A look at solutions to help ensure a

NEW! SE3 Series Industrial Ethernet Switches starting at only $78.00!

The new STRIDE SE3 series of unmanaged Ethernet switches provides low-cost, reliable Ethernet networking solutions for industrial applications. Built with a rugged IP30 metal housing, this series o ers:

• Fast (10/100 Base-T) and Gigabit (1000 Base-T) speeds

• Fiber optic connections (ST 100FX, SC 100FX, and SFP ports)

• Up to 16 ports total

• Plastic IP67-rated version with ve M12 10/100 Base-T ports is also available for applications that require higher protection from water intrusion

• PoE+ models provide both power and communication in the same port. With up to 120W (30W per port) of power, these switches reduce the time and expense of having electrical power cabling installed. Fast or Gigabit PoE+ Ethernet communication speeds are available

• 5-year warranty

Research, price, buy at: www.automationdirect.com/ethernet-switches

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

2.3x

Expected growth in demand for copper over the next 25 years.

The mining processing sector is in the early stages of a massive boom for various metals and minerals, courtesy of the world’s desire for more sustainable energy options. As countries attempt to move towards their net-zero targets by 2050, there will be an increasing reliance on metals such as copper, which will be instrumental in the global energy transition as we move towards decarbomniztion.

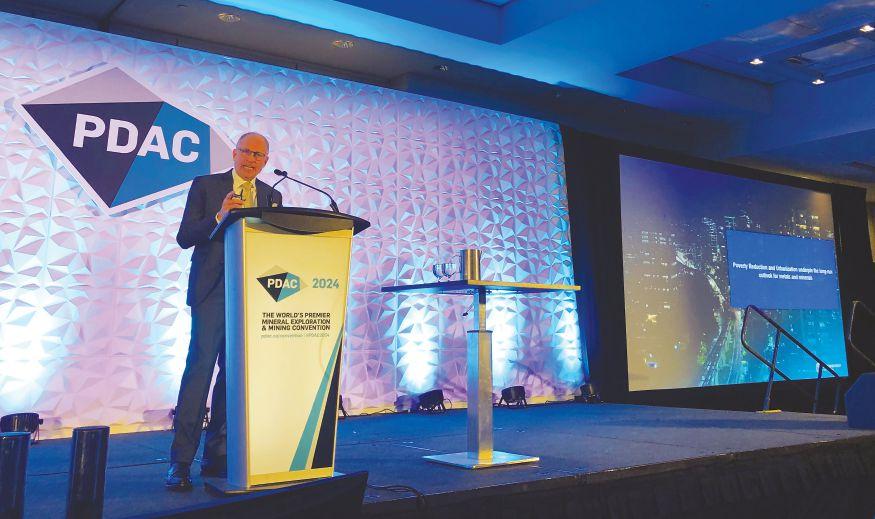

This increase in demand was highlighted during The World Bank’s recent keynote speech at the Prospectors & Developers Association of Canada (PDAC) 2024 Conference, which took place this past March at the Metro Toronto Convention Centre in Toronto. More than 26,000 people attended this important event for the mining sector.

The World Bank’s mining lead Michael Stanley told a packed house during his Mining Industry Outlook at PDAC 2024 that copper demand is expected to grow exponentially between 2021 and 2050 with the metal’s demand likely to grow by 2.3 times over the next 25 years.

While this kind of aggressive demand will present a variety of challenges for the industry, it will also present some great opportunities related to job creation and infrastructure development in many regions of the world, Canada included (for more details on Michael Stanley’s Mining Industry Outlook presentation, check out page 8).

Copper is only one of the metals and minerals that is highly sought after. In addition to the energy transition, many metals and minerals are needed for the creation of our smartphones, laptops, appliances, and vehicles. With global demand of all these items on the rise, mining operations should be able to enjoy significant growth for decades to come, if they can find a way to overcome the challenges related to geopolitics, capital investment, labour shortages, navigating evolving environmental regulations, and the many other challenges

that the mining sector deals with on a day-to-day basis.

In case you didn’t notice, Canadian Process Equipment & Control News has updated its look. This change is part of our team’s decision to showcase more insightful and relevant features for professionals active in the Canadian processing sector.

Our diverse readership is comprised of processing professionals active in the oil and gas, food and beverage, pulp and paper, chemicals, pharmaceuticals, plastics and rubber, wastewater, mining, and power generations industries, as well as others. We want to ensure that as the voice of the Canadian processing sector we are providing you the latest features, including industry-breaking news, technology-based case studies, and the latest products to help keep you informed and optimize your operations.

We hope you enjoy our chat with Chemistry Industry Association of Canada president Bob Masterson about potential solutions to help the chemistry and plastics sector continue to grow and thrive in a world focused on decarbonization (see page 14 for the interview).

If you’ve recently worked on an interesting project that you believe would be of interest to our readers, feel free to reach out anytime! We want to share your successes.

Know of an industry event coming up that you’d like to see us cover? Reach out and we will do our best to get boots on the ground and bring you coverage of important announcements as they happen.

We look forward to meeting many of you at upcoming conferences and trade shows and am excited to hear all about your operations.

Sincerely,

ANDREW SNOOK, editor editor@cpecn.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal

Customer Service

Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Audience Manager

Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

Brand Sales Manager Pat Lorusso 416.518.5509 plorusso@annexbusinessmedia.com

Editor Andrew Snook 416.510.6801 editor@cpecn.com

Account Coordinator Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

Group publisher/VP Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CPE&CN is published bi-monthly by: Annex Business Media 111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

Endress+Hauser recently announced that it will be acquiring Switzerlandbased Angenstein ESTECH AG, including the company’s production site in Cernay, France, ESTECH Industries Angenstein SA, succursale de Cernay. The two companies have signed a memorandum of understanding, according to a press release from Endress+Hauser. The company also stated that all workplaces at the metal processing company are to be retained.

For over 25 years, Angenstein ESTECH AG has been a key supplier of measuring tubes for Endress+Hauser flowmeters. The Cernay site and its 50 employees are already incorporated into Endress+Hauser’s operation.

“The acquisition of Angenstein ESTECH AG will allow us to retain the employees’ knowledge and integrate important work stages even deeper into our production processes,” stated Christophe Stoos, managing director of the Endress+Hauser Flow France plant in Cernay.

The owner families of Angenstein ESTECH AG (Wiese and Helfenstein) stated this is an “ideal succession arrangement” for the company.

“Our focus was on preserving jobs and securing the future of the company. We believe the acquisition by Endress+Hauser represents the best possible solution,” stated Martin Helfenstein, chairman of the board of directors for Angenstein ESTECH AG.

According the MOU, the two companies are interested in signing a purchase agreement by the end of September 2024 with the company transfer taking place on January 1, 2025.

Endress+Hauser stated that the main operation in Aesch, Switzerland, which also supplies Endress+Hauser Flow in Reinach will not be affected by the acquisition and will remain part of the ESTECH Group under the name: ESTECH Industries Angenstein AG.

JAMP Pharma Group recently announced that it has acquired the assets of Pharmalab’s manufacturing facility in Lévis, Que. The company ceased operations in August 2023. The purchase is subject to Superior Court approval and the fulfillment of customary closing conditions.

“For several years, healthcare professionals and patients have had to deal with inventory shortages. Our ambition was to bolster the local

Endress+Hauser announced that it will be acquiring Switzerland-based Angenstein ESTECH AG, including the company’s production site in Cernay, France, ESTECH Industries Angenstein SA, succursale de Cernay.

manufacturing capacity to facilitate access to affordable medicine and healthcare solutions. This is a significant milestone for Quebec and Canada. In addition to positively contributing to the creation of wealth in Quebec, JAMP Pharma Group becomes one of the largest Canadianowned pharmaceutical companies,” stated Louis Pilon, president and CEO of JAMP Pharma Group.

JAMP Pharma Group recently announced that it has acquired the assets of Pharmalab’s manufacturing facility in Lévis, Que.

JAMP Pharma Group stated that it plans to relaunch the manufacturing operations of the Levis-based plant “when governments, customers, and partners are calling for more local procurement solutions.”

The company stated that the acquisition will strengthen the Canadian supply chain and assist in addressing drug shortages like those experienced during the COVID-19 coronavirus pandemic. JAMP Pharma Group stated that it plans on hiring a “significant portion” of Pharmalab’s 250 former employees. The company currently has a workforce of more than 700 employees.

