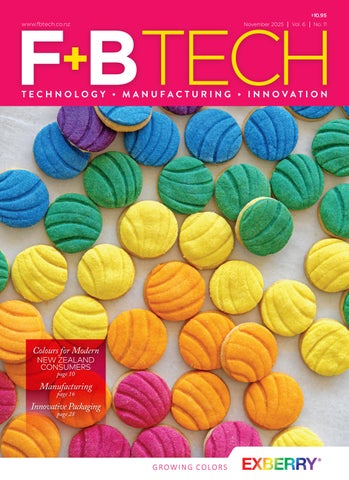

Colours for Modern NEW ZEALAND CONSUMERS

page 10

Manufacturing page 16

Innovative Packaging page 28

Colours for Modern NEW ZEALAND CONSUMERS

page 10

Manufacturing page 16

Innovative Packaging page 28

Caitlan Mitchell Editor-in-Chief caitlan@reviewmags.com

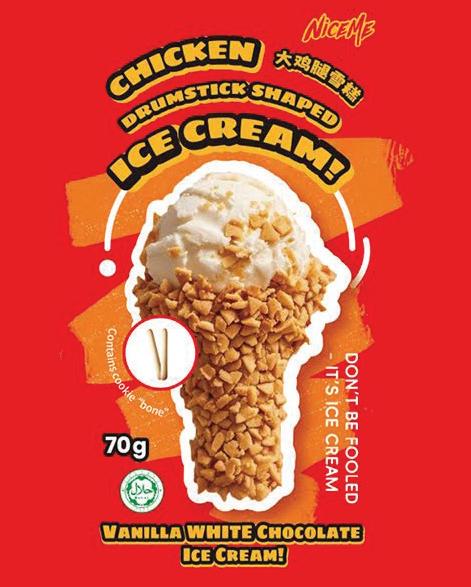

Globally, food and beverage brands are embracing what commentators have labelled chaos packaging, a strategy that places familiar products in unfamiliar formats to spark recognition and surprise. The idea is simple: swap the category cues. A drink in a pump bottle, a chocolate bar in a blister pack, or an energy gel in a toothpaste tube forces consumers to look twice, and in doing so, the brand earns mental space that traditional design may no longer guarantee.

Chaos packaging began in beauty and wellness, where form experimentation is easier. From there it has moved rapidly into ready-

to-drink and functional beverage niches. Products like Oshun’s electrolyte concentrate in a soap-style pump or Vacation’s whippedcream-can sunscreen have become design references, blurring the line between category humour and marketing science. Their packaging is the campaign, driving viral reach and social proof without major media budgets.

One overseas brand that has successfully moved beyond novelty to establish chaos as its visual identity is Liquid Death. Its skull logo, dark humour, and tattoo-

inspired graphics were designed to mock extreme beverage marketing. Yet what began as a shock tactic is now mainstream. The brand has built genuine loyalty, expanded globally, and proven that chaos packaging can evolve from attention-grabbing stunt to a coherent, lasting identity.

In Asia, a related movement has emerged through category format disruption, where the product itself mimics another food entirely. The viral chickenleg ice-cream trend, first popularised in China and now available in New Zealand, is a good example as it delivers the same jolt of disbelief that chaos packaging seeks, but through form rather than packaging.

The result is social-media shareability and impulse appeal, proof that playful visual subversion can cross markets. However, unlike structural packaging chaos,

this version still respects food-safety clarity: the pack signals dessert, while the product surprises.

In New Zealand, chaos packaging remains uncommon, but as brands seek low-cost ways to command attention, selective adoption is likely. The challenge will be balancing disruption with purpose, ensuring that novelty reinforces brand identity rather than distracting from it.

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES caroline@reviewmags.com, daniel@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC DESIGNER Raymund Santos

New Zealand has made progress in the fight against antimicrobial resistance, with sales of veterinary and horticultural antibiotics falling for the seventh consecutive year.

New Zealand Food Safety’s deputy directorgeneral Vincent Arbuckle said antibiotics are essential for the treatment of bacterial infections in humans, animals and plants.

“If they are not used carefully, and in the prescribed amounts, we run the risk that bacteria will develop resistance to the drugs, which could have devastating effects on our health and economy.”

The latest antibiotics sales figures for plants and animals, released in New Zealand Food Safety’s annual Antibiotic Agricultural Compound Sales Analysis report, are a clear sign that antibiotics are being more carefully used.

The falling sales are a result of a concerted effort by veterinarians, farmers, industry and New Zealand Food Safety to ensure these life-saving medicines are used appropriately so they work as intended. Read more here

A NZD 1.2 million Government–industry investment through AgriZeroNZ into a breakthrough technology to cut agricultural emissions, reduce farm costs, and boost productivity, has been welcomed by Economic Growth Minister Nicola Willis.

The investment supports the development of a wearable device for cows that could reduce nitrous oxide emissions by up to 95 per cent and nitrate leaching by 93 per cent.

“This is Kiwi innovation at its best: smart technology designed on the farm, for the farm, turning waste into a valuable fertiliser and maintaining New Zealand’s leadership in low emissions pasture-based farming,” said Nicola Willis.

It is the 16th project to be funded by AgriZeroNZ, a joint venture between the Government and leading agribusiness partners, and its first equity investment into nitrous oxide mitigation.

“A total of NZD 191 million has been committed over its first four years to accelerate development of emissions reduction tools for farmers that support the Government’s goal of doubling export value in 10 years.”

Read more here

The Recycling Leadership Forum (RLF) was established last year to bring together the brand owner, retail, packaging, food and grocery, recycling, and local government sectors.

The Recycling Leadership Forum’s Term One Annual Report is a comprehensive progress report which updates the Minister for the Environment, Hon Penny Simmonds, on the Forum and subgroups’ work to date and direction as of May 2025.

It provides expert advice and information to the Ministry for the Environment and the Minister on improving the recyclability and recovery of packaging materials. Read more here

Zespri’s final charter shipment of the 2025 New Zealand kiwifruit season has departed the Port of Tauranga bound for Japan.

The ship Whero is carrying more than 1.4 million trays, or more than 5,000 tonnes, of Zespri Green Kiwifruit and is expected to arrive in Tokyo mid-November, before sailing on to Kobe.

This will be Zespri’s 60th charter vessel of the season, used to ship New Zealand-grown Zespri Green, SunGold and RubyRed Kiwifruit to more than 50 markets.

Its final container shipments of kiwifruit will also depart New Zealand in the coming weeks. This season, Zespri has seen a significant increase in container usage, to 24,000, up from 20,500 in 2024.

CEO Jason Te Brake said this year’s crop of around 215 million trays, or more than 770,000 tonnes, has been the largest yet, and it’s been a huge industrywide effort to deliver record volumes to customers and consumers worldwide.

Read more here

The decision reflected recent changes in how New Zealand growers are using glyphosate.

After carefully considering industry, stakeholder, and public feedback on a proposal to change maximum residue levels (MRLs) for glyphosate in wheat, barley and oats, New Zealand Food Safety has decided to set a limit of 0.1mg/ kg (the same as the current default level) and to restrict the permitted use of glyphosate for these arable crops.

New Zealand Food Safety deputy director-general Vincent Arbuckle said that although they were confident the proposed limits would not have presented any health risks to consumers, after considering more than 3,100 submissions and meeting with a broad range of submitters and stakeholders, they found compelling evidence that the way glyphosate is used in New Zealand has changed over the past 5 to 6 years.

“Growers and millers have increasingly entered into contractual arrangements that require no, or extremely low, glyphosate residues in grains used for food, effectively prohibiting pre-harvest use of glyphosate,” said Arbuckle. Read more here

The world’s first commercial seaweed nanocellulose biorefinery has opened in Paeroa, New Zealand, and will positively impact a range of industries while minimising waste.

The multi-million-dollar biorefinery, owned by family company AgriSea, will convert seaweed left over from the biostimulant production process into nanocellulose hydrogel for medical, agricultural, manufacturing, and cosmetic applications.

Nanocellulose is a highly versatile material with exceptional properties, making it valuable across a range of applications. Most of the world’s nanocellulose is produced using chemically treated wood pulp.

Now, AgriSea and the Bioeconomy Science Institute have collaborated to create this material from seaweed.

AgriSea chief executive Clare Bradley said seaweed offers a surprising advantage over traditional woodpulp sources. Its cellulose chains are up to four times wider and longer, giving the resulting hydrogel twice the thermal conductivity of plant-based equivalents. Read more here

With over 2,500 trucks and 4,000 trailers, Tesco has one of the biggest LGV fleets in the UK. Its areas of focus for improvement included managing a vast fleet, ensuring accurate and timely deliveries, minimising empty runs and

In order to coordinate its vehicles, the supermarket giant recognised a need to track its fleet, in real-time, as well as keeping up with maintenance and safety standards.

Driver management also posed a challenge – from training and compliance to safety – which was another area of focus for Tesco.

Finally, it recognised the need to reduce empty runs to save costs and cut emissions.

Tesco’s integration of Microlise’s advanced technology aimed to transform its entire delivery operation. By implementing a comprehensive suite of software, it would enhance tracking capabilities and the overall management of its fleet.

