Where passion meets performance, Aarque Group has a team dedicated to customer success.

Darrin Weir, general manager at Aarque Group, says, “In today’s demanding market, I know that your success depends on having a partner who is as agile and reliable as you are.

“Many businesses find themselves stretched thin, dealing with suppliers who lack the scale to offer a comprehensive range of products or the local presence to provide truly responsive service. This can lead to critical compromises, settling for not so great media, waiting on cross-country shipments, or struggling to get expert advice when you need it most.

“With our three locations (Auckland, Wellington, Christchurch) and sales representation locally in Hamilton and Palmerston North, we have structured our entire business to solve these exact challenges, ensuring you never have to compromise on quality, speed, or support.

“This network provides you with a massive, pooled inventory of top-tier digital printer hardware, consumables, and a diverse selection of roll and rigid media, ensuring product availability and swift delivery.

“Whether you operate in one city or have projects nationwide, you get consistent pricing, familiar service, and expert support that understands your local market and is always within reach. Our multi-site presence is more than just a logistical advantage; it’s our commitment to being your most reliable

and comprehensive partner. I personally invite you to connect with your nearest branch and discover how our unique combination of national scale and local dedication can directly benefit your operations, improve your efficiency, and strengthen your bottom line. Let us show you what a true partnership can do for your business.

“Our ongoing customer loyalty and support has allowed us to develop our product range to cater to our customers’ needs while protecting their interests with coordinated sales support and service delivery.

“Having a strong team is critical to delivering on this, and I would like to introduce you to the Aarque managers who along with their respective teams really make a difference to how we continue to maintain such a high level of support throughout the country.”

Craig Harrison – national sales manager

“Craig is new to Aarque Group, but not the industry. Since he arrived, he has made an immediate impact. He is hands on and loving it. Craig, having previously been one of our key customers in multiple businesses, as well as sporting 39 years in the printing industry, is no stranger to understanding what is required to supply high functioning businesses. His sales team of nine throughout New Zealand provide proactive sales support exceeding expectations daily.”

Craig says, “In a market where quality, efficiency, and cost directly impact your profitability, navigating the complex landscape of digital printing can be a significant challenge.

“Many businesses struggle to align their printer hardware with the right consumables and media, leading to inconsistent results, wasted materials, and missed opportunities.

“As national sales manager, I understand you need more than just a supplier; you need a partner who can provide a cohesive, high-performance printing ecosystem. The frustration of dealing with multiple vendors, mismatched supplies, and unreliable media is a barrier to growth that you simply don’t have time for.

“Imagine having a single, dedicated partner for all your digital printing needs, from state of the art hardware to a vast inventory of premium consumables and a diverse range of printable roll and rigid media. This is the streamlined, integrated solution we offer.

“By consolidating your purchasing, you not only simplify your procurement process but also ensure perfect compatibility between your printer, inks, and media, guaranteeing vibrant, consistent, and professional results on every job. This synergy allows you to maximise your equipment’s potential, reduce costly trial-and-error, and confidently deliver the quality your clients expect.

“Our goal is to empower your business to achieve its full potential. We are committed to providing you with a competitive edge through reliable technology and a comprehensive product portfolio, all backed by expert advice and dedicated support.

“Let my team help you build a more efficient, profitable printing operation where every component works in harmony. I invite you to contact us for a consultation to explore how our integrated and multi-branded solutions can elevate your quality, streamline your workflow, and strengthen your bottom line.”

Playing a pivotal role in ensuring that the company consistently delivers exceptional service to its customers, Sharon oversees the daily operations with a focus on making sure that business processes run smoothly, efficiently, and in a way that puts customer satisfaction front and centre. Whether it’s refining workflows, optimising supply chains, or implementing new technologies, the goal is to create a seamless experience for every customer interaction.

Sharon says, “We have strategically built our business across three integrated sites – Auckland, Wellington, and Christchurch —for one reason: to deliver a superior and more reliable operational experience for you. This structure is the engine that drives your advantage. It ensures robust business continuity, meaning a disruption in one area won’t halt your supply. It provides you with access to a vast, national inventory of premier hardware, consumables, and media, all managed with sophisticated systems to guarantee consistency and rapid fulfilment.

“This operational design mitigates your risk, streamlines your procurement, and ultimately provides a stable, predictable platform upon which you can confidently build your business.

“Our commitment extends beyond just fulfilling orders. We aim to be a strategic asset that enhances your operational excellence.

By leveraging our multi-site network and centralised intelligence, we provide you with the reliability and scale needed to reduce your own inventory costs, improve your cash flow, and take on larger, more complex projects without hesitation. Let us provide the operational backbone that empowers you to focus on innovation, quality, and sustainable growth.”

service manager

“Possessing a keen eye for the detail, Clinton is the one processing the logistics for your hardware purchase, managing all things Health & Safety, and leading the team of service coordinators and service technicians,” says Darrin.

Clinton says, “In today’s competitive business environment, the last things you should be worrying about are printer downtime, unpredictable supply costs, and the hidden expenses of managing your own equipment.

“Too often, businesses face frustrating disruptions and escalating costs that pull focus from their core operations. These challenges can lead to decreased productivity and unnecessary financial strain.

“As a service manager, I’ve seen firsthand how these seemingly small issues can become significant burdens, impacting everything from employee morale to your bottom line.

“Imagine a seamless printing environment where your equipment runs efficiently, supplies are replenished automatically before you even know you need them, and your costs are consolidated into one predictable monthly account. This the peace of mind our service cover provides.

“Offering proactive maintenance to minimise downtime and expert support to resolve issues swiftly. This allows you to minimize un-expected costs and frees up your valuable resources to focus on initiatives that drive your business forward.

“I am confident that my team of technicians throughout the country will deliver the highest level of care to your business. We look forward to being of service.”

Mitch Boocock – national operations manager

Mitch says, “In the fast-paced world of digital printing, the success of your projects often hinges on something that happens long before the ink ever hits the media: operational excellence.

“I know that receiving the right products at the right time is critical, and there is nothing more frustrating than project delays caused by backorders, incorrect shipments, or inconsistent product quality. These logistical hurdles don’t just cause headaches; they can damage your reputation, strain client relationships, and impact your profitability. As the national operations manager, my primary focus is to eliminate these uncertainties from your workflow.

“At Aarque Group, we aim to deliver a supply chain so reliable and efficient that it feels like an extension of your own business. My team has meticulously engineered our logistics, warehousing, and quality control processes to ensure you get exactly what you need, precisely when you need it.

“We maintain robust inventory levels on all our hardware, consumables, and our wide array of roll and rigid media, which allows us to provide consistently fast and accurate order fulfilment. This operational backbone means you can confidently schedule jobs, minimise your own inventory holding, and trust that the products you receive today will be the same high quality as the ones you receive tomorrow.

“Our operational efficiency is designed for your peace of mind and profitability. By ensuring product availability and dependable deliveries, we empower you to operate more smoothly, reduce downtime, and exceed your customers’ expectations. We handle the operational complexities so you can focus on producing outstanding work and growing your business.”

2-5 Aarque Group: Top-tier digital printer hardware, consumables, media, nationwide service and support, and a team of outstanding industry professionals enables Aarque Group to deliver on its commitment to customers as their most reliable and comprehensive partner. PrintNZ p14-17

14-16 Helping Hand: Iain MacIntyre finds out how magazines have increased their readership in Aotearoa.

17 Comment: After 32 years of Pride In Print Awards, Ruth Cobb feels as enthusiastic as she ever has about our premier print programme.

10 ANZPPW: On October 14, together with PrintNZ, we will host the inaugural NZ Print & Packaging Forum, followed by the People In Print and Rising Stars Of Print Awards.

18 Currie Group: The Pro Cut Fold Stream range of print finishing systems will soon be available in New Zealand and Australia through Currie Group.

20 Konica Minolta: Canterbury-based print company Blueprint has installed a Konica Minolta AccurioPress C7100 printer.

22-23 Cyber: Bernard Cheong has silently and humbly turned Cyber Australia into one of the largest printing distributors in the Asia Pacific region.

