RHEA DESHMUKH FoY C 24-25

ELECTIVE IV

A21009

“ buildings too are children of earth and sun ”

1. Advantages

2. Disadvantages

1. Cigar Test

2. Biscuit Test

1. COB

2. Rammed Earth

3. Adobe Bricks

4. CSEB

5. Wattle and Daub

6. Straw in mud slip

7. 3D Mud Printing

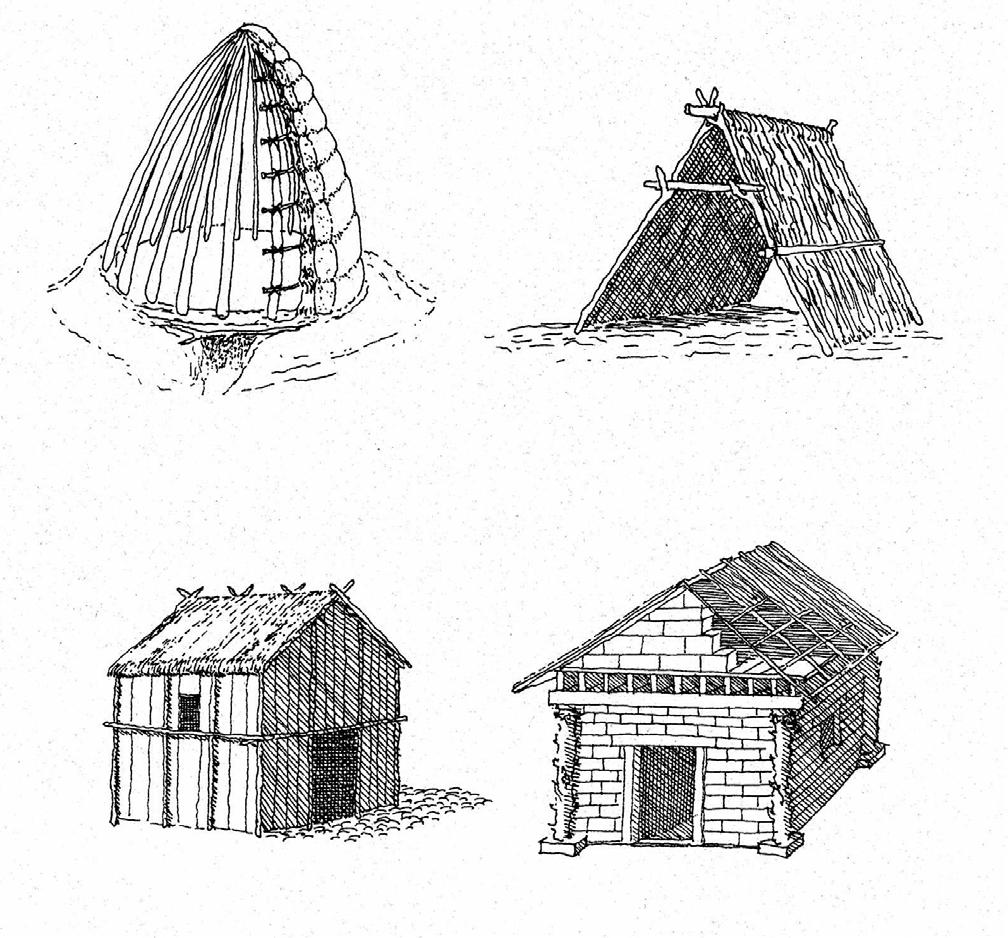

8. Earthbag Construction

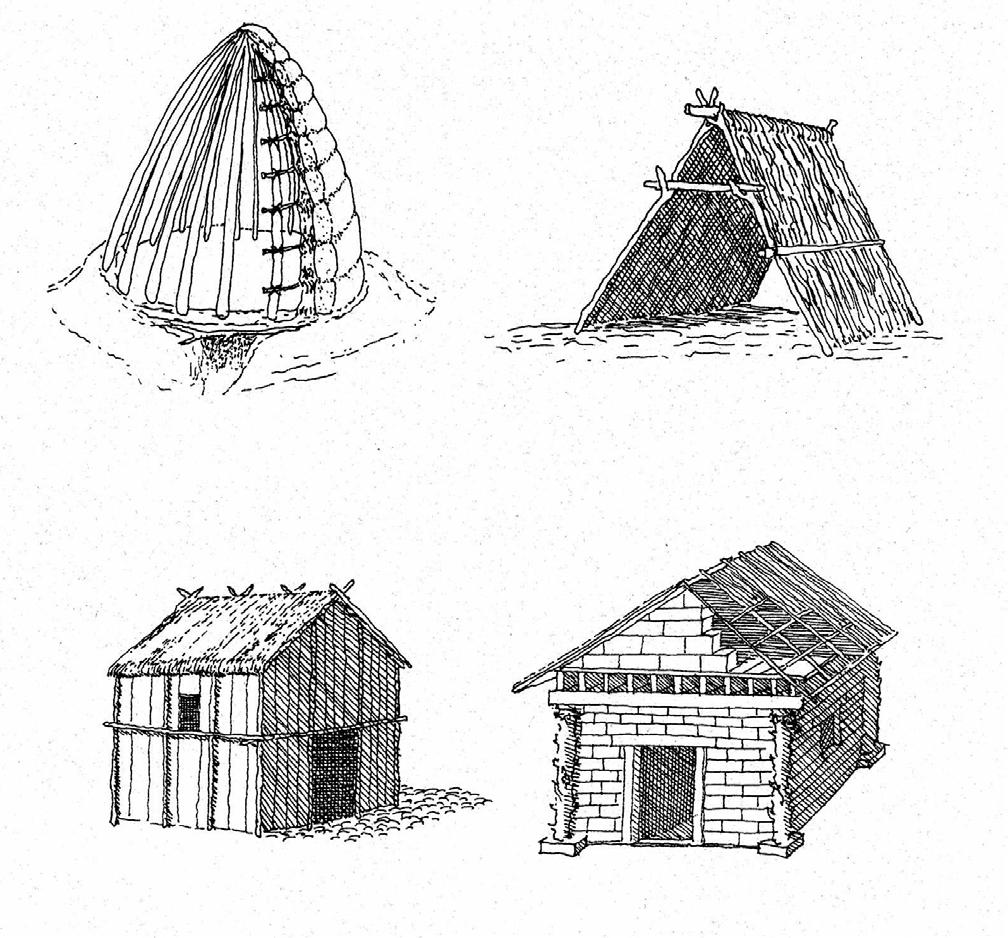

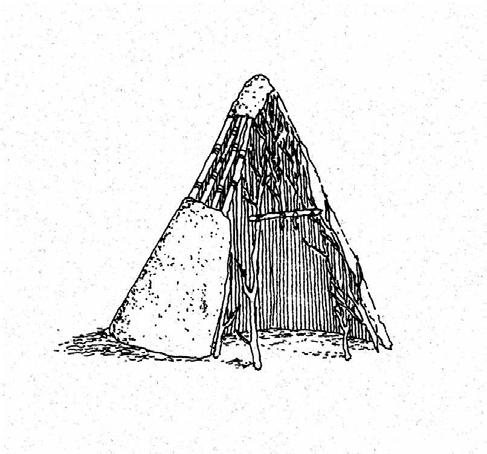

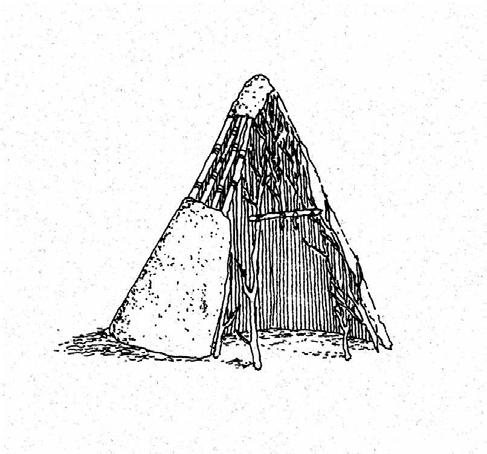

Mud as a construction material has been used in different forms since Neolithic times. Mud construction can be done anywhere around the world where mud is found in abundance. The rich history of adobe building has evolved with human culture along four distinct trajectories: mud bricks, wattle and daub, cob, and rammed earth. Although all these 4 methods have their unique characteristics, these technologies have one common base material. i.e. mud. Due to the recognized allure and environmentally friendly characteristics of earth-based construction, all four of these building techniques have undergone a resurgence in recent decades. The desire for raw, unprocessed building materials should not be limited to the same rural settings that hold most adobe buildings. That need is present in all of the global building cultures, but especially the developed and developing built environments where resources for materials are consumed in their most concentrated abundance.

1.Sustainability

Uses locally available materials, reducing transportation costs and environmental impact.

Produces minimal waste during construction and demolition.

