AUTOMATE NOW PLUS

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Brooke Shaw (519) 428-3471

bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

Anita Madden (416) 442-5600 x3596

AMadden@annexbusinessmedia.com

Scott Jaimeson

sjamieson@annexbusinessmedia.com

External Motor or Internal Roller Motor Options

Accumulation, Steady and Zoned Applications

Since

Running

Straight Running and Curve Conveyors

Light and Heavy Duty Applications

PASTA POINT OF RETURN

World’s largest pasta production plant a showcase for integrated robotics and sustainable distribution

By Jim McMahon

Founded in 1877, family-owned Barilla Group is the world’s leading pasta maker, with 45 per cent of the Italian pasta market and 35 per cent of the U.S. market. Based in Parma, Italy, the company produces pasta in more than 160 shapes and sizes, selling its products in over 100 countries.

In addition to pasta, Barilla owns 16 other food brands—making the company the leading manufacturer of sauces in Europe; bread in France; crisp-bread in Scandinavia and central Europe; and bakery products in Italy.

Barilla’s 29 production sites—15 in Italy and 14 worldwide – had annual 2019 sales exceeding US$4.3 billion.

Although steeped in history, Barilla has also been on the cutting edge of technology in recent years.

Embracing the connected food movement, the Italian pasta maker is using the Industrial Internet of Things (IIoT) and analytics to provide traceability in its supply chain and transparency to consumers.

Its field-to-fork initiative tracks all stages of Barilla›s food production—from local food harvesting to storage, processing, packaging,

Barilla’s flagship pasta production plant in Parma, Italy, is the world’s largest pasta products manufacturing site.

Parma

factory and distribution facility currently employs a fleet of 120 laser-guided vehicles for all of its product transfer needs, esentially eliminating the need for traditional conveyors.

distribution and, ultimately, consumption.

This supports initiatives of the U.S. Food and Drug Administration (FDA)’s Food Safety Modernization Act emphasizing food track and trace, quality and safety. Specifically worked with IT networking giant Barilla, in partnership with Cisco Systems, Inc. to created a prototype of a digital passport that takes the consumer on a journey—using a smartphone to scan a QR code on the back of a Barilla pasta box or tomato sauce jar—from where the specific product was grown to how it was processed and on to how it arrived at the store shelf.

An early adopter of sustainability practices, Barilla is constantly working on this means improving the efficiency of its production processes to reduce greenhouse gas (GHG) emissions, energy usage and water consumption.

Supplied by automation experts E80, the LGVs used at the Parma plant incorporate innovative rooler-bed design to ensure efficient and safe roll-on/roll-off procedures.

Today, 68 per cent of electricity used in Barilla plants comes from renewable sources. Since 2010, Barilla facilities have reduced water consumption by 21 per cent and GHG emissions by 30 per cent.

Beyond manufacturing, promoting more sustainable agricultural and farming practices for all Barilla companies’ strategic supply chains is a critical focus of its sustainability initiatives, with more than 3,000 farming companies worldwide are involved in various sustainable agriculture projects with Barilla.

The company utilizes only recyclable packaging materials from responsibly managed forests, and continually minimizes the quantity of packaging and distribution materials used, with 93-per cent Barilla’s production volumes are manufactured in ISO 14001 certified production plants meeting global standards for ef -

fectiveeffective environmental management system.

In 2018, Barilla announced its plans to invest about $1.3 billion over five years in modernizing its industrial assets to boost sustainability—by improving processes and technologies—and support innovation and geographic expansion.

A pivotal focus of this plan was transforming the distribution operations of its flagship pasta production facility in Parma into a showcase of Industry 4.0 operation of integrated robotic processes and energy sustainability.

Initially starting as a bakery shop 143 years ago, the Parma the location has remained the center of Barilla’s corporate headquarters since, as well as home to the company’s largest pasta production and distribution facility.

Claimed to be the largest pasta manufacturing operation in the

Barilla’s

pasta

world, the plant houses in a newly upgraded distribution facility, state-of-the art robotics, machine-to-machine communication, and IIoT networking—all integrated for optimized automation and streamlined throughput.

The distribution facility is not only an example of excellence in integrated robotics systems, but also for energy and environmental efficiency.

“The implementation of highly-automated flexible systems enables us to be absolutely suitable to the needs and the uses of the distribution facility, and this obviously implies a lower energy consumption,” says Parma plant director Alessandro Spadini.

“This is accented by the adoption of components that are significantly more efficient in terms of energy consumption and environmental impact, compared to our past systems,” he says.

“An essential part of this distribution project is having considered an overall and systemic integration of the project and not just single, discrete systems.

“Any distribution system that is not sufficiently flexible, that is based on a rigid scheme, will sooner or later become an issue,” Spadini points out. “The solution in trying to separate the various distribution processes —like high-density storage, transport of pallets, palletizing, stretchwrapping, and staging pallets at loading docks for shipping—comes from these processes ideally having flexible, adaptable solutions.”

As Spadini asserts, “The throughput flows and peaks that arise from just-in-time ordering and market shifts can only be managed optimally with distribution flexible solutions.”

To realize such an integrated-system and energy-efficient strategy at the Barilla’s Parma distribution facility, leading Italian automation systems integrator E80 Group (E80) was selected to design, manufacture and install a solution.

Specializing in creating automated solutions for companies that produce fast-moving consumer goods, particularly in the food, beverage and tissue sectors, E80 (www.e80group.com) has been a leading manufacturer of integrated-robotics systems for distribution facilities for almost three decades, with special expertise in laser-guided vehicles (LGVs), robotic palletizers and other end-of-line robotic systems. Having started developing the planning and distribution model simulations for the Parma facility in 2013, and continued with upgrades and expansions through to 2020.