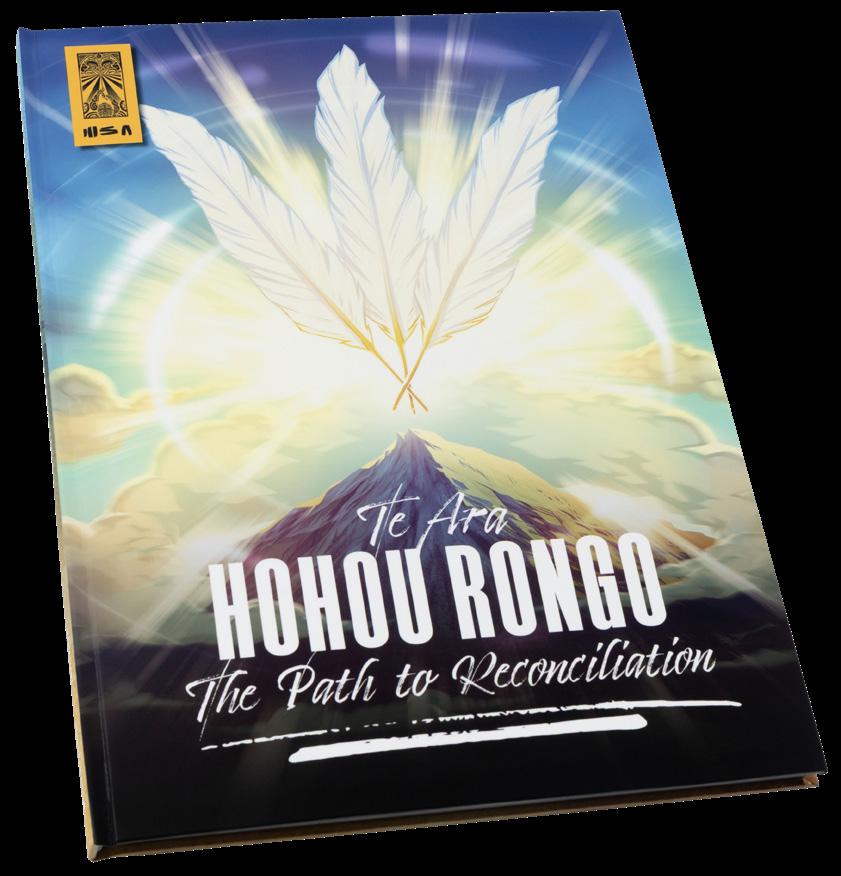

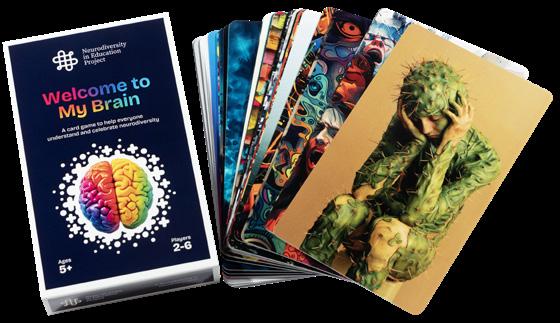

24-25 Supreme Award: This year’s Pride In Print Awards Supreme winner demonstrated how small companies can compete at the highest level in this industry.

16-32 Category Winners: From Sign and Display and Labels to Newspapers and Packaging, the 2025 Pride In Print Awards Category winners delivered outstanding work.

33-36 Process Winners: The cream of New Zealand’s print talent lined up to compete for the 2025 Pride In Print Awards Process medals.

38 Apprentice of the Year: Enthusiasm and attitude to learning helped a flexographic printer to become the BJ Ball Apprentice of the Year.

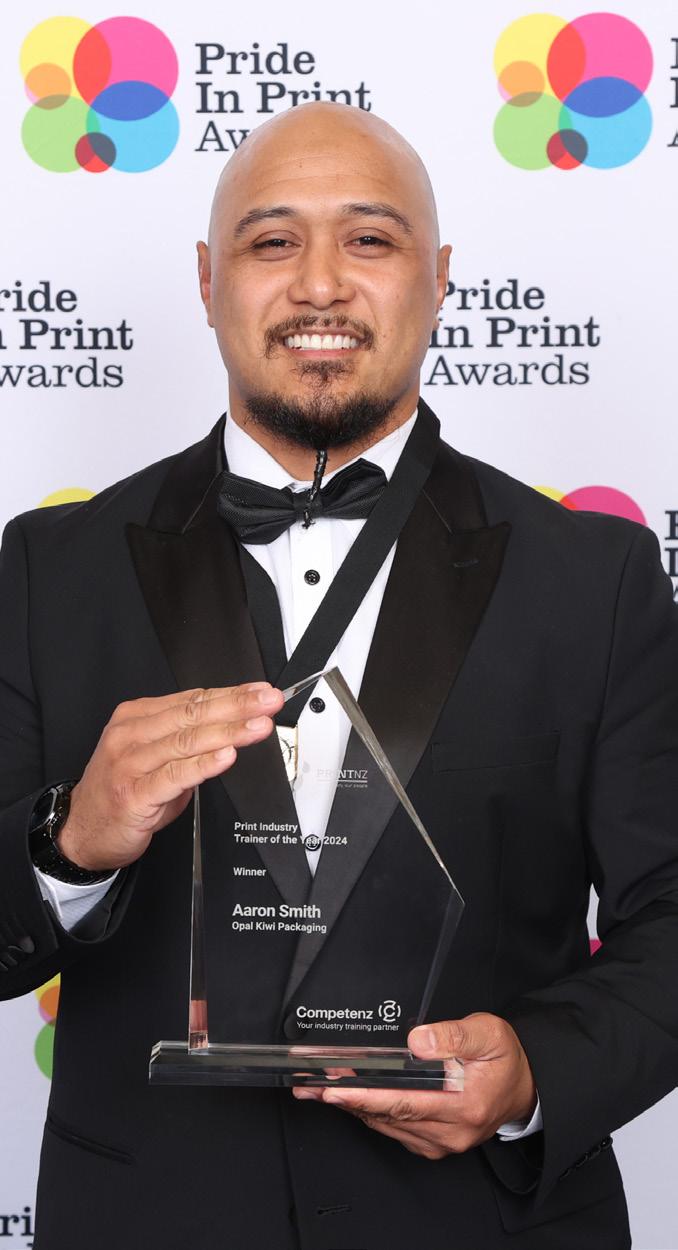

39 Trainer and Training Company of the Year: Our training winners share a commitment to sharing their knowledge and expertise.

40 Major Winners: See who took out this year’s major awards.

42 Durst: nnovation will take centre stage when Durst Group presents its new Open Software Initiative for the first time at Printing United 2025.

44 Wide Format News: Computaleta reveals its new owner, while the HP Latex R530 printer reaches a big milestone.

46-47 NZSDA President: Having a thorough conversation with potential clients can save you time and heartache, says Logan Sutton.

48 NZSDA Update: Mikayla Hopkins reports on the latest NZSDA happenings, including the Master Sign Maker accreditation.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS: Ruth Cobb, Mikayla Hopkins, Iain MacIntyre, Logan Sutton

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

1171 7912

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

Forum tickets ($199) include refreshments and lunch, and participation in the Awards.

Early Bird Forum ticket sales ($175) close September 19.

The day begins with a dynamic forum featuring a range of keynote speakers and panel discussions. The focus is on forward-looking topics, including new technologies, sustainability, and market trends that are shaping the future of printing and packaging in New Zealand. This is a chance for attendees to gain critical knowledge, share ideas, and prepare for what comes next.

• Owners and Directors of printing, packaging, and signage companies.

• Senior Managers and Operational Leaders responsible for production, sales, and strategy.

• Designers and Brand Representatives who are at the forefront of specifying materials and services.

• Emerging Talent and Rising Stars who will be the future leaders of the industry.

• Suppliers and Service Providers to the printing and packaging sectors.

The forum will address some of the most pressing and relevant issues facing the industry today. Topics will include:

• Future Trends & Technology: Exploring the latest advancements in digital printing, automation, and smart packaging, including AI.

• Sustainability & Circular Economy: Discussions on recyclable and compostable packaging, reducing waste, and meeting environmental compliance standards.

• Business Growth & Innovation: Case studies and strategies for diversifying services, improving efficiency, and staying competitive in a rapidly changing market.

• Workforce Development: Addressing the skills gap, attracting new talent, and fostering a culture of excellence.

Contact NZP editor, Bruce Craig on 021 631 559 or bruce@newzealandprinter.co.nz to nominate your peers (or yourself) for an Award.

Contact NZP publisher, Brian Moore on +61 410 578 876 or brian@newzealandprinter.co.nz to discuss the range of sponsorship packages available.

Contact PrintNZ event manager, Tania McDougall on 021 587 072 or tania.mcdougall@printnz.co.nz to book your place at the Forum and Awards.

Australia & New Zealand Printing & Packaging Week

This full day of events in Auckland on October 14, 2025, is proudly presented by New Zealand Printer magazine in partnership with PrintNZ as part of Australia & New Zealand Printing & Packaging Week 2025. The day is strategically designed to provide both high-level insights and valuable networking.

Awards tickets ($39)

Award nominations (including self-nominations) close 5pm Friday, October 3.

Nominate by 5 PM, Friday, October 3: newzealandprinter.co.nz/nominate2025

The Awards recognise the outstanding individuals and emerging talent driving innovation and success in the industry. It’s a powerful and positive close to the day, providing a perfect backdrop for celebratory networking and brand recognition. This smart-casual, stand-up affair with delicious food and drinks is an ideal opportunity to network, celebrate, and appreciate the people who make our industry vibrant.

THANKS TO OUR VALUED SPONSORS

PLATINUM SPONSOR

GOLD SPONSORS

SILVER SPONSOR

SUPPORTERS

Nominations have opened for the People In Print and Rising Stars Of Print Awards.

