for crane owners/providers for crane operating personnel for the working environment for the planet

Reduced operating costs due to elimination of diesel engine in superstructure

Noticeably lower engine vibrations in the superstructure cab

Heating and air conditioning always available, even in standby mode

High operational reliability thanks to redundant energy supply

Maintenance-free superstructure electric motor

No pollution from exhaust gas during crane operation

Significantly reduced noise pollution

Quiet crane operation makes acoustic commands easier to understand

New business working in areas sensitive to noise and exhaust emissions

Charging during crane operation is much easier than refuelling

Ability to charge using own solar system at depot

Approx, 60% reduction in CO2 emissions from crane operation

Boost to environmental image

Easy electrically powered de-rigging in an emergency

Cranes and Lifting Magazine cranes_and_lifting Cranes and Lifting

6 Up Front Tutt Bryant and Sany

Reviewing a successful INSANYTI Sany Crane Global Key Account Summit.

10 CICA CEO report

A look at a very successful CICA National Conference and Exhibition.

12 Holding Redlich Reshaping redundancy considerations.

15 CANZ

18 Franna

Fleurieu Cranes add more muscle and safety to fleet.

20 Regatta Registers

One-stop solution for all your lifting assets.

23 Tadano and General Crane Services WA Tadano Hybrid hits its straps.

30 Baden Davis Crane Connection and XCMG

The goal posts have moved.

35 XCMG

Hybrid on display globally and 4000t capacity crawler performs.

Tower Crane feature

38 CICA on Tower Cranes

Australian Standards set out specific requirements for the safe use.

40 Resolution Rigging Services

Celebrating 25 years of service and success.

42 Urban Cranes

Preparing for growth in Perth.

45 General Cranes

The force behind changing skylines of Australia.

48 Comansa Australia

Introducing Comansa Australia’s experienced team and quality product.

51 WA Universal

A towering presence in WA.

54 DLL and Potain

Strong cranes meet smart finance.

58 APS Equipment

From driveway to skyline in 15 minutes.

60 National Site Services

Lighting up the skylines, one crane at a time.

Vinage Customs

Making your business visible.

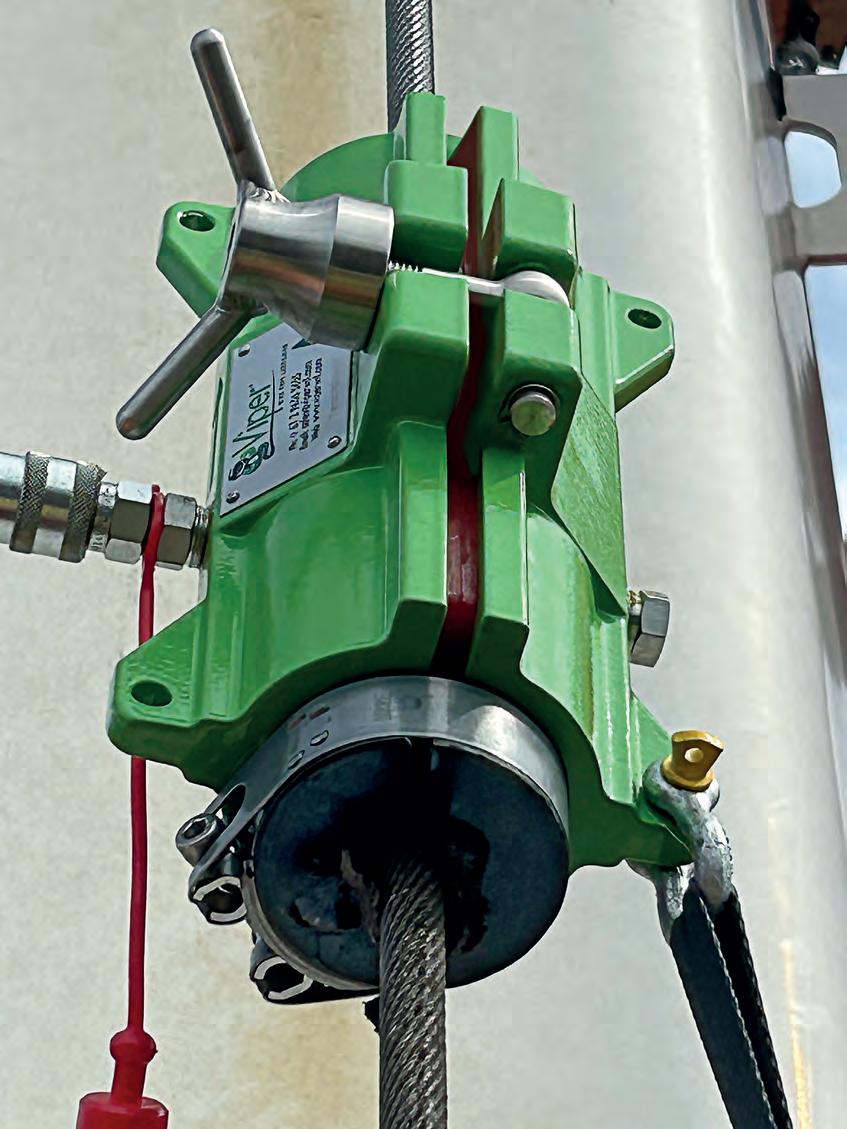

Viper Wire Rope Lubrication

Understanding the importance of ectly lubricating wire ropes.

The Buddie System

A seatbelt moment for the cranes and ting industry.

Liebherr Australia

Liebherr introduces a number of new

Zoomlion

New tower crane technology for safe and efficient lif ting.

Cranes at the centre of Melbourne’s big oad project.

Global Lif ting Group

Forging ahead with Australian-made ting gear.

86 Grove and Skylift Crane Services

New Grove to service continued growth.

88 Pace Cranes and Komp Cranes

New Maeda MK3053C knuckle boom for Komp Cranes.

90 LEEA

The Blueprint for Safe Lifting Operations.

93 DRA Engineering

Humma goes to Tanzania. 23

IN THIS ISSUE WE TAKE A ‘DEEP DIVE’ INTO the tower crane sector with a dedicated feature covering new product developments, industry challenges and opportunities. The recent Q3 Rider Levett Bucknall (RLB) Crane Index revealed interesting statistics. Construction activity remains steady, with 845 cranes recorded across Australia in September 2025.

Oliver Nichols, Rider Levett Bucknall’s Oceania Director of Research and Development, commented: “The Australian construction sector holds firm, with the national crane count rising slightly from 840 to 845, well above the long-term average of 775. This marks the eighth consecutive edition above 800 cranes – a clear sign of sustained building activity, though the mix of projects is shifting across regions and sectors.”

Sydney remains the nation’s epicentre with 370 cranes, followed by Melbourne (199), Brisbane (73) and the Gold Coast (67) with record highs reached in Adelaide, the Gold Coast and Wollongong. Residential

(58.9 per cent of total). Growth in mixed-use and data centre projects highlights evolving sectoral priorities. ABS data confirms total construction activity rose 3.0 per cent in the June quarter to $76.12 billion and non-residential approvals surged 30.6 per cent year-on-year, led by education, office, industrial and digital infrastructure projects. Cranes and Lifting magazine intends to feature the tower crane sector more frequently. In this edition, we celebrate Resolution Rigging Services 25th birthday and introduce Comansa Australia.

Also, The Baden Davis Crane Connection confirm arrangements with XCMG, Tadano’s Hybrid impresses General Crane Services WA and Complete Crane Solutions continue to invest in the future. Sany and Tutt Bryant Equipment impress a contingent of local crane hire businesses during the INSANYTI Sany Crane Global Key Account Summit.

As always, there is something for everyone in this issue and we hope you enjoy the read.

Simon Gould Editor, Cranes and Lifting Image: Comansa Australia

“The Australian construction sector holds firm, with the national crane count rising slightly from 840 to 845, well above the longterm average of 775. This marks the eighth consecutive edition above 800 cranes – a clear sign of sustained building activity, though the mix of projects is shifting across regions and sectors.”

