LEADING THE INDUSTRY IN PRODUCTION CAPACITY

FOR 25 YEARS AND COUNTING

For more than 20 years, Lico Machinery Inc. has stood out for the quality of its equipment, its adapted solutions, as well as its unique and unbeatable service. Lico specializes in the design and manufacture of sawmill and flooring equipment ranging from standalone machines to complete solutions. No compromise is made on the quality of the equipment, from design to installation, because we know that in a world where profitability depends on productivity, only quality performs.

Weather

Pastway Planing sets industry bars high in southern

Sawmill

and

entrepreneurs who own West of the 5th Sawmill in Bluffton, Alta. Read their story on page

EDITORIAL first cut

JENNIFERellson

jellson@annexbusinessmedia.com

Wrapping up the year

From planning to planing, this issue has got you covered

From plotting to planking, we’ve got the scoop in this issue!

But before we delve into the stories that await, let’s pause and appreciate the fact that this is actually CFI’s last issue for 2023 – the final curtain call of the year!

So, here’s a hearty round of applause for you, our readers, our contributors, and our ever-supportive community. Your passion and engagement have breathed life into these pages, and we’re immensely grateful. A massive thank you is in order for the just-as-massive support you gave to our team this year. Thank you for your contributions, feedback, story ideas, suggestions, editorial and advertising support. Most importantly, thank you for opening the pages and reading our coverage of the industry that we are all passionate about.

With our gratitude set, let’s unwrap the present we’ve prepared for you.

Picture this: a young family embarking on a new adventure, raising children and a sawmill business side by side in rural Alberta. It’s a tale of grit, dreams, and the unwavering support of a tight-knit community. West of the 5th Sawmill is not just a business; it’s a testament to the power of determination and the beauty of family.

As the weather cools and we gear up for 2024, our safety guru, Patrick McDonald, is here to help you figure your way through the safety maze. He’s armed with tips and tricks to ensure your sawmill is a fortress of safety and wellbeing, as he helps you navigate through the key considerations and best practices to effectively plan and roll out safety initiatives, tailored to sawmills.

Now, what about succession planning? Chris Duncan is your guide through this crucial aspect of business. Remember, no matter your age, it’s never too early to secure your legacy. Think of it as crafting the timeless story of your business’s lasting impact.

For the savvy sawfilers out there, Paul Smith’s clear-cut guide to benching wide bandsaws is a must-read. Trust us; it’s a game-changer.

This issue also shines a spotlight on Pastway

Planing, an industry icon in southern Ontario. They’ve been raising the bar for over half a century. Their secret recipe? Timing, chemistry, and a dash of outstanding employees. They’re not just any wood treatment facility; they’re a league of their own.

Ready for an update on the North American softwood lumber market as the year draws to a close? Keta Kosman has your back. She’s got the inside scoop to keep you in the loop.

Percy Guichon’s Final Cut column is nothing short of inspiring, as he brings his unique perspective as a survivor of a residential school and a dedicated Indigenous leader to the forefront of the forestry industry. His words resonate with wisdom and compassion, advocating for reconciliation in forestry. Percy’s passion for this cause, combined with his remarkable life story, makes him a beacon of hope and a true inspiration in the world of forestry and beyond.

And let’s not overlook our news pages brimming with the latest industry happenings, including the NAFTA decision on the U.S. anti-dumping and countervailing duties on Canadian softwood lumber; exciting funding announcements from federal and provincial governments for wood producers, and the groundbreaking Senate bill promoting eco-friendly materials in public buildings that became law, with inspiration drawn from Structurlam, a leading mass timber producer in B.C. We have more up-to-date news to help you stay ahead of the curve on our website, www.woodbusiness.ca

As we bid adieu to this year, know that I’ll be right here, eager to welcome you back in the new year. We might even meet in person at one of our industry events. The future is brimming with exciting stories – they’re your stories and I can’t wait to narrate them. We’re amped to deliver more fantastic stories and keep things fresh and exciting. As you very well know, we’re all about collaboration, so keep those suggestions and contributions coming.

Let’s make the next year a rollercoaster of knowledge, growth and good vibes. Until then, stay safe, stay curious, and stay connected.

The all-new 2956G Swing Machine can handle whatever you face in the forest and is available in log loader and harvester configurations.

More Productive

Increased horsepower and hydraulic flow allow greater efficiency and speed when loading trucks.

More Versatile

Operating weight without attachments under 90,000 lbs eases transport and speeds machine mobility.

More Support

Backed by Brandt – the besttrained support team around, available 24/7/365 so you can keep working.

NEWS upfront

Canada applauds NAFTA ruling on U.S. softwood lumber duties

Canadian Trade Minister Mary Ng said Canada is pleased to see the North American Free Trade Agreement (NAFTA) decision on Canada’s challenge of the U.S. final dumping determination on Canadian softwood lumber, released on Oct. 5.

“The NAFTA dispute panel agrees that elements of the U.S. dumping determination are inconsistent with U.S. law. These

duties are unwarranted – the only fair outcome is for the U.S. to revoke all duties on Canadian

softwood lumber without further delay,” Ng said. She added that the panel directed the U.S. to review key aspects of the determination.

B.C. Minister of Forests Bruce Ralston said that the NAFTA panel’s decision, “determined that the U.S. Department of Commerce erred in how it calculated important aspects of the anti-dumping duties applied to Canadian softwood lumber exports.”

Paper Excellence Crofton, B.C. Dec 1, 2023

Curtailment extended Woodtone Specialties Armstrong, B.C. TBD Capital expansion to increase efficiency and add a new product line Rayonier Advanced Materials Témiscaming, Que. Oct 7 - 27

One pulp line idled to optimize inventory levels and address low demand

Source: Madison’s Lumber Reporter

B.C. boosts wood producers with new funding

The B.C. government has announced new funding for several value-added wood producers through its BC Manufacturing Jobs Fund (BCMJF).

The province is contributing as much as $1.34 million toward Woodtone Specialties’ capital expansion of its Armstrong mill to increase efficiency, improve fibre recovery and add a new product line that will create 50 jobs. The line will produce smooth-face engineered cedar siding and fascia from second-growth knotty wood, which has high demand in a market that traditionally relied on old-growth trees.Woodtone operates its facility using second-growth fibre and uses material that is traditionally considered waste wood to

create sought-after custom lengths and sizes of value-added wood products.

As much as $400,000 is going to Creston’s J.H. Huscroft, a value-added speciality manufacturer of glulam, trim, boarding and flooring, to fund its new sawmill sort line that will increase its sorting ability by three times. The company will purchase and replace equipment that will boost productivity and capacity at its sawmill, protecting 75 jobs and expanding the types of logs that can be processed.

The BCMJF is also supporting three Indigenous-led planning projects from Ulkatcho First Nation-owned West Chilcotin Forest Products, Stuwix Resources, and Lil’wat Forestry Ventures.

Reader

Landmark agreement supports First Nations forestry participation

The Tlowitsis, We Wai Kai, Wei Wai Kum and K’ómoks First Nations, and Western Forest Products Inc. have reached an agreement for the Nations to acquire a 34 per cent interest from Western in a newly formed limited partnership for $35.9 million.

