A BOX THAT BUILT A BUSINESS

Spotlights its new experience centre in VIC

Heidelberg acquisition P10

Acquires Polar Mohr brand rights and tech

Ball & Doggett acquisition P05

Acquires Impak Films for bigger packaging play

CS Graphics buyout P06

Takes ownership of Aldus Graphics

Paolo Grasso joins Durst P06

Reinforces Durst’s commitment to packaging

Abbe acquires Oji in Australia P08

Move enables Abbe to extend its reach into QLD

CPP Oceania distie deal P08

Rodden Graphics becomes CPP sales agent

Opal’s ‘wonderland awash’ P11

Showcases its end-to-end capabilities

New CEOs for Close the Loop P11

Kesh Nair promoted to Australian CEO

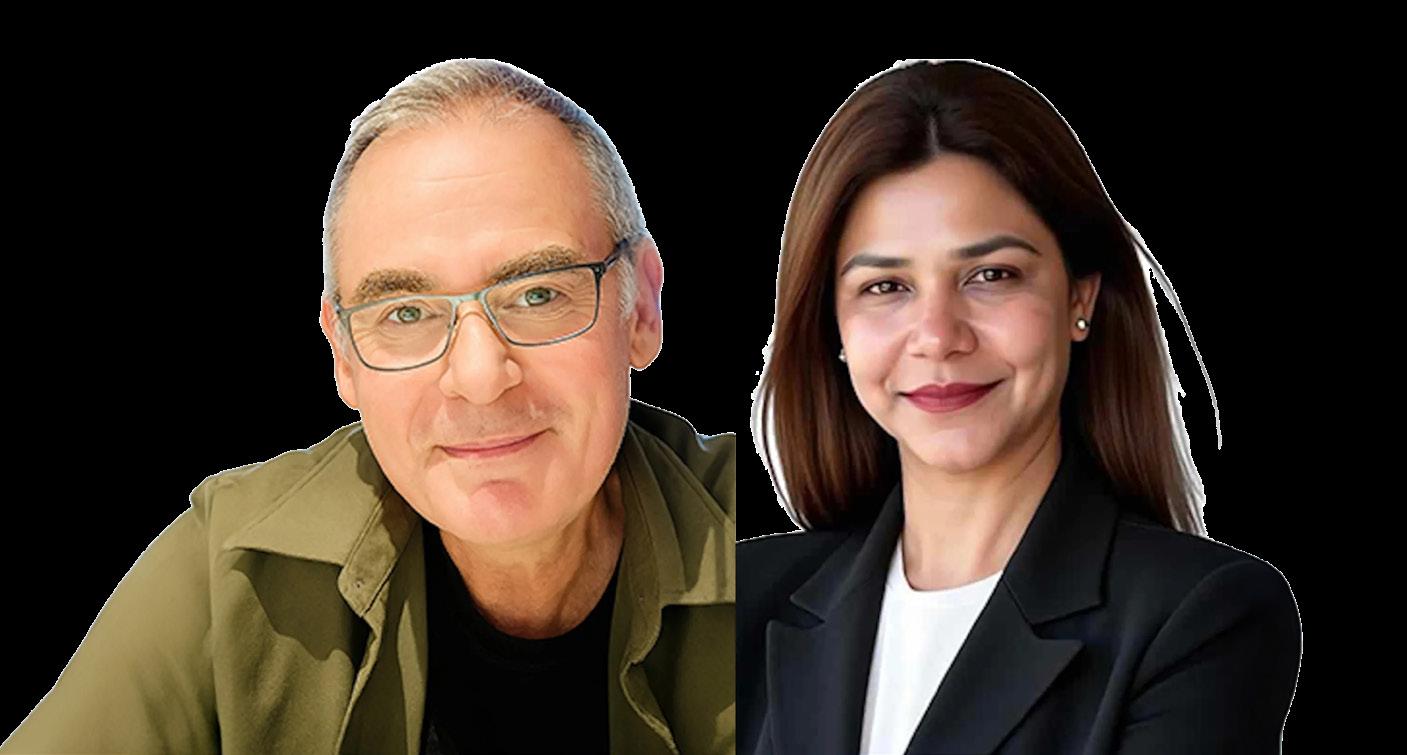

Helio arrives at Orora P12-13

Orora has partnered with Velox Digital for this Helio solution at its Dandenong facility

Pakko invests in its future with new QLD facility P14-16

Pakko enters the next chapter of its growth with the move into its new HQ in Virginia

Frank Stephenson on the emotional power of luxury P18-19

The visionary explores how emotionally intelligent design is redefining modern luxury

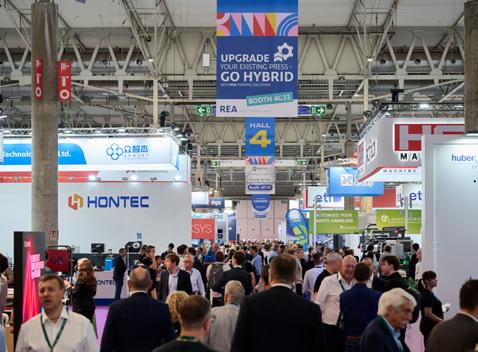

ProPack.pro’s extensive Labelexpo Europe review P20-27

Labelexpo Europe was a hotbed of innovation with exhibitors showcasing their latest tech

Currie Group delivers strong results at Labelexpo Europe P28

Labelexpo Europe was one of the company’s strongest tradeshow outcomes

A/NZ contingency gathers in Barcelona for function P30

A/NZ technology partners and converters came together for a night of networking and fun

Familiar faces spotted at Labelexpo Europe 2025 P31

Many well-known members of the industry were spotted on the floors of the tradeshow

FPLMA Technical Forum addresses ‘Adaptation and Innovation’ P32-35

Focuses on sustainable solutions, value creation and advancements in next-gen tech

And the winners of the FPLMA Awards are... P36

RollsPack and MultiColor Corporation win big Asian Sustainable Packaging roundtable takeaways: AIP P37

Key challenges and new ideas to advance sustainable food packaging were identified

So, you bought a business... What’s next? P38

Signing the deal should be considered only one of many milestones, says Peter Fotiadis

growth projected for printed packaging labels and release liners

A guide to the upcoming local and international events around the world

There’s nothing more thrilling for us than the adrenaline of being at a tradeshow. That too one as massive as Labelexpo Europe 2025, which was coined “the biggest Labelexpo event to date”.

Recently taking place in Barcelona, Labelexpo promised − and delivered on − bigger halls, more foot traffic, and

As the only A/NZ media in attendance at the event, we got to see first-hand many of these launches from industry-leading suppliers that exhibited at the show. This issue is dedicated to our most extensive review of Labelexpo Europe.

We also cover the recent FPLMA Technical Forum, which took place in Melbourne. We hope you enjoy the read.

Ball & Doggett has reached an agreement in principle to acquire flexible packaging supplier Impak Films, with a completion date scheduled for 31 October 2025.

Part of the OVOL, Japan Pulp and Paper Group, Ball & Doggett is Australia’s leading distributor of printable materials and consumables to the print, signage and packaging industries.

Established in 2005 by Andy Newman and Brian Christy, Impak Films specialise in the distribution of a wide range of flexible films into the packaging industry.

Ball & Doggett CEO Luke Wilkinson said, “We are delighted to welcome Impak Films into Ball & Doggett, further strengthening our position and commitment to the packaging sector”.

Impak Films managing director Andy Newman said, “This is an exciting next step in the Impak Films journey. Ball & Doggett have the resources, people, and infrastructure to take the business forward which will ultimately provide greater value to our customers, suppliers, and staff. We are excited about what the future holds”.

The business will continue to operate independently from its site in Tullamarine, Victoria with all staff remaining with the business.

Aldus Graphics and CS Graphics have announced the successful completion of a management buyout that will see CS Graphics take ownership of the core distributor operations from Aldus Graphics.

CS Graphics partners with global manufacturers including Mark Andy, Rotoflex, GEW, Maxcess, Rhyguan, DYM, Harper, Polywest, JM Heaford, Graymills & Enercon, to provide equipment, consumables and technical expertise for the label and packaging industries.

The companies said the move marks an “exciting new chapter” with Aldus proud to support the transition and confident that customers will experience minimal to no disruption during the changeover.

The establishment of CS Graphics ensures continuity of service for existing customers while positioning the company for strategic growth in the evolving print industry landscape.

The newly formed CS Graphics will be led by co-directors and industry veterans Chris Bodger and Sheetal Mishra, who bring decades of combined experience in the narrow web printing and converting sector.

CS Graphics said it will focus on delivering enhanced service and solutions to printing

Durst Group has appointed Paolo Grasso as its global account manager of labels and flexible packaging.

