Practical solutions to NSW’s waste management challenges

By Inside Waste

NSW’s waste system is creaking under the weight of rapid growth, rising costs and an approvals regime that few on the frontline consider fit for purpose. In a candid panel moderated by Brett Lemin, executive director of WCRA, four industry and local government leaders set out where the pressure is building most, why previous course corrections failed to take hold, and what practical steps could avert a crunch by 2030. The panel comprised Richard Collins, associate technical director at Arcadis Australia; Katherine Whitfield, chief growth officer at Veolia; Damien Vella, CEO of Breen Resources; and Steven Head, GM of Hornsby Shire Council.

The tone was frank from the outset. The panel discussed everything from putrescible capacity and the scarcity of inert landfill, to the fragility of transfer station networks and the absence of a geographically grounded plan. The recurring motif was the lack of certainty around most issues, and the way it seeps into pricing, deters investment and ultimately lands on the rates notice.

Pressure points across the chain

Ask five practitioners where the system is most strained and you will hear five answers that overlap but do not fully align. Each segment of the chain is feeling its own acute pinch, and those localised constraints are now compounding one another.

Collins said that transfer station constraints are the hidden choke points that hold back efficient, costeffective movement of waste and limit competition. In his view, they are not simply another waypoint in the network but a determinant of whether the network can breathe at all.

Whitfield saw the most pressing risk in putrescible capacity, warning of a looming shortfall by 2030 and expressing frustration that large energy from waste proposals remain stuck in planning. Her call was for diversity: landfill as part of a broader mix, not the only answer.

Vella focused on the inert stream.

(Continued on page 8)

08 Infrastructure woes

24 Energy from waste

28 Simple solutions for waste challenges

Australia’s circular economy push takes shape

By Inside Waste

Australia’s commitment to doubling circularity by 2035 is beginning to take form through a suite of strategies, policies and frameworks designed to shift the nation from a linear take-make-waste model towards one that regenerates and retains value in materials. Speaking at a national circular economy session at the ReGen Expo, panellists outlined the coordinated efforts now underway across government, industry and standards bodies.

Dr Nicole Garofano, head of circular economy at Planet Ark, opened the session by highlighting two major enablers identified in national reports: consistent and harmonised regulations, and access to high-quality information. According to Garofano, a lack of visibility into circular strategies and limited executive engagement in business culture are key barriers that must be overcome. To that end, the session brought together Chloe Bird, Emelia Addo-Appiah and Christie Rourke to explore how governance structures, standards and business guidance are aligning to create momentum.

Each speaker provided insight from their sector on how policies, standards and corporate engagement can help accelerate Australia’s shift to a circular model.

A national direction for circularity

Chloe Bird, branch head for supply chain Initiatives in the Circular Economy Division at the Department of Climate Change, Energy, the Environment and Water (DCCEEW), outlined the newly released national circular economy framework. This marks the first time Australia has set clear targets to retain materials in the economy and reduce waste, with a core goal of doubling circularity by 2035.

(Continued on page 18)

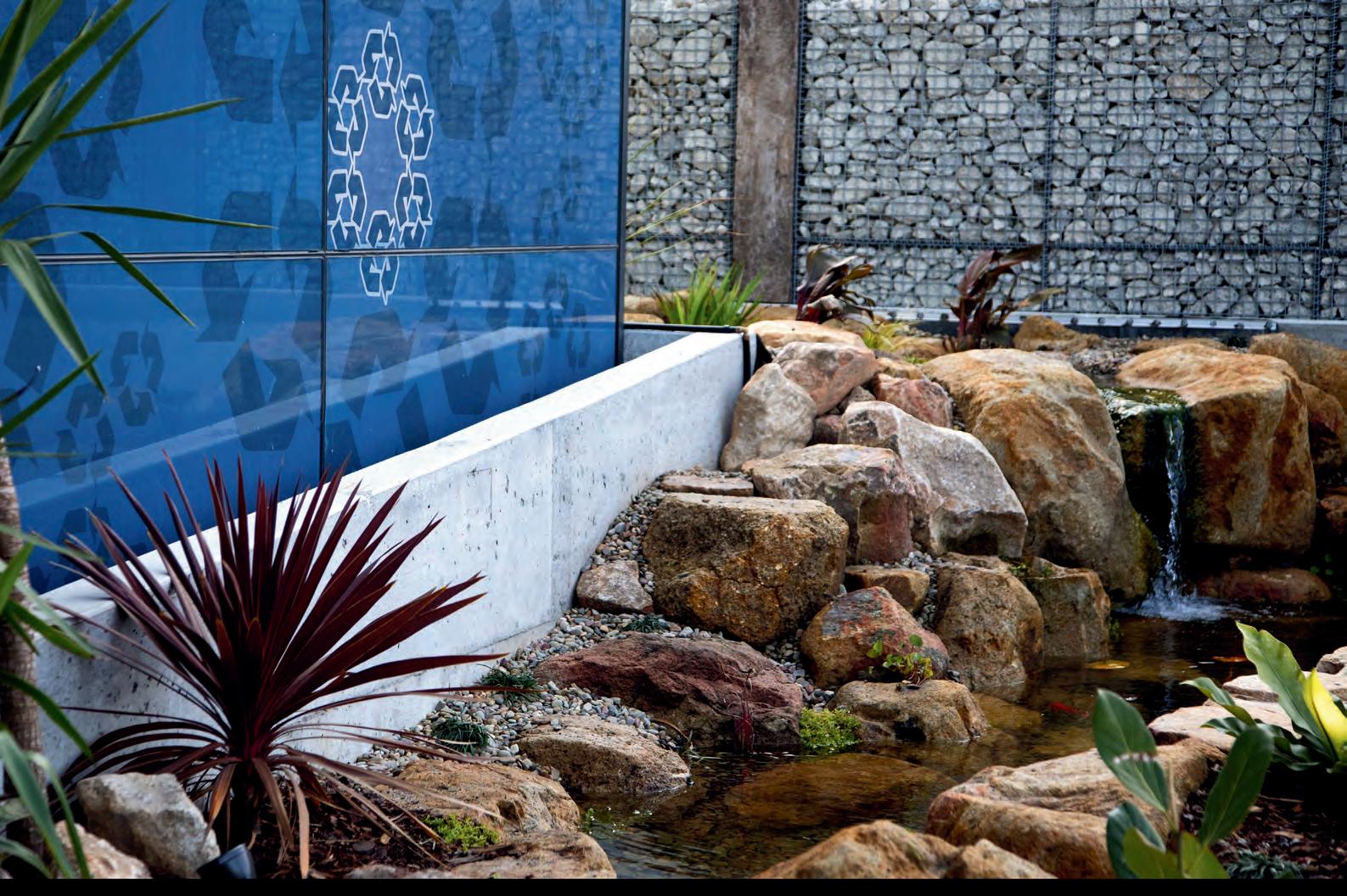

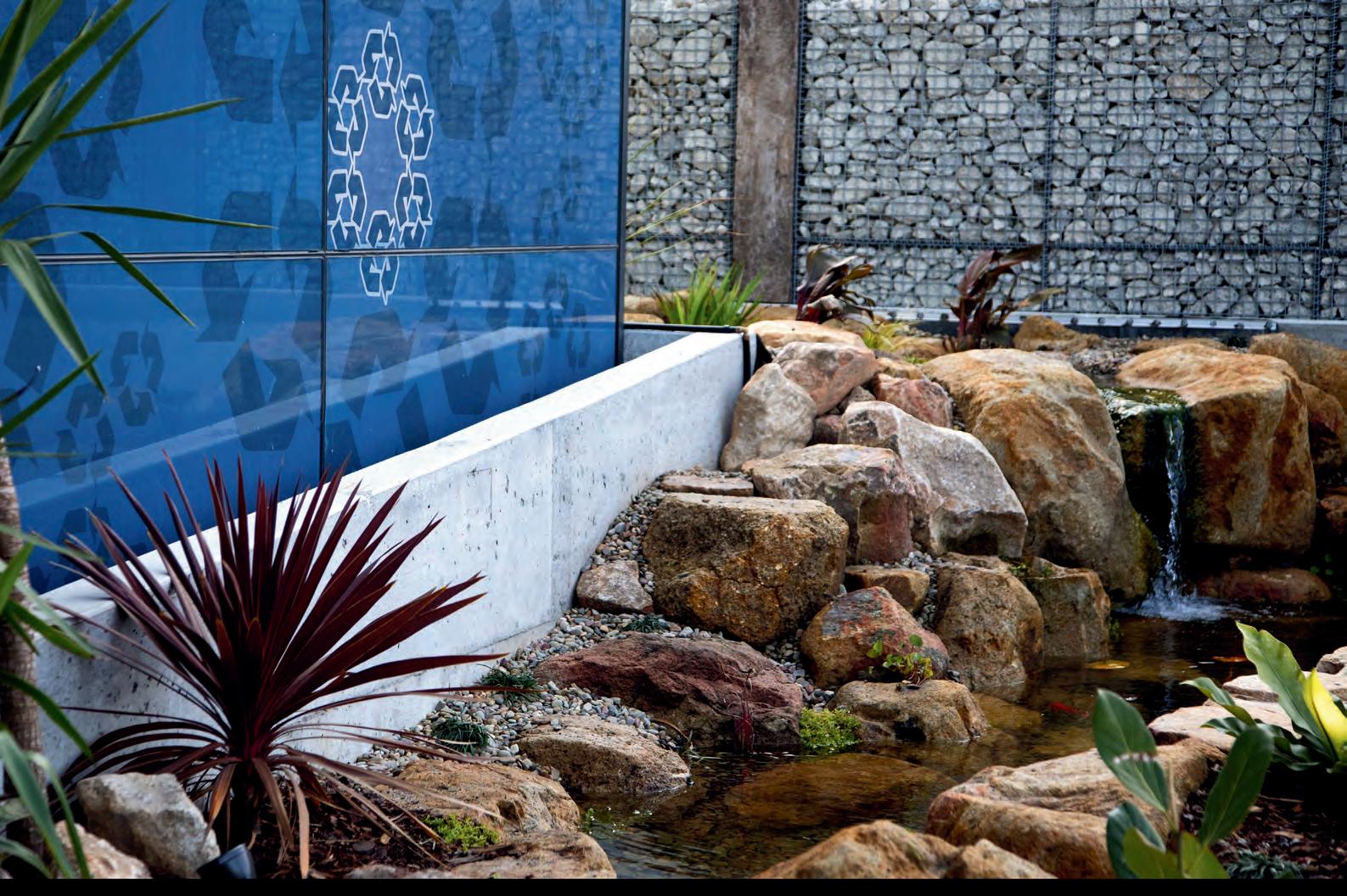

Well-run waste transfer stations are a key piece of infrastructure, but they have to run efficiently otherwise they create a choke point. Image: JuroX/shutterstock.com

Where to start?