Published by:

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman John Murphy E: john.murphy@primecreative.com.au

CEO

Christine Clancy E: christine.clancy@primecreative.com.au

Publisher Sarah Baker E: sarah.baker@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor

Simon Gould E: simon.gould@primecreative.com.au

T: 0404 865 109

Assistant Editor

Danny D’Cruze

E: danny.dcruze@primecreative.com.au

T: 0429 187 751

Business Development Manager Emily Schlegel

E: emily.schlegel@primecreative.com.au T: 0466 317 555

Client Success Manager Louisa Stocks E: louisa.stocks@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

We’re just getting started

When others reach their limit

We’re just getting started

REACH OUT NOW FOR A SIDE-BY-SIDE COMPARISON AND SEE THE DIFFERENCE FOR YOURSELF.

REACH OUT NOW FOR A SIDE-BY-SIDE COMPARISON AND SEE THE DIFFERENCE FOR YOURSELF.

Sany Group opened the gates of its Huzhou crawler-crane facility for this year’s INSANYTI Key Account Conference. The scale was unmistakable. Nearly 500 delegates from more than a dozen countries walked through production lines humming with robotic welders, automated assembly cells, and newly unveiled hybrid and electric cranes – a demonstration of where Sany’s global strategy is heading.

AMONG THOSE DELEGATES WERE representatives from 12 Australian companies – some of the country’s largest crane-hire and construction businesses –invited as part of a select group hosted by Sany Group and its Australian partner, Tutt Bryant Equipment, the authorised national dealer for Sany crane products. The two organisations are playing a central role in expanding Sany’s footprint across Australia.

“The event was designed not only to reward our existing customers but also to showcase what’s next,” said Philip White, Sany’s International Sales and Marketing Manager.

“It’s about showing the might and capability of Sany – how far we’ve come in technology, sustainability, and manufacturing.”

A SHOW OF SCALE AND CAPABILITY INSANYTI 2025 was staged across multiple Sany facilities in China, beginning at Huzhou – the crawler-crane factory –

before continuing by high-speed train to Changsha for tours of Sany’s all terrain and truck-crane plants. Over two days, guests experienced the company’s full range of cranes, from compact city models to 4000-tonne super-lifters, and took part in operational demonstrations on a dedicated test pad.

“Customers were amazed at the technology and the scale,” Philip said. “They were struck by how robotic our factories are, and how much of the work is done in-house – not just assembly but true manufacturing.”

The Australian contingent travelled under the coordination of Tutt Bryant Equipment’s team, which has been instrumental in connecting local customers to Sany’s global resources.

The trip was part of Tutt Bryant’s strategy to give Australian crane owners a direct access to Sany’s evolving product technology and manufacturing innovation.

AUSTRALIA WELL REPRESENTED Australia’s group – 23 visitors across 12 companies – included some of the country’s best-known names in crane hire, mining, and construction. The invitation list reflected Sany and Tutt Bryant’s close relationships with active or soon-to-be customers across the region.

Philip said Australia remained a strategic market within Sany’s international network. “It might look small compared to the global numbers – we’re producing around 16,000 to 18,000 cranes a year –but Australia’s role is important,” he said.

“The people who came with us are serious operators who influence where the market goes next.”

INSANYTI was more than factory walkthroughs. Delegates spent hours operating real machines under supervision from Sany engineers. Four models – including a 150-tonne diesel all terrain and a 90-tonne

rough-terrain – were made available for hands-on testing.

“The chance to actually jump in and operate was what made it memorable,” Philip said. “There were no strict barriers –everyone got to feel the responsiveness and precision for themselves.”

For Andrew Esquilant, Chief Executive Officer of Borger Group of Companies, the visit was both a professional insight and a personal milestone. Having spent decades in the crane industry, he admits his expectations were challenged.

“You continually hear that Chinese products are improving but still not at the quality of established brands,” Andrew said. “What I saw during the factory visits confirmed why manufacturers like Sany are expanding globally. The flexibility, the openness to redesign and re-engineer products to suit customers was impressive.”

Andrew was struck by how much of the crane is built on-site. “Sany manufacture 80–90 per cent of their machines themselves. They bend their own booms,” he said. “The robotic welding and the quality-control systems are up there with some of the best in the world.”

Borger Cranes was also among the few international customers to receive ceremonial keys for newly purchased cranes in a presentation witnessed by hundreds. “It was humbling,” Andrew said. “The welcome we received from Sany and Tutt Bryant Equipment was warm and genuine. It was an honour to represent our team on that stage.”

While the tour reaffirmed Sany’s manufacturing strength, it was the 250-tonne electric/diesel hybrid all terrain crane that generated the most conversation. The model, part of Sany’s new hybrid line, features a battery-electric upper and a diesel-powered carrier – a combination designed to reduce emissions without sacrificing mobility.

“The hybrid technology caught a lot of interest,” said Bailey Tuddenham, Queensland Manager at Advanced Cranes.

“It was the first of its kind we’d seen in that capacity. You can charge the battery while working, and it can switch to diesel when you’re travelling or on a site without power. It’s smart, and it fits where the industry is heading.”

Bailey said the crane’s dual-power system gave operators flexibility for urban jobs or long haul moves between projects. “For us, sustainability is a real focus,” he said. “Machines like that help balance performance and environmental impact. They show what’s possible.”

Philip confirmed that Sany and Tutt Bryant are working closely with several Australian companies to introduce the model locally. “We’ve started the ADR process for the SAC2500E PHEV Hybrid,” he said. “The carrier is based on our existing 250-tonne platform, so it’s a straightforward certification. It should be ready for the market soon.”

Both Andrew and Bailey commented on the automation they witnessed inside the plants – rows of robots performing precision welds on booms and chassis structures, while automated guided vehicles ferried components between stations.

Bailey compared it to what he’d seen in Europe. “I’ve seen other factories and Sany’s was very similar,” he said. “The robots handle most of the heavy welding and assembly work. They run a very tight operation – you can tell they’re building

serious volume with good quality control.”

According to Sany’s internal report, the Huzhou facility alone produces around 1200 crawler cranes each year – a number that continues to grow as automation expands across assembly lines. At the Changsha complex, annual output of truck and all terrain cranes exceeds 5000 units.

Delegates described INSANYTI as both an educational and relationshipbuilding exercise. The program combined factory tours with technical briefings on component development, hydraulic system design, and software integration. Sany engineers encouraged feedback throughout – a practice that connected favourably with many visitors.

“What impressed me most was the openness to customer feedback,” Andrew said. “They’re not just selling a machine and walking away. They want to codevelop, to make sure each market’s needs are understood. That’s how you build a global brand.”

Tutt Bryant’s involvement added another layer of familiarity for Australian delegates. The local dealer played an essential role in coordinating the visit and facilitating direct discussions between customers and Sany’s engineering teams. For many attendees, that access to both local and international expertise was invaluable.

The scale of the gathering highlighted Sany’s reach well beyond its domestic market. With delegations from Australia, Europe, the Middle East, Asia, and the Americas, INSANYTI 2025 served as a convergence point for industry feedback.

“Having 500 customers from so many regions in one place gives us insights we can’t get anywhere else,” Philip said. “It lets us understand where the market is moving and what our customers value.”

Reports from the conference describe a commitment to “digital intelligence and green manufacturing.” Sany unveiled advancements in its TC-Link system for tower cranes, autonomous logistics within the plants, and next-generation battery packs for large mobile equipment. The presentations showed how the company is pushing to integrate smart manufacturing into product development, and to do it at scale.

For Australian visitors, the trip reinforced confidence in Sany’s commitment to the region – a commitment being driven locally by Tutt Bryant Equipment.

The 250-tonne PHEV all terrain crane features a battery-electric upper and diesel carrier, delivering performance with lower emissions.

Through its national sales and service network, Tutt Bryant has been instrumental in supporting new crane deliveries, aftersales service, and training for operators across multiple states.

Some customers have expanded their Sany fleet’s since returning to Australia in a sure sign of confidence.

The presentation of ceremonial keys was a stand-out moment for many attendees. Only seven international customers

were recognised onstage – including Borger Cranes – as Sany and Tutt Bryant acknowledged major purchases and longstanding partnerships.

INSANYTI’s success has set the stage for next year’s milestone event – the 2026 Bauma China, which will run concurrently with INSANYTI. Philip hinted that it would be “the most comprehensive showcase of Sany technology ever assembled,” bringing together the company’s entire product range and innovation pipeline.

