ALTERNATIVE HOUSING SUPPLEMENT

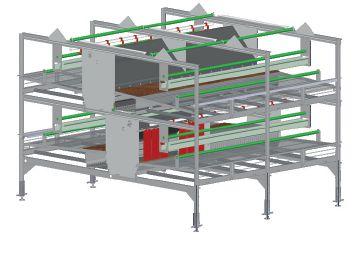

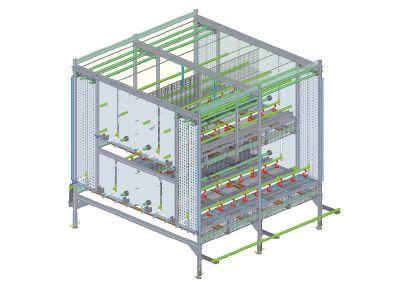

The VOLO BABY AREA is the ideal housing system for pullets, with all the main components integrated, while the SPACE COLONY, an enriched cage for raising laying hens, allows you to customize the multi-level configuration from 3 to 12 floors.

Valli-Italy operates on the premise of passion and quality to ensure each producer receives the ideal system for their operation.

A PLEDGE KEPT

McDonald’s Canada reaches 100 per cent free-run eggs, amidst trend towards enriched housing for laying hens.

BY TREENA HEIN

It was a surprise to many in the industry this summer, when – ahead of schedule – McDonald’s Canada announced it had achieved 100 per cent sourcing of cage-free (free-run aviary) eggs, served in its McMuffin, McGriddles and Bagel sandwiches.

Ian McFall, executive VP for foodservice & industrial sales at Burnbrae Farms (sole egg supplier to McDonald’s Canada since 2003) explains the collaborative journey started in 2015. “We worked hand-in-hand with the McDonald’s supply chain team, as well as with egg farmers across Canada, to ensure we could meet the demand,” he explains.

“Our aim initially was to achieve this milestone in 2025, so it was a super proud moment for the entire Burnbrae team, as well as the McDonald’s team, to achieve it this year.”

All Canadian egg farmers are currently phasing out conventional housing and moving to free-run, enriched, freerange or organic housing systems. This is expected to be reached during or before 2035. There are now over a dozen U.S.

states that have banned conventional housing or have set future ban deadlines, and this housing was banned across the European Union in 2012.

Before we look at the national hen housing situation in Canada in more detail, let’s look at what other chains beyond McDonald’s are doing with eggs. Some restaurants, including Chipotle Mexican Grill, Panago, Starbucks, Swiss Chalet, Harvey’s, IKEA cafeterias, The Keg and Taco Bell, have also achieved sourcing 100 per cent free-run eggs in Canada, according to various industry reports.

In the grocery realm, Whole Foods Market has done it. In food products manufacturing, Unilever has used only cage-free eggs in Europe since 2009, achieved this in North America in 2020, and has a goal to extend this globally by the end of 2025.

Most of these and many other firms committed to sourcing cage-free eggs around 2017. This is when the first Code of Practice for the Care and Handling of Pullets and Laying Hens from the

National Farm Animal Care Council was released and public concern about welfare in conventional housing was strong.

Major restaurant chains, members of the Retail Council of Canada (RCC), which includes giant grocery store chains like Loblaw, Sobeys and Metro, and giant food product makers (Nestlé, Kraft Heinz, etc.) all announced they would stop selling eggs from hens kept in any type of cages by 2025.

However, in 2021, RCC members announced they were abandoning their cage-free pledge.

Asked now about how McDonald’s keeping its cage-free pledge might impact other Canadian food businesses in terms of existing commitments to freerun, lapses in commitment or the possibilities of new commitments to free-run, RCC spokesperson Michelle Wasylyshen

ABOVE:

Burnbrae Farms enriches hen environments with hay bales, pecking stones, and hanging objects to encourage natural behaviours.

notes that Canadian retailers are committed to supporting the transition away from conventional hen housing.

She adds that RCC and its members are proud to actively support the codes of practice for egg and poultry meat producers. The five-year review of this code was completed in 2022, and amendments are being reviewed now in three areas: round feeder space for laying hens and pullets; minimum space allowance for pullets in multi-tier systems; and maximum number of tiers allowed in laying and rearing facilities. The public comment period extends to January 2025, with a completion date goal for the amendments of April 2025.

