AUTOMATE NOW PLUS

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

CIRCULATION MANAGER

Barbara Adelt (416) 510-5184

BAdelt@annexbusinessmedia.com COO

Scott Jaimeson

sjamieson@annexbusinessmedia.com

In 1945 the Master said, - Ernst Blickle, Founder“The Solution is Modular Systems”

See why he was right.

NOVEMBER 9-10, 2022 @ BOOTH #1109

Palais des Congrès de Montréal

WITH OPEN ARMS

Leading automation solutions provider seizes the day with major expansion of its Canadian operations

As an integral part of one of the world’s leading industrial automation companies, Bosch Rexroth Canada (www.boschrexroth. com) is not the type to mark its major milestones and achievements in half-measures.

From using a collaborative robot to perform the ceremonial ribbon-cutting to conducting informative on-site guided tours showcasing the company’s expertise and innovation, the recent opening of the company’s new Customer Experience Centre in Burlington, Ont., was a resounding display of the company’s commitment to the Canadian market and an impressive showcase of its prowess and know-how in the fields of motion control and factory automation.

Attended by the company’s senior executives—including Trevor Osborne, general manager of Bosch Rexroth Canada; Gregory Gumbs, chief executive officer and president of Bosch Rexroth North America ; Karl-Philippe Clement, vice-president of sales

development at Bosch Rexroth in Germany; and John Mataya, chief financial officer and director of operations, finance and administration at Bosch Rexroth Canada—the open house event provided plenty of opportunity for invited customers to get close and personal with the broad range of automation technologies offered by Bosh Rexroth to help make their manufacturing operations more efficient, productive and competitive in the global marketplace.

“It marks a really new day and a new chapter for us in the Canadian market,” Gumbs declared in his opening remarks.

“One of the key pillars of our growth strategy is factory automation, where we have made significant investments.

“With packaged goods, transportation of goods from one station to the other, or from different areas of the factory, we can handle it all ,” Gumbs stated. “Liquids with different temperatures, frozen foods, temperature-sensitive foods … we have the solutions for all these applications right in our backyard.

“The Canadian business has a very bright

Exterior view of the brand new Customer Experience Centre facility opened up in Burlington by Bosch Rexroth Canada last month.

future,” Combs stated, “and we we’re investing heavily both in people and products, and in organic R&D (research-and-development) to grow it further.”

According to general manger Osborne, the completion of the new, state-of-the-art 75,000-square-foot Customer Experience Centre facility has faced numerous challenges prior to completion, including COVID-19, city permits, labor strikes, and last-minute requirements to get formal occupancy sign-off from the municipality.

Mark Wilson, Bosh Rexroth Canada’s national sales manager, noted the new building is fully equipped to provide company’s customers “the capability to duplicate or replicate whatever is happening at the customer’s location” through the company’s powerful remote process control, equipment monitoring and diagnostics, and process simulation capabilities. “We are casting a vision of the future [and]

we’re building up our capabilities to enable that future,” Wilson said, citing the company’s concerted recent foray into next-generation AMRs (autonomous mobile robots) and collaborative robots, as demonstrated by Bosh Rexroth’s recent acquisition of leading Denmark-based robotics manufacturer Kassow Robots.

“There are many progressive companies that are starting to adopt some of the newer technology and experimenting with it,” Gumbs noted.

“And once they learn and get comfortable with taking on that technology, and as they transform their workforce to adopt this technology, then it will all start to move at a much faster pace.”

Added Osborne: “We will soon see a lot more AMRs with cobots moving around the factory workspace—replacing humans in some of those applications.

“We now have a new [ctrlX Automation] control platform, which will be featured across all

of our product areas,” Osborne added. “It is backward-compatible all with legacy products,” he said, “as well as being used and developed in every single detail required for all of our product areas.

“It’s kind of based on a mobile phone type of platform with apps, giving us compete flexibility and control to embed it into any fixed operating system or any of our products,” he explained.

“We look very closely where our customers are headed,” he said, “as we try to understand the future developments that will allows our

customers to gain a competitive advantage.

“It all about us having the application knowledge to be able to help our products and our technologies combine into full solutions that will make our customers more competitive and successful.”

www.boschrexroth.com

Please

A collaborative Kossow robot perfroms ceremonial ribbbon-cuttting at the opening of Bosch Rexroth Canada’s Customer Experience Centre.

The latest model of Bosch Rexroth’s AMR (autonomous mobiule robot) can support weight loads of up to 1,000 kilograms.

Bosch Rexroth Canada general manager Trevor Osborne (left) and Bosch Rexroth North America president Gregory Gumbs.

Bosch Rexroth’s acquisition of Kassow Robotics has expanded the company’s ability to supply total automation solutions for customers.

see the video of Bosch Rexroth Canada’s open house event here.

BREAKING GOOD

Thriving organic snack producer keeps up with soaring product volumes and market demand with world-class packaging line automation and technical support

By George Guidoni, Editor

Photos by Naomi Hiltz

Making good things better, healthier and tastier comes naturally for hardworking folks at the Riverside Natural Foods production facility just north of Toronto in the fast-growing city of Vaughan, Ont.

Founded in 2013, the privately-owned company has achieved phenomenal growth in market share and consumer loyalty since taking the snack-food market by storm with the launch of its signature MadeGood brand of organic nutrient-dense snacks infused with real vegetables and made entirely with organic ingredients.

Nowadays ranking as one of the bestselling brands of all-natural granola bars in Canada, the MadeGood brand’s rapid ascent has been a main driving force for the company’s capital investment in new production facilities and state-of-the-art equipment that have enabled it to grow its

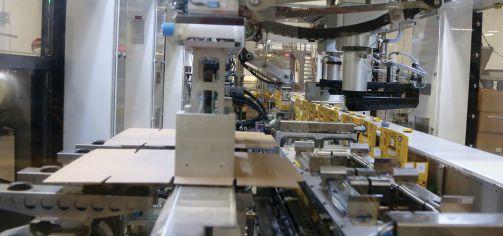

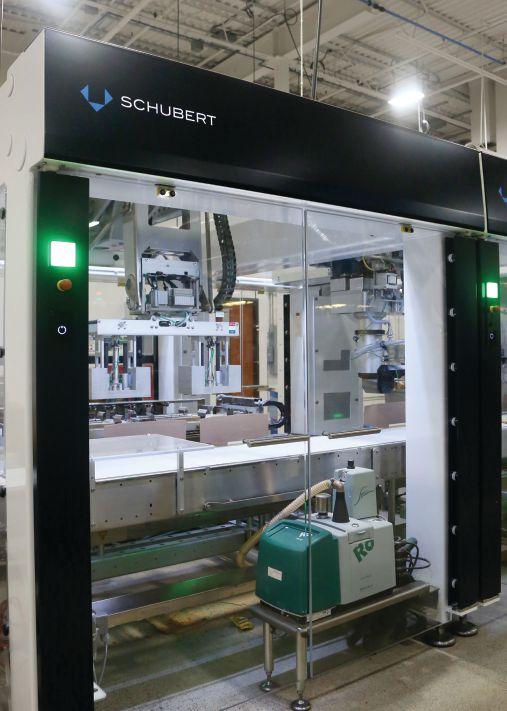

A side view of one of the Schubert TLM integrated picking and cartoning line packaging the flow-wrap packs of MadeGood organic snacks inside the different retail and e-commerce boxes in different quantities, bag sizes and flavor varieties.

the marketplace to date is made even more remarkable by the fact that is it a premium-priced product, the multitude of mass-produced granola and other snack bars available on the grocery retail shelves.