“It’s not just about machines,” he said. “It’s about showing the industry that Sany – alongside partners like Tutt Bryant – is here for the long run, engineering, manufacturing, and servicing equipment that meets the needs of modern lifting businesses everywhere.”

For the Australians who made the journey, INSANYTI 2025 was more than a corporate event. It was a glimpse into how the industry’s future is being shaped – one

defined by electrification, automation, and collaboration across borders.

“It was an eye-opening experience,” Andrew said. “I came away with a new respect for what Sany is doing and how they’re doing it. They’re a true manufacturer – and they’re serious about the global market.”

Bailey summed it up more simply: “They ran a very professional show,” he said. “We were thankful for the opportunity to go, and we took a lot away from it. I’d go again.”

THE 2025 CICA CONFERENCE IN BRISBANE was a huge success, bringing together over 600 people from across the country. This year’s theme, “Are you invested”, really struck a chord with everyone I spoke to, and set the stage for three days of learning, connecting and celebrating everything that makes our industry strong.

From safety and sustainability, to a future training model and the latest crane technology, the program was packed with sessions that gave us plenty to think about and take back to our workplaces. One of the real highlights was the keynote lineup. Hearing directly from industry leaders always sparks new ideas, and the conversations that I overheard or was involved in during the breaks showed just how much these topics resonated with everyone.

The Lift of the Year Awards were another standout. The entries were nothing short of incredible, showcasing the complex, challenging and impressive lifts being carried out across Australia. Congratulations to all entrants, it’s always inspiring to see the creativity, planning and teamwork on display. A big thank you also to Cranes and Lifting for sponsoring these awards once again. Don’t forget to keep next year’s awards in mind when planning your projects, we’d love to see even more entries in 2026.

The exhibition hall at the Brisbane Convention Centre was buzzing throughout the conference. It was the perfect opportunity to see the latest innovations first-hand and have face-to-face conversations with the manufacturers and suppliers who keep our industry moving forward.

A special thank you goes to UAA, our platinum sponsor this year, whose support makes an event of this scale possible. Thanks also to all our sponsors, speakers, exhibitors and delegates,

once again pulling everything together so seamlessly.

We’re already looking ahead to 2026 when we’ll gather in the Hunter Valley. Planning is about to get underway, so if you’re interested in sponsorship opportunities, please reach out to Justina. For now, save the date, we can’t wait to see you all there next year.

Finally, this issue of Cranes and Lifting is dedicated to tower cranes, a fitting focus given the critical role they play in construction. Tower cranes are often the first sign of a city growing and changing, and they remain central to delivering the infrastructure and buildings that shape our communities. Their presence is a constant reminder of how essential our industry is to Australia’s future.

There are a number of resources for Tower Cranes available on the CICA website, including the Tower Crane Procurement Guide and Code of Practice, go to https://cica.com.au/resources/towercrane-resources/ ‘Stay Safe’

Brandon Hitch CICA CEO

CICA BOARD

Marcus Ferrari – President

Karli Sutherland– Vice President

Danny Adair – Director

Danny Black – Director

David Solomon – Director

Anthony Grosser – Director

Andrew Esquilant-Director

Grant Gjessing- Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 0428 228 048 ceo@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CICA Site Operations Advisor 0488 004 274 pat@cranesafe.com.au

Sharon Pearce

Crane Crew Competency Officer 0491 134 533 sharon@cica.com.au

Damien Hense

CICA Road Policy Advisor 0488 007 575 damien@cica.com.au

Thomas Webber Communications Coordinator thomas@cica.com.au

Kate Galloway Traineeship & Industry Engagement Coordinator 0491 047 118 kate@cica.com.au

Michelle Verkerk

Communications and Special Projects Advisor michelle@cica.com.au

Just ina Blackman

Member Events and Engagement 0403 717 626 justina@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administrative Assistant Officer 0491 047 134 shane@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Email: admin@cica.com.au

Website: www.cica.com.au

Crane companies looking to restructure their business must be aware of the recent landmark High Court decision which broadened an employer’s redeployment obligations.

IN AUGUST THIS YEAR, THE HIGH COURT found that the obligation to redeploy a potentially redundant employee is not confined to considering current vacant roles, but rather, an employer has a broad obligation to consider whether changes can be made to its current workforce to create or make available a position for an employee to avoid retrenchment.

To assist companies operating in the crane industry with managing redundancies going forward, in this article we explain why it is important for an employer to comprehensively meet its redeployment obligations, and unpack the High Court’s decision and its implications on workforce planning.

Redeployment obligation

At law, a redundancy is only considered a ‘genuine redundancy’ where:

• t he role is no longer required to be performed by anyone

• t he employer has complied with any consultation obligation under the

applicable modern award or enterprise agreement and

• it was not reasonable in all the circumstances to redeploy that person into the employer’s business (or into the business of an associated entity).

Importantly, if a redundancy is a “genuine redundancy” at law, it is an absolute defence to an employee bringing an unfair dismissal claim. This means that an employer understanding the extent of its redeployment obligations is essential to a business minimising its legal risk.

Helensburgh Coal is a large mining company that employs workers to operate a coking coal mine owned by Peabody Energy in Helensburgh, New South Wales.

Helensburgh Coal engaged Nexus Mining and Mentser to supply contractors on an ‘as needs’ basis to supplement its permanent employee workforce at the

mine. Due to a reduction in demand for coking coal, Helensburgh Coal restructured its operations at the mine during COVID-19. While some of the contractors’ work was insourced to existing employees, Helensburgh Coal decided to dismiss 90 employees and reduce its contractor workforce by 40 per cent. There were no vacant roles within Helensburgh Coal, nor was it foreseeable that a vacancy might arise in the future. Despite these mass redundancies, Helensburgh Coal did not terminate its existing service agreements with Nexus and Mentser.

Twenty-two of the employees challenged their dismissals in the Fair Work Commission (FWC), arguing that their dismissal was unfair and not a ‘case of genuine redundancy’ as Helensburgh Coal could have redeployed them to other roles occupied by contractors from Nexus and Mentser.

The starting position for the High Court was the same as it has always been – a dismissal will not be a ‘genuine redundancy’ if it would have been ‘reasonable in all the circumstances’ for the employee to be redeployed within the employer’s enterprise or that of an associated entity. Like any employer, Helensburgh Coal argued that in considering what was ‘reasonable in all the circumstances’, the FWC couldn’t dabble into how the employer chose to run their business, in particular, couldn’t consider if the employer could have created a new position for the redundant employee.

The big change was the High Court completely disagreed. The Court found that the Commission could have regard to the very nature of the employer’s enterprise, and that how an employer uses its workforce or the reasons behind these operational decisions are relevant in determining whether it would have been ‘reasonable in all the circumstances’ to redeploy an employee within the employer’s enterprise. Most notably for employers, the High Court found in the circumstances before Helensburgh Coal that redeployment was ‘reasonable’ even where no vacant position exists within the employer’s enterprise, and redeployment would require a reorganisation of the employer’s workforce to create such a role.

The Court also found that other broad circumstances could be looked at by the FWC including:

• t he attributes of the redundant employee, such as their skill set, experience, training and competencies

• t he employer’s workforce policies, its appetite for risk, plans, processes, procedures, business choices (for example, a decision to terminate a contract in the future or a decision to continue using contractors)

• decisions regarding the nature of its workforce, such as whether it has a blended workforce of both employees and contractors

• contract terms, such as whether they are ‘as needs’ contracts and whether the contractors are on daily work orders or long-term fixed commitments

• practical concerns, such as whether redeployment would require the employee to undergo further training

• a nticipated changes, such as another employee going on parental leave or retiring, a contract expiring, or a position being performed by a contractor while waiting for an employee to be hired.

Relevantly, the High Court emphasised that the Commission can consider whether there was work or a demand for work within the employer’s enterprise (or that of an associated entity) at the time of the dismissal, which could have been performed by the otherwise redundant employee.

Take aways for the crane industry

Before undertaking a restructure, a company should adopt a detailed

Making a role redundant is no longer straightforward. A company may now have to reduce the use of contractors or labour hire workers and offer those positions to any employee that they are considering retrenching, in order to avoid an unfair dismissal claim.

process for considering redeployment opportunities before proceeding with a dismissal. This is because the Commission can enquire into a broad range of matters when determining whether it was reasonable to redeploy an employee prior to dismissal.