Today, Barilla’s Parma distribution facility handles approximately 1,000 different packaged SKUs (stock-keeping units) within its product line, divided into dry and fresh product categories.

The 430,000-square-foot distribution facility is a fully automated, lights-out, 24/7/365 operation, equipped with 120 LGVs and 35 robotic systems working like clockwork with high-density AS/ RS, palletizers, labelers and stretchwrappers. Combined, these systems handled over 438,000 tonnes of pasta in 2019.

“Keeping production going at the world’s largest pasta plant, while creating a complete distribution renovation, was a considerable challenge,” says E80 vice-president Vittorio Cavirani.

“It was achieved thanks to the great synergy and cooperation between Barilla and E80,” he says, “but also because the integrated robotic systems are flexible and adaptable as changing throughput

The electric-powered LGVs used at the Parma facility use the proprietary Flash Battery lithium technology that ensures minimal recharging downtime and maintenance requirements.

and needs have required.»

Adds Spadini: “One of the main reasons that made us decide to move forward with this renovation for Parma’s distribution was the desire to get away from conveyors and adopt LGVs for pallet transport within the facility.

“Traditional conveying systems are sized for production peaks, and not flexible enough to manage variations in throughput, in terms of both flows and volume,” he reasons. “ Therefore, pallet conveyor systems are typically highly inefficient.”

The 120 LGV systems supplied by E80 to the Parma plant fall into three types: those that carry a single pallet; those that carry two pallets at a time; and LGVs that carry four pallets at a time.

In operation, the LGVs interact with floor-positioned pallets and AS/RS induction stations, and picking up and dropping off pallets between receiving from manufacturing, palletizing, stretch wrapping, labeling, finished-goods warehousing, and staging locations for shipping.

The LGVs have roller beds that support the pallets, which allow efficient roll-on/roll-off procedure.

“An increasing number of manufacturers require 24-hour operation at continuous throughput,” says E80 president Enrico Grassi. “Parma’s LGVs have been designed to efficiently meet and exceed these requirements.

“The most recent automation developments in LGVs for pallet movement enable warehouse operators and plant production supervisors to optimize for system flexibility, modularity and scalability.”

The LGV’s laser navigation is based on target triangulation to keep the vehicles on course. Each LGV is equipped with a rotating laser which scans 360° around the vehicle for laser targets mounted on columns, walls and stationary machinery.

The reflections from these targets are measured relative to angles from the vehicle, and triangulated to allow the vehicle to determine its position.

This position is then compared to a CAD (computer-aided design)-type map stored in the LGV’s memory, whereby the system uses positive-positioning feedback in real time—computing algorithms hundreds of times per second.

With the steering is adjusted accordingly to keep the LGVs on track, it can then navigate to a desired target using the constantly updating position.

Even though this laser navigation can obtain tracking accuracy of about 0.39-inch, the Parma plant is currently reviewing the possibility of implementing vision navigation onto the LGVs, which uses cameras or lidars on-board the LGV to detect each vehicle’s surroundings and understand its position.

Introduced for use with LGVs by E80, the lithium Flash Battery technology—developed by Flash Battery Srl—provides a higher level of performance than other batteries for industrial vehicles.

The Flash Battery technology uses the latest in lithium iron phosphate (LiFePO4) chemistry to ensure low toxicity, well-defined performance and long-term stability. Having a very constant discharge voltage, Flash Battery technology allows the battery to deliver virtually full power until it is dis -

charged.

“Supporting the performance of Barilla’s fleet of LGVs and its Flash Battery technology, E80’s Flash Data Center continually monitors and controls every battery of Barilla’s integrated system to ensure the LGV network maintains its battery potential in peak performance to maintain plant uptime and efficiency,” Cavirani explains.

“The control electronics in the lithium Flash Battery keep it balanced and efficient, eliminating the need for regular maintenance,” Cavirani says, pointing out that the LGVs only require a single lithium Flash Battery each, compared to two batteries needed with traditional lead-acid LGV applications. Keeping all the LGVs running throughout the building at all times naturally requires state-of-the-art control technology, which is provided with E80’s SM.I.LE80 (Smart Integrated Logistics) controls platform.

“Controls systems are fundamental for managing traffic inside Parma’s distribution facility,” Grassi states. “It is fundamental because these [LGVs]are mobile robots, and what enables them to be efficient is the SM.I.LE80 controls system, which makes sure that these robots are in the right place at the right time.”

As Grassi explains, SM.I.LE80 continually updates the positional status of each LGV regarding such factors as whether it is loaded or unloaded, emergency stopped or soft stopped, operating in manual mode, and battery level.

A simulation module simulates the LGVs in the system, while the graphical HMI (human-machine interface) gives the operator a graphical overview of the LGV locations in the system and monitors each in real-time.

According to Grassi, the SM.I.LE80 controls ensure the integrated and automated management of all systems by communicating with AS/RS, palletizers, wrappers and shipping staging locations.

“Operational flexibility is a key factor,” Grassi states, “not just in its capability to direct and manage the fleet of LGVs, but also in its expandability.

“We can have any number of automated guided vehicles can

Robotic stretchwrapping in full swing at the end-of-line packaging area of the Barello pasta plant in Parma.

be added to the network at any time the facility’s production and distribution needs require.”

Designed to Parma plant’s production needs and seamlessly integrated with its LGV technology, the high-density warehouse uses E80’s AS/RS Crane Store systems of stacker cranes equipped with automatic product handling devices for double-depth storage.

Comprising six stacker cranes to support 47,000 pallet locations, the cranes can operate at heights of up to 130 feet—dramatically increase warehousing capacity—with minimal energy usage and maintenance requirements. An additional 50,000 pallet locations are utilized for LGV drive-in highdensity low-bay storage.

