International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

1-4

BTECH UG Students, Department of Computer Science And Engineering,TOMS College of Engineering 2Head of the department, Civil Engineering,TOMS college of Engineering

TOMS college of Engineering4 APJ Abdul Kalam Technological University, Kerala, India ***

Abstract - Mivan formwork is an advanced aluminum formwork system widely used in modern construction for its efficiency, durability, and cost-effectiveness. Developed by Mivan Company Ltd., this system enables rapid and highquality construction of reinforced concrete structures, making it ideal for mass housing and high-rise buildings. Unlike traditional formwork, Mivanoffers modular, reusable components that facilitate fastercycletimesandreducelabor dependency. Its lightweight nature, superior finish, and minimal requirement for post-construction plastering enhance overallproject qualityandsustainability.Thispaper explores the design, advantages, limitations,andapplications of Mivan formwork in contemporary construction practices, emphasizing its role in accelerating project timelines and improving structural integrity.

1.1 General

Mivan technology is a modern aluminum formwork systemdevelopedbyMivanCompanyLtdofMalaysiain the 1990s. It has gained widespread popularity as an efficient construction method, particularly for rapidly buildinglarge-scalehousingprojects.Thissystemutilizes large,room-sizedaluminumformstocastwallsandslabs in a single pour, resulting in a seamless monolithic concrete structure. Known for its speed, efficiency, and cost-effectiveness, Mivan formwork has been widely adopted in Mumbai, India, where numerous buildings showcase its suitability for local construction demands. Additionally, this technology is extensively used across Europe,theGulfregion,Asia,andbeyond.Akeybenefitof Mivan formwork is its ability to allow early removal of molds, facilitated by hot air curing or specialized curing compounds. Thisenablesrapidconstruction potentially completing up to two apartments per day. The process follows an organized assembly-line approach, ensuring precision, superior quality, and cost optimization.As the global population continues to grow, increasing the demandforhousing,Mivantechnologyoffersaneffective solution by accelerating construction timelines. It has becomeanindispensablemethodforhigh-densityurban areas, providing faster project completion without compromisingqualityorcost-efficiency.

1.Study Mivan formwork construction techniques, components,anddesign.

2.Evaluate itscompatibilitywithmodernconstruction practices.

3.Assessusability,strength,efficiency,andflexibilityin complexprojects.

4.Compare Mivan with timber, steel, and plastic formwork in terms of speed, cost, labor, and environmentalimpact.

5.Analyze timeefficiencyandsuitabilityforlarge-scale, high-densityprojects.

ThisstudyinvestigatesMivanformworktechnologyandits implicationsfortheconstructionindustry.Itfocusesonthe effectiveness of this innovative system in achieving satisfactory construction outcomes. The analysis will include the advantages and disadvantages of Mivan formwork in comparison to conventional systems, emphasizingaspectssuchascost,quality,duration,speed, and safety. Additionally, the study will perform a comparative analysis between Mivan and traditional formwork, examining construction speed, costeffectiveness,laborrequirements,andoverallefficiency.It will also explore the components of Mivan formwork, detailingtheassemblyprocessanderectiontimestoassess practicalapplicationsonconstructionsites.Furthermore, theresearchwillconsiderthefutureprospectsofMivan technology,highlightingitspotential forwideradoption among builders and owners, especially in high-rise and large-scaleprojects.Finally,thestudyaimstounderscore the cost-saving and time-efficient benefits of Mivan formwork, demonstrating its relevance in modern constructionpractices.

2.1 General

This literature survey explores the research on Mivan formwork technology and its impact on the construction industry,particularlyinthecontextofhigh-risebuildings. Mivan formwork technology, which uses prefabricated aluminum formwork panels, provides a highly efficient alternative to conventional formwork systems such as

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

timber or steel. research shows that the Mivan system enhancesstructuralaccuracyandminimizeswaste,making itasustainableoptionforlarge-scaleconstructionprojects.

Yogesh Radheshyam Jangid et al. (2023) This study provides a comprehensive overview of Mivan formwork technologyasaninnovativesystememployingaluminum components,particularlysuitedforhigh-riseconstruction.It traces the evolution from traditional timber and steel formwork to aluminum, citing improvements in constructionspeedandcost-efficiency.Thestudyidentifies key advantages such as reduced construction time, enhanced build quality, and overall cost-effectiveness. Although the initial investment and the need for skilled labor are noted as limitations, the study includes comparative insights on structural performance and reusability when evaluated against other systems. Case studies within the research highlight the successful deployment of Mivan technology in large-scale projects, offeringempiricalsupportforitsbenefits.