So, what should the process look like? Ultimately, what the process looks like will vary depending on the business, such as its size. This is because the reasonableness of redeployment is assessed on a case-by-case basis.

Workforce planning materials such as organisational practices, policies, procedures, strategies and plans will be centrally relevant in determining whether a redeployment opportunity is reasonable. However, broadly, the process should include an assessment of:

• whether operations could reasonably be adjusted both within the enterprise and across related entities, including an employer’s use of external contractors, labour hire employees, or insourcing a previously outsourced role • whether an employee can be retrained or redeployed to fill a shortterm vacancy.

We recommend that employers seek legal advice if they are uncertain about their redeployment obligations.

Authors: Holding Redlich Partner Michael Selinger, Senior Associate Olivia Lawrence.

Disclaimer

The information in this article is of a general nature and is not intended to address the circumstances of any particular individual or entity. Although we endeavour to provide accurate and timely information, we do not guarantee that the information in this article is accurate at the date it is received or that it will continue to be accurate.

Got your attention? In this world of Trumponomics, fake news and artificial intelligence it’s getting hard to work out what to believe any more. This headline however, is a little known or understood fact. I’ll explain soon.

IN 1975 A SMALL GROUP OF CRANE owners got together and formed the Power Crane Association (PCA) of New Zealand to represent the interests of crane owners in New Zealand. In 2006 the PCA changed its name to the Crane Association of New Zealand. CANZ currently has over 200 members who either own, operate, service, sell, lease or otherwise have an interest in the crane sector.

FOUNDING MEMBERS – “THE ORIGINALS”

• Diack Bros

• Jack Tidd-Ross Todd

• Kidson Construction

• Thelin Construction

• Hawkins Construction

• C Lund & Sons

• Mahy Crane Hire

• Drury Crane Hire

• McConnell Dowell Constructors

• Fletcher Industries

• UDC Finance

These businesses have formed the backbone of the industry’s executive

represented on council since the beginning when their founder Max Whiley (RIP) hosted the first meeting.

On the 16-18 July, CANZ celebrated its 50th Conference back where it all started in Wellington. Kicking off with the “Originals” meet and greet function, CANZ also hosted the various Life Members and founding member companies with a special dinner at Bellamy’s.

Now, back to the 425 billion-dollar

The Crane Association of NZ represents all manners of cranes, and the businesses associated with them.

The largest population of cranes are the ones most people don’t see, the gantry cranes in virtually every engineering workshop or manufacturing plant across all manner of industry.

Next up would be the knuckleboom cranes that most folk think of as Hiabs that are fitted to flatdeck trucks and used to deliver all sorts of loads such as building

that travel on the road or around sites known as hydraulic mobile cranes. Ranging in size from 2-axle around town city cranes to 8-axle all terrain cranes with lifting capacities between six and 450 tonne. There are many machines in New Zealand that drive legally down the road that will set up and lift well over 100 metres high. Most, if not all tower cranes are assembled and disassembled with a Hydraulic Mobile Crane.

Crawler Cranes are what I reckon are the next most populous lifting machines in NZ. On a track base, hence the crawler name, these machines are mostly lattice boom cranes used on medium to longer term projects in construction, infrastructure and industrial plant. These crawler cranes have a large range in capacity and boom configurations. In NZ crawler cranes are bookended in capacity by hybrid crawler / hydraulic boom machines ranging from two tonne to 1200 tonne capacity machines.

Ironically, the type of crane that most non-crane people think of, the tower crane, is the type in NZ there are the least amount of and are mainly used servicing traditional construction activities.

There is not a single area of economic activity in New Zealand that isn’t at some stage dependent on a crane of some sort for its actual existence in the first place, it’s growth or success.

The obvious example proving this statement is that there isn’t any

relies upon cranes every day to deliver whatever thing it is that makes money.

There isn’t a single MRI or CT Scanning machine that hasn’t had to have been lifted at some stage by a crane before it can be used to save lives.

Taylor Swift did not come to New Zealand because the mobile cranes she needed to construct the set for her concerts weren’t available at the times she needed them.

The America’s Cup, Sail GP and other marquee yacht races don’t happen without cranes.

Crypto trading, drop shipping, E-commerce, social media influencing, working from home and other activities dependent on the Cloud are all dependent on cranes. Cranes to not only build the physical infrastructure but maintain windfarms and other power generation as well as servicing and replacing the massive air conditioning requirements of data centres.

A recent survey by an international investment advisory agency calculated that the 2024 economic contribution to New Zealand of the Crane Industry was a staggering $425 billion. Coincidentally this also happened to be same as New Zealand’s total Gross Domestic Product.

In the interests of full disclosure, I made that last paragraph up. Oh, and the Taylor Swift bit.

Or did I?

From heavy industry and mining in the Pilbara to marine and infrastructure projects on the East Coast, our team of expert technicians and parts specialists deliver around-the-clock, on-site support you can count on.

We’re more than a service provider — we’re a true partner in keeping your operations moving. OUR SERVICES

Mobile crane repairs & diagnostics

With operations based in Karratha (WA) Perth Metro (WA) Sydney (NSW) & SEQ (QLD), we offer rapid mobilisation and local expertise to meet the demands of Australia’s most challenging worksites.

NEW DIRECTION. EXPANDED CAPACITY. SHARPER FOCUS. As CCS enters a new chapter of national growth, we’re investing in the people, systems, and scale to support major projects, port authorities, and private fleets across Australia.

Work

has steadily increased for Fleurieu Cranes, with cranes requested across various projects throughout South Australia.

Fleurieu Cranes continues to grow its fleet to meet South Australia’s rising infrastructure demands.

“IT’S BEEN REALLY EXCITING SEEING SOME of these projects developing from feasibility to reality,” said Chris Leane, Business Development Manager at the Adelaidebased company. The business forecast has prompted another fleet expansion – including the arrival of Franna’s new AT40-2, designed to handle heavier lifts in tighter spaces while keeping setup time to a minimum.

The new Franna fits in well with the current fleet that has seen steady growth over Fleurieu Cranes past 20 years of operation.

“We’re focusing on building South Australia’s future,” Chris said.

“We’ve got a few large projects still in their early stages, which always bring their own challenges – building efficiencies, coordinating logistics, managing resources –

but overall, we’re in a really good spot.”

The company’s workload for pick and carry cranes has expanded alongside South Australia’s infrastructure program, from road upgrades and bridge works to windfarm builds and industrial developments. The rising demand has led to strategic fleet investment – and the AT40-2 sits at the centre of that growth.

“This makes three AT40s in our fleet, with another one on the way,” Chris said. “There aren’t many of them in South Australia – three other companies have one each – so it positions us well for what’s coming over the next couple of years.”

The Franna AT40-2 represents the latest evolution of the pick-and-carry crane.

With a 40-tonne capacity at 1.1 metres, a Mercedes Benz OM936 7.7L Euromot Stage V diesel engine (230 kilowatt) and Allison 6-speed automatic transmission, it delivers a rare combination of muscle and manoeuvrability.

For Chris and the team, that performance is not just about raw lifting power – it’s about saving time and reducing complexity on site.

“The three-axle design eliminates the need for additional counterweight like we use on the MAC 25 or MAC 25 SL,” he said. “That means less setup, less handling, and a safer process overall. You can arrive on site and get to work faster.”

The process involving installing and removing the counterweight also cuts down on manual handling risks, a constant priority for Fleurieu’s safety program.

“We’re not placing counterweight on the ground or lifting them back into position,” Chris said. “That means fewer moving parts and less opportunity for error.”

The crane’s axle-control system, which lifts the third axle during operation, also enhances manoeuvrability in confined environments.

“When you’re working in tight spaces, it feels very similar to operating a MAC 25,” Chris said. “That’s something our operators appreciate – the same responsiveness they’re used to, but with more capacity.”

As project sites across Adelaide become denser and deadlines tighter, the need for cranes that combine mobility, and strength has never been greater. The AT40-2’s compact footprint – just 3.5 metres in height with a 19.8-metre main boom –makes it ideal for urban and industrial projects where access is limited.

