International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Naga Kiran Nayak MJ1 , Dr. KVSB Raju2 , Dr. B Viswanath3

Department of Civil Engineering,1, 2, 3., UVCE, Bangalore, India.

Abstract - The expansive soils are covered over most among the parts of India especially known by nameBlack Cotton Soil. This soil found to be major problem for construction. It has low shear strength, high shrinkage, swelling and compressibility characteristics. From the outcomes, it is evident that liquid limit increases with the increaseinxanthangumcontent.Theformationofhydrogen bonding and cation bridging by XG contributes to the reductionincompressibilityofthesoil-XGmixture.Onthe other hand, the addition of QL results in a substantial decrease in swell pressure, compression index, and coefficient of consolidation. The compressibility characteristicsofBCsoileffectimprovedbytheadditionof XG,BA,QLandtheircombination,offeringpotentialforsoil stabilizationapplications.

Key Words: XanthanGum,Bagasseash,Quicklime

Introduction

Soil is an essential element of nature. Without soil, it is nearlyimpossibletoimaginelifeonEarth.Theword"soil" comes from the Latin word "solium," which, according to Webster’sDictionary,referstotheupperlayeroftheearth thatcanbedugorplowed.Insoilengineering,soilisdefined asanunconsolidatedmaterialmadeupofsolidparticlesthat result from the disintegration of rocks. A land-based structure'sstrengthreliesheavilyonitsbase.Forthiscause, soil plays a crucial role in the accomplishment of any buildinginnovative.SoilcaneitherwaybeAcomponentof the foundation or serve as a component used in the construction process. Knowing the soil's engineering characteristicsisessentialforachievingpowerandfinancial durabilityinbuilding.Theprocessofstabilizingsoilinvolves enhancing the soil's appropriateness for a specific for building purposes. The phrase "modification" refers to a slightmodificationtothecharacteristicsofthesoil,whereas "stabilization"indicatesamoresignificantalterationofthe engineeringcharacteristics

allowingforconstructiontotakeplaceeffectively.Innearly every road construction project, one or both of these stabilization techniques are utilized. The most common methodofmechanicalsoilstabilizationissoilcompaction, while the addition of materials such as cement, lime, bitumen, or other agents constitutes a soil stabilization techniquethatuseschemicalsoradditives.Twoarepresent

primary Chemical and mechanical additives are the two types of additives utilized in chemical soil stabilization. Additivesthataremechanical,likesoilcement,enhancethe soil by adding a material that improves the current soil's abilitytosupportweight.Incontrast,additionsofchemicals like chemically, lime modify the actual soil, resulting in improvedcapacityforbearingloads.

BlackCottonSoil

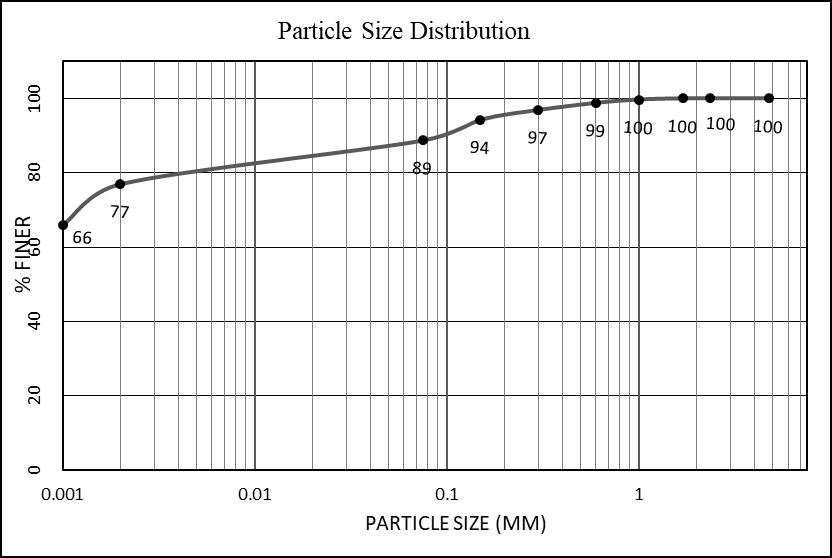

A sample of soil was taken from the Kalburgi district in Karnataka. The index characteristics of the soil are summarizedinTable1.