Overall, implementation included:

Fleet Tracking: Enhancing delivery tracking and performance.

One of the core benefits that Microlise offers is real-time tracking. This functionality allows Tesco to monitor the exact location of each vehicle – at any given time – providing a live overview of the entire fleet’s status. This immediate visibility is crucial for managing delivery schedules, responding promptly to any issues and ensuring that deliveries are made on time.

Driver Performance App: Allowing drivers to monitor and improve their performance, through real-time feedback.

Microlise’s driver app equips Tesco drivers with tools to monitor and improve their driving performance. The app delivers real-time feedback on various driving parameters such as speed, braking and acceleration, helping drivers to make immediate adjustments and adopt safer and more efficient driving habits.

on-time deliveries for large stores 99 % since implementing Microlise

Fleet Safety Management: Promoting safe and fuel-efficient driving practices.

The system monitors fuel usage, helping to identify opportunities for improving fuel efficiency. By analysing fuel consumption data, Tesco can implement strategies to reduce fuel usage and lower operational costs.

•99% on-time deliveries for large stores and 96% for convenience stores

•More efficient driving, better driving styles and improved safety on the road

“•Reduced emissions, enhanced hazard perception and improved the ability to forward plan I can’t imagine what my day would look like without the Microlise system, it really does give us everything we need to run an operation this big.”

Jamie FutcherLead Transport Manager, Tesco

Since implementing Microlise's solutions, Tesco has achieved remarkable improvements in delivery performance, with 99% on-time deliveries for large stores and 96% for convenience stores.

The driver app has ignited a culture of healthy competition, leading to more efficient driving, better driving styles and improved safety on the road. Additionally, the telematics system has contributed to reduced emissions, enhanced hazard perception and improved the ability to forward plan. As a result, Tesco is expecting to see a reduction in accidents and a significant improvement in overall road safety.

“We’re always keen to work in partnership with Microlise to test any new products, and any new innovation that Microlise might have to enable us to improve the service that we deliver to our stores and customers.

“Strategically, whilst we’re looking at multiple options in terms of alternative fuel vehicles while we are operating diesel trucks, it’s really important that we continue to use the Microlise telematics system to continue to improve our drivers’ score, continue to improve the MPG that we deliver and the associated emissions reduce as a result of that.

“Microlise is really important to us here at Tesco. It’s a key enabler for us to be able to deliver fantastic service to our stores and customers.” - Chris Jones, RTM North & Head of Fuel Logistics

Microlise's comprehensive transport solutions are essential to Tesco's logistics operations, enabling it to deliver exceptional service to both stores and customers.

Microlise works with nearly all supermarket chains in New Zealand and Australia.

The collaboration highlights how technology can drive efficiency and performance in large-scale logistics. Tesco values the critical visibility and improvements facilitated by Microlise that is essential for managing their expansive transport network.

Want to know more? Microlise solutions can help you to reduce costs and environmental impact, while increasing safety, efficiency and compliance.

Miguel Bielders, GNT’s Marketing Manager – APAC, explains how EXBERRY® colours made from fruit, vegetables and plants can provide manufacturers with a futureproof solution

Naturalness is important to New Zealanders. A 2024 survey of Australasian consumers found that – excluding taste and price – it ranked second only to nutrition when choosing which food items to buy.1

The survey also showed that seven in ten said they consider ingredient lists to be important, with additives (36%), chemicalsounding ingredients (26%) and genetically modified ingredients (20%) among the information many are looking out for.

This growing scrutiny makes natural food colours essential for gaining consumer trust and driving product acceptance. Many brands are already responding. Over the last five years, fewer than 15% of product launches in New Zealand have featured artificial colours, with their growth rate (CAGR) standing at -7%.2

As consumer expectations continue to evolve, manufacturers need futureproof solutions that can still deliver on performance. Our plant-based EXBERRY® colours are ideal. They not only allow for a complete spectrum of vibrant, stable shades in food and drink but support the natural label declarations that shoppers want to see.

Consumer-friendly colours

EXBERRY® colours are made from fruit, vegetables and plants and are processed without the use of chemical solvents. They are non-GMO, vegan, halal and kosher, and allow for simple ingredient listings such as “concentrates (carrot and blackcurrant)” or “turmeric concentrate”.

Importantly, they are also sustainable. GNT has been awarded an EcoVadis gold medal for our environmental and ethical activities, and we provide Product Carbon Footprint (PCF) data for the vast majority of EXBERRY® colours.

Continued on page 12.

Continued from page 11.

Our approach ensures that your products can satisfy diverse consumer preferences as well as regulatory requirements in New Zealand and beyond.

Making the switch simple

EXBERRY® is available in a wide range of formats to suit almost any food and drink application, but plant-based colours require careful formulation to ensure optimal results.

We’re passionate about working side-by-side with our customers to deliver the best possible outcome. We offer full support throughout the product development cycle, including colour selection and matching, stability testing, concept innovation and regulatory support.

Ideally, we’ll mimic your process as closely as possible, focusing on key parameters that impact colour performance, such as pH, heating conditions and base colour. By testing different dosages and blends, we fine-tune the colour to ensure it’s just right for your product.

With our global reach and tailored, local technical support, we can ensure cost- and time-efficiency by streamlining the product development process and increasing your speed to market.

For example, our Binder Accelerated Stability Chamber speeds up colour testing for food and drink by up to 20 times, offering rapid insights into dosage levels and raw material performance. This innovative tool helps us to efficiently identify the perfect solution for your products.

Colour solutions you can trust

EXBERRY® is the leading global brand of plant-based, sustainable colours for food and drink.

Whether developing a new product or reformulating a recipe, we’re here to help.

Trusted by everyone from start-ups to the world’s leading manufacturers, we know how to deliver colour solutions that will tick every box for the modern New Zealand market.

Hailing from the UK, Andrew Liley, Director of Juno Olives, had qualified as a doctor and was working in the industry for 25 years before he decided to move into New Zealand’s primary sector.

Of the many things he looked into, growing olives was a good fit for him, as the potential to produce a product with proven health benefits was a strong incentive.

This season has been great for Liley, as Juno Olives has produced more olive oil than in any other year, which Liley said was a testament to the changes made to land and tree management over the last five years.

“Like anything in farming, you make a change on a hunch but may not see results for several years afterwards. Sustainability is not all about what you do day to day, but what you can achieve over a year, a decade and longer,” he said.

“We are trying to be increasingly sustainable and biodynamic. I’m certainly of the opinion that we don’t want to be poisoning the ground we have been given to care for, and if we look after it, the olive trees will be all the better for it.”

At Juno Olives, the canopies have been managed to improve airflow and sunlight, reducing disease pressure and, in turn, spraying frequency. All pruning and solid matter is done after pressing and is ultimately returned to the grove.

Customer feedback has shown Liley that people seemed generally amazed by what was involved in growing olives to produce the best-quality product. They have also been quite surprised

by how different the oils taste depending on the olives and by how different Juno Olive oils are from the mass-produced olive oils. Additionally, the Tararuas’ landscape and freedraining soil made it ideal for olives and for daily grove management.

Although the pressing process is the same for each variety, by selecting at the optimal time and keeping each variety separate, Liley hoped to showcase each olive oil’s individuality.

“The varieties themselves vary in size and shape, the trees are all different, and the oils they produce each have their own individual character.”

His favourites vary year on year, but this year Liley said that the Picual and Moraiolo had produced very nice, balanced oils, with the former having just won an award.

Liley also enjoyed the production of Agrumatos, where the flavouring fruit or herb is actually put into the press with the olives. This produces a much more rounded oil flavour but is fraught with risk, as one can never be quite sure what one will get due to year-onyear variation in olives and fruit.

“When you get it right, it produces some real winners.”

Looking ahead, Liley said he would be focused on gradually reshaping canopies to suit mechanical harvesting, reducing the need for spraying and producing awardwinning olive oils.

The varieties themselves vary in size and shape, the trees are all different, and the oils they produce each have their own individual character.

Crafted using the finest ingredients for a superior confectionery experience, Mayceys Lollies have distinctive flavours and textures that taste just like they did a century ago.

Nostalgia is a strength for the brand as it has been connecting generations through the shared joy of classic Kiwi confectionery.

“From our family-owned origins to our new capabilities, we continue to create the lollies Kiwis love, using resourceful thinking, local pride, and the finest ingredients to ensure every bite is as memorable as the last,” said Cathy Phillips, Business Development Manager, Mayceys Confectionery Ltd.

The Stacey family sold the business four years ago to Jasmeet Singh of Precision Healthcare Limited, part of a family-operated conglomerate with business operations across the USA, Asia and New Zealand in supplements, pharmaceuticals and confectionery sectors.

The group exports to more than 35 countries worldwide. Under Singh’s leadership, the company has been modernising its processes and machinery, with a new factory commissioned this year to support growth and innovation.

The East Tamaki facility focuses primarily on healthcare products, including fortified gummies and lozenges. Singh, with a strong background in nutraceuticals, has brought extensive expertise in gummy manufacturing to New Zealand.

The new facility also includes an R&D lab, allowing the team, for the first time in years, to explore new flavours and formats, not only for traditional confectionery but also for functional, health-focused products.

