AUTOMATE NOW PLUS

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson

sjamieson@annexbusinessmedia.com

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid

energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls

FUTURE DIRECTION

New automatic vertical bagging machinery range is designed for future-proofing the end-users’ capital investment

By Andrew Snook

Packaging customers are always striving to get more production out of the same-sized factory footprint in their facilities. To do this, they are constantly researching the latest technologies and automated solutions in their market.

To try and stay on top of what these customers are looking for, packaging machinery OEMs (original equipment manufacturers) are also busy conducting their own market research to ensure their latest technologies meet the needs of their clients.

The time dedicated to bringing out a new technology often takes years and requires a significant number of resources dedicated to each solution.

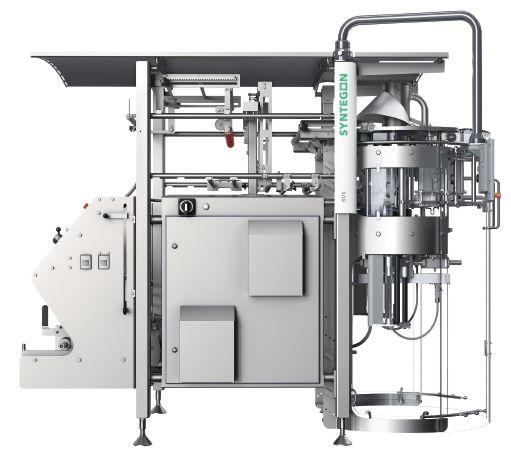

One example of this dedication of time and resources is Syntegon (www.syntegon.com)’s new SVX series of vertical packaging solutions, officially unveiled at the recent interpack 2023 global packaging exhibition in Düsseldorf, Germany, this past May. (See Pictures)

Syntegon’s product group sales manager for vertical machinery Jason D’Arcy says the debut of the SVX series—comprising the Agile, Compact and Duplex models—was preceded by more than

three years of engineering and design work, as well as several years of thorough market research.

“It’s something that’s been in the works for years now,” he says. “It will be the basis of our vertical portfolio.”

The SVX series is the answer to many of the problems that customers face in their packaging operations, D’Arcy says.

“What we wanted was a vertical bagger that’s not just faster, but also more efficient.

“This is more efficient with less packaging waste, and with more sellable packages coming off that bagger.”

The “heart” of the SVX series is the cross-seal drive system, which consists of four independently-controlled servomotors.

The company states that this design makes it possible for more accurate seal force control and best-in-class product-in-seal detection.

Operators can set a higher seal force on one side for asymmetric bag styles directly from the recipe, according to Syntegon, so there is no mechanical action required.

When designing the SVX series, Syntegon wanted the new machines to be future-proof solutions for their customers, whereby all these units offer the flexibility of being upgraded as a client’s operations grow.

The SVX Agile is capable of running speeds up to 300 bags per minute with one film lane, but it can also run a smaller number of larger bags (up to 400 -mm-wide), giving the customer a wide range of flexibility.

“The SVX Agile is capable of configuring up to nine different bag styles, everything from pillow bags to zip bags. It’s just change parts that the customer needs to do changeovers,” D’Arcy says.

With those field-upgradeable change parts, customers have the ability to adapt to changing

market demands quickly and efficiently, he notes.

“Let’s say a customer purchases the SVX Agile and right now and they’re making pillow bags, and that’s what they imagined they would always be running on that line.

“But the next year, their marketing team comes to them and says, ‘Hey guys, it would be really great if we’re able to make those zip bags?’

“In the past, that meant changing out that pillow bagging machine to a vertical zip bagger,” says D’Arcy.

“On the SVX Agile, we are able to add the parts that now allow them to use that same asset to make pillow bags and zip bags,” he says, “and change back and forth.

“This future-proofs that packaging line and helps the operations team be better equipped to handle those changing market demands,” D’Arcy says.

While SVX Duplex model has the same-sized frame as the SVX Agile, it has two forming tubes.

“Now imagine you’re making two bags for every one of those 300 cycles.

“Now you have a bagger that can produce up to 600 bags per minute,” D’Arcy says, adding the SVX Compact is the smallest version of the SVX series machines.

“It is under one-meter-wide, so it’s really small,” he acknowledges. “But again, it can produce up to 300 bags per minute, and we offer a paired version of the Compact that has two baggers side-by-side, with a larger size range than the Duplex bagger.”

The SVX Compact has a maximum flat bag width of 270-mm, while the SVX Duplex has a maximum flat bag width of 145-mm.

The entire SVX Series features proprietary software called Synexio, a Cloud-based software solution that collects, evaluates, and visualizes

Jason D’Arcy, Product Group Sales Manager, Vertical, Syntegon

production and equipment data.

“It helps customers take data off that line, whether they want to learn values from case-packers or cartoners, and it harvests that data and to look for ways that the customer can improve their packaging line operations,” D’Arcy says.

“It does that by presenting that data in a very clear manner, which helps the customer to visualize and understand where they can make improvements,” D’Arcy explains.

The robust software solution is offered with three value-added options that include:

• Synexio Monitor, which provides transparency by showing visualized data to understand operational performance.

• Synexio Uptime. Offering benchmarking and active support capabilities, it is designed to reveal opportunities for improvement in a customer’s processes that might otherwise be missed.

• Synexio Empower, offering the user a variety of tools—including component monitoring and expert training—to give them the know-how to maintain production gains year after year.

“With Empower, that’s when we start monitoring parts on that packaging line, helping predict when those need to be changed, and offering training to operators to help customers get to that next level to get the most out of their packaging lines,” D’Arcy relates. Designing a series of vertical packaging solutions that are easy to use was one of the most important features that customers are looking for in new packaging equipment, according to D’Arcy.