“The fact that it can lift heavier loads without the additional gear or counterweight is a real advantage,” Chris said. “It’s about doing more with less equipment around you.”

With Franna’s new Euromot Stage V-compliant powertrain, the AT40-2 meets some of the world’s toughest emission standards, reducing particulates and nitrogen oxide output while maintaining power. It is also fully compatible with HVO (hydrotreated vegetable oil) diesel which can reduce carbon emissions by up to 90 per cent. For Fleurieu Cranes, that aligns directly with its long-term environmental goals.

“We’ve always tried to be as green as we can,” Chris said. “Through our partnership with Trees for Life, we proactively offset our carbon emissions through the funding of tree plantations. Therefore, when manufacturers like Terex Franna bring out equipment with cleaner engines and reduced emissions, it fits perfectly with where we want to be as a company and provides cost benefits.”

Environmental awareness is one of Fleurieu’s three operational pillars, alongside safety and innovation. Each new addition to the fleet is assessed for how it improves overall efficiency and reduces site impact.

“Having the latest equipment minimises downtime and improves reliability,” Chris said. “It’s good for our customers, but it’s also good for our people – they take pride in operating modern, highperforming machines.”

The purchase continues a partnership between Fleurieu Cranes and Terex Franna that spans more than two decades.

“We’ve got 22 Frannas in the fleet now, across different models ranging from AT15

through to AT40-2,” Chris said. “It’s been a really strong and consistent relationship –we know the product, and they know how we operate.”

That familiarity translates directly into operational benefits. The maintenance team understands the platform, spare parts are readily available, and training requirements remain consistent.

“It just makes sense for us,” Chris said. “We know the cranes, our operators know them, and the support from Franna has always been great.”

Beyond the drivetrain and lifting power, the AT40-2 also introduces several operatorfocused improvements. The updated Dynamic Load Moment Indicator (LMI)

with patented Safety Radar shows the operator a simple and clear visual radar map of the safe working area for the load being lifted and most importantly for the actual working environment of the crane i.e. front/ rear and side slope. It will help the operator ensure the safest motions throughout every stage of the lift.

“It’s the kind of detail that helps operators feel confident on the job,” Chris said. “They’re not just working harder –they’re working smarter, and that’s what we want across the board.”

The AT40-2 retains Franna’s roadability and travel speed, reaching 80 kilometres an hour, making it one of the most versatile pick-and-carry cranes in its class. Its quick mobility between job sites allows Fleurieu Cranes to service multiple customers efficiently – a crucial factor given the volume of work currently moving through the business. With South Australia’s infrastructure pipeline continuing to expand, Fleurieu Cranes’ investment in the AT40-2 underscores its commitment to staying ahead of industry demands, with a modern fleet, experienced team, and a clear focus on efficiency.

“The key for us is staying proactive,” Chris said. “That means having the right equipment, the right people, and the right mindset. The AT40-2 helps us deliver on all three – it’s powerful, efficient, and ready for what’s next.”

Regatta Registers has been helping lifting companies keep their gear compliant and organised. Its cloud-based platform makes it easy to create lifting equipment registers, store inspection reports, and share certificates with clients – all in one place. Now, the team is taking that idea a step further.

A NEW ASSET MANAGEMENT FEATURE IS on the way, designed to help users manage cranes, forklifts, and other assets with the same simplicity the industry has come to expect from Regatta.

“We developed the system to manage lifting equipment, but now we want to help companies manage their entire fleet,” said Marly Pena, Marketing Manager at Regatta Registers. “Whether it’s a crane, a forklift, or a truck, users will soon be able to add their assets, perform checks, and record maintenance – all within the same system.”

At its core, Regatta Registers is a webbased SaaS platform that enables lifting and inspection companies to create digital registers and inspection reports. It’s already used by All Lifting, several service providers across Australia, and even

training organisations such as the Kabbalah Construction School. The upcoming asset management module builds on this foundation, adding a powerful layer of flexibility for both in-house and servicebased operations.

“The system will allow users to build their own forms – things like pre-start checks or maintenance records – and then action those forms directly under each asset,” Marly said. “They’ll first add an asset, and under that, they’ll be able to attach any number of forms. It gives them full control over how they want to track, inspect, and manage.”

That means a crane hire company could add each crane as an asset, create custom inspection forms, record maintenance activity, and even set automatic reminders for the next check – whether it’s daily, monthly, or annual. Everything stays stored

securely online and can be shared instantly with clients or auditors.

Unlike traditional asset management systems, which are often built for internal use only, Regatta’s new module caters to service providers as well.

“One of the biggest differentiators is that we allow customers to be part of the process,” Marly said. “Let’s say a business services cranes for multiple clients – they can add their customers, their sites, and the assets at each site. Those customers can then log in, view reports, and track maintenance records in real time.”

This structure makes the platform especially useful for contractors that maintain or inspect lifting assets for others. It also adds transparency and traceability

across projects – a critical advantage in a safety-driven industry. “By giving customers visibility, we make it easier for them to manage their compliance and trust the service provider’s work,” Marly said.

Currently, the Regatta team is developing and testing the module with a Melbourne-based service provider that maintains cranes across the state. “They don’t own any cranes themselves but service a number of them,” Marly said. “The system allows them to record every inspection, send reports to clients, and set reminders for the next maintenance. Their customers can then log in to view everything associated with their cranes.”

As Marly said, the idea for the new feature didn’t come from a marketing meeting – it came from the users themselves. “When we started, our customers loved the simplicity of our lifting equipment registers,” she said. “But many told us they wanted to use it for their assets too. They said, ‘I’ve got 10 cranes and I’d like to create registers for them the same way.’ That’s when we realised we needed to add assets as a base element in the system.”

From there, the development became collaborative. The team has been working closely with several partners to refine how

the feature should work in the field. “It’s being built with direct input from the people who’ll actually use it,” Marly said. “That’s what makes it so practical. It’s not a new system from scratch – it’s an extra module that fits naturally into what already exists.”

Regatta Registers is structured to suit both small and large operations, with three plans available – Basic, Pro, and Enterprise.

“The Basic plan is for one user, ideal for small operators with a single crane or piece of equipment,” Marly said. “The Pro plan allows up to six users, with unlimited assets and customer logins. It gives each business the flexibility they need, whether they’re managing their own gear or servicing clients.”

The platform is built to be intuitive –users can upload their logo, add customers and contacts, and start creating registers immediately. For many, setup takes less than an hour. “It’s very easy to customise,” Marly said. “You don’t need to be techsavvy to start using it.”

The asset management module is currently in active development, with early prototypes already in testing. “We’re ironing out

a few glitches before we start full-scale development,” Marly said. “We’re hoping to have it completed by early next year –around January or February.”

While the team isn’t officially launching the service yet, early adopters will soon be invited to trial the system. “We want to get people excited about what’s coming,” Marly said. “At the moment, they can use the lifting equipment registers, and by next year, they’ll be able to add and manage their assets too.”

Regatta is also considering offering early users a special introductory period –potentially including one month free. “It’s a way for us to thank those who help us test the platform and shape the experience,” Marly said.

Regatta Registers has already become a reliable tool for compliance, inspection, and reporting – and with asset management, it’s set to become a central hub for everything related to equipment tracking and maintenance.

“Ultimately, we want companies to have everything in one place,” Marly said. “Whether it’s their lifting gear, cranes, forklifts, or trucks – they’ll be able to manage it all through Regatta Registers. It’s about making their operations simpler, safer, and more efficient.”

General Crane Services WA (GCSWA) has built its reputation on delivering safe, reliable, and innovative lifting solutions across Western Australia.

KNOWN FOR OPERATING ONE OF THE region’s most modern and dependable fleets, the company has taken another significant step forward by introducing the Tadano AC 4.070HL-1 Hybrid.

This 70-tonne hybrid all terrain crane is already demonstrating the same proven performance as its conventional diesel counterpart while offering the additional benefits of quieter, low-emission operation. From early October, it began a 12-month non-process infrastructure (NPI) project at Rio Tinto’s Hope Downs 1 site.

“The introduction of the Tadano hybrid is a clear reflection of our values and commitment to our clients: providing modern, reliable, and future-focused solutions,” said Nick Bucciarelli, GCSWA, Managing Director.