NiteshBabanPatekaretal.(2023)Thispaperemphasizes thecontinuedrelianceonconventionalformworkduetoits lower upfront costs and flexible design compatibility. However,italsopointsoutdrawbacks,includingextended assembly time, higher labor demands, and substandard finishquality.Incontrast,Mivantechnology developedfor masshousing offerssignificantimprovementsintermsof speed,quality,andreducedlabordependency.Theresearch underscores the high reusability, strength, and quick assemblyofaluminumformwork,whichcontributetotime andcostsavingsinlargeprojects.Despiteitshigherinitial cost, the technology proves economical in the long run. Furthermore, the study discusses the reduced environmentalfootprintofMivanduetominimalwasteand longer material life span compared to timber or steel alternatives.

Prof. Santosh Mahadev Kinayekar et al. (2023) This study explores Mivan technology’s contribution to improving the efficiency and quality of precast structural components.ItexplainshowMivanenablestherapidand standardized production of durable concrete structures, making it ideal for high-rise and mass housing developments.Theresearchsupportsthewidespreaduseof this technology due to its time-saving and cost-reducing features,alongwithitsalignmentwithsustainablebuilding

Vedika Prasad Mahele et al. (2021) Thispaperhighlights theincreasingadoptionofMivanformworkinmasshousing andhigh-risebuildingsduetoitsspeed,cost-effectiveness, and sustainability. Introduced in India during the 1990s, Mivantechnologyisrecognizedforitsreusablealuminum components that reduce material waste and support environmentally responsible construction. The authors

conductdetailedcomparisonswithconventionalformwork intermsoftime,cost,andlaborefficiencyusingcasestudies andfieldresearch.TheyconcludethatMivanisparticularly beneficialforlarge-scaleurbanprojects,offeringsignificant long-termadvantagesthatoutweightheinitialinvestment

Pramod Shinde et al. (2020) This review analyzes various formwork systems and their impact on construction efficiency. It focuses primarily on the comparison between traditional and Mivan systems, especially regarding cost implications. While Mivan requiresahigherinitialinvestmentduetoitsspecialized materials and design, it delivers long-term savings by reducinglaborandexpeditingprojecttimelines.Thestudy highlights Mivan's ability to provide superior surface finish and structural quality. It also notes that project successisinfluencedbysiteconditions,workerexpertise, andmanagementpractices.Thepaperadvocatesforskill developmentamongworkerstofullyharnessthebenefits ofMivantechnology.

Sumit Ghangus et al. (2018) This research introduces thecomponentsofMivanformwork suchaswallpanels, rocker supports, and stub pins and explains how its lightweight aluminum structure aids in efficient installationandremoval.Theprefabricatednatureofthe system leads to faster construction cycles and quicker formworkturnover.ThehighreusabilityofMivan(200–300uses)comparedtotraditionalsystems(10–20uses) significantlyenhancesitseconomicvalueovertime.The systemprovidessmoothconcretefinishes,minimizingthe needforadditionalplastering.Moreover,itsperformance under seismic conditions makes it favorable in earthquake-prone regions. The study does, however, acknowledgethehigherinitialcostasapotentialbarrier.

Modern construction method that uses aluminum formwork for the rapid and efficient construction of concretestructures.OriginallydevelopedbyaEuropean company named Mivan, this technology has gained popularity in countries like India, especially for mass housingprojectsandhigh-risebuildings.

3.2

1. FastercompletionoffloorsLessernumber ofjointsandreducedleakages.

2. Smoothfinishingofwallandslab 3. Lowmaintenance

Moreseismicresistance

Hugecarpetarea

Goodqualityconstructionwork

Fastercompletion

Noneedforplastering

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

3.3 Disadvantages of Mivan Formwork

1. Alignmentmaintenanceneedsskilledlaborers.

2. Initialsetuptakestime.

3. Itisexpensiveandusedfortypicalfloorsonly.

4. It needs skilled laborers for alignment maintenance.

5. Constructionjointsshouldbesetproperly.

THE KEY USES OF MIVAN FORMWORK

Easytooperatewithinlesstime.