In his new role, Grasso will be responsible for managing international label accounts and supporting some of Durst’s global customers, ensuring that these customers can fully leverage the company’s industry-leading printing solutions and achieve their business goals with consistent, worldwide support. With this strategic move, Durst said it aims to strengthen its global customer focus and expands the support for international label customers.

It added that this appointment marks another important step in the continuous development of its labels and flexible packaging segment, reinforcing the company’s commitment to global growth, customer-centric partnerships, and sustainable technologies.

Grasso brings to the role over 25 years of international experience in the labels and packaging industry, where he has successfully led sales teams and globally developed key markets.

businesses throughout the region.

Aldus Group CEO Frank Floriano said, “At Aldus, we are incredibly proud of what this business has achieved and the strong foundation it has built. We are confident that CS Graphics will continue to deliver the same high levels of service, quality, and innovation that customers have come to expect. We wish the team every success as they begin this exciting new chapter”.

CS Graphics co-director Chris Bodger said, “We’re excited to launch CS Graphics as a dedicated partner for the A/NZ label print and packaging industry.

“This management buyout allows us to

focus entirely on what we do best –supporting our customers with the products, expertise, and service they need to succeed. CS are driven by customer service, customer satisfaction and customer success.”

CS Graphics co-director Sheetal Mishra added, “Our transition from Aldus Graphics represents more than just a change of name. It’s our commitment to building a company that truly understands and serves the unique needs of our valued customers”.

Both Aldus and CS Graphics are aligned in ensuring a seamless transition, with all existing customer relationships, contracts, and services continuing uninterrupted.

He most recently served as sales director at Actega Metal Print, an innovation-driven company focused on sustainable technologies. Prior to that, he was global head of sales at OMET, a longstanding Durst technology partner in the printing industry.

Grasso said, “I am honored to join Durst at such an exciting time. My goal is to bring true added value to our global customers by listening to their needs, strengthening collaboration, and supporting them with Durst’s cutting-edge technologies.

“Together, we will continue to shape the future of labels and flexible packaging with innovation, service, and trust”.

Durst Group labels and flexible packaging global sales director Thomas Macina said, “We are delighted to welcome Paolo to our global team. His international background, proven leadership, and extensive customer relationships will be instrumental in strengthening our partnerships and driving sustainable growth in the labels and flexible packaging sector”.

Australian independent manufacturer and supplier of corrugated and carton board packaging Abbe Group has announced its acquisition of Oji Fibre Solutions Australia, a manufacturer of pulp, paper, and woodfibre based packaging solutions.

Abbe Group said the move enables it to extend its reach into Queensland and further strengthen its existing corrugated capabilities in Victoria and NSW. The acquisition takes effect on 1 November.

“We are excited about the opportunities this acquisition brings to our customers, people and suppliers. It strengthens The Abbe Group’s infrastructure and service reach, reinforcing our capability to deliver high-quality products to customers across Australia,” the company said.

“The acquisition includes additional corrugating facilities for Abbe in Victoria, NSW, and Queensland, as well as regional distribution and erecting locations in Far North Queensland and the Sunraysia region.

“This investment reflects a long-standing tradition of innovation, operational excellence, and a deep commitment to customer service.

“This acquisition represents a major

Canon Production Printing (CPP) Oceania has announced the appointment of Rodden Graphics as a sales agent for the label and packaging sectors across Australia and New Zealand.

The announcement follows CPP Oceania’s recent expansion of its product portfolio, which introduced the sale, installation, and servicing of Edale flexographic label and carton converting systems (a Canon company since 2022), alongside the highly anticipated Canon LabelStream LS2000 digital label press.

With the expansion, Australian and New Zealand print service providers and converters will now benefit from a single-source supplier offering a complete range of CPP’s high-volume digital production inkjet systems, together with Edale’s world-class flexographic solutions.

Rodden Graphics, founded in 2018 by industry veteran James Rodden, has quickly earned its reputation as a trusted advisor in the label and packaging solutions market. Rodden Graphics has built its name on

milestone for Abbe. We warmly welcome the Oji Fibre Solutions Australia team to Abbe Group and look forward to an exciting future as we “Make Packaging Easy” for our customers.

The Abbe Group is proudly family-owned and operated and has built its reputation on decades of experience in the packaging industry.

In 1991, Abbe was established by John and Julie O’Sullivan. Their sons Anthony, Daniel,

and Chris O’Sullivan joined their father in the business in the following years, each starting from the ground up.

The family initially entered the corrugated space back in 1954 when John’s father Jack opened Cardboard Containers Manufacturing Co.

The family tradition continued in 2007, when the O’Sullivan and Barnes families joined forces and the journey with Austcor Packaging (NSW) was born. Shared philosophies of service and customer-first ethos, along with continued investment, enabled strong business growth.

The group was further enhanced in 2009 with the addition of Abbe Industrial Packaging, giving the collective business a unique point of difference – the ability to provide timber products to go hand in hand with its core offerings.

In 2012, Abbe relocated to Maffra St Coolaroo into a highly automated purposed designed site that enabled further expansion into new markets such as digital printing, die-cutters, specialty gluing, fanfold and automation.

An acquisition of ZacPac in NSW and Qld, combined with its growing regional presence in Sunraysia and the Griffith and Hunter regions created further expansion and access to new markets. In 2017, Abbe recognised the growth of the e-commerce segment and became the official distributor of on-demand packaging solutions, Panotec and CMC Packaging Machinery.

providing expert guidance, tailored solutions, and ongoing support. For the past seven years, Rodden Graphics has also represented Edale, successfully placing systems into Oceania.

“Rodden Graphics brings a wealth of experience, deep market knowledge, and strong customer relationships to our label and packaging business,” CPP Oceania managing director Craig Nethercott said.

“Their proven track record with both digital and conventional solutions makes them an ideal sales partner. Coupled with Canon’s significant service and support infrastructure across Oceania, which will enable us to support customers in achieving success with our label and packaging technologies,” he said.

Rodden Graphics founder James Rodden said, “We are proud to extend our collaboration with Canon Production Printing Oceania. This appointment builds on our history with Edale and allows us to offer customers a comprehensive portfolio – from flexographic solutions to Canon’s groundbreaking LabelStream LS2000. Together, we’ll help manufacturers and converters across Oceania access the right technologies to future-proof their businesses”.

Rodden Graphics will work alongside CPP Oceania to deliver consultative sales, installations, and after-sales service for label and packaging customers, ensuring they are equipped with the innovation, reliability, and support required to thrive in a rapidly evolving industry.

Enterprise workflows

Native PDF editors

Color management

3D prototyping & visualization

High-speed RIPs and DFEs

Printheads electronics

Zebra Technologies Corporation, a global leader in digitising and automating frontline workflows, has unveiled its new Australia and New Zealand headquarters, along with an expanded Zebra Experience Centre (ZEC) in Hawthorn East, Victoria.

The purpose-built space replaces the former Glen Waverley office and serves as the central hub for Zebra’s A/NZ operations, complementing existing teams in Sydney and Auckland.

The company said its new headquarters marks a significant investment in its expanding A/NZ presence and underscores its commitment to the local market.

Zebra’s local expansion follows rapid growth in the region, reflecting an increase in market share for rugged mobile computers, RFID devices, and label printers.

Zebra said the relocation to central Melbourne positions the company even closer to many of its customers and partners, offering increased space and functionality to meet the growing demand for its products and services, while enhancing engagement.

“Zebra continues to attract new partners to our award-winning PartnerConnect program in A/NZ, while our customer base grows,”

Heidelberg has reached an agreement with the Polar Group companies to acquire the technology, intellectual property (IP), brand rights, and additional assets of this long-standing partner.

Heidelberg said the move marks its step toward systems integrator status, especially within the packaging and labels sector, as Polar Mohr produces high-tech post-press machines for cutting, packaging, and label applications.

It is expected that the transaction will be concluded within the coming weeks, after which Heidelberg will have exclusive global sales, service, and marketing rights for the post-press products.

Heidelberg added that this agreement gives the business direct access to further packaging markets in the growth regions of Asia, South America, and the Middle East. The company also confirmed all processes relating to new machines, the supply of replacement parts, and service operations will remain the same as before for customers.

“Heidelberg is aiming to achieve targeted

Zebra Technologies Asia Pacific senior vicepresident and general manager Ryan Goh said.

“By relocating and expanding the Zebra Experience Centre in Melbourne, we reinforce our dedication to providing exceptional service to our partners and customers, empowering businesses to enhance frontline efficiency with technology.”

Central to the new headquarters is the enhanced ZEC, nearly twice the size of the previous centre.

It is designed to transform customer and partner engagements by showcasing

Zebra’s products and through facilitating digital transformation.