“It’s a brand that came out of nowhere to be everyhwere,” says Fluit, citing a strong retail base comprising more than 8,000 grocery stores across Canada, including the Costco chain of club stores, as well as growing list of clients in the foodservice, institutional and private label markets.

“We are also building a strong brand presence online, especially during the COVID-19 pandemic,” Fluit says, noting that the company now sells a substantial portions of its output online through its website and other mainstream e- commerce channels, complete with specially-designed pouches and cartons for shipping its products for home delivery.

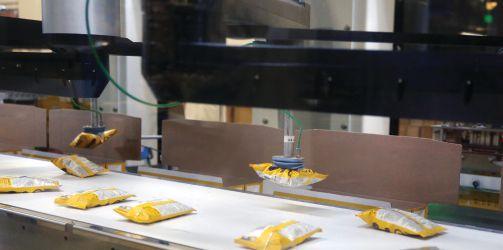

Top: Finished packs coming of off the tna vertical bagger are swiftly passed through the METTLER TOLEDO Safeline X-Ray machine to detect any product contamination inside the pouches.

product portfolio and customer base at a fast clip.

Today operating five production facilities totalling about 575,000 feet of production space, Riverside has expanded its mainstay MadeGood brand offering with many new flavor varieties and adding more other snack products into the mix—such as cookies, crsipie squares, granola bar, granola minis (bites) and crackers.

As Riverside’s vice-president of operation Justin Fluit, who joined the

company in 2015, explains: “We now have quite a wide variety of products like cookies, brownies, crispy squares, granola bars, granola clusters and other innovative products we introduced to leverage the market success of the MadeGood brand over the years,”

Fluit told Canadian Packaging on a recent visit to the busy 100,000-squarefoot Vaughan facility running two shifts per day, six days a week.

For Fluit, the sweet success enjoyed by the MadeGood brand products in

“The response has been great so far,” says Fluit, adding the company is currently looking at ways to break into the lucrative U.S. markets to replicate MadeGood brand’s success south of the border.

According to Fluit, the MadeGood line of granola treats was the classic case of a perfect product being lunched at a perfect time to tap into the larger health and wellness trend, along with the public’s growing interest in organic product, to provide a healthy, tasty and allergen-free lunchbox snacking alternatives for Canadian parents

Middle: The high-quality METTLER TOLEDO Safeline X-Ray machine provides exceptionally important and robust quality assurance and control capabilities for the Riverside plant’s high-speed production lines.

Bottom: Pouches of MadeGood cookies coming off the tna bagging machines are aligned and spread out on the transfer belt conveyor to proceed inside the Schubert TLM machine for picking and Cartoning.

A close-up view of the MadeGood Star Puffed Crackers being dispensed by the multihead automatic weigh-scale towering above the production line down to the tna Robobag E3 vertical form-fill-seal machines below to be placed inside flexible pouches.

concerned about their kids’ nutrition.

“There is a lot that differentiates the MadeGood brand from other products,” Fluit states, “notably the inclusion of vegetable nutrients.

“This is something that we see more and more competing products doing now,” he acknowledges, “but several years ago it was something very unique to our brand.

“Also, the fact that is allergen -free, thereby allowing anyone to eat it, is also something that has really set us apart over the years.”

As Fluit points out, the MadeGood organic snacks are produced in a dedicated allergen-free facility (Vaughan) without common food allergens like milk, eggs, wheat and soya, using organic, certified gluten-free oats sourced from a Canadian-based grower.

“You will see a lot of different certification symbols an all of our packages,” says Fluit, noting no less than eight different authoritative accreditations appearing on the pouches and cartons of MadeGood brand of school-safe, vegan-friendly and Kosher-approved cookies, crackers and other dry snacks.

Above all, the soft-baked MadeGood snacks are simply delicious and fun to eat, with a soft but crunchy and hearty texture that delivers instant gratification and pleasant after-taste bite after bite.

“At the end of the day, if the product tastes great and provides the nutritional features that appeal to parents, while still being enjoyed by kids, you can say that we have found the right balance between healthy nutrition and pure enjoyment of the snacking experience,” he says.

As the production volumes kept of growing at a rapid pace from year to year, the Riverside plant found itself in need of high-throughput, high-speed automatic machinery to keep pace not just with the volumes, but also with the growing variety of different packaging formats required by its diverse customer base.

Having had installed several high-speed vertical form-fillseal) Robobag 3E machines supplied by the Australian-based machinery manufacturer tna (www.tnasolutions.com) to pack the free-flowing product into the different bag size at

A sequential representation of different steps and movement taking place inside the Schubert TLM workcell to coordinate the movement of paperboard cartons with the picking action of the system’s F2 and F4 robots to pack and seal the filled boxes at robust speeds of up 400 boxes per minute.

speed rates of up to 200 pieces per minute, the plant needed to find the right automatic secondary packaging system for placing those bags into the retail folding cartons at similar throughput speeds, with quick changeovers to accommodate all the varying packaging formats executed over the course of the shift.

With multiple SKUs (stock-keeping units) often requiring for different product quantities and varieties of filled product pouches to be placed into all the different cartons to suit the customers’ varying requirements, superior speed and flexibility were naturally the two main capabilities that Riverside aimed to achieve through significant investment in packaging automation.

“If we wanted to keep building the brands and enter the US market, we needed to be cost-competitive, we needed to be highly automated, we needed to have enough production capacity, and we needed to be able to scale up very quickly to respond to market demand,” Fluit explains.

After conducting a diligent market search and vendor evaluations, Riverside ultimately decided to go with the high-performance TLM (Top Loading Machine) picking and cartoning line manufactured by renowned German machine-builder Schubert Group, which has been operating its Schubert Packaging Automation Inc. subsidiary in Mississauga, Ont., since 2006. (www.schubert.group)

“In addition to the state-of-the-art machinery Schubert showed us, I was really impressed by the level of the company’s commitment to the Canadian market,” says Fluit, describing the 2018 installation of the first of two Schubert TLM picking and cartoning lines now housed inside the Vaughan production facility to handle the soaring production volumes for the MadeGood brand products.

“As a growing company with big plans for big future growth

and expansion into new markets domestically and abroad, it was important to partner up with someone who would be there for us in terms of local service and support over the long-term,” Fluit explains.

Following a thorough discussion of Riverside’s application requirements, Riverside proceeded to order a TLM picking line comprise of four machines to perform the for the final packaging of flow-wrapped granola minis with packages of different flavors into a variety of carton sizes and in special bag formats.

As per customer specifications, Schubert developed various packaging sizes, which were created in close collaboration with Riverside in terms of packaging design and ideal machine operation.

Programmed to pack the five different flavors in four-, five and 28-bag boxes—each in one chosen flavor—the TLM line employs five identical pick-and-place robots to box 400 bags of MadeGood snack pouches per minute.

According to Schubert, the five different flavors can be intelligently pre-grouped—with the help of Schubert’s Transmodul transport robot and an inline image recognition system—so that the granola minis can be automatically packed on the TLM machine.

The products themselves, for their part, are fed by three identical vertical-form-fill-seal tna Robobag 3E machines with a capacity of up to 150 bags per minute.