The B.C. government helped to facilitate the partnership through Incremental Treaty Agreements with the Nations, all of whom are in Stage 5

P.E.I. increases support for small forestry businesses

Funding is now available to assist with clearing tropical storm Fiona-felled trees on essential forest access roads and on small woodlots that may pose a fire risk to nearby urban areas and infrastructure.

The Hurricane Fiona Forestry Recovery Program is open to small forestry businesses and woodlot owners who were not eligible for assistance under previous programs. The program is supported by investments of $125,000 from the P.E.I. government and a $975,000 funding from the Atlantic Canada Opportunities Agency.

Financial assistance is available for small woodlot owners (larger than one acre but less than 2.5 acres) where land is excluded from the Forest Enhancement Program, but where land intersects with urban and wildland areas and may pose a fire risk.

Support is also available for land where the forestry road is deemed necessary for sustainable forest management and fire suppression i.e., no other access roads are nearby, or where the road provides access to forest land near infrastructure.

Canada funds Ontario wood manufacturers

A $2.9-million federal government investment through the Wood Manufacturing Cluster of Ontario (WMCO) will help companies adopt technologies that will create 50 new jobs. WMCO will provide seed funding for up to 50 eligible SMEs undergoing digital adoption projects.

of the British Columbia Treaty Process.

The formation of the partnership and acquisition by the Nations, who are all member First Nations of the Na̲nwak̲olas Council, is subject to various closing conditions, including subdivision and tenure transfer approvals from the Ministry of Forests.

Western and the Nations are working toward closing the acquisition in the first quarter of 2024.

Canfor’s VIDA to buy sawmill in Sweden

Canfor Corporation has announced that VIDA AB, the Swedish company in which it owns a 70 per cent stake, has signed a deal to buy a 50 million board foot sawmill from Ingarp Träskydd for $6 million.

The Vancouver-based forestry company said the sawmill has the potential for expansion to 100 million board feet.

Senate bill for sustainable building materials becomes law

A Senate bill that would encourage the use of more environmentally sustainable materials in public buildings passed unanimously on Sept. 27 in the House of Commons and will now become law.

Originally introduced by NDP MP Richard Cannings, Bill S-222 requires the government to assess all building materials’ environmental benefits, including their carbon footprint, before approving their use in government buildings. It was originally inspired in part by the example of Structurlam, a producer of mass timber products in North America based in Penticton, B.C., now owned by Mercer Mass Timber.

Email: apotal@annexbusinessmedia.com

EDITOR - Jennifer Ellson (438) 483-7451 jellson@annexbusinessmedia.com

MANAGING EDITOR - Maria Church (226) 931-1396 mchurch@annexbusinessmedia.com

GROUP PUBLISHER - Anne Beswick (416)410-5248 • Mobile: (416) 277-8428 abeswick@annexbusinessmedia.com

ACCOUNT COORDINATOR - Shannon Drumm (416) 510-6762 sdrumm@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein (416) 510-5124 sdingeldein@annexbusinessmedia.com

NATIONAL SALES MANAGER - Josée Crevier Ph: (514) 425-0025 • Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

WESTERN SALES Tim Shaddick 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158

Kevin Cook lordkevincook@gmail.com Ph: (604) 619-1777

PRESIDENT/COO - Scott Jamieson sjamieson@annexbusinessmedia.com

LOGGING planning

SUCCESSION FOR YOUR BUSINESS

Taking the right steps ahead of time will pay off

BY CHRIS DUNCAN

A logger never truly retires.

Whether they continue running a buncher or advise the next generation about big business decisions from a sunny destination instead of in the pickup truck, there is rarely a time when a logger can fully step away from the business that they’ve spent their lives building.

According to results of CFI’s 2020 Contractor Survey, 36 per cent of contractors do not have a succession plan.

Not having a plan is the equivalent of driving a loaded logging truck down a hill without brakes and blind folded, you have no way to tell when to apply the brakes or turn the steering wheel.

Much like driving, many different issues can come up that change a contractor’s plans on when to get out or slow down with their business.

All business owners should be working on their succession plan despite how old they are. You and your family are the priority in a succession plan-

ning process. Managing your legacy while you can gives you the peace of mind, the clarity, and the ability to ensure your wishes are fulfilled.

THE PROCESS

Once you’ve decided you’re ready for a change, the right planning allows you to work at your own pace with an advisor to determine how best to approach the process.

It’s important to note that business transition planning is a continuum.

While it’s easy to plan for a start point, it’s common for an event to cause the trajectory to change – whether that’s an illness or death in the family, or someone wanting to get out of the business –forcing a reassessment of goals and strategies to meet them.

Your plan should be constantly evolving based on what is happening in life.

While every process will be unique, here are some things your advisor should help you with on your succession journey:

• Regardless of your initial goals, every plan starts with an initial info gathering meeting. This could be a single meeting or a series of meetings depending on your business and the complexities involved. By getting to know you and your family situation, your advisor can get a better

understanding of your wishes, expectations, and the opportunities available to you all. Many business owners choose to involve family members in one or more of the meetings.

• In some cases, business meetings and family meetings will be separate to help detach the two in a meaningful way. This can help preserve family harmony, setting aside time to be a family and other time to be business owners.

• Succession planning doesn’t just go over with what will happen to the business, it also works to build a wealth plan, a business plan, strategic plans (depending on timing), and contingency plans.

• Setting up milestones, or graduation dates, is another important part of the planning process. It’s helpful to ask what you want to have accomplished by a certain time to help set achievable and measurable goals and keep everyone on track towards your shared vision.

• Assessing things like governance and tax reorganization may seem like one of the more daunting aspects of transition planning but really, it can be made simple with your advisor’s help and knowledge of the industry. Additionally, tax incentives and breaks can help you plan and take advantage of government opportunities when you have the chance.

“ALL BUSINESS OWNERS SHOULD BE WORKING ON THEIR SUCCESSION PLAN DESPITE HOW OLD THEY ARE.”

• Asking questions about shareholder or family agreements – whether they’re needed and how they could help the process – provide more insight into family roles within the business and for the ownership of the business.

EXAMPLES OF SUCCESSFUL SUCCESSION PLANNING

In hypothetical scenario No. 1, two non-related business partners begin succession planning in their early fifties. While not prepared to exit yet, they start

to plan on how they can maximize the tax savings and sale price of their business.

The partners work with an advisor to restructure their business for tax purposes. This included moving land and buildings out of their operating company and into a holding company and forming family trusts.

They also work with the advisor to maximize profitability and grow the enterprise value of their business.

Fast forward to their late fifties and one partner wants to retire. They have

grown the company’s value and decide to sell with the help of the advisor.

After a successful sale of the business shares the partners keep the land and building and rent it back to the new owner.

In addition, with the restructuring they did a decade earlier, they can sell the shares and utilize their lifetime capital gains exemptions to minimize tax on the sale.

They now have the sale proceeds to retire and enjoy life, as well as a steady rental income stream. A decade of planning paid off greatly in this case.

