From the Editor’s desk

CHAIRMAN

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

EDITOR

Peter White peter.white@primecreative.com.au

JOURNALIST

Sean Gustini sean.gustini@primecreative.com.au

ADVERTISING

Adrian Kos: 0413 777 670 adrian.kos@primecreative.com.au

Ashley Blachford ashley.blachford@primecreative.com.au

DESIGN

Alejandro Molano

HEAD OF DESIGN Blake Storey

CLIENT SUCCESS MANAGER

Ben Sammartino ben.sammartino@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every e ort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

O cially endorsed by the VTA

Channel zero

The Australian Government has released its Net Zero Roadmap and Action Plan to reduce national emissions by 43 per cent on 2005 levels by 2030, 62-70 per cent by 2035 and net zero by 2050. This means both advantages and potential challenges for the transport industry.

The Transport and Infrastructure Net Zero Roadmap and Action Plan (one of six included plans) outlines a clear strategy to reduce emissions across the transport sector. Covering all transport modes and issues such as low carbon liquid fuels, freight and supply chains, systemwide efficiencies and infrastructure, it’s guided by five key priorities: invest in enabling low and zero emissions transport infrastructure; electrify and increase transport’s energy performance; switch to low carbon alternatives (LCLFs) to power transport where electrification is not feasible; innovate to expand cost competitive transport technology options; and scale up efforts to reduce embodied emissions in transport infrastructure.

While there are a plethora of steps and actions involved in the path towards net zero, the plan clearly states that a combination of low emission technologies and fuels will be required to decarbonise heavy vehicles, depending on payloads and distances. This includes the widespread adoption of battery electric vehicles (BEVs), transitioning to LCLFs and hydrogen, the use of battery swapping and range extending technologies and the uptake of productivity and efficiency improvements. But several obstacles stand in the way.

Australia’s lack of charging infrastructure, for example, will likely impact their roll-out. The widespread adoption of battery electric technologies will need to be supported by a national charging network.

According to the Australian Government, the additional weight of batteries in BEVs will have a significant

impact on the total mass of BEVs –especially for trucks which generally carry heavier loads over longer distances. The Government said the impact of this increased mass on road pavements will “result in additional road maintenance being required”, and additionally, that “more research and development will be needed” to decarbonise these vehicles.

On the plus side, increased productivity is one of the main benefits identified in the plan. It proposes that higher productivity freight vehicles will move more goods more efficiently. Additionally, modernising and efficiency improvements in internal combustion engine (ICE) trucks and their components is expected to reduce fuel usage, leading to cost savings and better emissions. There’s so much more to the Net Zero Roadmap and Action Plan that we haven’t touched on in this space. But one of its key messages is that the decarbonisation of Australia’s transport system will require collective action between all levels of government, business, industry and the community to ensure a fair and equitable transition.

Trailer Magazine Editor

Peter White

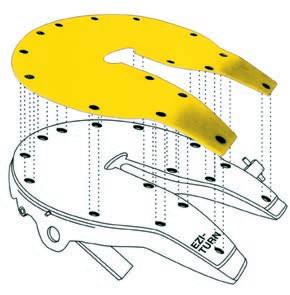

SAF INTRA

+ No Ubolts

+ More uptime

+ Low maintenance

+ Patented composite rotor

+ Frame bracket symmetry – no shocker bracing needed + SAF drum brake with quick release spherical anchor

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

SAF-HOLLAND (Aust.) Pty. Ltd

+ Long life disc brake technology SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

www.safholland.com.au

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763

Email: sales@safholland.com.au www.safholland.com.au

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd

(Aust.) QLD

(Aust.) QLD

(61-7) 3375 7033 Fax: (61-7) 3375 7044

Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044

(Aust.) WA

(Aust.) WA

Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730

November 2025 18 22

Business partnerships, people movements, developments that bolster freight productivity and more.

16 Economy

A new star rating system highlights where the biggest road safety risks are located and what upgrade opportunities there are.

18 Modern road tankers

See the industry’s latest tanker technology.

22 Low loaders

National Heavy Haulage and Ace Heavy Haulage have bolstered their oversized transport operations alongside two industry giants.

26 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

32 Moving floor

AAA Transport’s interstate waste and rubbish carting services have been notably strengthened by KEITH Walking Floor systems.

36 Weighing systems

Find out about the latest developments from KnorrBremse and Tramanco.

38 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

48 Safety insight

Safety is something that is deeply embedded into the operations of Norman Carriers.

50 Infrastructure spotlight

What you need to know about Australia’s biggest road projects this month.

52 World map

Although disparate in many circumstances, such as language, culture and geography, India and Latin America appear as the ideal partners in trade.

57 Fleet of the month

JD Refrigerated Transport, in the midst of a considerable growth period, is preparing to take the next step.

58 What’s on Upcoming shows and field days.

Vale Justin O’Donnell

Justin O’Donnell is remembered as a tireless advocate for safer roads and stronger industry practices.

He passed away on Tuesday 23 September 2025.

O’Donnell began his career with 3M Australia in 2010 and served in the company’s Transportation Safety Division for 13 years, leaving in 2023.

During that time, he was instrumental in introducing and promoting 3M’s reflective and conspicuity tapes – high-intensity markings that improve the visibility of heavy vehicles.

O’Donnell worked closely with the Victorian Transport Association (VTA) and its members, delivering detailed presentations and hands-on training sessions on the benefits and correct application of reflective technologies.

Many road transport operators, including FBT Transwest, adopted the technology as a result of his guidance and passion.

“Justin played a pivotal role in bringing and educating the industry on the safety benefits of conspic tape,” said FBT Transwest Managing Director, Cameron Dunn.

Former 3M employee, Mark Gorman, said O’Donnell’s professional approach was defined by diligence, integrity and quiet determination.

“The safer roads and stronger industry

practices evident across Australia today are a testament to his tireless efforts,” he said.

“His legacy lives on every time a truck or trailer marked with conspicuity tape is seen clearly by a driver at night, and every time a family member arrives home safely.”

VTA CEO, Peter Anderson, said Justin was a terrific friend of the VTA and a strong advocate for safety.

“We are saddened by his passing,” he said.

“Justin was a regular at VTA conferences, seminars and regional forums where he spoke with passion about innovative products to improve safety for all motorists.

“We extend our sincerest condolences to Justin’s family, friends and colleagues.”

Xtreme Freight Director, Amanda O’Brien, said O’Donnell was a respected figure in the transport community.

“His contributions and presence will be deeply missed by all who had the pleasure and privilege of working with him,” she said.

“He had a warm and supportive disposition and he always encouraged me throughout challenging times.

“His dedication and commitment left a lasting impact on many.

“My thoughts and heartfelt condolences go out to Justin’s family, friends and loved ones during this incredibly difficult time.”

Linfox launches NZ logistics operations for international partner

Linfox has extended its partnership with global diabetes management technology company, Dexcom, by launching logistics operations in New Zealand.

The move is one which follows two years of successful service delivery in Australia.

Linfox Executive General Manager New Zealand, Rob Farrar, said Linfox is looking forward to assisting Dexcom’s operations on this scale.

“We are proud to deliver services for a company that provides vital diabetes management and healthcare equipment for thousands of New Zealanders,” he said.

“Our distribution centre in Auckland enables us to provide specialised, temperature-controlled warehousing and reliable transport services across the country.

“The success of this onboarding reflects the dedication and collaboration of our project team, who ensured a seamless transition into the New Zealand market.”

Justin O’Donnell. Image: Mark Gorman.

Smart phone with Linfox’s logo displayed. Image: Timon/stock.adobe.com.

Kuehne + Nagel signage. Image: Ricochet64/stock.adobe.com.

Kuehne + Nagel launches FTL services in Australia

International intermodal transport provider, Kuehne + Nagel, has launched Full Trailer Load (FTL) solutions for its Australian operations.

The official rollout of this service has been in the works at Kuehne + Nagel Australia since last year, providing the transport operator with ample time to build a national network, create a market strategy and onboard partners.

Kuehne + Nagel Australia’s FTL offering has been developed to specifically target semi-trailers and B-doubles, with optional mezzanine floors.

These units are considered to be the market’s most common vehicle requirements according to Kuehne + Nagel National Road Logistics Business Development Manager, Anthony Robertson.

“Serving this demand positions us to immediately partner with and support a significant portion of the Australian FTL market,” he told Trailer

“Beyond these core services, our offering also includes road trains, flatbed trays, tilt trays, high cube and mass-managed vehicles across the country.”