At the same time, Phillips recognised the importance of evolving to stay relevant to new consumers—not only by maintaining the trusted quality and flavours people remember, but also by introducing modern twists, whether through new flavour profiles or betterfor-you formulations, now explored at the new factory in East Tamaki.

Over the past few years, Mayceys Confectionery has invested in machinery and factory upgrades to improve production efficiency. This includes new gummy and lozenge depositing lines at the new factory

Continued on page 18.

for greater precision in dosing and consistency in texture and shape.

The state-of-the-art German confectionery equipment ensures the consistency, texture, and flavour that customers have loved for generations, while improving efficiency, precision, and product quality.

Phillips mentioned that these new machines have much greater capacity than the older equipment with fewer manual processes. At the same time, the experienced team has continued to play a vital role in monitoring each stage of production to ensure that every batch meets quality standards. Several of the recent upgrades have focused on improving production efficiency. The new depositing and cooking systems have been designed to minimise product waste through more accurate dosing and better temperature control.

Mayceys operates under a strict food safety program with quality control points integrated throughout the manufacturing process.

“We have always had an effective traceability system, which allows us

to track raw materials and finished products precisely throughout the manufacturing process. This not only strengthens our quality control but also supports our commitment to food safety and regulatory compliance.”

“These upgrades have not only increased our production capacity but also allowed us to focus on new product development while maintaining the high-quality standards our customers expect from a New Zealand–made brand.”

Phillips said that, given the needs of sugar cooking, boiling, etc., energy tends to be a significant cost. Looking ahead, she mentioned that technologies that recover heat, optimise heating profiles, and use renewables could offer payback over time, and that advances can improve production efficiency and productivity.

However, maintaining the authenticity and nostalgia of products will remain extremely important to Mayceys, as many customers have become attached to taste, texture, look and feel.

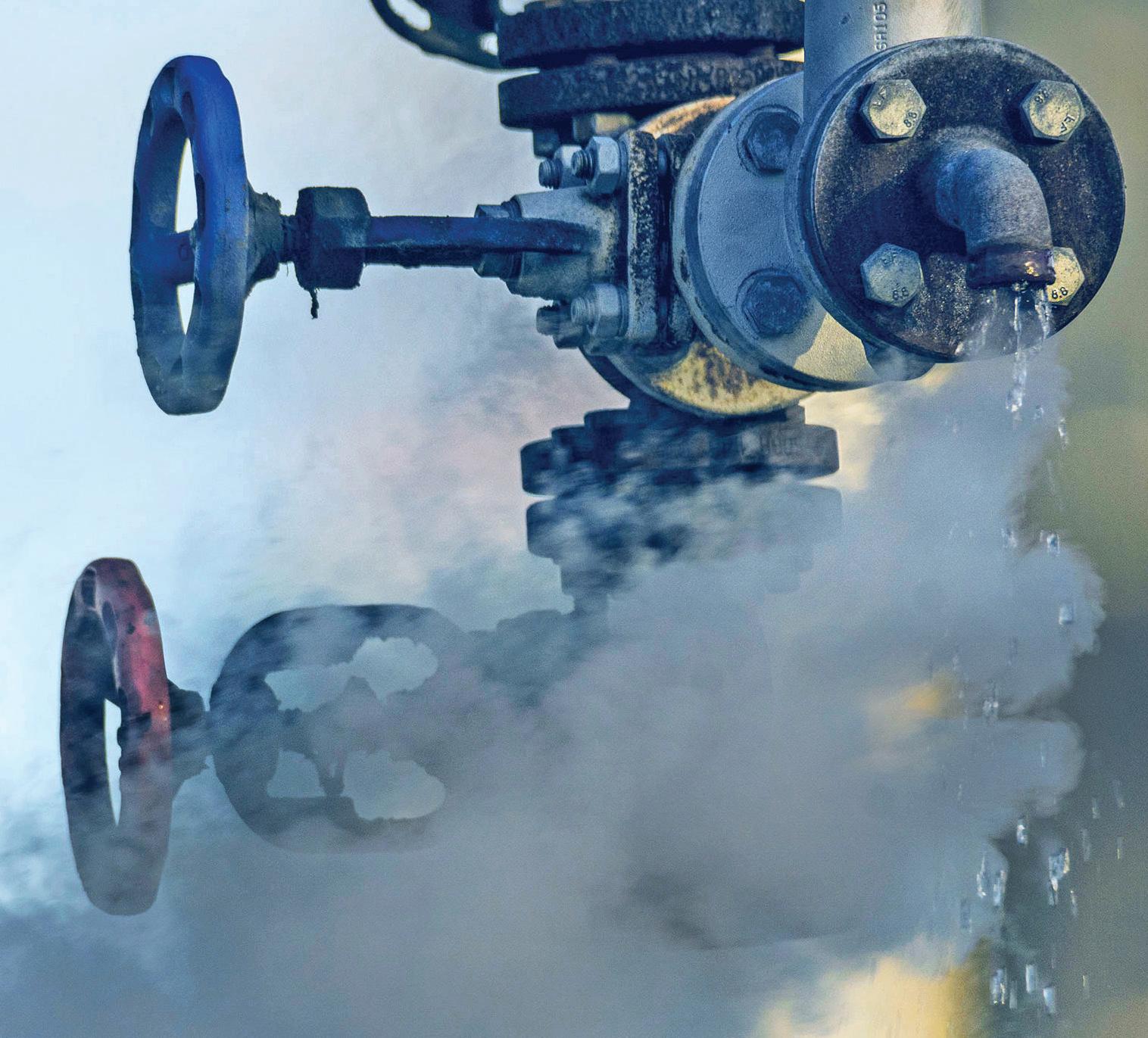

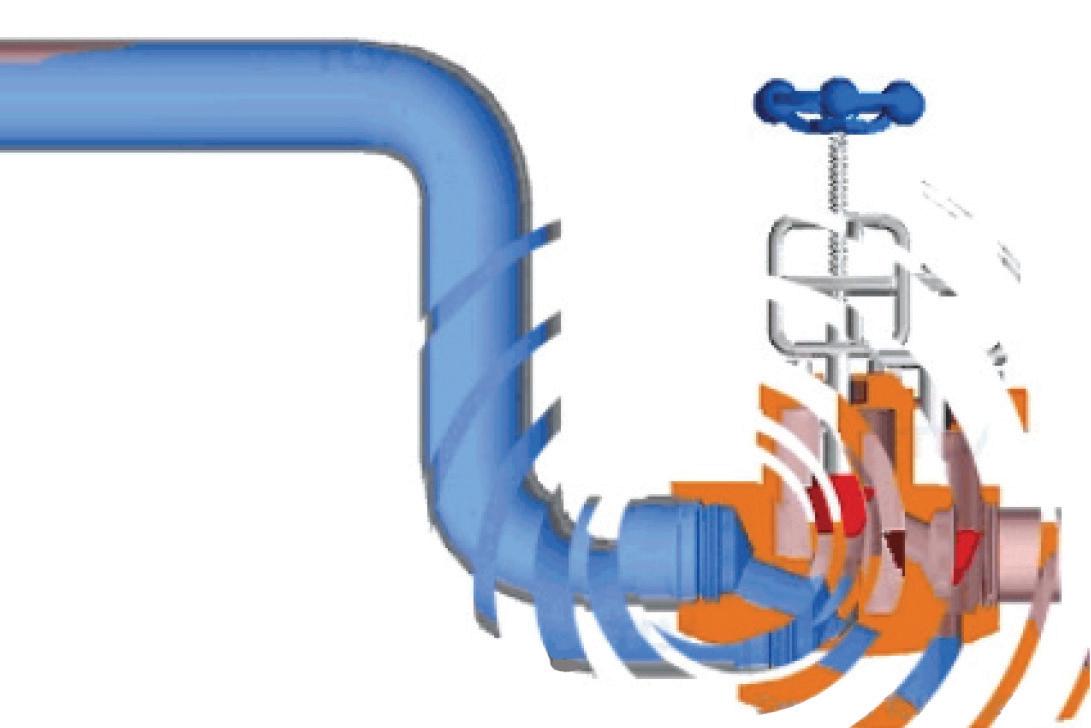

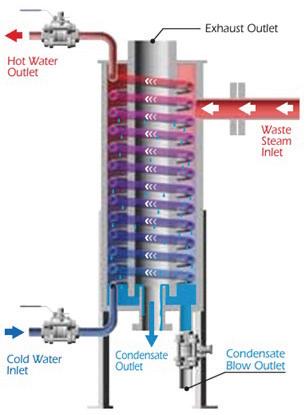

Steam is a highly efficient medium for heat transfer; however, there are areas in the steam reticulation system where efficiency can be lost through radiant heat losses, steam leaks, failed steam traps and unrecovered condensate, all areas which can be minimised or eliminated.

These conditions also pose safety hazards, as heat losses or leaks can lead to burns and scalds. Other areas of safety concern include poorly designed steam distribution systems, insufficient condensate removal, and inadequate isolation to ensure the plant is safe to operate and maintain.

TLV offers on-site Steam Application Surveys to identify and quantify sources of energy and condensate loss, safety concerns, and other areas for steam plant optimisation; and will provide consultation on best practices

LEFT: POORLY MANAGED CONDENSATE SYSTEMS RESULT IN ENERGY LOSSES AND SAFETY HAZARDS

and solutions to enhance the steam system.

