AUTOMATE NOW PLUS

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com COO

Scott Jaimeson

sjamieson@annexbusinessmedia.com

Tel: 416-442-5600

CLEARING THE BAR

Renowned Canadian cookies and bars producer hits the productivity sweetspot at breathtaking speeds with installation of leading-edge packaging automation technologies

By George Guidoni, Editor

Photos by Pierre Longtin

As companies in virtually every manufacturing industry continue to struggle with hiring enough people to get their operations back to pre-COVID-19 production levels, many of them are turning to automation technologies to future-proof themselves against such disruptions going forward.

Among the leading Canadian baked-goods producers, few have done so to date with the level of technological and operational excellence, along with remarkable foresight and acumen, as the legendary cookies and sweet-snacks producer Biscuits Leclerc Ltd.

Headquartered just outside of Quebec City in Saint-Augustin-de-Desmaures, Que., the family-owned company has naturally seen and addressed a multitude of other epic challenges throughout its long and illustrious history, which traces back all the way to 1905.

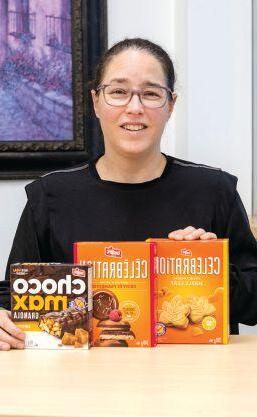

Emilie Allen, V-P, Projects & Logistics, Biscuits Leclerc, in front of the fully-automatic model TTM2 high-speed top-load cartoning system built by Syntegon and installed at the Cornwall facility by packaging systems integrators Charles Downer & Co. Ltd.

Equipped with an integrated HPS (high-performance slicer) unit, the Syntegon HRM flow-wrappers at the Cornwall plant typically run at throughput speeds of up to 800 products per minute per wrapper.

The Sigpack HRM is equipped with dual rollstock film reels in a tightly synchronized configuration the enables on-the-fly film changeovers without any interruption to production.

Syntegon HRM flow-wrapper incorporates robust inline Domino laser coding technology apply permanent best-before dates and other variable product information onto the individual flow-packs.

To say that the company has managed to overcome them all in good shape would be a huge understatement for a thriving business that nowadays annually produces over four billion snack and nutrition bars, more that 2.7 million kilograms of crackers, and about 21 million kilograms of cookies—adding up to an expansive product portfolio comprising more than 1,000 SKUs (stock-keeping units).

As impressive as that sounds, Leclerc’s production levels are poised to soar much higher still following the company’s recent acquisition of a massive 790,000-square-foot facility in Brockville, Ont., which it plans to equip with leading-edge automated packaging lines supplied by renowned global packaging machinery manufacturer Syntegon Packaging Systems AG. (www.syntegon.com)

For Leclerc’s vice-president of projects and

The packaging of nutrition bars produced at the Cornwall facility begins inside the fully-automated Sigpack HGDDE feeder station, where the patented Syntegon automated product distribution system aligns all the bars in perfect rows to enable flawless high-speed flow-wrapping of individual bars at next stage of the seamless production process.

logistics Emilie Allen, the choice of its preferred machinery manufacturer was largely a no-brainer, based on the resounding success and operational improvements that Syntegon systems have enabled at Leclerc’s 160,000-square-foot production facility in Cornwall, Ont., the company’ eighth production site, started up in the spring of 2019.

Employing about 100 people on a two-shift daily schedule, with plans to expand to threeshift 24/6 production by the end of this year, the Cornwall plant is a dazzling showcase of high-speed, high-performance, fully-automatic packaging machinery running like clockwork, day-in and day-out, with bare minimum of human intervention and supervision.

“With the high pressure on labor markets right now, Leclerc Group has continually in-

vested in its facilities with state-of-the-art production equipment,” says Allen, crediting Syntegon’s exclusive Canadian distributor Charles Downer & Co. Ltd. of Richmond Hill, Ont. (www.cdowner.com), for doing all the heavy lifting on the installation and commissioning of turnkey Syntegon packaging lines expertly laid out throughout the Cornwall plant’s packaging are—ensuring continuous high-speed production of high-quality granola and fruit-and-grain bars.

“Continuous improvement is a priority at Leclerc at all levels,” Allen states. “We have found Syntegon machinery to be easy to operate and easy to train new employees.

“It enables simple and fast changeovers,” she adds, “along with stable operation and easy cleaning and maintenance.”

With competition in the baked-goods in-

dustry always fierce, it is important for Leclerc to maintain “the highest level of automation possible,” according to Allen.

“We need to be able to provide a wide range of different products,” she says, “so the machines need to be flexible enough to handle many different formats and recipes.

“The level of automation we achieved with Syntegon equipment allows us to stay productive despite all disruptions.”

As Allen explains, “We are a leader in the food industry— recognized for the quality and variety of our products.

“We are always attentive to the market trends, and our R&D (research-and-development) department works day after day to develop innovative products that meet the needs of our consumers,” she adds. “We have deservingly won various industry awards for the quality of our customer service.”