“One of the big things that we’ve been hearing from our customers is that it’s increasingly challenging to find, train, and then retain skilled staff,” D’Arcy explains.

“To that end, they’re always looking for packaging lines and baggers that don’t have a steep learning curve,” he says. “Having machines with which operators can become be proficient quickly means that you are also able to operate more machines with the same number of operators.”

One of the features that are designed to assist with the training of inexperienced operators is the HMI 4.0 dashboard system, D’Arcy points out.

“It is a very intuitive guided process” he states. “It works very

similar to any multi-touch system, but one of the interesting things it does is guide the operators through the whole changeover and start-up process.

“It takes them through the step-by-step process every time,” D’Arcy elaborates. “Hence it doesn’t need to be memorized: it’s all indicated on the touchscreen to make sure it’s correct and consistent each time.”

Prior to the HMI 4.0 dashboard system, an operator would have what they thought was the best setting, so every shift change the operator would walk over to the touchscreen and change the settings to what they thought worked best.

“And there were times it was better, and times that it wasn’t,” D’Arcy points out. “You would see that efficiency difference in the line changes, depending on who the operator was.

“By having our guided process helps to take some of that tinkering out of it,” D’Arcy asserts.

“Every operator is looking to run as efficiently as possible, and

“One of the big things that we’ve been hearing from our customers is that it’s increasingly challenging to find, train, and then retain skilled staff.”

this takes all the guess work out of it.”

As D’Arcy details, the SVX series units’ dashboard system is set up for storing new recipes; requires less dependence on skilled operators through the use of enhanced graphics and less text; calculates the position of elements that need to be adjusted manually (such as a web tracking sensor, for example); and the HMI dashboard can be rotated to have the critical information available wherever the operator requires it.

Each model in the SVX series also features easy access from both sides of the machine for adjusting settings on printers, labelers, and format set angle. Moreover, adjustments to the machines can be made on-the-fly without any need to stop operations.

Notably, the SVX series machinery is constructed using stainless-steel parts to reduce contamination by design and allow for easy access to cleaning.

The efficiently designed changeovers of the SVX series result in the generation of very little packaging waste, according to D’Arcy, which is an important feature for companies from both a cost and sustainability perspective.

“In the past, it wouldn’t be uncommon to go through many bags worth of film during that changeover process, as you got that line set up with new bag sizes, D’Arcy explains. “We wanted to make a bagger where that first bag, that first impression on that reel, was a sellable product.

“So we’ve done things like shortening web length from the reel where the film is being unwound from,” he relates. “As a result, there is less film on that bagger overall,” he sums up, “so there’s less film tracking adjustments that the operators have to make, and it’s easier for them to make them.”

As D’Arcy concludes: “Those are all things that help reduce waste in that pack-style changeover.”

www.syntegon.com

SAVING LIVES

Breakthrough low-cost molecular diagnostic test uses Festo pneumatics to obtain faster results

The Fast MDx testing system is not only a game-changer in pathogen detection, it promises to be a life saver.

Available starting in June, Fast MDx is the world’s first fully automated, high-throughput, near-patient molecular diagnostic testing system.

Developed by the London, England-based social enterprise company of the same name with engineering support and automation technology from Festo (www.festo.com), this extremely compact, mobile platform cuts the typical 24- to 48-hour turnaround time for test results to just one to two hours.

Faster results mean earlier treatment and the possibility to contain infectious disease spread.

The Fast MDx requires just a single technician, who can process 1,000-plus samples during an eight-hour shift.

The company says that’s five times more efficient than manual test process-

ing, andythat in the fututre Fast MDx platforms will be set up close to patients in hospitals or clinics or in large medical practices.

Not having to ship test samples to a central biosafe lab will save both time and money on transport, as well as on the use and disposal of specialized packaging.

“Infected people receive faster, personalized treatment,” says Richard Lewis,” founder and chief executive officer of Fast MDx.

“Thanks to the close cooperation between Fast MDx and Festo, we were able to build the first prototypes quickly and efficiently, despite the extremely high degree of complexity,” says Lewis.

“We were able to combine Fast MDx’s extensive expertise in qPCR (quick polymerase chain reaction) thermal cycling with Festo’s proven 3D gantries, controllers and pipetting systems.”

Initially, Fast MDx will offer approved tests for common respiratory pathogens:

The compact, mobile Fast MDx is the world’s first fully automated, high-throughput, near-patient molecular diagnostic testing system, developed with Festo engineering support and technology.

influenza A/B, RSV A/B and COVID-19.

Over the nextone to two, additional tests are planned for healthcare-acquired infections such as C-Diff and MRSA, as well as for sepsis, which kills millions worldwide every year.

Eventually, genomic tests might be added that can detect hereditary diseases at an early stage.

As a social enterprise company, Fast MDx will lend out the platforms for free.

The reagents and other supplies will be the principal expenses, offering a low-cost alternative to centralized test processing, says Lewis.

“That makes it the first system to make near-patient, molecular testing and diagnostics accessible everywhere, not just in more affluent countries.”

The Fast MDx is a fully integrated system that covers every stage of test processing, including the electronic transmission of results.

It has a very small footprint—0.7x1.0-meter—and it is mounted on lockable casters, so it can be relocated as needed.

