Delivering differently

Martinus has grown by going deeper, not broader — building a rail delivery model defined by integration and system-level delivery.

The next generation PAGE 16

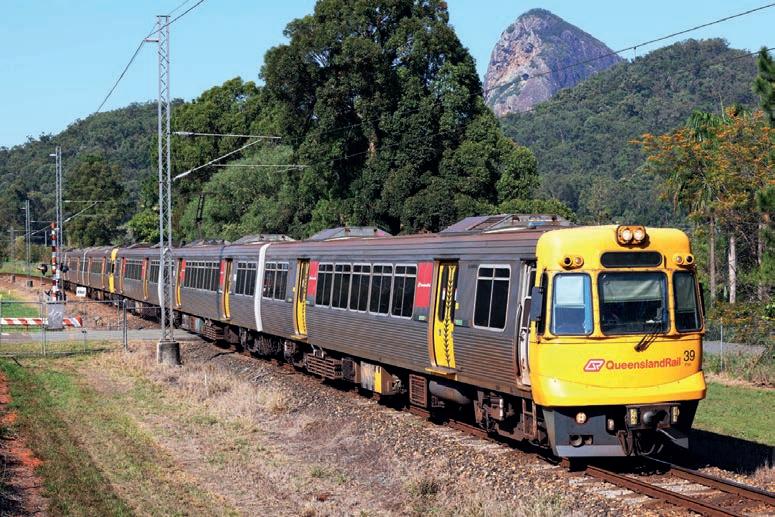

End of the line for EMUs PAGE 36

In defence of the SRL PAGE 40

New era in rollingstock solutions for Australian rail freight

To register your interest in the above-mentioned leasing products and locally manufactured rollingstock, please contact Rail First’s Chief Commercial Officer Vic Regina: vic.regina@railfirst.com.au

New and diverse leadership team

Each executive has 20 to 30 years of expertise in transport and logistics, rail supply chain operations, manufacturing, construction and/or commercials

Core focus on offering market leading long-term solutions to customers

New leasing options for customers

Purchase to Long Term Lease

Manufacture to Long Term Lease

Provides customers with flexibility to allocate capital to other business initiatives

Favourable pricing discounts for longer lease periods and increased volumes

New locally manufactured rollingstock

48-foot intermodal well wagons and 40 -foot intermodal skel wagons

Hoppers for bulk commodities

Crew vans

Local manufacturing provides shorter lead times in customisation and delivery

Better customer visibility of safety standards and quality control during production

Less embedded carbon emissions than that of offshore manufacturing

New $100 million investment in energyefficient locomotives

Australian-made UGL CF44 freight locomotives feature one of the most fuel-efficient engines in the market

Helping customers to reduce emissions in rail supply chain operations

From the Editor

Published by:

379 Docklands Drive

Docklands, VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman

John Murphy E: john.murphy@primecreative.com.au

CEO Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor Kayla Walsh

E: kayla.walsh@primecreative.com.au

Business Development Manager

Arron Reed

M: 0466 923 194 E: arron.reed@primecreative.com.au

Client Success Manager Ben Sammartino

E: ben.sammartino@primecreative.com.au

Head of Design Blake Storey

E: blake.storey@primecreative.com.au

Designer Apostolos Topatsis

Subscriptions subscriptions@primecreative.com.au

www.RailExpress.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the Publisher.

Kayla Walsh

Editor - Rail Express

Welcome to the August edition of Rail Express

It’s been a great month for the rail industry, with major progress across many projects, from Inland Rail to Victoria’s Level Crossing Removal Project.

I was lucky enough to attend the recent Urban Rail conference in Melbourne, where I enjoyed several informative presentations. Two that stood out to me were from Dr Deborah Hume, Deputy Director-General of Queensland’s Department of Transport and Main Roads (Translink division), and Frankie Carroll, Chief Executive Officer of the Suburban Rail Loop Authority.

Hume shared some of the unexpected benefits that have come with Queensland’s introduction of 50 cent fares in 2024, while Carroll hit back at media criticism of the Suburban Rail Loop. Read more on pages 40–43.

On another day out of the office, I got to visit Alstom’s train maintenance facility in South Dynon. I caught up with the team to learn about the work they do there and the development and delivery of Victoria’s VLocity trains.

Our cover star this month is Martinus, a company that has seen huge growth over the past ten years, developing from subcontractor to national delivery partner. We share how it has built a national reputation for integrated, governmentgrade delivery not by branching out, but by building in.

Also in this issue, I'm launching a new feature series in which I profile a different young person in the rail industry each month. Rail might be facing a skills shortage, but there's light at the end of the tunnel – as

these talented up-and-comers are proving.

Later in the magazine, MTR shares insights into the system integration case it has compiled for the Sydney Metro project, and Austbrokers City State Rail explains the ins and outs of Contract Works insurance, and how to avoid being left with potentially devastating losses.

We also home in on the theme of condition monitoring and asset management. Aptella talks through the benefits of Senceive’s InfraGuard, an advanced rockfall monitoring solution that is boosting safety and saving operators time and money. Siemens Mobility shares the many advantages of its high-tech Vehicle Equipment Measurement Systems, and voestalpine Railway Systems explains why operators should invest in zentrak, its ecosystem for condition monitoring, asset and maintenance management.

Vossloh tells us all about its two compact rail processing machines, and how they provide customers with an efficient maintenance solution.

And with thousands of people recently turning out to bid goodbye to the last of Queensland’s Electric Multiple Unit trains, we share some great photos of the fleet over the years.

Plus we have our regular columns from the Australasian Railway Industry and the Rail Industry Safety and Standards Board.

Happy reading!

kayla.walsh@primecreative.com.au

Vossloh Australia can offer locally manufactured components and complex integrated rail solutions from the Vossloh Group anywhere on the globe.

Final designs revealed for bridge

Final designs have been unveiled for the new road bridge that will replace the level crossing at Maidstone Street in Altona, Victoria.

The Victorian Government said removing the “dangerous and congested” level crossing and building a road bridge over the Werribee Line will boost safety and create more reliable travel times through the busy industrial area.

Site establishment and early works to remove the crossing have started, with major construction set to kick off in the coming months, and the boom gates gone for good in 2027.

The road bridge will feature patterned and textured surfaces finished in earthy browns, oranges and muted purples.

Porthole-inspired windows will offer pedestrians using the bridge views of the surrounding grasslands and the You Yangs to the west.

A new pedestrian path will also be built along the west side of the bridge to create safer connections for pedestrians, linking to an existing footpath network.

The designs include new street lighting over the road bridge, and landscaping featuring more than 70 native trees and

to reflect the biodiversity of the nearby Altona Grasslands.

More than 14,000 vehicles travel through the Maidstone Street level crossing every day, with the boom gates down more than 20 per cent of the morning peak.

The Werribee Line will be level crossing

Suburban Rail Loop takes step forward

The Suburban Rail Loop (SRL) East project has taken a major step forward, with construction beginning at the site of the new underground station in Clayton.

Suburban Connect crews have started excavating the underground station area, building the passenger connection to the existing Clayton station and underpinning one of the support piers of the elevated rail line. This will ensure trains can keep

As part of the works, buses will replace trains between Parliament and Westall stations from late August to early September.

Coaches will also replace Gippsland Line V/Line trains between Southern Cross and East Pakenham.

SRL East is the first stage of the SRL project, with 26 kilometres of twin tunnels running from Cheltenham to Box Hill and connecting six new underground stations.

Cranbourne Pakenham and Gippsland lines to SRL.

Tunnelling will begin next year, with the first trains set to take passengers in 2035.

Meanwhile, a new report released by SRL transport planners has shown that commuters will save up to 40 minutes on their commute when SRL East opens.

Students travelling from Cheltenham to Deakin University in Burwood or to Monash

An artist’s impression of the new Maidstone Street road bridge, looking towards Kororoit Creek.

Construction is now underway in Clayton, with cranes and piling rigs on site.

Celebrating Australian rail manufacturers

Nominations are now open for the 2025 Endeavour Awards – Australia’s premier manufacturing industry awards.

Does your company locally manufacture products used by the Australian rail industry – from trains and wagons to cables and components? We want to hear from you.

