AUTOMATE NOW

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson

sjamieson@annexbusinessmedia.com

THE VISION QUEST

Canadian packaging machine-builder leverages robotics and machine vision expertise to develop cutting-edge system solutions

By George Guidoni, Editor

Photos by Naomi Hiltz

Putting vision into action is nothing new for Chris Follows, founder and president of a well-established, proudly Canadian packaging systems builder and integrator Propack Processing & Packaging Systems, Inc. (www.propack.ca)

Founded in 1996, the privately-owned company has enjoyed a steadfast rise up the ranks of North American packaging machinery industry—celebrating its 25th anniversary last year with a stellar record of successful machine installations and line integration projects across major sectors of the food-and-beverage industries with exacting quality, performance and safety requirements.

Headquartered at a state-of-the-art 30,000-square-foot customer service and testing facility in Beamsville, Ont., the company operates three manufacturing locations in southern Ontario and

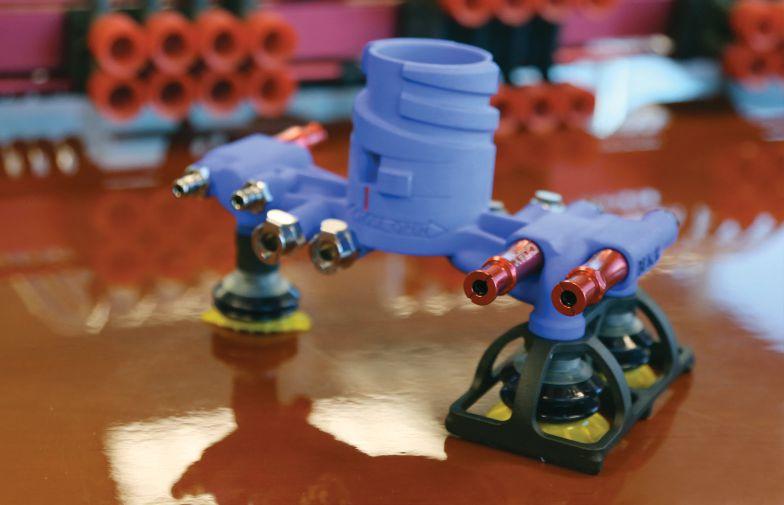

Propack Processing & Packaging Systems

founder and president

Chris Follows shows off some of the critical system components produced using advanced 3D printing technology, which Follows says allows the company the flexibility to make on-spec parts for its entire machinery range with exceptionally fast turnaround.

Quebec to produce various automation components and subsystems used in its turnkey workcell automation projects, while also offering ongoing customer support from service locations in Beamsville, Halifax, Chicago and Atlanta.

“We focus our attention on the North and South American markets, which is where we can bring the most value,” Follows told Canadian Packaging on a recent visit to the Beamsville facility, which is also the central location for the company’s FAT (functional acceptance testing) validations and equipment demonstrations.

“We export approximately 70 per cent of our equipment to the United States and South America, offering machine training and documentation in Spanish to support our South American customers.

“The technology we have today allows us to support our machinery remotely, irrespective of its installation location,” Follows points out, “but with our philosophy built on the idea of exceeding our customers’ expectations at every level, this also includes making complimentary visits to the site of our older machinery ensur-

ing they are running at peak performance.”

Says Follows: “Combining the requirements of our customers along with our innovative and patented technologies, Propack has the ability to design solutions to meet all their specific needs.”

As Follows explains, Propack primarily focuses on four strategic market segments that are highly dependent on the use of high-speed, high-throughput automated packaging lines incorporating the latest robotic and sensor technologies to crank out large volumes of energy and nutrition bars, confectioneries,

pastries, snacks and other mass-produced baked goods.

Incorporating high-end processing machinery manufactured in Canada by Sainte-Claire, Que.-based Équipements PRB—including dough dumpers; slab formers; kibblers; slitters; spreaders and guillotines—Propack has developed an exceptionally high level of expertise in integrating full turnkey lines for cold-form nutritional bar production: from early processing right through all the primary and secondary packaging stages at remarkably high speeds well in excess of 1,000 pieces per minute in continu-

(Left to right)

Propack’s new ProVision machine employs four ABB IRB 360 FlexPacker robots to pick and place up to 400 mproducts per minute from two running conveyor belts. Sealed pouches entering the ProVision workcell are inspected by high-speed cameras to define the center of the package to ensure proper grip by the robotic tooling.

ous operation.

“Propack offers superior machinery that will continue to meet extraordinary production results for our customers,” Follows proclaims, citing an expansive product portfolio that includes row distribution systems, high-speed collating-and-loading systems, bag-in-box automation systems, vision-guided robotics for pick-and-place applications, and vision-based product inspection systems.