DIFFERENT TYPES OF EGGS

Wasylyshen says, “Canada benefits from this unique model for setting animal welfare standards – one that speaks to our commitment to collaboration, consensus and science…We believe real progress is made by working collaboratively with farmers, sorters, processors, animal health and welfare experts and retailers and by educating consumers about the availability of different kinds of eggs.”

On that note, it’s important to acknowledge that there are welfare trade-offs for hens in different housing systems. As expert poultry welfare scientist Dr. Tina Widowski, Egg Farmers of Canada Chair in Poultry Welfare at University of Guelph and the scientific panel chair for the current amendments to the Pullet and Laying Hens Code, has noted in the past, for example, “the welfare outcomes for hens in enriched systems can be very good, but expression of dustbathing and foraging are limited. These behaviours can be performed in the litter in non-cage systems, but the risks for poor welfare outcomes such as mortality, feather pecking and injuries are greater.”

She has also noted that “there is evidence that the welfare problems that tend to occur more in non-cage systems, for example, higher mortality and feather pecking, can improve with management experience, but non-cage housing is not a good fit for all managers.”

There is much more to be said about welfare trade-offs and research continues

into welfare and other aspects of various hen housing systems in Canada and beyond.

For example, scientists at the University of California-Riverside have just released study results showing lice counts (and their associated skin lesions) are much higher in cage-free housing systems compared to cages.

MCDONALD’S AND BURNBRAE

With regards to the greater potential impact of its cage-free egg sourcing achievement, McDonald’s Canada shares that “we hope this move can inspire others to do the same to propel the industry forward. By choosing to source from free-run farms, McDonald’s Canada ensures that their eggs and poultry come from animals that have a better quality of life. This commitment to animal welfare aligns with the values of many customers who are increasingly concerned about the treatment of animals in food production.”

Asked about its other welfare-related goals for chicken and eggs, McDonald’s notes that in 2017, it announced a global commitment to source chickens raised with improved welfare outcomes. “In Canada, we continue to explore opportunities to enhance our animal welfare policies for chicken and are currently working closely with suppliers and industry experts to develop guidelines that address the specific needs of poultry welfare,” the company says.

“Our commitment to animal welfare is ongoing, and we will continue to engage with industry stakeholders. We hope to have more information to share regarding our progress later this year.”

For its part, Burnbrae Farms does not disclose its current housing percentages or future aims in that area. Among its comments, the company states that “we routinely visit with all our customers, including McDonald’s, about our hen care practices, new research and continuous improvement.

“We remain committed to working with our customers to meet their expectations and consumer preferences.”

In addition, Burnbrae says “we encourage the use of many different types of enrichments to promote positive

behaviour expression and hen wellbeing. Pecking enrichments like pecking stones, hay bales and hanging objects like CDs or rope encourage birds to express foraging behaviour and engage with their environment in a positive way.

“Radios can provide auditory enrichment and help introduce the birds to a variety of sounds. We also may alter our walking route during flock inspections to observe the birds and the barn from all angles and expose the birds to novelty.”

PRODUCTION SHIFTS CONTINUE

In phasing out conventional cage housing, Canada’s egg sector is shifting mainly to enriched housing. Drew Black, CEO of Egg Farmers of Canada (EFC), explains that “Canadian egg farmers have been leaders in evolving their approach to producing eggs to keep step with market demand.

Between 2016 and 2023, the proportion of hens in enriched colony housing has increased to 34 per cent and the amount of free-range, free-run and organic production has nearly doubled to 18 per cent.

It’s obvious that demand for all product varieties continues to be met by our farmers and Canada has avoided the oversupply situation experienced by other countries such as the U.S., where the proportion of free-range or free-run eggs have drastically exceeded market demand.”

Black adds that transitioning to a new housing system requires farmers to make a significant investment, and that coordination across all parts of the supply chain is the key to success.

“Important factors such as the welfare of hens, environmental sustainability trade-offs, cost of food and what consumers value must not be overlooked,” he explains.

“This is why we have embraced an orderly and steady transition, and strongly encourage farmers to discuss their plans with their egg board and grader prior to making investments. By being forward-looking in our approach, we can avoid last-minute rushes that could jeopardize the stability of our market and remain responsive to the needs of our value chain.”

LAYING OUT THE OPTIONS

On-farm study compared alternative housing systems on hen health and performance.

BY JANE ROBINSON

Canadian egg producers have about 10 years to complete the transition from conventional cages to alternative housing. According to Egg Farmers of Canada, about 48 per cent of hens in Canada are still housed in conventional cages. As the deadline approaches, producers are exploring the options to find the best fit for their birds and their operations.