The 2025 Endeavour Awards Gala is more than just an awards night, it’s a celebration of innovation, resilience, and excellence across the sector.

It brings together manufacturers from all corners of the country to honour achievements, connect with industry peers, and spotlight the inspiring people and companies shaping Australia’s manufacturing future.

The 2025 award categories include:

• Technology Application Award –Sponsored by Weld Australia

• Innovation in Aerospace

• Innovation in Health Technology

• Innovation in Food & Beverage Manufacturing

• Innovation in Transport

• O utstanding Start-Up Award

• L eader of the Year – Sponsored by BDO Australia

• Manufacturer of the Year

Nominate an exceptional Australian manufacturer, or a business that supplies to the sector, and give them the recognition they deserve. Key nomination guidelines:

• Nominations are free and must be submitted online by 11.59pm, Thursday 2 October 2025.

• Nominations cannot be withdrawn after the deadline.

• T he form must be completed in one sitting; progress cannot be saved for later.

• All nominated products or technologies must be manufactured and/or commercially available in Australia.

• Nominated companies, sites, and executives must be based and operating in Australia.

• Each nomination must include a highresolution image (minimum 1MB) suitable for print.

• Be prepared to upload any supporting materials (equipment specifications, photographs, marketing content) under 5MB per file.

• All finalists must ensure a representative attends the Gala Awards evening if successful.

Join us in celebrating the best of Australian manufacturing and help ensure the achievements of our industry continue to be recognised and shared. Get involved at www.endeavourawards.com.au.

City Rail Link celebrates ‘amazing achievement’

Auckland’s City Rail Link (CRL) has received two top-tier ratings from the Infrastructure Sustainability Council (ISC) – making the entire project officially recognised as meeting the highest sustainability standards ever awarded in New Zealand and Australia.

CRL has been given an As-Built leading rating for the overall project, covering the design and construction of its C1, C2 and C3 contracts – CRL’s entire 3.45 kilometre route of tunnels and stations.

It is the first project to be awarded ISC’s Leading IS (Mahi Rauora Aratohu version 1) As Built programme rating overall.

CRL also received an As-Built leading rating specifically for the design and construction of its main C3 tunnels and stations contract delivered by Link Alliance, covering the work to build the Te Waihorotiu, Karanga-a-Hape and Maungawhau stations, including its use of a tunnel boring machine between Maungawhau and Te Waihorotiu.

ISC Chief Executive Toby Kent congratulated the team on its success and praised its commitment to sustainability.

“The ISC is proud to see New Zealand’s biggest transport infrastructure project

adopt sustainability into the DNA of its operations,” he said.

“This has been an amazing achievement and demonstrates the overwhelmingly positive social, economic and environmental good that is possible to achieve through an IS Rating.”

CRL Ltd Chief Executive Patrick Brockie said the council’s independent assessment was a testament to the values and hard work demonstrated by the project team, contractors and subcontractors.

“Success for CRL Ltd and our Link Alliance delivery partner is testament to the passion, commitment, and tenacity of the many talented people who have delivered

a project that is not just good for Tāmaki Makaurau Auckland, but good for the sector, shifting the needle on how we integrate sustainability, environment, social outcomes and culture into large-scale infrastructure projects,” he said.

ISC was impressed by CRL’s protection of the environment: substantially reducing the project’s carbon footprint; savings around the use of construction and operational energy; more efficient use of water and materials; a dramatic reduction in waste earmarked for landfill; use of high-tech computer technology to help produce more efficient design and construction methodology.

The 2024 Endeavour Awards were a great success.

The City Rail Link has been recognised for meeting high sustainability standards.

Image: Prime Creative Media

Image:

CRL

Metro Trains cuts delays with new process

Metro Trains has implemented a new procedure for handling medical emergencies on its network, which has led to more efficient responses and fewer service delays.

In 2024, more than 700 passengers required medical attention on their trip – an increase of 14 per cent on the year before.

Despite this, the resulting service delays decreased, with 1636 minutes lost in 2023 compared to 790 minutes lost in 2024.

Some of the most common reasons for passengers needing medical assistance include: slips or falls, an existing or unknown medical condition (physical or mental), lack of food/hydration, use of alcohol or other substances, or the effects of the weather (for example, wearing heavy clothing during cold weather).

In a medical emergency, passengers on trains should alert the driver using the red emergency button, while passengers at stations should seek assistance from station staff or press the red “help” button on the platform.

Metro’s Control Centre will then coordinate a response, working with station staff, authorised officers, train drivers and ambulance services.

Medical assistance can be provided at the nearest, most suitable location, which includes major station junctions with trained medics onsite. The Control Centre also liaises with emergency services where required.

If an ill passenger on board a train requires medical attention, Metro Trains said it may prove quicker to continue the journey

to a more central location where they can be met by medical staff, rather than waiting for an ambulance at the closest station.

All staffed Metro stations have automated external defibrillators (AEDs) installed to help provide potential life-saving help in an emergency.

Metro frontline staff also receive first aid training to ensure they are fully up-to-date with AED usage.

Claire Potter, General Manager of Passenger Services at Metro Trains, said: “Passenger wellbeing and safety is our top priority.

“With a team approach, we are achieving better outcomes for passengers needing medical assistance, while keeping services moving.”

Hundreds of new rail jobs announced

A major hiring spree has been announced for the Queensland Train Manufacturing Program, with 300 jobs on offer.

The workforce mobilisation plan for the Torbanlea train manufacturing facility was activated in July, with expressions of interest now open.

Approximately 100 white collar roles and 200 trade roles are available, with boiler makers, mechanics, electricians, fabricators and painters in demand.

Recruitment will continue throughout 2025 and the full workforce is expected to be mobilised as manufacturing ramps up in 2026.

The Queensland Train Manufacturing Program will build 65 new six-car passenger trains at a purpose-built manufacturing facility at Torbanlea, in the Fraser Coast region.

The State Government has awarded the contract to manufacture the fleet to Downer, with the trains expected to be in service by 2032, in time for the Brisbane Olympic and Paralympic Games. The modern train fleet is intended to provide passengers with more efficient, reliable, and accessible travel across South East Queensland.

Minister for Manufacturing Dale Last said the recruitment drive marks a critical

turning point for the Queensland Train Manufacturing Program, creating hundreds of skilled jobs in the Maryborough region.

“The jobs spree includes a staged recruitment plan, with workers to be brought on in structured intakes as manufacturing at the Torbanlea facility scales up,” he said.

“Construction at the Torbanlea facility is progressing at pace, with structural works and roofing now complete, and internal fitout ongoing.”

Candidates can find out more about opportunities, including where to submit expressions of interest at: www.downergroup.com/qtmp.

The Queensland Train Manufacturing Program is set to build 65 new trains in time for the 2032 Olympics.

Image: Queensland Government

Young Professionals: Evelyn Tao

An engineer with big ideas

In the first of a new series profiling up-andcomers in the rail industry, we speak to a talented engineer working on the Metro Tunnel.

Evelyn Tao has always had a passion for public transport – and now she’s living her dream, working as a Risk and System Safety Assurance Advisor on Melbourne’s Metro Tunnel Project.

“I’m a huge advocate for public transport; it’s great to work on something that’s for the public good,” she said.

“I hope that my work on this project will help to influence people to use public transport that bit more often, by improving the reliability, punctuality and service that the operators and government are delivering. I can’t wait for the tunnel to open later this year – I’m hoping to be on the first service!”

Tao is working as a contractor for Metro Trains Melbourne, but her employer is environmental and engineering consultancy Ricardo.

Before this, she worked for the Victorian Government, on projects including the Next Generation Trams and the High Capacity Metro Trains.

She’s only been working for Ricardo for the past year, but is loving it so far.

“It’s been a really good experience,” she said. “It’s a completely different mindset shift.

“The work is challenging in a good way and more varied, and it’s been great for my professional growth.

“When I was with the State Government I was working on multiple projects, but with Ricardo there will be opportunities to work on projects outside of Victoria and even overseas.”

The Melbourne native said working on the Metro Tunnel has been fast-paced.

“The project world moves fast, but this project has been even faster than the other projects I’ve worked on,” she said.