Boasting several key certifications for product quality and purity—including BRC (Brand Reputation through Compliance) accreditation for food safety, OK Kosher certification, RSPO (Roundtable for Sustainable Palm Oil) certification and Peanut-free designation—the Cornwall facility is the most automated of all eight operating manufacturing plants Leclerc currently owns in Canada and the U.S., according to Allen.

“We are certified to the highest BRC standard level,” Allen states, “which means we are providing the highest level of food quality and product integrity you can find on the market.”

Supplying a diverse range of reputable customers in the North American retail, foodservice, institutional and private-label markets, Leclerc is not a newcomer to Syntegon technology, having had installed its first Sigpack brand automatic packaging machine at one of its Quebec locations years ago, and continuing to undertake similar projects ever since.

But the remarkably high levels of operational excellence and productivity achieved with Syntegon machinery in the last couple of years at Cornwall has prompted Leclerc to move quickly to install similar Syntegon systems at some of its other plants as well.

Such genuine endorsement is naturally music to the ears of

Jeff Downer, long-time president of the family-owned Charles Downer Co. Ltd. packaging automation integrator and distributor founded by his father Charles.

As Jeff Downer recalls, the massive influx of Syntegon machinery at the Cornwall plant began in earnest in 2020, when plant management noticed a significant difference in the performance levels between the first Syntegon line it installed there that year and the original packaging line from a competing machinery manufacturer.

Before long, Leclerc was calling on Jeff Downer again to help install more Syntegon equipment in Cornwall, on a far greater scale, to raise the plant’s productivity and efficiency levels to new heights of world-class operational excellence.

The sheer size and scale of all the Syntegon machinery assembled and integrated at the Cornwall plant is a testament to the Leclerc family’s long-enduring commitment to automation as a key strategy to growing the company, which it has done with aplomb over the years through a series of well-executed expansions and strategic acquisitions.

Along with building an expansive retail national brand portfolio comprising perennial bestsellers such as Celebration cookies, Go Pure fruit-and-oat bars and Choco Max granola bars, Leclerc is making optimal use of its new-generation Syntegon technology to serve a growing list of private-label brand customers across North America.

Souring its raw ingredients from nearly 400 suppliers, the plant’s bar production process begins in the processing area of the plant, where the raw ingredients go through all the required ingredients handling, dough preparation, dough feeding, dough processing, baking (for cooked products), cooling and cutting stages.

From there, the freshly made bars are directed into the packaging area, where six expertly integrated Syntegon packaging lines take over all the wrapping, box filling and box closing/sealing steps, and directing the filled and coded cartons on to the case-packing and palletizing stations to prepare the product for shipment.

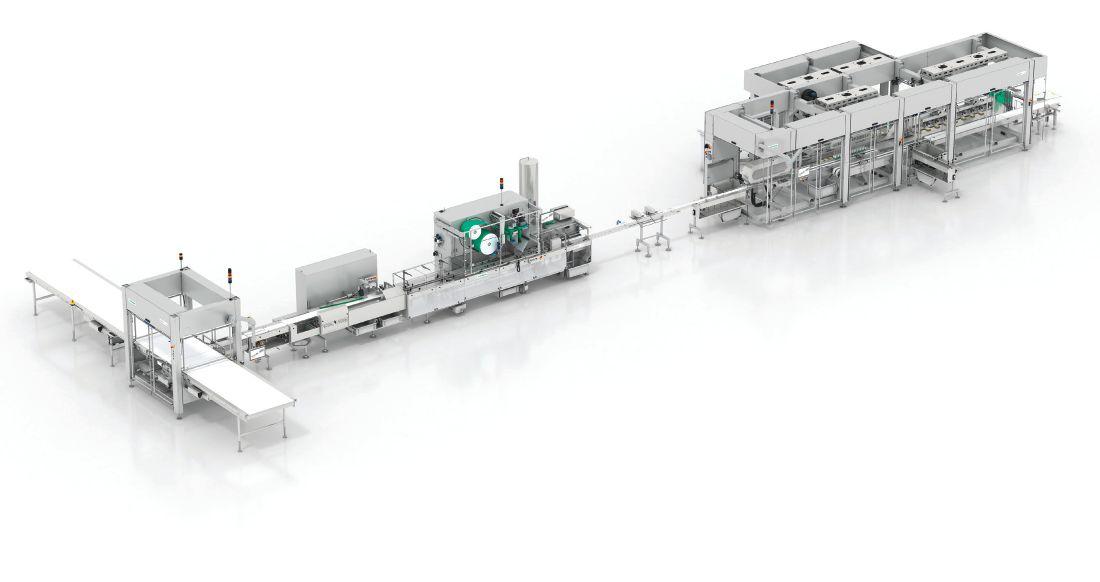

Installed in several phases throughout 2020, the three turnkey Syntegon lines at the Cornwall plant primarily consist

