AUTOMATE NOW PLUS

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson

sjamieson@annexbusinessmedia.com

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid

energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls

DESTINY CALLING S

Canadian inline label coating and converting machinery manufacturer leverages production excellence and technological expertise to redefine the industry’s value chain dynamics

elf-sufficiency is a much sought-after core competence for companies in virtually any business field, and for Montreal-based ETI Converting Equipment (www. eticonverting.com), being a master of its own destiny has been a driving force behind the company’s success in the global markets for inline label printing, coating and converting machinery.

Long before disruption became the trendy new buzzword and euphemism for game-changing innovation, company founder Francois Bayzelon had already embarked on a bold journey to shake up the existing label manufacturing supply chain models by helping label printers and converters take complete ownership and control of all their production needs in-house with innovative, leading-edge machinery

ETI Converting Equipment president Maxime Bayzelon standing next to the touchscreen Bosch Rexroth HMI panel displaying all the critical operating data of an ETI machine located inside the plant’s Technology Centre.

Right

A close-up of the VR Panel PC HMI (human-machine interface) supplied by Bosch Rexroth for all ETI machines.

manufacturing, product development and market development roles, before becoming company president in 2012.

distinguished by high levels of automation and technological excellence.

After arriving to Canada from France with a degree in mechanical engineering and a strong entrepreneurial spirit, Bayzelon proceeded to put his talents to use by founding Aquaflex in 1980.

Specializing in flexographic printing presses, the company is credited with revolutionizing the printing industry by launching the concept of quick-change cassette system, while becoming renowned for the quality and affordability of its equipment.

After selling Aquaflex years later, Bayzelon initiated a new project guided by the vision of enabling label printers to manu-

facture their self-adhesive labels from scratch, than merely decorate them after receiving the label stock from their suppliers—essentially eliminating the middleman from the equation.

To realize his game-changing vision, Bayzelon joined forces with an engineering firm IMAC to launch Equipements de Transformation IMAC (E.T.I.) Inc. in 2000.

The Longueuil, Que.-based company is now headed by the founder’s son Maxime Bayzelon, the firm’s principal shareholder, in partnership with three other co-owners.

A holder of a bachelor’s degree in mechanical engineering, Maxime joined ETI in 2007 to work in a variety of engineering,

In 2017, the company moved to its new current location in Longueuil, Que., on the outskirts of Montreal, to accommodate its growing business and to integrate its machining and manufacturing functions under one roof.

Employing 85 people, the rebuilt plant houses all of the company’s departments, including the machining workshop, assembly, engineering, sales and marketing, project management and administration.

This centralized mode of operation allows the company to retain full control of the manufacturing process to produce high-quality inline printing, coating and converting equipment for label producers around the world, building its systems from scratch to match the customers’ exact specifications and applications.

A bird’s-eye view of the ETI plant’s production floor, with a nearly assembled machine for a U.S. customer in the foreground.

Maxime Bayzelon at the entrance to the plant’s Technology Centre area.

“As a pioneer in the art of in-house coating, our expertise lies in creating specialized equipment for self-adhesive label printing, coating and converting that delivers a unique competitive edge through technical advantages, environmental sustainability, material cost-savings, linerless label capabilities, creativity and flexibility,” says Maxime Bayzelon.

“Our equipment is modular, flexible and scalable,” Bayzelon points out, “and our machines are always configured according to our clients’ specific needs, which may include printing, silicone coating, adhesive coating/laminating, die cutting, and/ or other converting processes.”

Having sold over 200 machines since its inception, with installations in over 40 countries, ETI enjoys a well-earned reputation as a pioneering trailblazer in many aspects of the label and narrow-web converting businesses, according to Bayzelon.

“ETI was the first to introduce the concept of inline coating for narrow-web converting,” says Bayzelon, citing other notable patented technological innovations that include:

• Pellicut die-cutting station to cut on very thin liners ;

• Cold slot-die coating station for water-based acrylic adhesive application;

• Pattern hotmelt roll coating station for adhesive application in any shape and size, with capability to produce striped coating at very low coat weights.

Says Bayzelon: “ETI has always been able to offer innovative solutions to its customers and has been recognized for its audacity and ability to undertake special projects that sometimes had a high level of complexity.

“We have sold to all major label printers around the world,” says Bayzelon, citing the company’s stalwart product portfolio offering label producers powerful in-house converting capabilities, including:

• The Cohesio brand of narrow-web printing, coating and converting equipment for inline label manufacturing;

• The LinerO series of linerless label manufacturing equipment;

• The Acuro line of flexible narrow- and mid-web coating and laminating machine for labelstock and tape manufac-

turing;

• The Metronome range of flexo printing and die-cutting equipment for inline pressure-sensitive adhesive label manufacturing;

• Custom web coating equipment and other custom solutions for made-to-measure labeling products.

As Bayzelon points out, ETI designs and manufactures all of the production units that go into making its machines, including printing, silicone coating, adhesive coating, and die-cutting stations.

“The fact that the machines are modular and scalable allows our customers to grow their product portfolio over time as needed by adding specific stations to their original machine,” he explains.

With about 95 per cent of its machines exported outside of Canada, “ETI is recognized as the solution that offers the most ROI (return-on-investment) for clients looking for innovative solutions to produce high volume products at lower costs,” Bayzelon says, “or unique specialty products with technical features that can’t be done otherwise than by coating in-house.

“Our technology represents a real paradigm shift,” says Bayzelon, adding ETI works in close partnership with all its customers to demonstrate many benefits of having more control of their label converting process in-house.

“The technology and solutions we propose create a significant change in their operations: like a shift from purchasing labelstock and printing/converting it, to producing their own self-adhesive materials inline,” he elaborates.

“Once they take the leap and see all the benefits, a large portion of our customers have gone on to purchase subsequent machines,” Bayzelon states.

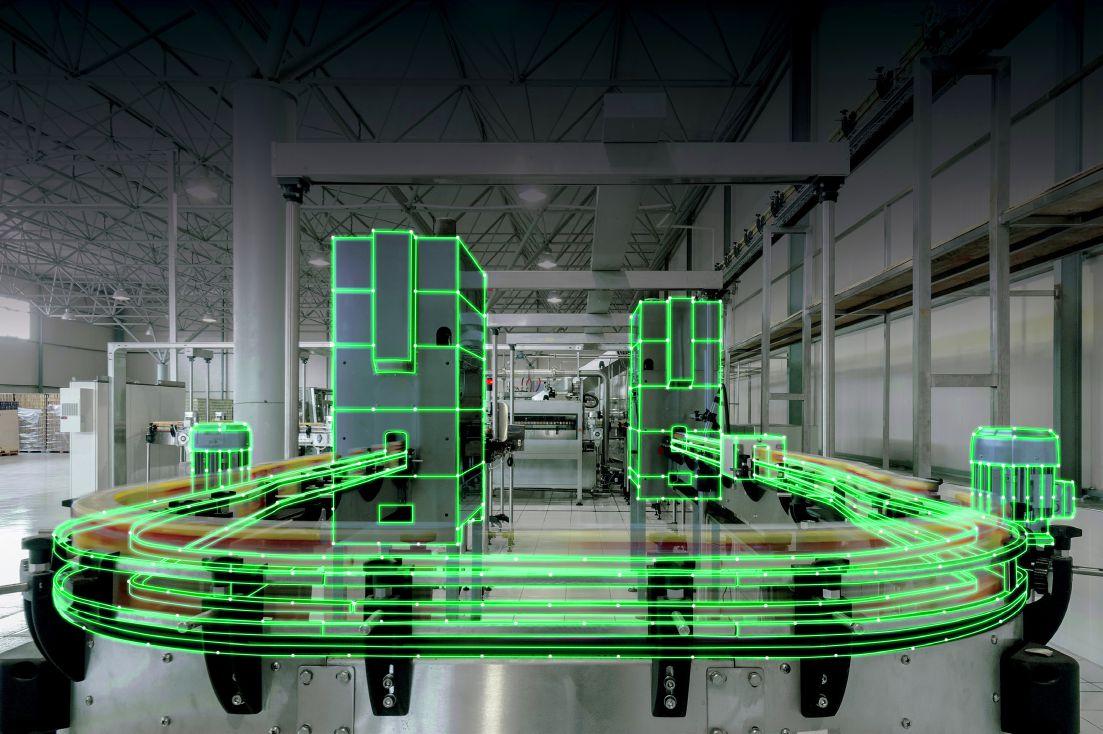

Built with multiple inline operations, ETI machines require skillful integration of various powerful process and motion control technologies and automation technologies to keep these interconnected systems perform with unfailing reliabil-

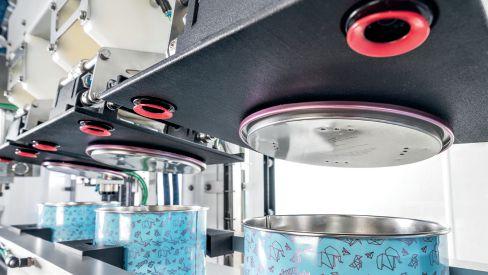

Different views of the Bosch Rexroth servomotors and drives controlling the rollers of the ETI machine running in the plant’s Technology Centre area.