“People work crazy hard on the Metro Tunnel because of the scale and the complexity, and there’s constant improvement and decision-making. I’ve had to learn to adapt quickly, but it’s been

Evelyn Tao is a Risk and System Safety Assurance Advisor on Melbourne’s Metro Tunnel Project.

Tao has previously worked on projects such as the High Capacity Metro Trains.

Images: Evelyn Tao

fantastic for someone like me, in the early stages of my career.”

The 29-year-old said that in the five years she’s worked in the rail industry, it has become noticeably more diverse and inclusive.

“When I started out in 2020 there wasn’t much of a female presence, but I can see how that has improved across different projects and different teams,” she said.

“I think there is a genuinely welcoming atmosphere for females to enter the rail industry.”

Tao is the Chair of the University of Melbourne’s alumni network for women in engineering.

“We want to build a support network for women and offer networking and knowledge sharing opportunities,” she added.

She is passionate about accessibility in public transport and was recently awarded a scholarship to attend Informa Connect’s Urban Rail conference in Melbourne, based

Tao’s idea involves three different elements that make it easier for people with accessibility issues to get a priority seat on a train.

She thought of it after she injured her ankle earlier this year, but as a young and otherwise able-bodied person, didn’t want to ask anyone to give up a seat for her.

“I am more than happy to stand, as I feel other people need the seats more than me,” she said.

“But it got me thinking that if you’re having difficulties, but you look fine from the outside, it can be difficult to approach someone and ask for a seat.”

The first system of the three would involve displays on the platform showing how crowded each carriage of the train is and how many priority seats are available.

The second system would allow people to enter their accessibility needs on a screen on the platform, and it would tell them

The third idea centres on what happens if that priority seat has been taken.

“If the seat isn’t vacated for the person who needs it, there would be an announcement in the saloon and a subtle vibration of the seat,” Tao said.

In 2019, Sydney Trains introduced carriage capacity indicator graphics on platforms, which make it easier for passengers to find a seat on approaching services.

The new Mariyung fleet uses onboard passenger counting technology to detect how many passengers are in each carriage, while the Waratah trains provide an estimate based on weight sensors built into the carriages. For the remainder of the fleet, a “shore-based” forecast is calculated based on historical Opal data. Collectively, this data allows for a carriage occupancy figure to be predicted.

Tao added: “I think it’s great that Sydney has this system and I would love for Victoria to introduce something similar.

A Global Partner in Transport Excellence

Built for rail

Martinus has grown by going deeper, not broader — building a rail delivery model defined by integration and system-level delivery.

In an era of multi-modal infrastructure, it’s easy to overlook a simple truth: rail projects are different. They don’t just move people or freight, they operate as systems.

Tracks, structures, signalling, interfaces, control. Each element has to work with the others, safely and continuously. Delivering them requires more than capability. It requires a contractor that understands how every part connects.

Martinus isn’t a diversified tier one. It’s a rail contractor. And over the past decade,

that distinction has shaped a very different approach to project delivery.

From brownfield freight upgrades in regional Victoria to complex corridor works on Inland Rail and station redevelopment in dense urban environments, Martinus has built a national reputation for integrated, government-grade delivery.

Its growth hasn’t been driven by acquisition or diversification, but by deepening technical capability, investing in disciplines that make or break major rail programs: systems,

structures, stakeholder engagement, and seamless integration from design to delivery.

Nicolas Jaramillo, Engineering Manager at Martinus, said that focus has shaped a delivery culture where rail expertise isn't siloed, it’s shared.

“Engineers walk the job with superintendents. Delivery leads work alongside systems specialists from day one. And lessons learned in one region are embedded in the next.

“It’s a model that scales without losing detail, because the people delivering the work are part of the thinking that shaped it.”

Now, with a national pipeline, a global footprint, and a growing role in station and network-scale programs, Martinus is entering a new phase – one where the skills of a rail specialist are being recognised not as niche, but as essential.

A DECADE IN DELIVERY

Over the past ten years, Martinus has shifted from subcontractor to national delivery partner, not by diversifying into new sectors, but by staying focused, and getting sharper.

That journey, from brownfield upgrades to full corridor programs, has been defined by a consistent principle: deliver differently, and back it up in delivery.

The early phase of that evolution began with a series of technically complex brownfield jobs for the Australian Rail Track Corporation (ARTC), including the Gunnedah Yard Upgrade in 2014 and Kooragang Arrival Roads in 2016.

Both projects tested Martinus’ ability to deliver safely in live environments –managing access, coordinating across disciplines, and meeting operational constraints under pressure.

More than milestone jobs, they became proving grounds for the kind of integration and interface management that would later define Martinus’ project model.

That model took a step forward with the Murray Basin Rail Project in 2017, where Martinus delivered one of Victoria’s largest freight upgrades. The program spanned hundreds of kilometres and five concurrent work fronts, integrating civils, track, structures and signalling. It was also one of the first demonstrations of the company’s stakeholder-led delivery model: engaging locally, managing complex approvals,

Martinus has built a strong reputation for integrated, government-grade delivery.

and achieving 38 per cent Indigenous participation over the life of the project, one of the strongest results in the state at the time.

That maturity was tested again in 2020 on the Carmichael Rail Network, a 210-kilometre freight line delivered through remote Queensland under a $580 million full Design and Construct (D&C) contract. The alignment crossed some of the most logistically and geotechnically challenging terrain in the country, calling for smart engineering, agile leadership and carefully staged delivery.

Martinus worked closely with the client to refine the rail alignment and reduce constructability risks, applying realtime problem solving across formation, structures and access.

The program also became a benchmark for Martinus’ mobile, cross-trained project teams, many of whom continue to lead major projects across the business today.

In 2021, Martinus was awarded the Rail Corridor Program on Inland Rail, delivered under an incentivised target cost model. It marked a shift: Martinus wasn’t just bidding for major government projects, it was being selected for them.

That trust was further reinforced in 2023 with the award of Stockinbingal to Parkes (S2P) and Albury to Illabo (A2I), two Inland Rail packages covering more than 350 kilometres of corridor upgrades. These weren’t construction-only jobs. They demanded full-spectrum delivery: managing freight and passenger interfaces, coordinating approvals across jurisdictions, embedding design within delivery, and

operating within live, heavily scrutinised environments.

“They also signalled something else: that the market was recognising the value of a delivery model purpose-built for rail,” said Jaramillo. “Not retrofitted. Not bolted on. Designed from the ground up to handle the technical, regulatory and operational complexity of a working system.”

S2P, completed in early 2025, delivered upgrades across 170 kilometres of corridor, including works at Daroobalgie Loop, Lachlan River Bridge, Forbes Station and Wyndham Avenue. The project engaged 596 workers over its life, including 55 First Nations employees, and delivered more than $12 million in local spend through 129 local businesses. A further $427,400 was procured through First Nations suppliers. The team also included 60 women and 39 tradespeople, with 184 local residents employed along the alignment, 34 of whom identified as First Nations.

Jaramillo said: “These outcomes tell a deeper story. One of local participation, meaningful engagement, and a delivery model grounded in direct employment and regional investment.”

The work continued with the Albury to Illabo (A2I) package, awarded within the same program. Spanning 185 kilometres of brownfield corridor, A2I introduced a broader geographic footprint, dual delivery hubs in Albury and Wagga Wagga, and a more complex mix of works including track lowering, station bridge replacements, level crossing upgrades and re-signalling, all within live operating conditions.

With the project underway, Martinus

is applying the same integrated model: aligning systems, engineering and stakeholder management from the outset.

INTEGRATION AS MINDSET, NOT AFTERTHOUGHT

In rail, complexity isn’t the exception. It’s the baseline. Every major program has overlapping agencies, compressed timelines, live networks and tight public scrutiny.

Managing that complexity isn’t a side task – it’s central to delivery. And it’s where integration, done early and led from within, makes the difference.

Martinus recognised that rail projects aren’t just collections of structures or standalone assets, they are systems. Systems that clients, operators and end users rely on to function day in, day out. Even small rail projects are interventions into existing, highly complex environments. These systems must be planned, delivered, and most importantly, integrated in a way that delivers on the intended enduser benefits. That means understanding how component, civil, structural, operational, digital, works together toward a shared objective.

