“Invested in

“Invested in

For over 50 years, UAA’s award-winning Mobile Plant and Machinery insurance solutions have powered the cranes and lifting industry - trusted by professionals who keep Australia moving.

Our seasoned claims team has access to a network of experienced industry repairers, assessors, and suppliers who are

We pride ourselves in creating insurance solutions that are handcrafted and can meet the varied needs of different businesses.

To learn more about UAA’s Industrial Special Plant products, we invite you to reach out to an insurance broker or visit our website uaa.com.au

12 CICA CEO report

Welcome to the CICA National Conference and Exhibition.

14 CICA AND NAAS

A new way to move your cranes without permit headaches.

17 All Cranes

The long game of All Cranes.

21 ANC Cranes ANC steps it up with new cranes. 24 CANZ

Crane parade a major success.

26 Smith Cranes

Australasia’s first Liebherr LR11000.

29 LEEA

Small shecks, big consequences: Inspection and maintenance.

32 The Buddie System

World first for Marr Group and The Buddie System.

34 Liebherr Australia

Careers that lift off at Liebherr.

37 RUD

Engineering strength, designing safety.

41 Dieci Apollo 20.4. Compact in size, smart in per formance.

CICA Conference QLD Focus

44 Sarina Crane Hire Focused on people, powered by cranes.

47 Origin Cranes

The origin of growth, trust and reliability.

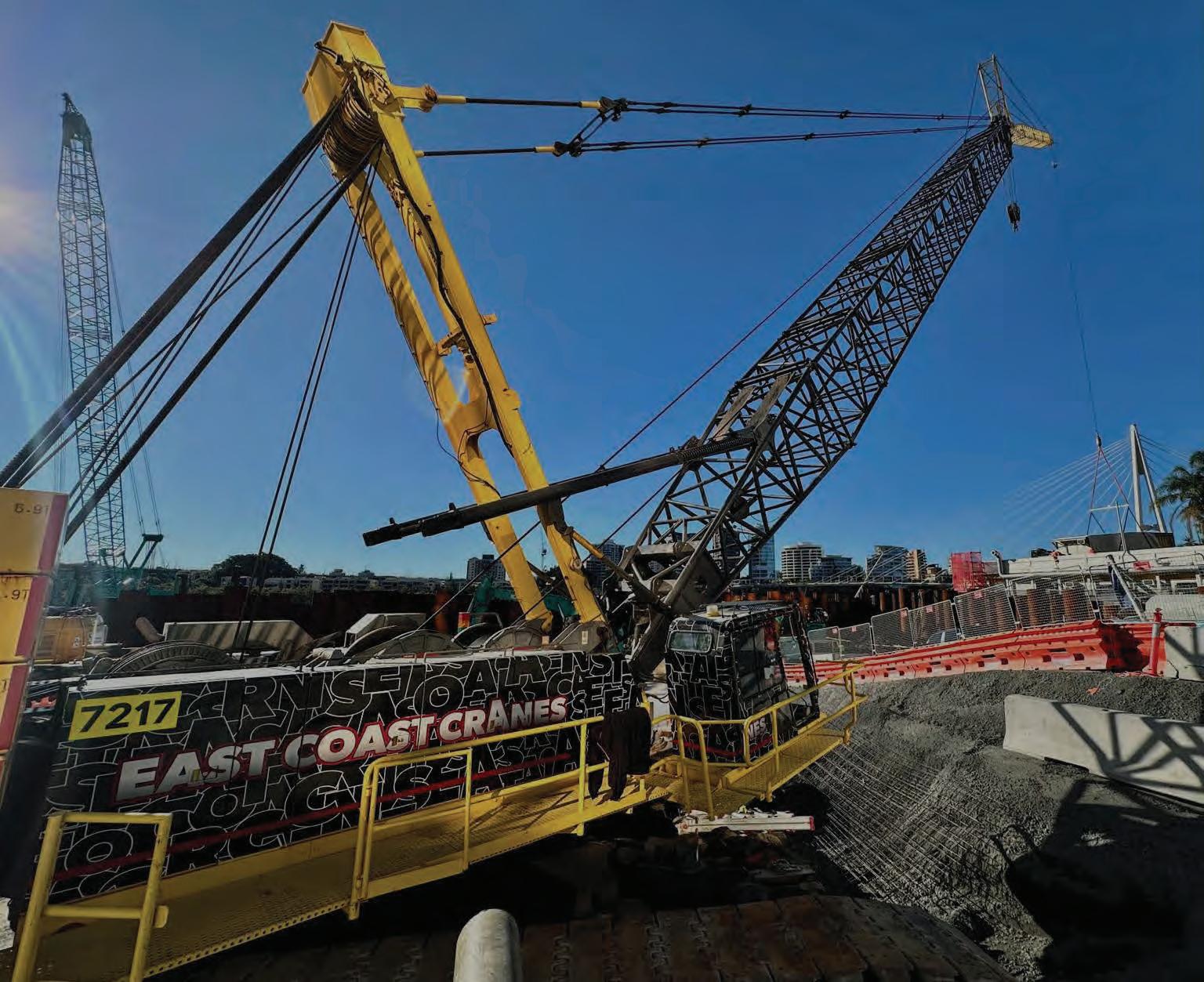

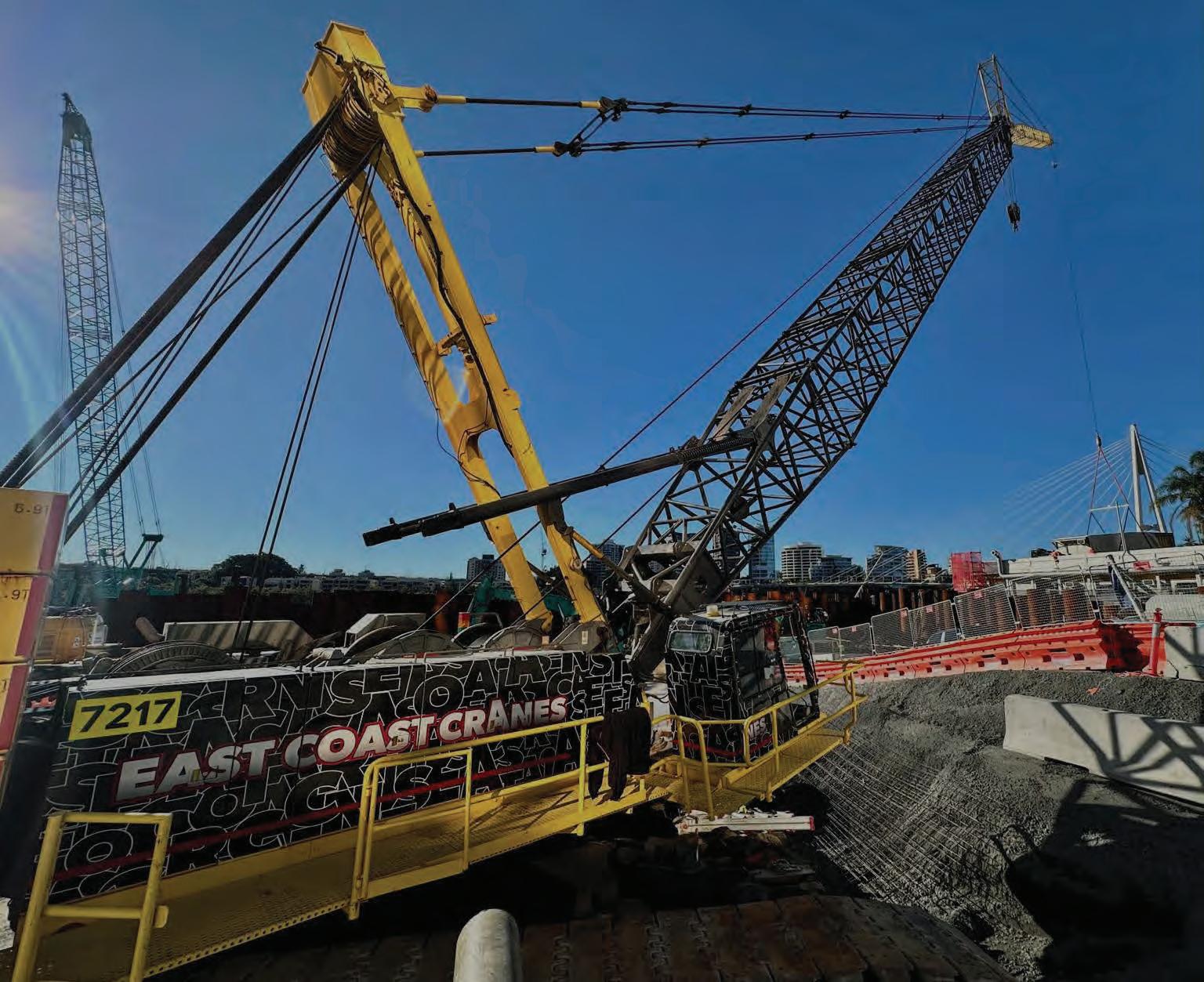

50 East Coast Cranes New Liebherr’s and Heavy Lift business.

54 XCMG and Brisbane City Cranes New XCMG for Brisbane City Cranes.

57 Superior Cranes Busy operations in Brisbane and Wagga Wagga.

60 Zoomlion Powering heavy lifts in Queensland.

63 Altequip Lifting with strong foundations.

66 Century Cranes

From crocs to construction, they lift it all.

69 Universal Cranes Major expansions in North Queensland.

72 DRA Engineering Pick and carry expert joins Humma.

75 DLL

Financing made simple for crane companies.