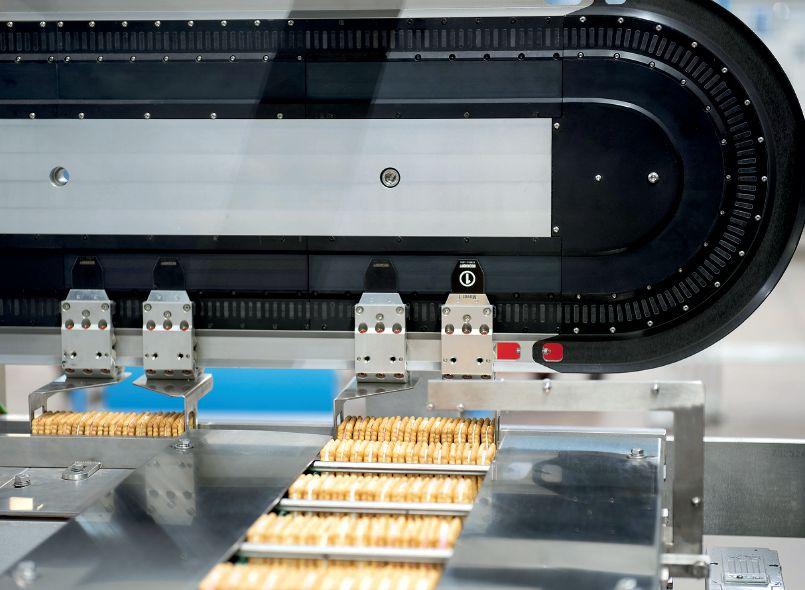

After exiting the HRM wrapper, the bars are turned 90 degrees and gently transferred with the overhead PFI linear drive infeed into the TTM2 cartoner, where pick-andplace robotic grippers place individual bars into their exact spots inside the folding cartons passing underneath.

of:

• Fully-automated distribution systems used to align rows of bars and create gaps in the product flow, prior to cross-feeding the bars onto the packaging leg;

• Integrated 3D scanning stations for quality control and defect rejection, followed by a contact-less infeed system supplying the bars into the flow-wrappers;

Designed for continuous operation, the Syntegon TTM2 cartoner incorporates multiple Staubli delta robots to handle all the carton forming, loading and sealing of the multipack folding cartons with exceptional precision and repeatability in one single pass, running at the Cornwall plant at speeds of up to 120 boxes per minute.

• High-speed Sigpack HRM horizontal flow-wrapping machine to group, distribute the bars into sort, pick up and insert the free-flowing bars into the flow-wrap film up to maximum speeds of 1,500 packs per minute;

• The model Sigpack TTM2 integrated top-load cartoner that forms, loads and closes/seals the cartons used to pack the finished flow-wrapped products coming off the Sigpack HRM flow-wrapper, with maximum throughput rates of up to 200 cartons per minute.

Designed to ensure maximum flexibility and throughput in flow-wrap packaging applications, the state-of-the-art Sigpack HRM horizontal flow-wrapper makes quick work of packing the bars, arranged individually or in groups, inside the flowpack material at film speeds of up to 150 m/min.

Moreover, the HRM processes many different types of films, including recyclable mono-material, and—when equipped with the Syntegon’s paper-ON-Form retrofit kit—even paper.

Modules to apply product codes and other required variable product information with inkjet, thermal-transfer or laser product coders can be added as required, while the on-board HPS high-performance splicer provides automatic and reliable splicing at high speeds without stopping the line.

The highly versatile HRM is equally adept at producing loose or tight-fitting flow-packs, with or without gusset folding, with longitudinally- or cross-crimped end fins, with straight, zig-zag or clip cut-off.

According to Syntegon, the servo-controlled machine’s modular construction is ideally suited to three-shift operation, with strict separation of product or packaging material handling drive elements meeting the highest hygiene standards in the industry.

Available in left-hand or right-hand orientation, the machine’s ergonomic design ensures easy access to all machine parts to facilitate comfortable operation, fast conversion to new sizes and shapes.

Surrounded by protective guarding to ensure safety and noise protection, the machine is operated via a large touchscreen HMI (human-machine interface) that allows the setting of product-specific parameters and, in case of error, displays a method for troubleshooting.

For its part, the Sigpack TTM2 integrated top-load cartoner is also a masterclass of engineering, design and operational excellence that seamlessly integrating multiple key secondary packaging functionalities in one turnkey solution loaded with performance-enhancing features and capabilities.

Requiring just one operator to run and to change over the machine, the Sigpack TTM2 is an integrated top-load cartoner providing reliable forming, loading and closing of cartons at speeds of up to 120 cartons per minute per machine, utilizing a patented tool-less changeover process with vertical restart. The precise carton forming process and the innovative carton transport ensure full carton control throughout the entire process.

Like all cartoners in Syntegon’s industry-leading TTM platform, the TTM2 is characterized by its high pack style flexibility that enables it to handle many different box designs and materials—including open and hooded trays, tri-seal closure and tuck-in lid boxes, shelf-ready display cartons and many more.

The highly flexible top-loading concept allows for superior secondary packaging of single products, small batches, or up to very large count numbers on the same machine, while also offering many different outfeed options.

The powerful combination of end-to-end turnkey operation and virtually limitless flexibility has provided the Cornwall facility with a formidable competitive edge in the hotly contested market segment for nutritional bars, says Jeff Downer.

“In addition to producing some world-class national retail brands, Leclerc is also very active in the private label space,

(Left)

high-precision

where it’s all about producing high-quality products at a lower cost than what brand-owners could do themselves,” Downer explains.

