VOLUME 117/11 | DECEMBER 2025

INDUSTRY INSIGHT

PROSPECT AWARDS

AUSTRALIAN POWER EQUIPMENT LEADS THE CHARGE IN MINING ELECTRIFICATION

PAUL HAYES paul.hayes@primecreative.com.au

VOLUME 117/11 | DECEMBER 2025

INDUSTRY INSIGHT

PROSPECT AWARDS

AUSTRALIAN POWER EQUIPMENT LEADS THE CHARGE IN MINING ELECTRIFICATION

PAUL HAYES paul.hayes@primecreative.com.au

As Australia’s mining sector continues to evolve, electrification is becoming one of the most significant forces shaping the industry’s present and future.

Mining operations have long relied on diesel-driven trucks, high-heat processing plants, and remote infrastructure to extract and process critical resources. Today, however, a new generation of battery-electric vehicles, electric motors and integrated energy systems is transforming the way mines operate, making them cleaner, safer and more efficient.

As companies seek to decarbonise, the transition to electric power is a business move as much as a sustainability one. Mines that adopt electrified equipment can reduce operational emissions, lower noise and particulate pollution, and improve on-site working conditions, all while maintaining or improving productivity.

The combination of electrification and renewable energy systems, particularly solar and wind in remote regions, offers not only emissions reductions but potential operational cost savings and greater energy independence.

The benefits extend beyond environmental. Electrified machinery has fewer moving parts, which can reduce maintenance requirements and increase equipment availability. Energy management systems and microgrids paired with battery storage are allowing mining operations to optimise loads, reduce fuel logistics, and improve resilience against supply disruptions..

But the transition is not without challenges. High upfront capital costs, the need for charging infrastructure, and grid limitations in remote areas require careful planning. Yet collaboration across the mining and equipment technology sectors is helping to overcome these barriers.

CHAIRMAN JOHN MURPHY

CHIEF EXECUTIVE OFFICER CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

Email: paul.hayes@primecreative.com.au

ASSISTANT EDITOR

ENGEL SCHMIDL

Email: engelbert.schmidl@primecreative.com.au

COVER IMAGE: Australian Power Equipment

Industry groups and consortia are sharing best practices, developing interoperability standards, and scaling up solutions that make electrification both practical and sustainable.

Viewed through a straightforward lens, electrification presents a strategic opportunity for Australia. Global buyers and investors increasingly prioritise low-carbon supply chains, giving mines that adopt electrification a competitive advantage in securing offtake agreements and investment. Moreover, as mining operations electrify, the local mining equipment, technology and services (METS) sector grows in importance, creating opportunities for Australian companies to supply the technology and expertise needed to support the global energy transition.

The momentum behind electrification signals a broader transformation in how Australian mines operate. By integrating battery-electric vehicles, electric motors and advanced energy systems, operations are becoming cleaner, more efficient and better able to manage energy use. This shift is helping miners reduce emissions, optimise costs and improve resilience, benefits that extend from remote outback operations to major processing hubs.

Electrification is becoming a core component of modern mining strategy. Mines that adopt these technologies are positioning themselves for long-term competitiveness in the global market. The choices made today will shape operational efficiency and Australia’s ability to supply the minerals critical to a decarbonised world.

Paul Hayes Managing Editor

BUSINESS DEVELOPMENT MANAGERS

by industry veterans who bring deep roots in power generation, utilities, resources and infrastructure, APE delivers tailored, safe and cost-effective equipment and engineering solutions across Australia. It combines technical know-how with pragmatic service: whether sourcing critical transformers, switchgear or energy systems, its aim is to get a job done on time and on budget, with safety and reliability front of mind. At the heart of APE is its commitment to innovation, sustainability and community. The company believes every project is an opportunity to do things better, reducing environmental impact, supporting regional capability and lift local communities.

Cover image: Australian Power Equipment

JOURNALISTS

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

PAUL HOWELL

Email: paul.howell@primecreative.com.au

BEN CARTWRIGHT

Email: ben.cartwright@primecreative.com.au

ETHAN BENEDICTO

Email: ethan.benedicto@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

JAMES PHIPPS

Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN

Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION

At Hastings Deering, businesses working within the mining industry can now take advantage of a new industry leading warranty with every Cat® Certi ed Rebuild. Get ‘as-new’ performance and bene t from the multiple lives designed into Cat machines, at a fraction of the cost of buying new.

8 INDUSTRY INSIGHT

From coal to critical minerals

A new chapter is unfolding in the Latrobe Valley, where Latrobe Magnesium’s new technology has propelled the region from a coal-fired past to a critical minerals future.

10 ELECTRIFICATION

Mining’s electric revolution

From battery-powered haul trucks to all-electric underground fleets, electrification is rapidly reshaping the way Australia mines.

12 ELECTRIFICATION

Powering the future of mining

With deep technical expertise and a sustainability-driven approach, Australian Power Equipment is redefining how mines harness electricity for safer, cleaner, more efficient operations.

24 DECARBONISATION

Partnerships power Real Zero push When it comes to climate commitments, Fortescue is showing that heavy industry can decarbonise profitably and rapidly.

56 INDUSTRY EVENTS

Ambition and action

26 INDUSTRY INSIGHT

Ore and order Australian Mining spoke to an economist to examine the nature of recent iron ore negotiations between BHP and China.

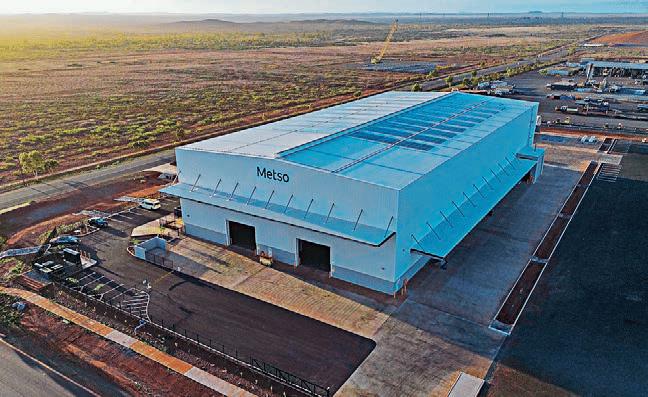

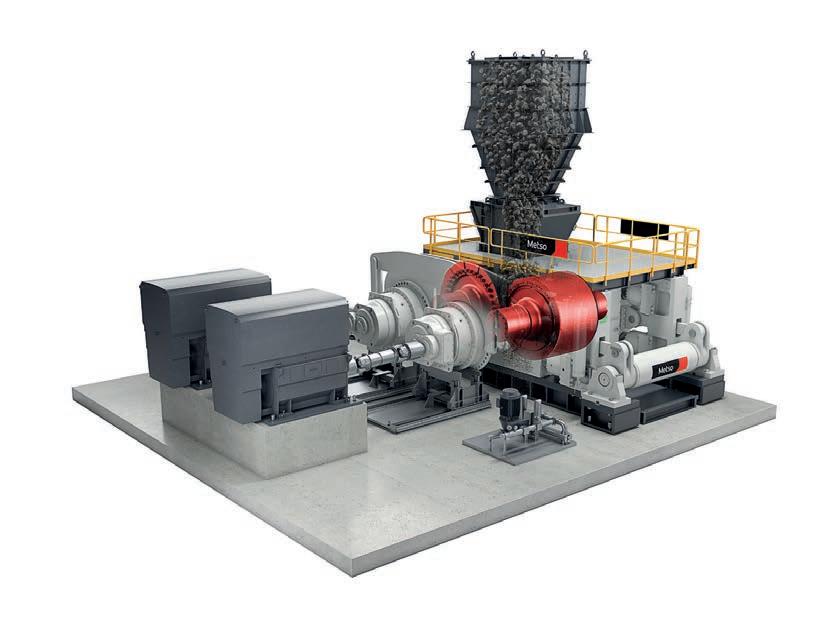

36 CRITICAL MINERALS

From ore to opportunity

Metso’s David Tulloch, Duncan Wyatt and Guillaume Lambert discuss the company’s innovations and the buzz around critical minerals.

The recent WA Mining 2025 showed technology’s time has well and truly arrived.

