ENGINEERING TO BE PROUD OF FIVE SPECIAL WINNERS 20 AWARDS OF EXCELLENCE + 20 3

•

•

By Tara Landes.

ENGINEERING TO BE PROUD OF FIVE SPECIAL WINNERS 20 AWARDS OF EXCELLENCE + 20 3

•

•

By Tara Landes.

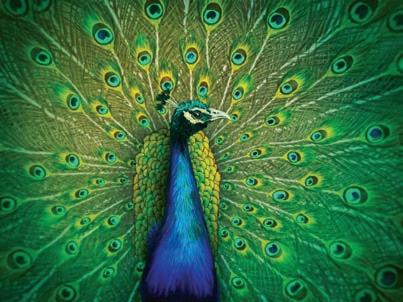

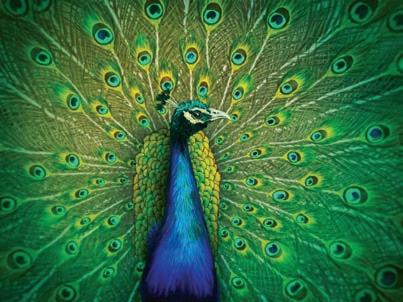

Given some of the bad press that engineers have been attracting from the Charbonneau and Elliot Lake Commissions, the Canadian Consulting Engineering awards are a refreshing reminder that engineers have very much to be proud of (hence the proud peacock on this issue’s cover).

Perhaps it’s because there are many more winners this year – 20 as opposed to 12 in previous years – that I have been struck more than ever by the sheer scale and complexity of engineers’ work. As I pore over the descriptions provided by the companies, it’s always a struggle to decide what must be left out for the articles in this issue. There are so many amazing aspects to each project. When I hear about Associated Engineering’s formidable steerage of the Deh Cho Bridge project in the NWT, or Dessau’s Herculean task of organizing, designing and managing the construction of the SIEPAC power line across six countries in Central America, I am left “gobsmacked” as we used to say in the U.K.

It’s not just the scale of the engineering that is astonishing, it’s all the issues the engineers must navigate through. There are the myriad technical decisions both large and small; there’s dealing with government rules, environmental sensitivities, extreme weather, difficult terrain, community groups who want to stand in your way, not to mention keeping clients and stakeholders happy. Engineering today is as much about dealing with people as about dealing with physical phenomena.

This year there are five special award winners (three new ones in addition to the Schreyer and Tree for Life Awards). All five exhibit extraordinary complexity, whether it’s the W12 sewer tunnel built deep below downtown Edmonton, the long-awaited remediation of the infamous Sydney Tar Ponds, the Allain Duhangan hydroelectric project built high in the Himalayas, or the work of a team of structural engineering experts in B.C. producing guidelines for retrofitting schools to make children safer. Golder’s charitable initiatives also involve coordinating a diverse range of programs across the globe.

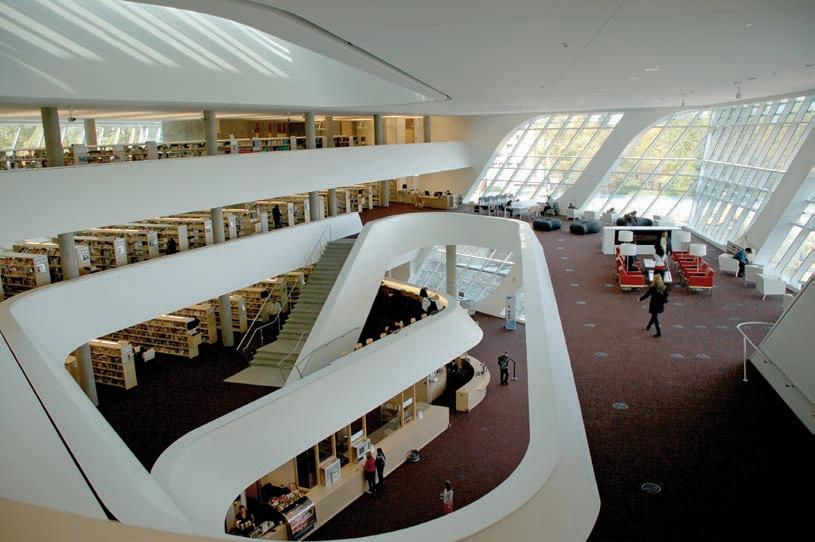

On the individual building scale, the engineering gymnastics that went into converting Toronto’s Maple Leaf Gardens into a retail store were so complicated they are compared to building a ship in a bottle, while having to dismantle a ship that was already inside. And at the Surrey City Centre Library and the Lazaridis Quantum-Nano Centre, we find structural engineers applying painstaking care and invention to create extraordinary architecture.

The brief descriptions on the following pages only brush the surface of the effort involved in the projects, and the short list of credits given at the end is also only a tiny fraction of the true picture. Movie-makers can let the credits roll for 10 minutes, listing everyone down to the people who trained the dog and brought the coffee. No such luck with the printed word. Given the straitjacket of the printed page, we have to impose strict restrictions on who the winning firms can mention. But we all know that behind the handful of names and companies listed, and the few faces that were able to be gathered for the winners’ photographs (p. 70), stand whole armies of engineers and people who made the projects a success. Bronwen Parsons

Editor

Bronwen Parsons

E-mail: bparsons@ccemag.com (416) 510-5119

Senior Publisher

Maureen Levy

E-mail: mlevy@ccemag.com (416) 510-5111

Art Director

Ellie Robinson

Contributing Editor

Rosalind Cairncross, P.Eng.

Advertising Sales Manager

Vince Naccarato

E-mail: vnaccarato@ccemag.com (416) 510-5118

Editorial Advisors

Bruce Bodden, P.Eng., Gerald Epp, P.Eng., Chris Newcomb, P.Eng., Laurier Nichols, ing., Lee Norton, P.Eng., Jonathan Rubes, P.Eng., Paul Ruffell, P.Eng., Andrew Steeves, P.Eng.

Circulation

Barbara Adelt (416) 442-5600 x3546 badelt@bizinfogroup.ca

Production Co-ordinator

Karen Samuels (416) 510-5190

Vice President, Publishing Business Information Group (BIG) Alex Papanou

President, Business Information Group (BIG) Bruce Creighton

Head Office

80 Valleybrook Drive, Toronto, ON Canada M3B 2S9 Tel: (416) 442-5600 Fax: (416) 510-5134

CANADIAN CONSULTING ENGINEER is published by BIG Magazines LP, a division of Glacier BIG Holdings Company Ltd.

EDITORIAL PURPOSE: Canadian Consulting Engineer magazine covers innovative engineering projects, news and business information for professional engineers engaged in private consulting practice. The editors assume no liability for the accuracy of the text or its fitness for any particular purpose.

SUBSCRIPTIONS: Canada, 1 year $60.95; 2 years $91.95 + taxes Single copy $8.00 Cdn + taxes. (HST 809751274-RT0001).

United States U.S. $60.95. Foreign U.S. $60.95.

PRINTED IN CANADA. Title registered at Trademarks Office, Ottawa. Copyright 1964. All rights reserved. The contents of this publication may not be reproduced either in part or in full without the consent of the copyright owner(s).

ISSN: 0008-3267 (print), ISSN: 1923-3337 (digital)

POSTAL INFORMATION: Publications Mail Agreement No. 40069240. Return undeliverable Canadian addresses to Circulation Dept., Canadian Consulting Engineer, 80 Valleybrook Drive, Toronto, ON Canada M3B 2S9. USPS 016-099. US office of publication: 2424 Niagara Falls Blvd., Niagara Falls, NY 14304-5709. Periodicals postage paid at Niagara Falls, NY. US Postmaster: send address changes to Canadian Consulting Engineer, PO Box 1118, Niagara Falls NY 14304.

PRIVACY: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us. tel: 1-800-668-2374, fax: 416-510-5134, e-mail: jhunter@businessinformationgroup.ca, mail to: Privacy Officer, BIG, 80 Valleybrook Drive, Toronto, ON Canada M3B 2S9.

Member of the Audit Bureau of Circulations.

Member of the Canadian Business Press

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities.

The redesigned Hammond DC4R Open Rack series is one of the most economical solutions to house IT equipment in wiring closets or data centers. In situations where the wiring closet itself is under lock and key and accessed by a limited number of people, full cabinets having locking doors and side panels may not be required resulting in a significant cost savings.

Features:

• Constructed of 12-gauge steel.

• Available in 24U and 44U and in two convenient infinitely adjusting depths.

• 24”- 36” for standard rack mount equipment.

• 32”- 48” for extra deep equipment.

• Includes two (2) pairs of 19” mounting EIA-310-D compliant square-hole rails.

• Includes one (1) set of two (2) horizontal cable manager bars. Additional cable manager bars available by ordering part number DC4RSHCM.

• Self-squaring design reduces assembly time.

• Optional pair of rails available for multiple mounting depths.

• Mounting rails include permanent rack unit space indicators.

• Rail depth L-bracket restrict the installer from over-extending the rack. This ensures the integrity of the rack.

• Suggested load capacity of 2,000 lb.

• Finished in smooth black powder paint.

Designed to enclose electrical and/or electronic equipment and protect against harsh, industrial environments for wall mount applications.

Provides a high level of protection where equipment is hosed down or otherwise be exposed to wet conditions where corrosion is a serious problem.

Ideal for processing plants, utility, outdoor municipal or petro chemical locations where easy yet secure access is required.

Features:

• Formed 304 or 316 stainless steel.

• Continuously welded seams ground smooth.

• Door stiffeners are provided where required for increased strength and rigidity.

• Formed lip on enclosure to exclude flowing liquids and contaminants.

• 316 Stainless pad lockable handle with 3 point roller latching system secures door.