As we navigate our way through the ups and downs of our industry, finding a starting point to help fix its woes is harder than ever. This was reiterated at a recent seminar where the subject was the lack of infrastructure in the resource recovery space. The five panellists were asked what the roadblocks were to getting New South Wales up to date with enough facilities to help it reach government-mandated recycling targets. The consensus? Well, there wasn’t one. There were five different answers. And maybe that was indicative of where we are as an industry (I’ll go on record, though, as stating that all five opinions were valid).

I harp on about harmonisation all the time in these pages, more because it seems such an obvious answer to a lot of our problems. Not just within a state like NSW, but the country as a whole. I’ve always felt that although Australia does have the geographic size to justify a federal government system, it doesn’t have the population. It seems endemic that governments at all levels – particularly state –have their own best interests (ie survival) at heart, not the main reason for their existence in the first place – getting things done for its constituents.

Chief Executive Officer

Christine Clancy christine.clancy@primecreative.com.au

Managing Editor

Mike Wheeler mike.wheeler@primecreative.com.au

Brand Manager Chelsea Daniel chelsea.daniel@primecreative.com.au

Art Director Bea Barthelson

Client Success Manager Ben Sammartino ben.sammartino@primecreative.com.au

Head Office

Prime Creative Pty Ltd 379 Docklands Drive

Docklands VIC 3008 Australia p: +61 3 9690 8766 info@primecreative.com.au www.insidewaste.com.au

Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au

Inside Waste is available by subscription from the publisher. The rights of refusal are reserved by the publisher

The amount of red tape and bureaucracy that investors and those working hard within the resource recovery sector endure makes it almost a fait accompli anything takes forever to get done. Sure, there are facilities coming online all the time, but the amount of time and money they spend getting there makes a lot of these investors say ‘never again’.

I’m hoping that somebody like Murray Watt might have the gumption to start getting the ball rolling and bringing the states into line with landfill levies, legislative considerations, consistency around approvals, and more importantly, stop listening to the lowest common denominator. Which is? The latest band of luddites who have the loudest voice and therefore give the politicians the impression their opinions will be the difference between them getting through the next election cycle or not. It would also be handy if those in power – and therefore hold the purse strings and permissions – did a little digging into issues themselves and looked at some facts instead of listening to soundbites. You know who you are.

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Waste is owned by Prime Creative Media and published by John Murphy.

All material in Inside Waste is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Waste are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

waste management challenges

(Continued from the Cover)

AS A CONSTRUCTION and demolition recycler who also operates landfill, he described an acute shortage of inert landfill capacity and insufficient processing headroom. The investment case, he said, is undermined by uncertainty around resource recovery orders that set the rules for product quality and testing.

Head brought a local government lens, and with it a different kind of urgency. His concern was not so much a certain type of processing plant is missing from the equation, but the absence of an actual plan that tells councils where capacity will be located, in what volumes, and on what timetable. Without that, councils are left to price risk into contracts and budgets, with inevitable consequences for households.

“The lack of an actual plan is the biggest pressure point. I do not feel I have any certainty around where we are going or how we are going to get there,” Head said.

That absence of certainty is showing up in council finances. Head placed the costs in stark relief, noting that Hornsby Shire charges the average household about $733 per year to deal with waste, compared with roughly $1,500 for every other

combined. The trajectory worries him. The risk, he warned, is that within a few years residents will pay more for waste than for everything else their council delivers.

“The sector has no certainty. If the sector has no certainty, you price risk into everything. In the end, my ratepayers, your communities, pay the bill,” he said.

Planning without a map

The panel returned repeatedly to planning, both the need for a strategic map of future facilities and the lived reality of assessments that drag on, change shape, and ultimately sap confidence. Head welcomed the state’s recent publication of the first chapter of an infrastructure strategy. He praised the intent yet stressed that a statement of a problem is not a plan. What is required, he argued, is a geographically anchored blueprint that identifies transfer stations, putrescible and organics capacity by region, volumes and siting, and then bakes those decisions into local p lanning instruments.

Without that clarity, councils cannot embed sites into their own plans, proponents cannot assemble land and capital, and communities are left in the dark about what will be built and why. The result is

a cycle of risk aversion on all sides that leaves the system vulnerable to shocks.

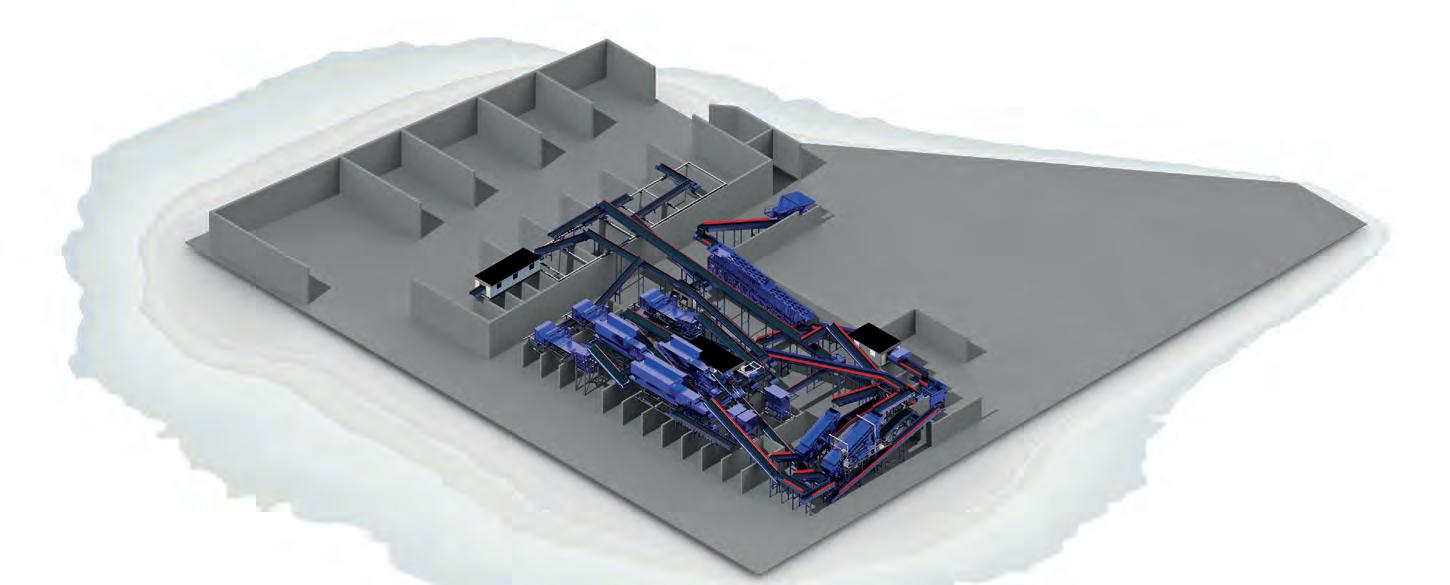

Vella described the practical barriers from a proponent’s perspective. A decade ago, he said, a recycler could trial a soil processing line with a relatively modest kit in the open. Today, sensitivity to dust, noise and amenity, along with reasonable expectations for enclosure and control, means facilities are ten times the cost. That is not a complaint about higher standards, he said; it is an argument for regulatory clarity so proponents can design to a known target and underwrite a business case.

“What is the quality of the product I need to produce? What are the standards and testing processes? Is it batch or continuous? It all comes back to resource recovery orders and exemptions, which have been in flux since 2019. It is really difficult to underwrite a business case,” Vella said.

The theme of protracted approvals and moving goalposts ran through multiple examples. Collins spoke of an Arcadis project that has been five years in approvals for a hazardous waste transfer station, with repeated rounds of questions that reset the clock that deterred investors who wanted to know how long and how much before they commit. Vella recalled a four-year

service

Left to right – Brett Lemin, Richard Collins, Katherine Whitfield, Damien Vella and Steven Head. Image: ReGen Expo Australia

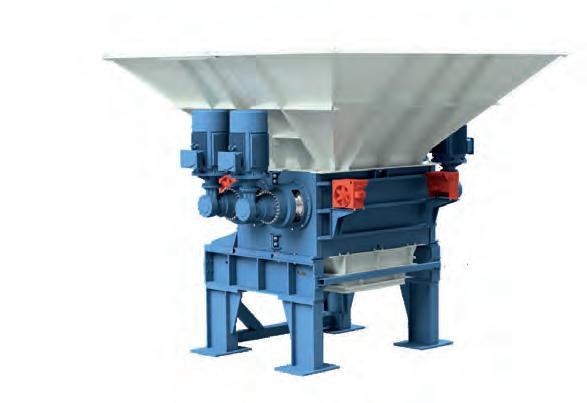

COMPACT GRINDER UNMATCHED POWER

ARRIVING SOON. BUILT FOR AUSTRALIAN CONDITIONS.

The Vermeer HG400TX is compact, powerful, and built for the real world. With steel tracks, 220 mm of ground clearance, and a full-function remote, it’s designed to handle rough terrain and tight spaces - without compromising on performance. Its efficient feed system, sideload screens, and Cat C4.4 engine make it ideal for green waste, mulch, and organics. Arriving soon in Australia, the HG400TX delivers serious results in a machine that goes wherever the job takes you. Reach out to your local product specialists at Vermeer Australia today!

assessment that required redesigns after different EPA teams came to the table at different stages. In both cases, time and cost escalated well beyond what a small- to mid-sized business can absorb.