Dr. Martine Boulianne sees this situation from a few angles. She works closely with industry in her role as Chair in Poultry Research and professor in the Faculty of Veterinary Medicine at the University of Montreal, and she’s a practicing poultry veterinarian. “I’ve been

called to new aviaries by producers who were experiencing health problems with their first flocks, with intestinal diseases, coccidiosis outbreaks and even necrotic enteritis,” says Boulianne.

“When I visited those barns, I also noticed the air quality with dust hanging in suspension.”

It was on those farm visits she thought about what more could be done to help producers prepare. “I wondered how we could equip producers with knowledge of what to expect as they transition their hens to new systems, and that was the idea behind the research project to compare various aspects of these alternative housing options.”

THE PROJECT

Boulianne gathered a multi-disciplinary team to compare bird health, performance, air quality and welfare between enriched colony housing and aviary systems. Her team included Dr. Stéphane Godbout, Institut de recherche et de développement en agro-environnement (IRDA), Dr. Caroline Duchaine, Laval University and Dr. Alexandra Harlander, University of Guelph. Several graduate students were also involved:

ABOVE:

Dr. Martine Boulianne and her team found very little difference in the health and performance measures they evaluated between enriched colony housing and aviaries.

Dalila Larios, Magali-Wen St-Germain, Eloïse Denis and Noémie Marcos.

Commercial poultry farms were recruited in Ontario and Quebec – 12 with aviaries and 12 with enriched colony housing. Enriched colonies held 10-100 birds per housing unit with 750 cm2 per bird, and had access to scratching and pecking areas, perches and nests. The aviaries had housing densities of 929 or 1,900 cm2 per bird, with access to scratching and pecking areas, perches, nests, dust bathing and litter.

From placement at 19 weeks of age until 65 weeks of age, birds were regularly monitored for laying rate, mortality, feed consumption, hen weight and egg quality. A sample of birds were examined from each flock throughout the lay period and scored for health and welfare parameters including keel bones, foot pad lesions and feather quality. Fecal samples were collected weekly, and mortalities were examined to determine cause of death. Air quality was evaluated at each visit looking at airborne dust and bacterial levels, ventilation rates and ammonia levels.

THE RESULTS

The most surprising result for Boulianne and her team was that there wasn’t much difference between the two housing systems for the parameters they measured.

Bird performance

All measures related to egg production and quality showed no difference between the layers in enriched colony housing or in aviaries. “We didn’t see any differences, which is good news, for laying rates, feed consumption, body weight and egg quality,” says Boulianne.

What they did find was an interaction between bird age and housing when measuring bird mortality. As expected, mortality increases with age in both systems, but there was a steeper increase in the aviaries. “More hens were dying as they got older in aviaries compared to en-

riched colony housing, and the difference was quite significant,” she says. Bird mortality was mostly caused by E. coli regardless of the housing type.

Pathogen load

Housing also had a significant effect on the presence of the bacteria that causes coccidiosis – with aviaries showing higher levels, and younger hens showing larger numbers.

They also looked for the presence of necrotic enteritis that’s caused by Clostridium perfringens – a bacteria usually present but with strains that are more pathogenic. “We were surprised to see a lot of Clostridium perfringens in both housing systems, but the aviaries are more likely to harbour more pathogenic strains,” she says.

Birds on litter in aviaries have more exposure to coccidiosis and Clostridium perfringenscreating what Boulianne calls a ticking bomb. “These two usually go together because coccidiosis can create some damage to intestinal lining and result in dead cells, which Clostridium perfringens loves as an easy source of protein so it can multiply and create necrotic enteritis,” she explains.

Welfare

Hen welfare was evaluated by looking for foot pad dermatitis, fractures of the keel bone and wings, and feather damage and cleanliness. Birds in enriched colony housing had more chance of feather damage but there was no difference between the two types of systems for overall feather damage. Food pad dermatitis was more likely in aviaries, as well as keel bone fractures.

“There was an age effect in both systems where we saw more keel bone deformity that is probably from active perching, so the keel bone adjusted over time as the bird ages and puts more pressure on it,” says Boulianne.

Air quality

The type of housing had a significant effect on ammonia and air quality with a high concentration of total

bacteria and archaea (fungi in suspension in the air) in aviaries compared to enriched colony housing. “There was more ammonia, visible dust and definitely more bacteria in the aviaries, and that reaches a peak in colder months (October to April) when there is less ventilation,” says Boulianne. “Aviaries also have a greater diversity of bacterial species in the air from dust, litter and feathers.”