“Propack is truly committed to our customers’ success: this is rooted in our DNA,” asserts Follows.

“All our machines are engineered specifically to each project requirement to ensuring optimal performance, versatility and flexibility,” says Follows, praising the “incredible quality” of Propack’s engineering and craftsmanship widely acknowledged in the industry.

Says Follows: “Our attention to quality, service, support and relationships with our customers to ensure their solutions are the right ones enable us to guarantee performance.”

Built for optimal longevity, durability and sanitation, “Our machines are designed for long-time service, to exceed 100,000 hours of reliable performance,” Follows states.

“We stand behind our systems, as our customers’ success is our top priority.”

As an early enthusiastic adopter of industrial robotic systems, Propack’s high level of proficiency with robotic integration is rooted in its long-standing relationship with leading robotics manufacturer ABB (www.new.abb.com) , whose flagship IRB 360 FlexPicker series pick-and-place robots are a common feature on many machines and lines supplied and installed by Propack.

“We actually bought the very first ABB FlexPicker robot in Canada all those years ago,” Follows points out, “and it (ABB) remains the world-class robotic technology to this day.”

Not surprisingly, ABB FlexPicker robots are employed at the heart of the new ProVision pick-and-place machine that Propack launched near the end of last year—designed for high-speed secondary packaging of transparently-wrapped products with variable shapes, sizes and dimensions.

Featuring advanced camera technology developed in-

(from top)

A close-up of suction vacuum cups at the end-of-arm tooling of the IRB 360 Flexpicker robots.

A close-up of a vacuum suction hose assembly made by an in-house 3D printer.

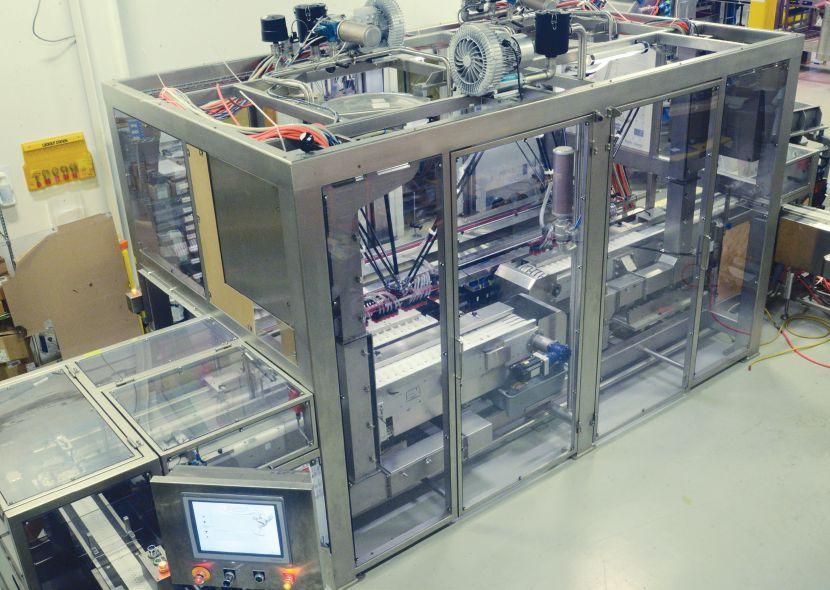

An overhead view ot new hygienic packaging machine assembled at Propack’s Beamsville facility.

house by Propack, the new ProVision system uses advanced image processing techniques that enables it to determine the perimeter of the package before guiding the robotic end-ofarm tooling to the center of that package each and every time. This is especially important for packages filled with loose bulk ingredients that tend to shift and clump together inside the primary wrap before being picked up by the robots.

The ProVision camera essentially makes sure that the robot will pick up the package right at the center even if the pack’s main contents have moved off to a side or a corner of the package— thereby ensuring consistent placement for the secondary packaging process.

Follows explains, “When you have product coming out of a vertical bagger, you tend to have ‘tear dropping,’ whereby a cluster of product shifts towards one side of it.

“Whereas the typical vision systems on ABB and other robots will determine that cluster to be the center of the package,” Follow says, “our ProVision technology is able to identify the outline of the package irrespective to where the cluster is.

“It determines and identifies the perimeter of the transparent film pouches,” he continues, “enabling the ABB robot to pick it up right in the center and place it into the flights of the infeed to the Campbell flowwrapper connected to the machine.”

