AutomationDirect has added more Hammond enclosure options to its lineup of enclosures and accessories. The brand makes NEMA rated products that carry industry-recognized approvals from a ISO9002:2015 certified facility. The additions include more wall-mount enclosure sizes, miniature cases in various sizes and colour choices, sanitary pushbutton enclosures, NEMA 1 rated wire troughs, and new rack or desktop-mount instrument enclosures. Accessories include drip shield kits, extender rings, and pulls/handles.

AutomationDirect

www.automationdirect.com

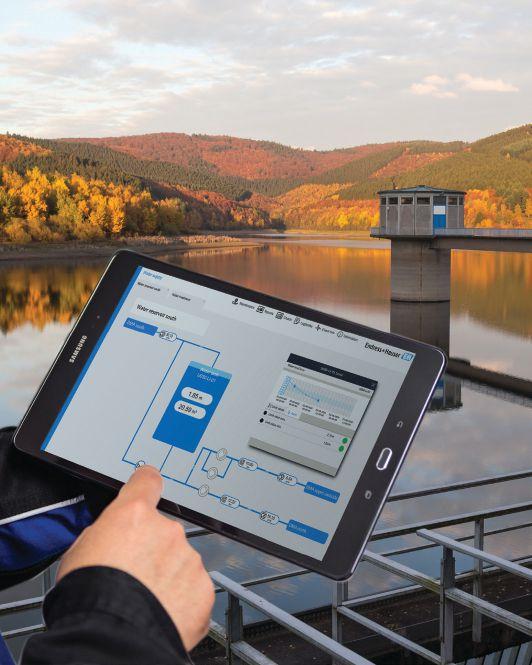

SYSTEM PERMITS WATER NETWORKS TO BE MONITORED AND OPTIMIZED REMOTELY

The Productivity Master platform from Festo is designed to show how digital manufacturing can offer customers individualized products created by a fully automated process, from order placement to delivery. The platform is said to seamlessly connect all handling hardware and software to create a digitalized production line that can be monitored by anyone from anywhere but is otherwise hands off from the vendor’s perspective. It requires no human interaction with the customer and only such intervention as is necessary to maintain the system. All components, axis mechanics and software are planned as a complete system. Festo www.festo.ca

Scadalliance's range of sensors and specialized data loggers/controllers allow for the creation of flexible solutions for flow measurement in open channels, flumes, or weirs. From simple local stand-alone flowmeters and data loggers to communicating systems, the company says, solutions can be adapted to most configurations and needs: entrance/exit of wastewater treatment plants; sewer or rainwater networks; storm overflows; watercourses, rivers, irrigation channels; industrial effluents; caustic and corrosive flows. Benefits include a choice of level and velocity measurement sensors, non-contact, submerged or hybrid, and a choice of data loggers and controllers, for local or telemetry operation. Solutions can also be easily integrated into existing control and SCADA systems, it adds.

Scadalliance https://scadalliance.com

Endress+Hauser has introduced Netilion Water Network Insights (NWNI), a system said to provide water and wastewater operators with all the critical data from their operations, from any location, any time of day and on any screen — a control room monitor, or a laptop, tablet, or smart phone. The transparency created can generate operational improvements, the company says, even important cost savings. NWNI interfaces with all levels of a water system wherever they are, offering utilities and process water monitors tailor-made solutions from a single source. These include everything from real-time monitoring of all field devices, providing components for data recording, transferring and archiving to performing data evaluation and one-of-a-kind forecasting functions. From their screen of choice, users can view all measurement data, be it water volume, pressure, level or chemical quality parameters. In case of failures or if limit values are exceeded, an alarm is sent automatically via email or SMS to a smart device or the control room.

Endress+Hauser Canada

www.ca.endress.com

Order your cut-to-length and bulk cables today and save with AutomationDirect’s affordable pricing - No gimmicks. No hidden charges

LUTZE SILFLEX® Control CableStarting at $0.22/ft (Q8105-1)

NEW Rugged industrial LUTZE SILFLEX® control cable is ideal for stationary and exible applications with limited mechanical stress and free movement without any tensile stress, loads or forced movements. Available in sizes from 20 AWG to 10 AWG with 3 to 41 unshielded or shielded conductors.

More Type J & K Thermocouple Extension WireStarting at $0.23/ft (Type J)

We just added more selection of Type J and K thermocouple extension wires. These wires allow connection of multiple eld sensors to instrumentation or PLC input cards with one run eliminating the need to install multiple extension wires. New additions include shielded and unshielded 20AWG & 16AWG sizes.

Cut-to-Length Cables with NO Hidden Fees

Don’t be fooled by suppliers that add cutting charges, hidden fees, and in ated shipping costs that end up tripling the cost at checkout.

At AutomationDirect, we’ve got you covered with these advantages:

• UL certified re-spooling facility - ensures that our cut-to-length cables maintain the UL certifications

• Low price per foot - Starting at $0.20 (PLTC3-20-1S-1)

• Low minimum cut lengths

• Free, fast shipping (typically 2-day delivery)*

• Easy online, phone or email ordering

• 30-day money-back guarantee* (yes, even custom cut cable)

Types of cables available:

• Flexible Portable Cord

• RS-485 & RS-422/RS-232

Data Cables

• Flexible Control

• VNTC Tray

• Power Machine Tray

• 600V Control

• Variable Frequency Drive (VFD)

• Servo Motor

• VFD / Servo Cable with Signal Pair

• DLO, RHH, RHW-2 Heavy-Duty Flexible Power

• Large Gauge MTW/THHW

• Instrumentation

• Continuous Flexing Control

• High Flex Continuous Flexing Control

• Tray rated Continuous Flexing Control

• Continuous Flexing Motor Supply

• Continuous Flexing Industrial Ethernet

• Cat5e Industrial Ethernet

• Continuous Flexing Profinet

• Continuous Flexing Profibus

• Sensor/Actuator

• Control and Signal

• Continuous Flexing Control and Signal

• Thermocouple & RTD Extension

Orders over

AutomationDirect has a large selection of quality MTW, THHN and TFFN electrical wire in pre-spooled lengths that meets all NFPA and NEC requirements at great prices.

MTW Machine Tool Wire - Starts at $23.75/500ft (MTW22BK)

• Available in sizes up to 20AWG and various color options

• Available in 500 or 2,500 ft. reels

TFFN Fixture Wire - Starts at $48.25/500ft (TFFN16BK)

• Available in sizes up to 18AWG and various color options

• Available in 500 or 2,500 ft. reels

THHN General Purpose Building Wire - Starts at $110.25/500ft (THHN14YL)

• Available in sizes up to 14AWG and various color options

• Available in 500 or 2,500 ft. reels

Bulk or Cut to Length shipped fast!

Research, price, buy at: www.automationdirect.com/multi-conductor-cable www.automationdirect.com/wire

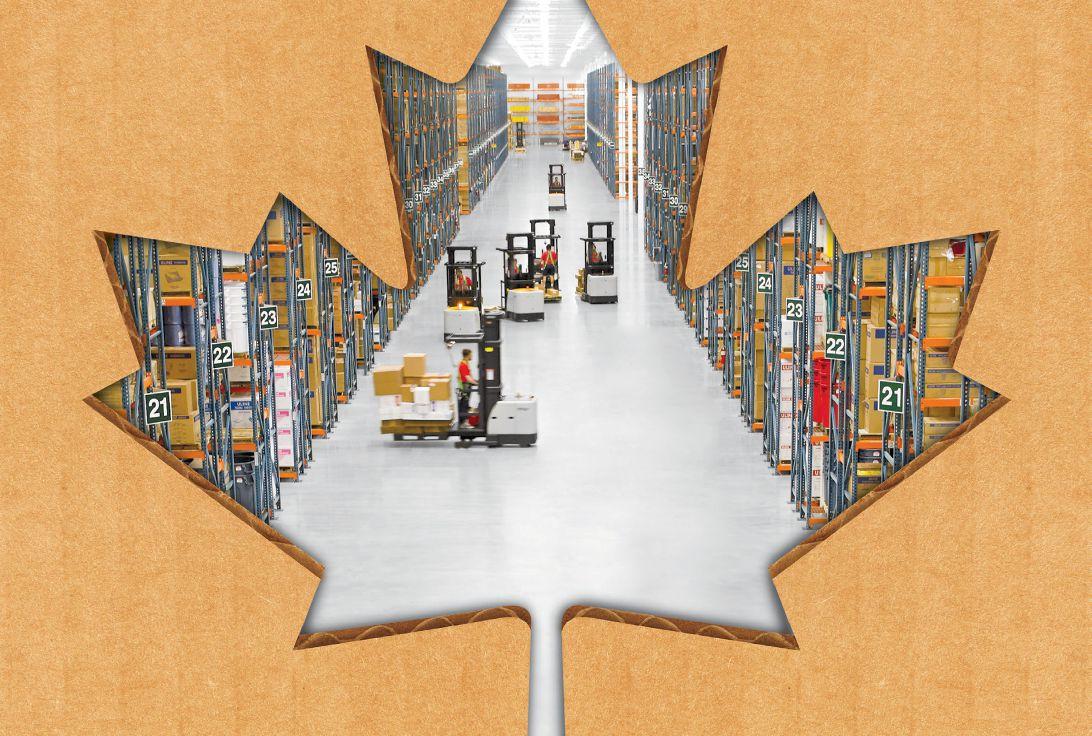

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees. See Web site for details and restrictions at: www.automationdirect.com/canada