“Considering that most producers pay roughly the same price for the ingredients, labor and other production inputs, it really comes down to running your production lines as efficiently as possible, with as few people as possible, to achieve the cost reductions you need at every stage of the process to offer customers a competitive price-point,” Downer elaborates.

“Combining Leclerc’s world-class products with the worldclass manufacturing capabilities of Syntegon packaging equipment is a win-win collaboration that I am very proud to be a part of,” says Downer, complimenting Leclerc for its proactive approach to investing in leading-edge packaging automation on a continuous basis.

“Our best customers are educated customers,” Downer says, “and Leclerc is very well-educated in packaging automation. “They have bought many Syntegon systems from us before, and they all proved to be good investments.”

schematic representation of the Syntegon equipment layout at the Cornwall plant.

For her part, Leclerc’s Allen says she appreciates the high level of professional customer service consistently provided by Charles Downer’s highly knowledgeable technical and support staff through all stages of the Syntegon equipment installation, integration and commissioning, with more to come at the company’s massive new plant in Brockville.

“For us, it is really important to have Jeff Downer involved in our automation projects,” says Allen, pointing out that Leclerc and Charles Downers had already collaborated on many projects even before Syntegon was rebranded from its earlier Bosch Packaging Technology banner.

“Being a large company based far away in Europe, it is very important to have the right person here who can reach the right department and communicate our concerns with the right people on the other side,” she explains.

“Jeff has been great in supporting us every time by expediting all our questions, quotes and support capabilities to make sure all our Syntegon machinery always runs smoothly and efficiently,” Allen acknowledges.

Emilie Allen displays Leclerc Biscuits’ bestselling brands. The

Robatech adhesive applicatiing system integrated into the TTM2 top load cartoner.

A

“Our latest machine installation, commissioning and training was handled very well by the Syntegon technician who came on-site to do it,” she relates.

“It is very important for us to have a technical resource nearby to help us make whatever adjustments we need to introduce a new product or packaging format.”

Moreover, Allen points out that having so many different packaging capabilities incorporated in all-in-one turnkey systems, assembled by a single manufacturer, also provides valuable space savings on the production floor with a more streamlined and compact footprint.

“With everything being integrated within the machine, we do not need separate conveyors or other auxiliary equipment taking up square footage,” she says.

“The flexibility of the Syntegon machines is very important to us,” Allen reiterates. “We don’t not want to buy a new machine every time we have a new product to launch, so being able to change the size of a box, box shape or a box count just by changing a little tooling, quickly and safely, is very convenient.”

Says Allen, “With the difficult recruitment challenges today making it hard to find enough people to fill all the plant jobs, it is important for manufacturers to achieve the highest levels of automation possible.

“For us, the Syntegon machines at our Cornwall facility provide the highest levels of flexibility, speed, precision and safety available in the marketplace today,” she concludes, “and we look forward to installing more Syntegon technologies at our new facility in Brockville and other Leclerc plants.”

www.syntegon.com

www.cdowner.com

Please see a video of Syntegon Packaging Systems secondary packaging machinery in action at the Biscuits Leclerc production facility in Cornwall, Ont., on Canadian Packaging TV at: www.canadianpackaging.com

(Above)

Performing a multitude of tasks in seamless turnkey operation, Syntegon machinery helps the Cornwall plant save valuable space on the production floor through compact, streamlined and ergonomic machine design.

(Right)

Named after his grandfather and company founder, Charles Downer works as sales representative for Charles Downer & Co. Ltd., headed by the company’s president and his father Jeff Downer.

SMART COOKIES

Italian packaging OEM optimizes its automated flow-packing machinery range with intelligent and innovative XTS technology

Founded in 1960 in Italy’s Piedmont region, Cavanna Packaging Group is a leading specialist in the flow-pack segment for both food and non-food products, especially the cosmetics and pharmaceutical industries.

After initially establishing itself as one of the first manufacturers of electro-mechanical flow-pack machines, over time the familyowned company focused on fully electronic machines and complete packaging lines: primary flow-packs for individual products and product groups; secondary flow-packs or box packaging, and tertiary packaging and display cartons.

To date, Cavanna (www.cavanna.com) has supplied roughly 6,000 machines for more than 900 customers worldwide.

The broad spectrum of food applications ranges from uniform and mixed cookie packages, chocolate, breakfast products, sweet and salty snacks, bread replacement products, cheese, coffee pods and frozen products. Whatever the product, Cavanna focuses on protecting the product and maintaining the product quality through appropriate pack -

aging, while enabling consumers to open the package easily.

The company’s engineering team considers all these requirements in the design of the flowpack machines in combination with high packaging quality, machine availability, and the lowest possible total cost of ownership.

In recent years, Cavanna has noted increased demands from its customers regarding their need for more flexible machinery to enable faster product changeovers, along with more gentle and efficient product handling.

To meet all these requirements with optimal innovative solutions that also reduce the machines’ footprint, time-to-market and cost, Cavanna looked for a dependable, globally-operating technology partner.

After evaluating its many options, Cavanna ultimately selected Beckhoff Automation Gmbh & C0. (www.beckhoff.com), a leading German supplier of industrial automation operating 40 subsidiaries worldwide, including Beckhoff Automation Ltd. in Cambridge, Ont.