“This recent acquisition by JAMP Pharma Group demonstrates its leadership in the Canadian generic drug industry and its commitment to the economic development of Quebec. Fonds de solidarité FTQ is proud to have supported the growth of this Canadian flagship since 2016 and continues to support the company in its

future endeavours,” stated Patrice Jolivet, vice-president, investments, for Agri-Food and Health at Fonds de solidarité FTQ, a partner of JAMP Pharma Group.

Moderna recently announced that its state-of-the art mRNA manufacturing facility in Laval, Que. has completed the construction phase of the project. The company stated that the facility should come online in 2025, and begin manufacturing respiratory mRNA vaccines for Canadians. Moderna is current awaiting regulatory approvals and certifications to ensure that “all vaccines manufactured meet the strictest quality, safety and performance standards.”

“With infectious diseases continuing to pose a significant health challenge, our mRNA platform can play a pivotal role against current and future threats. Canada’s role in global health is critical, and with this facility, Moderna is honoured to contribute to its robust scientific community and public health leadership in driving innovation and transformative medicine forward,” stated Stéphane Bancel, CEO of Moderna.

The company stated that the completion of the Laval facility “marks an important milestone in Moderna’s

strategic partnership with the federal government to support domestic preparedness for future pandemics for all Canadians,” and added that it will generate and support high-skilled employment opportunities. The facility’s construction was also partially funded by the Government of Quebec through Investissement Québec.

“Completing the construction of our mRNA facility marks a groundbreaking moment for Moderna and Canada as we

progress towards delivering a domestic mRNA vaccine supply chain. This building is a tangible example of concerted collaboration with the federal government, the government of Quebec, and the city of Laval, reflecting the lessons of the pandemic. We are proud to help drive Canada’s reputation as a mRNA centre of excellence and contributor to global health initiatives,” stated Stefan Raos, general manager, Moderna Canada.

Moderna’s new manufacturing site was

designed with environmental sustainability in mind, according to the company, which stated that minimal fossil fuel usage is needed since Quebec’s electricity is generated from renewable resources. The company stated that the facility works towards Moderna’s drive to achieve net-zero emissions by 2030 in scopes 1 and 2.

“We are grateful to our team and our partners who have contributed to the construction of this facility. Your urgency and diligence have laid the foundation for a healthier future for Canadians and set an enviable global benchmark in biotech facility design and construction,” stated RogerKetcha Ngassam, manufacturing site head, Moderna Canada.

Greene Tweed, a leading global manufacturer of high-performance sealing solutions and engineered components, has hired Justine Franchina as Greene Tweed’s new chief operating officer.

The company stated that Franchina is “an accomplished leader” and will bring “a strategic perspective and over two decades of experience in driving operational excellence, improving safety and quality culture, supporting organizational and talent development, and fostering strategic growth across global manufacturing operations to her role as COO.”

“We are thrilled to welcome Justine as an integral part of the executive leadership team,” says CEO Magen Buterbaugh. “Her deep experience in COO functions –spanning global manufacturing operations, end-to-end supply chain, procurement, quality assurance, and engineering – will be pivotal to Greene Tweed achieving our growth vision, as we continue to thrive in developing new products and solutions and expand into new markets and regions.”

Prior to joining Greene Tweed, Franchina held the position of COO at Ketjen, an Albermarle subsidiary providing advanced catalyst solutions provider to refining, petrochemical, and specialty chemicals industries. In this capacity, she led the global manufacturing operations, procurement, supply chain, CAPEX engineering, and process technology functions.

Neste Corporation has appointed Hanna Maula its vice-president of communications and brand, effective June 1, 2024. Maula will report to Hannele Jakosuo-Jansson, executive vice-president of HR, safety and communications.

“I am glad to have Hanna lead our

communications and brand function. Hanna has an extensive international experience in successfully managing these matters, and I would like to warmly welcome her to Neste,” stated Jakosuo-Jansson.

“I’m really excited to get to develop and lead Neste’s Communications and Brand function. Neste has a strong brand, and I know the company already from my previous career. I am looking forward to working with Neste’s businesses and stakeholders,” Maula said.

The Manitoba government is moving forward with a silica sand extraction project in Hollow Water First Nation and a solar glass manufacturing facility in Selkirk, Man., which will create good jobs and advance Manitoba as a leader in clean energy, Premier Wab Kinew and Environment and Climate Change Minister Tracy Schmidt announced this past February.

“These projects will create good Manitoba jobs in the trades for Manitobans right here in Selkirk, as well as in Hollow Water and surrounding communities,” said Kinew.

The proponent for the projects, Canadian Premium Sand, has signalled its intention to use silica sand extracted near Hollow Water First Nation in the Selkirk manufacturing facility to produce up to 800 tonnes of solar glass per day, a key component in the production of solar energy panels. The project will be North America’s only low-carbon patterned solar glass manufacturing facility and will appeal directly to countries like the United States that are looking to onshore manufacturing inputs.

The Manitoba Bureau of Statistics has assessed the overall economic impact of these projects which it reports would create 250 direct jobs for Manitobans as well as 600 to 700 jobs during the construction phase. The extraction project is estimated to create another 30 jobs near Hollow Water First Nation. The projects are estimated to generate $200 million in provincial taxes over a 10-year period, with similarly positive impact on provincial GDP and labour income, the minister noted.

“The Canadian Premium Sand project will be transformational for Selkirk, our region, and the province as a whole,” said Mayor Larry Johannson, City of Selkirk. “Not only will it see almost one billion dollars invested into our community, creating 250 direct jobs in Selkirk and generating tens of millions of dollars in local

economic activity each year, but it will make this region a vital hub in North America’s new low-carbon economy and be a magnet, attracting other commercial and manufacturing investments. We are excited to see the Canadian Premium Sand project reach this critical milestone.”

The Hollow Water First Nation and Selkirk projects were extensively reviewed by department experts and were the subject of Crown-Indigenous consultation, the minister

noted, adding that the projects received Environment Act licence approvals between 2019 and 2023.

Hollow Water First Nation and the Community of Seymourville have entered into confidential agreements with the Canadian Premium Sand to ensure economic participation, oversight and environmental and heritage resource stewardship, the minister said.

Source: Government of Manitoba.

Tired of endless phone mazes, unreturned calls, late delivery excuses, and all of the headaches associated with ordering a positioner—call VAC.

D400

• Rugged Aluminum Housing with LCD Display

• Modular design allows for adding accessories easily

• Unique Adaptive Control updates performance

D500

• Advanced diagnostics (pressure sensors) -SIL2-ESD

• Very high resolution, high air delivery

• Simple intuitive push button calibration and adjustments

Controls Inc. 2535 Stallion, St. Lazare, Qc, Canada J7T 2E4 J.C. Labelle: (514) 916-5895

Fax: (514) 500-5802

Email: jc@belletek.com

By Andrew Snook

Tens of thousands of mining professionals flocked to the Prospectors & Developers Association of Canada’s PDAC 2024 Convention in Toronto this past March to gain insights into the metals and minerals sector.

One of the highlights of the event was the Mining Industry Outlook presented by Michael Stanley, mining lead for The World Bank. Stanley has almost 40 years of experience in the sector spanning across North and South America, Europe and Central Asia, Africa, South Asia, and the East Asia/Pacific regions.

Stanley discussed the mining outlook up to the year 2050 with additional focus on the year 2035. He focused on the factors that are expected to cause the biggest impacts to the mining sector, starting with the world’s growing population and urbanization rate.

Sometime within the next 25 years, the world’s population is expected to grow to over 10 billion people, and most of those people will live in cities.

“The global population is urbanizing at an unprecedented rate, and by the year 2050, seven of 10 people, 7 billion people, will live in these urban centres,” Stanley told the crowd. “We are going through a transition that started in 1760 with the advent of the Industrial Revolution.”

With the world’s populations continuing to flock to large urban centres to gain access to better employment opportunities and infrastructure, this presents some big opportunities and challenges for the mining and energy sectors.

“The key to growth and economic opportunity starts with energy. Energy is the kingpin to ensure that we move forward as a society. It allows us to improve our places of work, our housing, our hospitals. It

allows for better delivery of education. It all starts with energy. And it also, in the urban environment, allows governments to deliver health, education, care for children and elderly,” Stanley said.