In one particular configuration designed for a long-standing customer, the Pro Vision system utilizes four FlexPicker delta robots that pick-and-place 360 products per minute, while pairing liquid-filled and particulate-filled clear pouches together in two-component, ready-to-mix granola mix packs.

“There was nothing like that available in the market,” Follows notes, “so we had our engineers develop it.

“We have some brilliant young engineers working here,” he says, “as well as some older engineers that are very happy to share their knowledge and expertise with them.”

As with the ProVision cameras, all the special robotic tooling and accessories used in the system have been 3D-printed to match the customer’s exact product handling specifications with minimal changeover requirements, according to Follows.

As Follows relates, 3D printing capabilities provide an important competence for Propack’s technicians to design and produce various machinery components designed to help its machinery maintain the highest possible sanitary standards.

“Sanitation is everything,” Follows states, citing the company’s new Propack machine— incorporating four FlexPicker robots—featuring stainless-steel frames and smooth contoured surfaces.

Designed for continuous 24hour pick-and-place operation at speeds of 200 pieces per minute in +3°C environment, the robust machine features an

IP69K rating and features an array of 3D-printed color-coordinated components and tooling with simple snap-inplace installation and removal for cleaning and maintenance.

“We can’t have any points along the machinery where bacteria can harbor,” Follows explains. “All of our equipment that we’re producing here is fully hygienic, with machines that can be completely disassembled for cleaning and sanitation, and then quickly reassembled.

“Efficiency and sanitation are the two biggest issues facing machinery suppliers today,” Follows states, “and Propack has been strategically developing patented technologies to provide our customers with enhanced automation capabilities.

“As a result, Propack has a unique market position because our machines are amongst the fastest and most efficient in the world, coupled with the flexibility to run a variety of different products with quick, inexpensive changeovers to provide our customers with robust and reliable packaging solutions to meet their specific needs.”

While Follows himself describes Propack as a “mid-sized company,” there is no doubt that the company is preparing itself

(from top)

The new high-speed hygienic design packaging system assembled at Propack is capable of throughput speeds of up to 200 pieces per minute to offer co-packers running a variety of products and cartons a highly flexible and cost-effective automated packaging solution.

(from top)

A high-speed flow-wrapping machine from Campbell Wrapper Corporation used in conjunction with Propack’s equipment for many turnkey line integration projects; a close-up of the signature-blue BRECOflex polyurethane belting used for product transfer inside the Propack workcells; more innovative machine parts and subsystem assemblies made with Propack’s in-house 3D printing systems.

for continuous robust growth in coming years.

As Follows points out, the 3.5-acre site owned by Propack in Beamsville offers plenty of space for future expansions, while the firm’s physical proximity to premier vocational training institutions like Brock University , Niagara College , McMaster University and Mohawk College—all located within a 20-minute drive—ensures access to a pool emerging young talent to take care of any future staffing needs.

That factor is bound to become ever more important as the company continues to focus its activities on new business opportunities in promising growth markets such as non-food consumer goods and convenience items, personal care products, and frozen and pet food markets.

As Follows confides, “Propack invests money into R&D without the pressures of quarterly thinking—that’s the big advantage of operating a privately-held company with a vision.

“The packaging technology is continually moving forward and changing, and we’re here to adapt to it and ensure that we’re continuing to supply the market not with just leading-edge technology, but truly cutting-edge technology,” he concludes.

“With the technology and the team we have here at Propack, we will continue to listen intently to our customers and customize our machines to meet their requirements.”

www.propack.ca

www.new.abb.com

AIR SUPERIORITY

Food packaging producer makes huge cuts in compressed air consumption through leading-edge automation to lower energy costs and reduce carbon footprint

While many companies claim their products or services pay for themselves, iZ Systems proves it—time after time.

Based in Macon, Ga., the company provides clients across a range of industries with energy auditing services and control systems that quickly deliver a complete ROI (return-on-investment) through the resulting energy use reductions.

“Almost every system upgrade we complete is based on green initiatives to reduce energy consumption at plants,” says Dean Smith, general manager and technical manager for iZ Systems.

“We guarantee these savings, and our technology platform proves that significant energy reductions are maintained in the long term.”

Since Smith founded iZ Systems in 1990, the company has continued to expand its product offerings and client base, gaining customers internationally as a division of its parent company Blake & Pendleton.

iZ Systems has long performed audits and upgrades of compressed air and industrial vacuum systems, and it now offers these services for cooling water systems as well.

With its standard control cabinets that include built-in HMI (human-machine interface) displays, iZ Systems supplies eco-friendly technologies that measure efficiencies, support remote data acquisition, and deliver insightful energy usage information to customers.