79 Maxirig Global Lif ting Partnering for a stronger local industry.

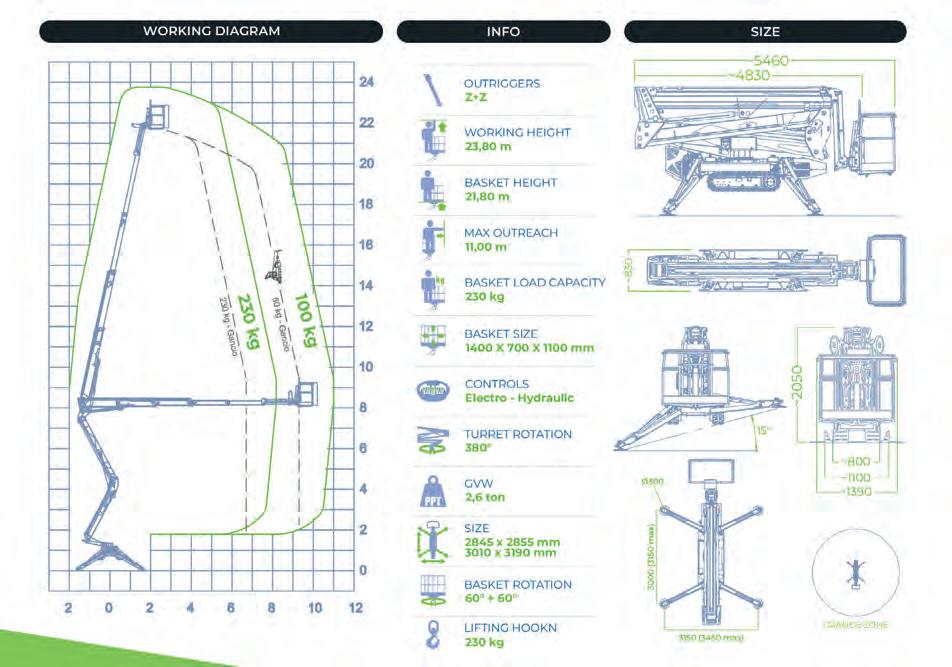

82 TRT and Maritime Construction New bespoke trailer and Kobelco.

85 All Lif ting & Safety The quiet strength of fabrication.

88 Bridco Specialising in stainless-steel lifting equipment.

91 Drake Trailers Steering heavy haulage forward.

94 Andromeda Industries Investment to service demand.

96 Tutt Bryant and Universal Universal appeal of new Sany from Tutt Br yant.

99 Sany Australia Inside Sany’s mega factories.

102 Finlease Brighter times come with spring.

78

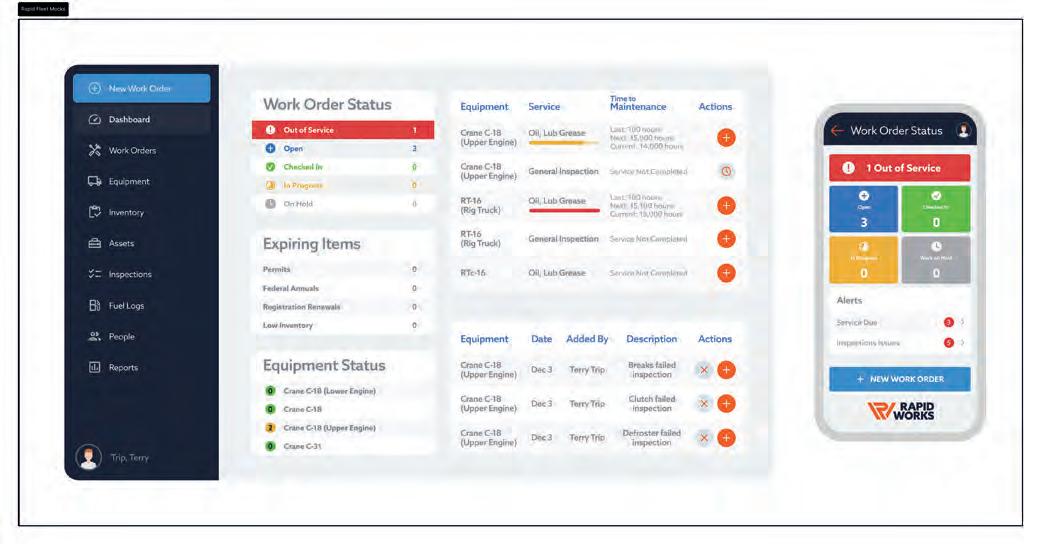

104 RapidWorks RapidWorks rolls out in Australia and New Zealand.

107 Protective Leaving no room for error.

110 Pace Cranes New name and Kings Award for tracked carrier.

113 Hardiquip First Jarlway hydraulic luffing tower crane installed.

116 Potain and Reds Global Reds Global partners with Potain.

119 Quadrent Finance built to bear the weight.

122 Pickles Auctions Pickles, leading in the second hand crane market.

124 Franna Safety in motion on the North East Link.

127 Dotmar Cutting costs without cutting corners.

130 Boom Logistics Challenges of attracting the next generation to the industry.

133 UA A Fully invested in CICA and the industr y.

136 MCT Equipment Examining MCT Equipment’s capabilities.

138 Complete Crane Solutions Tonnage takes the load.

141 Bridgestone Advantages of a Tier One Tyre supplier.

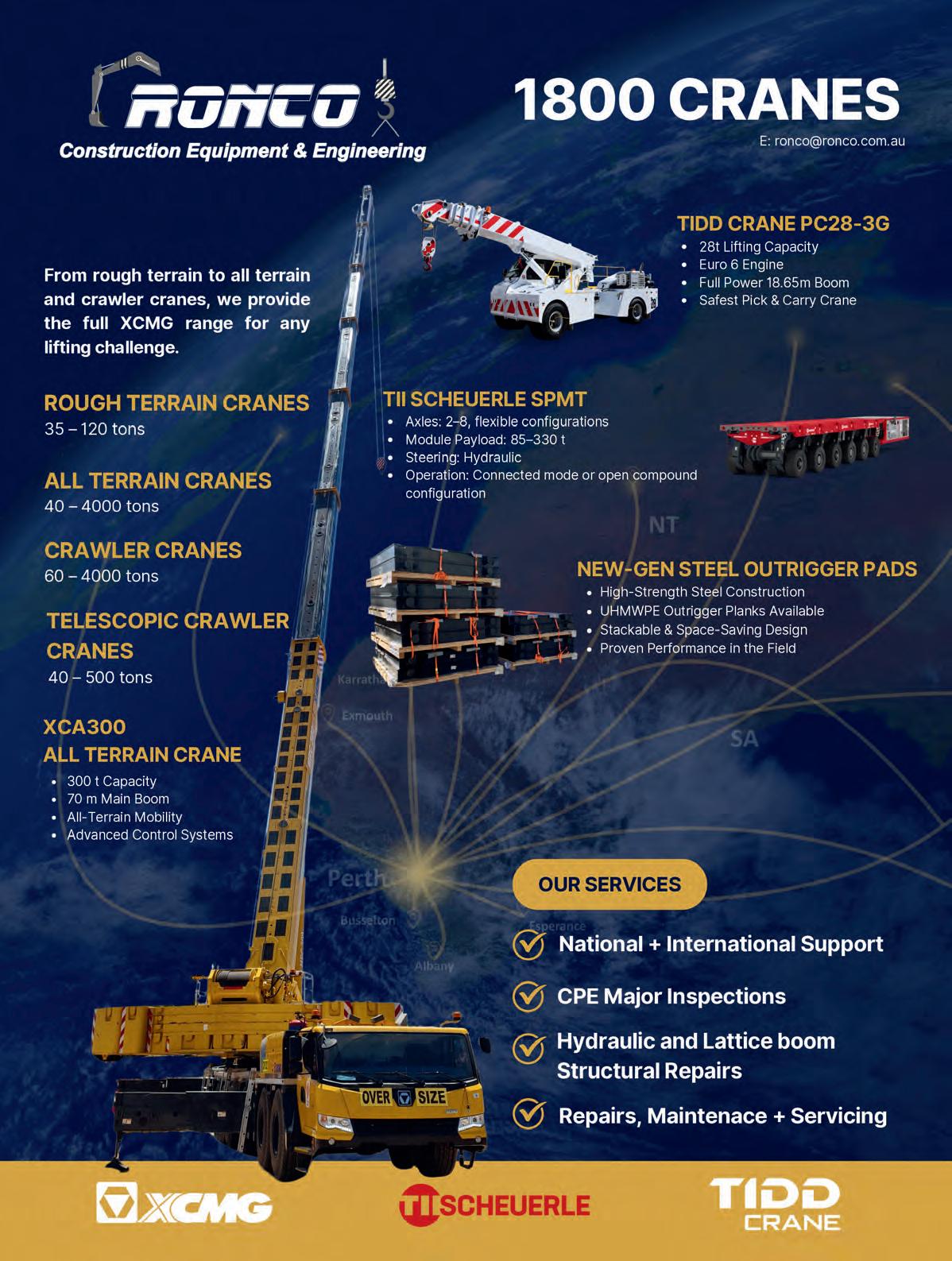

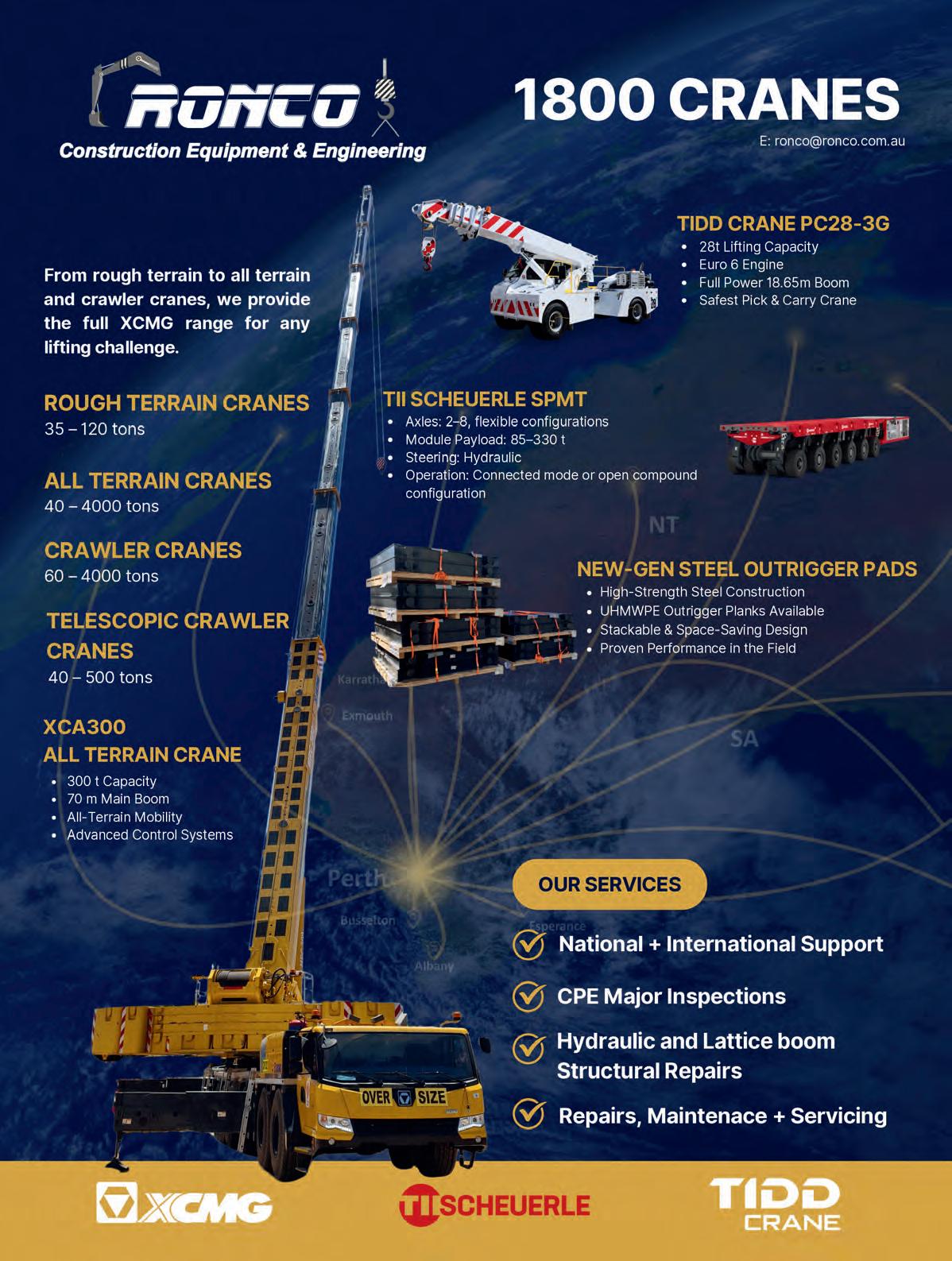

144 Ronco New faces, new perspective.

147 Manitowoc and Grove Grove first for the UK and Italy.

150 UAA Beyond Blue Building hope, one crane at a time. Melbourne Lif ting Strength in service.

Baden Davis Crane Connection Crane Connection appointed XCMG or.

esolution Rigging Services From hospitals, housing to schools: anes that deliver.

ace Cranes 30 years of service and maintenance ill loving it.

When others reach their limit We’re just getting started

450t Capacity 79m Luffing Jib

REACH OUT NOW FOR A SIDE-BY-SIDE COMPARISON AND SEE THE DIFFERENCE FOR YOURSELF.