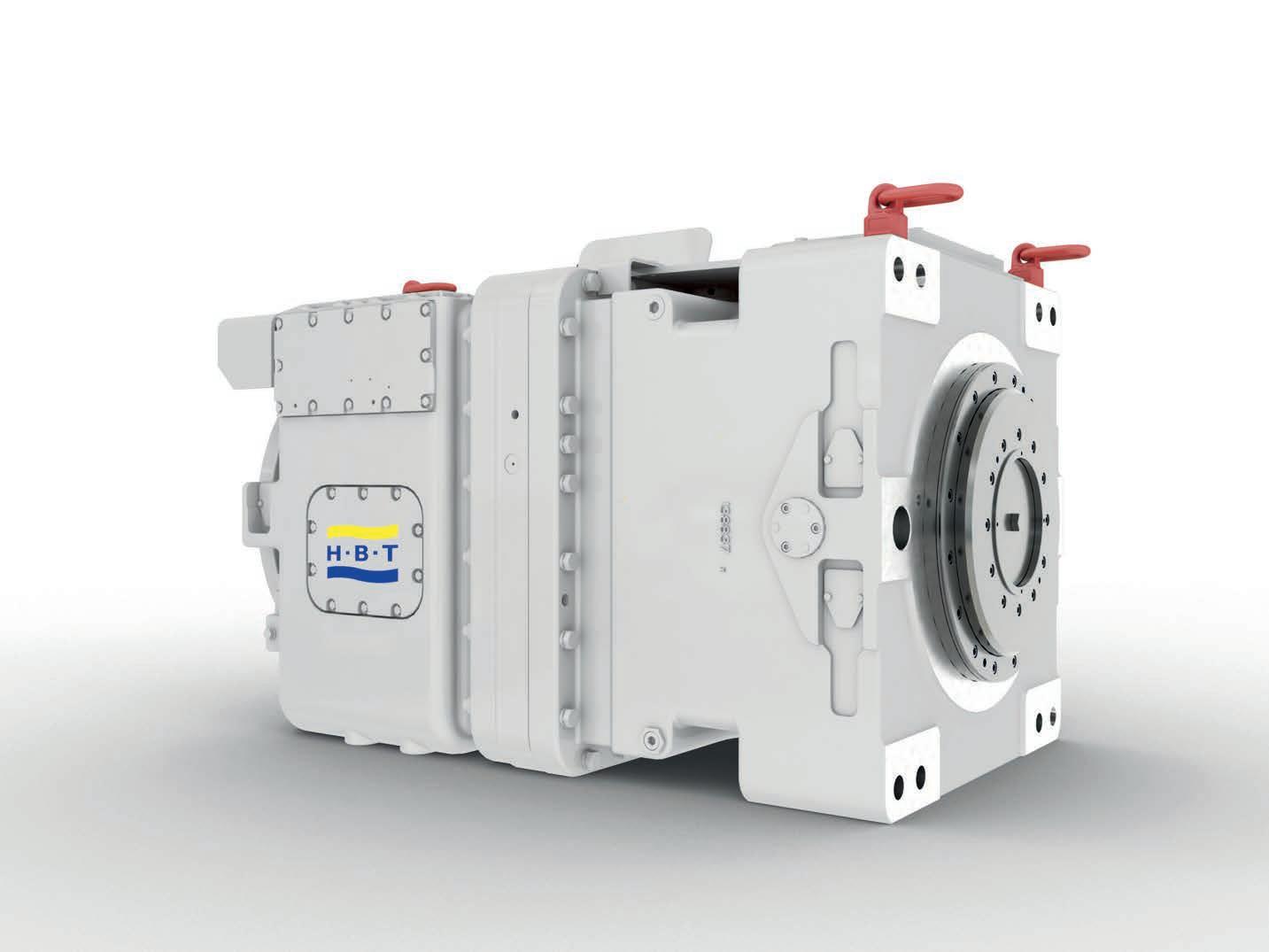

68MACHINERY

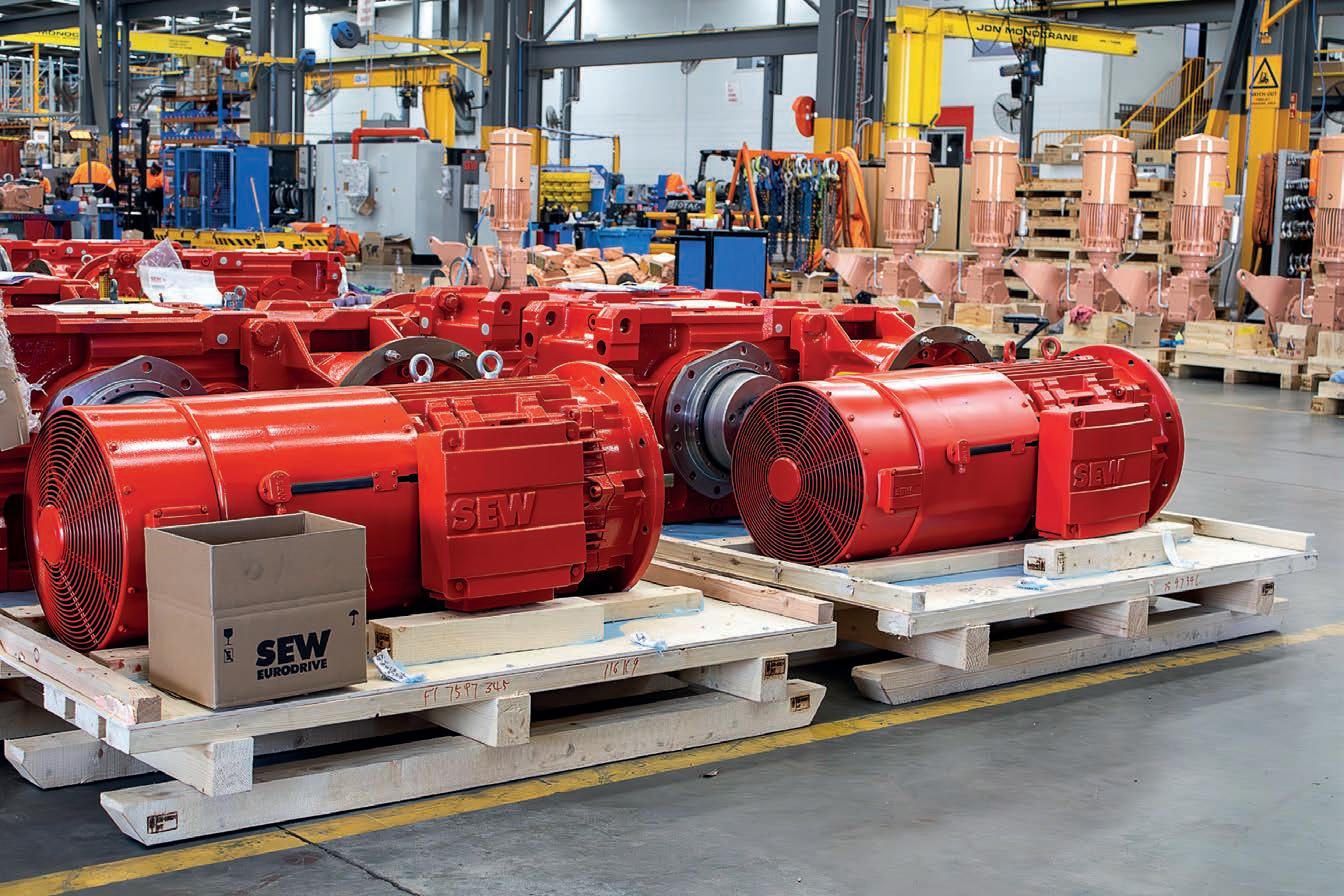

Mastering industrial gear service

SEW-EURODRIVE is redefining what longterm support looks like for industrial gear systems across Australia.

70 PROSPECT AWARDS

Ushering in a new era

The mining sector is no stranger to accolades, but the 2025 Australian Mining Prospect Awards carry a significance beyond celebration.

SACOME’S CEO NICOLA MCFARLANE SAT DOWN WITH AUSTRALIAN MINING TO DISCUSS HOW SOUTH AUSTRALIA’S MINING SECTOR IS UNIQUELY POSITIONED IN THE GLOBAL ENERGY TRANSITION.

With the mining sector looking to a more sustainable future, South Australia sits at the forefront of a rapidly developing industry.

Described by the State Government as at the “vanguard of the global energy transition”, SA has lifted its net electricity generation from renewable energy from one per cent to 74 per cent in just over 16 years.

This is just one of the reasons, according to one of the state’s leading industry bodies, SA’s infrastructure is “ready for the charge”.

“This is a huge opportunity for the state to benefit from what is specific in the ecosystem and environment here,” South Australian Chamber of Mines and Energy (SACOME) chief executive officer (CEO) Nicola McFarlane told Australian Mining

“We have all the puzzle pieces lining up – wind, solar, natural resources –and it’s allowed us to move quickly to providing renewable support.

“We have world-class copper and iron ore resources, including magnetite, to support the transition to green iron. The state is not only endowed with copper and magnetite but is rich in uranium, silver, gold and other critical minerals needed for the transition.

“We already have the key elements to enable a resilient resources sector to underpin South Australia’s longterm prosperity.”

McFarlane was appointed interim CEO of SACOME in August, having spent two decades leading highimpact projects and organisations in the global energy transition in Australia and the UK.

These include managing largescale hydrogen and decarbonisation efforts as the chief operating officer of the Office of Hydrogen Power in South Australia and as the Director for

McFarlane’s career began in oil and gas, where she provided safety and risk management advisory. The diversity of opportunities, she said, is what drew her to a career path in engineering and ultimately led her to become a leader in the global energy transition, working to support heavy industry.

“My background made it easy to transition to support the decarbonisation of the mining and energy sector. Here in South Australia, we are at the forefront of renewable energy generation and maximising the benefit of our natural and mineral resources to help decarbonise the planet.” McFarlane said.

“South Australia’s potential aligns with my purpose and drive to

support the realisation of the energy transition and achieving net-zero emissions globally.”

The ResourcefulSA campaign, in market since early 2024, is intended to educate and inspire the SA public about the fundamental role mining plays in everyday life.

The campaign also demonstrates how the resources sector is needed to support decarbonisation, whether it is copper for electric vehicles or silver for solar and iron for green steel production.

“It is important for the community to understand the role the resources sector plays in enabling us to prosper in a decarbonised economy,” McFarlane said.

This, McFarlane said, is just the start of the journey for SA, with SACOME’s priorities extending beyond the facilitation of the energy transition to focus on the future prosperity of the state.

“The focus for the sector is still on the enablers of energy security, infrastructure, regulation, community trust and workforce development,” she said.

“There is no doubt that resilient and focused collaboration not only within the sector but between the resources sector and government has the potential to drive progress, unlock new value, and shape the future of sustainable practices for the advancement of the sector.”

A NEW CHAPTER IS UNFOLDING IN THE LATROBE VALLEY, WHERE LATROBE MAGNESIUM’S NEW TECHNOLOGY HAS PROPELLED THE REGION FROM A COAL-FIRED PAST TO A CRITICAL MINERALS FUTURE.

It’s a long way from Victoria’s Latrobe Valley to Washington, D.C. – both geographically and industrially.

Not far from the site of the former Hazelwood Power Station, Latrobe Magnesium (LMG)

24/7 OPERATION

energy transition.

But in October, the Latrobe Valley and Washington, D.C. crossed paths in a moment that could reshape a region and a resource.

From the historic Lafayette Building, just around the corner from the White

landmark US–Australia critical minerals framework agreement.

The LOIs were extended to seven Australian companies: Arafura Rare Earths, Northern Minerals, Graphinex, VHM, RZ Resources, Sunrise Energy Metals, and LMG.

work we’ve put in,” Paterson told Australian Mining. “We were there [in Washington] alongside the big companies like Alcoa, Nyrstar and Iluka. I think the smaller companies like ours got picked on the back of what they produce and how they produce it.”

The recognition underscores the strategic importance of magnesium, and the unique position LMG occupies within that market. China currently produces about 90 per cent of global magnesium. Russia contributes another six per cent, with the balance coming from smaller, less reliable sources.

With magnesium crucial to lightweight alloys, green manufacturing and defence applications, the US has every reason to diversify supply. The metal was added to the US critical minerals list in 2018 and remains there today.

Australia currently imports all 8000 tonnes of the magnesium it consumes each year. The country’s Critical Minerals Strategy 2019 did not initially include magnesium, but the 2023 update identified it as an emerging mineral of interest.

Paterson said interest in LMG stems from three key factors: magnesium’s importance to advanced manufacturing; China’s dominance of the market; and the scarcity of reliable Western producers. That interest, however, would count for little if LMG was not delivering results. The company has spent years on research and development, refining its processes and progressing to the point where it can now reliably produce a commercially viable product.

“Firstly, it’s a good product,” Paterson said. “We’re using a completely new process; no one anywhere else in the world is close to what we’re doing.”

LMG’s patented hydrometallurgical

extraction and thermal reduction process extracts magnesium metal from fly ash generated by brown-coal-fired power stations, including the nearby Yallourn power station, which has enough fly ash to supply LMG for up to 50 years of operation.

The low-emission process converts almost 100 per cent of the ash into saleable materials, producing valuable by-products such as supplementary cementitious material (SCM), silica and iron oxide. In simplified terms, the process involves dissolving magnesium, iron and calcium minerals from fly ash using acid, removing impurities, and converting the resulting magnesium solution into magnesium oxide (MgO). The acid is recovered and reused, creating a circular system.

In 2024, LMG produced its first MgO from brown-coal fly ash at its 1000-tonnes-per-annum (tpa) demonstration plant in Hazelwood North, a landmark that validated the hydromet process and confirmed its potential to reduce production costs and emissions by up to 60 per cent.

Paterson recounted the whirlwind year that brought LMG to the attention of Washington.

“We put in a [US] Department of Defense whitepaper back in June, and we spoke to probably 50 Pentagon people in one sitting,” he said.

“Then there were more meetings with the Department of Commerce.”

That exposure ultimately opened doors to some of the world’s largest industrial manufacturers.

“We spoke to all the majors when we were there: Lockheed Martin, Boeing, GE, Raytheon, and others,” Paterson said. “After I spoke, they all just came and grabbed me and asked when they could come down to see our plant.”

As one of the only new Western producers of magnesium, LMG’s progress carries global weight.

“There’s a small producer in Israel with pollution problems, and another in Turkey but they’re not expanding and it’s done in a very archaic way,” Paterson said.

LMG’s next step is to build a 10,000tpa commercial plant in the Latrobe Valley, leveraging its breakthrough technology and materialhandling systems to achieve globally competitive costs and low emissions.

In the longer term, the company has partnered with Bechtel to plan a 100,000tpa international magnesium mega-plant using ferronickel slag feedstock, with Malaysia emerging as a likely location. The favoured site – Samalaju Industrial Park in Sarawak – offers access to hydroelectric power, potentially enabling fully renewable operations.