Includesthe3Sschemeofconstructionto givestrength,safety,andspeed.

Slabs and walls are easily formed in oneconsistentdevelopment.

Assembling and fitting the part of shuttering.

Beam construction and column are removed.

3.4 MAIN FEATURES OF MIVAN FORMWORK

1. AluminumFormwork.

2. MonolithicConstruction.

3. PrefabricatedPanels.

4. HighReusability

5. SmoothFinish

3.5 Formwork- Components

Mivan Formwork consists of many components which whenconnectedtoeachusingthedrawingprovidedthenit canbeusedforconcreting,thematerialusedformaking thesecomponentsare highstrengthaluminumalloy.

Themaincomponentsofmivanare

1. Wallcomponents

2. Beamcomponents

3. Deckcomponents

4. Othercomponents

5 METHODOLOGY

MIVAN FORMWORK COMPONENTS

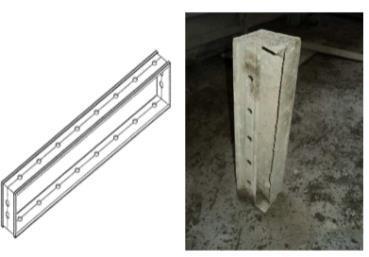

The standard component of the formwork is the panel, whichconsistsofanextrudedaluminumrailsection,joined to an aluminum sheet. It generates a low weight panel havinganoutstandingstiffnesstoweightratioandexhibits a minimal deflection with concrete load. Panels are fabricated in a given size and form to cater to the requirementsofindividualprojects.Thepanelsaremade outofhighstrengthaluminumalloywitha4mmthickskin plateand6mm thick ribbingbehindtostiffen the panels. ThepanelsareproducedinMivan'sdedicatedfactoriesin EuropeandSouthEastAsia.Uponassembly,theyundergoa

2025, IRJET | Impact Factor value: 8.315 |

trialerectioninanendeavourtoremoveanydimensionalor on-siteissues.Theentireformworkcomponentsarriveat thesitecomplainingthreemonthsfromthetimetheyare ordered.Afterarethecomponentsthatarenormallyusedin theconstruction.

a) Wall Panel: In Mivan formwork technology, the wallpanelplaysacrucialroleasitformsthefaceof thewallduringconstruction.Thesepanelsarecrafted from high- grade aluminum sheets, which are meticulously cut and shaped to match the exact dimensions of the wall to be constructed. This precisioninsizingensuresthatthewallsurfacesare smooth, uniform, and free from irregularities, enhancingtheoverallqualityoftheconstruction.The useofaluminumforthewallpanelsprovidesseveral advantages, including its lightweight nature, which makeshandlingandinstallationeasiercomparedto conventionalformworkmaterialslikewoodorsteel. Additionally,aluminum'sdurabilityandresistanceto corrosioncontributetothelongevityoftheformwork, allowing it to be reused multiple times, thereby improving cost-efficiency. By using wall panels designed for specific project requirements, Mivan formworkacceleratestheconstructionprocesswhile maintainingahighlevelofaccuracyandfinishinthe structuralelements.

b)Rocker: Therockerisanimportantsupportpartof the Mivan formwork system. Its main job is to help strengthenthewallstructureduringconstruction.It’s designedwithspecialopeningsthatallowstubpinsto fit in securely, helping connect and align the panels properly. When concrete ispoured, the rocker helps spreadtheloadevenly,keepingtheformworkfirmand in place. This is crucial to avoid any shifting or movement while the concrete sets. Besides adding stability, the rocker also helps make the setup and removal of formwork faster and smoother an importantbenefitintoday’sfast-movingconstruction projects.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

c)Kicker: The kicker is placed at the top of the wall panelsandactslikealedgetokeepeverythingfirmlyin position.Whenconcreteispoured,thepressurecanpush panels out of alignment. The kicker helps stop that by holdingthepanelssteady,makingsuretheystaystraight andintherightplace.Thisnotonlyimprovesthequality ofthewallbutalsoreducesthechancesofmistakesor theneedforcorrections.Bykeepingthingsaligned,the kicker plays a big role in achieving clean finishes and smootherworkflowonsite.