“The Zebra Experience Centre in Melbourne integrates the latest technology to create an interactive environment for our customers and partners. Experiencing technology firsthand is invaluable, and our expanded ZEC will host events, workshops, and demonstrations, highlighting our commitment to innovation for a connected frontline, asset visibility, and intelligent automation,” Zebra A/NZ and India sales vice-president Tom Christodoulou said.

growth through M&A activities in attractive market segments. This acquisition underscores our credentials as a full-range supplier for our customers in the packaging and label industry, including service, and gives us exclusivity in a growing market,”

Heidelberg CEO Jürgen Otto said.

“As a systems integrator, we cover the entire value chain of a packaging print shop –on a fully integrated and networked basis – to ensure production is highly productive. Polar Mohr systems play a key role in this context.”

Dating back to the 1950s, the partnership

between Heidelberg and Polar Mohr has been successful for both businesses. Polar Mohr develops and manufactures the systems, while Heidelberg has been responsible for large parts of the sales and service activities.

The Polar Group companies, owned by SOL Capital Management, will continue to operate as a partner of Heidelberg for the future development, production, and assembly of Polar Mohr systems.

The two parties have agreed that the details of the agreement will remain confidential.

Opal’s speciality packaging team has launched a ‘wonderland awash’ with vibrant colour, show-stopping design, and clever engineering – all made from cardboard and powered by cutting-edge digital technologies.

Spotlighting its end-to-end packaging capabilities, Opal’s Innovation Expo showcased new digital printing and cutting technologies that redefine the speed, flexibility and creative possibilities.

The event brought together customers, suppliers, designers, and creative agencies to experience first-hand how Opal’s design, manufacturing, and national delivery network can create bespoke, commercially effective and innovative packaging solutions.

A highlight of the expo was the national rollout of advanced digital printing and cutting systems from Kissel + Wolf, including the Revo and iECHO, integrated with the ESKO Automation Engine.

As part of a live demonstration of the new technology, attendees were immersed in a carefully staged experience. Their journey began with their photo being taken in front of a striking laneway scene.

Attendees then stepped inside a life-size

Close the Loop has appointed two new CEOs to lead its North American and Australian business units as it commences a restructuring initiative aimed at simplifying its operations and sharpening of its focus.

Kesh Nair, former Close the Loop Australia general manager of recycling and renewed solutions, has been promoted to CEO of the Australian operations. Nair also joins the board as an executive director.

Close the Loop said Nair has been an integral part of the group for more than 17 years, beginning his career with the company as IT systems manager and serving as chief information officer.

Throughout his tenure, Nair led numerous strategic initiatives, including new product development, public relations, and the oversight of sales and marketing teams. More recently, he has been instrumental in expanding the company’s ITAD capabilities and cultivating key partnerships across Southeast Asia.

cardboard house filled with creative and innovative packaging products, before moving to the factory floor to see Opal’s newest technology in action, including the high-speed Nozomi printer, Revo digital press, Highcon Laser cutting technology and iECHO cutting systems.

By the time the attendees reached the end of the Expo tour, their photos were printed, cut and finished in under 20 minutes, as a vivid reminder of the speed and quality now achievable with Opal’s printing technology. These technologies enable short- and medium-run print jobs, rapid prototyping and customised solutions for retail point of sale displays, specialty packaging and promotional and seasonal product campaigns – capabilities that were previously challenging to achieve in Australia at scale.

Opal speciality packaging Victoria regional general manager Paul Godenzi said Opal’s point of difference is its ability to provide

“Kesh is widely respected for his diligence, principled leadership, and steadfast commitment to excellence. His deep understanding of our operations and passion for our mission makes him the ideal leader to drive the next phase of growth and innovation in the region,” Close the Loop said.

Matthew Zimmer has been named as Close the Loop CEO of the North American business units, which include Close the Loop Renewed Solutions, Close the Loop Inc., and Close the Loop Plastic Recycling.

“Zimmer brings with him a wealth of experience and a proven track record in the

customers with fast, high-quality, striking printing solutions.

“The same print technology on show has been rolled out at Opal speciality packaging sites in New South Wales, Queensland and New Zealand, meaning customers can experience consistent, vibrant, high-quality printing across multiple locations, which can deliver freight efficiencies,” Godenzi said.

Kissel + Wolf managing director Jamie Weller, said Opal’s commitment and investment in advanced digital technology across multiple sites is a bold step that sets a new benchmark in the industry.

“We’re proud to collaborate with Opal to supply innovative digital solutions across multiple sites,” Weller said.

Attendees experienced the technology in action, met with the teams behind Opal’s creative and structural design, and explored a showcase of printed packaging solutions for diverse industries.

international ITAD industry. His deep industry knowledge and results-orientated leadership make him uniquely positioned to guide Close the Loop Group’s strategic growth initiatives in North America,” the company said.

“A decisive and results-driven leader, Matthew has consistently delivered strong business outcomes – boosting sales, enhancing profitability, and creating longterm value for the organisations he has led.

“His focus on operational excellence and innovation aligns perfectly with Close the Loop’s mission and growth ambitions.”

The company also said Lawrence Jaffe has stepped down from his role as interim CEO and from the board, and has assumed the role of chief commercial officer, with a focus on corporate development initiatives and portfolio optimisation including exiting noncore and unprofitable business segments.

“We are at a pivotal point in our development with several significant growth initiatives we are executing on. We are enthusiastic and excited about Matthew and Kesh’s respective appointments and confident both will make a significant impact to the success of Close the Loop,” Jaffe said.

Orora has partnered with Velox Digital and installed the new Helio solution at its Dandenong facility, transforming the way it designs and decorates cans

Orora recently installed Helio, a high-speed digital can printing solution, at the manufacturer’s Dandenong facility in Victoria, with the technology now in production.

Orora partnered with Velox Digital, an Israel-based global developer and manufacturer of industrial-grade direct-to-shape digital decoration solutions, to install this machine, which is the first digital printer of its kind by a major can manufacturer in the Southern Hemisphere.

Representing a significant innovation for the beverage packaging market across this region, Helio utilises direct-to-shape digital printing technology, unlocking endless possibilities in colour and texture for unique can design and decoration at 500 cans per minute.

Following successful implementation and commissioning at the Dandenong site, the print solution is now operational and producing custom decoration solutions for customers across categories including carbonated soft drinks, craft beer, Ready-To-Drink alcohol (RTDs), sparkling water and kombucha.

Eliminating the need for long lead production times associated with traditional can decoration and printing methods, Orora Cans executive general manager Chris Smith said customers will benefit from quicker turn-around times, as well as smaller minimum quantities – ideal for promotional campaigns, new product launches, and special events.

“As the largest can maker in the region that partners with some of the world’s and Australia’s biggest brands, this investment was about driving innovation for our customers, as it’s critically important to them,” he said.

“With the Helio solution, we’re able to provide them with infinite colour, infinite varnish, texture, and matt or gloss finish, all at speed, which takes production times from weeks to minutes, in any can size.

“That means our customers can achieve decoration that’s unachievable anywhere else, and randomisation for smaller minimum quantities, which is really valuable.

“Further to that, Helio plays a huge role in the marketing mix for a customer.

“It expands the thinking of our customers and unshackles the limits of how they think of marketing promotions using beverage cans.

“With the potential for every single can to be unique, it delivers on things like personalisation, one-in-X can frequencies, and can keepsakes. We just see this as another strong leg in a customer’s innovation marketing spend.”

Orora announced the Helio installation in December 2023 with full deployment initially expected by Q3 2024, but due to conflicts in the Middle Eastern region, shipping and install was delayed.

“We took a decision to invest in this leading global technology. It’s certainly the fastest producing, most flexible technology of its kind that exists. Unfortunately, when Velox Digital constructed the machine and it was ready to be dispatched, there was a conflict in the region, which delayed the machine getting to Orora. No one could have anticipated that,” Smith said.

“It took some time, but we were delighted when it got on the ship and arrived here at

Dandenong in April. Between then and now, we’ve had to commission and fine tune the machine, and perfect image prints.

“It’s now doing everything we know it should do, and we’re looking forward to getting the first cans using Helio out in the market.”

Victorian minister for industry and advanced manufacturing Colin Brooks visited the Orora Cans Dandenong site shortly after Helio was installed to celebrate the first cans to be decorated using the machine.

“Victoria is leading the way in advanced manufacturing, and Orora’s Helio technology is a great example of how local innovation is transforming global industries,” Brooks said.

“This investment is not only delivering cutting-edge packaging solutions but also supporting skilled jobs and strengthening our state’s manufacturing capability.”

In support of the benefits of the Helio technology, member for Dandenong Gabrielle Williams said, “It’s fantastic to see advanced manufacturing thriving in Dandenong, with Orora’s new technology creating local jobs and driving innovation in the heart of our community”.

The introduction of Helio follows the installation of an $80 million multi-size can line at Dandenong, which was completed in June 2023.