One of the more striking features about the Parma warehousing operation is the absence of any wood pallets.

“Removing wood pallets was an innovative choice, at least for Barilla, and it came from an overall vision of an integrated vision of our supply chain,” Spadini explains. “First of all, removing wood from production and many distribution areas means removing an element that may pollute the environment where we produce and package our products.

“But also, managing pallets without wood parts opens up the opportunity of handling and reprocessing of pallets in a completely automated way—improving efficiency and minimizing environmental impact.”

Eliminating wood pallets is only part of the unique palletizing process at Parma, where robotic palletizing stations form cases in palletized configurations directly on the palletizers› platform, which are then moved onto LGVs and transported to other end-of-line process stations in the facility where, a pallet is inserted underneath prior to storage and shipping.

As Grassi relates, E80 designed and manufactured an automated pallet management system for controlling the large volume of pallets within a small footprint, while also ensuring that only pallets complying with Barilla’s requirements are used in storage and shipping.

As with the other systems at play in Parma’s distribution operations, its end-of-line stretch wrapping and labeling are also fully robotized and integrated with its LGVs and other robotic processes, whereby the high-speed stretchwrappers employ automatic wrapping head changeovers—eliminating the need to stop production.

“We can manage not only very accurately the use of our stretch wrap film, but we have also reduced film usage by almost 30 per cent, compared to our previous stretchwrappers,” Spadini notes.

For their part, the robotized labelers are equipped with anthropomorphic robots that allow the application of labels on multiple sides and levels—ensuring optimal production flexibility.

The applicator arm is equipped with a camera to check the correct application of labels and the barcode readability, while using two printers make it possible to double the operating range and carry out reel changeovers without any production downtime.

Parma’s control and identification of each case of products throughout the distribution facility is also managed by the SM.I.LE80 controls system.

Once cases and pallets leave the facility, the labeled identification provides a tracking mechanism

A long row of robotic palletizing workcells perform the unique pallet-less load stacking and layering around-the-clock without the use of any traditional wooded pallets.

for complete track-and-trace through the supply chain.

“For Barilla, traceability means providing the right information, correct information and timely information on all our products—from the moment we received the lots of raw materials to the moment we actually distribute and display our products on the shelves,” Spadini states. “For us, full traceability is one of the main elements to ensure and guarantee our consumers the right to nutritionally safe products and also controlled products.”

Says Spadini: “The Parma operation is a very large, and a very important production and distribution plant for Barilla in terms of efficiency and effectiveness.

“The key to maintaining its ongoing performance is the 24/7 Cloud-based predictive maintenance, which is monitored remotely by E80,” he adds.

“But underlying all this is a strong cooperation and a trusting partnership between Barilla and E80,” Spadini concludes, “which has enabled us to reach a high level of management of the plant and achieve our postulated goals.”

www.e80group.com

MUTUAL BENEFITS

A long-time partnership with leading automation supplier enables casepacking machinery manufacturer to keep building on its marketplace success

By Andrew Snook

Operating for over 60 years out of Hamilton, Ont., Edson Packaging Machinery (www.edson.com) is a vital strategic asset in the vast brand portfolio of its parent company ProMach (www.promachbuilt.com), which nowadays owns over 40 different brands of packaging equipment manufacturers.

What makes Edson unique to packaging sector OEMs is that the company specializes in packaging for the tissue and non-woven industries, with between 85 to 90 per cent of its machines designed for high-speed secondary packaging of tissue and non-woven products.

“We are basically the only brand focused solely on the tissue and nonwoven industries,” says Josh Goulet, account manager for Edson Packaging Machinery.

“No matter what kind of rolled paper products you’re using at home, whether its kitchen towels or bath tissue, it was most likely packaged on an Edson case-packer,” Goulet says.

While Edson has worked with various suppliers over the years to build

Edson Packaging Machinery’s controls supervisor Mike Fluit standing in front of the high-performance new case-packing machine assembled at the company’s manufacturing facility in Hamilton in partnership with automation experts at Festo Inc.

AUTOMATE NOW PLUS

its machines, one of its longest relationships has been with Festo Inc. (www.festo. com), which provides automation technologies and technical educational solutions out of its headquarters in Mississauga, Ont.

According to Goulet, the two companies have worked together on multiple projects since 1999.

“When it comes to controls on our equipment, our preferred provider is Festo,” Goulet says. “Edson and Festo have been collaborating together for over 20 years now.”

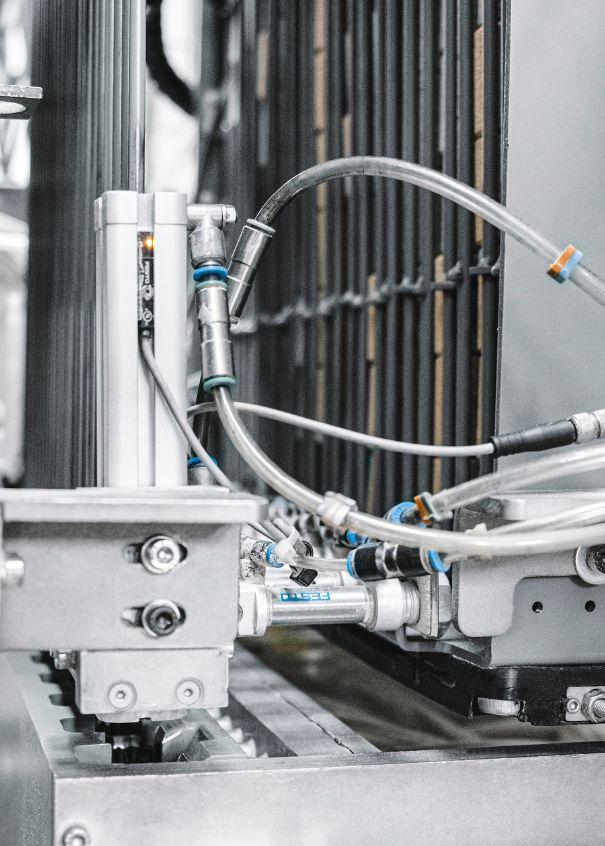

The latest project between Edson and Festo was a solution for Edson’s new model 3600HS High Speed Large Case and Tray Packer.