The inaugural New Zealand Printing & Packaging Forum is set to debut on October 14 at Sorrento in the Park, Auckland. Presented by New Zealand Printer magazine in partnership with PrintNZ, this full-day event is designed to give delegates the insights and connections needed to thrive in a rapidly changing industry.

The day kicks off at 9:30 am with a dynamic series of keynote speakers and panel discussions. The Forum isn’t just a day of talks; it’s a deep dive into the topics that matter most right now: future trends, new technology, sustainability, and workforce development.

Want to know how AI is changing printing? Curious about the latest advancements in smart packaging? Ready to tackle the challenges of a circular economy? The Forum is where you’ll get answers to these questions and engage with a community of peers. This is your chance to gain critical knowledge, share ideas, and prepare for what’s next.

The Forum: Who should attend?

This event is for anyone committed to the future of the printing and packaging industries in New Zealand. Whether you’re an owner looking to diversify your services, a senior manager focused on improving efficiency, a designer at the forefront of material specification, or an emerging talent seeking to build your career, the Forum has something for you. The programme caters to:

• Owners and directors of printing, packaging, and signage companies.

• Senior managers and operational leaders responsible for production, sales, and strategy.

• Designers and brand representatives who specify materials and services.

• Emerging talent and rising stars who are the future leaders of the industry.

• Suppliers and service providers to the printing and packaging sectors.

Ruth Cobb, chief executive of PrintNZ, says, “We are thrilled to work with New

Tuesday, October 14 2025 Auckland

PRESENTED BY: Credit: iStock.com/toxawww

The day transitions from forward-looking discussion to a celebration of excellence at the People In Print and Rising Stars Awards, starting at 4:30 pm. As in previous years, this is a smart-casual, stand-up affair with delicious finger food and drinks. It’s an ideal opportunity to network, celebrate, and appreciate the people who make our industry exciting and vibrant.

Brian Moore, publisher of New Zealand Printer, says, “These awards recognise the individuals who have made an extraordinary contribution over the past year.

“Print has evolved with astonishing speed into a high-tech manufacturing industry, and it’s more important than ever to acknowledge the visionaries, the determined, and the survivors who make it all happen.

“The event is a timely reminder that people are the heart of this industry. Join your peers to honour the incredible talent and ingenuity that continues to elevate printing and packaging in New Zealand.”

Durst Oceania returns once again as Platinum Sponsor for the awards and has signed on enthusiastically as Platinum Sponsor of the inaugural Forum.

Matt Ashman, managing director of Durst Oceania, says, “At Durst Oceania, we are incredibly proud to be the Platinum Sponsor for the inaugural New Zealand Printing & Packaging Forum as well as the People In Print Awards.

“This year’s events are a powerful testament to the resilience and collaborative spirit of the New Zealand printing and packaging community. We believe in celebrating the extraordinary contributions of the people who make this industry so vibrant - from the determined survivors to the creative minds and the committed leaders.

“We look forward to joining our colleagues and partners on October 14 to collectively honour the remarkable individuals whose hard work and passion are the cornerstone of our shared success.”

This full day of events is more than just an event; it’s an investment in the future of the New Zealand printing and packaging industry and those who drive it.

Learn more about the events

Visit the website to learn more about the day. register for the events. and nominate people for the awards: anzppw.com

Contact NZP editor, Bruce Craig on 021 631 559 or bruce@newzealandprinter.co.nz to nominate your peers (or yourself) for an Award.

Contact NZP publisher, Brian Moore on +61 410 578 876 or brian@newzealandprinter.co.nz to discuss the range of sponsorship packages available.

Contact PrintNZ event manager, Tania McDougall on 021 587 072 or tania.mcdougall@printnz.co.nz to book your place at the Forum and Awards.

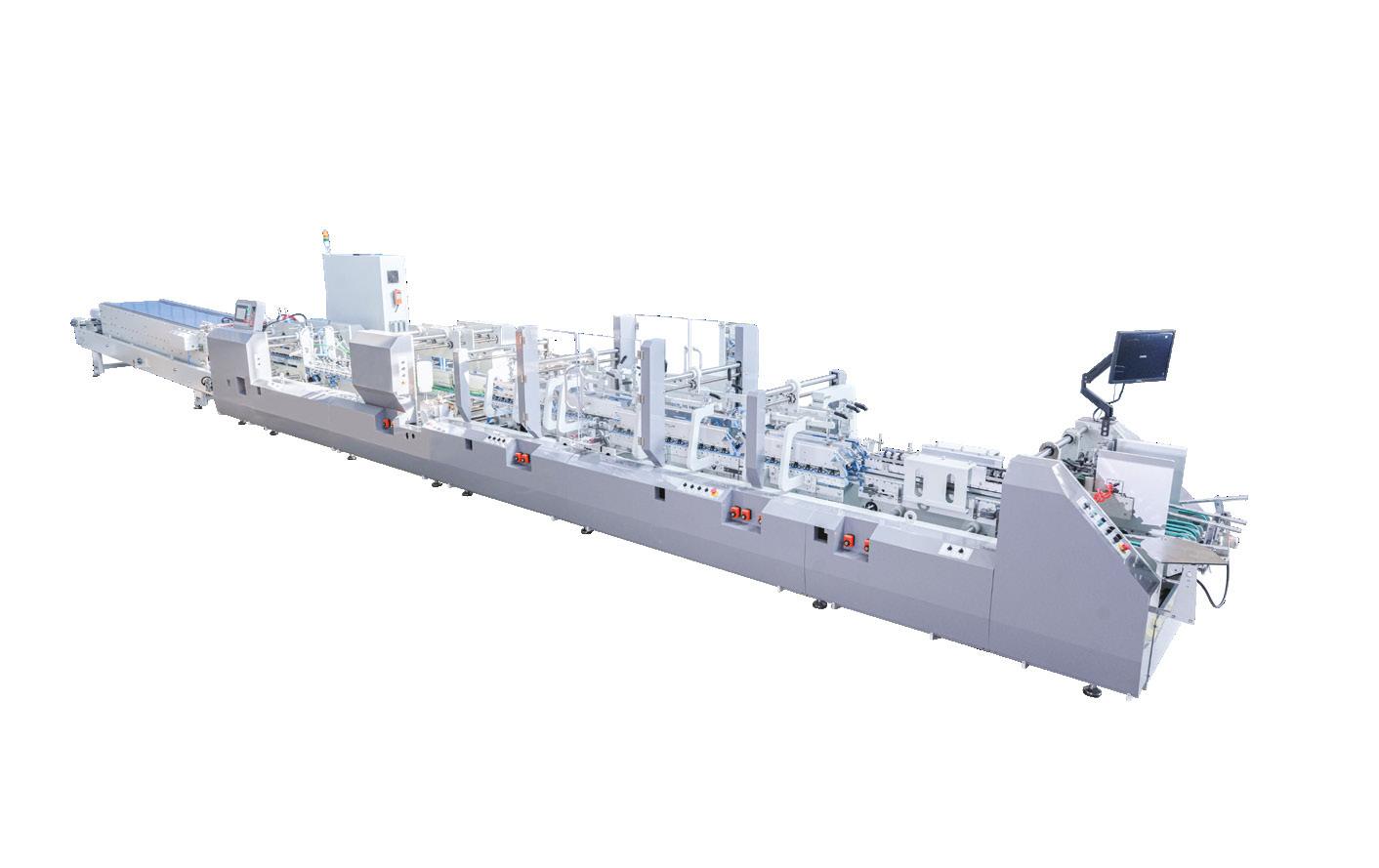

See our range of folding box gluers, board slitters, creasing machines, auto loaders, unloading cutting tables and more.

EPSON has been selected for inclusion in the FTSE4Good Index Series, which measures the performance of companies that demonstrate strong environmental, social and governance (ESG) practices. Epson says it aspires to achieve sustainability and enrich communities over the long term. The company sees its inclusion in this index as objective evidence that its efforts to address environmental and social issues have been recognised, and that it is seen as a sustainable company. This is the 22nd consecutive year Epson has made the index.

KODAK has launched a new Graphic Users Association (GUA) Online Forum, designed specifically for active users of Kodak Prinergy workflow solutions. The forum provides a collaborative space where the Prinergy community can interact with each other, and with Kodak, to exchange ideas and optimise workflow processes. Jim Barnes, Chief IT implementation officer at Kodak, says, “The launch of our new online user forum marks an exciting step forward in fostering collaboration, innovation, and knowledge-sharing among Prinergy users worldwide.”

DUPLO has acquired Bar Graphic Machinery (BGM), which manufactures finishing equipment for the labels and packaging industry. Duplo and BGM will continue to operate as separate, independent businesses. Hideo Tanaka, president of Duplo Corporation, says, “Our role will be to support BGM’s next phase of growth, offering investment, strategic guidance, and access to our global expertise in sales, marketing, research and development, as well as manufacturing.”

Graham Judd of Inkiana Press recently took his Albion printing press down country to run adult letterpress workshops, keeping a traditional printing process alive.

Starting at Greytown for the annual mid-winter Christmas celebration, people signed up to design and print cards, posters, tree decorations and Christmas coasters, and all left with a handful of letterpress items.