LMG has already completed the first phase of a pre-feasibility study for this project and signed a binding memorandum of understanding with Société Le Nickel (SLN) to supply 450,000 tonnes of slag per year over

20 years. The company is now seeking joint-venture partners to bring the project to fruition within five years.

The EXIM LOI has significantly raised LMG’s profile, as well as its credibility among institutional investors looking for sustainable producers in high-growth markets.

On the back of that support, the company can now accelerate its expansion plans, a welcome development for the company and a region preparing for the closure of the Yallourn power station in 2028 and Loy Yang in 2032.

Paterson said construction of the demonstration plant employed about 100 locals, directly and through contractors, and he hopes LMG’s next stages can deepen that impact.

“We want to make sure it stays as local as we can,” he said. “We’re very mindful of locals and our place in the region, and we’ve talked directly to green groups in the Valley. We discussed emissions and everything else. We had no objections at the EPA and none locally, which is amazing for any project of our size and what we do.”

Forecasts for sustained demand for magnesium are consistent across analysts. IndustryARC projects the global magnesium metal market will reach $US9.12 billion by 2030, growing at around 6.7 per cent annually. Coherent Market Insights forecasts almost $US10 billion by 2030, tracking almost 10 per cent annual growth.

SUSTAINABLE

None of these projections come as a surprise to Paterson.

The tight-knit LMG team set out on this path almost two decades ago and has faced more than a few setbacks along the way. But through it all, the company maintained faith in its technology and in the future of magnesium.

“We’re very much long-term focused, and that’s why we’ve taken it slow,” Paterson said.

Following the announcement in Washington, momentum is building for LMG as it prepares for what looks to be an accelerated phase of growth, and a new chapter for the Latrobe Valley. AM

ELECTRIC MACHINES CAN RESULT IN COSTS SAVINGS, AS WELL AS REDUCTIONS IN EMISSIONS.

FROM BATTERY-POWERED HAUL TRUCKS TO ALL-ELECTRIC UNDERGROUND FLEETS, ELECTRIFICATION IS RAPIDLY RESHAPING THE INDUSTRY.

The mining industry is entering an era of transformation. For Australia’s resource sector, which has long been defined by diesel-driven trucks, high-heat processing plants and remote operations, electrification offers a platform for growth, efficiency and reduced carbon emissions.

Turning that opportunity into reality means embracing a new generation of equipment, systems and energy-management strategies. The result is mines that are cleaner, safer and more productive.

Electrification matters because mining remains a source of direct emissions in Australia.

Skills, systems and infrastructure built on decades of operation now face a new imperative to reduce emissions while maintaining output. As mines look to decarbonise fleets,

processing circuits and energy systems, electrification becomes a sustainability statement and a business differentiator.

By swapping diesel haul trucks for battery-electric alternatives, replacing engine-driven hydraulic plants with electric motors and integrating renewables with on-site batteries, mining companies are positioning themselves for a low-carbon future.

One of the values of electrification is that the technology has matured enough to shift from pilot to deployment.

For example, at the Yandi mine in Western Australia, BHP deployed an electric excavator in 2024 to test the viability of replacing diesel machinery in its iron-ore operations.

The R 9400 E Liebherr electric excavator, wired to a trailing cable and deployed at Yandi, reflects BHP’s strategy to decarbonise equipment and diesel use at its WA Iron Ore operations.

That deployment is part of a broader trend. Joint studies such as the partnership between IGO, Perenti and ABB have confirmed the technical feasibility of an all-electric underground fleet in Australia, showing that batteryelectric vehicles can match diesel equipment productivity at cost levels that are not prohibitive.

“We believe in a cleaner energy future, and that extends to our underground mining operations, where the electrification of our fleets will create a safer, greener and more productive operation,” IGO head of technical services Chris Carr said.

These kinds of statements help to highlight the fact the industry understands that, beyond reducing emissions, electrification is about safety, productivity and economic resilience.

Electrification at Yandi is moving from concept to commercial pilot. The operation’s shift to its first

electric excavator was accompanied by infrastructure upgrades and a focus on data and systems that support electrified equipment in remote environments. The aim is to displace diesel use, improve safety underground or in isolated locations, and develop the learning curve across heavy-duty equipment.

This example shows is how a large miner uses electrification strategically, as part of a broader conversion of systems, power supply, energy management and operational planning. With diesel the biggest remaining source of operational emissions, BHP is treating electrification as a necessary innovation for their future.

The pilot at Yandi allows the company to de-risk new technology, build workforce capability and create a roadmap for deeper electrification across its portfolio.

While reducing emissions is often the headline, and with good reason, parallel benefits flow from electrification.

Battery-electric vehicles and electric motors produce lower noise, fewer particulate emissions and less on-site heat, all of which helps to improve working conditions. Maintenance regimes are simplified, mechanical complexity falls and downtime linked to traditional powertrains tends to decline.

For remote operations, which are often reliant on diesel logistics and expensive fuel delivery, electrified systems offer cost resilience and supplychain independence.

Australia’s abundant renewable resources add further upside. Mines located in remote zones benefit from high solar and wind potential, enabling hybrid or micro-grid solutions that pair renewables with battery storage and electrified mobile fleets. Converting a diesel haul truck to electric in the Australian context can not only lower emissions but create better cost outcomes. That combination of economics and sustainability is proving especially compelling.

Of course, the full transition is not without hurdles. The upfront capital cost of electrified machines and charging infrastructure remains higher than legacy equipment, and access is absent or expensive in many remote locations grid. Battery lifecycle management, infrastructure for fast charging and second-life use remain nascent.

Operationally, mines must rethink fleet scheduling to consider charging times, thermal management, availability and integration with production plans.

However, industry players are forming collaborations to accelerate progress. The Electric Mine Consortium, formed by major mining and equipment companies in Australia, promotes a shared approach to electrification, interoperability of systems, and scaling of fleet conversions. These partnerships help spread risk, accelerate learning and align standards for emerging technology. That common approach is critical when comparisons between diesel and battery systems still dominate decision-making.

Viewed through a national lens, electrification presents Australia’s resource sector with a powerful lever for competitiveness.

Global buyers and investors increasingly evaluate the carbon intensity of supply chains, preferring raw materials that align with decarbonisation pathways. Mines that can demonstrate lower emissions can potentially access better offtake terms, preferential finance and stronger reputational standing.

Electrification can also go a long way in strengthening the domestic value chain. As more mines adopt electric equipment, the local mining equipment, technology and services (METS) sector grows in significance.

Australian firms designing chargers, battery systems, vehicle conversions and

energy-management software are well placed to export expertise and to build an industrial capability aligned with the global clean-energy transition.

Electrification also supports regional jobs, upskilling and a diversification of mining roles. Where dieselmachinery mechanics once dominated, electric-power systems technicians, battery-maintenance specialists and digital-control operators now emerge. That shift helps to ensure that mining continues to contribute to regional resilience and skill development, not just commodity extraction.

Electrification will not be uniform across all operations: geography, commodity type, power infrastructure, site layout and mine lifespan will shape the speed and sequence of adoption.

Some sites might begin with underground light-vehicle conversions or ancillary equipment; others may tackle haulage trucks or processing circuits. What matters is that the direction is clear.

For Australia’s mining industry, the next few years will be pivotal. With pilot phases reaching maturity, standards being set and investment flowing, the sector is entering a moment where electrification becomes scaled and mainstream, not experimental. Mines that act early are more likely to embed cost savings, build workforce capability and position themselves as low-carbon suppliers in a changing global market.

Electrification is more than an environmental statement; it is a strategic advantage. For Australia’s miners, the transition to electric power is unlocking safer workplaces, leaner operations and greater export relevance.

The future of mining is not just about is dug out of the ground. It is also about how the industry powers the machines that extract it and the systems that refine it. Australia is beginning to write that future now. AM

STUDIES HAVE CONFIRMED THE TECHNICAL FEASIBILITY OF AN ALL-ELECTRIC UNDERGROUND FLEET IN AUSTRALIA.

