Chairman John Murphy

CEO Christine Clancy christine.clancy@primecreative.com.au

Managing Editor Eugene Duffy eugene.duffy@primecreative.com.au

Editor Timothy Bond tim.bond@primecreative.com.au

Business Development Manager Jake Niehus jacob.niehus@primecreative.com.au

Head of Design Blake Storey blake.storey@primecreative.com.au

Designer Apostolos Topatsis

Front Cover Image Stacked Learning

Copyright

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: The Precision Group 83-89 Freight Drive, Somerton VIC 3062 Ph: (03) 9490 1500

The Australian Pipeliner brand comprises: six editions a year, a news website, a weekly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

20,000+ website views each month

16,500+ e-newsletter subscribers 13,700+ magazine subscribers 3,300+ social media followers

Want to find out more?

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0466 929 675 or email jacob.niehus@primecreative.com.au

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: (03) 9690 8766

Sydney Office Suite 11.01, Level 11, 201 Miller St, North Sydney NSW 2060

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry. The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

When you partner with Bridger Photonics, you can have hundreds of sites and kilometres of pipeline scanned in a single day. You can receive high-precision methane data without the usual legwork. No boots, no delays, no wasted site visits.

Get leak-level intel fast, so you can:

Keep product in the pipe

Reduce unnecessary field time

Learn how Bridger works for operators like you.

Australian Pipelines and Gas Association CEO Steve Davies discusses how advocacy and policy are at the heart of everything the association does.

The APGA has been more active than ever to improve understanding and appreciation for the role of gas and gas infrastructure. Over the past year, APGA has provided members with 44 file notes on policy reports and processes, participated in 40 government reviews and consultations, having 25 already completed with 15 ongoing and lodged 32 formal submissions. Every submission has been backed by an engagement strategy, ensuring follow-up meetings with ministers, officials and stakeholders. This is how we make sure our members’ interests are represented.

use of gas more than new wind developments.

Policy outcomes in 2025 reflect this shift. Victoria has walked back earlier plans to ban gas appliances; the Future of the NEM Review confirmed gas-fired generation will remain essential; and the NGER Scheme was amended so that renewable gas blends are recognised as lower-emission fuels. Meanwhile, work is underway on a national renewable gas strategy.

So, what is the state of gas and pipelines in 2025?

The Federal election gave us a defining moment. For the first time, both major parties went to the polls with commitments to “fix gas.” This momentum has carried through to the Federal Government’s Gas Market Review, a process designed to resolve supply issues once and for all.

Opportunities outside gas are also becoming clearer. In water, new restrictions on artesian water use mean resource projects and data centres are driving strong demand for pipelines to transport water. In CCS, the International Energy Agency forecasts that at least 15 per cent of global emissions must be mitigated by capture and storage. In Australia, this means over 60 million tonnes of CO₂ every year and up to 20,000km of CO₂ pipelines.

An important part of our advocacy has been cutting through the noise with facts. Led by Paul Purcell, APGA’s EnergyShift has become one of our most valuable tools. This report takes the pulse of community attitudes to energy, providing insights not just for us but also for government and industry leaders. When we first ran EnergyShift in 2023, the findings were surprising. The Australian public was strongly supportive of natural gas, despite the headlines at the time suggesting otherwise. That evidence helped give government confidence to back gas in its Future Gas Strategy, gave energy users confidence to call for better gas policy and gave us the chance to speak to a wider range of stakeholders. Today, EnergyShift shows that Australians now back increased

APGA Secretariat

Registered Office: 2nd Floor, NFF House, 14-16 Brisbane Avenue, Barton, ACT 2600

(PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

ABN: 29 098 754 324

Five years ago, it was not widely accepted that gas would continue to play a role in electricity generation. APGA’s advocacy helped change that, with our 2021 Frontier Economics report showing that a system made up of 90 per cent renewables and 10 per cent gas was cheaper, more reliable and almost as clean as a fully renewable grid. That work challenged assumptions and contributed to the policy and market settings we now see.

While 2025 has been quieter on the project front, the outlook is strong. The ISP forecasts 13GW of new gas generation, and major opportunities are emerging in storage and transmission pipelines. It has not been an easy year, but it has been an important one. Through persistence and collective effort, we are shaping a stronger future for gas, pipelines and the communities we serve.

DAVIES APGA CEO

Chief Executive Officer

Steve Davies

Head of Corporate Services

Dhammith Abeysuriya

Head of Corporate Affairs

Paul Purcell

Head of Operations & Communications

Lawrence Shelton

Head of Engagement

Gayle Bower

Accounts & Membership Officer

Katy Spence

National Policy Manager

Catriona Rafael

Technical Advisor

Craig Bonar

Whether you’re testing open end pipe, systems terminating in long radius elbows, flange welds or isolating lines... count on the GripTight Family of Test & Isolation Plugs from Curtiss-Wright to perform above expectations, test after test.

Patented gripper designs, hardened components and single-body uninterrupted seals provide field performance that’s second to none. When safety and reliability matter most, it’s no wonder plants around the world trust GripTight for their testing & isolation needs!

• ID and OD solutions available

• Patented gripper designs for increased safety in high-pressure applications

• Eliminates welding end caps when testing pipe spools and piping systems

• Test flange-to-pipe welds without pressurizing entire systems

• Isolate & monitor upstream pressure and vapors during hot work

• Standard pressure ratings up to 15,000 PsiG (1034 BarG)

• ASME PCC-2 Type I, III & IV Testing Devices available

In recent months, the pipeline industry has seen some major developments across Victoria, with new plans and projects unveiled for the state.

ExxonMobil and Woodside have invested another $350 million into the development of Gippsland Basin gas assets.

The initiative, named the Turrum Phase 3 project, includes the drilling of up to five gas production wells via a jack-up rig. Drilling activities will take place at the Marlin B platform located in the Gippsland Basin in the eastern area of Bass Strait. The completed wells will be connected to the existing hydrocarbon production processing equipment located on the Marlin B platform.

“The gas this project delivers will help strengthen Australia’s energy security, powering Australian homes and business well into the next decade,” ExxonMobil said.

First gas is expected to be delivered to south-east Australia before winter 2027. According to ExxonMobil, it will produce four times more gas than Queensland supplied to the southern states in 2024.

This 50-50 joint venture project builds on nearly $1 billion in recent investments to deliver Gippsland gas to Australia, including the Kipper 1B project, the Kipper compression project, and the West Barracouta project.

Amplitude Energy targets

Otway Basin development

Amplitude Energy and O.G. Energy have formed a joint venture to develop an Otway Basin gas project.

Both companies have approved the East Coast Supply Project (ECSP), aimed at delivering additional gas supply to the east coast market. At a glance, the project entails a three well drilling program in the Otway Basin.

The venture is targeting supply of up to 90TJ per day through the existing Athena gas plant from 2028. This is subject to regulatory approvals, final investment decisions and

successful execution. The projected yield is roughly equivalent to the demand of over 600,000 Victorian homes, and will help to avoid potential gas supply shortfalls in Australia’s southern states.

The project will be conducted in two phases: Phase 1 encompasses well drilling, with well completions and subsea tree installations upon success, while Phase 2 encompasses subsea development and modifications at the Athena gas plant.

ECSP Phase 1 has an estimated cost of $240–270 million while Phase 2 is forecast between $140–185 million. Costs will be split on a 50/50 basis.

“In its latest Gas Statement of Opportunities released last week, AEMO highlighted the risk of peak-day gas shortfalls and seasonal supply gaps in the southern states arising from 2028, with annual supply gaps emerging from 2029,” Amplitude Energy CEO Jane Norman said.

“Our investment in the ECSP could potentially provide enough gas for over 600,000 Victorian homes for a decade from reserves and conversion of our resources. The project is structured to deliver first gas as early as possible, minimise exploration risks and maximise the use of existing gas infrastructure.

“We look forward to working with O.G. Energy to bring additional and much-needed gas supply to Australia’s southeastern domestic market.”