“That application had three different teams engaged at different stages and we redesigned more than once. A two-year, $500,000 planning cost became four years and four times the cost,” Vella said.

For Head, the planning challenge is inseparable from social licence. He pointed to a recent refusal of a build in the Southern Tablelands and suggested that insufficient community understanding of the urgency and the solution played a role.

“Unless we have the community with a genuine understanding of the problems, it is always going to be challenging. Waste should be treated as an essential service. This is a cross-government piece that needs every element at the table,” he said.

What is needed by 2030

The question of the ideal infrastructure mix prompted a reality check on timelines. Whitfield framed the answer around the waste hierarchy, emphasising avoidance and reduction first, then reuse and recycling, then energy recovery, with landfill at the bottom. She underscored the role of partnership among government, communities and industry, and argued for optimising the existing network in the short term while the long-term pipeline is brought to life.

“I am very passionate about energy recovery.

It is a key part of the mix. We need government, communities and industry working together. To me 2030 feels like tomorrow, so we must optimise what we have now and press on with approvals,” Whitfield said.

Collins agreed on the hierarchy but warned that the time left to 2030 is, in infrastructure terms, almost none. He did not foresee a significant change in the number of facilities by then, simply because approvals and delivery cycles are long. He suggested there is some breathing room on putrescible disposal, given extensions at major facilities, while non-putrescible capacity is more urgent and lacks a pipeline. On commingled recycling, he saw reason for cautious optimism as new material recovery facilities come online and proposed facilities seek approval.

Lemin highlighted findings from a recent discussion paper showing that NSW’s recycling rates have remained largely unchanged for the past decade, despite big increases in the waste levy. This plateau indicates that the levy alone is insufficient to drive improvement. He noted that investment in infrastructure and community education –approaches proven successful in South Australia and Victoria – are essential to changing behaviour, improving recovery rates, and capturing greater resource value.

Some panellists cautioned against treating landfill as the workhorse that can always be asked to do more. Even where expansions are approved, Whitfield argued, such space should be treated

IMPORTANT PUBLIC NOTICE

RELLIK GROUP PTY LTD GUILTY OF CONTRAVENTION OF WASTE TRANSPORTER DUTY OFFENCE UNDER THE ENVIRONMENT PROTECTION ACT 2017

On 9 September 2025, Rellik Group Pty Ltd, (ACN 610 626 036) entered a guilty plea at the Sale Magistrates’ Court to a charge laid by the Environment Protection Authority Victoria in relation to a contravention of the duty of persons involved in transporting industrial waste under section 135 of the Environment Protection Act 2017.

Rellik Group Pty Ltd was found guilty without conviction, fined $10,000 and was ordered to pay the Environment Protection Authority’s costs of $4,000. The Court also made an Adverse Publicity Order requiring Rellik Group Pty Ltd to publish this notice.

Rellik Group Pty Ltd were contracted for the transport of expired hand sanitiser to licensed premises in New South Wales. Rellik Group subcontracted the transport out to companies with the properly licensed vehicles. Initial transport commenced as planned, however when

as a precious commodity. That means limiting inputs to preserve life and forcing investment into alternatives, rather than filling newly created space and returning to the same conversation in a few years’ time.

“We have to treat landfill space as a key commodity and eke it out for as long as possible. Set limits on the waste going in so that alternatives are invested in,” Whitfield said.

Money, approvals and the missing incentives

If planning is the map, money is the fuel. The panel explored why private capital is not flowing at the scale required, and what the public sector can do to unlock it without simply writing cheques. Whitfield was blunt: certainty drives investment and uncertainty kills it. As mentioned, for an energyfrom-waste plant, or a major processing facility, proponents need regulatory clarity, planning clarity and confidence in long-term feedstock and offtakes. Without those, projects stall or leave for more certain jurisdictions.

Vella shared a preference for loans over grants. Grants are sporadic and can distort priorities. What proponents need, he argued, is co-investment finance that sits beside private capital, reduces risk, and is repaid. He pointed to models in other sectors where government finance corporations provide debt on sensible terms to crowd private capital into assets that are critical but hard to bank in early stages.

the facility reached capacity, Rellik Group and the transporter agreed to transport the waste to a rural property in Woodside, with no permission to receive the waste. 748 pallets, or approximately 374,000 litres of hand sanitiser was deposited at the premises, with Rellik Group’s knowledge.

S 135 of the Environment Protection Act 2017 requires that a person who has management or control of industrial waste, and who proposes to relinquish management or control to another person for purposes of transport, must take all reasonable steps to ensure that the industrial waste is or will be transported and received at a place or premises that is authorised to receive industrial waste.

This Adverse Publicity Notice was published and paid for by RELLIK GROUP PTY LTD pursuant to an order of the Magistrates’ Court of Victoria.

Procurement emerged as an underused lever. Head argued that the waste levy, which collects large sums each year, should be recycled back into the sector to fix the very problems it is intended to discourage. He also called for reform of local government tendering rules, which he characterised as cumbersome, slow and not necessarily value adding.

Stronger carrots and sticks in procurement could embed recycled content and pull through demand that, in turn, justifies private investment in sorting and reprocessing.

“We collect an enormous amount from the levy. There is a real opportunity for public sector investment back into the sector. Our tendering is slow and expensive. We need a more mature way of engaging and stronger levers on reuse and offtakes,” Head said.

Lemin sharpened the point with numbers. He noted that across two recent financial years the levy collected and the outcome for it being reinvested back into the industry was negligible.

“Out of $1.8 billion collected, $7.5 million went to waste infrastructure. This highlights that the government’s priorities for the levy money hypothecation is very wrong,” he said.

Collins proposed that councils act together to create the scale that investors need. Joint procurement can underwrite feedstock, and councils can bring land to the table for organics processing and transfer sites. He suggested that a council that contributes land might secure better rates for its own residents while enabling a facility that serves the region. It is a way for local government to be master of its own outcome rather than a price taker in a tight market.

“There is a big opportunity for Sydney councils to come together on procurement and, where possible, to put land into the mix. That could underwrite a FOGO facility and deliver a net win for the region,” Collins said.

Head reflected on how far the system has travelled. Councils once owned much of Sydney’s waste infrastructure. Corporatisation, and later sales, changed that landscape. Today, he said, the

“Out of the $1.8 billion [in levies] collected, only $7.5 million went back into waste infrastructure. This highlights that the government’s priorties for levy money hypothecation is very wrong.”

lack of open access to transfer stations is a key issue for councils, one that bites hardest when contracts are renewed in a constrained market.

One year to act, and why action lagged

Asked to nominate one decision the state must make within the next year to avoid hitting the wall, Collins, Whitfield, Vella and Head converged on the need to land decisions and lock them in. Collins listed the suite of reviews already in progress and argued that they must be resolved together so the sector can move. If forced to choose one, he would choose the levy: get the rate right, set it for the long term, and use it to underpin investment.

Whitfield’s priority was to preserve landfill life by treating space as precious and setting limits that force investment into alternatives.

Vella placed resource recovery orders and exemptions at the top of the list. In his view, urgent clarity on those rules is the prerequisite for investment decisions, with planning reform a close second. Head wanted the plan, with actions and dates fixed against it.

Why were not actions initiated earlier when the signals were visible years ago? The answers pointed mostly to time and politics. Whitfield noted that alternatives were flagged, and proposals lodged early. Investors then ran into the reality of multi-year planning processes, changes in personnel and policy, and the attrition

that comes with prolonged uncertainty. Vella described a landfill extension that has been in the works for 14 years, and a recent facility approval that still took four years despite extensive prelodgement engagement.

“We saw it a long time ago. We just have not been able to get the relevant approvals,” Vella said.

Collins observed that multiple energy from waste proposals failed to progress for different

cost – roughly $750,000 worth of waste in one week. The lesson, he argued, is that resilience is not a theoretical benefit, it is what keeps services running when something goes wrong.

He suspects political nervousness has delayed difficult decisions and believes the community will back them if leaders explain waste as clearly as they explain water, sewerage and electricity.

“It is an essential service. Sometimes we need to take a leadership step and deliver it so that

“During floods, Hornsby Shire could not sent waste to a major processing facility so had to divert roughly $750,000 worth of waste in one week.”

reasons, depriving the system of a residual outlet that could have eased pressure on landfill. For Vella, this underlines why government must sometimes plan for redundancy.

“Government needs to create surplus capacity for redundancy and emergencies. The private sector cannot build ‘just in case’ assets,” he said. “Support is needed while demand catches up, so that there is continuity long term.”

Head offered a case study in fragility. During the floods, Hornsby Shire could not send waste to a major facility and had to divert – at significant

quality of life can continue,” Head said.