For packaging in cartons, the products of one flavor are fed along up to three of the system’s continuously running conveyor belts.

At the same time, the different carton blanks are automatically taken out of the magazine, quickly erected by an F2 robot and glued together.

The Transmoduls then swiftly transport the boxes to the next station, where five F4 pick-andplace robots fill them with the products.

The TLM line is equipped with high-accuracy scanners that detect the orientation and position of the flow-packs over a width of 600 millimetres.

This information is transmitted to the F4 pick-and-place robots for the correct pick-up and placement of the flow-packs in the boxes.

The filled boxes are then transferred by a first F2 robot to a vacuum conveyor, and there closed by a second F2 robot in one step and placed on the outlet conveyor.

For the special format packaging of the flow-packs into larger pouches, the scanner also recog-

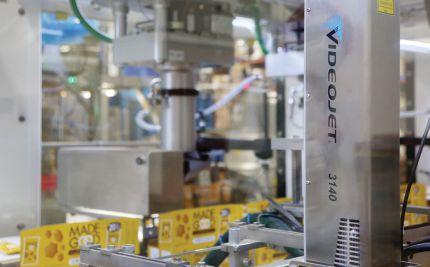

Top: individual pouches travel along the infeed conveyor inside the Schubert TLM machine for loading inside the multipack cartons moving in opposite direction. Bottom: High-speed model 3140 laser coder from Videojet Technologies applies permanent barcodes and other variable product information onto the cartons.

The Schubert TLM line incorporates the high-performance RO line of hot-melt adhesive applicators to ensure high-precision, high-strength gluing for all the paperboard containers used on Riverside production lines.

The packed and sealed cartons making their way out of the Schubert TLM machine quickly pass by the METTLER TOLEDO Hi-Speed checkweigher to verify the product weight inside each box to ensure strict compliance to exceptionally tight weight tolerances and deviations.

nizes the flavor based on product color.

This enables the intelligent pre-grouping of granola minis with different flavours, which are supplied unsorted on the product belt.

The flow-packs are pre-grouped in groups of four—each with two flavors—on the Transmoduls and transferred to the output conveyor by means of an F2 robot for further processing by Riverside.

While the color recognition function for the pre-grouping of different flavours was not originally part of the machine order, Schubert was subsequently able to integrate this capability on-site in time to put the system into operation.

In addition to proving continuous service and system enhancement to optimize the TLM line’s performance, Schubert has also provided Riverside technical staff with extensive in-house training both in Canada and at the company’s global headquarters in Crailsheim, Germany, which had a great

positive impact on the Riverside staff’s familiarity, comfort and confidence in Schubert’s modular and versatile TLM line technology.

So when the time came to add another automated packaging line to keep up with growing demand for Riverside products in the Club Store and e -commerce segments, ordering a second Schubert TLM line to handle new products and bigger packaging formats with more varied SKU selection was a natural choice.

Says Fluit: “With the diversity of our product line, we really like the TLM system’s flexibility of picking the primary pillow-bag packs containing crumbly or odd-shaped mini-sized products, and gently loading them into the cartons without any product damage.

“Being a young company with a relatively small engineering team, we relied heavily on Schubert’s team for their technical expertise and support,” Fluit points out.

“This is a company that has invested heavily into the Canadian market, not just in sales but also with full team project management, full-service capabilities and all the spare parts inventory we would ever need in the future,” Fluit says.

“This was something that really a separated Schubert from many other vendors for us.”

As Fluit relates, the commissioning of the second TLM line was a time-sensitive project because it was meant to coincide with a major launch of the new MadeGood cookies, with a large portion of that output reserved for production of large-sized 28-pouch Club Store packs and the 32-pouch e-commerce boxes.

“As I recall we had a four- to six-week window for start-up,” Fluit relates, “and Schubert was outstanding to meeting all our time requirements, with their modular design expertise and service experience greatly contributing to the speed of this instal-

Top: A user-friendly HIM (humanmachine inerface) terminal on the Schubert TLM line allows usesr to select from hundreds of pre-programmed recipes to enable quick and easy changeovers.

Middle: A close-up of the Shubert TLM machine’s cartonforming suction cups and folding mechanisms swinging into action to erect ready-to-fill multipack cases for loading the individual packs.

Bottom: The colorful corrugated shipper cases go through their various boxforming, filling/ loading and sealing stages performed with exceptional speed and precision by the Schubert TLM system.

A close-up of corrugated shipper master cases being formed for placement of finished filled cartons inside, after which the cased are quickly removed off the production line for palletizing.

lation.”

According to Fluit, the addition of the second TLM line has greatly reduced the manual labor requirements for producing a growing of variety packs—combining several different flavor varieties and styles in one box—popular with the Club Store and e-commerce customers.

“Before the Schubert line arrived we were doing it all manually, using a lot of labor and sill not getting the output we needed to meet our increasingly large orders,” Fluit says.

“So now that we have achieved higher throughput capabilities with the second line, we can focus on growing demand for our product rather than struggling to keep up with it,” he states.

“And with e-commerce increasingly becoming a large part of our business, we can easily accommodate the processing of all sorts of different types of variety packs on our Schubert lines with just a few programming changes, with minimal interruptions.

The colorful, multifold high-impact e-commerce corrugate box produced by Riverside’s long-time packaging partner Packaging Technologies Inc. (PTI), which is also located in Vaughan.

“As a growing company, we have big plans to continue expanding our markets,” Fluid concludes, “and we are confident that we will be able to achieve all our goals with partners like Schubert by our side.”

For Raphael Burkart, project manager with Schubert Packaging Automation in Mississauga, the company’s close collaboration with Riverside Natural Products is a strong testament to Schubert’s world-class technical expertise and customer service excellence.

“Our relationship with Riverside is amazing,” Burkart states. “We worked in very close contact with them throughout the project, especially in installation and commissioning of the machines, and the second line was operational within two weeks of arriving at the plant in crates.

“Although the machines’ performance has been excellent since installation, we still do on-site inspections and mainten-

ance to make sure their machines a running as well as they can,” he says.

“We have five full-time service technicians and three project managers working from our Mississauga office,” Burkart points out, “so we are always within easy reach for all our clients in the GTA (Greater Toronto Area) region to serve them whenever they require our assistance.

“The better we know our customers,” Burkart concludes, “the better we can channel our world-class TLM technology to help them accomplish their objectives.” www.schubert.group www.tnasolutions.com

From left: Justin Fluit, Raphael Burkart and Jeffrey Pett having a little discussion over the company’s shelf-ready Club Store packaging processed on the high-speed packaging lines delivered to the Vaughn plant by Schubert Packaging Automation.

Please see the video of Schubert’s TLKM line in action at Riverside Natural Foods here.

STICKING TOGETHER

West

Coast nutraceuticals supplier invests in high-performance packaging automation to build on its early manufacturing success

By Andrew Snook

Photos by Dave Buzzard

The story of Herbaland Naturals, Inc. in Richmond, B.C., is one of love, hard work and perseverance.

The company was founded in 2009 at the kitchen table of the husband-and-wife duo of Musharaf Syed (president and chief operating officer) and Aisha Yang (CEO).

“We were both immigrants to Canada 20-plus years ago, who wanted to give our families a better life.

“When our third child was born, we had a chance to start our business during my maternity leave,” Yang recalls.