A MODERN FLEET GETS GREENER

General Crane Services WA is recognised for a fleet that combines reliability with cutting-edge technology. Integrating the AC 4.070HL-1 hybrid expands

these capabilities, providing clients with greener lifting solutions that align with the sustainability priorities now emerging across all industries.

“Sustainable solutions and innovation are important to us, and partnering with Tadano was an easy choice,” Nick said. “Their 24/7 support and continued close collaboration help minimise downtime, allowing us to better meet our customers’ project expectations and timelines.”

For Wayne Mancini, one of GCSWA’s most experienced operators with over 20 years in the industry and six years at GCSWA, the hybrid crane represented something entirely new.

“I’ll be honest, I was a bit sceptical at first,” Wayne admits.

“You get so used to the sound of a diesel engine; it’s part of how you understand the crane’s movements. With the hybrid, it’s so quiet it took a little time to adjust, but once you get used to it, the operation is incredibly smooth; in fact, it’s the smoothest crane I’ve ever operated.”

Wayne soon discovered that the AC 4.070HL-1 wasn’t just about quiet operation, it’s also compact and highly manoeuvrable, making it ideal for tight or constrained job sites.

On-site performance has also impressed Wayne and the team.

“During one install, I ran the crane for three and a half hours straight lifting roofing sheets and still had 20 per cent charge left. Charging on site was no problem. For the type of work we do, I was impressed.”

The Tadano AC 4.070HL-1 combines trusted lifting performance with advanced hybrid technology.

Wayne also credits Tadano’s technical support team, particularly Russell Currie from Tadano Oceania, for ensuring a smooth introduction of the hybrid into day-to-day operations.

At the heart of GCSWA’s success is a commitment to its core values:

• Safety first – keeping people and projects secure.

Capacity: 70 t

Main boom: 11.1–52.1 m

Max tip height: up to 70 m with jib

Carrier: 4-axle, compact and highly mobile

Counterweights: modular, optimised for transport flexibility

“Russell’s on my speed dial,” Wayne laughs. “With any new technology, there’ll always be a few teething issues, but nothing we couldn’t solve together. A lot of the time it’s just like any electronic device; a quick isolation or restart gets you back up and running.”

What stood out was Tadano’s ability to remotely access live reports from the crane. “They could see the exact error code in real time, which made troubleshooting so efficient. Instead of waiting around, we got the crane back online fast and kept the job moving.”

The Tadano AC 4.070HL-1 combines trusted lifting performance with advanced hybrid technology. Its electrified superstructure, powered by an 800 V, 70 kWh battery, enables zero-emission and near-silent operation for hours at a time. The system can be recharged via grid power or regenerated by the carrier engine, offering flexibility across project sites.

• Reliability – a modern fleet backed by meticulous maintenance.

• Innovation – adopting technology that adds real client value.

• Integrity – building trust through honest, transparent relationships.

• Sustainability – ensuring tomorrow’s projects are supported by greener solutions.

The addition of the Tadano hybrid perfectly reflects these commitments. It demonstrates to clients that GCSWA is not only meeting current project demands but is also anticipating future requirements around emissions, noise, and environmental performance.

James Greenwood, Chief Operating Officer of Tadano Oceania, shares: “GCSWA has been a trusted partner of Tadano for many years. We don’t just see ourselves as a supplier, but as a genuine partner in their ongoing success. Providing advanced lifting solutions like the AC 4.070HL-1, along

Control system: Tadano AML-F, with Lift Adjuster to minimise load swing

with round the-clock support, is all part of that commitment.”

Since its arrival, this hybrid crane has proven its value in supporting GCSWA’s operations, with deployments across several sites (mentioned earlier in this article) and several weeks on Fortescue’s transmission powerlines projects.

Its deployment on the Rio Tinto project in October, working alongside a fleet of other cranes, highlights the confidence GCSWA and its clients place in the team’s ability to deliver complex projects efficiently, reliably, and with a strong focus on sustainable lifting solutions.

Stay tuned as GCSWA advances its capabilities to meet the increasing demands of clients in the industry.

SUPERFLEX SLINGS

SUPERFLEX STROPS

DOUBLE ENDED STROPS

STEEL FLAT WOVEN SLINGS

DEAN-0 SLING

SUPERFLEX

“ YOUR FIRST CHOICE IN LIFTING ”

“YOUR FIRST CHOICE IN LIFTING”

Complete Crane Solutions (CCS) has successfully implemented an apprenticeship program designed to attract youngsters to both the business and the industry.

JOE REGALI IS 21 AND HAS BEEN WITH CCS for 15 months. He started his apprenticeship with crane distributor WATM before moving to CCS. Joe is based in CCS’s Karratha operation.

“I moved to CCS to finish my trade and now I’m a diesel fitter and mobile plant HD (heavy duty). Working with the team at CCS has been really good for me. Josh John and the team made me feel really welcome from day one. I immediately felt at home and got straight into the work.

“I quickly developed great relationships with the guys and now it feels like I’m working with a bunch of mates. The more experienced guys were really generous with their time and happy to share their knowledge, and if I wasn’t

sure about something I was encouraged to ask the question.

“The work is really varied. I’ll be based in the workshop some of the time and then out on mobile servicing calls, so no two days are ever the same. The type of equipment we work on is also varied and in any week, you will see me working on cranes, trucks, trailers, telehandlers or EWPs, you name it, we work on it. You’re always learning something new and there are always challenges that you haven’t come up against before which makes the work really interesting. Everyone is there to get the job done and have a good time,” said Joe.

Mason Demanuele is 18 and works in CCS’s Sydney operation. He started his apprenticeship with Liebherr.

“I started with Liebherr and when CCS started the Sydney operation, I was offered an apprenticeship with them. As there were a number of the team leaving to work with Josh, I decided there were better opportunities working in a smaller company.

“I’m in the third year of my four year apprenticeship, and I’m really enjoying the work. It’s varied and I’m working on all types of equipment, not just the one brand which I really enjoy. I also enjoy the work culture at CCS.

“The team has encouraged me to work freely on projects and make my own decisions, but the more experienced guys are always there when I need help. The more experienced guys have been great, and they are prepared to teach me

everything they know. They don’t do a job without explaining what they are doing, and why they are doing it a certain way. They’ve taught me how to troubleshoot and eventually solve problems.

“Once I qualify, I don’t think I’ll specialise in any particular area, I’m just hoping to be a good all round service technician. I really enjoy the work I do. It wouldn’t be for everyone because there are days where you get dirty and oily but you grow accustomed to that. No two days are ever the same. I’m always working on different types of equipment and now I’m getting out more with mobile servicing which makes it all the more interesting,” said Mason.

positive work culture,” Digby said. “I was looking for an apprenticeship at the time and thought ‘Yeah, I’ll give it a crack. What can I lose? It’s all nuts and bolts and ‘mechanicing,’ so I took the job and haven’t looked back. The business has always looked after me, providing plenty of opportunities to ‘grow’ along the way.”

Digby operates out of Perth and Karratha and enjoys working in a strong team environment.

“When I complete my apprenticeship, my aim is to be the best possible service technician that I can be, an all-rounder so I can take on a job and make sure the result is 100 per cent and high quality. The team at CCS prides itself on providing a service and workmanship which is of the highest quality,” he said.

The work is varied, which Digby likes, and there are jobs where he has plenty of time to prepare for a particular challenge.

Digby Ellis is just over two years into his four year apprenticeship and works in the WA operation of CCS.

“I joined CCS having previously worked with earth moving equipment. I met a CCS employee and he was talking about the business, how dynamic it was, and what a great place it was to work with a really

“Obviously, we’ve got a number of juniors like myself in the team and then there’s a lot of experienced technicians. I love the work and there’s a good crew of boys, everyone has each-others back and everyone looks out for one another. It’s like a big working family.

“The experienced guys have been great, they take you under their wing and share their knowledge wherever possible. They want the best for you and everyone’s keen to teach you what they know, the tips and tricks and why we go about the work as we do,” said Digby.

“I move between Perth where my role is mainly focused on mobile servicing because we don’t have a workshop, although I understand the business is looking at this at the moment. It’s good to be out and mobile and meeting the customers in their yards.