“Bringing those components into service as a cohesive, functioning network is what defines systems integration,” said Jaramillo. “And it’s central to how Martinus delivers.

“At Martinus, integration has evolved into a core discipline that’s embedded from the start, not differed to handover. It reduces delivery risk by ensuring that the decisions made during design are grounded in operational and construction reality, ensuring the project is shovel-ready, where

Martinus says all of its teams work together towards a shared objective.

Images: Martinus

interfaces are resolved, systems are aligned, and the scope is genuinely ready to move into delivery.”

On complex rail programs, trying to resolve integration issues during construction is a shortcut to cost overruns, schedule pressure and handover risk.

That principle shapes how projects are scoped, planned and delivered. From early design development to long-term operational considerations, Martinus aligns its model around the railway as it functions, not just the site as it’s built. That means early systems input, proactive risk mapping, and a deliberate effort to eliminate the disconnects between civils, track, signalling and commissioning.

“Being exclusively rail-focused, our approach puts integration front and centre from day one,” said Jaramillo. “It helps different teams working on individual components of projects to stay aligned to a common goal.

“It’s what allows us to deliver safe, reliable, and sustainable rail assets, and not just hand over a finished scope. Integration influences every stage of our delivery strategy.”

Too often, Jaramillo said, systems integration is ill-defined, ill-conceived, and poorly aligned to project objectives. That model creates disconnects, misaligned timelines, and risks that ripple through commissioning.

“Martinus takes a different approach: it needs to be owned, and driven as a key tenant of project delivery. Because on a live railway, integration isn’t a downstream task. It’s the spine of the project.”

That mindset is critical in station environments where the interface between transport and people is immediate: trains, passengers, vehicles and precinct users converging in dense, timesensitive conditions.

In Auckland in 2020, Martinus was engaged by the Link Alliance to deliver a complex systems scope within Britomart, the city’s busiest commuter station. Part of the City Rail Link (CRL) program, the work was carried out under live operating conditions in one of the most constrained underground corridors in New Zealand. It involved protection works, demolition, temporary track, reinstallation, staging and close coordination with multiple delivery partners.

The project was delivered safely, ahead of schedule and under budget. In its formal performance review, City Rail Link Limited commended Martinus for its collaborative approach, effective risk management, and strong planning and interface coordination.

Back in Australia, in 2024, the

project involves the complete rebuild and relocation of a major suburban interchange within a dense, high-traffic corridor.

Loganlea combines above and below rail works, a new concourse, and a package of accessibility, safety and integration upgrades. The design connects directly with Logan Hospital, nearby schools and local precincts, and is built to support long-term growth along the Logan to Gold Coast corridor, part of Queensland’s broader Olympic-linked transport investment.

Construction is now underway, with Martinus delivering works in a live urban environment and coordinating with transport authorities, community stakeholders and precinct users. The project reflects a broader shift from corridor delivery into more complex, passenger-

Sydney, a complex brownfield program within Australia’s largest public transport project. SWM4 further demonstrated the company’s capacity to deliver multidisciplinary rail infrastructure in constrained, high-pressure settings.

“Our projects benefit from an engineering-first mindset and focusing on systems integration by shifting away from traditional discipline-led design to one that is interface-led and user-centred and outcome focused,” Jaramillo said.

Across other active programs, Martinus is also leading early engagement across federal, state and local authorities to support the design of three regional station footbridges. While technically complex, these structures are as much about community connection as they are about transport

Martinus was engaged by the Link Alliance to deliver a complex systems scope within Britomart, Auckland’s busiest commuter station.

outcomes that reflect operational needs, local identity, and long-term precinct planning.

Nichole Darke, Design Manager at Martinus, said early engagement in design gives the company the opportunity to shape solutions that will be accepted by the asset owners and celebrated by the community.

“By working closely with government and community stakeholders from the outset, we’re able to anticipate operational impacts and manage interface risks while creating an enhanced user experience that promotes connectivity, community and safety.

“As a rail-specific contractor, we are able to design footbridges that integrate with the rail corridor and strengthen the sensitive and unique railway heritage character of the townships to increase their legibility, strengthening connectivity whilst

decisions, reduces risk, and holds projects together as they grow in complexity.”

BUILDING FOR WHAT COMES NEXT

The next chapter of Australia’s rail build won’t be simple. Projects are becoming denser, more politicised, and more interfaceheavy. Timelines are tightening. Expectations are rising. And with greater public and government visibility, delivery partners are being judged not just on what they build, but how they deliver, and how consistently.

That’s why the delivery model matters.

“Martinus hasn’t grown by branching out. It has grown by building in,” said Jaramillo.

“Deeper integration, earlier collaboration, and a delivery strategy that reflects how modern rail infrastructure actually operates. Live environments. Mixed corridors.

"What stands out isn’t just what Martinus builds. It’s how.”

By owning the integration challenge early and holding key delivery capabilities in-house, the company has shown that complex rail projects don’t need to be overcomplicated, they just need to be owned, end to end, by teams who understand the system they’re delivering.

This isn’t a case study in growth. It’s a shift in what major rail delivery can look like in Australia: locally grounded, technically integrated, and built around the reality of how people, places and systems connect.

From track and stations to signalling and stakeholders, Martinus now plays a different role, not just a rail builder, but a partner in the public programs that shape how Australia moves.

Alstom: Delivering the next generation

Alstom is proudly connecting the heart of regional communities across Victoria by building and maintaining the dependable VLocity train in Victoria.

Increasing demand on the rail and transport networks connecting Victoria's regional hubs to the CBD, combined with the need for a more modern, accessible train, necessitated action.

In an endeavour to deliver more reliable transport services, the VLocity train was introduced to progressively replace the Sprinter and classic fleet trains, and meet passengers' evolving needs.

Capable of travelling at speeds up to 160 kilometres per hour, VLocity trains provide increased reliability, accessibility and capacity for commuters, with nine-car versions, accessible bathrooms and mobile signal boosters providing an improved overall experience for users.

So, how does one successfully develop, deliver and manage a resource so heavily depended upon by an entire state?

Alstom has a rich heritage of local manufacturing in Australia. Its

manufacturing site at Dandenong is a shining example of this, celebrating 70 years of manufacturing excellence in 2024, manufacturing three of Victoria’s key rolling stock projects and completing the Adelaide EMU A-City fleet last year.

The facility has delivered VLocity trains since production commenced in 2003.

Toby Garafillis, Head of Production, is based at the Dandenong manufacturing site and is responsible for overseeing the manufacture of the VLocity trains.

“The train is made end-to-end at Dandenong; we manufacture the car body shell, fitout and do the testing and commissioning,” he said.

“Remarkably, some of our team members who worked on the first VLocity trains are still with us today – a true testament to the commitment and craftsmanship behind every build,” he said. “It’s been an incredible journey to lead such a skilled

and passionate team building these reliable, regional trains for Victoria.”

On top of manufacturing these nextgeneration transport solutions for the Victorian Government, Alstom also expertly maintain the fleet, as part of the Regional Rolling Stock Maintenance Contract (RRSMC).

Under this agreement, Alstom is responsible for the upkeep of both the VLocity and classic train fleets for the next decade.

Jonathan Mendes, Project Director for the RRSMC, oversees Alstom’s servicing operations at the West Melbourne, South Dynon and Ballarat East servicing facilities.

He said he’s “incredibly proud” to be part of a team that’s keeping Victoria – and Victorians – moving.

“At Alstom, we are driven by a simple mission: Keeping fleets running safely and

Alstom builds the VLocity fleet at its home of manufacturing in Dandenong, maintaining the trains out of South Dynon, West Melbourne and Ballarat East.

reliably,” Mendes said. “Our VLocity trains are essential to regional Victoria, and we make sure they’re always running smoothly and ready to connect communities,” he said.

To ensure that it can effectively deliver on this mission, Alstom utilises the latest rail maintenance technologies to strengthen processes and deliver a range of improvements that enhance fleet availability and reliability.

"We’re preparing to implement HealthHub – Alstom’s state-of-the-art digital maintenance platform that leverages artificial intelligence, data analytics, and virtual reality to monitor train health and assist in optimising maintenance strategies,” Mendes said. “We’re extremely excited about the transformative impact it will have on performance, availability, and safety once deployed.”