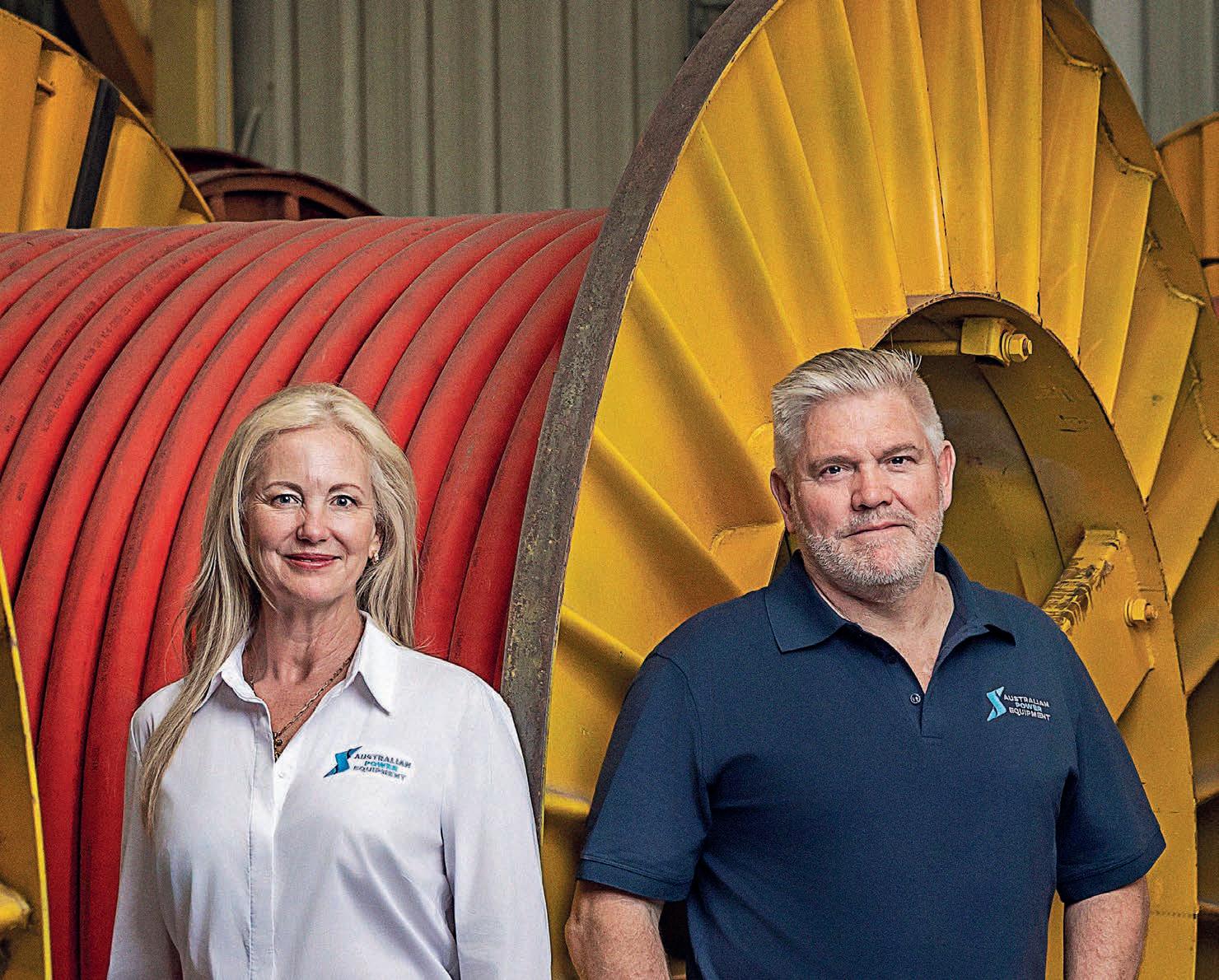

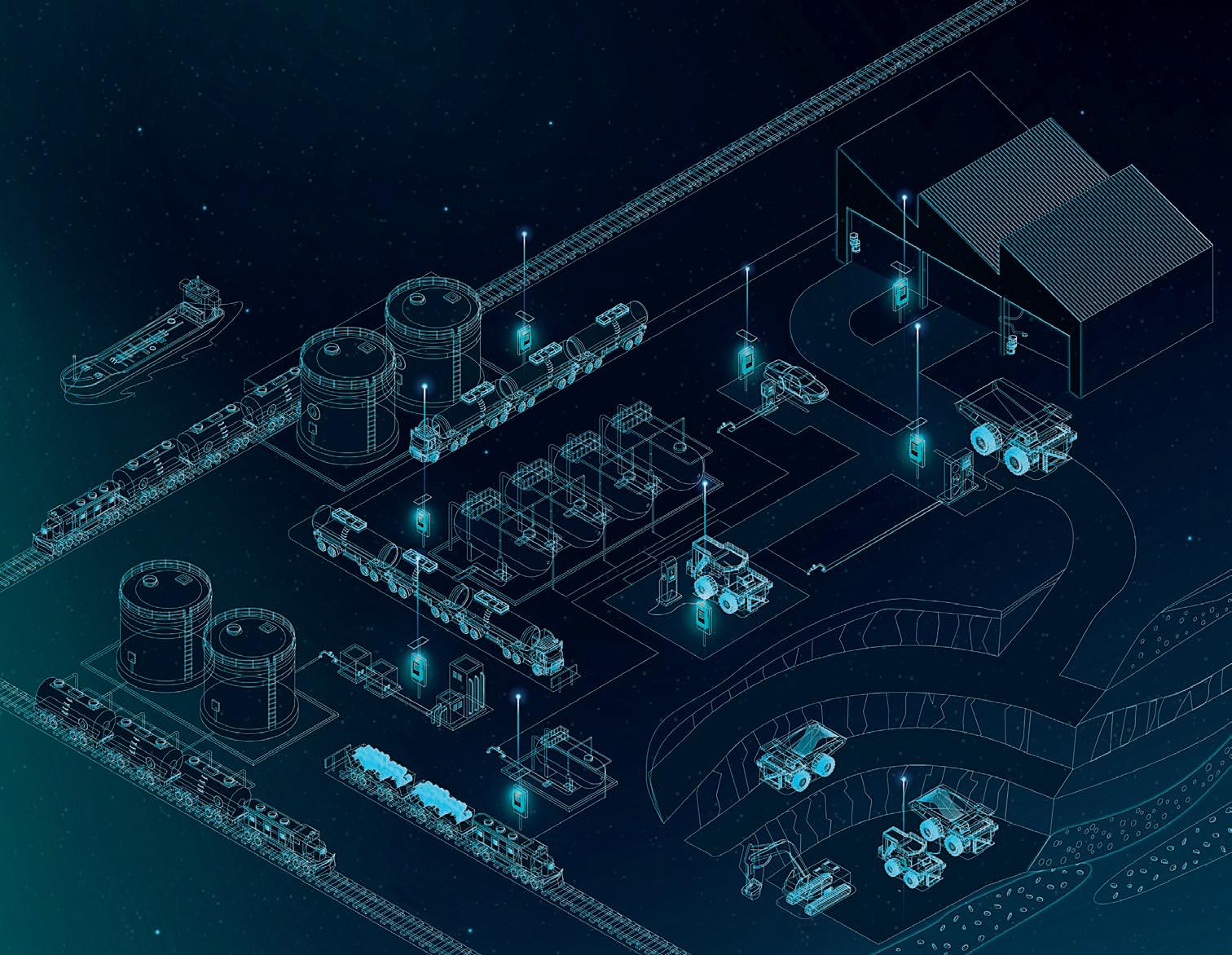

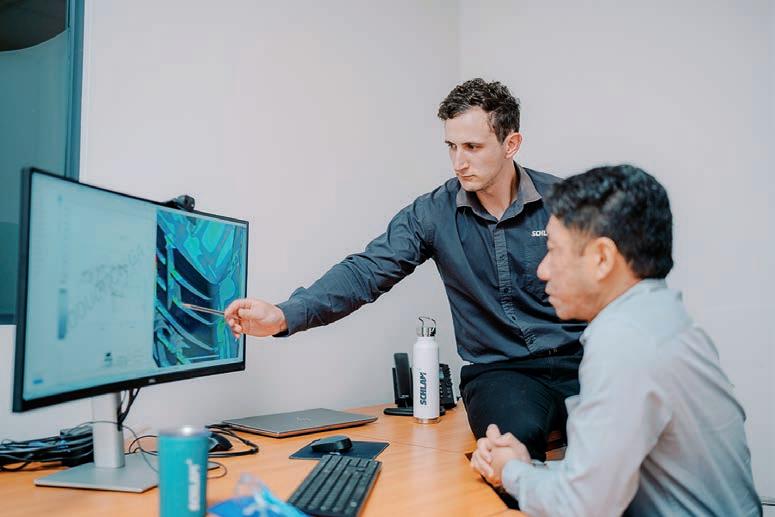

As the mining industry accelerates towards a low-emissions future, electrification has become the cornerstone of operational transformation, delivering cleaner, safer and more efficient power to some of the world’s toughest environments.

At the forefront of this shift is Australian Power Equipment (APE), a trusted national supplier delivering the electrical backbone that powers open-cut and underground operations.

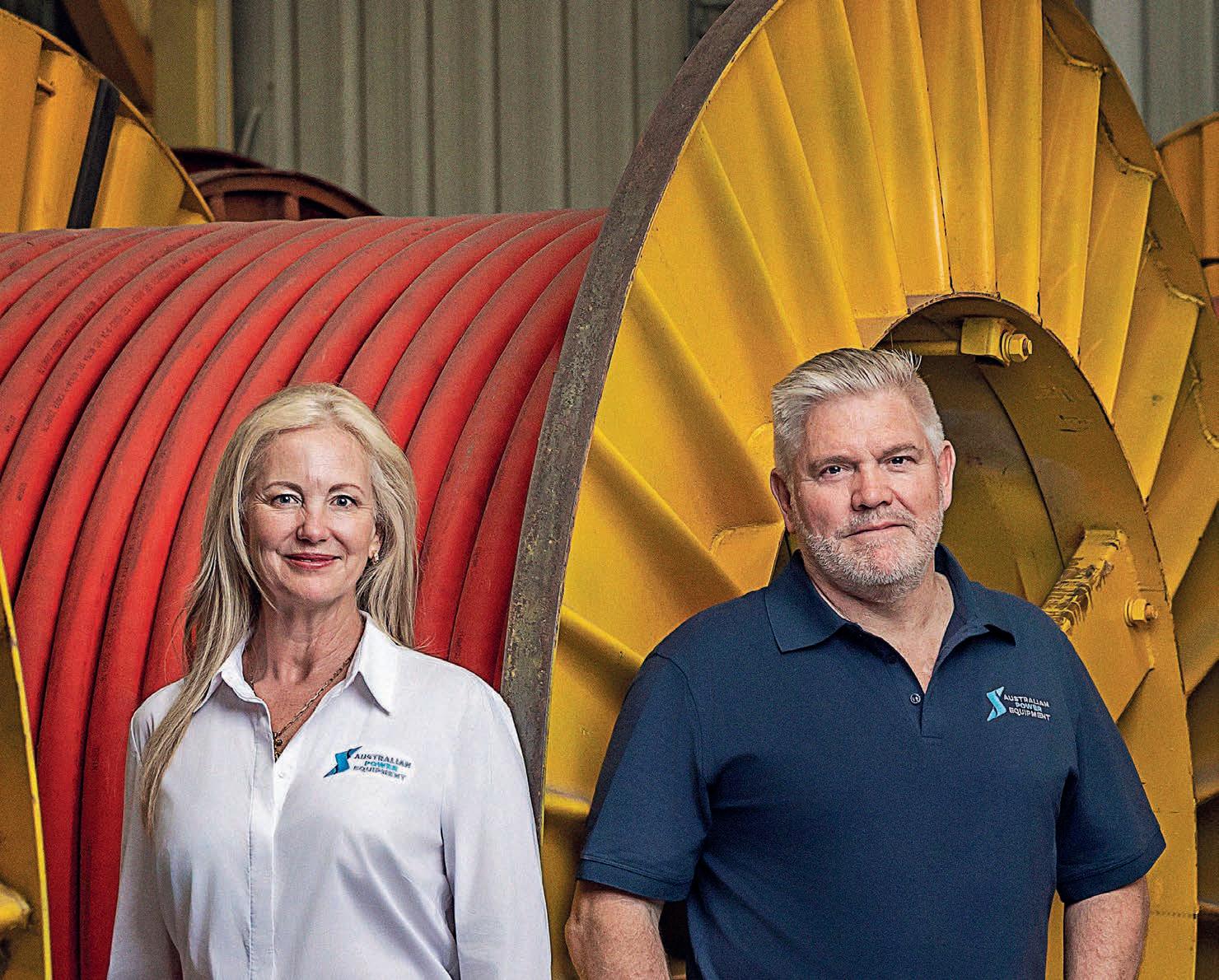

Founded by co-directors Abby Crawford and Andrew Cockbain, APE has rapidly grown to become one of Australia’s most recognised suppliers of high-voltage power equipment and infrastructure solutions. The business has earned national recognition, including being ranked 45th in the 2024 AFR Top 100 Fast Starters, by combining deep technical

expertise with a sustainability-led approach to equipment supply and lifecycle management.

From its base in Newcastle, APE provides transformers, switchgear, substations and high-voltage cable systems to clients across mining, tunnelling, renewables, agribusiness and defence sectors throughout Australia and around the world.

What sets APE apart is its dual capability to supply new and refurbished power equipment, enabling rapid response to critical site needs while advancing circular economy goals that reduce waste and extend asset life.

“Our business was built on reliability and responsiveness,” Cockbain said. “In mining, downtime costs are immense. Our job is to keep operations powered safely and continuously, whether that’s through fast-tracked sub-stations, reengineered transformers or complete cable reticulation systems.”

ELECTRIFICATION … MEANS BUILDING A COMPLETELY NEW ELECTRICAL ECOSYSTEM, ONE THAT’S ROBUST, SAFE, EFFICIENT AND ENGINEERED TO HANDLE THE UNIQUE CHALLENGES OF REMOTE AND HARSH MINING ENVIRONMENTS.”

Powering the next frontier

With Western Australia leading the global charge towards mine electrification, APE’s expertise in surface electrical systems that power underground networks has become increasingly vital.

The company’s cable reticulation systems form the arterial network that distributes energy from sub-stations to electric machinery operating kilometres below the surface, a critical link in achieving emissions reduction without compromising productivity.

“Electrification doesn’t just mean swapping out diesel machines for electric ones,” Crawford said.

“It means building a completely new electrical ecosystem, one that’s robust, safe, efficient and engineered to handle the unique challenges of remote and harsh mining environments.”

APE’s expertise has been forged through decades of hands-on experience

across Australia, Asia Pacific, the UK and Sub-Saharan Africa.

The company’s leadership team has played an instrumental role in the electrification of large-scale operations across the southern African mining belt, developing, specifying and supplying electrical infrastructure for both electric rope shovels and electric hydraulic excavators.