Different angles of the newly-built ETI machine being tested before shipment to a major U.S. customer.

“ETI allows label converters to have more control over their production and more freedom in label creation.”

ity, precision and accuracy.

To ensure these requirements are met, ETI has leveraged new control and automation technologies from the leading industrial automation supplier Bosch Rexroth Canada (www.boschrexroth. com) to maximize its machines’ performance and reliability.

“We started to do business with Bosch Rexroth approximately 15 years ago,” Bayzelon recalls, “when we switched to servomotors for all our machines.

“The support they have provided has greatly helped us in the realization of some clients’ special projects and has contributed to our own R&D,” says Bayzelon, lauding the Bosch Rexroth components and control software for their leading-edge Industry 4.0 capabilities.

Says Bayzelon: “The connectivity that is made possible by their equipment allows us to be even more efficient when it comes to assisting our clients, since we can access data in real time and intervene in a more targeted manner.”

Some of the most critical up-to-date technologies supplied by Bosch Rexroth to ETI in recent years include:

• New-generation MS2N motors, combining high dynamics with compact dimensions and optimal energy efficiency, while offering more torque and higher speeds. Available with lowand medium-inertia rotors, the MS2N motors serve as data sources in the Industry 4.0 environment to enable fully intelligent automation solutions.

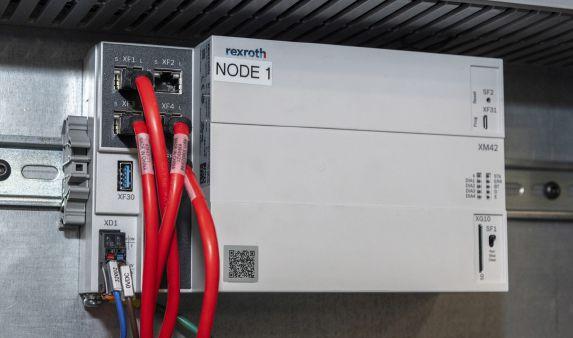

• The IndraControl XM platform for high-performance automation of a variety of motion

logic applications, whereby the local connection of the S20 I/O modules extends the control flexibly for high-performance process connection. The platform allows for easy integration of decentralized I/O stations for a robust design that design simplifies handling and allows for a wider range of applications.

• The SafeMotion drive-integrated safety technology, designed to form the basis for avoiding unintentional machine movements and ensuring safe braking, holding, moving and position monitoring throughout the process.

• The SafeLogic freely programmable safety PLC (programmable logic control) solution designed for complex machines and large-scale systems with a decentralized distributed periphery. In terms of hardware, SafeLogic upgrades the standard CML control components through the addition of a function module—enabling the non-safe and safe application to be centrally processed using only one control system.

• The VR Panel PC series from the ctrlX HMI (human-machine interface) range, combining the best attributes of box PCs (PR) and the positioned multi-touch displays (DR). Featuring versatile display format scaling, high performance and a variety of expansion options and standard interfaces, including real-time Ethernet communication, the Panel PCs feature TPM 2.0 chips to provide the necessary safety in the IIoT (Industrial Internet of Things) environment, making it ideal for robust I ndustry 4.0 applications.

• The compact ctrlX DRIVE modular drive

system, providing space-saving dimensions, maximum scalability, wide range of combination options, sophisticated engineering tools, and high energy efficiency.

• The XMD double-axis inverters of the ctrlX DRIVE range, using direct voltage to generate a controlled AC output voltage of variable amplitude and frequency for the operation of two motors.

• Planetary gearboxes and AFX-Series highspeed, high-performance gearboxes from Bosch Rexroth’s technology partner Apex Dynamics, Inc.

As Bayzelon concurs, the technological prowess, quality and reliability of Bosch Rexroth automation devices and software make it a natural fit for a technology-driven company like ETI, which is fully committed to continuous R&D (research-and-development) and product innovation.

“We have a dedicated R&D department,” says Bayzelon, “and innovation has played a large role in ETI’s success.

“The company has always strived to provide a technical edge to its clients through product development and a high level of expertise,” says Bayzelon, citing the company’s on-site Technology Center as compelling proof of the company’s commitment to customer service excellence.

Says Bayzelon: “It’s a one-stop test and trial facility for label industry suppliers, printers and converters) looking to test and/or develop new label constructions; evaluate sample performance at our in-house state-of-the-art laboratory; determine ways to reduce the cost of manufacturing; benchmark new products and production methods; and access our team of in-house project managers.”

According to Bayzelon, the company’s worldwide installation base is a testament not only to its technological know-how, but also to its overall

strategic approach to the label business.

“ETI has clients worldwide, “ he says, “with a concentration of machines sold in the U.S. and in Europe.

“The proximity of the American market certainly plays in our favor,” Bayzelon notes, “but despite the geographical distance between us and some of our clients, we have always made ourselves available to respond to our clients’ needs promptly at all stages of the cycle, no matter where they are on the globe.

“We have technical experts who travel for installations, training and support,” says Bayzelon, adding these experts also act as effective ambassadors for the company’s broader mission of enabling label makers take greater control of their processes.

“By removing the need for printers and converters to outsource the market for labelstock, ETI has created a revolutionary alternative that has led to a seismic shift in the value chain,” he states.

“In essence, we’ve developed the equipment and resources to help customers produce the pressure-sensitive material themselves, using their choice of raw materials including paper or filmic substrate, silicone and adhesive.

“ETI allows pressure-sensitive label manufacturers and converters to have more control over their production and more freedom in label creation,” Bayzelon concludes, “resulting in more economy, greater flexibility in the process, and increased profits.”

Bosch Rexroth controls

“ “

The Solution is Modular Systems

-

Ernst Blickle, Co-Founder

-

MASTERS IN MODULAR AUTOMATION SYSTEMS SINCE 1945

MOVI-C®

MODULAR AUTOMATION SYSTEMS FROM A SINGLE SOURCE

THE BIG THREE

Three ways to make packaging lines more sustainable with pneumatics and ultrasonic welding technologies

By Andres Abreu and Mark Densley

Sustainability is a high priority for today’s consumer packaged goods (CPG) companies. Driven by environmental responsibility, government regulations and customer preferences, CPG companies are actively seeking ways to decarbonize their packaging lines and use eco-friendly packaging materials.

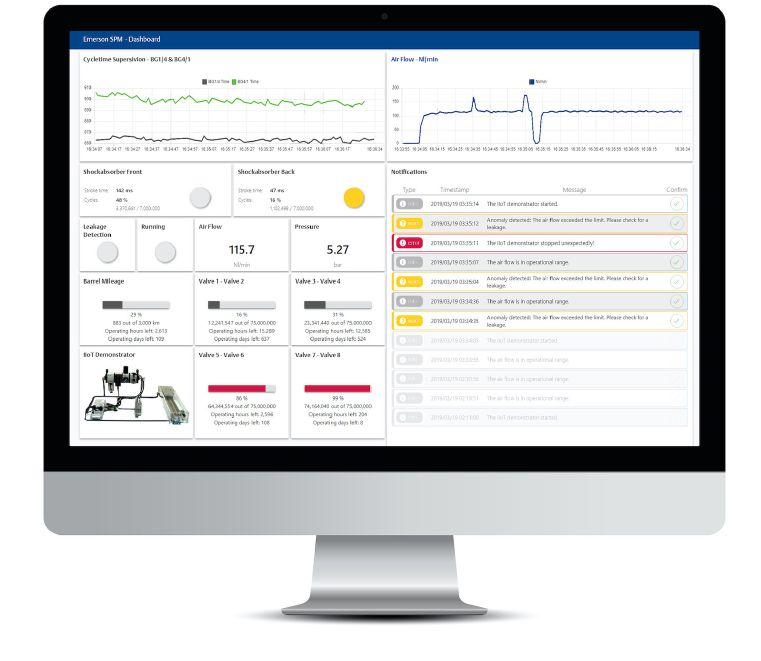

Many have started monitoring the energy consumption of their equipment in real time and have upgraded critical areas of their packaging processes using two key technologies: pneumatics and ultrasonic welding. By continuously monitoring pneumatic systems in real time, Emerson’s AVENTICSTM Series AF2

flow sensor can help CPGs detect and address compressed air leaks early.