Table1:characteristicsofBlackCottonSoilIndex characteristics | consideration | | | |

| Colour | Greyish |

| Atterberg Limits | 0 |

| Liquid Limit (%) | 83 |

| Plastic boundaries (%) | 39 |

| Shrinkage boundaries (%) | 7 |

| Particular Gravity | 2.59 |

| Mini Compaction Test | 0 |

| The highest dry density (g/cc)| 1.46 |

| Ideal moisture level (%) | 27 |

| Evaluation of Grain size | 0 |

| The dirt (%) | 0 |

| Rough Sand (%) | 0 |

| Mediocre Sand (%) | 0 |

| lovely Sand (%) | 8 |

| Silt (%) | 15 |

| Clay (%) | 77 |

| Free Swell Index (%) | 110 |

| FSR | 2.1 |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Figure 1 DistributionofBlackcottonsoilparticlesizes

XanthanGum(XG):

Inthisinvestigation,xanthangumwas sourcedfromLoba Chemie Pvt. Ltd. in Peenya 2nd Stage, Bangalore Urban District,KarnatakaState.Quicklime,alsoreferredtoasburnt limeorcalciumoxide,isachemicalsubstancethatisutilized extensively.Atroomtemperature,itisacrystalline,white, caustic,alkalinesolid.Xanthangum,whichhasthechemical formulaC35H49O29foritsmonomer,isananionicpolymer that is naturally formed when the bacteria *Xanthomonas campestris* ferments carbohydrates. In the 1950s, this chemical was initially found at the US Department of Agriculture.

Table2:ChemicalCompositionofXanthanGumUtilizedin theResearchStudy.

Tests

Appearance

Lossondrying

Specifications

Whiteoryellowish whitefree-flowing powder

Results

Yellowish free followingpowder

Max15% 7.90%

Odor Feeble no desabreable Feeble no desabreable

Particlesize 100-200mesh Passestest

Ashcontent 6.5-16% 11.66%

pH (1% solution in water) 6to8 6.24

Nitrogencontent(as N)

Max1.5% 0.54%

Pyruvicacid 2.40% 3.50%

Heavymetal(asPb) maximum0.001% 0.00%

maximum 10 parts permillion maximum 0.0005% 0.00%

Arsenic(As)

maximum 0.0002 percent 3

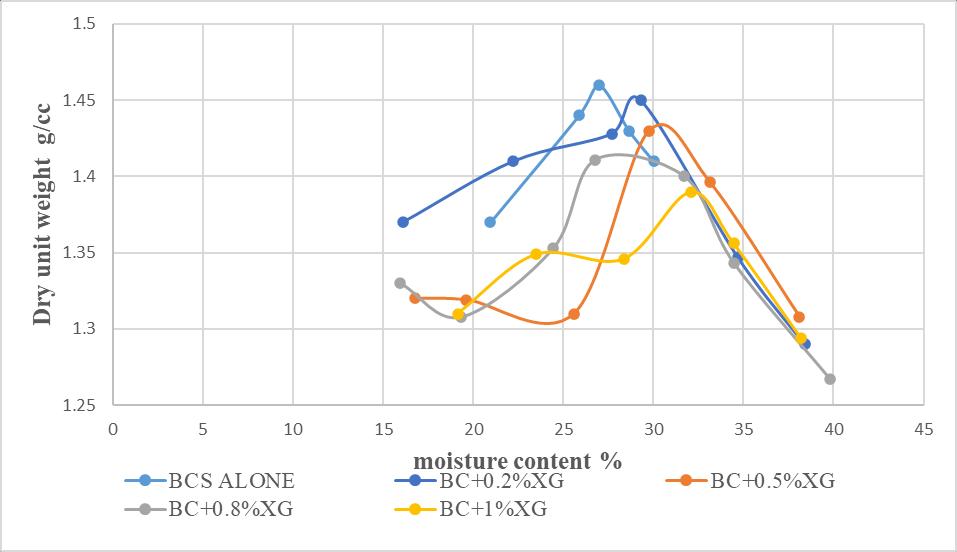

CompactionParameters:

A drop weight and a guiding frame make up the hammer assembly. The top, middle, and bottom are the three detachablepartsoftheguidingframe.Thedroppedweight is designed to float between the top and bottom sections. Thelowerpartoftheguidingrod,whichservesasanenergytransferringfoot,is8cmlongand3.65cmindiameter.The guiding rod's upper section is 3 cm long and also has a diameterof3.65cm.Thistopportionisusedtosecurethe assembly in place before the hammer is released. The guiding frame's centre section is 19.5 cm long and has a diameterof1.8cm.Itfeaturesa vertical rodthatactsasa bore guide for the hammer. This middle portion can be detachedfromthetopandbottomsections,allowingforan easychangeofthedropweightusedforthetestofProctor andmodifiedProctor.FortheregularProctortest,thedrop weightis1kilogram,whileforthemodifiedProctorexam,it is2.5kg.