Beach Energy approved for Otway Basin drilling

NOPSEMA has approved Beach Energy’s plans to undertake drilling and plug-and-abandon activities in the Otway and Bass Basins.

The proposed scope of work covers drilling of up to five wells in Otway, and plugging, abandonment and removal of well infrastructure above the mudline for five legacy wells.

Drilling is expected to take roughly 30–40 days per well, while abandonment activities are expected to take roughly 15–20 days per well.

Proposed activities will be undertaken with a single moored semi-submersible drill rig with a thruster assisted mooring system. The drill rig

will be supported with up to three vessels.

The company recently celebrated a successful quarter, producing five million barrels of oil equivalent for the period. This was partly powered by a 22 per cent increase in Bass Basin production.

Beach also made strides at its Moomba carbon capture and storage (CCS) project.

“Commissioning of the Moomba CCS project was an important milestone for both Beach and Australia’s emissions reduction journey,” Woods said.

“The project has capacity to inject and store all vented reservoir CO2 from the Moomba Gas Plant. This puts Beach on track to achieve its 2030 emissions intensity reduction target of 35 per cent.”

More than 800 homes in rural northern Victoria are receiving better drinking water following a major upgrade to the region’s water infrastructure.

Minister for Water Harriet Shing recently visited the newly upgraded Laanecoorie water treatment plant – a $5 million project delivered by Coliban Water as part of Victoria’s historic Big Water Build.

Households across Laanecoorie, Dunolly, Tarnagulla and Bealiba now benefit from a more efficient and reliable water supply, thanks to the construction of two new water storage tanks with a capacity of over two megalitres, alongside two new water pumps.

The tanks receive and store water from the South West Loddon Pipeline, which is operated by Grampians Wimmera Mallee Water.

The completed project marks the final connection between the Coliban Water system and the pipeline.

“Upgrading essential infrastructure like the Laanecoorie water treatment plant ensures we can deliver higher quality, reliable water supplies for our regional communities now and into the future,” Shing said.

The Laanecoorie Water Supply Upgrade is part of Coliban Water’s $500 million investment over five years in the Big Water Build – delivering one of the largest capital investment programs in the water authority’s history.

“Fronting up to the key challenges of climate change, population growth and ageing assets shaped our pricing submission…the Laanecoorie water treatment plant is just one of our Big Water Build projects,” Coliban Water managing director Damian Wells said.

APA Group will deliver a natural gas pipeline connecting its Roma Brisbane pipeline with CS Energy’s proposed Brigalow peaking power plant in Queensland.

The company has finalised a project development agreement and a gas transportation and storage agreement with CS Energy for the project.

The proposed power station will be

situated adjacent to CS Energy’s existing Kogan Creek power station, near Chinchilla in the Western Downs. It is designed to provide firming capacity during peak electricity demand periods and to complement variable wind and solar energy sources. The plant is capable of starting and stopping multiple times daily and can reach full output within five minutes.

will own and operate the pipeline under a 35-year gas transportation and storage agreement.

To facilitate this, APA will develop a new 23km pipeline to connect the power station to the Roma Brisbane pipeline. The pipeline will be designed to provide both natural gas transmission and storage services. Upon completion, APA will own and operate the pipeline under a 35-year gas transportation and storage agreement with CS Energy.

The project is targeted for completion in mid-2027, with total construction costs estimated at least $150 million.

“The completion of this agreement builds on our strategy to leverage our existing gas transmission network and capabilities to progress growth projects that deliver for investors and support energy security and transition along Australia’s east coast,” APA CEO and Adam Watson said.

“Along with the recent announcement of our agreement to acquire the Atlas to Reedy Creek pipeline and our ongoing east coast gas grid expansion work, this announcement demonstrates both our disciplined approach to capital allocation and the significant growth opportunities ahead in gas transmission and storage and gas-powered generation.”

Tamboran Resources has made a significant breakthrough as the first operator in the Beetaloo Basin to gain approval under the Northern Territory’s Beneficial Use of Gas (BUG) legislation.

The agreement, achieved in collaboration with Native Title Holders and the Northern Land Council, allows the Beetaloo Joint Venture to sell up to 60 terajoules per day of gas from Exploration Permits 98 and 117 over a three-year period, drawn from the proposed Shenandoah South Pilot Project.

Gas will be sold to the Northern Territory Government, with first delivery expected around mid-2026.

Tamboran’s Chairman and Interim CEO, Richard Stoneburner, described the approval as a landmark moment, expressing gratitude to Native Title Holders and the Northern Land Council for their support.

“The BUG legislation has been a significant initiative undertaken by the government, which allows for gas volumes to be sold into the market during the exploration and appraisal phase of the project life,” he said.

“Gas that would have historically been flared on site will now be delivered into the local Northern Territory gas market, delivering much needed energy security to the

market that is predominantly powered by gas.”

Tamboran Resources will construct the Shenandoah processing and compression facility as part of the project.

The company has also entered agreements with APA Group to support the development of the Sturt Plateau pipeline, which will be the first pipeline connecting the Beetaloo subbasin directly to gas markets.

Tesmec chainsaw trenchers are engineered to perform in the most demanding conditions, from steep slopes and hard rock to extreme heat or freezing cold. Trusted worldwide, they deliver unmatched reliability, efficiency, and safety, making them your ideal solution for trenching wherever pipeline projects push the limits. Contact us to optimise your next pipeline project.

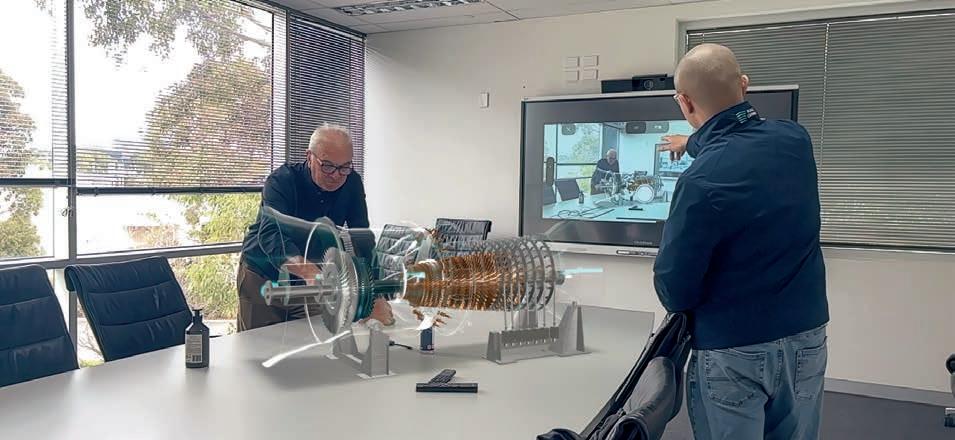

When The Australian Pipeliner discovered that AJSS had launched an ed-tech venture called Stacked Learning that was making waves in the engineering training space, we knew we had to take a closer look.

The training methodology seemed simple but enticing, taking real-world engineering scenarios and digitalising them to produce training modules that last for decades, accessible anytime, anywhere.

But as we entered the company’s Cheltenham training centre – an unassuming, red brick building – it was immediately clear that we had stumbled upon something that truly danced to its own music.

Pipeline industry veteran Arthur Stack is the man at the helm of this new venture, called Stacked Learning. Throughout his long career he’s seen firsthand the labour and skills shortages plaguing the industry.

“There are people with incredible skills that are retiring and leaving our industry, and retaining and passing on that knowledge is a key driver of why Stacked Learning exists,” he said.

“The pace of work has also accelerated, which means information has to be more readily available. It’s very difficult now for a young engineer or technician to go in and spend five years learning a specific set of skills, when the modern market demands that they learn in only one year. And where you might have had a crew of 20 a decade ago, now with costs cuts and efficiencies driving business you’ve got a crew of 12, and the efficiency drive is unrelenting.