• Stainless steel continuous hinge on door may be removed by pulling the stainless steel hinge pin

• Seamless poured-in place gasket.

• Collar studs provided for mounting inner panel.

• Bonding stud provided on door and grounding stud installed in enclosure.

• Cover and enclosure are natural stainless steel with smooth brushed finish.

Standards:

• UL 508 Type 3R, 4, 4X and 12

• CSA Type 3R, 4, 4X and 12

• Complies with

• NEMA 3R, 4, 4X, 12 and 13

• IEC 60529, IP 66

deemed one of best in 100 years

Confederation Bridge, the 13-kilometre crossing that joined Prince Edward Island to mainland Canada in 1997, has won a Centenary Award from FIDIC, the International Federation of Consulting Engineers. The award of excellence marked the bridge as one of the most important civil engineering projects of the past 100 years. AECOM and Stantec were presented with the award which was announced in Barcelona, Spain at FIDIC’s annual meeting.

The 13-kilometre bridge stretches across the Northumberland Strait to New Brunswick. It was completed as a fast-track design-build project, which was unusual at the time. It required innovative precast construction and was completed in under four years, despite the massive scale of the project and the difficult weather.

The project earned Stantec (then Stanley Consulting Group of Calgary) the Schreyer Award in the 1998 Canadian Consulting Engineering awards.

Opus acquires Stewart Weir of Alberta

Opus International Consultants has acquired Stewart Weir, an employeeowned company of 550 people. With four offices in Alberta and one in Fort St. John, B.C., the company is 100 years

panded its services from surveying and engineering to include industrial engineering, geographical information systems, and environmental services.

Opus International’s managing director and chief executive, Dr. David Prentice, suggested that the acquisi tion was partly to give Opus a bigger role in Canada’s grow ing pipeline and energy markets.

The new company will operate as Opus Stewart Weir, and Stew art Weir’s current chief executive officer, Brian Pearse, will stay as its president. The president of Opus’ Canadian opera tions will continue to be Sean Brophy, who is based in Vancouver.

Opus International acquired Day ton and Knight (now Opus Dayton Knight) of Vancouver in 2010, and now has 700 staff and 16 offices in Canada. It has 3,000 people around the world, in Australia, New Zea land, the U.K., U.S. and Canada.

Work continued early this fall on rebuilding bridges and roads in Alberta that were washed out during the floods at the end of June. Approximately 985 kilometres of provincial roads were closed due to flood damage, but by mid-September 87% of them had been reopened or partially reopened, including most of the major bridges.

The Association of Consulting Engineering Companies - British Columbia has won an award from the Canadian Society of Association Executives, B.C. chapter, in recognition of the work the association has done on amending the province’s Ultimate Limitation Period.

& Mail gets new digs

A new home for the Globe & Mail newspaper is due to break ground this month, with completion in 2016.

The 17-storey building is to be constructed in Toronto’s east downtown on

continued on page 8

ENERGY STAR Portfolio Manager has been officially launched in Canada. The U.S. Environmental Protection Agency program was tailored to the Canadian market in association with Natural Resources Canada. The new tool has Canadian weather, postal codes, both official languages, the metric system and other data specific to Canada. Over 4,000 Canadian buildings are using the tool to monitor and rate their energy use.

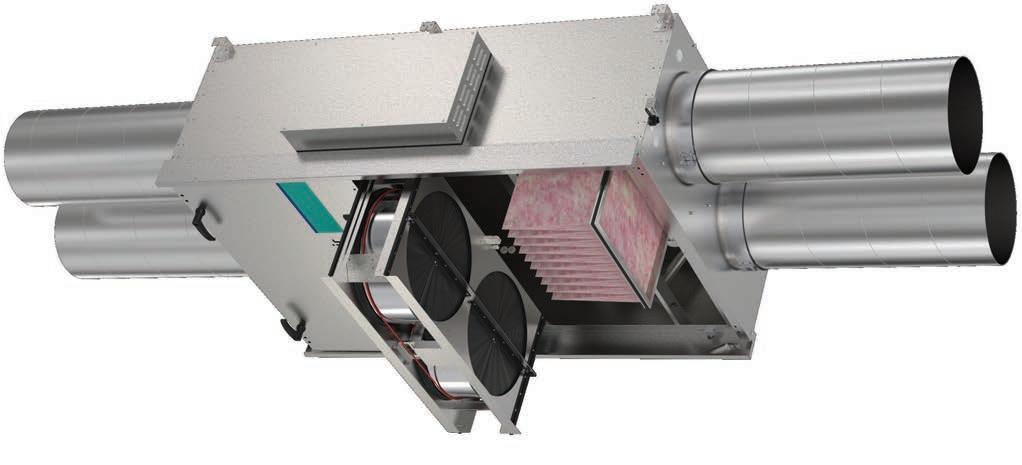

ANNOUNCING THE WORLD’S FIRST WATER-SOURCE, MODULAR 575V VRF SYSTEM

Whether for new buildings or for retrofi ts, our new watersource, 2-pipe VRF system uses less materials than 4-pipe systems and has a signifi cantly lower maintenance cost. Best of all, it’s 575V, so no transformer is needed.

And because it’s modular and installed indoors, there is no need for cranes or heavy equipment. In fact, our new 575V VRF system is so compact it is easier to incorporate into any design, plus it is less expensive to install and maintain.

Mitsubishi Electric’s new water-source, 575V VRF system is a game changer.

a block between King Street East, Front Street East and Berkeley Streets. It is within the original 10-block grid of the former Town of York, where Toronto began. The newspaper, which started publishing in 1844, has occupied offices on King Street before, but is currently in a building on Front Street West.

The new tower is being developed by First Gulf, with the Globe and Mail occupying levels 13 through 17. Level 17 has 15-foot ceilings, floor-to-ceiling vision glass, and a multipurpose room with adjacent terrace.

Diamond Schmitt Architects have designed the structure as stacked alternate-sized floor plates interlaid with terraces. Consultants include Read Jones Christoffersen (structural), Hidi Rae (mechanical-electrical), LMDG (code), RWDI (wind), Valcoustics (vibration), BA Consulting (transportation), and ERA Architects (heritage).

On September 24, Ontario’s Environmental Commissioner, Gord Miller, released “Building Momentum: Provincial Policies for Municipal Energy and Carbon Reductions.”

The report examined how development charges are used to fund municipal transit expansions. It found that the funding formula is biased against transit when compared to how it treats other municipal services like roads.

Miller pointed out: “Right now, municipalities are prevented from using development charges to cover 100% of the capital costs for new transit service; they can only cover 90% of the costs. But they [development levies] can be used to pay for 100% of the capital costs of other municipal services like roads. Transit is not treated fairly.”

Miller found that another factor hobbling transit funding is that because the income from development charges is based on the past 10 years of service that a municipality provided, those municipalities that want to expand their transit don’t get the funds they need.

In 2011 municipalities in the province collected $1.3 billion from developers to pay for infrastructure. The Ontario government is promising to consult with municipalities and review the 1997 Development Charges Act.

SNC-Lavalin has created a new position on its public relations front. Erik J. Ryan will be its new executive vice-president, marketing, strategy and external relations. Ryan is a Quebec native and will be based in Montreal. He comes to SNC-Lavalin from Rio Tinto Alcan.

At CH2M HILL, Lee McIntire will step down as chief executive officer of the Denver-based company on January 1. McIntire, who has been CEO since June 2009, will continue as chairman of the board. The new chief executive officer will be Jacqueline Hinman, previously pres ident of CH2M HILL In ternational. Hinman was a key executive in many of CH2M HILL’s proj ects around the world, such as the London 2012 Olympic and Paralympic Games. She also served as chair and CEO of Halcrow companies after CH2M HILL’s 2011 acquisition of the 6,000-person U.K.-based firm. CCE magazine interviewed Hinman in the May 2013 issue, “Conversations,” page 42.

MAILBOX

Ethical choices not easy

Re. “Perils of Whistleblowing” by Tom Sisk of the APEGNB, (CCE August-September 2013, p. 58).

As engineers and scientists, or even as ordinary citizens, all of us face this dilemma during our life under various situations — at work, with neighbours and even within one’s family. What does one do being aware of some truth, and the consequences both of being quiet, or of revealing it?

Now a senior citizen and engineer, I have not only read many such articles on the topic, but also faced many such dilemmas. In the past as a young engineer with a family to support, I had no choice but to grin and bear the situation and move on, hoping for the best. Fortunately, my decision did not disappoint me much except for a stomach ulcer and some sleepless nights. Just as with the Tom Sisk’s article, I always end, even now, with an uneasy feeling of indecision.

As much as these articles are interesting, they provide little or no guidance to us and especially to young engineers and scientists. Is there some guidance possible at all?

Raj S.V. Rajan, P.Eng. Sherwood Park, Alberta

ASSOCIATION OF CONSULTING ENGINEERING COMPANIES | REVIEW

he Association of Consulting Engineering Companies (ACEC), in collaboration with Canadian Consulting magazine, celebrates excellence in the consulting engineering sector at its annual awards gala. Interest in the awards has grown significantly in recent years and we are pleased to have expanded our awards program. This year, a record 20 exceptional projects were recognized with Awards of Excellence.

In addition to our annual presentations of the Tree for Life Award for environmental stewardship and the Schreyer Award – the highest honour for a consulting engineering firm in Canada – we have created three new special achievement awards. The Ambassador Award went to the project executed outside Canada that best showcases Canadian engineering expertise. Our Engineering a Better Canada Award was presented to the project that best showcases how engineering enhances the quality of life of Canadians, and the Outreach Award

MESSAGE DU PRÉSIDENT DU CONSEIL

recognizes an ACEC member firm for its contributions and services to a community. These new awards not only illustrate the diversity, innovation and creativity provided by Canadian consulting engineers, but also how their skill and expertise touches our lives.