In addition to this development, Orora also recently completed the installation of a new $114 million multi-size can line at its Revesby manufacturing facility in NSW. Construction is underway to install a new $135 million classic size can line at its Rocklea manufacturing facility in Queensland.

Smith said these projects form part of a comprehensive capacity expansion program to meet customer supply requirements over the coming years, as the aluminium can format has become an increasingly popular beverage packaging format amongst consumers.

“These investments will ensure Orora Cans is well positioned to meet the needs of our customers over the next five years and beyond. Cans are a terrific, highly sustainable packaging option, convenient for many occasions. Importantly, aluminium is an infinitely recyclable material, making cans an even more compelling choice for existing and new beverage offers,” he added.

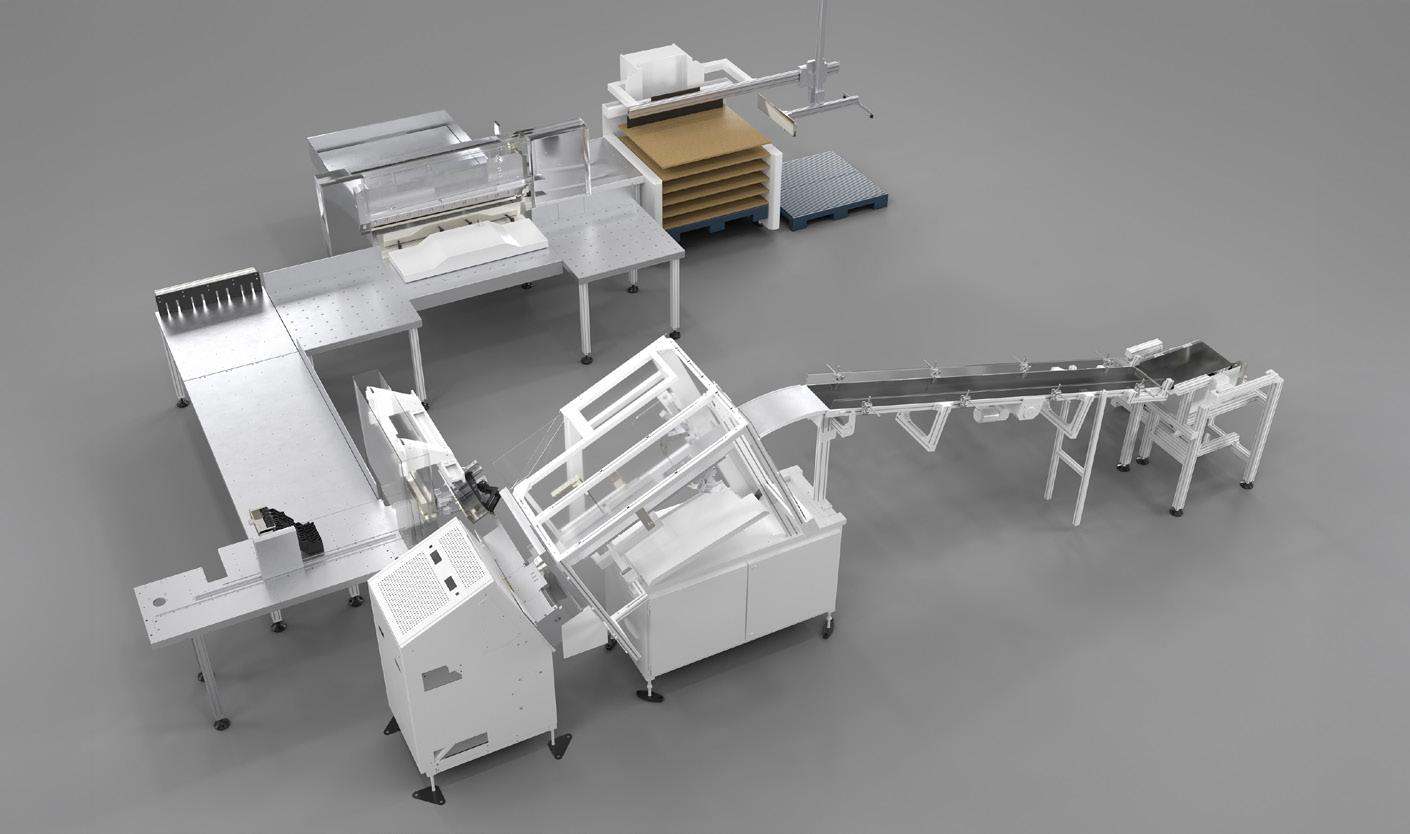

The new Pakko headquarters represents a smarter manufacturing environment, improved turnaround times, upgraded machinery and technology, as well as enhanced spaces for the team to do its best work

Brisbane-based packaging manufacturer Pakko is entering the next chapter of its growth, having just moved into its new headquarters in Virginia. This milestone marks a new era for the team — one that brings space to grow, streamline, and explore new possibilities

while staying true to the values that have shaped Pakko since day one.

Pakko realised it had outgrown its former Geebung site when machines kept getting pushed closer together and new mezzanines were built just to create more

room. After maximising every square metre, it became clear the business had to move to keep up with its growth.

“We were outgrowing the old premises. As our team, technology, and customer base expanded, it became clear we needed a purpose-built factory to match the scale and ambition of the business,” Pakko CEO and founder Nina Nguyen said.

Nguyen and the management team had been planning the move for about two years, but the stars aligned very quickly when this Virginia site became available.

“We had just started to think about expansion into Europe, and I had just visited Dubai to set up a hub. When this building came up, it felt meant to be, so we took a leap of faith, made an offer, and it was accepted,” she said.

“This new place is a blank canvas; we’re still retrofitting it to our needs and it’s a new learning experience.”

Leaving Geebung, however, was bittersweet.

“It was Pakko’s first home and it’s where I spent countless late nights, especially in the early days. That place holds many memories. It will always be part of our story, but this move was much needed for our future,” Nguyen said.

Previously a biscuit manufacturing site, the new Pakko headquarters is just two streets away from the old one. Sitting on a 5,335 square metre lot and spanning over three levels including a mezzanine and rooftop area, the new site is about three and half times bigger than the previous one.

However, according to Nguyen, the move isn’t just about more square metres. It’s about creating a smarter manufacturing environment, improving turnaround times, investing in better machinery and technology, and building spaces where the team can do its best work.

The move took eight months of renovations and layout planning before

Pakko officially settled in August. The team designed the space around workflows –from production lines to offices – to ensure the facility supports both current operations and long-term growth.

Among the upgrades are streamlined production lines and clearer communication between design, print, and finishing.

“This means faster turnaround times, better quality control, and smoother communication,” Nguyen said.

The move also supports Pakko’s growing interest in direct food contact packaging – a natural fit given the site’s former use. With sanitisation stations already in place, Pakko can continue expanding its work in food, health, and government packaging, which began when the company produced COVID-19 test kit boxes during the pandemic.

Today, the entire Pakko team of 25 employees and all major equipment have been relocated, including the Hanway HiJet2500 digital inkjet printer, foiling machines, folder gluers, die cutters and laminators. The new layout reduces forklift travel, while multiple electric forklifts and LED energy-efficient systems support Pakko’s ongoing sustainability goals.

“We’ve redesigned production lines to reduce bottlenecks, introduced clearer workflows between design, print, and finishing, and will be further investing in our development team to introduce technology and AI to automate administrative and sales tasks. This means faster turnaround times, better quality control, and smoother communication channels,” Nguyen said.

The extra space also enables Pakko to bring in more designers, operators, and customer support staff as demand grows.

In addition, Pakko has incorporated sustainable features into the new HQ, including LED lighting, sensor activated energy-efficient systems, and recycling stations throughout the site.

It’s also exploring solar options for the next phase.

“This entire move was a true team effort; everyone had a part to play,” Nguyen said.

“Our general manager Tony Ong was right there in the thick of it, and hands-on every step of the way, dedicating long hours to ensure everything functioned as planned. Our operations manager Kyle Wagner mapped out the 3D layouts and electrical plans to make sure everything flowed perfectly on the floor. Our senior IT developer Corey Fry handled the telecommunications and web servers to keep our systems and machines communicating seamlessly.

“Every team member took charge of their own area, and every decision we made was a collective one because it impacts us all.”

Pakko was born from a story rooted in family, resilience, and a deep desire to make a difference. When Nguyen’s parents decided to leave their comfortable home in Western Sydney to pursue farming in the Lockyer Valley, in regional Queensland, Nguyen supported their decision from afar.

It was on their farm that the idea for Pakko first took shape. Nguyen’s parents, who cultivated a variety of Asian vegetables, including snow peas, Japanese pumpkins, winter melons, snake beans, and okra, faced a constant challenge – finding packaging that was durable, moistureresistant, and capable of withstanding Australia’s harsh and varied climate.