As urban areas grow at fast rates in their early years, their demand for metals and minerals is great.

“They have fantastic consumption of metals and minerals, think of Shanghai, China… across the globe, we have more and more cities coming up crossing the 10- and 20-million mark. And so, the intensity of use is very important,” Stanley said.

The second major disruptor taking place is the energy transition.

“This is very important, because the world is now challenged to replace the electric systems and the energy systems that for the last 150 years have underpinned all economic development. They have underpinned infrastructure development, roads, rail, ports, have been tied to the energy system, and particularly coal. And it will all be replaced, but between now and

2050,” Stanley said.

The combination of poverty reduction and urbanization with the energy transition is creating a tipping point in the minerals industry, where the balance between supply and demand is suddenly tipping very heavily towards demand, he told the crowd.

The demand for copper is expected to grow exponentially between 2021 and 2050.

“The demand for copper is likely to grow by 2.3 times in the next 25 years, fantastic growth. That’s three- to three-and-a-half per cent compound annual growth rate,” Stanley said.

While the demand will increase over that period of time, the heaviest growth will occur between 2030 and 2040, he adds.

“The major demand for a carrier metal like copper actually occurs about 11 years from now. We have to have in place for 11 years from now, all of the metals that are necessary to the energy transition. And in an industry where the

average time from discovery to production is 14.9 years, we are already inside a fantastic transition, and the demand for metals is starting to climb,” he said.

The supply is expected to come from a combination of mining production doubling across the globe, and recycling operations tripling.

“We are inside a very fantastic energy transition-urbanization transition today,” he said.

One of the biggest challenges for meeting the growing global demand for metals and minerals is that the sector is currently operating in a time of very constrained capital access.

“It’s very difficult to move money into a lot of these mining sector projects. I want to say the reason for that is there’s a perception of risk that did not exist before, and it’s in two spaces,” Stanley said.

One area is the demand-side risk, where the adequacy and security of supply is now requested. This is because by 2035, the sector needs to meet significant demand for the

energy transition – 11 years from now in an industry that’s 14.9 years from exploration, discovery through to production, Stanley explained.

“So, there’s certainly a concern about security of supply,” he said. “There’s also, on the supply side with governments, a reframing of mineral developments. They are looking to see mineral development in a very different way than they did before. They have expectations for this industry that did not present themselves five years ago.”

The World Bank recently deployed a survey asking what investors want and need to go into countries.

“The first is geological potential. Well, that’s quite obvious,” Stanley said. “But after that, we have potential profitability of operations. Could I move my profits back and forth across international boundaries? Security of tenure. Do I have a license holding from exploration subject to compliance with the laws, the policies and regulations to have security and tenure that I can move to exploitation? Are there barriers placed in the way?

Consistency of mineral and tax policy… and then the last one, is perhaps the sleeper on the whole list: strong institutional governance. Does that government have the technical capacity to effectively implement the policy that is on paper, in terms of what takes place in mineral development?” Stanley said.

After geological potential, all the other factors are all under the control of the government, he notes.

“And so, governments are the largest determinant as to where mining investments flow, after you’ve gotten past that geological potential,” he said.

Operating in countries that are under economic distress will also play a factor in mineral and metals development.

“Currently today, 36 countries –13 low-income countries and 23 middle-income – countries have fallen into or are at high risk of debt distress. They’re in need of financial restructuring programs, and per capita investment growth in 2024 has fallen to barely half the average it was in the last two decades. And

May 23 - 25

without corrective action, global growth for the remainder of the 2020s is likely to remain very flat. If you are a government and a liberal producing country, these headwinds are very strong, and that sentiment is spilling over in late 2023,” Stanley said.

Operating in countries that are under economic distress will play a factor in mineral and metals development

Stanley said the enabling environment is going to be built on three factors, with the first being economic development.

“Leveraging jobs, jobs, jobs – inside the mine, outside the mine. How can we catalyze the small to medium enterprises and ecosystem around those mines so that we get more jobs?” Stanley said.

The second factor is public-private partnerships.

“Catalyze infrastructure for development, beginning with energy, because that is the driver that governments are looking for – energy access on the grid, mini-grid, and off-grid, and it starts with energy,” Stanley said.

The third factor is for the industry to make contributions and then downstream users of metals to make contributions.

“This contribution to value addition, that’s a longer or aspirational goal for many countries. But that’s also something that is certainly going into policies today,” he said. “The industry representatives and members that can meet these objectives, and frame how your mine is a driver of broader development is going to thrive in a market where the goal is going to be 10 billion people at a certain point.”

The PDAC 2025 Convention will take place from March 2 to 5, 2025 at the Metro Toronto Convention Centre. For more information on the 2024 and 2025 conventions, visit: www.pdac.ca/convention.

The CPCA annual conference is a must-attend for professionals in the process control industry to gather knowledge and network with colleagues who have a stake in building the sector. With a mix of education from thought-leaders and exciting social events, you will leave the conference better informed, connected and engaged in a host of new ideas to address challenges in the marketplace and learn how to adapt in an evolving industry. REGISTRATION OPENING SOON at cpca-assoc.com.

The annual conference is only one of the many benefits of joining. The only trade association for the instrumentation and automation industry in Canada, CPCA is comprised of members involved in the development, production, sales and service of process control and automation products and systems from coast to coast.

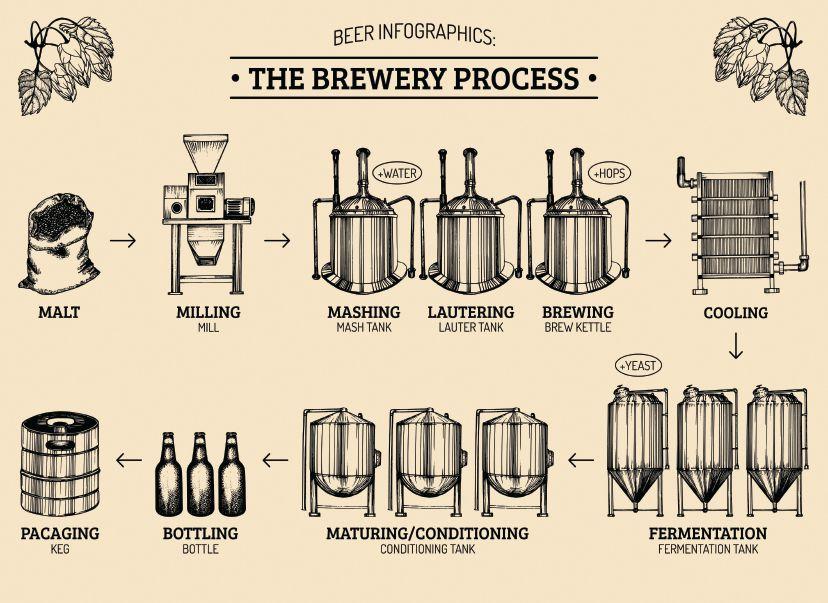

By Jeff Elliott

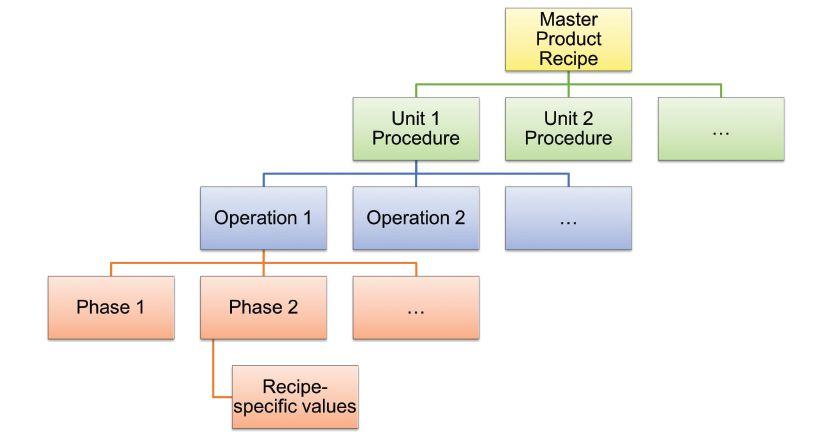

When the International Society of Automation first published its ANSI/ ISA88 standards in 1995, the goal was to provide processors with standards and recommended practices as appropriate for the design and specification of batch control systems. This spurred the development and release of S88-based software solutions designed to simplify the process of implementing and modifying recipe procedures without complex software programming.