The high-performance machine unit is designed for working with many types of KDF (Knock Down Flat) cases, which it erects as it collates the product, fills the cases, seals them, and discharges the finished boxed product downstream.

“The original KDF magazine loader used pneumatic technology to pick-andplace the unopened box into the case-packer, and this is where one customer was experiencing a bottleneck due to downtimes and reliability,” explains Nicolas Fleuriot, industry segment specialist for food and packaging at Festo Canada.

“The customer’s need was to increase the reliability and throughput of the machine by using better, more modern technologies and by speeding up the pick-and-place operation—thereby eliminating the bottleneck.”

As Fleuriot relates, Festo’s Customer Solutions (CS) engineering team used its cutting-edge Handling Guide Online

(HGO) software to simulate the customer application and confirm that the desired cycle time was achievable.

The CS team then customized the standard HGO solution so that it was a perfect fit for the customer, Fleuriot explains.

The end-result is a complete, fully assembled, and ready to install Festo twin 2D gantry using the Festo EGC tooth-belt as Y-axis and the EGSL electric ball screw as Z-axis.

The innovative solution increased the

(Right top)

Front end of the KDF (knock-down flat) magazine section of the new Edson case-packer.

(Left botttom)

Twin System

Gantry sized using Festo’s cutting edge HGO (Handling Guide Online) software where each KDF carton is being handled.

(Above right)

Close-up of the Festo vertical axis EGSL (upright) sliding sideways along the Festo EGC horizontal axis.

reliability of the process and improved the performance of the 3600HS High Speed Large Case and Tray Packer by 50 per cent over the original system.

According to Edson’s controls supervisor Mike Fluit, using Festo’s ready-to-install solution benefited Edson by freeing up time and resources to concentrate on its core business.

In addition, Festo provided total process reliability at every stage, including consultation and design, quotations and orders, engineering, production, assembly, testing documentation and global after-sale support.

“We have some retrofits going on in the field right now, which makes it very easy to remove the old design and place a new design in its place,” adds Fluit. “It’s very convenient.”

The 3600HS High Speed Large Case and Tray Packer begins its process with the stacks of KDF boxes being loaded onto a conveyor and moved individually into the opener.

“The opener portion takes the KDFs, erects them into a case, moves them in front of the packing station, and is then shipped out of the machine,” Fluit explains.

Once a stack of KDFs has been loaded onto a conveyor, the rollers advance that stack onto a scissor lift-table, where a servo elevates the table into a position within the Aux Mag station, where the Festo gantry unit can begin picking up the KDFs.

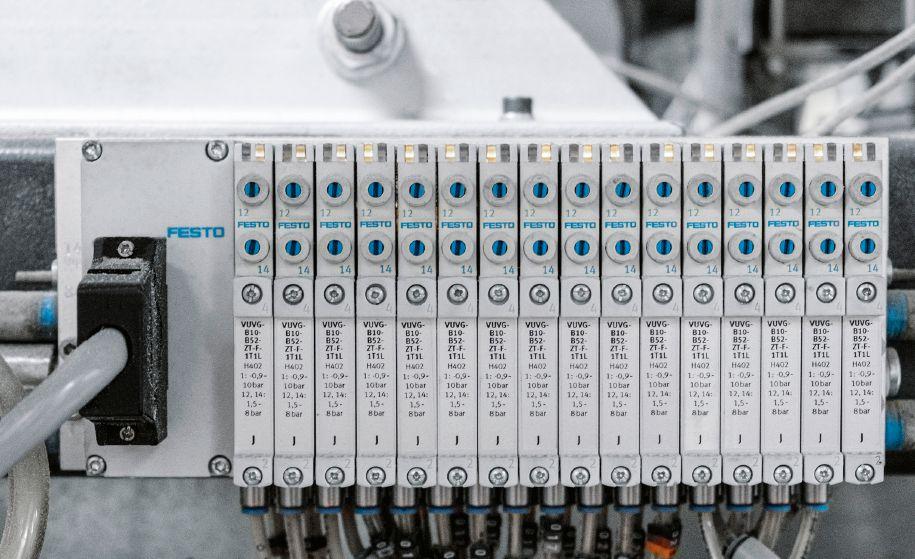

“The gantry unit was developed jointly with Festo and Edson to improve reliability and the speed of the machine,” Fluit says, adding that one of the most significant units from Festo on the machine is the Festo valve bank.

(Clockwise from top)

A row of grey-colored Festo control enclosures and a terminal valve block positioned at the top of the case-packer’s KDF box forming section ; erected KDF cartons moving to the front of the packing station; close-up of conveyor rollers delivering a stack of KDF cartons to the case-packer; A Festo rotary cylinders used to close the flap at the packing station; a touchscreen HMI (human-machine interface) terminal ensure user-friendly operation and programming.

“We are basically the only brand focused solely on the tissue and nonwoven industries.”

(Clockwise from top)

A Festo VTSA valve terminal; Nordson’s PROblue Lierty 14 hoit-melt adhesive applicator supplying glue for the carton sealing section; close-up of a pick-and-place vacuum gripper; close-up of one of the Festo cylinders deployed at each station of the new Edson case-packing machine; a close-up of the CPX remote I/O master.