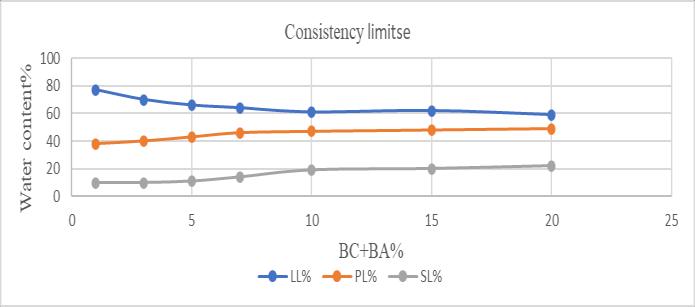

Consistencylimitsxanthangumofexpandingsoilmixtures:

Aspertheexperimentalprogramme,theexpandingsoilis mixed with xanthan gum and consistency limits were determinedimmediatelyafteraddition.Theeffectofadding xanthangumontheconsistencylimitsofexpandingsoilis discussedbelow.Theoutcomesindicatethatthefluidlimit increaseswithhigherxanthangumcontent.Whenwateris addedtobiopolymer-treatedsoils,across-linkingnetwork of monomers is initiated, consuming a notably greater amountofmoistureandraisingtheliquidlimit Additionally, adding xanthan gum increases the pore fluid's viscosity, whichpromotesmoreaggregationwithinthesoilmatrix.

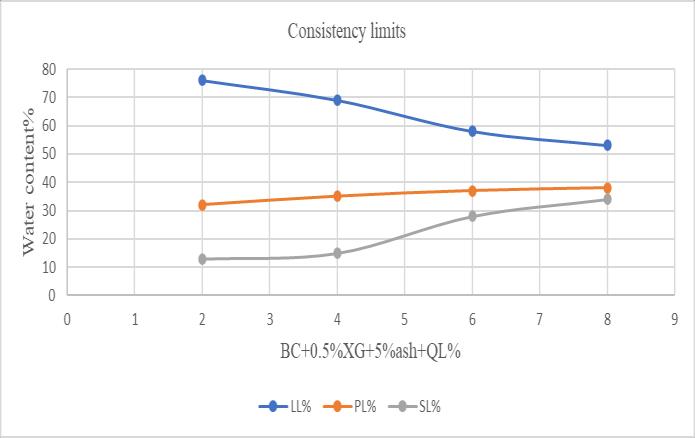

However,theshrinkagelimitdoesnotvaryconsiderablyas xanthangumcontentincreases.Becausetheporefluidhas lessviscosityatlowerxanthangumconcentrations,thereis lessopportunityforhydrogenbondingandcationbridging tobuildaninterconnectednetwork.Consequently,thisleads to reduced susceptibility to volume changes upon drying. Moreover, The more xanthan gum there is in the soil, the higher the plasticity index of the treated soil. Once more, whenwaterisaddedtosoilstreatedwithbiopolymers,the formationofthemonomercross-linkingnetworkrequires abnormallyhighmoisturelevels.

Fig 1 Variations in the BC soil's shrinkage limits when combinedwithbagasseash.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig 2 VariationsoftheboundariesofBCsoilshrinkage withquicklime-treated(BCsoil+0.5%XG+5%BA+8% QL)mixtures.

Fig 3 Relationshipsbetweenthesoil'smoisturecontent anddryunitweight-XGmixtures.

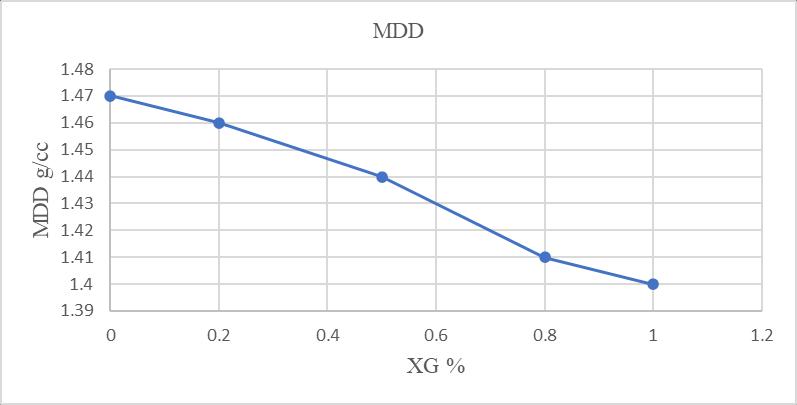

Fig 4 ChangeinMaximumDryDensitywiththeContentof XanthanGum.