Motivated to help, Nguyen began exploring options to import packaging from overseas. However, she soon encountered significant challenges, language barriers, fluctuating exchange rates, high minimum order quantities, inconsistent quality, and long delivery lead times of six to eight weeks. The experience was disheartening, but it also revealed a much bigger problem.

Nguyen realised that the difficulties her parents faced were shared by countless Australian farmers and small businesses who relied on imported packaging. Nguyen saw an opportunity to create something better, a local solution that could deliver high-quality, Australian-made packaging with faster turnaround times and no minimum order requirements.

With her parents’ financial backing and encouragement, Nguyen founded Pakko in 2017 as a cardboard manufacturing business designed to empower Australian growers and businesses with accessible, reliable, and sustainable packaging solutions.

From its inception, Pakko was built on more than just manufacturing. Nguyen envisioned a company that would play a vital role in revitalising Australian

manufacturing, one that would educate and guide businesses on how packaging could enhance brand value, improve customer satisfaction, and drive growth through thoughtful design and the unboxing experience.

Today, Pakko stands as a testament to Australian innovation and determination. What began as a daughter’s effort to help her parents has evolved into a thriving business that continues to support and inspire Australian enterprises, proving that great packaging can do more than protect a product. It can tell a story, spark emotion, and drive meaningful change.

Within just two years, Pakko acquired folding and gluing specialists, Glue4U in 2019, resulting in all custom packaging manufacture, printing, and supply being wholly handled under one roof at Pakko’s former factory.

Then, more recently, it acquired Boxes R Us in 2024, bringing in its key machinery and database to expand business capabilities. Nguyen said the acquisition wasn’t on the radar.

“It wasn't something we were looking at, but when the opportunity arose, I looked at Boxes R Us and found it to be a unique company. The way it operated was, storing a lot of pre-cut items stored on the shelf, which a customer selects from, and using a foiling machine to foil on corrugated boxes. It complemented Pakko so well as it’s short-run bespoke packaging for emerging start-up businesses,” she said.

“These companies have expanded our customer base, diversified our capabilities,

and strengthened our position as a leading Australian manufacturer. They’ve also helped us maintain local jobs and skills that might otherwise have been lost.”

In 2024, Pakko also broadened its offerings to include foiling on corrugated boxes, short-run digital printing, and eco-friendly pallet solutions through a partnership with Husk Pallets. Geographically, it’s now servicing every state in Australia with faster lead times.

But, regardless of its growth or size, Pakko has been built on three core values from the very beginning:

• Customer focus: Creating packaging solutions that empower brands

• Innovation: Finding new, smarter ways to manufacture

• Community and sustainability: Supporting Australian jobs and reducing its environmental impact.

This laser focus has resulted in Pakko being recognised for several awards. In addition to multiple ProPrint Awards over the years, Nguyen won the PIDAs 2021 Young Professional of the Year award, the 2021/2022 Young Businessperson of the Year Lord Mayor Business Award, and the 2022 Multicultural Entrepreneur Lord Mayor Business Award.

As a company, Pakko was the Telstra Business Awards 2022 State and National Winner for Progressing Australia.

Onwards and upwards

Nguyen has a sharp vision for Pakko’s future, saying she wants the company to be

a manufacturer that’s willing to collaborate, share knowledge, and push boundaries.

“We want to help lift the standard of packaging and manufacturing in Australia,” she explained, adding that Pakko aims to move away from being just a packaging manufacturer into a true solutions partner.

According to Nguyen, this is driven by customer demand, environmental responsibility, and a belief that Australian manufacturing can be innovative and competitive globally.

“These three things shape every decision for us. Standing in between being a traditional manufacturing and technology company, we’re now building a hybrid model that blends the best of both worlds,” Nguyen added.

“Our investment in R&D, digital tools, and collaborations is designed to create value not only for our clients but also for our trade partners.”

The next big thing for Pakko is smart manufacturing, integrating technology, sustainability, and creativity to deliver packaging solutions that go beyond the box. It’s also exploring international opportunities for its processes and products as the company advances with its Estimating System (ES) and Interactive Design Platform (IDP) systems.

Pakko has already taken the first step in this direction with its chatbot ‘Vira’, designed in-house in 2023 to deeply understand all aspects of Pakko’s operations and processes.

“Vira was built to do more than just provide answers; it listens. Most of the data we get from Vira comes directly from customer questions about packaging, processes, and capabilities. We analyse these questions to spot patterns, which then shape how we educate our customers,” Nguyen said.

“When we see the same questions coming up internally, it flags where our processes or communication need improvement. This feedback loop lets us fix bottlenecks, simplify workflows, and continuously improve both our customer experience and our operations.”

Pakko’s also investing locally, training locally, and sourcing locally wherever possible to ensure the Australian manufacturing and packaging industry remains strong and vibrant for years to come.

“By keeping our production in Australia, we reduce lead times, improve quality, and keep money and skills in the local economy,” she added.

The visionary behind iconic Ferrari, McLaren, and Maserati car designs explores how emotionally intelligent design is redefining modern luxury

At the heart of luxury lies a delicate balance between desire and accessibility, something not necessarily needed, but undeniably aspired to.

Frank Stephenson, whose unique perspective as a lead designer for some of the world’s most prestigious brands including Ferrari, McLaren, and Maserati, allows him to anticipate future trends in luxury, which he addressed at London Packaging Week in October.

Stephenson continues to expand the limits of what’s possible through Frank Stephenson Design, a studio that fuses innovation, sustainability, and emotional intelligence across a wide range of industries.

At London Packaging Week, he discussed what truly makes these items desirable and, more importantly, achievable – the emotional pull that good design evokes. Stephenson emphasised that the allure of luxury is more than a product’s function – it’s about creating an immediate and undeniable connection.

For Stephenson, design is both a science and an art, where function must never be sacrificed for beauty, but where beauty is essential to the experience. He argues that the real magic of design lies in crafting something that stirs emotions and sparks a connection from the very first encounter.

“Whether in the sleek lines of an automobile or the intricate detail of luxury packaging, the goal remains the same: to evoke that unmistakable feeling of love at first sight,” he said.

“In the luxury market, packaging isn’t just a wrapper – it’s a story, a signal of value, and a bridge to the consumer’s desire. It’s not about extravagance, but about subtlety, uniqueness, and attention to detail.”

The true challenge, he says, is designing a product that doesn’t merely meet expectations, but exceeds them, drawing consumers in with its magnetic, emotional appeal.

For Stephenson, good design is not about overcomplication but about

achieving perfect harmony between form and function – creating something timeless that resonates deeply, emotionally, and intuitively.

The allure of luxury design

But what makes luxury both desirable and attainable? According to Stephenson, the key lies in the emotional aspect of design – and the moment of connection is immediate, not gradual.

“The real trick is designing something desirable. And desirability shouldn’t develop over time – it should happen almost immediately. That moment of attraction, that first impression, is crucial,” he said.

He emphasised that a product shouldn’t require time to warm up to, adding that the “connection should be instant”.

For Stephenson, this instant attraction is the true mark of a design that stands out and stirs something within the consumer and compels them to act.

Packaging, too, plays a central role in this emotional connection and desirability. Stephenson said he has noticed how important packaging is for luxury items but cautions that luxury packaging doesn’t have to be extravagant – just thoughtful and purposeful.

“Take whiskey, for example. It’s not always the bottle that sells the whiskey. The bottle design – the packaging – is incredibly well considered, debated, and executed,” he said.

“This attention to detail and the seamless fusion of product and packaging are vital to a consumer’s experience and decisionmaking process. Product and packaging have to speak the same language, and both must be equally strong.

“Packaging can elevate a product’s desirability when done right, making it not just about what’s inside but the entire experience. Desirability stems from the complete package – not just the product itself.”

Stephenson said in today’s world, consumers are overwhelmed by choices, adding that the modern consumer has been exposed to so much already.

“You walk into any supermarket, shopping mall, or retail space and find countless versions of products that essentially do the same thing, just packaged or designed differently,” he said.

“This abundance of options has made design, not just function, the deciding factor for many. However, the creativity of designers continues to stand out, pushing boundaries in a way that AI cannot replicate – AI still can’t replicate the unique creativity of the human mind.”

Unfortunately, Stephenson believes this creative potential is often stifled in the design process, particularly due to shortcomings in education.

“Right now, we’re seeing a lot of work that’s different – but shockingly unappealing. This partly stems from a flaw in the design education system, where there is a lack of emphasis on fundamental design principles such as uniqueness, character, and proportion,” he said.

“As digital tools become more dominant in design, there is a growing risk of homogenising creativity, reducing the distinctiveness of each designer’s work. In the past, you could often recognise a designer’s ‘thumbprint’ on a product. Yet, this signature touch is becoming less common.

