At Chemipol Solutions, we’re more than just a raw material distributor – we’re your trusted partner in the paints, coatings, and inks industries

Our commitment to quality, innovation, and brand consciousness sets us apart as a premier supplier of raw materials sourced from leading global manufacturers.

EDITORIAL

EDITOR Sandy Welch

Tel: 084 525 0666

Email: sandy.welch@newmedia.co.za

SUB EDITOR Gill Abrahams

Email: gill.abrahams@newmedia.co.za

LAYOUT & DESIGN Kyle Martin

Email: kyle.martin@newmedia.co.za

ADVERTISING

ADVERTISING EXECUTIVE

Natalie Sanders

Tel: 082-450-2317

Email: natalie.sanders@newmedia.co.za

PHOTOGRAPHS

Unless previously agreed in writing, Coatings SA owns all rights to all contributions, whether image or text.

SOURCES

Getty Images, supplied images, editorial staff.

DISTRIBUTION & SUBSCRIPTIONS

Felicity Garbers

Email: felicity.garbers@newmedia.co.za

UPDATE YOUR DETAILS HERE

Email: register@media24.com

Web: www.diytradenews.co.za

PUBLISHING TEAM

GENERAL MANAGER: Dev Naidoo

HEAD OF CONTENT & DIGITAL STRATEGY: Varushka Padayachi

PRODUCTION MANAGER: Angela Silver

GROUP ART DIRECTOR: David Kyslinger

MEDIA24 MEDIA

CEO: Minette Ferreira

CFO: Lana Goliath

MEDIA24 CORPORATE

CEO MEDIA24: Raj Lalbahadur

CFO MEDIA24: Nelmarie Beyers

B2B JOHANNESBURG OFFICE:

Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146 Tel: +27 11 867 6111

PRINTING

Printed and Bound by Novus PrintCape Town Published by Media24 B2B

SAPMA AGM: Acknowledging a year of significant achievements

News: SAPMA Golf Day

News: Plascon Supplier Awards 2025, recognising excellence

News: SA’s labour laws set for major change

News: The impact of AI in manufacturing

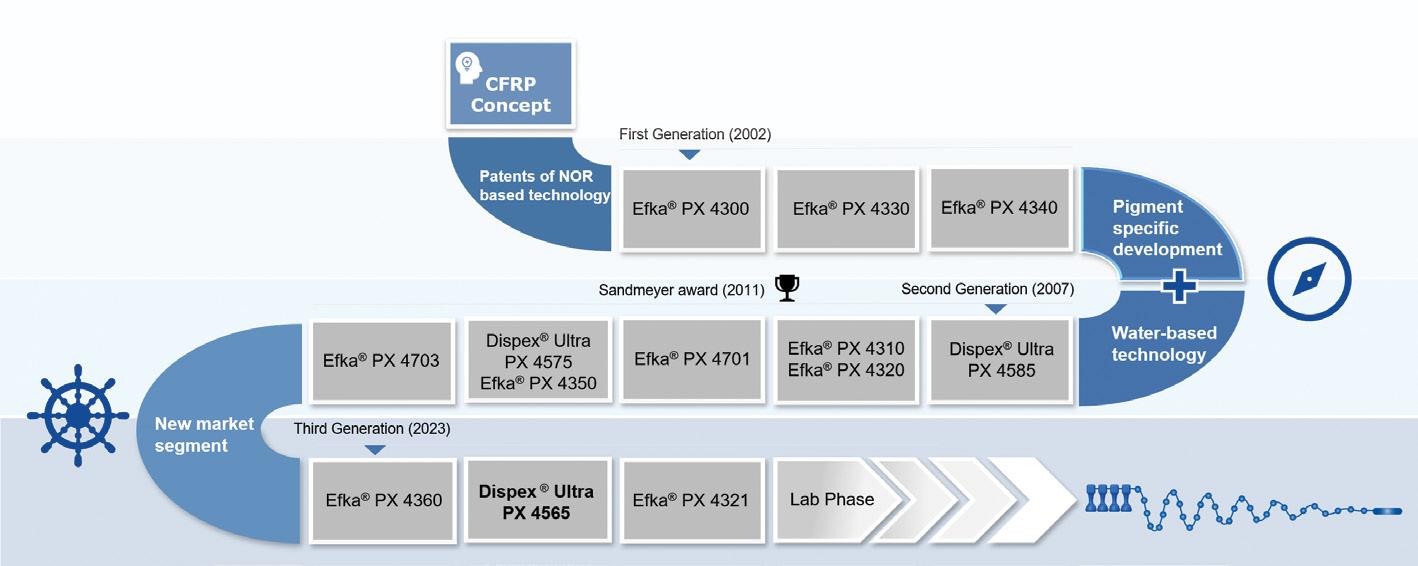

Feature: Controlled Free Radical Polymerisation (CFRP) for dispersing agents

Company Profile: SA Steelpack Solutions

Technical report: Rheology perfection meets sustainability

The coatings industry is no stranger to change, but the pace and scope of transformation today feel unprecedented. In this issue, we explore some of the innovations, challenges and celebrations shaping our sector right now. We start with pigment dispersion, a stage in paint manufacturing that is as complex as it is critical. With high-cost pigments, significant energy demands, and exacting performance requirements, the role of high-performance dispersing agents cannot be overstated. Precisionengineered polymer structures are proving key to ensuring optimal pigment performance and stability.

We also take a closer look at how AI is revolutionising manufacturing operations. From boosting efficiency to enabling predictive maintenance, AI is quickly moving from an emerging technology to an operational necessity, helping manufacturers navigate the megatrends redefining our world, from climate change and demographic shifts

to geopolitical uncertainty.

On the people front, we celebrate excellence with highlights from the Plascon Supplier Awards 2025, recognising the suppliers whose commitment and collaboration underpin industry success. And from the SAPMA Annual General Meeting, we report on a year of advocacy, technical leadership and education, proof that even in a challenging environment, our industry continues to make significant strides.

As always, our goal is to keep you informed, inspired and connected to the developments that matter most.

The South African Paint Manufacturing Association (SAPMA) held its 87th Annual General Meeting on 25 June 2025, at the Irene Country Club. The meeting highlighted a year of significant achievements despite ongoing economic and political challenges.

Comprehensive reports from various committees were shared, emphasising SAPMA’s expanding role in advocacy, technical guidance and industry education. Bobby Bhugwandin was the MC, and special welcome was given to Shaun Terblanche – chair of the Waterproofing Association, which has recently joined SAPMA.

The Chairman’s report focused on the world being in a precarious position and the need for a structured, cohesive approach from both government and the private sector.