While companies have long relied on the proven performance of pneumatic technologies in their packaging lines, the latest pneumatic devices feature specialized capabilities and connectivity that can help optimize energy use, improve overall equipment efficiency (OEE,) and maximize performance.

At the same time, ultrasonic welding offers greater precision, reliability and efficiency than traditional heat sealing, helping to minimize waste, improve packaging compostability and reduce energy consumption.

Here are three ways that CPG companies can incorporate these sustainability technologies to reduce the environmental impact, and boost the OEEof their packaging lines.

Operators can view pneumatics data and valuable insights on an easy-to-read local dashboard, making it simple to quickly respond to issues if they arise. (image courtesy of Emerson)

Above

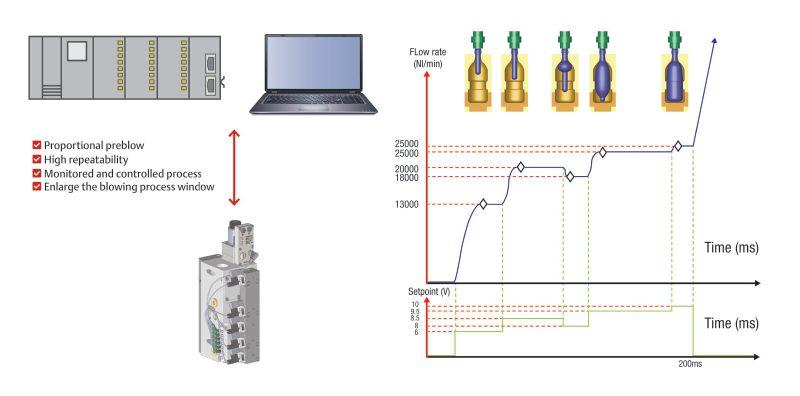

By integrating a proportional control valve instead of using on/off high-pressure airflow in their pre-blow expansion step, PET bottle manufacturers can better modulate bottle growth.

#1. OPTIMIZING COMPRESSED AIR USE

Compressed air is used to help operate equipment and power processes throughout packaging lines, including bottle production.While the prevalence of compressed air increases the potential for energy loss, certain tools can be used to optimize its use.

Not long ago, there was no reliable way to evaluate compressed air consumption, but the digital transformation of pneumatics has changed that.

Today’s smart pneumatic devices provide a more complete picture of pneumatic system performance,as well as actionable insights that give companies the ability to better understand and effectively control the energy use of their packaging lines.

Smart sensors, combined with an edge computing device, can continuously monitor system airflow

Left

and capture real-time flow, pressure and actuator speed. When properly understood using edge analytics, this data can help companies detect leaks and optimize compressed airflow (see Image 1). The data can also help operators see the relationship between air pressure, flow and the speed of the actuator more clearly. By better understanding the true nature of this relationship, operators can determine the optimal point at which compressed air is used for their packaging processes.

If the analyzed incoming pressure is higher than the process requires, and more compressed air is being used than needed, operators can reduce the pressure and modulate airflow while maintaining the same cylinder cycle time. By optimizing the amount of compressed air to meet operational requirements without affecting production, companies can minimize energy use.

In addition to optimizing compressed air use, monitoring software can also help operators detect leaks in near real time. Once it detects a leak, the system sends an alert to maintenance personnel, who can then investigate the equipment in question. This way, operators can address compressed air leaks much sooner, preventing compressed air loss and reducing emissions (see Image 2).

Companies that have implemented pneumatic solutions for early leak detection and optimized air consumption improve OEE and typically reduce their compressed air energy costs by 10 to 20 per cent—shrinking their carbon footprint by up to 10 per cent. System monitoring can help reduce downtime as well. Companies no longer need to plan downtime and have technicians test each machine for leaks, making sure the leaks are sealed before they can cause fluctuations in system pressure.

Leak-related fluctuations can make machines cycle more than necessary, and this extra work wastes energy, prematurely wears equipment and components, and increases maintenance.

#2. PERFECTING PET BOTTLE PRODUCTION

The polyethylene terephthalate (PET) bottle is the most widely used bottling product in the world. It is so popular that about 3,500 stretch blowmolding (SBM) systems are built and deployed annually to meet demand.

The precision and control of Branson ultrasonic welding components for vertical form fill and sealing (VFFS) systems by Emerson can hermetically seal bio-based materials more reliably than traditional heat-sealing tools.

The latest systems combine the SBM(stretch blowmolding) process with the bottling process in one continuous production flow.This production system makes packaging lines more compact and reduces a bottler’s carbon footprint by eliminating the shipping step that occurrs between bottle production and filling.

Pneumatic technology is a key part of the construction of SBM systems—powering several key areas of SBM machines.

Pneumatic air preparation systems improve efficiency and offer better control of the low- and high-pressure air that preform actuators and stretch blow bottle expansion steps use. And compact, high-performance blowing blocks provide bottle volume growth control through pre-blow, blow, recycling and exhaust functions.

Some suppliers have advanced SBM pneumatic performance, and sustainability, even further.

For example, one supplier offers a proportional control valve developed for the pre-blow expansion step in PET production that replaces an on/off high-pressure flow and revolutionizes this bottle production step. Whereas the previous on/off high-pressure flow set a uniform flow rate throughout the blow process, the new control modulates the flow to fine-tune each bottle’s expansion within the mold (see Image 3).

This advanced proportional valve technology combines a spe-

cially designed proportional valve, control electronics and software, which can either store the blowing sequence setpoints in the valve or respond to control directions from the programmable logic controller (PLC) that directs the blowing process.

The resulting bottle growth is intelligently modulated, giving end users the ability to perfect how the heated bottle expands within the mold (see Image 4).

The system can also capture feedback results for the quality of each blow, providing critical data needed by bottle manufacturers to perfect the process and minimize the number of rejected, wasted bottles.

It also provides condition monitoring data to support routine and preventive maintenance programs.

Proportional technology for PET blowing moves pneumatics to a whole new level of sustainability for this process.

It offers the potential to reduce material consumption with the capability to finetune bottle wall and shape formation, enabling thinner, more lightweight containers.

It also saves energy by potentially reducing blow air pressure required for high-quality bottle formation and by reducing the heating temperature in the pre-blow oven.

In addition to its energy saving benefits, proportional technology for PET blowing also enables the high throughput production of more complex bottle shapes, which is a critical marketing goal for bottlers.

It also increases manufacturing flexibility, since the process can be easily changed via software/PLC formula specific to each blowing station on the machine and finetuned for further improvement without stopping production.

#3. IMPLEMENTING ULTRASONIC WELDING

To make sealing applications greener, ultrasonic welding offers many advantages compared to traditional heat sealing.

It is precise, reliable and efficient—allowing users to reduce energy consumption, minimize product and packaging waste, and improve packaging recyclability and compostability. It also can be used confidently to seal biodegradable materials.

This sustainable technology can ultimately cut energy use by up to 25 per cent and reduce carbon footprints by up to 75 per

Pneumatics and ultrasonic welding technologies can help consumer packaged goods companies optimize energy use and improve OEE.

cent.

Ultrasonic welding systems simply use less energy than conduction heat-sealing systems by consuming energy in short bursts rather than continuously, like conduction sealing processes.

For example, to complete 100 welds per minute over two eight-hour shifts per day, a typical conduction-sealing system needs four 500-watt cartridge heaters (2,000 watts per hour or 32,000 watts per day) to constantly maintain its operating temperature.

On the other hand, an ultrasonic welder performing the same operations would be equipped with a power supply rated at just 1,500 watts and is only energized in short bursts (e.g. 200 ms per weld), consuming power for just 20 seconds out of each minute of production.

Ultrasonic welding is also more compatible with bio-based materials, such as polylactic acid (PLA), than traditional heat sealing.

Because biopolymers contain significantly less polymer content, it can be difficult for the simple time, temperature and pressure settings of a heat sealer to reliably bond this type of material and achieve a commercial-grade hermetic seal.

The precision and control characteristic s of ultrasonic welding make this technology far more capable of managing the narrower processing windows of bio-based resins (see Image 5).