Kuehne + Nagel Australia’s FTL value proposition will be operating nationwide, with a specific focus on transport lanes between capital cities as well as an overall capability to service any location accessible via road transport.

In addition to a wide range of vehicles and operating locations, the FTL offering is bolstered by stringent safety and compliance practices, which are fundamental to the company at large.

“Safety and compliance are and always

will remain core priorities for our business,”

Robertson told Trailer

“Our carrier onboarding process is robust, incorporating multiple checkpoints to ensure carrier compliance across legal, regulatory, and insurance requirements.

“In addition, our dedicated Quality, Safety, Health Environment team conducts random audits of our carriers to verify ongoing adherence to all standards and obligations.”

The rigor of this onboarding process extends to Kuehne + Nagel Australia’s selection of future carrier partners.

“We understand that our carriers are a direct extension of the Kuehne + Nagel brand,” Robertson said.

“Because of this, we hold them to the same high standards that define our reputation in the market.”

Team Global Express announces new logistics partnership

Team Global Express has entered a partnership with New Zealand A-Leagues football team, Auckland FC, to provide logistics services around Australasia.

As part of the agreement, Team Global Express will leverage its extensive multimodal transport network to ship Auckland FC’s new team jersey to fans across Australia, New Zealand and around the world for the upcoming season.

Team Global Express New Zealand CEO, Stewart Smith, said the company is proud to support Auckland FC’s transport

and logistics needs.

“Team Global Express supports Auckland FC’s mission to build and nurture talent, to punch above its weight and to succeed on the world stage,” he said.

“We’re incredibly excited for the season ahead and delighted to be a part of one of the most important sports and entertainment movements in Aotearoa.”

Auckland FC CEO, Nick Becker, said Team Global Express’ logistics network will help support the team with its

outreach to fans.

“The growth of Team Global Express has been impressive,” he said.

“They’re building a global brand here in New Zealand and Australia, mixing up the status quo and doing things differently. We like that a lot and are pleased to be partnering with this company.

“The support they will be providing us, in particular to our retail team, helping get much coveted merchandise out to fans, will be invaluable.

“They will be the team behind the team.”

Mineral Resources to acquire WA garnet miner

Mineral Resources (MinRes) has executed a binding Asset and Share Sale Agreement with a garnet miner based in Perth, Western Australia.

Under the agreement, MinRes will acquire Resource Development Group Limited’s (RDG) assets.

This includes the Lucky Bay garnet mine following creditor approval of MinRes’ proposed Deed of Company Arrangement (DOCA) proposal on 1 September.

Details of MinRes’ DOCA proposal were contained in the RDG administrators’ report to creditors as notified in an announcement on 25 August.

On 28 July, it was revealed that RDG (a business which MinRes is a secured creditor of and holds 64.3 per cent of its issued shares) would be entering voluntary administration.

MinRes had already been reviewing its arrangements with RDG including a request from the miner for a cash advance against existing loan arrangements to meet operating expenses.

The MinRes Board determined not to provide these arrangements at the time.

Now, MinRes will be assessing options to best realise value from the assets for RDG’s shareholders.

“The Board and I sought to ensure that MinRes shareholders could realise some value from their investment, and that there were no perceived conflicts in our decisions on RDG’s future,” Bundey said.

“I want to thank RDG’s employees for continuing to operate safely and productively during this process.”

All decisions relating to RDG and the acquisition have been undertaken by the MinRes Board.

MinRes Managing Director, Chris Ellison, and nominees on the RDG Board were not involved in deliberations.

Electric dolly innovation a game-changer for A-doubles

Intelligent transport specialist, iMOVE Cooperative Research Centre (CRC), will contribute part of $2.7 million to fund a new electric converter dolly for Electric Haulage Australia (EHAULA) under the Impact Extension Program’s second round.

The eDolly can be integrated into an A-double combination for testing and will be designed for seamless integration with Australia’s multi-trailer high-productivity vehicle configurations.

“The impact will be felt more significantly across mining, agriculture and long-haul logistics, sectors that carry the largest freight task and generate the highest emissions,” said EHAULA Finance Director, Jerome Coleman.

“These are precisely the areas where innovation will deliver the greatest carbon abatement. We call on regulators to modernise the Australian Design Rules so

we can safely deploy electric dollies and trailers across the country.”

By hybridising standard diesel combinations with the powered eDolly, operators will be able to achieve 40 per cent in fuel savings with lower capital investment.

EHAULA said that electric-powered trailers and dollies will play a major role in enabling heavy vehicles in Australia to transition to zero-emission road freight transport.

A 284 kWh swappable battery pack will be completed to help power the eDolly before testing begins at the Australian Automotive Research Centre.

This new hybrid approach will support the transition and provide the additional technology to allow full electric combinations to operate.

HVIA Powered Trailers Working Group

has expressed its support to start trialling the powered dolly technology.

However, range and potential payload reduction, and refuelling limitations will prevent heavy freight operators to adopt fully electric prime movers.

Electric trucks are also not designed to handle Australian road train weights and do not carry enough energy to meet the demands of the country’s freight tasks.

ThunderHaul, a ‘through-the-road parallel hybrid and drivetrain module’, and LightningVault, a scalable battery pack to suit required range and weight restraints, will help EHAULA deliver electric-powered dolly and trailer technology.

EHAULA’s partners Wettenhalls, Bulk Transport Equipment and Tiger Spider are expected to assist with the construction of the eDolly.

Two Mineral Resources autonomous road train combinations. Image: Mineral Resources.

Rentco announces new CEO

Mark Kirkpatrick has been appointed as Rentco’s new CEO.

Kirkpatrick brings more than 30 years of executive leadership across international freight, asset leasing and heavy maintenance to Rentco.

As CEO of Rail First Asset Management, he transformed one of Australia’s largest independent rail leasing businesses by driving service improvements, sustained growth and operational excellence.

Prior to that, he spent seven years at Aurizon in several General Manager positions.

Rentco Chairman, Bob Fast, welcomed Kirkpatrick to the business.

“Mark’s appointment signals an exciting new chapter for Rentco,” he said.

TRP launches new Victorian branch

PACCAR Parts’ TRP brand has opened a new truck and trailer parts store in Bendigo, Victoria.

The new store will stock well-known brand consumables for all major truck brands.

Owned and operated by Leake Group, the Bendigo site joins TRP 358 outlets worldwide including 19 in Australia.

“Graham Thomson Motors is proud to bring our award-winning spare parts team to Bendigo with a new TRP store,” said Graham Thomson Motors General Manager, Anthony Conte.

“Bendigo has been a cornerstone to Graham Thomson Motors’ success for many years, with valued customers and stakeholders in Central Victoria.”

Conte said the new Victorian site will service customers in Bendigo and surrounding areas through a range of quality, warranty-backed parts for all makes of trucks and trailers.

This range varies from filtration, lubricant and electrical products to brakes, suspensions, steering, wheel ends, trailer parts and accessories.

“We look forward to strengthening our partnership with existing stakeholders and forging new relationships to support the growth of the Bendigo area,” Conte said.

“With his proven leadership and industry insight, Rentco is well-positioned to expand our offerings and deliver innovative transport solutions while staying true to the values of reliability, service and trusted relationships that have shaped our business from the beginning.”

Rentco founder and outgoing CEO, Bob Shier, will remain with the organisation as Executive Director where he will continue

continue to support the leadership team and Board.

“I’m honoured to join Rentco at such a pivotal moment,” Kirkpatrick said.

“Bob and his team have built an exceptional business with a strong reputation for customer service and operational integrity.

“I look forward to working with the team to build on that legacy and lead the next chapter of growth.”

HELLA Managing Director steps down

HELLA Australia Managing Director, Darren Robinson, has announced his resignation.

Robinson’s 15-year tenure was split between the vehicle component manufacturer’s operations in both Australia and the United Kingdom.

Reflecting on his journey with HELLA, Robinson expressed his gratitude for those who worked with him and played a role in his transition to the Australian market.

“I would sincerely like to thank all those who have helped and supported me in my HELLA journey, and for making my transition from the UK to Australia a truly awesome experience,” he said in a statement online.

“I have had to make some tough decisions over the years, and on the way, I made my fair share of mistakes.

“But those who know me, know that I have given my all. I have been honest and open and have truly strived to make HELLA a strong partner, and a great place to work.