The panel’s diagnosis will be familiar to practitioners who have wrestled with approvals, tendering and long-term contracting while keeping trucks on the road and bins emptied. What distinguishes this conversation is the insistence on practical steps that do not await new ideas, certainty in the cases of the levy and the resource recovery rulebook. A geographically anchored plan that is written into local instruments is needed, as well as joint procurement that underwrites feedstock and

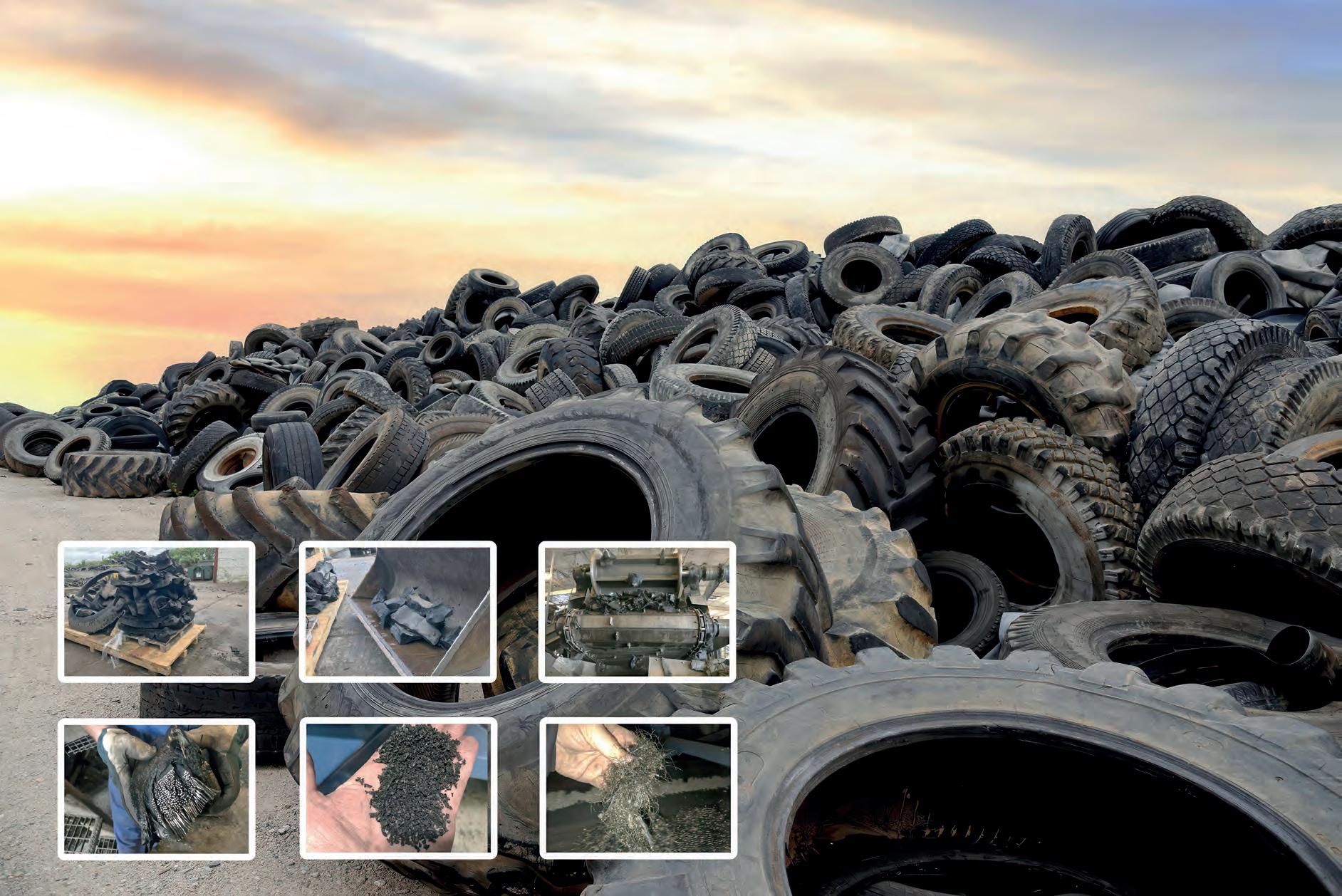

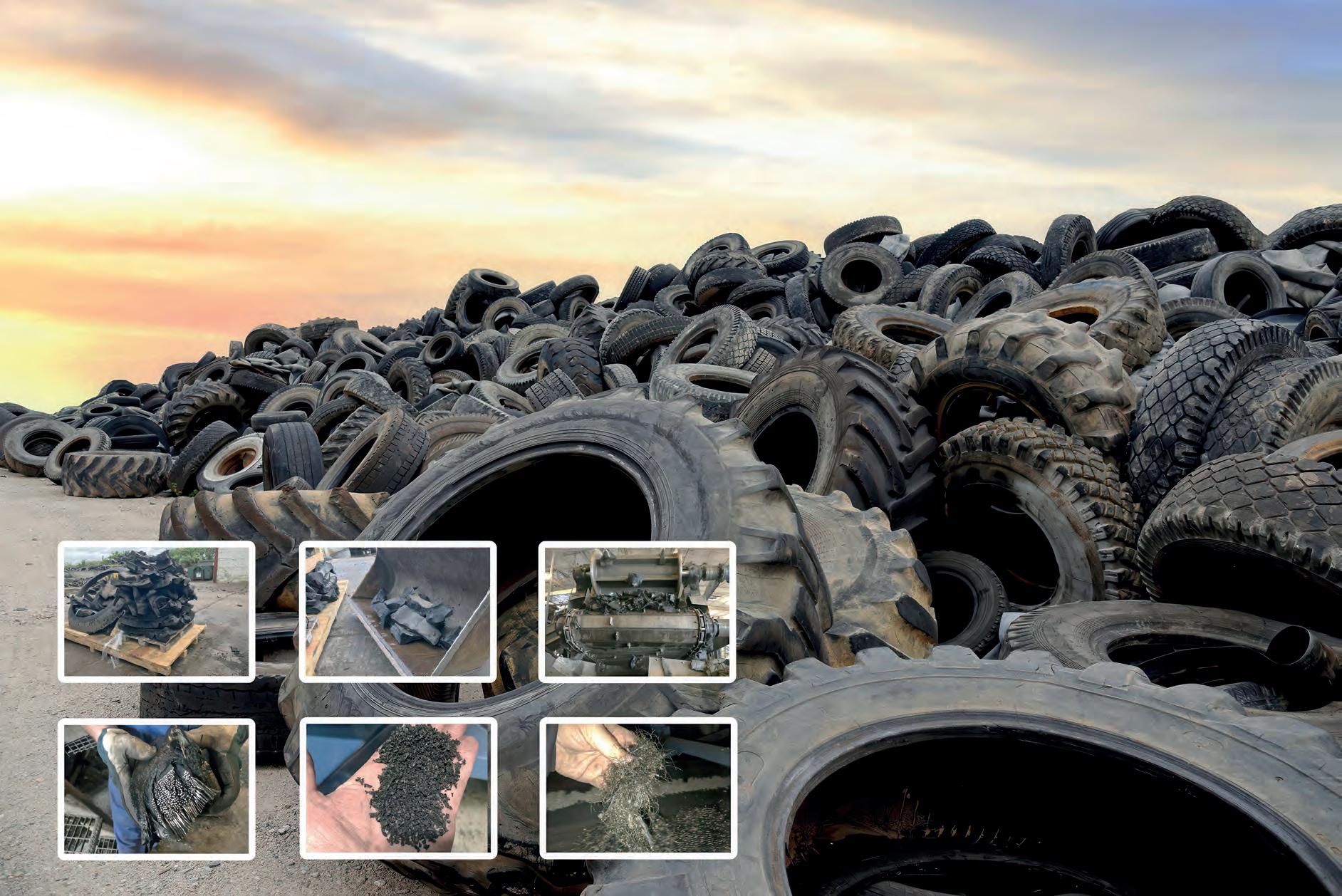

A landfill shouldn’t be treated as workhorse that can always be asked to do more. Image: Maksim Safaniuk/shutterstock.com

Innovative Environmental Experts

Innovative Environmental Experts

Experts

Ennovo provides comprehensive solutions for the management of recycled organics based on extensive experience with designing, constructing and operating recycled organics facilities.

Ennovo provides comprehensive solutions for the management of recycled organics based on extensive experience with designing, constructing and operating recycled organics facilities.

Ennovo provides comprehensive solutions for the management of recycled organics based on extensive experience with designing, constructing and operating recycled organics facilities.

Specialist Services

FOGO management and processing

Specialist Services

Specialist Services

Site assessment and approvals

FOGO management and processing

FOGO management and processing

Market assessment and development

Site assessment and approvals

Site assessment and approvals

Composting – open windrow and in-vessel

Market assessment and development

Market assessment and development

Process and product development

Composting – open windrow and in-vessel

Composting – open windrow and in-vessel

Ennovo’s Carbon Air system automates forced aeration for efficient composting in windrow and in-vessel applications. With telemetryenabled automation, it reduces costs, optimises operations, and ensures high-quality output, making it ideal for FOGO composting. Ennovo provides end-to-end solutions from design to market development.

Third party compliance support

Process and product development

Process and product development

Ennovo’s Carbon Air system automates forced aeration for efficient composting in windrow and in-vessel applications. With telemetryenabled automation, it reduces costs, optimises operations, and ensures high-quality output, making it ideal for FOGO composting. Ennovo provides end-to-end solutions from design to market development.

Ennovo’s Carbon Air system automates forced aeration for efficient composting in windrow and in-vessel applications. With telemetryenabled automation, it reduces costs, optimises operations, and ensures high-quality output, making it ideal for FOGO composting. Ennovo provides end-to-end solutions from design to market development.

Carbon credit development and management

Third party compliance support

Third party compliance support

Carbon credit development and management

Carbon credit development and management

“Government needs to create surplus capacity for redundancy and emergencies. The private sector cannot build “just in case” assets.”

invites capital in at scale. Then there is the reframed role for the levy as patient finance, not a tax that disappears into general revenue, plus a planning process with boundaries on referral input and a clear pathway for proponents. Finally, a social licence strategy that treats waste as essential and explains the trade-offs is also necessary.

None of these steps are remarkable in themselves. Together, and taken quickly, they could change the trajectory by 2030 from crisis management to managed transition. The message from the panel was that the time for pilots and position papers has passed. The pieces of a workable solution are already on the table. The task now is to pick them up, place them on a map of Sydney, and get on with the building.

During floods, Hornsby Shire had to divert its waste at significant cost – one week it was $750,000. Image: Alex Cimbal/shutterstock.com

YOUR PROVEN SOLUTION

Invest in the Best to Maximise Revenue

Eriez patented the world’s first Eddy Current Separator in 1969. Today, our full range of recycling equipment can be found all over the globe, increasing recoveries and maximising revenues. Eriez. Always the Right Choice.

Eddy Current Separators from Eriez effectively remove non-ferrous metallics from automobile shredder residue (ASR), municipal solid waste (MSW), plastics, glass cullet, electronic scrap, and more.