“Our industry is always focusing on working smarter, not harder, but proper and efficient training is a critical part of that ethos that is often overlooked.”

The technological backbone Stacked Learning Operations Manager Monica Savanovic leads the tour of the training facility, weaving us past several pieces of critical site equipment such as a Rolls Royce gas turbine, which is one of a number of engines and package components students can dirty their hands with – each one the price of a luxury vehicle. But the most impressive part of the facility isn’t what’s physically present, it’s what isn’t.

Using a mix of augmented reality (AR), virtual reality (VR), and artificial intelligence (AI), Stacked Learning can create digital twins of plant, equipment, and worksites, showing how they operate and interact with

different forces. This allows critical site and office staff to get incredibly detailed and hands-on training with machinery components, entirely risk-free.

The Stacked Learning team showed us several digital equipment representations such as a gas turbine and centrifugal gas compressor using AR, which appeared on the table at which we were sat. Each component could be manoeuvred and disassembled with ease.

“Learners come to us to simulate live work on high voltage power generation control systems with no fear of consequence or see the flow of gas inside of a pipeline.”

Savanovic said.

“We are aspiring to create a picture of realworld events to a level that’s not been seen before.”

Often, these training courses are created bespoke to help address specific challenges clients are having with plant and equipment. Entire worksites can even be digitalised for a fully immersive training experience.

This zero-consequence learning environment is perfectly suited to the pipeline industry, where assets such as high-pressure gas pipelines demand utmost care and competency.

In today’s pipeline industry, another common risk comes from hexavalent chromium, a highly toxic industrial byproduct that looks like a green or yellow dust. It can form on high-temperature components when materials containing both chromium and calcium are used, such as in some anti-seize or insulating products. Hexavalent chromium possesses a long-term health risk to many field workers throughout their careers.

Deadly as it is, the danger of hexavalent chromium isn’t completely understood by many, so much so that on average it costs companies $3 million in damages every year.

Fortunately, this is just one of many industry pain points that Stacked Learning is targeting through its digital training courses, making workers safer and more competent.

Arthur shows us into the ‘Ross Day’ Technical library, named for in honour of Ross who pioneered new and innovative forms of preventative, predictive and troubleshooting maintenance at ESSO Australia.

crammed in a tin. Just as Arthur has learned from and been inspired by other experts in the field, he now tries to pass on that passion and

knowledge to the next generation of operators, maintainers and young engineers. Both the room and the man are very much an allegory for the business itself.

Once again, the method to accomplish this goal is sound: recruit industry experts on the cusp of retirement, transcribe their knowledge through a series of highly technical interviews, and feed that data into a specialised AI learning system to form the basis of educational content. Dr Alasdair Lee, Stacked Learning Director of Training has leveraged his years of academic and educational training background in the sector to ensure that the tacit knowledge gathered from experts is not lost forever and remains as a digital archive.

In this way, lifetimes’ worth of knowledge is trapped in time and condensed into readily available learning modules. No more unwieldy thousand-page manuscripts and boring PowerPoint presentations; instead, information is intentional and accessible – its strength in its brevity.

Supported from the beginning by his colleagues Tom Chapman and Alison Robb, clearly Arthur’s passion is infectious, as he’s managed to recruit many veteran engineers, and some of Australia’s biggest names in gas infrastructure to champion his cause.

Tom continues to support the Stacked Learning team on content oversight and review, and it was Alison who drove the business transformation through its AJSS

instructors, leveraging a mix of physical equipment, cutting-edge digital tools, and engaging games that not only delivers sharp, sophisticated learning, but also fosters terrific engagement with the audience.

“We have a deep understanding of what the pain points are that operators, maintainers, technicians and engineers experience in the pipeline industry,” Arthur said. “We know what makes them tick. We know what keeps them interested.”

The company is young, only stepping out on its own in 2022 under the Stacked Learning banner, a major milestone in its mission to expand globally.

At the time of our visit, part of the Stacked team was scattered across Myanmar, Brunei, Thailand and the Philippines, as the business expands its footprint in southeast Asia. In early 2025, Stacked Learning signed a three-year licencing agreement in North America with similar agreement planned for LATAM Europe, the Middles East and Asia. In October 2025, Stacked Learning signed an agreement with the Adinin Training and Development Centre in Brunei to license its content across the Brunei oil and gas industry.

“We’re bringing Australian standards into countries where that kind of safety knowledge isn’t readily available,” Savanovic said.

The 2025 APGA Convention kicked off in a big way with the annual awards ceremony.

The 2025 APGA Convention kicked off in a big way with the annual awards ceremony. The pipeline industry came together to celebrate some of the most impactful people, projects, and initiatives in the sector – whether seasoned veterans or rising stars.

APA Group took out the Safety Award for its stay-in-business capital program.

“Over the last two years and counting, we are incident injury free. This represents more than 1.6 million people hours of work across more than 350 projects, and hundreds of people involved. We couldn’t be more proud,” APA Group’s Allyson Woodford said.

The Environment Award was won by MPC Kinetic for its Flare 360 solution, designed to prevent fugitive methane emissions during critical well maintenance.

“It’s very humbling to be recognised for a solution such as this, which is aimed at helping our clients to reduce their methane emissions,” MPC Kinetic’s Richard Wall said. “We appreciate the recognition from the APGA and the industry.”

Global Engineering and Construction took out the Diversity and Inclusion Award for its

efforts in showing how inclusion isn’t just a policy, but a culture. The company’s programs include targeted leadership development, pay equity initiatives, and ongoing education to challenge bias and foster request.

“I’m proud to be a part of Global Engineering and Construction,” Annelies

Maxwell said. “We are backed by an incredible leadership team that really support our initiatives that we roll out in the business, and that’s really endorsed by everyone at all levels, including in those remote locations where people are working long days in tough conditions. This award is a testament to them.”

John Rutherford, Operations Manager – HDD at Spiecapag, was the recipient of the Young Achievement Award. Rutherford has played an integral part in award-winning projects, and is currently leading the shore crossings for the Marinus Link project, connecting Tasmania and Victoria through a 345km high voltage interconnector.

“Receiving this award, I feel a mix of pride, gratitude and humility,” he said. “To be recognised by the APGA – an organisation that represents the backbone of Australia’s energy and pipeline industry – is truly an honour.

“I accept this award not just on behalf of myself, but on behalf of everyone who’s helped me through my career.”

APA General Manager Mark Fothergill received the Outstanding Achievement Award for his lifetime of service to the pipeline industry. For more than 35 years, Mark has helped to shape the modern pipeline sector in Australia – from delivering major infrastructure projects to leading APA’s engineering and operations team.

“I really appreciate this award. It brings back many memories of the people and companies I’ve worked with along the way,” he said.

“The award ceremony from APGA is perfect. I’ve really enjoyed seeing many of my colleagues get recognised over the years, so to join them today is one of the highlights of my career.”

Jamie Bell took home the Jeff Shepherd Construction Excellence Award. For two decades, Jamie has overseen some of the most complex pipeline projects in Australia, bringing them to life to the highest standards. His leadership style is defined by collaboration, creating a culture where safety, respect and excellence come equal first.

“It’s very humbling to be recognised, especially considering the calibre of award recipients that have come before me,” he said.

“I’d like to thank Nacap, where I’ve worked for 15 years. The guys there treat you like family. It’s a culture of safety, a culture of diversity – always striving to be better. Just a fantastic place to work.”

The Australian Pipeliner spoke with the Benton’s Gas team to learn.

Since 1999, Benton’s Gas has built a reputation in the pipeline industry for supplying high-quality products and services to Australia’s water and gas networks. But in an industry that prizes precision and reliability, it’s the human expertise behind the equipment that gives Benton’s its edge.

Among those driving this success is Shane Bishop, Project Manager and long-time member of the Benton family network. Having begun his career as a mechanic, Shane

Benton’s has the manpower and breadth of service to handle a wide range of projects.

brought with him a practical understanding of how machinery operates in the real world – an insight that has proved invaluable in expanding Benton’s service capabilities.