The goal of the software was to allow recipe creators or operators to modify recipe parameters, procedures, production schedules, batch start rules, equipment utilization, or to scale batch amounts more easily and at any time. The S88 standard also served to effectively separate the role of the control engineer (for programming) and recipe developers at the plant. At a chemical processing facility, that might be a chemist; at a brewery, it is the master brewer, for example.

“For years, if you were responsible for creating recipes in a plant, you had to also know how to program the control system. So, if it was your job to build recipes, that [task] always involved programming until the S88 standard came along,” explains Bob Ard, senior advisor at Valmet, a leading global developer and supplier of process technologies, automation, and services for many process industries.

Ard says now, with flexible batch control software, any programming is completed ahead of time and only for the lowest level of control tasks, such as opening and closing valves, increasing temperature, pH control, adding materials, etc. These fundamental building blocks are called “Phases in S88.”

A recipe developer can then group the Phases using a drag-and-drop interface to

create an operation. The order of operations for a processing unit is defined in the unit recipe. All the unit recipes required to make the batch from start to finish are grouped in the master recipe.

The result of this S88-style approach is a safer, more intuitive process that reduces the amount of programming, simplifies the implementation and modification of new recipes, and ensures batch cycles are more consistently executed with the proper timing and procedure.

According to Ard, the two primary automation methods used by Valmet are state-based control and S88 control using Phase logic and FlexBatch, the company’s proprietary software. State-based control generally works best for continuous processes, while FlexBatch is preferred for batch processes. However, some continuous pro-

FlexBatch Phases are easier to design, create, and maintain compared to state-based programming.

cesses operate like a batch process. By the same token, all batch plants contain some processes that are continuous or run sequences that do not require recipe control.

Setting that aside, Bob Ard says the general rule of thumb is to use flexible batch control for recipe-driven Units and state-based control for all others.

“State-based control is ideal for running the infrastructure in the plant, such as the boilers, air compressors, and glycol chillers,” says Ard. “I need those regardless of the product that I’m going to make and so I would automate those units using state-based control. But I would use FlexBatch control for the units that process the material to make the batch.”

With batch processing, one of the challenges is the communication and coordination between units – a task that

state-based control can only resolve with significant programming.

Many batch processes consist of a “train” of units where the batch material is introduced in the first unit and passed from unit to unit. Each unit is designed to process the material in some way, for example, heating, cool-

ing, adding other materials, blending, separating, etc.

“With a batch process, you are constantly trying to coordinate activity between units, and that requires a lot of programming to do if you’re going to do it in state-based control,” explains Ard. In his book, tentatively titled, “How

The software is designed in accordance with the ISA-88 standard for batch control and reduces the dependence on control engineers.

to D3,” Ard gives an example of batch processing by a brewery. The comprehensive guide to control system design is expected to be published in Q4 of 2023.

In a brewery, grain, water, hops, and possibly several other ingredients are processed by a series of units. In this example, the units would be a weigh scale, a mash tun, a lauter tun, a brew kettle, a whirlpool, and a fermenter.

The batch process would begin by milling and weighing the grain at a weigh scale. The program in the weigh scale follows a predefined series of steps to mill and weigh the recipe amounts of grains into the scale hopper.

The next unit is the mash tun, where the starches from the grains are converted into sugars. When the mash tun is loaded, a recipe amount of water is metered into the mash tun at a recipe temperature. The mash tun produces a mash of sweet water with just the right sugar profile for the style of beer to be made.

The mash is then transferred to a lauter tun, which separates the grain from the mash while keeping the extract that is suspended in the water. The result is called wort, which is then transferred to the kettle.

The brew kettle boils the wort to evaporate enough water to reach the specific gravity identified by the recipe. Various hops are added to the kettle during the boil state. Some are added early in the boil state, while others are added near the end. Some beers might require the addition of fruit, honey, dextrose, spices, and other flavorings or sugars. The brew kettle then coordinates the transfer of wort to the whirlpool.

The whirlpool allows the coagulated proteins suspended in the wort to settle to the bottom of the tank. This material is called trub and you do not want it in your beer. The wort is carefully decanted from the side of the tank and pumped through a cooler on its way to a fermenter. Yeast is pitched into the wort stream as it exits the cooler. The yeast work their magic in the fermenter to change wort into beer.

So, what are the benefits of using flexible batch control for this and other processes?

The Valmet D3 DCS system is perfectly capable of state-based batch control of a process like brewing beer with – or without – FlexBatch. However, with state-based control, the procedures are hard-coded into a series of “States” within a program. The program sequences through the states to process material within the unit. State-based control utilizes recipe data files to provide the recipe formula values.

Each recipe data file is loaded into the first unit in the sequence and passed down the line. Each upstream unit monitors its downstream unit to know when to transfer the recipe. The upstream unit allocates the downstream unit to the batch, and each unit deallocates itself from the batch when its part of the process is completed.

Although state-based control techniques work well, the programming required to achieve the necessary coordination level can be extensive. If the products being made require different procedures, it can be even more labour intensive.

With FlexBatch, the first question is whether the software provides benefits beyond the baseline DCS system.

The FlexBatch software integrates recipe management and the manufacturing process so that product developers, engineers, and production staff can quickly develop, produce, schedule, and manage documented, executable recipes using intuitive graphical tools.

With flexible batch control software, any programming is completed ahead of time and only for the lowest level of control tasks.

The software is designed in accordance with the ISA-88 standard for batch control and reduces the dependence on control engineers.

The FlexBatch procedure editor gives recipe developers the ability to draw up procedure charts using a dragand-drop interface to combine phases into operations, operations into unit recipes, and unit recipes into a master recipe.

“The recipe developer can mix-andmatch phases using a procedure editor and draw procedure charts to establish the sequence of phases and operations in serial or in parallel, as needed,” explains Ard. “You don’t need to be able to program a DCS to draw or redraw the procedure chart.”

New recipes and even modifications require no programming. Operators can force transitions (with sufficient privileges), schedule batches and equipment allocations, and watch live recipe procedure charts for greater awareness of batch execution.

“The live view of the FlexBatch procedure chart shows exactly what is happening with the process. Operators can clearly see which part of the recipe procedure has been completed, which part is currently executing, and what comes next. Providing that kind of visibility with state-based control requires a lot of graphics and additional programming,” says Ard.

Although there is a cost for the FlexBatch licenses and server, it is offset by reduced DCS implementation time. Even the fundamental building block

that still requires programming, the FlexBatch Phases, is easier to design, create, and maintain compared to statebased programming.

“Decades of experience demonstrate that a FlexBatch implementation requires up to 30-per-cent less programming,” says Ard.

Today, Ard says most processors expect an S88 flexible batch control software solution or will go elsewhere if one is unavailable.

The increasing demand was even cited as a key factor in the decision by Valmet to acquire NovaTech Automation’s Process Division – the original developer of FlexBatch – in January of 2023.

“What we were looking for was NovaTech’s batch control capabilities, and the FlexBatch software is an essential part of that,” says Kari Huovila, vice-president of North America automation systems at Valmet.

Valmet expects that adding the batch control capabilities of FlexBatch will only strengthen its own existing Valmet DNA system and help the company enter new industries with a highly competitive solution.

“At this point, there really are no disadvantages of using FlexBatch for batch control,” concludes Ard.

JEFF ELLIOTT is a Torrance, Calif.-based technical writer. He has researched and written about industrial technologies and issues for the past 20 years.