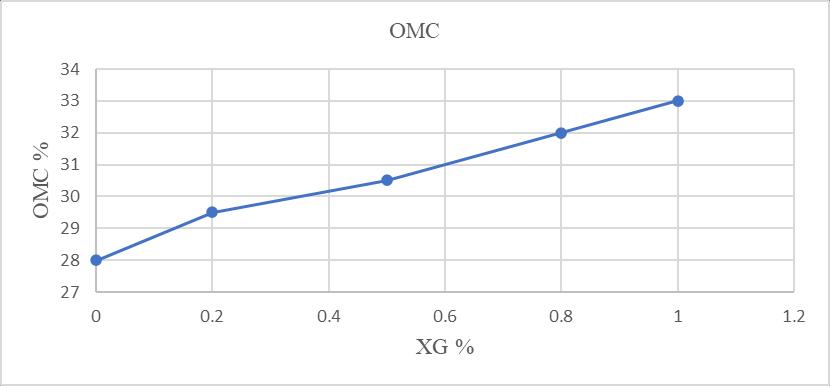

Fig 5 ChangeintheIdealMoistureContentwiththe ConcentrationofXanthanGum.

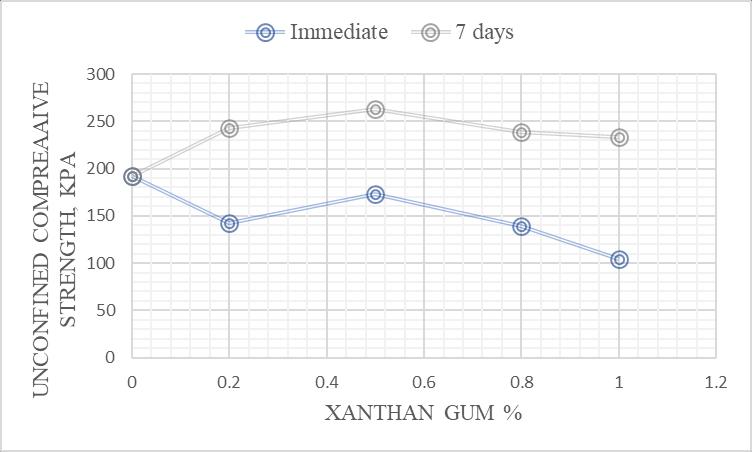

Fig 6. UnconfinedCompressiveStrengthofMixturesof ExpansiveSoilandXanthanGum

Unconfinedcompressivestrengthtestswereperformedon combinations of expansive soil and xanthan gum that had been compacted to maximum dry density and optimal moisturecontent(OMC).Bothimmediatelyafterthehealing period and seven days later, these tests were carried out. Strength increased slightly for the immediate tests up to 0.5%xanthangum,afterwhichitdecreased. Thestrength evaluatedaftercuringwashigherthanthatofthespecimens testedimmediately,andtestsconductedaftera7-daycuring interval displayed a similar pattern. Further tests were conducted with 14 and 28 day curing times once it was determinedthat0.5%wastheoptimalxanthangumlevel.

Overall,thesoilstrengthsignificantlyincreasedasaresultof theextendedcuringperiod.Curephasesare14and28days. Overall,itwasobservedthatthelongerthecureperiod,the greatertheincreaseinsoilstrength.Expansivesoil-xanthan gum combinations' unconfined compressive strength variationswereexaminedforboththeinitialtestingandthe seven-daycuringperiod.Forbothimmediatetestingandthe seven-daycuringphase,thestress-straincorrelationsforBC Soil alone and BC Soil treated with xanthan gum were displayed. This evaluation emphasized the variations in unconfined compressive strength between the ideal 0.5%

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

xanthangummixesandexpansivesoilwithrespecttothe curingtime.