For seven years, iZ Systems has provided these services to food packaging manufacturer Pactiv (www.pactiv.com) at its Macon facility, which focuses on molded fiber egg cartons.

The partnership began with a project to replace the compressed air systems supplying low-pressure blowers, according to David Powell, maintenance manager for

iZ

Systems completed compressed air system upgrades at the Pactiv plant in Macon, Georgia, resulting in a roughly $250,000 annual savings in energy costs.

AUTOMATE

Pactiv.

“With every blower we tested, the pressures would change too much even if a single nozzle was adjusted,” Powell says.

“The iZ Systems team promised a blower system that would not change in pressure, even if you shut off all but one nozzle, and their system has worked flawlessly.”

The system improvements for Pactiv resulted in unique technical specifications, highlighting the fact that greater system openness is increasing in importance across all industries.

To guarantee that customers’ systems achieve peak performance, iZ Systems must be able to monitor data remotely and make adjustments whenever necessary.

However, connecting to clients’ diverse networks can be difficult, according to Allen King Jr., inside application project manager for iZ Systems.

“The ability to access and analyze performance data with ease is very important,” King says. “To this end, we access data from systems across the globe using a common source and format.”

In addition to its thorough audits, the company accomplishes these goals through its turnkey iZ Compressed Air Automation and Data Acquisition System, which combines the automation controller, I/O and HMI in a single control cabinet and utilizes custom software.

This system must support an increasing number of connected devices— 50 compressors across a factory, for example—while reducing footprint, complexity for users, cost and, most importantly, unplanned downtime.

“Improved reliability is an ever-present demand from industrial clients,” Smith says. “A compressed air system that is not reliable has the ability to cost hundreds of thousands of dollars in lost production and energy costs.

“A reliable and well-managed compressed air system has the ability to save those dollars. Our iZ Compressed Air Automation and Data Acquisition System has the ability to assist in maintaining those savings.”

The engineering team at iZ Systems accomplished its mission at Pactiv using PC-based solutions from indus-

trial automation specialists Beckhoff Automation (www.beckhoff.com) of Savage, Minn.

Beckhoff and iZ Systems first partnered on projects about 15 years ago, using TwinCAT automation software to help the company establish remote monitoring of its compressed air automation and data acquisition systems.

Smith explains that interfacing horizontally via Modbus TCP to diverse compressor control systems within plants and vertically via OPC UA are important features that exemplify the system openness of PC-based control technology.

“The TwinCAT software platform provides tremendous flexibility to the process of applying our iZ Compressed Air Automation and Data Acquisition System software to any system,” he says.

Visualizing the numerous compressors and equipment spread throughout entire plants can easily clutter HMI, so iZ Systems has standardized on the Beckhoff CP2924 multi-touch control panel.

The 24-inch-wide screen panel implemented at Pactiv is mounted into a control cabinet cutout to enable easy identification of field components, according to King.

“Our trending screens use the multi-touch zooming function, allowing operators to draw a square around the area they want to see in greater detail,” he says.

“However, we know there is the capability to implement much more multi-touch functionality, and we hope to add interesting features, such as pinch to zoom, in the near future.”

The go-to machine controller for iZ Systems is the DIN rail-mounted Beckhoff CX5140 embedded PC, which features a four-core, 1.91 GHz Intel Atom E3845 processor.

The device provides 4 GB DDR3 RAM and the ability to add data storage with slots for microSD and CFast cards. With a compact form factor of 142x100x92-mm, the embedded PC reduces space requirements in the control cabinet, while providing advanced capabilities not available in traditional PLCs (programmable logic controllers)

To reduce energy requirements, iZ Systems implemented low-pressure blowers in place of more expensive compressed air.

“We standardized on the CX5140 because it supplies the necessary processing power to meet the needs of today’s Smart Factory concepts,” says King.

As with other iZ Systems projects, EtherCAT industrial Ethernet technology enabled real-time communication across the Pactiv production facility. EtherCAT and TwinCAT allow the automation system to identify any new compressor or other industrial component automatically, and BACnet/IP enables direct integration of building automation controls in the iZ Systems solution.

In addition to a range of standard digital and analog I/O terminals, iZ Systems also uses EK1501 and EK1541 fiberoptic EtherCAT coup-

lers along with EK1521 and EK1561 fiberoptic junctions in most compressed air applications to communicate with field devices.

“Fiberoptic wire provides absolute isolation between our system, the processor, the machine and the compressor,” Smith says. “Fiberoptics by nature provides excellent immunity to electrical noise and interference, and the EtherCAT I/O hardware offered us a big step forward in this regard.”