In his role as Project Manager, Shane also oversees hire and servicing operations, ensuring Benton’s customers achieve both efficiency and long-term cost savings. His knowledge of materials, project pricing, and operational integration allows Benton’s to provide a true point of difference at the tender stage.

“Understanding how materials behave in the field and how equipment performance affects outcomes means we can help our clients plan smarter and build stronger,” he told The Australian Pipeliner.

Working closely alongside Shane is Bevan McWha, Benton’s Gas Category Manager. Since joining the business in 2017, Bevan has applied his extensive experience with gas network assets across New South Wales to enhance Benton’s reach and capability.

His in-depth understanding of approved materials and asset requirements has helped reinforce Benton’s long-standing presence in Victoria and extend its influence interstate.

Bevan’s technical acumen, paired with Shane’s vision for enhanced customer service, was crucial in conversations with key partners such as Plasson, leading to the establishment of Benton’s Southern Region Hire and Servicing Department.

“By aligning our customer service vision with the needs of asset owners and manufacturers, we’ve been able to create a seamless support system that benefits everyone in the supply chain,” he said.

For Bevan and the team, this approach has borne fruit in 2025. The company left its mark on countless projects this year, including the Victorian gas renewal upgrade program, which involved works in rural and metro regions all over the state. Benton’s also played a role in multiple pipeline relocation projects, including for the Melbourne Airport Rail and the North East Link.

Bevan said the order books are already filling up for 2026, with supply contracts for

asset initial development and maintenance programs already lined up in South Australia and Victoria.

The continued trust of company founders Michael, Terry, Brian, and Wayne Benton, along with the efforts of every team member, has been central to Benton’s evolution from a modest plumbing supplies venture to a multi-branch enterprise serving Australia’s pipeline sector.

Bevan also gave a special acknowledgment to Rodney Griffin, Benton’s Gas Equipment Technician, whose commitment and technical skill have long underpinned the company’s reputation for reliability and precision.

From workshop to worksites, these are the people who turn Benton’s promise into performance. Their collective expertise, forged through years of experience and guided by family values, ensures that every piece of equipment leaving the depot – and every project it supports – meets the highest standards of safety, efficiency, and service.

At Benton’s Gas, people aren’t just part of the pipeline, they’re the reason it flows.

Benton’s Gas stocks an extensive product range, spanning PE and PVC pipe, fittings, valves, meters, tooling and safety equipment.

up under pressure since 1968

Pollard’s Sawdust Supplies has been a trusted national supplier of graded and bagged sawdust and wood shavings products for over 50 years

The pipeline construction industry has been entrusting our business to provide support for their pipe assets for many decades.

Our pipeline bedding Pack Tuff bags are:

3

Tesmec Australia is delivering bespoke, highly efficient trenching machines to some of Australia’s most important pipeline projects.

If you ask Tesmec Australia General Manager Adrien Merceron the thing he loves most about his job, he’ll tell you it’s the variety.

Whether it’s a cold call about a project in the middle of nowhere, finding the best trenching machine for a given job, monitoring the performance of machines out in the field, or answering a raft of geotechnical questions, it’s all part of the day-to-day for Merceron.

Such is the reality when working for a highly specialised company like Tesmec, which provides some of the most competitive, technologically advanced, and dialled-in trenching machines in the global market.

“In this job, it’s rarely the same kind of project with the same kind of machine,” he told The Australian Pipeliner

“One of the best parts is working with a wide range of people. When we work with smaller companies, it’s like a dream come true when their new trenching machine arrives.

“It makes me so happy to see their reaction, like purchasing a new car. They’re very, very happy.

“And on the opposite end, it’s always

exciting to deal with larger corporations on major pipeline projects, where we need to be hands-on from the beginning through early contractor involvement.”

It’s precisely this specialist approach that has allowed Tesmec to explode in popularity all over the globe, and 2025 has been no exception.

“Around the world and in Australia, we have definitely been quite busy, especially in the water industry,” Merceron said.

“Day-to-day around the country, we’re doing 20–50km pipelines, but we have some very large projects coming up next year in Queensland and South Australia.

“We’ve recently sold a few machines in Africa for big water pipeline projects, and we remain very busy in the Middle East doing a lot of oil and gas projects with the Saudi Arabian Oil Company. “

Innovation at the core

Key to Tesmec’s success, Merceron said, is its unending drive to innovate. At the heart of these innovations is Tesmec’s TrenchTronic 5.0, a sophisticated electronic control system that automates trenching operations.

By optimising depth control and trajectory

management, TrenchTronic 5.0 boosts productivity, reducing the need for manual intervention and minimising errors.

Complementing TrenchTronic 5.0 is TrenchIntel, a 3D-GPS automatic guidance system based on Topcon’s Real-Time Kinematic (RTK) technology.

TrenchIntel ensures trenching accuracy by automatically maintaining the correct running line, depth, and grade according to project specifications. Tesmec is confident this system outperforms traditional methods like laser systems, stakes, and string lines, by saving time and money from preventing undercuts, overcuts, and incorrect excavations.

“TrenchIntel really makes trenching a lot easier, increasing productivity and reducing costs,” Merceron said.

The company has also been leveraging artificial intelligence for condition monitoring, automatic reporting, and preventative maintenance on its trenchers. Monitoring this data – which is also sent to clients – is one of Merceron and his technical team’s role.

“In one recent example, we had a machine operating in the middle of nowhere and we noticed in the data that the engine and return system of this machine weren’t operating as normal,” he said. “So we reached out to the client and were able to determine that the air filter wasn’t correctly engaged after it had been removed for cleaning.

pedigree and local adaptability. There’s no one-size-fits-all solution in trenching; instead, Tesmec collaborates with clients early, works out what the rock conditions will be, what the environmental extremes are, what budgets allow, and then proposes or adapts machines accordingly.

Trust and honesty are core pillars of this approach.

“It’s important to be honest about what our machines can and can’t do, and about the rate at which they work. Sometimes drill and blast will be the only option, while other times, our trenchers will get the job done,” he said.

“In my view, it’s always better to overdeliver than to over-promise.”

Tesmec Australia provides a robust lineup of chainsaw trenchers that offer precise, reliable performance in any condition, from solid monolithic rock to

Pipe Tek has unveiled the company’s latest piece of pipeline equipment pioneering its capabilities in the Australian market.

Launched at the APGA Convention last month in Brisbane, Pipe Tek unveiled the latest addition to its fleet of equipment – a custom built inline inspection (ILI) pig transport trailer. Developed from insights gained from more than a decade onsite, the design of the trailer reflects the company’s practical understanding of what works in the field, addressing real-world challenges it faces every day on site.

The trailer is equipped with a high-tech laboratory, meaning data gathered from ILI runs can be reviewed while the pigs are actively navigating a pipeline. The ability to analyse data immediately on site also facilitates quicker decision making about next steps, whether that means continuing operations, performing targeted digs or scheduling repairs.

Pipe Tek Managing Director Myles Brannelly said the laboratory will also reduce downtime, improve accuracy and give greater flexibility onsite.

“In some cases, pipelines can be out of service while inspection data is reviewed. If this is done off-site then it can delay the reporting phase, and ultimately cost the operator money,” he said.

“The trailer will allow us to verify anomalies in the pipeline in real-time, which

we believe will reduce the risk of misinterpretation. When the data is available instantly, our team can work with pipeline engineers, contractors and the asset owner to interpret results, and develop a plan immediately.

“It will also mean our crews can adapt inspection plans on the fly, or re-run pigs in specific sections based on what they’re seeing in the data.”

The custom-designed trailer also has a built-in crane, meaning a separate winch or

pipeline and the configuration of the tool, but some can weigh more than a tonne. long distances and operate in remote and often demanding conditions.

“When you’re hundreds, or sometimes thousands, of kilometres away from a town or city, the reliability and durability of our gear is essential,” said Brannelly.