“Together, we have driven change, smashed targets, had more than a few laughs, and delivered what we promised.”

Mark Kirkpatrick with Rentco founder and former CEO, Bob Shier. Image: Rentco.

NEW PRODUCT, NEW STOCK. AVAILABLE NOW.

Engineered for durability with the finest materials and Krueger’s renowned chassis design and workmanship, our new dry van and refrigerated models are now available in versatile B or AB combination setups. Offering you range of options, specifications, and lengths from 33 to 48 feet, these trailers deliver unmatched performance tailored to your needs.

• Customizable Solutions for Freight Needs.

• Designed to offer flexibility, perfectly tailored to meet the demands of dedicated freight tasks.

• Expertly engineered for superior strength, ensuring long-lasting performance and reliability.

• Built using the world renowned FERROPLAST thermal technology.

• Interior used the advance Double-Decker loader system allowing greater ease and safer use in load management.

• Equipped with Krueger’s RFS Mark V suspension, designed for Australian Roads.

Fonterra reports strong financial year results

Dairy cooperative, Fonterra, has released financial year 2025 results which demonstrate continued success for the company.

Fonterra generated $26 billion NZD (approx. $22.91 billion AUD) in revenue during FY25. This was a 15 per cent increase year-on-year which led to a 30.6 per cent increase in total cash returns to shareholders of $16 billion NZD (approx. $14.10 billion AUD).

The cooperative’s final calculated Farmgate Milk Price for the 2024/25 season was $10.16 NZD (approx. $8.95 AUD) per kilogram of milk solids, resulting in $15.3 billion NZD (approx. $13.48 billion AUD) in milk payments to New Zealand farmers.

Fonterra also announced a FY25 full year dividend of $0.57 NZD (approx. $0.50 AUD) fully imputed. At the upper end of its dividend policy, this equated to $916 million NZD (approx. $807.28 million AUD) of cash to shareholders and unit holders.

Fonterra CEO, Miles Hurrell, said FY25 has been one of the company’s strongest financial years in relation to shareholder returns.

“We continue to see good demand from global customers for our high-quality products made from New Zealand farmers’ milk and this is driving returns through both the Farmgate Milk Price and dividends,” he said.

“Our vision is to be the source of the world’s most valued dairy. Our strategy is designed to grow end-to-end value for farmers by focusing on being a B2B dairy nutrition provider, working closely with customers through our high-performing

Ingredients and Foodservice channels.

“During the year, we’ve taken important steps towards this goal, including running a robust divestment process for global Consumer and associated businesses. This resulted in an agreement to sell the businesses to Lactalis for $4.22 billion (approx. $3.72 billion AUD), subject to approvals.”

Hurrell said Fonterra is being positioned to deliver further value through its Foodservice and Ingredients businesses.

This will include continuing to invest in new manufacturing capabilities to meet growing customer demand for its highvalue products.

“We have a pipeline of potential growth investments we’re assessing, with plans to invest up to $1 billion (approx. $881.42 billion AUD) over the next three to four years in projects to generate further value and drive operational cost efficiencies,” Hurrell said. These projects include growing the value of Fonterra’s existing protein portfolio; investments in site operations which include an Enterprise Resource Planning system replacement, data, AI and automation; and adding value to milkfat through new butter and cream cheese investments which will support the company’s Foodservice and Ingredients businesses.

Reported operating profit for Fonterra increased to $1.7 billion NZD (approx. $1.50 AUD), up from $1.5 billion the year prior.

Profit after tax was $1.1 billion NZD (approx. $969.57 million AUD).

The cooperative also delivered an increased Return on Capital of 10.9 per cent in line with its target range of 10-12 per cent.

Followmont Transport partners with Chemist Warehouse

Followmont Transport has collaborated with Chemist Warehouse by delivering a tailored IT solution to meet its complex freight needs.

The Followmont Transport team recently designed a customised pallet consolidation and carton tracking system

for Chemist Warehouse.

Seamlessly integrating into the Followmont Customer Portal, this provided Chemist Warehouse with full freight visibility across its network.

“This solution not only met operational requirements but also showcased the

Fonterra’s New Zealand head o ce. Image: JHVEPhoto/stock.adobe.com.

“This result was driven by higher operating profit in the ingredients business, due to demand for our protein portfolio and our use of margin hedging tools and indexed-based pricing,” Hurrell said.

“Foodservice sales volumes continue to grow off the back of continued demand in Greater China for our high-value products including UHT cream, butter and mozzarella.”

Fonterra’s business proposed to be divested, Mainland Group, benefited from sales volume growth in the Consumer business and the Australia business having a stable milk price against higher global commodity prices.

According to Hurrell, Fonterra’s balance sheet metrics are in line with the prior year, maintaining the cooperative’s robust position and providing optionality for the future.

Looking further ahead, as well as targeting earnings to return to current levels in three years, Fonterra has confirmed it is maintaining the strategic targets and policy settings announced in September 2024 if Mainland Group is divested.

This includes a target average Return on Capital of 10-12 per cent from FY26, which is above Fonterra’s five-year average.

“Our ongoing balance sheet strength, combined with our focused strategic direction, means the Co-op is well prepared for the future and positioned to continue delivering positive returns to shareholders,” Hurrell said.

innovation and adaptability of our people,” Followmont Transport said.

“A huge thank you to our sales and IT teams for working together to deliver this outcome quickly and smoothly, and to the Chemist Warehouse team for their collaboration throughout the process.

“This partnership is a great example of how working together and embracing innovation continues to drive Followmont forward as a trusted logistics partner.”

Linfox extends partnership with Pilbara-based iron ore company

Linfox has strengthened its partnership with one of the world’s largest iron ore mining companies, Fortescue.

Fortescue is a global metal mining company headquartered in Western Australia, with major mines in operation in the Pilbara region.

Linfox, a leading transport and logistics provider in the country, is extending its transport and logistics services with the company.

“We are proud to deliver specialised warehousing and distribution services for Fortescue as we grow stronger in WA and provide comprehensive supply chain solutions for the global company,” said Linfox President Resources and Industrial, Gary Pyne.

“With a large fleet of company-owned vehicles and a significant property footprint tailored to servicing the mining sector, Linfox leads the provision of vital freight services to mining customers in WA.”

Wodonga heavy vehicle training facility to receive major upgrade

Construction has started on the Logic Innovation Precinct in Wodonga, Victoria, with $24 million in funding provided by the Australian Government.

The funding includes $22 million to be added for a Heavy Vehicle Technology Program and $2 million for Phase One of an Advanced Manufacturing Centre of Excellence.

“Our investment in this cutting-edge precinct will create jobs and economic opportunities in the Albury Wodonga region, as well as benefitting Australia’s heavy vehicle industry,” said Victorian Minister for Regional Development and Local Government, Kirsty McBain.

“Transforming how heavy vehicle operators are trained will better equip them for new technologies and practices, making our roads safer for everyone.”

The new facilities will primarily include a heavy technology workshop. Once operational, they will also have experimental advanced manufacturing with 3D printing, robotics and automation.

The precinct is expected to draw in up to 1,200 students in its first four years by expanding Wodonga TAFE’s Heavy Vehicle Technology Program to include Advanced Manufacturing.

It will also support the Australian Defence Force (ADF) emergency services and education sector.

“Wodonga TAFE is excited to be able to provide this fantastic opportunity to our industries and communities,” said Wodonga TAFE CEO, Phil Paterson.

“With this funding and the facilities and capabilities it will bring, we are preparing our workforces for the skills needs of the future, as well as providing a space for collaboration, experimentation and innovation.”

Joss Construction has been appointed as the main works construction provider for the precinct.

The upgrades to the Heavy Vehicle Technology Program and Advanced Manufacturing Centre of Excellence are just two of the projects being funded through the Albury Wodonga Regional Projects initiative.

“Joss is thrilled to be a trusted partner for the delivery of these significant local projects, which will ensure the engagement of local trades and material suppliers throughout the entire construction phase,” said Joss Group CEO, Ed Whiting.

“Wodonga TAFE’s Vehicle Training Facility and Phase One of the Advanced Manufacturing Centre of Excellence will provide a substantial economic benefit to the region for the coming years and create a legacy we will all be very proud of.”