A LONG WAY TOGETHER

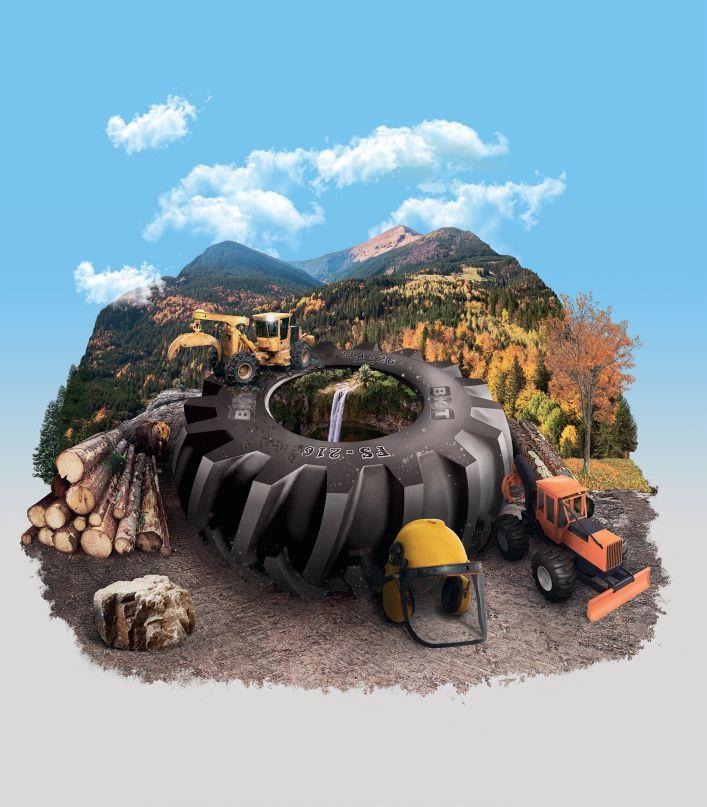

FS 216

No matter how challenging your needs, FS 216 is your best ally for all operations with loggers and skidders. This aramid-belted forestry tire has a robust log design with optimum angle and larger width for enhanced traction performance. FS 216 provides excellent cut and chip resistance as well as maximum protection against possible damages at any time.

FS 216 is BKT’s response to your needs even under the most critical operating conditions in forestry.

For info:

Western Canada 604-701-9098

Eastern Canada 514-792-9220

In hypothetical scenario No. 2, a family contracting business run by mom and dad has four sons. Two sons are currently involved in the business, but the rest are not.

Mom and dad want to step back as dad’s health is waning. They engage with an advisor and the family begins to have family and business conversations with their advisor to determine what they want, who wants what level of involvement, and how that might progress.

During a meeting, it’s expressed that mom and dad want to keep involved in the business but on a limited basis. They decide to relinquish management duties, but still be available for access if they are needed. The two active sons agree on their roles within the business and the two others remain focused on other plans outside the business.

Mom and dad still have preferred voting shares in the business and have been able to access their lifetimes capital gains exemptions by selling a portion of their shares to their two active sons.

Within 18 months from the start of the process, they had a firm plan, and all parties are pleased with the flexibility and confidence they have in the future of the business.

Just as every logging business is unique, so too will be their succession plan.

Be patient with yourself and your family and understand success isn’t immediate nor is it guaranteed, it’s a process and a continuum that takes time, reflection, and forward thinking.

Two similar loggers who harvest 150,000 cubic meters a year and have $10 million in equipment will have com-

pletely different goals and strategies when it comes to succession and their outcomes will be different.

Expectations, health situations, financial and economic situations may change

Succession planning for your forestry business won’t happen overnight, but taking the right steps ahead of time will pay off.

you’re young and succession is decades away for you, taking the time now to consider what you want your future, and the future of your family, to look like will help ensure you’ve done a thorough job of planning and making choices to reflect and hopefully help you attain your goals.

Chris Duncan, CPA, is a partner and the national leader of forestry and forest products services at MNP. Chris has deep industry experience delivering business advice to logging contractors, value-added wood processors and other forest industry-related businesses.

but your vision of your business and how it can support you in the future must be front of mind.

It’s never too early to start the process as a logging business owner. Even if

STRONGER, TOUGHER, SMARTER, FASTER

WOODPRODUCTS

TIMBER TIES

BY JENNIFER ELLSON

West of the 5th Sawmill is not your average sawmill. In October 2021, the sawmill came to life, thanks to the vision of Justin Levinsky, a former oil industry driller, and his wife Brittany. Their story is a testament to resilience and the pursuit of a dream. This family-owned sawmill, situated just outside Bluffton in rural Alberta, has quickly become a symbol of perseverance, commitment, and community support.

THE JOURNEY BEGINS IN BAHRAIN

Named for its location west of the fifth meridian, West of the 5th Sawmill’s inception is nothing short of remarkable. The company was born during a

momentous period in Justin and Brittany’s lives –when they became parents. The Levinsky’s path to parenthood was marked by challenges, as they struggled for years to start a family. Then, in a miraculous turn of events, they were blessed with the opportunity to adopt two full-sibling children from the foster system: a two-year-old girl and a one-year-old boy. This new family dynamic brought about significant changes. At the time, Justin was working overseas on a month-in, month-out rotation in Bahrain’s oil fields. This arrangement proved to be difficult for the young family.

“When the kids moved in, in September of 2020, Justin was working in the Middle East. This became

very difficult for me as a new mom, hard for the kids without their dad at home, and I know it was also hard for Justin as he wanted to be with his family,” Brittany says.

After enduring nearly 10 months of separation, Justin made a life-changing decision. He quit his overseas job and returned home to Bluffton. During his time in Bahrain, he had been quietly formulating a business plan for a sawmill. Upon his return, Brittany encouraged him to turn that dream into reality.

A LEAP OF FAITH

With unwavering faith in her husband, Brittany motivated Justin to launch the sawmill venture as soon as possible.

“We took out all of our savings that we both had and went allin on starting the business, full steam ahead,” enthuses Brittany.

Justin acquired the first sawmill – a Range Road Enterprises manual sawmill – and began cutting timber. He then replaced it with a bigger Cooks Saw AC-36 that is currently in operation at the facility.

The impact of the business went beyond financial success. For the Levinsky family, it was a chance to be together and build their home. The sawmill’s strategic location right next to their bungalow allowed them to be present for their daughter Ella, now five, and their four-year-old son Damian. Their seven-year-old golden lab Charlie and two-year-old black lab Mavis also enjoyed the increased family time.

“Our daughter really benefited – she was diagnosed with autism in early 2022, so she needed that routine: the time together and the consistency of her dad coming home every evening,” explains Brittany.

“It is truly an amazing feeling when the kids light up when dad gets home from work, even though they watch him throughout the day from the living room window. Having the business on our land and close to home helps with raising our family. Everything I could ever want is right here on these 10 acres we own: our family, our home and our livelihood,” says the 36-year-old mother.

SPECIES, PRODUCTS, AND THE DREAM TEAM

The mill produces approximately 650,000 board feet of spruce and pine lumber annually, primarily full dimension lumber. With the Cooks AC-36 sawmill, capable of handling logs up to 36 inches in diameter and 22 feet in length, they offer various sawn dimensional lumber, large timbers, beams for timber frame construction, and dunnage for oil field applications. Custom cutting services are also available.