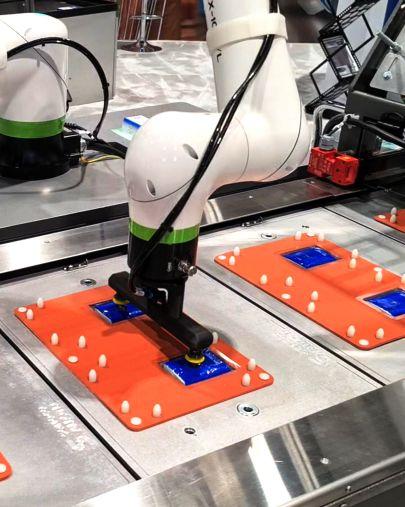

Each unit includes two Festo EXCM planar surface gantries with electric axes for precise pipette handling and for robot-assisted handling of the PCR microtiter plates.

The operator inserts three racks of pipette tips and a 96-well microtiter plate into the Fast MDx platform.

The assay kit with all reagents and controls is loaded into an aluminum block and clipped into place.

The 92 patient samples that have been collected in Fast MDx’s patented Pathtubes are loaded and tracked throughout the process using a unique barcode, laseretched on the bottom of each Pathtube.

During sample preparation, an EXCM gantry operates in the X and Y planes.

First, the Pathtubes are scanned using Festo optical sensors. The automated pipetting apparatus—a Festo DHOE pipetting head and DHAO disposable syringe tip ejecto— is mounted on the gantry in Z direction.

In the new near-patient Fast MDx molecular diagnostic testing system, Festo automated pipetting apparatus—a DHOE pipetting head and DHAO disposable syringe tip ejector—pierces the Pathtube cap to aspirate and pipette each patient sample.

The disposable tip pierces the Pathtube cap, and aspirates and pipettes the sample. Each tip is used for one sample prioor to being discarded.

“Piercing the Pathtube cap saves a lot of time and money, as no conventional opening and closing systems are needed, which eliminates human handling errors that so often happen with manually pipetting hundreds of samples,” says Hannes Rößer, handling technology expert at Festo.

In the next steps, an EXCM-30 gantry with an EHPS electric gripper picks up the filled microtiter plate and places it in a heat sealer for sealing with a plastic film. Then it is on to the RT block, which triggers the conversion of the RNA, if present, into complementary DNA (cDNA).

Ultrafast fluorescent detection determines whether the cDNA sequence of the pathogen of interest is present in a sample.

With Festo’s PGVA pressure and vacuum generator on board, Fast MDx doesn’t require an external compressed air supply for pressure-over-liquid pipetting.

The PGVA only needs 24-volt power to produce pressure or vacuum of +/-0.5 bar.

Dubbed the “Magic Box” by another Festo life sciences customer, the PGVA integrates compressor, air preparation including filtering, reservoir and electronic pressure and vacuum control in a package measuring only 210x76x208-m.

The quiet 50-decibel pump generates pressure or vacuum with a fast, energy-efficient piezoelectric regulator that controls the flow of air, filtered to 0.001-micrometer purity.

www.festo.com

SKIN DEEP

Famed French perfume house using robotic palletizing and advanced track-and-trace technology to boost capacity and fight counterfeiting

Located at the heart of France’s famed ‘Cosmetics Valley’ near Chartres, Guerlain is a subsidiary of luxury goods house LVMH and one of the oldest perfume and cosmetics houses in Europe—its brands marked with the distinct bee motif symbolising how it has flourished by making products that are cherished all over the world for their ability to protect and preserve.