“With our recent expansion into Western Australia, it’s feasible that the trailer might have to be able to withstand a more than 4,000 km journey – so we’ve incorporated that into the design.”

The trailer was unveiled on the company’s stand at the Convention, which coincided with Pipe Tek’s 10th anniversary celebrations. Brannelly said he and co-founder Taddam Farrant were humbled to share the milestone with so many pipeliners that have helped them achieve the milestone.

“Celebrating 10 years at the APGA Convention was a really special moment for the whole Pipe Tek team,” he said.

“The association and the wider pipeline community has played a big part in our journey, so marking that milestone surrounded by our peers and industry partners made it even more meaningful. We can’t wait to see what the next 10 years brings.”

Other

Compound

Helix

Custom

As kwik-ZIP celebrates 25 years of business, the company has paused to reflect on its many milestones, as well as the people who have helped shape its journey.

For a quarter of a century, kwik-ZIP has been at the forefront of engineering innovation, transforming the way centralisers and pipeline spacers are designed and delivered across the globe. Over the last five years alone, more than three million kwikZIP units – spanning a range of sizes – have rolled out from precision injection moulds, destined for projects on every continent.

From small-diameter centralisers used in monitor wells and foundation piling, to robust pipeline spacers capable of accommodating diameters in excess of 3.5m, kwik-ZIP’s applications reflect an impressive versatility. Each product is a testament to the company’s ongoing commitment to solving real-world challenges in civil construction, water infrastructure, and energy sectors.

Innovation runs deep at kwik-ZIP. The relentless pursuit of smarter, more effective solutions has resulted in an impressive intellectual property portfolio, with ten patents and two design registrations secured globally. Notably, the company’s most recent U.S. patent – granted just two months ago –speaks to kwik-ZIP’s continual evolution and relevance in a competitive landscape.

From the outset, materials engineering has played a central role in kwik ZIP’s success. Its products are manufactured from engineered thermoplastic blends that offer high flexural strength, excellent temperature resistance, low coefficients of friction, and resistance to abrasion. Crucially, these components are non metallic, which avoids many of the problems associated with corrosion, damage to composite casing, or complications in environments with chemical exposure.

Compliance and accreditation have also marked important milestones. kwik ZIP’s HD, HDX and HDXT Series casing spacers have been formally approved under the Water Services Association of Australia (WSAA) Product Specification WSA PS 324. This specification prescribes standards for casing spacers in terms of material, runner spacing, abrasion resistance, and more – meaning that kwik ZIP’s products are not just well engineered but recognised by relevant regulatory bodies.

kwik-ZIP products are also approved for use within many utilities’ infrastructure, including Melbourne Retail Water Association, South-East Queensland’s Infrastructure and Materials (IPAM) list,

kwik-ZIP’s spacers and centralisers help protect pipes from a wide range of risks.

Sydney Water and the WA Water Corporation. All products are certified by the Australian Water Quality Centre (AWQC) for use in contact with drinking water.

Behind every component, patent, and certificate is kwik-ZIP’s remarkable team of people who make it happen. The creativity, dedication, and resilience of the people behind

the brand have propelled it from a promising idea to a trusted name in the industry.

Founder of the company, Jason Linaker, remains a guiding figure, driving technical development, leadership and the ethos of practical innovation. At every level, from design to production, from sales and logistics to customer service, the kwik ZIP team has had to

balance strict technical requirements with the unpredictability of field conditions to deliver for its clients. Their unwavering commitment ensures that every centraliser or spacer produced not only meets rigorous standards but also advances the boundaries of what’s possible.

Of course, kwik-ZIP’s story is also one of trusted partnerships. kwik-ZIP’s loyal

customers worldwide have placed their confidence in the brand’s ideas, supporting its growth and challenging the team to keep raising the bar. Suppliers, too, have contributed through their reliability, flexibility, and spirit of collaboration, helping kwik-ZIP deliver on its promises, time and again.

These combined efforts have resulted in tangible achievements. kwik ZIP products help contractors comply with wastewater, sewerage and water well construction codes; they protect carrier pipes in slip lining applications; they reduce risk to composite casing materials where conventional steel centralisers could cause damage. In many large infrastructure projects, including pipelines and large diameter casing installations, kwik ZIP’s spacer and centraliser systems have been selected for their reliability, cost efficiency, ease of assembly, and technically validated performance.

As kwik-ZIP marks its 25th anniversary, the occasion is one for celebration and reflection. It’s a moment to honour the journey so far, appreciate the present achievements, and look ahead with excitement to the innovations yet to come. The legacy of kwik-ZIP is not just found in the millions of units shipped or the patents granted, but in the spirit of innovation and partnerships that have defined every step of the way.

Looking ahead, the challenges are many: evolving environmental regulations, increasing demands on sustainability, ever more ambitious pipeline projects, and much more. Yet, these are exactly the kind of challenges that are well suited to kwik ZIP’s culture. If there is one thing the company’s history shows, it’s that kwik ZIP does not rest when there is still room to improve.

kwik-ZIP Managing Director Jason Linaker summed it up neatly: “As the company looks to the future, it does so with gratitude for the past and an undiminished passion for what’s still to come. Thank you for being part of the kwik-ZIP story.”

The APGA Women in Pipelines Forum is connecting research, industry and students towards shaping the future of the pipelines industry.

The pipeline industry is feeling the pressure of a labour and skills shortage, battling to attract young talent in a competitive market, while industry veterans retire from the field. As an industry-wide challenge, association bodies like the APGA Women in Pipelines Forum (WPF) are leading the way in tackling these issues.

In September, the NSW WPF committee hosted a panel discussion and networking day at the University of Wollongong (UOW), which was sponsored by ROSEN and newly established Gas Infrastructure Research Australia (GIRA). The event brought together researchers, industry professionals, and university students to highlight the critical role of research and industry collaboration.

Over the course of the seminar, the audience heard from senior leaders spanning pipelines, future fuels, materials-engineering and asset-integrity, from organisations such as GIRA, APA Group, Jemena, and ROSEN.

Key themes included how research and industry must collaborate to tackle the technical, regulatory and commercial challenges of transitioning energy networks toward hydrogen, biomethane and other future fuels; how pipeline infrastructure and materials must evolve; and how universities like UOW are willing to engage with commercial partners to translate research into real-world deployment.

APA Principal Materials and Welding Engineer, Maina Portella, was one of the presenters. As a former researcher at UOW and a current pipeline professional, Maina perfectly embodies the spirit of the event. Her presentation focused on how she bases her engineering decisions on industry research.

“The idea was to help students make the connection that the things they will learn in university – the research they can be part of – have real world impacts on engineering projects,” she told The Australian Pipeliner.

“We also talked about potential career paths in our industry, planting the seeds to attract future pipeline professionals.”

NSW WPF Chair Larissa Villas-Boas, Jemena Risk and Assurance Specialist, said she is extremely proud of the committee’s efforts in conceptualising and bringing such event to life, highlighting the importance of collaboration and inclusion.

“This event was unique in bringing together not only industry members but also academia representatives and students,” she said. “It was very rewarding to see students interested in learning more about the topics

presented and potential career pathways into the pipelines industry.”

The event also included a tour of the UOW’s hydrogen lab – a leading hydrogen pipeline safety facility and the only one of its kind in Australia.

“People really enjoyed visiting the lab,” Maina said. “ROSEN’s lab technician Brad Davis did a wonderful job explaining the functioning of the equipment and how tests are performed. The feedback on the tour was excellent.”

In fact, the entire day was very well received by attendees, who had much to say in praise of the event:

“Everything was perfectly arranged. The WPF Chair [Larissa Villas-Boas] made a special effort to personally introduce herself to everyone, which created a truly warm and inclusive atmosphere. Kudos to the entire team for organising such a fabulous session, especially the NSW Chair. A wonderful experience at the Women in Pipelines Forum!”

“A good mix of speakers and excellent lab tour.”

“The topics and format chosen were excellent, and the location was thoughtfully selected to include university students in the discussions. It was great to see such inclusive planning.”

