said. “It has paid off because we can run our lines with less people, which at the end of the day makes the difference between running or not running your lines.

“And it’s evolving every year, becoming more flexible, faster and more reliable,” Alen stated, stressing the importance of working collaboratively with the company’s automation partners.

“We have key partners with whom we work with on a regular basis, who know how our needs and who know how we want to work,” she said. “That is very important to us.”

As Alen related, many of the packaging lines at Leclerc facilities are today running at high speeds with minimal personnel thanks to the highly automated flow wrapping and other packaging machinery supplied by leading global packaging equipment manufacturer Syntegon , which supplied some of the key pieces of equipment to the company’s most recently opened manufacturing facility in Cornwall, Ont., started up in 2019.

According to Alen, choosing Syntegon machinery for the Cornwall plant was based in large part on the considerable success that Leclerc achieved with Syntegon equipment at its other plants earlier.

Syntegon’s robotics product owner Michael Butler said the current labor shortages are forcing CPG manufacturers worldwide to look beyond quick ROI as motivation for automating their operations, but rather as a means to keep their lines running at all.

“Because of the workforce constraints, we’re seeing requests for automation in places like Central America, where typically automation could never justify an ROI,” Butler said.

“It has now become a decision between automating or shutting down,” said Bulter, citing “greater flexibility, greater redundancy and future planning” as new important considerations for justifying additional automation expenditures.

“Many of the companies we’re working with want to look at not just the bare bones minimum of what they can get by with through automation,” he explained.

“They are also looking at having future expansion, future capacity, and making sure that the system is done right the first time in a way that’s going to keep them their production up-andrunning consistently and robustly,” he stated.

According to FANUC’s Garrett, the customers’ growing demands for more innovative automation solutions is also driven by the fact that many of the “low-hanging fruit” applications at their factories have already been automated to their full potential and capacity.

“With palletizing and case-packing already automated, it’s now about getting more tasks done within the same footprint, where you not only case-pack, but also load the blanks, insert the slip-sheets and palletize, all with one robot,” he said.

“People are trying to automate everything they can.”

Butler agreed: “We are seeing more and more people are looking to automate (production of) more challenging products that were typically unapproachable with robotics and automation.

“Whereas packaging things like cookies has been well automated at this point,” he said, “packing donuts, or building sandwiches with robots, or mixing variety packs on the side with a high mix of products going into the same box … these are the more challenging applications for which companies are asking for automated solutions to be provided.

“And that’s where the real growth and opportunity are today, as more sophisticated end-effectors come into the market, with more sophisticated picking strategies, and more powerful software for the robots.

“The growth in the cobots market is not going to come from replacing the high-speed overhead delta robots,” he said, “but

rather from doing the intermittent low-speed tasks, whereby a cobot mounted onto and AGV (automated guided vehicle) would be used for machine tending, supplying raw materials from the warehouse, or to load rolls of film onto the wrapper.

“These are all things that still require a good number of operators to keep a line running,” he said, “but if that secondary level of the process can get automated, it would really get us closer toward that ‘lights out’ facility where the process just runs all day, with maybe just a couple of humans to oversee it.”

With rapid advances in machine vision and gripper technology, today’s robots and cobots are being increasingly used to handle more complex tasks that would have unthinkable even 10 years ago, the roundtable participants agreed.

“It’s great to hear about the complexity moving forward,” said Belmont’s Alexander. “I think the next phase in this evolution will be the integration of more advanced scientific instrumentation like spectroscopy.

“So that when a chicken breast is going along the conveyor, it (robot) might be able to make a qualitative decision about not just the shape, size and color, but understand whether it has too high of a fat content and make the right judgment call,” Alexander explained.

“So adding in more instrumentation to enhance that decision-making and taking on more complexity—making multiple decisions and performing multiple steps within one workcell, rather than in a larger footprint—is fantastic.”

According to the panel’s two Festo representatives, the rapid recent advances in AI technology will make further integration of advanced instrumentation and other cutting-edge increasingly possible and seamless, especially as CPGs become more comfortable with digitalization, machine learning, data analysis and other hallmarks of the fast-evolving Industry 4.0 smart manufacturing systems.

As Festo’s global product manager Frank Latino pointed out, AI-embedded automation devices and components are becoming an indispensable pre-requisite for smarter and more reliable machine performance across the factory floor through the use of predictive analytics and digital machine-to-machine networking.

“For customers using robotic vacuum technology to pick up

different items, for example, we can provide vacuum sensors to not only monitor the performance of the suction cups or soft grippers, but be able to predict their performance to inform people of any pending problem they may want to address earlier, rather than later, to avoid downtime,” Latino said.

“On the maintenance side of things, AI tools are going to become very dominant in the future for providing analytics for predictive maintenance and predictive quality,” Latino stated.

For Festo’s business development specialist Nicolas Fleuriot, there is no such thing as too much data when it comes to optimizing the performance of automated manufacturing and packaging equipment.

“When it comes to data,” Fleuriot stated, “you really want to collect as much data as you can.

“You may not need it right now, but in six or 10 years you may want to go back and look at this data,” Fleuriot said, “and be able to make a decision based on the history of what’s been done with this data.

“We (Festo) come into the picture by providing the OEMs’ (original equipment manufacturers) PLCs (programmable logic controllers) and instruments with the components to give access to data, which is also passed on to the SCADA (Supervisory Control and Data Acquisition), the MES (manufacturing Execution System), the ERP (Enterprise Resource Planning) and, finally, the Cloud,” Fleruriot explained.

“Automating the business process means populating all these areas are populating information into a (data) pool that all other users and stakeholders in the enterprise are able to subscribe to and use as they see fit.”

The above text is a sample of the Automate Now 2023 Roundtable podcast, initially broadcast to the North American packaging audience several weeks ago, edited for brevity and clarity. To see a video of the full event on Canadian Packaging TV, please go to www.canadianpackaging.com