2.Cost-Effective

Affordable due to the use of natural materials like soil, straw, and water. Labor-intensive but does not require expensive machinery or tools.

3.Thermal Insulation

Mud walls provide excellent insulation, keeping interiors cool in summer and warm in winter.

Reduces the need for artificial heating or cooling systems.

4.Eco-Friendly

Non-toxic and biodegradable materials make it environmentally friendly. Has a low carbon footprint compared to conventional construction.

4.Eco-Friendly

Non-toxic and biodegradable materials make it environmentally friendly. Has a low carbon footprint compared to conventional construction.

5.Customizability

Easily molded into various shapes and forms, allowing for artistic and aesthetic designs.

6.Low Embodied Energy

Minimal processing of materials results in lower embodied energy compared to concrete or steel.

1.Durability

Vulnerable to weathering, especially in regions with heavy rainfall or snow. Requires frequent maintenance to protect against erosion and cracking.

2.Structural Limitations

Lower load-bearing capacity compared to modern materials like concrete or steel.

Not suitable for high-rise buildings.

3.Moisture Sensitivity

Susceptible to water damage, making it necessary to add protective coatings or roofing extensions.

Can lead to swelling or weakening when exposed to prolonged moisture.

4.Pest Problems

Straw or organic materials used in the mixture can attract termites or rodents.

5.Labor-Intensive

Construction can be time-consuming and requires skilled labor for techniques like rammed earth or cob.