ACEC also made its annual presentation of the Beaubien Award, the highest honour bestowed on an individual for their lifetime contribution to the Canadian consulting engineering sector. This year, Norm Huggins was the deserving recipient of this honour.

Through these awards, consulting engineers receive well-deserved recognition for their contribution to our quality of life. The value we provide to our clients, and the contribution we make to society and to the economy, are matters of personal and professional pride to all of us who work in this extraordinary industry. We are all winners as Canadian consulting engineers build a sustainable future through innovative and exciting solutions.

JASON MEWIS, P.ENG. CHAIR, ACEC BOARD OF DIRECTORS

L’Association des firmes d’ingénieurs-conseils (AFIC), en collaboration avec la revue Canadian Consulting Engineer, célèbre l’excellence de secteur du génie-conseil lors de son gala des Prix annuel. L’intérêt pour le programme des prix s’est considérablement accru ces dernières années et nous sommes heureux de l’avoir étendu. Cette année, un nombre record de vingt projets exceptionnels ont mérité un Prix d’excellence.

En plus de la présentation annuelle du prix Un arbre à aimer pour l’intendance environnementale et du Prix Schreyer – qui est la plus haute distinction décernée à une firme de génie-conseil au Canada – nous avons créé trois nouveaux prix spéciaux. Le Prix Ambassadeur est octroyé pour le projet réalisé à l’extérieur du Canada et qui représente le mieux l’expertise canadienne en ingénierie. Le prix l’Ingénierie pour un Canada meilleur démontre comment l’ingénierie améliore la qualité de vie des Canadiens, tandis que le Prix Rayonnement reconnaît une firme membre de l’AFIC pour ses contributions et ses services à la communauté. En plus

d’illustrer la diversité, l’innovation et la créativité que procurent les ingénieurs-conseils canadiens, ces nouveaux prix démontrent aussi comment leurs compétences et leur expertise influencent nos vies.

L’AFIC a aussi présenté le Prix Beaubien, qui est le plus grand honneur décerné à une personne pour ses contributions au secteur canadien du génie-conseil. Cette année, le Prix Beaubien a été présenté à Norm Huggins.

Par le biais du programme des prix, les ingénieurs-conseils reçoivent une reconnaissance bien méritée pour leur contribution à notre qualité de vie. La valeur que nous procurons à nos clients et la contribution que nous faisons à la société et à l’économie sont des questions de fierté personnelle et professionnelle pour tous ceux qui œuvrent dans cette industrie extraordinaire. Nous sommes tous gagnants puisque les ingénieurs-conseils canadiens bâtissent un avenir durable par des solutions innovatrices et stimulantes.

JASON MEWIS, P.ENG. PRÉSIDENT DU CONSEIL D’ADMINISTRATION DE L’AFIC

It was a night of high spirits and celebration on October 22 when the 2013 Canadian Consulting Engineering Awards were handed out at the Ottawa Convention Centre. Cosponsors of the event ACEC and Canadian Consulting Engineer magazine welcomed attendees from across the country, including representatives of award winning firms, clients and dignitaries.

Mission Statement

The Canadian Consulting Engineering Awards are presented each year to the projects judged to have achieved the highest level of excellence in the quality of engineering, innovation and impact on society.

ACEC, together with the magazine, launched the awards in 1969 and they have been going strong ever since. While their roles are clearly defined –CCE manages the entries and judging process, and publishes a special edition on the winning projects, while ACEC looks after all affairs related to the awards gala and promotion – the organizations work and collaborate closely on all the big decisions.

Bronwen Parsons, editor of Canadian Consulting Engineer, reflected on the success of the long-standing relationship. “For the magazine, working with ACEC on this program helps us to deepen our involvement with the consulting engineering industry in Canada, and amounts to one of the best ways we can promote excellence in engineering,” said Ms. Parsons.

As the voice of consulting engineering in Canada, ACEC is a proud supporter of the awards which, for so many years, have brought to the forefront the technical expertise, innovation and ingenuity offered by its

member firms. Commenting on the significance of the awards, ACEC president John Gamble stated, “These awards showcase the important role of Canadian consulting engineers in every aspect of our lives.”

As a reflection of the increased recognition generated by

the awards and greater participation in recent years, the number of Awards of Excellence was expanded in 2013 and three new special awards were created.

ACEC and Canadian Consulting Engineer look forward to continuing their successful collaboration to provide an awards program that recognizes Canada’s outstanding achievements in engineering, thereby upholding and strengthening the consulting engineering industry.

ACEC’s Beaubien Award recognizes individuals for their exceptional work as members of the association and for their lifetime contributions to the advancement of the consulting engineering profession. Norm Huggins, P.Eng., is this year’s honoree, selected by his peers to receive this prestigious award at the 2013 Canadian Consulting Engineering Awards on October 22, 2013.

On winning the award, Norm remarked, “I sincerely believe that this award was earned not by me, but by the solid ACEC organization in Ottawa that keeps our industry as the go-to authority on Canada’s infrastructure future. Good business practices deliver good projects to secure sustainable infrastructure for Canada’s future. I would be remiss to not mention that my opportunity to receive this award comes only with the overwhelming support of CH2M HILL, and my family who now appreciate that my pas-

sion for consulting engineering has its rewards.”

Norm is known for his outstanding leadership and his contributions to the consulting engi neering industry. He is highly regarded by the many colleagues who have developed their careers under his tutelage, as well as by the communities that have benefited from his expertise.

Norm started his career at CH2M HILL, formerly known as Gore and Storrie, as a summer student in 1966. He joined the company full-time upon graduating with a degree in Civil Engineering from Queen’s University and this year, as Senior VicePresident, he celebrates his 45th year with CH2M HILL.

Norm has given a lifetime of service, since 1972, to ACEC and Consulting Engineers of Ontario, advocating in the interest of engineers to governments,

ACEC Member Organizations: Association of Consulting Engineering Companies - British Columbia, Consulting Engineers of Yukon, Consulting Engineers of Alberta, Consulting Engineers of Northwest Territories, Consulting Engineers of Saskatchewan, Association of Consulting Engineering Companies – Manitoba, Consulting Engineers of Ontario, Association des Ingénieurs-conseils du Québec, Association of Consulting Engineering Companies – New Brunswick, Consulting Engineers of Nova Scotia, Consulting Engineers of Prince Edward Island, Consulting Engineers of Newfoundland and Labrador.

clients and the public. Throughout his career he has also dedicated time and effort with the Toronto and Ontario chapters of the Engineering Institute of Canada and the Pollution Control Association of Ontario.

During his tenure on the Board of ACEC-Canada and as Chair, Norm was a strong advocate for the use of Qualifications-Based Selection for the procurement of professional engineering services. During this time, ACEC collaborated with the National Guide to Sustainable Municipal Infrastructure, also known as InfraGuide. As a result, when InfraGuide released its best practice for selecting a professional consultant, Qualifications-Based Selection was the recommended procurement method. This is one of the most important achievements of the consulting engineering sector in recent memory. To this day, ACEC continues to promote InfraGuide and QualificationsBased Selection.

One of Norm’s greatest interests has been to encourage more young people to enter the consulting engineering indus-

try. He identified building human capital as one of his goals as Chair of ACECCanada and is known as a great mentor and model to other engineers for his quiet leadership, ethical behaviour, and strength in bringing groups together to accomplish common objectives.

As a recipient of the Beaubien Award,

Norm joins a list of over 30 individuals who have been identified by their peers for their outstanding contributions to the consulting engineering industry and engineering profession. The award was created by ACEC in 1984 in honour of Dr. James de Gaspé Beaubien, who founded ACEC in 1925.

During the recess of the House of Commons over the summer, ACEC’s government relations team has worked hard on behalf of the association’s members to move forward on some key policy areas.

The Standing Committee on Finance is one of the most influential committees of the House of Commons. This committee provides recommendations, based on the submissions and testimony of government stakeholders such as ACEC, to the Department of Finance for the creation of the federal budget. In August, ACEC was pleased

to put forward the following positions on infrastructure to the Finance Committee on behalf of ACEC member firms.

ACEC continues to promote investments in public infrastructure as a key to Canada’s economic prosperity. ACEC’s position is as follows:

• ACEC applauds the government for its commitment to a 10-year infrastructure plan which was announced in the 2013 federal budget (to be implemented in the 2014 budget).

• It is urgent that the framework and an efficient application process are in

place so that the new investments can begin immediately in 2014-2015. With the current program ending, jobs and expertise are already being lost, undermining some of the economic benefits of a stable, predictable 10-year program before it begins.

Recognizing that inter-governmental framework agreements can be complicated and take time, ACEC is concerned that there is already a lag between the expiry of the current Building Canada Fund and the launch of the new program. We therefore encourage the government to work quickly with the provinces and territories to establish the framework imme-

continued on page 14

ACEC Calls for Fast Action on Framework Agreements continued from page 13

diately so that applications for projects can commence and projects can get approved and underway.

We believe the government will be receptive to this request.

Developing Canada’s North

ACEC believes there is enormous economic potential for Canada and opportunities for ACEC members through the development of infrastructure in northern and remote regions of Canada. ACEC’s position is as follows:

• There is an acute need to access Canada’s natural resources and transport these resources to market.

• Lack of northern and remote infrastructure is a barrier to investment by Canada’s resource sector.

• The federal government can and should do its part to create a better business climate for private sector investment in the North.

Despite efforts by successive federal governments to create programs to assist in the development of northern communities, Canada’s North remains largely underdeveloped. ACEC is partnering with the Mining Association of Canada, the Prospectors and Developers Association of Canada and the NWT Chamber of Mines to study the challenges of doing business in the North. The

intent of the study is to identify the opportunities the North presents, the barriers to private sector involvement, and some specific recommendations that the federal government could implement to create a more favourable business climate for investing in the North. ACEC has also met with senior government officials who are interested in the results of the study and keen to hear forthcoming recommendations on creating prosperity in Canada’s northern regions.