Poster workshops followed in Masterton, and Te Awamutu. Graham added a children’s Matariki poster print, which saw children hand setting their names and adding the type to make personalised posters. The North Island tour finished with a day in Hamilton, running two more

HP has updated its home/office range with the new HP OfficeJet Pro 9120e, designed to make high-quality printing effortless across home, business, and creative environments.

The new printer has application for small businesses, working remotely, or managing a house, offering speed, smart

adult workshops.

For the workshops, Graham took a selection of wood and metal type. He guided attendees through the process of setting up, locking a forme, and learning to ink and print their designs on the 1833 Albion press, which former Brebner Print director Neville Smith donated.

Graham teaches workshops based at the Birkenhead Library, and through the Printing Museum in Wellington. These workshops include

features, and sustainable design to support families, professionals and business owners who print regularly.

Key features of the HP OfficeJet Pro 9120e include a faster print speed of up to 22ppm black & white, and 18ppm colour; automatic two-sided printing; smart wireless printing; professional quality; built-in scanner and copier; HP+ enabled for cloud printing, security, and ink subscriptions; made from 40 per cent recycled plastic; as well as a compact design.

learning how to run Heidelberg Platens and cylinders. He says, “It is amazing that what was just another trade in my apprenticeship days, today has great interest among designers and creative people wanting to learn to print by this 500 year-old method. The interest in understanding and experiencing traditional letterpress methods is strong. We always have full classes with people keen to spend a few hours setting up and printing type.”

The new printer offers the option of HP Instant Ink, which means you receive ink before you run out, delivered to your door. The HP OfficeJet Pro 9120e includes a three month trial of HP Instant Ink and an extended warranty.

Nekkorb Solutions has appointed Sam Kay to the new role of technical sales specialist.

Frank Brokken, managing director of Nekkorb Solutions, says, “Sam’s skills and industry knowledge will be highly valued by our customers and at Nekkorb as we continue to innovate and grow.

“With over 15 years of practical experience in labels and packaging printing, Sam now brings his seasoned expertise to his new role at Nekkorb Solutions. His deep understanding of printing processes, coupled with his genuine enthusiasm, makes him an asset to the Nekkorb team and its clients.

“His extensive experience across a spectrum of printing technologies includes label, finishing, lamination, UV-flexo, gravure, solvent-based laminating and digital printing,

Of the 3,000 organisations that environmental campaign Two Sides has challenged over their greenwashing claims, 1,320 have agreed to withdraw or amend unsubstantiated statements like “Go Green – Go Paperless” or “Help save a tree”.

In Australia and New Zealand, sustainably managed forests produce paper and print, and the countries

along with traditional embellishing units for labels and packaging.”

Sam completed his reel fed flexographic apprenticeship in 2014.

boast some of the highest recycling rates globally (62 per cent and 67 per cent respectively). Based on the facts, Two Sides argues, greenwashing claims particularly misalign with the facts.

Despite the greenwashing claims often used to justify digital-only communications, consumers see through it. The 2025 Two Sides Trend Tracker shows 68 per cent of Australians and 58 per cent of New Zealanders believe the real motivation is cost-cutting. A strong majority, 81 per cent in Australia and 83 per cent in New Zealand, report they should be able to choose how they receive

Attributing much of his growth to the knowledgeable mentors who equipped him with vital skills and confidence, Sam followed their guidance into supervisory roles. His hands on approach, carrying out machine maintenance and troubleshooting, has become an asset, enabling him to engage effectively on equipment support and after sales service issues.

Frank adds, “From our Auckland headquarters, Sam will now work closely with Nekkorb clients on their new machine investment projects, instilling confidence and delivering solutions that meet the highest standards.

“His journey underscores a fundamental truth in our industry: passion paired with expertise drives success. At Nekkorb, we are proud to support and celebrate professionals like Sam who embody this spirit.

“The future of printing is bright, and with dedicated professionals like Sam leading the way, exciting times are undoubtedly ahead.”

bills and statements, whether by paper or digital.

Kellie Northwood, chief executive officer, Visual Media Association and country manager for Two Sides ANZ, says, “Claims that digital is always greener than paper are misleading and unfair. Paper is a renewable, recyclable, carbonstoring and carries strong nature positive credentials. Our industry continues to innovate and invest in sustainable practices, and we play an important role in educating marketers and businesses across the environmental credentials of our channel.”

Increasing readership proves the value of printed magazines.

“Ionce picked up a magazine on anti-gravity. I couldn’t put it down.” A Dad joke for sure, but it could be the sentiment expressed by millions of New Zealand readers who are not only maintaining, but steadily driving up, the circulation of a significant number of locally-printed titles.

This trend is evident in the Nielsen’s National Readership Report for the year to the third quarter of 2024 and highlighted in the Visual Media Association (VMA) ‘Industry Insight #2’.

VMA noted that in New Zealand, for the population aged over 15 years:

• Over 40 per cent read magazines, either print or online.

• Women aged 20-plus, 46.9 per cent of the population (1.99 million), are magazine readers, “represent a significant portion of the magazine audience”.

• Main household shoppers, 46.5 per cent (1.98 million), are regular magazine consumers, “highlighting the importance of magazines in reaching

key purchasing decision-makers”.

• Main income earners, 64.4 per cent (2.74 million), “demonstrate continued trust in print for utility, lifestyle and value-driven information. This underscores the value of magazines in targeting economically-active readers”.

VMA stated: “The enduring appeal of magazines in New Zealand reaffirms their critical role in a diversified and fragmented media environment. As digital fatigue continues to affect audiences, magazines remain a trusted medium, offering both reliability and relevance.

“Their influence extends beyond passive consumption, providing readers with inspiration, guidance and content tailored to distinct lifestyles and interests.

“More than just entertainment or information, magazines in New Zealand are a bridge between brands and their consumers, shaping opinions and driving purchasing decisions. In reaching key demographics, especially economically active individuals and primary household decision makers, magazines continue to demonstrate their irreplaceable value in both print and digital forms.”

Nick Burrowes, chair of the Magazine Publishers Association (MPA) and general manager of The Pluto Group, concurs with the sentiments. He says, “In parallel, during the same period, almost ten million print magazines were sold at retail, a number that doesn’t further include paid subscriptions, business to business and industry titles, as well as custom brand publications.”

Stuart Dick, general manager of Are Media New Zealand, embraces additional Nielsen data released for the first quarter of this year, which confirms all six of his firm’s titles have risen in readers per issue:

• NZ Woman’s Weekly, plus three per cent to 419,000.

• Woman’s Day, plus three per cent to 329,000.

• Your Home & Garden, plus three per cent to 113,000.

• The Listener, plus four per cent to 215,000.

• The Australian Women’s Weekly NZ Edition, plus eight per cent to 343,000.

• Kia Ora, plus four per cent to 468,000 – “highest ever recorded readership”.

Stuart says, “We’re thrilled to see every one of our titles growing in readership. We reach over 1.88 million readers via print and our brands are also available online, reaching a further 600,000 unique users per month. It’s a clear signal that audiences are drawn to quality content and the enjoyment of immersing themselves in their favourite magazine.”

Fred Soar, joint managing director at SCG, says readership growth continues across most titles in his firm’s stable, including Dish, which has just enjoyed a 10 per cent year on year rise to 37,000. Readership of titles developed with clients have also increased with AA Directions

lifting almost six per cent in the year to March 2025 to reach 816,000 and Habitat by Resene rising 144 per cent in the year to Autumn 2024 and currently remaining at 962,411.

He says, “With the bi-monthly Dish, we have had steady growth both in retail copies and subscriptions since we bought that title about 15 years ago, and we are now about to further increase our distribution in Australia.”

Sarah Tuck, chief executive and editor of Dish, appears on the TV1 Breakfast Show monthly to talk about the magazine and share some recipes and shall be doing something similar on Channel 7 in Australia. Fred continues, “But it really comes down to Sarah and Claire Aldous, our food editor, creating 70 great recipes per edition, and there is a bit of lifestyle content in there as well typically around

travel. With the food too, they are great recipes, but that don’t blow the budget and are not hard to prepare.

“The photography and printing are excellent. It is just something that looks good lying around at home, that people can browse.”

As this edition of New Zealand Printer heads to press, news broke that North & South magazine will return to print in November, after moving to a digital only newsletter in January. Positive growth and audience engagement has since spurred its publisher to again return to a physical magazine.

Nick Burrowes believes that growing social media fatigue is contributing to reinforce the role that magazines continue to play in the overall media mix.

He says, “Furthermore, there will always be a need for trusted, authentic and in-depth content, produced through a local lens, in an increasingly-flat and algorithm-driven media environment.”

Stuart Dick adds that there is growing recognition that “putting devices down for a moment can be a good thing”. He says, “But mostly, it’s about the long-term connection we have with our readership. They feel part of a community and our editors work tirelessly to deliver a curated parcel of high-quality content for them every issue. And for those that prefer to engage with us online, we have that option.