Starting with the cookie packaging segment, Cavanna recently made the strategic decision to equip its flow-pack machines with Beckhoff’s intelligent eXtended Transport System (XTS) and EtherCAT communication Cavanna’s first XTS application is a 90-degree transfer system for packaging slugs of cookies.

The slugs get tilted by 90 degrees before being handled by the XTS movers.

technology to develop the ideal PC-based control and drive solution that would enable Cavanna to advance all its machine offering in accordance with changing customer requirements, while providing exceptional product transfer flexibility in a very small space.

For its first XTS application, Cavanna developed a new pack-

aging system that can package 4,200 cookiesper minute after they have been compiled into slugs.

In addition to high system flexibility that enables it to handle round, rectangular or square-shape cookies, the machine can package the cookies in various flow-pack formats at speeds of up to 130 packages per minute with up to 32 cookies per package.

Functioning as a feeder unit in this system, two XTS movers are deployed to receive the cookie slugs from a chain track after they have been rotated 90 degrees, and then transport the slugs to the tubular bag for the final flow-packing stage.

According to Cavanna, the XTS system’s main advantage is that all the settings needed to change over to a new product format are stored in the control software and can be executed automatically.

This way, the XTS can adapt to the product on-the-fly, which is a vast improvement over conventional solutions based on servomotors that require extensive mechanical conversions.

Another example of the ways Cavanna uses the XTS system is for transferring product stacks from one chain track to another, with varying distances between the separators on each chain.

Cavanna also uses the XTS as a distribution system to split an incoming product stream into two streams—also at low cost and with exceptional flexibility.

From Cavanna’s perspective, XTS offers huge potential for innovation due to its wide range of software functionalities with mostly automatic configuration, as well as its modular, application-specific variations and track geometries.

These attributes make it easy to implement a wide range of applications for individual product transportation, in combination with a continuous material flow.

With its high energy efficiency and significantly reduced footprint, XTS delivered the best possible solution in terms of cost, compactness and innovation for Cavanna’s packaging machines— opening door to a new world of packaging applications that allow packaging OEMs (original equipment manufacturers0 to adapt their machines even more effectively to their customers’ needs.

With Cavanna working on achieving even higher speeds and more precise synchronization across its entire machine range, the company is already working on extending the benefits of XTS technology into additional application areas with the help of Beckhoff Automation experts.

www.cavanna.com www.beckhoff.com

GROWTH DRIVERS

Corn chip conveyor line gets timely retrofit to make improvements in productivity and energy efficiency

Amajor U.S. producer of snack foods, operating worldwide manufacturing locations, recently with locations worldwide, faced a potentially very costly problem at its processing plant in Arkansas.

As an integral part of the plant’s process, the production line features bowl feeders, vibratory conveyors and stainless-steel, washable components attached to a 50-feet-long vibratory conveyor that moves cooked corn chips from the fryer to the packaging area.

Due to its age and degraded original equipment, it was no longer able to run the line at maximum production speeds, while also causing frequent downtime and excess vibration that prompted the chips to fall off the conveyor. But rather than proceeding to make major capital investment to change the entire line, the company looked for a cost-effective retrofit solution to resolve its problem.

Happily for the plant, it did not have to look far, with one of its existing technology suppliers quickly stepping

up to the plate to help the chip-maker find the right solution.

Located in Acworth, Ga., SE Packaging Systems (www.sepackaging.com) is both an equipment OEM and retrofit/upgrade provider, operating in the automated packaging space since 2003.

In 2015, the company formed a strategic partnership with Comek srl (www.comek.it), a prominent Italian manufacturer of automated weighing, wrapping and packaging systems used by food and non-food consumer goods industries worldwide.

On behalf of Comek, SE Packaging Systems provides on-site assistance for lines already installed in the U.S., Including repairs or upgrades, supply of new equipment, and optimized integration in existing processes.

Owned by its president, SE Packaging Systems is also a designated Authorized Solution Partner for global automation giant Siemens AG (www.siemens.com), which was brought on-bard for this project.

Ali Ali, the national accounts manager for Siemens, led the project alongside James and a local distributor.

Enclosure of three drives to control one bank of the vibrating feeders, with the entire system consisting of 18 banks of drives.

As Ali relates, the plant’s entire line control was reconfigured, and updated with Siemens drives, motors and related hardware automation, with James supplied the wiring diagrams for the retrofit to existing PLCs (programmable logic controllers) on the original equipment.

In addition to enhancing the line’s operations with the introduction of precision VFD (variable frequency drive) technology for proper synchronization of all the line elements, SE Packaging also custom-engineered special level sensors to help the line’s vibrators adapt to the increased weight and height—eliminating the annoying problem of having chips falling off the conveyor.

According to James, having the these sensors integrated to interface with the analog inputs on a Siemens SINAMICS

G120 VFD resulted in overall production process improvement of over 10 per cent, along with impressive energy saving

of approximately 20 per cent.

As James explains, these energy savings are the result of the upgraded system being able to power down when the pans are empty, compared to a simple fast-slow setting on the previous line controls.