According to Sam Aarts, Business Development Manager, TLV NZ, common challenges with steam in production plants stem from system design and steam conditioning. Steam is a hot, pressurised gas that flows at a reasonably high velocity and may contain water droplets and particulates that can be erosive to internal equipment surfaces.

“Ensuring that adequate steam conditioning equipment is in place, including steam traps at determined positions, water separators, strainers and filters, is critical to preserving the life of valves and process equipment,” said Aarts.

“This will significantly help reduce waterhammer, steam hammer, and erosion of valves and process equipment. TLV’s steam trap survey service will identify any failed steam traps on site and provide recommendations to optimise steam system design to minimise the issues described above.”

Given the nature of steam, a highenergy fluid that flows at reasonably high velocities, these valves will inherently experience wear and fatigue over time.

Aarts added that any heatdemanding process has an optimal amount of energy required to meet the setpoint at given conditions –if it receives too little energy, the setpoint will not be achieved, resulting in a poor-quality product or rework requirements, and too much energy could spoil the product, resulting in wastage.

Ensuring that steam supply to the process is properly conditioned and controlled, and that steam traps are functioning effectively to remove condensate from the heating space, is critical to achieving acceptable, consistent product quality.

He said that it is difficult to manage what is not measured, so the use of instrumentation such as pressure gauges/transmitters, temperature transmitters, and flowmeters in steam-using applications is recommended to assist with process optimisation, ensure repeatable results, and allow benchmarking.

Scheduled maintenance of valves, steam traps and ancillary equipment is essential to ensure the integrity of the steam system, reduce breakdowns, maintain reasonable process control and minimise energy losses. If a small leak through a valve or steam trap is rectified early, it can prevent a significant event that raises safety concerns, causes downtime, and results in costly replacements.

As traditional fossil fuels become scarcer and more costly, and as industry faces pressure to reduce its carbon footprint, Aarts said the need to optimise process heat systems is

increasingly urgent.

TLV will continue to develop marketleading products designed to ensure their longevity in service, along with innovative products for heat transfer and recovery applications.

These include COSPECT pressurereducing valves with an in-built separator and steam trap, QS-series compact steam-trapping stations for minimised installation requirements, SteamAqua plug-and-play instantaneous water heaters, and SRseries steam condensing heat recovery units, among many other innovative solutions.

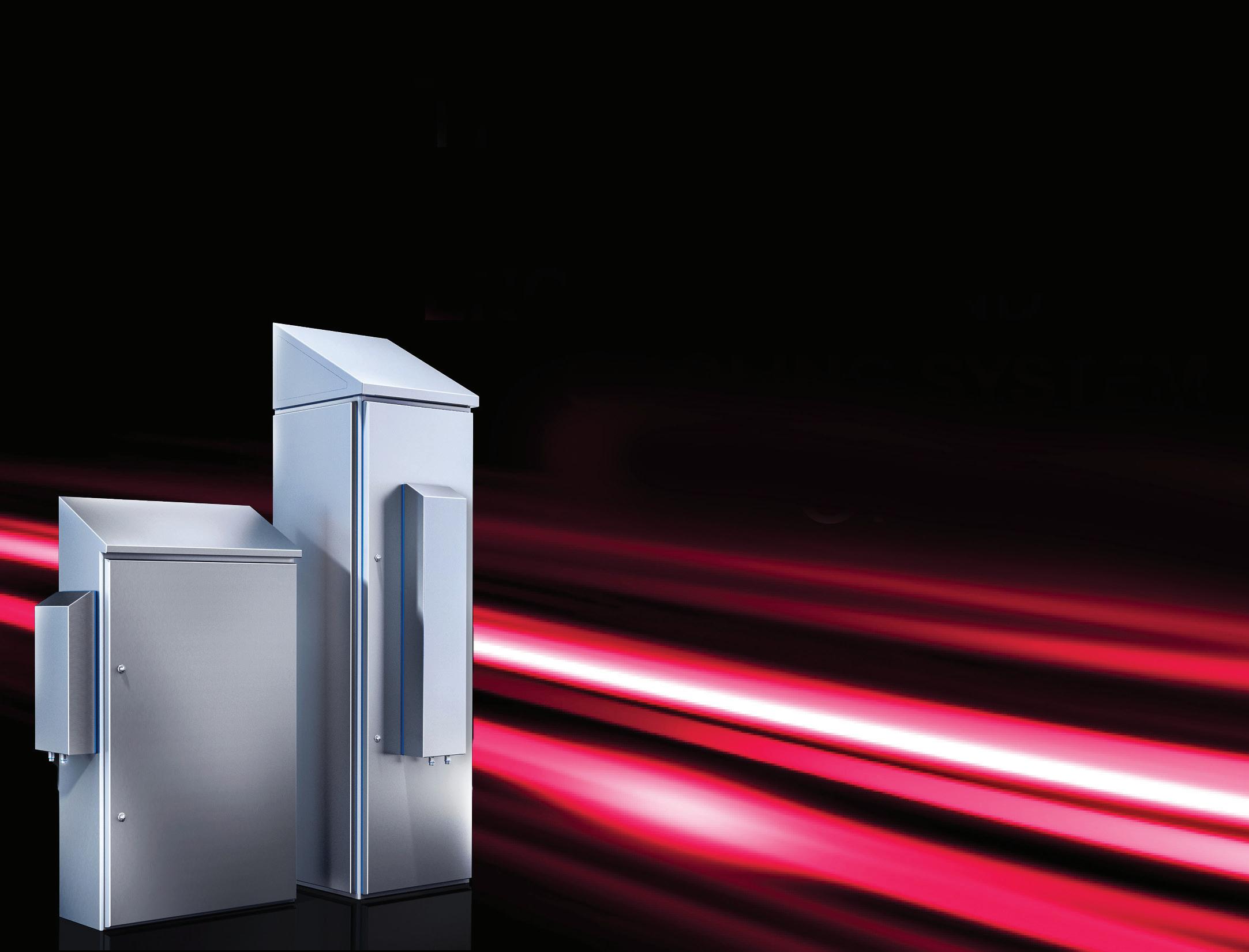

Ensure compliance, equipment protection, and energy efficiency in hygiene-critical zones this summer.

As we head into the warmer months, New Zealand’s food and beverage manufacturers face increased pressure to maintain product quality, hygiene standards, and operational continuity. With rising ambient temperatures and more frequent washdowns, enclosure systems are under greater strain, especially in hygiene-critical zones.

Rittal’s Hygienic Design (HD) enclosures, paired with Blue e+ cooling technology, offer a complete, systembased solution designed to meet global food safety standards, protect sensitive electronics, and support

sustainable production.

Summer heat and intensive sanitation protocols can quickly expose the limits of standard enclosures. Thermal instability, condensation, and cleaning inefficiencies can all lead to unplanned downtime, equipment failure, or non-compliance, each with a cost to your operation.

Rittal’s HD system is engineered specifically to address these pressures and help manufacturers operate with confidence under increasing regulatory and environmental demands.

Integrated Automation Limited (IAL), a leading NZ automation provider, recently adopted Rittal HD enclosures as standard across its food and beverage projects. In a recent conveyor system installation, IAL needed a solution that could withstand washdowns, variable temperatures, and housing for sensitive automation equipment.

“The HD series has a superior design, high-quality stainless steel, and hygienic blue seals that support the standard we aim for in every automation system,” said Donovan Ryan, Managing Director, IAL.

This shift reflects a broader movement across the industry, where future-ready infrastructure is becoming non-negotiable.

Food-grade performance doesn’t stop at clean surfaces. Rittal’s enclosures also integrate digital tools like ePOCKET, a QR-code-enabled wiring plan system that replaces bulky manuals with cloud-based schematics and real-time version control.

Whether you're working in dairy, meat, seafood, or ready-meal production, Rittal’s HD enclosures with integrated cooling and digital servicing tools provide a cleaner, smarter, and more resilient foundation for New Zealand food manufacturing.

The global paper packaging materials market is set for strong expansion, driven by increasing consumer awareness of environmental sustainability, stricter regulatory mandates, and rising adoption of eco-friendly packaging solutions across multiple industries.

According to a recent industry report by Fact.MR, the market is expected to expand significantly over the coming decade.

Paper packaging materials include a wide range of solutions such as corrugated boxes, cartons, paperboard, and specialty papers designed to reduce environmental impact while maintaining product protection and usability. These solutions serve various sectors, including food and beverages, e-commerce, personal care, pharmaceuticals, and industrial packaging, offering both sustainability and operational efficiency.

The global paper packaging materials market was valued at USD 294 billion in 2024 and is projected to reach USD 582 billion by 2035, registering a notable CAGR of 6.4 percent during the forecast period. This growth represents an absolute opportunity of approximately USD 269 billion. Several factors are propelling the growth of the paper packaging materials market. Consumers increasingly prefer products with reduced environmental impact, encouraging companies to adopt recyclable, biodegradable, and

compostable paper-based materials.

The surge in online retail is driving demand for durable, lightweight, and sustainable packaging solutions that enhance customer experience while minimising ecological footprint. Innovations in barrier coatings, functional papers, and high-strength corrugated materials are improving shelf life, durability, and product safety.