The Syntron brand of iris valves from Lorenz Conveying Products are used to control the flow of powders, granules, flakes, or crystals in a wide range of production equipment like hoppers, bins, dryers, blenders, bulk bag unloaders and vertical pipelines. The iris valves are designed to permit free flow of materials without binding or seizing of the valve and without damaging product. The FV series iris valves operate by rotating the control handle through a 180° arc to vary the size of the orifice from

closed to fully open. To lock the valve in a selected position, turn the control handle clockwise and tighten. SFV/DFV iris valves have single sleeves and trigger-type handles that lock in multiple precise orifice settings for rapid and frequent opening and closing. When handling abrasive, fine, or dusty materials, adapter spools and wear sleeves may be required to effectively manage wear and tear plus dust control.

Lorenz Conveying Products www.syntronirisvalves.com

Antaira Technologies has expanded its wireless communication portfolio with the introduction of the ARS-7235-5E-AC dual-band 802.11a/b/g/n/ac WLAN access point with added router capabilities and five gigabit Ethernet ports. Available from Davis Controls, the product is designed to address the high-throughput requirements of dense industrial applications and supports a net data rate of up to 867 Mbp with 2x2 MIMO communication. It is embedded with the Qualcomm IPQ4029 SoC chipset so it can concurrently operate on both the 2.4 or 5 GHz bands, plus is backwards-compatible with 802.11a/b/g/n deployments to maximize existing wireless investments. Five gigabit Ethernet ports enable connectivity to laptops, PCs and other wired devices. Davis Controls www.daviscontrols.com

The wireless AquaMaster4 Mobile Comms flowmeter from ABB is for continuous flow measurement, the logging of accurate data and communication of information for water management. With its connectivity on 4G-LTE and NB-IoT networks, the company says, the electromagnetic flowmeter enables 60 percent lower power consumption, identifying leaks ten times faster than the market standard. Said to be the world’s first electromagnetic flowmeter with bidirectional connectivity, units provide near-real time data. Operators can be hundreds of miles away and read values from the device remotely, giving them access to manage the device and their operations wherever they are located and at any time. Historical logged values of pressure, flowrate, alarms, battery life, and activity record can also be retrieved remotely. The enhanced flowmeter is also unique in its ability to identify lowflow nighttime leaks that would otherwise be undetected. ABB

http://ca.abb.com

The quest for minerals to fuel the raw materials required in electric vehicles is going full bore in Canada and globally. This means the investment in mining resources has to continue apace.

According to MIT News, researchers at MIT have found that the cost of Lithium-ion batteries has dropped by 97 percent since they were first commercially introduced in 1991. This rate of improvement is much faster than many analysts had claimed and is comparable to that of solar photovoltaic panels,

which some had considered to be an exceptional case, according to a report published in the journal Energy and Environmental Science

In addition to helping to boost the ongoing electrification of transportation, the report says, further declines in lithium-ion battery costs could potentially also increase the batteries’ usage in stationary applications as a way of compensating for the intermittent supply of clean energy sources such as solar and wind. It adds both applications could play a significant role in help-

ing to curb the world’s emissions of climate-altering greenhouse gases. With such an appetite for Lithium and other minerals found in rechargeable batteries, cost reductions are clearly being offset by shear volume. And, says report co-author and MIT associate professor Jessika Trancik, the new study can play an important role in energy-related policymaking. However, "there’s a real need to treat the data with care," she says. Mike Edwards medwards@cpecn.com

April Focus on... Plant Communications Supplement: Bulk Powders & Solids

Editorial closing date: March 4

June Focus on... Maintenance & Safety Supplement: Pumps, Seals & Piping

Editorial closing date: April 29

August Focus on... Environment Supplement: Motors & Drives

Editorial closing date: July 8

October Focus on... Fluids Handling Supplement: Data Acquisition

Editorial closing date: September 4 CONTACT:

The Basic Filler from Flexicon for bulk boxes, totes, bins, or other intermediate bulk containers (IBCs) loads bulk solid materials free of dust. The unit’s fill head can be raised or lowered using a forklift and secured with clevis pins to minimize the clearance between the rectangular dust hood and the opening of IBCs ranging from 48 to 78 in. tall. A fill head port can be vented to a filter sock to contain displaced dust, or to a central bag house that causes a clear flexible skirt to vacuum-seal against the container’s exterior. A vibratory deck can densify and stabilize the material during filling, and/or load cells that signal a PLC when to stop the flow of material by stopping a conveyor or closing a rotary valve or slide gate once a programmed weight is gained. Rated for loads up to 6500 lb, the frame is offered in carbon steel with stainless steel material contact surfaces, or in all-stainless construction to sanitary standards. Flexicon Corporation

www.flexicon.com

Engineers at municipal water or wastewater facilities and industrial plants will find the new OIW80 sensor from Electro-Chemical Devices (ECD) is said to help them quickly, accurately, and economically detect oil in water leak incidents requiring fast response actions to prevent further contamination of drinking water, fouling of batch processes, damage to plant equipment and/or contamination of sensitive water ecosystems. The sensor is designed to reliably measure oil in water over a range of 0 to 30 ppm (mg/L), and it can be factory preconfigured to measure oil in multiple ranges or easily set in the field. The sensor operates over a temperature range from 5° to 45°C to detect leaks and alert plant technicians. The device features a builtin wiper cleaning system to remove bio solids and films that might cloud the sensor window’s visibility. The sensor features a built-in automatic screen window wiper that reduces technician manual checks and the frequency of scheduled maintenance.

Electro-Chemical Devices

www.ecdi.com

Compatible with automated systems employing PLCs or DAQs require sensors to control and monitor unattended processes,

Gigahertz-Optik’s PLCD series detectors with internal amplifier can be set-up for common radiometric and photometric measurements like illuminance (lux) or UV-C irradiance (W/m²). The sensor outputs current (0 to 20 mA or 4 to 20 mA) over ten scalable gain range options. The standard detector with built-in amplifier housing is 37 mm diameter x 25 mm high including cosine diffuser. OEM versions in custom design housings, optical filtering, and input optic to fit a particular application are available.

Giga-Hertz Optik

www.gigahertz-optik.com

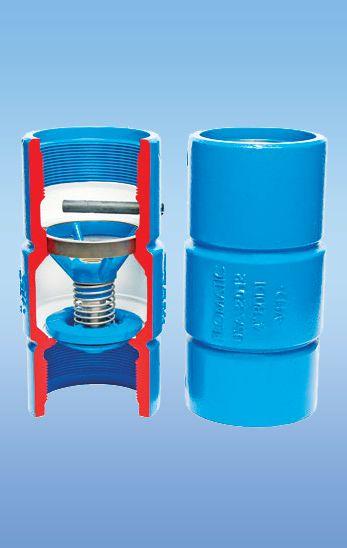

NSF 61 & 372 Certified

The NS Series ball valves are available in sizes 1/4”-6” with threaded, socket weld, butt weld (3-piece) and flanged (2-piece) connections.

The NS Series butterfly valves cover 2”-24” sizes in wafer and lug style.

APPLICATIONS

• Water Treatment

• Potable Water Service

• Reverse Osmosis

• Desalination

For Canadian industrial process facilities, membrane filtration is a valuable, commonly used means of filtering water and wastewater. The challenge is that membrane systems are delicate and can be easily damaged by large particulates in the water. A pre-filtration step eliminates this risk by removing oversized suspended solids to prevent damage, eliminate unnecessary maintenance, and reduce the cost of premature membrane replacement.

Among the pre-filtering options available, automatic self-cleaning scraper strainers are increasingly popular among Canadian processors because they are affordable, require very minimal maintenance or attention, and can remove solids down to 75 microns. The strainers allow for continuous, uninterrupted flows even during blowdown cycles. When compared to filters that must be manually cleaned or even conventional backwash systems, automatic scraper strainers can save substantial costs on maintenance and membrane replacement.

Although various filtration methods use membranes, the most mature is pressure driven membrane filtration, which relies on a liquid being forced through a filter membrane with a large surface area. Depending on the size and type of the particles involved, the process could be categorized as reverse osmosis, nanofiltration, ultrafiltration, or microfiltration.