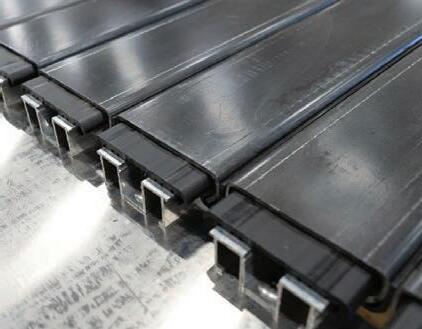

• 30 + years in the market place

• Clean, grease-free fifth wheel

• More cost effective

• Easy to fit

• Consistent steering characteristics

• Environmentally friendly

• Australian designed & manufactured

• Used by some of the most highly

companies since 1990

Austroads’ star rating program is identifying which roads pose the highest risks of death and serious injury and where road upgrades will have the greatest impact. Image: mastersky/stock.adobe.com.

Follow the stars home

Australia’s freight routes keep the economy moving, but not all roads are built equal. A new star rating system highlights where the biggest safety risks are located and what upgrade opportunities there are.

With transport and commuter traffic surging across the country’s busiest highways, a nationally coordinated effort is addressing critical road safety concerns.

Austroads has launched safety star ratings for Australia’s major arterial roads in a significant step towards making them safer.

The star ratings are part of the Australian Road Assessment Program (AusRAP), a nationally coordinated effort led by Austroads to identify which roads pose the highest risks of death and serious injury and where road upgrades will have the greatest life-saving impact.

The AusRAP star ratings assess how safe a road is on a scale from one to five. One star indicates the least safe while five represents the safest.

The stars reflect the level of safety built into the road and consider factors such as road layout, speed limits and traffic volumes, not necessarily driver behaviour.

Identifying these factors, according to Austroads, will help classify where road upgrades are needed to make roads safer for drivers and the community.

Austroads Chief Executive, Geoff Allen, expressed great enthusiasm for the star ratings system, emphasising how it will

make it easier for government to prioritise critical road developments.

“We know not all roads are equal when it comes to risk,” he said. “That’s why the focus of AusRAP is on the country’s most travelled roads – the highways and major arterial routes where millions of Australians drive every day, and where fatal and serious injury crashes are most likely to occur.”

Allan explained that Australia has a vast road network, and while many regional and local roads also need safety improvements, this phase of AusRAP is intentionally focused on the busiest corridors –where the risk is highest because of the sheer volume of traffic and higher travelling speeds.

This targeted approach, used together with or alongside other tools, will look to assist governments to prioritise investments where they will save the most lives, the soonest.

Future phases will also expand coverage as new assessments and data become available.

“Road safety star ratings are a robust and trusted tool for communicating road safety information to the public, and Austroads is proud to coordinate and publish our

members’ results,” Allan said.

“Importantly, these results provide a snapshot in time of the safety of our roads – and there is still much work to be done to reach our goal of having 80 per cent of all travel occur on roads rated 3 stars or better by 2030.

“By publishing star ratings and crash history data on a single, national dashboard, we’re giving governments and the community a clear line of sight to where upgrades will have the greatest impact,” he said.

“That’s why the focus of AusRAP is on the country’s most travelled roads – the highways and major arterial routes where millions of Australians drive every day, and where fatal and serious injury crashes are most likely to occur.

“The roads that carry the most people are where the greatest risks, and greatest opportunities lie.”

The AusRAP platform has already analysed 71,441 kilometres of road and more than 128 billion kilometres of travel to date.

Victoria has the most kilometres tracked by AusRAP out of any state – AusRAP’s analysis covers 24,501 kilometres of road carrying around 49 billion vehicle kilometres

of travel each year.

Meanwhile, an AusRAP assessment of the majority (~95 per cent) of Western Australia’s state-controlled road network has been completed.

Analysis of these results covers 18,888 kilometres of road, carrying roughly 26 billion vehicle kilometres of travel each year.

According to Austroads, WA is the first jurisdiction world to use newly emerging AiRAP methodology to assess the road network.

AiRAP utilises artificial intelligence and machine learning techniques to extract the required features from mobile laser scanning.

Relative to road use, 82.3 per cent of traffic on the analysed state-controlled network in WA travels on three-star or better roads.

By road length, 77.7 per cent of the analysed state-controlled roads in WA are rated three stars or better – the highest rating of any state in Australia.

“It is encouraging to see that currently 82 per cent of vehicle travel on the WA state network is on three-star standard, or better,

roads,” said WA Deputy Premier, Treasurer, Minister for Transport; Sport and Recreation, Rita Saffioti.

“We are committed to continuing to maintain and improve our state network to provide safer travel for all road users.

“WA is pleased to be part of this national initiative as it is one that supports both increased road safety as well as a consistent evidence-based approach to identifying and prioritising high risk roads.”

Results from Queensland, South Australia and Tasmania, as well as further assessments in other states and territories, will help the AusRAP platform reach a target of nearly 190 billion kilometres of travel.

All of Australia’s national AusRAP results are published through the interactive AusRAP Dashboard, an evidence-based tool which shows AusRAP star ratings, crash history metrics and traffic volumes.

Full force

McKittrick Bulk Haulage has deployed a Holmwood Highgate Performance-Based Standards 30m B-double tanker to increase productivity and revenue.

Canberra-based McKittrick Bulk Haulage is known as a transporter of bulk diesel to many. But its former identity meant the fleet had associated with a completely different sector of the industry and customer base for much of its existence.

McKittrick Bulk Haulage originally set out in 2010, with a truck and dog tipper combination to cart mining materials from quarries to concrete plants and landscape businesses throughout the east coast. But a very competitive market saw McKittrick Bulk Haulage Director, Todd McKittrick, shift gears and transition to fuel tankers. That was five years ago now.

“It was very hard trying to make money out of truck and dogs,” Todd explains. “A lot of people were coming in and cutting rates to get work which was making the job harder for everyone. I just wanted to change.”

Todd, having been a tanker operator for

another business before starting his own, decided to return to something familiar.

“We got into the fuel industry,” he says.

“We started off with transporting bulk diesel to two BP sites and grew until we were doing it for everybody.

“Transporting bulk fuel is so much better than what we were doing before, especially on the maintenance side. Tippers are very hard on brakes and tyres, but tankers don’t use them as much because they’re mostly just going up and down the highway.”

McKittrick Bulk Haulage went on to expand rapidly following the alteration of its operations.

“We’ve had big growth phase in the last three years,” Todd says. “We’ve received some pretty big contracts that have made our operations larger.

“In terms of our fleet, I wasn’t going to go past five combinations at the start. We’ve

ended up with 11 B-doubles.”

The 11th unit is a recently deployed Holmwood Highgate Performance-Based Standards (PBS) 30m B-double tanker which is made up of a new quad-axle A trailer and pre-existing quad-axle B trailer. McKittrick Bulk Haulage invested in this combination to increase the amount of fuel it can carry, and with a payload of 61,500 litres of diesel at a Gross Combination Mass (GCM) of 77.5 tonnes, the B-double is on the right path to achieve that.

“We get paid by the litre”, Todd says, “so the more fuel we can get on, the more we get paid. We already had a quad B trailer which we bought four years ago, and instead of running that as a single, I decided to make it into a PBS B-double so that we could cart bigger loads.”

The new PBS combination has been in operation for around two months,

Todd says the Holmwood Highgate unit has already increased McKittrick Bulk Haulage’s workload by allowing it to transport more bulk fuel – exactly what the company originally set out to do.

“The trailer set does everything that we need it to do,” he says. “We’ve been carrying more diesel with it and we’re therefore turning much more over.”

Todd has been very impressed with the PBS combination’s on-road performance so far.

“It handles really well,” he says. “The tankers are being pulled by a new Kenworth, and they sit dead straight behind it. It’s a very good combination.”

Equally impressive has been the overall quality of the Holmwood Highgate product.

“The finish is what really stands out to me,” Todd says. “Holmwood finishes off really nice trailers. They might be a fraction dearer, but you get the quality that you pay for. You always get a really good product at the end of the day.”

Quality is one of the main reasons why McKittrick Bulk Haulage chose Holmwood Highgate for this latest application.

“I always knew that Holmwood’s trailers were Australian-built,” Todd says. “The barrels are made in Queensland and everything else is built in Victoria.

“It’s a very durable product. I’ve got Holmwood trailers from 2005 that are still

going strong with no issues at all.”

Todd says there have also been several other elements in his past dealings with Holmwood Highgate which have made him feel like a very valued customer. This has allowed him to place his trust in the OEM for more trailers beyond the latest delivery as well.