The Safety Station is a multi-purpose drench shower, eye/face wash and safety supply storage cabinet all in one. It is ideal for laboratories where persons may be exposed to potentially hazardous chemicals. Sanitary white polypro construction means there is no wood or metal to rot or rust. The Safety Station is equipped with a pull rod activated shower and push handle eye/ face wash for quick rinsing of eyes, face, and body. Towels and first aid supplies can be stored in the cabinet below. Unit available in 24”, 30” or 36” wide by 24” deep and 84” high. Safety Stations are fully assembled and ready for installation to water supply. HEMCO Corporation www.HEMCOcorp.com

EchoTherm SC20 and SC25 models

Torrey Pines Scientific, Inc. has released its new EchoTherm SC20 and SC25 models. The SC20 is a simple digital unit while the SC25 is fully programmable having a five-program memory making both ideal for use with biological and other samples. Both have a temperature range from -20°C to 100°C and incorporate a variable speed orbital shaker for mixing and controlling

the temperature of samples simultaneously. Both units have a 30-day countdown timer with alarm and auto-off, data logger, and RS232 I/O port for data logging or controlling the units from a computer. The SC20XT and SC25XT accommodate accessory sample blocks available for 0.2, 0.5, 1.5, 15 and 50ml centrifuge tubes. Also available are blocks for 2ml vials, 20ml scintillation vials, PCR tubes and plates, 96-well and 384-well assay plates of all shapes, deep-well assay plates, and other blocks for various sizes of test tubes. The units are

Peltier driven, with control to 1°C, shaking range from 200 to 1,000 rpm and have a backlit two-line alphanumeric display. These instruments are excellent molecular biology tools and can be used to run temperature/time profiles, unattended restriction digestions or ligations, automatic enzyme reactions and deactivations, storing oocytes at 17°C, storing DNA libraries at the workstation, and more.

Torrey Pines Scientific www.torreypinesscientific.com

The UFK 1.1100 EX is an advanced solution for transferring liquids at high flow rates with low pulsation. This self-priming, three-diaphragm pump offers flow rate up to 11.5 liters/minute and is run-dry safe.

Learn More at knf.com/en/us/ufk-11100-ex

A look at solutions to help ensure a successful transition

By Andrew Snook

The Chemistry Industry Association of Canada (CIAC) recently released a fact sheet titled, “Investing in decarbonized chemistry to strengthen Canada’s economy,” which focuses on the need for decarbonizing the chemistry and plastics industry. As chemistry and plastics combined make up Canada’s fourth-largest manufacturing sector, significant investment is required to assist these industries in making the transition to a low-carbon future.

To learn more about what is required, Canadian Process Equipment & Control News spoke with CIAC president Bob Masterson about potential solutions to help the sector continue to thrive well into the future.

When asked what it will take for Canada’s chemistry and plastics industries to hit their climate change, and circularity requirements and other commitments? Masterson says the answer is capital.

“We need investment. None of these things happen without massive investment in our industries. I would say Canada, until very recently, has been very poor at capital attraction,” Masterson says. “But in the last few years, the provinces – Alberta, Quebec and Ontario – have gotten much more effective and really levelled the playing field, especially with U.S. states. And now you’ve seen the Government of Canada do its best to level the playing field with the U.S. federal government’s IRA (Inflation Reduction Act) initiatives. So, you’re starting to see companies being ready to invest in Canada – the capital of traction is there.”

As a rough estimate, Masterson says Canada’s chemistry and plastics industries has somewhere between $200 billion and $300 billion worth of built infrastructure in Canada today. And if the industries are to decarbonize that by 2050, they’re going to need to recapitalize and attract another $200 billion to $300 billion in new investment.

“It’s certainly doable, but not on the path we were on previously. I do feel that we’re getting closer to that now,” he says.

How will the industry transition the global chemistry and plastics industries to low carbon, and which solutions will be the easiest and toughest to implement? Masterson says carbon capture utilization and storage (CCUS) technologies are already part of the solution.

“The chemistry industry in Alberta has used carbon capture to meet its climate change compliance obligations for 20 years now, under the Alberta program. It’s relatively easy. Costly, but relatively easy,” Masterson says. “When you look at Ontario, though, until this year, it was prohibited to sequester carbon underground, and we still lack the regulatory policy in Ontario, and the regulatory and policy framework that will let anybody do carbon capture today. Ontario has proposed some pilot projects, but a pilot project isn’t the type of solution we see in Alberta today.”

One area where Ontario is currently pursuing a different decarbonization strategy than Alberta is in its investment in small modular reactors.

If Canada’s chemistry and plastics industries are to decarbonize by 2050, they will need between $200 billion to $300 billion in new investment.

“There’s some interest, broadly, in looking at putting some of those small modular reactors into industry intensive areas, whether that’s places like Sault Ste. Marie or southwest Ontario – Hamilton, Sarnia, places like that,” Masterson says. “It’s a possible solution that’s a lot easier to contemplate somewhere like Ontario, where you’ve got that long history with nuclear power. Certainly, it’s an opportunity in Western Canada, but is society ready for nuclear power out there? They don’t have the regulatory and policy structures to support that today.”

One company that could move small modular reactors forward in North America is Dow.

“If small modular reactors get a toehold in industrial settings in North America – and Dow has proposed a project with X-Energy down in Texas – that’ll be a game changer for everybody,” Masterson says.

What are the market implications for Canada’s chemistry and plastics industries if they cannot meet emissions targets in some major world markets? Could Canada’s sector be shut out completely? That’s unlikely to happen anytime in the near future, Masterson says.

“I’d say that there’s no risk of that anytime in the foreseeable future for a long, long time. Why? Well, first of all, Canada has one of the highest carbon prices anywhere on the planet – and that’s set to go even higher in the next six years. So, it’s hard for someone else to lock out Canada’s industries because they haven’t hit some targets when no other country is getting any further along, and they don’t have the same price on emissions,” he says.

According to the CIAC’s fact sheet, Canada’s recycling infrastructure capacity gap will require capital investment ranging from $4.6 billion to $6.5 billion. Masterson believes that regions like southern Ontario can take advantage of its large population as part of the solution for some of the companies operating in the province meeting their climate change targets.

“Large companies like a Dow or Nova Chemicals will tell you that 30 per cent of their climate change ambitions will be realized by not making plastics in the first place, that they will recover and repurpose the plastics we’ve already put out into the economy, the idea of the circular economy,” he says. “When

you look at a province like Ontario, and you’ve got what, maybe 12 million to 13 million people in southern Ontario, that’s your feedstock, right? You can really make a lot of things happen in a circular economy… I think in the coming years you’re going to see a lot more activity around plastics recovery and circularity. That’s an exciting opportunity, and you’ll see that in Ontario, just because of the size of the population.”

One thing holding companies back are burdensome policy barriers that need to change.

“As an example, in Ontario, even today, if you want to save, take, receive recovered plastics, for the purpose to remanufacture, you have to get a waste disposal permit. You are basically [treated] as a waste disposal site,” Masterson says, despite these companies typically operating primarily as light manufacturers. “The current rules are that you’re a waste disposal site, and you have to seek that approval. It’s too difficult, people won’t do it. We’ve got halfway there with the government, they did get rid of the requirement to go through an environmental assessment as a waste disposal site, but they still approve you. So, we have to finish getting those types of barriers out of the way.”

Hydrogen production and CCUS technologies are currently two of the most promising options for reducing emissions on a large scale, Masterson adds. However, the chemical and plastics industries are also experiencing increased investment in the renewables sector.

“You see the industry also making investments in renewable energy with Shell investing significantly in solar power at its Scotford Complex. Companies like Imperial are investing in battery storage in Sarnia. So, you see some things like that as well. They’re not as large, and definitely much longer term,” Masterson says.

Masterson says one of the industry’s current concerns is related to the potential extension of the Accelerated Capital Cost Allowance (ACCA) programs. The CIAC stated that the ACCA programs should be extended until at least 2040 with no phase out or wind down until 2030 to better align with Canada’s ITC timelines.

“We are concerned that ACCA will phase out if it’s not renewed and extended. It’s important. It’s another piece of the puzzle,” he says. “Just as Canada is levelling the playing field, you don’t want to turn the advantage back to the Americans again. I can’t quantify for you with the rest of the programs where that fits, but it is an important component, because it’s there in the U.S. It’s permanent, and it’s much broader than here in Canada.”

“Big credit in particular goes to Alberta and Quebec, and certainly the federal government’s got things in place,” he says. “Ontario, on its own, has done a really good job. They are very responsive when anybody comes forward and says, ‘I’m thinking of doing something in Ontario.’ They’re very responsive, but they don’t they don’t have a program in place the way Alberta does, or Quebec does… you have to go in and get there on a case-by-case basis, but they’ve attracted enormous capital in the last few years.”