This international background underpins APE’s approach to today’s mining projects, ensuring the systems designed for WA’s electrification drive are informed by proven field performance under extreme conditions.

Key achievements by APE’s team and leadership include specification development for sub-stations, switching stations and cable systems suited to tropical and remote environments; supply of high-capacity sub-stations (including dual 10–1MVA 33/6.6kV units) for electric shovel and mine

power distribution; development of medium- and high-voltage cable systems to enhance operational flexibility and equipment availability; training frameworks and operational systems to increase cable life, improve safety and optimise machine uptime; and cable selection, handling and management procedures that reduce risk and extend asset reliability.

These initiatives have laid the foundation for APE’s leadership in modern mining electrification projects, helping Australian operations adopt the next generation of electric mining fleets with confidence.

APE’s cable management philosophy is underpinned by one principle: sustained performance relies on intelligent design and disciplined practice. The development of correct cable selection, handling and management systems, as well as the development of integrated electrical protection and relay systems, is not merely an operational detail, but rather the backbone of mine safety, availability and energy efficiency.

As mines scale up electrification, the demand for higher voltage distribution and longer feeder runs introduces complex challenges in thermal loading, protection coordination and mobility.

APE works closely with engineering partners, original equipment manufacturers (OEMs), and site maintenance teams to deliver fully integrated solutions that encompass substation design, switching infrastructure,

reticulation layouts, and custom cable systems, all built to withstand Australia’s most demanding conditions.

“Electrification will reshape the way mines think about energy,” Cockbain said. “It requires the same engineering precision as the machines it powers. Every cable run, sub-station and connection must work seamlessly to deliver reliable energy underground.”

Beyond engineering excellence, APE continues to drive sustainability through

initiatives such as APE LOOP, a circular economy framework that promotes refurbishment, repurposing, and recycling of high-voltage equipment.

The company also supports wildlife conservation programs with Aussie Ark and Taronga Conservation Society, reflecting a belief that industry progress and environmental protection can, and must, coexist.

“Our commitment to sustainability isn’t just about compliance,” Crawford said. “It’s about leadership, proving that the electrification of mining can

reduce emissions, extend asset life, and contribute to a more sustainable energy future.”

From surface sub-stations to underground reticulation systems, APE is helping mines across Australia and beyond navigate the path to full electrification safely, sustainably and intelligently.

As the industry redefines what it means to be powered by electricity, APE stands ready to deliver the systems, expertise and vision that keep the future of mining switched on. AM

THE MINING INDUSTRY’S JOURNEY TO ACHIEVE NET-ZERO IS UNDOUBTEDLY A CHALLENGE, BUT IT’S ONE XCMG AUSTRALIA IS TACKLING HEAD-ON.

The Australian mining industry is at a crossroads.

Environmental responsibilities and the pursuit of efficiency are converging and the industry is entering a transition phase; dieselpowered heavy mobile equipment (HME) still plays a key role, but battery electric technologies are paving the way for a cleaner, more sustainable future.

Yet making that transition in Australia, home to some of the world’s harshest mining environments, is far from simple.

XCMG Australia is tackling this challenge with bold innovation, precision engineering, and a clear mission to deliver zero-emissions HME that not only meets but exceeds the performance miners have relied on for decades.

The reality of going zeroemissions

thick dust and rugged terrain, running for up to 20 hours a day while hauling enormous loads.

Battery performance is the first major hurdle. Even the most advanced lithium-ion must balance energy density, weight and durability. Oversized batteries compromise mobility, while underpowered systems risk downtime that can cost millions.

Then comes charging infrastructure.

Remote mine sites are often off-grid, and recharging massive haul trucks isn’t as simple as plugging in overnight.

Rapid recharge cycles, reliable energy supply and precise scheduling are critical, otherwise productivity declines and downtime equals lost revenue.

Integrating zero-emissions equipment into existing mine fleets adds another layer of complexity. Modern mining operations are intricate ecosystems of machines, software and logistics. New technology must integrate seamlessly

modular maintenance, operators and technicians must be retrained to ensure reliability and uptime.

Facing these challenges, XCMG Australia said it is “rewriting the rulebook” with a holistic approach that combines engineering excellence, smart systems and operational support.

XCMG’s zero-emissions HME is powered by advanced battery technology and intelligent energy management systems that extend

extreme Australian conditions, maintaining performance where it matters most – on the ground, in demanding, continuous operations.

But a single electric machine doesn’t change an operation; an intelligent fleet does. XCMG’s zero-emissions HME integrates directly with central fleet management systems, enabling real-time health monitoring, automated charging schedules, and performance optimisation across the entire site.

This connectivity allows mining companies to plan workloads, manage power distribution, and keep every machine operating at peak efficiency.

Reliability also remains nonnegotiable in mining, and XCMG has

engineered this into every stage of its zero-emissions design.

Each machine is equipped with predictive diagnostic tools that identify potential issues before they cause downtime. Modular component designs simplify servicing, and maintenance programs are tailored to ensure consistent, long-term performance.

Technicians are trained to manage and optimise new technologies, helping to ensure fleets remain productive, efficient and safe, even in the harshest conditions.

Innovation at every level XCMG believes a proactive approach to innovation is what sets it apart. Rather than waiting for problems to arise, the company anticipates them, developing solutions that make zero-emissions mining practical and profitable.

From enhanced cooling systems and energy-efficient drivetrains to digital monitoring and data analytics, every feature is designed with the goal of making zero-emissions equipment not just viable but superior.

XCMG leverages its worldwide research and development (R&D) capabilities while customising each solution to suit Australia’s unique mining landscape of high temperatures, long haul routes, and remote operations.

While mining remains a cornerstone of the Australian economy, it is also under increasing scrutiny. Governments, investors and communities are demanding tangible progress toward decarbonisation.

XCMG’s zero-emissions fleet offers transformation in addition to compliance. Cleaner air, quieter operations and reduced reliance on fossil fuels are, according to the company, “just the beginning”.

For mining companies, the benefits extend to improved worker safety, reduced maintenance costs, and greater operational resilience. For the planet, it represents progress toward sustainability.

By combining technological strength with local insight, XCMG is proving that environmental responsibility and productivity are not opposing forces but rather partners in the future of mining.

The shift to zero-emissions mining is a strategic evolution that will no doubt take years of innovation and adaptation.

But XCMG said it is already a leader on that journey. Every challenge

overcome, every new model introduced brings the industry closer to a future where zero-emissions HME is the standard, not the exception.

The technology exists. The strategy is in motion. And the results are real.

With XCMG Australia driving this transformation, the path to sustainable mining is no longer a distant vision; it’s happening right now.

The future of mining is here. And it’s electric. AM

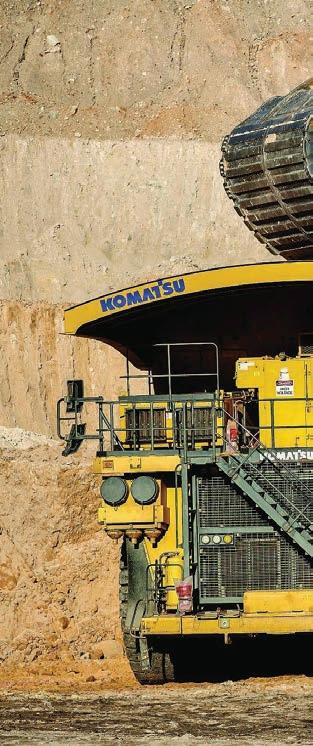

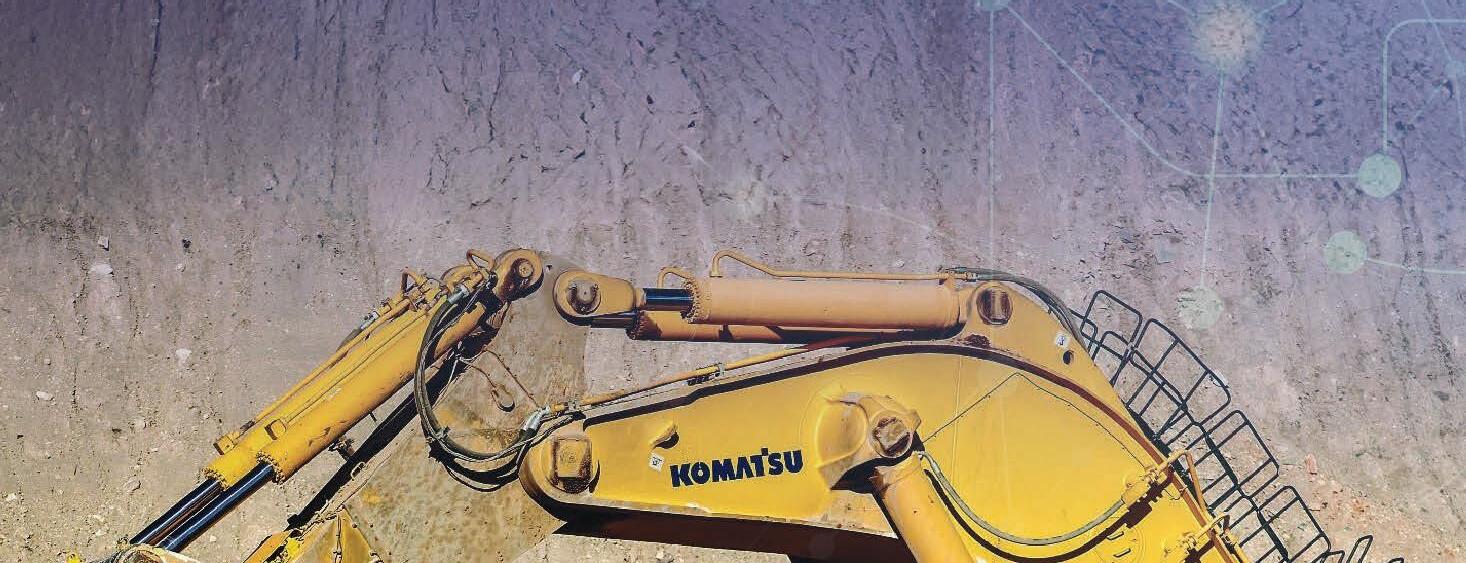

KOMATSU CONTINUES TO SET NEW STANDARDS FOR FUEL EFFICIENCY AND PRODUCTIVITY WITH THE NEW PC950-11.

Komatsu is changing the game in large-scale earthmoving with its new PC950-11 hydraulic excavator, now rolling out across Australia and New Zealand. Built for the toughest mining and quarrying conditions, the machine combines raw power with smarter efficiency and enhanced safety, giving operators an edge in even the most demanding environments.

At a time when operators are under pressure to cut emissions, manage fuel costs and improve productivity, Komatsu’s latest release offers a compelling combination: up to 48 per cent greater productivity while consuming up to 40 per cent less fuel than its predecessor, the PC850-8E0.

Komatsu Australia national business manager for construction excavators Mark Boyes said the PC950-11 has been built from the ground up to meet operator feedback.

“Our development teams took this customer feedback on board and delivered more power, increased dig forces, greater drawbar pull, superior durability, easy safe access and surround visibility systems, all while maintaining ultra-low fuel consumption,” he said.

“It’s designed to handle Australia and New Zealand’s toughest conditions, while helping our customers run more efficient, sustainable operations, whether that be on mine sites or in quarry operations.”

Driven by a 405kW (543HP) Komatsu SAA6D140E-7 engine, the PC950-11 combines brute strength with smart technology.