Ultrasonic welding produces high-quality, consistent package seals without adhesives or consumables.

The plastic-to-plastic bond it creates not only simplifies package design, but, since

there is no contamination within the seal surface, it also improves material recycling and/or compostability.

In addition to creating a more reliable seal, an ultrasonic weld can reduce packaging material consumption as well as eliminate seal failures due to contamination.

Ultrasonic welds require only 0.25-inch of total package length when sealing the ends of small snack bags, while conventional heat seals consume about 1.0 inches. In this way, ultrasonic welding uses 0.75-inch less of material to complete a high-quality seal than heat sealing.

Ultrasonic welding also prevents seal failures due to contamination at the seal interface by package-fill residue.

The high-frequency, vibratory motion (usually 20, 30 or 40 kHz) of the ultrasonic welder actually drives residue out of the seal area.

Conventional heated tools, in contrast, often encapsulate these residues, making leaks or failures more likely (see Image 6).

Consumer packaged goods companies have long counted on pneumatics for effective, reliable production of packaging as diverse as soda bottles, cereal boxes, single-serve snack pouches, and pharmaceutical blister packs.

And the latest advances in pneumatics, including the digital transformation of the packaging line, promise even greater benefits.

At the same time, ultrasonic welding is making the sealing process substantially greener.

CPGs can eliminate contaminants, decrease waste and reduce weld failures using ultrasonic welding, which creates neat, hermetic seals between package contents— even liquids and purees.

The right technology will power more compact and environmentally friendly packaging lines.

However, it is important that CPG companies work with an automation expert that understands these new, smart pneumatic and ultrasonic technologies if they want to achieve their most ambitious sustainability and performance goal of significantly reducing their carbon footprint—all while considerably improving OEE.

WWW.EMERSON.COM

Andres Abreu is packaging business development manager for assembly and welding, and Mark Densley is director of business development of factory automation at Emerson, a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets.

HEALTHY TRENDS

Medical packaging industry leading the shift towards thermoforming automation

By Brian Golden

Automation of the thermoforming process has been embraced in the medical packaging industry more quickly than in other markets. Originally this trend was driven by stringent quality requirements and the need for high levels of repeatability.

Automation has also brought other benefits of strategic importance to medical packaging producers, including facilitating higher and more predictable throughput, as well as helping to address the challenges of attracting, training, and retaining a quality manufacturing workforce.

So what is so different or special about medical packaging?

Thermoformed medical packaging is designed to protect a wide variety of items—ranging from implantable medical devices to surgical instruments, and on to disposable catheters and syringes.

The selection of materials and the forming and sealing processes are crucial to ensuring that the integrity of the sterile barrier system is maintained during shipping and handling until the product is opened by the user.

Medical items are often delicate. Therefore, the packaging must protect the products from damage during shipping and handling, securely holding each item in place and separating multiple items packaged together from damaging each other.

For sharp objects such as needles, screws, and drills, the packaging must be designed to protect the safety of the people handling and opening the package.

Ensuring an effective and durable sterile barrier starts with material selection, with PETG and HIPS often selected for medical packaging applications.

Polyethylene terephthalate glycol-modified (PETG) is created by adding a glycol modifier to PET— making it slightly softer for tighter seals and also more suitable for withstanding high-temperature sterilization processes.

In addition to the polyethylene family of plastics, high-impact polystyrene (HIPS) is also commonly used for thermoforming in medical packaging. The HIPS plastics are impact-resistant and clear, and they have excellent hygienic qualities.

The shape of the packaging typically differs for medical products.The entire package must withstand the temperature and pressure extremes of the sterilization process.

The flange must have the required thickness and rigidity, and smooth surface, to accept and maintain a hermetic seal to the Tyvek lid.

The sidewalls must also have adequate and consistent strength and thickness to prevent cracking and leakage during transport and handling.

The most challenging aspect of medical packaging design is often the complex geometries required to isolate individual items into separate compartments and to lock each item in place.

When properly designed and manufactured, undercuts allow each part to be snapped into place and held securely.

Most medical packaging applications call for enclosing the thermoforming machinery in a protective enclosure to minimize exposure to airborne particulates that can cause gaps during the hermetic sealing process.

It is imperative that measures are taken to eliminate static that will attract particulates and to ensure that the cutting process does not generate particulates that can migrate to the product.

Enclosing the machinery is important not only for protection against particulates, but also for isolating the system from ambient air and temperature that cause fluctuations in the heating of materials and in the air pressure of pneumatic components.

These various special requirements for medical packaging have led to the wide-scale adoption of form/fut/stack thermoforming systems. Simpler and less costly Contact Heat systems are suitable for only a small fraction of medical packaging applications because they lack plug assist capabilities required for complex geometries and the higher clamping forces that form/cut/ stack systems offer, which ia why Contact Heat systems are primarily used for simple package designs and low production volumes.

For their part, the form/cut/stack systems are usually enclosed in a protective envelope protecting the process and the product from airborne particulates and ambient temperature and humidity.

Hwncw they can be more fully automated and therefore more precisely monitored and controlled, especially machines with 100-percent servo motors and drives.

Investment in automation offers many advantages in medical packaging manufacturing. More precision and control result in much higher repeatability, which means higher quality products as well as fewer defects and less waste.The process improvements also achieve faster cycle-times and more predictable output for higher throughput and scalability.

Precise control and repeatability are also critic-

al to the calibration and production consistency required by the strict standards and government regulations for medical packaging, such as ISO 11607:2019 and Title 21 CFR Part 11.

Automation may also include vision systems and other inspection technology that provide automatic, continuous real-time quality control.

In general, the more automation, the greater the opportunity to collect data for process improvement and for traceability.

In addition to the benefits of better product quality and higher production quantity, another factor driving increased investment in automation is the increasing challenge of recruiting, training and retaining manufacturing employees.

Medical packaging manufacturing faces the same workforce challenges as all industries. The 2021 Deloitte and The Manufacturing Institute Manufacturing Talent study found that U.S. manufacturing is expected to have 2.1 million unfilled jobs by 2030, a trend that began before the pandemic and has been accelerated since.

The study also reiterated the obvious: “The pace of digital transformation in the manufacturing industry will likely continue to redefine work for humans.”

Traditionally, the operation of earlier generations of thermoforming equipment was often known as more of an art than a science, with operations acquiring a feel for what works after decades of experience. As the veterans of the industry are moving on to other roles and retiring, and it is difficult to transfer these skills to new equipment operators, especially when employee turnover rates are so high.

Automation addresses these workforce issues in several ways.

Obviously, automated systems are less labor-intensive. Instead of requiring one or

more operators per production line, a single operator can cover multiple lines. this requires that the machines autonomously perform the forming, cutting, and stacking processes with little or no hands-on engagement by the operator.

For high-volume production, robotics are increasingly employed to automatically perform downstream packaging and palletizing functions. But the autonomous operation of these functions is only one element of automation.

The procedures for changing tooling between SKUs and for replacing roll stock also need to minimize human error and effort.

The right tooling needs to be installed in exactly the right way, for every production run, and rollstock can weigh up to 1,500 pounds. Therefore, thermoforming equipment should be designed with procedures and tools for streamlining these processes and preventing errors and with ergonomic aids for lifting and correctly positioning heavy objects.

Moreover, the Human-Machine Interface (HMI) must be designed to be intuitive and easy-

to-learn for new employees, while also being very efficient and easy-to-use during production every day.

The latest HMI systems employ large high-resolution displays that support multitouch gestures, taking advantage of the skills new employees now universally bring with their years of smartphone experience. Like smartphones apps, these new interfaces should require little training and no paper documentation.

The whole concept of a form/cut/stack thermoforming machine is to integrate and automate these multiple functions in a single system. Medical packaging manufacturers have been at the forefront of the trend toward automation, initially driven by the need for high quality, repeatability, and traceabilitym, along with increased scalability and throughput.

Brian Golden is sales director for the Americas region at GN Thermoforming Equipment in Chester, N.S.

MODULAR DELIVERY

Reimagining the space and flexibility requirements in e-commerce micro-fulfillment applications

By Jim McMahon

The fulfillment aspect of online retailing is commanding considerable attention from retailers, particularly with the advent of COVID-19, as consumers have evolved to more fully rely on online shopping. Fulfillment is the decisive moment with the customer, and where much of the real e-commerce profit is derived. The retailer can catch its revenue flow on the front end with an attractive and easyto-navigate website, an easy-to-use online shopping cart, and a credit card capturing system in place.