“We’re losing that recognisability, that human touch,” he said, highlighting how

the commodification of design through digital tools erodes the essence of what makes a luxury product luxurious.

For Stephenson, the solution lies in a return to the organic and natural forms that inherently appeal to human sensibilities.

In the world of luxury design, he advocates for uniqueness and subtlety – designs that remain desirable without resorting to shock value.

“Shock value rarely works. The goal should be to push boundaries while staying within the limits of what people can immediately connect with,” he mentioned.

The essential role of packaging design

Stephenson stressed the importance of considering the full experience when discussing packaging design, noting that packaging is a profession in itself.

“I don’t think anyone serious about design creates packaging without considering the full experience: who the consumer is, what kind of product it is, and how the packaging contributes to the overall impression,” he said.

For Stephenson, packaging is not just about containment; it’s about creating an emotional connection with the consumer. He argues that packaging should not feel disposable or unimportant.

“A great designer considers whether the packaging is something the consumer would want to keep. In some cases, it’s not even something you can separate from the product – the packaging becomes an essential part of the design,” he said.

This level of design, according to Stephenson, requires constant attention to detail and an openness to new technologies.

“Technology is now opening up new possibilities – especially with things like

3D printing. You can create complex forms without overthinking manufacturing constraints,” he said, pointing to designs like Ross Lovegrove’s Ty Nant water bottle as an example of how simplicity and innovation can elevate a product.

“It was stunning in its simplicity, and to me, it’s a design icon,” he said, highlighting how the bottle’s packaging became just as significant as the product itself.

“The evolution of materials and production methods also means that luxury is no longer defined by rarity alone. Now, luxury might involve sustainable materials –biodegradable leathers, Kevlar, or innovative composites.”

For Stephenson, this shift toward sustainability is deeply tied to the designer’s responsibility to improve the world. He believes that design involves working within boundaries, including considering the environmental impact of materials and production methods.

“Design, by its very nature, involves working within boundaries. Without limits, you’re just creating art – free expression without constraints,” he said.

“This perspective aligns with the growing awareness among consumers who are increasingly informed and responsible when it comes to environmental concerns. It’s our job to exceed expectations – not just to meet them.”

For Stephenson, design is not merely about replication but innovation – creating products that didn’t exist before, shaped by a responsibility to future generations.

With his unique global upbringing and exposure to diverse cultures, he brings a broad perspective to his work, fostering a deeper understanding of people and the world. This perspective undoubtedly shapes the thoughtful and intentional designs he’s known for.

Labelexpo Europe 2025 was a hotbed of innovation, with leading and forward-thinking exhibitors showcasing their latest and greatest technologies

Labelexpo Europe 2025, held for the first time in Barcelona in its 45-year history, attracted record visitors and international participation, with organisers saying it was “the biggest show to date, both in exhibition space and attendance”.

Show statistics revealed over 43,000 net sqm of exhibitor space and more than 37,000 attendees.

This year, Labelexpo Global Series also announced its transition to the new brand, LOUPE, beginning with the Americas show in September 2026. The LOUPE portfolio remains labels-focused while acknowledging the industry’s expansion and diversification in the past decade into flexible packaging and in-line folding cartons.

The next European edition of the show will return to Barcelona from 5-8 October 2027 as LOUPE Europe 2027.

Labelexpo Europe 2025 served as a hub for innovation, with leading exhibitors showcasing the following cutting-edge technologies:

BGM took to Labelexpo Europe to showcase several of its new and latest technologies, including its 370eDSRT Easy Load Die Cut Slitter Semi-Automatic Turret Rewinder.

The 370eDSRT boasts rotary die-cutting speeds of up to 250m/min and features a two-spindle semi-automatic turret that splices material and advances tails onto cores. A tail layon system applies tails to the cores during operation.

Dies receive support from a bottom guide rail system for effortless loading, improving setup time while reducing damage from incorrect loading. The dual-spindle design allows operators to pre-load cores on one spindle while the other rewinds. The company said users report productivity improvements of up to 60 per cent.

At the event, BGM also launched a 22-inch finishing system, the BGM Elite 550iSR, featuring large capacity unwind with integral roll lifting and CAP constant air pressure technology. The Elite 550iSR incorporates BGM’s latest GPS gear positioning system, enabling operators to load master rolls into the braking system position with self-alignment requiring no operator intervention.

BGM is distributed in A/NZ through Nekkorb. Bobst

Bobst shone a spotlight on applicationdriven demonstrations and diversification opportunities at Labelexpo Europe, including the launch of its FlexJet module –

described as an industry-first, all-digital label solution that allows converters to produce pure digital multilayer labels.

The new module also offers the ability to print digitally on the glue-side and the liner, opening the doors to highermargin niches and helping converters respond more easily to rapidly changing market dynamics.

Bobst launched the FlexJet module as a new option for its Digital Master 340 and 510 platforms, expanding application offering and boosting productivity for label converters.

Seamlessly integrating into the Digital Master series platform, it creates digital multilayer solutions featuring multiple digital print units working inline. This fully integrated workflow enables single-pass production of complex label jobs such as multilayer, glue- and back-side printing.

The new FlexJet module, currently equipped with one black printbar, is powered by Bobst Inkjet Technology with 1200dpi by 1200dpi resolution delivered at full process speed using Fujifilm Dimatix Samba printhead technology. This enables converters to print independently on the front, back, liner, or adhesive surfaces, all inline, in a single pass.

Bobst is distributed in A/NZ through Print & Pack Australia.

Canon confirmed at Labelexpo Europe 2025 that it is in the final phase of developing its first water-based, five-

colour (CMYK + white) inkjet digital label press, the LabelStream LS2000.

Canon Europe marketing and innovation senior manager Edoardo Cotichini said, “The reality is that we’re in the final phase of developing the product and are in the delicate phase where we’re expanding, especially the media validation, of the product ourselves. We made the decision of continuing those developments and not interfering with it”.

Based on Canon Qualinx technologies, the LabelStream LS2000 is designed for production at speeds of up to 40m/min with a maximum printing width of 340mm, making it ideal for label converters looking for a reliable, sustainable, productive and easy-to-operate digital press.

Suitable for a wide range of applications, including labels used on the exterior of food packaging and everyday items such as food and beverages, personal care, household goods and electronics, the LabelStream LS2000 inks are compliant with several food safety standards.

In addition, Canon showcased the Edale CartonLine, a single-pass flexographic carton production line that offers high quality printing, multiple in-line embellishments and in-line flatbed finishing.

With this production line, Edale, a Canon company, demonstrated how flexo can streamline existing carton production processes by reducing high labour costs, minimising work-in-progress and freeing up valuable factory space to unlock new revenue opportunities and enable more efficient operations.

Canon is distributed in Australia through Canon Production Printing.

At Labelexpo Europe, Cerm unveiled a new and fresh-looking user interface for its MIS for labels and packaging, featuring its Cerm 7.33 software.

The user interface can be tailored to the needs of a specific group or department, and individual users can also customise their

own user interface. In addition, the latest version of the Cerm MIS comes with further improvements of the Production Flows concept. Production Flows is a product configuration and description technology, tailored to complex label solutions and folding carton. It details the entire production process from simple linear steps to complex multi-run and multi-part workflows with converging production lines, no matter how complex a production process is.

At Labelexpo Europe, Cerm also identified new standard partner integrations that it says strengthens its leadership in connected workflows.

This includes:

• The Durst Analytics partner integration (more details below) that transfers production data from Durst Tau label printing systems directly and seamlessly into the Cerm MIS Software.

• The MPS partner integration that delivers real-time production feedback from MPS presses directly into the Cerm MIS Software.

Dantex showcased a variety of technologies including the upgraded PicoJet 1200 DRS digital UV inkjet press.

The PicoJet 1200 is built on a modular platform – so is available as a reel-to-reel press or as a bespoke hybrid system –allowing the incorporation of features such as semi-rotary finishing, flexo, lamination, and slitting station options. It can also be custom configured in a variety of base and additional colour stations.

The introduction of DRS (Dynamic Resolution System) to the PicoJet offers eight grey levels, the highest currently available in the UV inkjet label sector, according to Dantex. In addition, the PicoJet uses a 2.5pl ink droplet size, offering exceptional ink coverage without any loss of quality or colour integrity. It delivers high-quality results even on challenging jobs at an effective resolution of 1,200dpi.

The PicoJet also uses an energy-efficient LED final cure with a temperature-

controlled backup roller for temperaturesensitive substrates. In addition, it incorporates static control, web cleaning, and corona treatment for wide choice substrate printing capability.

Dantex also used Labelexpo Europe as a platform to unveil its most advanced sustainable water-wash inline plate processing solution to date, the Aqua X.