In general, reverse osmosis is used to produce potable water or deionized water. Nanofiltration is used in wastewater treatment as well as by the petrochemical industry to purify gas condensates, and the chemical industry for solvent recovery. Ultrafiltration and microfiltration are increasingly used in water and wastewater treatments.

Numerous Canadian industries have high water usage that can require further treatment of water, including automotive, aerospace, oil & gas extraction, refining, textiles, and pulp & paper mills. Ultrapure water, which must meet strict limits of certain constituents in the water such as suspended and dissolved solids, dissolved gases, organic carbon, and biological organisms, is utilized in electronics and pharmaceutical manufacturing processes.

In industrial applications, water treatment is also vital to protect downstream equipment from fouling, scaling, corrosion, and other forms of damage or premature wear due to contaminants present in the source water. For these reasons, cooling tower and boiler feed water are generally pre-treated.

Membrane filtration is also utilized to treat non-potable water sources such as gray water and reclaimed/recycled “purple pipe” water.

Because the membranes are made using thin, porous sheets of material, failing to sufficiently pre-filter any large, suspended particles from the water can cause severe damage and fouling –leading to premature replacement and unnecessary maintenance, according to Robert Presser, VP of Acme Engineering Prod., Inc., a Montreal-based manufac-

turer of industrial self-cleaning strainers.

“Most membrane filter manufacturers recommend that all influents be pre-screened from 100 to 500 microns to maintain membrane filter efficiency,” says Presser, whose company is an ISO 9001:2015 certified manufacturer of environmental controls and systems with integrated mechanical, electrical and electronic capabilities.

He adds that automatic scraper strainers are typically installed before the intake plenum of membrane filters, after the supply pumps.

As an alternative to sand filters, centrifugal separators, and basket type strainers, automatic scraper strainers provide superior membrane protection while drastically reducing required maintenance.

Automatic scraper strainers like those from Acme Engineering can provide continuous removal of suspended solids to comprehensively protect membrane systems. The automatic units are motorized and designed to continually remove suspended particulates in industrial process water and wastewater to the specific size required down to .003 inches (75 µ).

Conventional manual strainers can become clogged quickly due to limitations in straining area. When that occurs, cleaning or media replacement is required, which increases maintenance costs. The other alternative for fine straining is automated backwash-style strainers of various designs. As particle sizes grow larger, however, large contaminants can jam up the backwash system or remain in the body of the strainer, requiring manual removal and interruption of the process flow.

With the automatic scraper strainer, cleaning is accomplished by a spring-loaded blade and brush system, managed by a fully automatic control system. Four scraper brushes rotate at 8 RPM, resulting in a cleaning rate of 32 strokes per minute. The scraper brushes get into the wedge-wire slots and dislodge resistant particulates and solids. This approach enables the scraper strainers to resist clogging and fouling when faced with large solids and high solids concentration. It ensures a complete cleaning and is very effective against even organic matter “biofouling.”

With this type of system, manual maintenance for cleaning is eliminated. Blowdown occurs only at the end of the intermittent scraping cycle when a valve is opened for a few seconds to remove solids from the collector area. Liquid loss is well below 1% of total flow. With so much to gain, Canadian industrial plant managers should consider selecting an automated, self-cleaning system that is essentially “set-and-forget,” where automatic scraper strainers comprehensively protect delicate membranes and allow personnel to focus on other aspects of the facility.

This article was contributed by Acme Engineering Prod. Inc. Acme Engineering Prod. Inc. www.acmeprod.com

EXPLOSIONS. GOOD IN MOVIES. NOT AT YOUR FACILITY.

Trust KNF for proven liquid and gas pump performance in safety-critical applications.

• Suited for NEC/CEC Class1, Division1, Groups C & D; IEC EX, ATEX, and other protection levels available

• Choose from a broad range of pump head and diaphragm materials

Learn more at knf.com/en/us/exproof

Analog pressure gauges are very common in industrial installations — they’ve been around for over 170 years. There are several reasons for analog pressure gauges’ popularity, including that they are relatively inexpensive, they don’t require electricity, and they can be readily used outdoors and in hazardous locations. They can be well suited for less critical applications that may only need pressure readings at infrequent time intervals.

But how pressure gauges are now used is quickly evolving as industrial processes become more sophisticated, more precise, and more demanding. The following article helps you compare analog vs. digital pressure gauges for your application’s specific needs.

As you consider your application, it’s good to understand the basic technologies of both types of pressure gauges.

Analog or “mechanical” pressure gauges (also called “pressure meters”) all rely on precision mechanical linkages. The most common analog pressure gauge technology uses a Bourdon tube (invented in 1849), where pressure moves — slightly uncoils — a curved tube. The Bourdon tube is, in turn, connected to a series of linkages, gears, and a hairspring that moves the gauge’s dial (pointer). The other two analog gauge sensing technologies — diaphragm (aka “membrane”) and bellows — also depend on very precise mechanical linkages.

With digital pressure gauges, there are no moving parts. A sensor measures pressure variations and converts them into proportional electrical signals. An integrated microprocessor then converts those electrical signals into numeric values, which are shown on the gauge’s digital display.

lAborAtory AccurAcy vs reAl-worlD, in-tHe-FielD AccurAcy

As most pressure gauge users already know, “accuracy” is not always a simple comparison of percentages. There are different types of accuracy specifications: percentage “of full scale,” percentage “of reading,” combined percentage “of reading” and percentage of “full scale,” and percentage “of span.” One type of accuracy isn’t better than another; it comes down to how the gauge will be used over an anticipated range of pressures.

But if we’re comparing, for example, two pressure gauges — one analog and one digital — with the same laboratory accuracy specifications (say, 0.1% of full scale) and the same pressure ranges (e.g., 0 to 1000 psi), then we can meaningfully compare how the two technologies differ when used in the field. For example:

#1 Vulnerability to Extreme Temperatures: High or low temperatures can severely affect the accuracy of analog pressure gauges. (Think of all those mechanical linkages, thermally expanding or contracting.)

On the other hand, when given the expected high and low temperatures of a given application, manufacturers of quality digital pressure gauges can electronically compensate (or “characterize”) the device to accurately work from -20°C to +50°C.

#2 Pressure Pulsations & Wear: Continual rapid pressure pulsations cause the precision mechanical linkages of an analog pressure gauge to wear out over time, making it impossible to keep the gauge in calibration.

With no moving parts, pulsations are much less of a concern for digital pressure gauges.

rePeAtAbility: tHe key to AccurAte Pressure reADings

“Repeatability conditions,” as defined by ISO.org, include the same measurement or test procedure, done by the same operator, using the same measuring or test equipment, in the same conditions and location, done repetitively over a short period of time. Some basic considerations regarding repeatability and pressure gauges include the following:

#3 Analog’s “Parallax Effect”: Analog gauges are often misread — they are meant to be read exactly perpendicular to the dial face. The angle dependency of analog pressure gauges is known as the “parallax effect.” Readings taken at other than 90° to the dial could potentially impact accuracy more than the accuracy rating of the gauge. Parallax problems are further compounded when gauges are in hard-to-reach locations.

Angle dependency (parallax) isn’t an issue for digital pressure gauges —

the numeric values shown don’t change based on the user’s position.

#4 Analog Requires Interpretation: When we look at an analog dial, we’re interpreting where the pointer lies, trying to visually align it with hash marks and then mentally counting or estimating the hash marks between major designators. For example, the pointer on this 0 to 1000 psi analog gauge is about two thirds of the way between 400 and 450 psi, which is (quick!) what value? In this case, the reading is further compromised by the distortion caused by the liquid-filled face.

Using the same example as above, under the best-case scenario you’re interpreting where the pointer lies with a plus or minus of a hash mark, which in this situation is ±10 psi. With digital pressure gauges, there’s no interpretation — just digits to read: 433.3 psi.

#5 Poor Lighting: The ability to accurately read an analog gauge — that is, the location of its dial and the appropriate hash marks — is diminished by poor lighting and shadows.

Conversely, digital pressure gauges can display their readings in large, clear, backlit numbers in a pitch-black location.

#6 The Effects Of Constant Pulsation On Gauge Readability: On analog gauges, continual pressure pulsations can make accurate pressure readings difficult or impossible because the needle is rapidly bouncing around so much. The dial face can be filled with liquids like glycerin to try to somewhat “dampen” the bouncing, but the liquid can interfere with readability — e.g., causing distortions — and any leaks are very messy to deal with.

Digital pressure gauges, on the other hand, can be digitally dampened to adjust their presentation rate of the pressure values. For example, on Ralston LC pressure gauges, you can change the refresh rate from slow to fast, making even precise values easy for a technician to read.

#7 More Precise Leak Detection: The increased readability of presented values — and, subsequently, the more accurate user readings — of digital pressure gauges provides more precise results when testing for small leaks than analog gauges.