“We use it to control all the cylinders on the machine, and it also provides us with remote I/O capabilities,” says Fluit, adding that Festo components play critical roles in every aspect of the machine.

“Each unit has its own custom valve bank, with a remote I/O block that allows us to connect most of the electrical sensors and pneumatics,” Fluit says.

“This new design allows us much greater travel without losing any speed.

“It will actually pick up the case, move it forward over the belts, and then drop it onto the belts,” he says. “We no longer need pinch rollers, reducing jams in this area.”

The Festo cylinders are deployed at each station of the 3600HS High Speed Large Case and Tray Packer.

“At the case-eject station, linear cylinders eject individual cases,” Fluit explains.

“At the forming station, the Festo valve creates a vacuum that is used to pull the case open, while at the packing station, a Festo rotary cylinder is used to close the flap,” he continues.

“On the next station, on the other side, there’s another Festo rotary cylinder, and on the compression section we have two linear cylinders that are used to compress the case to attach the glue.”

As Fluit relates, Edson was “thrilled” with this new solution for its 3600HS High Speed Large Case and Tray Packer, with Festo also delighted to be part of its long-time client’s success.

(From left) Edson Packaging Machinery account manager Josh Goulet and Festo’s industry segment specialist for food and packaging Nicolas Fleuriot.

“For me, we have a very healthy relationship, a very open relationship with Festo,” Fluit says.

“As we continue to develop new concepts and equipment over the next several years, it’s great to know we can count on our partner Festo,” adds Goulet. “With our equipment and Festo’s components, the future looks bright.”

Adds Festo’s Fleuriot: “To be part of Edson’s success, to be able to contribute to the performance of their machines, and to be on-board partners with them on their machines is indeed very satisfying.” www.edson.com wwww.promachbuilt.com wwww.festo.com

INCH BY INCH

Larger tubular drag conveyors helping food processors increase profitability and bolume

By Del Williams

Food processors and packagers have long sought a safer, more energy-efficient means to convey bulk product. Although tubular drag conveyors have long offered these desired attributes compared to belt, bucket or pneumatic systems, many in the industry still selected the more traditional options to move higher volumes or larger-sized products.

Now, however, the new-generation eight-inch-diameter tubular drag conveyors have essentially doubled the throughput volumes of their smaller six-inch predecessors—provides comparable volumes and pricing to conventional industrial systems, while enables the transport of much larger product sizes than previously possible.

Tubular drag cable conveyors gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop, along with circular discs (flights) attached to the cable, to push which push the product through the tube without the use of air. These conveyors excel in transporting delicate, precise blends for a wide variety of food types in versatile layouts and configurations.

Today, food processing and packaging professionals are increasingly turning to the higher-volume tubular drag cable conveyors to improve power use, safety, product preservation, product quality and production uptime, according to Bob Owen, director of product performance at Cablevey Conveyors (www.cablevey.com), a mechanical conveyor manufacturer that serves the specialty food, coffee, nut, powder, produce and pet food markets.

According to Owen, the eight-inch tubular drag cable conveyors can move up to 2,000 cubic feet and 80,000 pounds per hour, depending on the bulk density of the transferred materials.

The new generation of eight-inch-diameter tubular drag conveyors allow processors of bulk food product a very cost-effective means of safe product transfer with remarkably low energy requirements to operate them.

“The units can transport product as large as whole potatoes and mid-sized grapefruit, and are increasingly used to convey pet food, cereal, nuts, and whole fruit,” says Cablevey Conveyors engineering manager Clint Hudson.

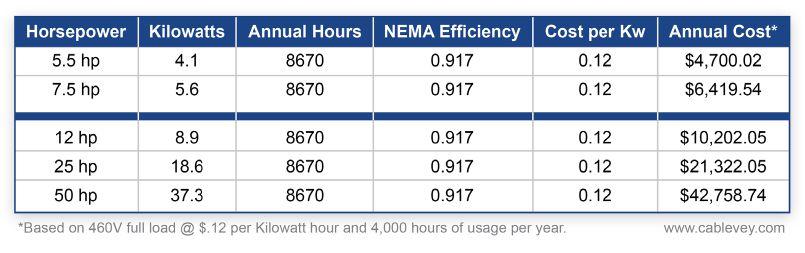

As energy prices continue to rise, food packagers are paying more attention to reducing the power required to convey materials.

Within plants, the motors needed to convey large volumes of food materials can vary greatly in power consumption.

At the high end are pneumatic conveyors that utilize air to move product at high velocity through an enclosed line by creating air pressure above or below the atmospheric level.

High-volume pneumatic conveyors generally require larger, power-hungry motors—up to 20 to 50 HP or more—that run fans, blowers, and rotary valves.

At the mid-range of power consumption are belt conveyors and bucket elevators.

In a typical conveyor belt system, a belt forms a closed loop and stretches across two or more pulleys with a drive pulley that enables it to rotate continually.

Bucket elevators move material using buckets attached to a rotating belt or chain. The buckets pick up material, move it to an endpoint, discharge material, and return to the starting point to pick up a new load.

To convey a similar, high-volume amount of material, belt conveyors and bucket elevators would typically utilize approximately 20-HP motors, says Owen.

At the low end of power consumption are eight-inch tubular drag cable conveyors, which would usually use a 7.5-HP motor to move a comparable, amount of material.

“The drag cable pulls the solid circular discs

The eight-inch tubular drag conveyors can enable food processors to move up to 80,000 pounds of product per hour, depending on product density, while handling an extended range of individual product shapes and sizes.