Engineered for use with Dantex’s Aquaflex plate range, the Aqua X is a fully automatic, ultra-high-speed, water-wash system that aims to set new standards in sustainable, solvent-free flexographic processing.

Dantex is distributed in A/NZ by Nekkorb.

Domino took the wraps off two new machines at Labelexpo Europe, including the new entry level Domino N410 press and an upgraded N730i digital UV inkjet label press.

The Domino N410 prints at speeds of 30m/ min at 600dpi quality with white and CMYK. Configurable to print up to five colours, the CMYK+W combination makes it possible to achieve a wide pantone spectrum and a high white opacity.

In addition, it features energy-efficient UV LED curing technology, offering lower power consumption for a more sustainable and cost-conscious operation.

“The N410 is a great addition to the Domino family. If you’re thinking about digital as your next step and don’t want to make a huge investment into the bigger machines, this is a good way to step into digital with GMS Pacific, a brand you can trust that has been around for more than 50 years,” Domino’s Australian distributor GMS Pacific managing director Andrew McNamara said.

GMS Pacific will start taking orders for the N410 in October/November for A/NZ, with delivery by the end of Q1 or early Q2.

The N730i was officially launched to the market at the last Labelexpo Europe as Domino’s flagship press but since been upgraded from a 70m/min press to a

90m/min press at full 1,200dpi quality. The enhanced N730i is already available in A/NZ in either a CMYK + two whites configuration or CMYK + orange + violet + two whites option.

compatibility for substrates from paper to films and aluminium foils within a 20 to 500µm thickness range, ensures application diversity across labels and flexible packaging.

The machine architecture, based on the proven Tau RSC design, introduces intuitive LED status displays, improved ergonomics, and optimised serviceability. A redesigned cooling system, electrical cabinet, and improved component accessibility simplify handling and maintenance. The ergonomic inspection unit, equipped with D50/RGB lighting and flexible adapters for inspection systems, further enhances process reliability.

The Durst Group unveiled its latest highlight for the labels and flexible packaging industry: the Tau G3 Portfolio. With the two models – Tau G3 Core and Tau G3 Peak – Durst is setting new benchmarks in productivity, ease of use, and print quality, under the guiding principle “Reliability, Simplicity, Performance”.

Durst Group director global sales labels and flexible packaging Thomas Macina said, “With the Tau G3 platform, we are opening the next chapter in digital labels printing. Our customers benefit from maximum print quality, easy operation, integrated software solutions, and a platform designed for reliability and future-proof performance”.

The new Tau G3 platform delivers 1,200dpi by 1,200dpi native resolution for razorsharp print quality. In terms of speed, the Tau G3 Core reaches 61m/min, while the Tau G3 Peak achieves 80m/min and can optionally be expanded to 100m/min, depending on configuration. Print widths range from 244mm to 510mm, offering scalability for different production needs.

For maximum colour flexibility, the Tau G3 supports CMYK plus extended gamut options – Orange, Violet, Green, and White – available with both UV and LED curing. This versatility, combined with

The Tau G3 also integrates the new Durst ARC (Automatic Register Control) for realtime colour registration, waste reduction, and quality enhancement, and the new Durst MEP (Material Edge Protection), which safeguards printheads with optical edge sensors and protective plates.

In addition, Durst HAWK AI, Durst’s intelligent monitoring and assistance system, can be included to automate the colour-to-colour register and to provide closed loop nozzle correction during printing.

The official market launch for the press is planned for Q2 2026.

Alongside the Tau G3, Durst continues to offer the Tau 340 RSC E as an entry-level solution, its proven Tau RSCi high-end model, and the hybrid systems KJET and XJET for advanced production requirements.

Durst Group CEO and co-owner Christoph Gamper said, “With more than 550 highend Tau systems in the field and over 4,200 active inkjet installations worldwide, Durst is the leading force in digital production.

“The Tau G3 production platform is the logical next step – setting new benchmarks in innovation, in ecological and economic leadership, and in the integration of AI. It represents the future of intelligent and sustainable production”.

At Labelexpo Europe, Durst also announced a new partnership with MIS specialist Cerm. With the newly developed connector between Durst Analytics and Cerm MIS, production data from Durst Tau label printing systems can now be transferred directly and seamlessly into the Cerm MIS Software.

“The demand for full integration of production and business data has been strong in our industry for years,” Durst software and solutions product manager Serge Clauss said.

“By connecting Durst Analytics with Cerm, we are now offering our customers

a solution that delivers maximum transparency and control.”

Durst said the partnership is a strong signal of the innovative strength of both businesses, adding that it reflects their joint commitment to providing customers with forward-looking solutions that create sustainable added value and strengthen the competitiveness of the label industry.

and Pantone coverage. A White ink option will soon be made available, and will be field-upgradable.

As it is equipped with newly developed PrecisionCore printhead and optimiser liquid technology, the L-5034 delivers a native resolution of 1200 dpi, ensuring outstanding image quality for fine details, small text and smooth gradations.

Fujifilm took to Labelexpo Europe to introduce new technologies, including its new ‘5UPER COLOUR’ 5-colour press.

Epson launched its new water based digital label press, the SurePress L-5034, confirming three units have already been sold worldwide.

Epson’s largest global customer, Osaka Sealing Printing (OSP) from Japan, was the first to purchase the L-5034 among the initial three buyers.

Through the SurePress L-5034, Epson said it further underscores its commitment to digital labels and to offering print businesses flexible and more sustainable options to support their shift from analogue to digital printing.

The new SurePress L-5034 inherits the features of the previous SurePress series in a new, water-based ink digital label printing platform, engineered for higher productivity without compromising print quality, for label converters looking to increase productivity and operational efficiency.

The SurePress L-5034 also uses an advanced, newly developed six-colour water-based ink set (CMYK + Orange and Green), offering an extensive colour gamut

Esko unveiled its latest innovation at Labelexpo Europe – the Esko XPS Spark 4835, a new plate exposure unit that aims to deliver on the unique combination of performance and a small footprint.

Designed for packaging converters and trade shops seeking precision, sustainability, and simplicity, the new XPS Spark combines single-side UV LED exposure with an optional integrated UV finishing device (UVA + UVC), all in one compact and optimised package.

Esko director of flexo product management Pascal Thomas said, “The XPS Spark is designed to make high-quality LED plate exposure accessible to a broader range of flexo users. As well as delivering optimum quality, the XPS Spark speeds up work with a full LED exposure surface. This also improves energy efficiency and lowers operating costs while contributing to sustainability objectives by eliminating tube waste”.

Following the official unveiling at Labelexpo, external testing will begin later this year, with a worldwide release planned for the second half of 2026.

Ideal for packaging producers, the ‘5UPER COLOUR’ press offers high-speed output, excellent media flexibility, and impressive print quality that rivals offset, thanks to advanced toner technology and highresolution laser imaging.

Fujifilm also presented new enhancements to its flagship digital flexible packaging press, the Jet Press FP790, which now offers extended compatibility for label applications, in addition to flexible packaging. The press has been upgraded to support faster throughput, a broader range of sustainable substrates, and new practical applications.

The Revoria Press SC285 digital press was also featured, showcasing pre-made pouch printing, offering brands and converters a high-speed, high-quality solution for shortrun, digitally printed pouch production.

A central focus of Fujifilm’s exhibition was also the official debut of FleneX Pro –a new concept in flexo plate processing, designed to challenge conventional workflows and enable greater production efficiency. This launch was accompanied by the introduction of two new flexo plate solutions, FleneX Midori and FleneX Pure.

Gallus, a subsidiary of Heidelberg, unveiled two new presses at Labelexpo Europe –one all-digital and one hybrid.

The new Gallus Five is a high-performance hybrid press built on the Gallus

Labelmaster platform. The new press offers 1,200dpi by 1,200dpi resolution and production speeds of up to 100m/min.

Built on Gallus’ modular System to Compose concept, the Gallus Five is available in 340mm and 430mm widths and is fully compatible with the existing Gallus Labelmaster portfolio. Meanwhile, its newly introduced SDC Pro semi-rotary die cutter offers high-speed cutting at up to 100m/min, rapid job changeovers, and optional cutting-depth adjustment.

The press incorporates the newly developed Heidelberg Saphira UV05 ink set – with a high-pigmentation formulation that significantly cuts ink consumption. It also delivers premium colour performance, covering up to 95 per cent of the Pantone colour gamut, while ensuring compliance with the latest ink safety regulations.

Serving the other end of the market is the new Gallus Alpha, a digital-only printing solution addressing the needs of converters looking for an efficient, costeffective entry point into digital printing.

Available in 340mm width, the Gallus Alpha roll-to-roll press comes in two configurations – four colour + white or sixcolour + white – and offers high-resolution printing of 1,200 dpi by 1,200 dpi at 65m/ min. Notably, the press offers a pure rollto-roll digital configuration for operational simplicity and seamless integration into existing production workflows.