By implementing open, PC-based solutions, iZ Systems kept its promise to Pactiv. As a result of the blower equipment upgrades, Pactiv reduced its energy consumption for compressed air by 45 per cent.

“By using blower air, we replaced nearly 400

horsepower of compressed air with 50 horsepower. “This amounts to a cost savings of nearly $250,000 each year,” Powell says.

“The improvements to our air compressor design have stabilized our pressure, and the remote monitoring has given us peace of mind.”

The results are impressive by any standard, but they are not unusual for iZ Systems.

As Smith relates: “For some clients, we have reduced compressed air energy costs by more than 50 per cent and we can prove that we have maintained those savings ever since.”

More importantly, the systems with Beckhoff components achieve the utmost reliability. Secure communication with customer machinery via OPC UA allows iZ Systems to monitor any

changes in performance that could require maintenance.

Powell says this, along with excellent support, has been crucial for Pactiv: “The system alerts me when there are any abnormalities with the compressors, but iZ gets the warnings as well, and their engineers are usually working to address the issue before I call them.”

In addition to boosting reliability, iZ Systems has reduced control cabinet footprint by twothirds on average by implementing Beckhoff controls.

“Our old cabinets were much larger because the previous PLC generated an excessive amount of heat, increasing our cooling requirements and energy consumption.

“With the Beckhoff hardware, heat generation is not a problem, and we increased our own energy efficiency like we do for our customers,” King says.

The flexibility and scalability of Beckhoff components allows iZ Systems to build and stock standard control cabinets for future use, rather than designing a custom cabinet for each client. By creating open systems that support multi-vendor architectures, iZ Systems has the unique opportunity to apply energy-saving solutions from one industry to another.

For example, the blower solution implemented at Pactiv has also worked for clients in the steel casting industry, among others.

“In many facilities, we installed these low-pressure blower systems to provide cooling or control of fluids and coolants, and it basically produced a 25-to-one reduction in energy,” Smith concludes.

While Pactiv still uses compressed air in its production process, the iZ Systems upgrades reduced compressed air energy requirements by 45 per cent.

DOWN THE STRETCH

Boston Dynamics secures big order for a fleet of Stretch robots to automate DHL warehouses over the next three years

DHL Supply Chain, the global and North American contract logistics leader within Deutsche Post DHL Group, has announced a US$15- million investment in robotics solutions from Boston Dynamics, the global leader in mobile robotics, to further automate warehousing in North America.

The companies have signed a multi-year agreement that begins with equipping DHL facilities with Stretch, Boston Dynamics’ newest robot specifically designed to automate the unloading process in distribution centers. This agreement is the culmination of strategic collaboration between the two companies over the past few years as Stretch was being developed and tested.

Headquartered in Waltham, Ma., Boston Dynamics (www.bostondynamics.com) will deliver a fleet of Stretch robots to multiple DHL warehouses throughout North America over the

next three years.

The deal with DHL marks the first commercial purchase of Stretch , which was unveiled in 2021.

The investment is part of DHL Supply Chain’s Accelerated Digitalization agenda, a strategy for developing and scaling innovative solutions and new technologies.

Stretch will tackle several box-moving tasks in the warehouse, beginning with truck unloading at select DHL facilities. Following the first deployment, the multi-purpose mobile robot will handle additional tasks to support other parts of the warehouse workflow, which will effectively automate

warehouse operations.

“At DHL Supply Chain, we are committed to continuous innovation and digital transformation to optimize the end-to-end supply chain. Investing in warehouse automation plays an important role in increasing operational efficiency and improving service for our customers,” says Sally Miller, chief information officer at DHL Supply Chain North America . ( www.dhl. com)

“We’re excited to partner with Boston Dynamics to deploy its best-in-class robotics in our warehouses. The Stretch robot addresses complex industry challenges through flexible automation, which we’ll be able to replicate and scale regionally and globally.”

Stretch’s technology builds upon Boston Dynamics’ decades of advancements in robotics to create a flexible, easily integrated solution that can work in any warehouse to increase the flow of goods and improve associate safety by taking over

physically demanding tasks.

The Stretch is equipped with a compact, omni-directional mobile base, custom-designed lightweight arm as well as a smart gripper with advanced sensing and controls that can handle a large variety of box types and sizes. It also includes Boston Dynamics’ computer vision technology, which enables it to identify boxes easily and without any pre-programming. The Stretch robot is capable of working autonomously through complex situations like disordered stacking configurations and recovering fallen boxes.

“Stretch is Boston Dynamics’ newest robot, designed specifically to remedy challenges within the warehouse space,” said Robert Playter, Boston Dynamics’ chief executive officer.