HealthHub uses advanced data analytics to monitor the condition of trains, allowing Alstom’s service teams to minimise train downtime, while also optimising operational performance.

the best trains we can to move Victorians

This local ‘know-how’ comprises more

Dandenong, South Dynon, West Melbourne and Ballarat East sites. Thousands more are supported across the entire supply chain.

Beyond maintaining and delivering the next generation of transport solutions, Alstom is also helping to develop the next

Evelyn Yong is a Graduate Engineer at Alstom working on the RRSMC in Melbourne’s west, part of the team that’s responsible for

company’s commitment to giving local reliably for communities across the state,”

For example, teams can make sure that components are only replaced at the key moment they are required to, helping to reduce the environmental impact of Alstom’s facilities.

Mendes said it’s technologies and tools like these – drawn from Alstom’s global expertise and adapted locally – that have

Evelyn Yong, Jonathan Mendes and Toby Garafillis were happy to show the Rail Express team around the South Dynon facility.

Alstom is Australia’s only end-to-end rail manufacturer.

VLocity trains are essential to keeping regional Victoria moving.

MTR: Preparing Sydney’s new system

As the integrator of the Sydney Metro project, MTR Corporation has compiled a system integration case.

Sydney Metro City & Southwest is an Unattended Train Operation (UTO) railway extending the Sydney Metro Northwest Line by 30 kilometres.

The first stage of the new M1 Northwest and Bankstown Line was an extension from Chatswood on the North Shore to Sydenham in the city's southwest via the Sydney CBD, with the following stage being a further extension to Bankstown.

It stands as one of the world’s pioneering railway projects, upgrading a Grade of Automation 4 (GOA4), also known as Unattended Train Operation. This involves the fully automated control of trains without on-board staff.

Led by MTR Corporation, the Integrator of the Sydney Metro project, a unique approach to system integration has been implemented across 21 contractors.

SYSTEM INTEGRATION

Prior to the commencement of works, a comprehensive design stage encompassed

capabilities identified for the project. SIFs and their corresponding SIF Monitoring points provide the System Integrator, in this case MTR, visibility of the integrated progress. It allows for an early identification of issues which may impact the project.

The next stage of the project, the Sydney Metro Trains Facility North (SMTF-N) –Depot Expansion, was undertaken to provide stabling and maintenance capacity for new trains, growing the fleet from 22 to 45 trains.

The expansion included the installation of new rail tracks, rail systems, lifting beams and access platforms, as well as the building and fitting out of maintenance sheds, new access roads, the expansion of the existing maintenance building, fitting out sheds and rooms, installation of overhead wiring and modification of some existing roads.

Phil Hawkins, MTR's Principal Systems Integration Manager (Testing and Commissioning) for Sydney Metro City & Southwest, said the depot expansion was implemented in two phases to allow the first

To continue with the next phase of the depot expansion, safety assurance activities were planned. These involved safety assurance reports, used to establish a “So Far As Is Reasonably Practicable” (SFAIRP) argument, demonstrating the depot expansion to be safe and sound to commence operations.

Once new trains were delivered and tested, mixed fleet operation (MFO) commenced.

In the fleet, newly commissioned City & Southwest trains were embedded in the existing north west fleet carrying passengers on the Northwest section of the line. Twenty-three new train sets were commissioned in batches, with assurance of the first batch tested.

This assured the safe integration and operation of subsequent batches on the North West Line and eliminated the risk of rolling stock integration with signalling. It also improved confidence in train reliability for dynamic testing in the city.

documented in a safety assurance statement

evaluation (M&E) systems were documented

The Sydney Metro project will extend the Metro Northwest and Bankstown Line from Chatswood on the North Shore to Bankstown in the city’s southwest.

Passenger Rail

to ensure the safe operation of the new trains in the existing Metro North West Line corridor, under MFO.

System integration acceptance tests and dynamic tests are now complete and transitioning to trial running.

TESTING AND COMMISSIONING

Before trial running began, the testing and commissioning phase included the demonstration of availability of system integration functions at OCC, stations and rolling stock and signalling.

Dynamic train testing is conducted to validate the performance of trains and signalling under real-world conditions, including speed management, train separation and braking.

Multiple stages of dynamic train testing in the city have proven the performance of City & Southwest trains and signalling, regarding safety, efficiency, and reliability. This ensured the extended metro

functioned optimally before commencing the trial run.

Hawkins said this reduced operational risk and enhanced passenger safety.

“City trial running involved progressive asset handover and trial running in three stages,” he said.

Trial running was conducted as part of an operational readiness plan. This was a comprehensive set of tests and drills led by the operator and supported by the integrator, in this case MTR.

An integrated engineering safety case can be used to draw conclusions regarding system readiness, the validation status of safety requirements and functions.

The safety case can also identify any constraints and support the operations and maintenance (O&M) contractor before the first passenger service.

In the case of the Sydney Metro City & Southwest project, the engineering safety case has been updated progressively from

the end of design. Further updates will be implemented at the end of the testing and trial run phases to provide the SFAIRP argument, supporting the commencement of the first passenger service.

CHALLENGES AND SOLUTIONS

Addressing system integration challenges in the complex contractual environment involves strategic planning and the execution of technical, operational, and organisational integration activities.

Hawkins said critical success factors include timely and consistent risk and opportunity management across design, construction, testing, and commissioning phases.

“It also involves cultivating collaboration and communication among project stakeholders.”

“These factors are essential for navigating project intricacies and successful project delivery.”

Sydney Trains suburban network

zentrak CONNECTING EVERYTHING

The intelligent, conscious and living railway ecosystem

The voestalpine Signaling Group offers innovative drive, locking, and detection technologies as well as signaling systems for all types of rail transport. Together with customized solutions in the areas of diagnostic and monitoring technology, asset management, and axle counting systems, we enable sustainable performance optimization of your rail infrastructure and fleet. Through intelligent digital solutions, we create the foundation for modern track management with zentrak, in line with our brand promise: “Performance on Track®”.