He also emphasised the importance of monitoring the impact of the African Continental Free Trade Agreement, particularly threats from Egyptian suppliers. SAPMA now represents 126 members, including manufacturers, suppliers, retailers, and contractors. This diverse membership reflects the sector’s strength and SAPMA’s growing influence in a industry-wide challenges was highlighted as an area needing support.

Higlighted in the success of Tara Benn in leading SAPMA was recognised, alongside gratitude to vice chairs on MANCO: Stephen Reinecke, Bobby

Bhugwandin, and Verusha Malapermal.

Vice chairman Stephen Reinecke outlined SAPMA’s vision:

2026 Focus: Align technical expertise and training, including:

• Expansion of lead-free certification

• Sustainable formulation initiatives

• Integration with accredited training bodies.

2027–2030

• Develop a skilled artisan workforce via partnerships and mentorship programmes

• Promote sustainable innovation, including eco-friendly products and greener packaging

• Advance transformation efforts for broader local talent development.

Overall industry goal by 2030

• Ensure a cleaner, smarter and integrated paint and coatings industry

• Recognise paint as a national asset crucial for infrastructure, housing, and industrial growth.

ACHIEVEMENTS

The technical committee, reported

progress in regulatory compliance and stakeholder engagement:

1. Lead in paint regulations

• Following May 2025 regulations, SAPMA developed compliance guidelines

• Collaboration with the Department of Health (DoH) and the Lead Exposure Elimination Project (LEEP) clarified implementation.

2. National lead exposure prevention

• Continued participation in the National Lead Exposure Prevention Working Group (NLEPWG) for implementation strategies.

3. Methanol regulation

• Advocated for methanol-related safety regulations via public forums with the DoH.

4. Standards development

• Updates on SANS 731 road marking paint standards, though consensus is pending

• Participation in SABS TC35 meetings planned.

The Education Committee, highlighted critical training and skills development.

• SAPMA’s re-accreditation process through the QCTO (initiated in 2018) is on track.

Skills development

• Kgomotso Mokubyane was appointed as Skills Development Facilitator, assisting with WSP submissions. Both Mokubyane and Dr Ivor Blumenthal represent SAPMA in the CHIETA chamber

Training Programme success

• 64 students completed SAPMA/ BCF training in 2024

• 46 students enrolled for 2025.

Academic collaboration

• Engagement with the University of Port Elizabeth’s Diploma in Polymer Science programme, incorporating five SAPMA Technical Modules.

The report outlined SAPMA’s involvement in industry partnerships.

International relations

• BCF (British Coatings Federation)

• WCC (World Coatings Council)

• MCCM (Multistakeholder Committee on Chemicals Management).

Domestic committees

• BUSA/NEDLAC sub-committees (economic, trade, tax, small business, social, health, and education policies).

Training partnerships

• Collaboration with Signify Software to customise LMS platforms for SAPMA members

• Expansion of online training. Forums within SAPMA:

• Import/Export Trade Forum

• Consultant Forum

• Human Resources Forum.

Advisor Dr Ivor Blumenthal highlighted SAPMA’s representation initiatives:

Labour relations

• Of 160 members, 15 joined the Surface Coatings Employers Association (SCEA), contributing to a National Bargaining Council for the Chemical Industry (NBCCI) agreement (2024–2026).

Quality assurance

• Pilot of the Internal Member Accreditation Service, with PROMAC as a test site

• Launched the Guarantee Verification Scheme (GVS).

Professional body development

• 13 executives completed a senior executive manager professional designation.

• Expanded designations planned for roles like:

1. Professional mixologist/tinter 2. Professional paint chemist 3. Waterproofing contractor.

BUSA membership

• SAPMA gained direct membership to BUSA, participating in NEDLAC sub-committees.

Acknowledged challenges included:

Economic pressures

• Infrastructure decay, energy instability, and regulatory inconsistencies.

Standards development

• Difficulty securing quorum for SABS TC35 meetings, slowing progress.

Environmental concerns

• Lack of viable substitutes for banned PerFluoro Alkanes (PFAs).

Training resources

• Shortage of tutors for BCF and technical modules.

For more please visit www.sapma.org.za or call: 0767920048

The South African Paint Manufacturers Association (SAPMA) hosted its annual Golf Day on 26 June at the scenic Irene Country Club, drawing

The prestigious Plascon Supplier Awards 2025 took place at the Fairlawns Boutique Hotel & Spa, honouring the suppliers whose commitment and collaboration have played a key role in Plascon’s success.

The event was hosted by Sam Batohi, HR and communications director who emphasised that brilliance is not just about the final finish but about the foundation – the people. She praised suppliers for their hard work and dedication, whether in raw materials or transformative technology.

Batohi then introduced Prejay Lalla, head of Kansai Plascon Africa who shared the journey Plascon embarked on since 2016 and an exciting strategy to extend Kansai Plascon’s market leadership position across the African continent. “Africa remains a key priority within the Kansai Paint Group” says Lalla. Growth will be driven by leveraging Plascon’s leading market share in its operating regions and targeting above-market growth by defending its decorative coatings leadership, expanding in industrial and protective coatings, and maximising synergies under the One Africa strategy. Lalla highlighted the importance of the suppliers who stayed loyal through challenging times, calling them ‘the backbone of our success’.

SMALL (UNDER R25M SPEND)

FINALISTS – Eisotex, Swift Chemicals, SA Steelpack Solutions .

WINNER – SA Steelpack Solutions (William Mkhabela and Anneline Rajoo), presented by Alan Cotton — general manager Southern Africa.

The awards ceremony recognised suppliers who have demonstrated excellence in quality, service, and

partnership. Their commitment to innovation, reliability and collaboratiion has set a benchmark for the industry.

MEDIUM (R25m–R75M SPEND)

FINALISTS – Brenntag, Synthetic Polymers, Metcan Manufacturing.

WINNER – Synthetic Polymers (Sanjeev Bhatt and Mukesh Hadia), presented by Bobby Bhugwandin director business development (B2B) and procurement.

LARGE (OVER R75M SPEND)

FINALISTS – BASF South Africa, Pailpac, NCS Resins.

WINNER – NCS Resins (Rajan Chetty and Kavir Birijbal), presented by Prejay Lalla.

GUESTS THEN ENJOYED A SUMPTUOUS LUNCH BEFORE THE SECOND SET OF AWARDS.

CATEGORY 2 AWARDS – FROM METRICS TO MEANING

Category 2 awards – group pic.

BUDDING STAR AWARD (POLVIN AWARD) HEARTS AWARD (CASHMERE AWARD)

Shifting from metric to meaning –emerging talents in the supply chain.

WINNER – Eisotex (Denzil and Anusha Mohanlal), presented by Thori Aphane, Head of Procurement.

Recognising those who have won hearts beyond performance metrics.