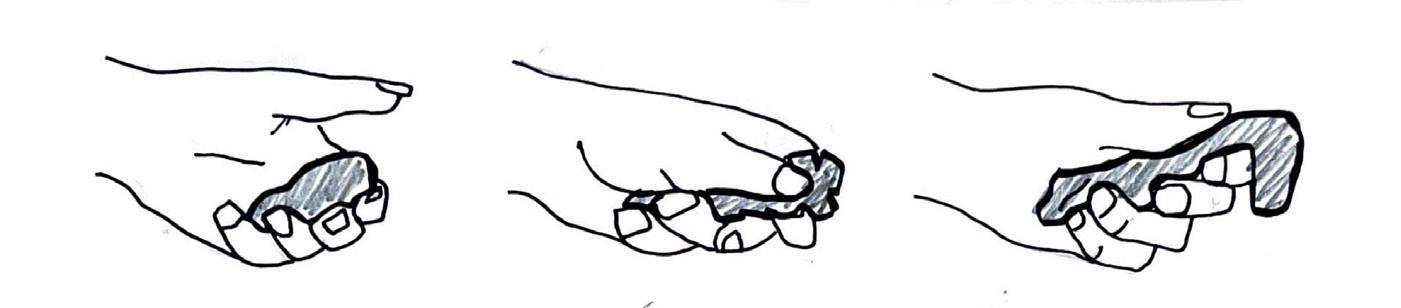

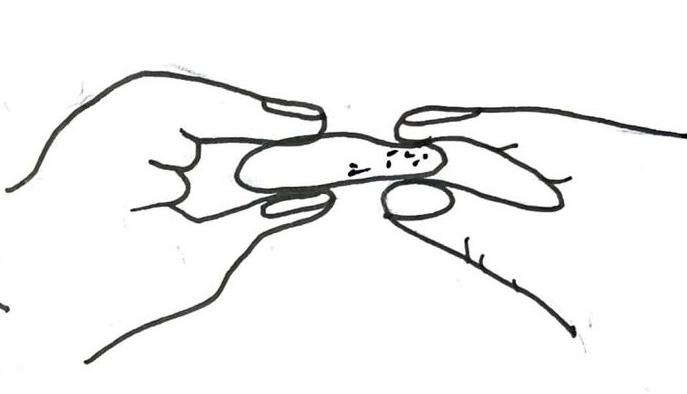

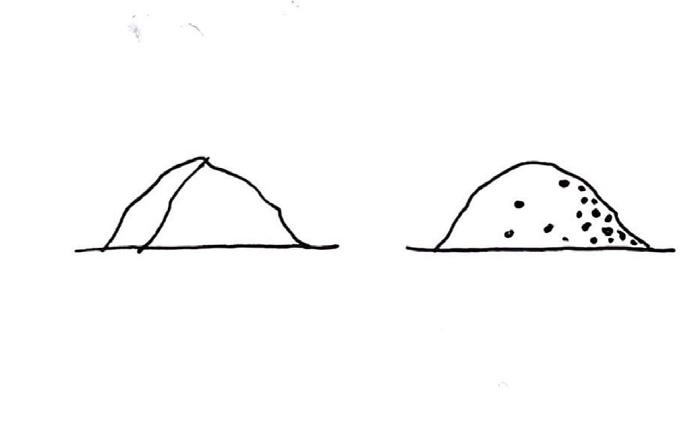

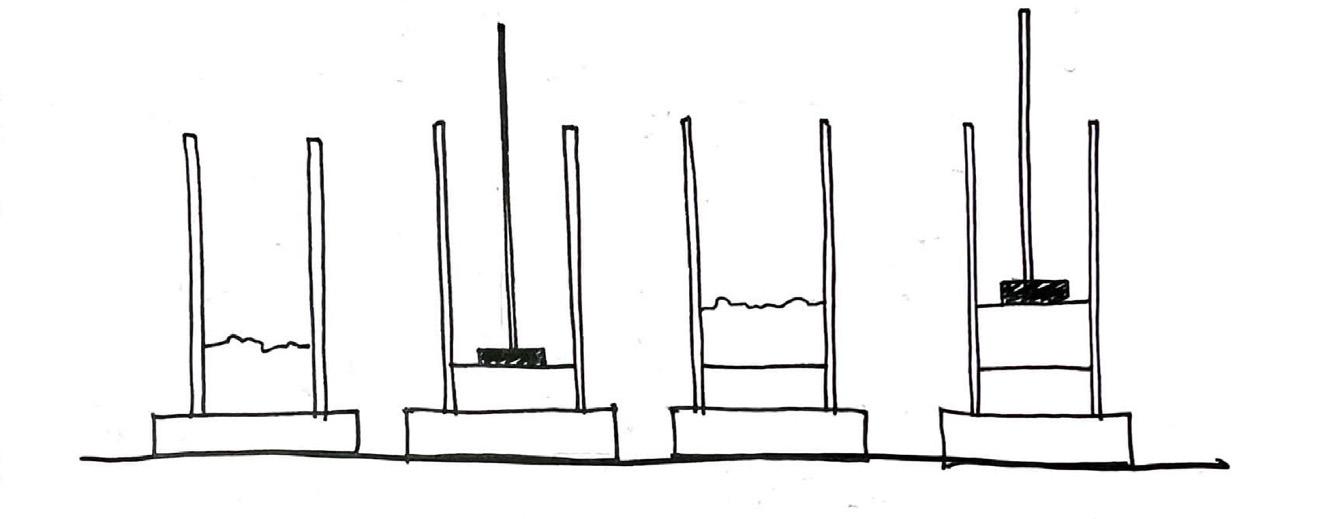

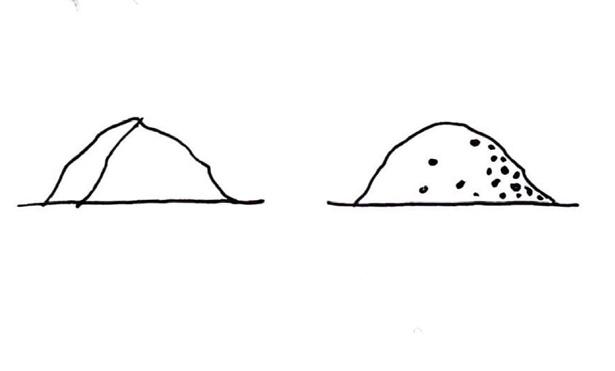

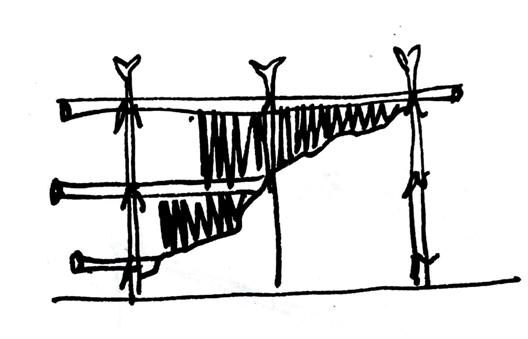

Roll a small handful of-soil (to which just enough water has been added to make it stick together) into a cigar or Sausage shape.

With the thumb and forefinger squeeze the end of the cigar until; it is about a quarter of an inch thick and go on squeezing and pushing it out of your palm to see how long it is before it breaks off and it falls to the floor.

1. If it just falls to pieces and cannot be shaped and pushed out it is too sandy and has practically no clay content at all. So it will only-be usable if you add a stabiliser to it, or get some clay and mix it in with the sandy soil.

2. If you can squeeze about two or three inches before it drops off, it means that there is sufficient clay in the sand and it will probably make a good building mud.

3. If you can go on squeezing and pushing it out until it is eight or nine inches long, it means that it is mainly clay and you will have cracking and shrinking problems unless sand or the right stabilisers are added. Naturally gravels will not stick together and you cannot even make a cigar and, similarly there is no point in testing organic soils as they are no use for building t’ work even if you can make a cigar with them. But don’t forget the organic soil may be only a surface layer and good building soil may be underneath it.

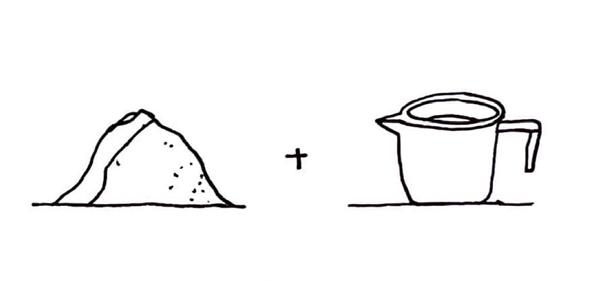

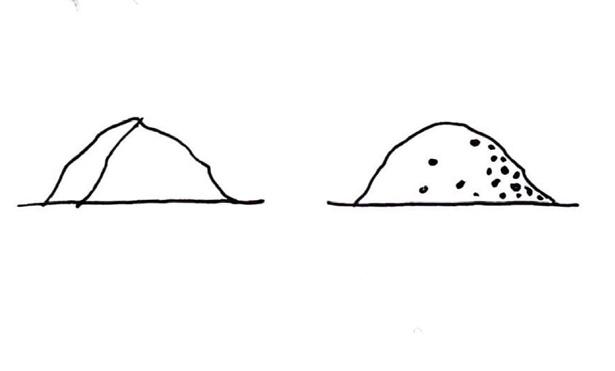

After moistening your soil, make a small fat “biscuit” shape (about 1/4” thick and 2” in diameter). Put it to dry thoroughly in the sun.

1. If when dry it crumbles to pieces and can hardly be picked up, or if you can crumble it easily with your fingers, then it will not be a good building material without stabilisers.

2. If you can break it into pieces without much difficulty, hut it takes some pressure to crumble it between your fingers - then it will probably be a good wall building mud.

3. If it is hard and difficult to break, or if it breaks with a snap like an over, baked biscuit, and you cannot powder it, it will be useless unless with stabilisers or unless a sandy soil is mixed with it.

Play about with your moistened soil until you are thoroughly dirty and then wash your hands clean.