Parliament Hill Day 2013

ACEC’s Parliament Hill Day contin -

ues to be the cornerstone of the association’s government relations program, bringing representatives of award winning firms to Ottawa to participate in advocacy on behalf of ACEC and the Canadian consulting engineering sector. On October 22, an ACEC delegation went to Parliament Hill to brief Members of Parliament from all parties on the messages outlined above. ACEC sincerely thanks the participants of this year’s Parliament Hill Day for their dedication and support, and for advocating effectively in the interest of all ACEC member firms.

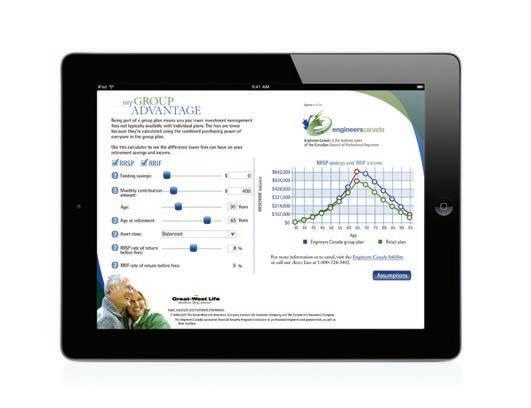

All organizations need to know if they are paying their employees competitively, if their group insurance benefits and retirement plans are appropriate, and that they have sound compensation policies and procedures in place.

ACEC-Canada has partnered with Western Compensation & Benefits Consultants to produce an annual

survey of Canadian Consulting Engineering companies.

The report which is published in October will contain comprehensive information on:

• Current salaries and bonuses for 80 positions including: engineers/scientists, technician/technologist; executives/senior management, HR, IT, accounting and payroll, and administra-

• Expected changes in salaries for 2014

• Group insurance benefits and retirement plans

• Compensation best practices.

Members of ACEC-Canada receive a 15% discount.

For more information visit: www. wcbc.ca/surveys/consultingengineers.

ACO StormBrixx is a unique and patented plastic geocellular stormwater management system. Designed for surface water infiltration and storage, its versatility, and ability to handle heavy loads (up to 420 kN/m2), allows it to be used in applications across all construction environments: Residential, commercial, and industrial.

Recycled polypropylene construction provides tough, highly corrosion resistant structure

High strength ribbed columns

Lightweight design for easy manual handling and fast installation

Access groove provides a clear path for inspection cameras or jetting equipment

High void ratio - 95%

Weep holes provided to maximize void ratio

Side walls create debris and silt traps and provide additional lateral support

Two injection moulded pieces clip together to form one single tank unit

Units can be cut in half to accommodate tank configurations

In this, its 45th year, some exciting changes have been made to the Canadian Consulting Engineering Awards.

Five special awards are being given, and the number of Awards of Excellence has increased from 12 to 20.

Having more awards reflects the evolution and growing scope of the program, which now attracts many more entries than it did historically. And having special awards heightens the drama of the announcements and builds their profile.

The Schreyer Award was inaugurated in 1981, and the Tree for Life Award began in 2008.

This year, in addition to these two, the jurors were invited to assign an additional three special awards. These three in different ways recognize the contributions and vital role that engineering makes to society.

continued on page 18

All the projects that received an Award of Excellence were then considered for additional recognition as five special awards.

The Schreyer Award is presented annually to the project that best demonstrates technical excellence and innovation.

The Tree for Life Award is presented annually to the project that best demonstrates outstanding environmental stewardship in terms of protecting the natural environment, reducing pollution and conserving the earth’s resources.

The Ambassador Award is presented to the project, constructed or executed outside Canada that best showcases Canadian engineering expertise.

The Engineering a Better Canada Award is presented to the project that best showcases how engineering enhances the social, economic or cultural quality of life of Canadians.

The Outreach Award is presented for a company’s role in donating their time or services for the benefit of a community or group either in Canada or on the international stage.

Projects are given Awards of Excellence based on the following criteria: originality or innovation in the use of new technology or a new application of existing technology; complexity; environmental impact; social and economic benefits; and fulfilling the owner’s or client’s needs. These criteria are weighted differently for non-technical vs. technical categories.

Technical entries are in the building, transportation, water resources, environmental remediation, natural resources, mining, industry and energy, and special projects categories. Non-technical entries are in the international, project management, and community outreach categories.

Note that awards are given for merit, not assigned per category.

CONSULTING ENGINEERS SHOW LEADERSHIP THAT GOES BEYOND TECHNICAL SOLUTIONS

What could be more enjoyable than reviewing some of Canada’s most interesting engineering accomplishments with a group of distinguished professionals? This year I had the privilege of chairing the 2013 Canadian Consulting Engineering Awards selection committee. It was an honour to work with the jurors who are distinguished professionals with a keen appreciation for the value that engineers bring to society.

The jurors selected 20 of the best entries for Awards of Excellence and five for Special Awards. The variety and scale of the projects was considerable and all demonstrated the incredible dedication and skill of Canadian engineers. We selected the award winners through a consensus process, a significant challenge that speaks volumes about the professionalism of the group.

It is gratifying to see engineers contributing in a significant way to the overall benefit of Canadians. Not only are engineers producing solutions to some

gineered solutions that will reduce the future impact of human activities.

Canadian consulting engineers are advancing the application of science to the benefit of society not only in Canada but internationally as well.

Of particular interest to me is the extent to which some of the awardwinning projects demonstrated the leadership role undertaken by engineers. Their contributions extended well beyond technical solutions to include public consultation, negotiation and communication. Who better to bridge the gap between the interests of commerce and community than consulting engineers?

I would like to thank ACEC and Canadian Consulting Engineer magazine for continuing to support these awards and for the opportunity to be a part of this event. I wish all the ACEC member firms the very best success in their future endeavours.

THIS N’ THAT

Program sponsors

The awards are held as a joint program by the Association of Consulting Engineering CompaniesCanada (ACEC)/l’Association des firmes d’ingénieurs-conseilsCanada (AFIC) and Canadian Consulting Engineer magazine.

The 2013 winning projects were presented at a gala dinner held at the Ottawa Convention Centre on October 23.

To see all projects entered Projects entered in 2013 and recent years are viewable in full as PDF files. Visit the Showcase of Entries in the Awards section of Canadian Consulting Engineer’s website. http://www. canadianconsultingengineer.com/ awards/showcaseOfEntries.aspx

Number of entries (last year in brackets)

Total 61 (77)

Entries per category

Buildings 10 (23)

Transportation 15 (11)

Water Resources 7 (14)

Environmental Remediation 6 (4)

Natural Resources, Mining, Industry and Energy 10 (4)

Special Projects 7 (9)

Project Management 3 (2)

International 2 (6)

In-House Initiatives and Community Outreach: 1 (4)

Province of entering firms

British Columbia 13

Alberta 13

Saskatchewan 1

Manitoba 3

Ontario 18

Quebec 8

New Brunswick 1

Nova Scotia 4

Ronald De Vries, P.Eng is a civil engineer and former (retired) senior vice-president of opera tions with Defence Con struction Canada where he spent 29 years. He has been a member of many boards and commit tees involved in advancing procurement standards and innovative practices within the consulting and construction industry. He is currently a member of the Canadian Construction Documents Committee.

Chantal Guay, ing., is vice-president of the Stan dards Council of Cana da’s Accreditation Servic es in Ottawa. From 2008 to 2011 she was chief ex ecutive officer of Engineers Canada. A graduate in geological engineering from Université Laval and in environmental management from the Université de Sherbrooke, she has been involved in establishing an environmental engineering firm and planning brownfield redevelopment projects.

Jean Claude Champagne, ing., arch., PMP was corporate vice-president of development and real estate with Loto-Québec between 1999 and 2010. For 10 years before that he was head of construction with the Société d’habitation du Québec. He has degrees in architecture from the Université de Montréal and in civil engineering from the Royal Military College in Kingston, Ontario.

Christophe Guy, P.Eng., Ph.D, FCAE, O.Q., is chief executive officer of Poly technique Montréal, one of the largest engineer ing schools in Canada. He is a professor, researcher and ex pert in environmental and chemical engineering and has helped support the establishment of several Quebec firms that emerged from university research. The author of eight invention patents, he is also vice-chair of the Consortium for Research and Innovation in Aerospace in Quebec.

Guy Felio, Ph.D., P.Eng., is a civil engineer with 30 years’ experi ence in civil, geotechnical and municipal engineer ing. Now president of In frastructure Strategies & Research, he was instru mental in producing the first Canadian Infrastructure Report Card and the National Guide to Sustainable Municipal Infrastructure, or “InfraGuide.” He is also an elected councillor for the city of Clarence Rockland in Ontario.

Darin Lamont, P.Eng., vice president of engineer ing and operations with Saint John Energy in New Brunswick. A graduate in electrical engineering, he is currently responsible for engineer ing, operations, metering and information technology with the utility. He is a member of the Saint John Emergency Management Organization and sits on the planning advisory committee for the town of Quispamsis, N.B.

continued from page 20

Alistair D. MacKenzie, P.Eng., FCSCE, FEIC, professor emeritus at Ry erson University in To ronto. He was previously chief engineer at George Wimpey in Canada where he worked on civil and oil and gas projects. He is a past president of the Canadian Society for Civil Engineering and chaired its national history committee for several years. He is also the author of scores of conference papers and magazine articles.

Bob McDonald host of the Canadian Broadcasting Corpora tion’s radio show Quirks & Quarks. He has hosted the show since 1992 and is also a regular science commentator on the CBC news net work. His awards include the NSERC 2001 Michael Smith Award for Sci ence Promotion and the Royal Soci ety of Canada’s McNeil Medal for the public awareness of science. He has six honorary degrees and was made an Officer of the Order of Canada in 2011.