(flights) attached to the cable at low speed through a loop, which requires less energy than conventional methods,” says Owen. “The ample size and number of the discs on eight-inch units enable conveying a similar amount of material as traditional belt, bucket or pneumatic units.”

Open systems such as bucket elevators and belt conveyors are common in the food industry, but they have substantial drawbacks in terms of the potential for contamination.

With either type of system, any product that is left uncovered can potentially expose it to contaminants and moisture in the surrounding environment. Open systems also allow product spillage onto the plant floor, which can present a slip and fall hazard if not promptly addressed.

Unlike open systems, closed systems like tubular drag cable conveyors and pneumatic units effectively seal off product from the outside environment and any potential contamination from that source.

The enclosed nature of the systems ensures no dust escapes, which could lead to an unsanitary and potentially dangerous coating of dust on the floor or process equipment. The result is a safer, cleaner, dust-free work environment and reduced risk of dust explosions if the product is in powdered form.

The enclosed systems also eliminate the inherent risk of slip and fall incidents due to product discharge onto the processing area floor.

Enclosed conveyors prevent the product loss intrinsic to open systems such as belt or bucket utilizing units. Once food product is in the enclosed tube, it cannot fall out, and no powdered product is lost in the form of escaped dust.

Preventing product loss can offer considerable benefits to the food processor’s profitability, with surprisingly quick ROI (return-on-investment) in some cases.

In the example of one well-known global pet-food manufacturer, the company’s existing bucket elevator was found to be allowing excessive product loss due to spillage.

“When the pet food manufacturer switched to an eight-inch tubular drag cable conveyor, they minimized product spillage and reported a one-year ROI for the system,” says Owen.

For product that is delicate or presents a higher value in undamaged form, preserving product integrity is important. However, the rough mechanical action of scooping/dumping product from buckets can cause incidental damage—lowering value. So can the high-velocity conveyance of pneumatic systems through vertical/horizontal tubing, turns, and sweeps, which can batter product during the process.

In contrast, tubular cable conveyors offer a gentler alternative. When the systems move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop, the solid circular discs attached to the cable push the product at low speed through the tube without the use of air—preserving product integrity and minimizing waste.

“After one well-known cereal manufacturer turned to a high-volume tubular cable conveyor, it was able to reduce product damage,” says Owen, adding that the premium for processing high-value products whole and unblemished can be even greater for some products like nuts.

“One food processor that used almonds in its recipe was only able to sell its product for 40 cents a pound if the almonds were damaged,” he relates. “ The same product sold for $4 a pound if the

almonds were whole and undamaged,” says Owen, noting the processor quickly chose to use a tubular cable conveyor to minimize product damage and optimize the sales price.

To reduce production downtime, food processors also increasingly expect conveyor systems to be designed for easy cleaning and maintenance. In this regard, bucket elevators are particularly difficult to clean in preparation for production line changeovers.

To clean them, each bucket must be time consumingly removed and cleaned inside and out to remove accumulated residue. Belt conveyors are usually cleaned with scrapers, but this can still leave product residue that must be removed with a more thorough method.

If not cleaned properly, the food product conveyed must be discarded due to contamination, which equates to lost profit. Even worse, any harm to consumers would result in costly recalls, damage to brand and reputation, or even potential litigation and liability.

With closed conveyors, cleaning is also a mixed bag. Pneumatic conveyors can still be relatively time-consuming to clean and sanitize if any manual procedures are involved. With regard to maintaining cleanliness, tubular drag cable conveyor systems generally offer more options for dry and wet tube conveyor cleaning. These include brush boxes, urethane wipers, air knives, inline sponges, inline bristle brushes, and multi-step, essentially automated Clean-In-Place (CIP) wet cleaning.

“Using more automated forms of cleaning like inline wipers, sponges, and air knives or CIP wet cleaning can result in hours of additional production uptime after every product change, compared to conventional manual methods,” says Owen.

Food processors and packagers are generally more familiar with traditional belt, bucket, or pneumatic systems than with tubular drag cable conveyor systems. Previously, they selected these familiar systems when higher capacity was required.

Today, however, eight-inch tubular drag cable units can basically match the high-volume output of the traditional systems but with significant advantages in power consumption, safety, product preservation/quality, and production uptime.

Del Williams is a technical writer based in Torrance, Ca.

www.cablevey.com

PUT A CORK IN IT!

Automation is the ultimate space-saver

in shipping wine corks

Corks are so light they float, but when shipped in bulk to wineries around the world, they tend to be big space-takers. In order to save energy and CO₂ emissions during transport, Portugal’s ESI (Engenharia, Soluções e Inovação) has developed a system for packaging corks that reduces packaging volume by 30 per cent, while also elimnating the need for plastic bagging.

Traditionally, sealing wines with oak corks creates a leak-proof barrier while still allowing the wine to “breathe” a little, allowing for just enough ambient air can permeate the cork for the wine to mature but not spoil.

However, the usual way of shipping corks—packing them in plastic bags and stacking them on pallets—is as inefficient as it is outdates, with the inherent instability of cork-filled bags often complicates logistics and even damage some of the product.

Using Festo’s technology, Portuguese cork producer ESI has been able to develop an innovative automated system for loading bottle corks for export in neat rows inside corrugated shipping cartons, freeing up about 30 per cent of the space in shipping containers that the same loads would occupy when the corks were packaged loose inside plastic bags.

To address this issue, ESI developed an innovative robotic system for packaging corks in an orderly, space-saving manner in cartons.—reducing the overall volume required for transporting the product by 30 per cent compared to the traditional bag.

“This means a big reduction in logistics costs,” says ESI commercial director Gil Sousa, “which has a direct impact on the final cost of the product and significantly reduces the environmental footprint of transport.”