“We are thrilled to be working with DHL Supply Chain to deliver a fleet of robots that will further automate warehousing and improve safety for its associates.

“We believe Stretch can make a measurable impact on DHL’s business operations, and we’re excited to see the robot in action at scale.”

Deployment of the first Stretch units in DHL warehouses will begin this spring, and DHL plans to gradually scale Boston Dynamics’ robots for additional tasks and across multiple facilities in phases over the next few years.

www.bostondynamics.com

MADE FOR EACH OTHER

KHS and Ferrum adopt pioneering role in hygienic machine design through close strategic partnership strengthened by breakthrough technology developments

An increasing number of beverages are being filled into cans worldwide, with the diversity of products seeing a similar increase. It is for precisely for this reason that canners make particularly high demands of flexibility and the hygienic design of their machinery.

Vereage production machinery exoperts KHS Group (www.khs.com) and Ferrum (www.ferrum.net) take on a pioneering role in this field. Their technical systems, perfectly attuned to one another thanks to many years of partnership, enable beverage producers to market high-quality products that are hygienically flawless.

The compact Innofill Can C from KHS, for example, is convincing with its flexible, taste-neutral filling, among other features. This is supplemented by matching seamer systems FC06 and FC08 from Ferrum, which with their open design are especially easy to clean. Combined, both machines make for a very efficient filling process.

The world demand for trend beverages such as hard seltzer, energy drinks and craft beer continues unabated.

Here, the can is often the container of choice, says Manfred Härtel, filling technology product manager at KHS.

“It’s light, easy to recycle and keeps products fresh for longer with its excellent barrier properties.”

This type of container is increasingly being favored for established beverages such as soda pop, water and mixed beer beverages. According to Härtel, this is prompting a good number of beverage operations to increase their range in the can segment and fill more and more dif-

During development of the Innofill Can C, special attention was paid to the hygienic machine design and providing protection against flavor carryover. The filling valves are thus equipped with PTFE (Teflon) expansion joints.

ferent products on the same line.

“This means higher demands are made of the machine’s flexibility and hygiene,” the KHS filling expert explains. “For the greater the product variety on a line, the greater the risk of contamination and flavor carryover.”

“Our mutual customers have exacting standards when it comes to the quality of their products,” states Marc Zubler, head of Sales and Product Management at Ferrum.

An optimum hygienic machine design that reflects the current demands and requirements of the market is just as important as the consultancy service that goes with it.

Härtel claims both companies share a deep understanding in this area; many years of partnership have created systems that are perfectly attuned to one another.

“We offer a complete package of first-class technology and advice. Our jointly developed filler/seamer block gives our customers plenty of added value,” Zubler declares.

KHS provides two fillers for the can segment that have long proven themselves on the market: the Innofill Can DVD for the high-performance range; and the Innofill Can C, designed for small to medium filling quantities.

Thanks to a new addition to the series that boosts capacity to up to 60,000 cans per hour, the Innofill Can DVD’s little brother can now be integrated into lines with higher outputs even more effectively. It is also extremely flexible, enabling several different products and formats to be processed on a single line.

“The Innofill Can C is distinguished by its fast format changeovers and setup times. This in turn increases the availability and economy of the system,” is how Härtel describes the benefits of this particular filler.

In view of the increasing number of beverage variants being processed, during development special attention was paid to the hygienic machine design and providing protection against flavor carryover.

In the product area the filling valves on the KHS can fillers are thus equipped with PTFE (Teflon) expansion joints in place of conventional seals.

On its seamers Ferrum attaches the greatest importance to the hygienic design of all components. The seamer section is made entirely of stainless steel and provides maximum durability even when aggressive cleaning media are used.

The sliding seals in the bell guides have also been replaced by Teflon expansion joints to create gapless, hygienic seals. These effectively protect the product from contamination and are easier to clean. Moreover, the electropneumatic lifting and positioning of the bells when sealing cans further contributes to a safe filling process.

“Also doing away with water lubrication in the filler carousel area shortens exterior cleaning intervals by up to 20 per cent,” Härtel says.

As an option, the Innofill Can C can also be fitted with a HEPA filter that removes potential bacteria from the air in the machine interior. Another option available on request is warm filling.This prevents condensation and thus microbiological contamination such as mold from being formed.

Like KHS, Ferrum makes the highest demands of the hygiene of its machinery.

The greatest importance is attached to the hygienic design of all components in both the ferruBasic and FC series with seamers FC06 (15,000 to 45,000 cans per hour) and FC08 (19,000 to 60,000 cans per hour).

“When developing our seamers, we consciously went for an open design without cladding. This makes the components easy to clean and the machine readily accessible to operators,” explains Jörn Winkelmann, process engineer and hygiene expert at Ferrum.