The logs used at the mill come from private landowners in Central Alberta, with additional timber purchased from neighbouring logging contractors, including Barmac Contracting in Drayton Valley, McColm Construction in Bluffton, and Lil Mule Logging in Red Deer.

“Logs are loaded onto the roll way via skid steer and then are loaded onto the sawmill with the hydraulic loading arms. Once sawn they are stacked onto their respective bunks, anything that needs to be edged travels down the dead rolls to the edger and is edged into the largest available clean dimension,” explains Justin.

While the industry has its ups and downs, the mill has managed to navigate the challenges successfully.

“At times fibre supply has been an issue. We are quite new

GREEN MEANS BUSINESS

BioCharger ®

Eliminates up to 10 tons of wood and vegetative waste per hour while generating electricity to recharge multiple machines.

A Clearer Vision. A Cleaner Solution.

Boost your bottom line while fighting climate change with Air Burners®. Tested and proven by the USEPA, we cleanly and cost-effectively eliminate wood waste. Requires no permanent facilities, secondary fuel source, grinding or hauling.

Contact us for a quote today.

BurnBoss ®

Reduces stumps, logs, slash and other wood waste by 98% and the left over ash and biochar can be mixed straight into the soil.

FireBox

Burns wood waste 40x faster than an open burn, and the air curtain technology significantly reduces smoke and particulate matter.

TrackBoss ®

Mobile, maneuverable, and controlled via a remote control unit to clear the areas where a truck cannot navigate.

CharBoss ®

Self-contained with a refractory-lined burncontainer and internal system to create biochar from waste materials.

to the industry and are sure to encounter more obstacles as time progresses, but so far everything has gone quite well for us.”

The Levinskys are currently working on applying to the Alberta government’s Community Timber Program, aiming to expand their operations.

“We had hopes this year of bidding on a block offered through public auction, but with the devastating fires this year, they never offered any for auction,” explains Justin.

Their small, dedicated team, consisting of Justin, Brittany, sawmiller Tom Bourque, and a part-time employee, operates the mill on an eight-hour shift, five days a week. Brittany manages the books, while Justin and Bourque handle sawmill and edger maintenance. Their network of skilled tradespeople in the community is a valuable resource when complex issues arise.

“We’re very fortunate to be surrounded by a community with many different trades people if we run into something we can’t fix ourselves,” Justin says.

Brittany agrees: “With our family, the team we have created at West of the 5th Sawmill, and with the incredible support of our community, the good days definitely outnumber the bad.”

“WITH INCREDIBLE SUPPORT FROM OUR COMMUNITY, THE GOOD DAYS DEFINITELY OUTNUMBER THE BAD.”

SAWMILL RESIDUALS AND FUTURE PLANS

As for sawmill residuals, West of the 5th Sawmill ensures minimal waste. First cut slabs find new life in the community, used for firewood or crafting. Sawdust serves local farmers and ranchers as animal bedding, dust control, and garden mulch.

Justin’s plans for the future are ambitious. They intend to expand the sawmill building, add a 3-strand log deck to their operation, and install a dust and chip extractor for efficient sawdust management.

“We have looked into a small-scale pellet press to turn the sawdust into pellets and are continuing to do more research.”

Moreover, they plan to add a small kiln and a planer moulder to diversify their product range, as they welcome clients not only from Central Alberta but also from British Columbia, thanks to word-of-

mouth. This summer, Justin added a Valley edger to the facility.

With their continued growth, the Levinskys aim to create a workshop closer to the sawmill and transition to threephase electric power. While they anticipate challenges, they remain optimistic, driven by the opportunity to offer quality products at competitive prices and the satisfaction of supporting local businesses.

Rising costs and staffing difficulties have been challenges they’ve faced, but their dedication and community support have been unwavering. West of the 5th Sawmill stands as a testament to the power of perseverance and the fulfillment of a dream, enriching the lives of the Levinsky family and the community they serve.

“For ourselves and other smallscale family-run sawmills, I see great opportunity to offer quality products at reasonable prices that you might not find in a big box store,” explains the 39-yearold Justin.

“Also it gives people a sense of value for shopping and supporting local. Having a small business gives us an opportunity to meet many different people, have conversations and develop relationships.”

WOODPRODUCTS CANADIAN WEATHER TIGHT

BY MARIA CHURCH

A reman and wood treatment facility in southern Ontario is going on half a century setting high industry standards and their secret recipe is a mixture of good timing, chemistry and employees.

Pastway Planing is among Canada’s only wood treatment facilities that also has a complementary planing plant. The facility in Combermere – a twohour drive west of Ottawa ¬– sits in the Ottawa Valley wood basket, allowing access to a steady, year-round supply of softwood plantation trees.

The site will treat around 65 million board feet, and dress about 45 million board feet of predominantly red pine each year, with some hardwoods as well.

Pastway was acquired by CanWel – one of Canada’s largest wood treatment players – in 2013. Today, more than 70 employees keep the operation running, many of which have been with the company for 20 years or more.

Peter Hattin, general manager of Eastern Canada for the CanWel Treating Division, is among the long-time Pastway employees and has had a front-

Peter Hattin is the general manager of Eastern Canada for the CanWel Treating Division and a long-time employee at Pastway Planing.

ABOVE: Pastway Planing treats around 65 million board feet, and dresses around 45 million board feet a year.

row seat to the changing forest industry in central Ontario. While many companies specialized to maintain competitive margins, Pastway integrated vertically and kept its planing facility in full operation.

A big factor of the plant’s recent success was a well-timed “calculated business risk” that Hattin took in 2012, just before the CanWel acquisition, to introduce a new preservative treatment that, as they now say with pride, changed the treated wood market from green to brown.

MARKET LEADER

Pastway holds bragging rights as the first to market with a pressure treatment preservative that offered, for the first time, a better alternative to traditional green pressure treated lumber in Canada: MicroPro Sienna, or micronized copper azole (MCA), from Timber Specialities.

Wood treated with MCA is a warm, natural brown colour. The new preservative not only bucked the green colour standard, it also halved the environmental footprint of traditional treated wood. The treatment process uses less energy, is more environmentally friendly, and has lower greenhouse gas emissions than the standard treatment process.

Timber Specialities – the Canadian arm of U.S.-based Koppers – developed and researched this brand-new wood preservative in early 2010s, and worked with Pastway to bring it to market.

On Nov. 12, 2012, the first piece of treated MCA lumber came off the line for

market at Pastway. The day marked the beginning of a market upset with a brandnew wood preservative.

“We changed the pressure treated wood market to brown,” says Jana Proctor, marketing manager with Timber Specialties. “Consumers didn’t want green PT anymore, they wanted brown. We forced the market to switch to brown.”

Mobile fleet

• 5 Volvo and Hyundai loaders

• 5 LiftKing rough terrain forklifts

• 3 CAT, Toyota and Hyster standard forklifts

• 1 Champion grader

• 1 GMC sander/water tanker truck

• 1 Kenworth W900 transport truck

While MCA wasn’t exclusive to Pastway, the goal at the time was to get ahead of the curve, Hattin says. The company led the product to market, producing more than 30 million board feet of MCA treated wood in the first year. Being first to market was key to the success of launching the new brand, MicroPro Sienna.