The couple decided to partner Syed’s engineering expertise and experience in the health-and-wellness industry with Yang’s sales and marketing experience and start up Herbaland Naturals.

“In the beginning we tried many different things like capsules and tablets for health and wellness, and we found that gummy vitamins had the best return in

Herbaland Naturals, Inc. president and chief operating officer Musharaf Syed shows off a sample of the company’s growing range of vitamin gummies at the company’s headquarters in Richmond, B.C.

AUTOMATE NOW PLUS

sales,”Yang says. “So, we decided to focus on doing the gummies.”

When the company was originally founded, its gummy products were being produced by a third party, but that all changed in 2013.

“In 2013, because of a supply chain issue, our supplier did not continue supplying gummies to us,” Yang relates.

“So then we decided to buy our own machine and start manufacturing gummies ourselves. Since then, our company has grown really fast.”

Fast-forward to present day, with Herbaland Naturals now employing more than 250 staff and four manufacturing locations totaling 160,000 square feet in size. Exporting its products to more than 40 countries around the world, the company produces approximately 70 million bottles a year of gummy vitamins per year.

“We are the largest nutritional gummy manufacturer in Canada. [and] we rank in the Top Three in North America,” yang says. “We’re also expanding that by end of 2024.

“We will double our capacity to add an additional 150,000 square feet manufacturing site,” she says, “which is a done deal.

“We’ll have that added capacity by the end of 2024.”

As Yang explains, Herbaland Naturals sells direct to major retailers and health store chains, as well as doing significant online sales through Amazon and other e-commerce platforms.

To date, the company has more than 280 NPN (natural product license num-

(Clockwise from top)

An overview photograph of the two side-by-side packaging lines equipped with the PrimoCombi multihead weighscales; a rotary accumulation table indexes the bulk empty jars into a single file to enter the filling station; machine operator placing a large quantity of bulk gummies directly into a weighscale for portioning and dispensing.

bers) issued by Health Canada, allowing it ti sell its product anywhere in the country.

“For offline, we’re also in the regional retail locations like Whole Foods, Loblaws and Sobeys,” Yang says.

“In Canada, we’re in 2,500 locations. For the global market, we also have pretty good market share.”

Back when Herbaland Naturals decided to start producing the gummy vitamins, Syed spent a great deal of time researching the various types of packaging equipment available.

While there are many options available for packaging tablets and capsules, gummy vitamins are a more challenging product to package due to their sticky composition.

Syed traveled to various trade shows in the U.S. and overseas as part of his research into finding the right equipment for his operation.

“I was looking for a packaging machine going to different shows in Chicago, Las Vegas, Korea, Taiwan.

“Then finally, I stopped by WeighPack in Las Vegas and I talked to them,” he recalls.

Luis Pilonieta, sales manager with the Paxiom Group (www.paxiom.com) , sister company and sales/services provider of WeighPack Systems Inc., recalls the first time he dropped by Herbaland Naturals to speak with Syed about his packaging options in 2015.

“We met him in one of his first buildings, a very small office, and it was for his first machine back when he was considering expanding,” Pilonieta recalls.

“At the beginning, like for any business owner, selecting the first machine is scary, especially when you’re putting out over $300,000 on a piece of equipment.

“He got a business loan with Business De-

From left: An incline bucket elevator carrying pre-measured quantities of bulk gummies up to the mezzanine level to be dispensed inside the PrimoCombi multihead weighscale (center), which then dispenses the proper quantities of gummies down into the SpinDexer rotary container filling system (below)

velopment Canada, which was a big investment for them as well.

“And right now, almost 10 years later, we’ve been with him and growing with him at the same time.

“His business was probably around $700,000 a year in sales back then,” Pilonieta says, “whereas now he’s looking at $70 million a year.

“It has been growing exponentially year after year after year.”

That first machine purchased by Syed was a combination of WeighPack’s PrimoCombi multihead weighing machine with the SpinDexer rotary container filling, conveying and indexing system.

Syed says he was very impressed with the equipment’s performance.

“They’re really very good at making a gummy packaging line,” Syed says. “Gummies can get very sticky. Their composition makes the packaging process difficult sometimes, especially when we are counting and weighing the product.

“Their weighscales are very good,” Syed points out.

“They have a special technique for separating the gummies using different vibrations, which has been a very effective solution for us.”

As Herbaland Naturals’ business grew, they continued to invest in WeighPack PrimoCombi and SpinDexer machines—installing them at each of its four facilities.

And as Herbaland Naturals has evolved, so have the technologies within WeighPack’s equipment.

“We bought the last two machines this past year. They are different: much more improved with a lot of things.

“They’ve become more computerized, they have a camera, a metal detector, and a new type of screening,” Syed says.

Adds Pilonieta: “The SpinDexer is a very unique machine because gummies are a very challenging product. Not all gummies are made the same way.

“For Musharaf, he has a wide variety of gummies to process: some are sugar-coated, some are oily, some are

Left: Close-up of the Primo360 HMI (human-machine interface) control panel chowing real-time displays of the product flow running through the PrimoCombi weighscales.

Below: Rigid jars filled with gummies exiting the filling station in a single file to move on to the next packaging stages downstream.

really sticky.

“The challenge for gummies is to rely on a piece of equipment that is going to give them accuracy and reliability when packing them into the bottles.”

One of the other challenges related to packing gummy vitamins is the shape of the bottles.

“Most of the vitamin gummies in nutraceutical that you buy in a Shoppers Drugs Mart, or any other stores like that, they have a big fat bottle with a very tiny neck,” Pilonieta says.

“So, when you have all those gummies going through a very tiny neck it’s challenging because they get clogged, not only when handling the gummy right from the beginning but from conveying to weighing to dispensing.

“To get all those counts of gummies into the bottles becomes even more challenging,” Pilonieta says.

The installation and commissioning of the last two machines went fairly smooth, but Pilonieta admits there was a learning curve at the beginning of his company’s relationship with Herbaland.

“When it‘s the first time that you’re implementing something, you are learning,” he says. “It was no different with the packaging requirements and technology that they’re in.

“For the first one, the learning curve was a little bit longer, but we got the hang of it,” he continues.

“The second one was faster. For thee third and fourth ones, we had changed the technologies on the multihead weighers, so it was a little bit of a new software learning process that they had to do,” Pilonieta relates.

“But they were really quick to absorb that and are loving the new version of the software.”

To help ensure that Herbaland Naturals has minimal downtime at its facilities, WeighPack’s technical service team helped train inhouse technicians to deal with minor issues.

“We learned from their technical people and now we have three people to fix and repair things,” he says. “For everything minor, we solve things ourselves. For anything major, we call them.”

The gummies begin their journey when they are placed into a hopper from bulk bags by an operator.

“It is crucial to keep the gummies separated from each other, so we can have an accurate count,” notes Pilonieta.

“The operator places them into a mesh and makes sure there are no clumps, and the machine will then automatically vibrate product right onto the conveyor system, so it can be later weighed and dispensed into the bottles,” Pilonieta explains.

After the machine vibrates the gummies onto the conveyor, they move into the fill station.

As the product makes its way to the scale, the WeighPack PrimoCombi multihead weighing machine will automatically weigh and dispense the programmed product count into the bottles.

“Our systems are all equipped with a webcam system,” Pilonieta points out. “It allows us to take a look and see what’s happening in the top portion of the production process, enabling the machine operator downstairs to see what’s happening with the product in real time. We also offer free online support via this camera system.”