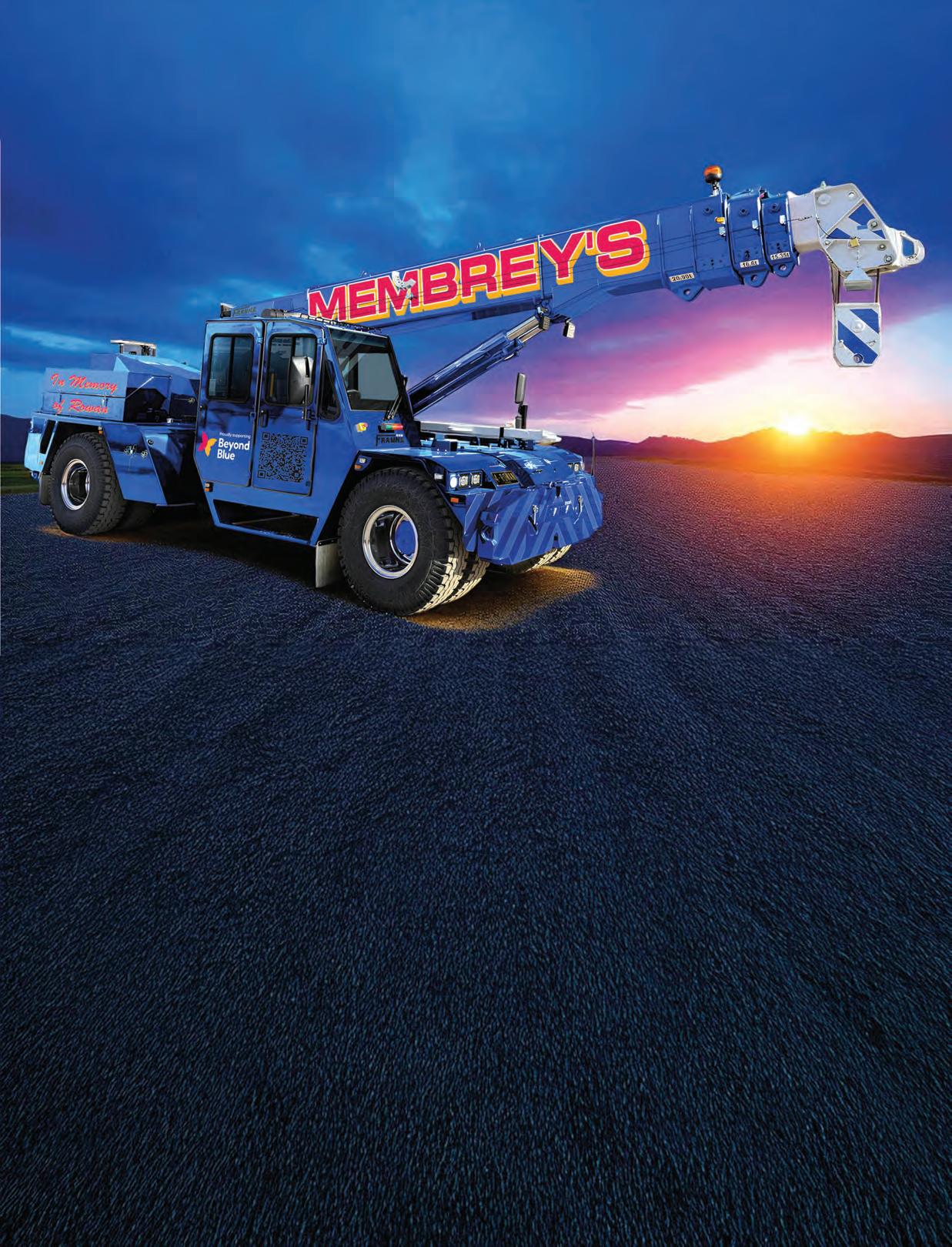

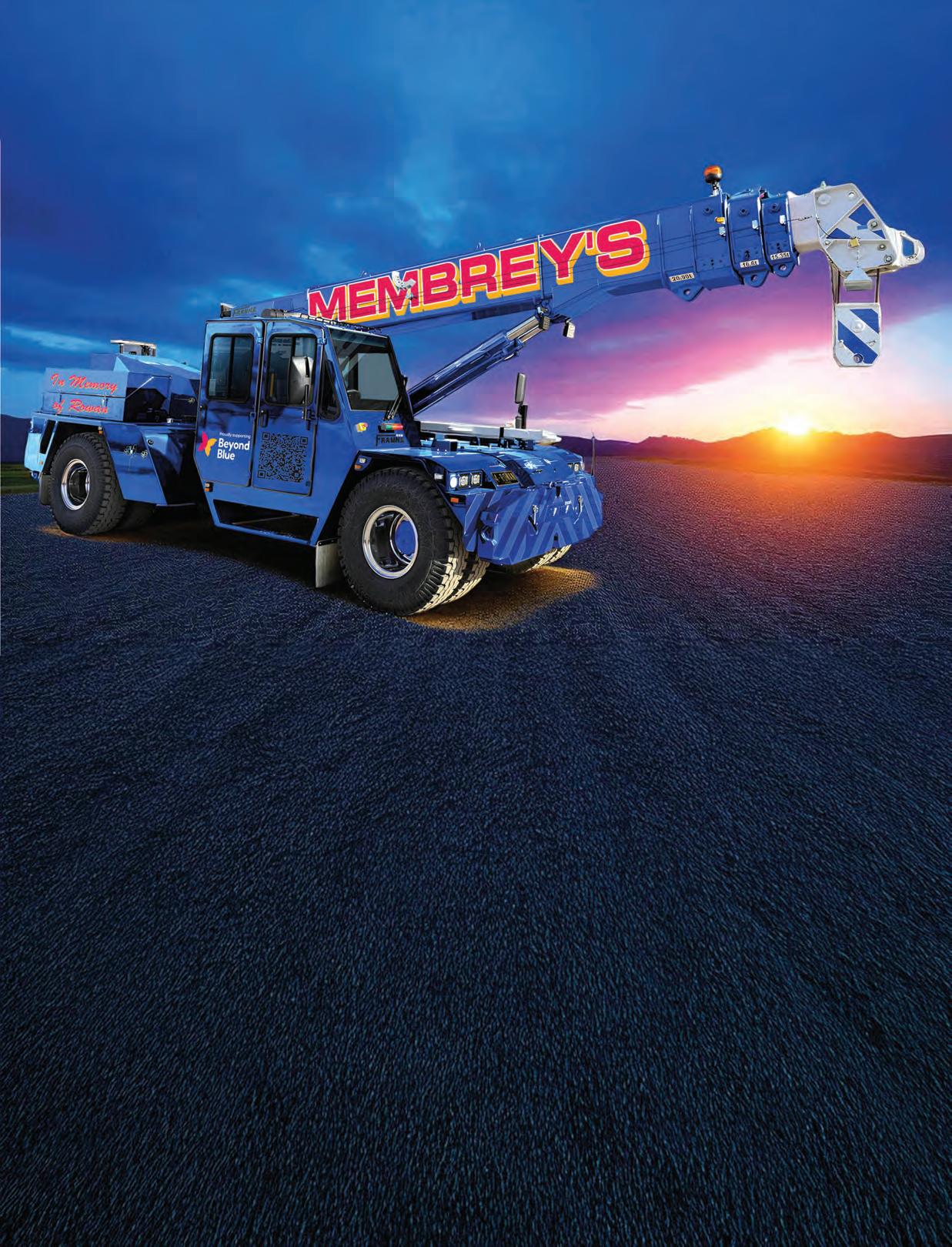

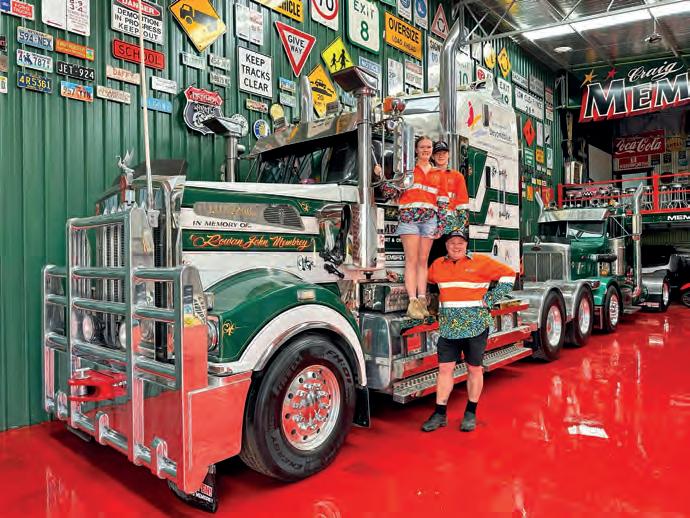

IN WRITING THIS COLUMN, I ACKNOWLEDGE that early September was a dark and difficult period for the industry but Craig Membrey, Managing Director of Membrey’s Transport and Crane Hire, with support from the industry, brightened the mood immensely. One crane now holds something deeply personal for Craig: the memory of his son Rowan, and a message he has carried for more than a decade – that talking about mental health can save lives.

Over time, Craig began to dream of extending that legacy into the lifting sector – a space that has been central to Membrey’s for decades. When he learned Franna was about to deliver its 2000th MAC25, he saw the opportunity to bring that dream to life. Working with long-time friend Danny Black, General Manager of Franna, and securing the support of Beyond Blue, Craig ensured the milestone crane was finished in Beyond Blue livery. You will read the full story in this issue.

We congratulate The Crane Industry Council of Australia on the success of

Below: Franna’s 2000th MAC25 is finished in Beyond Blue livery for Membrey Cranes and Transport in memory of Craig’s son Rowan.

The National Conference and Exhibition. Predictions are for one of the largest conference delegations and the most comprehensive exhibition ever. The CICA Lift of the Year awards have been well supported with each category receiving numerous nominations. It will be interesting to see who succeeds when the winners are announced during the Gala Dinner.

This issue also includes our first ‘deep dive’ into the Queensland crane sector where a number of crane hire companies have taken the opportunity to promote their businesses and most recent acquisitions.

As always, the Cranes and Lifting team have worked hard to bring you this issue of the magazine and we hope you enjoy the read.

BOOMS UP!

Simon Gould Editor, Cranes and Lifting

Published by:

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman John Murphy E: john.murphy@primecreative.com.au

CEO Christine Clancy E: christine.clancy@primecreative.com.au

Publisher Sarah Baker E: sarah.baker@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Assistant Editor

Danny D’Cruze

E: danny.dcruze@primecreative.com.au T: 0429 187 751

Business Development Manager Emily Schlegel E: emily.schlegel@primecreative.com.au T: 0466 317 555

Client Success Manager Louisa Stocks E: louisa.stocks@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen

Subscriptions

Frank Rapone T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

Underwriting Agencies of Australia (UAA) is supporting Membrey’s Transport & Crane Hire to raise funds for Beyond Blue’s 24/7 Support Service ahead of the CICA Conference.

Every dollar donated will go towards funding Beyond Blue's 24/7 Support Service. This means with your support, we can be there for people experiencing anxiety, depression or at risk of suicide whenever they reach out for help.

Scan below to donate today:

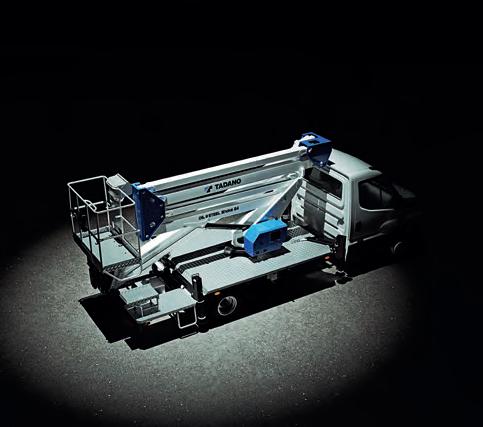

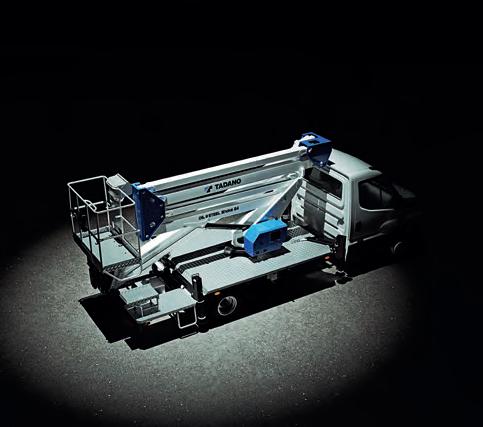

Tadano continues to shape the future of lifting and access solutions by combining relentless innovation, a clear sustainability strategy, and investment in customer service infrastructure. The result is a company firmly committed to both industry progress and customer success.

TADANO’S COMMITMENT TO INNOVATION spans safety systems, electrification, and digitalisation.

At tech event CES 2025 in Las Vegas, the company showcased advanced technologies such as artificial intelligence (AI)-powered prognostics and health management, surroundings monitoring, ground collapse prevention, and suspended-load motion assistance under the theme “Safety. Every Day. Every Lift.” This global focus on next-generation

This global focus on next-generation technology continued at bauma 2025 in Munich, where Tadano presented one of its strongest product portfolios to date.

technology continued at bauma 2025 in Munich, where Tadano presented one of its strongest product portfolios to date.

Highlights included the new AC 5.250L-2 all terrain crane with a 79 metre boom and 736 tonne-metres load moment, the next-generation CC 78.1250-1 lattice boom crawler crane designed for wind and infrastructure projects, and the premiere of the eGR-1000XLL EVOLT fully electric rough terrain crane. Tadano also debuted new aerial work platforms

from the Nagano and Oil & Steel ranges, alongside digital innovations such as the Hey Tadano AI assistant and the new 3D job planner.