However, if the customer cannot get the product when and where they want it, the retailer risks alienating and, ultimately, losing the customer. Today’s consumers are in a power position. They want flexibility and options, and they are requesting different service levels.

Same-day delivery and immediate local-store pick-up are no longer perks for e-commerce consumers: they are expectations. The typical e-commerce consumer expects cross-channel services like

click-and-collect and order-to-deliver, wider online SKU (stock-keeping unit) offerings, reliable order accuracy, fast and free delivery, free returns, mobile and social media retail sites, and consistent brand experiences across brick-and-mortar, online and social media storefronts.

Of these expectations, consumer demand for fast and free delivery is causing retail supply chain executives the biggest challenge to remaining competitive and profitable.

Essentially, e-commerce fulfillment is a delivery proposition. If a customer wants it, and the retailer has it, the retailer needs get that item to the customer in the fastest and most efficient way possible to meet the expectations of the customer.

The e-commerce consumers are willing to change brand allegiance to get better value and service.To remain competitive, every step in the fulfillment process must be handled accurately, efficiently and quickly to maintain a positive customer experience.

Conventional models for retail distribution utilize central distribution centers (CDCs) to ship inventory out to stores, and separate centralized e-fulfillment centers to ship direct to consumers.

Managing retail e-commerce from these e-fulfillment centers, however, cannot accommodate today’s customized needs of consumers who are pushing retailers for more engaging in-store

experiences with their e-commerce orders.

However, localized in-store micro-fulfillment and nano-fulfillment can do so, along with the capacity of delivering orders more cost-efficiently than centralized e-fulfillment centers.

Nano-fulfillment centers—also known as ‘dark stores’ and smaller than micro-fulfillment locations—are typically plug-andplay robotic solutions located within urban centers, typically carrying a fraction of the SKUs of full-size DCs.

To achieve a faster and more flexible level of fulfillment for e-commerce orders, a streamlined, interconnected micro-fulfillment distribution system—where local retail store channels are utilized to pick, pack and deliver small orders directly to consumers—is a must.

A strategy of utilizing system-wide inventory, combined with local retail stores to fulfill customer orders across all channels, can provide an enhanced customer experience.

This includes capturing sales that otherwise would be lost, gaining a better price point and improving margins, while reducing the investment and operating costs of centralized DCs.

A retailer fulfilling an order placed online through a central fulfillment facility in Omaha, Neb., for delivery to a consumer in San Francisco, Ca., must factor the cost of packing and shipping to that customer across the country.

Compare this to having that same item sitting in the retailer’s store in San Francisco, where it can be picked from the floor and delivered in a two to three-hour time window to the customer. Or, if the customer prefers, it can be picked-up from the store location in a matter of hours.

Not only does the customer get the item faster, but the retailer saves on the cost of order packing and transportation.

Because the retailer could make the item available at a local store, it also prevents the customer from looking at another retailer that might have it available locally.

This approach supports a highly efficient inventory strategy of fulfilling e-commerce orders for faster-moving SKUs from retailers’ stores, while making slower-moving SKUs available from central fulfillment centers.

An additional benefit is the fact that the item from the retail store is sold at full price.

By making the retailer’s inventory more universally accessible to the consumer, the incidence of excess inventory that would eventually have to be marked down can be significantly reduced.

Utilizing any and all inventory to fill every order is intended to maximize top-line revenue, while optimizing fulfillment costs to leverage as much margin as possible.

By implementing this strategy of in-store fulfillment—moving

Inventory visibility is critical to successful e-commerce fulfillment operations.

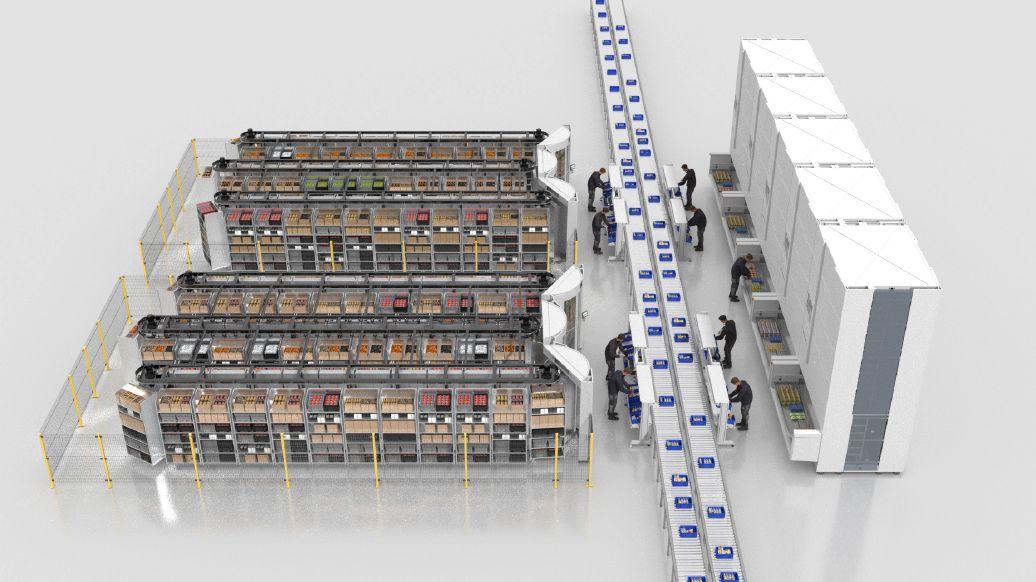

Automated goods-to-person micro-fulfillment floor layout. Reusable plastic totes bing filled with products for e-commerce orders.

much of the pick, pack and delivery operations into stores, enabling those stores to receive online orders and fulfill them—retailers can markedly reduce the fulfillment space required in their distribution centers, and even reduce the number of distribution centers in their network.

For geographic areas that are home to multiple stores of a given chain, one store might be designated as an alpha-store. If it’s a part of a group of three stores, for example, this store would be stocked from the distribution center with a higher volume of faster-moving and seasonal SKUs, and it could replenish the other two stores within its area quickly as dictated by demand.

In a very populated area where several stores are in close proximity, the alpha-store might be designated as the sole pick, pack and ship location for the larger group of stores.

To facilitate this precision level of fulfillment, the retailer must have visibility to what inventory it has on its retail store floors and back rooms, in-transit and on-order, as well as the stock in its centralized e-commerce fulfillment centers.

This determines the most timely and cost-effective fulfillment solution to meet the customer’s service requirements.

The benefits to retailers of implementing an in-store fulfillment

strategy are considerable and rewarding.

If a store has an item in stock, it can be sold to a customer to fulfill an online order. Similarly, a slow-moving item from another store can be redirected to fill the order.

If the item can be fulfilled from a store that is closer to the customer than the distribution center, the customer will receive the item faster. Coming from a local store, compared to a distant distribution center, the shipping costs will also be reduced.

In-store fulfillment can improve store employee utilization, particularly with back-of-store fulfillment reducing the amount of in-store picking required to fill orders.

Space utilization within retail stores and e-commerce fulfillment warehouses is at a premium today for many reasons. The continuous increase in the cost of land, construction, labor and facilities has put a heightened demand on more efficient space utilization within these operations.

Many e-commerce fulfillment operations have completely outgrown their warehouse space, forcing them to rely on leased off-site facilities and 3PLs (third-party logistics) suppliers.

However, this presents a new set of issues. Increased rental and transportation costs, coupled with the loss of last-touch product control, can result in increased product damage and returns, which is particularly troublesome in the food-and-beverage and pharmaceutical environments.

Consequently, retail stores and e-commerce fulfillment centers are looking ever more closely at how they can optimally balance their inventory against fulfillment and delivery.

A successful e-commerce fulfillment implementation requires a carefully planned processes, optimized space utilization, scalable operations, and highly efficient automated systems to address the speed of throughput and space challenges at the individual store level.

For retailers, space utilization is a prime consideration. The tipping point for in-store micro-fulfillment centers is being able to store more SKUs within a limited space.

To support this, companies must invest in flexible in-store micro-fulfillment solutions that can be easily configured to fit different store space models, accommodate for variations in ceiling heights and obstacles, and yet provide the scalability to expand or

contract as the store’s e-commerce needs require.

Expanding or reducing SKUs, fluctuations in throughput volume, seasonal influences, and the rise and fall of the popularity of items offered online are all key factors that necessitate the need for highly flexible and scalable requirements in an e-commerce micro-fulfillment system.