Once the product is weighed and dispensed, the products move to the SpinDexer rotary container conveying indexing system, which will take an empty bottle and index it to the fill station, where the gummies will be dispensed.

“The challenge for gummy manufacturers is to fill the batch of gummies into such a small bottle opening, and that’s why the SpinDexer has a great technology to do that,” Pilonieta says.

It starts with the operator putting empty bottles into the rotating unscrambling table where it will spin the bottles and feed them into the machine. After the PrimoCombi has accurately weighed and dispensed the product, it falls down a funnel to get into the bottle.

“The machine, as it is indexed, will vibrate multiple times until it finalizes with all the gummies inside of the bottle and goes to the next

“We have strongly believed since Day One that we can be an industry leader not only in Canada, but also in the global market.”

stage of the packaging process,” Pilonieta says.

In addition to growing competition in the marketplace for vitamin gummies, supply chain issues, labor shortages and unforeseen inflation have made things challenging for companies, including Herbaland Naturals.

Yang says these issues have made forecasting ahead difficult.

“Right now we are producing gummies, so we need to source the raw materials and make sure there will be good orders to keep our production costs of expense stable,” she says. “But that’s not just an issue for Herbaland: everyone in the industry is having a similar type of challenge.”

Despite that, Herbaland remains committed to continuing its growth strategy.

“As a leader in a company, I think we need to empower people by how much we believe in our goal and going through it together,” she says. “For me and for Musharaf, we have strongly believed since Day One that we can be the industry leader not only in Canada, but also in the global market.”

www.paxiom.com

Please see a video of WeighPack Systems equipment in action at Herbaland Naturals here.

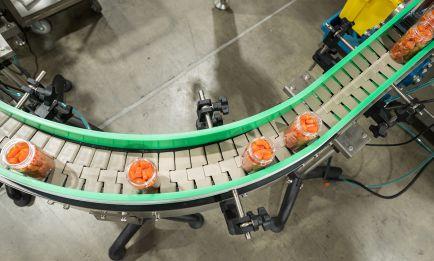

Food-grade plastic conveyors carrying filled jars of vitamin gummies away from the filling station and on to the capping and labeling stages.

GOOD IN THE HOOD

Stalwart end-of-line machinery builder keeping close eye on packaging trends to develop modern solutions to challenging issues

Digitalization, films made of recycled material, and the increasing use of robots … mechanical engineering companies operating in the packaging sector are facing a relentless tidal wave of continuous changes these days.

They can adapt themselves, but they can also be pioneers and set trends just like BEUMER Group (www.beumer.com), a leading global supplier of heavy-duty packaging, palletizing, conveying and other industrial machinery for high-volume applications in numerous manufacturing industries.

“We clearly feel the changes in the packaging sector,” says Jörg Spiekermann, BEUMER’s sales manager for palletizing and packaging systems for consumer goods at the company’s global headquarters in Beckum, Germany.

“Our customers require solutions permitting them to further relieve their staff, make their processes more flexible, and increase their production and resource efficiency,” he explains.

“On request, the system provider delivers the packaging sector complete packaging lines: from filling up to the palletized stack and also from one single source.

“This means that interfaces can be omitted or minimized and the customer only needs one point of contact.”

With BEUMER system solutions, full pallets or individual bags can be forwarded to a

The easy, intuitive and reliable and reliable operation of the new BEUMER stretch hood A is especially appealing to customers.

connected warehouse or directly to the loading space of a truck.

The system components are mainly transport technologies such as conveyors or vehicle-based systems, with various solutions for product handling and manipulators—such as robots, buffer and storage modules—also available as well.

As BEUMER Group always uses components from a modular system, the solutions can be expanded at any time and can grow with the customer’s needs.

“For best results and to ensure full material and data tracking, the filling, palletizing and packaging components as well as other system components must be perfectly matched,” says Spiekermann.

“It is more and more important to network logistic processes and to control them in an automated way.”

For this, BEUMER Group has developed a modular software suite as a superior data processing system, which can be adapted individually to the particular tasks.

“Since we want to consider and optimize the process as a whole, our experts are of course able to easily integrate products from third-party suppliers,” explains Spiekermann.

A cross-program user interface shows process data and reports, and all available data can be accessed without having to switch between different applications.

With the BEUMER Group warehouse control system, the software suite can be easily con-

nected to the warehouse management system or the customer›s ERP solution. This way, BEUMER Group ensures the communication between the different control levels for the user.

Furthermore, BEUMER Group can create an intelligent connection between the individual systems and integrate them into the existing processes and inventory control systems of the customer.

According to Jörg Spiekermann, the trend goes towards digital solutions that increase automation potentials and further optimize supply chains and processes.

But for many mechanical engineering companies in Germany this is a huge challenge.

“They simply miss the necessary know-how,” he states.

For BEUMER, digitalization means cooperation, interaction and data interchange,” says Spiekermann, noting that this new reality also changes the role of the packaging system suppliers and cooperation with the customer.

“There are many young companies with a lot of know-how ready to surprise the market,” says Spiekermann. “But we don’t want to wait for them to take us off the hook with their fresh ideas,\.

“”We prefer to take the helm by ourselves, we look for and support promising start-ups and thus carry digital projects into our company,” he says, providing an example that is only remotely related to the packaging sector:

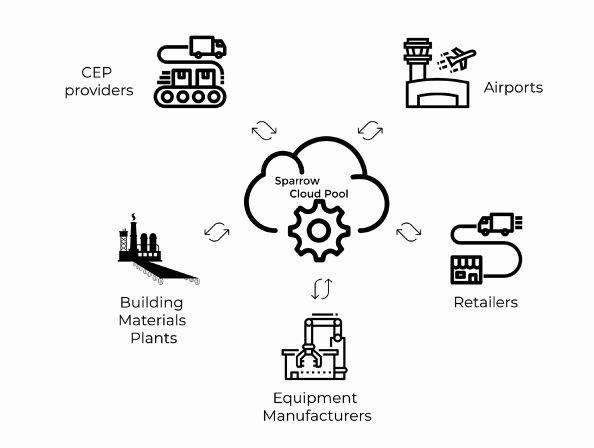

With its digital marketplace, the start-up Sparrow Networks ensures that the participants are

Sparrow is a virtual stock room operating on a digital platform enables members to share spare parts among themselves.

The BEUMER robotpac is able to palletize large barrels in a very efficient way.

supplied with the appropriate spare part as quickly as possible in the event a component in their systems fails.

Sparrow connects the stock of the system operators with each other. Thanks to the network, a suitable supplier can always be found quickly—preventing long downtimes and expensive storage costs.

The start-up receives extensive support from the Berlin-based, autonomous company builder Beam, a spin-off of BEUMER Group.

“We try to solve unique problems in logistics together with start-up teams,” explains Spiekermann. “It is important to find entrepreneurs with promising business ideas.”

The systems provider is planning on founding three start-ups per year and transferring them (while being consolidated under Beam) into a separate company.

Spiekermann says he also sees a further trend in the increasing use of robots, citing the petro-chemical industry as an example.

“Here the products are filled in special bags, barrels, canisters, cartons or buckets. To palletize them, BEUMER Group offers its space-saving articulated robot, the BEUMER robotpac,” says Spiekermann.

Depending on the packaged items, BEUMER Group equips the robot with the appropriate gripping system which can be easily and automatically changed if the packaged items change.