TREATMENT FLOW

With a focus on locally sourced red pine, Pastway’s preserved wood products are sold in building material retailers throughout Ontario and western Quebec.

All fibre entering Pastway’s gates is bundled lumber or cants, either surface-

green or surface-dry.

Bundles heading to the treatment facility are first unwrapped and prepped for treating. All staples are removed and a visual grader pulls any low quality boards. A custom-built automated stacker nests the pre-treated lumber with large stickers to allow for optimal treatment and air flow. Staff also hand-applies the end tags at this stage.

The stacks are then be moved by forklift to the infeed of an entirely self-contained treatment facility. A forklift inside the facility transfers the stacks onto the infeed tracks of one of two retorts – 80-foot long, six-foot round cylinders from J.H. Lock. Once a charge of product is loaded into the retort, it fills with solution and is put under pressure and heat for between 60 and 90 minutes, depending on the product and temperature. Two Boilersmith boilers supply heat for the process.

The MCA chemical solution – a special combination of registered preservatives, pigments, dyes and moldicide – is blended for each charge and results are checked regularly throughout the day by the facility manager ensuring a tight quality control program from start to finish.

Once the treatment cycle is complete, a negative vacuum removes the remaining liquid, which is then recirculated for the next charge. The treated stacks are then moved to a drip pad in the facility and will sit for a minimum of 48 hours before they are manually wrapped and moved to the yard for storage. The treatment process is kept as homogenous as possible, Hattin

says. “We don’t want to overtreat and we don’t want to undertreat.” They work hard to segregate the different products into separate charges to undergo the right level of time, pressure and chemical solution.

PLANING FLOW

Much of Pastway’s planing plant is still a manual process, which Hattin says is a decision to remain flexible and adaptable to customer orders. Customers expect quality, and so jobs such as grading are all visual. Most fibre arrives on site as squares

and is milled into products from 1x2 up to 8x8s, with some speciality jobs creating products up to 40 feet.

For their 2-inch dimensional products, boards are first sent across a custom built 100-foot grading line with an auto stacker and Samuel strapping machine.

The planing plant has three Yates A20 planers, each of which is fed with TS Machinery-built tilt hoist. Operators watch to remove off-spec boards both before and after the planer. Line 1 has a Stetson-Ross XLRipper1 and lines 2 and 3 have Yates-

American bandsaw resaws, one of which was reconditioned by TS Machinery. Boards are then manually stacked using lath either purchased or made on site from a Stetson-Ross XLRipper1 multi-rip saw. All residuals from the planer mill are dried in a drum dryer and sold as shavings for animal bedding.

PLANNING AHEAD

With products mainly destined for home improvement stores, and much of it for decking, Hattin notes they have a short selling season and must carefully plan for it.

Continuous wood drying greatness

“The TC kiln saves up to 50% energy, compared to traditional batch kilns”

JD Irving, Canada

“Everyone wakes from their winter doldrums and is itching to do a backyard project,” Hattin says. By September, backyard renovations are done, the nice weather is gone and the demand dries up. Pastway meticulously manages its resources to account for the anticipated boom and bust of that season. Keeping the planer process manual allows for the flexibility to shift products as needed.

The “covid years” threw a wrench in that pattern, with the renovation market exploding and extreme volatility - the new normal. “We had to tighten down our inventory and wait it out,” Hattin says. “I think we’ve come back to stability here, but we’ve all gone through 30 months of extreme ups and downs.”

Expertly navigating the tumult allowed Pastway to continue employing its full complement of staff today, many of whom are like family. For Hattin, being able to keep the facility’s most valuable resource, its people, employed full-time during challenging times is what drives them to be market leaders.

Pastway Planing has a very humble beginning with Ray Pastway and even before, with his father Frank in the 1930s.

“It started out as a small family operation and, as it grew and became a market leading dominant player in the treated industry, the company has not waivered in keeping focused on looking after its most cherished resource, its people. While they all have different last names, they are still family with a solid work ethic and that is what makes this such a successful company,” Hattin says. “And I cannot see anything but great things for Pastway Planing and its employees in the years to come. The future looks bright and we will welcome any challenge that comes our way.”

HIGH PERFORMANCE

LIGHT CURTAINS MADE FOR SAWMILLS

Telco Sensors has been supplying high-performance photoelectric sensors for the harshest, most demanding applications in the wood products industry for over 30 years. Simply put, Telco works where others fail.

Like all Telco products, our new SpaceScan series light curtain is designed and built around 5 core values: water resistance, extreme penetration power, resistance to shock & vibration, easy alignment and immunity to sunlight. All Telco products carry a full 3-year warranty.

Telco offers light curtains in discrete, analogue, RS485, IO-Link and diffuse proximity models.

Telco Sensors Inc.