#8 (Small) Size Matters: For analog pressure gauges to truly deliver highly precise (e.g., 0.1% FS) accuracy over a large pressure range (e.g., 0 to 1000 PSI), the size of its dial must become quite large. This can be a problem for space-restricted installations or when the gauge is being used as a calibrator for other pressure gauges. With a technician carrying around multiple gauges for different pressure ranges, their toolbox can become crowded with large analog devices.

By comparison, digital pressure gauges are much more compact. They’re also less vulnerable to shocks while being carried around in a toolbox.

#9 Multiple Engineering Units: Unless they have a double set of hash marks, analog pressure gauges can provide only one set of engineering (measurement) units, e.g., either PSI or Bar or kPa, etc.

Due to the flexibility of their microprocessors, digital pressure gauges have no such limitation: they can provide as many as 15 different engineering units that the user can scroll through by simply pushing a button on the gauge. More sophisticated digital pressure gauges connect to software that allows the user to select only the units they need. Some digital gauges even give you the ability to use your own custom engineering units, such as displaying pressure in torque or force units.

#10 Storing Measurements: Analog pressure meters with additional “follower” pointers can record high and low pressure events, but these recordings are approximate and the pointers are difficult to reset.

Many digital pressure gauges, on the other hand, can accurately record maximum and minimum pressure values, which are stored in the gauge until cleared by the user. Digital meters can also record pressure spikes, which is beyond the capability of most analog pressure meters.

#11 Remote Sensing/Data Logging/Control Interconnects: Digital gauges will be your choice if you want to use USB, Bluetooth, Zigbee, or other com-

munication protocols to remotely monitor and record pressure, in addition to reading the gauge where it’s located.

Vulnerability

#12 Typical Pressure Gauge Vulnerabilities.

Typical damage to analog pressure gauges include:

• Broken windows and damaged pointers

• Leaks (glycerin) coming from the gauge’s face

• Discolored liquid in the gauge’s window

Typical damage to digital pressure gauges include:

• Punctured displays

• Damage to the faceplate/keypad

That said, quality digital pressure meters are made from study materials, such as — aluminum or stainless steel — with thick, crack-resistant plastic faces that offer substantial protection from hazardous chemicals, drops, shocks, and flying debris.

recalibration & How often GauGes Go out-of-calibration

Both types of pressure gauges are verified using the same steps: connecting the gauge to a well-regulated pressure supply and running a series of testing steps to verify that the gauge is within calibration. One significant difference is that the analog gauge must be verified in its installed position (orientation), which can make the verification awkward to perform; there is no such requirement for pressure gauges.

#13 Recalibrating A Gauge: If an analog gauge is found to be out-of-calibration, it will probably need to be moved to the more controlled environment of the maintenance shop for steps such as removing the window, adjusting screws on the dial or screws on the pointer itself, internal inspection, cleaning, and possibly the disassembly and reassembly of the precision mechanical linkages. Given these complications, the potential for errors, and the cost of skilled plant technicians, “problem” analog gauges are frequently just thrown away and replaced with new gauges.

By comparison, recalibrating a digital pressure gauge can be simple and fast. Here’s an example using the Ralston LC Series: while the gauge is still connected to the well-regulated pressure supply, the technician connects a USB cable to the gauge and uses software for the 3-point recalibration process. In most cases, it literally takes just a few minutes.

#14 How Often Gauges Go Out-Of-Calibration: The precision mechanical linkages used by analog pressure gauges makes the linkages vulnerable to being loosened or moved out of position (and, therefore, the gauge out-of-calibration) by the vibrations, shocks, and overpressure typical in industrial applications. Even the act of shipping a well-packaged analog gauge can, for example, take an analog pressure gauge out-of-tolerance.

By comparison, quality digital pressure gauges can withstand significant vibrations, shocks and overpressure without losing their calibration due to their solid-state design.

Therefore — and this is a key point — digital pressure gauges stay calibrated much more reliably than analog pressure gauges.

Pressure GauGe costs & Power requirements

Comparing Costs — Analog vs. Digital Pressure Gauges: When compar-

Angle dependency (parallax) isn’t an issue for digital pressure gauges — the numeric values shown don’t change based on the user’s position.

ing quality pressure gauges, digital gauges can be several times the cost of analog gauges.

But for all the reasons listed in this article, buying an analog gauge could be “false economy” based on your intended use. Reliable (and highly readable) pressure readings not only keep your production online, but they also keep your employees safe. And rather than constantly calibrating analog gauges, digital pressure gauges free up your maintenance people for higher-value activities.

Power — Digital pressure gauges require electricity, whether that is from common batteries (e.g., AA alkaline), loop, or solar. For reference gauges, this really isn’t too much of an issue: you just put a set of new, spare batteries in your tool bag.

For process pressure gauges, hardwired to power and installed in a panel, you might want to leverage the gauges’ connectivity as well — running your data line parallel with the 120/240 VAC line.

This article was from a blog by Ralston Instruments. The pressure calibration specialists offer three series of digital pressure gauges, suitable for measuring the pressure of air, alcohol, antifreeze, ethylene glycol, hydraulic oil, inert gas, mineral oil, natural gas, petroleum-based oil, Skydrol, windshield washer fluid, transmission fluid, light motor oil, Ralston calibration oil, and water.

Ralston Instruments www.ralstoninst.com

Since 2001, Valve Accessories & Controls has built a reputation as a company comitted to quality products, and a commitment to service, second to none.

• Pneumatic, Analog, and Digital Positioners

• Wide selection of Mounting Kits

• No Phone Mazes to Navigate

• Experienced Staff

• Service and Technical Support Canadian Master Distributor: Belletek Controls Inc. 2535 Stallion, St. Lazare, Qc, Canada J7T 2E4

J.C. Labelle: (514) 916-5895

Fax: (514) 500-5802

Email: jc@belletek.com

The Dynatrol Interface Level Detector Type CL-10DJI from Automation Products, Inc. is said to have the unique ability to detect the interface between black liquor and soap. This level system provides easy installation, has no moving parts, and does not require field adjustments, the company says. The detector interface can save on costly shutdowns, it adds, as well as increases efficiency of the boiler recovery operation, maximizes soap recovery, and requires minimal operator attention while controlling soap level. Units have stainless steel and Hastelloy C wetted parts, and are explosion proof with approvals for Class I, Group C & D, Division I. The EC-501A Control Unit employs the On/Off signal from the Dynatrol Interface Level Detector to operate a SPDT relay in the control unit. The relay contacts actuate alarms, indicator lights or process control equipment.

Automation Products, Inc. – Dynatrol Division

www.dynatrolusa.com

With impressive +/-0.1% full scale accuracy, intuitive controls, and convenient design features for easy installation, it’s the ideal reference-grade gauge for panel mounted applications.

• Perform live viewing of pressure or set up tests for continuous monitoring.

• Test multiple pressure ranges at one station.

• Easily customize the gauge to your needs using the included FieldLab Desktop software.

• Available in ranges up to 10,000 psi (70 MPa).

• AC powered with battery backup.

Emerson has announced the release of its easy-e Trim Cartridge, a trim repair solution for its Fisher easy-e globe valves. The factory-assembled repair cartridge combines all valve replacement parts, plus the bonnet, the company says, into a simple and ready-to-install repair solution, streamlining the repair experience while creating time and money savings throughout the maintenance process. Before the introduction of this solution, it adds, any suspected globe valve issues, such as leaking or sticking, typically required disassembly of the valve to identify the required replacement part(s). Once identified, the parts had to be ordered, and then installed after receipt. In the best case, these activities could be performed in the field by an experienced technician, albeit with some difficulty due to the required precision of installation tasks and the multiplicity of parts. In the worst case, a valve would need to be removed from service, resulting in significant added repair cost and labour, and additional downtime. The pre-assembled Trim Cartridge is ordered as a single part number.

The DewTrak II hygrometer with DX sensor from Edgetech Instruments was created to assist new technology battery researchers develop next-generation batteries that have high energy densities to meet market demand for higher volumetric energy, lower cost, and safer batteries, especially for grid energy storage. With long term stability and repeatability without the need for recalibration, the hygrometer uses the company’s DX primary method chilled mirror dew/frost point sensor with integral PRT temperature sensor. The DX sensor can be inserted into gas streams or used to monitor local environments. Active cooling is said to give the sensor enhanced stability and a dynamic range of -40° to 95°C dew/ frost point, over a wide range of ambient conditions.

Edgetech Instruments www.edgetechinstruments.com

Rusco has expanded its product portfolio with three new filter cartridges, including a carbon block, pleated, and melt blown (spun) media. The cartridges will enhance sediment removal capabilities and widen applications to address chemical contamination concerns, the company says. Previously offering mesh filters limited to a 15 μm capacity, the latest installment of spun and pleated filter cartridges improves sediment removal efficiency to as low as one micron through advancements in composition, surface area and pore size.