1. If you are quickly clean with no effort it means that you were playing with loose sand, which by itself will not be a good mud wall material.

2. If it takes a little time to get clean and you feel as though you are getting rid of flour (atta or maida) and there is a powdery feel - it means you are playing with silt. You can use it only if you add stabilisers.

3. If you feel that you are using soap and your wet hands are slippery and it takes some time to get clean, you are washing off clay, and again, this will be no use for building without adding sand. Very often the soils are already mixed - so you can feel the gritty sand as well as the soapy slippery clay in “sandy clay” or “clayey sand”. This will mean you have a good building mud.

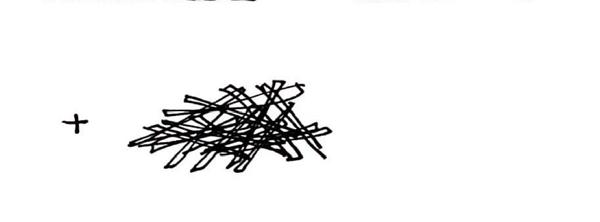

Materials

01

02

03

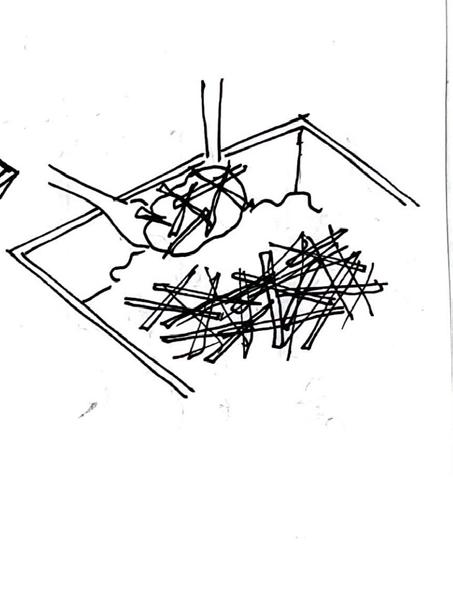

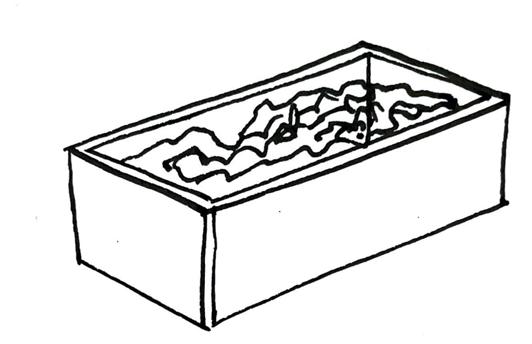

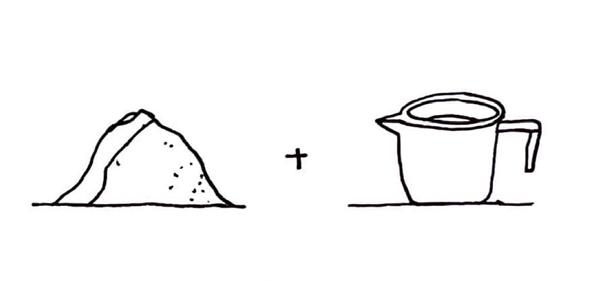

Mix together soil and water in a big container . Using the stomping technique, mix this together until thoroughly combined.

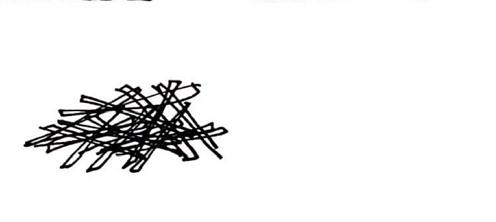

Take some soil and straw in your hands and form circular balls around the size of your palm. The straw should be properly covered by soil.

30-40cm long cob balls with 15 cm diameter

Cob homes are made of low-cost and natural materials. In fact the four main materials used in building Cob homes are made of clay, water, straw and earth. Though some individuals may think that this is a primitive form of living, the truth is that this low-cost building has higher durability than more traditional homes and offers an increasing amount of comfort for the owner.

Cob homes fall under a geothermal energy efficiency category. For example, a Cob home will naturally heat the home during the winter and cooler home during the summer. This means that there is virtually no electric bill. In fact, the individuals who do have electric bills for their Cob homes generally used electric to run small appliances, Internet capabilities and kitchen area appliances.

Advantages:

Cob is a sustainable material

Cob walls can maintain the moisture content of indoor spaces

Cob walls are breathable and have thermal properties that can create a comfortable living environment

Disadvantages:

Cob construction can be labor intensive and slow

It can be difficult to get a mortgage for a cob house

Cob walls can’t be built in wet or freezing weather

Insects and rodents can burrow into the walls and weaken them

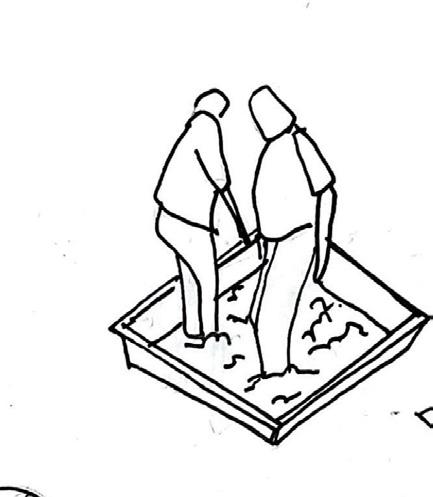

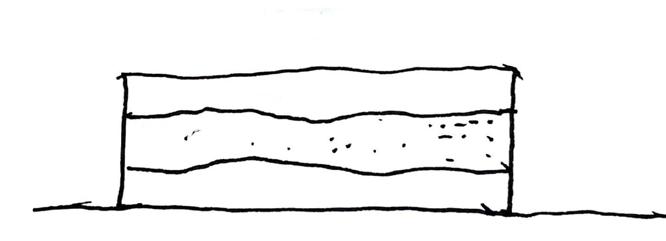

Rammed earth involves compacting layers of a soil mixture between formwork to create solid walls.

Materials

Mix soil and M sand in 1:1 proportions. Ensure a homogenous mixture.

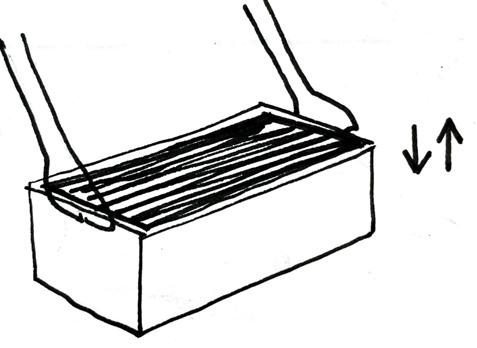

Create a formwork with the desired dimensions. Ensure no gaps are left between the edges. Add extra bracings if required to withstand

Pour the sand and soil misture into the formwork. With the help of a tamping rod, start tamping the soil till there is no loose soil visible. The layer should be firm .