“We’ve got another 25m B-double and an A trailer coming,” he says. “I’ll stick with Holmwood because of their service and the way they look after us. It’s just a matter of calling them. If there’s ever an issue or something that we need help with, they’ll sort it out over the phone. If they can’t, they’ll come over and see me straight away. They’re pretty good with things like that.”

Holmwood Highgate has provided McKittrick Bulk Haulage with an unconditional level of service over the years. This has gone far beyond just aftersales support.

“Holmwood recently conducted a Safe Load Program (SLP) training course for me,” Todd explains. “They taught me how to do inspections on my trailers so that I could ensure they would pass to get into terminals to load bulk fuel.

“This was a pretty big deal for me because you don’t get through if you don’t have that pass. And instead of having to pay someone to do a SLP inspection beforehand, I can now do it myself.

“Holmwood also services my fleet every six months. They’ll go through and check them to make sure everything is alright. So, the service that you get from Holmwood is exceptional. It’s why I go to them and it’s why I’ll stay there.”

Contact Holmwood Highgate

Ph: 03 9936 0360 | 07 3440 9000

Web: www.holmwoodhighgate.com.au

Fuelling trust

Stevemacs Bulk Fuel Haulage’s reputation as a leading fuel transporter in Western Australia is upheld by its use of tanker components from Liquip West Coast .

Stevemacs Bulk Fuel Haulage has always been on the front line of Western Australia’s fuel transport network. The company was established as a family business in 2003 by owner, Steve McWhirter, out of Perth’s Kewdale and began its operations in the commercial heart of the state. This meant proximity to WA’s road networks, an essential factor for the fleet to cart fuel for customers across far distances.

The prime location of Stevemacs Bulk Haulage, coupled with Steve’s ambition to provide a personal and high-quality service to customers, effectively ensured the company would grow. And grow it did.

Stevemacs Bulk Fuel Haulage expanded its network to cover a solid and wide corridor of WA over the following 22 years. The business now carts fuel for a variety of customers across a network which extends from as far north as Broome to Albany, Esperance in the south and Kalgoorlie in between.

“Our linehaul bulk fuel transport services deliver fuel to a range of customers,” Steve says. “This includes

Perth Airport, air bases in the state and multinational companies like BP and Viva Energy.”

With this expansive customer base came an enlarged operation. Stevemacs Bulk Fuel Haulage therefore grew its personnel considerably and, by extension, its fleet.

“We operate 35 prime movers and 150 tanker trailers in a variety of configurations such as singles, doubles, triples, pocket road trains and quads,” Steve reports. “We also employ 45 people.”

The reliability of this sizeable fleet is integral to Stevemacs Bulk Fuel Haulage and its daily operations. This is why the business has chosen to invest in key trailer components from Liquip West Coast for the last seven years.

Liquip West Coast has been exclusively distributing products from Australian bulk liquid equipment and storage manufacturer, Liquip International, throughout WA since January 2017 –under ownership of Petroleum, Aviation and Mining Supplies (PAMS). PAMS Project Manager, Victor Benjamin, says

the two entities are strongly aligned.

“Liquip West Coast is purely functioning to replicate the range of services which Liquip’s head office offers,” he says. “We have been providing direct access for the stocking and supply of Liquip equipment since our commencement as its WA distributor in 2017.

“The partnership has been strong since origin. There’s a lot of synchronicities between the two companies because our agendas and goals are quite united.”

Stevemacs uses a range of Liquip products including VOH451 hatches, SLV5ARO foot valves, API valves, Haz-Chem signs – all of which provide critical benefits to its operations. The VOH451 hatch in particular is standardised in cast aluminum with metric threads. It’s equipped with four provisions which allow Stevemacs Bulk Fuel Haulage to conveniently mount additional Liquip equipment such as overfill probes, air operated vapour vents, dip and fill tubes and Diptronic measuring devices.

Meanwhile, the SLV5-ARO foot valve ensures high flow rates and the safe loading and discharge of the fleet’s

VOH451 hatch.

tankers. Steve has been more than pleased with the performance of all of these components in his fleet of trailers from Tieman Tankers.

“We chose to use Liquip products years ago because of their high quality and the trust that the name carried,” he says. “If we wanted to stay competitive and safe, it only made sense for us to use their components.”

Liquip West Coast greatly benefits from the market reputation and product knowledge Liquip carries by distributing its products via PAMS. Victor says the OEM’s strong impressions on the market have largely been fuelled by the sheer size of its value offering.

“Liquip is a major brand in the marketplace due to its extensive offering, product availability and overall history in Australia,” Victor says. “Liquip West Coast has definitely benefited from its name. Although we haven’t been around for too long, we have capitalised on its brand awareness for our customers.”

Both Liquip brands champion safety and commitment. Victor believes that Liquip West Coast’s approachability in the

marketplace is what attracts customers to use its products and services.

“We pride ourselves on customer service,” he says. “Our dedication to the customer means we can go above and beyond when needed. That involves doing the extra work to make things happen, such as keeping substantial stock available.

“For example, we don’t have to wait for products to arrive from interstate in the case of a potential breakdown. We are self-sufficient and able to service market requirements in WA independently.”

The self-sufficiency of Liquip West Coast’s operations is a testament to the quality and durability of Liquip products in general. Although Liquip is based on the east coast, its components are manufactured to the highest standards so that they will perform the same way anywhere in Australia.

“Given the harsh conditions of WA, we have pretty high requirements for how our tankers are expected to perform,” Victor says. “They cover exceptional distances over very rugged terrain and aren’t really put under that same strain on the east coast.

“It’s substantially hotter over here –temperatures in the northwest during summer can easily exceed 45º C every day. But the beauty of Liquip’s products is that they act as a universal solution.

Even though they aren’t manufactured in these conditions, they’re so well-built that they perform without a hitch in these regional applications.”

At Stevemacs Bulk Fuel Haulage, Steve is looking to further ensure safety and performance across his equipment. As a result, he will continue to invest in Liquip components alongside his upcoming fleet expansion.

“Safety, quality and professionalism are cornerstones for our business, so we’ll continue to use Liquip components on our tankers for a long time,” he says.

“We have our own reputation in the industry to uphold, and Liquip is critical to that.”

Contact

Liquip International

148 Newton Road, Wetherill Park NSW 2164

Ph: 02 9725 9000

Web: www.liquip.com

Stevemacs Bulk Fuel Haulage’s fleet. Image: Stevemacs Bulk Fuel Haulage.

Larger than life

National Heavy Haulage utilises a trustworthy Drake Trailers fleet of 23 low loaders to carry out some of the biggest transport tasks in Australia.

When it comes to the transport of oversized equipment, there’s nothing too big for National Heavy Haulage. The Queensland-based earthmoving fleet has moved thousands of tonnes of heavy plant machinery during its 14 years in the industry and, as a result, has constructed an extensive portfolio of some of Australia’s largest freight tasks.

The pièce de resistance for National Heavy Haulage was transporting the world’s second largest mining trucks in 2018. The tactical assignment took place over five separate trips during September and October and involved moving five 160-tonne Liebherr T 282 C Ultra-Class dump trucks from Mackay, Queensland, to BHP’s Peak Downs Mine in Winchester. The more than 200-kilometre journey would have been quite the sight to see for those able to get a glimpse of it.

This colossal project presented many challenges to the emerging transport company. Liaising with government bodies and authorities, for example, was required to get permits, escorts and road closures actioned. A fairly stringent survey and analysis process also needed to be completed beforehand to ensure the fleet’s route would be effective and free of any infrastructure obstructions. Yet the heavy hitter emerged victorious like many other times with another trophy to add to the shelf.

National Heavy Haulage’s next showpiece objective arose in early 2024. The company received a contract from a valued client in the Northern Territory to transport a 265-tonne excavator onsite at Groote Eylandt, an island just off the northern coast of Australia in the Gulf of Carpentaria. So, the fleet headed off to Darwin, shipped one of its first ever trailers (a 13-year-old Drake Trailers 11x8 Steerable Full Modular Low Loader) on a barge vessel to the island and pulled off one of the greatest examples of its ability to execute out of the ordinary requests.

These are just some of the many larger than life projects which have given National Heavy Haulage a name that is extremely reputable within the industry.

“We’ll go where the work is and just make it happen,” says National Heavy Haulage General Manager, Woody Scott. “Customers choose us because of this. Our can-do attitude, safety and Chain of Responsibility compliance attract a lot of people who want a very reliable and well-managed business.”