WINNER – Pailpac (Malusi Madikizela and Nick Vincent), presented by Jay Venkanna – chief financial officer.

FINDING EXCELLENCE AWARD (VELVAGLO AWARD)

For high performers who align with Plascon’s vision and deliver purpose-fit solutions.

CLOSING THE CELEBRATION

The event concluded with a heartfelt vote of thanks from Bobby Bhugwandin, who acknowledged the challenges and successes of the past years. He thanked suppliers for their trust, innovative solutions, and the role they have played in Plascon’s achievements.

Thori Aphane closed the awards by thanking her partner in organising the event, Lee-Anne Du Plessis, and presented her with a bouquet of flowers.

The event ended with dessert and an open bar – a fitting celebration of South Africa’s largest paint company and its exceptional partners. c

WINNER – NCS Resins (Rajan Chetty and Kavir Birijbal), presented by Sam Batohi. For more information, Call: 0860-204-060 or visit www.plascon.co.za

By Dr Ivor Blumenthal

South Africa’s workplaces are on the cusp of change. In 2025, the Department of Employment and Labour is pushing for updates to the Labour Relations Act (LRA), a law that shapes how workers and employers interact.

These proposals, born from heated discussions at the National Economic Development and Labour Council (NEDLAC) starting in April 2022, include 47 amendments aimed at modernising the labour market. But not everyone agrees on the path forward. The government has a vision for balancing worker protections with economic growth, while businesses and unions are voicing strong opinions.

The government proposes to limit unfair labour practice disputes to clear, process-related claims such as unfair suspensions, disciplinary actions short of dismissal, and harm to whistleblowers. Promotions, demotions, training, and benefits would no longer fall under this banner. The rationale is to decongest the CCMA and Labour Court, encouraging internal dispute resolution through collective agreements, especially in the public sector. Business strongly supports this shift, seeing it as a long-overdue reduction in legal risk and operational micromanagement, particularly in HR decisions. However, labour, especially SAFTU, is vehemently opposed. They argue that it strips workers of recourse in cases of opaque and biased managerial decision-making.

The proposal introduces a threemonth probation period, extendable with justification, during which new employees cannot claim unfair dismissal except in cases of discrimination or victimisation. Government sees this as a calculated risk to stimulate hiring by reducing early-stage litigation anxiety

for employers. Business is fully in favour. They view it as essential for reducing the cost of entry-level hiring and allowing flexibility during onboarding. But unions are incensed.

They argue it formalises precarity by effectively denying vulnerable new workers any real protection for their first three months. Labour is particularly concerned this will become a loophole for short-term exploitation.

3.

Under the new proposal, procedural challenges to large-scale retrenchments would occur after dismissal rather than before. The CCMA would take over the power to issue rules for facilitation, and severance pay would be doubled from one week to two weeks per year of service. Government views this as a dual-purpose reform. It would speed up business responses during economic distress while cushioning the blow for workers through better severance. Business supports the procedural streamlining but is uneasy about the cost implications of increased severance, particularly for SMEs and distressed firms. Labour cautiously welcomes the increase in severance pay, which they see as overdue. However, they are suspicious of the post-dismissal challenge structure.

They argue it may delay justice and weaken workers’ ability to contest unfair dismissals effectively, especially without strong CCMA oversight and enforcement capacity.

The amendments propose that employees earning more than R1.8 million annually would not be

eligible for reinstatement if unfairly dismissed, except in exceptional cases such as discrimination or whistleblowing. Government argues that reinstating executives is impractical. Business backs this unreservedly. It notes that high-level disputes are costly and disruptive. They believe this will promote mobility in the C-suite and reduce the reputational and financial risk of litigation. Labour, however, is deeply critical. They argue this creates a two-tier system where senior professionals are left with reduced remedies simply because they earn more. In their view, legal protection should not be rationed according to income level.

The proposal allows disputes under the Labour Relations Act and the Employment Equity Act to be jointly resolved through a single arbitration or court process. Government sees this as a pragmatic improvement that will enhance access to justice and cut down on duplicative litigation. Business cautiously accepts the principle. It hopes this will lead to faster and less costly dispute resolution.

However, there is concern that discrimination and harassment claims, which were previously court-only, could now become more frequent at CCMA level.

Labour fully supports the reform. It believes it will improve accessibility for low-income and marginalised workers. If implemented, these reforms will reshape the rules of engagement in every workplace. For employers, it is a call to professionalise HR practices and prepare for increased regulatory scrutiny, even in areas where the law now appears more permissive. c

A decade of dedication, growth, and invaluable contributions. Synthetic Polymers celebrates its 10th anniversary with pride not just for the years passed, but for the collaborative journey that brought us here. From pioneering solvent-based resins for the coatings industry to fostering lasting partnerships, this milestone reflects our unwavering commitment to quality, consistency, and loyalty to customers delivering high performance solutions without compromise. We are deeply grateful to our loyal customers for their continued support, trust, and partnership, which have been instrumental in our success. For 10 years, we’ve combined technical expertise with service excellence, earning trust across the industry. As we reflect on our achievements, we’re also looking ahead to the next decade, which will bring even bolder advancements, driven by our passion for cutting-edge polymer solutions and sustained commitment to the coatings sector.

• Over 100+ solvent coatings formulations developed since 2015

• 100% locally manufactured in South Africa

• Proudly level 4 BBBEE

s t a b i l i t y i s r e q u i r e d . . .

s t a b i l i t y i s r e q u i r e d . . .

A P P L I C A T I O N M E T H O D S A P P L I C A T I O N M E T H O D S Tro wel

Block Brush Spo nge D e si gnPlas tic or rol l e r

S a n c r y l C h e m i c a l s h a v e l a u n c h e d S U N C R Y

A h i g h i n t e r a c t i v e , s p e c i a l t y p o l y m e r d e s i g n e d

f o r t h e u s e i n h i g h v i s c o s i t y c o m p o u n d s , w h e r e a

t e x t u r e d c o a t i n g i s d e s i r e d .