The activated carbon units, which operate at a rate of 10 microns, are said to address areas not covered by existing products, including: taste and odor, lead and chlorine, and volatile organic compounds (VOCs) and chemicals.

Rusco

Koch Modular Process Systems of Paramus, NJ, a provider of engineered and fabricated modular mass transfer systems for the chemical processing industry, has announced its fabricated process modules have been installed in support of the first manufacturing plant for Origin Materials (Origin), located in Sarnia, ON. Installation of the key production modules of the plant (Origin 1) was completed in October of 2021, six months ahead of their schedule.

Koch Modular was engaged early in the process by Origin because of the company’s demonstrated expertise in reaction, distillation, and filtration unit operations. The front end of Origin’s process was a primary focus, converting biomass to sustainable materials including chloromethylfurfural (CMF) and hydrothermal carbon (HTC). Downstream of Koch Modular’s system, Origin’s process involved the conversion of CMF into PET (polyethylene terephthalate); a strong and lightweight thermoplastic material commonly used in packaging, textiles, and many other products.

Koch Modular designed and manufactured the plant’s 17 core process modules. The plant remains on track for completion by the end of 2022, with commissioning and production start-up thereafter.

Origin’s technology will turn carbon found in biomass, such as wood residue, into useful materials such as plastic. The technology eliminates the need for fossil resources and captures carbon in the process. The carbon negative products created with this technology are expected to be cost competitive with petroleum-based products and recyclables.

Koch Modular Origin Materials www. kochmodular.com www.originmaterials.com

Federated Co-operative Limited (FCL) has signed a memorandum of understanding to form a joint venture (JV) partnership with AGT Food and Ingredients. The JV will look to construct a $360 million canola crush facility.

The partnership with AGT is a 51%49% split, with FCL holding the majority ownership stake. The canola crush facility will supply approximately 50% of the feedstock required for a 15,000-barrelper-day renewable diesel plant, with the remainder of the supply contracted from other canola crush facilities.

The canola crush plant is part of a $2 billion investment FCL is making in the construction of an Integrated Agriculture Complex (IAC). The announcement builds on the company’s recent announcement that FCL is advancing plans to construct a renewable diesel facility in the Regina area at the IAC. AGT Food and Ingredients http://agtfoods.com/ Federated Co-operative Ltd. https://www.fcl.crs/home/

Food and Beverage Ontario has partnered with the City of Brampton to identify workforce barriers and find solutions to the growing labour crisis for food and beverage processors in the region.

This new regional workforce pilot is part of Food and Beverage Ontario’s CareersNOW! initiative that is connecting job seekers and students with employers in Ontario’s food and beverage processing industry.

The province’s 4,000 plus food and beverage processor businesses are the number one manufacturing sector employer, but forecasts indicate a 25,000, or 20 percent, employment gap by 2025.

“Brampton is home to more than 300 small to medium-sized and multinational food and beverage processors supporting 8,500 jobs, but we continue to have challenges connecting employers with job seekers,’ said Chris Conway, CEO, Food and Beverage Ontario. Food and Beverage Ontario

https://foodandbeverageontario.ca/careersnow/

Thompson Pump and Manufacturing Company has announced the retirement of John Farrell, VP of Sales and Marketing. Bobby Zitzka now assumes the position and Pat Broderick moves to national sales manager.

Farrell was hired 38 years ago at Thompson Pump when he was hired as a purchasing agent. He then rose through the ranks to purchasing manager, regional sales manager and in 2002, was promoted to vice president of Sales and Marketing. Farrell also travelled the world meeting with customers, attending trade show and growing Thompson Pump’s international and municipal business as well as its dealer and distributor network to more than 40 business partners across the U.S. and Canada.

Zitzka began his career at Thompson Pump in 2002 as the branch manager for the company-owned rental branch in Orlando, then was promoted to national sales manager in 2013. He then moved to Thompson Pump’s corporate headquarters in Lenexa, KS, where he spent time with Farrell learning about the distribution network and national accounts.

Thompson Pump and Manufacturing Company www.thompsonpump.com

Mitsubishi Electric Automation has promoted Sloan Zupan to senior director of corporate marketing. Zupan has 22 years of experience in the automation industry.

In his role of senior director of corporate marketing, Sloan Zupan will lead a transformed marketing department at Mitsubishi Electric Automation. He will oversee marketing efforts in several spaces, including strategic marketing, product management, and product marketing.

In his 16 years at Mitsubishi Electric Automation, Zupan has held titles such as product manager for software, programmable automation controllers (PACs), controllers and human-machine interfaces (HMIs), senior marketing manager, and director of corporate marketing. Since his start the organization has grown significantly not only in revenue but also in process improvements, marketing technology adoption and capabilities. Before joining Mitsubishi Electric Automation, Zupan held positions at Schneider Electric and EESCO, a division of WESCO Distribution Mitsubishi Electric Canada

https://ca.mitsubishielectric.com/en/

Rotork plc, the global flow control and instrumentation group headquartered in Bath, UK, has announced the appointment of Kiet Huynh as CEO. Huynh was managing director of the group’s Water & Power and Chemical, Process & Industrial (CPI) divisions. He also joins the Rotork board.

Huynh said: “I am very proud to have been appointed CEO of Rotork. I have spent most of my career in the flow control and instrumentation sectors, delivering high value solutions and services to customers and end users, including the last four years heading divisions of Rotork. I look forward to leading the team to drive growth and leverage the benefits of the Growth Acceleration Programme.” Rotork Controls Canada www.rotork.com

Endress+Hauser subsidiaries SpectraSensors, Inc. and Kaiser Optical Systems, Inc. have joined forces to form Endress+Hauser Optical Analysis, Inc. For the parent Endress+Hauser Group, this merger consolidates its expertise in laser-based measurement technology, strengthens its focus on laboratory and process analysis and positions it to provide customers with even better support for analysis tasks in the future.

SpectraSensors and Kaiser Optical Systems boast a long history of innovation and offer market-leading product lines for optical analysis. These two US-based companies were acquired by Endress+Hauser in 2012 and 2013 respectively. Adding SpectraSensors strengthened the Endress+Hauser Group’s position in gas analysis with tunable diode laser absorption spectroscopy (TDLAS) technology. Kaiser Optical Systems, a global leader in Raman spectroscopy, brought on board great expertise in solid, liquid and gas analysis across a wide range of applications, including vaccine production, the company says.

Through these subsidiaries, Endress+Hauser is now said to be able to support customers from product and process development to production with advanced analysis and quality measurements to process engineering applications.

The analysis technology segment of its business now accounts for almost one-quarter of the

Group’s sales.

“We want to further develop and expand our portfolio for laboratory and process analysis,” says Dr. Manfred Jagiella, who is responsible for the analytical business on the Endress+Hauser executive board. Together with Endress+Hauser Liquid Analysis and the Analytik Jena subsidiary, Endress+Hauser Optical Analysis forms an important element of our Group’s analysis strategy, he adds.

“Our customers expect easy-to-use, robust measurement instruments that fit their applications,” says managing director John Schnake, who leads the new unit. With laser-based measurement technologies, Endress+Hauser offers an integrated product portfolio for analysis that supports industrial customers from product and process development through to quality control and production. Endress+Hauser Optical Analysis is headquar-

THIN CLIENTS ENSURE A SECURE FUTURE.

tered in Ann Arbor, MI, where Raman spectroscopic instruments are developed and manufactured. TDLAS instrumentation continues to be produced in Rancho Cucamonga, CA. The new company, with around 200 employees, remains a wholly owned subsidiary of the Endress+Hauser Group.

Endress+Hauser Canada Ltd. www.ca.endress.com

ABB has announced it is working with Amazon Web Services (AWS) to accelerate the adoption of new and sustainable technologies in mining. The two companies are now creating solutions for digitally integrated all-electric operations to help meet industry goals on net-zero emissions.

In a first demonstration, ABB Ability Operations Management System (OMS) has already been integrated with heavy-duty EV drivetrain developer MEDATech’s cloud data collection system on AWS.

Telemetry data, including battery state and speed of charge, was transmitted in real time from MEDATech’s first-ever 100 percent electric haul truck – paired with ABB’s fast charging pilot solution, ABB Ability eMine FastCharge – while ensuring data security using AWS’s Internet of Things (IoT) services.

The team used the gathered data to perform a real-time production optimization for test purposes as shown at MINExpo in

Las Vegas in September 2021.

Such seamless digital integration of electrical equipment across industrial operations is said to be increasingly important for operational efficiencies through optimized scheduling and planning. Battery electric vehicles (BEVs) and their related charging infrastructure present a challenge and an opportunity as the industry commits to decarbonization and reduced resources and energy consumption.