Typically, th e more efficient micro-fulfillment e-commerce solutions are those that have achieved high density cubic space utilization, coupled with a low footprint, for storage of single-item and small-case SKUs.

Essentially, they have a space configuration that allows for the maximum number of SKU positions to fit into the system and utilize both the footprint and the facility height optimally.

Whereas it was once considered acceptable for a picker to spend 60 per cent of the time traveling and 40 per cent of the time picking—as is typical in a person-to-goods fulfillment model—e-commerce executives are increasingly looking for more efficient solutions to minimize the amount of wasted time between picks to increase the number of e-commerce orders processed per picker.

Manual picking is a highly labor-intensive function that can

Vertical lift modules providing automated fulfillment for e-commerce orders.

Anthropomorphous robot picking product from a VLM bay.

provide significant cost-savings when it is automated.

As a company’s e-commerce needs fluctuate, its pick, pack and delivery model should be able to accommodate these changes.

While flexibility and scalability with online fulfillment is critical, just making improvements in stationary rack storage locations can only be stretched so far.

The correct solution in most circumstances is to automate the fulfillment operation by implementing the right automated system for that application—one that can support the fluidity that its e-commerce fulfillment demands.

The right micro-fulfillment automation facilitates the minimization of manual touches, resulting in more accurate orders, improved ergonomics, lower labor costs and travel time, lessened returns, and space savings enabled by a smaller footprint.

In an automated goods-to-person micro-fulfillment concept, incoming goods or cartons are placed into totes or trays, which are stored in high-density automated storage and retrieval systems.

As the orders come in, the SKUs are automatically retrieved from storage and brought to the picker at a pick/pack station.

Because the picker does not have to travel, the pick/pack station benefits from improved ergonomics and higher productivity by eliminating the significant travel element inherent in traditional person-to-goods picking operations.

Such automation should yield:

• Improved results in throughput, productivity and accuracy;

• It should be capable of becoming operational quickly with minimal disruption to throughput;

• It needs to be an affordable capital investment while realizing a short-term ROI;

• It should have location flexibility, and a high density of space utilization with a minimal footprint.

Over the past decade, highly automated goods-to-person systems for efficient single-item/small-order fulfillment in e-commerce have made considerable advancements towards realizing these objectives.

Automated e-commerce micro-fulfillment solutions come in a variety of forms and configurations. They can incorporate highdensity storage systems, pallet-based or tote/carton-based systems, horizontal and vertical carousels, robots and vertical lift modules.

The solution selected needs to fully embrace the needs of the e-commerce fulfillment operation.

An increasing number of e-commerce executives are embracing a goods-to-person fulfillment approach based on vertical lift modules and horizontal carousels as a solution to achieve more efficiency in their micro-fulfillment storage and picking processes.

This approach enables the inventory to be moved to the picker, who is comparatively more stationary, utilizing advanced technology to facilitate the inventory storage and movement.

Based in Lewiston, Me., Modula Inc. (www.modula.us. com) has recently introduced two new-generation systems for high-density, low-footprint automated storage and retrieval for micro-fulfillment: the Vertical Lift Module (VLM) and Horizontal Carousel (HC).

Capable of handling thousands of different SKUs, these systems allow inventory to be stored, picked, packed and shipped with a very high level of efficiency, optimized labor usage, and

minimized operational costs.

They provide an excellent example of the latest state-of-the-art technologies and system capabilities for micro-fulfillment.

The modular, scalable design of these latest-generation VLMs and HCs allows them to be easily installed and implemented in any existing or greenfield retail store, warehouse, manufacturing facility or distribution center—excelling in both high- and low-ceiling height applications, as well as at facilities with unusual configurations.

Designed for high throughput, these systems permit the flexibility to easily be extended or contracted as needed to accommodate changes in SKU counts and throughput volumes, including for storage of temperature-controlled products between 35.6°F and 77°F.

The goods-to-person concept embodied within these two systems is simple.

To start, the incoming goods are inventoried into the high-

Combined horizontal carousels and vertical lift modules used for supporting high-throughput e-commerce fulfillment operations.

density, automated-storage VLM or HC.

As e-commerce orders are required to be filled, the items are automatically retrieved from the storage system and brought to the picker at an ergonomic receipt station, where the items are picked from the partitioned trays.

The goods are automatically delivered to the operator with a simple touch of a user-friendly HMI human-machine interface) co-pilot controller, or with the scan of a barcode.

This feature eliminates the need to search for items and ensures that the right item is delivered

with the order—significantly reducing picking errors, while increasing productivity and efficiency.

The systems also allow for a large inventory of goods to be quickly accessible while being stored in a safe and secure environment—permitting user authentication with badge, Amazon EKS and RFID (radio frequency identification) readers. Moreover, Modula’s VLMs and HCs incorporate a WMS (Warehouse Management System) software that provides complete inventory management, seamlessly integrating with an

e-commerce company’s ERP (Enterprise Resource Planning) or DMS (Document Management System) for automatic tracking of picking operations and recording of inventory levels in real time.

One of the Modula VLM’s many attributes is its minimum footprint, enhanced by its ability to utilize all the available ceiling height As such, it has the capability to hold thousands of SKUs, positioned in trays located within the VLM.

Depending on the VLM design, each tray can have a payload capacity of up to 2,200 pounds, and the VLM is capable of delivering up to 130 trays and per hour to the operator, with picking speeds of up to 300 lines per hour.

Moreover, the VLM is capable of presenting trays internally or externally. While internal bays are best used for limited floorspace application, the external bays offer optimum ergonomics for operators, as well as adapting picking aids like cranes or mechanical manipulator interfaces, such as anthropomorphous robots.

The system can be set up for single or dual-tray delivery. Whereas single-tray delivery is suitable for situations with less stringent throughput requirements or quick picking time, dual-tray delivery reduces wait time for the next tray—enhancing productivity.

With simple visual picking aids, operators can quickly and easily identify the items needed to be picked or replenished. These include X-axis LED bars, alphanumeric pointers, laser pointers, putto-light and external picking monitors.

This latest-generation VLM also provides invaluable makes available an energy recuperation capability , whereby a specially designed inverter generates energy from the VLM’s system’s movement.

In a nutshell, it converts the kinetic energy produced by the descending elevator into electri-

city—feeding it back into the grid and supporting the VLM’s environmental sustainability profile. This functionality results in saving up to 40 per cent on energy used by the VLM.

Where ceiling height is limited, such as in an existing brownfield facility where a VLM would not be an efficient option, the Modula HC is designed for use in these operations.

Each of the system’s trays has a payload capacity of 1,200 pounds, and it is capable of picking speeds of up to 550 lines per hour., with its put-tolight system enabling fast and nearly error-free picking operations.

Multiple horizontal carousels can be combined to achieve higher picking performance by using Modula’s WMS to create a batch of orders that can be filled at the same time.

As the operators select the total quantity of each SKU for all orders, picking aids such as batch picking lights, direct the operator to select and place the correct items in the correct orders. Since the operators only visit each SKU location once during each batch, increased accuracy and reduced picking times can yield productivity improvements of up to 65 per cent.

Many retailers and smaller e-commerce companies are facing with the challenge of scaling up the efficiency of their storage, picking and fulfillment operations.

The latest generation of vertical lift and horizontal carousel systems, like those from Modula, present extremely optimized solutions for highdensity, low-footprint, highly scalable and cost-efficient micro-fulfillment automation for retailers and for virtually all e-commerce fulfillment requirements.

POUCH AND GO

Pouch technology can play a critical role in optimizing reverse logistics

The cost of handling returns can have an enormous effect on a logistics facility’s bottom line. Unless action is taken the problem can only get worse, as omnichannel shopping becomes increasingly prevalent and the rate of returns continues to rise.

Any returns that simply languish on the shelves are a drain on the bottom line, because they take up valuable space, do not bring a financial return, and can easily depreciate in value. So what can be done?

One of the key challenges to handling returns is the many manual touches involved in the process. But what if the logistics center could remove many of those steps to reduce the labor required and the time taken to make the returns available for sale again?

Happily, the advanced pouch technology from BEUMER Group (www.beumer.com) eases the handling of returns by placing each item directly into a pouch that circulates on an overhead conveying system rather than sending it back to the shelf or regular storage, where it has to be picked again if it is ordered.

The pouch system serves as an intermediate buffer for return items, which are typically sold again within three days. Returns needed to fulfil an order are automatically retrieved

from this dynamic buffer and sent direct to sortation.