“While the original controls on the line were from another manufacturer, SE Packaging and Siemens won the project thanks to their cost-effective solution that provided a 20-percent reduction in maintenance cost, zero downtime in the first year of operation, and much higher reliability,” James states.

James relates that the Siemens strategy involved technically empowering and partnering with the snack food plant to create an optimized G120 application-specific drive solution.

For example, the over-current relays, effectively protect the single-phase motor output, while the on-board VFDs enable the motor current to remain within the set torque limits during vector control—resulting in a more stable “ride” for the chips, according to James.

“This is the first installation for Siemens at the plant of this well-known snack food producer, though it certainly won’t be the last,” James states.

Adds Siemens’ Ali: “I’m happy to report that everything is operating successfully.

“The company is very pleased with the results as well as the training we’ve provided,” says Ali, adding he’s confident that the new relationship with the customer with continue into the future with possible new retrofits and new line projects.

Other Siemens products incorporated on this project were the Simatic PLC and various food-grade components.

As James concludes: “Because we were able to be essentially a one-stop shop for the customer, providing the solution, engineering, product, installation and training, all at a nice price, we won the day.

“We expect that this success will lead to us securing more business in the food-and-beverage sector, together with Siemens and their global network of distributors.”

www.siemens.com

www.sepackaging.com

www.comek.it

Vibrating feeder with low product level, with the drive operating at low amplitude.

Vibrating Feeder with high product level, with the drive operates at higher amplitude.

Sensor used to look at product level in vibrating tray, whereby the drive amplitude is adjusted based on level measurements to prevent product damage and save power.

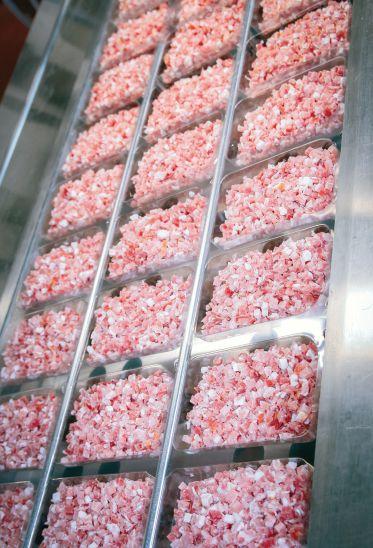

Made in Germany by MULTIPOND, new J Generation model MP-30-1000-4oo-J multihead weigher is a fully-automatic 30-bucket system enabling leading ham processor to achieve output rates of 12 cycles of 18 packs per minute.

WEIGH OF THE WORLD

Ham processor achieves optimal precision with the next-generation multihead weighing technology

For one long-standing MULTIPOND customer, a renowned German manufacturer of meat and sausage products, quality, craftsmanship and innovation have alwasy been the three core pillars of a sound business philosopy driving the familyowned company’s growth for three generations. As a leading supplier of pre-cut ham cubes,

used as meal ingredients or topping acorss a broad range of popular meat dishes and recipes, the company has long made extensive use of multiple-head weigh scales manufactured by MULTIPOND Wägetechnik GmbH (www. multipond.com ), a family-owned German manufacturer of industrial weighing equipment for over 70 years.

With the increased focus on food safety in recent years around the world, it was always in

the cards that the two companies would remain in close touch.

“In recent years, there has been heightened consumer awareness about product safety, quality and hygiene,” says the ham processor’s technical manager, explaining the company’s recent purchase of MULTIPOND’s new MP30-1000-400-J model multiheaded weigh scale for precision wighing of the diced ham chunks.

According to both companies, the plant’s limiting height of only 4.5 meters was the greatest challenge for this project, making it imperative to account for every single millimeter in the planning stages.

In fact, after installation the gap between the upper end of the system and the ceiling ended up bing just a few millimeters.

“This was a very special equipment construction project,” recalls the technical manager. “From our previous experience, it was clear that only MULTIPOND would be able to do this.”

In operation, the diced ham is transported onto the platform via an inclined belt conveyor, supplied by Gröneweg , while another feed conveyor transports the diced ham onto the MUTIPOND weigher.

According to Mutipond, the new J Generation multihead weigher is of the company’s

latest machinery range developed specifically for use in food production areas with extremely high hygiene requirements.

“The weigher’s hygienic design was, without doubt, another big reason for our decision to go with MULTIPOND,” the technical manager notes. “MULTIPOND is always a good step ahead of the industry here as a whole.”

Once the diced ham has arrived on the weigher, it is first conveyed to the pre-feed hoppers by radially positioned feed trays, and then directed to the weigh hoppers underneath.

Using the partial portions, a computer determines the combination that comes closest tohitting the 125-gram target weight for the individual portion.

All product contact parts are precisely adjusted to the production requirements and the properties of the diced ham in order to guarantee a smooth product flow.

The weigher is controlled and operated using a convenient color touchscreen monitor, while the fully automated calibration of the proprietary load cells ensures the highest accuracy and availability through the integrated calibration in each weighing cell.

According to MULTIPOND, it is the only multihead weighers worldwide with the unique ability to automatically calibrate itself while running.

The 30-head weigher is equipped with a three-way outlet, with a motor-driven timing hopper installed under each of the outlets to transfer the ham portions to the downstream transfer system.