At the same time, governments worldwide are imposing stricter guidelines on single-use plastics, prompting manufacturers to transition toward paper-based alternatives.

North America remains a key market, with the United States driving growth through strong consumer spending, environmental initiatives, and regulations promoting sustainable packaging.

Europe and East Asia are expected to capture significant market shares by 2035, leveraging established manufacturing capabilities and growing demand in the food, beverage, and e-commerce sectors. Southeast Asia, Central and South America, and Australia are also witnessing steady growth, supported by localised sustainable packaging initiatives.

The global paper packaging materials market is highly competitive, with leading companies investing in research and technological innovation, as well as eco-friendly solutions, to strengthen their market presence.

Companies are increasingly focusing on developing innovative and sustainable paper packaging solutions tailored to diverse industry needs. By prioritising eco-friendly materials and customisable offerings, manufacturers aim to capture environmentally conscious consumers and maintain a competitive edge.

The paper packaging materials market is expected to grow strongly in the coming years, driven by innovations in sustainable materials and increasing demand from eco-conscious consumers.

Companies that successfully balance sustainability, functionality, and cost-efficiency are likely to emerge as leaders in this rapidly evolving market. The sector presents significant opportunities for stakeholders, delivering both economic and environmental benefits.

These insights are based on a report on Paper Packaging Materials Market by Fact.MR.

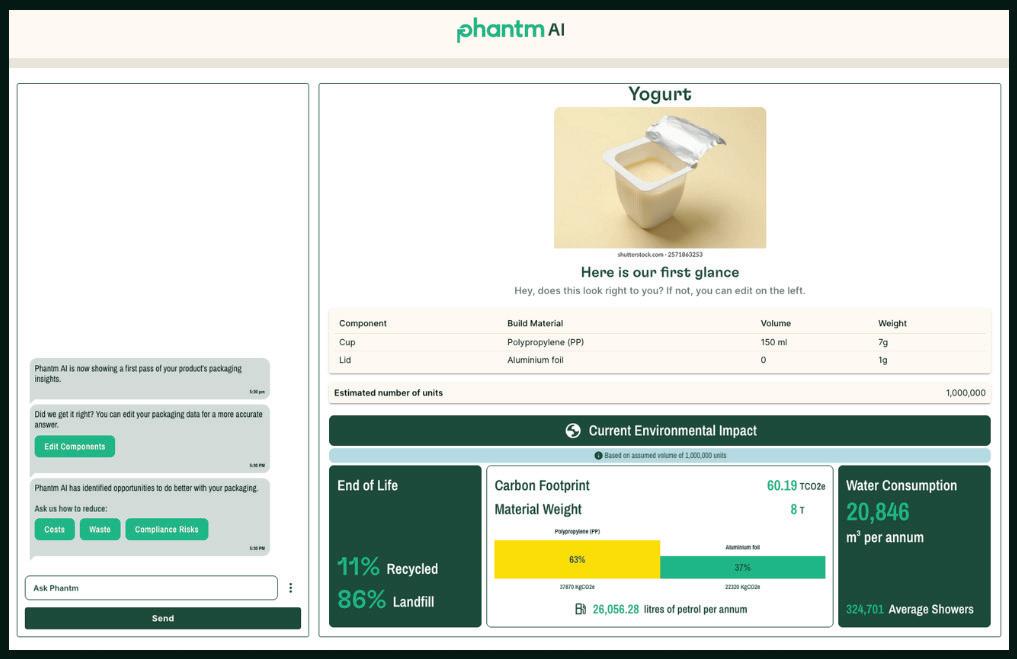

Despite growing pressure from consumers and regulators, most businesses have no easy way to measure or manage their packaging impact.

Phantm was launched to solve this problem by providing businesses with the data they need to take real action to reduce costs, waste, and compliance risk.

Co-founder and CEO Elliot Costello, who previously led social impact ventures at ygap, built the Phantm platform to help companies place less product packaging on the market through innovative technology applications.

Today, Phantm works with leading brands including Amazon, David Jones, Danone, Unilever, and MECCA. In addition to FMCG brands, Phantm

serves industries including packaging, food and beverage, and horticulture.

“While major brands with significant product portfolios are key clients, the platform doesn’t exclusively cater to large companies; it has supported the needs of start-ups through to multinational organisations,” said Costello.

Businesses face rising noncompliance risks in both Australia and New Zealand, with penalties already being issued in Australia for failing to respond to packaging-specific EPA information requests.

Phantm has been currently working with several forward-thinking

businesses in New Zealand who are focused on digitising their complex packaging portfolios. Costello added that this motivation goes beyond simply preparing for an uncertain regulatory future; they see it as an opportunity to get ahead, optimise packaging, and reduce both costs and impact.

With EPR set to come into effect in Australia and New Zealand, companies must start capturing packaging data now, simplify and reduce materials, and ensure their materials data links to sales data.

In the context of shifting regulations and lagging infrastructure, such as Australia’s underperforming recycling systems, Costello said it was clear why even well-intentioned companies struggle to develop and implement sustainable packaging initiatives.

Phantm AI helps companies by initiating a fast start at mapping a product or portfolio’s complete packaging footprint, from global warming potential to recyclability to compliance risk.

Feedback on the Phantm AI indicates it helps make packaging data usable and fast. It simplifies and accelerates onboarding by turning scattered PDFs, images and spreadsheets into a single, queryable view.

This lowers the on-ramp for Phantm customers to build out a packaging data asset that can be continually used to identify opportunities to reduce packaging costs, reduce waste (items going to landfill), and minimise compliance risks.

According to several clients, the technology and advisory insights have been invaluable in making the case for change across procurement, operations, sustainability, and finance, as well as with senior decision-makers.

Leading social enterprise Thankyou Group emphasised that while they tried to build Phantm’s capabilities in-house, they recognised the need for partners who “live and breathe it 24/7” to assess and accelerate sustainability achievements.

“We rebuild scattered data into a single source of truth, and our materials experts help translate insights into practical, ongoing improvements,” added Costello.

“We help businesses see not just the environmental benefits, but the commercial case for change, showing that, in most cases, the most sustainable choice is also the most prudent one.”

Although still in the early days, generative AI is poised to fundamentally reshape the packaging industry in ways that mirror past technological revolutions.

For packaging specifically, Costello said innovation and R&D will be key drivers for growth, especially given the global focus on sustainability and transition to green materials.

Gen AI can boost R&D productivity by helping companies generate new ideas through intellectual property and patent analytics, providing customer analysis, generating customisation options, accelerating the idea-tovisualisation process, and streamlining

field-testing feedback.

At Phantm, the team has seen this transformation firsthand. Just as accounting software revolutionised business operations by making financial data usable and visible, AI has done the same for packaging data. It enables scaling packaging data capture and compiles it quickly, making it visible and meaningful across departments. This prompts conversations about efficiency and impact, as stakeholders can back up their assertions with data and clear metrics.

However, Costello mentioned that AI outputs are only as good as their input. Organisations need a solid foundation of packaging data to ensure accuracy, which is why human validation remains central to our approach and will be for some time yet.

As regulations strengthen and shift towards EPR, early movers who adopt digital packaging intelligence will benefit significantly before regulation drives wider adoption. Phantm wants to be the platform of record for packaging intelligence worldwide, with sustainability embedded in everyday business decisions, not bolted on as an afterthought.

The recent launch of Phantm AI’s image-based technology that converts packaging visuals into structured data is a leap forward in connecting packaging, data and sustainability to help companies move beyond compliance toward proactive, costeffective impact reduction.

Costello said that the mission is to prevent thousands of tonnes of unnecessary packaging by shifting millions of units from landfill-bound materials to circular alternatives.

After servicing the Asia-Pacific region, our primary focus is on deploying the technology in Europe and North America, particularly in regions with significant plastic consumption but limited recycling infrastructure.

With EPRs rolling out worldwide, Phantm is positioning itself to help businesses prepare for regulatory shifts and drive leadership-driven systems change toward a more innovative, more circular materials economy.

Over the past two decades, New Zealand has emerged as one of the most advanced wine markets in the world in terms of closure technology.

Today, around 90 percent of all wines produced in the country are sealed with aluminium screwcaps, a figure that reflects both technical maturity and widespread consumer acceptance. This shift has been driven not only by the functional benefits of screwcaps but also by the country’s strong export orientation. In 2024, wine exports exceeded NZD two billion, confirming the sector’s role as a major contributor to the national economy and highlighting the importance of consistent quality, brand integrity and compliance with international standards.

While overall alcohol consumption per capita in New Zealand has been gradually declining in line with the global trend towards mindful drinking, the wine industry has responded by focusing further on premiumization and sustainability. Producers are investing in lighter bottles to reduce environmental impact, adopting sustainability certifications, and selecting packaging components that combine technical reliability with a reduced ecological footprint. In this context, aluminium closures have gained a reputation not only for their ability to preserve wine quality but also for their recyclability and absence of cork taint risks. Research from the Aluminium Closures Group

suggests that consumers increasingly associate screwcaps with both quality and environmental responsibility, reinforcing their role in the premium wine segment.