From the CEO’s desk

Supercharging decarbonisation news

With all the talk about the pending updated 2035 emissions reduction targets, I can’t help but wonder if one way of getting our national policy mojo back is greater emphasis on the link that waste and resource recovery (WARR) has to carbon. The reality is that Australia’s 43 per cent emissions-reduction target by 2030 and net zero by 2050 are achievable if we mobilise every lever, including the WARR industry. Continuing to reduce “waste” to an end-of-pipe problem squanders

Environment Ministers will meet for the second time this year on 7 December, following the first 2018 Meeting of Environment Ministers (MEM) in April, which was in part a response to the import restrictions driven by China’s National Sword Policy and the effects this policy has had across the Australian waste and resource recovery (WARR) industry. Key decisions derived from the April MEM include:

•Reducing waste generation, endorsing a target of 100% of Australian packaging being recyclable, compostable or reusable by 2025, and developing targets for recycled content in packaging.

• Increasing Australia’s domestic recycling capacity.

only be developed to reduce the landfill’s liability and create Safeguard Mechanism Credits (SMC), which has not yet been not enough of an incentive. The reality is that landfills often share a resource recovery precinct with other facilities. In some interpretations of the Safeguard rules, even facilities that do not have any connections to a Safeguard landfill could be barred from creating ACCUs: clearly an anti-competitive and perverse outcome. Decarbonisation options on sites that most need them can be financially harder to stand up unless the Safeguard baseline and/or on-site investments do the heavy lifting.

date for universal FOGO and continue to utilise the Recycling Modernisation Fund to co-fund composting/ AD capacity with consistent quality specifications. Methane abatement is immediate and bankable.

industry however the Queensland Government has embarked on the development of a waste management strategy underpinned by a waste disposal levy to increase recycling and recovery and create new jobs. The State will re-introduce a $70/ tonne landfill levy in March 2019. There are also strong attempts to use policy levers (levy discounts and exemptions) to incentivise the use of recycled material and make it cost competitive with virgin material. However, little has been done establish new markets and Government has not taken the lead in the procurement of recycled material. There are grants available for resource recovery operations in Queensland although no monies have been allocated to assist in 2018. This troubling as Queensland rolled out its Container Refund Scheme on 1 November, which will likely impact the cost and revenue models of the State’s MRFs – as have seen most recently in NSW.

• Nationalise methane performance expectations and incentives. Create minimum methane capture/ management requirements for all medium-to-large landfills, harmonised across states, with robust monitoring and public data. That removes the incentive for “leakage” to weaker jurisdictions.

• Let’s copy what works in Europe: use less, for longer.

A practical agenda for Australia

WESTERN AUSTRALIA

By keeping materials circulating longer, designing out waste, and diverting organics from landfill, we cut emissions across whole value chains while building sovereign capability. Direct “waste sector” emissions (mostly landfill methane) are a small slice of the inventory, but the avoided emissions from material efficiency are larger: every tonne of aluminium, glass, paper, steel or plastic we reuse or recycle avoids energyintensive virgin material extraction and production.

• Increasing the demand for recycled products.

• Exploring opportunities to advance waste-to-energy and waste-to-biofuels.

•Updating the 2009 Waste Strategy by year end, which will include circular

It is time to take stock and examine what has been achieved since these decisions were announced. Now, seven (7) months may not seem like a long time, however in that time we have seen further markets close (Malaysia, Indonesia, Vietnam) and if you are an operator under continued financial stress, seven (7) months could make or break you.

Organics is the fast win: stop food and garden waste entering landfill and you curb methane. The European Union (EU) recognised this by requiring separate collection – clarity that drives infrastructure roll-out and end-market investment. To date we only have one state that has mandated. Those jurisdictions that have opted to introduce separate collections remain focused on household waste, with very little attention being given to the C&I sector despite business offering a huge opportunity for diversion.

Following the April MEM, we have had three (3) states step in with varying degrees of financial assistance for industry (councils and operators). This should be expected considering almost all states (except Queensland and Tasmania) have access to significant waste levy income each year. On the eastern seaboard, Victoria has approximately $600 million in waste levy reserves in the Sustainability Fund and NSW raises more than $700 million per annum from the waste levy. There is certainly no lack of funds that can be reinvested into our essential industry.

What’s not working

Much of the accredited abatement is tied up in landfill Australian Carbon Credit Units (ACCUs), without driving circular demand. ACCUs remain a compliance currency and the landfill gas method is being reformed and extended, reflecting how much methane abatement has relied on this route. It is anticipated that the soon-to-bepublic, revised landfill gas method will materially expand ACCU supply in coming years. Yet an ACCU created at a flare or engine doesn’t, by itself, create a market signal to use recycled content, design for repair, or avoid waste in the first place. That leaves a demand-side gap that procurement and product policy must fill. Safeguard rules cover landfills, but also restrict co-located ACCU abatement. Non-government large landfills fall under the Safeguard Mechanism. By design, if abatement would reduce covered emissions at a Safeguard facility, that project is not eligible to earn ACCUs. This is an anti-double-counting rule that, in practice, blocks co-locating new ACCU crediting projects at big, covered landfills, and undermines industry’s ability to co-locate facilities at existing WARR precincts, capitalising on the existing planning and transport infrastructure. Instead, those projects can

Funding helps but as we know, the money goes a much longer way with Government support and leadership, as well as appropriate policy levers.

VICTORIA

Fragmented state settings create cross-signals. States set levies, service standards and licensing. The result: different landfill levies, different organics service timelines, and varying methane management expectations. NSW is now funding a Landfill Emissions Abatement Program given a large number of smaller and/or council landfills lack comprehensive methane controls, while other states take different approaches. We are also increasingly seeing different emissions reporting and compliance levels on state-based policies when compared with national and other state policies. These divergences raise cost and uncertainty for national WARR operators and investors, and they blunt the climate signal. Crucially, they do not offer a direct incentive to commercially maximise reduced emissions. There is no dedicated waste sector decarbonisation plan, yet. The Commonwealth sectoral net-zero industrial plan, which explicitly lists WARR as a sub-sector, remains outstanding. However, a standalone, published pathway for WARR is not even on the agenda, meaning policy instruments like described above land piecemeal. A clear sector plan would lock in priorities, timelines and investment sequencing. I also despair about the effectiveness of proponent-led methodologies given there would also appear to be no prioritising process, meaning I am unclear how we could drive incentivisation through this pathway in the foreseeable future. Leaving each proponent to figure out their own waste and resource recovery plans without input from our industry is doomed to fail.

Victoria has arguably been the most active and earnest in supporting the industry post-China, with two (2) relief packages announced to support the recycling industry, valued at a total of $37 million. The Victorian Government has also gone above and beyond all others states by announcing it would take a leadership role in creating market demand for recycled products.

One economy, one set of rules

SOUTH AUSTRALIA

1. S et a national materials-intensity goal for priority sectors and align procurement, standards and investment to hit it. This shifts focus from end-of-pipe credits to material efficiency and will assist with Australia’s target to double material circularity.

The Western Australian Government set up a Waste Taskforce in direct response the China National Sword. As part of this announcement, the State Government urged all local councils to begin the utilisation of a three (3)-bin system - red general waste, yellow for recyclables and green for organic waste - over the coming years to reduce contamination. While this taskforce is a step in the right direction, we are yet to see any tangible results from it or any funding for industry. In October, the WA Waste Authority released its draft Waste Strategy to 2030, which comprises a comprehensive and detailed roadmap towards the State’s shared vision becoming a sustainable, low-waste, circular economy.

2. Make packaging reform a genuine market-maker: tie design for recyclability to mandatory local Australian recycled content thresholds, in order that processors see bankable offtake and invest.

3. Go hard on organics: universal FOGO by a national date, standardised service design, and national compost quality specs (that address safe levels of PFAS) embedded in soil and procurement programs.

COMMONWEALTH

4. Complete the net zero industry plan and align national carbon policy to reduce reporting burden on industry, while creating a thoughtful regulatory environment that decarbonises the economy, not simply creates a compliance burden.

Following the MEM in April, Australia now has a new Federal Environment Minister, Melissa Price, who in October reiterated to media MEM’s commitment to explore waste to energy as part of the solution to the impacts of China’s National Sword, which is troubling (EfW is not a solution to recycling). The Commonwealth also backed the Australian Recycling Label and endorsed the National Packaging Targets developed by the Australian Packaging Covenant Organisation (APCO), which has to date, failed to incorporate industry feedback in the development of these targets. To the Commonwealth’s credit, there has been significant coordination in reviewing the National Waste Policy, with the Department Environment bringing together industry players and States during the review process.

5. Improve the proponent-led ACCU pathway to enable method development that supports keeping materials circulating longer, which supports capital investment in remanufacturing in Australia and reduces reliance on virgin materials.

6. Count what counts: evolve emissions reporting and procurement guidance in order that avoided emissions from reuse/repair/high-value recycling show up in decision-making and finance. Clearly link to the forthcoming net-zero sector plans so WARR’s role is explicit rather than incidental.

The payoff if we do

The updated Policy will now go before Environment Ministers on 7 December. Commonwealth can play a key role – one that goes beyond the development of National Waste Policy. WMAA is supportive of the Federal Government maximising the levers it has, including taxation and importation powers, to maintain a strong, sustainable waste and resource recovery industry.

Fragmentation is solvable. The Commonwealth and states need to make circularity the default, with consistent rules:

• F inish packaging reform and mandate design and local Australian recycled content. Move from voluntary targets to enforceable product-level rules. That is how you turn the ACCU abatement focus into materials abatement and sovereign manufacturing demand.

Government announced a $12.4 million support package comprising $2 million of additional expenditure, $5 million additional funding for a loan scheme, together with targeted funding from the Green Industries SA budget. The Government has also offered grants for recycling infrastructure.

