International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Ms. Tejaswini Chandrakant Kamble1 , Prof. Bhanu Pratap Singh2

1PG Scholar, Dept. of Electrical Engineering, ZCOER, Pune, Maharashtra, India

2Assistant Professor, Dept. of Electrical Engineering, ZCOER, Pune, Maharashtra, India

Abstract - This paper demonstrates the design and development of a solar-powered composting machine using food waste as the main raw material. The increasing concern about waste management and the need for sustainable agriculture have led to the search for new solutions to utilize waste materials into valuable products. The proposed system uses a two-stage process: first, the waste is an aerobically digested to produce biogas and digestate, and then the digestate is thermallyprocessedusingsolarenergytoproduce organicfertilizer, reducingoperatingcostsandenvironmental impact by reducing reliance on conventional power. The system is designed to be easily usable by urban households, encouraging local waste management and engaging communities in cultural activities. Experimental studies have shown that food waste is reduced and organic fertilizers are producedthat canimprovesoilhealthandcropyields.Theaim of the project is to contribute to the circular economy by transforming waste into resources and to find solutions to both waste management and agricultural sustainability problems

Key Words: fertilizer,pesticides,Photovoltaic,Generator, solidwasteetc.

1.INTRODUCTION

The rapid urbanization and population growth in recent decades have led to a significant increase in food waste, particularly in households. According to the Food and AgricultureOrganization(FAO),approximatelyone-thirdof foodproducedforhumanconsumptioniswastedeachyear. This not only represents a lost resource but also poses seriousenvironmentalchallenges,includinggreenhousegas emissionsandincreasedlandfillusage.Simultaneously,the demand for sustainable agricultural practices is rising, driven by the need to enhance soil health and reduce relianceonchemicalfertilizers.Inresponsetothesepressing issues, this project proposes the development of a solarbasedfertilizermanufacturingmachinethatutilizeskitchen waste as a primary raw material. The machine, which transformsorganicwasteintonutrient-richfood,solvesboth wastemanagementandpermcultureproblems.Theuseof solar energy in this process further strengthens its sustainability by reducing the carbon footprint associated withtraditionalenergysources.Thenewsystemusesatwostage conversion process: anaerobic digestion produces biogas and nutrient-rich digestive, followed by solar-

poweredthermal processingtoproduceorganicfertilizer. Suitable for urban families, the design encourages community participation in recycling and supports environmentalstewardship.Theaimisnotonlyto reduce foodwaste,butalsotoencouragecommunitiestosupport sustainable agriculture and ultimately support a circular economy that transforms product waste into valuable resources.

The increasing amount of food waste produced by urban households is causing a major environmental problem, leadingtowastedisposal,greenhousegasemissionsandthe consumptionofdiscardedproducts.Modernwastedisposal methods are often inadequate, leading to unsustainable wastemanagement.Atthesametime,agricultureisfacinga growingneedforalternativefertilizersthatcanimprovesoil health while reducing environmental impact. Current solutions such as composting and chemical fertilizers are laborintensive,timeconsumingorharmfultotheecosystem. We need new, efficient technologies that can transform wasteintovaluablefoodwhileusingrenewableenergy.This project addresses the two challenges of organic waste disposal and sustainable agriculture by implementing a solar-poweredfertilizerusingfoodwaste,offeringasolution tourbanfamilies.

Comprehensive review of existing technologies related to organic waste conversion, anaerobic digestion, and solar energyRadiantEnergy.Thedifferenceintheprocessisthe designthatcombinessolarenergywithanaerobicdigestion and thermal processing. System Design Machine Components: Design a system consisting of three main components: Anaerobic Digester: Produce biogas and digestatebyproductsbydigestingfoodwaste.SolarThermal Unit:Usesolarenergytoheatanddrydigestatebyproducts. Size,material andpowerrequiredforeverything.Building the Model¢ Material Selection: Select environmentally friendlyanddurablematerialsforconstruction,ensuringthe productisresistanttocorrosionandabrasion.plates,storage tanksandpipingsystemsforbiogasandliquidmanagement. Testing and Optimization Finished Products: Sampled a varietyoffoodwastesincludingfruitandvegetablescraps, coffee grounds and egg shells. Operate the anaerobic digesters under controlled conditions to monitor biogas productionanddigestatequality.Monitortemperature,pH

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

andstoragetime.Measurenutrientcontentoftheresulting compost. Data collection and analysis Data collected on biogas production, digestate composition and compost quality during the experimental period. Efficiency in convertingwasteintocompost.CommunityAssessmentand Participation.PerformanceEvaluation:Evaluateallaspectsof thesystemintermsofwastereduction,energyconsumption and good composts. Gather user input on usability and practicality.Includefeedbacktoimprovedesign.