Tadano’s Green Solutions innovation pipeline is also broadening into access and aerials, with electrified and hybrid platforms like the NUL07E-7, NUS21W-7, and AT-100TTE providing lower-emission solutions for diverse environments. Together, CES and bauma allowed Tadano to demonstrate its twin

“The first AC 4.070HL-1 in Australia is now at work with General Crane Services WA, marking an important milestone in bringing hybrid lifting solutions to Western Australia.”

The Tadano Green Solutions (TGS) portfolio consolidates initiatives such as the ESTA-award-winning E-Pack electro-hydraulic kit for zero-emission operation, engines compatible with renewable diesel alternatives, and electrified cranes.

“By 2030, the company aims to cut carbon dioxide emissions from operations by 25 per cent and from product use by 35 per cent, on the path to achieving full climate neutrality by 2050.”

focus: applying digital intelligence and safety systems while accelerating electrification and hybrid technology across its product line.

Hybrid innovation is not just a concept – it’s already working in the field. The AC 4.070HL-1 all terrain crane can operate a full workday on battery power, with equal performance to diesel. Its rapid-charge system reaches 80 per cent capacity within an hour and can operate while charging, providing flexibility and efficiency.

The first AC 4.070HL-1 in Australia is now at work with General Crane Services WA, marking an important milestone in bringing hybrid lifting solutions to Western Australia. In parallel, the E-Pack electro-hydraulic

system has been successfully deployed with Boom Logistics, enabling whisperquiet, zero-emission operation in sensitive urban environments.

These local projects demonstrate how Tadano’s global innovations are already supporting Australian customers in realworld conditions.

Under its 2024–26 Mid-Term Management Plan, Tadano has positioned decarbonisation as a central growth strategy. By 2030, the company aims to cut carbon dioxide emissions from operations by 25 per cent and from product use by 35 per cent, on the path to achieving full climate neutrality by 2050.

The Tadano Green Solutions (TGS) portfolio consolidates initiatives such as the ESTA-award-winning E-Pack electro-

hydraulic kit for zero-emission operation, engines compatible with renewable diesel alternatives, and electrified cranes. Solar panel installations across manufacturing plants in Japan and Germany, combined with a modal shift toward sea freight, further reduce emissions and improve operational efficiency.

The TadanoPro app, meanwhile, supports digital transformation by reducing paper usage, providing digital access to brochures and manuals, and aligning with the company’s environmental commitment.

Tadano’s global growth strategy is underpinned by solid foundations. Under Chief Executive Officer Toshiaki Ujiie, the One Tadano model aligns operations in Japan, Germany, and the United States for greater efficiency and stronger support networks.

Strategic acquisitions including Nagano Industry, Manitex (with PM, Oil & Steel, and Valla), and the IHI Transport Machinery business, have expanded Tadano’s presence across all major crane segments, aerial work platforms, and wind power solutions.

Tadano’s governance framework supports this growth, with a sustainability committee, dedicated environmental and social governance subcommittees, and a carbon dioxide/ energy reduction subcommittee reporting directly to the board.

Tadano continues to back innovation with world-class service. In Oceania, Tadano operates branches in Perth, Melbourne, Sydney, and Brisbane, each staffed by factory-trained technicians and supported by a genuine parts supply network to minimise downtime.

Globally, Tadano invests in process upgrades, research and development, and manufacturing improvements. With more than 100 sales and service locations worldwide, it continues to build enduring partnerships founded on reliability, customer trust, and shared success.

Investing in cranes is a big step but with the right finance options, it doesn’t have to be a heavy lift.

Tadano proudly partners with DLL to offer flexible finance and leasing solutions tailored for crane customers.

Whether you’re growing your fleet, upgrading equipment, or managing cash flow, DLL’s deep industry experience and flexible programs can help you stay competitive and grow with confidence.

Let’s build something great together!

Reach out to Brendon today:

Brendon Mayo

Account Manager Construction, DLL Mobile: +61 482 180 702

Email: brendon.mayo@dllgroup.com

Scan the QR code to find out more about DLL and how we can help your business thrive.

IT’S A REAL HONOUR TO WELCOME YOU to the 2025 CICA National Conference in beautiful Brisbane – once again one of the biggest crane industry gatherings in the southern hemisphere. Our theme, “Are you invested?”, is a reminder that what we do in this industry goes far beyond equipment and contracts. Being invested means committing our time, our knowledge, and our energy to building an industry that is safe, innovative, and sustainable.

The crane industry is and always has been about people. We stand on the shoulders of those who came before us – the visionaries and pioneers who laid the foundations for what CICA is today. Their commitment and foresight created an industry built on strength, ingenuity, and collaboration.

That legacy continues every day through the people who own businesses, operate cranes, and work tirelessly to make life better for others in the community. Machines may be the tools of our trade, but it is people

who drive progress and shape the future of our industry. This Conference is a chance to reflect on that, to learn from one another, and to look ahead with confidence.

What makes me proud is seeing how many of you have made the effort to be here – some travelling long distances, others juggling already packed

schedules. It’s no small thing, and your presence is greatly appreciated. This Conference only comes to life because people are willing to show up, share their experiences, and be part of shaping the future of our industry.

I’d also like to acknowledge the generous support of our sponsors. A special thank you goes to our

Brandon Hitch CEO CICA

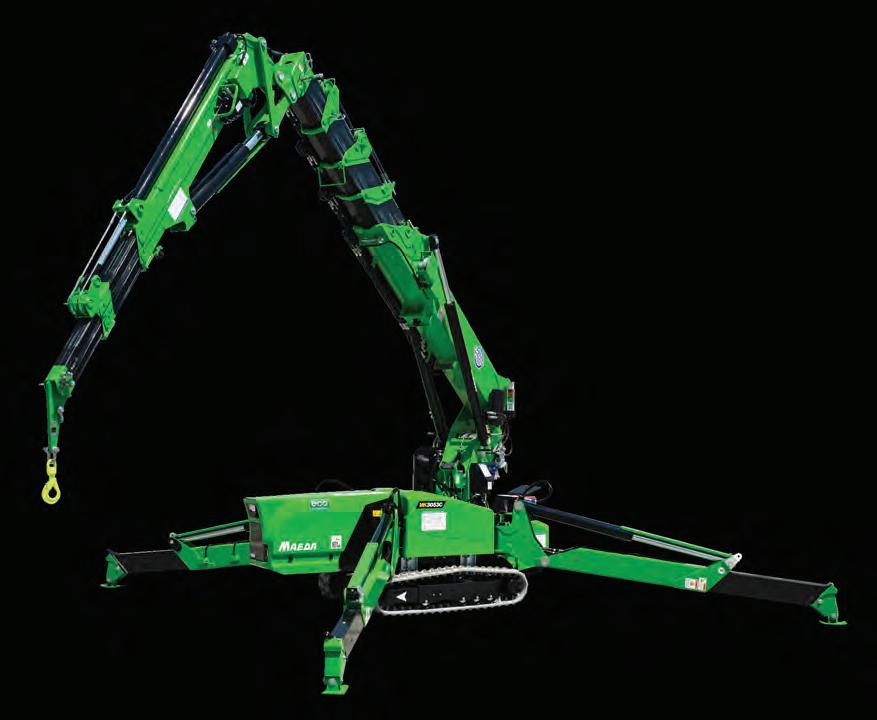

without whose support this Conference simply wouldn’t be possible. Thank you also to our Networking Dinner Sponsor, RUD, our Gold Sponsor, Liebherr, and our Silver Sponsors: Tadano, Terex Franna , XCMG, and Zoomlion / Nationwide Machinery Group. We’re grateful as well to our Lanyard Sponsor, Sany, and our Bronze Sponsors: Finlease, Manitowoc, Sennebogen, Maeda Pace, and RapidWorks. A big thank you also to our Keynote Sponsor, Robway, our Family Hour Sponsor, Tadano, and our Coffee Cart Sponsor, PNO Insurance. Finally, thanks once again to Cranes and Lifting Magazine for their support of the Lift of the Year and Photo of the Year awards.

This Conference is the result of so many people coming together; delegates, speakers, sponsors, and organisers and it’s a privilege to see it all come to life again this year. Thank you for being invested, thank you for making the effort to be here, and above all, I hope you have a wonderful and rewarding Conference.

Brandon Hitch CICA CEO

CICA BOARD

Marcus Ferrari – President

Danny Adair – Director

Danny Black – Director

David Solomon – Director

Karli Sutherland– Director

Anthony Grosser – Director

Andrew Esquilant-Director

OFFICE

Brandon Hitch Chief Executive Officer 0428 228 048 ceo@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CICA Site Operations Advisor 0488 004 274 pat@cranesafe.com.au

Sharon Pearce

Crane Crew Competency Officer 0491 134 533 sharon@cica.com.au

Damien Hense

CICA Road Policy Advisor 0488 007 575 damien@cica.com.au

Thomas Webber Communications Coordinator thomas@cica.com.au

Kate Galloway Traineeship & Industry Engagement Coordinator 0491 047 118 kate@cica.com.au

Michelle Verkerk

Communications and Special Projects Advisor michelle@cica.com.au

Just ina Blackman Member Events and Engagement 0403 717 626

justina@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administrative Assistant Officer 0491 047 134 shane@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170 Phone: 03 9501 0078

Email: admin@cica.com.au Website: www.cica.com.au

For information, please visit our website or call the CICA office.

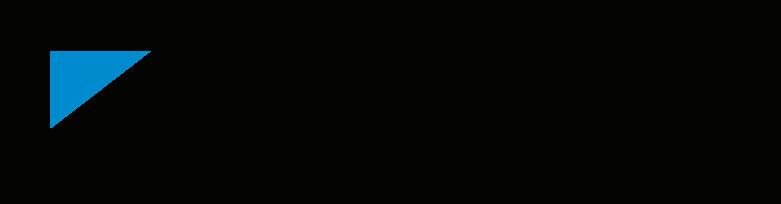

The current permit process can take weeks, with operators often left in the dark until every road manager has responded.

Anyone who’s ever had to move a crane to a site knows the somewhat frustrating process of navigating the permit process, whether it’s due to unfamiliar roads, complex regulations, or unexpected logistical challenges. Then there’s the paperwork, weeks of waiting, and the uncertainty of whether that last 500 metres of access will be approved.

SOUND FAMILIAR?

That’s the challenge the National Automated Access System (NAAS) is designed to tackle. NAAS is Australia’s next big step in heavy vehicle access. And for the crane industry, where jobs are often last-minute, time is money, and lastmile access can make or break a project, it’s set to be a game-changer.

Cranes are different to trucks. They’re usually larger, heavier and their main purpose is lifting. The work they do, raising pool shells, placing bridge beams, or hoisting air-conditioners onto rooftops, is often urgent and time-critical. The current permit process can take weeks, with operators often left in the dark until every road manager has responded. By then, the job may have fallen through,

costs have blown out, or the customer is already frustrated.

NAAS changes that by giving crane operators:

• Faster answers – Generate a map and instantly see where your crane can travel across the whole network.

• More options, more flexibility –Test different crane types or sizes and see which can access the site most efficiently.

• Last-mile certainty – Visibility on those tricky final stretches into job sites.

• Clarity across borders – Different rules in different states are made transparent through a single system.

• Practical planning – If Route A is blocked, you can check Route B on the network map before sending the crane out the gate.

For an industry built on speed and

reliability, NAAS means operators can plan with confidence.

Brandon Hitch CICA Chief Executive Officer, summed it up: “The NAAS is a game-changer for the crane industry. Having a clear, consistent and immediate process for assessing access to the road network means operators can plan with certainty, reduce delays, and improve safety outcomes. For an industry that already works under tight timeframes and complex logistics, NAAS gives us the confidence that we can get the right equipment to the right place to progress key projects, without unnecessary red tape holding projects back.”

NAAS is built on the proven Tasmanian HVAMS (Heavy Vehicle Access Management System) platform, which

has been successfully working for nearly a decade. It provides a digital, legally recognised way to confirm access, without waiting weeks for multiple road managers to respond to permit requests.

Here’s how it works, step by step:

1. Create your vehicle profile

Enter crane details into the system – axle configuration, weight and dimensions.