“Essentially, a publisher’s focus today has to be on supplying content in “whichever medium our audience would like to consume it. Each of our brands is a true omnichannel experience and each platform is quite a different experience – sitting and relaxing, flicking through the pages of a magazine, or visiting a www.nzwomansweeklyfood.co.nz to find a specific recipe.

“So, it isn’t a case of either-or, or that they are competing with each other. It is more about delivering the right content via the right platform at the right time, depending on what the audience wants.”

Fred Soar is adamant his stable’s printed titles would not be enjoying their ongoing growth trajectory without the blend with social media and online advertising. He says, “For example, the Dish community is very strong. We have Facebook and Instagram pages and people are often posting on them, sharing meals and sharing tips.

“You get a community of people with a magazine who share a common interest and that speaks to the power of advertising in magazines – you’ve got all these people who are specifically interested in a topic. We also do online advertising, including via solus EDM (electronic direct marketing).

“And in the case of Dish particularly, a lot of the content is pictures of the beautiful dishes, and it is something that when people are preparing meals, the printed publication is easier to use than a phone or iPad, as well as easier to share with friends and family and discuss recipes.”

Nick Burrowes describes magazine publishers now exploring a “wide range of models and channel mixes” to strike success. He says, “For most, the printed publication remains the core audience and revenue centre as it is where the direct relationship between reader, editorial and advertisers lie. Digital channels can augment reach and frequency, extend the value of editorial investment, and provide time-sensitive tools to enhance the publishing mix and

better meet the needs of readers and advertisers alike.”

One of the most significant challenges before the local magazine sector is rising NZ Post costs, which Fred puts at about 30 per cent increases annually. He says, “Every time that happens, it causes additional cost pressures.”

Ruth Cobb, chief executive of PrintNZ, confirms that over the past two years, her association has “strongly” lobbied both NZ Post and the government on this issue. She says, “The increases they have been applying, seemingly without cap, are having an increasingly-negative impact on printed matter, in particular magazines and direct mail.

“The letterbox remains the only way to connect with every household in New Zealand, and we want the significance of that to be recognised.”

Likewise, Nick Burrowes confirms that in conjunction with other industry groups and businesses, the MPA has lobbied successive governments and relevant ministers to “take NZ Post’s bulk mail increases as a serious issue”.

He says, “This is not just for the industries involved, but for all New Zealanders with

a mailbox. Work in this area has been ongoing, but it is fair to say engagement with our plight has been low.”

Stuart Dick adds, “We strongly oppose the aggressive price increases which are currently running at over 25 per cent per year, and over 100 per cent in the past three years. This compromises all New Zealanders’ ability to viably post mail to each other, including businesses that rely on the network.”

Notwithstanding such challenges, all interviewees consider there to be a positive future for the magazine sector in this country.

Stuart Dick says, “New Zealand has a vibrant, diverse and innovative collection of magazine publishers who will continue to deliver high-quality local content to audiences that seek it out, which they still do in very significant numbers as you can see from the latest Nielsen data.”

Nick Burrowes adds, “Titles that continue to offer well made, relevant content with a clear editorial perspective will prosper. In a media landscape that can often feel generic or globalised, magazines still have the ability to connect with readers through a distinctly local lens, which remains a powerful point of difference. Unlike many digital channels, magazines aren’t at the whim of algorithm changes or shifting platform priorities, which gives publishers more control over how they reach and engage their audiences.

“While the market is certainly challenging, we’re seeing publishers evolve by combining strong printed products with smart digital extensions and other diversified revenue streams. The path forward isn’t one size fits all, but for those who stay close to their audience and adapt commercially, there’s still opportunity.”

Fred Soar concludes that magazines are simply a “different experience”. He says, It is a bigger thing to look at, it’s tactile and easier to share with friends and family. I’d draw a parallel to a University Prospectus. We still do a heck of a lot of those because obviously that is a physical document used by students and their parents.

“There are some things that, when you want to discuss matters and need the material in a more tactile form that is more readily available and more lasting.

“A printed magazine is a physical product that is there, not just a file that you look up.”

Iain Macintyre

For Ruth Cobb, the thrill of attending the Pride In Print Awards has not diminished one little bit over the last 32 years since the first took place.

From the first event held in 1994, to the event held last month, it is always a highlight for me to celebrate the absolute best of our industry: the products, the people, and the businesses. And, to do it in such style

Pride in Print is much more than the name of the Awards and all they encompass. It is a feeling, and it reflects who we are as an industry.

We work in such a creative industry, evidenced by the work that won awards on the night, from the smallest of small labels to an actual house which included a lawn and a letterbox.

It never ceases to amaze me that when we think we have seen the most intricate, the most beautiful, the most skilled piece of work, a clever creative takes it a step further with a new idea. And because we have such skilled talent in our industry, we push the boundaries and bring it to life, making what is possible in print stretch a little further.

However, the Awards are not just about creativity, they exist to recognise excellence. And whether they deliver that through what is big and fancy, or what is small and everyday such as business print, packaging, magazines, and newspapers, it all deserves recognition.

Each year, we hear questions raised about the number of gold medals awarded and people comment: “Everyone gets one”. Well, be assured, they don’t. The

judging panel comprise experts in their field who scrutinise each entry with a fine tooth comb and an eye glass. If an entry doesn’t meet the extremely high bar of excellence, it doesn’t win. And the bar continues to rise. As the level of skill increases, so too does the standard required to achieve gold.

Yes, we see a lot of gold medals, but every one of those jobs earned one. Should that excellence go unrecognised? Should we have an awards programme that gives out first, second, and third and everyone else, despite the calibre of their work, doesn’t make it? Would we want an event that only gives out 15 gold medals and everyone else gets to tell their clients that their work isn’t good enough, when we know that it is? Would that only leave room to recognise the most intricate, the most embellished of work, and ignore the vital bread and butter work that keeps our industry running?

You also need to consider the purpose of the Awards. They were set up to recognise excellence and encourage businesses to improve the quality of their work to meet that standard. Their focus is not on boasting to other printers about how many medals you got, it is about using those awards as a platform to promote both your business and our industry.

So, make the most of those gold medals and don’t just tell the clients whose jobs won, tell all your customers that you are an award winning printer.

Nobody questions how many gold medals are given out at the Wine Awards each year. But we certainly know to look for those (printed) gold medal labels when we are buying a bottle, because they signal the wine has achieved a level of excellence and we can trust that it will taste good.

The Pride In Print Awards have their own equivalent. Our winners’ logos are available for you to use anywhere and everywhere as your own gold medal label.

The Awards PR machine works hard to promote the winners and to showcase the diversity and excellence of print in New Zealand as well as the businesses that produce it, from the smallest to the largest. But it is not just up to us, you also have a role to play in sharing that story. We are an industry that you can count on to deliver excellence, and we should all be proud to say it.

When the Awards started 32 years ago, their mission was to lift the standard of excellence in our industry and that they have surely done. As technology and capability advance, so too does the level required to achieve gold.

And if we ever have year where every entry reaches that gold medal level of excellence, then we know our job is done.

Ruth Cobb

Currie Group has announced it will partner with Pro Cut to supply the Fold Stream range of print finishing systems to the Australian and New Zealand markets.

Pro Cut, a family-owned, German-based manufacturer, has provided systems integration and custom solutions for the print finishing market for over 20 years. At drupa 2024, Pro Cut launched its own range of innovative, tailor made finishing solutions to the market under the Fold Stream brand name.

The new partnership will expand Currie Group’s range of finishing solutions by adding new, high efficiency, short to medium run folding and glueing options, which ideally complement the solutions from some of the company’s existing partners such as Horizon, Kama, and Foliant.

Alan Tam, Currie Group’s category manager for Post-Press Equipment, explains that he and director of operations, Marcus Robinson, connected with Pro Cut’s founders Dirk and Jacqueline Stunkel at drupa, through their close relationship with existing Currie Group partner, Horizon.

Tam says, “Pro Cut and Horizon in Europe have a great working relationship, with the Fold Stream range providing efficient and cost-effective entry level folder gluer systems which complement the Horizon product portfolio.

“We were impressed with the quality and productivity of the machines we saw on the Pro Cut stand at drupa, and particularly with their ease of use.”

Currie Group says Pro Cut machines are extremely fast and simple to set up, especially compared with traditional folder gluers. Setting up and changing over between jobs can be done in a matter of minutes.

This is complemented by high run speeds of up to 10,000 units an hour for straightline box production, and between 4,000 to 6,000 an hour for more complex products like pillow boxes, wallets, and folders. Tam comments, “This makes the Fold Stream machines a very profitable solution for short or medium runs. Because they are so simple to use, they don’t require much training or expertise to operate, which is a real bonus with the current shortage of skilled tradespeople.”

Dirk Stunkel, Pro Cut founder, is excited to bring the company’s innovative solutions to the ANZ Market. He says, “Building on the overwhelming positive response we received at drupa 2024 for our Fold Stream range, we’re excited to bring these innovative solutions to Australia and New Zealand.

“Our machines’ ease of use and flexibility make them perfect for short-run productions, similar to the challenges faced in Europe where labour shortages and high costs are a challenge.”