d)Stub Pin: Thestubpinisasmallbutessentialpartof theMivansystem.Itconnectstwowallpanelstogether securely, ensuring they stay properly aligned while concreteisbeingpoured.Withoutit,panelsmightshift or become misaligned, affecting the quality of the finishedwall.Stubpinsalsomakeitquickerandeasier toassembletheformwork,whichhelpssavetimeand laboronsite.Becausetheymaketheprocessbothfaster and more reliable, stub pins are a key part of what makestheMivansystemsoefficientandprecise.

a) Beam Side Panel Beam Side Panel: Thebeamside panelisusedtoshapeandsupporttheverticalsidesofa concrete beam while it is being poured. It holds the concreteinplacesothatthebeamformscorrectlyand maintains its exact size. These panels are usually rectangular and are part of the Mivan formwork system, which helps speed up construction and ensuresaccuracy.Whilestandardsizesarethenorm theycanbemodifiedtosuitvariousdesigns.

b) Prop Head for Soffit Beam:Thepropheadholdsthe lower sectionofthebeamreferredtoasthesoffitwhen casting the concrete. It has a V-shape design that providesfirm,stablesupportandmaintainstheshapeof thebeamwhiletheconcretehardens.Thedesignalso enables easier and safer removal of the formwork without cracking the fresh concrete. Because it is adjustable,itcanaccommodatebeamsofvarioussizes, thus being great for a wide range of activities. It generallyaidsinacceleratingthebuildingprocessand decreasestheamountofadditionallaborrequired.

c)Beam Soffit Panel: The soffit panel constitutes the bottomofthebeamandislevelintheformworksystem.It makes the bottom of the beam smooth and level and assists in maintaining the shape of the structure as the concretecures.Thesepanelsaretypicallyconstructedof heavy-dutymaterialssuchasaluminumorsteelthatare capableofsupportingtheweightofwetconcrete.InMivan systems,panelsareavailableinstandardsizessotheycan easilybeinstalledandremoved.Whentheconcretehas set, they can be used again on another section of the project,conservingtimeandminimizingmaterialwastage.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

d)Beam Soffit Bulkhead: The beam soffit bulkhead functionsasanendcapofthebeamtopreventconcrete spillingoutasitispoured.Itprovidesverticalsupportand makestheterminalendofthebeamcleanandaccuratein shape. These bulkheads are designed using strong materials such as aluminum, steel, or plywood and are compatiblewiththeMivansystem.

5.3DECK COMPONENT

a)Deck Panel: Adeckpanelisakeypartoftheformwork usedtoshapethehorizontalsurfacesofconcreteslabs like floors or roofs while they are being cast. It holds the concreteinplaceasitsets,helpingkeepthesurfaceflatand properly aligned. In Mivan construction, these panels are usually made ofaluminum,which makes them strong but lightweight easytohandle,install,andremove.Theysiton topofsupportslikepropsandbeams,helpingdistributethe weight of the wet concrete and avoid sagging. Because they’re reusable, they help cut costs and reduce material waste. Their smooth finish also reduces the need for additionalplastering.Speciallocking features help ensure thepanelsfittightly,leavingnogapsandmakingsurethe slabthicknessstayseven.

b)Deck Prop:Adeckpropisaverticalsupportusedtohold upthedeckpanelswhileaconcreteslabisbeingformed.It staysinplaceuntiltheconcretebecomesstrongenoughto

supportitself. Theseprops areoftenadjustable inheight and made of steel or aluminum to be both sturdy and lightweight. In Mivan systems, deck props help keep everythingalignedandstableduringthepour,preventing panels from moving or sagging. They are easy to use, reusable, and help save time and money on construction site.

c)Deck Mid Beam: Adeckmidbeamsitsbetweenthemain beamsandsupportstheformworkinthemiddleofaconcrete slab. Its job is to carry and spread out the weight of the concretetokeepthesurfacelevelduringpouringandsetting. Usuallymadeofsteeloraluminum,thisbeampreventsthe slabfrombendingorsagginginthemiddle.InMivansystems, mid beams are designed for quick assembly and reuse, helping to build slabs of uniform thickness. They are especiallyusefulinlargerprojectsbecausetheyreducethe needformanypropsandmakeiteasierforworkerstomove aroundtheground.