Toll Free: 800 253 0111

Email: info@telcosensorsusa.com

Web: www.telcosensors.com

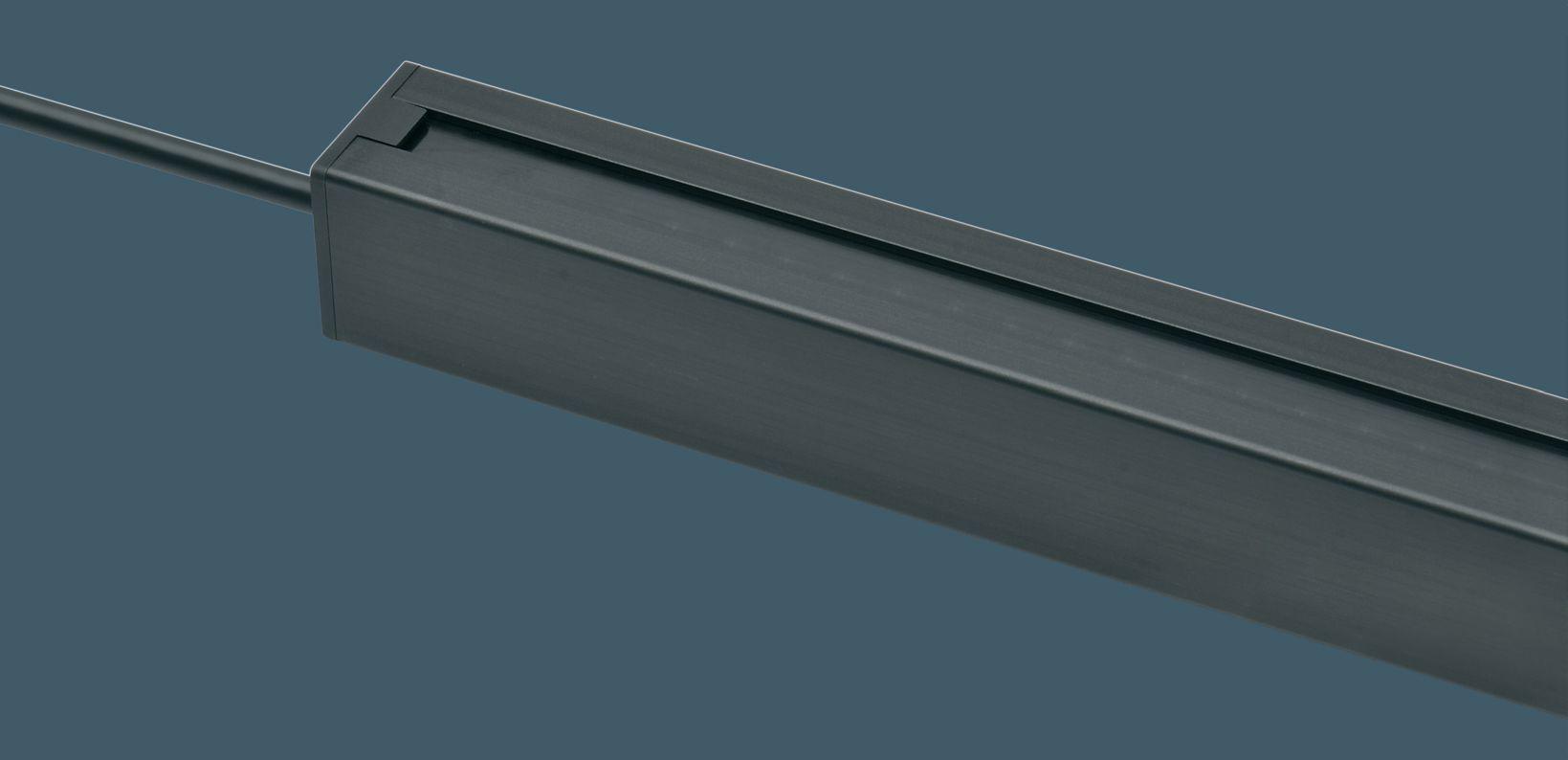

BY KETA KOSMAN

2023 YEAREND UPDATE

Toward the end of October, North American softwood lumber prices began their usual annual seasonal drop. Customers, whether retailers or end users, continued to make purchases for immediate needs only, keeping inventories quite lean. Sawmills kept production volumes tight to stay in line with weakening demand as this winter season truly comes on. After the volatility of the previous two years, these more normal price fluctuations were welcomed by industry players. Now that the previously unimaginable price highs are relegated to history, builders and lumber producers are better able to gauge what might come in 2024.

The price high for Western SPF 2x4s this year was US$476 mfbm in the week of Feb. 9, then was $458 for most of July; while the low was in the beginning of January at $370, which is very close to the current price. This more usual price swing of approximately $100 mfbm throughout the year is much closer to what sellers and customers were accustomed to in the past. This means they can more confidently make their business plans for the near future, specifically spring building season 2024.

For the week ending Oct. 20, the price of

benchmark softwood lumber item Western SPF 2x4 #2&Btr KD (RL) was US$374 mfbm, down $8 or two per cent compared to the previous week when it was $382. That week’s price is down $39 or nine per cent from one month ago when it was $413.

Compared to the same week last year, when it was $445 mfbm, the price of Western SPF 2x4 was down $71 or 16 per cent, and down by $221 or 37 per cent compared to two years ago when it was $595.

Western SPF traders in the U.S. noted that sawmills drew a line in the sand toward the end of October, especially regarding what they were willing to entertain in terms of counters. While some buyers backed off, accepting this might be the price bottom, plenty others continued to run their meagre field inventories down to bare pavement rather than capitulate. Order files at sawmills slowly stretched into November, making the waiting game a less appealing course of action.

Demand continued to limp along for Western SPF lumber, according to suppliers in western Canada. Takeaway in the field remained soft, as cooler weather further dampened overall demand. Sawmills reported strong counter offers requiring

Figure 1. Madison’s TOP SIX Benchmark

Dimension Softwood Lumber and Panel Prices

PHOTOS and GRAPHS: All figures courtesy Madison’s Lumber Reporter

review on a case-by-case basis, with order files stuck at less than two weeks in most cases. Buyers maintained lean field inventories and mostly covered their needs through the distribution network via LTL and mixed load orders. Eroding prices and weak sales increased chatter regarding potential curtailments to bring supply more in line with anemic demand.

The U.S. Thanksgiving long weekend usually marks the beginning of true slowdown for construction activity across the continent, thus for lumber manufacturing as well. Looking back over this year’s rather stable trendline for price changes, the expectation for next year is a continuation of this more “normal” cycle.

The Madison’s Lumber Prices Index for the week ending Oct. 20 was $402 mfbm. This is down two per cent or $9 from the previous week when it was $411.The new formulation having existed for 14 months, Softwood Lumber Futures, as traded on the Chicago Mercantile Exchange, dropped from a high of $578 mfbm in mid-July to $488 toward the end of October.

After spiking to unsustainable highs during the disruptions to society in the past couple of years, U.S. housing starts trended further downward in August 2023. Permits for authorizations of new home building increased, however. Demand for new construction has been boosted by an ongoing acute shortage of previously owned homes on the market. Realtors estimate that housing starts and completion rates need to be in a range of 1.5 million to 1.6 million units per month to bridge this inventory gap. Expectations among construction industry insiders and financial lenders alike is that single-family construction starts could rebound in the coming months, if builders are able to keep their skilled labour.

Coming off real highs in the previous two years, August total housing starts in the U.S. fell 11 per cent from the previous month to 1.283 million units compared to the 1.447 million units reported for July 2023, and were down 15 per cent from the August 2022 rate of 1.505 million units.

Building permits meanwhile, as an indicator of construction activity to come, continued a recent rising trend to increase by almost seven per cent at 1.543 million units from the July rate of 1.443 million. This is three per cent below the August 2022 rate of 1.586 million. These permits will eventually become starts and will help to underpin residential construction.

August starts of single-family housing, the largest share of the market and construction method, which uses the most wood, dropped slightly, down four per cent to a rate of 941,000 units, from July’s 983,000 units. Single-family authorizations were at 949,000

units, which is two per cent above the July figure of 930,000 units.

Now that the severe volatility and series of extreme circumstances are in the past, the construction and the forest products industries can both use the sales volumes and price data of 2023 to better make their business plans for next year. As the underlying dynamics of the housing market unfolds – not enough homes for the demographic currently reaching home-buying age – expectations are for an uplift in home building next year. Given the ongoing slowdowns and curtailments at sawmills over the past more than one year, there is enough lumber manufacturing capacity able to come online to serve this need.

Keta Kosman is the owner of the weekly Madison’s Lumber Reporter. Established in 1952, Madison’s Lumber Reporter is your premiere source for North American softwood lumber news, prices, industry insight, and industry contacts.

GUIDE TO BENCHING WIDE BANDSAWS

Before embarking on the journey of benching bandsaws, it’s essential to gather the right tools and expertise. This guide outlines the essential elements to get you started.