The Pro Cut Fold Stream range is completely modular and tool-less to operate, so systems can be configured to suit individual requirements, and units can be added as production requirements change.

Options include manual hand-feed or continuous feeders, shingle conveyors and delivery stackers, tape applicators, hot melt or cold glue applicators, tipper plates and cross-folding units for wallets and pockets. The three-point glueing (for auto lock bottom boxes) and rotary creasing options were released recently.

The Pro Cut range will find a home with businesses that need to produce several different jobs a day, in runs from the low thousands to tens of thousands. Tam says, “That’s definitely the sweet spot. It really will be the perfect solution for a range of businesses, from smaller packaging operations to commercial printers who want to expand into the label and packaging market, or larger print service providers who need a more efficient and profitable way to produce those shorter runs.”

Rob Mesaros, Currie Group chief executive officer, says the new partnership is another demonstration of the company’s commitment to providing total solutions for the Australian and New Zealand markets. He says, “We are delighted to be partnering with Pro Cut to bring these high quality, value for investment finishing solutions to the market in this part of the world.

“The new partnership is part of our ongoing quest to ensure print service providers in Australia and New Zealand have access to the solutions which best suit their production requirements and can invest with confidence knowing that they have the full support of the largest technical support and service team in the region.

“As a family-owned company with a history of customer focused service and innovation, Pro Cut is a great fit for Currie Group, and we look forward to working with them.”

Pro Cut co-founder Jacqueline Stunkel says her company is equally pleased. She says, “We are thrilled to be partnering with Currie Group, a well established and respected player in the printing industry in Australia and New Zealand.

“We believe that our shared commitment to providing exceptional solutions and service makes us a natural fit, and we’re looking forward to working closely together to bring innovative print finishing technology to this region.”

Full service print business makes the most of its first Konica Minolta solution.

Innovative Christchurch-based print company Blueprint produces a comprehensive range of print products and services from design through to mailing.

Last year, Blueprint installed a Konica Minolta AccurioPress C7100. Derek Smith, digital manager at Blueprint says, “The AccurioPress C7100 didn’t replace anything. It is our first Konica Minolta machine and sits beside another digital press doing different work and overflow work.

“We only have one operator at a time, so the AccurioPress is great to load up and leave to purr away on either NCR or longer runs. It gives us the opportunity to produce more work in house. We received good training from Konica Minolta. They are always available to login and show us what to do when something tricky pops up.”

Chris O’Hara, national production and industrial print manager for Konica Minolta New Zealand, says, “Konica Minolta designed the AccurioPress C7100 series to support print companies in growing their business and getting the most out of their investment. Its high speed, high productivity and high uptime help achieve short turnaround time with

impressive media flexibility and superior print colour quality.

“Among the new technologies built into its engine are a more durable lubricated drum, double corona wires with automatic cleaning, an optimised paper transport solution, and a double swing registration system for improved paper compatibility and feeding accuracy.”

The AccurioPress C7100 offers numerous auto control and adjustment features including the Intelligent Quality Optimiser IQ-501. Derek says, “The IQ-501 is awesome. It centres the job on the sheet and checks alignment before printing the job. It has been a bit frustrating at times with rejecting paper, until you realise the paper isn’t square. So, make sure your paper is right, alignment is right and therefore finishing is easy.”

Chris adds, “The IQ-501 takes colour consistency and registration accuracy to the next level. With highly automated image registration and colour control, this closed-loop system constantly monitors and adjusts printed output, and automated colour calibration and profiling. Apart from streamlining operator time, the IQ-501 helps you to reduce print waste, and to increase productivity.”

Derek adds, “The AccurioPress C7100 delivers excellent print quality with very ‘natural’ looking colours in photographs. For colour management, it is selfchecking all the time, so it gives us good consistent colour.”

Konica Minolta says it is essential for high-volume printers to feed each sheet smoothly and precisely through the digital press. To ensure this, the company’s paper feeding ensures smooth paper processing. Derek says, “The vacuum paper feeding is very good. It is easy to adjust, and we can view how sheets are feeding to make sure it is running well.

“For media handling, it produces excellent NCR through to 400gsm Offset and Satin and no issues with SRA4 to banner stock.

“The Konica Minolta RIP is also great, very user friendly and more intuitive than other RIPs we have used. It is very easy to operate and to use for NCR numbering/ perfing work. It stores all the information, so for repeat numbering jobs, you find the previous job on the RIPs and just change the numbering sequence.”

Konica Minolta’s inline TU-510 four edge trimming unit cuts, creases, and perforates to produce full bleed trimmed book jackets, imposed cards, business cards, coupons and more. Removing the need for off-line finishing means fewer operator touchpoints for faster and more efficient print runs. Derek says, “We use the inline trimming for banner stock when printing say a 6pp trifold (finished to A4). The job comes out trimmed and creased ready for folding.

“We also use the inline perforation (it can do both directions at same time) a lot when we are doing NCR or raffle books. As long as maintenance is followed to schedule, then this works very well

“The banner capability is excellent. We are doing up to 900mm long out of the trays. It is great for Landscape A4 books. They come out collated and text ready for stapling and trimming.”

MINOLTA

More profitable business through a press that works smarter, not harder, with the AccurioPress C7100 series. You serve more customers and complete more jobs with innovative technologies that power your success.

Find out more at k konicaminolta.co.nz/C7100

Giving Shape to Ideas

Bernard Cheong shares how a conversation with New Zealand Printer’s sister magazine Australian Printer influenced the birth of Cyber’s Australasian subsidiary.

Business leaders have varying personalities. While extroverted personalities are more visible in the public eye, they don’t necessarily have an advantage over introverted leaders. These silent entrepreneurs keep their heads down and work smart in gaining business.

Cyber Australia managing director Bernard Cheong is one of them. Within a span of more than 20 years, Cheong has silently and humbly turned Cyber Australia into one of the largest printing distributors in the Asia Pacific region.

Real estate is another of the company’s key assets. In Singapore, the company recently relocated to a new office and began leasing out its former multi-story premises, which it owns.

He said, “Cyber’s assets are mainly in real estate. We’re fortunate because we’re asset rich. We have our own building in Australia and the four factories we own in Malaysia for showrooms, a refurbishing

centre, warehousing, and a candy plant spanning five hectares, are all owned by us. We don’t have any additional overheads for our real estate, allowing us to focus on what matters most, our customers.”

While Bernard Cheong leads Cyber Australia, his older brother John now heads up the wider Cyber entity ever since their dad Herbert took a step back from the business a few years ago due to health reasons. Another brother, Paul, also works within the business as sales director.

It’s hard to speak of the origins of Cyber Australia without detailing the lesser known fact that New Zealand Printer’s sister magazine Australian Printer is intertwined with the company’s first foray into this region.

It started with a relationship between Brian Moore and Cheong. Moore, who was formerly publisher and sales director

at Australian Printer, is a long-standing part of the magazine’s 75-year history – 24 years and counting, to be exact.

During his time with Asian Printer Magazine in Singapore, Moore established a strong working relationship with Cheong and Cyber, a then Singapore-based company. That professional partnership naturally fortified when Moore returned to Sydney to run the Printer Media Group, parent company of Australian Printer

A few months later, in what was just a simple discussion about the Australia and New Zealand printing markets between Moore and Cheong, Moore planted the seed to what has now grown into Cyber Australia, which holds the RMGT agency in this region.

“It was actually Brian who sparked my interest in setting up Cyber Australia,” Cheong recounted.

“I had known Brian from his time in Singapore, and we never miss an opportunity to catch up whenever he visits the country. We were once having a simple conversation about the A/NZ markets shortly after he returned to Australia, when Brian asked me if I knew much about that space.

“With Cyber having a big play in only the Asian market at that time, I replied that I didn’t know much about it; I thought Australia was a ‘sleepy town’. Brian then told me ‘You should check it out, because there’s a world of opportunity’.

“I did my research and made a few trips over to study the A/NZ printing landscape and true enough… there was an untapped opportunity for Cyber to make its mark in this region. The Ryobi distributorship was also available, so we took on the challenge.”

The rest was history.

Cyber Australia was established in 2004, with the company showcasing several Ryobi presses at PacPrint 2005.

“At PacPrint 2005, our first PacPrint, all major exhibits were sold,” Cheong said.

In 2009, Cyber Australia first unveiled the Ryobi 920 series in its Singapore showroom. The 925, an SRA1 fivecolour offset printing machine, was first purchased by CMYKhub in Australia sight unseen as a vote of confidence in Cyber and Ryobi.

“We truly appreciate the partnership and confidence CMYKhub has in us. The superior cost performance of the 925 led to more presses being purchased from the group over the years,” Cheong said.

“This includes Australia’s first 925D five-colour with UV coater, the first 928P LED eight-colour convertible perfector with LED system, and the new 970PF-8 LED with PQS-D A1-plus-size 8-colour convertible perfector with LED and Smart-Automatic Printing (SAP), featuring non-stop automatic registration and colour control and inspection. CMYKhub bought a total of 15 offset printing presses from us.”