NAAS saves this as a reusable vehicle code, so you only need to do it once.

2. Generate a tailored network map

Based on your vehicle, NAAS instantly shows the full available network for your crane. Each network is valid for 14 days.

3. Update when needed

If the job falls outside that window, revisit NAAS, enter your saved vehicle code, and generate an updated network, which will be valid for another 14 days. No waiting for paperwork.

4. Plan your trip with a Route Card

For each job, you can create a specific route and generate a Route Card with turn-by-turn directions, conditions, and restrictions (like speed limits, curfews, or bridge conditions). Everything you need is captured in one document – no piecing it together from multiple approvals.

5. Backed by gazette notice

These maps carry legal effect. They’re not just advisory – they give operators certainty that what’s shown is valid under the law.

In short: NAAS replaces route-by-route guesswork with a network-wide view of access. What once took weeks of backand-forth now takes minutes and gives far more visibility across the entire network.

Of course, scaling up NAAS is no small feat. It has to align with multiple governments, hundreds of councils, and a whole range of vehicle types.

That’s why the rollout is incremental. It begins with performance-based standards (PBS) vehicles in Tasmania, then expands to defence, oversize/overmass vehicles and cranes across other states and territories. More areas and vehicle types will come online gradually.

One important note: Permits won’t

disappear and they’re not meant to.

NAAS is designed to reduce the number of movements that need a permit, not replace the permit system entirely. For certain cranes or roads, you will still need to apply for a permit. But as NAAS grows, more routine access will be handled instantly through the system.

To set clear expectations:

• Some cranes simply won’t be able to access certain parts of the network with or without permits. There are lots of reasons for this such as bridge capacity or space constraints,

• The NAAS will not magically provide access to all roads and bridges. It will, however, show you where the pinch points are quickly to allow you to discuss access with the road manager, research alternative routes or vehicles, or apply for a permit.

• Road managers remain central. Their rules, conditions, and expertise are what NAAS displays making access transparent for everyone.

NAAS streamlines the access process, automating where appropriate, while leaving decisions for the highly complex moves where they belong.

The long-term vision for NAAS is big: a truly national, digital access system for heavy vehicles. One that reduces

duplication, improves safety, and makes life easier for operators and road managers alike.

For cranes, that means:

• Less waiting.

• Fewer headaches.

• More certainty when planning jobs.

The rollout will take time, and the network will grow in stages. Some areas will come online sooner than others, but every step forward reduces complexity and brings more benefits.

As one industry spokesperson put it: “NAAS is about reducing red tape while maintaining safety, improving national consistency, and giving both industry and road managers the tools they need.”

Moving cranes has always been one of the toughest challenges in transport. With NAAS, that challenge gets a little easier. It won’t remove every permit. It won’t open every road. But it will provide faster answers, clearer rules, improved flexibility and a growing national solution to help crane operators get the job done with more certainty and confidence.

Marking 10 years in business, All Cranes proves that relationships and integrity are just as important as the machines they sell and hire.

FOR PETER SHELTON, CRANES HAVE been more than a career – they’ve been a lifelong calling. After starting as a storeman at Franna in 1989, he worked his way up to General Manager, before later holding leadership roles at James Equipment and Tadano. By 2014, after 15 years in corporate management, Peter was ready to step away. What he didn’t expect was that a family business with his son Todd Shelton would soon become his next chapter.

“All Crane Sales started almost by accident,” Peter said. “I had a couple of cranes for sale, put the word out, and

within months we realised there was a real business opportunity sitting in front of us.”

From the back deck of their Brisbane home in January 2015 (celebrating ten years this year), the father-son duo began answering calls, setting up spreadsheets, and selling cranes. What started with a handful of machines quickly grew into something much larger. “We thought we’d sell maybe five or six cranes in the first year. We ended up selling 15 to 20,” Todd said. “That’s when we knew we were onto something.”

What began as a small fatherand-son venture quickly grew into something much larger. As demand increased, the Sheltons brought their two business arms under one banner. The dry hire operation, Australian Machinery Hire, and the sales arm, All Crane Sales & Equipment, were merged to form All Cranes. The move made it clear to the industry that one company could now provide both services – crane hire and crane sales – through a single, trusted name.

Both companies were go-to names in their respective fields: one specialised

With more than 400 cranes sold and a 25-crane dry hire fleet, All Cranes delivers both sales and hire solutions under one trusted banner.

“Our aim was to change the way the used crane market worked –be more transparent with pricing as well as delivering prompt and efficient service throughout the entire sales process.”

From heavy industry and mining in the Pilbara to marine and infrastructure projects on the East Coast, our team of expert technicians and parts specialists deliver around-the-clock, on-site support you can count on.

We’re more than a service provider — we’re a true partner in keeping your operations moving. OUR SERVICES

Mobile crane repairs & diagnostics

With operations based in Karratha (WA) Perth Metro (WA) Sydney (NSW) & SEQ (QLD), we offer rapid mobilisation and local expertise to meet the demands of Australia’s most challenging worksites.

NEW DIRECTION. EXPANDED CAPACITY. SHARPER FOCUS. As CCS enters a new chapter of national growth, we’re investing in the people, systems, and scale to support major projects, port authorities, and private fleets across Australia.

With growth, accreditation, and unforgettable projects, ANC Cranes is on a remarkable upward trajectory – strengthening its team with industry-leading expertise, expanding its fleet with cutting-edge cranes, and proudly securing ISO accreditation.

and Director Craig Davies, alongside seasoned industry professional Jay Gower, the company is charting an exciting new chapter defined by growth, innovation, and opportunity.

With more than two decades of experience representing global crane original equipment manufacturers (OEMs), Jay Gower brought a wealth of knowledge when he joined ANC Cranes in January. His role is intentionally versatile, ensuring he can contribute wherever the business needs him most – from managing lift studies and site inspections to customer engagement and technical troubleshooting.

“At ANC, titles don’t matter nearly as much as teamwork. I find myself wearing many hats – inspections, safety compliance, supporting the crews, and even helping interpret error codes on Tadano cranes. It’s hands-on, fast-paced, and incredibly rewarding,” Jay shared.

Craig added: “Having Jay on board has been a game-changer. His industry insight, technical know-how, and can-do attitude make him a huge asset to the team.”

This year, ANC Cranes proudly achieved AS/NZS ISO 9001, AS/ NZS ISO 45001, and AS/NZS ISO 14001 certifications – a milestone that not only recognises excellence but also positions the company for even greater opportunities.

Jay explained the decision: “We

pursued ISO not just for the work we’re doing now, but for the work we want to do in the future. With industry changes from SafeWork NSW and ongoing regulatory updates, we wanted to stay ahead of the curve. By engaging a specialist safety consultancy, we lifted our systems to industry-best practice, putting in place the right framework for long-term success.”

Craig noted the cultural shift it created: “The accreditation process brought everyone together. The whole team embraced the changes – from new safety forms to updated procedures. It wasn’t about ticking boxes; it was about raising our standards as a business. It was inspiring to see everyone step up.”

ANC’s growth is also evident in its cranes. The fleet now stands at 25 cranes, including an impressive

collection of Maeda mini crawlers. New arrivals include an 8TMaeda, a 25T Franna, and a 100T all terrain crane, with a Maeda 174 scheduled to arrive in October.

will number 16, ranging from the 174 through to our 8T crawler.”

“The all terrain purchase from the McPhan family on the Central Coast was perfectly timed – a real win-win.

“We’re not trying to be the biggest, but we are determined to be one of the most trusted and reliable. Our goal is to consistently deliver quality work – safely, compliantly, and efficiently. That’s what sets us apart.”

Craig explained the strategic value: “We don’t see our Maedas in the yard often, which is a great sign – they’re always out working. The addition of the Maeda 174 bridges the gap between our larger mini cranes and smaller jobs, giving customers safer, more efficient options and reducing manual handling risks. With this arrival, our mini crane fleet

And while I resisted adding a Franna for years, Jay convinced me. It hasn’t stopped working since! I used to say, ‘I’m not driving a Franna,’ but now I realise I don’t have to – I’ve got skilled operators for that.”

With ISO accreditation and a strengthened fleet, ANC Cranes is

positioned to secure more complex projects and compete confidently in larger tenders.

“It moves us higher up the list,” Jay said. “We’re not trying to be the biggest, but we are determined to be one of the most trusted and reliable. Our goal is to consistently deliver quality work – safely, compliantly, and efficiently. That’s what sets us apart.”

ANC’s expertise was recently put to the test with one of its most unique projects yet: lifting fullsized dinosaur models into a private backyard in the Blue Mountains.

“The logistics were challenging –from cobblestone driveways to low tree canopies restricting our access and creating barriers to overcome. We had to get creative and use two different cranes,” Jay recalled. “Craig was onsite to help steer the operation,

and it really came down to meticulous planning, teamwork, and quick decision-making.”

The T-Rex and Triceratops, each weighing around 300 kilograms, were positioned safely and precisely, despite the obstacles. The project highlighted ANC’s ability to think outside the box, adapt under pressure, and deliver results that delight customers.

ANC Cranes is more than just a crane hire company – it’s a team united by a passion for excellence, safety, and service. With new expertise on board, an upgraded fleet at the ready, and ISO accreditation elevating its credentials, the company is poised to take on bigger opportunities and continue exceeding expectations.

Craig summed it up best: “We’re growing with integrity, expanding with purpose, and building a reputation we’re proud of. The future is looking very bright for ANC Cranes.”

On Saturday 19 July 2025, Wellingtonians were treated to a once-in-a-lifetime spectacle as the Crane Association of New Zealand (CANZ) rolled out a crane parade to celebrate its 50th annual conference.

THE EVENT WAS NOT JUST ABOUT showcasing impressive machines, but also about bringing cranes into the public eye, raising awareness of crane careers, and creating a memorable family day out.

For most people, cranes are glimpsed only from a distance – towering above construction sites, hidden behind fences, and seemingly out of reach. The Crane Parade flipped that script, connecting the community with the industry in a tangible, up-close way. Families could not only see these extraordinary machines moving through the heart of the capital but also get hands-on once they parked up.

The parade aimed to spark curiosity about the world of cranes, inspire future operators, and give the public a chance to celebrate alongside the industry in marking CANZ’s half-century milestone.

The response from the industry was overwhelming. In the lead-up, CANZ confirmed 23 cranes in the parade – with companies still calling the day before, eager to be part of the action. On the day, Wellington delivered picture-perfect sunshine as crowds lined the streets to welcome the machines.

Excitement built as the convoy left the staging area at Wellington Stadium, winding its way through the city and onto Cable Street. As the flashing pilot lights of the cranes appeared, the energy in the crowd was palpable. Children squealed with delight as operators tossed out lollies and merchandise from cab windows, while crane enthusiasts of all ages gathered to watch the slow, powerful procession.

Once parked up on Cable Street, the real magic began. Skilled operators manoeuvred their cranes into place with surgical

precision, turning the waterfront into a living showcase of engineering excellence. The public wasted no time getting involved – queues 20-deep formed at every crane as kids and adults alike waited for their turn to sit in the cab of these massive machines.

The looks of pure joy on children’s faces as they climbed into the driver’s seat said it all. Parents took photos, operators answered questions, and the atmosphere was one of genuine community celebration.

Feedback from the day has been nothing short of incredible. Families and crane lovers raved about the experience, and requests have already poured in from other cities to host their own crane parades. Wellington locals, too, are keen to see the event return.

The operators and companies involved were thrilled by the turnout and

engagement. For many, it was a chance to proudly share their work with the public and feel that appreciation reflected back. Perhaps the most rewarding moment came when one young visitor asked how they could sign up for a crane apprenticeship – a perfect reminder of why the event was held in the first place.

The Wellington Crane Parade was a fitting tribute to 50 years of CANZ and a glimpse into the future of the industry. It celebrated the machines, the people who operate them, and the communities they help build. Most importantly, it showed New Zealanders that cranes aren’t just construction tools – they’re symbols of possibility, careers of the future, and aweinspiring feats of engineering that capture the imagination of every generation.

As CANZ looks ahead to the next 50 years, one thing is certain: cranes have never been more loved.

With decades of experience, skilled professionals, and modern equipment, we deliver innovative, safe, and cost-effective solutions for all clients. Our extensive fleet of cranes are available to support all your lifting needs throughout New Zealand.