“Maina did a fantastic job presenting, and Laura [Fothergill] chaired the sessions – both of them did so with confidence and professionalism. They were an excellent representation of APA, creating opportunities for and building connections between the industry and the UOW, as well as showing real courage in initiating, leading and managing the event.”

Overall, the event emphasised that future of the pipeline industry will not be about academia working in isolation nor industry simply buying technology. Instead, it will require cooperative designed research and development, shared risk, real-world trials, and a workforce with the right mix of skills and experience.

•Hot Tapping

•Line Isolation & Bypass

•Pipe Cutting

•Commissioning

•Decommissioning

•Equipment Maintenance

•Training

The Australian Pipeliner takes a closer look at what makes PIPA so indispensable to the pipeline industry.

Almost everyone in the pipeline industry has heard of the Plastics Industry Pipe Association of Australia (PIPA), and perhaps just as many are familiar with the work it does in championing plastic pipe through education and advocacy. But few, no doubt, understand just how much work goes on behind the scenes.

The Australian Pipeliner was lucky enough to sit down with PIPA Australia Executive General Manager Cindy Bray for a rare glimpse at the inner workings of this machine. And what we found was a vast web of passionate and generous people, all dedicated to elevating the pipeline industry.

At a glance

Industry associations are crucial for advancing, standardising, and advocating for entire sectors, providing a unified voice and expert guidance that no single organisation could achieve alone, and here PIPA is no exception.

PIPA acts as the peak body for plastic pipes and fittings in Australia, dedicated to contemporary, best practice use of these systems across many different industries.

The approach to achieving this is fourfold. It involves advocacy through working closely with industry authorities, governments, and global partners; education through technical insights and training; technical leadership through setting standards for manufacturing, installation, and use; and sustainability through championing environmentally responsible design and recyclability in plastic pipe systems.

As the powerhouse behind PIPA Australia, Cindy Bray wears a lot of hats. On any given day she might be working with her technical committees developing or update industry guidelines, consulting with government bodies, educating on the critical role plastic pipes play – just not before a morning cup of coffee.

Bray has spent decades in the pipeline industry, with experience spanning marketing, technical roles, product management and innovation, which she said gives her a holistic view of the industry – a major boon in her position at PIPA.

“I suppose I’m a bit of a storyteller, sharing the story of plastic pipes,” she said.

“I’m constantly sharing our industry’s story with different audiences, explaining how

plastic pipes deliver essential services every single day. These pipes are hidden underground or behind walls, so most people don’t even realise the critical role they play. Yet plastic pipes are the unseen infrastructure that keeps our world moving – delivering clean water, energy, sanitation, and stormwater management. Though largely out of sight, they quietly improve our lives, keeping communities healthy, protecting the environment, and helping build a cleaner, more sustainable future. A great deal of expertise and care goes into keeping them running smoothly.”

One of the common challenges in the plastic pipe industry is overcoming negative perception due to a false conflation with single-use plastics.

Unlike single-use plastics, plastic pipes are engineered and designed to last more than 100 years, and at the end of their long life span can be recycled back into non pressure

manufacturing, use, repair, and recyclability.

“One of my favourite parts of the job is talking to people who know little about plastic pipes – or who may even have negative preconceptions about them,” Bray said.

“I enjoy talking about the role plastic pipes

“Plastic pipes perform vital and often unseen functions as part of our everyday lives. As part of the PIPA technical committees, I work on developing industry guidelines and technical documents for the safe, sustainable, and effective use of plastic pipes systems in a range of applications.”

Lucy Croker, Vinidex Product Applications Specialist

conversation, seeing their whole perception change is incredibly rewarding. If I can get that through to one person, they might go on to share it with someone else. Every conversation has an impact.”

The human engine Bray isn’t alone in her passion for the industry. The work PIPA does, particularly its technical guidelines and notes, is powered by the tireless contributions of its members.

Teams of industry experts develop technical guidelines, notes, and codes of practice that ensure quality, safety, efficiency, and sustainability across every stage of plastic pipe manufacturing and installation. These guidelines are regularly updated through research, international collaboration, and

“These teams consist of technical managers, engineers, or industry specialists, and most have dedicated decades to the industry. They come from various backgrounds – but every one of them lives and breathes plastic pipes. Their passion and expertise are what keep the sector moving forward,” Bray said.

“I think we often underestimate the value of these people and the depth of their knowledge. For them to volunteer their time, spending

“For me, PIPA represents a valuable and vital opportunity to be able to contribute and collaborate with my industry peers on a range of technical matters such as development of guidelines, standards and other materials that address a range of technical topics.”

, Iplex National Technical Services Manager

best practices. Similarly, Bray regularly collaborates with her plastic pipes associations international colleagues, drawing on a vast network of knowledge to advance the sector.

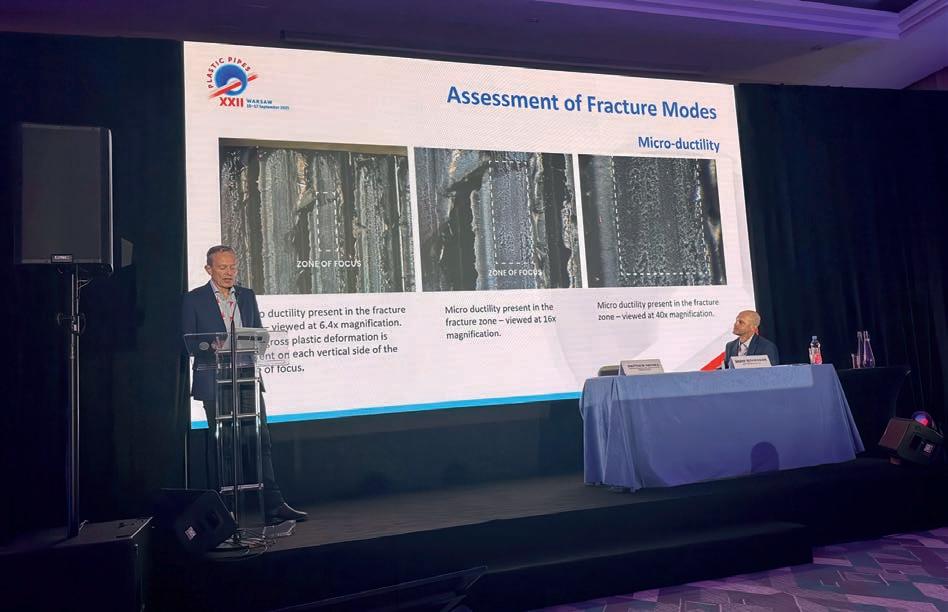

In September, PIPA Australia presented three technical papers at the Plastics Pipes Conference Associations PPXXII Global Conference in Warsaw, Poland.

“It’s exciting to share the research and initiatives we’re undertaking here in Australia with the world,” Bray said. “It’s truly worldclass work, and none of it would be possible without our members.”

APGA Head of Communications and Operations Lawrence Shelton talks about carrying the Convention spirit into 2026.

The 2025 APGA Convention and Exhibition reminded us of something essential: our industry thrives when we share. It is collaboration that has long defined the pipeline sector in Australia. What we witnessed in Brisbane was a living example of that culture in action.

Throughout the Convention, professionals from across the supply chain came together not just to present their work, but to share their challenges, reflect on lessons learned, and offer solutions that others could take back to their own organisations. The effort behind this, preparing papers, delivering presentations, stepping into difficult conversations, was significant. It takes courage to be transparent. It takes conviction to turn your experience into insight for others. That willingness to contribute is what made the 2025 Convention exceptional.

From technical sessions to plenary panels, the Convention featured speakers who were unafraid to share not only what went right, but also what was difficult. We saw complex project case studies, emerging technology evaluations, operational challenges, and lessons from the frontlines of asset management. Each of these sessions reflected not just technical skill, but a deeper commitment to raising the collective capability of our sector.