NEW SOUTH WALES

At first glance, New South Wales’ eye-watering $47 million recycling support package was heralded as the spark of hope industry needed. However, on closer inspection, the bulk of this package that was funded via the Waste Less, Recycle More initiative and therefore the waste levy, was not new, making it very difficult for stakeholders, including local government, to utilise the funds as they were already committed to other activities. Some of the criteria proposed by the NSW EPA also made it challenging for industry to apply to these grants. On the plus side, efforts are being made by the NSW Government to stimulate demand for

AHEAD OF MEM 2

Clear, consistent rules turn today’s patchwork into an investable national program: methane falls fast via organics and better landfill performance; upstream emissions shrink as design, repair and recycled content become non-negotiable; and Australia builds a competitive circular economy.

There may be movement across Australia, with some states doing better than others, but the consensus is, progress is still taking way too long. It is evident that there are funds available in almost all States to assist with developing secondary manufacturing infrastructure, however the only way that this will really happen if there is government leadership around mandating recycled content in Australia now, not later.

• S cale demand through procurement. The Federal Environmentally Sustainable Procurement Policy must be expanded with clear recycled-content minimums for priority goods. Government and private industry are the market-makers; pull signals convert remanufacturing capacity using recycled materials into emissions cuts.

• Harmonise organics policy and timelines. Set a national

Europe shows that when policy signals align, industry delivers. If we align Commonwealth and state levers, finish packaging reform, sharpen the Safeguard/ACCU interface, complete the Net Zero Industry plan, and make procurement pull recycled content through supply chains, WARR becomes a frontline climate solution, not just a service industry, but a decarbonisation engine for a net-zero Australia.

Gayle Sloan is the CEO of WMRR

Voluntary schemes like the Used Packaging NEPM, under which APCO is auspiced, are not working. We have 1.6million tonnes of packaging waste in Australia, which needs to be used as an input back into packaging. Barriers to using recycled content in civil infrastructure must be identified and removed, and Government must lead in this field and prefer and purchase recycled material. A tax on virgin material should also be imposed as it is overseas. MEM must show strong leadership on issue. Ministers have, since April, dealt directly with operators and councils that are under stress and we have a chance to create jobs and investment in Australia

Celebrating correctional centre success

IN CORRECTIONS, stories often focus on negatives. When something goes wrong, it is guaranteed to make headlines. Yet for Larry Guilfoyle, Manager of Industries at the Lotus Glen Correctional Centre for Queensland C orrective Services, recognition at the 2024 Waste Innovation and Recycling Awards offered something rare: a moment of pride and affirmation for everyone involved.

The centre’s recycling program, which collects, sorts and repurposes materials including food waste, plastics and clothing, won the Outstanding WARR Project: Regional/Rural award. For Larry, the accolade was more than just a trophy.

“We were all over the moon with the win,” he said. “I was shocked because we were up against some incredible contenders. But what made it truly special wasn’t just the recognition; it was the impact on the people behind it.”

The recycling initiative, established in 2022, has already diverted between 700 and 1000 tonnes of waste from landfill, making it Queensland’s largest program of its kind within a correctional centre. Currently, about 50 per cent of the centre’s waste is diverted, delivering strong environmental benefits while providing inmates with valuable skills and a renewed sense of purpose.

“It was really affirming for the prisoners,” Larry explained. “After the news broke, it was even s hown on the TVs in the centre, and the reaction was massive.”

For participants, the program represents more than just recycling. It builds confidence and opens

doors to future opportunities. One inmate has even told Larry of plans to pursue a career in the recycling industry after release.

“This award was a huge confidence boost for all of us,” he says. “It has also shown the nation we are not just working to rehabilitate prisoners, we’re providing a positive output for the community.”

The award has sparked further ambition at Lotus Glen, with Larry exploring new proposals such as converting food waste into chemical-free fertilisers. The momentum from the recognition continues to fuel innovation and morale within

eyond Lotus Glen, the Waste Innovation and Recycling Awards play an important role in shining a light on unsung heroes across the resource recovery sector. Larry recalls his amazement at learning the full scope of projects underway across Australia.

You tend to hear bits and pieces about programs here and there, but I was blown away seeing the detail that night,” he says. “The awards are a great platform to learn, to share in success and to gain confidence just by being nominated.”

The 2025 awards, held alongside the Waste Australia Expo, will take place on 29 October at the Melbourne Arts Centre.

Since 2022, Lotus Glen Correctional Centre has diverted between 700 and 1000 tonnes of waste from landfill. Image: Prime Creative Media

Australia’s circular economy push takes shape

(Continued from the Cover)

BIRD EXPLAINED that the framework focuses on sustainable design, reuse, repair and recycling.

“Going circular is an innovation opportunity with broad-ranging benefits,” she said, pointing to new jobs, stronger supply chain resilience, and reduced emissions, particularly in sectors like manufacturing, food and construction. The framework targets four key industries identified by the CSIRO for their potential to deliver high-impact change. Bird noted that the government’s role is to establish direction, regulation and incentives, while industry must lead implementation through innovation and redesign. The strategy’s emphasis on co-delivery reflects the interconnected systems required to make circular practices the norm across sectors.

Bird also stressed that the circular economy is now embedded in more than 30 federal government policies and programs representing around $150 billion in investment. Initiatives

such as the national traceability framework, environmentally sustainable procurement policies and an upcoming Remade in Australia brand are all reinforcing market signals to support circular outcomes.

Standards paving the way

Representing Standards Australia, strategic initiatives manager Emelia Addo-Appiah explained the organisation’s role in developing both national

“Standardisation is key to simplification,” said Addo-Appiah. “Clear, consistent standards enable businesses to evaluate and communicate product circularity with confidence.”

Addo-Appiah highlighted the adoption of three ISO standards in 2023 as a milestone. These included foundational guidance on circular vocabulary, business model transition and measurement. An additional ISO standard focused on product circularity data has since been

“Clear, consistent standards enable businesses to evaluate and communicate product circularity with confidence.”

and international benchmarks that support the uptake of circular practices. As a n on-government, not-for-profit body, Standards Australia facilitates harmonisation across jurisdictions and industries, a function in progressing consistent and trusted approaches.

released, and while not yet adopted in Australia, it offers a practical framework to evaluate and report on product circularity in a consistent way. Beyond published standards, Standards Australia is also investigating how recycled content can be safely and reliably used in infrastructure.

Left to right: Chloe Bird, Nicole Garofano, Emelia Addo-Appiah and Christie Rourke.

Image: ReGen Expo Australia

Design. Build. Save.

Steelcorp delivers turnkey waste-sector structures, engineered to use 20–30% less steel without compromising strength or compliance. •

ISO standards are a good start when it comes to standardisation across the board. Image: Anucha Tiemsom/shutterstock.com

“We’re really focused on making the case by linking circularity to core board responsibility and business outcomes.”

With sectors like construction demanding clarity, this work is vital in shifting infrastructure procurement towards circular practices.

Bringing directors into the fold

Christie Rourke, senior policy advisor and climate lead at the Australian Institute of Company Directors (AICD), shared the organisation’s efforts to support boards, large and small, in understanding the opportunities the circular economy presents. While directors often lead waste management or sustainability i nitiatives, many are unfamiliar with the language of circularity.

To bridge this gap, AICD recently released a primer titled Opportunities in the Circular Economy , aimed at demystifying the topic and linking it to core governance responsibilities.

Rourke said the response had been positive, and that the institute is using case studies and storytelling to bring circular economy concepts to life for its 50,000-plus members.

“We’re really focused on making the case by linking circularity to core board responsibility and business outcomes,” Rourke said. “It’s about unlocking innovation, improving productivity and delivering cost savings through resource efficiency.”

She added that mandatory climate reporting, which requires disclosures on waste and embodied carbon, provides a further lens through which circularity is becoming essential to corporate strategy.

Procurement as a circular lever

Procurement is emerging as a powerful tool to drive change, particularly within government.

Bird described the environmentally sustainable

procurement policy introduced last year, which applies to construction procurements above $7.5 million. While still gaining momentum, it is already having an effect.

“We’re seeing both purchasers and suppliers becoming more engaged with circularity, looking beyond compliance to broader benefits,” said Bird.

She noted that innovative suppliers with circular capabilities are beginning to be recognised, nd that procurement processes are increasingly considering the full lifecycle of products and services.

arofano added that seven of the 14 principles outlined in the procurement policy relate directly to circular economy goals. This policy, she said, as the potential to influence market behaviour, sending strong signals through government purchasing power.

Supporting consistency and harmonisation

A recurring theme throughout the discussion was the need for greater harmonisation across Australia’s states and territories. Bird acknowledged that navigating different regulatory approaches can hinder progress, particularly for businesses operating nationally. Efforts are underway to address this.

“There’s a roadmap for harmonising kerbside

RECYCLING EQUIPMENT

Landfill Compactors

Heavyweight Compaction. Light on Downtime.

From 24 to 57 tonnes, BOMAG landfill compactors, the BC473, BC573, BC773, and BC1173, deliver the muscle and precision needed to turn waste into stable, highdensity landfill. Available through Tutt Bryant Equipment, these machines are built with BOMAG’s proven polygon wheels with teeth for unmatched shredding and compaction, self-cleaning scrapers and wire cutters for consistent performance, and fuel-efficient engines that cut running costs. Whether it’s spreading, crushing, mixing, or compacting in one seamless pass, BOMAG sets the benchmark for landfill efficiency! No frills, no fuss, just serious compaction power backed by nationwide support.

BC 473

BC 773

BC 1173

said. “States and territories are very engaged, but it takes time to steer the ship.”

She pointed to cross-jurisdictional collaboration on the recycled content traceability framework as a proactive example.

Developed before specific standards existed, this framework now informs procurement policy in New South Wales and Queensland.

Rourke added that guidance from the Australian Competition and Consumer Commission on

“Yes, standards provide consistent ways of doing things, which simplifies the process,” she said. “Stakeholders can participate in standards development through working groups or suggest new areas where guidance is needed.”

She noted that guidance documents are also a useful interim step for emerging issues, offering flexibility while maintaining a degree of standardisation. These lower-consensus pathways are particularly helpful in fast-moving areas like

“Stakeholders can participate in standards development through working groups or suggest new areas where guidance is needed.”

collaboration for sustainability has helped ease industry concerns, although more could be done.