C O AT I N G A D VA N TA G E S

C O AT I N G A D VA N TA G E S

S U N C R Y L 1 0 3 o f f e r s t h e

f o r m u l a t o r t h e a b i l i t y t o

f o r m u l a t o r t h e a b i l i t y t o

m a n u f a c t u r e v a r i o u s t y p e s

m a n f a c t r e v a r i o s t y p e s

o f t e x t u r e d c o a t i n s f o r

o f t e x t u r e d c o a t i n g s f o r

m u l t i p l e a p p l i c a t i o n s s u c h

m u l t i p l e a p p l i c a t i o n s s u c h

a s t o w e l , b u s h & s l a p -

b r u s h S U C L 0 3 o e s t h e

a s t r o w e l , b r u s h & s l a p -

b r u s h

• E x c e l l e n t s t a b i l i t y

• E x c e l l e n t s t a b i l i t y

• H i g h f i l m b u i l d

• H i g h f i l m b u i l d

• H i g h o p e n t i m e

• H i g h o p e n t i m e

• E x c e l l e n t A d h e s i o n

• E x c e l l e n t A d h s i n

• I m p r o v e i n d i n g p o w e r

• I m p r o v e d b i n d i n g p o w e r

• I m p r o v e d a k a i r e s i s t a n c e

• I m p r o v e d a l k a l i r e s i s t a n c e

• L o w t e m p e r a t u r e d u r a b i l i t y

• o w t e m p e r a t u r e d u r a b i l i t y

• E a s e o f a p p l i c a t i o n

• E a s e o f a p p l i c a t i o n

Due to excellent mechanical stability, coatings manufactured using SUNCRYL 103 support various Textured Coating application methods and tools.

These may include troweling, block brushing, sponging or using specially designed plastic or sponge rollers.

Textured Coatings are typically applied on various substrates and the type of application is dependent on the applicators desired effect

The manufacturing sector is undergoing a significant transformation driven by various megatrends like climate change, technological disruption, demographic shifts, a fracturing world and social instability.

Impacts include a shift towards green practices, global changes in production footprints, increasing digitalisation, tightening regulations and workforce challenges. Rising costs from inflation and energy prices further amplify these pressures.

In a recent PWC report, AI in Operations: Revolutionising the manufacturing industry, the pressing forces reshaping the sector are highlighted. These challenges demand bold, forward-thinking strategies, and local businesses must adapt or risk being left behind. AI, including traditional forms such as machine learning and newer developments like generative and agentic AI, is playing a crucial role in addressing the challenges.

In a study of over 400 operations executives across 30+ countries in Europe, the Middle East and Africa, results show that manufacturing companies believe strongly in AI’s potential to increase profitability. Nearly 70% of global respondents and 81% of South African respondents expect it to increase operating profits by at least three percentage points by 2030 and more than 56% of South African respondents anticipate an even greater rise of five percentage points in operating profits.

“AI is revolutionising our approach to operations by drastically reducing the time needed for a whole range of core operations processes, from R&D and supply chain to production and

procurement,” says Stefan Schrauf, Global Supply Chain and EMEA operations transformation co-leader, partner, PwC Germany. “As AI evolves into an indispensable decision support assistant, it will not only enhance our decision-making processes but also autonomously handle repetitive tasks, driving efficiency and innovation.”

The PWC research underscores that the rewards of AI integration are nonetheless significant. AI is increasing sales delivery in volumes, enhancing decision-making, enabling the reduction of operational costs and providing new revenue from additional products and services. It is also helping address skill gaps within the industry. 'AI Operations Champions' are reaping the most benefits by effectively scaling and integrating AI across their operations. Looking forward, survey respondents anticipate impressive improvements.

Although expectations are high, only 15% of South African respondents report significant financial returns from AI in operations. “While 50% have moved beyond pilot phases, the pace of implementation and return on investment remain measured. However, this does not negate the fact that AI is already delivering measurable improvements in decision-making, productivity, flexibility and delivery volumes,” says Pieter Theron, partner, PwC South Africa.

As companies increasingly rely on AI to drive critical decisions and operations,

confidence in the integrity and reliability of these technologies is essential. Trust is critical to reap the rewards of GenAI too. The results of PwC’s 28th Annual Global CEO Survey: Sub-Saharan Africa perspective highlight this clearly: 34% of CEOs express high and very high trust in AI integration – matching global confidence levels.

“The biggest hurdles to AI adoption in South Africa include the cost of AI software, data quality and a shortage of specialised AI talent. However, despite these challenges, 72% of South African companies plan to adopt or expand AI initiatives in the next 12 months,” says Nqaba Ndiweni, consumer and industrial products and services industry leader, PwC Africa.

“Leaders are taking a balanced approach to AI adoption, priortising purposeful implementation rather than rushing to match global adoption rates, while still achieving comparable or better efficiency gains when they do implement,” says Ndiweni.

AI is complex. Many pieces of the puzzle need to come together to successfully scale AI use cases across the organisation and realise tangible business benefits. However, operations leaders should not wait any longer to see how AI evolves before setting out their AI strategy and committing to AI investments.

The longer they wait, the greater the risk of losing ground to more ambitious competitors. c

Delta Colours is proud to partner with DDChem as their exclusive distributor in South Africa for epoxy hardeners.

high-performance product portfolio serves the coatings and construction industries, offering innovative solutions for:

• Epoxy hardeners

• Curing agents

• Polyamide resins

• Polyaspartic technology

• Waterborne systems

Together, Delta Colours and DDChem are bringing world-class technology and local expertise to support your formulation needs. Contact us today to find the right solution for your next project.

By Vasantraj Nadar, Manfred Jorna and Steffen Onclin

Pigment dispersion is a crucial stage in the paint manufacturing process – this involves high-cost pigments with significant energy consumption and is critical in determining the characteristics of the final coating. To ensure optimal pigment performance, specialised high performance dispersing agents are essential.

Dispersing agents must meet two primary criteria: they need to exhibit a strong affinity for the pigment surface and they need to offer effective stabilisation to prevent flocculation. These performance requirements are best achieved when the polymer structure of the dispersant can be precisely engineered.

CFRP TECHNOLOGY: MAKING POLYMERS MORE EFFICIENT BY DESIGN

Commercial pigment dispersants are synthesised using a variety of polymerisation techniques and can be broadly categorised into two groups. The first group comprises conventional dispersants, typically produced via polymerisation processes that offer limited control over macromolecular architecture, resulting in random copolymers. Although such polymers can exhibit satisfactory dispersing performance, polymers with more defined structures generally demonstrate superior performance.

The development of BASF’s Controlled Free Radical Polymerisation

(CFRP) technology allows for the synthesis of dispersing agents with precisely defined block copolymer structures that perfectly fit to pigment surfaces and their surroundings. The anchoring block also has a high density of pigment-affinic groups and the stabilising tail is optimised to ensure enhanced stability.

This ensures numerous advantages over conventional dispersing agents, including higher efficiency and broader compatibility, which also enables optimal rheology and improved colouristics for superior formulations.