Masterson says governments will need to use all the levers at their disposal to attract investment. “Certainly, things like capital cost allowance, investment tax credits, those are no brainers,” he says. “You’ve got to build. You’ve got to operate. You’ve got to sell your product to a customer that wants it. You’ve got to make profit, and you have to pay taxes, and then you pay a little less tax. That’s a pretty winning combination, right? We think that’s what the government has to do.”

Despite current policy challenges, Masterson says the provinces are moving in the right direction to stimulate needed growth and change within the chemical and plastics industries.

Adopting technology that could significantly reduce manufacturers’ energy consumption

By Carolyne Van Der Meer

mart building technology is getting more and more airplay these days, particularly in the manufacturing sector, where facilities large and small emit a significant percentage of greenhouse gases. In general, buildings are responsible for nearly 30% of all GHG emissions1—so imagine what a difference it could make if the manufacturing sector adopted technology that could significantly reduce energy consumption. The path to net zero emissions would certainly be smoother. But how do we get there? What are the things we need to think about?

SCanadian Process Equipment & Control News had an opportunity to talk with ABB Canada’s business development manager for the food and beverage segment, Stan Wachon, about the “factory of the future.” With 30 previous years in industrial automation where he saw firsthand the issues that can arise in an industrial environment, and now several years with ABB, Stan has expert knowledge on what it takes to become an efficient, effective facility with streamlined operations that reduce waste and ultimately point the way to a greener, more sustainable future. In our discussion, Stan explained how a company can achieve the sought-after status of not just being forward-looking but actually making a difference in terms of energy efficient operations.

BEFORE WE GET INTO THE HOW OF IT, CAN YOU TELL US WHAT IS MEANT BY THE TERM “FACTORY OF THE FUTURE”?

For me, it’s an efficient, effective factory that can provide you with valid data on your operations, data that enables you to

be predictive and preventative about your assets within the factory.

With data on your operations, you are now in control of your factory, versus the factory controlling you and causing you to be reactive. Data will enable you to understand exactly what your factory is doing, from the electrical side all the way down to the finished product. Setting it up can be costly, but the end result can be very functional and very, very beneficial to the environment.

BEFORE WE TALK ABOUT COST AND STEPS AND STAGES, CAN YOU TELL US WHY GATHERING BUILDING DATA MATTERS, WHAT KIND OF DATA CAN BE GATHERED—AND HOW?

Gathering data helps you understand what your factory is doing. And from there, you can find deficiencies that will ultimately enable you to create efficiencies. For example, in the food and beverage industry, I have customers that come to me knowing that they have inefficiencies, and know they need to upgrade, but because they can never stop production without incurring a loss, they can’t fully understand or address any of the issues that would make them more efficient. If they could gather data about their activity, that would start the conversation about what needs to happen next.

Let me give you an example to show you what kind of data can be gathered

With data on your operations, you are now in control of your factory, versus the factory controlling you and causing you to be reactive.

and how. Last year, I was approached by a company with a 100-year-old multilevel facility. As demand grew, they expanded the facility and added electrical systems with every expansion. Over time, some of the equipment became old and dated—and there is no metering being done to reveal and track the inefficiencies of these systems. To undertake any further expansion, they needed to gain a better understanding of their facility. We mounted non-intrusive panels beside their electrical equipment on various levels of the facility that allowed us to meter and monitor the energy being used. After three months of metering, they had a solid understanding of their power draw, what systems needed to be replaced and where they could further expand their facility. Essentially, the first step is information—in other words, data. Once you have this, you can start to have a conversation about what comes next.

ONCE YOU HAVE AN UNDERSTANDING OF YOUR ENVIRONMENT, WHAT IS THE NEXT STEP IN THE PROCESS? AND IS THE CONVERSATION AS APPLICABLE TO SMALL FACILITIES AND PROJECTS AS IT IS TO LARGE ONES?

With this conversation, we can start to build a plan to move things forward—and this can be as small as the replacement of breakers because they’re energy hogs. Or it could be a matter of changing lighting

or upgrading motors that are too old. Making a reduction in one place can lead to adding a positive in another place.

SO, LET’S TALK A LITTLE MORE ABOUT DATA COLLECTION. HOW DOES IT WORK?

There are cloud-based systems that will actually gather information from the electrical lines, telling you how much power you’re drawing in kilowatt hours. With the information we collect, based on electricity rates, we can determine the cost per day of the facility. So, it’s more than just basic data; it’s information about your power consumption and the energy you’re using. And in Ontario, where different rates are charged during the day, that understanding is key to someone who is running a 24/7 facility.

AND ONCE YOU HAVE THE DATA, WHAT HAPPENS NEXT? WHERE DO YOU START TO MAKE CHANGES?

The data actually dictates the next steps, such as whether you make a change from the front end or somewhere else in the process. Let’s say that someone is experiencing voltage sags from the electrical delivery provider. Dips in power delivery can disrupt electrical device operation. When the power comes back, there are two possible scenarios: you are operational, or the dip was so low that with an immediate powerup, the system gets damaged. In my experience, damage can be anywhere from $10,000 to $300,000 because of a fluctuation in the power. If we know that within three months, there have been 10 fluctuations that led to the replacement of equipment, that means you will want to start from the front end. You don’t want unplanned outages to result in equipment replacement. When that happens, you end up dealing with a panoply of other issues: the motors you need are not in stock, your production is stalled, and unfinished product was wasted.

STARTING FROM THE FRONT END MEANS BEING PREVENTIVE; IN OTHER WORDS REPLACING THE OUTDATED EQUIPMENT, AS OPPOSED TO REPAIRING IT WHEN IT BREAKS, OR ONLY MAKING A CHANGE WHEN A POWER DISRUPTION FORCES YOU TO.

Exactly. The newer technology won’t draw as much power, so you’re now removing the additional energy being used at the front end. Once you have dealt with this, you can begin to tackle other issues that might be deeper in the factory. The plan you initiate could be in small steps, first by reducing the amount of energy used and then by tackling the more expensive issues, like a power conditioning system, which would be a capital expenditure.

HOW DOES GATHERING DATA AND THE PLAN THAT COMES FROM THAT LEAD TO INCREASED SUSTAINABILITY AND A REDUCED FOOTPRINT?

The plan will allow you to use more energy-efficient equipment and you can consider bringing in automation that will increase that efficiency. You can add renewables such as solar panels so you can actually drive the building to be even more energy efficient. I’ll give you a recent example from a discussion I had with a large general contractor that believes green energy buildings are the way of the future. We discussed how we could incorporate the circulation of air through the floor so that the building would not require a lot of heat. This is something you could plan for—a little bit more costly up front, but the return is much quicker once you are operational because you’re not using that energy. This is an example of an opportunity to be more predictive and preventative in your system instead of reactive. In the factory of the future, every little piece actually has an effect on another piece.

We also have to ask ourselves what the goal is when we say we want to be sustainable: I want to be sustainable in the way I create my product: create no waste, have no recalls. I want to make

things on my own without worrying about anything else. I want carbon neutrality, net zero. You can only get to this dialogue once you can corral the issues within your plant. And some of these are smaller issues that can be dealt with during downtimes or during sanitization, for example.

CAN YOU TALK ABOUT THE TIMEFRAME AROUND BECOMING MORE ENERGY EFFICIENT BECAUSE YOU ARE ABLE TO GATHER DATA AND UNDERSTAND YOUR ENVIRONMENT?

With a facility that is looking to improve energy efficiencies but doesn’t need to consider large changes or capital expenditures, data can be gathered, and a plan developed and executed within three to six months. If it’s a large build, potentially a year. At ABB, we offer analytics and engineering studies to help the customer figure out the direction. We come in and actually set up equipment to do the data collection for them for a certain period of time, and analyze it, generate a report and work with them to build a plan. For this, you need three to six months. Many companies nowadays don’t have engineering departments or large maintenance departments. They rely on external suppliers, so when there’s an issue on site, an external electrical contractor comes in and, on demand, and fixes the issue. That’s more reactive than proactive, right? If a facility can just get data, they can actually be more proactive about what they’re doing in the face of issues they know will arise.

Immediate change causes a lot of disruption and might be more costly, but gradual change can be sustainable and can give us a little bit more satisfaction: of saying I’m doing something to make it better. This is what will get us even closer to the ultra-efficient factory of the future.