Jane Pagel, M.Sc., been president and chief executive officer of the Ontario Clean Water Agency since 2010. She also serves on the board of Sustainable Development Technology Canada and was a longstanding member of the Prime Minister’s Advisory Coun cil on Science and Technology. Her previous experience includes executive positions with Stantec, Jacques Whitford and Zenon Environmental Laboratories.

Tarlachan S. Sidhu, Ph.D, , has been dean and professor in the Fac ulty of Engineering and Applied Science at the University of Ontario In stitute of Technology in Oshawa since January 2012. Before that from 2002 to 2011 he was chair of the Electrical and Computer Engineering Department of the University of Western Ontario in London. He is a fellow of the Institution of Engineers in India and of the Canadian Academy of Engineering.

Brian Watkinson, OAA, had an architec tural practice for 20 years in Niagara Falls, Ontario, before joining the Ontar io Association of Archi tects where he was execu tive director for several years. Now the principal of Strategies 4 Impact! he provides strategic advice to the construction sector, including helping Infrastructure Ontario adopt new industry practices and contracts.

Chan Wirasinghe, Ph.D., P.Eng., has been a profes sor at the University of Calgary’s Department of Civil Engineering since 1976. He served as the university’s dean of engi neering for 12 years and was the found ing dean (emeritus) of the Schulich School of Engineering. A graduate of the University of California at Berkeley and the University of Ceylon, he has over 40 years of experience and research in transportation engineering and planning. He is a member of the Natural Sciences and Engineering Research Council of Canada.

SMA CONSULTING AND ASSOCIATED ENGINEERING

The Schreyer Award is presented to the project that best demonstrates technical excellence and innovation. This year it goes to a project constructed to reduce outflows of stormwater and sewage into the North Saskatchewan River in Edmonton. The completely successful result was achieved thanks to expert engineering and using sophisticated models and decisionsupport tools.

JUROR COMMENTS

“This was a difficult project to execute in a small space and it has resulted in a 100% reduction in combined sewer overflow events in its first year of operation.”

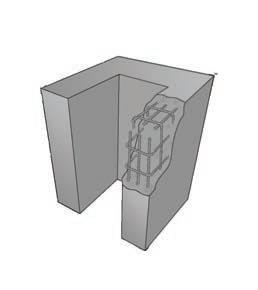

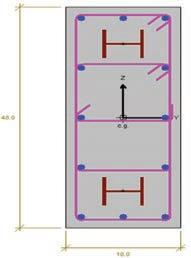

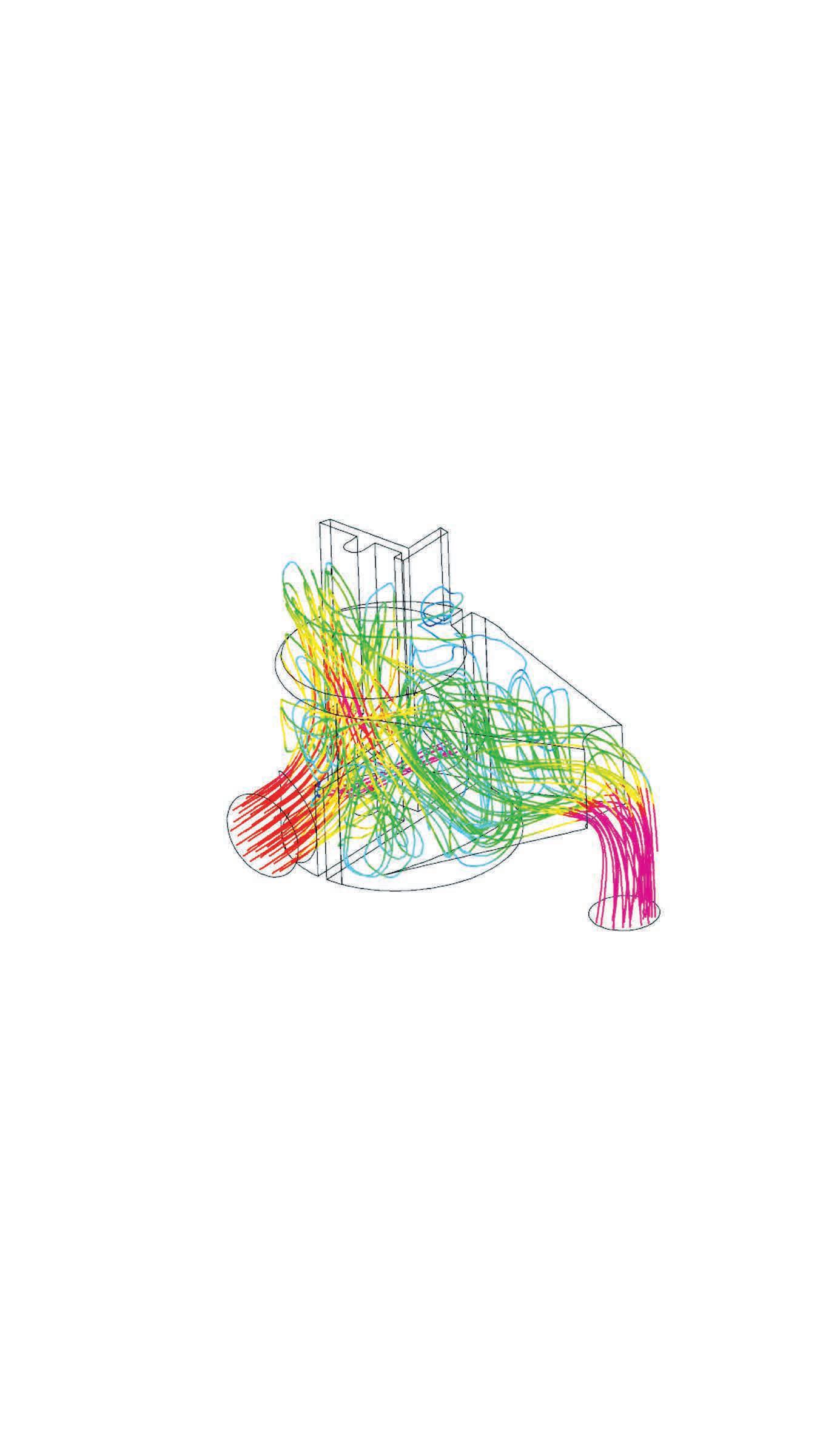

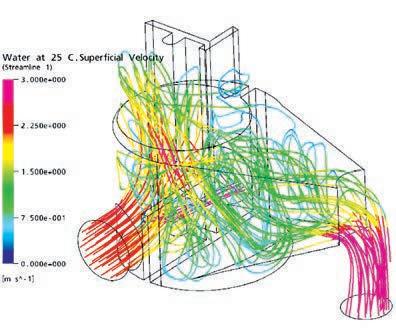

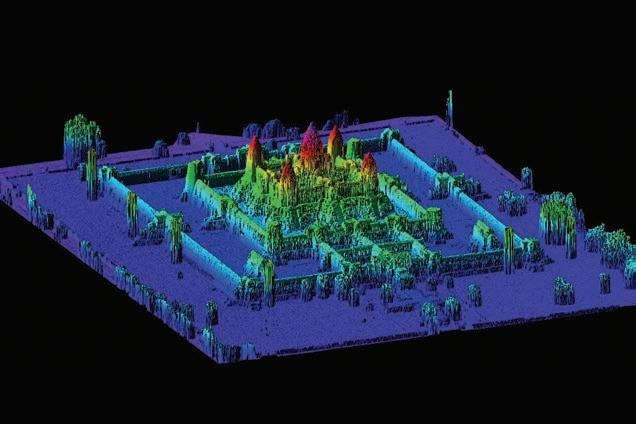

Three-dimensional model of the real-time control structure. It had to be tied into an existing old brick pipe under live flows.

The North Saskatchewan River that flows through the City of Edmonton supplies drinking water for the city and dozens of downstream communities. Unfortunately, like most pre1940 municipalities, Edmonton has sewer systems that also serve as stormwater systems, and during heavy rains these combined sewers occasionally overflow into the river.

A combined sewer outfall at Rat Creek located in the river valley near downtown was responsible for 6080% of the city’s combined sewer overflow. The outfall discharged up to 2 billion litres annually into the river, affecting water quality and fish

habitat, and raising safety concerns.

As part of Edmonton’s West Edmonton Sanitary Sewer (WESS) project, the city decided to remedy the situation at the Rat Creek outfall by building the WESS W12 syphon. The syphon, completed in 2011, connects the Rat Creek combined trunk sewer to the South Highlands Interceptor. This then conveys the overflow safely to the Gold Bar Wastewater Treatment Plant on the south side of the river. The work done by SMA Consulting and Associated Engineering on the W12 syphon has been highly successful. The project was expected to reduce combined sewer overflows by

80%. Yet between November 2011 and July 2012 overflow events at the Rat Creek location were reduced 100%. The project has improved the water quality for Edmonton and municipalities downstream and provides much-needed capacity to accommodate Edmonton’s booming growth.

For this complex and high-risk project, the City of Edmonton’s Drainage Design and Construction Branch brought in Associated Engineering (AE) to design the tunnel and SMA Consulting (SMA) to optimize the project’s delivery.

AE was the lead design consultant for the W12 tunnel and additional projects that link it with the city’s existing drainage network. AE’s role included the design of control structures and tunnel connections; construction costing; hydraulic modeling of the system and syphon; computational fluid dynamics analysis of the inlet, control structures and drop shaft; odour control design; environmental impact mitigation; and public consultation.