Used this way, the pouch system dramatically reduces the cost of handling returns: the fewer times an item is touched—and the shorter and cleaner the process—the more value the item retains.

Onlythe items that are not sold after a few days are returned to shelf as part of an automatic, easy housekeeping process that is run during low-throughput periods.

With this type of sortation, the facility knows exactly what is in every package. If it opts to resell its returns on the secondary market, it can receive a higher value because of the way they have been sorted, segmented and treated. Instead of returns being a loss, this higher-level sortation can create a value chain within the supply chain.

As well as having to handle a rising number of returns, fulfilment operators have to contend with the ‘New Normal’ of an unpredictable global economy, disrupted supply chains and labor shortages.

In order to stay ahead they must make adjustments to achieve greater efficiency, and one of the most cost-effective ways to do this is through the use of real-time data.

All fulfilment centers, from large fully-automated facilities to small operations, have valuable data points in their sorters, scanners, scales, chutes and conveyors from which they can begin automating in ways that enable efficiencies and future growth.

The goal is to condense these vast data points to unearth issues that must be resolved, or to reveal opportunities to achieve greater efficiency.

The process starts with digitalization, which is the collection of enormous amounts of information—generated from equipment and operations in the fulfilment center—that is stored as data. When this is done, e-commerce logistics providers can begin to unlock proactive decision-making abilities through real-time data analytics that present facts to help them understand what is happening in their processes.

Data brings to light contributing events and their impacts, allowing managers to deal with problems immediately.

Today’s logistics systems enable machines to communicate with each other at a high level, enabling managers to align their operations in all areas of their fulfilment operations and make

determinations about efficiency, machine communication and operator performance.

Further development of data analytics systems will result in self-learning machines that use real-time data to self-optimize the system. Thus the future will lie in prescriptive analytics, with material handling systems actually telling operators the action

they need to take to avoid problems.

There will also be greater integration with third-party data, allowing operators to further optimize their processes, from sourcing materials to the last-mile delivery.

WWW.BEUMER.COM

External Motor or Internal Roller Motor Options Accumulation, Steady and Zoned Applications

Running

Landmark snack-food manufacturing facility cranks up its cracker production volumes with cutting-edge packaging automation

By George Guidoni, Editor

Photos by Naomi Hiltz

PACK TO SNACK W

ith snacking continuing to evolve as a daily eating ritual across the world’s cultures and geographies—keeping hunger at bay between meals and providing a welcome boost of energy and nutrients—snack-food manufacturing has become an integral part of Canada’s consumer economy, serving a growing domestic market worth an estimated $13 billion annually.

As one of the country’s largest producers of crackers, cookies and other popular snack foods, Toronto-based Mondelēz Canada—part of the Chicago-headquartered multinational Mondel ē z International Inc.—puts a high premium on continuous improvement in

Mondelez Canada’s site engineering manager Annamaria Reda proudly displays colorful packages of some of the most popular brands of crackers and cookies produced and packaged at the company’s’ venerable East York manufacturing facility in midtown Toronto.

its production and packaging capabilities to retain and grow its significant share of the fast-growing global market for baked snackfood products.

Operating five manufacturing facilities in Canada, the publicly-owned company has invested millions of dollars’ worth of new equipment into its Canadian production assets over the last decade, with particular emphasis on modernizing and expanding its venerable cookie and cracker production site in Toronto’s midtown borough of East York.

Originally opened in 1949, the East York plant has undergone multiple upgrades and expansions over the years under various former owners, but its most recent comprehensive capital upgrade has arguably set a new benchmark standard for successful integration of automated processing and packaging machinery—raising its skillset and efficiency levels to the proverbial next level of worldclass manufacturing excellence.

In 2017, the company expanded the existing East York building on Bermondsey Road to a total of 462,000 square feet of production space, while installing multiple new-generation processing and packaging machinery to accommodate a fast-paced, around-the-clock production environment to enable the peanut-free certified facility to produce over 160 million pounds of product annually for the Canadian and U.S. markets.

“Some of the major brands we make here at East York include Oreo, Premium Plus, Ritz, Wheat Thins, Crispers and Peek Freans cookies,” says site engineering manager Annamaria Reda.

“We have over 100 SKU (stock-keeping

unit) offerings—comprising different flavors and a wide variety of packaging formats—here on-site,” Reda expands.

“We have the capability to produce cookies in trays—directly in overwrap, or overwrapped and cartooned—stand-up pouches, overwrapped slugs in a carton, and bag-in-a-box formats.”

“The product offerings we manufacture at East York bakery are mostly private-label direct-to-customers,” she adds, “with a small volume of portion-packs made for foodservice clients.”

As Reda explains, the East York plant operates a total of eight high-capacity commercial ovens to make its product range, with each of the ovens feeding multiple processing and packaging lines to produce the final products and ready it for shipment to customers.

“Our eight ovens are evenly split between cookie and cracker lines, as they use unique forming equipment for the different types of products,” Reda notes.

“We are busy all year with both,” she says, “but one of the heaviest seasons is the lead-up to the fall and winter seasons, when we see higher cracker sales.”

Making the manufacturing processes run smoothly and seamlessly at all times requires a fairly high level of automation to maintain a high level of product quality and consistency, Reda points out, while ensuring robust productivity levels and reduced reliance on manual labor for some of the more repetitive and physically strenuous tasks.

“Automation is important to help us stay competitive and also to be able to offer higher-skilled jobs in the labor market,” Reda

Top Freshly-baked and cooled cracker strip entering the breaker, supplied by Charles Downer & Co., to be separated into individual crackers.

Bottom Individual crackers travel in bulk along the the six-lane vibratory coneyorstowards the Syntegon FGMT feeder/ loader.

states.

“We do have a combination of fully automated lines where we make consistent products,” she notes, “although we also have some manual packaging lines where we either need more flexibility or have lower volumes.”

As Reda relates, the recent building expansion went hand-inhand with a multiphase installation of a whole new production line for high-speed, high-volume processing and packaging of cracker products, including the bestselling Premium Plus line of crackers.

Carried out in step with the ongoing building construction and infrastructure installation, the new L30 line comprises some of the most advanced processing and automated packaging equipment available in the market, including multiple primary and secondary packaging machines manufactured by leading global packaging equipment group Syntegon. (www.syntegon. com)

“The overall goal was to expand the facility to enable the production of various cracker SKUs here at the bakery,” Reda says.

“The project was installed in a separate building,” she notes, “so our other production lines were able to operate normally, and generally were not impacted.

“As with many large projects, it had its challenges,” she acknowledges, “but overall we have been able to learn the new process and equipment very well over the years.

“We are now running the machines at efficiency levels in the high 90s (per cent),” Reda states, “and Syntegon was a great partner in this project by providing support when it was needed to bring us to these operating levels.

“The Syntegon installation is one of our most fully automated lines end-to-end,” she states, “and we operate with the best-in-class crew.

“As a full new line, the L30 installation project added over 65 million pounds of additional output from the East York facility,” Reda says, complimenting the outstanding support and customer service provided to the project by Syntegon’s Canadian distributor and packaging line integration experts Charles

Above

A close-up of the Syntegon FGMT portioning system dividing the bulk crackers into individual slugs for packaging.

Right

Finished overwrapped slugs of crackers passing through the METTLER TOLEDO metal detector for quality control.

Downer & Co. Ltd. of Richmond Hill, Ont.

Actively involved in the L30 line installation from start to finish, Charles Downer provided the required equipment for all the product handling, transfer and packaging stages from the oven—starting with product breakers and spreaders—right to the end-of-line packaging and palletizing.

According to Charles Downer’s president and owner Jeff Downer, the L30 line boasts one of the largest single-line instal-

lations of Syntegon packaging machinery anywhere in Canada, including:

• Six Sigpack FGMT feeders with cross-feeding chains.

Designed for high-speed stacking and portioning of crackers, cookies and other dry, oily and brittle baked goods with a separation knife, the Sigpack FGMT feeder is a continuous motion-portioning machine that uses two separating swords per lane to allows the product column to advance continuously, rather than intermittently, to produce up to 400 slugs (stacks) of product per minute on each machine.

After the products are baked in the oven, cooled down and fed into the FGMT by vibratory channels, one sword moves into the product flow, while the second sword holds the leading edge of the formed slug.

Once the swords advance the column to the lowering shovel, an overhead counterholder takes control of the leading edge— allowing for the second sword to return and start the next portion—while the counterholder guides the slug into a shovel for lowering the portion into the cross-chain.