ABB and AWS are also proving scalability. AWS enables OMS to ingest, store, process, and analyze operational data from stationary and mobile equipment and dynamically scales to meet the operational demands. The new ABB Ability eMine approach relies on the reliable and standardized exchange of equipment and process data to effectively integrate electrical and digital systems from mine to port.

ABB

https://new.abb.com/ca

By Jon Sanders

Nearly every pressure sensor has some sort of environmental temperature specification on its data sheet. This technical note explains the environmental temperature effects on pressure sensors, quantifying the impact, and ways to minimize the impact.

Have you ever wondered how much impact environmental temperature has on your pressure sensors?

To understand the environmental temperature effect on your sensor, it is helpful to first understand some common terms you may see on a pressure sensor specification sheet.

Operating Temperature Range: This is the temperature range over which the sensor can be used without causing damage.

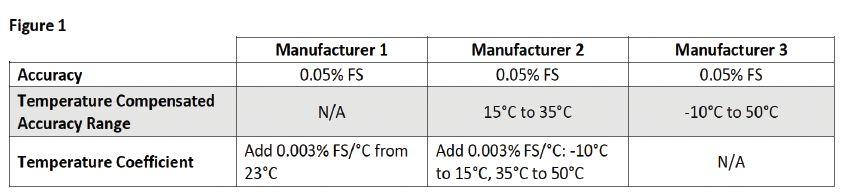

Temperature Compensated Accuracy Range:

This refers to the environmental temperature range over which the accuracy of the sensor is applicable.

Temperature Coefficient: An additional error that needs to be considered when used outside of the temperature compensated accuracy range. Many sensors are only tested and calibrated at laboratory temperatures. In this case, the temperature coefficient will need to be considered in the measurement accuracy when using the sensor outside of laboratory temperatures.

the environmental temperature effect

So how much will the ambient temperature impact your measurement accuracy?

Well, this will depend on the temperature compensated accuracy range and the temperature coefficient.

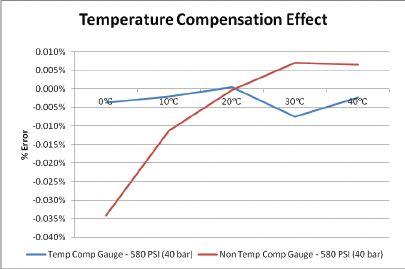

Above is a chart comparing the non-temperature compensated gauge with the temperature compensated gauge.

Minimizing

The temperature effect on a pressure sensor will be negligible when used at the same laboratory temperature in which it was calibrated. This, however, is often not practical for your measurements.

Why pressure sensors are impacted by environmental temperature changes

Jon Sanders

Much like anything else in the physical measurement world, pressure sensors are subject to changes in environmental conditions. Temperature effects tend to have the largest impact on pressure measurement accuracy. Temperature effects also directly influence the pressure sensor and the circuitry used to measure the sensor. Digital pressure sensors use electronic circuits which provide an analog output proportional to the inlet pressure.

There are three factors of a sensor’s circuitry that are affected by environmental temperature changes: zero pressure output voltage, pressure sensitivity span and bridge resistance. Temperature-compensated sensors employee some techniques to correct for and minimize the impact of temperature changes on these factors.

To demonstrate this, let’s consider three different gauges. As you can see from the specifications in Figure 1, they all have the same accuracy specification of 0.05% FS.

With sensor technology advances, we have found a variety of ways to minimize the temperature effect on pressure sensors and with confidence define a large temperature compensated accuracy range.

First, regularly zero your digital pressure gauges. By zeroing the pressure gauge, you are aligning the zero pressure output voltage to the cur-

However, as you consider the temperature compensated accuracy range and the temperature coefficient you’ll see a fairly large variation between the three gauges.

The graph below left shows the total specified accuracy when considering the temperature effects on the pressure gauges. As you can see in one case here, the lack of temperature compensation and inclusion of the temperature coefficient specification more than triple the 0.05% FS accuracy specification.

To further show temperature compensation has real effect, we placed a non-temperature compensated pressure gauge in a temperature chamber and pressure tested it from 0 to 580 psi (0 to 40 bar) and over the environmental temperature range of 0°C to 40°C.

We then performed the same test on a temperature compensated gauge. As you may expect—the higher the pressure, the larger the impact from the environmental temperature.

rent environmental conditions. You should only zero the pressure gauge when you do not have any inlet pressure on the gauge.

Because each sensor is unique and performs differently due to environmental temperature changes, at Additel, we pressure test every sensor in a thermal chamber at different temperatures so we understand its pressure performance relative to environmental changes. Each sensor contains a temperature-compensated circuit which we load coefficients representing the temperature testing of the gauge.

This allows for you to confidently use our sensors over the range -10°C to 50°C without having to add a temperature coefficient error to the accuracy.

The author Jon Sanders is president of Orange County, CA-based Additel Corporation, represented in Canada through SRP control systems of Mississauga, ON.

With the EL7062 dual-channel EtherCAT terminal, Beckhoff enables the direct connection of two stepper motors in the medium power range of up to 3 A and for a voltage range of 8 to 48 V. With flexible parameterization and minimized channel costs, the flexible motion interface is said to be suitable as a low-cost drive for a wide range of stepper motor applications. The 24-mm-wide EtherCAT terminal contains two stepper motor output stages, two digital inputs for limit switches and one encoder interface per channel for a wide range of 5 V encod-

ers. Via parameterization, the EL7062 flexibly adapts to the connected stepper motor and its corresponding application requirements. Regarding the input encoder signal, the module supports the spectrum of TTL encoders (5 V differential, single-ended/open collector).

Beckhoff Canada

wastewater 1c ad 4/5/05 2:53 PM Page 1

www.beckhoff.ca

• Manual, automatic and actuated (pneumatic & electric) valves; relief, check, diaphragm, ball, solenoid, and shut-off. Also pressure regulators, metering pumps, basket strainers, sight glasses, and gauge guards.

• Innovative Engineering –Dedicated Craftsmanship.

• 100% inspection and individual testing of each product, to ensure dependable performance and long-life.

• PVC, CPVC, Polypropylene, PTFE and PVDF. Valves from 1/8'' to 3'',Sight glasses to 8'' and Basket Strainers to 14''.

CEDAR GROVE, NJ 07009 (973) 256-3000 • Fax: (973) 256-4745 info@plastomatic.com•www.plastomatic.com

The HPC50 handheld pressure calibrator from Cameron Instruments is an intrinsically safe, dual pressure calibrator with options to add an additional two external pressure (APMi) or temperature (ATMi) modules. With the external modules users can measure up to four pressures simultaneously. When combined with ATMi (temperature) modules, users can probe to measure two pressures and two temperatures, or three pressures and one temperature. The series is fully temperature compensated for pressure, temperature, and electrical measurements from -20° to 50°C. It can read in gauge, absolute and differential pressure up to 10,000 psi. Previously used screens can be stored and recalled with the unit’s advanced simplicity “non-menu” interface. The calibrator offers 0.035% of reading accuracy and high accuracy thermometer with “True Ohm” technology.

Cameron Instruments

www.cameroninstruments.com

Rotork has improved its range of smart positioners to offer enhanced diagnostic and operating abilities. The YT-3400 smart valve positioner has undergone extensive hardware and software development, the company says, to extend and enhance its range of smart explosion-proof pneumatic positioners. The YT-3400 range is available in multiple housing options (aluminum and stainless steel) for different regional certification requirements. The positioner valve signature, advanced step tests and Partial Stroke Test (PST) can be operated from local or remote positions. Local display and push buttons are said to allow fast setting and commissioning operations, while remote position triggering via the Digital Input control simplifies (for example) PST activation when the device is not easily reachable. Alarm prioritization is available with clear NE107 symbols, while Device Description (DD) and Device Type Manager (DTM) files allow for full HART host compatibility. Rotork

www.rotork.com

The rotary batch mixer model 700-THCX-600-MSL from Munson Machinery Company is said to blend abrasive materials in six to eight minutes with total uniformity and little to no shear, degradation, or heat. Constructed of carbon steel, the mixer is intended for demanding applications including concrete premix, ceramics, powdered metals, fertilizers, plastics, and catalysts. It has a usable batch capacity of 17 m3 and achieves uniformity with equal efficiency from 100% to 15% of rated capacity, regardless of disparities in the bulk densities, particle sizes or flow characteristics of batch ingredients. Its horizontal rotating vessel contains proprietary mixing flights with replaceable wear liners made of abrasion-resistant steel that tumble, turn, cut, and fold material gently, preventing degradation and imparting minimal energy to the batch, the company says. The flights also direct the material toward and through a stationary, pneumatically actuated plug gate valve for total discharge, it adds, eliminating residual that would otherwise be wasted or require manual removal prior to cleaning. Munson Machinery Company www.munsonmachinery.com