Extensive range of specialised equipment, including ancillary gear, temporary staging, man cages, construction hoists, and more.

With over 30 years in the industry, our team brings proven expertise and practical knowledge.

For Tim Smith, founder of Smith Crane & Construction, the story of cranes is inseparable from family, grit, and a fair share of Kiwi ingenuity.

FROM A ONE-MAN OPERATION WITH A second-hand 20-tonne crane, Smith Cranes has grown into one of New Zealand’s largest crane and construction companies, boasting close to 180 cranes and nearly 300 staff. Now, the company is preparing to add a machine unlike anything else in Australasia – the Liebherr LR11000 crawler crane.

“It’s sort of the peak of my career,” said Tim, with his usual mix of humility and humour. “When you start off with a 20-tonne Kato truck crane and end up with a 1000-tonne crawler, it’s pretty exciting.”

The Smith family’s story goes back to the 1950s, when Tim’s father moved from New South Wales to New Zealand. What began as civil contracting – drainage, culverts and bridges – gradually morphed into crane work. By the time Tim set out on his own, he was determined to chart

a slightly different path. “I bought a little 20-tonne Kato, drove it down from the North Island to Christchurch, and set up as an owner-operator,” he said. “It was just one man and one crane. Then I bought another, and another, and it sort of turned into a bit of a cycle.”

That has since become an empire with 800 pieces of equipment, from excavators to drill rigs, and a crane fleet spanning mobiles, towers, and crawlers. Yet Tim insists the success isn’t just about machines.

“It’s basically the people that work for me. I’ve got great guys – loyal, long-serving, and experienced. We’re still a family business at heart, just on a bigger scale.”

The latest chapter in this growth is the arrival of the Liebherr LR11000, a crawler crane that redefines capability in the region.

The Liebherr LR11000 will give Smith Cranes unparalleled reach for turbines, bridges, and industrial projects.

With a lifting capacity of up to 1000 tonnes, a maximum hook height of 220 metres, and a radius stretching 182 metres, the LR11000 sets a new benchmark for heavy and complex lifting.

Tim’s decision to buy the LR11000 was strategic. Smith Cranes could continue tackling wind projects with its Kroll 1650 tower crane, but it would’ve required substantial further investment in ballast, tower, and boom sections.

A high-rise commercial building opportunity also emerged, making the case for a large lattice boom crawler. The LR11000 opened opportunities in wind and infrastructure across New Zealand and Australia.

Soon after, it was secured for major bridge-lifting works, previously requiring multi-crane lifts, falsework, and bridge strengthening. With the LR11000, the entire lift can be executed with a single crane, benefiting clients. The crane has arrived in New Zealand and is currently being rigged and tested at Tauranga Port.

The crane was sourced from South Korea, where it had spent its working life on shipbuilding and nuclear projects –

environments that demand precision but don’t wear out machines through constant relocation. “It’s only about ten years old and has low hours. With all the gear that came with it – the superlift, luffers, jibs –it’s well equipped. Cranes aren’t just about size these days, it’s about what fruit you’ve got with them,” Tim said.

The LR11000 was engineered for exactly the type of projects Smith Cranes is targeting. Its wide range of boom and jib configurations allow it to be tailored to different tasks. The M-Wagon ballast system ensures efficient mobilisation and reduced transport costs – a crucial factor when moving a crane of this size around New Zealand’s diverse terrain.

Its first assignments are already locked in. One is at Dargaville in Northland, where the crane will erect a dozen turbines up to 140 metres tall – beyond the reach of Smith’s existing LTR 11200 telescopic crawler. Another job is the replacement of a cyclone-damaged bridge near the city Gisborne in New Zealand.

“With two smaller crawlers, we would’ve needed complicated planning – strengthening temporary bridges, coordinating tandem lifts. The LR11000

makes it simple. One big crane, one lift, and the job’s done. That’s what I like about it – it makes hard jobs easy,” Tim said.

What sets this addition apart is not just its capability but its rarity. While Australia has multiple LG 1750 and LG 1800 cranes, Tim points out there isn’t another LR11000 operating in the region. That, he believes, creates opportunities across the Tasman as wind farms scale up.

“A lot of turbines in Australia are getting beyond what the 1750s and 1800s can handle. There could be a market there for us,” he said. “We’ll see how it goes, but it’s the sort of machine that can open doors.”

Despite the scale of the business, Tim remains grounded. He speaks about his sons joining the business: “I didn’t let them start straight with me. They had to get their own jobs first – one’s a diesel mechanic who’s now operations manager, another’s a builder, another drives trucks. They’re all starting to get involved now,” he said.

The generational mindset extends beyond family. Smith Cranes is well known for training apprentices – currently around

15 to 18 across its workshops. “Every one of my managers was once a crane driver, a mechanic, or a fitter. I like promoting from within. They understand the culture, they’ve grown with the business, and they know how we operate,” Tim said.

That approach has paid dividends. Smith Cranes has repeatedly taken out top honours at the New Zealand Crane Awards, and its operators are considered some of the most experienced in the country.

“We’re not too corporate or complicated. We’re just a family business that’s kept growing. We’re now two or three times bigger than the next guy in New Zealand, but we’re still the same bunch, doing the hard jobs with good people,” Tim said.

With the LR11000 soon to arrive in Tauranga, the company is ready for a new era of lifting – one where bridges, wind farms, and mega-projects across Australasia might all fall within reach of a single machine.

As Tim puts it: “It’s a big step for us. We’ve got the crane, we’ve got the people, and we’re ready to take on the big jobs. If anyone’s got work in New Zealand or Australia that needs a thousand tonnes lifted – give us a call.”

In the lifting industry, even the smallest oversight can have catastrophic results. Routine pre-use checks and scheduled thorough examinations are more than paperwork – they are lifesavers.

construction site in 2018, a crane’s concrete bucket dropped when a missing split-pin allowed the hoist assembly to fail, killing one worker and crippling another. WorkSafe Victoria noted that careful inspections “never occurred,” and that a reasonably practicable check of that pin could have prevented the tragedy. This article explains how simple checks and competent inspections, backed by proper training, safeguard Australian and New Zealand lifting operations against similar failures.

Lifting equipment inspection typically involves three levels: pre-use, interim, and thorough examinations. The first level is the pre-use check, performed by the operator before each lift. This is a quick visual inspection for obvious defects –damaged hooks, deformed links, missing markings, abnormal noises or changes in performance. Any problems found must be reported immediately to maintenance teams. These routine checks form the first line of defence: in a Western Australia mine incident (2014), a cracked sheave was missed during a pre-start check and later catastrophically failed, narrowly missing a worker.

Between pre-use checks and thorough examinations, interim inspections (also called frequent inspections) are conducted. Their frequency and scope are based on a risk assessment and may coincide with routine maintenance or follow repairs. Interim inspections zoom in on high-stress or wear-prone parts (for example, hooks, pins, brakes, ropes) that could fail before the next major exam. Finally, a thorough examination (or periodic inspection) is an

in-depth check carried out by a qualified, independent inspector. This thorough exam often includes measurements, testing or non-destructive evaluation, ensuring the equipment is safe for continued use. Standards such as AS2550.4 (tower cranes) and AS2550.1 (general) specify that thorough exams be done at defined intervals depending on equipment and conditions.

By law, a thorough examination must be done by a competent person – someone with the training, experience and ability to spot defects and understand relevant standards. For example, AS2550.1 2020 requires a competent person to inspect lifting equipment, and inspection reports must be kept. A competent inspector can be an accredited third-party examiner, or a LEEA-certified Lifting Inspector. LEEA’s guidance emphasises that if a defect is found during a thorough exam, it often points to a flaw in the inspection or maintenance regime,, underscoring

the need for inspectors who know what to look for.

LEEA supports competency through training and membership. All LEEA members and accredited companies undergo regular technical audits and training updates to ensure inspectors and users stay sharp. The association offers courses focused on rigging safety, inspection techniques and thorough examination of lifting gear. Users are encouraged to look for the LEEA logo on inspectors or service providers – a badge of competence and industry-best practice. Together, these measures mean inspections are not just a formality but an effective safety check on lifting equipment.

(AUS/NZ LAW)

Under both Australia’s Work Health & Safety Act and New Zealand’s Health and Safety at Work Act, the person conducting a business or undertaking (PCBU) has primary responsibility for plant safety. This includes cranes, hoists, slings and all lifting

accessories. The duty holder must ensure, so far as is reasonably practicable, that the equipment is safe and subject to proper testing and inspection. They must provide information, training and instruction to staff, maintain the equipment, and ensure inspection reports are recorded. Importantly, WHS law dictates that these duties cannot be transferred – a PCBU remains responsible even if inspections are subcontracted to others.

In New Zealand, crane controllers are explicitly required to ensure cranes have current inspection certificates issued by recognised inspection bodies. In Australia, regulations often prescribe periodic major inspections for registered cranes. For example, WorkSafe guidance notes that major crane examinations must include detailed visual inspections of all structural and wear components (brakes, ropes, sheaves, etc.) for corrosion and wear. Duty holders must also keep records of all tests, inspections and maintenance, and act promptly to remedy any defects identified.

• Victoria 2018: A tower crane’s concrete bucket fell to the ground after a missing split-pin in the hoist assembly worked loose. One worker was killed and another critically injured. The operator was fined $400,000; WorkSafe investigators noted that a thorough inspection when the crane was installed would have caught the missing pin.

• Queensland 2025: A tower crane’s hoist rope and hook assembly collapsed and dropped 10 metres. Investigations found significant corrosion on a swivel bolt due to harsh coastal conditions –corrosion that should have been detected during inspections. The crane had passed its annual check just two months earlier, highlighting the importance of competent, detailed examinations and perhaps more frequent checks in adverse environments.

• Western Australia 2014: At a mine site, a mobile crane sheave (rooster sheave) suddenly failed while slewing under load. A post-incident review found that the sheave had pre-existing

damage that daily pre-use checks had failed to identify. The two-kilogram nylon fragment narrowly missed a rigger below. This case shows how even routine operator checks must be thorough.

• New Zealand 2022: A Rotorua precast yard used a homemade mobile crane (converted from an old log skidder) with no formal inspection certificate or safety devices. A 17-year-old worker was struck by a swinging 412kg beam and badly injured. WorkSafe NZ observed “the crane should not have been operational” and warned businesses to “regularly check all their equipment” – especially older or modified gear.

Each of these incidents stemmed from missed or improper inspections. In every case, diligent checks by trained personnel could have identified the fault before it became catastrophic. In the words of one NZ regulator, “businesses must manage their risks. This includes regularly checking all their equipment to check it’s fit for purpose and compliant”.

LEEA’s Code of Practice (COPSULE) is a free resource that lays out best practice for lifting inspections worldwide. Section 1 of the latest COPSULE covers inspection intervals, roles (users, maintenance staff, examiners) and responsibilities. By consulting COPSULE (alongside local standards), Australian and New Zealand businesses can align with global best practices.

LEEA membership further helps users meet their obligations: members gain access to expert advice, regular technical updates and tailored training on lifting safety. Whether through LEEA’s accredited courses or its library of guidance documents, lifting operators can ensure they understand and fulfill the inspection and maintenance duties required by law.

‘Small checks’ at the start of each lift and scheduled thorough examinations have big safety payoffs. Operators, supervisors and duty holders in Australia and New Zealand must implement robust inspection

1. WorkSafe Victoria – I ncident: Crane bucket fall due to missing split-pin (2018). https://www.worksafe.vic. gov.au/news/2021-03/clark-cranesfined-over-fatal-crane-collapse

2. SafeWork Australia – Managing the Risks of Plant in the Workplace Code of Practice. https://www. safeworkaustralia.gov.au/doc/ model-code-practice-managingrisks-plant-workplace

3. A S2550.1-2020 – Australian Standard: Cranes, hoists and winches – Safe use – General requirements. (Available through SAI Global, not freely accessible online)

4. L EEA COPSULE – Section 1 – Code of Practice for the Safe Use of Lifting Equipment (2024). https://leeaint. com (available via LEEA membership or authorised distribution)

5. WA Department of Mines, Industry Regulation and Safety – Safety Bulletin: Crane rooster sheave failure (2014). https://www.dmp.wa.gov.au/ Documents/Safety/MSH_SB_144.pdf

6. WorkSafe Victoria – Safety Alert: Soft sling failure due to improper inspection/use. https://www. worksafe.vic.gov.au/safety-alerts/ soft-sling-failure

7. WorkSafe Queensland – Incident Report: Tower crane failure and hoist drop (2025). https://www.worksafe. qld.gov.au (Specific case report may be available upon request or FOI)

8. WorkSafe New Zealand –Prosecution: Homemade crane incident in Rotorua precast yard. https://www.worksafe.govt.nz

9. H ealth and Safety at Work Act (NZ) – Duties for PCBU and inspection responsibilities. https:// www.worksafe.govt.nz/laws-andregulations/acts/hswa/

10. L EEA – Training & Competence Programs. https://leeaint.com/ training

regimes. Working with competent inspectors (for example, those trained via LEEA) and following regulators’ codes ensures compliance with WorkSafe/ Victoria, SafeWork NSW and WorkSafe NZ expectations. As one regulator put it, ensuring lifting equipment is safe is a fundamental duty of care. By treating routine inspections as integral to all lifting operations, companies turn liability into assurance – preventing the next preventable accident.