TOOLS NEEDED:

• Bench with anvils and stretcher roller to accommodate the size and width of bandsaw to be benched

• Straight edges and tension gauges to properly fit the band

• Correct size, weight, and style of hammer(s) for different applications

• Back gauge

• Experienced sawfiler and apprentice, if available Clean: Before anything, make sure the band is clean with no rust, dust or resin all the way around on both sides.

a band is a lot

Inspect: Load the cleaned band onto the bench. Most filers will find the butt weld and start inspecting from there. Inspect all around for any cracks, bent or broken teeth, any damage, or imperfections. If any of these are found, refer to your experienced sawfiler for the mill’s safety protocols and how to proceed. If the band checks out, move to next step. Level: Again, starting at the butt weld, use the correct length straight edge to check for flatness. The straight edge should be long enough to reach from back of band to gullet. One should have a shorter straight edge about half the length of first one to hone in on smaller knots and lumps. Sections of the band should be looked at as the bandsaw is pulled through. The section to be worked should be no longer than the anvil and the band should lay flat on anvil without pressure. As you work the straight edges down the bandsaw you will knock

the high places or bumps down with correct hammer.

Remember that a bandsaw should never be hammered where it is not needed. The object is for the bandsaw to be flat with the straight edge. If the straight edge shows a dip or valley, then it will have to be pushed through from other side. A good rule is that if you can’t rock the straight edge on the bandsaw, then do not hit it with the hammer. Therefore, if you can’t rock it don’t knock it. After completely going around the band, then do the other side. This can be accomplished by performing the same technique on the bottom anvil, if present. If there isn’t a bottom anvil, the bandsaw must be taken off the bench and inverted. After inverting, put the bandsaw back onto the bench and continue. This should be repeated from side to side until the bandsaw is flat. Auto levelers can be used to make this job easier, but most of the time, an experienced filer can do a better job.

Tensioning: Again, it would be good practice to start at the butt weld. For this step use the tension gauge, ground to the correct specifications for the band; and utilize the stretcher roller. Start by putting the tension gauge directly down across the width of the bandsaw without leaning the gauge either way.

In other words, the gauge should be 90 degrees from bandsaw. When using the correct gauge, the bandsaw can be picked up about three feet behind where it is being checked and the gauge should fit the bandsaw, showing little or no light under the gauge. Too much light means too much tension. If the gauge doesn’t fit the band or it isn’t flat, it does not have enough tension. Some benches will have an air-operated cylinder to lift the bandsaw. Just as with the leveling, do not roll where it isn’t needed or it can make the band worse. Tension should be even and the same all the way around. This process also must be performed from side to side until both sides are the same and properly tensioned. An automated tensioning bench set up and maintained properly can make this job much easier.

Tire lines: As with every aspect of the bandsaw, correct tire lines are important. The tire lines determine where the bandsaw will run on the wheels.

The front tire line enables the bandsaw

to cut a straight line without wash boarding. Normally the front tire line on hardwood is run closer to the gullet than in pine lumber. The further back from the gullet the tire line, the less likely one should experience gullet cracking. Tire lines are moved by pushing them one way or another with the stretcher roller. Remember that when moving tire lines, it is highly likely that tension can be added or taken away.

Checking and rolling correct back: Although this may be one of the last checks in repairing bandsaws, it may well be the most important. The back of the bandsaw needs to be uniformly longer than the cutting edge for the entire length of the blade. When correct, it will keep the bandsaw from running back off the wheels while keeping the front edge taut. The cutting edge must be shorter than the back as the back follows the cutting edge and should just glide without issues behind the cut. As with all aspects and processes to repair bandsaws, this may be the most important when it comes to safety. If done incorrectly, leaving the back longer than the front can allow the band to come off

the wheels, endangering operators and equipment.

Every series of actions in benching a bandsaw will affect different actions already performed in separate ways. For example, adding tension may cause flatness, tire lines, and back to move in a way that will no longer allow the bandsaw to operate and run satisfactorily. An uncomplicated way to look at benching a band is a lot like solving a Rubik’s cube. Every action mentioned above must be performed correctly without adversely impacting a previous step. The object is to end up with all of the actions showing the true colours of the experienced filer at work. As an influencer, I suggest an experienced sawfiler perform the benching of the mill’s bandsaws. Of course, using an apprentice with an experienced sawfiler is even better. Equipping the filing room with a fully automatic benching machine is a way to increase output, enhance safety, and to consistently put out quality bands. Adding automation doesn’t mean eliminating the experienced filer, it means that person isn’t burnt out by repetitive tasks and is freed up to work with and train apprentice filers.

Combustible Dust Specialists

Allied brings 49 years experience to help you meet current NFPA Standards with: system design/documentation, spark detection, isolation, grounding, PLC, venting, blast path management, clean-up systems and duct audits — CWB certified and member SMACNA.

WOODPRODUCTS CANADIAN

SAWMILL SAFETY INITIATIVES

As we gear up for 2024, safety remains a top priority in the wood products manufacturing industry. For safety managers, mill management, safety co-ordinators and safety committees, the coming year presents an opportunity to reinforce and enhance safety programs in sawmills. Implementing safety initiatives demands a strategic approach rooted in the fundamentals of project management. Let’s navigate through the key considerations and best practices to effectively plan and roll out safety initiatives, tailored to sawmills.

SCOPING DOCUMENT: BLUEPRINT FOR SAFETY SUCCESS

The journey toward enhanced safety starts with a well thought out scoping document. This foundational step is like crafting a blueprint that guides the entire project. Safety managers, in collaboration with key stakeholders, define the scope, identify crucial deliverables, establish major milestones, and estimate costs and resources. This document becomes the compass for the entire safety initiative.

Key aspects include a clear delineation of goals, a comprehensive assessment of potential risks, and a strategic plan to engage all relevant stakeholders. To ensure alignment and commitment, the scoping document should be signed off by top management – a tangible expression of their support for the safety project.

PROJECT MILESTONES AND TIMELINES: CHARTING PROGRESS TOWARD SAFETY EXCELLENCE

With the scoping document in hand, the next critical step is to break down the project into manageable milestones and establish realistic timelines. A detailed visual timeline ensures that everyone involved understands the sequence of events and the deadlines associated with each milestone. This collaborative effort involves management teams working closely with safety to ensure alignment

with broader organizational goals.

Milestones can include the development of training programs, implementation of new safety procedures, and the introduction of branding and signage. Timelines should be ambitious yet achievable, fostering a culture of continuous improvement.

COMMUNICATIONS PLAN: ENHANCING SAFETY CULTURE

Effective communication is the lifeblood of any successful safety initiative. A well-defined communications plan outlines the approach for engagement activities, the choice of communication channels, and the identification of key stakeholders. Safety managers and co-ordinators collaborate to define campaigns and activities that resonate with the workforce.

Communication channels can range from traditional methods like crew talks and newsletters to modern approaches such as videos, QR codes and digital signage. Identifying key stakeholders

for communication and branding ensures that the right messages reach the right audiences. A dynamic action plan further ensures the consistent delivery of safety information throughout the project’s lifecycle.

BRANDING AND SIGNAGE STANDARDS: MARKETING SAFETY EXCELLENCE

In the realm of safety, branding isn’t about products. It’s about cultivating a brand of excellence in safety practices. Safety managers and co-ordinators collaborate on establishing branding and signage standards that visually communicate the importance of safety. This includes consistent use of colours, logos, fonts, and catalog items for purchasers.