Such monstrous operations require trailing equipment that can be relied on in the most extreme conditions. For this reason, The Drake Group has long been National Heavy Haulage’s trailer supplier of choice.

“All of our heavy haulage trailers are from The Drake Group,” Woody explains. “It was a known factor that Drake were the best

when we were starting out. The quality and reliability of their equipment was second to none, and it still is today.

“Our first trailer combinations were two Drake Steerable Full Modular Low Loaders in 7x8 and 8x8 configurations. These units are 13 years old and they’re still in operation.

When the business grew and we were in a position to buy more trailers, there were no questions about where we would get them. We just knew that we would need to ring Sam Drake.”

That phone call was made, and many more followed. National Heavy Haulage now has a total of 23 low loaders, 10 clips and 12 dollies from The Drake Group in its fleet.

Five of these latest combinations were deployed this year. They include a Quad Full Widener and dolly, 8x8 Steerable Platform with a 2x8 Steerable Clip and dolly, 7x8 Steerable Platform with a 3x8 Steerable Clip and dolly, and two 5x8 Swingwing Low Loaders with dollies.

“We have seen a lot of expansion in the business over the last year,” Woody says. “There’s been a lot of improvement in our market share and an increase in demand, and we needed more trailers to keep up with the growth.”

The Full Widener, Steerable Platforms and Swingwing Low Loader combinations in particular have transformed National Heavy Haulage’s freight capacity. From Woody’s

8x8 Steerable Platform with 2x8 Steerable Clip and dolly. Image: National Heavy Haulage.

perspective, these trailers have essentially unlocked a new level of productivity and efficiency for the business.

“Our most recent Drake trailers have vastly improved our capabilities,” he explains. “They have positioned us in a different market because we’re now able to get a lot more volume. On top of that, we have the ability to take up more work and the confidence to put more combinations on the road because we aren’t seeing any breakdowns or issues.”

The five new low loader combinations were well spec’d with the latest and greatest components that The Drake Group has to offer. Woody, having a great eye for detail, ensured the units would be best suited for the varying applications that they would go on to endure. For the Steerable Platforms, this meant requesting something very specific to his applications.

“I went to The Drake Group with an idea to simplify the bleeding of the steering system,” he says. “Byron Foss took it to the table with their engineers and designers, and they ended up fitting it on the last two Steerable Platform combinations.”

The final product allows oil to be automatically filtered into the steering hydraulic tanks of these units. Woody says this has been a major safety benefit for National Heavy Haulage.

“The bleeding system is great because it eliminates the need for drivers to manually

tip oil into the steering hydraulic tanks,” he says. “Our operators were previously climbing on top of units and working at heights to refill the tanks themselves, but they’re being kept on the ground now.”

National Heavy Haulage’s fleet of Drake trailers predominantly operates in Queensland and New South Wales, but due to the business’ flexibility, it also has the capacity to be deployed anywhere in Australia. Within these operations, the low loader units have proven to excel at carting large-scale mining assets and earthmoving equipment with their renowned durability and reliability.

“The Drake Trailers product is something that supports National Heavy Haulage significantly,” Woody says. “I know that I can send my trailers anywhere. It doesn’t matter where they go because they’re going to get there and get back.

“This impacts what we do to a great extent. We don’t have any issues with breakdowns, downtimes or operational delays at all. So putting our trust in the Drake product to such an extent has paid off greatly.”

National Heavy Haulage’s Drake trailers are bolstered with an effective maintenance system in place. Widespread access to spare parts has increased productivity and reduced downtimes even further by ensuring all trailers are constantly operational.

“The Drake Group is very good for parts and back-up service because they’ve got everything on hand,” Woody explains. “We’re able to stock parts in our facility, so if we happen to have a landing leg failure, for example, there are more units on the shelf which can be installed on the spot. This conveniency has made a massive difference for us.”

This sense of availability is something that is also fairly prominent within The Drake Group’s customer-centric approach. This is another factor which has contributed to National Heavy Haulage’s long-term reliance on the OEM.

“I’m very happy with The Drake Group,” Woody says. “I’ve developed a very close relationship with them over the years.

“The Drake Group is a family business and the people there treat you like that. The guys always ask me how my kids are going and what my wife is up to, and that makes me feel like they actually care.

“I’ll continue to buy Drake trailers as the National Heavy Haulage business grows because the product works really well for us and we’re supported by the people behind it.”

Drake Group 19 Formation Street

Wacol QLD 4076

Ph: 07 3271 5888

Web: www.thedrakegroup.com.au

7x8 Steerable Platform with 3x8 Steerable Clip and dolly. Image: The Drake Group.

Ace of spades

Ace Heavy Haulage invested in two 4x4 Tilt ‘N’ Slide Wideners and two 10x8 Steerable Low Loader Platforms from Tuff Trailers in a bid to increase efficiency and profitability.

Integrity and service. These are two very powerful words which resonate with Ace Heavy Haulage. The Queensland-based transporter, focused on ensuring every task is completed to the highest level of safety and care, has taken all necessary measures to solidify itself with these values over the last 20 years – an effort which seems to have paid off based on the extensive portfolio of contracts and clients it has collected since.

Ace Heavy Haulage was originally set up on the back of a rental business in 2004. Founder, Michael Sheldon, was running a machinery rental company at the time and needed a way to transport his equipment around. So, rather than relying on third parties to do the job, he set up his own transport operation.

Ace Heavy Haulage was born. But its final form arrived in 2012 when Michael’s business partner, Tom Willis, took over as Managing Director and steered the business in a different direction.

“I wanted to take the company away from the carting of its rental equipment and down

the heavy haulage route,” he says. “So, we stopped doing the rental equipment side of work. We went off and became a completely separate entity so that we could move everyone’s gear. We’re now in the position where we have the trailers to do just about everything.”

Ace Heavy Haulage found its breakthrough around three years ago when it won a contract to transport six 165-tonne renewable transformers to the MacIntyre Wind Farm in Cement Mills, Queensland. Tom sees this event as the main turning point for the business.

“That was what put us on the map,” he says. “We really stamped out our presence in the sector through it. That was about six months’ worth of flat-out work, and it was our first big project job.”

Paramount to Ace Heavy Haulage’s expanding operations in recent years have been four new low loaders from Tuff Trailers. The two 4x4 Tilt ‘N’ Slide Wideners and two 10x8 Steerable Low Loader Platforms have increased versatility, efficiency and productivity by large margins.

“We bought a 4x4 Tilt ‘N’ Slide Widener first,” Tom explains. “There was a hole in our business due to all of the longer buildings and machines that we couldn’t get to, and after I saw these Tuff Trailers Tilt ‘N’ Slide Wideners getting around, I purchased one.

“I was a bit hesitant about it at first because I didn’t know whether it was going to fit into the business or not. But it did, and I liked it so much that I went and bought a second one. I’d buy a third if I had the money.”

The two Tuff Trailers Tilt ‘N’ Slide Wideners have since become integral to Ace Heavy Haulage’s operations of carting heavy machinery.

“The Tilt ‘N’ Slide trailers are a very important part of our business,” Tom says. “They are extremely versatile. You can use them as general low loaders or for specific applications like modular buildings and accessing machines that are mechanically locked up.”

The story around the deployment of the two Tuff Trailers 10x8 Steerable Low

Ace Heavy Haulage transporting an eight-metre-long dragline excavator. Image: Ace Heavy Haulage.

Loader Platforms is pretty meaningful for Ace Heavy Haulage. This is because Tom pinpoints the arrival of the first unit as his biggest milestone.

“That purchase has been the most significant part of my career so far,” he says. “It was my first brand-new platform trailer. It was a really good time for us as a business and a super significant time for me as an individual.”

Tom was so impressed with the first low loader platform that he went back for more. The second unit followed suit just one year later in 2024 and joined its three siblings in several heavy haulage applications around Australia. Together, all four low loaders have since proven to be extremely durable throughout a variety of applications and operating conditions.

“Our Tuff Trailers low loaders are the absolute workhorses behind everything we do,” Tom says. “They’re working flat out all day, every day, Australia-wide.”

The 10x8 Steerable Low Loader Platforms in particular have been a gamechanger for Ace Heavy Haulage due to their maximum manoeuvrability.

“The steering on these units is unbelievable,” Tom says. “There are no fixed axles on the 10-row platform trailers, so every single axle steers. This is a massive benefit when it comes to getting into places.