“We’re seeing great examples of localised collaboration, especially in regional areas where circularity needs to be adapted to community scale,” she said.

Opportunities through clearer standards

During a question-and-answer segment, Addo-Appiah responded to a query about how

packaging or climate-related disclosures, where expectations and practices are still evolving.

Garofano reflected on how broad the influence of standards can be, especially when circularity begins to intersect with traditional sectors like construction or packaging.

“When you start to unpack it, you realise just how many standards are relevant,” she said.

In response to a question about how general contractors are expected to apply circular principles under the new procurement rules, Bird explained

market. Suppliers must submit a sustainability plan outlining how they’ll meet circular requirements, which then becomes part of the contract, she said. Although the process involves several steps, she believes familiarity will increase over time and guidance is available to help contractors comply.

Moving forward with shared responsibility

The session closed with a renewed call for collaboration. Government can set the direction and provide incentives, but it is industry, supported by coherent standards and governance frameworks, that must implement circular practices.

Garofano summed up the importance of systems thinking in the transition to circularity.

“It’s not something that happens in a vacuum. Like nature, it’s a system that only functions when every part works together,” she said.

With a national policy framework in place, strengthened by harmonisation efforts, procurement reforms and standards development, Australia is now equipped with the tools to accelerate progress. Whether that momentum continues will depend on active engagement from all sectors and a shared understanding of the circular opportunity ahead.

EfW – challenges and opportunities

JASON PUGH, country president and managing director of Kanadevia Inova, describes energy from waste (EfW) projects as among the most complex initiatives in any jurisdiction. And with good reason. These projects involve an array of stakeholders, each with distinct roles, expectations, and regulatory requirements. Lenders, local and state governments, federal regulators, network providers, and community groups all influence the project lifecycle, which is why coordinating these groups requires meticulous planning, constant communication, and flexibility to adapt to evolving needs.

“ Energy-from Waste” as an asset class is probably about as difficult as it gets in any jurisdiction, due

to the way the projects are financed, also due to the number of stakeholders, and the amount of misinformation that is produced,” he said.

The complexity is compounded by the lengthy timelines these projects require. Pugh, who was the former CEO of the WA-based East Rockingham Waste to Energy Facility – one of the first to come on-line in Australia – said the WA projects took longer than anticipated to reach full operation. However, he highlights that despite these delays, the long-term benefits became increasingly clear. Engaging communities during construction played a crucial role in building trust and support. Hundreds of visitors, including council members, politicians, industry groups and local residents,

have now toured the facility, which has led to a better understanding of the intricacies of such a complicated piece of plant. Observing construction and operations firsthand helped reduce scepticism and foster understanding of the environmental and social advantages.

Pugh notes that the early stages of current projects on the east coast face similar dynamics. At the conceptual stage, fear and confusion are natural reactions. As environmental impact statements are prepared and community consultations are held, stakeholders gain more information, which gradually reassures the public and demonstrates the practical benefits of the projects. This process of engagement and education is essential to move beyond initial misconceptions.

Turning waste into data

A defining feature of energy-from-waste (EfW) facilities is the ability to collect detailed operational data that councils and regulators previously lacked. When the projects began, reliable information on waste composition was scarce. In particular, the calorific value of waste, a critical input for plant design, was almost entirely unknown. This data enhances operational efficiency and provides councils with insights to guide local waste management policy.

“The volume of data the operational plants generate is game changing. We can track calorific value, waste composition, biogenic fraction, a well as metals content of the waste by month, by season, by year – we can see who’s putting what in the wrong bin. This information is then provided to our council customers to focus waste education activities,” said Pugh.

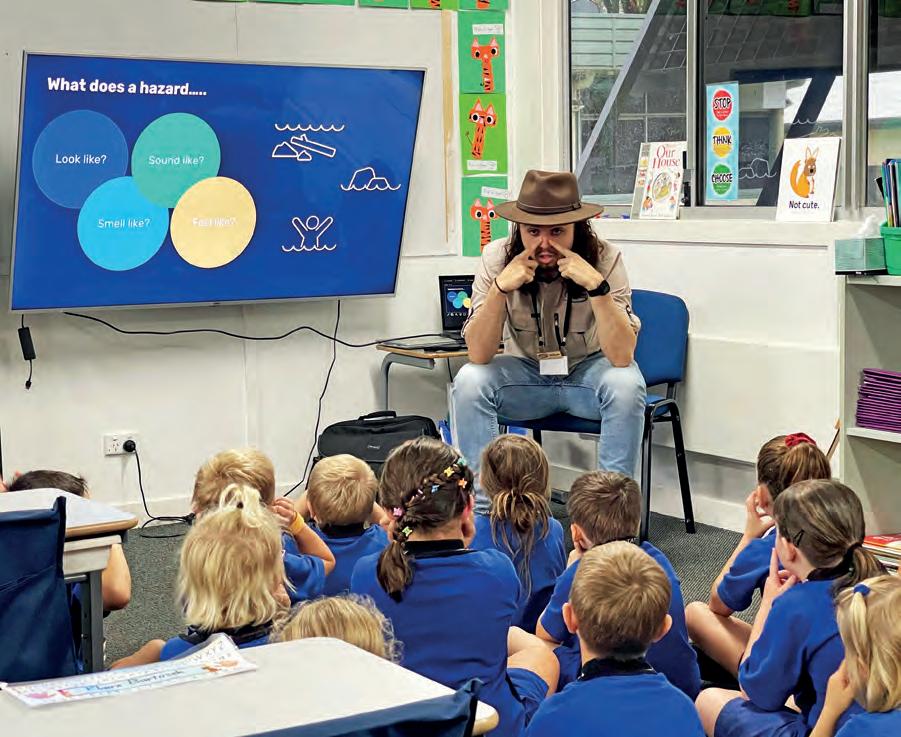

Beyond operational advantages, these facilities offer educational benefits. School groups and community organisations can tour the plants to learn about the waste hierarchy and sustainable practices. While only a small part of the curriculum is about energy-from-waste technology itself, the visits offer a broader understanding of environmental responsibility. By interacting with functioning facilities, residents gain tangible examples of the impact their waste disposal decisions can have.

Pugh emphasises that this data collection has a dual purpose: it not only improves operational outcomes but also strengthens community engagement. By providing transparent, science-based insights, residents can see the positive impact of energy-from-waste projects and make informed decisions about their own behaviour.

Building community confidence

One of the most effective strategies for fostering public support is exposure to operational plants. Pugh has taken community leaders, council representatives, and politicians to see facilities in action, allowing them to understand operations beyond theoretical explanations. Observing the safety measures, monitoring systems, and environmental controls first-hand helps to build confidence and demystify the technology.

In Western Australia, this strategy proved highly effective. Visitors were able to witness

This EfW facility built in Ireland had extensive community engagement before coming to fruition. Images: Kanadevia.

“The volume of data the operational plants generate is game changing. We can track calorific value, waste composition, biogenic fraction, metals content of the waste by month, by season, by year, we can see who’s putting what in the wrong bin.”

the environmental benefits of diverting waste from landfills, generating renewable energy, and gathering operational data. On the east coast, Pugh applies the same approach, drawing lessons from previous projects to guide discussions with councils and politicians.

“While it’s appropriate to evaluate the risks of EfW, the frightening legacy of continued landfilling is being overlooked,” he said. “The environmental and social advantages of EfW over landfilling are real and compelling”.

During the recent WMRR EfW Conference, the Gold Coast council presented the Advanced Resource Recovery Centre (ARRC) project featuring an energy from waste facility as part of the overall waste precinct. The council acknowledged the limitations of landfill capacity and communicated openly with residents. By owning the problem and explaining the

Scientific foundations and environmental safety

Environmental impact remains an area of public concern. Pugh emphasises that energy-fromwaste facilities are carefully engineered to prevent contamination. All process fluids are contained within the plant, and emissions are continuously monitored. Predictive modelling allows operators to assess ground-level concentrations before construction, ensuring that potential impacts are well understood. This scientific rigour contrasts with landfills, where long-term emissions are harder to predict, and environmental consequences are more uncertain.

“With EfW there is no risk of liners splitting and water contamination,” he said. “If we don’t decide to refurbish that plant after 30 years, we’ll demolish it and restore the land to the way it was when it started, which a landfill simply cannot do.”

EfW plants are designed to operate for decades, with refurbishments extending life.

At EcoBatt, we are driving real change through our nationwide Battery Collection Service, which is designed to significantly reduce the number of batteries ending up in landfill. With over 7,000 collection units located across Australia in partnership with major retailers, we are making battery recycling more convenient and accessible than ever before.

Improper battery disposal can have serious consequences. From fires in waste trucks and landfill sites to toxic chemicals leaking into soil and waterways, the risks to our environment, wildlife and community health are far-reaching.

Recycling batteries correctly is a simple yet powerful way to protect what matters. By working together, we can create a cleaner, safer future and preserve valuable resources for generations to come.

Western Australian EPA commissioned detailed studies in Europe to evaluate energy-from-waste technology, assessing both environmental and health impacts. These studies confirmed that operations adhering to best practice standards are acceptable, establishing a framework that can guide future projects.

Operationally, EfW facilities are not typical power stations. Basically, it is a base-loaded renewable energy power station that requires coordination with network operators to manage load changes and interruptions safely. Continuous monitoring and auditing ensure renewable energy claims are verifiable and that plant adjustments are performed safely, maintaining both compliance and community trust.

Industry growth and future prospects

Looking forward, Pugh highlights the long-term sustainability of EfW facilities. Plants are designed to operate for decades, with refurbishments extending life and maintaining efficiency. Revenue comes from a combination of gate fees for waste intake and electricity sales, typically with a 75 per cent to 25 per cent split. This dual income stream provides financial security, allowing investors to achieve returns without relying on decades of continuous operation.

“By the year 2025, the volume of residual waste is not dropping off as everyone would have hoped. We need to get moving,” he said.