d)Soffit Length:Soffitlengthisthedistancethat defines theundersideof a beam orslabina formwork setup. It determines how wide the bottom area is that needs support duringconcretepouring. InMivansystems,the lengthdependsonthestructure’ssizeandhowmuchload itneedstocarry.Accuratemeasurementiscrucial ifit's off, it can lead to uneven surfaces or poor support. The soffitisheldinplacebyelementslikedeckpanels,props, andsoffitpanels,whichallworktogethertomaintainthe formwhiletheconcretesets.Thislengthcanbeadjusted usingdifferentpanelstofitdifferentbuildingdesigns.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

e)Deck Beam Bar:Deckbeambarsaresteelrodsplaced insidebeamsandslabstostrengthenthem.Concretealone isstrongunderpressure(compression)butweak when stretched(tension).Thesebarshandlethepullingforces sothestructuredoesn’tcrackorfail.InMivansystems,the barsarecarefullyplacedbasedondesignplans.They’re tied together before the concrete is poured, forming a strong internal skeleton. These bars help the structure resist bending, vibrations, and other forces from the environmentorheavyloads.

a)Internal Soffit Corner: Aninternalsoffitcorneris theplacewhereaceilingmeetsawallfromtheinside, forminganeatjoint.Ithelpshideelementslikewires, airducts,orbeamswhilealsogivingtheroomaclean andfinishedlook.Inmodern constructionmethodslike Mivan formwork, these corners are made using precise aluminum molds, which produce smooth, sharp finishes. This reduces the need for extra plasteringand speeds up the construction process, making the final result more uniform and professional-looking.

b)External Soffit Corner: An external soffit corner is wherethebottomedgeoftheroof(thesoffit)meetsthe outerwallofabuilding,usuallyattheroof’soverhang.It serves two main purposes: protecting the roof from weatherdamage(likerainorwind)andallowingairto circulateundertheroof,whichhelpspreventmoisture buildup. It also improves the building’s overall appearance by creating a smooth and tidy edge. With Mivanformwork,thesecornerscanbeformedquickly andaccurately.

c)External Corner: Anexternalcorneriswheretwo outerwallsofabuildingcometogether,typicallyata 90-degreeangle.Thiscornerisimportantforboththe shape and strength of the structure. It needs to be sturdytosupportthewallsandalignedproperlyfora cleanlook.UsingMivanformwork,externalcornersare made with high accuracy. The system uses prefabricated aluminum panels, which ensures all corners are neat and consistent, saving time and reducingerrorscomparedtotraditionalmethods.

d)Internal Corner: Aninternalcorneriswheretwo insidewallsjoin.Thesearecommonlyfoundinevery room and are important for both supporting the structureandmaintainingtheroomlayout.Well-built internalcornerspreventcracksandallowforsmooth wall finishes.Mivan technology helps create these cornerswithprecisionandminimaleffort.Sincethe aluminum formwork gives a perfect shape to the concrete,there'slittleneedfortouch-upsafterward. This results in a faster, cleaner, and more reliable construction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Conventional formwork refers to the traditional methodofconstructingtemporarymoldsorstructures tosupportfreshly pouredconcretewhileithardens and gains sufficient strength. Typically made from materialsliketimber,plywood,orsteel,conventional formwork is known for its flexibility, allowing for diverse designs and custom shapes. This method, whileversatile,islabor-intensiveandrequiresskilled workmanship, leading to longer construction times andhigherlaborcosts.Additionally,theassemblyand dismantlingprocesscanbetime-consuming,andthe potential for inaccuracies in alignment or finishing may increase the need for rework. Despite these challenges, conventional formwork remains widely used,particularlyinprojectswherecustomizationand adaptability are key priorities, such as complex or smaller-scalestructures.

6.1 COMPARISON BETWEEN MIVAN FORMWORK AND CONVENTIONAL FORMWORK SYSTEM

1. Qualityofsurfacefinish:Mivanformworkisknownfor givingbuildingsaverysmoothandcleanfinish.Since itusesaluminiumpanels,thesurfacecomesoutneat anddoesn’tusuallyneedextraplastering.Thissaves bothtimeandmoney.Ontheotherhand,traditional formworkoftenleavesroughorunevensurfaces,so extraplasteringisusuallyneededtomakeitlookgood, whichincreasescostsanddelaysthework.

2. Pre-Planning of Formwork System: Using Mivan formwork requires proper planning before construction starts. This includes getting the design right,planningtheworkschedule,andmakingsureall materialsarereadyontime.Withoutthispreparation, thingscangowrongduringconstruction.Conventional formworkdoesn’tneedthismuchplanningandcanbe set up more freely, which might be okay for smaller projectsbutcancauseproblemsinlarge-scalework.