To achieve visual consistency across sites, it’s essential to partner with suppliers who understand and align with the safety branding standards. This collaborative effort ensures that safety is not just a set of rules but a culture that permeates every aspect of the sawmill.

TRAINING: EQUIPPING THE WORKFORCE FOR SAFETY SUCCESS

A well-trained workforce is the backbone of a safety-conscious workplace. Safety, in collaboration with HR, take the lead in planning and developing required training programs. These could include crew talks, instructor-led sessions, online LMS (learning management system) courses, blended training approaches, and specialized certification requirements.

Consideration should be given to the diverse learning styles within the workforce. The training plan should not only cover essential safety protocols but also instill a sense of ownership and responsibility among employees. How you will be defining competency should be considered during this step.

IRS (INTERNAL RESPONSIBILITY SYSTEM): EMPOWERING EVERY EMPLOYEE

Integral to safety management is the internal responsibility system (IRS), a framework that identifies responsibilities by stakeholder within the company. Safety managers, in collaboration with senior management teams, ensure that the IRS is effectively communicated and embraced at all levels. This system empowers every employee to take ownership of safety in their respective roles, fostering a culture of collective responsibility.

Tying the IRS with a safety management system (SMS) can further enhance accountability and streamline safety responsibilities throughout the organization.

Safety manual policy: A guiding document for safe practices

Consider creating a safety policy that complements the safety initiative. The policy acts as a guiding document that outlines the overall requirements of the initiative and ties it into the safety program. Safety managers, in co-ordination with HR managers, should review or create these policies that not only meet regulatory requirements but also reflect the unique aspects of sawmill operations. This may involve a blanket policy that aligns with safety legislation in relevant provinces.

Forms and templates should be created along with the policy to build consistency across safety processes and standardization at various operations.

SITE SAFETY PROCEDURES: KEEP SAFETY PRACTICAL

No two sawmills are identical, and safety procedures should be tailored to the unique context of each site. Safety co-ordinators, with input from mill management teams, develop site-specific safety procedures that complement the initiative. These procedures could be both paper-based and digital, providing a practical and accessible resource for all employees.

AUDITING VIA SMS: ENSURING CONTINUED SUCCESS

The journey toward safety excellence doesn’t end with the implementation of new safety measures; it’s a continuous process of improvement. Safety managers, co-ordinators, and committee members collaborate to implement a SMS that includes regular audits and assessments.

Auditing ensures that the implemented safety measures are effective and identifies areas for improvement. An annual review becomes a crucial component of the SMS, providing an opportunity to celebrate successes, address challenges, and define future safety initiatives.

Successful planning and execution of safety initiatives in sawmills demand a collaborative and strategic approach rooted in the fundamentals of project management. By following these key elements – from the scoping document to communications plans, marketing to annual auditing – wood products manufacturing industry leaders can foster a culture of safety, protect their workforce, and pave the way for a more secure and productive future in 2024 and beyond. Safety isn’t just a project; it’s an ongoing commitment to the people who make sawmills thrive.

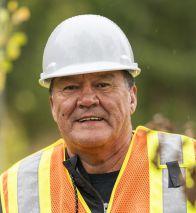

COLUMN final cut

Reconciliation in forestry

Uniting for a more equitable future

Equity. A powerful word that, unlike equality, champions the promise of fairness by recognizing individual needs rather than aspiring to achieve sameness. As Indigenous people seeking to collaborate and lead in the forest industry, we desire equitable opportunities. I believe to reach true equality in the future, we need to walk the pathway of equity, and the way forward starts first in understanding the meaning of truth and reconciliation.

As a survivor of a residential school, I’ve witnessed the profound pain and trauma that has affected not only my own life but also countless families and generations of survivors. As a previously elected Chief and a current councillor, I am deeply engaged with balancing my personal experiences while harnessing a progressive business perspective. My role as the executive director of Central Chilcotin Rehabilitation has further confirmed my beliefs that reconciliation is not just about acknowledging the past; it’s about reshaping the present and future to embrace the ideals of unity, opportunity, collaboration, and equity. While many times I see the tendency to lean toward offering economic incentives as the solution to help heal past injustices, it’s becoming more evident to me that a more comprehensive approach is important. While it’s good to strive to create opportunities for work, we must also place strong emphasis on building understanding and acknowledging that both healing and empowerment require a holistic approach.

In the forestry sector, the road to reconciliation is a winding one mixed with challenges, yet there has been significant progress and transformation. These are three areas where I believe we can start:

Recognize and understand the barriers for Indigenous communities: Many Indigenous communities have faced systemic barriers in accessing resources and opportunities in the industry. In some cases, opportunities remain elusive due to a lack of capacity, resource availability, or even preconceived notions that limit access. The offer of forest licences, for instance, can be a gesture of goodwill, but it requires substantive follow-through to truly empower

communities. Acknowledging these barriers is crucial for creating a more equitable forestry sector.

Empower Indigenous communities: Empowering Indigenous communities in forestry can include recognizing their right to make decisions about the management of their lands and resources. It may involve co-management agreements, joint ventures, or granting Indigenous communities a stronger role in helping shape forest management practices. When Indigenous communities can help shape their futures, it can lead to more sustainable and culturally aligned forest management solutions.

Work at all levels of government to take a unified approach: Achieving equity in forestry requires all levels of government to work collaboratively with Indigenous communities to develop forestry policies that align with reconciliation principles. This means addressing land rights, resource-sharing agreements, and regulatory frameworks that respect Indigenous knowledge and values. And it starts with listening to the aspirations of Indigenous communities and working in collaboration to find mutually beneficial solutions for everyone. I have seen progress being made through many government agencies opening their doors to greater Indigenous involvement and an increased understanding of the need to incorporate Indigenous practices into land management.

I invite all readers to join this journey. Whether you’re a seasoned forester, a student or a concerned citizen, we can make a difference by opening our minds to both traditional and innovative ways of doing things, listening, and learning. Reconciliation in forestry is about recognizing historical imbalances and taking steps to move forward together. It’s not about equal rights to a resource; it’s about working toward a fair distribution of benefits while preserving the forest for future generations. Think of equity as our collective guide toward a future where the opportunities for Indigenous communities are holistic in approach and tailor-made to help us catch up and thrive in a country that has been moving forward without us for far too long.

Like Father, Like Son

“Yep. Believe it or not, my whole life we have always run Log Max gear. I just can’t imagine harvesting our diet of wood with anything else,” says Cohen Connors (who incidentally is four years old).

Second Generation Logging is based out of the rural community of Blackville, located in Northumberland County, New Brunswick which is situated along the beautiful Southwest Miramichi River and smack-dab in the heart of logging and salmon fishing country.

Cohen lets his Dad, Justin look after the day-to-day operations “only because I don’t have my driver’s license yet!”

Five Log Max 6000’s mounted on Deere carriers make up the bulk of the company’s harvesters: two newer Log Max 6000V’s and three previous model 6000B’s. “Dad says he really likes the 6000V’s. They’re faster, stronger and the numerous updates make it a perfect fit for what we do. And, as long as the room and board is free, I’m gonna listen to Dad. You should too!”