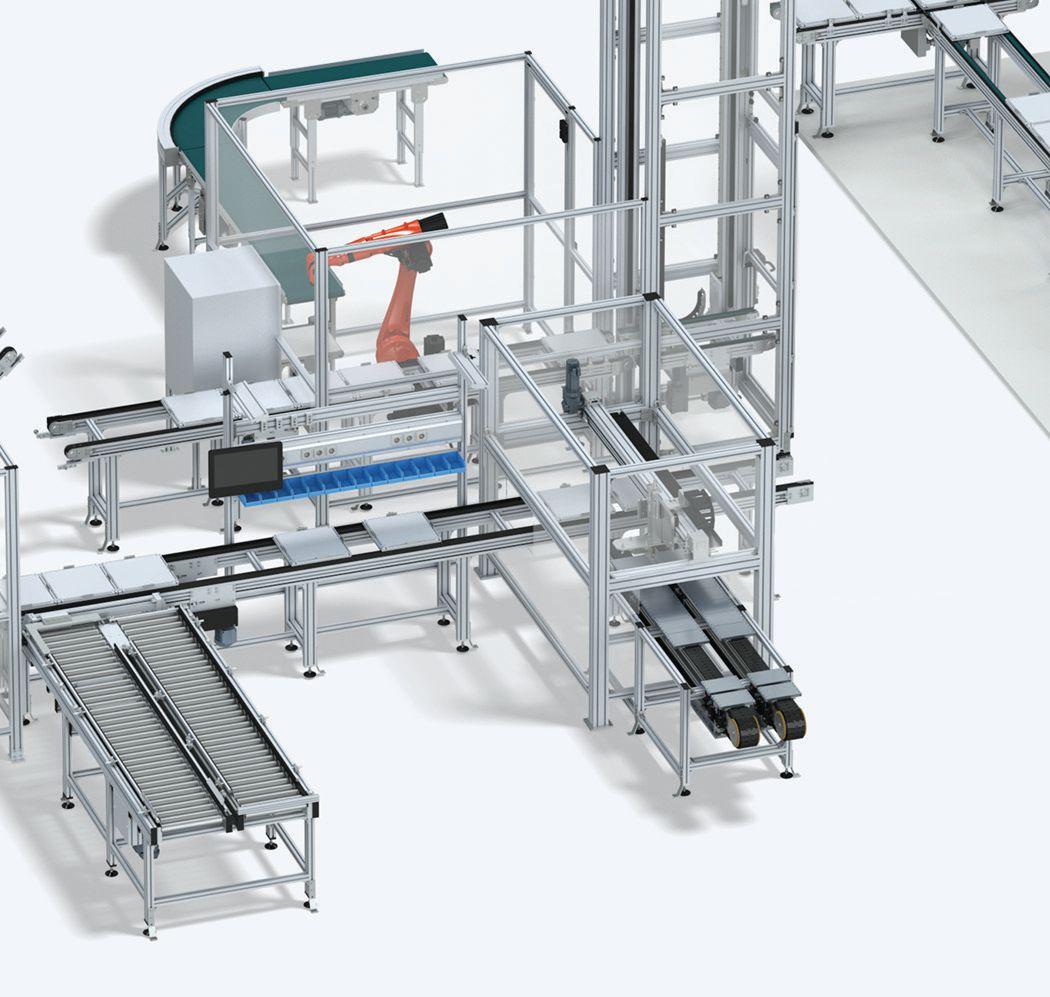

To help keep its product integrity safe from counterfeiters, and to increase it production capacity, Guerlain recently turned to renowned French packaging machinery manufacturer Sidel (www.sidel.com) for an effective long-term solution.

Headquartered in Octeville sur Mer, Sidel already enjoys a reputation within this world-renowned cluster, with many other luxury brands choosing its robotic case-packers, pal-

Aurélien Bernier, investment capacity project manager at Guerlain, stands in front of the highly automated end-of-line packaging workstations installed at the factory by leading French packaging machinery manufacturer Sidel.

letizer,s and combination solutions for the high levels of efficiency and product care that this exclusive industry demands.

The champagne and cognac industries have also selected Sidel technology for its traceability and aggregation capabilities, as has the pharmaceutical industry, which uses even more complex and stringent serialization and track-and-trace systems with real-time marking, tracking and aggregation.

“Sidel embedded every aspect of product labelling, control and rejection that we requested, and adapted the end-of-line process to suit our traceability needs,” says Aurélien Bernier, investment capacity project manager at Guerlain.

The robotic packing and palletising combi solution, designed by Sidel to function in a compact space of less than 20 square meters, manages the physical flow of products, cases and pallets.

It handles 60 cartons of skin-care products bottles per minute in four formats. Each carton, case and pallet is tagged using bar

codes and labels which are read, recorded and aggregated into the Guerlain central database.

This means that Guerlain, at any time, can guarantee the product origin and full characteristics by searching its central database; remove any counterfeit products that are not recorded; or identify any product distributed in the wrong marketplace.

Sidel’s end-of-line equipment is tasked to generate more than 4,000 information exchanges per pallet to control the full quality assurance process, while at the same time keeping a high level of machine availability and efficiency with error margins of less than one per cent per production order.

In this high value-added industry, product care and integrity is key. Hence the cartons are fully protected from infeed, batch collation and case-packing by adapted belt and guides fitted with a protective felt covering to ensure limited abrasion and friction.

“We were aware of Sidel’s reputation for high levels of trace-

ability and were very impressed by its ability to tailor and fine-tune the automation to our process needs and traceability requirements,” says Bernier.

“Sidel also had to adapt their machine automation and communication protocols into our IT and central database set-up:,”Bernier adds. “We can’t permit modifications because the same system is used throughout LVMH Group perfume and cosmetics facilities.”

All in all, Sidel has provided its luxury goods customer with a tailored automated solution, while at the same time as strengthening its quality processes.

Its agility and expertise has enabled Guerlain, with its long history of making hand-crafted beauty products, to retain the precision and adaptability of manual operation while moving to full automation.

www.sidel.com

Folding cartons packaged with Guerlain’s high-end skin-care products bing conveyed to the ernd-of-line packaging stations.

The highly automated Sidel end-of-line packaging station integrates a high-speed cartoner with a robotic palletizer.

A Guerlain plant worker scans the barcode applied to a finished carton of product to ensure full product traceability.

“ “

The Solution is Modular Systems

-

Ernst Blickle, Co-Founder

-

MASTERS IN MODULAR AUTOMATION SYSTEMS SINCE 1945

MOVI-C®

MODULAR AUTOMATION SYSTEMS FROM A SINGLE SOURCE

DOCUMENTS, PLEASE!

Digitalized plant data an integral part of Industry 4.0 transformation for all manufacturers

By Martin Dubovy

We are living in a time of perpetual change—a reality which is often mirrored in today’s industrial production environments.

Manufacturing processes are continually adapted and optimized, while products are increasingly being individually manufactured and personalized.

This is not new, because in the past production plants were also often in a state of perpetual change: failed components were replaced, software patches and updates were installed, process optimization programs were developed, and much more.

Nevertheless, this trend is gaining speed and processes are becoming more dynamic.

The so-called “as-built documentation,” meaning documentation that reflects the actual state of a new plant, has always been required for commissioning, but in fact the time and resources involved in preparing the relevant documents is always immense.

And controlling the delivered documents, to make sure they really do tally with plant reality, is always very time-consuming—thus quality control process is generally confined to some random checks.

Thus often enough, plant documentation does not even correspond to plant reality at the start, and even if it does correspond initially, the task of keeping the status of this documentation up to date is anything but trivial.

The bigger and more complex the plant, the greater this challenge appears. It may even sound a little schizophrenic to be talking about digital twins on the one hand, whereas in many places a daily struggle is still going on to master plant documentation with the aid of paper documents, Excel lists, and complex file structures.

However, this is exactly where Plant Documentation 4.0 can make a vital contribu-

Developed by Rösberg Engineering, ProDOK is the I&C-CAE system for the planning and operational support of process control equipment in process plants.

tion, especially if a system is also able to simplify the management of changes.

In sectors such as petrochemicals, chemicals, logistics, manufacturing, in power plants, plant construction or the pharmaceutical industry, production processes are generally complex, and plants often assume gigantic proportions.