“If we’re in a tight spot, we can just steer the axle with a remote control and drive forward with the truck to manually steer

it around. We can also operate the whole thing standing 10 metres away which is very handy from a safety point of view.”

Low maintenance has been another advantage of utilising Tuff Trailers’ low loaders. Tom says the 4x4 Tilt ‘N’ Slide Wideners and 10x8 Steerable Platforms are “almost non-serviceable”.

“The trailers have a grease nipple on top of the slack adjusters and the ballrace, and that’s it,” he says. “There isn’t the element of grease lines everywhere, and I’ve found that the team and I don’t need to constantly watch the trailers as a result. The drivers are also more refreshed because everything’s running true and perfect.”

These latest units join three Tuff Trailers drop decks which have also been at Ace Heavy Haulage since 2013. The low loaders, still in their original condition from 12 years ago, are a testament in themselves to the durability of the product.

“It was a no-brainer to invest in these

latest trailers because I knew they were tried and tested products,” Tom says. “I did my research on the people that had them before me and on what they thought, and it seemed that everyone agreed that they are a great benefit. We’ve since seen that firsthand.”

In addition, the customer experience received from Tuff Trailers has made the whole experience a very positive one for Ace Heavy Haulage.

“Tuff Trailers is really good to deal with,” Tom explains. “They’re not in it to sell you something and move on.

“Tuff Trailers has a genuine interest in what you’re doing and where your business is going. They really want to see you do well, and the world needs more of those sorts of people.”

An older Tu Trailers drop deck low loader at Ace Heavy Haulage. Image: Tu Trailers.

One of the fleet’s two Tilt ‘N’ Slide Wideners. Image: Tu Trailers.

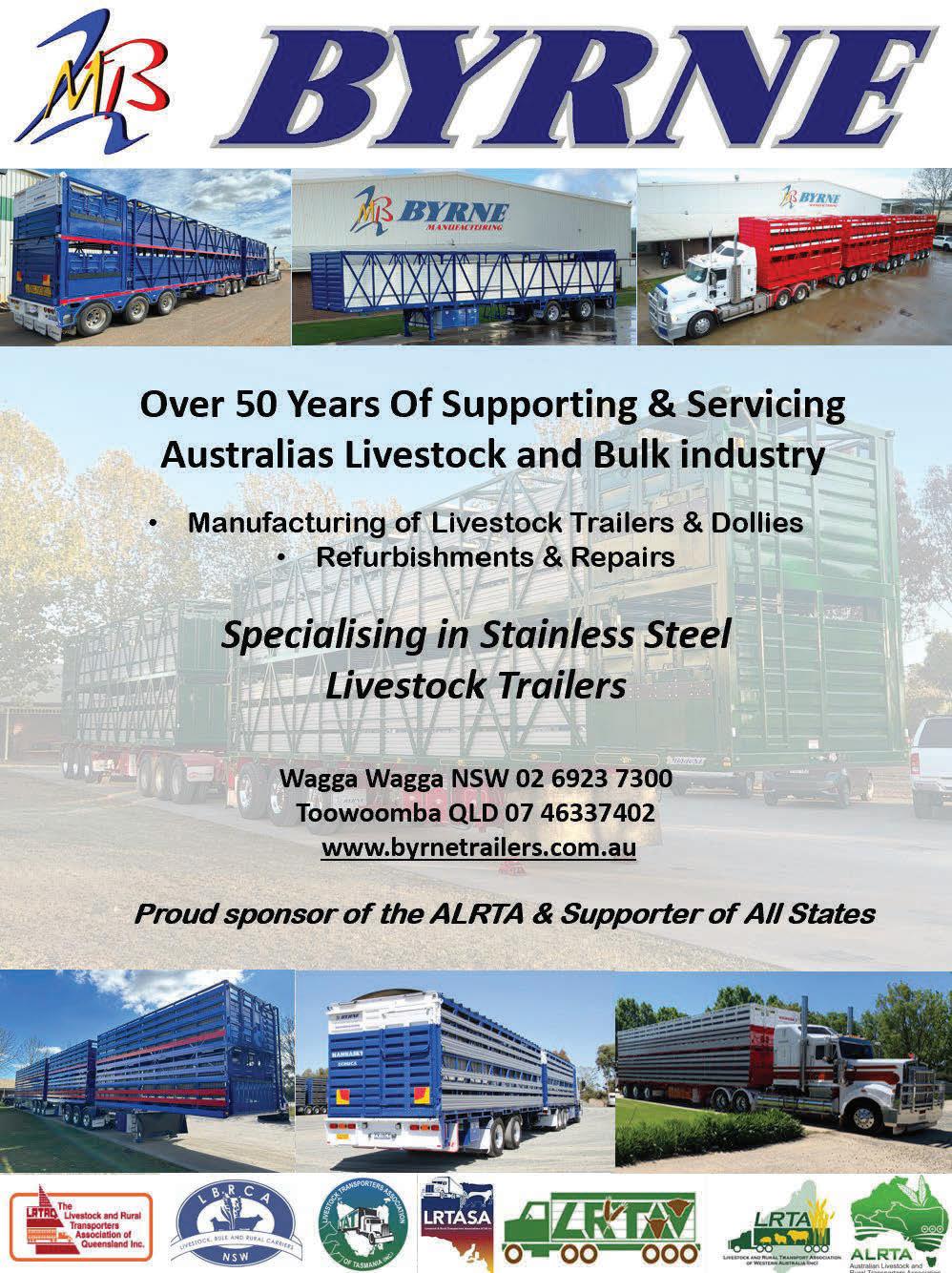

Feel the Byrne

Byrne Trailers has strengthened its manufacturing processes and leadership team in a move which bolsters the business synonymous with livestock transport.

For manufacturers like Byrne Trailers, change is a given. The family business’ patriarch, Mick Byrne, was seemingly no stranger to adaptation, having worked an assortment of jobs around the regional town of Peak Hill, New South Wales, at the beginning of his career. In addition to being a steel merchant and welder, Mick was also a driver, carting livestock with his brother, Bill, in the early 1970s.

Mick’s ability to change and adopt skills with ease was complemented by a critical understanding of road transport equipment. So, when he was directly approached to build a trailer in 1974, he dropped everything to do it. With the help of his other brother, Des, Byrne Trailers was born. Mick and his wife, Teri, helmed operations

while also raising a family. Their son, Jonathon Byrne, remembers the two endeavours going hand in hand.

“Byrne Trailers’ first piece of equipment was manufactured at our old home in Peak Hill,” he recalls. “That was when the idea for the business was conceived. We bought the block of land next to our house and put a shed back there which we eventually built into a small factory.”

Business wins came early after Byrne Trailers was fully established. This was particularly seen in the form of Mick’s own livestock trailer designs which changed the entire industry.

“Livestock trailers were only built with three decks of sheep back in those days,” Jonathon explains. “Dad designed the four-

decker which required a larger height of 4.6 metres. He lobbied with the National Party of Australia at the time and got the law changed to accommodate his trailer height.

“But that wasn’t all. Cattle trailers were predominantly tin-sided trailers in those early days and wooden-sided trailers before that. My dad designed a monocoque diamond pattern which is now used by the vast majority of trailer manufacturers in Australia.”

This string of innovations and subsequent success eventually prompted further changes in Byrne Trailers. In 1988, the company relocated to a new factory in Wagga Wagga, NSW. The business became an interstate operation shortly afterwards in 1993 when it set up a dedicated repairs depot in Toowoomba, Queensland, to

Mick Bray. Images: Byrne Trailers.

service its northern and western customers.

These facilities have seen their share of managerial changes this year alone.

The Toowoomba depot was the site of an operational shake-up in January when Jonathon purchased the business segment from his parents.

“The ownership of the business has shifted a bit, but we still work very closely together,” Jonathon says. “The relationship between both sites is strong. We’re still aiming to achieve the same business goals.”

Additionally, Byrne Trailers welcomed its new General Manager, Mick Bray, at its Wagga Wagga site. Mick has long been associated with the Byrnes in some form or another.

“ My mum actually taught Mick when he was in primary school,” Jonathon says. “He ended up working for us in Peak Hill for some time before he left. Then, in 2019, he came back as a salesman and worked his way up to General Manager.”

Having seen Mick in action, Jonathon is confident that his wide scope of expertise and personability will be a boost for the business.