Within this evolving landscape, Guala Closures has developed the Above Wine range, a portfolio of aluminium screwcaps designed specifically for the needs of quality-driven wine producers. The range brings together technical precision, aesthetic versatility and environmental consideration. Each closure is engineered to deliver controlled oxygen transmission, ensuring that the wine’s aromatic profile and structural balance are maintained over time. The designs allow for a high degree of visual customisation, enabling producers to align packaging with brand identity without compromising performance. Sustainability is embedded in the manufacturing process through the use of recycled aluminium and formats that facilitate separation from the bottle for efficient recycling. At the same time, the closures are fully compatible with existing bottling lines, allowing wineries to adopt them without significant operational changes. For those seeking to integrate digital engagement or traceability, NFC and QR code technologies can be incorporated discreetly into the design.

The Above Wine range includes different formats, each with distinct characteristics. Divinum offers a versatile and elegant solution suitable for a wide variety of wine styles. Wak combines the familiar silhouette of a traditional wine bottle

with the technical advantages of a screwcap, providing an uninterrupted surface that lends itself to extensive decoration. Savin Premium employs a patented invisible thread, creating a smooth, modern appearance and a larger printable area, making it particularly suited to brands seeking a refined and contemporary presentation.

A notable example of the range’s application can be found in the collaboration between Guala Closures and Cloudy Bay Vineyards, one of New Zealand’s most recognised wine producers. For Cloudy Bay, the choice of closure was not solely a technical decision but also a strategic one, aimed at ensuring that the packaging reflected the same attention to detail as the wine itself, focusing on the quality and reliability of the closures, and on the closeness of Guala Closures to the market, also thanks to a local production plant in Auckland.

The experience of Cloudy Bay illustrates a broader shift in the industry: closures are no longer a purely functional component but an integral part of the overall product and brand strategy. In a market where quality, sustainability and brand differentiation are closely intertwined, the choice of closure can influence not only the preservation of the wine but also the perception of the brand in competitive export markets. Aluminium screwcaps and ranges such as Above Wine have established themselves as a credible and forwardlooking solution, aligning with both the technical demands of winemaking and the evolving expectations of consumers.

The closures are fully compatible with existing bottling lines, allowing wineries to adopt them without significant operational changes. For those seeking to integrate digital engagement or traceability, NFC and QR code technologies can be incorporated discreetly into the design.

First impression is everything, and great packaging is where that story begins.

Chaos Packaging is a relatively new term in the industry that has brought together innovation, storytelling, and sustainability to the forefront of product design. Coined by Michael J. Miraflor in an X post early last year, chaos packaging has fueled innovation.

Built on the idea that packaging should be more than a container, chaos packaging has turned ordinary boxes, bottles, and wrappers into memorable brand moments.

Brands can take the opportunity to surprise and engage, blending strategic thinking with bold visual execution.

Whether through tactile finishes, playful typography, or unexpected structural designs, each part of the packaging can tell a story.

Sustainability can also play a central role, as various brands have experimented with recyclable, compostable, and minimal-waste materials.

From artisan food brands to beauty lines, chaos packaging has allowed businesses to stand out on shelves and served as a bridge between art and business.

As smaller brands continue to find their way onto supermarket shelves, we’re seeing a wonderful influx of fresh ideas, from coffee and muesli bars to toothpaste and tea. But with all these choices, how do you tell one little white toothpaste tube from another? Easy! You pop it in a jar.

It’s exciting to see so many brands using packaging as a true creative medium. Gone are the days when colour blocking alone made you stand out. Today, it’s about form, feel, and function, and smaller brands often have the upper hand. Traditional packaging formats come with high MOQs, which can push smaller producers to think differently: a jar instead of a tube, a tin instead of a pouch, etc

When working with clients at Creative Jam, I like to run through a few key considerations before diving into any format:

• Shelf life: Cool packaging means nothing if it shortens your product’s life.

• Usability: Test how it works in real life. Powders stuck in tin lids are nobody’s friend.

• Transport: If it breaks in the DC, that’s on you.

• Shelf presence: Trial before you commit, will it stand, stack, and look the part?

• Scalability: What works for 3,000 units may not work for 10,000. Make sure you create good relationships with your supplier!

• Consumer testing: Tools like StickyBeek or Idealy can help you gauge real-world interest.

• sits alongside your other SKUs.

We’re entering an exciting era of playful jars, clever tins, and creative thinking, hopefully with less plastic and more sustainability in the mix.

By Laura Feavearyear, Creative Jam

Following the ban on fish-shaped soy sauce droppers in South Australia, sustainable design studio Heliograf has launched a plastic-free, compostable alternative.

After five years of highlighting the problem of soy fish with their award-winning recycled lamps and searching for alternatives, Heliograf has delivered a solution.

The fish-shaped soy dropper is made from bagasse pulp, a natural, renewable plant material that is plastic-free, home-compostable, and compliant with plastic bans in all Australian states.

The small plastic fish, beloved for their convenience, serve their purpose for only a few minutes but persist for centuries. If they escape into the environment, they can harm marine life and degrade into microplastics that may end up in our food supply.

“It’s a small change, but we truly believe every drop matters,” said Heliograf co-founder Angus Ware.

“We wanted to show that we can still create moments of joy when being sustainable.”

Collaborating with award-winning industrial designers Vert Design and leading sushi restaurants, Heliograf has created a practical, planet-friendly

alternative that retains the familiar joy and function of the original soy fish, without leaving microplastics in its wake.

Instead of being filled in a factory far from the restaurant, Holy Carp! droppers are filled fresh in the store. Switching allowed Heliograf to select a more easily compostable material, and means the soy is fresher. It also gives stores the flexibility to choose which sauce (or sauces) they offer.

Holy Carp! is also larger than a typical plastic soy fish. The designers observed that many customers grab a handful rather than just one, adding even more waste and plastic pollution.

The container has been carefully designed to resist spills and leaks and can be optionally sealed with a compostable sticker for trips on ‘stormier seas’. It safely holds soy for 48 hours.

Designed to comply with plastic bans and inspire others to voluntarily make the switch, Holy Carp! offers sushi lovers and restaurants an easy, sustainable swap with a feel-good message.

It’s a small change, but we truly believe every drop matters. We wanted to show that we can still create moments of joy when being sustainable.

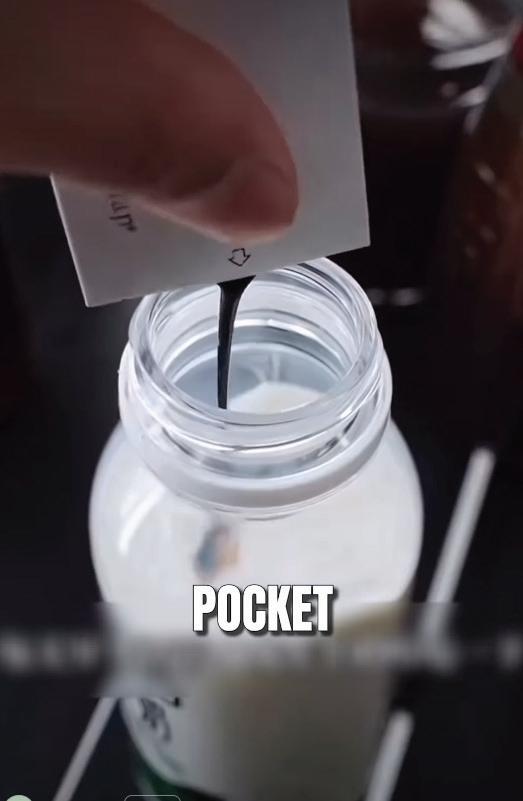

No Normal Coffee is on a mission to change how people experience coffee outdoors.

Founded by lifelong friends Alexander Häberlin and Philippe Greinacher, the brand was born in Switzerland, inspired by the duo’s countless outdoor adventures where great coffee was hard to come by.

Determined to find a better way, they created a solution that was light, flexible, and uncompromising in quality: coffee in a tube. Designed for convenience, the tube packaging offers lightweight transport and high flexibility, making it ideally suited for any outdoor adventure.

Aluminium tubes are a sustainable, protective, and practical choice for coffee packaging. They safeguard against oxygen, light, and moisture, keeping coffee fresh without preservatives.

Lightweight and easy to transport, they allow precise dosing and minimal waste. Their sleek, premium appearance also enhances brand appeal, reflecting the quality of the coffee inside.

Compared with traditional instant coffee, No Normal’s paste offers richer flavour, higher concentration, and smoother texture. Its brewing process preserves the natural aroma and complexity of coffee, avoiding the bitterness often associated with instant granules. The result is an elevated experience that merges convenience with craftsmanship. From hot or iced coffees to creamy milk-based drinks, the paste adapts to every preference. It even doubles as a versatile ingredient and can be spread on toast, mixed into yoghurt, drizzled over desserts, or added to baked goods for a caffeine kick.

A teaspoon of paste equals the caffeine strength of an espresso shot, giving adventurers that essential boost on the go. The tube stays fresh for months without refrigeration, making it ideal for travel and outdoor life.

Each No Normal Coffee tube represents the future of coffee; it fits neatly in your backpack.

Designed for convenience, the tube packaging offers lightweight transport and high flexibility, making it ideally suited for any outdoor adventure.