Thus these sectors of industry have had to rely on digital documentation for a long time now to keep track of the as-built status of their plants and manage the relevant interrelated processes.

So it is not surprising that a company like Rösberg Engineering (www.roesberg. com) of Karlsruhe, Germany, already active in these sectors for decades, has developed digital solutions many years ago in order to keep an overview of the flood of information in these types of plants.

As Rösberg Engineering account manager for plan solutions Christian Stolz explains: “With our I&C-CAE system ProDOK we primarily document the planning and construction of plants.

“However, it is also important to know the current status and components built in during the operational phase. Our software tool helps with the administration and documentation of changes.

“A main focus of the tool is on simply find documentation updates and enabling the changes to be made available to everyone quickly and easily.”

When envisaging Plant Documentation 4.0 probably, the first aspect to be considered is the advantages for maintenance. Here, of course, it is extremely useful to know the current state of the plant and be able to easily document the changes.

“To do this, maintenance crews can simply enter the change on a tablet with a stylus, and it is saved together with the information about who made the change, when, and an explanation, if necessary,” says Stolz. “Workflows built into the system then ensure that the original documentation is reviewed regularly and thus stays clear and up-to-date.”

In addition to maintenance, many other areas benefit from digital documentation.These include troubleshooting, large-scale revisions, project-related documentation, loop checks and the management of assets, the integration of package units, and know-how transfer.

And when it comes to audits, it certainly pays off to have up-to-date, legally compliant documentation at hand at all times.

When something goes wrong, every minute counts. In a situation of this kind valuable time is lost if the current documentation status of the plant first has to be assembled.

In the worst case, inability to react fast enough may result in damage or danger to people and the environment. In large-scale revisions, too, time is usually tight.

Numerous employees need to be coordinated and very many changes made to the documentation simultaneously. This makes it all the more important to ensure that everyone involved in the process has access to the current documentation at all times.

Similarly, loop checks also involve the coordination of large numbers of employees and the structured execution of various tasks.

Digital documentation is also beneficial for effective asset management. For instance, when a manufacturer discontinues an asset, making it necessary to know how many of the relevant components are built into the plant and where;

Christian Stolz, Account Manager, Plant Solutions, RÖSBERG Engineering.

or when compiling an overview of components that will no longer receive support in the near future.

Only a company managing its assets effectively can keep production running reliably. Another aspect that necessitates digital documentation is the trend in the process industry towards integrating “package units,” meaning the distribution of large plants into smaller units.

This raises the question of how the documentation that is delivered together with a functional unit can most easily be transferred into the already-existing plant documentation. When engaging in extensive plant retrofit or extensions, or for inspection purposes, many project-related documents also have to be immediately available as and when required. If these documents only exist in paper form, or are only available from different sources and in assorted file formats, compiling them is effort-intensive and inefficient.

Another advantage of consistent digital documentation is that know-how can be preserved, because the knowledge no longer exists solely in the minds of experienced employees. This substantially facilitates knowledge transfer to new employees.

“In all these and many other use cases, LiveDOK has been proving its worth for decades now,” Stolz says.

“With digitalization the focus was on the PC, but with Industry 4.0 the focus is on the Internet. This also applies, so to speak, to Plant Documentation 4.0.

“We have been creating digital documentation for a long time now, but we have consistently developed our concepts further, for instance regarding Cloud enablement, in order

to stay with the pulse of the times.

“Thus our customers get a tried and tested product that uses today’s state-of-the-art technologies to fulfill the technical and legal requirements of tomorrow.”

In the use cases described above, the documentation tool enables documents to be found fast; provides a realistic overview of the components built into the plant, while helping to keep documentation up-to-date; ensures standardization in documentation in line with current legal requirements; gives all disciplines involved in a project access to the documentation without media discontinuity; and ensures that everyone in the team is working with the same documents.

Companies who wish to consistently implement Industry 4.0 cannot do so without digital, Cloud capable plant documentation, especially where large plants are concerned.

Nevertheless, many companies are still put off by the initial effort and expense of digitalizing their documentation at all in the first place.

Here the process automation experts can reassure them that numerous projects carried out in the past have shown that getting started is much easier than users generally fear.

“And not only that—very often digitalization opens up many optimization opportunities, so the effort pays off much faster than many people think,” says Stolz, www.roesberg.com speaking from his own experience. www.roesberg.com

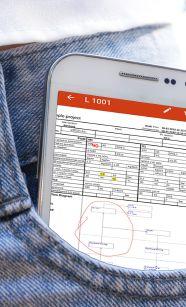

Top

Changes can be noted very simply, for example by a handwritten notice on a tablet

Below

LiveDOK makes distributed documentation of large-scale plants digitally available to engineers and plant operators, regardless of their format and medium.

MARTIN DUBOVY is head of plant solutions at Rösberg Engineering GmbH.

UP IN THE AIR

Warehouse drones being replaced by a more efficient, safer and cost-effective technology that fully embraces in computer vision-enabled cycle counting

By Jim McMahon

Few technologies have been as hyped for automated cycle counting in warehouses as drones, or unmanned aerial vehicles (UAVs), for inventory audits, cycle counting and stock finding. It has only been a little more than five years since the first commercially viable UAV drones were deployed in warehouses for inventory management.

Drones continue to intrigue large warehouse operations mostly because they promise to reduce manhours required for inventory cycle counting, and also because these flying robots are visually striking—allowing warehouse operators to showcase their forward-looking and innovative approaches for managing inventory.

All technology, however, is prone to close scrutiny, analysis and assessment.

Many of the warehouses that took the leap with drones are finding that these flying inventory trackers come with their own sets of challenges. As a result, many warehouses and distribution centers have moved on, and are eyeing more efficient, safer and cost-effective automation for their warehouse cycle counting.