SMA facilitated the decision-making process during the preliminary and detailed design phases using sophisticated decision-making support tools. For example, SMA’s structured risk analysis process was used to help the team make several key decisions, along with other techniques such as construction simulation, value analysis, failure mode and effects analysis (FMEA), and the analytic hierarchy process (AHP). These tools were used to help determine the best construction sequence, to provide input on design decisions, and to determine the reliability of parts of the system. As well, SMA provided 3D and 4D visualizations that made it easy for decisionmakers to discuss solutions in workshops involving several city branches and experts.

SMA also conducted project controls during construction, preparing daily site visit reports, tracking the budget and schedule, and using analysis modelling and forecasting techniques to predict performance and manage change orders.

The design and construction of W12 was extremely challenging. Almost the entire project is situated at an extreme depth — 70 metres below downtown Edmonton — and much of it is within the footprint of abandoned coal mines. Five deep shafts and a 1.2-km tunnel had to be constructed in ground laden with coal seams, water pockets, and voids. Methane gas under pressure was detected in several locations.

Access was also severely limited: the northern construction site was in Edmonton’s downtown, and most of the tunnel alignment was under the Riverdale Golf Course and the river itself, running between two coal seams.

A real-time control structure (RTC) was installed for the Rat Creek outfall. Operated from ground level, it has precisely configured gates for controlling flow. The design required tying into an old, brick 3200-mm pipe while it continued in service with live flows. Multi-

ple rounds of modeling helped simplify the design to ensure its constructability.

The complex RTC structure has to function flawlessly to avoid flooding basements upstream or releasing unnecessary overflows into the river. At the north end, in a residential area, special odour scrubbers were installed.

Thanks to the W12 project’s success, Edmonton’s river is now cleaner and safer. The project also protected the environmentally sensitive river valley during construction, such as by locating the working shaft for the tunnel boring machine in a previously disturbed area. This area was then later re-landscaped as parkland. CCE

Project name: West Edmonton Sanitary Sewer (WESS) Stage W12 Syphon

Award-winning firms/prime consultant, project controls, decision support: SMA

Consulting (Hussien Al-Battaineh, P.Eng.; Mohammed Al-Bataineh, P.Eng.; Ethan (Yang) Zhang, P.Eng.).

Prime consultant, design: Associated Engineering (Herb Kuehne, P.Eng.; Jason Lueke, P.Eng.)

Owner: City of Edmonton

Other key players: Thurber Engineering (geotechnical); Maple Reinders (constructor); BPR-CSO (gate control strategy); gh3 (architect RTC#3 facility); City of Edmonton Design & Construction, Drainage Services (design)

AECOM CANADA AND CBCL

The Tree for Life Award goes to a project that demonstrates outstanding environmental stewardship. This year it went to the remediation of one of Canada’s largest and most complex industrially polluted sites, located in the centre of a town in Nova Scotia.

JUROR COMMENTS

“A contaminated site that has been a very large issue for a significantly long time has a solution that allows the land to be given back to the community. This is a model for future clean-up projects.”

The Sydney Tar Ponds in Sydney, Nova Scotia were the result of over 100 years of steel production. The process of turning coal into coke (used for steel production) had left behind polynuclear aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs), polychlorinated biphenyls (PCBs), mercury and other heavy metals. What remained in the heart of Sydney was one million tonnes of contaminated soil and sediment spread over three major sites — the North Tar Pond, the South Tar Pond, and the former Coke Oven sites.

Spanning a total of 100 hectares, this was Canada’s largest and most complex urban contaminated site. There had been two previous attempts to design and implement a remedial solution which had failed. Then, in 2006, the Sydney Tar Ponds Agency, an implementing agency formed by the Province of Nova Scotia and the Government of Canada, engaged a team led by AECOM to perform detailed design engineering and construction oversight on a $400 million remediation and site restoration project.

Remediation and treatment addressed approximately 750,000 tonnes of sediment contaminated with coal tar and other pollutants such as those mentioned above. This took place in a marine estuarine environment connected to Sydney Harbour.

The results have been called “the signature Federal Canadian Contaminated Site Remediation Project.”

The $400-million project’s scope of work included:

• handling, stabilization, in-situ solidification and capping of PCB and PAH contaminated sediments;

• restoring creeks and creating channels;

• implementing groundwater collection and treatment systems;

• creating a barrier wall;

• capping the 70-hectare Coke Oven site;

• creating a material removal, handling, recycling and decontamination facility;

• creating site-wide road infrastructure and a landfill;

• site-wide environment, social and economic restoration.

The remediation successfully implemented the world’s largest marine application of solidification and stabilization (S/S) technology on a heterogeneous contaminated site. The customized solidification and stabilization mixture successfully met environmental, health and safety, sustainability, leachability, hydraulic conductivity, structural integrity, compressive strength and constructability criteria.

The following are among the technical achievements:

• site specific procedures were developed to test the toxicity of leachate from the S/S remedy;

• compressive strength parameters in the solidified material were developed, assessed, and customized to ensure that the remediated site would allow for the future use of the land for building, development, recreation and other community use;

• intensive modeling of ground and surface waters was done for hydraulic conductivity to ensure a preferential deflection of ground waters on the site.

The remediation also included one of the largest water control and management systems amongst remediation projects in Canada and abroad. The control system, involving steel

four x 4-ft. diameter discharge HDPE pipes, allowed the coal tar contaminated sediments to be treated in the dry. The system controlled any water intrusion from the ocean through Sydney Harbour and captured and pumped incoming streams sequentially around the working areas.

On the large 100 hectare site, which has materials of variable depth intermingled with large quantities of debris and with variable chemical and moisture content, construction activities needed to be carefully and precisely managed.

Community relations critical

This high profile project required the rigorous management of stakeholder and community relations. Stakeholders included the federal and provincial governments, as well as local govENVIRONMENTAL

The AECOM team developed com prehensive public and project specific websites, formed a community liaison committee and held workshops, open houses, progress meetings, media placements, technical presentations and tours.

The project required extensive quality control and quality assurance measures. To control the air and odour emissions, for example, required a high rate of treatment and processing.

Now that the remediation is complete, brownfield development is underway and the STPA plans to transform the site into urban parkland. The park will include public art, walking trails, bike paths, a sports field, an amphitheatre and several lookout points, by late 2013.

In 2008, a feature story on a pilot

voted the “Discovery Channel’s fea ture story of the year.” CCE

Project name: Sydney Tar Ponds and Coke Oven Sites Remediation, N.S.

Owner: Sydney Tar Ponds Agency Award-winning firms/prime consultant: AECOM (David Wilson, P.Eng.; Bruce Noble, P.Eng.; Randy Pointkoski, P.Eng.; Ian Shrimpton, P.Eng.; Doug Allingham, P.Eng.; Colin Smith, P.Eng.; Paul Murray, P.Eng.; Don Shosky; John Fairclough, P.Geo.).

Design-construction oversight: CBCL (Dan MacDonald, P.Eng.; Ann Wilkie; Kevin Bezanson, P.Eng.; Pat Fitzgerald, P.Eng.)

Other key players: Conestoga-Rovers (independent engineer); Stantec (independent quality assurance); Dillon (environmental monitoring); All-Tech (air monitoring); Nordlys/J&T VanZutphen, Tervita, Joneljim Concrete, McNally (contractors).

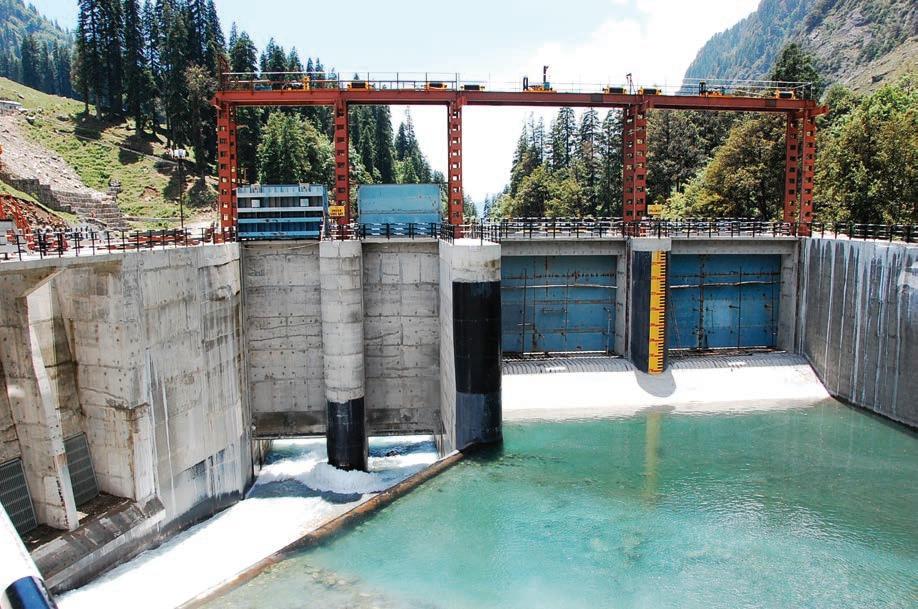

AECOM The Ambassador Award is presented for a project, constructed or executed outside of Canada, that best showcases Canadian engineering expertise. It went to Montreal engineers who dealt with huge natural and human constraints to deliver a 192-MW run-of-river hydroelectric project in the Northern Himalayas.

Above: desanding basin and sluiceway.

On behalf of AD Hydro Power in India, AECOM’s Montreal office provided the detailed design and construction supervision for this 192-MW underground run-of-river hydroelectric project that harnessed the flow of two rivers high in the Northern Himalayas.

JUROR COMMENTS

“This project was very innovative, with the majority of the construction located under ground. The jury also appreciated the fact that the project brought social and community benefits such as creating new roads and using local people to do the work.”

AECOM’s professionals had to deal with huge natural and human constraints to deliver this low environmental impact project in an inaccessible region with inclement weather. The plant, supplying hydroelectricity in a region that traditionally relies on coal-fired power, will reduce CO2 emissions by more than 5 million tons over 10 years.