Repeat this process till all the layers are done.

03 Remove the formwork. Different layers of mud should be visible.

While tamping, start tamping fro m the edges and then move to the centre. This helps achieve perfect and compact corners .

The rammed earth technique may be one of the oldest known construction methods, but it may be worth investigating updating it for modern times. Being an environmentally-friendly, strong, and even aesthetic material, rammed earth has a lot of potential for the future – just as much as it was a staple of the past.

Advantages:

•Extremely durable.

•Provides thermal mass for temperature regulation.

•Minimal maintenance required.

Disadvantages:

•Labor-intensive.

•Requires precision in soil mix proportions.

Adobe is a building technique where sun-dried mud bricks are used to construct walls. It has been used for centuries in arid regions due to its thermal properties.

Materials

Soil M Sand Wooden Shavings

Soil M Sand Rice Husk MIXTURE 01 MIXTURE 02

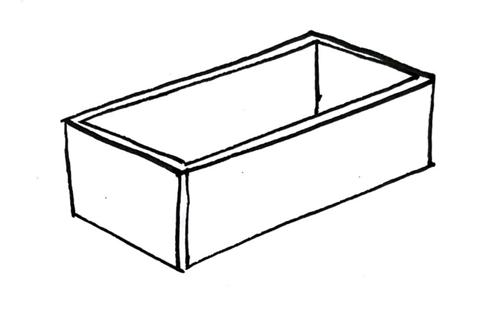

They can be of any size. But if the block is too big then it is difficult to lift. An ordinary, large burnt brick size is good, masons need no special training to build it. Different moulds can be designed so that several blocks can be made at one time.

They can be the same as an ordinary burnt brick (about 9” x 4.5” x 3”) or they can be bigger (l2” x 6” x 4”) if a thicker wall is preferred or indicated. Smaller bricks are more prone to develop cracks.

Prepare a mix of soil, straw, and water to the required consistency.

Compact the mixture by shaking it vigorously.

Pour the mix into wooden molds to form bricks.

Dry the bricks in the sun for 10-14 days until fully hardened.

Advantages:

•High thermal insulation.

•Low embodied energy.

•Cost-effective and eco-friendly.

Disadvantages:

•Not suitable for high-rainfall areas.

•Requires maintenance against weathering.

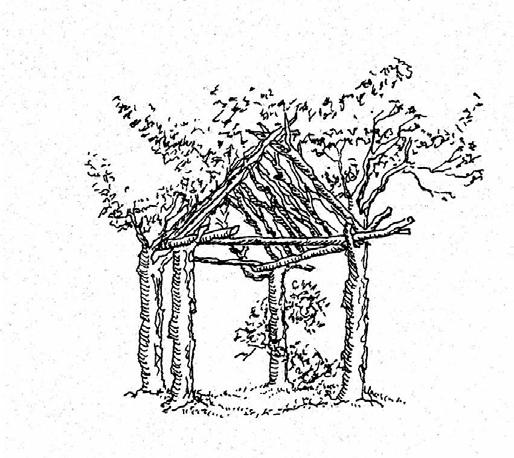

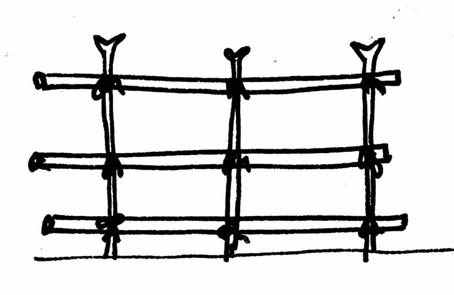

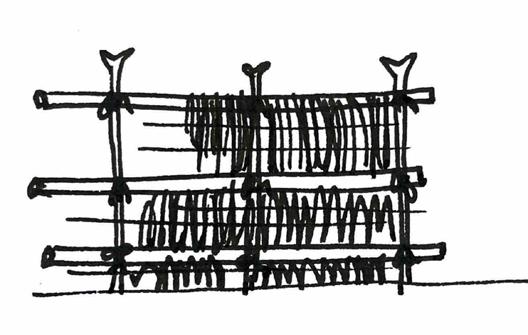

A traditional technique using a woven framework filled with mud to create walls.

Materials

02

Construct a woven framework of bamboo or sticks (wattle). 01

Prepare the daub mixture by mixing soil, straw, and water.

04

Apply the daub to the framework in layers, ensuring it adheres 03

Lime plaster can be applied over the daub.

Let the wall dry naturally.

Advantages:

•Uses locally available materials.

•Flexible and resistant to minor seismic movements.

Disadvantages:

•Limited durability in wet climates.

•Requires regular maintenance.

CSEB are compressed blocks made from soil stabilized with a small amount of cement or lime, providing strength and durability.

Mix soil, stabilizer, and water to a consistent texture.

02

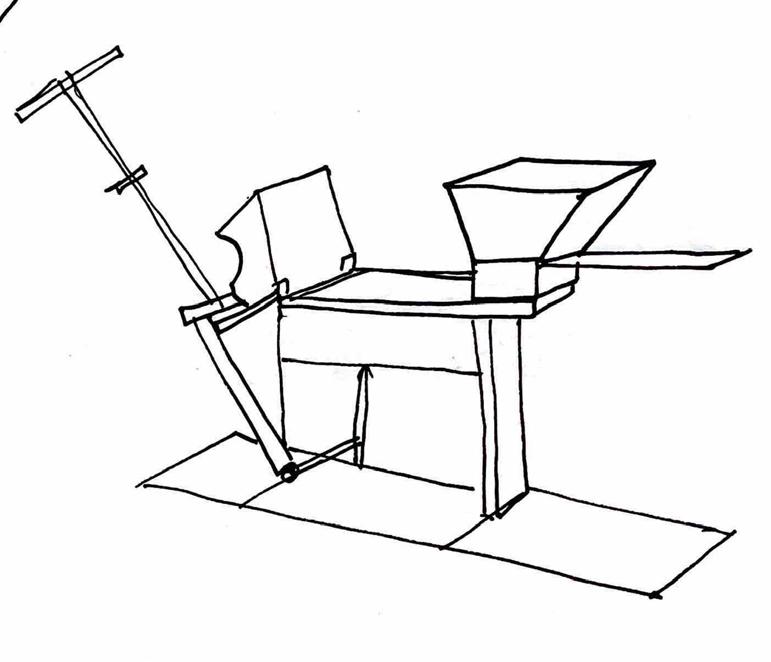

01 Place the mix into a mechanical press to form blocks.

03 Cure the blocks by covering and sprinkling water for 7-14 days.

Advantages:

•High strength and stability.