Eriez has announced that 6- and 18-inch belt sizes are now available for its Xtreme metal detector conveyor systems with automatic rejects. The units, along with the 12-inch belt systems launched last year, have new options and offered for fast delivery through the company’s Quick Ship program. The systems are designed with push arm or air blast rejects, lockbox, reject confirmation, stainless steel motor/reducer, improved guarding, emergency stop and side guides. Features include 7-inch touch screen interface, multiple pre-programmed languages, easy set-up and reporting, multiple USB and interface ports, remote access and 24/7 technical support capabilities, the company says. Eriez www.eriez.com

Using a LAKOS separator from John Brooks Company as a pre-filter prior to finer filtration improves efficiency and minimizes liquid loss. As a result, the company says, installations can reduce disposal cost, minimize labour, maintenance downtime and filter media replacement costs, while extending the life of finer filtration and water treatment systems, as well as increasing the life of filter cartridges and bags and eliminates water treatment

SERFILCO JM & FM filtration systems from Service Filtration of Canada are said to be compact, corrosion resistant and extremely simple to operate. Designed with very simple internals that will enable the user to change quickly from cartridge to disk to bag, dependent on the application the new systems offer cost effective filtration while maintaining the highest possible standards of performance and longevity, the company says. The systems are manufactured with no plastic welds as these have been identified as the primary cause of chamber failure on plastic systems. This new design is said to have dynamic sealing faces using O-rings which are suitable for static and dynamic sealing applications where materials expand and contract — assuring users that whether being used at 70°F or 160°F these systems will not leak. The systems also simplify maintenance as they can be easily disassembled for cleaning and O-rings can be replaced in the way welded joints cannot. Service Filtration of Canada http://service-filtration.com/

processes. Separators are also said to offer effective protection for heat exchangers against fouling, maintaining design efficiencies for better heat transfer rates resulting in energy savings. In addition, the separators remove solids from liquids in industrial processes and allow reuse of the liquid, it adds, reducing disposal costs. Other benefits of the separators are that they remove solids that clog spray nozzles and other small orifices, while as part of a process cooling system minimize accumulation of solids that typically settle in sumps and basins.

John Brooks Company www.johnbrooks.ca

Yokogawa has introduced the EJA565E/EJA564E series of pressure transmitters with 3-A cer tification as new models in its OpreX Field Instruments lineup. The certification makes them suitable for pressure and level measurements in hygienic and sanitary applications of the food, beverage, and pharmaceutical industries. With a polished stainless-steel housing, the transmitters meet 3-A Sanitary Standards, Inc. (SSI) require ments for 3-A certification. The active tempera ture compensation design locates a tempera ture sensor directly behind the flush isolating diaphragm to quickly react to changing process conditions, the company says, providing a robust, stable measurement to help ensure quality and safety. The series is said to have a comprehensive selection of process connections to fit different applications. Yokogawa www.yokogawa.com/ca

R. Stahl has introduced the pac-Carrier 9295 — a space-saving integration solution for the company’s 12 mm ISpac intrinsically safe (IS) isolator barriers. The ISpac devices and the pac-Carriers are ideal for seamless use in decentralized installations due to approval for use in Zone 2 and Class I, Div. 2. The pac-Carrier can also be used for functional safety applications up to SIL 3. The carrier is said to significantly simplify the installation and wiring of the isolators into the controllers’ (PLC/DCS) I/O cards from numerous manufacturers. Prefabricated connecting cables reduce the risk of wiring errors, while the installation labour is reduced by up to 40% thanks to the tool-free mounting of the ISpac isolators, the company says. The integration system is suitable for projects involving a high number of channels. The carriers are available in 8- and 16-slot versions, thereby enabling up to 32 signals to be connected. The variant with 8 slots is 110 mm wide. An additional HART multiplexer coupling requires 36 mm of extra space. The 16-slot version further increases the channel density.

R. STAHL

www.rstahl.com

Alfa Laval has introduced CM Connect, a subscription-based condition monitor and cloud gateway. It enables plant operators to access data of rotating equipment on processing lines from a remote location. With data on actual runtime, trend analysis, and time to next service close at hand, the company says, plant operators can make informed maintenance decisions using their personal computers and mobile devices. The gateway is said to protect process continuity and critical assets, improve workplace safety, save time and money, and deliver competitive advantage. Acting as a gateway communicating via Bluetooth, the CM Connect can link up to 10 CM wireless vibration monitors the company launched last year.

Alfa Laval

www.alfalaval.ca

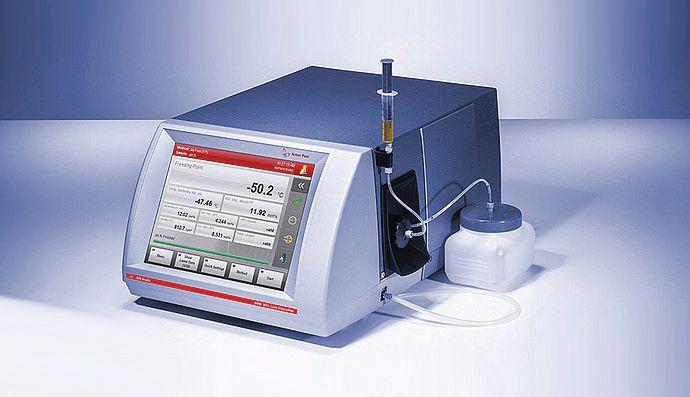

The Anton Paar model SVM 3001 kinematic viscometer can distinguish between natural flavouring (essential oils) and artificial flavouring (synthetic aroma chemicals). Commercial flavours are mainly available as liquids dissolved or emulsified in a carrier solvent (pure vegetable oils, propylene glycol, triacetin, ethanol), further as extracts, concentrates, and others. Units have a

temperature range from -60° to 135°C. All samples, from jet fuel to wax, can be sampled without changing the capillary. The viscometer is compliant to ISO 23581, EN 16896, ASTM D396, D975, D7666, and other standards. In addition to kinematic viscosity and density, unit cold properties can determine the cloud and freeze points from the same sample. The company's SVM kinematic viscometer series — now referenced in the SAE J300 engine oil viscosity standard as an alternative to the ASTM D445 capillary test method – is a step ahead of capillary viscometers. SVM (ASTM D7042 test method) reduces operating costs and delivers results in seconds. The smart kinematic viscometer covers the entire viscosity and density range with one measuring cell and does not require a liquid bath for temperature control — providing all the flexibility you need in a single instrument.

Anton Paar www.anton-paar.com

Canada has always been an active proponent of environmental sustainability. In 1970, responding to calls for action to protect the quality and distribution of its water, Canada passed the Canada Water Act; the following year, the Canadian Department of the Environment was established.

While the federal government of Canada has some responsibilities in regard to water that include fisheries and navigation, individual provinces are actually responsible for the day-to-day management of their water resources.

New Health Canada Guidelines

Health Canada is a federal department responsible for “helping Canadians maintain and improve their health.” With the Federal-Provincial-Territorial Committee on Drinking Water (CDW), these entities establish draft guidelines for maintaining the quality of drinking water based on the most recent scientific research. Once drafted, these guidelines proceed through what can be a years-long process to potential changes in existing guidelines.

In 2019, Health Canada responded to new research by updating Canadian Drinking Water Guidelines. Included in the new guidelines was a maximum acceptable concentration (MAC) level for manganese in drinking water supplies where none had existed before. The new MAC for drinking water was set at 0.12 mg/L.

In addition, because manganese causes aesthetic concerns due its propensity to create water discoloration that can stain laundry and other items, an additional aesthetic objective was set at 0.02 mg/L. This new guideline value, one of the lowest in the world, is lower than the 0.3 mg/L maximum contaminant level (MCL) guidelines of the U.S.

Following the announcement of the new national guidelines, provincial governments alerted their citizens of the need to test their drinking water. In Nova Scotia, for example, where 40 percent of households access private wells for their drinking water, citizens were urged by the chief medical officer of health to test their well water regularly in order to prevent exposure to bacteria and chemicals.

So, why did the guideline change? Until recently, manganese was considered merely a nuisance chemical. The new MAC for manganese was based on new research about the risks of manganese toxicity, including potential impacts on memory, motor function, attention spans and the neurological development of infants and young children.

Following the announcement, Health Canada issued recommendations for applying the manganese guidelines, including:

• Sampling water sources in periods when manganese is most likely to be elevated;

• Frequent monitoring of surface water and water treated water by utilities to remove manganese; and

• Monitoring within the distribution system and at consumer taps for systems where manganese is or was historically present in the course water.

Monitoring for manganese is recommended primarily at consumer taps with a portion of samples collected from sites located near the treatment plant. Homeowners with private wells are also encouraged to have their water tested annually to ensure that the water supply is below the MAC.

In Canada, private wells and many small drinking water systems rely on certified products to meet requirements for drinking water.