“The fork gripper was, for example, designed for palletizing bagged goods and cardboard boxes.

“The finger gripper is particularly suitable for the efficient handling of bagged goods,” he explains.

For maximum performance, BEUMER

Jörg Spiekermann, Sales Manager, Palletizing & Packaging , Consumer Goods, BEUMER Group.

Group offers a double gripper for both types.

They also offer parallel grippers for dimensionally stable packed items, suction grippers for items with a smooth surface, and many other special grippers and combination tools.

The modular structure permits adaptation of this series to special market- and customer-specific requirements.

The Bags stacked accurately onto pallets, which can then be transported successfully to the downstream packaging system, such as the BEUMER stretch hood.

“Our BEUMER stretch hood packaging system is highly energy efficient,” says Spiekermann.

“An intuitive human-machine interface simplifies operation and makes quick work of film roll changes,” he says. “Operating parameters can be changed as well.”

As Spiekermann relates, BEUMER Group

not only committed itself to evaluate this packaging system comprehensively on the levels of economy, ecology and social responsibility, but for all products it makes—demonstrating full commitment to the company’s TVO (total value of ownership) methodology and metrics. (TVO).

“We consider the systems in its entirety, not only from its cost side,” says Spiekermann.

“For example we continuously look to reduce energy and resource consumption in the production cycle and during operation, as well as keeping emissions to a minimum,” he explains.

“Not only the machines but also the packaging are sustainable, at least a strong trend goes in that direction, since the plastic products are being criticized for some time now,” he says.

“After using them, they often end up as waste on landfills or— and this particularly applies in case of consumer goods—in nature, polluting the environment considerably.

“Since the beginning of 2019 the new packaging law has therefore also been in force. Its aim is to avoid packaging waste and to strengthen recycling.

“Therefore many films will include recycled material in future, which might considerably change their characteristics and handling.

“Many packaging system owners, who fix and package goods ready for dispatch by using stretch film for transshipment on pallets, are of course unsettled,” says Spiekermann, who knows his customers.

“Can we further use our packaging systems?, they often ask and “Yes, you can,’ I always respond,” he relates.

The BEUMER stretch hood A processes these films as usual in a very reliable way.

In this regard, the experts in cooperation with the film manufacturers have performed tests and analysis with various films in the inhouse R&D centre in Beckum.

With the BEUMER stretch hood A packaging system, the system supplier supports his customers along the line, and with regard to safety.

“The high restoring forces in the stretch film make sure that the film fits tightly to the entire stack, like a ‘second skin’, and thus ensures the necessary stability,” Spiekermann describes.

The products are thereby fully protected from the environment, he explains, while the palletized goods are clearly visible due to the smooth surface of the transparent, highly flexible film.

And underlaying barcode labelling is quickly and consistently recognizable, while logos and text can also be printed on the film to be used as an advertising medium.

Tamper protection is also important: Unauthorized persons cannot take goods from the pallet without damaging the film.

The packaging also protects against dangerous substances by making sure the hazardous the content does not come in contact with the surface of the container.

This is the case for lubricants and adhesives, anti-freezes, resins, brake cleaners, as well as for bulk material such as pellets.

The packaging system can also be used to line the inside of the container with a film hood, according to Spiekermann..

“We know the market and the requirements of our customers,” Spiekermann concludes.

“With our solutions we always want to be one step ahead.”

www.beumer.com

CASCADING EFFECTS

Paper products powerhouse gets a better grip on its energy distribution and management with a space-saving enclosure solution

Founded in 1964, Quebec-based forest products group Cascades Inc. is widely respected for providing sustainable, innovative and value-added solutions for many diverse packaging, hygiene and recovery needs.

The company employs approximately 10,000 employees who work in almost 80 facilities in North America.

With a well-defined mission to improve the well-being of people, communities and the planet by providing sustainable and innovative solutions that create value, Cascades (www.cascades.com) specializes in producing, converting and marketing packaging and tissue products that are composed mainly of recycled fibres, including: Their product lines include:

• Packaging Solutions. Eco-friendly packaging solutions from Cascades reflect the trends and challenges of the market.

• Hygiene and Tissue Solutions, designed for residential, commercial or professional needs, and made primarily with recycled papers. .

• Fiber-based Materials, comprising many effective, eco-friendly packaging solutions are made with linerboard and corrugated medium (fluting paper), and speciality paper is made from recycled fibers. Everything that the company does is done for a greener, cleaner future.

In 2022, for the third consecutive year, Cascades has been recognized as one of the world’s 100 most sustainable corporations, according to the prestigious Global 100 index produced by Corporate Knights.

At Cascades, they believe there is always a better way of doing things: a better way to package and protect products, a better way to manage residual materials; a better way to create a cleaner world.

Hence, Cascades believes in working with tried and tested eco-friendly equipment of the highest quality that can conserve energy and resources in terms of materials, people, time and money.

Recently, Cascades was looking for an efficient solution to address motor control, power management and quality control challenges in their plants.

The objective of this project was to succeed in maximizing the space in each of the panels compared to the use of a Motor Control Centre (MCC) Solution.

Also, previous projects used wall-mounted enclosures but as the bottom of the wall space was wasted, more wall space was required in existing electrical rooms.

Using the Motor Control Panel (MCP) solution maximizes the wall space that is often lacking in factories.

Cascades had a long-standing relationship with Jacmar (www. jacmar.ca), a leading industrial automation and controls distributor in Quebec, and one of Rittal’s oldest partners in Canada.

Having been using Rittal’s market-leading enclosures for the past 20 years, Cascades knows well what sets Rittal (www.rittal. ca)apart from other industrial automation suppliers is their capacity to meet specific client needs reliably and quickly scalable industrial automation solutions necessary to remain competitive and agile in a quickly changing marketplace.

Not only could Rittal provide market-leading enclosure solutions, but their team could also use EPLAN power engineering and configuration software to design the solution from start to finish.

Cascades had worked on projects involving drives which are sometimes integrated into MCCs or wall-mounted enclosures. For a recent major project, the panel and MCC solutions were not viable from a space availability point of view, so Cascades were

ready to consider Rittal’s MCP solution which saved more than 30 per cent of space in the electrical rooms.

Moreover, sourcing Rittal’s Motor Control Panel (MCP) solution from a local distributor like Jacmar, provided Cascades with access to local stock, faster delivery, and convenient part replacement.

Jacmar carried out panel mounting simulations with the most frequent drive in the project, 25 HP, using EPLAN engineering software, which allowed them to confirm that two 25 HP drives could be assembled in an MCP solution, whereas in the MCC Arcflash solution, only one drive could be installed.

This made it possible to reduce the number of panels required for the project by half, thus obtaining savings in terms of space and costs.

Based on Rittal’s proven architecture of their free-standing TS

8 enclosure system, Rittal’s Motor Control Panel (MCP) with EPLAN design software, was the perfect solution to address Cascades’ motor control, power management and quality control challenges.

The benefits of Rittal’s MCP solution included:

• speed of design and build,

• customization from standard parts,

• flexibility of design,

• cost-effective integrated solution,

• easy configuration with Rittal power rngineering,

• CSA/UL certified for use in Canada,

• Plug-and-play operation and standard parts,

• Configurable at all stages.

Designed, engineered and manufactured to meet the needs of Canadian specifiers and contractors, the modular design enables

Front entrance to the Cascades global headquarters in Kingsey Falls, Que.

easy configuration and short delivery times.