voestalpine Signaling www.voestalpine.com/railway-systems

Condition Monitoring and Asset Management

Keeping rail running: The power of automated inspections

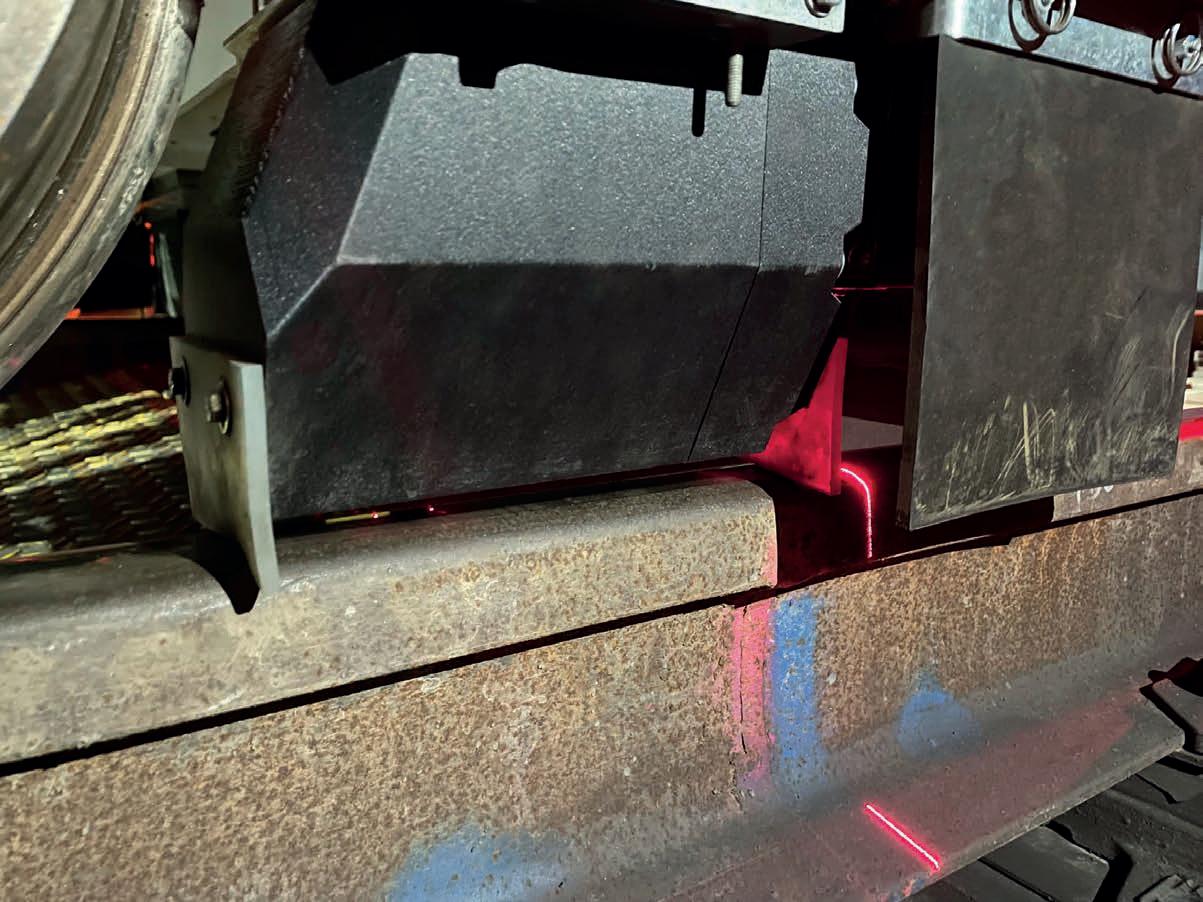

Siemens Mobility shares the benefits of its high-tech

Vehicle Equipment Measurement Systems

In today’s fast-paced and resourceconstrained rail industry, operational efficiency and safety are paramount.

Every minute counts – with passengers depending on rail operators to get them to work on time, and mining operations relying on trains as a critical cog to turn over billions of dollars a year.

Rail operators face increasing pressure to maintain service reliability while managing costs and workforce limitations. This challenge is compounded by rising maintenance demands and a global shortage of skilled labour.

In Australia, according to the Australasian Railway Association’s ARA Skills Report from 2024, approximately 34 per cent of the rail workforce is aged over 50 years, with the projected experience gap expected to reach 63,000 people by 2026.

Across the rail industry, operators are also faced with the challenge of rising maintenance needs for existing infrastructure that is beyond its end of life due to investment limitations and increased pressures on rail systems.

Automated vehicle inspection systems have emerged as an innovative, vital

(VEMS).

a data-driven approach to improving maintenance processes. These solutions are typically installed on or beside the track and will use technology such as measurement and visual cameras, lasers, and sensors to perform roll-by checks of vital fleet components, such as wheels, brakes, and current collectors. This offers depots critical insights into the condition of their fleet –every time a vehicle rolls by.

These automated vehicle inspection systems, like Vehicle Equipment Measurement Systems (VEMS) developed by Siemens Mobility, are helping operators to improve safety outcomes as well as save time, money and resources.

VEMS are supported by a comprehensive Data Management System (DMS), complete with a measurement database, as well as facilities for analysing, viewing and exporting the data collected. This empowers operators with on-demand access to essential measurement data, and in-built alerts to ensure issues can be addressed as they occur.

We spoke to Franziska Renault, Head of Operations for Automated Measurement Solutions at Siemens Mobility, to find

THE BENEFITS OF AUTOMATION

Scheduling inspections and maintenance based on time or distance is still a rail industry norm – but it doesn’t have to be.

By automating inspections, operators can inspect their fleet every time a vehicle rolls past the automated inspection system. This allows operators to closely monitor the wear and tear of assets, transitioning from interval-based to condition-based maintenance.

“With interval-based inspections, operators are often replacing components before they need to,” Renault explained. “With VEMS you can see exactly how much wear there is and only replace parts when necessary.”

“Brake pads and wheels in particular can create a lot of costs for operators, so it’s a big benefit to be able to extend their lifespan.”

Reducing maintenance and the need for manual inspections also means the trains don’t need to go to the depot as often.

“If you’re manually inspecting each train and carrying out maintenance that might not even need to be done, you’re taking up valuable time and space in the depot,” Renault said.

“You’re also reducing fleet availability.”

“With VEMS the trains are only going into the depot when they need to be there, which is a game-changer.”

VEMS can also help operators to streamline their maintenance teams’ workflow.

Renault said there is a global skills shortage in the rail industry, particularly for more blue-collar work like maintenance. Having an automated solution gives operators more flexibility.

“You can plan your maintenance activities in advance, have a scaled-down team and optimise your workforce’s different skillsets,” she said.

“There is less of a need for workers to be on standby or doing manual inspections and measurements as often, if at all.”

In addition, using automated vehicle inspection systems keeps maintenance crews out of harm’s way as much as possible.

VEMS data can be accessed on the go, via a phone or tablet.

crews are working in overhead areas and in areas with high voltages,” Renault said. “Automation can significantly reduce the frequency and need for personnel to be in these areas, meaning rail personnel are safer, with less unnecessary ontrack inspection time, and more time for maintenance and capacity planning.”

“By focusing on the essentials, you can reduce the time workers spend in those zones, which is better for everyone.”

By extending the life cycle of components, VEMS also reduces waste, which can help operators meet their sustainability goals.

Renault noted that optimising the maintenance cycles of a fleet can ultimately lead to fewer trains being needed.

“By having your trains in service as much as possible, you won’t need as many extra trains in the fleet as back-ups,” she said. “That’s the end goal.”

The latest generation of Siemens’ automated inspection solutions are “very easy to install” according to Renault, requiring less than 24 hours of on-track time.

They are also interoperable with other existing systems, and collected data can be accessed from mobile devices for ease of use.

Siemens Mobility has already installed more than 200 automated inspection solutions worldwide, each one in a unique environment that brings different challenges.

“We are working with mining operators in Australia and South Africa, where there are harsh environmental conditions as well as a very high volume of trains and cars,” Renault said.

“We have a customer in the United Kingdom that was the first customer to have five of our latest version installed, that can provide so much data, which is great.

“And we have some of the systems in North America, in a monorail airport environment. Airports, like with some of the big mining companies, operate 24 hours a day, so we’ve had to be very organised and stick to tight deadlines for the installation.”

for each customer, depending on individual requirements.

“We can choose what sort of components they want to monitor, what their use case is, what their pain points are,” Renault said.

“Depending on the year and the model of each train, they have different issues – some older trains, for example, can have ongoing issues with abnormal wear patterns on wheels or brake pads.”

Some operators face high penalties if they don’t bring out enough trains in the morning, as it has a big impact on their operations.

Renault said these operators value the time-saving that VEMS offers, as well as optimising their maintenance planning.

For large mining operators, with heavy haul trains stretching several kilometres, she said automation is an obvious choice.

“It can take hours to inspect the length of the train – imagine if someone had to physically measure all those wheels.”

With manual measurements, errors are more likely, which can also cause safety problems.

“Manual measurements aren’t as reliably accurate – there will always be small deviations depending on who is measuring, where the start point is and where the end point is.”

“Some of our customers have had our automated inspection solutions installed for 25 plus years now, and the wealth of accurate information they have is amazing.

“If anything were to go wrong, you’d have a perfect record of how certain components of your fleet have developed. There is so much value in having a complete, clear, accessible overview of all your data.”

Renault said a major advantage of Siemens Mobility being a global company is the depth of knowledge and experience it has acquired over the years.

“Siemens Mobility has been an integral part of the railway industry for a long time,” she said.

“We have experts all over the world that we can get advice from, discuss use cases

and pain points with, and it’s all very open and supportive because we’re all one company.”

USING ARTIFICIAL INTELLIGENCE

VEMS are supported by a comprehensive data management system (DMS), complete with a measurement database as well as facilities for analysing, viewing and exporting the data collected.

Meanwhile, Siemens Mobility’s camera-based inspection system picks up external issues with the train.

“Using Artificial Intelligence (AI) and machine learning, it detects whether anything is missing from the train, if anything is dragging or if there are any issues such as graffiti, stains, opened doors, or misaligned torque indicators,” Renault said.