1 Canada Green Building Council. “LEED: The global standard in green building.” Accessed February 27, 2024.

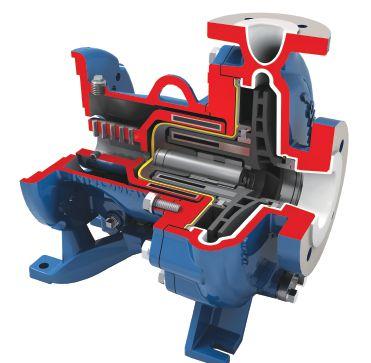

Single impeller, compact footprint, fewer parts among features for regenerative turbine

By Stephen Basclain

Operators often select regenerative turbine and side-channel pumps for difficult liquid transfer or processing jobs. While different in their construction and capabilities, both technologies can be commonly found in applications dealing with liquids near their vaporizing point. These liquids prove challenging for other process pump technologies because of their near gas-like state, leaving some pumps struggling to reach and maintain prime or generate pressure when pumping these low-viscosity, high vapor pressure substances. These types of challenging substances include Autogas, liquified petroleum gas (LPG), carbon dioxide (CO2), ammonia, refrigerants, blowing agents (such as DME), solvents, propane, butane, and other hydrocarbons.

Regenerative turbine and side-channel pumps are designed specifically to move these near-gas liquids from one place to another without difficulty. It is, however, the differences between these two technologies that separate them from being a good process pump for these applications to being an exceptional option.

While operators will still get strong performance out of either solution, regenerative turbine pumps have clear advantages over side-channel pumps in these applications. This article will ex-

plore all the facets of these two pump technologies to show why regenerative turbine pumps have a significant edge when processing near-gas liquids.

UP CLOSE WITH REGENERATIVE TURBINE PUMPS

Regenerative turbine pumps are rotodynamic, operating via a rotating, non-contacting, free-wheeling disc with several small cells on its periphery that function as an impeller. About 50 to 60 cells on each side of the impeller capture the liquid as it enters through the suction port. The impeller then accelerates the liquid within the cells around a narrow hydraulic channel. This motion creates the pump’s differential-pressure capability, which enables it to consistently transfer the sometimes near-gas liquid at the required flow rate.

This technology excels at transferring a variety of substances that many other pumps struggle with. Regenerative turbine pumps can effectively process li-

Typical regenerative turbine pumps generate flow rates up to 52.8 gpm (200 L/min) however some variations of these pumps are capable of handling even higher flow rates. Some newer iterations of this technology can reach peak flow rates as high as – and potentially higher than – 158.5 gpm (600 L/min).

quids at or near their boiling point, while also handling entrained vapors and liquids at high pressure and low flow. Other pumps run into problems with these fluids because they are not engineered to properly handle the range between liquids and vapors. The consequences of running those fluids through other pump technologies include cavitation, vibration, noise and unreliable performance, which all reduce the life of the pump and can cause damage to workers and other equipment.

The reason regenerative turbine pumps do not suffer the same fate comes down to their design and construction. The impeller and its cells provide versatility, with the spiral motion and speed smoothing liquids and collapsing vapor bubbles as they form, which prevents cavitation and pulsation. Having a hydraulically balanced design coupled with smooth flow rates also means that the pump can operate without noise or vibration in most situations.

The capabilities of regenerative turbine pumps can be found not only in their design but also in their fluid-handling capabilities. This technology can handle viscosities of 0.1 to 50 cSt with differential pressures up to 20 bar (300 psi) and a maximum allowable working pressure of up to 34 bar (493 psi). Typical flow rates reach up to 200 L/min (52.8 gpm), with some variants (newer iterations especially) hitting flow rates as high as 600 L/ min (158.5 gpm).

Side-channel pumps share similar capabilities with regenerative turbine pumps, yet also have more complex designs, require more space and feature more wear parts.

Like regenerative turbine pumps, side-channel pumps have similar characteristics and processing abilities. How the technology achieves them is the difference, though. Side-channel pumps feature a multistage impeller system and one or two flow paths. The impeller system, which features straight radial vanes, pressurizes low-viscosity fluids, vapors and near-boiling point substances.

The side-channel design features a small gap between the blades and the casing. It is in this gap that the pump grabs the liquid and sends it to the impeller blades and through the side channel. This motion moves the substances several times between the side channel and the impellers, creating steadily higher pressures for eventual transfer.

Side-channel pumps are known to have the same characteristics as both positive displacement and centrifugal pumps; the narrow clearance between the casing and the blades has a similar function to the close clearance in a positive displacement pump while the impellers are similar to those found in centrifugal pumps.

Operators select side-channel pumps for their versatile nature. The pump’s complex design allows it to generate up to 10 times the pressure of a centrifugal pump operating at the same speeds. This makes side-channel pumps ideal in similar applications to those where regenerative turbine pumps excel.

Typical applications for side-channel pumps include refrigerants, fuels, aerosols, butadiene, solvents, hydrocarbons and water, among many similar substances. They also can self-prime, another feature shared between this technology and regenerative turbine pumps.

When pitting the two pumps against each other, it might be difficult to spot their differences when it comes to performance. After all, regenerative turbine and side-channel pumps are exceptional in handling poor suction conditions and both possess the ability to self-prime in the right conditions. They also can handle the same types of fluids without setbacks or performance detriments.

The differences, though, are plentiful.

Side-channel pumps require larger frames and space for installation, while the regenerative turbine pump has a more compact footprint. Side-channel pumps can be up to two or more times larger than regenerative turbine pumps and up to three times the weight. Additionally, regenerative turbine pumps also consume less power than side-channel pumps but can still achieve the same flow rates and pressures. They also have a smaller profile and motor, which can also reduce electrical installation costs.

Side-channel pumps are also more complex in their design than regenerative turbine pumps, boasting up to as many as eight impellers in their larger variants, especially those found in LPG applications. Having multiple stages requires larger frames to accommodate them, while regenerative turbine pumps can accomplish similar performance results with single-stage construction in a compact frame.

Like any processing technology, maintenance must occur to keep it functioning as intended. With the complexities of the side-channel pump design, operators have multiple wear parts and functional pieces to account for when performing maintenance. To be precise, side-chan nel pumps have 20 wear parts, which includes sleeve bushings, a mechanical seal, several impellers, bearings and seal rings among many other compon ents. Keeping track of that many components means maintenance can require multiple hours and more frequent visits given the number of wear parts and the likelihood they all won’t need to be replaced at the same time.

Comparatively, re generative turbine pumps only have one wear part –the mechanical seal. Oper ators can spend less time maintaining this type of pump because they only need to track the performance and condition of that single wear part. Even with a major rebuild, the replacement

Regenerative turbines combine the high discharge pressure of a PD pump with the performance flexibility of a centrifugal pump.

parts would be one mechanical seal, two bearings, one impeller and four to five O-rings.

Regenerative turbine pump maintenance is also much more seamless and streamlined compared with side-channel pumps. Typical repairs on a regenerative turbine pump can be accomplished in one to two hours without disconnecting the motor or even removing the pump from the pipework. Less downtime for maintenance bodes well for the bottom line for

bine and side-channel pumps. Both technologies will get the job done effectively and neither will struggle to pump those substances like other pump technologies do.

However, if operators want to get the most efficient and effective pump technology for these types of applications, then the regenerative turbine pump serves as the best choice. It features a simple, single-impeller design with a compact footprint and low power consumption. Operators can handle all maintenance concerns with minimal tools and without taking the motor or the pump itself offline. Removing the front cover of the pump also provides full access to its interior.

While both pumps function exceptionally well in the field, regenerative turbine pumps hold an edge over side-channel pumps. They can reach the same performance metrics in half the size and complexity, with less downtime for maintenance while also providing power-consumption savings. Operators can get the job done with either pump, but will enjoy more benefits with a regenerative turbine pump, resulting in an optimized pumping system that features difficult-to-handle near-gas liquids or those near their boiling point.

STEPHEN BASCLAIN is the Business Development Manager for Ebsray, Cromer, Australia, a leader in the design of regenerative turbine and positive displacement pump technologies, including sliding vane, gear and lobe pumps. He can be reached at Stephen.Basclain@psgdover.com.