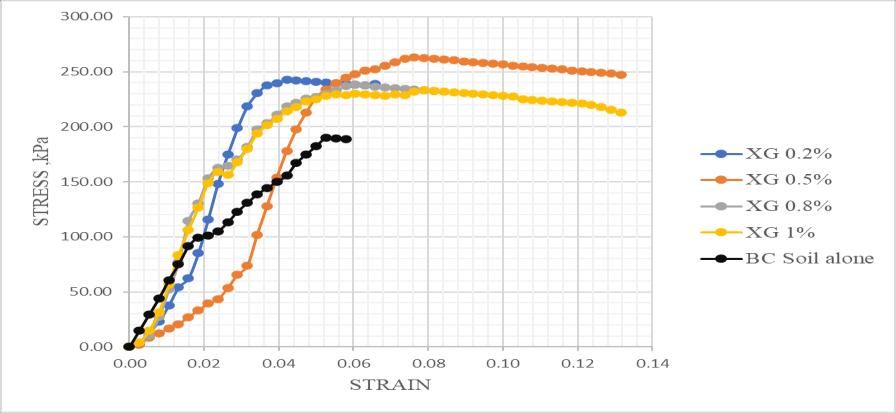

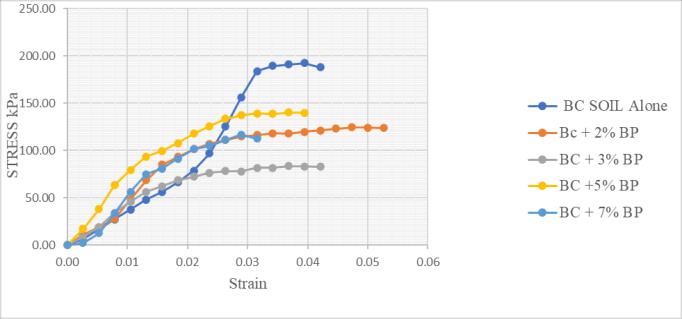

Brittlebehaviorwasdemonstratedbythesoil,whichfailed atlowerstrainsduetoitspeakstrength.Theresilienceofthe soilmatrixtoloadwasgreatlyincreasedbytheadditionof xanthangum,andthefailurestrainprogressivelyincreased as the xanthan gum content increased. The soil's stressstrainbehaviorwasalsoimpactedbyincreasedxanthangum viscosity,whichledtoaprogressiveincreaseinstressuntil failure.Adistinctpeakwasseenateverytestedxanthangum %, suggesting that xanthan gum has a propensity to agglomerate within the soil matrix. Strength gradually decreasedastheamountofxanthangumwasreduced.Inall measured xanthan gum percentages, the production of hydrogenbondsandcross-linkingcomponentsstiffenedthe soilmatrix,increasingitsunconfinedcompressivestrength andloadresistance.

The differences in unconfined compressive strength of expansive soil-xanthan gum mixes are highlighted in this presentation,takingintoaccountbothimmediatetestingand theseven-daycuringtime.

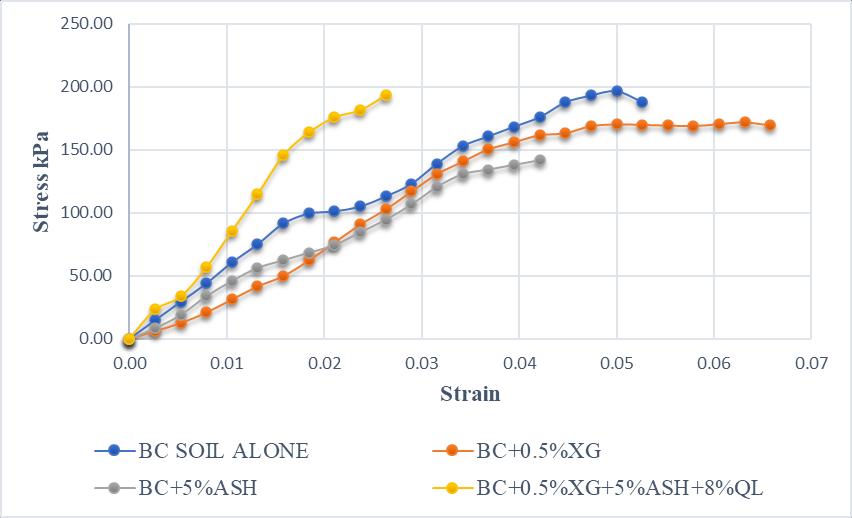

Fig 8. Stress-strainrelationshipsofBCSoilandBCSoil treatedwithXanthanGumaftera7-daycuringperiod.

When0.5%xanthangum(XG)wasadded,anotableincrease in soil strength was noted. and extended aging time. The

resultsshowedthatatthisdosage,soilstrengthimproved significantly, rising from 172.63 kPa to 391.75 kPa by the 28thdayofcuring.Xanthan gumpossessesa highspecific surfacearea,whichfacilitatesexcellentinterlockingbetween soilparticles,increasingthesoil'sstrengthandstiffness.The strengthincreasesshownforallxanthangumpercentages throughoutvariouscuringtimesshowthatthebiopolymer doesnotbreakdownbutratherkeepsstrengtheningthesoil matrixbyaggregating,forminghydrogenbonds,andforming cross-linkingcomponents.Ithasbeenobservedthatasthe soilmatrixporescure,moregelisformed,whichpromotes improvedsoilparticleaggregation,thecreationofanetwork of interconnected cross-links via cation bridging, and the creationofhydrogenbonds.