“Mick has a lot of industry knowledge and a lot of respect in the sector,” he explains. “The industry can be a bit old school as far as the values it holds and the things it expects. The space is a lot more rural, too. But Mick was brought up in a country area and he has already had so much exposure through his career. I think he’ll be great at building relationships which will be really good for business.”

Mick is spearheading a seismic shift within Byrne Trailers’ operations by steering the business away from some of its manufacturing niches and instead focusing on its main product type –livestock trailers.

“We’ve been doing a lot of bulk

transport with tippers and walking floors over the years”, Jonathon says, “but as of late, we’ve changed our direction and put that on the back burner to purely focus on livestock. It’s like a return to our foundation.”

This refocus was made largely in response to growing demand from the livestock sector. From what Jonathon and the team have seen, this part of the industry is doing very doing well in a period where others are struggling.

“Demand in the livestock space is huge, while other sectors have slowed down a bit,” he says. “The pricing of beef is what’s driving this at the moment. The number of feed lots opening up in the last four to five years has really helped the cattle numbers throughout Australia.

“This is particularly in Queensland, a state which has more cattle than the rest of Australia. That, combined with a few wet seasons in the north which have allowed for an increase in beef production in recent years, makes it very attractive for people to sell cattle.

“All of this, as a result, means more people need to cart cattle. This is where our builds come in and it’s why we’re tailoring our operations to this space. As a business, we’re simply catering to the market demand.”

Accommodating market demand is something that has always been a strength for Byrne Trailers. Jonathon says the team has the capacity to satisfy its clients by shifting its attention away from non-livestock trailer builds in a sense.

“Some customers are very specific about what they want,” he says. “Requirements always vary from customer to customer, but we do get a lot of repeat customers. This allows us to learn the combinations and specifications that they need over time.

“We’re there to service our customers’ needs, and being familiar with them makes this process much easier.”

Byrne Trailers’ flexible manufacturing process has been cultivated over decades of customer feedback, technological changes and the internal development of more efficient methods. One of the company’s more recent innovations, for example, is its stainless steel trailer designs which have been a specialty of the Wagga Wagga site since 2016.

“We’re pulling materials from three or four different countries around the world to manufacture these trailers,” Jonathon says. “Every trailer coming out of the Wagga Wagga factory is completely stainless from the chassis up.”

The Toowoomba depot, which began manufacturing its own trailers four years ago, has largely followed suit.

“Our semi-stainless builds are in Toowoomba because there’s a higher risk of rust in the area,” Jonathon says. “This is due to the climate and the effluent from the animals that customers carry.”

Between these relatively new builds, the company’s bolstered management structure and the business’ altered direction, it is clear that a new age of Byrne Trailers has been ushered in.

“Our products and services have greatly evolved from when the company was founded,” Jonathon says. “But, with everything that’s been happening this year and our future plans, there’s a lot more for us to do.”

www.byrnetrailers.com.au

A Mitchell’s Livestock Transport stainless steel ABB quad in Western Australia.

Diesel delivery

Winslow’s fifth rigid refueller from Holmwood Highgate will be the latest delivery in a near decade-long arrangement.

Before becoming an interstate civil construction empire, Winslow began in a backyard. Founder and Managing Director, Dino Strano, conceived the company out of his home in Rosanna, Victoria, in 1985. In the beginning, the operation was equipped with nothing more than a single piece of equipment and all the ambition Dino could muster. It’s safe to say that things have changed since then.

Winslow expanded across Australia in the years that followed, amassing machines and people along the way. Today, the company’s presence extends to Queensland, New South Wales and South Australia, with more than 800 pieces of equipment and an army of 1,600 full-time workers across various construction applications.

Winslow’s fuel division plays a vital role in supporting site operations and logistics. Within this part of the business, Winslow works closely with trusted partners such as Holmwood Highgate which have built and customised its fleet of fuel tankers, hose reels, barrels and related systems.

Holmwood Highgate has provided Winslow with four rigid refuellers so far. A new unit is expected to join the fleet before Christmas and will change Winslow’s operations quite significantly.

“We outsourced the fueling of our machines to other companies entirely

for some of our sites in the past,” says Winslow Fuel Service Manager, Dimitrios Gountsiotis. “This incoming rigid refueller will allow us to do it ourselves in a specific area of our operations.”

Though it may seem like a big task for one rigid refueller, the unit is custom-designed to get the job done. It features a total payload capacity of 22 tonnes, including a 15,000-litre fuel barrel and two additional tanks carrying lube oil and AdBlue diesel exhaust fluid.

The rigid refueller is also equipped with Alfons Haar pumping equipment and a specialised hose reel for diesel metered deliveries. In addition, a dedicated control unit inside the truck cab allows operators to directly adjust fuel pressure and ensure precise control when refuelling machinery.

“Some of our machinery can take up to 1,000 litres of fuel a day, while others only take 20,” Dimitrios says. “Being able to adjust this fuel pressure is very important so that we don’t damage certain equipment or waste fuel.”

The Holmwood Highgate rigid refueller will also include toolboxes on both sides for storing essential equipment such as grease cartridges. These features have become standard due to the OEM’s long-term understanding of Winslow’s operational needs.

“One of the biggest benefits of working

with Holmwood is how straightforward they are,” Dimitrios says. “We’ve been partnering with them for close to 10 years, so they know what we like.

“The equipment they provide us suits our operations perfectly. It doesn’t get much easier than that.”

Holmwood Highgate’s expertise in design, fabrication and engineering has been a key factor behind Winslow’s success. Its ability to deliver custom, high-quality builds which perform reliably under demanding site conditions has made the OEM a trusted partner for the fleet. With a strong focus on safety, precision and innovation, Holmwood Highgate has ensured that every unit is built to the highest standard – helping keep Winslow’s fleet running smoothly and efficiently across all job sites.

“We were still a big company 12 to 13 years ago, but we only had two fuel trucks,” Dimitrios says. “We decided to look for new partners with deeper knowledge and expertise, and Holmwood Highgate had exactly that. They don’t waste time when solving problems because they understand the size and complexity of the operation we run.”

Contact Holmwood Highgate

Ph: 03 9936 0360 | 07 3440 9000

Web: www.holmwoodhighgate.com.au

A Holmwood Highgate rigid refueller. Image: Holmwood Highgate.

A game-changing delivery system

By popular acclaim, the SWIFT Delivery System from Liquip is the industry’s simplest, lightest, smartest and – yes –fastest fuel-delivery solution.

The SWIFT’s innovative metering delivery system uses level gauging to accurately and conveniently deliver multiple products through a single pump – whether the method of delivery is gravity-fed, bulk-drop or hose reel.

Make the SWIFT Delivery System the star of your fuel-delivery production!

Holmwood Highgate is a leader in the tanker manufacturing industry, renowned for its diverse range of capabilities. With cutting-edge technology and a commitment to innovation, we specialize in creating tankers that cater to various sectors, including oil, gas, and chemical transport. Our expert team blends engineering excellence with sustainability practices, ensuring each tanker is built for efficiency, longevity and safety. From bespoke designs to robust production processes, Holmwood Highgate, and it’s associated brands, are dedicated to delivering high-quality solutions that meet the evolving needs of our global clients.

With growth in our brands we have seen the expansion into local firsts and industry demanding transportation systems. We offer various applications for bulk liquid, gas, bitumen, food, ANE and more to cover Australia’s ever growing need and hunger for unique transportation options.

OUR CAPABILITY

BITUMEN TANKERS

AMMONIUM NITRATE EMULSION

FOOD AND MILK

INDUSTRIAL GASES - (LPG & CRYOGENIC)

DRY BULK

AVIATION FUEL

COMMERICAL GRADE FUEL

Queensland 07 3440 9000

20-26 Burchill Street, Loganholme, QLD, 4129

Victoria 03 9936 0360

425 Fitzgerald Road, Derrimut, VIC, 3026

A walk in the park

AAA Transport’s interstate waste and rubbish carting services have been notably strengthened by KEITH Walking Floor systems.

AAA Transport is as much a family heirloom as it is a company. The operation was established over 30 years ago in Sydney, New South Wales, to specialise in the transport of waste and rubbish products such as glass, paper and scrap metal for recycling companies.

With time, AAA Transport’s influence in the industry grew. As did its scale. The company would eventually spread into surrounding suburbs in Victoria, South Australia and the Australia Capital Territory with efficient services.

AAA Transport Director, Omar Kreidie, is the latest holder of the heirloom, and he’s proud of it.