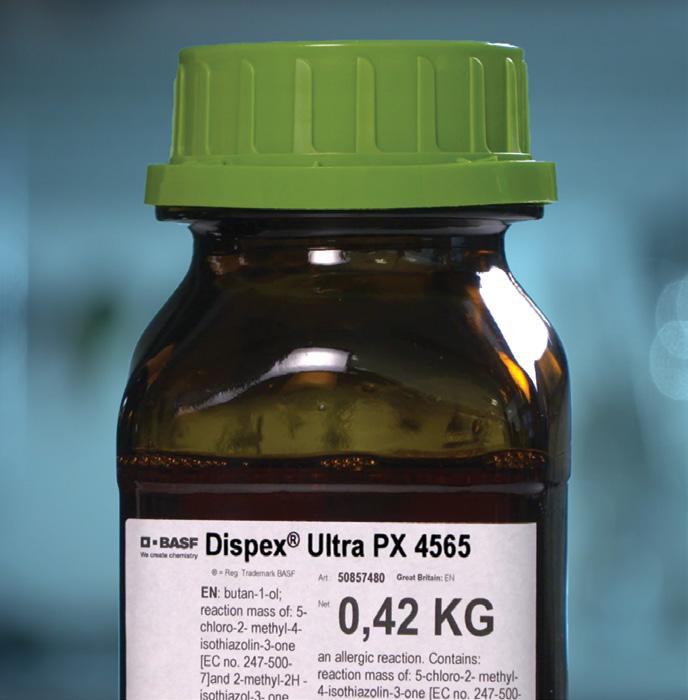

Acrylic chemistry provides a versatile selection of monomers suitable for the synthesis of BASF’s breakthrough CFRP technology. Since the commercial release of firstgeneration CFRP products in 2002, BASF has continuously expanded its portfolio, now offering a widerange of dispersing agents designed for water-based, solvent-based, and solvent-free formulations. CFRP dispersant technology has introduced high-performance additives such as Efka® PX 4310 and Dispex® Ultra PX 4585, which redefined the benchmarks for carbon black pigments within the coatings industry. These dispersing agents exemplify the impact of CFRP products on pigment dispersion efficiency, particularly for challenging applications where highest jetness is required.

Advancements in processing techniques and raw material selection have enabled the development of a new generation of CFRP-based dispersing agents with enhanced value in use. These next-generation products are particularly well-suited for industrial applications with diverse binder systems and end-use requirements, where optimising performance with cost control is essential.

Designed for solvent-based systems, Efka® PX 4360 is distinguished by its unmatched pigment compatibility, delivering optimal performance across organic pigments and medium colour carbon blacks. Launched in 2024, this dispersing agent marks a new era of CFRP, providing high colour strength in solid shades and excellent compatibility across a wide range of industrial resin systems.

Introduced shortly after Efka PX 4360, Dispex® Ultra PX 4565 is a dispersing agent optimised for water-based formulations that can significantly reduce viscosity during pigment milling, enabling higher pigment loading and improved processability which in turn allows for shorter milling cycles, reduced energy consumption, and increased throughput.

Both Efka® PX 4360 and Dispex® Ultra PX 4565 are CFRP-powered solutions from BASF that fulfil the needs for both solvent- and water-based industrial formulations respectively. A further benefit stemming from the exceptional processability of CFRP products is the increased sustainability and reduced carbon footprint due to lowered dispersion times, shorter cycles and reduced energy demand, enabling manufacturers to formulate the next generation of coatings. c

For more information, contact: BASF South Africa PTY LTD Jivesh Raghunundan, account manager (Resins & Additives) Email: jivesh.raghunundan@basf. com

Bodo Moeller Chemie South Africa

Mrs Mareta le Roux, Divisional Manager | CASE Email: m.leroux@bm-chemie.co.za

We are proud to be associated with leading paint manufacturers & have a key focus on EXPORT markets in Africa. We boast a team of highly skilled polymer chemists in the laboratory as well as on the plant to ensure quality control and superior standards of resin. Adding to the mix is our MAINTENANCE team of qualified engineers, fitters, welders & electricians. Our high-quality polymers are the key to vibrant decorative, industrial, automotive, and other coatings. Our state-of-the art laboratory boasts cutting-edge technology and a team of R&D chemists who endeavour to develop products for our customers.

The vision is to RE-DEFINE the COATINGS INDUSTRY with our QCCP (Quality, Consistency & Competitive Prices) THEORY.

Are you looking for lightning-fast delivery? Our 20-metric ton bulk delivery vehicle guarantees your order will arrive within 24-72 hours.

• Long, Medium & Short Oil Alkyds

• Urethane Alkyds & Oils

• Hydroxy Functional Acrylics

• Thermoplastic Acrylics

• Speciality Alkyds

• Short & Medium chain stopped Alkyds.

• Styrenated & Acrylated Alkyds

• Amino Resins (Urea & Melamine Formaldehyde)

• Thermoset Acrylics

• Saturated Polyesters

Experience the MAGIC with SYNTHETIC POLYMERS!

SA Steelpack Solutions, known simply as Steelpack, is one of South Africa’s most dynamic players in the metal packaging industry. Specialising in high-quality tinplate cans, pails, and aerosol containers, Steelpack has built a reputation for delivering exceptional packaging to the chemical, industrial coatings, cosmetics and speciality sectors.

With a strong focus on innovation, quality, and customer service, Steelpack combines decades of experience with cuttingedge technology to offer solutions that not only meet local and international standards but often exceed them.

Steelpack manufactures a broad range of tinplate packaging solutions, including:

• Decorated and plain cans, pails and tins

• Sizes from 200ml to 25L

• Rectangular range 500ml /1L and 5L

• Triple tight and dome top closures

• Lug lid or lever lid mechanisms (20L and 25L options)

• Multiple handles, spouts and lid accessory options

• Three-piece aerosol cans in all standard diameters and custom heights.

Customers can choose between plain and decorated finishes, with world-class printing and decoration technology that allows for low minimum orders, highresolution graphics, and flexible artwork changes between production runs –removing the old barrier of large print plate commitments.

Steelpack is committed to reducing its environmental footprint through waterwise operations, waste minimisation practices, and fully recyclable tinplate products. Its focus on sustainability aligns with its vision of being a responsible partner to customers, communities, and the planet.

Steelpack runs a rigorous quality control programme, with regular interval testing and a culture of continuous improvement. The company’s ISO9001 SGS certification reflects this commitment, and its operational standards continue to evolve to meet growing demand and complexity.

Steelpack’s mission is clear: “To be a reliable and agile supplier of quality decorated tins cans, pails and aerosol cans to meet customer requirements in the chemical, industrial coatings, cosmetics and speciality sectors.”

Its values are embedded in every decision:

• Integrity

• Respect

• Mutuality

• Sustainability

• Fairness.

Headquartered in Durban with a strong presence in Johannesburg, Steelpack operates three state-of-theart production facilities in Tongaat and Mount Edgecombe, supported by a satellite distribution and storage hub in the East Rand.

Deeply rooted in the local community, Steelpack remains actively involved in initiatives that uplift and support the people who work for – and with – the company.