The countdown has officially begun for Packaging Innovations & Empack 2026, the UK’s biggest packaging event, returning to the NEC Birmingham in February 2026.

Bringing together over 7,400 packaging professionals, 450 suppliers, and 80 expert speakers, the 2026 edition has promised two unmissable days of discovery, inspiration, and connection.

Whether your focus is sustainability, automation, or cutting-edge materials, this year’s show offers curated zones, live machinery demos, and hands-on experiences for every corner of the industry.

Packed with more new features than ever before, Packaging Innovations & Empack 2026 offers visitors a front-row seat to the latest developments across the industry.

Attendees can explore the Innovation Gallery, a curated showcase of bold concepts and practical innovations, culminating in a live reveal of the winning entry. The Startup Zone runs alongside

this, giving emerging brands and early-stage innovators a platform to showcase fresh ideas, connect with potential partners, and gain visibility among leading industry professionals.

Meanwhile, the Future Trailblazer Awards, in partnership with IOM3, celebrate the rising stars shaping the next era of packaging, and the BCMPA’s Pitch the Co-Packers invites start-ups and early-stage brands to pitch their big ideas live for a chance to win GBP 1,500 and expert consultancy.

On the show floor, the Automation & Robotics Wall brings live demonstrations of cutting-edge machinery and smart manufacturing technologies, giving visitors a frontrow seat to the innovations driving efficiency and transformation across the packaging supply chain. They can also access tailored one-toone sessions and CPD-accredited

workshops with specialists covering policy, printing, outsourcing, materials, and more.

At the same time, the Discovery Theatre offers a front-row seat to insights from start-ups, SMEs, and suppliers showcasing breakthrough technologies, allowing attendees to discover the next generation of packaging solutions and connect with experts driving innovation across the industry.

Speakers will also be giving a glimpse of the bold ideas shaping the 2026 agenda, tackling realworld challenges through innovation, insight, and collaboration. That sense of collaboration and shared purpose runs through every part of Packaging Innovations & Empack.

It’s not just a place to see the latest technologies and materials. It’s where the industry connects, learns, and inspires one another.

Skellerup’s practical approach to innovation has always focused on serving the dairy farmer. Founded in 1910 and supporting the dairy industry for more than 85 years, Skellerup has built a proud legacy in the design and manufacturing of rubberware.

Its focus on durability, innovation and animal health has earned the trust of farmers in New Zealand and around the world. The business controls every stage from compound formulation and tooling design to processing parameters and final assembly, ensuring every product is engineered to exact specifications. This vertical integration delivers consistent quality, faster development, and continuous improvement through quick prototypes, rigorous lab testing, and on-farm trials and farmer feedback, ensuring every solution performs where it matters most.

At Skellerup, innovation is essential, guiding every step from concept to final product. Each product is purpose-built to meet real New Zealand on-farm demands, combining practical design with proven

performance to keep dairy operations running efficiently today and ready for the future, across cow breeds, milking systems, cow comfort, and long-term durability.

Thriver by Skellerup, available in Screw-In and Pull-Through Teat options, was developed to replicate the natural feeding experience while enhancing performance through precision engineering.

The goal was to create a teat that feels natural to the calf while delivering superior hygiene, flow control, and durability. The soft yet durable rubber formulation replicates the feel of a cow’s teat, encouraging a natural latch.

At the same time, the one-way valve and internal geometry ensure smooth milk flow without leaks or backflow. Antibacterial properties

Continued on page 40.

20 minutes with . . .

A

well-engineered teat promotes a secure latch, consistent milk flow, and minimal air intake, supporting a natural feeding experience and reducing the risk of choking and pneumonia.

Continued from page 39.

reduce cross-contamination, and a vanilla scent helps calves latch more quickly, promoting quicker adaptation and improving on-farm efficiency. The result is more efficient feeding, healthier calves, and stronger performance throughout the rearing season.

Teat design has a direct impact on how well calves feed, grow, and thrive. A well-engineered teat promotes a secure latch, consistent milk flow, and minimal air intake, supporting a natural feeding

experience and reducing the risk of choking and pneumonia.

Designing and manufacturing locally in Christchurch has allowed engineers to work directly with farmers, testing and refining solutions in real on-farm conditions. With complete control over production, Skellerup’s handson, end-to-end approach ensures its products perform exactly as farmers need, day in and day out.

The machinery is engineered inhouse to maintain exact tolerances, while each compound and product

is rigorously tested for performance both in the lab and on-farm. Guided by ISO 9001 quality standards and a culture of continuous improvement, every batch delivers the same proven reliability under demanding dairy conditions.

Skellerup is looking beyond today to shape the future of New Zealand dairy farming and develop the solutions farmers will need tomorrow.

Built on a legacy of technical expertise and continuous improvement, its products evolve to meet the next

generation of challenges, from animal welfare and efficiency to long-term value.

Guided by sustainability and circularity, Skellerup has created smarter solutions that support farmers and their herds today, while preparing the industry for what comes next.

With warnings of a gas crunch on the horizon, researchers are conceptualising a pilot plant to produce fossil fuel-free food-grade carbon dioxide (CO2).

Researcher

University of Canterbury

Researcher

University of Canterbury

For many food and drink producers, CO2 is essential. The gas boosts fruit and veggie growth in greenhouses, forms the bubbles in carbonated beverages, is pumped into meat trays to prolong freshness and makes the dry ice that keeps produce fresh during transport.

A fossil gas refinery in Taranaki produces the bulk of the country’s supply. When it suffered issues in 2023, food businesses across the sector felt the crunch. Beer brewers, for example, had to curb production as the cost of food-grade CO2 skyrocketed as high as 600 percent.

With their recent experience, many producers will be doubly worried by predictions that domestic gas supply could drop precipitously in the coming years.

University of Canterbury researchers Rebecca Peer and Karan Titus say New Zealand has an opportunity to replace increasingly unreliable fossil CO2 with “green” CO2, which doesn’t add to climate change.

The gas could be produced from waste wood instead: the slash left over from the harvesting of commercial forests.

This waste material is a growing issue, because the often-large boughs and branches are increasingly becoming debris during extreme weather events. As this material washes down gullies and rivers and out to sea, it can damage downstream communities, homes and bridges.

“Our solution could be a win-win, solving multiple problems,” said Peer.

In fact, New Zealand already produces a lot of “green” CO2. Every woodburning boiler in the country releases it. Beyond innovative small systems capturing some gas for greenhouses, the vast majority goes to waste.

Titus said current wood-burning boilers aren’t set up to produce the extremely pure concentration of CO2 that food and drink manufacturers require. Food-grade CO2 needs to be at least 99.5 percent pure.

But within an engineered pureoxygen environment, a wood-burning boiler would produce a rich source of green CO2, said Titus. He and fellow members of the Government-funded Carbon Removal Project are currently conceptualising a pilot plant capable of producing food-grade CO2 from slash.

The combustion of the wood would also provide a source of heat. This energy could power nearby factories or generate electricity, said Titus.

“This is a major opportunity for a company planning to switch to biomass, such as wood pellets,” said Titus. “A plant producing both green CO2 and energy would have two highly desirable products from which to earn revenue.”

A fossil fuel-free source of foodgrade CO2 could also offer a unique selling point for food businesses.

A Danish plant produces food-grade green CO2 from animal manure, livestock bedding and food waste. But New Zealand could construct the first plant producing green food-grade CO2 from wood waste – a story likely to be more enticing to customers.

“By purchasing green CO2, food companies would get access to a more reliable supply plus reduce the carbon

footprint of their products,” said Peer.

“If I was shopping for a chilled drink, and spotted that one had fossil fuelfree bubbles, I know I’d be drawn to it.”

Peer and Titus would like to connect with food and beverage companies wanting to know more about their research.

“We’re keen to gauge the interest across the sector in making the switch to green CO2. To make this a reality, we’ll need to bring together all the pieces of the puzzle: the technology, producers and potential customers,” said Titus.

The wider research will also investigate how some green CO2 could be captured and stored underground, actively removing greenhouse gas from the atmosphere to fight climate change.

The team – researchers from the Universities of Auckland, Canterbury and Waikato, the Bioeconomy Science Institute, Earth Sciences New Zealand and Mahi Ngātahi Law – is supported by a five-year Endeavour Grant from the Government.