In 2019, the Canadian Water Quality Association produced a standard for these products that allow their manufacturers to certify their health-based manganese removal claims. It is hoped that this new standard will help companies address the growing concerns about the potential threat that manganese poses in Canada and other countries.

This article was contributed by AdEdge Water Technologies. AdEdge Water Technologies https://adedgetech.com/

Over the past couple of decades, the process industries have seen many changes when it comes to the design and implementation of emergency shutdown/safety systems.

The introduction of several international and regional standards requires a more rigorous approach to the overall safety lifecycle of a system compared to the use of best engineering design practices of the past. As a result, a broader and significant increase in the implementation of these standards has been noted within the industry.

The standards most commonly being referenced by customers are:

• IEC 61511: Functional Safety - Safety Instrumented Systems for the Process Industry Sector

• ANSI/ISA-84.00.01 (IEC 61511 Mod) - Functional Safety: Safety Instrumented Systems for the Process Industry Sector

• IEC 61508: Functional Safety of Electrical, Electronic, Programmable Electronic Safety Related Systems

mented Function (SIF), being used to calculate Safe Failure Fraction (SFF) of a product, evaluate required Hardware Fault Tolerance (HFT) and allowing a design engineer to perform PFDavg calculations. To ensure that FCI provides unbiased failure rate data, we utilize independent, authorized third parties such as exida and TÜV Nord to perform the FMEDA (Failure Modes, Effects and Diagnostics Analysis) per IEC 61508 for several of our thermal meters and thermal switches.

The industry segments that appear to be driving the most demand currently is chemical, petroleum refining and oil and gas. FCI is seeing more requests for “SIL” ratings when it comes to our thermal mass flow meters, flow switches and level switches. FCI has responded and today provides more SIL compliant thermal dispersion technology products than any other supplier.

SIL (Safety Integrity Level) is just one piece of data required to meet the requirements of these standards, but it continues to be the initial focus of inquiries. Reliable failure rate data is just as critical when it comes to evaluating the impact an individual sensor will have on the overall Safety Instrumented System (SIS) design and validating that particular Safety Instru-

One thing that tends to get lost in this focus on standards is whether the instrument selected will be able to perform the desired safety function. Ideally, the instrument selected will comply with the relevant safety standard as well as perform the necessary measurement. However, it is hard to justify the selection of an instrument that has a strong pedigree but will not bring the system to a safe state when a demand is placed upon it. In those cases, it may be best to fall back on a proven-in-use approach based on site experience with a particular instrument in an application.

FCI’s thermal mass flow meters and thermal flow/level switches have been used extensively within the process industries as safety instruments, helping customers limit the risks associated with potentially hazardous processes. As the implementation of newer standards related to safety instrumented systems continues to increase, customers can continue to rely upon FCI to meet their instrumentation requirements and provide them with the proven benefits associated with thermal flow meters and thermal flow switches.

This article is from a blog presented by FCI at http://rb.gy/idh1mk. Fluid Components International www.fluidcomponents.com

Dear valued readers,

Yesterday was Groundhog Day when I wrote this and since Covid 19 has descended on us two years ago, a lot of days feel the same. Fortunately, we work in industries that are “essential” and we keep on going.

The biggest effect for our company has been our inability to conduct our Process & Automation Shows across Canada. We miss visiting you folks with our merry band of exhibitors.

Keep a watch on your email and in the magazine for details.

This is a big year for us here at Canadian Process Equipment & Control News, as we are celebrating our 50th anniversary. We’ll have more on that in the next issue.

There is a glimmer of hope, however, as governments begin to open meeting spaces. If things go as planned, we should be able to be back in your area for a show before summer.

Up next in our April issue the focus will be on Plant Communications and editor Mike Edwards’ supplement will delve into all things to do with Bulk Powders and Solids Handling. The issue closes March 4th for contributions.

Stay safe and healthy until we meet again,

Rob Sommerville

Teledyne FLIR has expanded its Ignite Cloud Workflow to three families of FLIR infrared cameras: the T8xx-Series, T5xx-Series, and the Exx-Series, along with offering secure cloud storage free

(up to 1GB). The expansion is an effort to help speed up workflow for professional thermographers, the company says. The expansion also includes Ignite Sync, giving users the ability to efficient-

ly sync their respective online image libraries to their PC or mobile device, in addition to seamlessly transferring images between the camera, client devices, and the cloud for efficient collaboration with colleagues and clients. Maintenance managers, thermographers, and technicians are said to be able to easily connect their cameras to the FLIR Ignite library while in the field. With the Automatic Upload feature, users can upload their thermal images and video data directly and seamlessly to the cloud, instead of relying solely on SD card storage and cumbersome USB cables for file transfers.

Teledyne FLIR

http://ignite.flir.com

Natural gas submetering thermal flow meters from Fluid Components International (FCI) offers basic to advanced feature sets and with comprehensive agency approvals, including, Div1/Zone1 and SIL ratings, to measure local gas usage. The thermal flow meters are said to be economical and easy-to-install, versatile solutions to measure the flow rate and totalized flow of air and natural gas. Units are direct mass flow measuring, wide range 100:1 turndown instruments, all with precision calibration in natural gas flowing at actual installation temperature and pressure conditions. Their inline or insertion designs provide a threaded or flanged connection into the piping from 0.25 inch [DN6] to the largest of line sizes, powering by AC or DC sources, and large choice of local digital readouts, analog, and digital bus outputs.

Fluid Components International www.fluidcomponents.com

HYDROGEN DETECTION TAPE DETECTS AND DISPLAYS LOW LEAK CONCENTRATIONS OF H2

SinnovaTek has introduced continuous flow bulk microwave sterilization systems for processing high quality shelf stable bulk fruit and vegetable purees. Its sterilization skid can plug into new or existing production lines to improve the flavour, texture, and colour of existing products and to convert frozen puree products to shelf stable product lines. Microwave processing is a direct, volumetric form of thermal processing that is 2.5x more energy-efficient than steam processing, it adds, an indirect form of thermal processing characterized by energy loss through thermal transfer. Three models are available. The portable Nomatic system is designed to accommodate throughputs from 0.5 to 3 lpm, operate at 2450 MHz, and can range from 6kW to 18kW of applied microwave power. The Pilot and Commercial Scale systems are for larger scale processing and operate at 915 MHz. The systems can accommodate throughputs from 2 to 30 gpm. SinnovaTek www.sinnovatek.com

Hydrogen detection tape DX-2106H from Nitto allows for the visual detection of hydrogen gas leaks by permanently changing colour when in contact with hydrogen gas. Tape visually changes colour, from amber to black to reveal leak location, in as little as 10 s when exposed to H2. The tape can detect hydrogen leaks that contain as little as 1% H2 concentration and will not return to its original colour once exposed to hydrogen gas. The product is said to be easy to use, applies the same as a typical silicone /polyimide PSA, and can be used in most indoor or outdoor environments. Less influenced by wind, position, duration, and skills, the company says, it can be easily applied to or wrapped around pipes, flanges, fittings, valves, and access panels. Nitto

www.nittodetectiontape.com

Warren Controls has announced the 1852N Seawater Deballasting Valve, suitable for deballasting seawater from

welldecks. The 8-inch size 1852N model is used by the US Navy on its LHA, LHD, and LPD class amphibious assault ships, which have welldecks that require seawater to be rapidly raised and lowered.

Seawater is notably corrosive, and the special materials of construction allow these valves to survive decades of use. Part of the company’s 1800 line of heavy-duty globe valves, the 1852N valve can be supplied in conformance with MIL-V-18030 service applications, including high pressure differentials, corrosive materials, liquids, gases, steam, and seawater. The valves can be used for modulating or on/off control in 2-way or 3-way mixing and diverting designs. units are available in bronze, steel, and iron with a wide selection of trims, electric and pneumatic actuators, and accessory instrumentation.

Warren Controls www.warrencontrols.com

Pfannenberg has introduced the PQF Premium Quick Filter, a way to filter out particulates and oily mist from an air inlet on critical equipment enclosures. The product is designed to increase the life of equipment and reduce downtime from overheating caused by a clogged airflow path. Magnetic mounting on the exterior of the air inlet makes for quick and easy installation and replacement, the company says. Installation takes less than 5 seconds and requires no training or shutdown procedure. No drilling, tapping, or gluing is required, and the magnetic installation allows the filter to be installed vertically, horizontally or in any other position to fit around the air inlet.

Pfannenberg

www.pfannenbergusa.com/accessories/

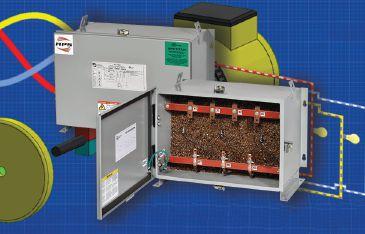

3-PHASE ENCAPSULATED TRANSFORMER SAFETY RATED