Steelpack has received multiple accolades over the years, including:

• GAPP Awards

• Gold Pack Awards

• Supplier of the Year awards from key partners.

Whether you're in paint, coatings, industrial chemicals or cosmetics, Steelpack is your trusted partner in premium metal packaging – built to protect, perform and promote. c

Rheological effect of biobased NiSAT grades and their contribution to the sustainability of paint formulations.

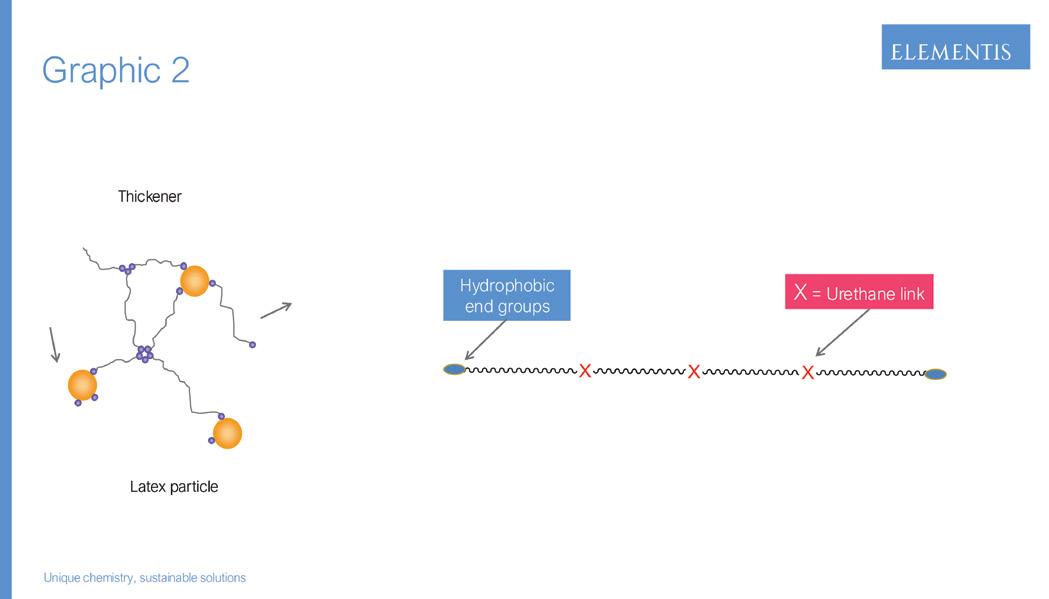

Numerous kinds of associatively acting rheology modifiers are in the market for aqueous applications. These standard products offer the possibility to tailormade individually required flow characters to meet properties of paints, coatings, adhesives and others based on various binder technologies such as polyurethanes, acrylics, styrene acrylics, Vina-Veova, Vinyl ester, etc. Examples of these product classes are hydrophobic modified acrylic thickeners, so called HASE grades, or NiSAT products, which are known in the market for instance as polyurethane thickeners. Most of the products are available as aqueous liquids for easy handling. Alternatively, powder versions of certain NiSAT grades are available to achieve a better carbon footprint and a biocide and surfactant free thickener.

HASE based grades are anionic, and find mainly use in decorative formulation, eg as liquid alternatives to cellulosics. NiSAT thickeners, which term itself abbreviates ‘Non-ionic synthetic associative thickener’, are of nonionic nature and are offering the most modern approach in formulating water based industrial and decorative coatings. They are acting pH independent over a broad range

of applications

across all gloss ranges. Further, sag/levelling balance, film build and hiding power can precisely be steered. The influence on the water sensibility and the corrosion of the substrate is very low.

Another huge benefit of the NiSAT pure associative thickeners is the possible addition directly to the system using only moderate shear. Other ingredients in the formulation will impact the effectiveness of NiSAT range such as co-solvents and surfactants. These effects are relevant for all associatively acting thickeners, independently if they are based on biobased or conventional chemistry.

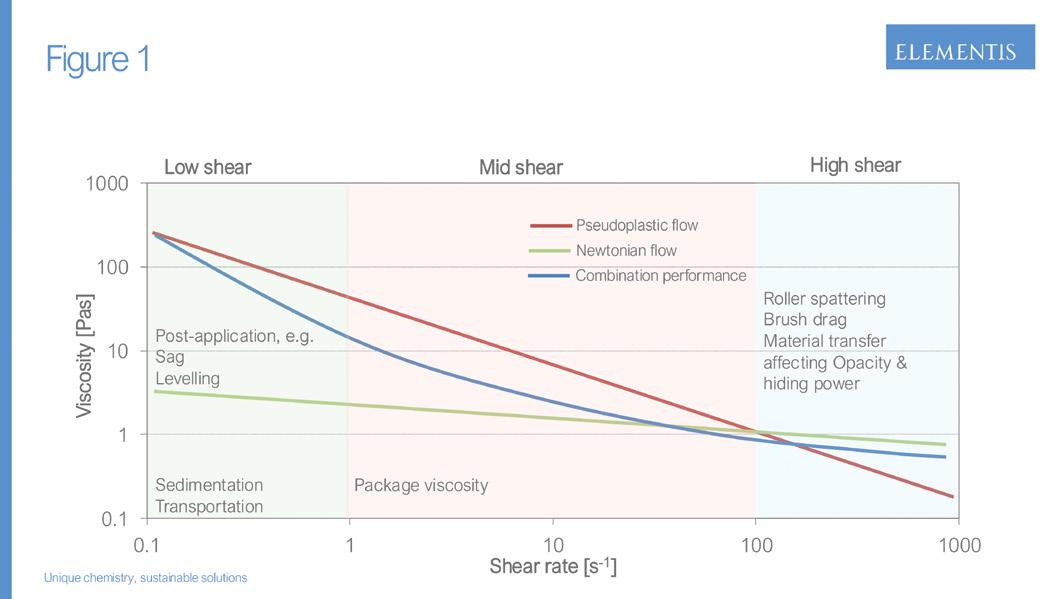

Depending on the choice of NiSAT grades certain shear rate ranges are being affected. Those grades building up low shear viscosity are typically controlling the pre- or postapplication behaviour eg levelling/sag balance and sedimentation. As these products are typically acting shear thinning, the atomisation during spray application of industrial coatings can be optimised. So called Newtonian grades are focusing on the high shear side promoting the application behaviour like roller spattering, levelling or also the material transfer by a brush drag

increase which directly affects the hiding power/opacity.

Typically, these kinds of additives are being combined for a perfect balance of the mentioned properties including the in-can viscosity of the final product.