The machine offers three selectable work modes (P+, P and E), allowing operators to prioritise power or fuel efficiency depending on the task. In its high-performance P+ mode, the machine achieves top productivity, while E mode delivers strong fuel savings without sacrificing output.

A redesigned hydraulic system with an electronically controlled closedloop swing circuit enables independent control of swing and digging operations, resulting in smoother handling and reduced fuel consumption.

Enhanced cooling performance through a larger core and optimised airflow helps to ensure reliability even in extreme temperatures common on Australian mine and quarry sites.

Weighing between 94–99 tonnes and capable of carrying buckets from 4–6 cubic metres, the PC950-11 is built for heavy-duty excavation.

Reinforced booms, arms and undercarriages provide durability, while rock protection, internal welds and partition walls in high-stress areas enhance longevity. Maintenance has also been simplified with ground-level refuelling, walk-through catwalks, longlife filters and extended service intervals.

Komatsu’s KOMTRAX Plus system provides real-time monitoring of machine health, including alerts such as hydraulic filter clog detection to prevent costly downtime.

Recognising the industry’s focus on safety and skilled operator retention, Komatsu has equipped the PC950-11 with a suite of advanced features.

The standard KomVision 360° camera system offers full surround visibility, while LED lighting, wide catwalks and a hydraulically operated access stairway enhance on-site safety.

Inside the cab, comfort and ergonomics take centre stage. A high-back air suspension seat with heating, automatic climate control and reduced lever operation force help operators remain productive and alert during long shifts. The cab is highly rigid and acoustically insulated, reducing fatigue and improving overall working conditions.

Digital tools such as a large highresolution LCD monitor display machine data and camera feeds simultaneously, while ECO guidance

features coach operators on achieving optimal fuel efficiency.

These innovations are designed to not only enhance the operator experience but also contribute to lower total cost of ownership through smarter, more efficient operation.

Boyes said the PC950-11 represents more than just a power upgrade; it’s a step forward in sustainable, operatorfocused design.

“This excavator is not just about power,” he said.

“Every feature has been designed with the operator in mind, from safety and comfort through to lower total cost of ownership.

“We believe the PC950-11 will quickly become the new benchmark for large-scale earthmoving in Australia.”

With its combination of cutting-edge engineering, fuel-saving systems and operator-first features, the Komatsu PC950-11 delivers a clear message: heavy equipment can be powerful and responsible. AM

At Australian Power Equipment (APE), we deliver more than high-voltage power solutions – we deliver peace of mind. From brand-new transformers to expertly refurbished equipment, we help industries stay switched on with smarter, faster, and more sustainable options.

Our circular economy model means we don’t just supply power—we give old equipment new life. By refurbishing quality assets from decommissioned sites, we minimise waste, reduce lead times, and keep urgent projects moving. It’s better for business and better for the planet.

But our commitment doesn’t stop there. We actively support wildlife conservation and rewilding efforts across Australia –because powering progress should never come at the cost of our environment.

With a nationwide network and a lean, responsive team, APE sources and delivers critical equipment when and where it’s needed most. Whether it’s mining, infrastructure, or renewables, our clients trust us to keep operations running and downtime to a minimum.

Backed by decades of experience and a clear vision for the future, we’re proud to be shaping a more sustainable tomorrow.

AGENTS FOR

As mining operations decarbonise, remote microgrids powered by solar, wind and battery storage are becoming increasingly critical to site independence. But while the focus often lands on generation and storage capacity, it is connectivity that in many cases determines whether those systems operate reliably – or fail under pressure.

Unlike urban sub-stations, mining microgrids operate in harsh, often unmanned environments where dust, vibration, moisture and temperature extremes can compromise ordinary networking gear.

Industrial connectivity hardware is designed to ensure every component in the power chain stays online, visible and controllable.

Madison Technologies, a distributor of commercial and industrial technology products, sits at the forefront of ensuring connectivity in the most remote locations. Battery energy storage systems (BESS) with local power sources like solar panels are commonplace in these kinds of mine sites – but with that, industrial-grade networks are needed.

“In rugged environments such as mining, we provide network solutions from our global vendor partners in what we call ‘make, never break’ communication infrastructure,” Madison Technologies chief executive officer Paul Calabro told Australian Mining

and Transport for NSW, and system integrators such as Acubis, Yokogawa and John Holland, Madison Technologies pairs trusted equipment with expert support and tailored services to simplify deployment, enhance performance and deliver resilience across critical environments.

“We’re deploying technology that’s built for harsh environments – vibration, dust, impact, temperature,” Calabro said. “We know that we’re not in suburbia with this infrastructure and it’s imperative we have solutions that are up to the challenge.”

Madison Technologies partners with proven companies in the communications space such as Moxa, Cisco Industrial, Rajant and Teltonika, distributing technology from industrial ethernet switches to wireless mesh networking and 5G gateways for remote access and monitoring.

“One of Madison’s biggest strengths is the depth and breadth of our technology partnerships,” Calabro said. “We’ve built an ecosystem where everyone benefits, from the products and technologies themselves to the local support that backs them. No single manufacturer can deliver a complete, end-to-end level of ruggedness or resilience on their own.

“That’s where we come in. Madison Technologies acts as the glue, as the conduit that connects world-class manufacturers with the specific needs of market sectors like battery and energy

issues of downtime and cybersecurity also must be considered, especially when downtime from failed communications or cyber-attacks could cost a site tens of thousands of dollars every hour.

“Our technology partners have cybersecurity at the core of their technology to ensure that mine sites have peace of mind that networks can’t be attacked or penetrated,” Calabro said.

This and many other situations are front-of-mind when Madison Technologies offers industry training.

“We deliver manufacturer-certified training that helps individuals earn industry-recognised certifications,” Calabro said. “Accredited across all the brands we represent, we’ve trained over 200 professionals this year in industrial communications.

“Demand has grown by around 40 per cent from last year, driven by the

we help build stay connected, secure and ready for whatever comes next.”

Calabro said there are four key pillars that support the mining industry in achieving greater connectivity beyond simply ensuring infrastructure is fit for purpose: industrial connectivity; edge computing; camera as-a-sensor; and industrial internet of things (IIoT)

“Edge computing ensures real-time analytics at the mine site with local data processing capabilities, camera as-a-sensor allows visual monitoring for safety and performance, and industrial IoT gives sensor-based data collection to allow for environmental and equipment monitoring,” he said.

As electrification drives the future of mining, reliability won’t just depend on how much power you can store but on the strength and stability of the networks that connect it.

With connectivity at the core, Madison Technologies helps deliver technologies that stay online, stay visible and stay resilient – no matter how remote the operation. AM

Mining companies across Australia are exploring battery-powered fleets, renewable energy systems and electrified infrastructure as part of their decarbonisation strategies.

Mines can now reduce diesel use through tethered underground loaders, electric drills, cable-electric shovels and even diesel-electric hybrid trucks that can cut fuel consumption by up to 30 per cent.

Renewable energy sources such as solar, wind and battery energy storage systems are being integrated to replace fossil fuel power generation, while modern fleet management systems and artificial intelligence (AI) optimise operations and minimise diesel use.

The economic case is also becoming clearer. Lithium-ion battery prices have fallen significantly over the past decade, reducing capital hurdles, while electric motors offer higher efficiency, faster operation on ramps, lower maintenance costs and quieter, cleaner workplaces.

Underground, electrification can slash ventilation and cooling costs, creating safer, more sustainable work environments.

AS MINERS LOOK TO DECARBONISE, THE NEED FOR KNOWLEDGE OF IMPLEMENTING NEW TECHNOLOGIES IS GROWING.

While these advances are undoubtedly promising, challenges remain. Infrastructure investment, energy storage and process changes are essential, and workforce capability must be developed in parallel.

Upskilling staff members, embedding change-management strategies and fostering a culture open to innovation are critical for successful implementation.

As decarbonisation shifts from a corporate goal to an operational priority, mine electrification has become one of the biggest changes shaping the Australian mining landscape.

For all the discussion around batteryelectric vehicles and net-zero targets, the real challenge lies in turning pilots into fully operational electric fleets without compromising safety, productivity or profitability.

To help the industry take that next step, the Australasian Institute of Mining and Metallurgy (AusIMM) has launched the Mine Electrification Associate Certificate, an online course designed to give mining professionals the knowledge to turn ambition into practical, on-site results.

The program was developed in partnership with Canadian consultancy

Zero Nexus, whose president David Lyon brings years of experience helping mines around the world adopt battery-

“There’s been a lot of innovation on the equipment side, but not enough support for the mine operators trying to adopt these technologies,” Lyon said. “This course is designed to fix that.”

AusIMM head of online education Australian Mining that electrification has emerged as one of the most pressing skill gaps in mining.

“This course came from a clear signal from the industry,” Horden said. “Electrification is no longer a future concept; it’s something mining professionals need to understand and

Mining has always relied on engineering ingenuity, but electrification demands a broader mix of skills that span charging infrastructure, ventilation design and energy management.

The four-module program takes participants through every stage of that journey. It starts with the fundamentals of

how battery-electric vehicles work, their performance characteristics and their impact on mine design, before diving into infrastructure planning, battery safety and organisational transformation. The course is designed for anyone involved in mining operations, from supervisors and safety officers to compliance specialists and strategic planners.

“You don’t need to be an electrical engineer to take part,” Lyon said. “We’ve built this course to be accessible to a wide range of professionals.

“Whether you’re new to electrification or already trialling electric equipment, you’ll find practical value in what we’ve built.”

Delivered entirely online, the program includes around 20 hours of content across virtual classes, study materials and discussions.

Participants who complete the course earn professional development hours and a digital credential recognised across the mining industry.

AusIMM designs new courses to reflect where the industry is heading,

and Horden said the response to the electrification course has already been strong.

“Every year we launch new programs that help professionals build the skills they’ll need for the future. Mine electrification is clearly one of those areas,” he said.

“We already have strong interest and multiple intakes planned annually.”

While technology plays a huge part in the transition, Horden and Lyon agree the human side of change is just as important.

“Underestimating the changemanagement effort is one of the most common mistakes we see,” Lyon said. “Getting your workforce on board early and often is critical.

“Electrification isn’t just a technology shift; it’s a cultural one.”

Zero Nexus’ experience in Canada, where mines have been running electric fleets for more than a decade, forms the backbone of the Mine Electrification Associate Certificate program. Participants explore real-

world case studies that highlight what works, what doesn’t, and how to scale up electrification safely and efficiently.

“We draw on lessons learned from mines that have already gone through it. Someone’s already done that early learning for you,” Lyon said. “We’re bringing that directly into the course so participants can skip the trial-and-error stage and move faster.”

The course also explores topics such as battery lifecycle management, charging infrastructure, and integrating renewable power systems into mine operations.

Lyon said the AusIMM course’s whole-of-system approach what sets it apart.

“Most existing training focuses on operating specific machines,” he said. “Our course looks at the full system, the vehicles, the infrastructure, the safety standards and the people who make it work.”

As electrification accelerates across the sector, there is a growing demand for professionals who can navigate these new complexities. The Mine

Electrification Associate Certificate helps participants develop the technical and strategic understanding needed to lead that transition.

“This course equips professionals to be part of the future, not just reacting to it,” Lyon said. “It’s about helping people build the skills and strategies to make meaningful change.”

For AusIMM, the course reinforces its broader mission to prepare the mining workforce for what’s next.

“We want to make sure the industry has the right mix of knowledge and capability to keep pace with change,” Horden said. “That’s what this course is all about.”

