Lifestyle and Fashion

take back project

Group 6

Peng Jie

Ayda Amini

Valentina Centurion

Camila De Brasi

Group 6

Peng Jie

Ayda Amini

Valentina Centurion

Camila De Brasi

The most sustainable garment is the one that already exist.

Must Had is a refashion platform for upcycled clothing and accessories. It offers high-quality and unique clothing exclusively produced from fashion industry waste. Also, it has a sustainable model because the fashion items that they sell are made from what already exists. This plataform connects responsable brands and conscious costumers. The values of the brand are to renew the fashion industry, revolute the way we consume and to accelerate the transition towards a regenerative fashion.

Upcycling is the act of of repurposing textile waste into new products of higher quality or value than the original. The benefits of upcycling go way beyond the environmental sustainability, it also helps in supporting small artisans, brands and designers, by encouraging creativity, craftsmanship and innovation.

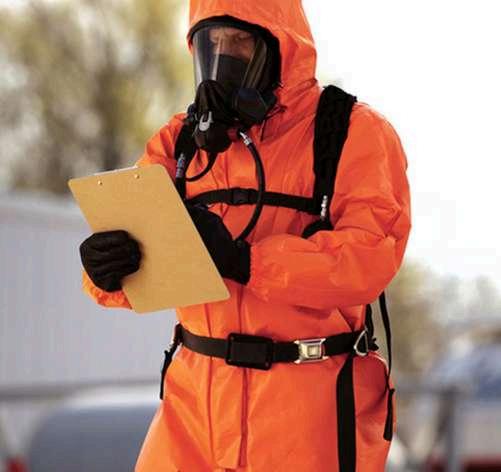

Disposable suits are a type of personal protective equipment consisting of an impermeable, full-body suit for protection against hazardous materials. Disposable suits are used by firefighters, emergency medical technicians, paramedics, researchers, personnel responding to toxic spills, specialists cleaning up contaminated facilities, and workers in toxic environments.

Disposable suit is also widely used in the medical industry, and during the covid-19 pandemic, it was the "battle dressing" of front-line medical personnel. Medical disposable suit provides a barrier and protection against potentially infectious patient blood, body fluids, secretions, airborne particles, etc. that medical personnel are exposed to while working. Medical staff must wear protective clothing when treating patients to prevent cross-infection. Therefore, major hospitals are urgently raising protective supplies, and protective clothing is included in strategic supplies.

Tyvek is a 100% synthetic material made from high-density polyethylene fibers. Tyvek is lightweight, strong and breathable, yet waterproof, abrasion resistant, resistant to bacterial penetration and aging, making it an extraordinary material that can be used to enhance a variety of applications in many areas.

Tyvek is available in rigid constructions for HomeWrap bags and medical packaging, as well as soft constructions with woven finishes for protective clothing and commercial applications.

When Tyvek fibers are spun and bonded at high pressures and temperatures, Tyvek acts as a thermoplastic material, recovering its high density and taking on a semi-solid state, preventing liquids from breaking through the surface.

Because Tyvek does not use adhesives, it retains tiny pores that allow water vapor to penetrate the material, thus preventing water and other liquids from entering, thus making Tyvek highly breathable.

Tyvek consists of continuous fibers that are inherently resistant to microbial penetration, preventing harmful substances such as asbestos, mold, fiberglass and lead from penetrating the material.

Tyvek fibers are randomly aligned and compressed to provide excellent tear and puncture resistance for reliable, long-lasting protection.

Tyvek is a non-biodegradable material, so it cannot be buried in the soil, but can be recycled. And it offers unique performance benefits for a variety of applications, including benches, playground equipment and more.

industrial protective clothing manufacturing, automotive, and utilities

take back project

Controlled environments & cleanroom protection cleanrooms and controlled environments demanding high levels of microbiological protection hazmat responders, law enforcement officers, hospital first receivers and military personnel