As visualised in Figure 2, NiSAT molecules are typically acting associatively with hydrophobic parts of the formulation such as mainly binders but also to pigments and fillers. This forms network which affects the described rheological effects. The rheologically active molecule consists typically of a hydrophilic, water-soluble backbone, surrounded by at least two hydrophobic end groups. The structure can be linear or branched; this also impacts the performance of the product. The hydrophilic part can be based on conventional raw materials, or, as in the case of the RHEOLATE® BIO products on renewable resources. A molecule weight of typical NiSAT can be typically found in an average range of 20000-50000 g/mol.

The decision, if a NiSAT performs Newtonian or shear thinning is mainly controlled by the strength of the hydrophobic groups. If the hydrophobicity is dominant, the

thickener provides shear thinning flow with a strong effect of the low shear viscosity. In the case of less hydrophobic end groups, the molecule focusses on the high shear paired with Newtonian flow driven viscosity by its hydrodynamic volume. In this case, typically the loading levels are higher due to the less pronounced hydrophobicity compared to pseudoplastic grades.

Apart from its pure thickening characteristics, NiSAT products are affecting the viscoelasticity of the end system tremendously.

This data is beside the pure viscosity important for a better understanding of the application properties.

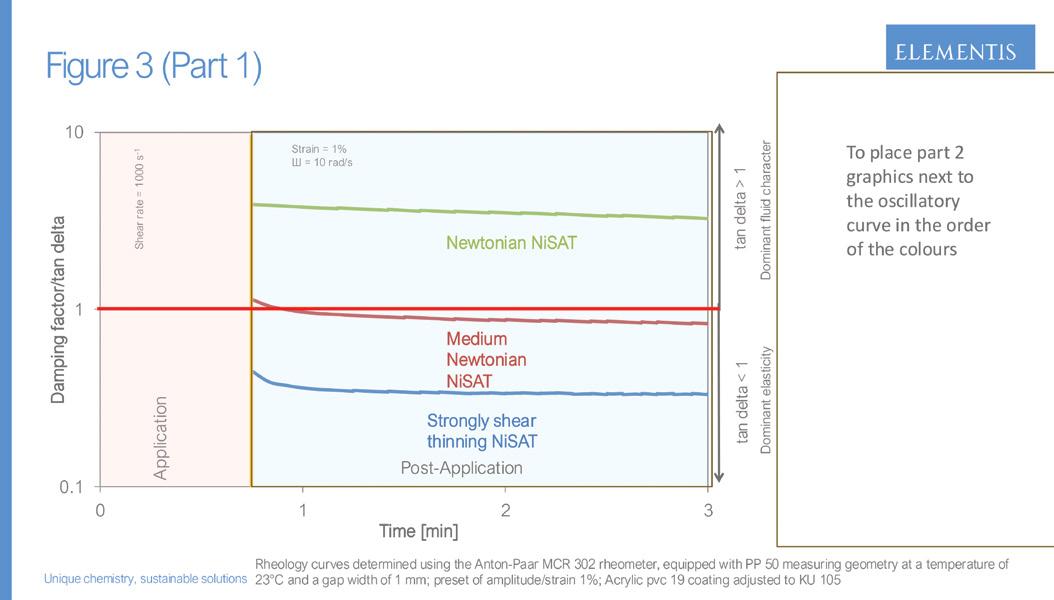

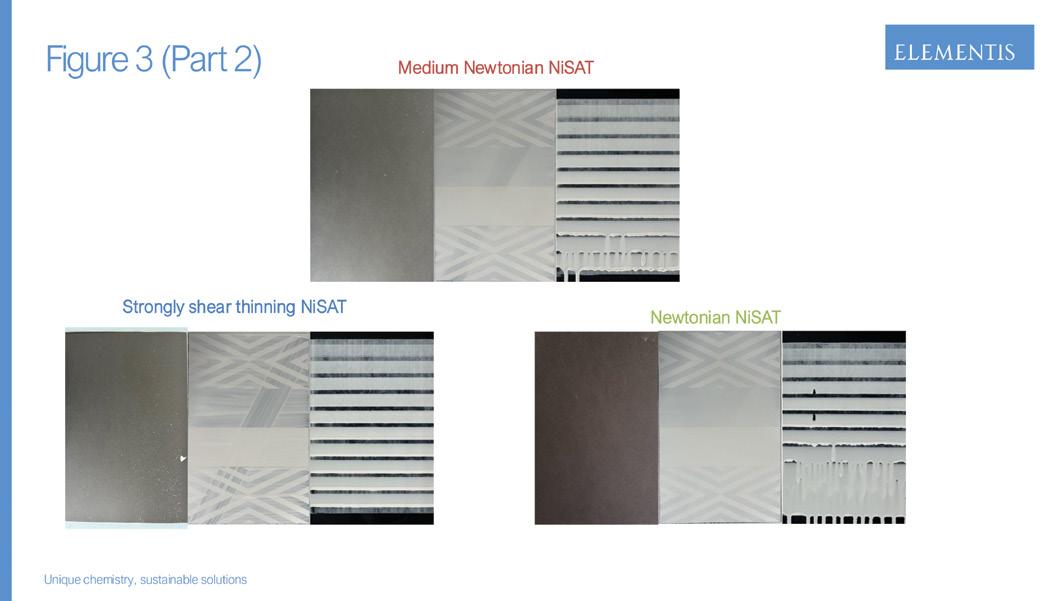

In Figure 3 the structure recovery test data of a pure acrylic, PVC 19, paint formulations equipped with various NiSAT thickeners a visualised as damping factor, or tan delta value.

Figure 3 (Part 1 and 2)

The damping factor have been generated in an oscillatory, structure recovery test which simulates a coating application. The first part of the diagram shows a rotational high shear part.

As only oscillatory tests are generating these data, this part of the diagram remains void. In the second part, the post-application properties are shown. Strain and angular frequency were presets to a low range, in which the behaviour is usually elastic dominated.

As in the rotational part all structure has been broken, the exact time of the recovery can be read off when plotted on a time scale.

A damping factor of below one, shows a dominant elastic character whilst a value of above one describes Newtonian, fluid like behaviour.

In the case of the strongly pseudoplastic NiSAT grade, the tan delta value acts significantly below one indicating a strong elastic character. In a context with the application results, this guides to good sag control, however, levelling and spatter resistance, were a bit inferior.

On the other hand, a Newtonian rheology modifier gives better levelling and spatter resistance, whilst the sag control remains behind. Damping factor in this case is far above one which displays a strong fluid character and practically no structure.

becomes obvious that the hydrophilic, water-soluble main part of the NiSAT active raises the highest interest as it represents depending on the product up to 95% of the entire molecule mass.

Consequently, this part has the strongest influence when made from renewable resources.