Another factor that made it efficient for Cascades and Rittal to work together, was the fact that they received direct support from the manufacturer at all stages of the build.

Rittal was able to build the enclosure, providing proof of concept along with CAD drawings, in their state-of-the-art Modification Centre in Ontario, so shipping to Quebec was not an issue at all, saving valuable transportation costs.

For large engineered industrial processes at Cascades, power distribution can be very complex undertaking,which was readily addressed by using a control panel that would inlcude all the required VFD (variable frequency drive) pump and motor components.

Each motor was connected separately to a VFD, and that starter is individually mounted or contained in a larger control panel. Rittal’s MCP offered Cascades the best of both worlds: the efficient component organization of a control panel, as well as for optimal distribution of current and decreased resistance.

Cascades was pleasantly surprised that it took just about a week for the power engineering, and about two months to build the solution from start to finish.

When translated into costs and ROI, the benefits were immediately apparent

Cascades first project with Rittal, has made it possible to optimize the space in the electrical rooms.

Another major project is in design and the use of the MCP solutionwould make it possible to add more new motors in the existing electrical room

As Cascades technical advisor Marc Payeur proclaims, “Rittal’s MCP solution checked off all the boxes for Cascades: the space and energy savings was in keeping with our search for green-

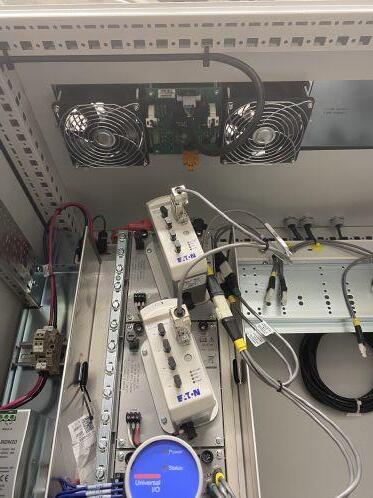

The free-standing Rittal TS 8 enclosure system housing all the required components comprising the MCP power distribution solution.

er, environmentally-friendly solutions, and we also appreciated the overall efficiency of this modular, well-organized integrated solution.”

André Bousette, president of Rittal Systems Ltd., adds: “The major advantage of Rittal’s MCP solution is the huge savings in engineering, lead, preparation and assembly time, as well as most importantly, the ability to configure the solution even after the order.

“We are pleased to have been able to deliver this solution to Cascades on time and within their budget,” Bousette concludes, “and we are confident that this will provide them with a more efficient way to produce their world-class packaging and recycling products and services.”

www.cascades.com

www.ritall.ca

www.jacmar.ca

A top-down view of the MCP solution components assembled inside the TS 8 enclosure, including two 25 HP drives.

A side view of some of the key electrical and automation components and controls incorporated into the MCP solution.

Housed in a separate electrical room, the heavy-duty VFD motors are linked to the Rittal MCP solution to ensure optimal power distribution.

MODULAR FILTRATION

Beverage equipment manufacturer uses high-end automation controls to improve its filtration skids for wine producers

By Audrey Richard and Sebastien Janci

In winemaking and the production of distilled spirits, clarification and stabilization are critical processes by which insoluble matter suspended in the wine or spirits is removed before bottling.

Filtration, especially through carbon-based filters, contributes to the stability and long shelf life of the wine or spirits.

Filtration also helps winemakers and distillers achieve very specific, delicately refined tastes and aromas for their products and saves time waiting for spirits to age.

These high-volume filtration systems can filter up to 23 liters in a few minutes, they and have the capacity to filter multiple batches using just one set of carbon pads.

Conventional filtration systems from the beverage industry are also used in the spirits industry.

These include sheet or stacked disc cartridge filters, which are fitted with depth filter sheets or stacked disc cartridges made up of depth filter sheets. Other filtration options include cartridge filters,

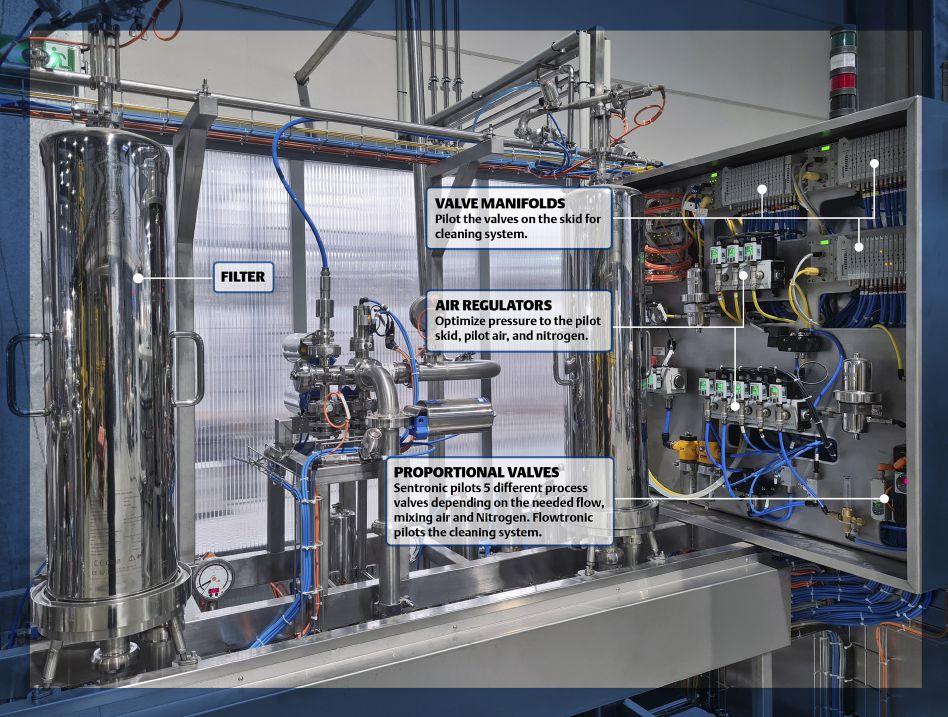

Fourage collaborated with Emerson to create a complete pneumatic control panel solution.

crossflow filters and pre-coat filters, in which diatomaceous earth, perlite or cellulose are used as filter additives.

Based in La Haie-Fouassière, France, family-owned Fourage CTI has been providing provides these kinds of filtration products for the wine industry for over 60 years—working closely with its with its end-user spirits and wine producers to provide the most cost-effective and efficient filtration skidsbased on the producers’ unique product and process requirements.

An as the wine industry has evolved over time, so has the demand from spirits and wine manufacturers requiring more advanced filtration capabilities.

Beverage producers must assess what colloidal haze-causing substances need to be removed—materials such as polyphenols, proteins, polysaccharides, sugars and microbiological loads—while simultaneously preserving valuable ingredients that contribute to taste, aroma and color.

For companies like Fourage, it has become essential to have the right resources available to let them refine their designs and build filtration skids without having to make extensive investments in finding and integrating multiple components.

Recently, Fourage CTI encountered a complicated challenge: There was strong demand for its filtration systems, but supply chain constraints made it difficult to reliably source all the components used to efficiently operate the filtration skid.

The time and effort to obtain and integrate these components threatened to interrupt skid manufacturing and delivery to its customers.