A warehouse management system (WMS) is only as effective as the data it receives. Since stored inventory data can become out of date quickly, the

usefulness of a WMS diminishes unless the warehouse maintains a strong understanding of near real-time inventory location, quantities and condition of goods.

One of the most important KPIs (key performance indicators) for any warehouse is high inventory accuracy, and cycle counting is the most effective process for achieving this goal.

For most warehouses, however, cycle counting comes with a high cost, including excessive amounts of man-hours and the risk of employee injury during high-bay cycle counting.

Shutting down aisles or complete areas of warehouses to conduct cycle counting often interferes with picking and put-away processes.

Even with regimented manual cycle counting, warehouses are still unable to achieve acceptable levels of inventory accuracy, which in turn leads to reduction in picker productivity, lost inventory, missed shipments and a multitude of other costs.

In 2018, drones were first introduced to conduct automated cycle counting in the warehouse for full production environments.

Over the ensuing five years, drones have been deployed in a growing number of warehouses and have certainly demonstrated their capability to reduce the need for workers to perform cycle counting tasks.

One of the promises of employing drones for cycle counting is their capability for independent and autonomous operation, without the need for human intervention to conduct their missions.

While there is unquestionable value in the data generated by sensors and cameras mounted on drones, the reality of independent and autonomous operation has failed to materialize.

The notion that drones wake up on a pre-defined schedule during off-shift operations, take off, hover in the warehouse for hours, capture data, and return to the nest to recharge themselves—all in a completely autonomous manner—represents a skewed perspective of drone oper-

The StorTRACK system represents the latest evolution of computer vision-enabled cycle counting.

ations.

In reality, drone operations require consistent human monitoring. Similarly, fleet management software that enables multiple drones to fly autonomously, hover accurately and land precisely, is only possible with continuous human monitoring.

The factors that prevent truly 100 percent autonomous operations include safety risks—both for humans as well as warehouse assets—as well as technology shortcomings which limit operating efficiency.

Perhaps the number-one reason drones cannot operate entirely autonomously has to do with warehouse inventory conditions.

Even the best managed warehouses have unattended loose material like shrink wrap, packaging tape, corrugate or paper on their shelves and floors. If not removed, these items get sucked into the drone’s rotors, causing a risk to workers and damage to inventory and warehouse assets.

Drones entangled in shrink wrap crash into shelves or on to inventory and also pose a fire risk due to the battery on the drone. As a result, frequent and thorough floor and shelf inspections are essential prior to every single drone mission.

This not only requires labor, which dilutes the notion of a fully-autonomous solution, but it also eliminates the possibility of operating during off-shifts as desired by many warehouse managers.

Warehouse UAV’s batteries provide a maximum flight time of 30 minutes in the best-case scenario. Out-and-back to the launch pad for recharging gives about 12 to 15 minutes of time for actual cycle counting per mission. Warehouse workers need to be on-hand to ensure safe drone returns, change out batteries, and charge the depleted power sources.

Even with auto-charging, the limited battery life of these drones necessitates additional drones to cover large warehouses and expedite cycle count missions, increasing the

personnel needed to monitor them and the overall costs of the solution.

In an effort to keep drones light, there is a limited amount of equipment weight that can be supported. This is one of the reasons UAV batteries are so small, and the reason why they typically only include a single camera.

While a single camera limits the weight, it also reduces the drone’s field of view (FOV). The smaller the field of view the longer the time required to scan parts of the inventory and, as mentioned, drones have very short flight times due to battery limitations.

As a result, very little inventory can be covered in a single flight.

Should the UAV encounter a mis-operation event either because of programming or flight interference, employees, inventory and structures are at risk. This further enforces the necessity for manual supervision while the drone is in flight performing cycle counting.

Warehouse drones used for cycle counting are not an autonomous solution, and should technically be considered manually-assisted robots. These factors limit drones for application in a lights-out autonomous warehouse.

Concerns about drones for inventory cycle counting are not isolated to a few industry professionals. One of the first companies to introduce and scale indoor drones as a means of capturing images of warehouse inventory was Vimaan (www.vimaan.ai), a California-based privately held technology company.

“After five years of operational experience deploying drones for inventory cycle counting, scanning millions of items across Fortune 500-owned warehouses, both we and many of our customers understand that warehouse environments are not a good fit for drones,” says Vimaans’ chief executive officer and founder KG Ganapathi.

Vimaan exclusively developed drones to capture inventory information from racks that can be as high as 35 feet. The company has flown more missions and conducted more inventory location scans using drones than any other North American solution provider, making them very unique domain matter experts in the benefits and challenges of warehouse drone technol-

ogy.

“Drone technology for cycle counting really exists to reduce worker labor hours,” points out Ganapathi.

“It’s a great story, but factoring in their limitations, when you do the math it just doesn’t add up.

“Our approach and experience with cycle counting has allowed us to gain significant insight into the shortcomings of using drones in the warehouse,” says Ganapathi.

“Limited battery life, the inherent risk in having objects flying around warehouse workers, and drone flights preventing and delaying put-away and picking task execution, have now steered Vimaan completely away from supplying drones for inventory cycle counting.

There are now better alternaticdes to drones in the warehouse, which fully embrace the latest capabilities in computer vision-enabled cycle counting.

Simply extracting linear barcodes or QR codes by drones for cycle counting is just not good enough any longer.

A new paradigm in inventory management has considerably expanded the capability for information acquisition in cycle counting.

Computer vision-enabled inventory tracking revolutionizes cycle counting by capturing full images of goods on racks, providing information that goes far beyond barcode reading.