The project was complex in terms of its design, partly due to the space limits that did not allow traditional storage solutions at the site. Another challenge was

the difficulty in maintaining an appropriate flow in conditions varying from scarcity to flash floods.

Two river intake sources

Were it not for its many innovations, this project would never have seen the light of day. From upstream to downstream, AECOM’s team provided creative solutions for tremendous constraints, such as two very different river intakes located at a differential elevation of 40 metres, which created a difficult hydraulic balance in the system. The rivers’ flows converge towards the underground penstock into a combined flow of 26 m3/sec, under a gross head of 876 metres – one of the highest in the world.

A specially designed surge shaft was

needed to reduce the impact of the “water hammer” effect created by the transformation from free flow to pres sure flow in the tunnel from the Du hangan river intake.

To harness a total of 308,500 m water storage required to operate the plant during its four-hour daily peak during a lean period, an intermediate storage reservoir, with a capacity of 221,400 m3, was built at an altitude of about 2,500 metres above the sea level. The natural reservoir upstream added a total volume of 61,400 m which was insufficient, so the team calculated the volume available in the headrace tunnels and desanders and turned them into residual tanks with a capacity of 25,700 m

The intermediate reservoir incor porates several innovations in order to keep its ecological footprint to a mini mum. For example, cantilever instead of gravity walls were used to increase the storage volume with a minimal amount of concrete. The high perfor mance underground drainage system discharges excess water from below the reservoir slab into the river.

In order to deal with free flow and pressure flow entering the Duhangan tunnel, the engineers developed a mathematical study model and validat ed the results with a hydraulic model in a Montreal laboratory. Due to the size of the hydraulic system, the pipes rep resenting the headrace tunnels of the hydraulic model had to take the form of a labyrinth and additional pressure losses needed to be compensated.

In a hydraulic structure of this size, any solid particles above 0.2 mil limetres can cause extensive erosion and cavitation to turbines, so AECOM conceived an ultra-efficient desilting chamber as the water filtration sys tem. It was necessary to develop two

NPE-Advanced & NPE-Standard.

•Energy Star highest rated gas water heater.

•2" System 636 up to 60'.

• 1⁄2 " gas pipe capability up to 24'.

•Dual stainless steel heat exchangers.

•Field gas convertibility.

Advanced high efficiency condensing tankless water heaters. NPE-A’s have all the features shown above, plus the exclusive ComfortFlow™ technology with buffer tank and recirculation pump.

0.98 EF ultra condensing technology (the industry’s top rated unit for energy efficiency) and all the standard NPE advantages but without the ComfortFlow™ feature in NPE-A models.

learn more visit: www.TanklessMadeSimple.com or www.NavienAmerica.com

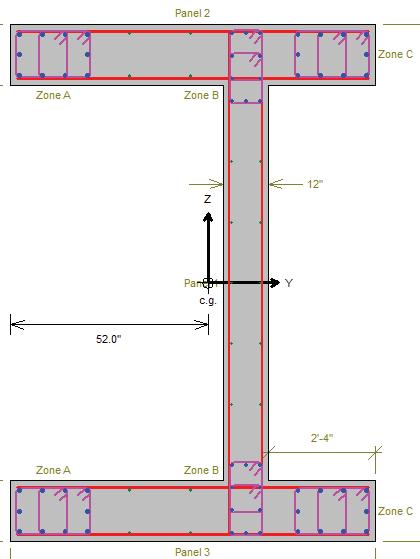

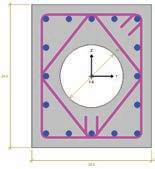

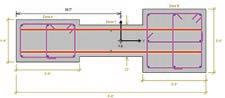

AUSENCO ENGINEERING, BUSH BOHLMAN & PARTNERS, READ JONES CHRISTOFFERSEN, GENIVAR, ET AL

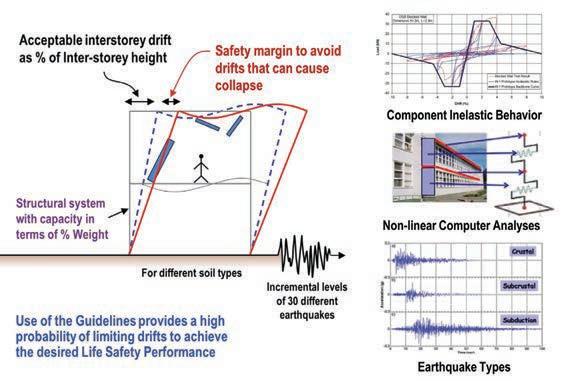

ACEC engineering firms were part of a team that collaborated to produce powerful structural engineering tools for making schools safer in British Columbia. Their project won the Engineering a Better Canada Award, which is given for engineering that enhances the social, economic or cultural quality of life of Canadians.

JUROR COMMENTS

“This project takes a real problem and finds a solution that allows for priorities to be set for doing retrofits. The technical stakeholder community worked together and the result is a guideline that can be used worldwide.”

The British Columbia Ministry of Education is implementing a billiondollar-plus program to mitigate the seismic risks of the province’s school buildings. For this, the Ministry wanted a common engineering approach using innovative methods for assessing and then retrofitting existing schools.

In response, a unique collaboration between government, academia and the engineering community, with key involvement of ACEC-BC firms, has produced the Seismic Retrofit Guidelines for BC Schools, a nine-volume, 300page manual, together with a companion web-based “Seismic Performance Analyzer.” The Ministry contracted the Association of Professional Engineers and Geoscientists of B.C. (APEGBC) to prepare the guidelines, and APEGBC subcontracted the various other parties involved (see credits below).

The combined experience of over 150 years of seismic upgrading in B.C. was used to produce two volumes containing a “library” of 35 proven retrofit

details and 14 seismic retrofit strategies. This was the result of a collaborative sharing of information from the consulting firms involved.

The state-of-the-art and unique analyzer and guidelines enable structural engineers to rapidly and consistently determine the seismic risks of existing school buildings. The tools also enable engineers to optimize retrofits to achieve a “life-safety” seismic performance.

For example, the use of the guidelines by structural engineers has relieved them from selecting earthquake ground motion records or carrying out non-linear analyses; this is already done with results accessible in the analyzer. The tool allows engineers to focus on determining the capacity of the existing building to better determine risk, and enables them to consider a variety of retrofit options that address issues such as disruption, schedule, phasing, cost, implementation and constructability.

The guidelines also offer the capability of mixing different new structural systems in combination with existing systems.

The “performance-based” guidelines have proven to be effective in selecting a very efficient, cost-effective retrofit scheme for a building. The required lateral capacity for the new structural components, to ensure specific drift limits are maintained, can be as low as 50% of current code force levels for new buildings, thus directly contributing to cost savings.

The use of the guidelines has allowed more school buildings to be upgraded and made safer within the available Ministry budget. By effectively assessing the building’s existing components, fewer buildings are ranked “high risk,” leading to less demolition and replacement (less landfill material, less energy for new materials). More heritage buildings are also expected to be retained.

A key aspect of the approach taken in the analysis and guidelines is that it allows for the contribution of archaic materials that are commonly found in existing buildings but not addressed by current standards. The approach also allows for novel materials and innovative retrofit methods as the guidelines evolve and further

research and testing is done.

The Association of Professional Engineers and Geoscientists of B.C. (APEGBC) has endorsed the guidelines for use on all low-rise buildings in the province. This has resulted in private entities, with large inventories of buildings, using the guidelines and developing seismic mitigation programs. CCE

Project name: Seismic Retrofit Guidelines for BC Schools

Award-winning ACEC-member firms (structural engineering for peer review; liaison with owner and other project participants): Ausenco Engineering Canada; Bush Bohlman & Partners; Read Jones Christoffersen; Genivar (John Sherstobitoff, P.Eng.; Clint Low, P.Eng.; Tim White, P.Eng.; Ron Devall, P.Eng.; John Wallace, P.Eng.), Owner: BC Ministry of Education

Client: APEGBC

Other key players: University of B.C. (lead developer); TBG Seismic (subconsultant to UBC); David Nairne & Assoc. (peer review), JWE, EPR

External peer reviewers: Robert Hanson, PE; Farzad, Naiem, PE; Michael Mehrain, PE.

A Canadian consulting engineering company and its employees are dedicated to making a positive contribution around the world, providing a range of humanitarian aid and long-term programs. Their generosity and initiative have earned them this year’s special Outreach Award.

JUROR COMMENTS

"This project demonstrates the dedication of the company and its staff in contributing to the present and future wellbeing of the communities in which they operate. The initiatives extend beyond Canada’s borders to every country in which Golder is located."

Golder Associates’ purpose, “Engineering Earth’s Development, Preserving Earth’s Integrity,” reflects a commitment to sustainable development. Sustainable development is commonly defined as “... development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

To uphold these values, Golder continually strives to make positive contributions to local communities and national and international nongovernmental organizations. The company is dedicated to promoting the empowerment, knowledge, growth and development of its employees, providing staff opportunities for taking time off from work to volunteer in the communities in which they live, work and play. Each of the 180 Golder offices across 25 countries has a guideline of returning approximately 1% of their budgeted operating income to the community.

Building a culture of engagement across 180 offices across Africa, Asia, Australia, Europe, North America and South America has required coordinated effort at a local and global level.

Golder routinely coordinates efforts to financially support aid efforts when humanitarian crises arise, such as raising $111,2000 in 2011 for Japan’s 9.0-magnitude earthquake and following tsunami. Below, however, are some of the company’s special long-term initiatives.