The gimbal-mounted transfer system is equipped with a special Gröneweg-made reject mechanism designed specifically for this application—acting as an the interface between the

The MULTIPOND multihead Generation J weigher’s patented Rise and Fall product distribution system ensures smooth product transfer and highly precise portioning of diced ham into the cavities of the plant’s thermoform packaging machine, to be packed and sealed in 125-gram flexible packages.

weigher and packaging machine.

The system’s swivel hoppers distribute the weighed portions into the 6x3 format hopper, after which the patented “Rise and Fall” 6x3 format distribution unit ensures that the portions are transferred correctly into the trays of the downstream thermoforming machine, and that the sealing seams remain dry throut the filling process.

The entire system was designed for an output of 12 cycles of 18 packages per minute, with

the target weights of the final packages ranging from 75 to 125 grams.

The mean value achieved, a decisive criterion for the give-away, corresponds exactly to the target weight, with the standard deviation for 125-gram target weight being about 1.3gram.

The hygienic design of the weigher is the basis for fast and simple cleaning, and all J Generation multihead weighers have protection class IP 69 as standard.

Natrally, the weigher undergo a complete wet-clean process daily, during which the enitire weigher is placed under water.

The quick and tool-free removal of product contact parts effectively reduces the system’s downtime for cleaning and maintenance work to an absolute minimum, while a Gröneweg wash wall, also installed on the platform, further simplifies the cleaning processr.

“Drawing on its long-standing experience of weighing the most difficult products, MULTIPOND was at our side offering a wealth of knowledge,” notes the ham producer’s technical manager. “Our extremely positive experience with MULTIPOND in the past was yet another key decision factor for our selection.

“This weigher is now the fifth multihead weigher from MULTIPOND at our plant.

“All MULTIPOND systems at the plant run almost fault-free and are completely reliable,”he adds, citing “excellent on-site service” as another decisive plus point.

Employing over 250 people worldwide, MULTIPOND services a diverse global client base in both food and non-food sectors, with each installed system tailored to the customerss exact requirements.

According to MULTIPOND, “We consciously commit to a high level of vertical integration and production. Customer focus has become our corporate maxim.”

All of the company’s sales and project planning are handled by the headquarters in Germany and one of four subsidiaries operating in France, Holland, U.K. and the U.S.

In Canada, the company’s products are distributed by Abbey Equipment Solutions of Burlington, Ont.

www.abbeyequipment.com

DO IT YOURSELF!

Large DIY gantry robot package delivers quick payback in palletizing applications

Affordability is often used as a reason for companies not to automate some of their heavy lifting in end-of-line packaging and palletizing, but there are many innovative automation providers, such as igus Gmbh (www.igus.com), doing their best to put that excuse to rest.

Headquartered in Cologne, Germany, the global leader in motion plastics has just expanded its growing range of low-cost automation solutions with a new drylin three-axis linear gantry robotic system that the company hopes will enable smaller manufacturers to overcome the cost barrier to higher productivity.

With an action radius of 2,000x2,000x 1,500-mm, the new XXL Large DIY three-axis linear gantry robot is particularly suitable for palletizing applications

of up to 10 kilograms, with the pricing for the new robot starts as low as US$7,000, including the control system.

The system is easy to set up and program using the “do-it-yourself” principle without the help of a system integrator, according to igus.

“This DIY kit enables companies to install, quickly and easily, a robust pickand-place, three-axis linear gantry for tasks related to palletizing, sorting, labelling and quality inspection,” says Alexander Mühlens, head of the igus’ Low-Cost Automation business unit.

“Palletizing robots, created in collaboration with external service providers, typically cost between US$95,000 and US$135,000, which is beyond the budget of many small companies.

“We have therefore developed a solution that is many times more cost-effective, due to the use of high-performance plastics and lightweight materials such

The self-lubricating and maintenance-free drylin XXL three-axis linear robot from igus lifts up to 10 kilograms and costs up to 60-percent less than comparable solutions.

as aluminum.

“For example, the drylin XXL Large DIY palletizing gantry robot costs between US$7,000 and US$10,000, depending on the expansion stage,” he states. “It is a low-risk investment that usually pays off within a few weeks.”

The best part, according to Mühlens, is that the igus DIY kit can be quickly assembled without prior knowledge.

The buyer receives the three-axis linear gantry as a DIY kit, which consists of two toothed-belt axes and a toothed rack cantilever axis with stepper motors.

The package also includes a control system, cables, as well as the free igus Robot Control (iRC) software.

According to igus, users can assemble the components into a ready-to-use system in just a few hours—without external help, prior knowledge, or lengthy training. And if additional components such as camera systems or grippers are needed, users will quickly find them on the company’s online robotics marketplace RBTX. (www.rbtx.com)

As an example, a cartesian robot can be used on conveyor belts that transport products away from injection-molding machines.

In this scenario, the robot would picks parts weighing up to 10-kg weight conveyor belt, transport them at speed of up to 500-mm/sec, and position them on a pallet with a repeatability of 0.8-mm.

This automation would relieves employees of physically demanding and time-consuming palletizing work—freeing up resources for more important tasks. Moreover, the system also requires no maintenance, according to igus.