This automated cycle counting system includes full high resolution image reconstruction of the rack face, including barcode reading, label text reading, case dimensioning, empty bin reporting, damage detection, discrepancy reporting against the WMS, and location and inventory search features.

Developed by Vimaan over the past several years, computer vision-enabled cycle counting was first employed on the company’s line of warehouse drones.

“After five years of operational experience deploying drones for inventory cycle counting, scanning millions of items across Fortune 500-owned warehouses, both we and many of our customers understand that warehouse environments are not a good fit for drones.”

“Vimaan wanted to create a whole new dimension to inventory cycle counting,” continued Ganapathi.

“We wanted to record inventory information that is far beyond the barcode, like quantities, expiration dates, case serial numbers, labels and dimensions.

“This breadth of information capture is unique to Vimaan’s computer vision technology.”

“Warehouse managers have expressed that they would benefit from more contextual imagery that displays other goods found on a shared or nearby rack, or even on shared pallets,” explains Ganapathi. “So Vimaan developed a solution to make that possible.”

Images captured by the computer vision sensors are automatically uploaded to the facility’s WMS, available for near real-time analysis, as well as stored in photo archives for future and ongoing analysis.

These stitched-together inventory images are combined to provide the most complete views of racks, pallets and packages for analysis.

Users gain an environmental insight of neighboring assets, much like a Google street view of their warehouse.They can easily zoom, pan and scroll through stitched images to spot and resolve inventory and storage utilization issues.

When discrepancies and anomalies are quickly resolved, it supports a higher degree of inventory accuracy and control over their stored goods.

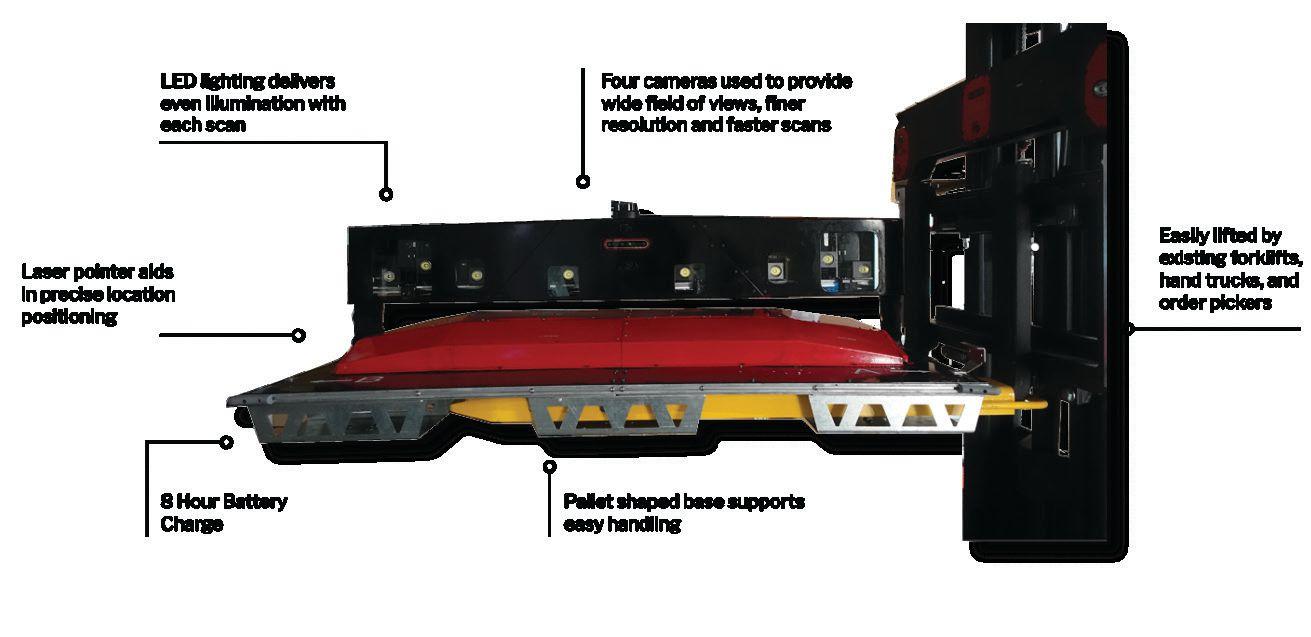

Replacing the drone, and supporting computer vision-enabled cycle counting, is a stand-alone hardware module, StorTRACK, that is lifted and maneuvered by any pre-existing material handling equipment in the warehouse, such as human-operated forklifts, automated-guided vehicles, AS/RS cranes, and pallet shuttles.

To enable a cycle count, the operator picks up the unit with the material handling equipment, just as he would a pallet, and then drives it to the appropriate aisle location with the guidance of an HMI tablet display to start the scanning mission.

The system is then raised by the material handling equipment and automatically begins scanning inventory from the floor to the highest storage bay, and every rack location between.

Inventory scanning happens as fast at the material handling equipment lifts and lowers the industrial strength vision system, and this process is repeated along each aisle.

The unit incorporates multiple smart cameras and integrated

lighting, enabling a field of view four times larger than a drone, which allows for more efficient and faster inventory scanning.

The system incorporates location and navigation capabilities with an integrated tablet HMI for intuitive, real-time guidance to the material handling equipment operator on exactly how to conduct the cycle count. The tablet also keeps track of finished and unfinished scanning tasks.

The StorTRACK is equipped with several computer vision-enabled cameras and integrated lighting that ensures even the most densely packed inventory is accurately scanned and read.

The system’s battery lasts up to eiught hours, which is 24 times longer than a typical drone, permitting the cycle-counting operator to function continuously from aisle to aisle for long periods of time, increasing labor efficiency.