lifestyle and fashion

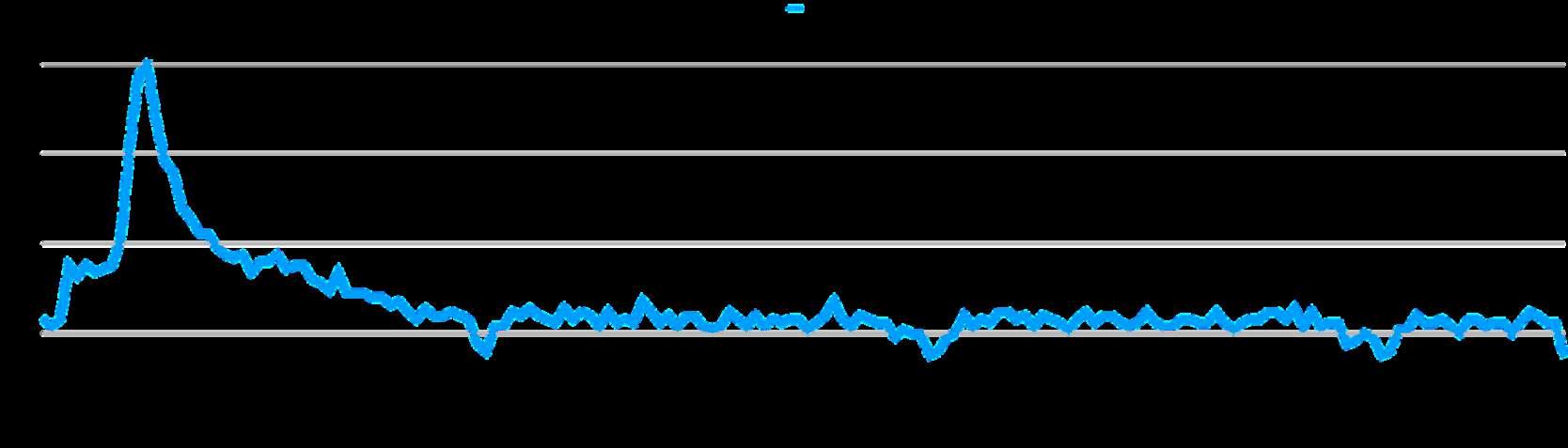

During the covid-19 pandemic, there was a surge in demand and use of protective clothing with Tyvek as the primary material. Now that the covid-19 pandemic has faded and protective clothing has a large shelf life, recycling of materials is also critical for environmental protection and sustainability.

Tyvek

Step 1-Collecting

Collecting from factories that make protective clothing or from professional places such as hospitals and laboratories after use by staff.

*Step 2-Sterilization

Sterilizing used suits and making it into raw material.

Step 3-Remake

Using the raw material and making new products.

Step 4-Selling

Selling new products

Our brand main propose is to reuse disposable materials and give them a new life. We combine sustainability with fashion for creating original and useful pieces.

'I dive into the future and i'm reborn in every moment, so who knows what I'll become. More than just recycle, this is my revival.'

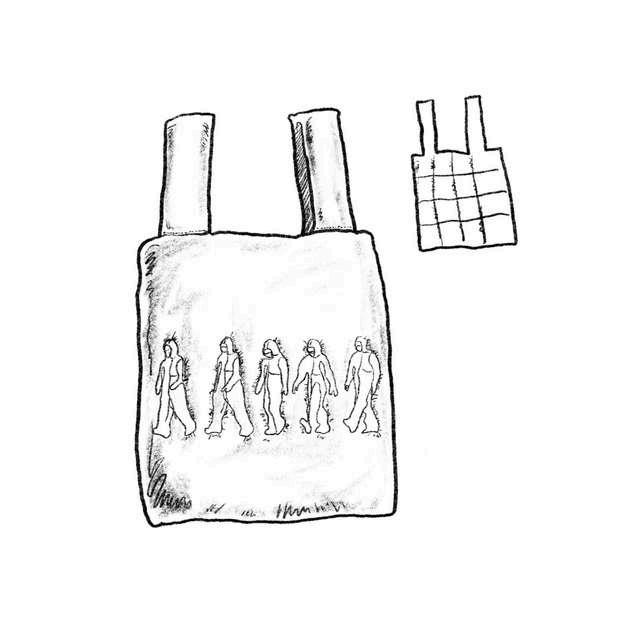

We are more focus on making accessories. We will design original patterns and sew them on the surface of the bag.

Sustainable

Adaptable

Spacious

Unique

Timeless

Versatile

Biodegradable

Accesible

take back project

lifestyle and fashion

take back project

lifestyle and fashion

take back project

lifestyle and fashion

and fashion take back project

lifestyle and fashion take back project

phone bag1-eye phone bag2-abby road vase bag-butterflyFounded in the 90s with base in Milan, Italy and becoming the firts company launching a sustainable insulation. It takes care of the research, development, production and marketing of the thermal insulation for apparel and accessories. at the time, it is mostly centered on eco-friendly innovation using PET bottles mostly. Furthermore, Thermore counts with a global sales network and has its center of production in the far east and in Europe.

Ecodown is a sustainable alternative to down feathers. the company Thermore creates this material by fully recycling PET water bottles, being it the only durable thermal insulation product 100% persent made with used plastic bottles.

this material not only helps to reduce the amount of waste in the planet, but also, helps to reserve energy for future generations by working with used bottles instead of oil.

what is more, we are taking about a non sensitive material that can be washed really easy and provides long term warmth

It becomes 10% warmer after washing

Even and stable

Structure of fibers minimizes cold spots and clumping versatile

before washing after washing

Step 1-Sorting

PET bottles recycled following standard procedure

Step 2-Melting

PET flakes are melted and spun into new fibers

Step 3-Producing

Fibers created are used to produce thermal insulation

take back project lifestyle and fashion

take back project lifestyle and fashion

We are also willing to design teddy bear toys for children. Compared with traditional plush teddy bears, our teddy bear toys will use recycled tyvek fabric, which makes the surface layer of teddy bear toys have the performance of tyvek, which is more antibacterial and less bacteria than traditional plush teddy bears hazards to infants and young children.