Electrification is a chance to reshape the way mining operates, to create quieter, cleaner and safer workplaces while improving efficiency and sustainability. AusIMM’s Mine Electrification Associate Certificate offers the tools and insight to make that future possible, giving mining professionals the confidence to lead the change from concept to reality. AM

AS THE MINING INDUSTRY MOVES TOWARDS NET-ZERO TARGETS, SOLARH2E IS FOCUSED ON ACCELERATING ELECTRIFICATION AND DECARBONISATION FOR MINERALS HAULAGE FROM PIT TO PORT.

Major strides have been made in just a few years to electrify and decarbonise the mining and transport sectors. One of the areas of focus has been heavy-duty haulage and logistics.

And Solarh2e is helping accelerate this transition.

The company’s mission is to decarbonise industries that rely on pointto-point materials transport, including mining, a sector Solarh2e chief executive officer Richard Zee, a trained geologist and mining veteran, knows well.

“Decarbonisation of open-pit mining can already take place with modular renewables, electric excavators, loaders and dump trucks,” Zee told Australian Mining. “Mine-to-port haulage can also be decarbonised through electric onroad trucks when adequate charging or battery-swap infrastructure is available.”

Strength in partnerships

Solarh2e works with partners across the engineering and energy value chain, – including infrastructure providers, original equipment manufacturers (OEMs), engineering, procurement and construction (EPC) contractors, and financiers – to design and deliver decarbonised haulage solutions.

The company recently announced a landmark partnership with SANY, one

of the world’s largest heavy-equipment manufacturers, to deliver Australia’s first charge and fully automated battery-swap hub for heavy electric vehicles.

“This partnership with SANY marks a major step towards building the backbone of Australia’s zero-emission freight network,” Zee said.

“Together, we’re combining advanced vehicle technology, energy-systems engineering and forward-thinking investment to create a scalable, practical pathway to decarbonisation.”

SANY, which has expanded its Australian presence with new facilities in Sydney, Brisbane, Perth and Melbourne, is ready for the challenge.

“With three models of our electric trucks already ADR-certified, including a 588kWh prime mover and two 85kWh light trucks, SANY is ready to lead the transformation of Australia’s heavy-transport fleet toward zero emissions,” SANY international development general manager Yang Gao said.

Under the new partnership, Solarh2e has signed its first transport operator, which will deploy two SANY trial trucks as part of a framework for 30 trucks in the first year. The initiative will help fleet operators meet environmental, social and governance (ESG) and emissions-reduction targets over the next three years.

Zee said the rollout represents a pivotal milestone in decarbonising Australia’s heavy-transport sector.

“SANY has committed to supporting Solarh2e in energising a first-year target of 30 electric prime movers through our inaugural charge-and-swap

Solarh2e’s rollout strategy combines proprietary hubs with collaboration from third-party infrastructure developers. This hybrid approach ensures accessibility, interoperability and broader network coverage for electric heavy vehicles nationwide.

The company is in discussions with transport infrastructure investors to fund a national network of charge and swap hubs, beginning with a flagship site in Victoria and expanding along Australia’s east coast to connect Melbourne, Sydney, Brisbane and Adelaide.

This rollout is backed by the expertise of Solarh2e’s engineering partners, Shoal Group and Global Power Energy (GPE), providing advanced simulation, systems design and power-integration expertise to ensure reliability and scalability.

“By combining SANY’s proven EV technology with Solarh2e’s infrastructure vision and the expertise of Shoal Group and GPE, we’re building a future-ready solution for sustainable heavy transport in Australia,” Zee said.

By integrating global vehicle technology, local engineering and renewable-energy infrastructure, Solarh2e is delivering more than just a single project; it’s building the foundation for a national zero-emission logistics network.

The new SANY partnership, combined with existing alliances, positions Solarh2e at the forefront of Australia’s heavy-transport transformation. For the mining sector, in particular, the implications are profound: lower operating costs, reduced carbon exposure, and a pathway to sustainable haulage from pit to port.

“With these key partnerships in place, Solarh2e is helping drive the mining industry and other sectors toward a decarbonised and sustainable future,” Zee saidß. AM

You commute to the far ends of the earth. Your workplaces are in the most challenging environments on the planet. The unrelenting pressure you face to cut costs while being safer, more sustainable and more productive demands more than partial solutions or occasional transactions. It demands a trusted partner, committed to meaningful support, data-driven insights and solutions that connect all parts of a mine. We’re Hexagon. One partner. For the life of your mine.

WHEN IT COMES TO CLIMATE COMMITMENTS, FORTESCUE IS SHOWING THAT HEAVY INDUSTRY CAN DECARBONISE PROFITABLY AND RAPIDLY.

Fortescue is accelerating its Real Zero journey, forging global partnerships to turn ambition into action. The company’s latest collaborations bring together some of the world’s most advanced technology and manufacturing leaders. The partnerships include BYD, LONGi, XCMG, Envision Energy and Liebherr, together with its newly consolidated renewable technology company Nabrawind.

Together, these alliances connect Fortescue’s operational expertise in the Pilbara with innovation and manufacturing powerhouses across the globe, creating a global network designed to deliver Real Zero at industrial scale.

Fortescue’s decarbonisation program is already taking shape across its Pilbara operations. Major renewable energy infrastructure is under construction and solar farms are already beginning to power the network with clean energy.

A 100MW solar farm at North Star Junction is now generating 180GWh of energy annually, enough to supply around 25 per cent of Iron Bridge’s power needs with renewables. Construction is also progressing on the 190MW Cloudbreak solar farm, which will be capable of generating enough

power for the equivalent of more than 70,000 households once operational.

To connect these renewable assets, Fortescue has expanded its high-voltage network, adding roughly 140km of transmission lines. This brings the total installed transmission lines to 460km across the Pilbara.

renewable supply and stabilise energy across mine sites.

According to Fortescue director of mining operations Steve Cole, the transformation is already visible.

“We have 10 electric excavators operating across our sites, with another two about to be commissioned.

FORTESCUE’S CLOUDBREAK SOLAR FARM WILL BE CAPABLE OF GENERATING ENOUGH POWER FOR THE EQUIVALENT OF MORE THAN 70,000 HOUSEHOLDS.

“Our first electric drill is already in operation and it’s performing exceptionally well, with another four assets already on order. These aren’t trials, they’re working assets, delivering tonnes and value.”

Fortescue’s approach to decarbonisation is ambitious yet

storage – by uniting global partners and

Recent discussions between mining giant BHP and Chinese buyers have underscored the normal rhythms of global iron ore negotiations, with temporary purchase pauses and price talks reflecting standard business practice rather than market disruption, according to RMIT University applied economist Ashton De Silva.

Reports indicated that talks touched on pricing adjustments and contract settlement terms, including currency considerations. While some observers speculated on the potential use of yuan in future trade, no formal shift had been confirmed at the time of writing.

For analysts, the currency consideration is less a sign of upheaval and more an example of how major resource contracts evolve over time. While the yuan may feature in exploratory discussions, De Silva said such proposals often form part of a broader negotiation process rather than a concrete policy shift. In his view, conversations about settlement mechanisms typically reflect both sides’

desire to streamline trade and hedge against market volatility, rather than an immediate move away from the longestablished use of the US dollar in iron ore transactions.

Speaking at a business event in Perth, BHP Australia president Geraldine Slattery emphasised that such negotiations are a regular part of operations.

“Commercial negotiations are a normal part of that; they happen every year,” she said.

Australian Prime Minister Anthony Albanese echoed the sentiment, noting that while temporary pauses were “concerning”, they formed part of the normal dynamics of international trade between major partners.

“These measures are always disappointing; let’s hope, certainly, that they are very much shortterm,” Albanese said. “I want to see Australian iron ore to be able to be exported to China without hindrance. That is important.”

Reinforcing that view, De Silva told Australian Mining the situation is less about crisis and more about process.

“Given that Australia is the largest exporter of iron ore, we’re in a pretty strong position,” he said.

“We should certainly watch the situation, and we should do that closely, but I don’t think it’s anything we need to be alarmed about.

“These [stalled negotiations] are pretty standard in terms of a country

such as China wanting to get their best value for money, and they’re looking at doing that in different ways.”

According to reports, the Chinese Mineral Resources Group (CMRG) had paused some purchases following BHP’s proposal for a 15 per cent price increase under a US dollarsettled long-term contract. China, in

turn, reportedly sought discounts based on ore quality variations and shifting production rates.

When discussing whether Australia required policies to safeguard against such disputes, De Silva said no.

“These parties are establishing the ground rules for business going forward, so from a national perspective I don’t

think there’s any real safeguarding that’s actually needed,” he said.

De Silva described the back-andforth as a natural part of buyer–seller dynamics, reflecting China’s broader effort to secure more favourable pricing in a volatile commodities market.

Geological Survey’s 2025 annual report, Australia produced 930 million metric tonnes of usable iron ore in 2024, more than double Brazil’s 440 million and well ahead of China’s 270 million.

“Whilst I can see that it will have some economic disruption, Australia has benefitted a lot from the iron ore price and it’s going to be inevitable, to a large extent, that this happens,” he said.

Despite the attention surrounding the talks, reports from Reuters and the China Global South Project indicated that disruption to BHP’s supply chain had been minimal. According to the GMK Centre, the effects of the CMRG’s restrictions might not be felt until January 2026, when new contracts take effect.

De Silva compared the negotiations to BHP’s 2010s shift from annual to market-based pricing, which reshaped how iron ore deals were structured globally.

“The CMRG is a result of what BHP managed to broker several years ago, and that has really benefitted Australian mining companies and the country’s economy in general,” he said.

“But I want to go back to the fact that China, I think, has brought all this together to try and create some sort of buying power, and while there are other sources of iron ore, they’re not nearly as large or as accessible.”

Australia’s position remains clear. According to the United States

De Silva said that despite China’s dominance in demand, consuming over 70 per cent of the world’s seaborne iron ore, Australia’s reliability as a supplier gives it lasting leverage.

“You can think of Brazil as being one of the competitors, and there might be some other iron ore resources located closer to China, but the point is they just can’t be mined at this point,” he said.

“It doesn’t make economic sense to move away from Australia as a supplier. I don’t think this is going to have any immediate impacts.

“I do think more negotiation tactics like this are going to happen, but is it something that we should be worried about? No. Is it something we should expect? Yes.”

While De Silva noted that China’s growth “is starting to come off the boil”, he framed that as part of the natural cycle of global trade, not a signal of instability.