We extend our thanks to every speaker, paper author, and panellist who took the time

to engage so meaningfully. The value of what was shared will ripple well beyond Brisbane, influencing how others approach their own projects and decisions.

This is what makes our industry, and our community through pipelines, unique. While we operate in a competitive space, we have proven time and again that we are capable of setting that aside in service of something greater, advancing the industry as a whole.

There is no better example of this spirit than the panels led by the Young Pipeliners Forum and the session on psychological safety. These conversations challenged us to broaden our view of industry leadership, not only in terms of technical excellence, but in how we support people, foster inclusive workplaces, and build for the long term.

Likewise, the work of the Pipeline Operators Group showcased a shared commitment to technical advancement and operational transparency. Presentations on redefining ‘unpiggable’ pipelines, and overcoming the limitations of in-line inspection under difficult conditions, spoke to the collaborative mindset that continues to push our industry forward.

None of this happened in isolation. It was made possible by our volunteers, our members, and the community that continues to engage with APGA throughout the year.

Looking ahead: The energy transition requires us all As we turn our focus toward 2026 and

beyond, this collaborative foundation will be more important than ever. The energy transition is accelerating. Our industry is being called upon to help deliver decarbonisation, ensure reliability, and support the evolving needs of communities, governments, and markets.

We cannot do that in silos. The complexity of the challenges ahead will require us to work even more closely across companies, sectors, and disciplines. It will require a shared language, a shared commitment to continuous learning, and a shared willingness to contribute. This is not just about responding to change, it is about leading it.

At APGA, we are deeply proud of the role we play in bringing the industry together. The Convention is just one piece of the puzzle. Year-round, we will continue to facilitate forums, site visits, webinars, and committees where ideas are exchanged, best practices are shaped, and progress is made.

But we cannot do it alone. The Secretariat will continue to rely on the industry to bring its voice to the table. We will rely on volunteers to lead conversations and challenge norms. We will rely on our members to invest in their people, to speak up, and to help shape the future of the pipeline sector.

The success of the 2025 Convention belongs to everyone who participated. The opportunity in 2026 and beyond lies in how we build on it. The invitation is open. The momentum is real. Let’s carry it forward together.

Fleet Helicopters provides client focused aviation solutions for all stages of your pipeline project. From aerial surveys for pipeline easement identification, pipeline construction support and operational fugitive gas leak detection. Specialising in operations in Australia’s hardest to reach places we can cater to all of your aviation support needs.

Fleet Helicopters has been providing aviation services to private and Government sectors for over 41 years.

Fleet Helicopters specialises in operating in remote, difficult environments with an unmatched record for safety and reliability.

Fleet Helicopters operates a fleet of 19 aircraft ranging from single engine aeroplanes through to multiengine, heavy lift, transport category helicopters.

Fleet Helicopters has over 30 years history supporting the gas industry Australia wide providing charter, aerial survey, external load and gas leak detection operations.

Fleet Helicopters is the sole operator of the Boreal GasFinderAB laser based aerial gas leak detection system in Australasia. Leak detection surveys have been conducted for clients including SANTOS, Shell, the APA group, QGC and Origin Energy. The Boreal system ishighly sensitive with methane levels as low as 0.5ppm being detectable with surveys able to achieve up to 1000km of survey per day.

At the heart of every event this year was a simple truth: we thrive when we connect. The Women in Pipelines Forum and our events this year became a place to find allies, mentors, and friends. The power of networking – of showing up for one another – was the thread that ran through every gathering, and it’s what made 2025 so unforgettable.

This year bought a series of events across the country, which couldn’t have happened without the hard work of our volunteers and sponsors:

In September, the NSW Women’s Pipeline Forum hosted Delivering the Future of Energy Together: The Critical Role of Research–Industry Collaboration, bringing together professionals from APA, ROSEN, Jemena, GIRA, and the University of Wollongong (UOW). Attendees participated in seminar sessions covering technical developments and regulatory updates in the pipeline and hydrogen sectors. A highlight of the event was a guided tour of the UOW Hydrogen Lab, which conducted mechanical testing for the Parmelia Gas Pipeline Hydrogen Conversion Project. The event also provided valuable networking opportunities with APGA members, industry leaders, and UOW engineering students and researchers. Special thanks to Maina Portella Garcia Barnett (APA) and the NSW WPF committee for organising an insightful and engaging event.

The Western Australia and Queensland Women’s Pipeline Forum state committees hosted two successful golf-themed networking events. The WA committee held a golf clinic sponsored by ROSEN, while the Queensland committee organised a

sponsored by PFP. Both events provided relaxed, engaging environments for members to connect outside of formal settings. Special thanks to Donna Fox (APA) from the WA committee, and to Kayla Pizzica (APA), Stephanie Johnson (PFP), and Elizabeth Wheeler (LERA) from the QLD state and advocacy committee for their efforts in coordinating these valuable networking opportunities. Elizabeth Wheeler also took out the longest female drive at the Vermeer Gold Classic at Convention – proof that practice pays off.

Our Victorian subcommittee held their second annual netwalking with executives event. Melbourne put on some fantastic weather where our attendees had an informal mentoring session with some great industry executives. The opportunity to share concerns and gain experience from each other was invaluable for both mentors and mentees. Thank you to the Victoria state committee, particularly Cara Robb and Katie Cuic.

Finally, in October, the APGA Convention was held in Brisbane, kicking off with the 4th annual Women’s Pipeline Forum networking event. Attendees had the opportunity to connect with peers and update their professional headshots. Guest speakers Allyson Woodford (APA) and Samantha Angelo (Zinfra) encouraged attendees to build authentic workplace environments and expand their networks. Throughout the convention, the WPF booth provided a space to engage with industry professionals and showcase some fun with mini golf. A special thank you to everyone who visited the booth, and to the volunteers who ran the hole-in-one competition and helped facilitate conversations throughout the week.

As we step into 2026, anticipation builds for what’s to come. Planned updates, new initiatives, including the Safety for All Code of Practice and evolving conversations promise to keep the WPF as engaging as ever. We invite every member – new and seasoned – to help shape the next chapter.

Collaborative research continues as GIRA takes over from Future Fuels CRC.

Ifollowing its formal establishment as the successor entity of Future Fuels Cooperative Research Centre (FFCRC) earlier this year. With the FFCRC reaching the end of its seven-year term – preceded by the Energy Pipelines CRC’s 10-year term – the transition to GIRA and away from the CRC model is a change for the industry, but one that represents an opportunity for industry to drive innovation in developing the future of Australia’s gas infrastructure.

In addition to the formal set up of the company and the associated administrative processes, the recent focus of GIRA has been to continue the momentum of the FFCRC, while also using this period of transition to reset and refresh the research priorities. GIRA recently held an interactive ‘research planning workshop’, which was well-attended by approximately 30 key stakeholders from APGA’s research and standards committee and ENA’s gas technical reference group. During the workshop participants brainstormed, discussed, and ranked research ideas, providing a valuable input to ensure the research delivers practical outcomes which address the key challenges and opportunities for the industry. Based on the outcomes of the workshop, GIRA’s initial research plan is beginning to take shape, structured around

Research to inform the design, construction and repurposing of infrastructure, including topics related to materials/welding and the challenges associated with emerging fluids such as hydrogen and carbon dioxide.

• R P2: Gas infrastructure operations

• Research to enable the safe, efficient and sustainable operation of gas infrastructure, including emissions management, predictive maintenance, corrosion control and the mitigation of threats to pipeline integrity (such as geohazards, third-party interference).

• R P3: Strategic research

• Facilitating an improved understanding of the role of gas infrastructure in a changing energy landscape; topics include techno-economic modelling (such as biomethane viability), policy and regulation, and community and consumer understanding.

developing

The GIRA team has had the opportunity to participate and present at several recent industry meetings and events, once again continuing the FFCRC legacy of bringing people together and building relationships.