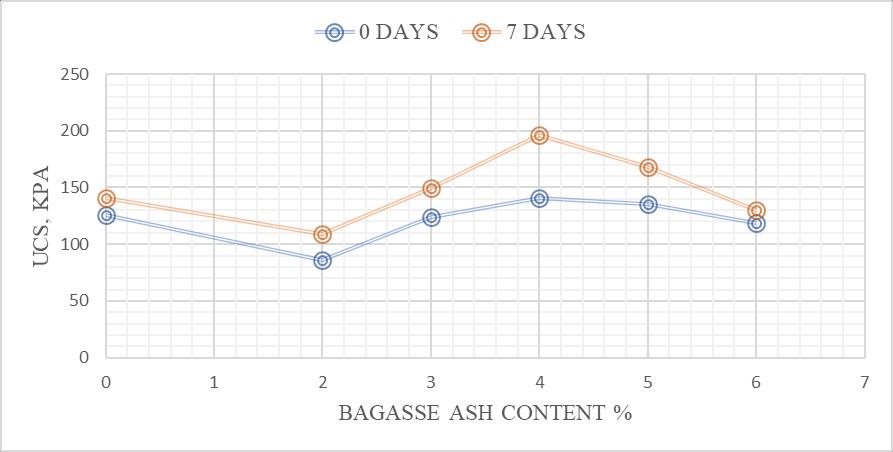

Several combinations of expansive soil and bagasse ash, compacted to reach maximum dry density and optimal moisture content (OMC), were subjected to unconfined compressivestrengthtesting.Bothimmediatelyandaftera seven-day curing period, these tests were conducted. The mixtures' strength rose nonlinearly for the immediate testing. On the other hand, adding bagasse ash to the soil resultedinaconstantimprovementinstrengthfollowinga 7-daycuringperiod.Comparedtothespecimensexamined rightaway,thestrengthseenaftersevendaysofcuringwas greater.Inparticular,addingbagasseashraisedthestrength from140.31kPato193.56kPa.Cationexchangeisoneofthe factorsresponsibleforthisstrengthrise Aggregationand flocculation. An increase in the curing duration was associatedwithanotableimprovementinsoilstrength.Up to 5% Bagasse ash, the strength increase percentage increased;afterthat,itstartedtodecline,suggestingthat5% Bagasseashistheidealamountforstability.Furthermore, for both the immediate testing and the seven-day curing phase,thestress-strainrelationshipsofBCSoilaloneandBC SoiltreatedwithBagasseashwereshown.Thisshowshow expansivesoil'sunconfinedcompressivestrengthvariesand how the ideal 5% Bagasse ash blends relate to the curing time.

Fig 11. Stress-strainrelationshipsofBCsoilaloneandBC soiltreatedwithbagasseashforimmediatetesting.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