As already explained, chemically this part of the molecule consists of a polyol chain. In the new biobased NiSAT product family, this part has been based on bioethanol originated by sugarcane molasses.

This raw material is classified as waste or residue as it is not intentionally produced. Consequently, it does not compete with food supply.

The use of biobased polyol allows the content of biobased carbon content to be higher than 90% determined by the biobased carbon C14 segregated approach.

The medium Newtonian grade acts in between offering the best sag/levelling balance indicated by a tan delta value of roughly around one.

From a sustainable perspective, it

The current range of biobased NiSAT’s consists of two grades, RHEOLATE® BIO 5010 a Newtonian and with RHEOLATE® BIO 5075 a pseudoplastic acting grade. Formulated alone or combined even with other classes of rheology modifiers eg clays, acrylic thickeners or cellulosics, the adjustment of the desired flow characteristic is guaranteed.

Comparing the pseudoplastic RHEOLATE® BIO 5075 to its conventional counterpart it becomes visible that the rheological performance of both grades acts very closely.

The rheograms were determined in a standard PVC 50 paint exemplary equipped either with a styrene-acrylic and a pure acrylic binder emulsion.

The concentration added was in both cases 0.66%. As the active content with both additives are identical, the content of rheologically active material in the system was equal as well.

Figure 4

A very similar picture can be taken when comparing RHEOLATE® BIO 5010, the Newtonian grade, to its conventional equivalent. Also in this case, the active content in

both products have been identical. Consequently, the added thickener concentration of 10.5% the styreneacrylic and 5% to the pure acrylic result in both cases in equal active loading as well.

In all cases the rheological characteristics are very similar, so that a 1:1 replacement from the conventional to the biobased version can be realised without affecting the rheological characteristics adversely. However, to simulate the behaviour under real conditions, both, Newtonian and pseudoplastic, rheology modifiers must be combined. Only in that case, the rheological characteristics can be perfectly equalised for balanced sag,

levelling, workability and other characteristics required. For this study, the styrene-acrylic based PVC 50% paint was selected.

As a base viscosity for this and to compare the efficiency of the individual additive combinations to each other the Krebs-Stormer and the high shear viscosity at 10000 s-1 was taken. The Krebs-Stormer (KU) viscosity is often taken to represent the in-can viscosity and acts approximately in a shear rate range of 100-200 s-1. Due to the conditions in KU measurement an accurate shear rate cannot be calculated. Consequently, the result will be measured just unitless.

In the given case displayed in Figure 5, the KU viscosity has been adjusted to roughly 100 units whilst the highshear viscosity was set to about 1.1 Poise.

Figure 5

In the case of the RHEOLATE®

BIO combination and the blended conventional RHEOLATE® grades the required concentration to obtain the mentioned viscosity values are equal and confirmed therefore the findings of the individual testing. However, when comparing the equal the active containing biobased market reference grades, it becomes obvious that these are requiring higher loading levels for the same effect. In the case of the Newtonian, it was 7.5%, the pseudoplastic side required 8.1% more.

The resulting rheogram, visualised in Figure 6, shows that equally preadjusted paints behave very similarly.

Figure 6

Differences could only be noticed on the low shear side, in which the market reference combination produces somewhat lower values. In the mid shear rate range between 10 s-1 and 100 s-1 a slight dominance of the RHEOLATE® BIO combination can be seen.

However, besides the pure rheological characteristics, further application properties are being of high importance and are influenced by the choice of rheology modifiers. The in this case evaluated and shown properties are levelling up on brush application, sag control, roller spattering resistance and storage stability are visualised in the Figures 7-11. Further properties such as dirtpick-up, staining resistance etc of the final paint have been tested as well.

It is becoming obvious that changing from conventional to RHEOLATE® BIO NiSAT grades no remarkable changes in the application properties are noticed. Also, in comparison to the combination of the market reference biobased products no properties have been majorly changed.

However, the sag control displayed in Figure 7 with the biobased market reference thickeners is remaining slightly behind. These findings are in line with the rheological findings on the low-mid shear side which were discussed earlier.

Levelling after brush application shown in Figure 8, the so-called brush

out properties, showed in all cases the same behaviour. Also, no visual differences in the opacity were seen. For this test the same amount of 40g of all threetest paint was brought on the brush. After the application by identical number of brush swings, the material amount really transferred to the substrate was calculated back to ensure similar paint transfer.

In the case of the material stored for 28 days at 50 °C in Figure 9 stable conditions were noticed. Only minor syneresis was seen.

Brush applied demonstrated in Figure 10 is showing no differences in between the differently tested paint samples. For this test, again an equal amount of 200g of paint was placed on a roller. During the 10 roller applications swings on a vertical, potential spatters are being collected on a black leneta chart positioned underneath. The lower the number of spatters collected the better the result and the better the rating.

Besides the test paint system shown in this publication our RHEOLATE® BIO products have been tested in further systems equipped with different binder emulsions.

NiSAT thickeners are acting associativity with hydrophobic parts of the final formulations. Depending on the chemical composition and its hydrophilic/hydrophobic balance of the thickener molecules certain areas of the shear rate scale can be affected. This allows exact steering of the flow characteristics of paints

It is becoming obvious that changing from conventional to RHEOLATE® BIO NiSAT grades no remarkable changes in the application properties are noticed.

The new product line performs dominant in the terms of efficiency and provided sag control.

and other aqueous systems by individual or combined choice of rheology modifiers. Those kinds of properties can be underlined by relevant rheological measurements displaying flow characteristics and viscoelastic data.

Watching the chemical structure, it becomes obvious that a large part of the rheologically active molecule can be formulated by biobased renewable resources for a strong impact on the sustainability of the product and the final formulation. Elementis new biobased products, RHEOLATE® BIO 5010, a Newtonian, and RHEOLATE® BIO 5075, a pseudoplastic acting thickener, are consisting of minimum 90% C14 verified biobased carbon.

From a functional point of view both RHEOLATE® BIO 5010 and RHEOLATE® BIO 5075 grades are in line with its conventional counterparts showing only minor differences in the flow characteristics and application properties provided. In comparison to commercially available biobased market reference thickeners with equal application spectrum, the new product line performs dominant in the terms of efficiency and provided sag control.

Based on these results, the new line of RHEOLATE® BIO grades provides additional options for paint formulations, ensuring a better match between rheological performance and today’s sustainability requirements.

Literature

Elementis rheology handbook. c

The ONE SUDARSHAN combines the global portfolio and service of Clariant pigment division, Heubach and Sudarshan Chemical.

• Leading color solutions provider

• Extensive range of organic, inorganic, pearlescent pigments and liquid dispersions

• Diversified asset footprint: 19 sites across 11 countries

• + 4,000 customers in more than 120 countries

sudarshan.com