SUPERFLEX SLINGS

SUPERFLEX STROPS

DOUBLE ENDED STROPS

STEEL FLAT WOVEN SLINGS

DEAN-0 SLING

“ YOUR FIRST CHOICE IN LIFTING ”

SUPERFLEX “YOUR FIRST CHOICE IN LIFTING”

Marr Contracting (Marr) has become the first business in the world to implement new crane safety technology, The Buddie System, on two Sydney construction projects.

MARR CRANE CREWS WORKING WITH Parklife D&C Joint Venture on c onstruction of the new Sydney Metro Airport Terminal Station, and with Richard Crookes Constructions on the Sydney House mixed-use development, (former City Tattersalls Club site) in the Sydney CBD were the first to trial the system in a live environment.

Developed by experienced crane industry professionals Gary Panagiotidis and Jade Harris, The Buddie System is designed for crane operators and dogmen / slinger signallers to reduce the risk of

accidents caused by two-way radio issues or miscommunication between crane crews.

With up to 30 per cent of crane accidents (Crane Accident Statistics: Market Data Report 2025 ) involving miscommunication between operators and ground crews, The Buddie System has real potential to prevent injuries and fatalities on construction sites. The wireless safety alert device overcomes the shortfalls of existing two-way radio technology by allowing dogmen to instantly alert crane operators to stop if something goes wrong.

“I’ve

been in the industry for 30 years and Marr has always stood out as a company that leads from the front when it comes to innovation and safety.”

“Safety is always our number one priority and with The Buddie System we have an innovative solution to a common safety issue on construction sites,” said Marr’s Managing Director, Simon Marr.

“What we love about it is its simplicity and the fact that it was designed by people who’ve worked on the tools and understand the real risks of crane and lifting operations,” Simon said.

The Buddie System was officially launched at the Crane Industry Council of Australia (CICA) Conference with Marr the first to trial the system in a live environment.

With strong interest from crane owners and operators in Australia, the United Kingdom and other markets, Marr’s implementation on a large-scale infrastructure greenfield site and innercity high-rise environment is paving

the way for others in the industry to follow suit.

“We couldn’t have picked a better launch partner than Marr,” said Gary Panagiotidis.

“I’ve been in the industry for 30 years and Marr has always stood out as a company that leads from the front when it comes to innovation and safety.”

“Big cranes, big lifts, and big responsibilities. Marr’s reputation is built on getting all three right,” added Jade Harris.

“Their willingness to be first to adopt this technology proves they’re serious about safety.”

Following the success of the trial, Marr intends to roll out The Buddie System across its fleet in Australia and the United Kingdom over the coming months.

Marr Contracting is a world leader in the design and delivery of heavy lift luffing tower cranes and heavy lifting services. With almost 100 years’ experience working on large-scale construction projects in Australia and around the world, its expertise spans the large-scale construction, mining, oil and gas, power, nuclear, major transport infrastructure, technology and marine sectors. Not just a crew and cranes for hire, it offers big thinkers and problem solvers who love a challenge with a string of ‘world firsts’ to their name – including the world’s highest capacity tower crane, the Marr 2480D Heavy Lift Luffing (HLL) crane. www.marr.com.au

The Buddie System (TBS) is a wireless instant safety alert device designed for crane operators and dogmen/ slingers enabling rapid alarm activation in emergencies. The TBS device overcomes the shortfalls of two-way radio failure and often inaudible backup whistles.

The TBS device allows a dogman/ slinger to instantly transmit an alarm signal to a crane operator to stop. A quick snap on the TBS lanyard activates the alarm. www.thebuddiesystem.com

With staff loyalty running well above industry averages, Liebherr has created a culture where people grow, stay, and thrive.

Ask anyone new to the heavy equipment industry what they’re looking for, and the answer is usually the same: stability, growth, and the chance to do meaningful work. At Liebherr, those opportunities are built in.

FROM APPRENTICESHIPS TO LEADERSHIP roles, the company has created a culture where people don’t just work with cranes and machinery – they build lasting careers.

Most people recognise Liebherr for its cranes or excavators, but the brand stretches far wider. With business interests in mining, construction, aerospace, refrigeration, and even hotels, Liebherr is one of the world’s most diverse industrial groups. For employees, that diversity is a source of confidence.

“Because of the diversity within our company, we are somewhat protected. Not against everything, of course, but

having so many different industries in play ensures our people feel secure,” said Andrew Wilder, the General Manager of Maritime & Construction Cargo (MCC) division in Australia.

Dino Mosca, the National Service Manager of the Mobile and Crawler Crane division, echoed the point. “It’s a big company, and there are many opportunities for people within the business. We recruit purely for the long term. People generally come for a career, not just a job,” he said.

Employee loyalty is a hallmark of Liebherr in Australia. Staff tenure across its divisions outpaces the national average,

with many employees staying for more than a decade.

“Our average employee tenure might say four years, but if you take out those who’ve joined recently, the average quickly climbs to six or eight years,” Andrew said. “Longevity is built into the culture here. Many of us, myself included, have been with the company for over a decade.”

That retention is not by chance. Both leaders point to the balance of global scale and local independence. “What differentiates us is our ability to act independently,” Andrew said. “We can make decisions quickly for the best interests of our team and our customers. That flexibility makes a big difference.”

For Dino, the appeal is in the smallteam structure. “We’re a large division, but we’re broken down into smaller groups where you have that close relationship among your team. It’s a good culture, and it’s one of the biggest reasons people stick around,” he said.

Liebherr places strong emphasis on developing talent internally. Dino said that starting as an apprentice is often the

best way to progress. “We have many team members who’ve moved from apprenticeships into leadership positions. With roles like service coordinators or technical advisors, it’s critical to start with that foundation of product knowledge,” he said.

Andrew highlighted similar stories in his division. “We’ve got people who started in junior roles and are now in management. Even if they move between divisions, they remain within Liebherr. That continuity means we don’t lose talent, and people know they can grow with the company,” he said.

For staff, career growth is supported by extensive training. Technicians frequently travel to Liebherr factories in Germany, Austria, or Ireland for advanced programs, sometimes spending weeks overseas.

“We invest heavily in training packages. Our technicians may travel once or twice a year to complete specialised courses,” Dino said.

The focus is on equipping people not only for their current roles but also for future opportunities. “Even if someone wants to step off the tools and move into training or technical advising, we support that,” Dino said.

Not every career path looks the same, and Liebherr’s global and sizeable local presence means there is space for different lifestyles. In the maritime sector, for instance, some roles involve offshore work – flying out by helicopter and spending weeks at sea.

“It’s well-paid and offers a unique lifestyle. For those who want travel and variety, it’s a great fit,” Andrew said. For others, the appeal is in transferring between divisions. Employees have moved from apprenticeships in workshops to technical advisory, or from mobile cranes into sales. That flexibility, according to both leaders, keeps careers dynamic and ensures employees remain within the company.

As the industry evolves, Liebherr is preparing for new kinds of roles.

Andrew sees opportunities in training and technology. “We need to empower customers as much as possible, and training roles are a way for experienced technicians to step off the tools. There’s also the technology side –artificial intelligence is becoming part of our business, and that’s an exciting opportunity,” he said.

Dino added that whatever the role, the company’s culture remains the constant. “When you come on board, you’re part of the family. We’re not delivering services that make people instantly happy – we’re solving problems. That takes the right

kind of team, and people here genuinely want to stick around and help,” he said.

Liebherr’s machines are recognised worldwide, but behind them is a workforce that reflects the company’s values: stability, growth, and commitment. By combining global resources with local independence, Liebherr has created an environment where people don’t just work, they thrive. For anyone considering a career in cranes, mining, maritime, or beyond, Liebherr shows that the heavy equipment industry isn’t just about machines. It’s about people, and the futures they can build.

Founded in Germany in 1875 and celebrating 150 years in 2025, the RUD Group is one of a global leader in chain technology and lifting solutions, with over 1700 employees and products sold in more than 140 countries. RUD was founded by the Rieger family who continue to blaze a path with a strong legacy of innovation, quality and technical excellence.

RUD AUSTRALIA WAS ESTABLISHED in 1984 and has been led by the Nuttall family since inception. It has been supporting the crane industry with innovative lifting and lashing solutions for the past 40 years through local offices across Australia and New Zealand.

RUD’s focus on safety is exemplified by the quality of its products, especially the ICE 120 chain slings which are manufactured to meet the highest safety standards for crane operators and on-site staff.

Mark Read, Director of SureLift Crane Hire, a long-term RUD customer, attests to the quality of RUD’s chain slings, labelling them the “best chains in the industry”.

SureLift Crane Hire, which started with one crane in Moranbah, Queensland, now operates more than 16 cranes and exclusively uses RUD

products because of their performance which Mark believes “embodies the message of safety.”

RUD Australia has an advanced 6000 square metre engineering and manufacturing facility in Brisbane which offers bespoke lifting and material handling solutions for the crane industry. The production facility includes expanded positional robotic welding technology and multiple 200/500-tonne test beds ensuring quality work that exceeds industry standards.

RUD provides customised lifting kits and lashing solutions for the crane industry. RUD’s ICE 120 chains can be tailored to meet specific site requirements. The ICE Grade 120 chain is 30 per cent lighter than grade 80 which is a critical safety factor. Additionally, a RUD ICE 16 millimetre chain, when used with a balancer,

can lift up to 48 tonnes – the highest in its capacity class. Mark highlights the balancer as a “huge point of difference” that allows higher capacity lifts while maintaining safety.

Brisbane-based Hulk Lifting, consistently turns to RUD for lifting and lashing solutions. “Knowing that we’re using RUD’s products provides us with a sense of comfort and reassurance,” said Ben Rose, Director of Hulk Lifting. “RUD really are ‘bestin-show’ for us: through the design, manufacturing and final build stages; everything is simply top-notch.”

RUD designs and manufactures a range of lifting and spreader beams locally, specified to customer applications. It also offers more than

700 boltable and weldable lifting points featuring load ranges all the way up to 250 tonnes.

RUD Australia is known for unrivalled after-sales service and support, which is highly valued by customers.

“RUD is always available to provide advice on maintenance, new products and different lifting solutions,” Mark said.

His sentiments are similarly echoed by Ben of Hulk Lifting, “Whenever we get something in from RUD, there’s always an engineer coming afterwards to inspect the product and ensure that it’s performing exactly as it should.”

Configuring lifting chains for applications can be a time-consuming and complex task. There are multiple factors which influence safety that can complicate the choice of the right sling chain. The new Sling Configurator from RUD makes it easier to configure the perfect chain sling for any lifting application – in only six easy steps.

In addition to choosing between a VIP-100 and an ICE-120 chain, there is a choice of components, information on lifting accessories, tips on lifting and the option to save a chain configuration as a PDF or CAD (computer-aided design) file and email it to RUD.

• C alculate lifting means in six easy steps.

• G et a 3D view of final configuration.

• C ompare components and parts

• D ownload a CAD file that can be used in lift plans.

The Sling Configurator provides a list of the parts in a configuration, making it easy to discuss the sling chain with a team and contact RUD to place an order or for more information.

RUD’s Configurator app helps users configure chain suspensions and lifting points for specific lifting and material handling needs.