•Reduced environmental impact compared to fired bricks.

•Can be produced on-site.

Disadvantages:

•Requires equipment for compression.

•Limited workability in wet conditions.

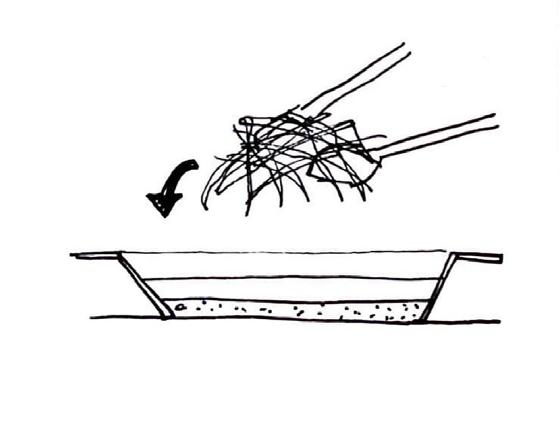

Straw in mud slip involves coating straw with a slurry of mud and using it as an infill material for walls.

Mix soil and water to create a slurry (mud slip). 01

03

02

Coat straw with the slurry until fully saturated.

Pack the mixture tightly into wooden frames or between

04

Allow the wall to dry and apply a mud plaster for finishing.

Advantages:

•Lightweight and insulating.

•Environmentally friendly.

Disadvantages:

•Limited structural strength.

•Susceptible to moisture damage.

Earthbags filled with soil are stacked to create walls, offering a versatile and earthquake-resistant technique.

Use barbed wire between layers to add stability. Plaster the wall for finishing. 03

Advantages:

Place the bags in rows, tamping each layer for compaction.

•Highly durable and disaster-resistant.

•Suitable for various climates.

Disadvantages:

•Time-consuming process.

•Requires skilled labor for proper tamping and plastering. Fill polypropylene bags with soil.

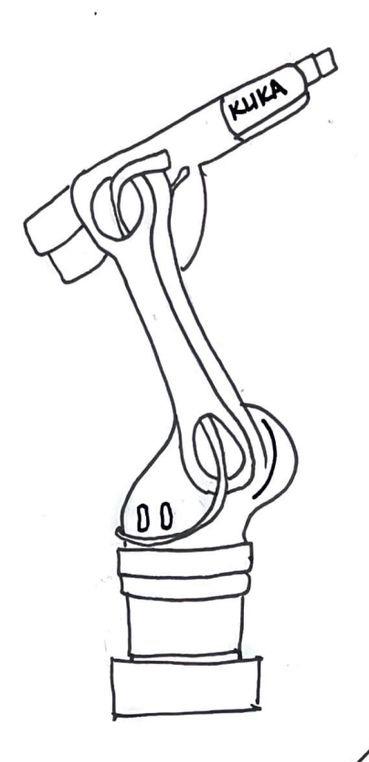

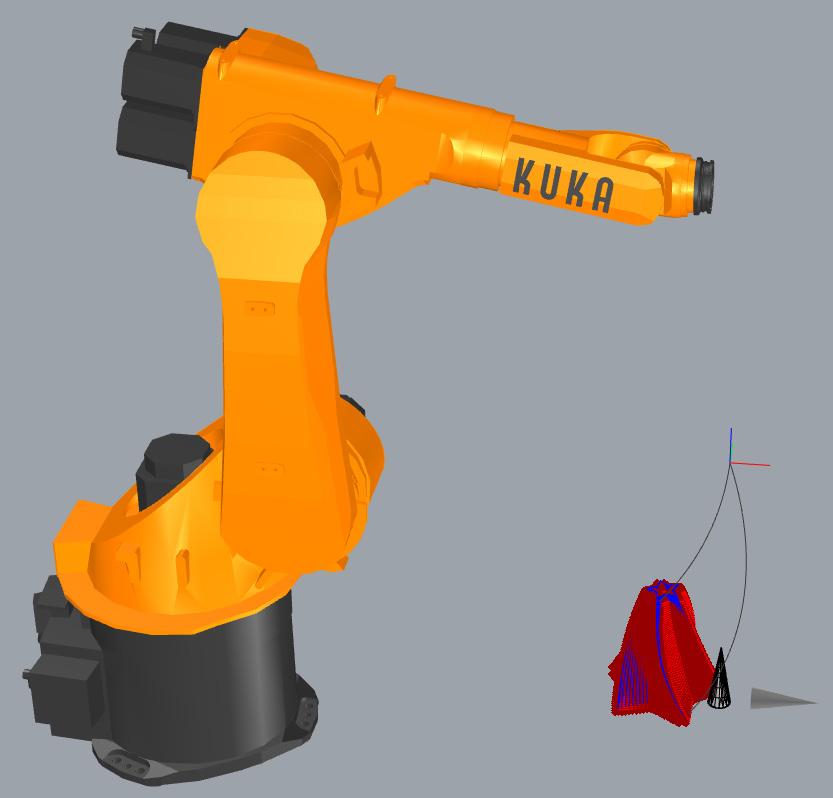

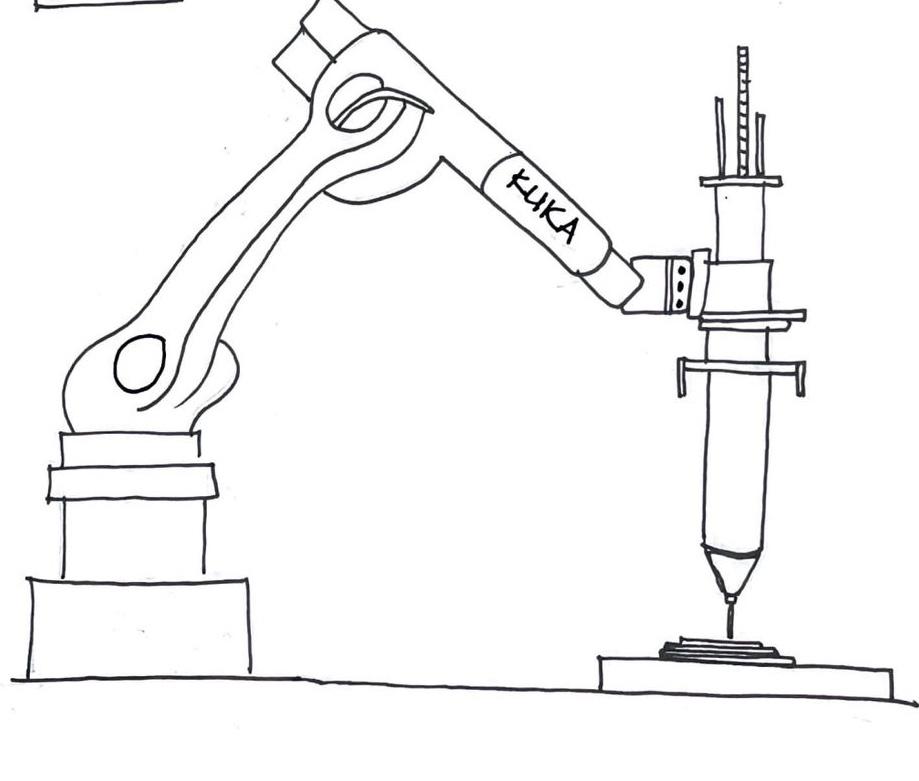

The KUKA KR 30-3 robot is a 6-axis robot arm, it has a payload of 30 kg and a reach of 2033 mm. Manufacturing applications include Remote TCP. A container with a 5mm nozzle is attached to this robot to 3d print the desired output.