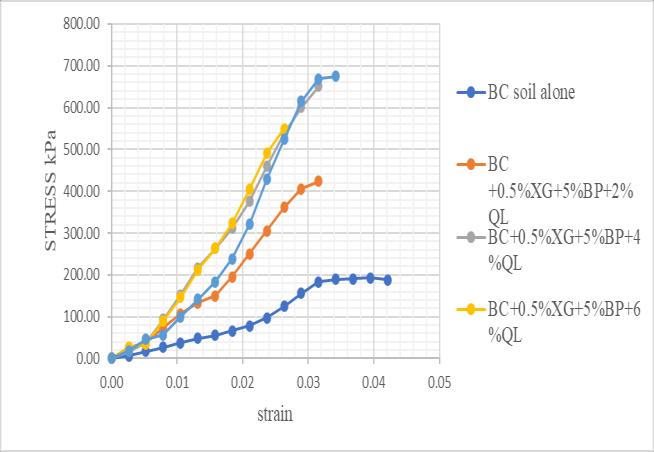

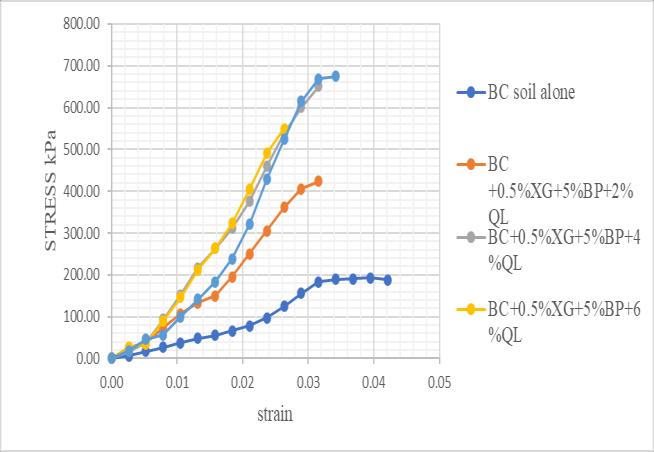

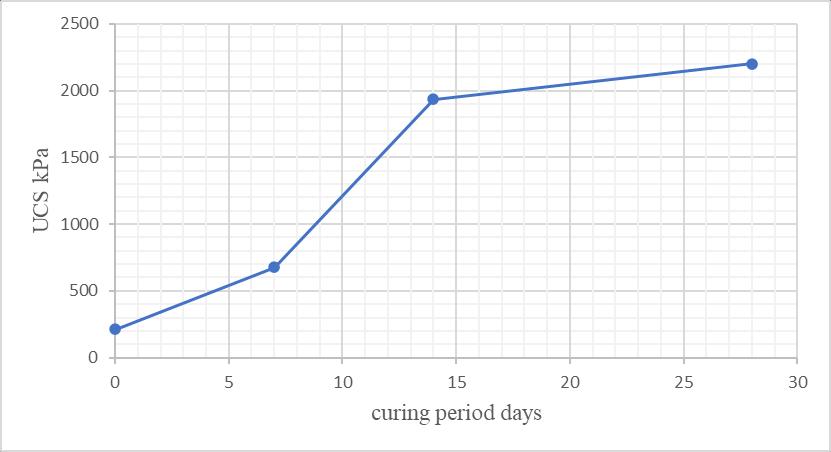

Fig 12 UnconfinedCompressiveStrengthofexpansivesoil (0.5%XG)treatedwithbagasseashandquicklime.

Theoutcomesshowed thestrengthincreasedwiththequick lime content up to 8%, after which it began to decrease Therefore,8%quicklimewasdeterminedtobetheoptimum amount for stabilizationUpon curing for 28 days, the strengthwas1923.68kPa.Furthermore,thedifferencesin unconfined compressive strength between the immediate andseven-daycuringperiodsfortheexpansivesoiltreated with fast lime mixes were examined. During immediate testing,thestress-straincorrelationswereshownforBCsoil byitselfaswellasforBCsoilmixedwith0.5%XGtreated withquicklime.Impactofthecuringtimeontheunconfined compressive strength of expansive soil treated with quick lime and bagasse ash and containing 0.5% XG. The soil specimen tested immediately after the preparation of the sample with 8% content was found to have a strength of 212.38kPa.However,thisstrengthincreasedwiththecuring period.Aftercuringfor7days,theformationofhydrogels resulted in an increased strength of 675.05 kPa. As the hydrategelscontinuetohardenovertime,thesoil'sstrength furtherimproved,withcompressivestrengthsrecordedat 1568.64kPaand1923.68kPaaftercuringfor14daysand28 days,respectively.

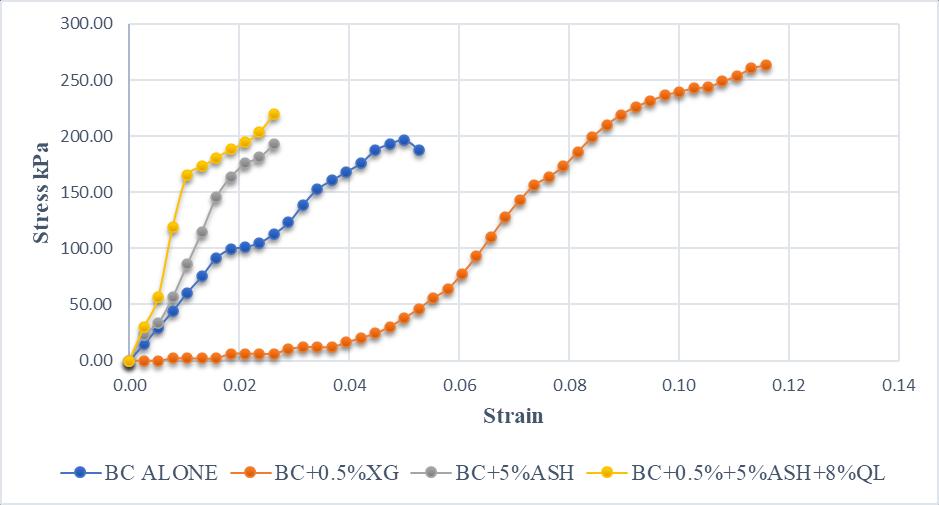

Fig 13. connectionsbetweenstressandstraininBCsoil treatedwithbagasseash,xanthangum,andquicklimefor aseven-daycuringperiodvsBCsoilleftalone.

Fig 14 VariationintheUnconfinedCompressiveStrength (UCS)ofamixtureconsistingof0.5%xanthangum(XG), 5%boneash(BA),and8%quercetin(QL).

Fig15 StrengthpropertiesofBCsoilthathasbeentreated withtheidealproportionofxanthangumandquicklime.

Thesoilbecomesmoreviscousandresistanttoloadwhen xanthan gum is added. Higher xanthan gum (XG) concentration causes ductile failure, which indicates the development of a vast network of interconnected biopolymersoilmatricesthatarebetterabletowithstand loads at higher strains. In contrast, brittle failures were observedinboththebiopolymer(BC)soiltreatedwithbioash (BA) and quicklime, as well as in samples containing 0.5%XGcombinedwithBAandlime.