Golder’s employees formed the Golder Trust for Orphans in 2003 to support children and families in Africa who have been orphaned or displaced by the AIDS pandemic. The Trust, which is funded mainly by contributions from Golder employees and

Golder’s operating companies, supports organizations of all religions and ethnic groups and directs most of its funding towards development projects that help organizations fund their own activities in a sustainable way. As Golder covers all administrative costs, 100% of donations go to the projects. To date the Trust has supported 11 projects in five countries in Africa, helping to improve the lives of over 1,500 children. Since 2003, over $2 million USD has been donated to the Trust and passed on to its projects.

The Row for Kids is an annual event held in support of the Stollery Children’s Hospital Foundation and youth rowing programs at the Edmonton Rowing Club. Golder first became involved in 2008, but that experience led to the company eventually taking over as Chair in 2012. Last year Golder provided over 20 volunteers to run the event, plus raised $25,600 as part of a total fundraising effort of almost $133,000. Golder’s participation has served as a team builder for the Edmonton offices.

Golder Associates’ sustainability awards provide an opportunity to celebrate how its own offices and people are applying sustainable development principles to their office environments and communities.

Each entry is evaluated based on the criteria of social/community, environmental, and economic benefit; staff engagement; client/stakeholder engagement; technical excellence; innovation or improvement over existing approaches; and value to Golder and the client or stakeholder.

For example, one winner in 2012 was Golder’s Pretoria, South Africa office. Along with friends and family, the staff spent a “Fun with Nature” day at a children’s home teaching value and conservation of the environment

through fun activities. Another winner was the Edmonton office for its “Green Initiatives” such as recycling the sample wastes from its geotechnical laboratory.

Golder believes that corporations, more than any other organiza-

tions, have the power and influence over human resources, and have the means and responsibility to promote the growth and development of all levels of society. The principals and associates of Golder are expected to champion the culture of caring, but the core values were developed in a broad-based consultation involving staff at all levels. The culture of 100% employee ownership provides the company with a strong platform from which to apply its core principles. CCE

Project name: Golder Associates

Charitable Initiatives

Award-winning firm: Golder Associates. Calgary

BOUTHILLETTE PARIZEAU

An Award of Excellence goes to a building in downtown Montreal that serves as an educational model for sustainable buildings. The mechanical and electrical consulting engineers were instrumental in synergizing the system features and systems to create high energy savings.

On behalf of its client Équiterre, Bouthillette-Parizeau provided the mechanical and electrical engineering for the Centre for Sustainable Development (Maison du développement durable) in downtown Montreal.

64% less energy than a reference building of similar size and reduces potable water use and sewer discharges by 54%.

JUROR COMMENTS

“This project is a showcase of fine engineering practice in the field of sustainable development. The jury liked the idea of it being a living laboratory for educating the public in green building. The proposed environmental model is a vision of the future.”

Built on a confined property on Ste. Catherine Street West, the complex is a centre for education in green buildings where the public can visit and learn about sustainable design. It was designed for LEED Platinum certification and built to exceed the latest environmental standards as a model for future generations. The five-storey, 68,450-sq.ft. building’s tenant spaces are mostly offices for Équiterre and other non-profit organizations.

The design team performed a rigorous analysis of the functionality, occupancy profiles, building geometry, and local climate conditions. The synergy of these analyses helped optimize the architectural performance and reduced the requirement for mechanical and electrical infrastructure.

The result is a building that consumes

A geothermal system satisfies nearly 100% of the building’s heating and cooling requirements. During summer cooling is provided solely by the geothermal heat pumps and a conventional water tower was not required.

Air distribution is achieved by an under-floor system which uses an air stratification strategy throughout the office areas. This measure allows for lower supply air rates and temperatures thereby reducing energy use, and it provides flexibility for reconfiguring the space. Another benefit is that no additional perimeter heating equipment is required.

In order to cool the atrium during hot summer days, windows and motorized dampers located at the top and bottom are used to create air movement. A 65-ft. tall living wall acts as an air filter,

continued on page 36

“Incentives for new construction helped us design and build new facilities that use less electricity and lower our operating costs.”

Darryl K. Boyce, P. Eng. Assistant Vice President Facility Management and Planning, Waterfront Project, Carleton University

energy makes sense – business sense.

Incentives are available on:

• Energy-efficient new construction and major renovations (up to 50%)

• Design assistance

• Modeling your building (up to 100%)

Energy efficiency incentives from your local electric utility are available for builders, architects and property owners like you. Whether your next project is for an institutional, commercial or manufacturing site, you may be covered for up to 100% of the cost of modeling your buildings’ electricity usage. And you could get additional financial incentives for major renovation projects and implementing energy efficiency measures in your new buildings’ design.

Big or small, every Ontario business can benefit from energy efficiency.

Contact your local electric utility or visit saveonenergy.ca/newconstruction

continued from page 34

humidifier and decontaminant. Its plants and lighting were carefully chosen to promote photosynthesis. Return air is sent through the atrium for pre-treatment before being returned to the HVAC systems.

From the start, all the mechanical and electrical strategies were validated and refined by means of space usage analyses, load calculations, energy simulations and detailed heat balances.

The simplicity of the system and ease of operation was a priority to facilitate the maintenance and extend the useful life of the equipment.

An integrated design process based on shared knowledge and collaboration between the client and all the professionals involved was used. At the design charrettes the stakeholders could use the presentation console to

display their information. These recordings are now part of the educational materials and animations used to explain the building’s innovative construction to the users and visitors.

An education pathway has windows into the mechanical room to expose the services, and glass floor tiles to expose the operation of the underfloor air distribution system.

Actual energy bills indicate that the design achieves an energy intensity of 63 Btu/sqft/year compared to a conventional building of similar size which typically uses approximately 180 kBtu/sqft/year.

Measures to save water include low flow fixtures and an underground tank that collects rainwater from the green roof (the roof plants require no watering). For domestic hot water,

heat recovered from the cooling system is used to preheat incoming city water. The results are reductions in potable water of 54%, in sewer discharge of 54%, and in energy used for water heating of 80%, compared to a MNECB reference building. CCE

Project name: Centre for Sustainable Development (Maison du développement durable), Montreal

Award-winning firm (prime consultant, mechanical-electrical engineering):

Bouthillette Parizeau (Jacques Lagacé, P.Eng., Pierre Jean, P.Eng., Alain Morin, Tech., Philippe Leblanc, Tech., Nathalie Boulet, eng., Mathieu St-Germain, eng., Jean-Sébastien Laberge, Tech.)

Owner: Équiterre

Other key players: Menkès Shooner Dagenais Létourneux (architect); Pasquin St-Jean (structural engineer)

Supplier: Zurn (sinks, urinals)

Zurn congratulates Bouthillette Parizeau Inc. on their award winning project Centre for Sustainable Development.

Zurn provides lean construction and engineered solutions that will reduce material cost, site work and labor. Our goal is serving the customer through innovative products that create efficiencies in new construction and retrofit applications. Choose Zurn for a reliable, recognized manufacturer to supply your entire installation, from behind the wall rough-in, to finish trim product and fixture systems.

Unique product solutions that save time and money. zu rn .c m 905-405-8272

Our industry is constantly evolving and the needs of our customers are becoming increasingly sophisticated. Responding to those needs and delivering powerful solutions is what drives us.

The Mircom Group of Companies began as an intercom and fire alarm system provider. We’ve come a long way since 1991. Today, we’re extremely proud of our industry leading and award winning portfolio of products and services including Fire Alarm, Emergency Audio, Mass Notification, Communications, Security, Nurse Call and more. Contact us

exp SERVICES

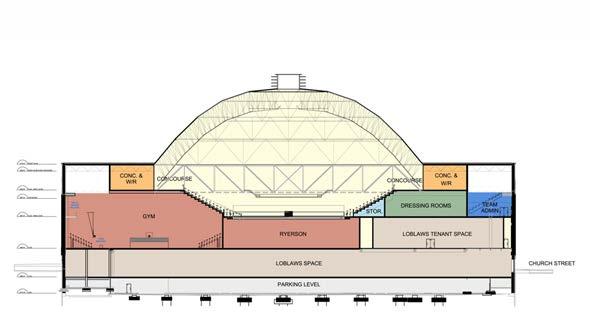

Constructing both a retail store and an athletic centre with a rink inside Toronto’s famous historical hockey arena was an engineering feat.

Built in 1931 and declared a Heritage Building in 1991, Maple Leaf Gardens in downtown Toronto stood empty and unused for 12 years after the NHL team moved. But in a unique partnership, the iconic building was redeveloped into a Loblaw store and Ryerson’s Athletic Centre.

loading dock would eventually be constructed. Figuratively, constructing the new structure was similar to building a ship in a bottle. The exception, being that the bottle already contained a ship that had to be dismantled piece by piece without breaking the bottle.

JUROR COMMENTS

“This is an outstanding example of the adaptive reuse of a heritage building where the requirement to fully preserve the historic brick facade and dome roof led to highly innovative engineering solutions. The engineers likened the challenge to building a ship in a bottle — after first dismantling the ship that was already there!”

The redevelopment of this landmark was more than just a cosmetic renovation to an existing building. Constructing a multi-level parking, retail store and athletic centre is in itself not uncommon. But to construct these inside a heritage building with limited access for materials and equipment while preserving the historic brick façade and domed roof — this required detailed engineering and planning.

Loblaws required a store at ground level and a loading dock; Ryerson needed an arena with seating for 2,500 people, plus a gymnasium and training facilities. The Ryerson rink is on level 3, with a concourse level at the top of the seating bowl.

For much of the construction, the only access in and out was a new opening 18 ft. wide and 15 ft. high where a

Shoring the old, inserting the new Starting in January 2010, demolition, excavation and construction proceeded simultaneously. Construction drawings were issued on a floor by floor basis.

Temporary steel bracing was installed within the original concrete frames at the east and west sides of the building, and at the north and south ends large temporary box trusses, 10 ft. deep and 26 ft. wide spanning 202 ft., were installed between existing buttresses at the corners of the building.