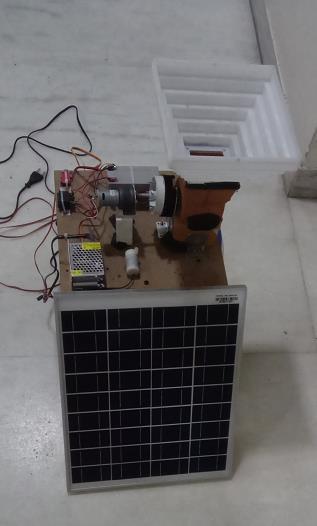

Fig -1:Systemdesign

Table -1: storagebatterychargingtimeforprototype hardwaremodelwhenonlypvisconnected

waste.Thesolutionistocreateanenvironmentallyfriendly machinethatturnswasteintofertilizer.Usingrecycledwaste materialsaseffectivefertilizercanimprovesoilhealthand structure,reducedroughtandreducetheneedforadditional water, fertilizer and pesticides. The composting process is fully automated and includes several steps based on environmentalcontrolstospeeduptheprocess.Aconcept aimedatreducingfoodwastewasstudiedandexperiments were conducted to determine the optimum temperature, humidityand volume enhancingagentsto produce quality household products within hours. We produced the prototypebygivingimportancetoaestheticsandcreateda stylishmachinethatcanfitintoeverykitchen.

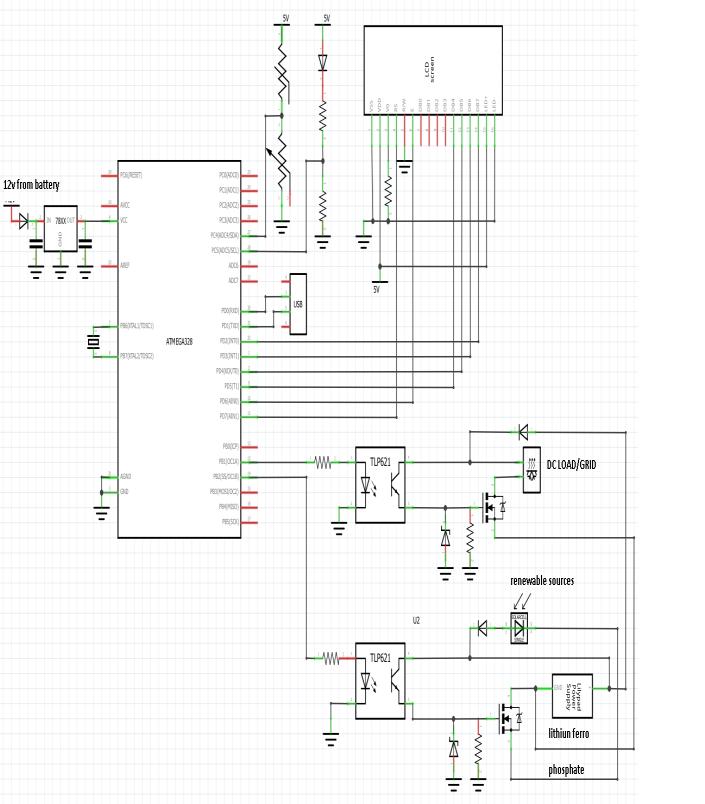

Setup in figure2 consist of crusher assembly, solar panel 20w,manualoperation,12v2amperedcelectricsupply,12v 12ampere lithium ferro phosphate battery, charge controller,dynamo.

System develops 20kg of organic fertilizer within a month timeperiodfromapproximately50kgofkitchen/foodwaste whichcanbesellingto20rsperkginindia.Onekilogramof organicfertilizerissufficientforonepot.So20kgfertilizer canbeutilizefor20potspermonth.