Fig 16. Thestress-strainrelationshipsforoptimal percentagesofadditivesshouldbetestedimmediately.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig 17. Thestress-strainrelationshipscorrespondingto theoptimalpercentagesofadditivesforacuringperiodof sevendays.

QLcontributescausespozzolanicreactionsandcementitious compoundproduction,whichleadtoincreasedstrengthover time.Thecuringperiodiscrucialforthesoilmixes'stressstrainbehavior.Theunconfinedcompressivestrength(UCS) valuesgenerallyincrease withtime,thoughvariationsare observeddependingonthetypeandcontentoftheadditives. However,shrinkagelimitremainsconstantacrossvarious percentages of xanthan gum change attributed to lower specific gravity xanthan gum compared to the soil, which affectsitsstructure.Conversely,theadditionofQLaltersthe soilstructuretoaflocculatedstate,whichincreasesthevoid ratio and results XG enhances the soil's strength through cross-linking and hydrogen bonding, resulting in higher risesupto0.5%XGbutthendecreasesforboth0-dayand7daycuringperiods.Therefore,aconcentrationof0.5%XGis identified as optimal for stabilization. The UCS values continue to rise with the addition of QL, although the percentageincreaseinstrengthvarieswiththeQLcontent. reactionswithQLcontributestothisstrengthincrease.The optimal stabilization percentages are 8% QL and a combination of 0.5% XG, 5% BA, and 8% QL, based on strengthcriteria.

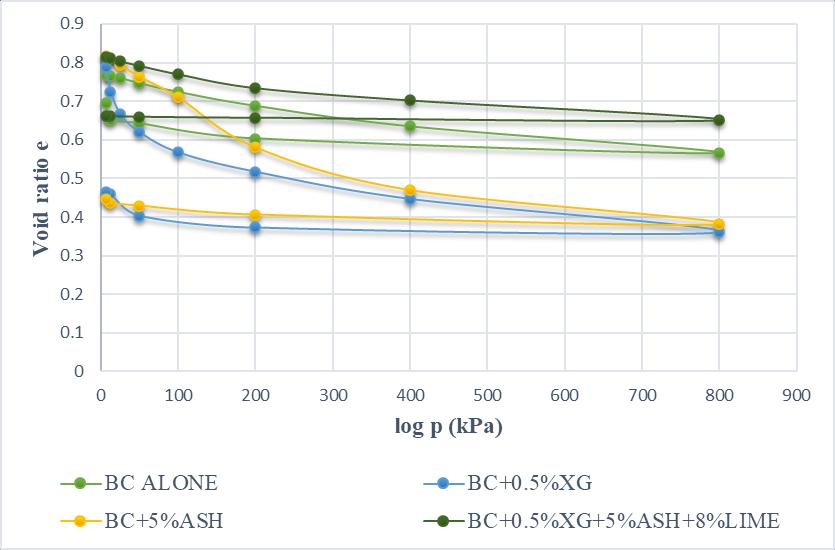

Meanwhile,addingQLresultsinasubstantialdecreasein swell pressure, compression index, and coefficient of consolidation,furtherreducingthesoil'scompressibility.

BC +0.5% XG+

Table1:Compressibilitypropertiesofsoiltreatedwith blackcottonanoptimalcombinationofXGandbagasse ash.

Fig 19 evslogpcurvesforBCsoiltreatedwithXG,BA,and QLandBCsoilalone

TheresearchindicatesthatthecombinationofXanthanGum (XG), Bagasse Ash (BA), and Quick Lime (QL) can successfully enhance Black Cotton (BC) soil's engineering qualities and strength. XG, a biopolymer, enhances soil strengthbyformingcross-linksandhydrogenbonds,while

|

1) Antonio Soldo and Marta Miletic, "Study on Shear StrengthofXanthanGum-AmendedSoil,"

2) Amit S. Kharade, Suhas K. Salukne, Mahesh D. Dadage, “Effective Utilization of Waste from the Sugar Industry, 'Bagasse Ash', in Enhancing the PropertiesofBlackCottonSoil”

3) IS: 2720 Part 20, 1992 - Determination of Linear Shrinkage.NewDelhi:BureauofIndianStandards.

4) IS:2720Part4,1985.Grainsizedistributionofsoil. NewDelhi:BureauofIndianStandards.

5) IS: 2720 Part 40, 1977. Determination of the free swell index of soils. New Delhi: Bureau of Indian Standards.

6) IS:2720Part41,1977.Determinationofswelling pressure.NewDelhi:BureauofIndianStandards.

7) IS 2720 Methods of test for soils, Part 10 (1991) Determinationofunconfinedcompressivestrength (secondrevision)(ReaffirmedMay2010),Bureauof IndianStandards

8) IS2720(Part40)(1977):Methodsfortestingsoils anddeterminingthefreeswellindexofsoils