The other concern for air quality in aviaries is for producers. Dr. Duchaine is currently recruiting egg producers and workers for a study to see if there is a need to come up with recommendations for protective gear in aviaries.

THE RECOMMENDATIONS

Boulianne understands that choosing new alternative housing for hens is a multi-faceted decision. “It’s a huge investment for producers to transition and one that needs to be well throughout,” says Boulianne. “I was very happy that our project was able to come up with some answers and insights to give producers more information.”

To assist producers in making informed decisions, Boulianne shares the following recommendations:

• Develop a coccidiosis plan with your veterinarian for aviaries to come up with the best preventative model for each barn and discuss possible necrotic enteritis vaccination.

• There are personal preferences – some people like enriched colony housing and some like aviaries because there is closer contact with the birds.

• There are no differences in performance and only slight differences in health issues that can be prevented, and further research is ongoing.

• Visit/talk with producers who have enriched colony housing and aviaries – there are different types of systems so think about factors other than the economics of building.

WHY YELLOW NESTS WIN

Colour design isn’t just for looks – it’s driving better egg production.

BY BEN KAISER, KAISER AG SOLUTIONS

Our design team has been working on a new aviary system these past months, and colour is very much part of the design process. As designers, we must adhere to the rules and requirements set by the National Poultry Council, but there is always that desire to give your creation some beauty. A desire to have your design elevated from mere function, to increase its allure and appeal, and to instill a sense of elegance into it. Adding colour allows us to put a bit of personality into our systems, but there are other reasons we inject colour into our designs.

THE SCIENCE

Colour has a way of influencing our

emotions, and in laying hens, colour can very much influence behaviour.

Back in 2019, the Kaiser Ag design team was working on a floor-system, with a particular focus on broiler breeders. We spent many hours combing through research papers written by poultry scientists from all around the world. There have been countless hours dedicated to understanding poultry behaviour. These doctors and researchers, these “chicken whisperers”, are running numerous experiments on laying hens, and this data is of immense value to all of us in the poultry industry. For us here at Kaiser Ag, this research helped us finalize colour choice in our Vitanest floor system.

At Kaiser Ag, we often say that there is nothing we can do about bird genetics, farm management practices, or bird nutrition quality, but we can design systems with as much thought as possible put into “how do we get the farmer more saleable eggs?”. System design is the singular area where we can help egg producers increase their returns.

For the broiler breeders, the organic egg producers and anyone running any kind of free-run operation, the system design must consider how to encourage hens to lay in the nests. Colour becomes a very real part of nest and system design. Nest curtains colour, in particular, is so important. What is the ideal nest curtain colour?

WHY YELLOW DOMINATES

Over the years, numerous research groups have explored the question of which colour best attracts laying hens. Dr. Giulio Pillan and his team at the University of Padova in Italy conducted an extensive study to investigate this. In a paper titled “Factors Affecting Space Use by Laying Hens in a Cage-Free Aviary System,” they examined the impact of nest lighting and curtain colour. Their trial, conducted at the experimental farm “Lucio Toniolo,” involved a mock barn with a two-tier aviary system housing 1,800 Lohmann Brown-Classic laying hens.

The study revealed that colour preferences in laying hens varied across different research papers. However, certain trends were clear: blue often triggered adverse reactions in chickens; red signaled danger; and yellow consistently attracted the birds. This preference for yellow was reinforced by hens’ choice of yellow nests over those with neutral tones or plastic flaps.

Interestingly, the preference for yellow can be traced to early life exposure. Hens seem to gravitate toward yellow because of their association with the colour from their first day as chicks.

Research by Beat Huber-Eicher in Switzerland further supported this. In his study, chicks were exposed to

blue, green, yellow, and red during the first 12 days of life. The majority – 50.5 per cent – chose yellow as their preferred colour. Even those exposed to other colours early on showed a strong preference for yellow when it came time to lay eggs.

Despite initial exposure to other colours, the dominant preference for yellow in laying nests held firm across multiple studies. The findings suggest that yellow is not only appealing but also consistently the top choice for hens, solidifying its place in aviary design.

So, yellow is the winner!

TIME FOR A COLOUR CHANGE?