3. Type of Construction: Mivan is mainly used for buildingswherethewallsandslabsarepouredatthe sametime,creatingastrongandcontinuousstructure. This method makes the building more solid and durable.Incontrast,conventionalformworkisoften

usedinRCCframedbuildingswherecolumns,beams, andslabsaremadeseparately.Thisapproachisless strong,especiallyduringeventslikeearthquakes.

4. Wastage of Formwork Material: One big plus of Mivanformworkisthatitproducesverylittlewaste. Sincethepartsarepre-madetofitperfectly,there’s not much cutting or trimming needed on-site. This saves material and reduces cleanup costs. Conventionalformwork,especiallywhenusingwood orplywood,createsmore wastebecauseofmanual adjustmentsandcutting.

5. Accuracy in Construction: Buildings made with Mivan formwork are usually more accurate in dimensionsandalignment.Thesystemisdesignedto beprecise,whichhelpsmaintainqualitythroughout the project. In traditional formwork, accuracy dependsontheskilloftheworkersandthematerials used, so mistakes and uneven measurements are morelikely.

6. Coordination Between Different Agencies:Mivan construction needs good teamwork between architects,engineers,andcontractors.Everyonehas toworkcloselytomakesurethedesign,plumbing, electrical,andothersystemsallfittogetherproperly. Traditional formwork is more flexible and doesn’t require as much coordination, but this can sometimesleadtoclashesormisalignmentsduring construction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

7. Resistance to Earthquake: BecauseMivanformwork createsacontinuous,joint-freestructure,ithandles earthquakesbetter.Thestructureismorerigidand connected, making it stronger during shaking. In comparison, conventional buildings made with separate columns and beams might have weaker spotsthatcanfailunderearthquakestress.

8.Reusage value: Mivanformworkcanbereusedmany times upto250oreven300times whichmakes itagoodinvestmentforlargeprojects.Incontrast, traditionalmaterialsliketimberandplywoodwear out much faster and may only be reused 30–50 times, meaning you’ll need to replace them more often,whichaddstothecost.

Table 1 COMPARISON BETWEEN MIVAN FORMWORK AND CONVENTIONAL FORMWORK SYSTEM

Sl No Characteristics Mivan Formwork Conventional Formwork

1 Speedof construction Fourdayscycle perfloor Tendayscycle perfloor

2 Qualityofsurface finish Excellent plasteringisnot required Bad

3 Pre-planningof formworksystem Required NotRequired

4 Typeof construction Castinsitu cellular construction Simple RCC framed construction

5 Wastageofform workmaterial VeryLess Ingreatamount

6 Accuracyin construction Accurate construction LessthanMivan

7 Coordination betweendifferent agencies Essential Not necessarily required

7.RESULT AND DISCUSSIONS

Mivan formwork technology has emerged as a gamechangerintheconstructionindustry,particularlyforhighrise and mass housing projects. Its key advantages lie in speed,quality,andcost-effectiveness,whicharecrucialfor addressinglarge-scaleinfrastructurechallengeslikeIndia's affordable housing demand. The system utilizes prefabricated aluminum panels that are lightweight, durable, and designed for repeated use. This reduces the reliance on skilled labor and speeds up construction

timelinesconsiderably,oftenleadingtoprojectcompletion in half the time compared to conventional formwork systems. The precision and uniformity offered by Mivan formwork significantly improve the overall quality of construction. Walls and slabs cast using Mivan are monolithic, which enhances the structural integrity of buildings,reducingrisksofleakageorcracks.Moreover,the smoothfinishesachievedusingthistechnologyeliminatethe needforextensiveplastering,furtherreducinglaborcosts and material consumption. One of the most discussed aspectsofMivantechnologyisitscost-effectivenessinthe long term. Though the initial investment in Mivan formwork is higher compared to traditional systems, the benefits of reuse (up to 250 times) spread these costs over multiple projects, making it highly economicalforlarge-scaleventures.Therapidconstruction pace also reduces overhead costs, such as project supervisionandrentalsforscaffoldingandcranes.Despite itsadvantages,Mivanformworkhaslimitations.Itismost effectiveforrepetitivelayoutsanduniformdesigns,which can constrain architectural creativity. Additionally, while highlyefficientinlargeprojects,itmaynotbecost-effective forsmallerorirregularlyshapedbuildings.Thereisalsoa learning curve associated with its adoption, requiring propertrainingandcarefulcoordinationtoavoidmistakes duringassemblyanddisassembly.