“When I’m working in the Pilbara I might have a six or seven hour drive just to get to the machine, so you have plenty of time to think about your plan of attack. You have been given some information so most of the time you know what to expect. It’s the same in the workshop, we discuss a plan before we actually get to the job

Noah Ratajczk is 22 and has been with the Sydney operation for eight months having worked in the AV and production industry previously.

and then work together to execute the plan,” said Digby.

Noah Ratajczk is 22 and has been with the Sydney operation for eight months having worked in the AV and production industry previously.

“Although I’ve come from a completely different industry, I’ve always been mechanically minded and enjoyed working on my own cars and trucks. I wanted an apprenticeship, get qualified and get a trade so when the opportunity came up to join CCS, I jumped at it,” said Noah.

He’s been impressed with the ‘can do’ attitude of the Sydney team.

“From day one, the team has been really good to me. There is endless amounts of experience and knowledge in the team, which has been really beneficial. For every question, there is always someone there with an answer.

“It’s great working with professionals that are specialists in their field, you learn so much and very quickly.

being a mechanic is one of the trades that really fulfills that,” he said.

Kai Young is 19 and at the end of the third year of his apprenticeship. He’s been working in the Karratha workshop for three months.

“I worked with Liebherr Australia in the Sydney workshop for the first two years of my apprenticeship which was a good experience. But moving to CCS has been really good for me mainly because I find myself working on many more types of equipment not just the one type of machine.

“Already, I feel the move to CCS is generating more confidence in my work and I’ve pretty much got my hands in everything now. It’s a great place to work and the more experienced guys are happy to share their knowledge with you and there is no such thing as a silly question.

“Everyone in the workshop is great and there is so much knowledge in the team and it’s all shareable. If you’ve got a question, you just ask, and someone will help you out. The team has come from a wide range of backgrounds, and everyone has experience on something, so you’re never really stuck. If you do get stuck, like I said, you just ask and everyone’s there to help. You’ve got a

“Everyone in the workshop is great and there is so much knowledge in the team and it’s all shareable.”

“Another thing I love about the work is the variety of equipment we work on, no two days are the same. The good thing about CCS, is we work on just about anything from cranes, trucks and trailers through to EWPs and telehandlers. We get to work on a bit of everything, which means you never get bored,” said Noah.

“I’m now getting to site quite often which is good fun because you get to see different and unique locations. We’ve been working on cranes on boats, and you get to think on your feet because some locations are less than ideal for servicing equipment.

“I love the challenge of working on such a broad range of equipment because there’s pretty much an endless amount to learn. I’m always trying to learn and better myself and

lot of support around you which is great,” said Kai.

The workshop is always busy said Kai.

“There are always jobs happening and there’s a lot going on every day. I get involved in multiple different jobs, and when I finish one, I’m straight onto the next, helping out the other guys. We are always working on a wide range of machines including crane, trucks and forklifts which helps broaden your knowledge.

“I work with a great team and everyone’s there to help. Like I said, if you’ve got a question, you ask it, and someone will have dealt with the same issue before and will have the answer. The knowledge in the team is ‘shareable’ which helps you learn quickly.”

The Baden Davis Crane Connection has been appointed the XCMG distributor for the ACT, New South Wales and Queensland.

INDUSTRY EXPERTS AND DIRECTORS OF the Crane Connection, Anthony Davis and Ben Baden, provide an in depth look into the appointment and what the industry can expect.

“We were in discussions with XCMG for a number of months and in the end it came down to a straight forward business decision. For some time, we have seen market conditions change with various European and US manufactured brands getting increasingly expensive and crane hire companies finding it harder and harder to see a return on their investment, particularly on new cranes.

“In contrast, we have watched the Chinese brands evolve and develop their products to meet various globallyrecognised standards particularly for the European and US markets, and we have also seen brands like XCMG becoming

increasingly accepted by the local market,” said Anthony.

“What’s more, the cranes are obviously delivering performance because crane hire companies, both large and small, have come back to buy multiple units. We could see the timing was right to move our business in this direction.”

During the months of negotiation, it became clear to Ben and Anthony that XCMG has a strong, long-term focus for the Australian market.

“XCMG don’t want to rush products that are not ready for entry into the Australian market. The decisions they make are thoughtful and calculated, and the products we will be bringing in have been thoroughly tested to the high and exacting standards your typical Australian

crane customer is expecting,” said Ben. “We appreciated that this approach wasn’t just in theory, it is based on a thorough understanding of the high standards the Australian market requires, and this was one of the fundamental reasons we decided to go with XCMG.”

During this years’ bauma, XCMG announced it had joined forces with Sarens Group, an international giant in crane rental services and heavy lifting, to establish a strategic partnership aimed at transforming the landscape of heavy lifting operations.

As part of this collaboration, XCMG successfully delivered the first batch of its cutting-edge five-axle 250-tonne all terrain cranes, the XCA250G7-1E, to Sarens. Designed with the European

market in mind, the XCA250G7-1E represents a significant milestone in XCMG’s commitment to innovation and excellence in machinery design. Sarens will integrate these advanced cranes into its fleet, enhancing its ability to execute complex lifting projects with precision, efficiency, and reliability. These models will be coming to the Australian and New Zealand markets.

“We were in negotiations with XCMG well before bauma, but the Sarens announcement certainly cemented our opinion that we were headed in the right direction,” said Anthony.

“Seeing the launch of the new models and watching a leading lifting business like Sarens, purchasing large numbers of XCMG cranes, and publicly endorsing the XCMG range, certainly made our decision easier.

“XCMG is developing cranes for the global markets including Europe where the EU Standards include EN 13,000. These are standards which are applicable for the Australian market. XCMG has also ensured the axle weights on the mobile crane range suit most of our states,” he said.

XCMG recently unveiled its latest lineup of fuel-efficient and low-emission cranes at major European industry events. The company introduced the XCA60_EV, a hybrid all terrain crane, at Vertikal Days in the UK and at France’s JDL, drawing strong interest from industry stakeholders.

Purpose-built for European job sites, the XCA60_EV is equipped with a proprietary oil-electric hybrid drivetrain that cuts fuel consumption and reduces carbon output by up to 40 per cent. The launch demonstrates XCMG’s advancing capabilities in sustainable engineering and next-generation lifting solutions.

Taking on the XCMG distributor means a departure from a recognised element of The Crane Connection’s business model.

“We won’t be importing used cranes anymore, but obviously we can still ‘trade

in’ local cranes, refurbish and resell them locally. Now we have the opportunity to offer new machines which are Australian Design Rule (ADR) compliant with a two year warranty from XCMG.

“At this stage, not every model is ADR compliant but the factory is working hard on this. Currently the 40 tonne and 60 tonne all terrains are, and there is an 80t a 250t and there’s a 120t four-axle coming as well. There’s also a 260t tele crawler on the way. ADR compliance doesn’t just happen overnight, so it will take a while for the factory to go through this process and to have additional models compliant and available,” said Anthony.

Anthony and Ben expect demand to be across the XCMG range.

“One hundred per cent we expect demand to be across the entire range including the larger capacity cranes. Even though the 600t to 4000t all terrains are not ADR compliant at this stage, they can still can be floated from site to site around Australia.

“Economically, and from a business perspective, this becomes a viable option because the purchase price is significantly

lower than European and US manufactured product. Massive capacity all terrains are ideally suited for large infrastructure projects and wind farm construction, and we expect to be having interesting conversations with the larger players around these types of applications,” said Ben.

With a rich crane heritage, purpose-built crane facility and experienced service and support personnel, The Crane Connection is the ideal partner for XCMG.

“We’ve been in the industry for 30 years and that time, we’ve built a purposebuilt crane facility. We have a dedicated team of highly qualified mechanics and technicians many of whom have been with us over a very long term. Each continues to receive high levels of training and are now being exposed to XCMG factory training across the range,” said Anthony.

“Levin from XCMG’s factory has been working with us on the technical training and also on the spare parts strategy and this will be an ongoing process as the different models arrive. We’ll be stocking parts for the models as they come in

“At the moment, we have a 40t all terrain a 100t tele-crawler in the yard and we have the critical spare parts for these plus the fast-moving parts such as filters. As different models arrive, like the 60t arriving shortly, the parts will come in for these models as well.