What does this mean though for those with curtains other than yellow in colour? Well, if you’re system is running well, it means very little, after all, “if it ain’t broke, don’t fix it”; but if you’re one of those producers fighting to have your birds lay their eggs in their designated nesting areas, or if you think your floor egg percentage is simply too high, maybe it’s worth taking a look at the colour of your curtains.

Maybe it’s worth a small trial to see if nest acceptance can be increased. After all, there are only so many hours in a day and no one wants to pick up more eggs off the ground than absolutely necessary! Maybe it’s time to try yellow.

KEY TAKEAWAYS ON COLOR PREFERENCES IN LAYING HENS

• Yellow Attracts Hens: Research consistently shows that yellow is the most preferred colour for nest curtains and other nesting materials, attracting hens more effectively than other colours.

• Impact of Early Exposure: Hens exposed to yellow early in life tend to prefer yellow nests throughout their laying period, demonstrating a lasting influence of early colour exposure.

• Adverse Reactions to Blue: Blue colour is linked to negative reactions in hens, making it less desirable for use in nesting systems.

• Red Signifies Danger: Red is often perceived as a danger signal by hens, which can deter them from using nests with red-coloured components.

• Study Validation: Both Dr. Giulio Pillan’s research and Beat Huber-Eicher’s studies confirm that yellow is the optimal choice for encouraging nest use and improving overall egg collection efficiency.

Yellow curtains help guide hens to their preferred nesting spots and improve egg collection efficiency.

3 KEYS TO PREPARING PULLETS FOR AVIARIES

BY ERIKA PREWITT

A great hen starts with a great pullet! A well-grown pullet can really set an egg producer up for a successful layer house. There are some key attributes that a pullet must have to be a great pullet, though. In this article, lets discuss three key points for a prepared pullet to make the move to the layer house.

Before we get to these key points, I would first like to stress the importance of communication between the pullet grower and the layer farm. Preparing the best pullet possible goes hand and hand with knowing where this pullet will be placed.

The movement from pullet to layer barn can go much more seamlessly for the layer producer if the pullet grower is on board with communicating current and future conditions.

1. WALKING THE PULLETS

From the very beginning pullets should be getting walked frequently. Even before they are released it is important for the pullets to get used to people. This is important both once they are released from the system and when they arrive at the layer house. Pullets are usually transferred to the layer house sometime between 16 to 19 weeks (preferably 16 weeks). Which means there is a short period to get used to their new environ-

ment before they start laying. If birds are flighty and not used to being in the aisle with people, this can draw them out of the nest or flee to the back of system when people are walking the aisle in the mornings. The solution here is not to forgo walking in the morning or you’ll be more subject floor eggs. If scared hens hover in the back of the system during morning lay and don’t feel comfortable moving to the nest, you’ll have increased numbers of mislaid eggs also. This can be habit that is tough to break.

2. PERCHES OUT/MOVEMENT AIDS REMOVED

Starting at about 10 to 12 weeks, we start to focus on transitioning the pullet house to mimic the layer house. All layer houses should have perches, but most do not have movement aids such as ramps. However, this number is growing, and in the future, I think this will flip flop and most layer houses will also have movement aids.

Once the pullets have mastered nighttime training, we can start to focus on gradually removing movement aids. Remove a few per day, allowing them to learn to be less dependent on them. I don’t recommend removing any platforms or ramps if pullets are not successful at going into the system at night. At about 10 weeks, the perches should be fully extended if they are adjustable.

Erika Prewitt is aviary systems specialist with Big Dutchman. In this column, she shares cage-free management tips for egg producers.

3. ADJUST INTENSITY AND SUNRISE/SUNSET TIMES

As mentioned above, it is important to communicate with the layer house on current and ideal conditions for the pullets. Both parties should do their best to match up light intensities and schedules.

If an earlier or later sunset or sunrise period is desired by the layer grower, now is the time to make small changes to help the pullets adjust.

Again, make sure to not make any adjustments if pullets are not trained to go back into the system.

If that’s the case, the pullet grower’s focus should still be one sunset training. Only once that is mastered can you take on the next task of meeting the layer house wish list.

Adjustments should not be made in any more than 15 to 30-minute increments. Pullets should be monitored to make sure they are still going back into the system at night with the adjustments.

Light intensity in the pullet and layer house can vary greatly. Measure intensities with and LED light meter to make sure breed standards are being met and that there are no large changes with intensities when they make the move to the layer barn. Intensities from pullet to layer barn should differ no more than one-to-1.5-foot candles.

extensive

custom-made

outstanding

easy

healthy