In the FC series – that is incidentally perfectly compatible with the KHS Innofill Can C – the use of several different angled levels allows condensation and other unwanted liquids to easily run off and not enter the open beverages cans.

For the same reason the conveyor segment features regularly spaced openings and the components have an extremely high surface quality to prevent microbiological deposits. Another item of note is the design of the seals that are easy to sanitize as they are installed on the exterior of the machine.

The seamer section is made entirely of stainless steel and

provides maximum durability even when aggressive cleaning media are used. In this market segment most cleaning is performed by hand; only the gas injection system and bubble breaker are foamcleaned in a fully automatic process.

Cleaning for the product area is also available as an option. In order to perfectly maintain hygienic conditions both inside and outside the machine, Ferrum supports its customers with extensive training for personnel.

For can seamers F12 (35,000 to 105,000 cans per hour) and F18 (51,000 to 150,000 cans an hour) in the ferruBasic series, the Swiss company provides optional hygiene packages whose components are largely installed in the FC series as standard.

These include, among other things, installation of an inclined base plate (on the F12 only) and various adaptations to tools that have a positive impact on the machine hygiene.

Furthermore, since very recently the welded cladding around the upper parts in the standard version has consisted entirely of stainless steel. Ferrum systems F12 and F18, designed for the high-performance range, are therefore a useful addition to the KHS Innofill Can DVD can filler.

In the future KHS and Ferrum will further intensify their cooperation.

“Our machines are already very well coordinated with one another,” states Zubler “However, we want to offer our customers even more integrated systems.”

Härtel nods in agreemen, adding adds that this also applies to the extensive range of consultancy and other services, where the two partners aim to function even more strongly as a unit in the years to come.

www.khs.com

www.ferrum.net

Smart technology: both KHS can fillers and Ferrum seamers are equipped with modern HMI panels that considerably facilitate the work of the operating personnel.

Marc Zubler Manfred Härtel

LASTING CONNECTIONS

Leading machine-builder’s independent consulting services on packaging processes provide a pragmatic blueprint for value-added packaging automation

Based in Crailsheim, Germany, S chubert-Consulting is a division of Schubert Packaging Systems, which has its roots in Gerhard Schubert GmbH, the innovative market leader in packaging machinery. Based on decades of expertise in the packaging sector, director of consulting Michael Graf, and his team advise customers on all processes relating to product packaging.

The main focus of customer support is the comprehensive, fully manufacturer-independent analysis and optimisation of entire process chains for greater efficiency, cost-effectiveness and sustainability. In this interview, Michael Graf reports on how Schubert-Consulting ( www.shubertconsulting.com ) supports customers in meeting current and future market requirements.

What are you currently working on at Schubert-Consulting?

What is keeping us very busy at the moment is something that is known as ‘Connecting,’ or in other word, bringing together the various participants involved in the entire packaging

process.

This begins with the different customer departments and extends to external partners. When a commissioned architect designs a modern factory hall on a greenfield site, they should know from the outset about the cubic metres of the machinery involved, the planned layout and the personnel requirements. Otherwise, the machines may have to be adapted to the hall and the production processes can no longer be implemented in an optimal manner. Our team at Schubert-Consulting helps bring the parties involved to the table at the beginning of a project and find a joint solution that makes the actual packaging process as efficient as possible.

The topic of packaging development is also definitely in line with current trends. Here especially, Connecting is absolutely necessary because packaging today has to meet numerous requirements that go far beyond product protection and transport. Just think of recyclability, enhanced marketing at the point of sale or market trends such as the individualisation of products and e-commerce. In collaboration with all partners, we can create economic added value through the development of new packaging, which is generated through-

Michael Graf, Director Consulting, Schubert-Consulting. g

out the entire process chain, all the way to the consumer.

At what stage do customers turn to you and why?

Most often, we provide support when manufacturers are planning a new packaging process and the implementation becomes difficult – when they are stuck in a project that is not progressing as it should.

This often entails ideas and objectives that go beyond a single packaging machine as a solution, because the upstream and downstream processes strongly influence production. In cases such as this, it is important to take a close look at the entire supply and production chain in order to identify and eliminate any bottlenecks.

This is why we specialise in the strategic planning of processes and corporate goals, especially for the fast-moving consumer goods and pharmaceutical industries. Our customers are very international:We offer our services in several regions of the globe, ranging from German-speaking countries to Europe and North America.

You were on board from the very beginning. How did Schubert-Consulting originate back then?