Mivan technology is an innovative construction technique that uses aluminium formwork to build buildings quicker and more accurately. It is used particularlyforhigh-volumeworklikeapartmentblocksor estateswherethesamedesignisrepeatedoverandover again.Perhapsthebestthingishowmuchtimeandlaborit saves.Becauseeverythingissotidyandeverythingslots together so perfectly, the process of building is much quickerandmoreeffective.Thissystemalsoensuresthat everyunitisthesametoviewandoperate,whichisagood thingwhenyou'rebuildinglotsofthesamehouses.

AlthoughtheinitialcostofMivanformworkishigher thantraditionalprocesses,itischeaperinthelongrun especially for repetitive design. This is because one formwork typecanbereusedmultipletimes,even250–300times.Traditionalformwork,however,ischeaperto startandmoreflexible,hencemoresuitableforsingleor smallbuildings.It,however,isslowertobuildwithandless long-lasting.

Mivanformworkalsoincreasesthestrengthandquality ofthebuilding.Itreducesdelaysandkeepsconstruction cost under control through faster completion of each phase. Compared to traditional formwork, which can be usedafewtimes,Mivanpanelsareextremelyreusableand evenpossessscrapvalueafterbeingusednumeroustimes, furthercontributingtosavings.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

In a nation like India, where low-cost housing is in massivedemand,Mivantechnologyisanexcellentsolution. Itmakeshousessimpletoconstructandcheaperinthelong run,withitbeingtheperfectsolutionformassivehousing schemes. Even research has concluded that for high-rise structures, Mivan is marginally more cost-effective by about3% thanconventionaltechniques.Duetothis,Mivan isturningintoafirst-preferencechoiceforprojectswhere quality,affordability,andquicknessareneeded.

[1]Yogesh Radheshyam et.al(2023) ‘MivanFormwork in construction’ InternationalResearchJournalofEngineering and Technology (IRJET) Volume: 10 Issue: p- ISSN: 23950072 e-ISSN: 2395-0056.

[2]NiteshBabanPatekaret.al(2023)‘Assessingtheimpact conventional formwork and Mivan Formwork on constructionproductivityandefficiency’WorldJournalof AdvancedEngineeringTechnologyandSciences,240–247.

[3]DarshanKumarPatel,et.al(2022)‘AReviewPaperon ComparativeAnalysisofMivanFormworkTechnologyand ConventionalFrameworkTechnology’InternationalJournal ofResearchPublicationandReviewsVol3,pp1432-1441

[4]Pramod Shinde et,al (2020) ‘A Review Paper on Feasibility of Mivan Formwork Technology Over Conventional Formwork Technology for Construction Project’InternationalResearchJournalofEngineeringand Technology(IRJET)Volume:07Issue:p-ISSN:2395-0072 e-ISSN:2395-0056

[5]Sumit Ghangus et.al (2018) ‘A Comparative Study of Aluminum Form Work (MIVAN Shuttering) with other Conventional Form Work’ International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor:6.887Volume6IssueVI

[6]Vedika Prasad Mahele et.al(2021) ‘Optimizing Construction Efficiency with Mivan Formwork System’ International Journal of Creative Research Thoughts (IJCRT)VolumeIssue3|ISSN:2320-2882

[7]Prof. Santosh Mahadev Kinayekar et,al (2023) ‘Mivan ConstructionTechnology:EnhancingEfficiencyandQuality in Precast Structural Elements’ International Journal of Research Creative Research Thoughtse-ISSN:2319-8753; pISSN2347-6710 Volume 13 Issue 6

[8]Shivam Hawaldar et.al (2022) ‘Study Paper on Mivan Technology’InternationalJournalOfProgressiveResearch inScienceandEngineeringVol.3,No.06

MUHAMMEDSHAHA Student

TOMSCollegeofEngineering

APJAbdulKalamTechnological University

SIMIKRAVEENDRAN AssistantProfessor

TOMSCollegeofEngineering

APJAbdulKalamTechnological University

HARITHAHARESH Student

TOMSCollegeofEngineering

APJAbdulKalamTechnological University

ANANNYASURESHM Student

TOMSCollegeofEngineering

APJAbdulKalamTechnological University