“The cameras are installed around the track, which can be modified, to see 90-, 180-, 270- or 360-degree views of the sides undercarriage, or top of the vehicle or both.”

THE FUTURE OF AUTOMATED INSPECTIONS

Looking to the future, Renault expects exciting developments in the use of AI in automated inspections.

“I think we’ll see some gamechanging advancements in our AI feature detection,” said Renault.

“There are a lot of developments going on in that area – and the more data we get from our customers, the more we can fine-tune our algorithms and work towards 100 per cent accuracy.

“It seems like every week it’s

VEMS uses cameras, lasers, and sensors to perform roll-by checks of vital fleet components.

Automated inspections help operators to boost safety and save time and money.

Building the #NextGenRailways of tomorrow

Contract Works insurance: Getting it right

Austbrokers City State Rail shares the importance of Contract Works insurance, and how working with an experienced broker could save businesses from devastating losses.

When it comes to carrying out construction on a multi-million or billion-dollar rail project, the stakes are high.

From natural disasters and flooding to power outages and accidents, things can –and do – go wrong.

Contractors need to have the right insurance or pay the price, and that price could easily be an eye-watering figure.

As Brian Barreto, Director of Austbrokers City State Rail, explained: “If you’re doing a $10 million package of works on a $1 billion project, and that project has an excess of $2 million, that’s the excess you are exposed to.

“Your profit margins aren’t going to cover that. It can be crippling for a business.”

So, what kind of insurance do you need for contract works, what exactly is covered, and how can you make sure you’re not overlooking anything important?

Barreto and his colleague Kyla Parry, another experienced broker from AB City State Rail, tell us more.

WHAT IS CONTRACT WORKS INSURANCE?

Contract Works insurance covers work completed under contract – this could be a rail contractor delivering a package to build a certain length of rail or upgrade a train station, for example.

It covers all physical loss or damage during the contract period, unless something is specifically excluded.

The policy will typically provide cover for risks throughout Australia, including offsite storage and inland transit risks (up to a specified limit). It usually covers losses from the start of the contract until work is completed, as well as some time after that,

which is known as the “maintenance period” or “defects liability period”.

Parry said: “Cover during the defects liability period is limited to losses occurring as a result of something that happened on the site during the construction period, or losses which are the result of the contractor complying with its defects liability obligations.”

WHO NEEDS CONTRACT WORKS INSURANCE?

Any party who is carrying risk, either contractually or otherwise relating to works under contract, needs to take out Contract Works insurance.

This includes the Principal [the party that initiates/funds the project], head contractor, project managers, construction managers and all contractors and subcontractors.

It may also include consultants, manufacturers and suppliers (in regard to their on-site activities).

Typically, subcontractors would be insured under the head contractor’s policy, but Barreto said this is not always the case.

“We have seen examples where head rail contractors will try to push it down the line, because they have poor loss histories,” he said.

“Say there was a washout, you would then have four different contractors involved and four different insurers.

“That creates quite a segmented approach to insurance, which can be difficult to overcome in a claim situation.”

Barreto advises that the head contractor procures the insurance and ensures all subcontractors are covered.

For larger and more complex projects, the Principal may choose to effect the insurance – particularly where there are a large number of contracts being performed or the Principal’s future revenue stream could be impacted if the project is delayed due to loss or damage during construction.

If there are lenders involved, the lender’s agreement often requires that the Principal

effect and maintain the insurance. No matter which party effects the insurance, the policy will cover all parties to the contract, to avoid each party having to effect insurance and apply the cost to its contract price.

Parry added that all insured parties need to make sure they get a full copy of the policy document and keep it on file so they can make a claim directly if necessary.

THE SUM INSURED

The sum insured on the policy should be the contract value – which is the maximum exposure to loss at the time “immediately prior to practical completion” of the work.

The policy will usually contain a clause which allows for an increase to the sum insured of 15 per cent from the estimated contract value.

“If you sign a contract for $100 million, more often than not, that contract value is going to creep up over time,” Barreto said.

The policy will also include cover for various extra costs (over and above the contract value) which could crop up, such as removal of debris, consultants’ fees, expediting expenses, plans and documents and continuing hire fees.

“As an example, if you’re building a section of rail and there’s heavy rain and a washout, the insurance would cover the rectification, replacement and removal of the damaged section,” Barreto said. “If you wanted to hire additional staff to reinstate the works more quickly, or you had specific materials needed to air freight in, there’ll be a limit under the policy that allows you to do that.”

In the event of a claim, the insured will have to pay a policy excess/deductible. This will be a set amount that forms part of the policy terms and conditions. There may be a range of policy excesses applying to different types of loss.

HOW AUSTBROKERS CAN HELP

Austbrokers City State Rail boasts a team of expert brokers specialising in Contract Works insurance.

Barreto and Parry have a combined 40+ years’ experience within the industry with majority of their tenure working within the construction and rail sectors. Other members of the team also have extensive experience in the industry.

“Frontline brokers often struggle because they’ve got to be a specialist in everything,” Parry said.

“For us, it’s easy to navigate the complexities, because we’ve been doing Contract Works insurance for a long time and we know what to look out for.”

Austbrokers City State Rail also has strong relationships with insurers, which comes with several benefits.

“One – we get pricing benefits,” Barreto said. “Two – we get flexibility with underwriting criteria.

“We have millions and millions of dollars with Australian insurers, so where they might decline other brokers, they are more inclined to help us out.”

Barreto said Austbrokers’ flexibility when it comes to underwriting criteria should not be underestimated, especially when it comes to multi-million-dollar projects, where the risk is too large for one insurer to

Olivia Falconer, Brian Barreto, Kyla Parry and Jessica Dimoski from Austbrokers City State Rail.

“For us, it’s about attention to detail. It’s about fighting for our clients and not rolling over. That's what we're here for.”

Brian Barreto, Director of Austbrokers City State Rail

take it on individually.

“If that is the case, we need to build a program that could involve up to seven insurers,” he said.

“What we basically do is source it from the market. We get an insurer to lead the program, and then we approach other insurers to build 100 per cent security to service that risk.

“So, the client might have several different insurers, but they only receive one piece of paper that says they are covered.”

Because Austbrokers City State Rail specialises in the construction space, they know and understand exactly how to structure an insurance program and present the risks in the right way.

Austbrokers customers also benefit from special manuscript wordings, which provide “more generous and broader” coverage than the standard policy wordings that you would get through other brokers.

“We have agreements with all major insurers in Australia and the United Kingdom, to write Contract Works and liability risks on the basis of these specialist policy wordings,” Barreto said.

“We might use the same insurance company as another broker, but we have very specific wordings that we use, with all the little one percenters that go in the way of the client.”

Enhancements that come with Austbrokers’ specific wording include Additional Cost of Working (ACOW), which provides additional expenses to prevent delays to a project which would typically be excluded under a consequential loss exclusion.

“Customers also benefit from the inclusion of hold harmless agreement, inflation protection costs, and waiver of subrogation, just to name a few,” said Parry.

“They make a pretty significant difference for our customers.”

STANDING UP FOR THE CLIENT

Barreto said he and the other brokers at Austbrokers don’t back down when it comes to getting a fair payout for their clients.

He gave an example of a claim lodged by one of their customers, where a retaining wall structure collapsed after heavy rain.

After carrying out an investigation, the insurers partially declined the claim, saying that the retaining structure failed because of faulty design (under LEG2 provision).

“I think it was about a $10 million loss in total,” Barreto shared. “We didn’t believe the insurer had taken a fair view. Working with the insured, we engaged our

own engineers and hydrologists. It was discovered there was actually a spring under the retaining wall, which nobody could have reasonably known about through normal geotechnical investigations.

“This spring activity contributed to the loss, and we were able to successfully renegotiate the position with insurers.”

After this, the loss in its entirety was paid to the client – a difference of $1.5 million between the partial decline and full settlement.

“For us, it’s about attention to detail. It’s about fighting for our clients and not rolling over. That’s what we’re here for.”

Flooding is a major risk along some rail corridors.