Russelectric automatic transfer switches with manual bypass/isolation

The Russelectric RTS-30 Series and Russelectric RTS-03 Series transfer switches provide all the functions of a Russelectric automatic transfer switch plus the ability to bypass power from a live source to load in the event the transfer switch is disabled. Russelectric RTS-30 Series automatic transfer switches with manual bypass/isolation are the most complete line of 480 VAC 30-cycle and 3-cycle UL tested switches available today, the company states. They have been fully tested, listed, and labeled for 30-cycle and 3-cycle closing and withstand ratings under UL-1008. Full draw-out construction allows safe and easy removal of the transfer switch, eliminating the need to make any electrical or mechanical disconnections. Built rugged for long life, minimum maintenance, and trouble-free service, the RTS-30 Series features contact assemblies designed to handle the rigors of 30-cycle closing and withstand performance and offer exceptional arc- and track-resistance. Russelectric https://usa.siemens.com/bypassswitches

The new Type 3700 Proportional Pressure Regulator from Bellofram Precision Controls is the efficient solution for unwavering precision and streamlined operations in diverse applications. The Type 3700 offers absolute control with 0.5% full-scale accuracy,

unmatched versatility to conquer any challenge from tension control to fluid coating with one powerful tool, and streamlined performance that optimizes both space and efficiency with a compact and lightweight design. The Type 3700 has an LED display for clear output pressure monitoring. With a high flow rate, it ensures seamless operation and maintains output pressure even during power loss. Fast response minimizes pressure fluctuation. The IP65-class protection helps ensure durability

in various environments. Its compact and lightweight design allows for effortless installation, suitable for both standalone and modular setups. Straight and right-angle cable options are available. Bellofram Precision Controls provides expert design and manufacture of direct-acting, high-performance air pressure regulators that offer precision control, high accuracy, maximum stability, large flow, and exhaust capabilities. Bellofram Precision Controls www.marshbellofram.com

You strengthen your plant’s safety, productivity and availability with innovations and resources.

Q – for increased plant productivity

We understand how you need to reduce complexities at your plant. Do you want to learn more? www.eh.digital/3RBV8Cm

• Best in class flow measurement in custody transfer applications in mass or volume units due to unmatched accuracy for density determination, up to DN 250 (10”)

• Ideal for hydrocarbons with entrained gas thanks to the patented Multi Frequency Technology (MFT)

• Patented Heartbeat Technology for device verification during operation and permanent self-diagnostics

The Horizontal Container Pump Lutz B200 features a centrifugal pump with axial impeller in a compact design. It is directly connected to the bottom outlet valve of the IBC with a standard union nut (S60 x 6). Additional features include a variable drive concept (different universal and air-driven motors); easy disassembly; no suction line necessary, so it has a significantly lower product release when disconnecting; explosionproof versions; and significantly better hydraulic capacity in comparison to a hydrostatic outlet. The pumps have a quantity up to 64 gpm; delivery head up to 50 ft.; spec. gravity up to 2.8; and viscosity up to 650 cps. This very compact pump is a great alternative when containers are stored on top of each other. Lutz B200 is directly connected to the bottom outlet valve. Lutz Pumps www.lutzpumps.com

Cavitation, poor piping design, operator error, system upsets, suction event, ball bearing failure, dry running, solids, leaking shaft seal... INNOMAG handles real world problems. The INNOMAG

TB-MAG sets a new benchmark for magnetic drive pump value and performance. This versatile sealless pump is engineered to provide low total cost of ownership and exceptional leakage protection in extremely corrosive and environmentally critical applications. While the TB-MAG boasts many innovative design elements, the key to its proven performance is its revolutionary dynamic thrust balancing system. This cleverly engineered system eliminates the need for thrust bearings and results in highly efficient operation with outstanding reliability, even in applications containing solids. The fluoropolymer-lined INNOMAG TB-MAG chemical process pump is compliant with ASME B73.3 or ISO 2858/15783 standards. Flowserve www.seallessfirst.com

pump

Watson-Marlow Fluid Technology Solutions (WMFTS) has launched the Qdos H-FLO chemical metering and dosing pump, designed specifically for higher flow rates up to 158 gallons per hour (600 lph). Qdos H-FLO delivers the same outstanding accuracy and reliability as other Qdos pumps but for higher flow rates with a variety of pumpheads and a range of different tube material to ensure chemical compatibility with the process fluid. The Qdos H-FLO high-precision pump offers flexibility to be scalable with a customer’s process, whether it is in water and wastewater treatment, mining and mineral processing, chemical applications in food and beverage or pulp and paper. The release of Qdos H-FLO enhances the range of Qdos pumps by offering flow rates up to 158 gallons per hour (600 lph) and pressure capability up to 102 psi (7 bar). Qdos H-FLO cuts costs through higher precision chemical metering, with an accuracy of ±1% and repeatability of ±0.5% in dosing. Qdos H-FLO will bring benefits to applications including: disinfectants; coagulants; flocculants; acids/alkalis; mining reagents; and surfactants. Benefits of the new Qdos H-FLO include: flowrates from 2.0 mL/min to 600 L/h (158 gallons per hour); pressure capability up to 102 psi; RFID Pumphead detection ensures confirmation of correct pumphead; revolution counter for pumphead service maintenance; leak detection and fluid containment prevent spills and chemical

exposure upon pumphead expiry; network integration, control and communication options include EtherNet/IP, PROFINET and PROFIBUS for easy integration with SCADA / PLC; one common pump drive with several pumphead options for changing process conditions and chemistries. Watson-Marlow Fluid Technology Solutions www.wmfts.com

New Pump Handbook from Alfa Laval

Alfa Laval just published a brand-new edition of the company’s renowned Pump Handbook. The 375-page handbook is free and contains scholarly information on basic pump functionality and in-depth guidelines for sizing and selecting the right pump type for optimum efficiency. The handbook is packed with real-life examples to increase its user-friendliness. The first edition of the Alfa Laval Pump Handbook was published 25 years ago and soon became part of the syllabus at engineering schools around the world. The book also found its way into manufacturing sites, serving as a reference work to technicians in the daily operation of fluid handling processes. Over the years, the handbook has gone through minor revisions, and in 2023, a major overhaul was undertaken to make the handbook up-to-date on the most recent technologies. The authors of the book are all experienced pump engineers with extensive theoretical knowledge and hands-on experience from pump installations and training of technical staff in fluid handling industries. The handbook is free and available online. It can be downloaded from www.alfalaval/. PumpHandbook and contains a series of videos on for instance pump functionality, troubleshooting and maintenance guidelines.

Alfa Laval www.alfalaval.com/PumpHandbook

IMO 3-screw rotary pump technology for transformer ester and mineral oil purification service

CIRCOR International, Inc. announces its IMO 3-screw positive displacement rotary pump technology, ideal for lowering transformer oil purification operating costs. The IMO 3-screw design excels under low/ vacuum inlet pressures and provides enhanced

reliability and longevity. The pumps are available in the 3D and 3E series for transfer/circulation of transformer insulating oil. Series 3D pumps, available in 19 different displacements, incorporate full hydraulic balance that cancels axial and radial thrust loads due to discharge pressure. The pump shaft is generously sized to allow belt drive if desired for mechanical seal versions. The pumps are equipped with replaceable housings for simple repair, and most sizes are available with an optional steel case. Series 3D pumps are offered for outlet pressures up to a maximum of 500 PSIG (34.5 BAR) and inlet pressures up to a maximum of 75 PSIG (5.2 BAR) for sizes 106-187 and 50 PSIG (3.4 BAR) for sizes 218 and up.

CIRCOR International, Inc.

www.circor.com

Three-diaphragm liquid pump

KNF’s UFK 1.1100 EX is a revolutionary threediaphragm liquid pump engineered to provide high flow rate and low pulsation in HazLoc areas. It offers one of the market’s most advanced solutions

for liquid transfer, providing KNF’s best performance yet from a HazLoc pump. It has a durable, die-cast aluminum housing with high torque motors and elastomer diaphragms to prevent contamination. The UFK 1.1100 EX is self-priming and capable of running dry, reducing the need for additional equipment.

KNF

https://knf.com/en/us/ufk-11100-ex

Pumping solution for battery manufacturing