Says Sousa: “This solution underlines the cork processors’ commitment to environmentally sustainable processes,” adds Sousa.

The patented SI’s patented solution consists of an autonomous cell and palletizing system, with an articulated robot and pneumatic components from leading German automation devices and domponents manufacturer Festo Group. (www.festo.com)

Since the production environment is filled with small cork dust particles, the selected components had to have high abrasive resistance.

Festo’s compact DSNU round cylinders are rugged enough for this dusty environment, and ideal for compressing the corks while they are sucked in by the vacuum cups and placed in the carton.

The 20 cylinders are controlled by a VTUG valve terminal. Despite its compact dimesnions, this small valve terminal is noted for its short reaction times, high flow rates and excellent energy efficiency.

Says Sousa: “Our partnership with Festo has existed since we were founded in 2007.

“Festo has alwasys given us valuable technical support in the selection of components, while providing us with the rsources for testing and helping us validate our concepts,” Sousa states.

“Festo components and solutions have helped us to create many innovative solutions that have enabled our customers to increase their productivity and competitiveness.”

www.festo.com

JUST LIKE US

Man, machine, or both?

Humanoid robots are no longer just science fiction. They are reality.

Leading German motion plastics manufacturer igus (www.igus.com) has been researching humanoid robotics for some time now and presented a prototype of its motion plastics ‘bot’ at Hannover Messe 2022 earlier this year.

The igus motion plastics bot is a humanoid robot that combines the advantages of high-performance plastics and low-cost automation. Robots have become an integral part of our everyday lives. Since the transition to Industry 4.0, more and more tasks are being automated. As a result, the industry is seeing new forms of robotics emerging.

But robots can also make things easier in our daily routines. A humanoid that is both functional and friendly and has human features can support humans not as a machine but as a partner.

There has been steady progress in humanoid robotics research and development.

For example, a research team at the Chemnitz University of Technology is developing an e-skin material—a touch-sensitive electronic skin that could make humanoid robots even more human-like.

Driven by the question of the direction into which robotics can develop, igus has spent some

time working on its own vision of a humanoid robot—the motion plastics bot.

“With the igus ReBeL and our drytech range, working components were already available to enable a robot to move,” explains Alexander Mühlens, head of the Automation Technology and Robotics business unit at igus.

“The humanoid robot is a project we worked on with the robotics experts from TruPhysics, a Stuttgart-based startup who assembled the intelligent humanoid from our motion plastics and other components.

“It is available there under the name Robert M3,” says Mühlens. “We hope the bot will demonstrate the interplay between integrated intelligence and our products made of high-performance plastics—at an affordable price.”

For a long, trouble-free service life without maintenance, the igus tribo-polymers in the motion plastics bot offer a clear advantage: no lubricants needed.

At the same time, high-performance plastics allow a lightweight design. They reduce the motion plastics bot’s weight to just 78 kilograms at heights up to 2.70 meters, and a span of 1.5 meters.

The motion plastics bot features a self-propelled AGV (automated guided vehicle), a telescopic body, and a head with an integrated screen and avatar for interactive communication.

Another central component is the igus ReBeL—a service robot with cobot capabilities that is used as the bot’s arms.

Humanoid robots opening up a whole new world of possibilities as true companions

The fully integrated tribo strain wave gear with motor, absolute-value encoder, force control system, and controller make up the core of the ReBeL. The motion plastics bot moves at a walking pace and has a load capacity of two kilograms per arm. It is controlled as an open-source solution via the Robot Operating System (ROS) software.

This is because the entire igus Low Cost Automation product range can be mapped in the ROS.

By studying the motion plastics bot, igus is combining the advantages of their high-performance plastics for movement and their ‘Low Cost Automation’ expertise to further advance the development of the next generation of robots.

“We see a lot of potential in humanoid robots,” says Mühlens, “but our world is built by people for people.“So instead of just using individual automation parts, it makes sense to study humanoids and androids.

The question is when the market will be ready.”

Human-like robots can perform dangerous as well as simple and monotonous tasks. In a professional environment, work can go beyond the mere pick-and-place performed by robot arms.

In the household sector, a bot can replace several robots. It could vacuum autonomously, mow the lawn, go shopping, cook, do laundry and perform all sorts of other tasks—even caring for the sick. It would be not just a machine but a companion that could provide people relief for a long time.

“Such a robot has so far been associated with high costs, but if you take into account the possible service life, it would pay off in the long term,” says Mühlens.

“It is our goal to use motion plastics components to demonstrate simple, cost-effective solutions for humanoid robotics.”

www.igus.com

BETTER SOLUTIONS

Conveyor manufacturer leverages knack for innovation with design flexibility to provide a solution for every transfer challenge

Located in Bloomfield, Conn., mk North America (www. mknorthamerica.com) has been supplying the North American market with product transfer conveyors and t-slot aluminum extrusion solutions since 1988.

Operating on the customer-focused philosophy aptly captured by the company’s motto of “Better Products, Better Solutions,” mk’s flair for innovation has enabled many of its products to become a common sight at packaging lines all over the continent.

In the last couple of years, however, the company’s recently-launched VersaFlex line of flexible flat top chain conveyors has become

operational

allows users to customize them for

The VersaFlex flat-top chain product conveyors from mk North America are designed for optimal

flexibility that

their specific product applications, accommodating a broad range of product shapes and sizes.

a new benchmark for the company’s design and manufacturing prowess.

Since being introduced in 2019, the VersaFlex line has been subject to nearly constant product expansions and additions; including two wider width units unveiled in 2021, as well as a small pallet-handling line in 2021.

Additionally, VersaFlex is slated to also release a new pallet-handling line later this year.

So how exactly is VersaFlex and how is it revolutionizing the packaging industry?