By combining a long-standing legacy of quality with cutting-edge technology and a strong focus on customer service and safety, RUD aims to be a preferred partner for crane operators seeking a safe and reliable investment.

RUD is having an open event on 15 Oct at its premises at 12 Commerce Place, Larapinta QLD 4110

Limited spots are available. The company will be showcasing its lift technologies for the crane industry including break tests for chains, lifting beams and lifting points. RUD will also demonstrate its new robot and ICE Tensioner load cell technology.

Call on 07 3809 1300 to register!

The course instructors are seasoned professionals who will mentor course participants through real-life scenarios, preparing them for the challenges and responsibilities of a Crane Lift Supervisor.

Crane Lift Supervisors are in high demand globally. Completing this course enhances employability and opens doors to a wide array of job opportunities and career growth.

The curriculum covers a wide range of topics, including lift planning, load calculations, safety protocols, communication strategies, and legal compliance.

Scan the QR code to book or to fill out an EOI to help to determine next year's course dates.

Sydney 17-18 September 2025

Adelaide 1-2 October 2025

The course gives participants the confidence and skills to take control of lifting operations safely and effectively.

—Brandon Hitch, CEO, CICA

* Dates subject to change – See CICA Website for latest information

Maritime, Mobile and Crawler Crane technician roles available across Australia and New Zealand

Liebherr-Australia continues to grow, and we’re looking for talented people to join us. Our Service Technicians are at the heart of our success, ensuring reliability, performance, and service excellence.

Whether you’re an experienced professional or building your career, this is your chance to work with world-class technology and be part of a company known for quality, dependability, and innovation. Enjoy great employee benefits, including early access to long service leave, novated leasing, and training with the latest technologies.

If you’re interested in a career with Liebherr, simply scan the QR code and email us your resume at las-careers@liebherr.com

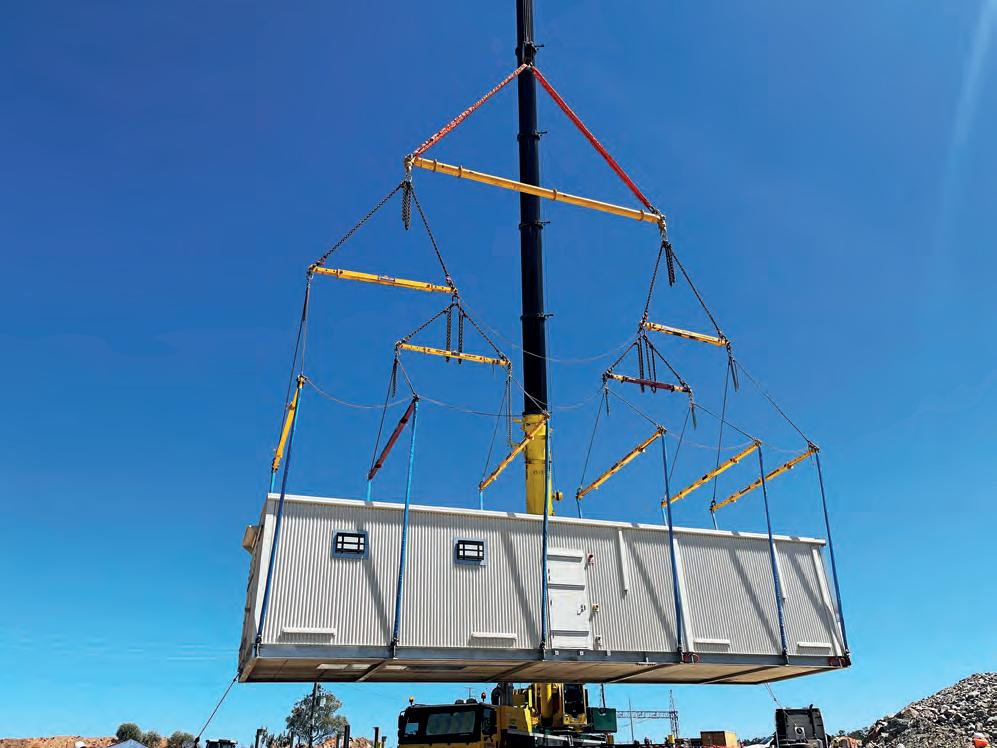

Able to handle heavy loads in tight spaces, Dieci’s new Apollo 20.4 ‘Smart Telehandler’ provides both strength and savings in one small but powerful machine.

CONTRACTORS, CRANE HIRE COMPANIES and machine operators are often faced with the challenges of having to work in confined areas or construction sites with tight space tolerances. Applications like these have generated a strong demand for equipment and special function vehicles that are more compact, more efficient, highly manoeuvrable and safe to use.

Similar limited-space handling challenges are often present on many work locations where materials need to be quickly moved, lifted, transported or stored.

Dieci’s 20.4 Smart Telehandler is a brand new model that is typical of the latest generation equipment that has been designed in response to this need.

Dieci National Sales Manager Bob Mules said the Apollo 20.4 – referred to as “smart” due to its advanced features that enhance efficiency, manoeuvrability,

and ease of use – addresses a market need for equipment that is more compact, agile, faster and more efficient.

“This telehandler has been designed specifically to deliver high-performance and effortless manoeuvrability in tight spaces, without compromising on power or precision,” he said.

“This product was only released recently. Rapid sales immediately following the introduction of this model is a clear indication that this new machine is satisfying a need in the market.”

The telehandler is powered by a 37 kilowatt Kubota engine, enabling it to travel at speeds up to 25 kilometres per hour.

“The advanced engine and transmission deliver an unbeatable combination of power and efficiency,” Bob said.

“The Apollo 20.4 features a Euro Stage V-compliant engine and a hydraulic flow system that enables the operator to use multiple functions at the same

time without losing speed or function enhancing the efficiency and productivity of the machine.”

Three steering modes –two-wheel, four-wheel and crab steer – make for smooth navigation and responsiveness even when carrying full loads.

Bob said that despite the telehandler’s compact dimensions, it provides several comfort-focused features designed to enhance the operator’s experience.

The cab is roomy and ergonomically optimised, ensuring operator comfort even during extended periods of use. There is an updated dashboard layout for improved accessibility and ease of operation, contributing to a more intuitive and efficient operating experience.

The controls, including a proportional joystick, are designed for ease of operation, reducing fatigue and allowing precise handling of the telehandler. All-round visibility is ensured by the cab design,

which includes large windows, providing excellent views in all directions, enhancing safety and convenience.

“Our engineers have also added patented features that simplify maintenance access.

The Apollo 20.4 Smart brings both strength and savings together in one powerful machine,” said Bob.

“Weighing in at 4300 kilograms unladen, the telehandler has a robust boom that can handle heavy loads up to two tonnes

manoeuvrability in tight places,” said Bob.

The Apollo 20.4 Smart isn’t just for construction sites, it can provide a more cost-effective versatile and efficient solution by combining the lift capacity of a hydraulic forklift with the reach and elevation of a crane.

A wide range of attachments ranging from buckets and jibs to forks and aerial work platforms mean operators gain the ability to take on multiple tasks with a

“The Apollo 20.4 is ideal for compact construction sites with tight height and space tolerances and ideal for underground and tunnelling applications due to its excellent turning circles and manoeuvrability in tight places.”

to an impressive height of 4.35 metres, while its horizontal reach is 2.67 metres.

“For great flexibility, the fork has a swivel angle of 133 degrees and the machine can climb angles up to 56 per cent. The Apollo 20.4 has an overall height of only 1.93 metres making it a compact, strong machine and an excellent lifter in confined spaces.

“The Apollo 20.4 is ideal for compact construction sites with tight height and space tolerances and ideal for underground and tunnelling applications due to its excellent turning circles and

single machine. Its compact dimensions also make it perfect for applications such as loading and unloading trucks, stacking pallets, and transporting goods within storage areas.

“Telehandlers are useful in moving heavy fabricated assemblies on construction projects and for the loading or unloading of machines on the job; their lifting capacity can streamline work and reduces risks associated with manual handling.

“Other jobs where the Apollo 20.4 Smart really shines is in applications such as public works landscaping where

its efficiency and speed makes it ideal for moving in confined spaces, while handling and transporting soil, mulch, large plants, and landscaping materials,” said Bob.

Compared to forklifts, the 20.4 has the ability to reach higher and further due to the telescopic boom, and it has greater visibility given by its lateral positioning. On landscaping projects, it can easily lift and transport logs, clear debris and has the necessary reaching power to manage heavy loads and handle bulk materials, transport tools and equipment in difficult environments. In recycling and waste management, the machine is ideally suited to handling materials, moving heavy bins, sorting materials, and handling waste materials for processing.

After-sales service plays a crucial role in the overall cost of ownership.

“Like every Dieci telehandler, we aim to ensure that the customer gets the best possible experience,” Bob said. “It’s about making sure sales, parts and service functions are integrated to deliver a great seamless experience, whether they are buying one or 20 machines. Dieci Australia has a commitment to customisation to suit market needs and has a proven record in specialised products that are supported by a strong national parts and service network.”

For more information call Dieci Australia on 1300 888 479, or visit www.dieciaustralia.com.au

Scott and Cathy Goode, owners of Sarina Crane Hire, started the business in 2007 with a single 12-tonne Franna. They weren’t aiming to just hire out equipment – they wanted to build a company that delivered complete lifting solutions, backed by a strong safety culture, skilled people, and a commitment to doing the job right the first time.

EIGHTEEN YEARS ON, SARINA CRANE HIRE has grown to a fleet of 36 cranes ranging from 13-tonne city crane through to a 250-tonne Kobelco lattice boom crawler, supported by heavy haulage and access equipment services. “We’re more of a onestop shop,” said Scott. “One phone call –

we turn up, do your job, supply everything. One contact, one bill.”

It’s a model that wins work, “If we’re doing the lift and the shift, and something doesn’t turn up because of an oversight on our part, I don’t charge the client. They like that. It’s about delivering on what we promise,” Scott said.

BUILT ON RELATIONSHIPS AND EXPERIENCE

Scott’s own background spans rail, mining and sugar, giving him a strong foundation in both technical lifting and customer service.

“I built a lot of relationships on the ground in those early years,” he said. “In the first five to ten years, I worked incredibly hard to build the name. Now the work comes to us – we don’t need to hunt for it.”

The company operates across a vast region Scott calls “the triangle” – from Bowen in the north, out to Emerald, and down to Gladstone in Queensland. Within this area, the team services industries including ports, sugar, mining and rail.

Sarina Crane Hire’s main hub is in Sarina, complete with a fully equipped maintenance workshop. “We do all our own servicing and ten-year rebuilds inhouse,” Scott said.

“My son, Ethan is the workshop supervisor – he’s a dual tradesman and has been with us ten years. We’ve got contract fitters and engineers come in when needed, but most of it we handle ourselves.”

Additional yards include a large 130-acre facility in Coppabella, which houses the big gear servicing the Bowen Basin, and a yard in Mackay – recently upgraded to a full operation after a competitor’s exit created an opportunity.

The crane fleet is dominated by Liebherr slew cranes, (120-130-150-200-220 and 250 tonne), Franna pick and carry cranes (20-40 tonne), supported by Grove rough terrains, a Tadano truck mount, and a Kato city crane. Highlights include two Liebherr 250-tonne cranes, an LTR 1220 and the 250-tonne Kobelco.

The heavy haulage side includes 13 prime movers – mostly Mack, with one Kenworth – and a wide range of trailers. “We’ve got step decks, blade trailers, ten-row low loaders, a lot of Drake trailers, and about eight or nine from Australian manufacturer

John Pace, JP Trailers,” Scott said. Offering both lifting and haulage provides clients with a seamless solution. “You don’t need to deal with multiple contractors – we take care of everything,” Scott said. “It’s one less hassle for the customer.”

From day one, Scott embedded a strong safety culture, drawing on his time as a health and safety representative during a major legislative shift in the early 2000s.

“The old Act told you what you could and couldn’t lift; the new one was about risk assessment,” he said. “I was in the pilot programs, so when I started my business, I was fully aware of my obligations. That’s been carried right through to today.”

Every task has a Safe Work Method Statement (SWMS), and a Job Safety Analysis (JSA) is completed before every lift or movement – whether loading a semi or shifting heavy equipment.

“The process is the same across all parts of the business,” Scott said. “That way, if people swap between divisions, the safety rules don’t change.”