Both the Gallus Five and Gallus Alpha are now available to order. The Gallus Five delivers within five to six months of ordering, while the Gallus Alpha is available to order now, with delivery expected five to six months from early next year.

including the DoseGuard inline UV monitoring and automatic UV dose control.

DoseGuard, powered by ICADtechnology, consists of a scanning optic (ICAD unit) which is mounted underneath each of the lampheads on a UV system, whether conventional UV Arc or UV LED.

DoseGuard continuously measures the UV light that reaches the substrate, across the entire width of the system, and will issue a warning if the level of UV output delivered to the substrate changes during production, for any reason.

DoseGuard also significantly improves the UV curing process by automatically adjusting the power of the UV lamps to maintain a target UV dose, independent of speed or UV lamp condition, even for multiple lamps on a single print or coating station.

Another Labelexpo launch was the next generation OxyGuard oxygen control system, which uses state-of-the-art technology to rapidly achieve and maintain the optimal curing atmosphere for low odour, low migration production, siliconisation and other high performance curing applications.

GEW is distributed in A/NZ by CS Graphics. Grafotronic

“This machine does up to 200m/min semi rotary, and the biggest point is that it’s a single anvil design, which means that you will have almost no waste and it’s uncomplicated to operate as well,” Grafotronic business development manager Morten Toksværd said.

The finishing equipment manufacturer also showcased its latest Grafotronic IQ, the compact SCF with semi-automatic turret, new high-quality Grafotronic Haptic embellishing technology and the Grafotronic Infinity fully automatic turret rewinder powered by Serame.

In addition, the company unveiled its next-generation Sci-Fi Laser, a fully modular laser finishing system available in roll-to-roll, roll-to-parts or hybrid versions, which offers digital converting capabilities for printed labels and stickers, while the new Haptic embellishing technology advances finishing capabilities.

Grafotronic is distributed in Australia by Maxteq.

Scan

see

see

GEW introduced several new technology advancements at Labelexpo Europe,

Labelexpo Europe marked the world premiere of the X-1 semi-rotary die-cutting unit, which Grafotronic calls “the fastest single-anvil die-cutting system in the universe, and the easiest to master”.

The X-1 features a single anvil design for enhanced control from setup to highspeed operation. The machine represents a significant development in semi-rotary die-cutting technology.

Hybrid Software has added another company under its umbrella, with the acquisition of Belgium-based software development and consultancy firm for the printing and packaging industry, Conics. The acquisition announcement was made at Labelexpo Europe 2025.

Conics specialises in partnering with customers to assist the selection and implementation of graphical software and bridges gaps with custom development and integration services.

Hybrid Software CEO Mike Rottenborn said, “With the addition of Conics, we strengthen our position in project management and consultancy. Conics’ experience in successfully delivering complex projects is a perfect complement to our existing expertise and is increasingly requested by printers and brands.

“In addition, Conics’ expertise in AI and in particular to their products are a perfect fit with our own offering for labels and packaging. We are planning to jointly develop even more innovative software

solutions that will have a significant impact on the labels and packaging industry.”

jAImes is the AI-assistant that supercharges customer request processing activities so that a converter’s team can focus on what matters.

Conics co-founders Frederic Vandelanotte and Dries Maerten said, “We will remain a separate business unit of Hybrid Software and will continue to operate out of our offices in Ypres, Belgium. We integrate software solutions from many industry vendors as required by our customers, and this will continue into the future”.

Konica Minolta

At Labelexpo Europe, Konica Minolta revealed the first details of its new AccurioLabel prototype, a system designed to push automation and productivity to new heights while addressing key industry challenges.

Building on the proven success of the AccurioLabel 230, this prototype is designed for mid-range digital label production.

With digital label production expanding at record speed, Konica Minolta said this prototype introduces an optional Intelligent Quality Optimiser (IQ) that simplifies workflows, enables longer print runs of up to 1,600 linear metres, and ensures colour registration accuracy even at full speed (23.4m/min).

Print resolution has also been raised to 1,200dpi by 2,400dpi, offering sharper, more vibrant output.

Visitors to Labelexpo Europe saw the technology alongside Konica Minolta’s full portfolio of digital label and packaging workflow solutions, showcased in partnership with MGI Digital Technology.

Other highlights include the AccurioLabel 230 (CMYK) for providers transitioning volumes from conventional to digital, the AccurioLabel 400 (CMYK + White), and MGI’s JETvarnish 3D Web 400 for digital embellishment.

Also featured on the stand was the MGI Octopus Web for hybrid digital cutting and finishing, and the GM DC350Mini Basic for semi-rotary die-cutting and lamination.

Under the motto ‘re:think what’s possible’, Kurz presented its latest machine developments for industrial label finishing.

Kurz had on display its DM-UNILINER 3D, presenting a platform for industrial digital 3D finishing of labels and other roll applications. The solution combines Digital UV spot coating and digital metallisation in a single, highly automated process for fine haptic effects, brilliant metallic highlights, or matte accents.

The modular system also allows for the integration of additional process steps such as a laminating station, a flexographic printing unit for applying UV-based primers, and a die-cutting station for the direct production of finished labels.

Thanks to its industrial design, exceptional productivity, and outstanding output quality, the DM-UNILINER 3D not only increases production capacity but also reduces time to market.

Kurz also presented the DM-FLEXLINER 3D in action for the first time – in a particularly realistic environment. With the new 360° demo tool, machine configurations were explored interactively and functions experienced intuitively.

For an authentic application scenario, the DM-FLEXLINER 3D was integrated into a Gallus One – the result of close cooperation with Kurz’s partner Gallus. This allowed visitors to experience digital finishing in a realistic production context.

Mark Andy

variable data printing press in the industry that’s built to increase productivity without compromising on quality.

The Digital Series HD is Mark Andy’s most advanced, fully scalable digital hybrid. Mark Andy says it runs any job at speeds of up to 146m/min, delivering on the capability to be both efficient and high quality.

The Digital Series HD HighSpeed 1200 press combines the power of production speed digital printing with the flexibility of inline converting. It is capable of faster changeovers, produces up to 20 per cent less waste, and streamlines job setup.

It also tackles more complex jobs with an extended gamut, as it can support 5-colour to 8-colour configurations including highopacity digital white, and provides support for diverse substrates and SKUs.

A modular design and seamless ProWORX Digital Front End (DFE) integration keeps the press competitive and workflows optimised, delivering additional productivity by streamlining pre-press workflow and colour management.

“This machine is the most productive inkjet machine anywhere in the market. What we’ve done is doubled our production speeds to 146m/min without any sacrifices to image quality or colour gamut – in full colour VDP,” Mark Andy chief technology officer Scott Warhover said.

“All of this functionality is available as a hybrid or roll-to-roll machine to maximise your production and performance.”

Mark Andy is distributed in A/NZ by CS Graphics.

MPS debuted its EF Packaging press platform at Labelexpo Europe, promising to bring its known performance to an even wider range of the flexible packaging market with the same precision, efficiency, and consistency users expect.

EF Packaging builds on MPS’ EF platform, adding enhanced mid-web capabilities, advanced automation, and robust connectivity through MPSConnect

for real-time performance monitoring and optimisation.

With EF Packaging, converters can expand into flexible packaging, wrap around and shrink sleeves, as well as in-mold labels –without compromising on speed, print quality, or efficiency.

The machine combines automation with MPS’ industry leading ink drawer system and E-sleeve, offering print stability and print performance at higher press speeds over a wide range of materials.

Some of its unique features include:

• A patented E-Sleeve system for predictable print quality with lower waste and longer lifetime

• A Slide-out ink drawer offering quick and ergonomics ink-change

• Crisp.Dot technology for superior print quality assurance

• MPS’ Tresu ink system with redesigned ink pump for optimised ink management and a small footprint for lower waste usages.

MPS is distributed locally through Nekkorb.

Screen

Screen showcased a technology preview model of its upcoming water-based ink label press with wider web width. The new Truepress LABEL 520AQ brings Screen’s proven water-based inkjet expertise to label production, delivering offset print quality with the efficiency and flexibility of digital.

Designed for converters facing rising production costs and growing demand for premium, sustainable labels, the 4-colour press with room for a 5th colour achieves a 1,200dpi by 1,200dpi resolution at production speeds of up to 100 linear metres per min on a 520mm web with 508mm printing width.

Powered by Screen’s proprietary Truepress SC+ Inks and Advanced Ink Amount (AIA) control system, this solution maintains image fidelity, sharp contrasts, with reliable colour accuracy and, combined with NIR (Near InfraRed) drying technology, converters can efficiently produce labels with dense ink coverage even on PP (Polypropylene) and BOPP (Bi-axially Oriented Polypropylene)

films and offset coated papers, without additional pre-treatment.