East coast projects, such as Maryvale, are moving toward financial close. Careful planning and transparent stakeholder engagement underpin this progress. Parliamentary inquiries and public forums offer platforms for fact-based discussion, allowing stakeholders to examine evidence and understand both operational and

operational expertise, community engagement, and scientific evidence. By demystifying EfW technology and providing transparent insights, the organisation helps communities understand the benefits and challenges of these projects.

Combining operational data, educational initiatives, and environmental safeguards positions these facilities as essential elements of Australia’s sustainable waste management strategy.

“If we don’t decide to refurbish that plant after 30 years, we’ll demolish it and restore the land to the way it was when it started, which a landfill simply cannot do.”

environmental benefits. While it is impossible to persuade every individual, providing access to data ensures informed decision-making and greater sector confidence.

“The projects in Western Australia, and the Gold Coast conference, demonstrated that, when approached responsibly, waste-to-energy facilities can achieve environmental, social, and operational success,” said Pugh.

Kanadevia Inova’s strategy balances

Pugh remains confident that lessons from Western Australian projects can guide east coast expansion. Transparent processes, rigorous environmental monitoring, and engagement with communities are key to replicating success. As the sector grows, these approaches will ensure that EfW projects deliver measurable environmental, social, and operational benefits, addressing both the current landfill crisis and long-term sustainability goals.

All process fluids are contained within the EfW plant, and emissions are continuously monitored.

Simple solutions address plastic and textile recycling challenges

SOFT PLASTICS and textiles have long been regarded as some of the most challenging waste streams, contributing to environmental pollution. Their complex composition and contamination issues make them difficult to process, yet innovative solutions are emerging that are reshaping recycling possibilities.

At the ReGen event held recently, Suzanne Toumbourou, Chief Executive Officer of ACOR, introduced a panel discussion emphasising the simplicity that underpins some of these emerging solutions. Toumbourou highlighted that while

these materials have traditionally been viewed as problematic, industry leaders have developed practical approaches that demonstrate these legacy issues can be administered effectively. She framed the conversation around the idea that, with the right technology and collaboration, what appears complex can become manageable.

Panel member Adrian Jones, co-founder of BlockTexx, has been at the forefront of addressing textile recycling in Australia. He explained the issues surrounding the problem.

“Textiles are really, really complex to recycle, because everyone thinks recycling textiles is easier if you just give it to somebody else and they do something with it,” he said.

Jones’s company has developed a chemical process capable of separating polyester from cotton in post-consumer garments, creating distinct polyester and cellulosic work streams. This approach allows for truly textile-to-textile recycling. However, he noted that even with a solution, adoption is slow

due to a lack of regulatory frameworks, education, and domestic end markets.

The same applies to soft plastics, according to Graham Knowles, group general manager of IQRenew. Soft plastics, such as bags and bin liners, are collected and then processed into different grades of recycled resin. This material can be transformed into everyday products, but establishing consistent markets for recycled material remains a hurdle. Knowles highlighted the complexity of turning a problematic waste stream into a commercially viable product.

“We have the resin as our A grade. We have a flake that’s turned into a resin,” he said. “One day, you might walk into a supermarket, drop off your bag of soft plastics, and you might buy a shopping basket made from 50 per cent recycled from a soft plastic.”

IQRenew’s work on soft plastics demonstrates the challenges of scaling recycling processes

to meet national demand. Its facility processes plastics collected through return-to-store schemes, sorting them into different grades to be reused by manufacturers. The company has partnered with global brands to trial products made from recycled plastic, aiming to create a domestic circular economy.

Innovation at commercial scale

The development of large-scale recycling solutions is only part of the equation. Both Jones and Knowles emphasise that commercialisation requires years of experimentation, research, and regulatory navigation.

Jones recounts the journey of BlockTexx from inception to operating a plant in Queensland capable of processing 100 per cent post-consumer textile products.

Jones’s process is designed not only to produce new textiles but also to create accessories such as buttons and zips that are recyclable. By replacing non-recyclable components in garments, the entire product becomes easier to recycle. He also notes the potential for cellulosic fibres to be repurposed in agriculture and paper products, showing how recycling innovations can have cross-sector applications.

Market failures and economic barriers

Despite technological solutions, economic barriers continue to prevent widespread recycling adoption. Barry Cosier, co-CEO of Soft Plastic Stewardship Australia, pointed out that many recycling schemes

“One

are not economically viable without external support. He said that, while a large proportion of soft plastics is technically recyclable, much of it still ends up in landfill due to insufficient collection, processing, and market infrastructure.

Cosier illustrates the challenge using the example of the RedCycle program. While it made progress, a lack of coordinated end markets and funding limited its impact. Soft Plastic Stewardship Australia aims to address these gaps through industry collaboration and regulatory frameworks that provide long-term certainty for recyclers and investors.

“That’s the key issue, the key barrier we’ve all got to overcome,” he said. “And that’s where Soft Plastic Stewardship Australia comes in. If it was easy, everyone would do it.”

The economic reality is that collecting and processing soft plastics costs more than the raw materials are worth.

To overcome this market failure, product stewardship schemes must raise funds from brands and redistribute them to support the recycling infrastructure. Without such frameworks, technological solutions alone cannot achieve sustainability goals.

Regulatory frameworks and EPR

Both textiles and soft plastics highlight the importance of regulatory frameworks. Jones explains that Extended Producer Responsibility schemes are

day, you might walk into a supermarket, drop off your bag of soft plastics,

and

you might buy a shopping basket made from 50 per cent recycled soft plastic.”

A chemical process can separate polyester from cotton in postconsumer garments. Image: Supakorn Limteerayos/shutterstock.com

The RedCycle scheme was given as an example of an idea that needed better support from everyone. Image: Mario Viani/ shutterstock.com

with meaningful pricing signals ensure that the cost of recycling is reflected in the product, incentivising producers to participate.

“You have to recognise that there’s carrots and sticks, but carrots usually follow sticks, and the most effective way to change behaviour is around the prices” Jones said. “At BlockTexx, we wholly believe that EPR schemes are effective, but you have to make that price signal meaningful enough to change the behaviour.”

Cosier emphasised that regulatory certainty is equally important for soft plastics. Without clear guidelines and government support, voluntary schemes struggle to attract sufficient participation and funding. By following global best practices, such as those established in Belgium and the Netherlands, Australia can develop more effective stewardship programs.

Another recurring theme is the need for domestic end markets. Jones and Knowles both highlight that recycled materials are often exported or undervalued due to cheaper alternatives.

For textiles, domestically produced recycled content must be prioritised to ensure a sustainable circular economy.

Jones noted that government procurement policies and mandates could help support local recycling industries by specifying that recycled content be sourced domestically.

“Our average price of imported clothing is one of the highest in the OECD, and all that ends up in

Knowles pointed to the example of soft plastics, where recycled resin may initially be grey or imperfect.

He argues that over time, as manufacturers increase use, the quality and affordability of recycled products improve, similar to how recycled paper has evolved. Government support and consumer acceptance are critical to sustaining this transition.

“It’s not perfect, but as other manufacturers and recyclers start using more soft plastic, the price will come down,” he said.

he said. “You can go from food-grade packaging to food-grade packaging.”

Jones highlighted that in textiles, design choices play a crucial role. Garments with complex features or blended materials are difficult to recycle unless designed with end-of-life considerations in mind.

By reducing complexity and using recyclable components, the lifecycle of textiles can be extended significantly.

“The only way to really deal with contamination is not design it in in the first place,” he said.

“With clear guidelines and government support, voluntary schemes struggle to attract sufficient participation and funding.”

Contamination woes

One technical challenge in both textiles and plastics is contamination. For soft plastics, physical contaminants such as aluminium or organic matter must be removed before recycling. IQRenew employs a combination of mechanical sorting, magnets, optical units, and washing processes to ensure clean, usable material.

Cosier adds that global packaging standards are increasingly designed to prevent contamination from the outset.

Materials such as flexible PVC are excluded from food-grade packaging, enabling safer and more efficient recycling processes.

Australia is at a pivotal point in addressing legacy waste streams. Innovative technologies exist for recycling both textiles and soft plastics at a commercial scale, but success depends on market development, regulatory certainty, domestic production, and thoughtful design.

Extended Producer Responsibility schemes, proper pricing signals, and global best practices provide a roadmap for scaling these solutions.

By combining technology, economic incentives, and regulation, the country can transition from a recycling economy to a circular economy where soft plastics and textiles are no longer waste burdens but valuable resources.

than just off-the-shelf insurance solutions. This is where Criterion Underwriting steps in to deliver bespoke, purpose-built insurance policy wordings that recognise the realities of operating in a high-pressure environment.

Criterion Underwriting does not shy away from the hard-to-place risks and occupations. It has developed an appetite for risks across the full spectrum of waste and recycling, by combining its insurers, niche product expertise and deep industry knowledge. Criterion Underwriting provides cover that not only protects against traditional risks exposures but also accounts for regulatory, environmental and operational realities of the industry.

Criterion believes it gives business owners and operators confidence that their assets, staff and business continuity are safe guarded. This industry faces an array of risks that extend beyond standard property and liability exposures.

Fires and machinery breakdowns are just some of the challenges businesses must navigate on a daily basis. Add this to stringent environmental and safety regulations that govern operations, and it becomes

insurance solutions for their businesses,” says AORA NEO John McKew. “This is our first partnership of this type, and we hope our members see the value in it over the coming months.”

Criterion Underwriting’s cover is designed to address these exposures with policies tailored to include protection against property damage, business interruption, public and product liability, environmental liability, heavy machinery and commercial plant and equipment. One of company’s strengths is its ability to insure a variety of waste streams and recycling activities that include:

• Organic and biodegradable waste including food waste, biomass, garden waste and biogas.

• Dry and recyclable waste that covers off on metals, glass, plastics, textiles and paper.

• Vehicle and metal recycling, such as end-of-life vehicles, electronic waste, fridges and freezers.

• Construction/industrial waste including demolition and industrial by products.

• L iquid, hazardous and clinical waste, such as oils, solvents, hazardous liquids and medical sharps. Other considered risks include lithium-ion batteries,

diverse operations.