The larger field of view and the increased battery life enable large sections of the warehouse to be cycle counted in a single mission. The system can scan one face of a 30-feet-high, 300-feet-long aisle in less than 60 minutes, compared to a drone that would take several hours.

The StorTRACK system is also future-proof. It can work with fully-automated forklifts and AGVs in a completely autonomous manner—without the risks and shortcomings of an autonomous drone.

Unacceptable inventory accuracy rates continue to plague the vast majority of warehouses that use manual methods to conduct inventory cycle counting.

Those warehouses that have employed drones have likely seen the benefits of cycle count automation, which has contributed to better accuracy rates, but at a cost of babysitting a fleet of buzzing robots that have their own sets of limitations.

While drones are not the silver bullet for cycle counting, they have introduced the potential that computer vision automation can offer warehouses.

Due to their inherent drawbacks, smart warehouse operators are looking past drones and investigating alternative cycle count automation methods, like those employing computer vision-enabled cycle counting with advanced scanning capabilities and weigh the cost/benefits options www.viamaan.ai. www.viamaan.ai

COME OUT AND PLAY

Company turns virtual reality environment into a marketplace for low-cost robotics and motion plastics

Alow-cost robot operated via a VR headset. Spare parts identified and ordered in seconds using AI on a smartphone. A mobile app that immediately identifies potential applications for lubrication-free parts on an excavator.

It’s all part of the igusverse—a virtual reality environment developed by leading motion plastics manufacturer igus (www.igus.com) to help customers provide access to the right plastic product in a fun, carbon-neutral and plastic waste-free way.

Launched at the recent 2023 Hannover Fair, the igusverse digital space drew plenty of traffic to the igus exhibition stand in Hall 17, where visitors would use VR glasses to control a robot arm in virtual reality, while a real-life robot next to them would mirror their exact movements.

In this digital space, engineers, material experts, and project planners can meet and build 3D models of new machines, systems and assemblies on a 1:1 scale.

No long boring meetings, expensive journeys and associated carbon emissions. Instead, the products are developed faster, sustainably, reliably and at a lower cost, while any problems can be ironed out at an early stage.

“The possibilities of virtual reality for mechanical engineering design are absolutely fascinating,” says igus chief executive officer Frank Blase. “We want to develop new solutions that even small companies with limited budgets can easily use.”

When igus opens up the igusverse in the future companies can benefit from this platform, which is fully managed by igus, with no development outlay with a new Cloud-based app igusGO.

The user takes a photo of a machine, an excavator for example, and artificial intelligence analyzes where lubrication-free parts from igus

igus chief executive officer Frank Blase as an avatar in the iguverse.

could be used cost-effectively.

The igus range of low-cost robotics, intended to promote automation in SMEs (small and medium enterprises), is also growing. For example, a new smaller cobot, ReBeL KID , has been available since May for only about $6,000, with optional voice control.

But that’s just a tip of the iceberg, as the company’s RBTX online marketplace showcases over 350 automation projects, all of which can be copied for similar applications. Ninety-eight percent of these complete solutions are already available, with prices ranging from $3,000 to $10,00

In addition to low-cost robotics, igus expands the range of smart plastics. These are standard parts, such as energy chains and plain bearings, which are equipped with sensors and integrated into IIoT networks. This allows SME’s to implement Industry 4.0 trends, such as condition monitoring and predictive maintenance. The smart plastics can be expanded with a new service called “superwise,” a digital product that links customers to the igus field service team.

Another completely new service is the igus-managed platform called kopla. Designed to allow companies create their own online expert systems and calculation tools, it is aimed specifically at medium-sized companies that operate internationally and would like to expand their product offerings online.

“The possibilities of virtual reality for mechanical engineering design are absolutely fascinating...We want to develop new solutions that even small companies with limited budgets can easily use.”

“Our own experience with the development and use of online tools, using a Cloud-based modular principle, is now available for others to use, massively reducing the implementation lead time compared with conventional software solutions,” says Blase.

While last few years had many challenges, igus has continued to grow.With over 188,000 customers, igus has around 5,000 employees at 31 locations globally, with annual sales exceeding €1billion (euros) for the first time in 2022.

Now the next goal has been set, with igus is aiming for one million active customers by 2030.

To get there, igus continues to invest in the development of motion plastics and in fast local logistics, with the aim of making all moving applications in the world maintenance-free and long-lasting.

Many online tools help engineers to calculate the life of igus products, giving a reliable and sustainable solution.

Says Blase: “No matter if an engineer needs a tiny bearing or the world’s largest plastic energy chain, the life can be calculated online.

“The new digital tools make motion plastics easy for everyone to access.”

All this new technology does not mean the environment is forgotten, with igus sharing a new solution for re-using factory energy.

Aiming to make its own production plant in Cologne, Germany, carbon-neutral by 2025, igus has developed a new system that uses the spent coolant water from the plant’s injection molding machines to heat the factory.

“This is not only good for the environment but also for the finances in times of rising energy costs,” says Blasé, which is why igus has decided to make this energy solution available to other industrial companies under the name MHRS (Machine Heat Recovery System).

“We searched for weeks for a solution and could not find one anywhere,” says Blasé. “So we built our own, and we want to share this with others.”

Also, igus has been improving the environmental balance of plastics for years, and one key area is recycling. This year, igus has expanded the popular Chainge recycling program. Since 2019, any disused energy chains have been collected and reprocessed by customers in exchange for credit vouchers. The Chainge online platform now covers all technical plastics, from polyamide to PEEK.

As Blase proclaims, “Our growth must be linked to the sustainable use of resources.

“The creativity and energy of my igus colleagues impresses and motivates me,” he concludes.

“The fact I work with these people makes me humble and excited about what the future holds.” www.igus.com