Brand KUKA

Model KR 30-3

Type Robot Arm

Axes 6

Payload 30 kg

Reach 2033 mm

Repeatability 0.05 mm

Weight 665 kg

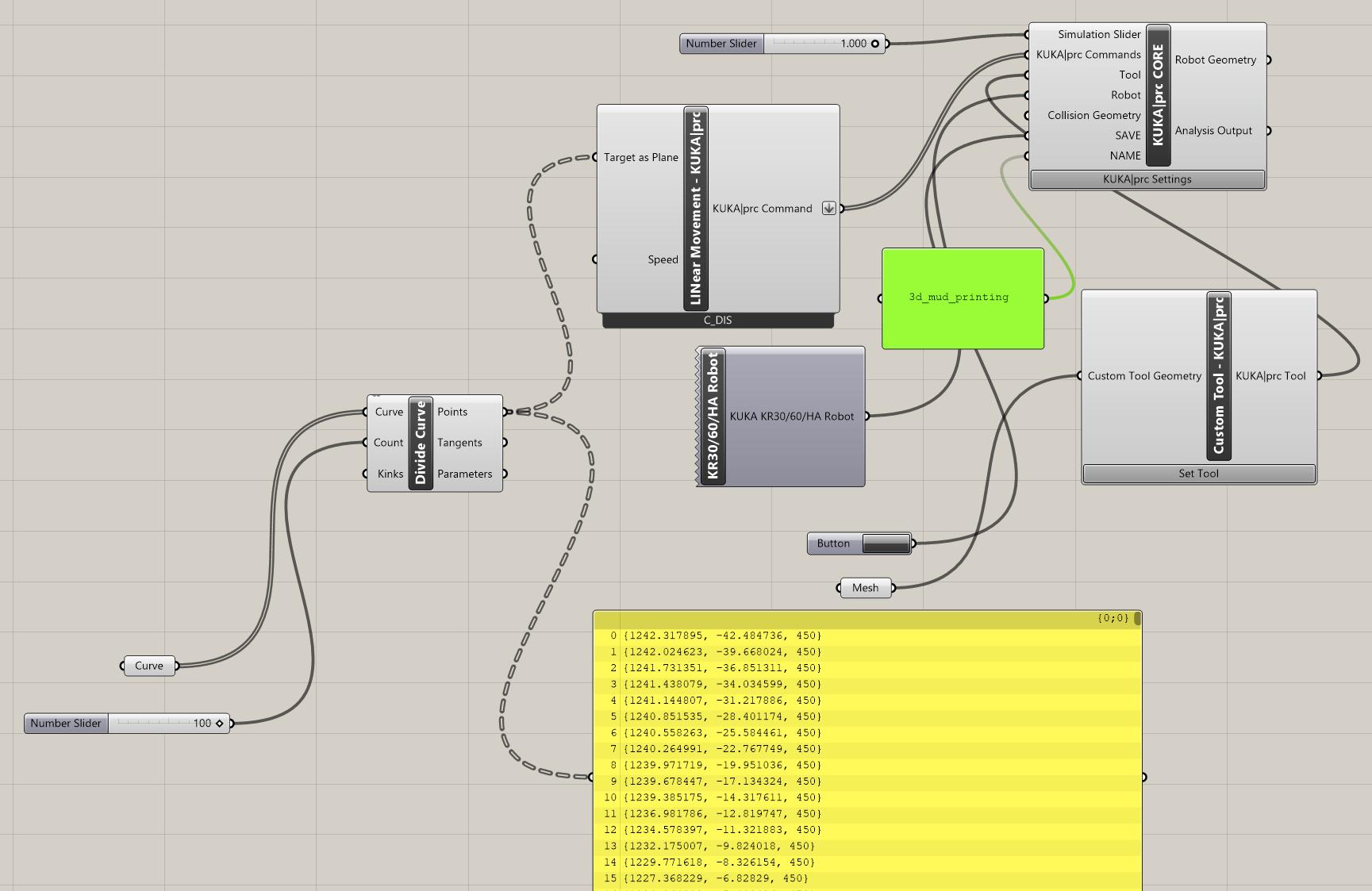

Extract the coordinates of all the points in an .SRC file. 01

Create the desired model in rhino. Using the contours command, create 5mm contour lines.

Export this is Grasshopper.

Divide the contours into multiple points. More the points, more accurate the output will be.

02

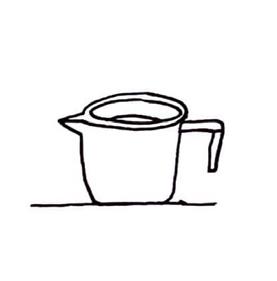

Soil Sand Shadu Water

Prepare a mixture of 2kg mud, 300g shadu, and 600g sand, a total of 3kg (capacity of the container is 3kg)

03

Input the .SRC file into the KUKA robot machine.

Load this mixture into a container with the 5mm nozzle.

Start the desired job on the robot.

Working in Argentina, they frequently use 3kg adobe bricks measuring 35cm x 16cm x 6cm with a resistance between 8.5 MPa and 9.0 MPa (based on empirical trials). The mixture used to make the bricks is clay earth with horse manure (4:1 ratio), to which we then add 1 part sawdust to 4 parts of the clay/manure mixture. It’s possible to render a lighter adobe mixture by adding more sawdust but it’s important to test the edges of the brick for resistance to pressure and friction.