To learn more about the research and connect, please visit www.carbonremoval.tech

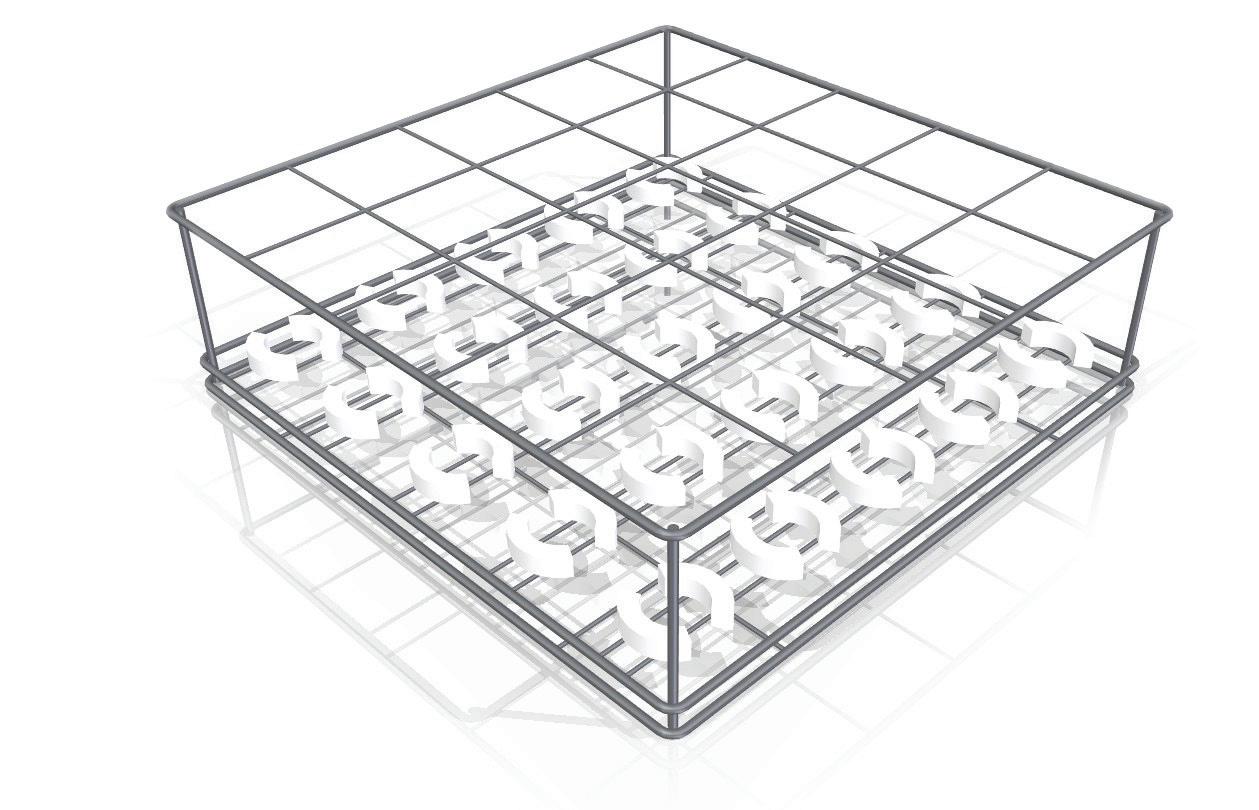

Rhima prides itself on being solutions-focused. From simple underbench units to massive industrial tunnels, the product range is a building block for a customised solution.

One of its key innovations includes custom-designed bottle washing.

“Our leadership really comes down to mastering one thing: building a washing solution that makes reusing bottles genuinely viable, hygienic, and profitable. Most of our competitors offer dishwashers; we offer dedicated bottle hygiene systems,” said Keagan Bond, marketing coordinator at Rhima.

shift away from single-use plastics at the point of sale.

For industries such as dairies, where hygiene standards are non-negotiable, Rhima machines feature a Thermostop system, which means the machine won’t proceed to the final sanitising rinse cycle until the water reaches the critical minimum temperature (usually 82°C).

“We don’t just adapt a machine; we engineer it from the ground up for bottles. Our Pass-Through and Underbench Bottle Washers feature dedicated nozzle racks. That means water isn’t just sprayed near the opening; it’s injected right inside, ensuring a guaranteed, HACCPcompliant clean of the internal surface, the most critical part.”

Rhima’s washing philosophy relies on a high volume of water at low pressure, as it effectively washes away residues like dried milk or beer without the aggressive force that can cause bottle breakage.

Its latest system, GoodTergo, was another exciting step beyond the factory. It’s a dedicated cleaning and sanitising system for reusable cups and bottles in places like cafes, offices, or public venues, fully supporting the

For a microbrewery starting, Bond said the RBW50U is perfect. As they scale, Rhima can integrate it with Conveyor Bottle Washers and even automation and robotics for loading and unloading, making the process seamless from start to finish.

“A milk bottle, a stubby beer bottle, a wine carafe, they all have different shapes. We design custom-moulded racks that cradle the specific bottles and align them perfectly with our spray jets, guaranteeing an efficient wash every time.”

An example Bond provided was of Rhima’s partnership with Schulz Organic Dairy in Australia. He said that Schulz was determined to eliminate plastic and transition its entire milk line to reusable glass bottles.

This presented a massive cleaning challenge: how do you wash thousands of glass milk bottles, known for their

Sustainability isn’t just a buzzword for us; it’s a design principle. Our entire focus is on getting the best possible hygiene result using the least amount of resources.

notoriously difficult cleaning due to milk residue, and guarantee absolute hygiene?

The Rhima team worked hand in hand with them to customise an industrial washer, developing unique racks and an injection control system to ensure a perfect, verifiable clean every time. This enabled Schulz to launch its return-and-reuse program successfully.

The result was a massive sustainability win as each glass bottle sold saves approximately 40g of plastic from landfill. Bond said it proved that when you combine a commitment to the environment with the right technology, circular-economy goals are achievable.

“Sustainability isn’t just a buzzword for us; it’s a design principle. Our entire focus is on getting the best possible hygiene result using the least amount of resources.”

Its industrial units, such as crate washers and bottle washers, have been designed to be extremely waterefficient. The wash tank water is continuously filtered and recirculated throughout the cycle, so only a minimal amount of fresh water is required for the final, hygienic rinse.

By using separate heating tanks and ensuring items are hot from the

main wash, the 82°C final rinse water causes items to ‘flash-dry’ almost instantly upon removal. This eliminates the need for energy-intensive drying tunnels, saving significant time and energy.

“We see our role as the crucial technological enabler for the entire ‘re-use’ movement. Without a reliable, certified way to hygienically clean returned packaging, these sustainable ventures can’t exist.”

The biggest hurdles for beverage producers, according to Bond, were public confidence and operational costs. Rhima’s validated, HACCPcompliant washing systems remove that hurdle. It gives producers the assurance they need to re-wash and refill containers, turning a waste problem into a truly circular, profitable loop.

“The Rethink. Reuse. Rhima. Ethos isn’t just a slogan; it reflects our commitment to working with companies and community initiatives that are trying to eliminate singleuse waste. We provide the essential technology that transforms a used item into a ready-to-use, safe container.”

Looking ahead, Bond said the future of commercial washing is about taking the circular economy to the next level, making reusables faster, safer, and

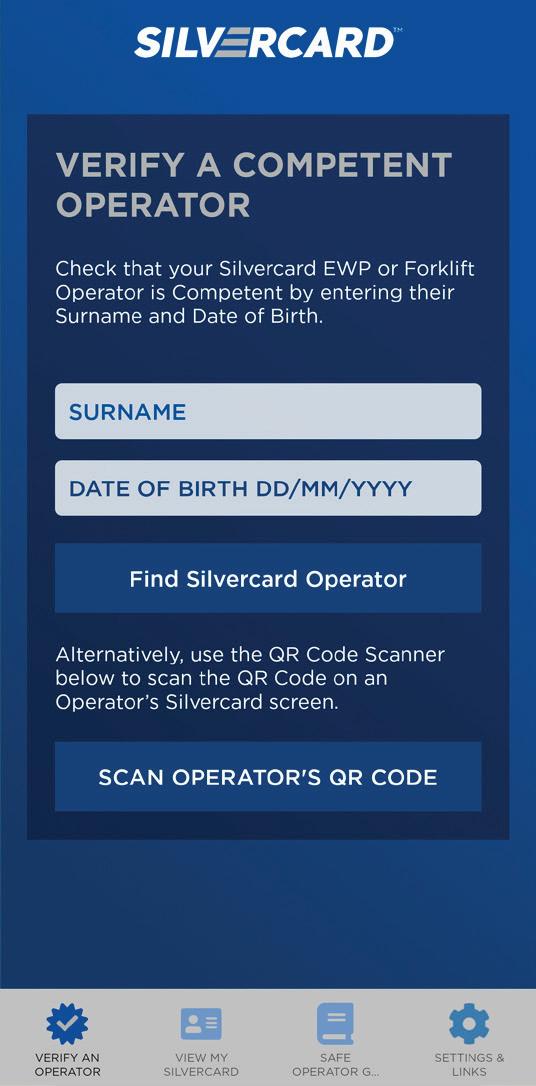

completely invisible to consumers. He said that right now, Rhima can track wash data; in the future, businesses will need digital passports for every reusable item. Innovation will focus on integrating RFID or QR codes with the washing machine’s control system to create a verifiable, cloud-based record of the cleaning cycle (temperature, detergent levels, time) for every single bottle. This will make hygiene instantly verifiable and will be the standard for mass-market reusable adoption.

Rhima has also consistently pushed the envelope on water efficiency, but the next step would be achieving near-zero water waste. This means pioneering advanced internal water treatment systems that recycle and further purify wash water, significantly reducing demand for fresh water and lowering discharge costs.

Additionally, as the volume of returned packaging grows, the bottleneck will be handling.

“We’ll see washing systems integrated with AI-powered sorting and inspection systems that can rapidly identify damage, filter contaminants, and automate the loading/unloading process with minimal human input, keeping labour costs down and throughput high.”