According to mk North America, VersaFlex is more than just a flat-top chain conveyor. It’s a highly flexible line that allows you to easy convey product in three-dimensional space.

Products as small as 15-mm-wide or as large as 300-mm-wide can now be safely and easily moved horizontally, vertically, and around corners with one conveyor.

Need to do more than that? The VersaFlex may still be the conveyor system for you. With wedgestyle conveyors you can print or inspect the bottom of packages or product.

Do you need a storage solution? Alpine conveyors from VersaFlex can do that too.

And while it isn’t standard practice to convey packages on pallets, it is totally acceptable to convey packages, especially boxes, directly on pallet style conveyors, using diverts and merges to allow for various packaging lines to come together on a single conveyor.

VersaFlex conveyors can handle nearly anything: from tea bags to boxes of tea bags; from single bottles to shrinkwrapped multi-packs of bottles.

Snack boxes, medicine and prescription bottles, large boxes, pop-up display boxes, plastic jugs and

so much more—the list just goes on and on. Chances are good that if you have a packaged product, it can be conveyed from point to point using VersaFlex conveyors.

The VersaFlex flat-top chain conveyors also excel in conveying product in tight spaces, over long or short distances. And they can be fitted with rollers allowing for streamlined transfers between conveyors.

It’s easy to see how VersaFlex is a better conveyor solution for many applications, but it’s also a better total system solution.

The VersaFlex conveyors can provide solutions for a myriad of pain points a factory may be experiencing, and it can help free up your labor force to tend to more urgent tasks, while significantly increasing production speeds and accuracy.

But mk’s solutions are more just a conveyor to solve a problem: the company’s mk will work with you from concept through completion and beyond.

According to the company, “Our team members take the time to listen and understand your product and process before suggesting the best conveyors for unique applications.

“And if for whatever reason VersaFlex isn’t the appropriate conveyor for your particular situation then mk has more than 30 other conveyor types to offer.”

And the VersaFlex conveyor solutions and products are still growing—so stay tuned for even more exciting news to come later this year.

www.mknorthamerica.com

Empty bottles being swiftly and safely transferred towards a filling station in a single file on top of a VersaFlex flat-top chain conveyor.

The flexible VersaFlex range of product transfer conveyors facilitate swift and gentle product movement horizontally, vertically and around the corners with just one conveyor.

BEATING THE COLD

Eliminating forklift brake performance inconsistency in cold room environments

By Mathieu Ruault

While cold rooms are essential for storing products in the food and beverage industry, the very conditions that allow preservation present a very real challenge to power transmission equipment. As any motorist will know, brakes can be particularly susceptible to performance drop-off in cold or moist conditions.

To ensure that forklift truck brakes can operate reliably in cold-room environments, experts at the clutches and brakes manufacturer Warner Electric (www.warnerelectric.com) have developed custom brake friction material that provides consistent performance despite extreme temperature variance and the effects of moisture. Positioned in line with the motor or between the motor and the gearbox, spring applied electromagnetic motor brakes are utilised on forklift trucks to provide service and parking braking.

To ensure that forklift truck brakes can operate reliably in cold room environments, Warner Electric has developed custom brake friction material that provides consistent performance despite extreme temperature variance and the effects of moisture.

It’s a fact that many OEMs (original erquipment manufacturers) typically require specialized braking systems for forklifts operating in the food and beverage industry, due to the multiple application challenges of operating in cold rooms.

Brakes must provide consistent performance in all condi tions. However, moving in and out of cold rooms into differ ent environments around the facility demands consistent brake performance across a wide temperature range.To present a further challenge, this variance in temper atures can cause condensation to build up on brakes, which can lead to another phenomenon: sticking.

Sticking happens when moisture causes stan dard friction materials to bond with the counter-friction surface when the forklift is parked. Consequently, the brake and motor are locked in place, stopping the truck and causing downtime while maintenance is arranged.

With tight contract delivery schedules for supermarkets, suppliers and other vendors to be met, having a forklift truck out of action for any period is undesirable in the food and beverage industry.

To help improve uptime for end users, Warner Electric, a global manufacturer of electromagnetic braking solutions for forklift trucks, addressed these multiple environmental challenges with a new material solution.

A leading brand of Altra Industrial Motion Corp. (www.altramotion.com) Warner Elec tric has developed proprietary friction material specifically designed for cold room and outdoor en vironments with high moisture levels and wide temper ature differentials. Developed and tested in-house, the new material retains stable torque characteristics for static parking and high energy stopping in tough cold and wet en vironments. Moreover, it is specialized to combat the ‘sticking’ phenomenon.

To prove the performance of the new material, rigorous testing was

A popular selection for forklift trucks, power dense PK brakes are available with an enclosed design, ideal for applications where the brake may be exposed to moisture.

carried out. A climate chamber was used to simulate the extreme temperature changes of moving in and out of the cold room. The results were then compared with cold environment tests in the field, ensuring the material would perform in the real-world. Engineers also conducted endurance testing. Both the lab and field test results confirmed that there was virtually no sticking—not even a tenth of a Nm of drag torque.

The new material is currently available on all Warner Electric PK motor brakes in different configurations depending on customer requirement. A popular selection for forklift trucks, power dense PK brakes are available with an enclosed design, ideal for applications where the brake may be exposed to moisture.

With the global cold storage market expected to be worth US$212 billion by 2025, forklift operators in the sector need reliable brakes to improve uptime and unlock new efficiencies, so that they can capitalize on the strong market growth. The development of PK motor brakes is bold move in that direction.

Mathieu Ruault is vice-president of sales and market development at the ECB Division of Altra IndusCorp.

www.arnerrelectric.com www.altramotion.com