After the portion is released and the empty shovel is raised,

Pre-printed Z-flute board cartons being formed from blanks inside the Syntegon TTM toploader.

Filled cartons being closed by the robotic closing section of the Syntegon TTM toploader.

Side view of the Sigpack TTM toploader capable of filling up to 150 cartons per minute.

Side view of the Syntegon Elematic case-packer recently installed at the East York facility.

The Sigpack TTM toploader design incorporates a Nordson hot-melt applicator for inline gluing of the pre-loaded cracker boxes.

the next portion is guided in.

The alternating functions of the two swords allow the product to advance in a continuous flow, according to Syntegon, thereby reducing back pressure and product stress.

Top Left

Close-up of robotic grippers inside the Sigpack TTM integrated topload cartoner.

Bottom Right

A close-up view of the Zambelli tray-packing and shrinkwrapping machine in action.

Bottom Left Corrugated boxes from Atlantic Packaging Products used to ship the finished cartons.

• Six Sigpack FIL with HCS horizontal slug flow wrappers.

The slugs are transferred from the FGMT by the intelligent infeed named FIL, which uses linear motor technology instead of conventional chains.

The main advantage is the extremely gentle handling of the transfer, which is nevertheless still performed at high speeds.

Once transferred to the wrapper, the FIL carries the slugs into the folding box of the HCS wrapper. the slug streams go gently from cross chain unit right into FIL and HCS folding box.

The FIL infeed also acts like a small buffer, which stabilizes the wrapping speed for a highly efficient and reliable system.

The FIL/HSC also allow for very quick changeovers: within 10 minutes from long to short slugs.

The HCS is compatible with a wide range of heat- or cold-sealable monolayer or laminated film structures at speeds up to 400 packs per minute.

Capable of producing longitudinally or cross-crimped end fins with straight, zig-zag or clip cut-off, the machine folds and shapes the film like a hose to wrap around the product, which is then longitudinally and transversely sealed.

Offering a variety of optional features—including print code, carton insert, label or coupon, tear strip, tear notches and other easy-opening features—the machine’s automatic film splicing enables fast and easy film reel changeovers.

• Six Sigpack TTM top-load cartoners.

Designed for 24/7 production, the Sigpack TTM integrated topload cartoning platform delivers high-speed carton forming, loading and closing many types of cartons—including triseal closure, open tray, tray and hood, or tuck-in lid—at speed of up to 150 cartons per minute.

Requiring only one operator to handle all operations via a touchscreen HMI (human-machine interface) terminal, the Sigpack TTM can handle both solid paperboard and corrugated containerboard, as it automatically removes carton blanks from the loader, erects the cartons, loads them with the grouped product, closes the filled cartons, and passes the finished cartons on to the outfeed belt.

Incorporating a product infeed conveyor, a driven blank magazine, three-axis robots, controls and drives from Rockwell Automation, and an integrated hot-melt adhesive applicating system, the high-performance machine can handle a broad range of carton sizes, while facilitating remarkably quick and easy changeovers. In addition to the Syntegon primary

“These feed into the three Zambelli units and four Euroimpianti palletizing robots, which are shared with another line,” she adds.

“It’s very important that all six legs run consistently with little downtime,” Reda points out, “as it would be inefficient to stop the oven process should one packaging leg stop producing.”

So far, all the Syntegon equipment has worked as well as promised, according to Reda.

In fact, the outstanding performance delivered by Syntegon machinery on the L30 line has enticed the East York plant to invest in yet another fully-automatic Syntegon secondary packaging system—an Elematic case-packer—on another one of the facility’s production lines.

“We have enjoyed good support from the Syntegon team,” Reda states.

“As it occurs in every project, there were some challenges, but overall we’ve achieved good performance results quickly after startup.

tion and layouts, to ensuring we have the right support for the installation and commissioning phases.”

Reda says Mondelēz Canada takes pride in sourcing as much of its raw materials and packaging from Canadian suppliers as possible, and working with Canadian packaging automation experts like Charles Downer is a valid reflection of that local sourcing mindset.

According to Reda, the East York’s largescale investment in packaging automation played a key role in enabling facility to carry on largely “business as usual” even during the peak months of the COVID-19 pandemic, when demand for foods like crackers and cookies actually surged above normal levels.

“The food industry is a very competitive business,” she says, “and our key competitive strength is our team’s ability to react and lead through challenges like that to ensure that products that our consumers love are always available on the shelf.

and secondary equipment integrated into the L30 line, three Zambelli tray-packing and shrinkwrapping machines, as well as several Euroimpianti robotic palletizers, corner post applicators and RGVs (rail-guided vehicles) at the end of the line.

“They have expanded the palletizing system twice now in order to handle the entire facility with 10 robotic palletizing systems,” says Downer.

As Reda comments, “Our L30 Syntegon line has a single oven splitting into six packaging legs, which is why we have six full sets of the FGMT, FIL-HCS and TTM units.

“The service from Syntegon has also been very reliable; their team is highly responsive, and we have a local representative that can support on-site when necessary,” she sates.

As for Charles Downer’s contribution, “We found Charles Downer & Co. to be very knowledgeable on equipment capabilities and new technology offerings,” Reda states.

“They supported the project from end to end, including ideation of equipment selec-

“Having the right technology in place to ensure that shelf presence is a big part of that competence,” she states.

“As a business, we are always working towards giving people a wide range of high-quality snacks so they can make great informed choices,” Reda concludes.

“It’s about keeping true to our existing brands that our consumers know and love, improving the sustainability of their production, and also offering new snack options that people truly love and feel good about.”

Above

One of several Euroimpianti robotic palletizers installed at the East York facility.

SWEET AND SIMPLE

Venerable French pastry manufacturer proudly carries on its legacy of culinary excellence with leading-edge packaging automation

Producing a great variety of products and many different packaging formats is a challenging combination that still often requires a fair bit of manual labor for many manufacturers.

That’s no longer the case at Madeleines Bijou, a renowned French pastry manufacturer now packing its famed golden-colored madeleinettes and other sweet baked goods with effortless ease—thanks to an advanced packaging solution from stalwart German packaging machinery manufacturer Gerhard Schubert GmbH. (www.schubert.group.com)

With robot-assisted technology, customized 3D-printed tools and clever packaging design, Schubert’s TLM packing line ensures maximum flexibility for the family business

Pick-and-place robots place the packages onto Transmoduls. The transport robots are designed so that all carton and tin formats can be picked up regardless of their geometry.

At Bijou, the TLM machine from Schubert packs madeleines, biscuits and other baked goods at a rate of up to 360 products per minute into a wide variety of cartons and tin formats.

with the highest level of automation.

Modern and playful, inspired by current trends but never losing sight of its heritage is a fitting way to describe the character of Madeleines Bijou, a family-owned business that has been producing its eponymous Madeleines since 1845.

To ensure maximum freshness, the small pastries have been individually packed into flow-packs for decades.

While the Madeleines have become Bijou’s brand ambassador, embodied by the ‘Mady’ mascot, the range is continuously growing, along with production volumes.

In 1990, the first automation lines were introduced at the com-

pany’s headquarters in what is now the Nouvelle-Aquitaine region.

Just nine years later, the site had to be expanded to three times its original size.

Gerhard Schubert accompanied the planning and introduction of automated packaging processes at an early stage.

For over 20 years, many Bijou delicacies have been packaged on equipment from the family-owned machine-builder based in Crailsheim, Germany.

To further increase the efficiency of the site, Jean-Philippe Dubois, president of Madeleines Bijou, called for the automated filling of a variety of different mixed formats and special tin formats with

madeleines, small pastries, biscuits and wafer rolls —all individually protected by flow-packs.

“The challenge with this project was to create an automated production line from a hand-packing situation,” recalls Schubert’s sales account manager Christiane Buchstab, who is responsible for sales and customer service for the territory comprising France and Switzerland.

As the project progressed, the requirements and wish-list grew steadily as well.

What initially seemed like simply a matter of automating the filling process became a major endeavor of adding more and more

functions were eventually added in various steps of the process.

After they have been baked at various locations throughout the factory, the madeleines and wafers, pastries and biscuits are collected at a central location.

Unsorted and not yet correctly oriented, the sweet baked goods arrive at the packing line on six different conveyor belts, where, after being separated by vibrating conveyors, they are fed via a hopper style buffer system.

Each of the six stations is responsible for one product and has a 2D scanner to check the orientation.

If a printed logo on the flow-pack points downwards or the product is upside down, it is brought into the correct orientation with the help of a turning station.