In 2010, Ryobi and Mitsubishi came together to form RMGT. The integration of the two product lines enabled Cyber Australia to bring to market the best of both worlds, giving the business an added advantage.

Through the years, order numbers increased, and Cyber Australia became a household name.

The Cyber of today

Cheong provided an update on Cyber Australia’s more recent business, saying the pandemic actually ended up being favourable for the company.

“In a single year, during the Covid period, we experienced the best business performance in our history in Australia,” Cheong said.

“Because shipping was an issue for printers during Covid, the Made in Australia movement resulted in more products being produced locally. This meant printers needed efficient machines to deliver quality solutions, and many turned to us as their trusted technology provider.

“Every cloud has a silver lining. You’ve only got to look for it in the right places.”

One of the more recent installations was at CCS Media Packaging, which installed a new RMGT Ryobi 970 seven-colour press with aqueous coating in 2024, bringing in the final piece of a 12-month, multi-million dollar investment. He said, “CCS is a unique client of ours. They used to print for record companies, but with

music now going digital, the need for prints for CDs and other related materials became obsolete. So, the company pivoted into the food packaging space and needed the machinery to support production.

“But now, with record labels at boutiques making a comeback, it has become the icing on the cake for CCS because they have already been involved in the music industry.”

Of late, with the prolific growth in packaging, Cheong finds the number of print service providers purchasing machines from Cyber Australia specifically for packaging purposes has escalated.

“Half of our installations are now to companies that have taken on packaging work in addition to their printing capabilities,” he said.

“This was, again, brought on since Covid, when peoples’ purchasing patterns shifted from in-store to online.”

In New Zealand, the company is currently in the process of installing two presses.

“In New Zealand, a lot of print service providers’ equipment are getting old. Their hands are being forced to either update their machinery and continue operations, or close down,” Cheong explained.

Across Asia, most of the company’s sales come from Malaysia and Vietnam.

“There’s greater demand for machines in the developing markets in Asia as they invest a lot more than the developed markets. This is because most of the work is outsourced to printers in these countries,” Cheong said.

“When Covid hit in Malaysia, for example, business did stall momentarily but it was the first to pick up because the country sees a large production of latex and with the requirement for latex gloves, our print

service providers needed to print glove boxes rapidly.

“Since Covid until now, the Malaysia market hasn’t stopped. In fact, it’s been really strong for us. With Donald Trump slapping tariffs on China, I think it’s only going to fuel the Malaysian market to be even stronger.”

The move back to offset

According to Cheong, Cyber’s customers are making the move back towards offset equipment as technology has made offset printing more affordable than before.

“For non-collated products, we have clients that were strong digital users for more than a decade embark on an offset journey because they find it cheaper to print on offset. Offset was dying because the last major adoption in that space was CTP. But now, with modern offset printing equipment, it is equally easy to print on it because everything is automated,” Cheong said.

“With digital, it’s all click charge; you pay for every sheet. With offset, you pay for the commodity, which is ink and plates. They’re cheap.

“So, RMGT’s R&D division focuses heavily on digitising offset equipment. The focus is very much on the mechanical engineering, improving reliability, increasing speed, and simplifying makeready times and staffing requirements.

“In fact, the company used to manufacture some digital machines, but when comparing the cost of print to automated offset presses, it found that printing on automated offset was still cheaper.”

One example that Cheong mentioned was US-based Pacific Printing. Previously, a lot of the company’s short run work was digital. But, the ability to get to colour quickly enabled it to move a lot of that work over to offset, changing the capabilities for the business in terms of what it can gang-run and put on press in a short amount of time.

But even with the change in market demands, the core of Cyber remains the same.

He added, “Our focus from when we first started until today is the same. We are very much a customer orientated business that evolves together with our customers.

“We are not fixated on any single market. Whatever the customer wants, in whatever direction that they move, we are there for them.

“Our customers are our compass for change – they show us the direction, and we adapt accordingly.”

Small Avondale-based company wins with “stunningly designed wedding invite”.

Auckland’s Cordis Hotel hosted the 32nd annual Pride In Print Awards recently, with more than 500 print industry professionals packing the Cordis for the industry’s night of nights.

Emcee Jason Gunn hit the ground running with a barrage of quickfire quips, stating his aim of keeping the awards flowing. He gave detailed instructions for the award winners and the audience, who responded positively throughout the evening. Having emceed the Pride In Print Awards before, he knew the process and said, “I am really humbled to be here tonight because this is about excellence, and it is about you.

“As an emcee, I have few balls I am juggling but I want you to remember

that this is your moment of excellence. Think about what it means for every person and every company that gets their name called out. It represents the time, the effort, the hours, and the teamwork that goes into the work and receiving the award. So, what I am saying is that even though I will try and keep things moving, we will pause to celebrate when we need to because this is about you.”

Fraser Gardyne, convenor of judges, welcomed everyone to the event. He said, “I have been coming here since the first awards 31 years ago. There is one other person here tonight, who was here on that first night, and who has kept things going, and that person is Ruth Cobb.” (Ruth later pointed out that the first awards were, in fact, 32 years ago).

Fraser continued: “I really want to thank the Patrons and Sponsors of the awards, who have also kept the awards going and they have done a damn good job. Also, the judges, who have delivered their support. The judging process sees competitors working together and that is also something special.”

The Pride In Print Awards is indebted to the unwavering support of the Patron and Sponsors. The Pride In Print Awards Patron for 2025 is Fujifilm Business Innovation New Zealand. The awards Sponsors are B&F Papers, BJ Ball Group, Currie Group New Zealand, Koenig & Bauer, Kurz New Zealand, Nekkorb Solutions, Paper Source, Reproflex3, Ricoh New Zealand, Spicers New Zealand, and UPM Raflatac. The media sponsor is New Zealand Printer.

The Friends of the Awards 2025 are Blue Star Group (New Zealand), GratPak, Kale Print, Sealed Air (Hamilton), SCG, and Wholesale Print.

“Beautiful job” wins out

Avondale-based Studio Q-Laserfoil claimed the Pride In Print Supreme Award, and the Specialty Products Category Award, with what judges called “a stunningly designed overseas wedding invite suite perfectly realised through flawless execution of a range of traditional and contemporary print techniques”.

Judges glowed over the four-piece Kaya and Brian Wedding Invite Suite, noting the “huge technical difficulty” required to achieve such quality across digital and letterpress printing, light debossing, die cuts, foiling, hand-stitching “and much more”.

They commented: “Wow, this beautiful job is more than a wee bit different. Its customised detail additionally involved the incorporation of actual vintage American stamps, a personalised seal, a precisely-bowed ribbon, and handmixed Pantone colours on bespoke stock.

“The suite further impressed through its precision, achieving a perfect line up of elements on even the back of the envelope. The time that would have gone into such detailing on all these features would be immense and everything was done technically and aesthetically perfectly.

“We saw a number of these beautifullyproduced wedding invites for overseas customers this year, with this print buyer being based in New Jersey. The fact that these customers are coming to Aotearoa New Zealand printers ahead of anywhere else in the world to have these invites done here is absolutely amazing and speaks volumes to the passion evoked and quality produced in this country.”

Interviewed immediately off stage, Studio Q-Laserfoil’s director/owner Dave Trotter, letterpress specialist Tim Morris and account manager Liesl Trotter described being “blown away” by the evening.

They said, “Over the years we have won quite a few golds, and the process award several times, but we have never won a category award before tonight.

“We are a small company, and we didn’t expect to win the Supreme Award; there are some big companies out there doing outstanding work.”

The trio paid tribute to client Michaela McBride Calligraphy, noting growing international reputation. They said, “She is an amazing New Zealand designer and calligrapher. Her market is almost entirely overseas, designs for beautiful weddings all around the world. Because of her reputation, she manages to attract those customers. She has an attention to detail that matches our attention to detail, and she trusts us.”

They also highlighted the ecological values of the Colorplan paper used in the job, noting it required no polymer or plastic enhancements. They also mentioned the continuing and evolving relevance of the platen letterpress, and the crucial benefits of in house capability.

They said, “We can take a digital print to the machine, die-cut it and, if it is not perfect, change it a bit and go back and do another print, until it is perfect. There is no other way you can get that alignment. If you have a finishing house doing it separately, they will do the best they can, but they will be chasing it. We literally went back and forth until it was aligned because it is all in house.

“This job is also a celebration of modern and old techniques, and that is what Studio Q-Laserfoil is about. But we are not just using the old presses in a traditional way. Let’s not forget what has gone before and let’s not overlook what is coming up.”

50 & 100 Club & Business Awards

Over 32 years, 16 companies have won 50 or more gold medals. They are Admark Visual Imaging, Amcor Flexibles Asia Pacific Christchurch, APC Innovate. Blue Star Auckland Print & Packaging Constellation, Blue Star Wellington, Crucial Colour, Fuzed, Gravure Packaging, Kiwi Labels, Logick Print & Graphics, MCC Albany, Permark Industries, SCG, Wakefields Digital, and Webstar. Of those 16 companies, three have won 100 or more gold medals. They are APC Innovate, Blue Star Wellington, and MCC Albany.