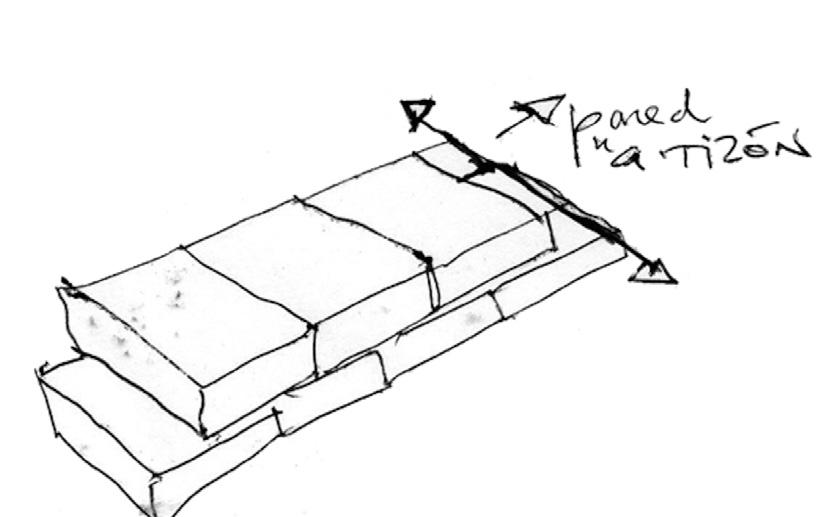

header technique, which lays the brick in a way that leaves the width side or “header” exposed, resulting in a wall that is as wide as the length of the bricks.

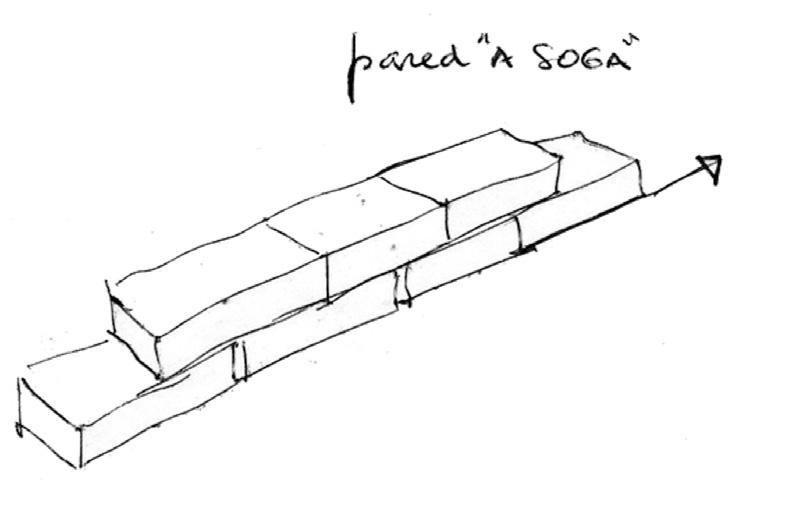

“stretcher technique,” where the bricks are laid in a longitudinal fashion, leaving only the stretcher side of the brick exposed, and resulting in a thinner wall depending on the width of the adobe bricks.

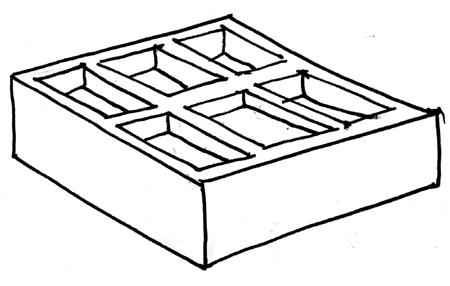

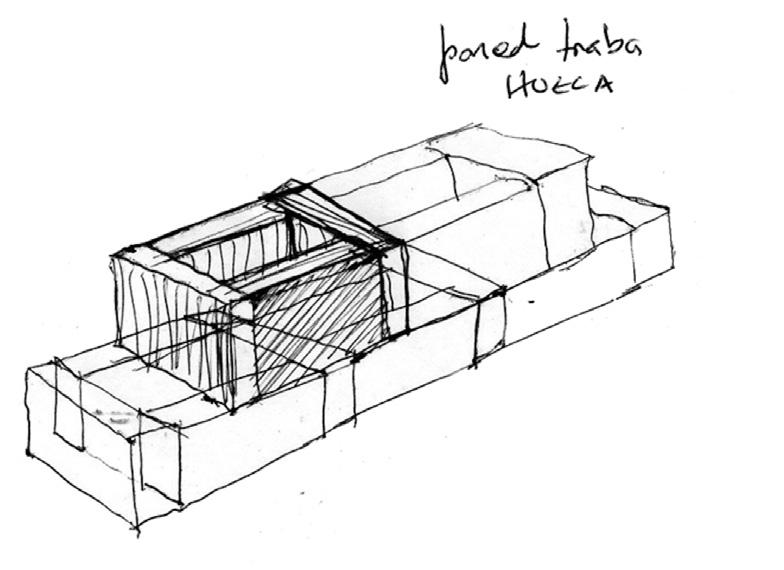

“hollow” technique, where 4 bricks are laid leaving their bed side exposed and forming a squareshaped “hollow” space between them. This square set of bricks then form a unit. When using this technique, every fifth set of bricks then uses a “header” technique as a way of pressure and seismic reinforcement.

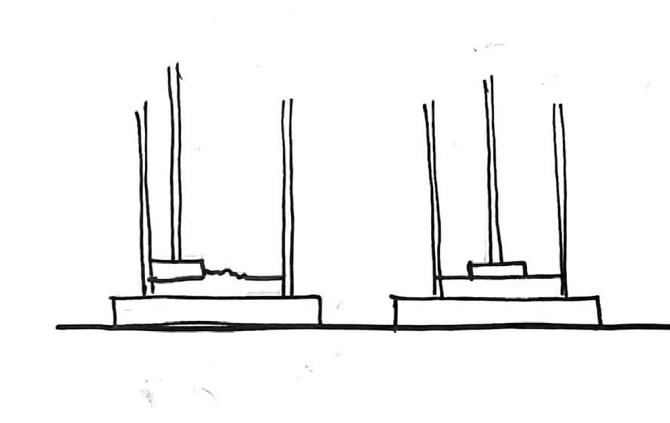

Pavilion Experiments - Pavilion 1 (2022): Learning from Mistakes

The first pavilion focused on learning through trial and error. Initially, participants struggled with mixtures but eventually optimized the process, building a sturdy two-meter wall. The wall now stands as a testament to the team’s growth.

Pavilion 3 (2024): Pillars, the third pavilion explored the limits of the earth’s structural potential by constructing slender cylindrical pillars reinforced with rebar and coconut fibers, which doubled the material’s strength. The seven two-metertall pillars demonstrate Earth’s versatility and resilience.

Pavilion 2 (2023): Modular System Building on earlier lessons, this project introduced modular systems and refined techniques like pneumatic compaction. A student workshop explored how modular earth systems could address modern housing challenges. The system continues to evolve.

Why Build with Earth? - There are several advantages to building with earth. It boasts the lowest carbon footprint of all building materials, is readily available (even as construction waste), and has excellent living properties, such as moisture regulation, heat accumulation, and the ability to bind harmful substances. These qualities make it a sus-