“We can also draw on the parts XCMG already has in Melbourne and in Kalgoorlie and there is also a large parts depot in Welshpool in Western Australia. There is quite a crossover of parts between the crawler cranes and all terrain cranes which simplifies the process to a degree,” he said.

“As far as service is concerned, we will continue to work with our network of service providers and agents, many of which have been working with us for many years. XCMG also has technicians on the ground in Australia as well so we are very confident that we will maintain the high levels of after sales service and support customers of The Crane Connection have come to expect.”

P.A. Construction Equipment Pty Ltd (Pace Cranes) was established in 1987 to provide the construction industry with an independent Australian owned and operated crane sales, crane service and crane spare parts organisation.

For over 30 years Pace Cranes have offered premium quality equipment to the Australasian market with a dedicated and unrivalled service, supported by specialist technical advise across the full range of equipment sold.

XCMG recently unveiled its latest lineup of fuel-efficient and low-emission cranes at major European industry events.

THE COMPANY DISPLAYED THE XCA60_EV, a hybrid all terrain crane, at Vertikal Days in the UK and at France’s JDL, drawing strong interest from industry stakeholders.

Purpose-built for European job sites, the XCA60_EV is equipped with a proprietary oil-electric hybrid drivetrain that cuts fuel consumption and reduces carbon output by up to 40 per cent. The launch demonstrates XCMG’s advancing capabilities in sustainable engineering and nextgeneration lifting solutions.

XCMG has consistently intensified its focus on sustainability, intelligent engineering, and localised product development, launching a range of premium cranes designed for Europe’s demanding construction environment. These initiatives strengthen the company’s position as a trusted partner in supporting Europe’s transition toward loweremission fleets and modernised urban infrastructure.

Notable models from this Europeanfocused portfolio include:

• Th e XCA60_EV, featuring a 400V plug-and-play electric drive system that supports fully zero-emission lifting operations. It is powered by a 170kW electric motor, complemented by a dual-engine transport system with a total output of 400kW, delivering fuel savings without compromising lift capacity or reliability.

• C ompact, high-performance cranes engineered on XCMG’s G2 technology platform excel in dense urban environments. The XCA80G7-1E boasts a streamlined footprint of 12.73m × 2.55m × 3.89m and a tight

XCMG has consistently intensified its focus on sustainability, intelligent engineering, and localised product development, launching a range of premium cranes designed for Europe’s demanding construction environment.

turning radius of 7.75 metres. Equipped with a 60-metre main boom and a dual-hook coordination system ideal for complex city projects, the XCA250G7-1E supports remote-controlled operation, allowing a single operator to manage tasks efficiently, and incorporates an innovative telescoping mechanism tailored for confined spaces. Both all-terrain models come with 360 degree vision systems for enhanced jobsite safety and operator awareness.

XCMG continued showcasing its XCA60_EV hybrid crane at GIS EXPO 2025 in Piacenza, Italy, in September. At the event, the company also debuted another Europe-specific model –the XCR50_E rough-terrain crane. Featuring an ultra-narrow body width of

“XCMG

is committed to supporting sustainable and intelligent infrastructure development across Europe.”

just 2.5 metres, the crane complies with European Union transport standards and significantly improves mobility and access on congested jobsites.

“XCMG is committed to supporting sustainable and intelligent infrastructure development across Europe. ‘Rooted in Europe, Dedicated to Europe’ is both our strategic focus and our commitment to customers and the environment,” said Sun Jianzhong, Vice President of XCMG Construction Machinery and General Manager of XCMG Crane.

The strategy is already gaining traction. XCMG’s low-emission cranes have secured bulk orders from customers in Germany, France, the Netherlands, and other European markets, underscoring growing regional trust in the company’s advanced lifting equipment and customer-driven solutions.

A central element of the standard is the requirement for pre-erection and commissioning inspections.

AS 2550.4 (2004), Cranes, hoists and winches - Safe use - Tower cranes, sets out the specific requirements for the safe use, inspection, maintenance, and operation of tower cranes in Australia.

TOGETHER WITH AS 2550.1, WHICH provides general provisions for all crane types, it forms the basis for safe tower crane practice on construction sites.

A central element of the standard is the requirement for pre-erection and commissioning inspections. These must be undertaken by competent persons and cover both the manufacturer’s requirements and critical safety checks. Particular attention is given to nondestructive testing of vital welds, inspection of connections, slew ring bolts, and attachment points.

The standard places a strong emphasis on documentation. Essential records include pre-operation checklists, design registration, inspection reports, safe work method statements (SWMS) for erection and climbing, commissioning documentation, major inspection records, and lifting gear inspection registers. This body of documentation provides both traceability and assurance that the crane is being managed in line with statutory

and industry requirements. Another key area is the validation of foundations, footings, anchorages, and ties. These must be verified by engineer-approved reports, often supported by geotechnical assessments, to confirm that the crane has a safe and stable base for operation.

The standard also requires a structured approach to maintenance and ongoing inspections, to be carried out in line with manufacturer’s instructions or competent person advice. All work must be properly recorded.

In addition, major inspections are mandated at defined intervals: when the crane reaches its design working period.

CICA’s CraneSafe crane inspection program plays a vital role in facilitating this process. By providing an independent, consistent inspection framework across a range of crane types, CraneSafe supports compliance with AS 2550 requirements.

Its structured reporting system helps owners and operators identify issues early, maintain thorough records, and

demonstrate that cranes are being managed and operated safely.

Complementing this, tools such as StartSafe for pre-starts provide crane owners with a practical way to capture and manage daily safety checks. StartSafe streamlines the pre-start process, ensuring operators complete inspections before each shift and that records are stored digitally. This not only promotes compliance but also provides crane owners with immediate visibility of potential issues, helping them to respond quickly and maintain operational safety.

AS 2550.4 further highlights the importance of safe work practices, including correct erection procedures, the use of fall arrest systems, maintaining operator competency, and implementing clear emergency procedures. These are treated as minimum requirements that must be observed on every site.

AS 2550.4 ensures that tower cranes are erected, operated, and maintained to a consistent national standard. By enforcing mandatory inspections, comprehensive documentation, engineering validation of structural supports, and adherence to both manufacturer and competent person guidance, supported by industry programs such as CraneSafe and practical tools like StartSafe, the standard plays a critical role in reducing operational risks and maintaining safety compliance across the crane industry.

For more information on CraneSafe and StartSafe, go to www.cica.com.au

RRS operates a versatile fleet of 28 diesel and electric tower cranes for diverse project needs.

This year marks a significant milestone for Resolution Rigging Services (RRS) as the Sydney-based company celebrates 25 years in business. From its beginnings as a small, family-driven operation, RRS has grown into one of Australia’s most respected names in tower crane hire and rigging, with a reputation built on reliability, safety, and long-standing relationships.

FOR PROJECT MANAGER RHYS NORONHA, the anniversary is a moment to reflect on how far the company has come. “It’s a proud achievement for the family and for everyone who has been part of the business over the years,” he said. “Resolution Rigging has always been more than just a company – it’s something we all carry as our own name.”

FAMILY ROOTS AND STEADY GROWTH

Resolution was founded in November 2000 by Tony Noronha, who remains actively involved in the business today. In the early years, the company was strictly labour-only, supplying crews for crane erection and dismantling. Rhys recalls that the first employee was Tony’s brother, Fern, who still oversees operations. Alison

joined to manage accounts, and Leonie became a steady presence in the office –making RRS a true family business from the start.

For more than a decade, the company subcontracted cranes from other suppliers while focusing on rigging. The turning point came around 12 years ago, when RRS bought its first tower crane. “Since then, as our clients expanded, we expanded with them,” Rhys said. Today, the fleet has grown to 28 tower cranes, reflecting the company’s steady progression from a small labour provider to a fully-fledged crane hire and rigging business.

One of the features that sets RRS apart is the versatility of its crane fleet. The company operates both diesel and electric tower cranes, including luffing and hammerhead models, giving clients greater flexibility across different projects.

“In Sydney and Melbourne, power isn’t always available on every site, so having

both diesel and electric options means we can always find the right solution,” Rhys said.