To overcome these obstacles, Fourage partnered with leading industrial automation provider Emerson (www.emerson.com) to create a complete, turnkey pneumatic control panel solution with all valves and other control devices pre-assembled and ready to install. The integrated panel would include a full cabinet with panel mounting and plexiglass door.

While Fourage CTI and Emerson had partnered for 10 years prior, this was the first time Emerson provided a complete solution for Fourage.

The panel combined a range of Emerson devices with products sourced from other suppliers. The components include:

• Filter: For the skid, Fourage needed prefiltration, coalescent filtration, charcoal filters and nitrogen filters.

• Regulator: The AVENTICS AS2 pressure regulator used in the panel provides significant flexibility.

Multiple regulators can be set inline while custom-configuring the pressure required from each regulator, and a bicolor screen positioned on top of the AS2 pressure quickly turns red if there is a pressure issue, providing a quick and simple visual diagnosis for the operator.

• Electronic Fieldbus Valve Platform: A modular and flexible solution designed to replace conventional hardwired systems, the AVENTICS G3 platform provided an easy-to-assemble and easy-to-commission solution to pilot the process valves and the filtration system’s pumps.

The G3 platform’s functionality allows programmable logic controllers (PLCs) to

The AVENTICS CL03 Clean Line Valve System features a high protection class of 1P69K, making it suitable for sanitary design in beverage processing applications.

The AVENTICS Series AS2 pressure regulators used in the panel provides reliability, safety and efficiency for Fourage operators.

turn the valves on and off, and to channel data from sensors, lights, relays, individual valves or other I/O devices via various industrial networks more efficiently.

• Proportional Control Valves: Two types of proportional control valves were needed as part of the complete panel, whereby proportional pressure regulation allows for handling the aseptic valve opening to regulate the filtered fluid.

To do this, Emerson’s AVENTICS 617 Sentronic LP was chosen, as it provides better regulation, response time and precision.

For its part, Emerson’s FlowtronicD 607 flow rate control valve regulates the movement of cleaning shell into the pipes. The product provides real-time control, allowing Fourage to have precise control of the cleaning system’s speed.

All in all, Emerson provided three complete panels, completing the seamless project in only eight weeks and proved to be seamless; there were no issues with skid integration.

Emerson’s complete panel solution eliminated multiple headaches for Fourage.

Rather than scour suppliers looking for different components and then spending engineering time integrating them all together, Emerson’s solution saved time and provided a tested and proven solution with all pneumatic control functionality pre-installed and ready to be integrated into each filtration skid.

Emerson worked closely with the Fourage team to develop a solution that would work specifically for the company’s needs. www.emerson.com

Audrey Richard is a product marketing manager for life sciences, Europe, and Sebastien Janci is a services and solutions manager at Emerson.

The AVENTICS 652 Series Redundant Safety Exhaust

Valves (left) feature the industry’s highest flow rates, according to Emerson, helpin ensure that air preparation products optimize the machine’s performance in a system.

VIRTUAL BENEFITS

Virtual commissioning for servo hydraulics opens up new possibilities for drive simulation

With process simulation becoming an integral part of most automation projects these days, the need for reliable simulation software had never been greater.

For leading electric automation and drives specialists Baumüller Group (www. baumueller.com), this need drives continuous refinement and upgrading of the company’s ProSimulation software suite, designed for virtual set-up, testing and optimization of ser-

vo-drive systems of machines and production lines.

Recently, Baumüller has significantly extended the functional scope of its ProSimulation product family.

In addition to the controller and mechanics models, there are now new models available for hydraulic systems, with which the dynamic operating behavior of the servo hydraulics can be simulated at early stages.

By mapping pump properties such as the volumetric and hydraulic-mechanical efficiency and taking into consideration system properties such as variable oil volume, pipe losses and

leakage behavior, complete servo hydraulic applications can be designed in the simulation and commissioned virtually. These events can be transferred to the real application later, saving the considerable time and cost of developing and commissioning servo hydraulic machines and systems.

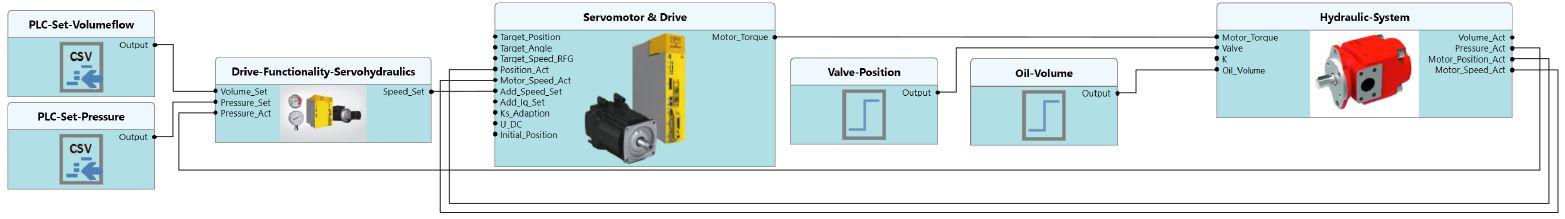

As Figure 1 illustrates, the structure of a servo hydraulic system in ProSimulation simulates all the critical process stages and tests them in advance.

With ProSimulation, not only can the ideal controller settings for the subsequent machine be determined, but it can also simulate all the critical stages can also band their effects on the process, as well as test the behavior of the drive system.

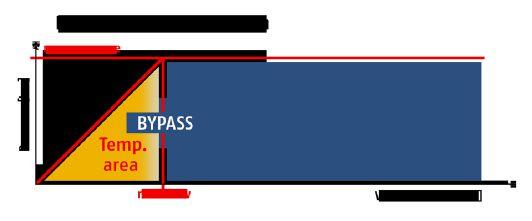

One example is the controller-integrated “thermal pump protection” function.

This smart function is available as an optional feature for Baumüller servo converters and prevents a thermal overload in the hydraulic system. This can occur in the machine cycle, particularly in case of long hold times of high pressures and low flow, thereby increasing wear and possibly leading to premature pump failure.

A temperature model is directly used in the controller to calculate the pump’s thermal capacity utilization. If a critical threshold value is reached, hydraulic bypasses are connected to relieve the pump, which in turn ensures higher flow and improved heat transfer.

This shifts the pump’s operating point out of the temporarily allowable operating range and into the continuously allowable operating range to prevents the risk of damage due to hot running.

As shown in Figure 2, the pump is flushed in good time before the hot running to prevent damage. This drive-based function can be tested virtually in ProSimulation during the virtual hydraulic system be set-up and testing.

In the second step, the machine cycle is simulated and tested for thermal overload of the pump. If critical operating points occur, the pump protection function described above can also be activated in the simulation. In this way, critical operating points can be identified and avoided during the development process.

The new functions in ProSimulation substantially expand the

area of use of drive simulation for machine manufacturers, while increasing efficiency in the development process, and significantly reduce the time-to-market.

In view of rising costs and competitive pressure, it also helps mechanical engineers can further optimize their internal processes. At the same time, the optimal controller settings can be tested directly on the model prior to application, with all the parameters for the drive loaded by the application engineer during the real commissioning.

Drive simulation also promotes sustainability, as the exact design of the motors helps to avoid the over-dimensioning of the servo drive, with motors running within the optimized load range. Depending on the machine running time, there are many energy savings to be had, along with an optimized machine footprint.

www.baumueller.com

Figure 1

Figure 2