The system’s linear axes consist of corrosion-free aluminum and the carriages move via plain bearings made of high-performance iglide plastics. The self-lubricating properties of the igus bearings enable a low-friction, dry operation without external lubricants.

For its part, the 3 iRC software from igus enables simple and intuitive robot programming and control—including programming of different robot kinetics—to facilitate easy entry into robotic automation.

“For many companies that don’t have in-house IT specialists, programming robots is often fraught with problems,” Mühlens explains.

“That’s why we developed iRC: a free software application that visually resembles commonly used office software and allows intuitive programming of movements,” he adds.

“What makes it special is that the resulting low-code programming can then be used 1:1 on the real robot.”

The core of the software is a 3D digital twin of the three-axis linear gantry, which can be used to define movements with just

a few clicks.

As Mühlens explains, “Prospective buyers can use the 3D model to check whether desired movements are actually feasible before making a purchase.

“Furthermore, we invite all interested parties to try out our robots live or via the Internet free of charge.

“We will support them during commissioning and show them what is possible with low-cost robots,” Mühlens concludes. “It makes the investment virtually risk-free.”

www.igus.com

THE BUFFER ZONE

Mixed-case palletizing has often been difficult, if not impossible, to automate. Traditionally, this labor-intensive operation requires material handlers to store the cases for an order until there are enough cases to build the pallet.

Recently, many organizations have began the process of automating the storage and sequencing of their goods to make human packers more efficient, but such material handling equipment is expensive and has a large footprint.

But with robots getting smarter all the time, making previously challenging applications like mixed-case palletizing possible is easier than ever thought possible.

With Mujin-powered palletizers, the robot can buffer and re-sequence cases without the need for upstream material handling equipment. These palletizers eliminate the manual operation and automate without huge operational and infrastructure changes.

“Robots are becoming more intelligent, and new applications such as mixed-case palletizing are now possible,” says Mujin Corp. co-founder Ross Diankov.

“With Mujin solutions, all warehouses need to do is send the boxes directly to the robots, and they’ll

re-sequence them before placing them on the pallet. That’s it. The process is significantly easier, more reliable and much less costly.”

With each application, Mujin’s flagship product, the MujinController, controls robots from top robotic arm vendors Fanuc, Kawasaki, Mitsubishi and Yaskawa Motoman using advanced sensing and real-time motion planning.

The MujinController guides the movement of any robot arm via machine intelligence, a new and advanced category of artificial intelligence (AI), which Diankov says automatically manages potential downtime scenarios through perception and autonomous decision-making, without the need for human intervention. www.mujin-corp.com

THE LUCKY SEVEN

Strong, fast and simple, the new lightweight KR1018 industrial collaborative robot from Kassow Robots is strong enough strong enough to perform machine tending with heavy metal and plastic parts, and nimble enough to carry out a broad range of pick-and-place tasks at high payloads.

With 18-kilogram payload and 1,000-mm reach,

the seven-axis robot provides a cost-effective solution for machine tending, material handling and related industrial applications to complete precise and industrial tasks requiring superior strength.

According to Kassow, the easy-to-use interface and plug-and-play concept of the seven-axis cobot make it accessible to small and medium-sized enterprises (SMEs) without robot engineers.

“The KR1018 is a very strong, compact cobot with a weight of only 34 kilograms, ideal for performing various jobs at industrial companies,” says Dieter Pletscher, the head of global sales at Kassow Robots. “SMEs without their own robotics specialists can achieve complex automation and programming cost-effectively and independently with the KR1018.”

As Pletscher explains, the KR1018 is well-suited for industrial applications like machine tending, assembly, quality assurance, palletizing, and pick-and-place packaging tasks.

Its unique seventh axis, or “wrist joint,” and the safety-compliant design inherent to the cobot class of automated material handling solutions allow for human–robot collaboration. At just 34 kg, the KR1018 is easy to relocate to perform tasks in different areas of a facility.

According to Kassow, the seventh axis gives KR1018 a small footprint (160x160-mm), increased manoeuvrability, and an increased range of motion to perform such tasks as the loading and unloading of heavy parts for the metalworking industry, or heavy lifting in the food-production sector.

The seventh axis also enables continuous dispensing, welding and material removal applications, regardless of access angle, without the need to reorient the arm. www.kassowrobots.com

FASTER CYCLES

Designed for high-speed production of plastic lids and container packaging, the new six-axis robotic case-packer from Muller Technology incorporates an industrial six-axis robot to deliver highly efficient cycle times of up to 64 cavities every six seconds for lids, and five-second cycle times for containers, according to the company.

The six-axis case packer delivers even greater productivity than Muller’s recently launched collaborative robot (cobot) case-packer, says Taras Konowal, Muller’s director of sales and marketing for North America.

“The unit is one of our most productive systems for high-volume packaging lines, offering higher cavitation for the manufacture of blowmolded bottles and thermoformed packaging,” says Konowal.

With fast changeovers for different size configurations, the new case-packer can operate as stand-alone, or be integrated into Muller’s new fully automated M-Line system for even greater flexibility in the production of injection-molded packaging products.

www.muller-technology.com