Before founding the company in 2011, I had gained experience as a senior project manager, in the pharmaceutical industry amongst others. One of my responsibilities was to prepare validations for the complex packaging processes used for pharmaceutical products.

This gave me an opportunity to familiarise myself in depth with the topic of quality assurance. At the same time, a new business field emerged at Schubert Packaging Systems, at that time still operating under the name ‘Engineering Consulting.’ Since then, Peter Gabriel and I have gradually built up the area. In 2016, the company was renamed Schubert-Consulting.

Our first projects arose from the customer’s wish for us to accompany the investment and realisation of a new packaging machine over the course of the project – also as a service provider. Customer support continues to be one of our central consulting pillars.

From the very beginning, however, it was also my goal to transform the expertise acquired from other industries into the sectors that Schubert serves.

I remember the early days at Schubert Consulting, where we were able to make very fast confectionery packaging machines even more efficient for our customers with the right quality

management.

Because reducing waste throughout the entire packaging process is and remains an important factor to this day. We are not only referring to the robots in the packaging machine, but also pre-processes such as baking ovens in which the product to be packaged is manufactured.

How has your portfolio evolved over the years?

The next topic alongside quality assurance was logistics, including track-and-trace functions. This is more relevant today than ever before, when consumers would like to know which farm their milk on the breakfast table was sourced from.

Schubert-Consulting’s range of services has therefore expanded from projects in existing factories and halls to simulations and new planning on greenfield sites. The most important working tool for us is a holistic view of the packaging processes as well as line integration, customising and customer advice on automation, digitalisation and sustainability.

For each project we take on, we put together a new team that not only consists of one or more of our own employees, but also includes collaborations with universities, suppliers, associations such as the VDMA (Verband Deutscher Maschinen und

Connecting: Merging packaging visions with technical viability. Customizing: Late stage customization.

Optimizing: Reducing costs and increasing efficiency

Anlagenbau e.V.) and other institutions, as required. Within the Schubert Group, we work together strategically across several business units.

Central to Schubert-Consulting, however, is our general independence from other Schubert companies. We attach great importance to manufacturer-independent consulting! This means that anyone who uses our services always has a choice of several different process solutions. The reason why we nevertheless carry the Schubert name in Schubert-Consulting with a certain pride is the packaging expertise we can demonstrate, resulting from decades of experience.

What has been your experience with consulting and what do your customers have to say?

A. Many customers are under intense competitive and time pressures. Only very few have sufficiently comprehensive expertise in-house to establish new packaging processes or improve existing ones.

The feedback we receive is consistently positive. We solve problems, we get production running and we make it more cost-effective as well.

A key factor is also to find solutions that reach far into the future for the customer. This is why we always try to clarify how

and where a customer wants to develop and grow.This sometimes results in scalable projects that are implemented gradually over several years.

All of this can only be achieved in a relationship based on confidence and collaboration. And this is why personal contact, in-depth preliminary discussions and the creation of a true partnership are the absolute prerequisites for a successful project.

And for us, talking to our customers means, above all, understanding our customers. Tht means listening, always asking different questions and thinking ahead, and changing perspectives all the way to our customers’ customers.

For example, if you have to unpack a medicine and struggle with the packaging, you are less likely to be compliant in taking it. With this in mind, our maxim has changed over time from ‘accompanying customers’ to ‘understanding customers.’

How are you driving Schubert-Consulting into the future, especially in terms of the key issue of sustainability?

A. We have been working on this for quite some time and have adopted the “Rethink’ aspect of the 5Rs on sustainability as our guiding principle. Rethinking conventional approaches is exactly what is needed for the transformation to a more sustainable world, and it corresponds 100 per cent with the essence of Schu-

bert-Consulting.

We are broadening our view once again and looking at the process virtually from A to Z—from the raw product to the end consumer and, of course, recycling. This is based on the approach of keeping processes so stable that there are no rejects along the entire process chain. Because sustainability comes to a large extent from efficiency.

From this wider perspective, it follows that we also want to enter other niches, start-ups and sectors. We are committed to being trailblazers, to creating a think tank for the future, among other things with alliances and experts from a wide range of fields and institutions, such as the Fraunhofer Institute, research groups, manufacturers, etc. In doing so, we strive to lead our customers’ visions to sustainable success.

I am delighted when our customers embark on their new projects with enthusiasm, because much more can be achieved than they initially thought possible. Premium added value, inspiration for further developments that we can give them and financial success for both sides—this is my goal and, ultimately, it’s what makes consulting fun.

www.schubertconsulting.com www.schubert.group

Realizing: Shaping future production

Simulating: Increasing planning reliability by process flow simulation. Visualizing: Successful project marketing through visualization