Presentthefindingsinacomprehensivereportoutliningthe design process, test results and user feedback. Provide guidanceforfuturedevelopmentsandpotentialexpansions 3]so that these technologies can be used more widely in society.burninginthefieldproducesharmfulgases.Inthis article, we will present a solution for recycling household

1-Materials:Differentmaterialshavedifferentcarbonand nitrogencontents.TheoptimumC:Nratioisbetween25:1 and 30:1, above 30:1 heat production slows down and decompositionslowsdown(Smithetal.,n.d.).Notonlydoes it vary according to the type of organic matter, but also differentformulationsofthesamechemical.Thehigherthe contentofthematerial,themorenitrogensupplyisneeded (Swarthout, 1993). Many bacteria, including aerobic bacteria,needoxygen.Theyneedoxygentoproduceenergy, growrapidlyandusemorematerials.Naturalventilationis the process of warm air rising in the compost pile during composting, bringing in fresh air from the surrounding environment(Smithetal.,n.d.).Lackofoxygencausesodour andslowsdowntheprocess;thisprocesscanbeaccelerated byaddingcornstalkstoprovideoxygen(CompostandFood Waste Guide, 2013). In aerobic composting, the aim is to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

maintain oxygen levels at 8% or higher (Anon, 2017). , excessive moisture will slow down decomposition (Anon, 2017). Low moisture limits bacterial activity, while high moisture can lead to anaerobic processes and cause unpleasantodours(SmithandFriend,n.d.).However,there is no universally accepted moisture content for compost materials. This is because all materials have physical, chemical and biological properties that affect the relationship between moisture content and its associated factors (water availability, particle size, porosity and permeability). 4- Temperature Factors: The rate of decomposition is between 90°F and 140°F, lower temperatures mean the process is slower, while temperatures above 140°F reduce the activity of most diseases.Regularturningofthemixtureshouldbedoneto ensure that the material always reaches a warm place (Compost Yard and Food Waste Guide, 2013). The organization also states that to reduce the risk of serious illnessduringcomposting,thetemperatureofthepileshould bemaintainedataminimumof40°Cforfivedaysandabove 55°C for at least four hours. Most microbial organisms cannotsurviveabovetemperaturesof60-65°C(Trautmann, 1996). The interface between the surface and the air. For small objects, bacteria can produce enough heat to digest them (Smith and Friend, tt). To achieve this, composters mustundergocertainprocessessuchaschopping,shredding orcuttingthecompostmaterial(GuidetoCompostingSites andFoodWaste,2013).

All in all, this paper aim is to show the importance of recycling food waste and helping the environment by buildingamachinethatconvertsfoodwasteintocompost. ThemachineiscompletelymanufacturedinQatar.Thisfood waste recycler machine is to be built and used at home safely. The design methodology and the engineering solutionsthatwillbeusedinthisprojectwereexplainedin theengineeringdesignprocess.Followedbytheidentifying the customers, knowing their needs and taking their feedbacks, which are considered important since our purposeistosatisfythecustomer’sneeds.Furthermore,a qualityfunctiondeploymentwasusedtotranslatecustomer needsintodesignspecifications.Inaddition,theexternaland internal constraints and the design standards were identified.Moreover,theconceptualdesignforthemachine, the design alternatives, alternatives evaluation, and the machine’sfinaldesignallwerediscussedbrieflyandshown in detail in this paper. Since the world is seeking sustainability, our machine aims to lessen the food waste that is thrown into the landfills, which pollute the environmentbyrecyclingthefoodwasteandturningit,in lessthan24hours,tocompostthatcanbeusedinfertilizing thesoiltoplanthealthyandorganicfood,andcontributingin creatingasafeandsustainableworld.

[1] Moller,K.,&Stinner,W.(2016)."Anaerobicdigestionof organic waste: Biogas production and nutrient recovery." Waste Management, 48, 165-174.DOI: 10.1016/j.wasman.2015.11.027

[2] R. Nicole, “Title of paper with only first word capitalized,”J.NameStand.Abbrev.,inpress.

K.Elissa,“Titleofpaperifknown,”unpublished

[3] Hassan,M.F.,etal.(2019)."AReviewofCompostingand Vermicomposting as an Effective Waste Management Strategy."WasteManagement

[4] Amin, S. (2019). "Renewable Energy and Sustainable Waste Management: A Case Study of Solar Energy Utilization."JournalofCleaner

[5] Amin, S. (2019). "Renewable Energy and Sustainable Waste Management: A Case Study of Solar Energy Utilization." Journal of Cleaner Production, 227, 673682.DOI:10.1016/j.jclepro.2019.04.025

[6] Ravindranath, N. H., & Venkataraman, C. (2018). "Sustainable Waste Management in Urban Areas: OpportunitiesandChallenges."EnvironmentalScience& Policy,87,140-146.DOI:10.1016/j.envsci.2018.06.013 López,M.A.,etal.(2020)."UtilizationofOrganicWaste for Sustainable Agricultural Practices." Sustainability, 12(6),2341.DOI:10.3390/su12062341