Additionally, 2025 PrintNZ Business Awards Gold Medal winners are:

• Innovation – 5 Digital

• Sustainability – Amcor Flexibles Christchurch

• Sustainability – Blue Star Group

• Sustainability – SCG

• Sustainability – The Print Room

• Sustainability and Wellness –Transcontinental Packaging NZ

ABC Original Print claimed the Sign and Display Print Category with the Hydroflow Rainbird FSDU. Judges commented: “A very well designed and stable unit, this display stand features a variety of consumer products that can be readily removed and easily returned to well-made cutouts. Great attention to detail has been shown in what is both a

APC Innovate won the Print Industry Promotion Category with its APC 2024 Christmas Wine Box

Judges said: “A 10 out of 10 for concept, this well-presented gift box features a design that enables it to be repurposed for the socially-engaging cornhole game. A perfect execution of a beautifully aesthetic design, in combination with practical functionality.”

Karl Sciascia, national sales manager

very attractive and functional display.”

James Hedger, operations general manager at ABC Original Print, said, “Hydroflow’s partner Rainbird needed an eye catching unit to communicate their new automated irrigation products to the farming and industrial community. Using our latest UV digital flatbed printing technology, we certainly delivered.

“The unit needed to be robust to hold all the components. Our structural team took care to measure every component so they would be housed safely and securely in the display. Power cable access also needed

to be incorporated into the display so the LED component could be powered up so functions could be demonstrated in store.

“The unit is recyclable, constructed from FSC sourced corrugated board, in line with Hydroflow’s sustainability initiatives. We have received great feedback from store managers and customers. After installing the stands into stores, interest in the Rainbird Irrigation System has increased tenfold.

“The ABC Original Print team are incredibly proud to get this recognition for a job well done.”

for APC Innovate, said “Every year we challenge ourselves to come up with our take on a festive Christmas wine box which we give to our clients to say thank you.

“It requires a real collaborative approach from the team to push the concept, structural and graphic design

elements. The 2024 edition is one we are extremely proud of, and the client feedback was incredible.

“At APC Innovate, we feel great about getting the recognition of this award, and the judges’ comments make all the hard work worth it.”

Blue Star Auckland Display & Distribution won the Industry Development and Creativity Category Award with its One NZ Advent Calendars.

Judges noted: “Very sturdy, all the doors and creases are clean and seamless, the digital print is punchy, and the sustainability focus of being able to be reused each year also gains top marks. Also printed inside, outside, back and front and a very complex design, having all the doors fold in, glued and self locking. The assembly would have taken

Blue Star Auckland Display and Distribution won the Structural Design Packaging Category with its Panadol Liquid Caps packaging.

Judges said, “Everything is all so seamless. It is beautifully designed, has great print quality and is extremely well put together. The whole finishing of it is pretty much perfect. This is one of the best presentation boxes you’re ever likely to see.”

Robert Thorn, Blue Star Display & Distribution design team member, said, “It was designed to support the launch of Panadol’s first liquid capsule format in New Zealand.

“The primary audience for this kit was retail buyers: individuals making

hours. You can also shut it in half to minimise space when storing away. As a concept we thought it was very cool and a bit different.”

Sarah Wharfe, Blue Star Display & APC Innovate general manager, said, “The brief was for it to be life sized and hold prizes for staff, and we recommended that we design it in a way that was reusable. We also suggested they use vouchers for the prizes instead of designing the unit to hold specific weighted items, as changing this year on

year would have been more difficult. The date doors were removable so that it was clear which prizes had been taken and highlighted the countdown to Christmas and was very interactive for the staff.

“To have the One NZ staff excited about this Christmas internal activation was really positive and a huge success. We are so proud that our customers have the trust and faith in us to be able introduce an idea that we can build on to deliver their needs.”

decisions about what products earn space on crowded shelves. This meant the experience had to be compelling, concise and visually persuasive. By integrating both the brand’s credibility and the new format’s differentiation into the physical structure, the kit allowed buyers to understand the why behind the product in a matter of seconds. It also provided key product info and marketing support at a glance, essential for time-poor retail decision makers.”

The seeding kit was viewed not just as a sales tool, but as a creative

expression of Panadol’s first new product development in 11 years. The feedback noted the presentation as ‘best in class’ within their regional toolkit. This project represents the power of collaboration between structural design, brand strategy and production craftsmanship. It’s more than just a presentation box. It is a storytelling vehicle. Being recognised by Pride In Print for this work is a testament to the impact that well executed design can have when it seamlessly aligns with commercial objectives and consumer expectations.”

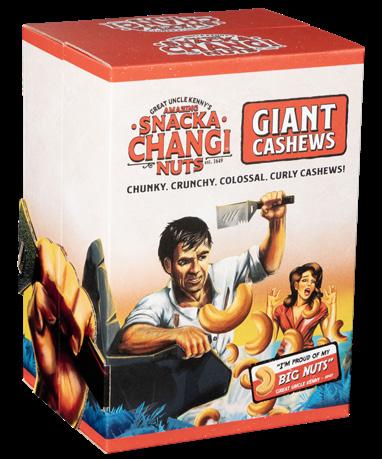

APC Innovate won the Paper and Board Packaging Category with the Snackachangi Presenter/PR Box.

Judges said, “The cutting and assembly is perfect, the tear tab is tidy, the hinging is beautiful, all images line up spot on and the print speaks for itself. This job has had much more structural design detail go into it to make it fit for purpose and it is well displayed, a really nice design and very well put together.”

Karl Sciascia, national sales manager

Blue Star Auckland Print & Packaging won the Business Print Category with the Mercury – Integrated Report 2024.

Judges commented: “Printed on a challenging recycled paper with an older press, this annual report nonetheless features a vibrant yellow that has been reproduced consistently throughout. With all line ups also perfect, we basically could not find a fault; It is just a beautiful job.”

Emma Selwood, Blue Star Auckland Print & Packaging customer services manager, said, “The design and print execution were critical in delivering a publication that reflects both the company’s innovation and commitment to sustainability.

“A standout feature was the precise colour consistency required throughout the publication, particularly the spot yellow and subtle background tints, which

at APC Innovate, said, “Our design team had their work cut. After extensive prototyping, managed to come up with the overall creative and design elements that not only looked stunning but provided an engaging reveal factor when

opening the box. The client was thrilled with the feedback and so were we.

“To win the Paper and Board Packaging Category for this distinctive design is a great result and one that the team at APC is proud of.”

had to remain perfectly balanced across multiple sections and stock weights.

“The report was printed on Eco100, a 100 per cent recycled uncoated paper, using soy based inks. The careful selection of materials and processes ensured the final product aligned with Mercury’s sustainability commitments while also maintaining high production quality.”

“For readers, particularly stakeholders and investors, the report needed to feel polished and intentional. The seamless interplay between design and print helped elevate the user experience, making it

a piece that people would engage with, retain and reference.”

“Mercury felt the report was a true reflection of their brand and appreciated how the production aligned with their environmental values. Feedback has been overwhelmingly positive, both internally and from shareholders.

“The success of the Mercury 2024 Integrated Report is a testament to strong collaboration between client, designer and print partner, and we’re proud to see this recognised at the Pride In Print Awards.”

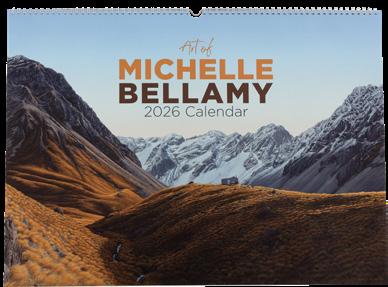

easy2C Calendars and Promotional Products won Promotional Products Category with the Art of Michelle Bellamy calendar.

Judges commented: “Combining a slightly older offset press with digital overprinting, this calendar was an excellent representation of prepress, registration and binding. The artwork itself and the finishing is so clean, on a beautiful stock. Also, the images distract you from everything; hand-painted and then overprinted, it is just gorgeous. Vibrantly faultless, the result is an amazing reproduction of beautiful hand painted, epic New Zealand scenery.”

Anna Chesterfield, easy2C Calendars New Zealand and Australia marketing

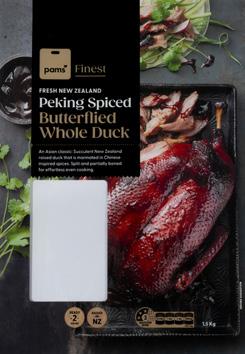

Sealed Air Hamilton claimed the Flexible Packaging Category and Flexographic Process Awards with the Pams Finest Peking Spiced Whole Duck packaging.

Judges said: “A great design has been brought to life in execution of a print process not normally associated with topof-the-line reproduction. Colours were solid, with great contrast ensuring the food dish reproduced looks real.”

Damion Robinson, printing/laminates and prepress group performance leader at Sealed Air Hamilton, said “We used Vortex technology on a plate supplied by R3, which enabled us to print what was

and design manager, said, “The calendar comes in three formats: a large wall calendar, a booklet, and a desk version.