Condition Monitoring and Asset Management

A smarter solution: zentrak

How zentrak, voestalpine Railway Systems’ integrated solution for infrastructure and rolling stock monitoring and asset and maintenance management, is helping operators make better decisions.

In an era of increasing urbanisation and a growing demand for freight, Australia’s rail operators are facing unprecedented challenges.

The rising demands on rail infrastructure and the requirement for 24/7 availability have led to more maintenance and higher life cycle costs.

In order to remain competitive, operators must optimise efficiency and safety while cutting unnecessary spending.

It's why, according to John Smith, Senior Vice President Sales and Marketing for Digital Track Solutions at voestalpine, they are turning to zentrak, voestalpine Railway Systems’ ecosystem for monitoring and asset and maintenance management.

With three integrated modules – Rolling Stock Monitoring, Infrastructure Monitoring, and Asset & Maintenance Management –zentrak allows operators to develop and manage productive, reliable and highperforming networks.

THE NEED FOR CHANGE

Australia is one of the most urbanised countries in the world, with over 86 per cent of the population living in urban areas.

“This is a rising trend globally and nowhere more so than here in Australia, so there are more and more people requiring urban transport networks in Australia’s cities,” said Smith. “Freight is another big area of growth – it is increasingly being

moved from road to rail, which is far more environmentally sustainable.”

“Operators are not able to build new railways at the same speed that demand is growing, so they need to run more passenger and freight trains on existing infrastructure.”

As a result, operators are facing a double challenge.

“You need to do more maintenance because you’re using the infrastructure more intensely than it was designed to be used, but at the same time you’ve got less opportunity to carry out the maintenance because you have more trains running,” he said.

“There needs to be a way of changing traditional ways of maintaining rail infrastructure, and that’s where zentrak comes in.”

A SMARTER SYSTEM

zentrak is an intelligent diagnostic and monitoring system that records the condition of assets, facilitating life cycle management at the push of a button.

It paves the way for operators to move from traditional, interval-based maintenance to modern predictive maintenance.

Smith said zentrak is easily installed and can be configured to the needs of the customer.

“Using a modular approach, a range of sensors are installed at trackside locations,” he explained. “We can focus on the biggest pain points for operators, which are usually turnouts and point machines – where a disproportionate amount of maintenance spend goes.”

Highly customisable functions in zentrak allow it to meet clients' precise needs – from data acquisition to reporting.

zentrak aims to transform traditional railway systems into proactive, predictive, and prescriptive ecosystems.

Images:

voestalpine Railway Systems

The solution improves maintenance planning, reduces on-track crew requirements, and optimises management and spare parts logistics.

As an example, Smith said an advanced sensor could be fitted to the crossing point of a turnout, otherwise known as the frog.

“That sensor will essentially listen to the characteristic signal of a train passing over, and determine if there’s a deterioration in the crossing or if it’s wearing down.”

If any deterioration is detected, an email or SMS alert will be sent to the customer.

“They can then access the system and peel back the layers of detail, consider what’s going on, and use that information to make a decision on what action they are going to take,” said Smith.

“The system is available on mobile phone or tablet, and a lot of maintenance teams use that functionality because they are remote or on the go.

“Looking at the same data set as someone in the control centre, they can have a conversation about the next steps.”

By detecting failures before they happen, operators are able to run safer, more efficient networks.

“Obviously if something fails in service, it’s a disruptive event.

"Very often, you have to stop trains, you have to send a mobile team, and they could

be travelling a long distance to get there. If we provide advanced information, it gives operators the benefit of being able to plan their maintenance.

“You are moving from a ‘find and fix’ approach with manual inspections to a ‘predict and prevent’ approach, which reduces the number of failures that the network will see.”

This also reduces the need for crews to be out on the track, which has a number of benefits.

“The largest category of injury in the rail industry is slips, trips and falls,” Smith said. “Network maintenance often happens at night, so you have crews of people walking around in the dark, potentially on wet wooden sleepers.

“The fewer boots on the ballast, the less the risk of injury.”

zentrak supports operators by giving them a whole-of-life asset management solution, using the advantages that come with digitising infrastructure to create a more cost-effective approach.

It performs advanced analytics, looking at trend data to predict how much use is left before an asset will need to be maintained or replaced.

This means assets aren’t replaced before they need to be, saving operators money.

On the other side of the coin, it means operators can intervene in emerging situations before it’s too late.

“Where you’ve got a degradation in performance, there’s normally a way of detecting it,” he said.

“If our monitoring system suggests that an asset is deteriorating slowly, and may fail in six months, you could schedule maintenance to take place at the same time as another planned intervention.

“If the degradation is much faster, our system will warn that a failure is going to occur much sooner – and you need to carry out maintenance now or you’re in trouble.”

With the Asset and Maintenance Management component of zentrak, operators start with what is essentially a digital twin of an asset as it comes out of the factory.

voestalpine Railway System, which is a leading manufacturer of turnouts, has adopted zentrak Asset and Maintenance Management in its factories, and encourages its customers to use it also.

“When we ship that physical turnout, we can also ship the digital information file that goes with it, which has all of the parameters that the turnout was designed for.

“It's got all the serial numbers for all the components that make it up. So it's a full digital passport that goes with the turnout.”

Smith said that because condition monitoring is integrated in zentrak with asset maintenance management, over the life cycle of the asset, it can compare its as-is condition with its ideal condition as installed.

“With traditional methods, you might replace a turnout after 20 years. It could still be perfectly functional, and you don’t know because you don’t have condition monitoring.

“Or it could have worn out three years earlier, and it’s cost you a fortune to keep it alive when it couldn’t be kept alive.”

Smith said asset management follows the “iceberg model” and operators need to move away from the idea that the purchase cost is the most important consideration.

“About 20 per cent of the cost of an asset is the bit that’s sticking out of the water –the installation cost.

“The other 80 per cent, the part that’s below the water, is the cost of owning and maintaining the asset through its life cycle.

“Operators need to look at the whole life cycle cost and see what opportunities there are to be more efficient.”

Condition Monitoring and Asset Management

Green light for targeted rail maintenance

Vossloh’s smart HSG-city grinding machine is revolutionising rail maintenance. Business Development and Operations Manager Mathew Waterhouse explains.

As urbanisation expands, it’s pleasing to see a rapid, almost exponential increase in passenger numbers on public transport. However, it’s also a trend that poses a challenge for network operators in many respects.

In order to be able to absorb the increase in passenger numbers, operators are having to increase service frequencies and lengthen schedules. What’s more, the track network must be more efficient and, if necessary, extended and modernised.

This inevitably increases both the scope of the maintenance required for the infrastructure and the frequency of the necessary measures.

At the same time, the time windows for inspection and maintenance measures are becoming shorter, which further increases the complexity of maintenance.

With our smart HSG-city grinding machine, we are revolutionising rail maintenance. While the High Speed Grinding (HSG) technology enables grinding at speeds of up to 60 kilometres per hour within timetable, the integrated sensors ensure that the condition of the rails is continuously recorded.

In addition to the complete transverse profile (including rail head deviation, wear and tear and the longitudinal profile for corrugation identification), the track gauge, track position and possible deformations are also recorded by sensors.

In tramway networks, the groove depth is also measured by the non-contact optical measuring system with fully integrated laser triangulation sensors. As soon as the measurement is triggered, the odometer starts, which ensures that the location is accurate to the metre. In addition, global navigation satellite systems (GNSS) support the position determination.

After each measurement run, the collected data is pre-processed and uploaded to Vossloh’s innovative mapl-e application, gradually creating a digital twin of the network that the customer can access from any end device.

The track condition recorded is displayed in traffic light colours for a simplified

assessment – “good”, “bad” or “critical”. Asset managers can incorporate their own preferences or threshold values via variable tolerance bands.

At the same time, mapl-e supports the minimally invasive implementation of measures during operation, as the measured sections are divided into several treatment sections depending on the type and depth of the fault. Track sections to be treated can be

prioritised and corresponding activities – for example, for sustainable noise reduction –can be planned in a targeted manner.

Before and after comparisons from mapl-e show the effectiveness of the grinding measures on the first autonomous metro system in the Sydney metropolitan area.

The now cyclical grinding campaigns are intended to keep the roughness of the rails at an acoustically acceptable level.