Wollongong, hosted by the NSW APGA Women in Pipelines Forum, with over 50 attendees including industry professionals, academics, researchers and undergraduate students. The event highlighted the importance of collaboration between academia and industry not only in terms of research outcomes used within the industry, but also as a pathway for the development, training and education of the future workforce.

GIRA also had the opportunity to engage with the broader pipeline community at the APGA Annual Convention and Exhibition, which included a joint presentation on the transition from FFCRC to GIRA delivered by David Norman (FFCRC CEO) and Doug Proud (GIRA Research Manager).

Some key themes discussed at the convention which align closely to the research plans of GIRA included technical, regulatory and economic challenges related to the decommissioning of infrastructure; management of aging assets and improvements in integrity management; design and safety management challenges for storage pipelines and CO2 pipelines; and international collaboration and knowledge sharing.

The Australian Pipeliner caught up with Fleet Helicopters after the APGA Convention.

For the team at Fleet Helicopters, the recent APGA Convention represented more than just another trade show. Instead, it marked a coming-together of past relationships, fresh leads and a chance for the company to showcase its continually evolving aerial-capabilities to the pipeline industry.

On the exhibition floor, the foot traffic was steady. “We’ve had some good conversations,”

Fleet Helicopters CEO Mike Watson told The Australian Pipeliner. “It sounds like there’s some fairly good, decent-sized construction projects coming up in the future that we hope to be a part of.”

Many of these discussions were with clients that Fleet Helicopters has worked with before. In some cases, those commercial ties go back decades.

“It was interesting to know that there are people still in the industry that we worked with almost 25 years ago,” Watson said.

Other attendees at the stand were new contacts, drawn by Fleet’s proven aerial prowess. One of the standouts on display was the company’s Boreal GasFinderAB laser system, an aerial leak detection technology.

“I think what resonated was the accuracy of the system and its history. People were surprised to hear we’ve been operating it

successfully for a long time – the technology has many runs on the board.”

Utilising the Boreal GasFinderAB laser system on board its helicopters, the company is able to scan pipeline infrastructure on an enormous scale to detect gas leaks.

“Our aerial leak detection surveys are much more economical and efficient than traditional ground inspections,” Watson said.

“The system uses an infrared laser that’s tuned to the frequency of light absorbed by methane. It’s very accurate and very sensitive, measuring down to 0.5 parts per million.

“And by measuring at the aircraft, it’s physically reading the gas rather than trying to sense it at a distance.”

Beyond gas detection, Fleet Helicopters also had productive technical conversations around equipment and personnel transport in remote areas. Multi-engine passenger transport, as well as the capability to transport equipment up to 1.5 tonnes, gives Fleet Helicopters a uniquely broad scope that few others can match. These capabilities enable the company to fly into truly remote easements and infrastructure corridors –terrain that wouldn’t be well served by road or fixed-wing operations. Reflecting on 2025, the company has cause to be proud.

The team ticked off a major aerial faultfinding project across New South Wales. The work required capturing high-definition imagery of more than 51,000 utility assets and flying more than 600 hours across roughly 7000km of easement. These numbers underline the scale and ambition of what is now achievable via aerial assetmanagement technology. Watson said the team is exploring ways to integrate artificial intelligence-based change recognition into these capabilities. In application, this technology would be able to analyse the difference in an asset’s health between surveys.

Looking ahead, Fleet Helicopters is excited about continuing the development of its aerial technology and exploring different avenues where it can be utilised.

“It’s only really limited by your imagination,” Watson said.

If 2025 was about scale, validation and technology build-out, then 2026 looks to be about application, extension and impact. For operators seeking rapid mobilisation of crews and gear, high-precision inspection services or advanced emissions detection capabilities, Fleet Helicopters stands ready to deliver.

Pipeline technology specialist STATS Group has played a leading role in SGN’s LTS Futures world-first project where a live 18-inch high pressure hydrogen pipeline was safely isolated.

STATS Group patented BISEP® tool –which is widely deployed on global oil and gas assets – has been proven as a leaktight line stopping technology which is safe to use on high pressure hydrogen pipelines.

Achieving the UK’s net zero emissions target presents one of the most complex and demanding challenges of our time. As the energy sector transitions away from fossil fuels, innovative solutions are needed to repurpose existing infrastructure.

The SGN LTS Futures project explored one such solution by converting the local transmission System (LTS) from transporting natural gas to hydrogen.

This initiative is ever relevant to STATS, with expertise in pipeline isolation, integrity, and intervention technologies that will be critical in enabling such transformations safely and efficiently.

The success of the trial is a significant development in the drive to meet net-zero emission targets and could lead to the repurposing of SGN’s 11,600km UK gas network from transporting hydrocarbons to hydrogen.

The project was part of SGN’s successful LTS Futures trial carried out on a representative 30km stretch of pipeline which runs from Grangemouth to Granton in Edinburgh.

SGN was delighted with the outcome and said the lessons learned on LTS Futures would create a blueprint for repurposing the entire LTS to hydrogen and provide a resilient backbone for a net zero energy system.

The scope of work included the installation of a DNV proprietary Grouted Tee, to provide access for STATS to perform hot tapping, line stopping, swarf (drill cuttings) dispersal, and completion plug installation. As part of the live trial, the STATS BISEP line stopping tool delivered a fail-safe, 100 percent leak-tight double block and bleed isolation.

The BISEP had to be validated to operate safely and leak-tight in high pressure hydrogen, which presented unique operational parameters. Unlike traditional line stopping technology, BISEP guarantees zero-leakage isolation, significantly increasing safety and reducing environmental risks.

STATS worked closely with DNV who

provided a Grouted Tee to provide a branch offtake suitable for use with hydrogen – which provides an alternative to live welding.

STATS Senior Business Development Manager Neil Mackay said close collaboration between SGN and STATS has proven the BISEP tool as the world’s only double block and bleed isolation technology for high pressure hydrogen pipelines.

“For the first time, hot tapping and leaktight line stopping operations have been successfully executed on a UK hydrogen pipeline, overcoming challenges of horizontal deployment, swarf dispersal, and hydrogen’s unique properties,” he said. “This required not just process adaptation but also the development of new procedures, tooling, and assurance processes.”

The safe isolation and modification of pipelines like the one used in the LTS Futures trial is essential to the entire hydrogen transition.

“Until now, no proven hot tapping or line stopping method existed which could ensure that repair, maintenance or modifications can take place safely and efficiently,” Mackay said.

“Not least the reduced emissions from the

For more information, visit statsgroup.com

use of BISEP technology whether in use for hydrocarbon gas or hydrogen.

“SGN provided leadership within the LTS Futures program, while STATS contributed world-class line stopping services, working alongside DNV to remove a fundamental barrier to hydrogen deployment.

“This innovation will support every UK network operator, benefit millions of customers, and accelerate decarbonisation. It is a world-first, delivered through collaboration, innovation and ambition, resulting in a body of evidence and operational knowledge that is transferable across the UK gas networks and beyond.”

SGN Chief Strategy and Regulation Officer Tony Green said the project is a milestone for SGN and the wider energy sector, showing that the UK’s gas infrastructure can be repurposed for a net zero future.

“It demonstrates both infrastructure and workforce readiness for hydrogen, with our skilled engineers gaining vital experience through the live trial,” he said. “Collaboration has been crucial, and working closely with INEOS and other partners has turned a complex concept into a success.”

Michels in Motion: Between March 2023 and February 2025, Michels completed 3 record-breaking HDDs in New South Wales. The 2,250-metre HDDs included elevation changes of 590 metres.

Curtiss-Wright’s Double Block and Bleed Isolation Plug helps a Spanish refiner complete critical hydrotests faster, safer and more efficiently.

When the ILBOC refinery in Spain faced a tight maintenance window, Curtiss-Wright EST Group’s Double Block and Bleed (DBB) Isolation Plug provided the ideal solution.

Designed for quick, safe pipe isolation during maintenance and repair, the plug can be repositioned rapidly across new welds for successive hydrotests – saving valuable time and reducing operational costs.