“The growth will still be there, but it’s not going to be the same scale, and so I think there are going to be some pressures even internally in China, given the fact that they won’t have as much spending money,” he said. “So yes, they are going to be more proactive in looking to drive down prices, but again, that’s just what happens in markets.” AM

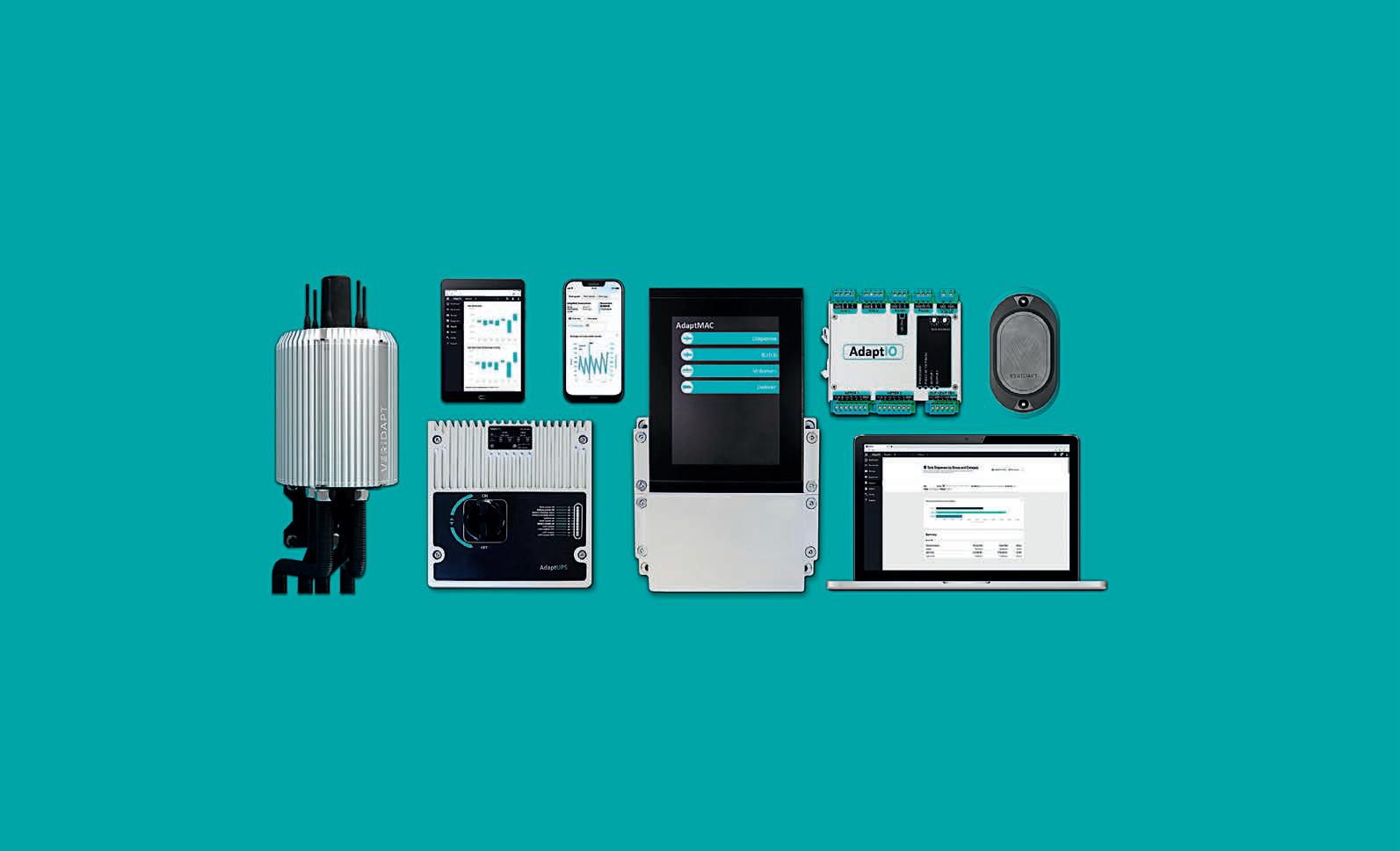

FROM HUMBLE BEGINNINGS, VERIDAPT HAS EXPANDED ALL OVER THE WORLD OVER 20 YEARS. BUT IT HASN’T FORGOTTEN ITS ROOTS AS AN AUSTRALIAN COMPANY.

VERIDAPT CHIEF EXECUTIVE OFFICER DAVID THAMBIRATNAM.

rom a rugged fuel controller on a dusty Australian mine site to a global technology platform tracking everything from diesel to data, Veridapt’s twodecade journey is a story of endurance, innovation and evolution.

As the company marks 20 years of operation, Veridapt chief executive officer David Thambiratnam reflects on a milestone few Australian tech firms reach, and what it means to keep innovating in an industry that never

“In 20 years, we’ve never lost a customer,” Thambiratnam told Australian Mining. “Every single one of our customers has grown with us, stayed with us and expanded with us. That talks to the robustness of the solution and how well everything works.”

AS THE MINING INDUSTRY TRANSITIONS TO CLEANER ENERGY, VERIDAPT IS AGAIN AHEAD OF THE CURVE.

That kind of loyalty represents a major achievement in a sector where reliability is everything. From its earliest days, Veridapt’s technology has been relied on to power and monitor some of the world’s most demanding industrial operations, environments where failure is not an option.

Veridapt’s story began in 2005, when fuel systems in the mining industry often couldn’t survive the harsh conditions of remote Australian operations. This prompted the team to build its own units, developing technology that was durable by necessity and intelligent by design.

Those early lessons in durability, connection and the marriage of software and hardware laid the foundation for a company that has consistently anticipated the next wave of industrial transformation.

By 2010, Veridapt had created the world’s first touchscreen fuel management system, AdaptMAC, and later pioneered cloud-based industrial monitoring through its AdaptIQ and AdaptSCF platforms.

“Technology changes all the time,” Thambiratnam said. “The trick is applying just the right amount of technology, the right people and the right rationale.

“You can pick the wrong technology and end up with an expensive or ineffective solution.

Thambiratnam said Veridapt’s problem-solving process has always been about understanding the customer deeply and then choosing what really works.

That balance of innovation and practicality has guided the company through two decades of rapid technological evolution, from on-site

ethernet systems to satellite connectivity, cloud platforms and now artificial intelligence (AI).

In an industry known for its relative volatility, Veridapt’s longevity stands out. The company has outlasted most Australian start-ups and scaled globally while remaining independent and profitable.

“Not a lot of companies make it to 10 years, let alone 20,” Thambiratnam said. “So to make it this far and be thriving is quite an achievement in itself.”

That endurance, he said, is not just about technology. It’s about people.

“We’ve been very deliberate about who we bring into the team,” Thambiratnam said. “It’s astounding what we pull off for our size. There’s a lot of goodwill, passion and dedication that goes into making this work.”

That human focus underpins Veridapt’s DNA, a culture of adaptability reflected in its name. The company rebranded to Veridapt in 2020, symbolising its commitment to verification and adaptation as the twin engines of progress.

While its roots are firmly in Australian mining, Veridapt’s expansion into international markets has brought opportunity and challenge.

The company is currently deployed on more than 300 sites worldwide, supporting leading Tier 1 mining and rail clients with innovative solutions that keep operations running safely and efficiently.

Veridapt’s global journey revealed that what works in one region often needs recalibration elsewhere.

“You can think a mine in Australia is the same as one in Canada or Chile, but every region has its nuances,” Thambiratnam said. “The business models for fuel delivery, the regulatory environments, even what customers value. It all differs.”

In some markets, enterprise-grade cloud analytics are essential; in others, reliability and simplicity rule.

The company learned to tailor its products, from AdaptSMU to AdaptNX, to meet distinct needs without losing its core promise of robust, reliable insight into industrial energy and asset use.

That flexibility has been key to Veridapt’s success in new sectors such as rail and logistics, where real-time visibility and control are critical.

And as the mining industry transitions to cleaner energy, Veridapt is again ahead of the curve. Its technology, originally designed to track and manage diesel fuel, is now integrating electric vehicle (EV) chargers, hydrogen systems and renewable energy sources into a single intelligent monitoring platform.

“At the heart of what we do is helping customers with large industrial fleets manage their energy, whether that’s refuelling or recharging,” Thambiratnam said. “The good thing about us is that we don’t really care what the energy source is. We can integrate with EV chargers, hydrogen pumps. The logic of what we do stays the same.”

This transition is only just beginning in mining, but Veridapt’s readiness gives it a significant head start.

As mines adopt mixed-energy fleets that combine diesel, biodiesel, hydrogen and electric, Veridapt’s platform helps them track consumption, cost and emissions in real-time.

The company’s roadmap also extends to monitoring mining outputs. Beyond managing fuel and energy, Veridapt is now helping clients track their commodity inventories, from gold and uranium stockpiles to fertiliser production.

“It’s the same problem,” Thambiratnam said. “You need to know where it went, how much is left, and reconcile it accurately.

“We’ve started doing that for our mining customers. It’s new, but it’s growing quickly.”

After 20 years, Veridapt’s biggest challenge is not finding growth, but managing it responsibly.

“The market is massive and our challenge is growing too quickly,” Thambiratnam said. “We need to scale in a way that keeps our customers front and centre.”

Looking ahead, the company is preparing for further expansion into adjacent industries such as transport,

logistics, aviation and defence – sectors facing familiar challenges in energy management, sustainability and data integration.

At the same time, Veridapt plans to deepen its offering within mining, leveraging AI and predictive analytics to give companies clearer visibility and control over their operations.

“Mining is at the core of our business,” Thambiratnam said.

“There’s so much you can do with the data. Bringing AI into the applications and making it easier for customers to achieve their outcomes is still core to what we do.”

As Veridapt celebrates its 20th anniversary, the company has shared its ‘20 Lessons from 20 Years of Fuelling Innovation’, a reflection of the milestones and philosophies that shaped its growth

The company has simple – yet powerful – lesson after two decades of adaptation and success: innovation never clocks out. It’s a fitting summary of a business that continues to thrive by staying restless, relevant and relentlessly customer-focused.

EVERY SECOND MATTERS IN MINING, AND THAT’S WHY MASPRO HAS DESIGNED A SUPPLY CHAIN MODEL THAT KEEPS OPERATIONS MOVING.

Asingle failed part can stop a multimilliondollar piece of mining equipment in its tracks.

For MASPRO, those moments – when drill availability hangs in the balance – are when reliability matters most.

The Australian manufacturer has earned a reputation for getting critical components where they need to be, fast, proving that local supply can keep the industry moving even when global networks falter.

As talk of the next mining boom grows, so does demand for Australianmade parts. But it’s not just about growth, it’s about resilience.

MASPRO chief executive officer Greg Kennard told Australian Mining the industry’s future will depend on how well it can keep supply chains running when under pressure.

“We’re here to support local miners and those across Southeast Asia,” Kennard said. “As we expand our footprint, reliability, responsiveness and scalability are absolutely central to what we do.”

That philosophy shapes MASPRO from the ground up. Its vertically integrated production facilities on the east coast handle everything in-house, from design to manufacture, assembly to testing, giving the company total control over quality and delivery.

“Being able to do it all ourselves is a real strength,” Kennard said. “It gives us ultimate control over product quality and supply.”

Control is only part of the story. MASPRO has built distribution hubs across Australia and is identifying global opportunities to realise its strategic potential.

The goal is simple: keep critical spare parts close to the customer, not stuck in a shipping container halfway around the world.

Earlier this year, that network was tested like never before. MASPRO delivered a vital part in just 28 minutes from the initial call to the truck rolling out. It started at 10:29am, when a longtime customer called with a rig that was down and needed a MASPRO cradle assembly immediately. The order was processed by 10:33am and the truck was on the road by 10:57am.

an hour.

Quick deliveries like this prove to the company’s customers they can count on MASPRO when the stakes are high.

For mines, that kind of responsiveness can be the difference between productivity and a major loss. MASPRO’s agility isn’t just about people, it’s about systems.

“We’re adopting advanced technology for inventory planning and monitoring supply performance,” Kennard said. “Automation and digital inventory systems let MASPRO anticipate demand, ensuring the right parts are in the right place at the right time.”

This predictive approach means the company can prevent breakdowns as well as respond to them.

MASPRO measures success with a simple formula: supply in full, on time, in spec.

“If you send the wrong part or something is off, it can cost thousands of dollars,” Kennard said. “Our goal is to ship parts within three to five days; automation and data insights help make that target the standard.”

Even with optimism about the next mining cycle, Kennard maintains a measured view.

“There are good times and challenging times happening at the same time,” he said. “Our job is to be ready for both.”

Being ready means a resilient, technology-driven supply chain that can adapt to changing markets and unpredictable global events.